Page 1

GETTING STARTED GUIDE

NI PXIe-5630

6 GHz T/R Two-Port Vector Network Analyzer

Note Before you begin, install and configure your chassis and controller.

This document explains how to install, configure, and test the NI PXIe-5630 (NI 5630). The

NI 5630 is a 6 GHz, 2-port vector network analyzer (VNA) with support for vector

measurements of transmission and reflection (T/R) coefficients. The NI 5630 ships with the

NI-VNA instrument driver, which you can use to program the device.

To access NI 5630 documentation, navigate to Start»All Programs»National Instruments»

NI-VNA»Documentation.

The specifications document for your device is installed with the driver software. Refer to

ni.com/manuals for the most recent specifications for your device.

Caution The protection provided by this product may be impaired if it is used in a

manner not described in this document.

Contents

Electromagnetic Compatibility Guidelines...............................................................................2

Verifying the System Requirements......................................................................................... 2

Unpacking the Kit.....................................................................................................................2

Verifying the Kit Contents................................................................................................ 3

Preparing the Environment....................................................................................................... 4

Installing the Software.............................................................................................................. 5

Installing the NI 5630............................................................................................................... 5

Connecting Signals........................................................................................................... 7

Configuring the NI 5630 in MAX...........................................................................................11

Programming the NI 5630...................................................................................................... 12

NI-VNA Examples......................................................................................................... 12

Making Uncalibrated Measurements with the NI 5630..........................................................13

Calibrating the NI 5630.......................................................................................................... 13

Making Calibrated Measurements with the NI 5630..............................................................14

Troubleshooting...................................................................................................................... 15

What Should I Do if the Module Fails the Self-Test?.....................................................15

Why Is the ACCESS LED Off When the Chassis is On?...............................................15

What Should I Do if the NI 5630 Doesn't Appear in MAX?..........................................15

Where to Go Next................................................................................................................... 17

Worldwide Support and Services............................................................................................ 17

Page 2

Electromagnetic Compatibility Guidelines

This product was tested and complies with the regulatory requirements and limits for

electromagnetic compatibility (EMC) stated in the product specifications. These requirements

and limits are designed to provide reasonable protection against harmful interference when the

product is operated in the intended operational electromagnetic environment.

This product is intended for use in industrial locations. However, harmful interference may

occur in some installations, when the product is connected to a peripheral device or test object,

or if the product is used in residential or commercial areas. To minimize interference with

radio and television reception and prevent unacceptable performance degradation, install and

use this product in strict accordance with the instructions in the product documentation.

Furthermore, any modifications to the product not expressly approved by National Instruments

could void your authority to operate it under your local regulatory rules.

Caution To ensure the specified EMC performance, operate this product only with

shielded cables and accessories.

Caution To ensure the specified EMC performance, the length of all I/O cables

must be no longer than 3 m (10 ft).

Verifying the System Requirements

To use the NI-VNA instrument driver, your system must meet certain requirements.

For more information about minimum system requirements, recommended system, and

supported application development environments (ADEs), refer to the product readme, which

is available on the driver software media or online at ni.com/updates.

Unpacking the Kit

Caution To prevent electrostatic discharge (ESD) from damaging the device,

ground yourself using a grounding strap or by holding a grounded object, such as

your computer chassis.

1. Touch the antistatic package to a metal part of the computer chassis.

2. Remove the device from the package and inspect the device for loose components or any

other sign of damage.

Caution Never touch the exposed pins of connectors.

Notify NI if the device appears damaged in any way. Do not install a damaged device.

3. Visually ensure that the inner and outer center conductors of PORT 1 and PORT 2 are not

damaged and are centered in the middle of the outer connector conductor.

4. Unpack any other items and documentation from the kit.

Store the device in the antistatic package when the device is not in use.

| ni.com | NI PXIe-5630 Getting Started Guide

2

Page 3

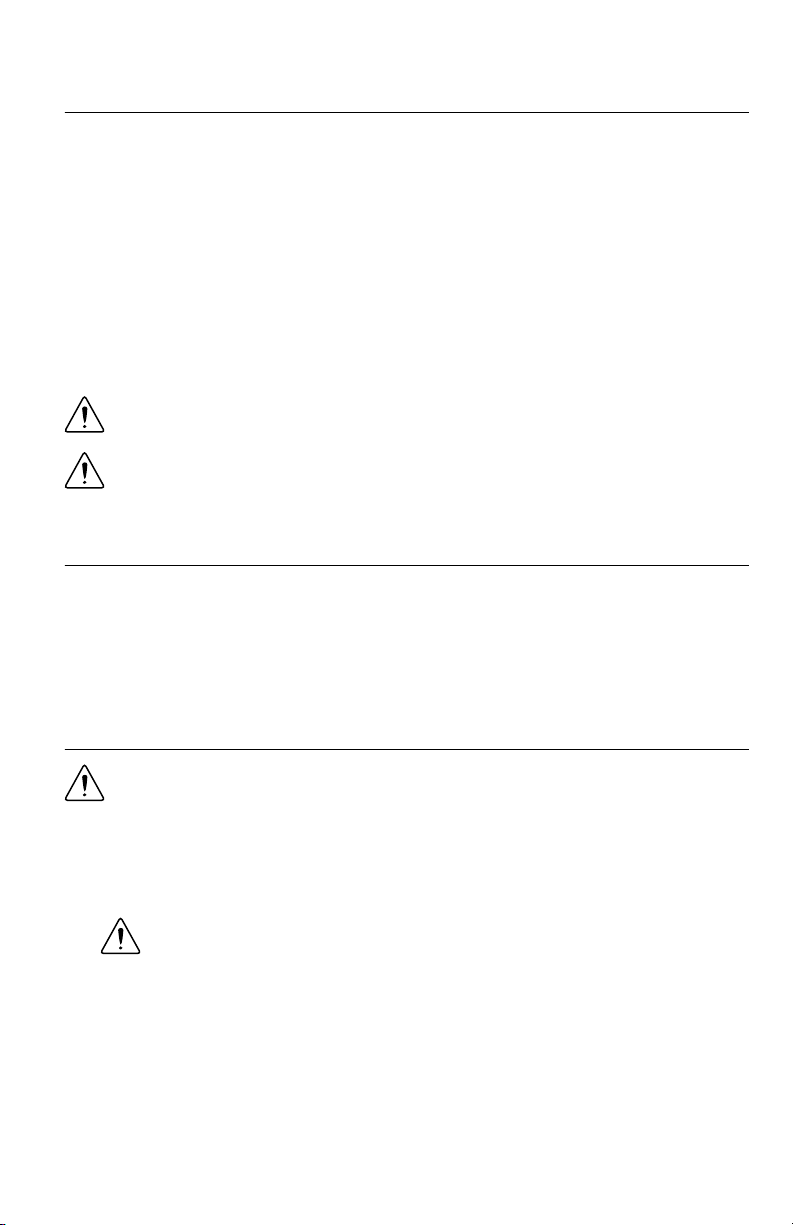

Verifying the Kit Contents

2 3

4

5 6 7 8

1

Figure 1. NI 5630 Kit Contents

1. NI PXIe-5630 Vector Network Analyzer device

2. SMA Driver Bit, part number 190487A-01

3. 1/8 in. Combination Phillips/Flathead Screwdriver,

part number 772006-01

4. NI-VNA Driver Software DVD

5. Read Me First: Safety and Electromagnetic

Compatibility

6. Maintain Forced-Air Cooling Note to Users

7. NI PXIe-5630 Getting Started Guide (this

document)

8. NI 5630 Calibration Certificate

Other Equipment

There are several required items not included in your device kit that you need to operate the

NI 5630. Your application may require additional items not included in your kit to install or

operate your device.

Required Items

• A PXI Express chassis and chassis documentation. The NI PXIe-1075 chassis is one

available option for your device. For more information about compatible chassis options,

refer to ni.com.

• An embedded controller or MXI controller system that meets the system requirements

specified in this guide and chassis documentation.

• 0.9 N · m (8 in-lb) torque wrench

Optional Items

• PXI Chassis Slot Blocker kit (NI part number 199198-01)

• NI 2598 Dual 26 GHz Transfer Switch module (NI part number 778572-98)

• The following accessories available on the NI 5630 product page at ni.com/products:

NI PXIe-5630 Getting Started Guide

| © National Instruments | 3

Page 4

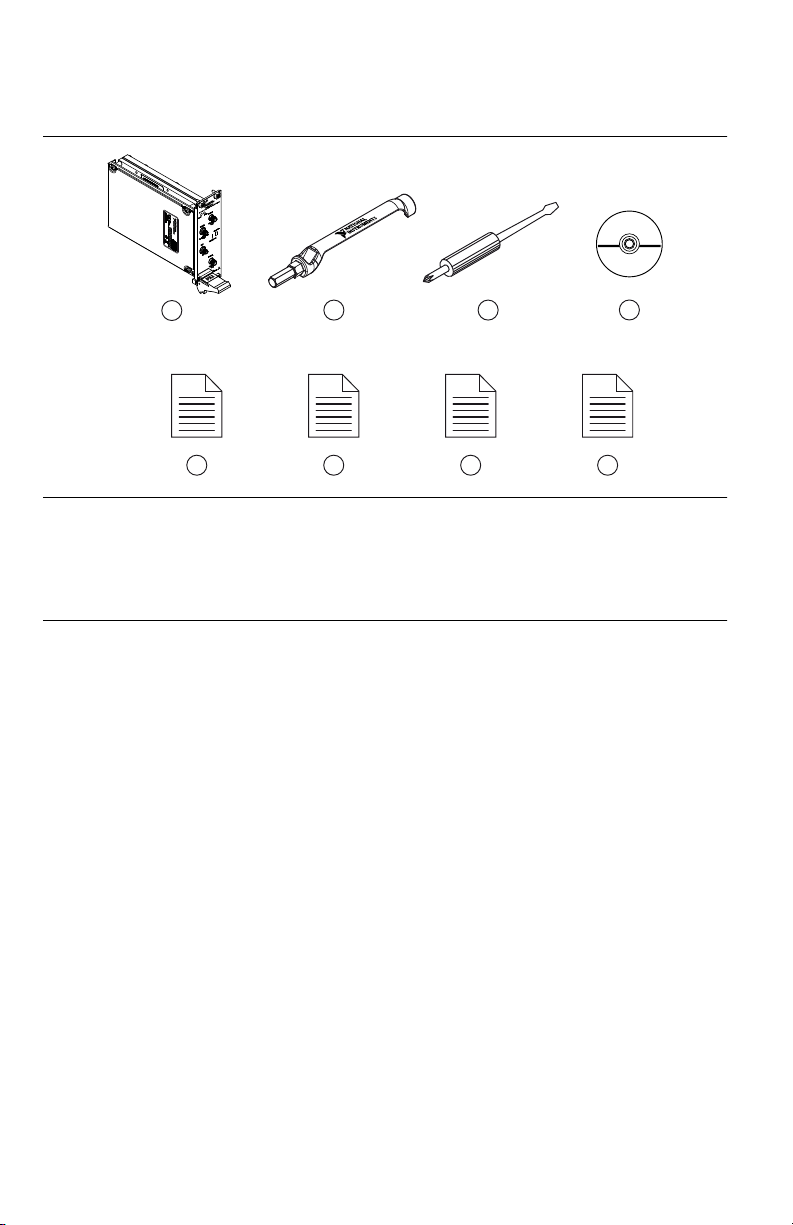

Table 1. NI 5630 Accessories

Accessory Part Number

Manual VNA Calibration Kit, K-Type 781587-01

Manual VNA Calibration Kit, N-Type 781588-01

Automatic VNA Calibration Kit, K-Type, Male-Female, 70 KHz to 9 GHz 782364-01

Phase-Equal Precision Adapter Kit, K-Type 781595-01

Phase-Equal Precision Adapter Kit, N-Type 781596-01

Precision Coaxial Cable, 0.6 m, K-Type, Male-Male 781607-01

Precision Coaxial Cable, 0.6 m, K-Type, Male-Female 781608-01

Precision Coaxial Cable, 0.6 m, K-Type Male to N-Type Male 781609-01

Precision Coaxial Cable, 0.6 m, K-Type Male to N-Type Female 781610-01

Calibrated 5/16" Torque Wrench, 8 in-lbs (0.9 Nm) 781615-01

Preparing the Environment

Ensure that the environment you are using the NI 5630 in meets the following specifications.

............................................................................Operating ambient temperature

(IEC-60068-2-1, IEC-60068-2-2)

............................................................................Operating relative humidity

(IEC-60068-2-56)

............................................................................Maximum altitude 2,000 m (800 mbar) (at 25 °C ambient

............................................................................Pollution Degree 2

Indoor use only.

Caution Clean the hardware with a soft, nonmetallic brush. Make sure that the

hardware is completely dry and free from contaminants before returning it to

service.

Note Refer to the NI PXIe-5630 Specifications at ni.com/manuals for complete

specifications.

4 | ni.com | NI PXIe-5630 Getting Started Guide

0 °C to 55 °C

10% to 90%, noncondensing

temperature)

Page 5

Installing the Software

NI PXIe-1062Q

1

2 3

4

5

You must be an Administrator to install NI software on your computer.

1. Install an ADE, such as LabVIEW or LabWindows™/CVI™.

2. Insert the driver software media into your computer. The installer should open

automatically.

If the installation window does not appear, navigate to the drive, double-click it, and

double-click autorun.exe.

3. Follow the instructions in the installation prompts.

Note Windows users may see access and security messages during

installation. Accept the prompts to complete the installation.

4. When the installer completes, select Restart in the dialog box that prompts you to restart,

shut down, or restart later.

Installing the NI 5630

Caution To prevent damage to the device caused by ESD or contamination, handle

the device using the edges or the metal bracket.

1. Ensure the AC power source is connected to the chassis before installing the modules.

The AC power cord grounds the chassis and protects it from electrical damage while you

install the modules.

2. Power off the chassis.

3. Inspect the slot pins on the chassis backplane for any bends or damage prior to

installation. Do not install a module if the backplane is damaged.

4. Remove the black plastic connectors from all the captive screws on the module front

panel.

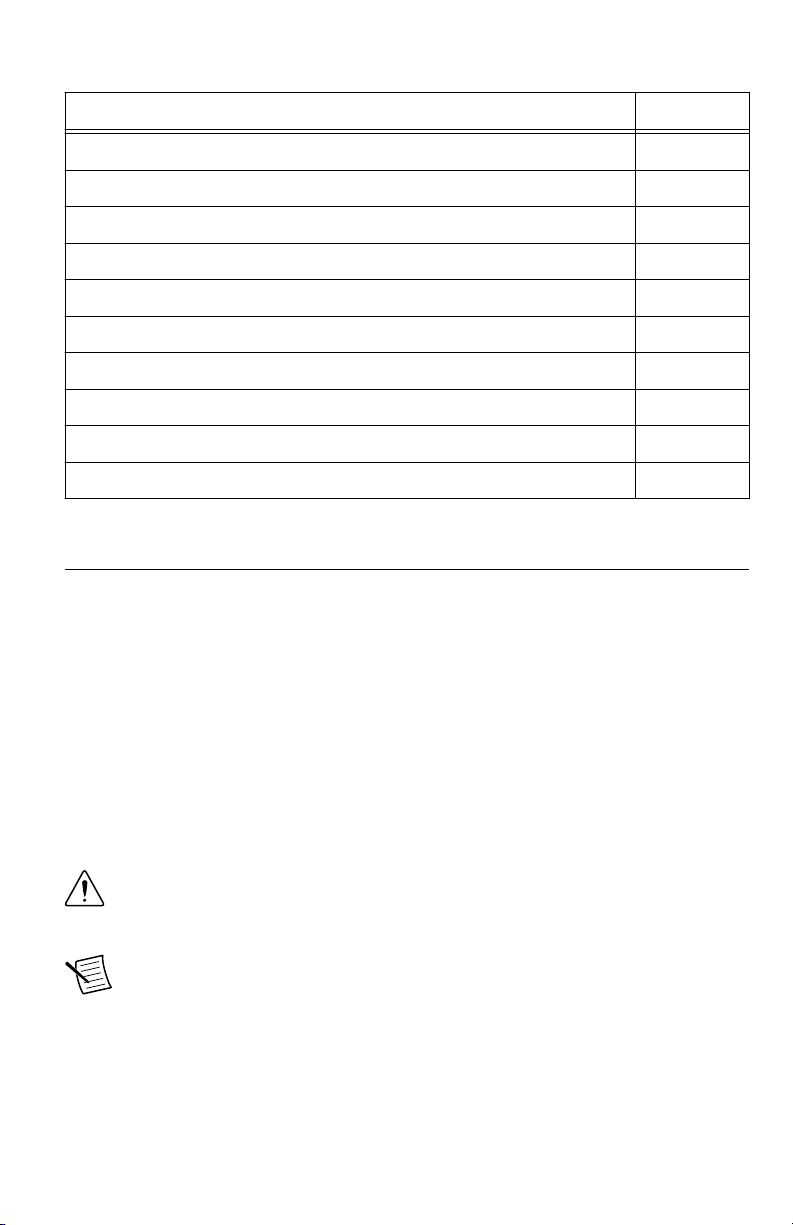

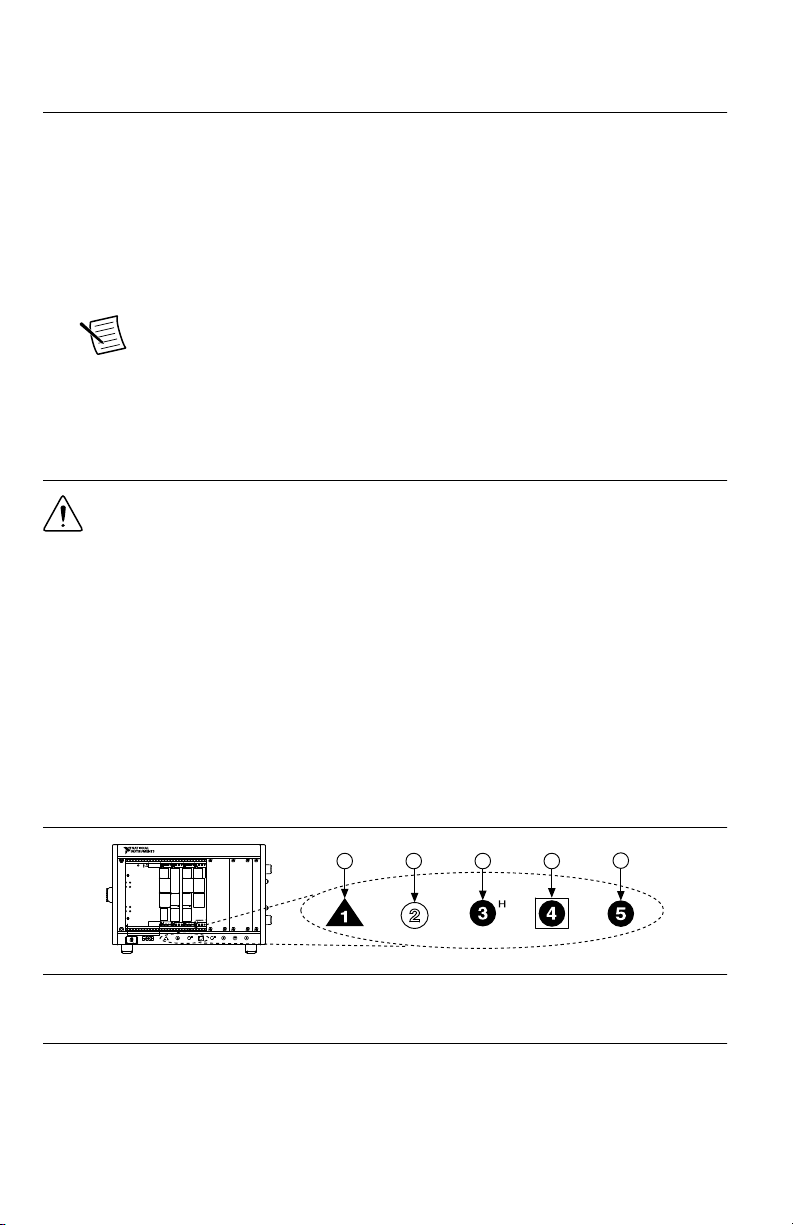

5. Identify a supported slot in the chassis. The following figure shows the symbols that

indicate the slot types.

Figure 2. Chassis Compatibility Symbols

1. PXI Express System Controller Slot

2. PXI Peripheral Slot

3. PXI Express Hybrid Peripheral Slot

4. PXI Express System Timing Slot

5. PXI Express Peripheral Slot

The NI 5630 can be placed in PXI Express peripheral slots or PXI Express Hybrid

peripheral slots.

NI PXIe-5630 Getting Started Guide

| © National Instruments | 5

Page 6

6. Touch any metal part of the chassis to discharge static electricity.

2

3

NI PXIe-1075

1

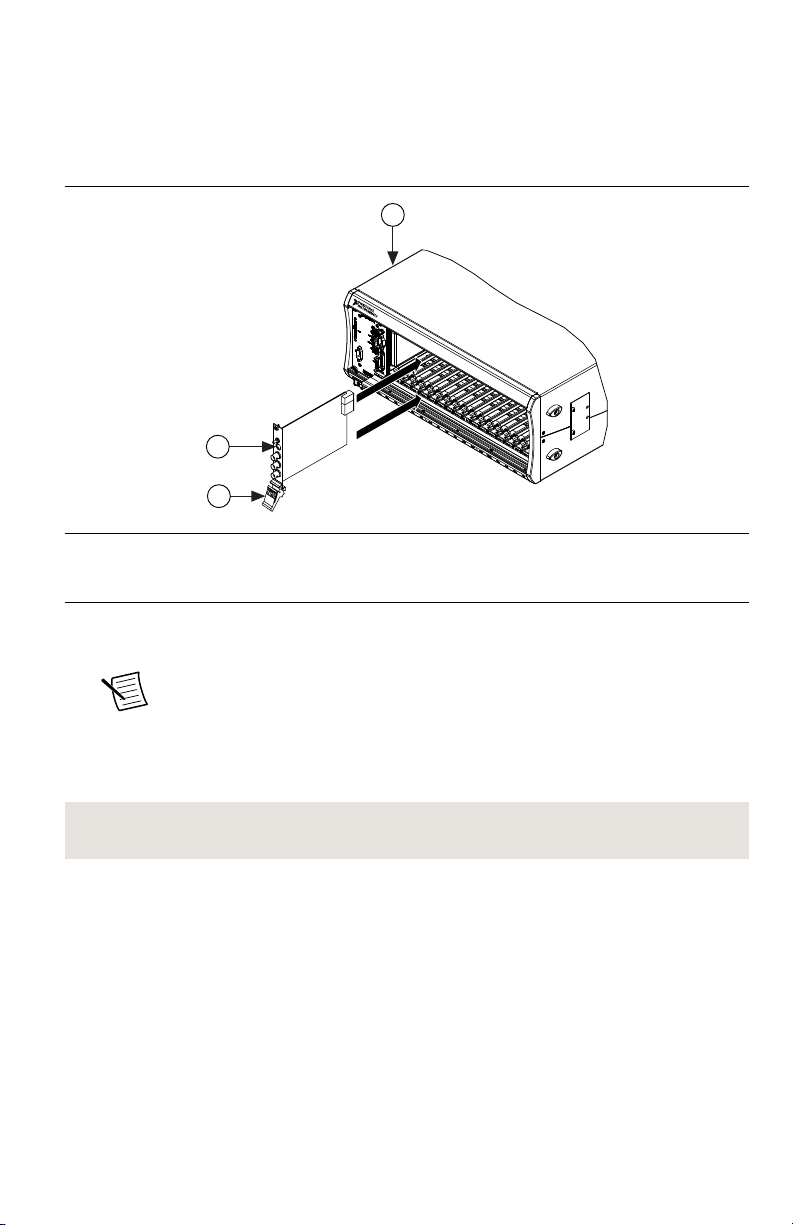

7. Ensure that the ejector handle is in the unlatched (downward) position.

8. Place the module edges into the module guides at the top and bottom of the chassis. Slide

the device into the slot until it is fully inserted.

Figure 3. Module Installation

1. Chassis

2. Hardware Module

3. Ejector Handle in Down (Unlatched) Position

9. Latch the module in place by pulling up on the ejector handle.

10. Secure the device front panel to the chassis using the front-panel mounting screws.

Note Tightening the top and bottom mounting screws increases mechanical

stability and also electrically connects the front panel to the chassis, which can

improve the signal quality and electromagnetic performance.

11. Cover all empty slots using filler panels or slot blockers to maximize cooling air flow.

12. Power on the chassis.

Related Information

Installing the Software on page 5

| ni.com | NI PXIe-5630 Getting Started Guide

6

Page 7

Connecting Signals

1

2 3

4 4

Use appropriate shielded cables to connect signals to the NI vector network analyzer to ensure

you achieve the best measurement accuracy possible.

Unsuitable cabling can adversely affect the vector error correction, producing unreliable and

misleading results. Precision coaxial cables are available for purchase from ni.com. Ensure

you take the following precautions when connecting signals to the NI 5630.

• Use phase-stable cables to make connections with the NI 5630. Phase-stable cables help

ensure that the reference plane remains stable across shifts in cable position after

calibration.

• Maintain placement of any accessories or cables that you attach to the NI 5630 to ensure

that the reference plane remains constant between calibration and measurement.

Tip You can also use phase-equal adapters after calibration to preserve the

reference plane.

The following figure shows an example of the reference plane for a male and female

connector.

Figure 4. Connector Reference Plane and Pin Depth

1. Reference Plane

2. Female Connector

3. Male Connector

4. Pin Depth

Related Information

Refer to the NI Vector Network Analyzers Help for more information about reference planes

and pin depth.

Direct Connections to the NI 5630

The NI 5630 is a precision RF instrument that is sensitive to ESD and transients. Ensure you

take the following precautions when making direct connections to the NI 5630 to avoid

damaging the device.

NI PXIe-5630 Getting Started Guide

| © National Instruments | 7

Page 8

Caution Apply external signals only while the NI 5630 is powered on. Applying

10 MHz

-10 dBm to +3 dBm

50 Ω

+23 dBm MAX

50 VDC

50 Ω

+23 dBm MAX

50 VDC

50 Ω

PORT 1

REF IN

TTL

PFI 0

NI PXIe-5630

10 MHz - 6 GHz Vector Network Analyzer

ACCESS ACTIVE

PORT 2

TRANSMISSION

REFLECTION

ESD

SENSITIVE

external signals while the device is powered off may cause damage.

• Ensure you are properly grounded when manipulating cables or antennas connected to the

NI 5630 PORT 1 or PORT 2 connector.

• If you are using noninsulated devices, such as a noninsulated RF antenna, ensure the

devices are maintained in a static-free environment.

• If you are using an active device, such as a preamplifier or switch routed to the NI 5630

PORT 1 or PORT 2 connector, ensure that there are no signal transients greater than the

RF and DC specifications for the device that are being generated and sourced to the

NI 5630 PORT 1 or PORT 2 connector.

NI 5630 Front Panel

The NI 5630 contains four connectors and two LEDs.

Figure 5. NI PXIe-5630 Front Panel

8 | ni.com | NI PXIe-5630 Getting Started Guide

Page 9

Table 2. Device Front Panel Icon Definitions

Refer to the user documentation for required maintenance measures to ensure user

safety and/or preserve the specified EMC performance.

The signal pins of this product's input/output ports can be damaged if subjected to

ESD. To prevent damage, turn off power to the product before connecting cables and

employ industry-standard ESD prevention measures during installation, maintenance,

and operation.

Table 3. NI 5630 Front Panel Connectors

Connector Use

PORT 1 Input/output terminal for NI 5630 measurements.

REF IN Input terminal for an external reference signal for the NI 5630.

PFI 0 Input terminal for an external trigger signal.

PORT 2 Input terminal for NI 5630 measurements.

Table 4. NI 5630 LEDs

LED Indication

ACCESS Indicates the basic hardware status of the NI 5630.

OFF—The device is not yet functional.

AMBER—The device is being accessed. Accessed means that the device is being

communicated with over the PXI Express bus.

GREEN—The device is ready to be programmed by NI-VNA.

RED—The device has detected a hardware error, such as a hardware failure. The

LED remains red until the error condition is removed.

ACTIVE Indicates the state of the NI 5630.

OFF—The device is not yet functional.

AMBER—The device is armed and waiting for a trigger.

GREEN—The device has received a Start Trigger. This state also indicates that

the device is making a measurement.

RED—The device has detected a spurious error, such as when the PLL becomes

unlocked. The LED remains red until the error condition is removed.

NI PXIe-5630 Getting Started Guide | © National Instruments | 9

Page 10

Connector Care

The NI 5630 is a high-accuracy precision laboratory device and should be carefully handled.

Follow the precautions listed in this section when handling or connecting devices. Complying

with these precautions guarantees longer component life and lower equipment downtime

because of connector or device failure.

Tighten Connectors Without Rotating the Center Pin

Never tighten the connectors, adapters, or cables such that the center pin rotates. Damage

occurs to the mating plane surfaces if the center pin rotates.

Avoid Touching Connectors with Bare Hands

Avoid touching connector mating planes with bare hands. Natural skin oils and microscopic

dirt particles are difficult to remove.

Observe Pin Depth of Mating Connectors

Make sure to use the proper connectors to mate with the NI 5630. NI recommends that you use

precision or instrument or metrology grade Type-K, 2.92 mm, 3.5 mm, or SMA connectors.

Always check the point depth of a connector with a pin depth gauge before use to determine

whether the pin depth is within the specified range.

Avoid Lateral Pressure

Never put lateral pressure on the center pin of the connector.

Always Torque Connectors to 0.9 N · m Using a Torque Wrench

Do not overtorque connectors; doing so may damage the connector center pin. Always use a

0.9 N · m (8 in-lb) torque wrench when tightening 2.92 mm, 3.5 mm, and SMA connectors.

Finger-tighten N-type connectors. Never use pliers.

Avoid Mechanical Shock

Precision connectors are designed to withstand years of normal bench handling. Handle the

connectors carefully and avoid dropping them. Mechanical shock significantly reduces their

service life.

Avoid Applying Excessive Power

The NI 5630 is rated for a specific maximum continuous input power. Exceeding the

maximum input power level permanently damages the internal components. Before making

connections, verify the maximum input levels labeled below the ports on the module front

panel.

Clean Connectors Carefully

Dirt and other contamination on the connector interfaces can affect the performance of the RF

components. To clean the connector interfaces, use only pure isopropyl alcohol as a cleaning

solvent. Do not use excessive amounts of alcohol, as this prolongs drying time. Apply the

alcohol with a foam-tipped swab instead of cotton swabs, because the cotton can become

lodged in the connector.

| ni.com | NI PXIe-5630 Getting Started Guide

10

Page 11

Use low-pressure compressed air to remove foreign particles and to dry the connector. After

cleaning, verify that the center pin has not been bent or damaged.

Store Connectors Properly

When not in use, keep the connectors covered with the dust cap included in the NI 5630

shipping kit.

Configuring the NI 5630 in MAX

Use Measurement & Automation Explorer (MAX) to configure your National Instruments

hardware. MAX informs other programs about which devices reside in the system and how

they are configured. MAX is automatically installed with NI-VNA.

1. Launch MAX.

2. In the Configuration pane, double-click Devices and Interfaces to see the list of installed

devices.

Installed devices appear under the name of their associated chassis.

3. Expand your Chassis tree item.

MAX lists all devices installed in the chassis. Your default device names may vary.

Note If you do not see your device listed, press <F5> to refresh the list of

installed devices. If the device is still not listed, power off the system, ensure

the device is correctly installed, and restart.

4. Record the device identifier MAX assigns to the hardware. Use this identifier when

programming the NI 5630.

5. Self-test the device by selecting the device in the configuration tree and clicking Self-

Test in the MAX toolbar.

The MAX self-test performs a basic verification of hardware resources.

Related Information

What Should I Do if the Module Fails the Self-Test? on page 15

What Should I Do if the NI 5630 Doesn't Appear in MAX? on page 15

NI PXIe-5630 Getting Started Guide

| © National Instruments | 11

Page 12

Programming the NI 5630

You can acquire data interactively with the NI 5630 using the NI-VNA soft front panel (SFP),

or you can control the device programmatically using the NI-VNA instrument driver. You can

then use NI-VNA to program the device in the ADE of your choice.

Table 5. NI 5630 Programming Options

Application

Programming

Interface (API)

Location Description

NI-VNA SFP Available from the Start menu at Start»

All Programs»National Instruments»

NI-VNA»NI-VNA Soft Front Panel.

NI-VNA

Instrument Driver

LabVIEW—Available on the LabVIEW

Functions palette at Measurement I/O»

NI-VNA.

A software representation of

a traditional benchtop vector

network analyzer.

Features a set of functions

and attributes that exercise

all the functionality of the

NI 5630, including

C or LabWindows/CVI—Available at

Program Files\IVI Foundation

\IVI\Drivers\niVNA.

Microsoft Visual C/C++—Use

examples located in the <NIDocDir>

\NI-VNA\examples directory, where

<NIDocDir> is one of the following

configuration, control, and

other device-specific

functions.

You can modify an NI-VNA

C example to create an

application with Microsoft

Visual C/C++.

directories:

• Windows XP—Documents and

Settings\All Users\Shared

Documents\National

Instruments

• Windows 7/Vista—Users

\Public\Documents

\National Instruments

Related Information

Refer to the Getting Started section of the NI Vector Network Analyzers Help for detailed

instructions about how to acquire data in a specific ADE.

Refer to the Creating an Application with Microsoft Visual C/C++ topic of the NI Vector

Network Analyzers Help to manually add all required include and library files to the project.

NI-VNA Examples

Examples demonstrate the functionality of the device and serve as programming models and

building blocks for your own applications. The NI Example Finder is a utility available for

| ni.com | NI PXIe-5630 Getting Started Guide

12

Page 13

some ADEs that organizes examples into categories and allows you to easily browse and

search installed examples. You can see descriptions and compatible hardware models for each

example or see all the examples compatible with one particular hardware model.

Table 6. Locating NI-VNA Examples

ADE How to Locate Examples

LabVIEW or

LabWindows/CVI

ANSI C or Microsoft

Visual C/C++

Locate examples with the NI Example Finder. Within LabVIEW

or LabWindows/CVI, select Help»Find Examples and navigate

to Hardware Input and Output»Modular Instruments.

Locate examples in the <NIDocDir>\NI-VNA\examples

directory, where <NIDocDir> is one of the following directories:

• Windows 8/7/Vista—Users\Public\Documents

\National Instruments

• Windows XP—Documents and Settings\All

Users\Documents\National Instruments

Making Uncalibrated Measurements with the NI 5630

Performing uncalibrated measurements with the NI 5630 can be useful for measuring device

raw performance, custom measurement configuration, and other specialized measurements.

You can perform uncalibrated measurements using the NI-VNA Soft Front Panel (SFP) or the

NI-VNA driver API.

1. Prepare for the measurement.

a) Warm up the device and the DUT as specified in the device specifications.

b) Make signal connections as directed in the Connecting Signals section.

c) Verify that the device is within the factory calibration interval.

2. Set up an initial, uncalibrated measurement.

a) Preset the NI 5630.

b) Configure the source parameters, including reference frequency, output power, and

IF bandwidth.

c) Connect the DUT to verify setup, cables, adapters, and operation.

d) Select which S-parameter(s) to measure, and choose the display format.

3. Start the measurement.

4. Observe the uncalibrated response.

5. Remove the DUT.

Calibrating the NI 5630

Frequent calibration is particularly important for the NI 5630 because it allows you to remove

certain errors from the actual measurements. Calibration removes errors caused by

NI PXIe-5630 Getting Started Guide

| © National Instruments | 13

Page 14

temperature, test environment, cables, and other test fixture differences. You can perform a

calibration by using either the NI-VNA Soft Front Panel (SFP) or the NI-VNA driver API.

1. Choose whether you want to perform a new calibration or load data saved from a

previous calibration.

2. To perform a new calibration, complete the following steps:

a) Set the measurement parameters such as power, frequency, and number of points.

b) Set IF bandwidth and averaging to minimize noise during calibration.

c) Choose the proper calibration kit or input calibration standard definitions.

Tip Keep the reference plane constant between your initial, uncalibrated

measurement and your calibration setup. The reference plane is

established at the location where the VNA connects to the AutoCal

module or to the calibration standard. For example, your reference plane

may be located at the end of an adapter connected to the end of a precision

cable.

d) Calibrate manually or use automatic calibration.

e) Verify calibration quality using a known verification standard.

Note Do not use the same calibration standards that you used for

calibration to perform the verification.

f) Save the instrument state and calibration.

3. To load a saved calibration, complete the following steps:

a) Select the calibration file.

b) Ensure that the source parameters you specified in step 2b of the Making

Uncalibrated Measurements with the NI 5630 section match those that were used in

the calibration.

Perform a new calibration if the settings do not match.

Related Information

Refer to the NI Vector Network Analyzers Help for more information about reference planes.

Making Calibrated Measurements with the NI 5630

Performing calibrated measurements with the NI 5630 is useful when you need to minimize

sources of error so that you can acquire the most accurate data for your test system. You can

perform calibrated measurements using the NI-VNA Soft Front Panel (SFP) or the NI-VNA

driver API.

1. Measure the DUT.

2. Ensure you are applying the proper correction from the Calibrating the NI 5630 section.

3. Measure and save the DUT parameters.

4. Verify that the calibrated measurement falls within your expected range.

| ni.com | NI PXIe-5630 Getting Started Guide

14

Page 15

Troubleshooting

If an issue persists after you complete a troubleshooting procedure, contact NI technical

support or visit ni.com/support.

What Should I Do if the Module Fails the Self-Test?

1. Restart the system.

2. Launch MAX, and perform the self-test again.

3. Power off the chassis.

4. Reinstall the failed module in a different slot.

5. Power on the chassis.

6. Perform the self-test again.

Related Information

Configuring the NI 5630 in MAX on page 11

Why Is the ACCESS LED Off When the Chassis is On?

The LEDs may not illuminate until the device has been configured in MAX. Before

proceeding, verify that the NI 5630 appears in MAX.

If the ACCESS LED fails to illuminate after you power on the chassis, a problem may exist

with the chassis power rails, a hardware module, or the LED.

Caution Apply external signals only while the NI 5630 is powered on. Applying

external signals while the device is powered off may cause damage.

1. Disconnect any signals from the module front panels.

2. Power off the chassis.

3. Remove the module from the chassis and inspect it for damage. Do not reinstall a

damaged device.

4. Reinstall the module in a different chassis slot.

5. Power on the chassis.

6. Verify that the device appears in MAX.

7. Reset the device in MAX and perform a self-test.

What Should I Do if the NI 5630 Doesn't Appear in MAX?

1. In the MAX Configuration pane, click Devices and Interfaces.

2. Expand the Chassis tree to see the list of installed devices, and press <F5> to refresh the

list.

3. If the module is still not listed, power off the system, ensure that all hardware is correctly

installed, and restart the system.

NI PXIe-5630 Getting Started Guide

| © National Instruments | 15

Page 16

4. Navigate to the Device Manager.

Operating System Description

Windows 8 Right-click the Start screen, and select All apps»Control Panel»

Hardware and Sound»Device Manager.

Windows 7 Select Start»Control Panel»Device Manager.

Windows Vista Select Start»Control Panel»System and Maintenance»Device

Manager.

Windows XP Select Start»Control Panel»System»Hardware»Device

Manager.

5. If you are using a PXI controller, verify that a National Instruments entry appears in the

system device list and that the NI PXIe-5630 is enabled. If the device is disabled, rightclick NI PXIe-5630, and select Enable from the shortcut menu. If you are using a MXI

controller, right-click PCI-to-PCI Bridge, and select Properties from the shortcut menu

to verify that the bridge is enabled.

Related Information

Configuring the NI 5630 in MAX on page 11

16 | ni.com | NI PXIe-5630 Getting Started Guide

Page 17

Where to Go Next

custom applications within

an application programming

interface (API).

NI-VNA Examples*

NI Vector Network

Analyzers Help*

NI-VNA Soft Front Panel

NI-VNA Instrument Driver

about hardware features

or review device

specifications.

more about your products through ni.com.

NI PXIe-5630

Specifications*

NI Vector Network

Analyzers Help*

the application development

environment (ADE)

for your application.

Learn LabVIEW Basics

Getting Started with

LabWindows/CVI

Support

ni.com/support

*This item is also installed with the driver software.

EXPLORE LEARN CREATE

DISCOVER

RF Solutions

ni.com/rf

Services

ni.com/services

NI Community

ni.com/community

Located at ni.com/gettingstarted

Located at ni.com/manuals

Located using the NI Example Finder

Refer to the following figure for information about other product tasks and associated

resources for those tasks.

Tip The NI Vector Network Analyzers Help is an HTML version of a traditional

user manual that includes detailed information about RF fundamentals, device

features, and programming with NI-VNA.

Worldwide Support and Services

The National Instruments website is your complete resource for technical support. At ni.com/

support, you have access to everything from troubleshooting and application development

self-help resources to email and phone assistance from NI Application Engineers.

Visit ni.com/services for NI Factory Installation Services, repairs, extended warranty, and

other services.

NI PXIe-5630 Getting Started Guide

| © National Instruments | 17

Page 18

Visit ni.com/register to register your National Instruments product. Product registration

facilitates technical support and ensures that you receive important information updates from

NI.

A Declaration of Conformity (DoC) is our claim of compliance with the Council of the

European Communities using the manufacturer’s declaration of conformity. This system

affords the user protection for electromagnetic compatibility (EMC) and product safety. You

can obtain the DoC for your product by visiting ni.com/certification. If your product supports

calibration, you can obtain the calibration certificate for your product at ni.com/calibration.

National Instruments corporate headquarters is located at 11500 North Mopac Expressway,

Austin, Texas, 78759-3504. National Instruments also has offices located around the world.

For telephone support in the United States, create your service request at ni.com/support or

dial 1 866 ASK MYNI (275 6964). For telephone support outside the United States, visit the

Worldwide Offices section of ni.com/niglobal to access the branch office websites, which

provide up-to-date contact information, support phone numbers, email addresses, and current

events.

Refer to the NI Trademarks and Logo Guidelines at ni.com/trademarks for information on National Instruments

trademarks. Other product and company names mentioned herein are trademarks or trade names of their respective

companies. For patents covering National Instruments products/technology, refer to the appropriate location: Help»

Patents in your software, the patents.txt file on your media, or the National Instruments Patent Notice at ni.com/

patents. You can find information about end-user license agreements (EULAs) and third-party legal notices in the

readme file for your NI product. Refer to the Export Compliance Information at ni.com/legal/export-compliance for

the National Instruments global trade compliance policy and how to obtain relevant HTS codes, ECCNs, and other

import/export data. NI MAKES NO EXPRESS OR IMPLIED WARRANTIES AS TO THE ACCURACY OF THE

INFORMATION CONTAINED HEREIN AND SHALL NOT BE LIABLE FOR ANY ERRORS. U.S. Government

Customers: The data contained in this manual was developed at private expense and is subject to the applicable limited

rights and restricted data rights as set forth in FAR 52.227-14, DFAR 252.227-7014, and DFAR 252.227-7015.

© 2010—2014 National Instruments. All rights reserved.

375565C-01 Sep14

Loading...

Loading...