Page 1

CALIBRATION PROCEDURE

PXIe-5185/5186

This document contains information for calibrating National Instruments PXIe-5185/5186

digitizers. The PXIe-5185/5186 digitizers were developed jointly between Tektronix and

National Instruments. The devices use Tektronix, Enabling Technology

™

to deliver wide analog

bandwidth and high-speed sampling on the National Instruments Synchronization and Memory

Core (SMC) technology with TClk synchronization.

For more information on calibration, visit

ni.com/calibration.

Contents

50 Ω and 1 MΩ Devices ...........................................................................................................2

Software Requirements............................................................................................................. 2

Related Documentation ............................................................................................................2

Password ..................................................................................................................................3

Calibration Interval...................................................................................................................3

Test Equipment.........................................................................................................................3

Test Conditions.........................................................................................................................5

Calibration Procedures .............................................................................................................6

Initial Setup....................................................................................................................... 6

Self-Calibration ................................................................................................................6

MAX......................................................................................................................... 7

NI-SCOPE Soft Front Panel ..................................................................................... 7

NI-SCOPE ................................................................................................................ 7

External Calibration.......................................................................................................... 7

Test System Characterization ........................................................................................... 7

Zeroing the Power Sensor......................................................................................... 8

Characterizing Power Splitter Amplitude Imbalance............................................... 8

Verification....................................................................................................................... 14

Verifying DC and Programmable Vertical Offset Accuracy.................................... 14

Verifying 50 Ω AC Amplitude Accuracy and Bandwidth .......................................17

Verifying 1 MΩ AC Amplitude Accuracy and Bandwidth...................................... 20

Verifying Timebase Accuracy.................................................................................. 23

Adjustment........................................................................................................................ 23

Worldwide Support and Services ............................................................................................. 29

Page 2

2 | ni.com | PXIe-5185/5186 Calibration Procedure

50 Ω and 1 MΩ Devices

Early versions of the PXIe-5185/5186 support only 50 Ω input impedance. Check the part

number of your device to see what input impedance is supported by your device:

• PXIe-5185 module part numbers 199363x-0zL and PXIe-5186 module part numbers

193537x-0zL (where x is any letter and z is any number) only support 50 Ω input

impedance. These devices require NI-SCOPE 3.8.7 or later.

• PXIe-5185 module part numbers 152962x-0zL and PXIe-5186 module part numbers

152961x-0zL (where x is any letter and z is any number) support both 50 Ωand 1 MΩ input

impedance. These devices require NI-SCOPE 3.9.6 or later.

50 Ωdevices need to be tested for only 50 Ωinput impedance because they have no 1 MΩ input.

Software Requirements

Calibrating the PXIe-5185/5186 requires installing the NI-SCOPE instrument driver on the

calibration system. Refer to the 50 Ω and 1 MΩ Devices section to see which driver version your

device requires. You can download the NI-SCOPE instrument driver from the NI website at

ni.com/downloads/drivers. NI-SCOPE supports programming a self-calibration and an

external calibration in multiple application development environments (ADEs). When you

install NI-SCOPE, you need to install support for only the ADE that you intend to use.

LabVIEW support is in the

niScope.llb file, and all calibration functions appear in the

NI-SCOPE Calibration palette. For LabWindows

™

/CVI™ users, the NI-SCOPE function panel,

niScope.fp, provides access to the available functions.

For the locations of files you may need to calibrate your device, refer to the NI-SCOPE Readme,

which is available on the NI-SCOPE media.

Related Documentation

For information about NI-SCOPE and the PXIe-5185/5186, consult the following documents:

• NI High-Speed Digitizers Getting Started Guide—provides instructions for installing and

configuring the PXIe-5185/5186.

• NI High-Speed Digitizers Help—includes detailed information about the PXIe-5185/5186

and NI-SCOPE VIs and functions and information about creating applications using

NI-SCOPE.

• PXIe-5185 Specifications—provides the published specification values for the PXIe-5185.

• PXIe-5186 Specifications—provides the published specification values for the PXIe-5186.

These documents are installed with NI-SCOPE. You can also find the latest versions of the

documentation at

ni.com/manuals.

Page 3

PXIe-5185/5186 Calibration Procedure | © National Instruments | 3

Password

The default calibration password is NI.

Calibration Interval

NI recommends a calibration interval of one year to ensure the warranted specifications for the

PXIe-5185/5186 are met.

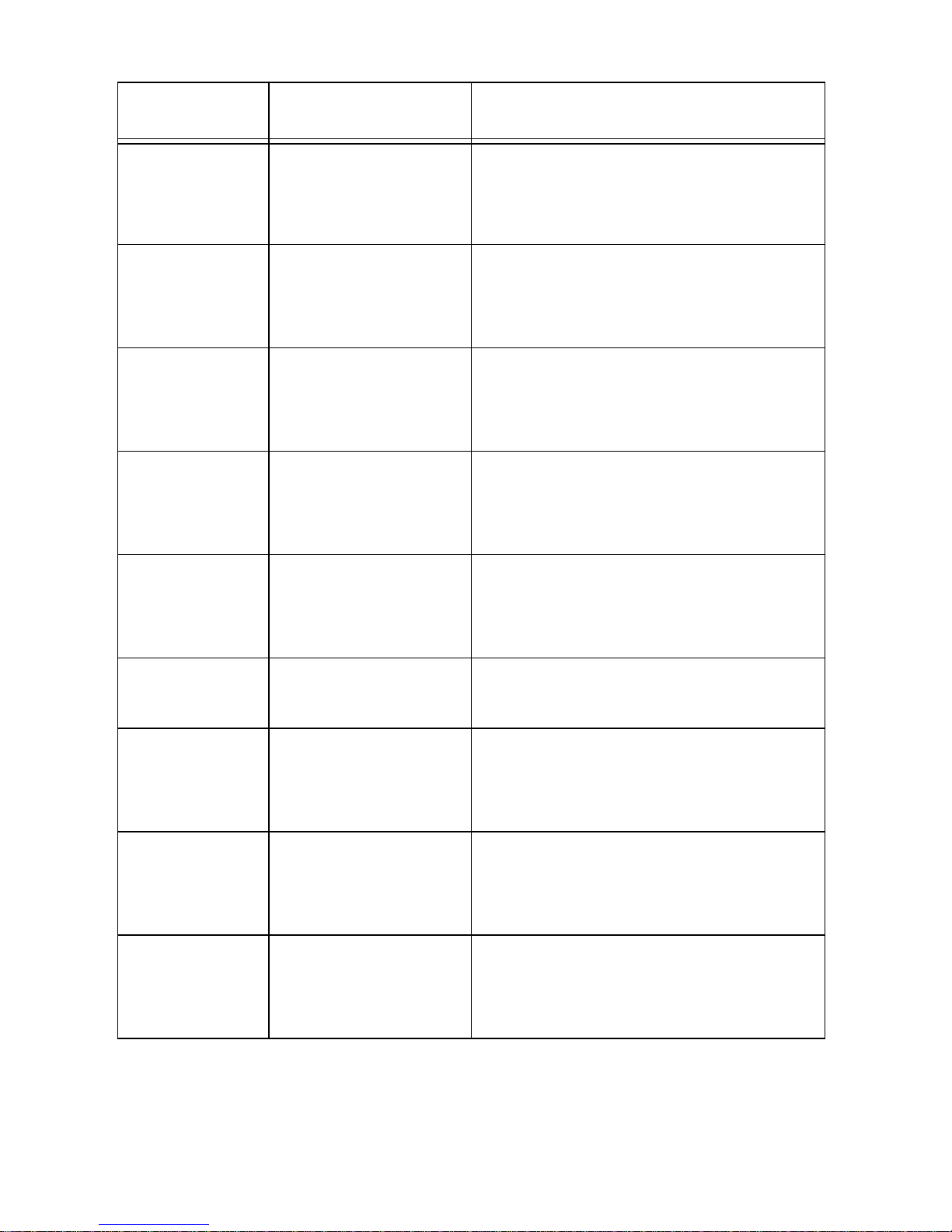

Test Equipment

National Instruments recommends that you use the equipment in Table 1 for calibrating the

PXIe-5185/5186. If you do not have the recommended instruments, use these specifications to

select a substitute calibration standard.

Table 1. PXIe-5185/5186 Test Equipment

Equipment

Recommended

Model

Requirements

Oscilloscope

calibrator

Fluke 9500B/3200 DC Output Range: 2 V to -2 V into 50 Ω,

6.5V to - 6.5 V into 1 MΩ

DC Voltage Accuracy: DC ±0.3% of output

into 50 Ω and 1 MΩ

Leveled Sine Wave Amplitude Range:

0.9 V

pk-pk

into 50 Ω

Leveled Sine Wave Frequency Accuracy:

±4 ppm

Square Wave: 8.0 V

pk-pk

at 100 kHz

into 1 MΩ

3.2 GHz output

module

Fluke 9530 Active

Head

Power sensor Rohde & Schwarz

NRP-Z91

Range: -26 dBm to 10 dBm

Frequency range: 50 kHz to 5.0 GHz

Absolute power accuracy:

• <0.048 dB at 50 kHz

• <0.063 dB at 5.0 GHz

Relative power accuracy:

• <0.022 dB at 50 kHz

• <0.031 dB for frequencies > 50 kHz and

< 5.0 GHz

VSWR: <1.11

Page 4

4 | ni.com | PXIe-5185/5186 Calibration Procedure

Signal generator Rohde & Schwarz

SMA100A

Frequency range: 50 kHz to 5.0 GHz

Amplitude range: -20 dBm to 16 dBm

Harmonics: <-30 dBc

Power splitter Aeroflex/Weinschel Frequency range: 50 kHz to 5.0 GHz

VSWR: <1.1

Amplitude tracking: <0.5 dB

50 Ω BNC

terminator (f)

Fairview Microwave

ST3B-F

Frequency range: DC to 0.5 GHz

VSWR: <1.2

Impedance: 50 Ω

50 Ω SMA

terminator (f)

Fairview Microwave

ST1852F

Frequency range: DC to 5.0 GHz

VSWR: <1.1

Impedance: 50 Ω

SMA (m)-toSMA (m) cable

— Frequency range: DC to 5.0 GHz

VSWR: <1.1

Length: ≤1 meter

SMA (m)-toBNC (f)

Fairview Microwave

SM4723

Frequency range: DC to 100 kHz

Impedance: 50 Ω

SMA (f)-toN (m) adapter

Fairview Microwave

SM4226

Frequency range: DC to 5.0 GHz

VSWR: <1.05

Impedance: 50 Ω

SMA (f)-to-N (f)

adapter

Fairview Microwave

SM4236

Frequency range: DC to 5.0 GHz

VSWR: <1.15

Impedance: 50 Ω

SMA (m)-toSMA (m)

adapter (×2)

Fairview Microwave

SM4960

Frequency range: DC to 5.0 GHz

VSWR: <1.1

Impedance: 50 Ω

Table 1. PXIe-5185/5186 Test Equipment (Continued)

Equipment

Recommended

Model

Requirements

Page 5

PXIe-5185/5186 Calibration Procedure | © National Instruments | 5

Test Conditions

Follow these guidelines to optimize the equipment and the environment during calibration:

• Keep connections to the device as short as possible. Long cables and wires act as antennae,

picking up extra noise that can affect measurements.

• Verify that all connections to the device, including front panel connections, are secure.

• Use shielded copper wire for all cable connections to the device. Use twisted-pairs wire to

eliminate noise and thermal offsets.

• Maintain an ambient temperature of 23 ±3 °C. The device temperature will be greater than

the ambient temperature.

• Keep relative humidity below 80%.

• Allow a warm up time of at least 25 minutes to ensure that the measurement circuitry is at

a stable operating temperature.

• Ensure that the PXI Express chassis fan speed is set to HIGH, that the fan filters are clean

if present, and that the empty slots contain PXI chassis slot blockers and filler panels. For

more information, refer to the Maintain Forced-Air Cooling Note to Users document

available at

ni.com/manuals.

• Plug the chassis/PC and the calibrator into the same power strip to avoid ground loops.

BNC (f)-toN (f) adapter

Fairview Microwave

SM3526

Frequency range: DC to 0.5 GHz

VSWR: <1.2

Impedance: 50 Ω

SMA (m)-toBNC (m)

adapter (×2)

Fairview Microwave

SM4716

Frequency range: DC to 0.5 GHz

VSWR: <1.3

Impedance: 50 Ω

BNC

feed-through

terminator

Fairview Microwave

ST0150

Frequency range: DC to 0.5 GHz

VSWR:

• <1.1 at 100 MHz

• <1.25 at 500 MHz

Impedance: 50 Ω

PXI Express

Chassis

Any NI PXI Express

chassis that meets the

requirements

100 MHz reference clock for PXI Express

slots with an accuracy of ±25ppm

Table 1. PXIe-5185/5186 Test Equipment (Continued)

Equipment

Recommended

Model

Requirements

Page 6

6 | ni.com | PXIe-5185/5186 Calibration Procedure

Calibration Procedures

The calibration process includes the following steps:

1. Initial Setup—Install the device and configure it in Measurement & Automation Explorer

(MAX).

2. Self-Calibration—Adjust the self-calibration constants of the device.

3. Verification—Verify the existing operation of the device. This step confirms whether the

device is operating within the published specifications prior to adjustment.

4. Adjustment—Perform an external adjustment of the device that adjusts the calibration

constants of the device. The adjustment procedure automatically stores the calibration date

on the EEPROM to allow traceability.

5. Re-verification—Repeat the verification procedure to ensure that the device is operating

within the published specifications after adjustment.

These procedures are described in more detail in the following sections.

Initial Setup

Refer to the NI High-Speed Digitizers Getting Started Guide for information about how to install

the software and hardware and how to configure the device in MAX.

Self-Calibration

The PXIe-5185/5186 includes precise internal circuits and references used during

self-calibration to adjust for any errors caused by short-term fluctuations in the environment.

Note Allow a 25 minute warm-up period before you begin self-calibration.

Self-calibration can be initiated from MAX, NI-SCOPE Soft Front Panel (SFP), or NI-SCOPE.

MAX

To initiate self-calibration from MAX, complete the following steps:

1. Launch MAX.

2. Select My System»Devices and Interfaces.

3. Select the device that you want to calibrate.

4. Initiate self-calibration in one of the following ways:

• Click Self-Calibrate in the upper right corner of the window.

• Right-click the device name under Devices and Interfaces, and select Self-Calibrate

from the drop-down menu.

NI-SCOPE Soft Front Panel

To initiate self-calibration from the NI-SCOPE SFP, complete the following steps:

1. Launch the NI-SCOPE SFP.

Page 7

PXIe-5185/5186 Calibration Procedure | © National Instruments | 7

2. Select the device you want to calibrate using the Device Configuration dialog box by

selecting Edit»Device Configuration.

3. Launch the Calibration dialog box by selecting Utility»Self Calibration.

4. Click OK to begin self-calibration.

NI-SCOPE

To self-calibrate the digitizer programmatically using NI-SCOPE, complete the following steps:

1. Open a session and obtain a session handle using the niScope Initialize VI.

2. Self-calibrate the digitizer using niScope Cal Self Calibrate VI.

3. End the session using the niScope Close VI.

External Calibration

External calibration involves both verification and adjustment. Verification is the process of

testing the device to ensure that it is within certain specifications. You can use verification to

ensure that the adjustment process was successful.

Adjustment is the process of measuring and compensating for device performance to improve

the input accuracy. Performing an adjustment updates the calibration date, resetting the

calibration interval. The device is warranted to meet or exceed its published specifications for

the duration of the calibration interval.

Test System Characterization

The following procedures characterize the test equipment used during verification.

Caution The connectors on the device under test (DUT) and test equipment are

fragile. Perform the steps in these procedures with care to prevent damaging any

DUTs or test equipment.

Zeroing the Power Sensor

1. Ensure that the power sensor is not connected to any signals.

2. Zero the power sensor using the built-in function, according to the power sensor

documentation.

Characterizing Power Splitter Amplitude Imbalance

These procedures characterize the amplitude imbalance of the two output ports of the power

splitter over a range of frequencies. You must perform separate characterizations for the two

different connector types used in verification.

Page 8

8 | ni.com | PXIe-5185/5186 Calibration Procedure

SMA Adapters

This procedure characterizes the power splitter imbalance when using SMA adapters. The

results of this characterization are later used as a correction in the Verifying 50 Ω AC Amplitude

Accuracy and Bandwidth procedure.

1. Connect the SMA (f)-to-N (f) adapter to the power sensor. Refer to this assembly as the

power sensor.

2. Zero the power sensor as described in the Zeroing the Power Sensor section.

3. Connect the RF OUT connector of the signal generator to the input port of the power splitter

using an SMA (f)-to-N (m) adapter and an SMA (m)-to-SMA (m) cable.

4. Connect an SMA (m)-to-SMA (m) adapter to one of the power splitter output ports. Refer

to this assembly as splitter output 1.

5. Connect the 50 Ω SMA terminator (f) to splitter output 1.

6. Connect the other SMA (m)-to-SMA (m) adapter to the other output port of the power

splitter. Refer to this assembly as splitter output 2.

Table 2. Power Splitter Characterization for SMA Configuration

Configuration

Test Point

Impedance

Frequency

(MHz)

Amplitude (dBm)

1 50 Ω 0.05 -0.5

2 50 Ω

(PXIe-5185 only)

3000 -0.5

3 50 Ω

(PXIe-5186 only)

5000 -0.5

Page 9

PXIe-5185/5186 Calibration Procedure | © National Instruments | 9

7. Connect the power sensor to splitter output 2.

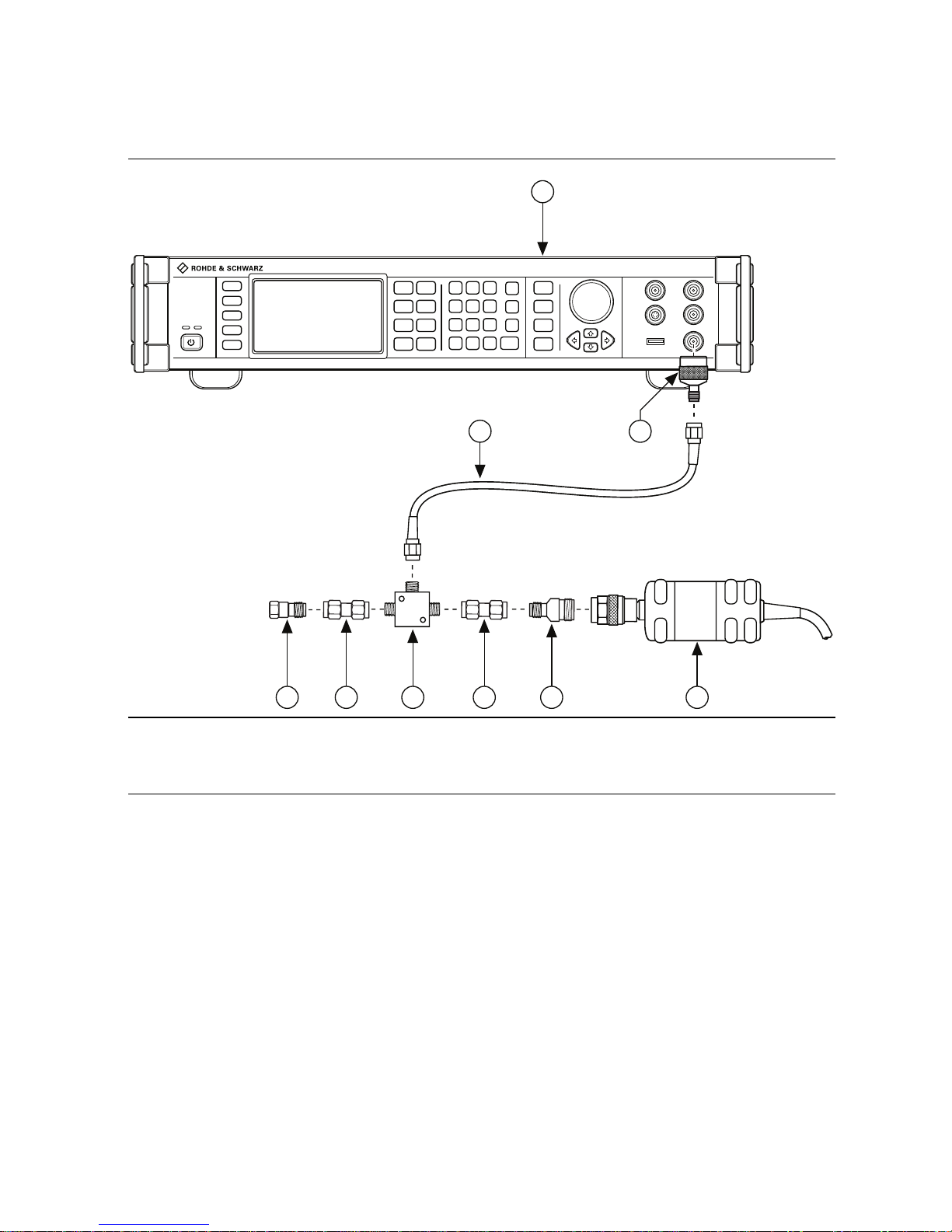

The following figure illustrates the hardware setup.

Figure 1. Connection Diagram for Measuring at Splitter Output 2 (SMA)

8. Configure the signal generator to generate a sine waveform with the following

characteristics:

• Frequency: the Test Point Frequency value from Table 2

• Amplitude level: the Test Point Amplitude value from Table 2

9. Configure the power sensor to correct for the Test Point Frequency value using the power

sensor frequency correction function.

10. Use the power sensor to measure the power in dBm.

11. Repeat steps 8 through 10 for each configuration in Table 2, recording each result as

splitter output 2 power, where each configuration has a corresponding value.

12. Disconnect the power sensor and 50 Ω SMA terminator (f) from splitter output 2 and

splitter output 1.

1 Signal Generator

2 SMA (f)-to-N (m) Adapter

3 SMA (m)-to-SMA (m) Cable

4 50 ΩSMA Terminator (f)

5 SMA (m)-to-SMA (m) Adapter

6 Power Splitter

7 SMA (f)-to-N (f) Adapter

8 Power Sensor

1

64 5

3

7

8

2

5

Page 10

10 | ni.com | PXIe-5185/5186 Calibration Procedure

13. Connect the power sensor to splitter output 1.

14. Connect the 50 Ω SMA terminator (f) to splitter output 2.

The following figure illustrates the hardware setup.

Figure 2. Connection Diagram for Measuring at Splitter Output 1 (SMA)

15. Configure the signal generator to generate a sine waveform with the following

characteristics:

• Frequency: the Test Point Frequency value from Table 2

• Amplitude level: the Test Point Amplitude value from Table 2

16. Configure the power sensor to correct for the Test Point Frequency value using the power

sensor frequency correction function.

17. Use the power sensor to measure the power in dBm.

1 Signal Generator

2 SMA (f)-to-N (m) Adapter

3 SMA (m)-to-SMA (m) Cable

4 Power Sensor

5 SMA (f)-to-N (f) Adapter

6 SMA (m)-to-SMA (m) Adapter

7 Power Splitter

8 50 ΩSMA Terminator

1

3

8

6

7

6

5

4

2

Page 11

PXIe-5185/5186 Calibration Procedure | © National Instruments | 11

18. Repeat steps 15 through 17 for each configuration in Table 2, recording each result as

splitter output 1 power, where each configuration has a corresponding value.

19. Calculate the splitter imbalance for each frequency point using the following equation:

splitter imbalance = splitter output 2 power - splitter output 1 power

20. Disconnect the 50 Ω SMA terminator (f) from splitter output 2. Refer to the remaining

assembly as the power sensor assembly. The power sensor assembly will be used in the

Verifying 50 Ω AC Amplitude Accuracy and Bandwidth procedure.

BNC Adapters

This procedure characterizes the power splitter imbalance when using BNC adapters. The results

of this characterization are later used as a correction in the Verifying 1 MΩ AC Amplitude

Accuracy and Bandwidth procedure.

1. Connect the BNC (f)-to-N (f) adapter to the power sensor. Refer to this assembly as the

power sensor.

2. Zero the power sensor as described in the Zeroing the Power Sensor section.

3. Connect the RF OUT connector of the signal generator to the input port of the power splitter

using an SMA (f)-to-N (m) adapter and an SMA (m)-to-SMA (m) cable.

4. Connect an SMA (m)-to-BNC (m) adapter to one of the power splitter output ports. Refer

to this assembly as splitter output 1.

5. Connect the 50 Ω BNC terminator (f) to splitter output 1.

6. Connect the other SMA (m)-to-BNC (m) adapter to the other output port of the power

splitter. Refer to this assembly as splitter output 2.

Table 3. Power Splitter Characterization with BNC Configuration

Configuration

Test Point

Impedance Frequency (MHz) Amplitude (dBm)

1 1 MΩ 0.05 -0.5

2 1 MΩ 425 -0.5

Page 12

12 | ni.com | PXIe-5185/5186 Calibration Procedure

7. Connect the power sensor to splitter output 2.

The following figure illustrates the hardware setup.

Figure 3. Connection Diagram for Measuring at Splitter Output 2 (BNC)

8. Configure the signal generator to generate a sine waveform with the following

characteristics:

• Frequency: the Test Point Frequency value from Table 3

• Amplitude level: the Test Point Amplitude value from Table 3

9. Configure the power sensor to correct for the Test Point Frequency value using the power

sensor frequency correction function.

10. Use the power sensor to measure the power in dBm.

11. Repeat steps 8 through 10 for each configuration in Table 3, recording each result as

splitter output 2 power, where each configuration has a corresponding value.

12. Disconnect the power sensor and 50 Ω BNC terminator (f) from splitter output 2 and

splitter output 1.

1 Signal Generator

2 SMA (f)-to-N (m) Adapter

3 SMA (m)-to-SMA (m) Cable

4 50 ΩBNC Terminator

5 SMA (m)-to-BNC (m) Adapter

6 Power Splitter

7 BNC (f)-to-N (f) Adapter

8 Power Sensor

1

64 5

3

7

8

2

5

Page 13

PXIe-5185/5186 Calibration Procedure | © National Instruments | 13

13. Connect the power sensor to splitter output 1.

14. Connect the 50 Ω BNC terminator (f) to splitter output 2.

The following figure illustrates the hardware setup.

Figure 4. Connection Diagram for Measuring at Splitter Output 1 (BNC)

15. Configure the signal generator to generate a sine waveform with the following

characteristics:

• Frequency: the Test Point Frequency value from Table 3

• Amplitude level: the Test Point Amplitude value from Table 3

16. Configure the power sensor to correct for the Test Point Frequency value using the power

sensor frequency correction function.

17. Use the power sensor to measure the power in dBm.

18. Repeat steps 15 through 17 for each configuration in Table 3, recording each result as

splitter output 1 power, where each configuration has a corresponding value.

1 Signal Generator

2 SMA (f)-to-N (m) Adapter

3 SMA (m)-to-SMA (m) Cable

4 Power Sensor

5 BNC (f)-to-N (f) Adapter

6 SMA (m)-to-BNC (m) Adapter

7 Power Splitter

8 50 ΩBNC Terminator

1

3

8

6

7

6

5

4

2

Page 14

14 | ni.com | PXIe-5185/5186 Calibration Procedure

19. Calculate the splitter imbalance for each frequency point using the following equation:

splitter imbalance = splitter output 2 power - splitter output 1 power

20. Disconnect the 50 Ω BNC terminator (f) from splitter output 2. Refer to the remaining

assembly as the power sensor assembly. The power sensor assembly will be used in the

Verifying 1 MΩ AC Amplitude Accuracy and Bandwidth procedure.

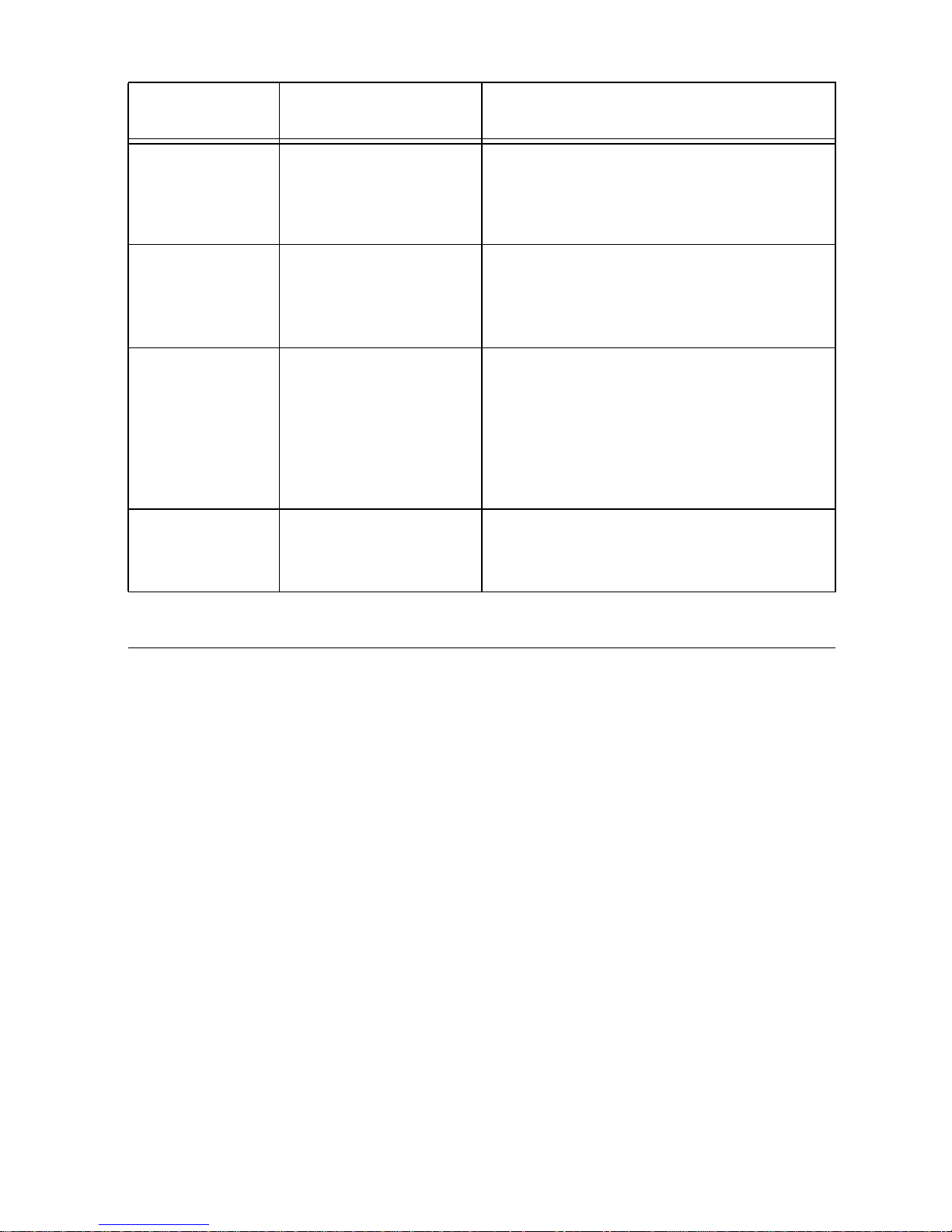

Verification

This section provides instructions for verifying the PXIe-5185/5186 specifications. Refer to

Table 4 for a list of the verification tests and the equipment needed for each test.

Verifying DC and Programmable Vertical Offset Accuracy

To verify the DC and programmable vertical offset accuracy of the PXIe-5185/5186, compare

the voltage measured by the device and the value sourced by the voltage standard. Table 5 lists

the settings for each channel.

1. Connect the calibrator test head directly to the channel 0, 50 Ω input of the

PXIe-5185/5186.

2. Configure the PXIe-5185/5186 with the following settings:

• Vertical coupling: DC

Table 4. Verification Tests

Test Type

Specification

Recommended

Equipment

50 Ω 1 MΩ

DC Accuracy ±(2% of Input +

0.35% FS +

0.7 mV)

±1.2% of Offset

Setting

±(2% of Input +

0.9% FS + 1.3 mV)

±1.2% of Offset

Setting

Fluke 9500B

Fluke 9530

AC Amplitude

Accuracy

±0.35 dB ±0.5 dB Rohde & Schwarz

SMA100A

Rohde & Schwarz

NRP-Z91

Bandwidth (-3 dB) 3 GHz

(PXIe-5185)

5 GHz

(PXIe-5186)

425 MHz Rohde & Schwarz

SMA100A

Rohde & Schwarz

NRP-Z91

Timebase

Accuracy

±25 ppm Fluke 9500B

Fluke 9530

*

1 MΩ input available on PXIe-5185 module part number 152962x-0zL and PXIe-5186 module part

number 152961x-0zL, where x is any letter and z is any number.

Page 15

PXIe-5185/5186 Calibration Procedure | © National Instruments | 15

• Input impedance: The Input Impedance value from Table 5 for the current iteration

• Max input frequency:

(PXIe-5185) 3 GHz, (PXIe-5186) 5 GHz

• Programmable vertical offset: The Programmable Vertical Offset value from

Table 4 for the current iteration

• Range: The Vertical Range value from Table 5 for the current iteration

• Sample rate: 12.5 GS/s

• Minimum number of samples: 1,048,567

3. Configure the calibrator output impedance to match that of the PXIe-5185/5186 for the

current iteration listed in Table 5.

4. Configure the calibrator to output the Test Point voltage for the current iteration listed in

Table 5.

5. Enable the calibrator output.

6. Wait 2.5 s for settling, then record the measured voltage.

7. Use the following formula to calculate the voltage difference:

error = V measured - Test Point

8. Compare the error to the Test Limit provided in Table 5.

9. Repeat steps 2-8 for iterations 2 through 16 listed in Table 5.

10. Connect the calibrator test head directly to the channel 1 50 Ω input of the PXIe-5185/5186

and repeat steps 2 through 9.

Note If your module supports 1 MΩ input, follow steps 11 and 12. Otherwise, DC

and programmable vertical offset accuracy has been verified. 1 MΩ input is available

on PXIe-5185 module part number 152962x-0zL and PXIe-5186 module part number

152961x-0zL, where x is any letter and z is any number.

11. Connect the calibrator test head directly to the channel 0, 1 MΩ input of the

PXIe-5185/5186 and repeat steps 2 through 8 for iterations 17 through 44 listed in Table 5.

12. Connect the calibrator test head directly to the channel 1, 1 MΩ input of the

PXIe-5185/5186 and repeat steps 2 through 8 for iterations 17 through 44 listed in Table 5.

Table 5. PXIe-5185/5186 DC and Programmable Vertical Offset Accuracy Limits

Iteration

Input

Impedance

Vertical

Range

(V

pk-pk

)

Programmable

Vertical

Offset (V)

Test

Point (V)

Test Limit

(V)

1 50 Ω 0.11 0 0.045 ±0.0020

2 50 Ω 0.11 0 -0.045 ±0.0020

3 50 Ω 0.11 0.25 0.295 ±0.0100

4 50 Ω 0.11 -0.25 -0.295 ±0.0100

Page 16

16 | ni.com | PXIe-5185/5186 Calibration Procedure

5 50 Ω 0.2 0 0.08 ±0.0030

6 50 Ω 0.2 0 -0.08 ±0.0030

7 50 Ω 0.2 0.25 0.33 ±0.0110

8 50 Ω 0.2 -0.25 -0.33 ±0.0110

9 50 Ω 0.5 0 0.2 ±0.0065

10 50 Ω 0.5 0 -0.2 ±0.0065

11 50 Ω 0.5 0.25 0.45 ±0.0145

12 50 Ω 0.5 -0.25 -0.45 ±0.0145

13 50 Ω 1 0 0.4 ±0.0122

14 50 Ω 1 0 -0.4 ±0.0122

15 50 Ω 1 0.25 0.65 ±0.0202

16 50 Ω 1 -0.25 -0.65 ±0.0202

17 1 MΩ 0.11 0 0.045 ±0.0032

18 1 MΩ 0.11 0 -0.045 ±0.0032

19 1 MΩ 0.11 0.25 0.295 ±0.0112

20 1 MΩ 0.11 -0.25 -0.295 ±0.0112

21 1 MΩ 0.2 0 0.08 ±0.0047

22 1 MΩ 0.2 0 -0.08 ±0.0047

23 1 MΩ 0.2 0.25 0.33 ±0.0127

24 1 MΩ 0.2 -0.25 -0.33 ±0.0127

25 1 MΩ 0.5 0 0.2 ±0.0098

26 1 MΩ 0.5 0 -0.2 ±0.0098

27 1 MΩ 0.5 0.25 0.45 ±0.0178

28 1 MΩ 0.5 -0.25 -0.45 ±0.0178

29 1 MΩ 1 0 0.4 ±0.0183

30 1 MΩ 1 0 -0.4 ±0.0183

Table 5. PXIe-5185/5186 DC and Programmable Vertical Offset Accuracy Limits

Iteration

Input

Impedance

Vertical

Range

(V

pk-pk

)

Programmable

Vertical

Offset (V)

Test

Point (V)

Test Limit

(V)

Page 17

PXIe-5185/5186 Calibration Procedure | © National Instruments | 17

Verifying 50 Ω AC Amplitude Accuracy and Bandwidth

Follow this procedure to verify the 50 Ω AC amplitude accuracy and analog bandwidth of the

PXIe-5185/5186 by generating a sine wave and comparing the amplitude measured by the

PXIe-5185/5186 to the amplitude measured by the power sensor.

Before performing this procedure, complete the Test System Characterization procedures and

calculate the splitter imbalance of your power splitter.

Table 6. 50 Ω AC Amplitude Accuracy and Bandwidth Verification

1. Connect splitter output 2 of the power sensor assembly from the Test System

Characterization section to the channel 0, 50 Ω input of the PXIe-5185/5186.

31 1 MΩ 1 0.25 0.65 ±0.0263

32 1 MΩ 1 -0.25 -0.65 ±0.0263

33 1 MΩ 2 0 0.8 ±0.0353

34 1 MΩ 2 0 -0.8 ±0.0353

35 1 MΩ 2 2.5 3.3 ±0.1153

36 1 MΩ 2 -2.5 -3.3 ±0.1153

37 1 MΩ 5 0 2 ±0.0863

38 1 MΩ 5 0 -2 ±0.0863

39 1 MΩ 5 2.5 4.5 ±0.1663

40 1 MΩ 5 -2.5 -4.5 ±0.1663

41 1 MΩ 10 0 4 ±0.1713

42 1 MΩ 10 0 -4 ±0.1713

43 1 MΩ 10 2.5 6.5 ±0.2513

44 1 MΩ 10 -2.5 -6.5 ±0.2513

Iteration Sample Rate Test Point (dBm) Test Limit (dB)

1 1.25 GS/s -12 at 50 kHz ±0.35

2 12.5 GS/s (PXIe-5185) -12 at 3 GHz

(PXIe-5186) -12 at 5 GHz

-3 to 1

Table 5. PXIe-5185/5186 DC and Programmable Vertical Offset Accuracy Limits

Iteration

Input

Impedance

Vertical

Range

(V

pk-pk

)

Programmable

Vertical

Offset (V)

Test

Point (V)

Test Limit

(V)

Page 18

18 | ni.com | PXIe-5185/5186 Calibration Procedure

Note The power sensor assembly must match the configuration used in the Test

System Characterization section, in which the power sensor is connected to splitter

output 1 and the signal generator is connected to the input port of the power splitter.

The following figure illustrates the hardware setup.

Figure 5. 50 Ω AC Amplitude Accuracy and Bandwidth Verification Cabling Diagram

1 Power Sensor

2 SMA (f)-to-N(f) Adapter

3 SMA (m)-to-SMA (m) Adapter

4 Power Splitter

5 PXIe-5185/5186

6 SMA (m)-to-SMA (m) Cable

7 SMA (f)-to-N (m) Adapter

8 Signal Generator

3 GHz 12.5 GS/s 8-Bit Digitizer

ACCESS

ACTIVE

REF CLK

CLK IN

+16 dBm Max

(1.4 Vrms)

50˖

+9 dBm Max

(0.6 Vrms)

50˖

1 Vpp measure

± 1 V MAX

1 Vpp measure

± 1 V MAX

10 Vpp measure

± 42 V MAX

10 Vpp measure

± 42 V MAX

CH 0

CH 1

TRIG

ESD

SENSITIVE

NI PXIe-5185

50˖

1M˖

50˖

1M˖

50˖

± 5 V

MAX

6

5

8

7

2

1

3

4

3

Page 19

PXIe-5185/5186 Calibration Procedure | © National Instruments | 19

2. Configure the PXIe-5185/5186 with the following settings:

• Vertical coupling: DC

• Input impedance: 50 Ω

• Maximum input frequency: 3 GHz (PXIe-5185), 5 GHz (PXIe-5186)

• Range: 0.11 V

pk-pk

• Sample rate: The Sample Rate value from Table 6 for the current iteration

• Minimum number of samples: 1,048,567

3. Configure the signal generator to generate a sine waveform with the following

characteristics:

• Frequency: the Test Point frequency value from Table 6

• Amplitude level: the Test Point amplitude value from Table 6

4. Configure the power sensor to correct for the Test Point frequency using the power sensor

frequency correction function.

5. Use the power sensor to measure the power in dBm. Record the result as measured input

power.

6. Calculate the corrected input power using the following equation:

corrected input power = measured input power + splitter imbalance

Note Select the splitter imbalance value from the list of test points from the Test

System Characterization section for the current Test Point frequency from Table 6.

7. Use the PXIe-5185/5186 to acquire and measure the power using the Extract Single Tone

Information VI, converting the result from Vpk to dBm. Record the result as device input

power.

8. If the Test Point frequency from Table 6 is 50 kHz, proceed to the following step.

Otherwise, go to step 12.

9. Calculate the power reference using the following equation:

power reference = device input power - corrected input power

10. Compare the power reference to the test limit for Iteration 1 in Table 6 to verify the 50 Ω

AC amplitude accuracy.

11. Go to step 14. The power error is not calculated for this configuration.

12. Calculate the power error using the following equation:

power error = device input power - corrected input power - power reference

13. Compare the power error to the test limit for Iteration 2 in Table 6 to verify the 50 Ω analog

bandwidth.

14. Repeat steps 2 through 13 for each Iteration in Table 6.

15. Connect splitter output 2 of the power sensor assembly to the channel 1 50 Ω input of the

PXIe-5185/5186 and repeat steps 2 through 13 for each Iteration listed in Table 6.

Page 20

20 | ni.com | PXIe-5185/5186 Calibration Procedure

Verifying 1 MΩAC Amplitude Accuracy and Bandwidth

Follow this procedure to verify the 1 MΩ AC amplitude accuracy and analog bandwidth of the

PXIe-5185/5186 by generating a sine wave and comparing the amplitude measured by the

PXIe-5185/5186 to the amplitude measured by the power sensor.

Before performing this procedure, complete the Test System Characterization procedures and

calculate the splitter imbalance of your power splitter.

1. Connect the 50 Ω BNC feed-through terminator to the channel 0 1 MΩ input of the

PXIe-5185/5186. Connect splitter output 2 of the power sensor assembly from the Test

System Characterization section to the 50 Ω BNC feed-through terminator.

Note The power sensor assembly must match the configuration used in the Test

System Characterization section, in which the power sensor is connected to splitter

output 1 and the signal generator is connected to the input port of the power splitter.

Table 7. 1 MΩ AC Amplitude Accuracy and Bandwidth Verification

Iteration Sample Rate Test Point (dBm) Test Limit (dB)

1 1.25 GS/s -12 at 50 kHz ±0.5

2 12.5 GS/s -12 at 425 MHz -3 to 1

Page 21

PXIe-5185/5186 Calibration Procedure | © National Instruments | 21

The following figure illustrates the hardware setup.

Figure 6. 1 MΩ AC Amplitude Accuracy and Bandwidth Verification Cabling Diagram

2. Configure the PXIe-5185/5186 with the following settings:

• Vertical coupling: DC

• Input impedance: 1 MΩ

1 Power Sensor

2 BNC (m)-to-N (m) Adapter

3 SMA (f)-to-BNC (f) Adapter

4 Power Splitter

5 50 ΩBNC Feed-Through

6 PXIe-5185/5186

7 SMA (f)-to-SMA (f) Cable

8 SMA (m)-to-N (f) Adapter

9 Signal Generator

3 GHz 12.5 GS/s 8-Bit Digitizer

ACCESS

ACTIVE

REF CLK

CLK IN

+16 dBm Max

(1.4 Vrms)

50˖

+9 dBm Max

(0.6 Vrms)

50˖

1 Vpp measure

± 1 V MAX

1 Vpp measure

± 1 V MAX

10 Vpp measure

± 42 V MAX

10 Vpp measure

± 42 V MAX

CH 0

CH 1

TRIG

ESD

SENSITIVE

NI PXIe-5185

50˖

1M˖

50˖

1M˖

50˖

± 5 V

MAX

7

6

9

8

2

1

3

4

5

3

Page 22

22 | ni.com | PXIe-5185/5186 Calibration Procedure

• Maximum input frequency: 425 MHz

• Range: 0.11 V

pk-pk

• Sample rate: The Sample Rate value from Table 7 for the current iteration

• Minimum number of samples: 1,048,567

3. Configure the signal generator to generate a sine waveform with the following

characteristics:

• Frequency: the Test Point frequency from Table 7

• Amplitude level: the Test Point amplitude from Table 7

4. Configure the power sensor to correct for the Test Point frequency using the power sensor

frequency correction function.

5. Use the power sensor to measure the power in dBm. Record the result as measured input

power.

6. Calculate the corrected input power using the following equation:

corrected input power = measured input power + splitter imbalance

Note Select the splitter imbalance value from the list of test points from the Test

System Characterization section for the current Test Point frequency from Table 7.

7. Use the PXIe-5185/5186 to acquire and measure the power using the Extract Single Tone

Information VI, converting the result from Vpk to dBm. Record the result as device input

power.

8. If the Test Point frequency from Table 7 is 50 kHz, proceed to step 9. Otherwise, go to

step 12.

9. Calculate the power reference using the following equation:

power reference = device input power - corrected input power

10. Compare the power reference to the test limit for Iteration 1 in Table 7 to verify the 1 MΩ

AC amplitude accuracy.

11. Go to step 14. The power error is not calculated for this configuration.

12. Calculate the power error using the following equation:

power error = device input power - corrected input power - power reference

13. Compare the power error to the test limit for Interation 2 in Table 7 to verify the 1 MΩ

analog bandwidth.

14. Repeat steps 2 through 13 for each Iteration in Table 7.

15. Connect the 50 Ω BNC feed-through terminator to the channel 1 1 MΩ input of the

PXIe-5185/5186. Connect splitter output 2 of the power sensor assembly to the 50 Ω BNC

feed-through terminator and repeat steps 2 through 13 for each Iteration in Table 7.

Page 23

PXIe-5185/5186 Calibration Procedure | © National Instruments | 23

Verifying Timebase Accuracy

To verify the timebase accuracy of the PXIe-5185/5186 compare the peak frequency of a leveled

sine wave measured by the PXIe-5185/5186 and the value sourced by the calibrator. Table 8 lists

the settings.

1. Configure the PXIe-5185/5186 with the following settings:

• Vertical coupling: DC

• Input impedance: 50 Ω

• Max input frequency:

(PXIe-5185) 3 GHz, (PXIe-5186) 5 GHz

• Range: 1 V

pk-pk

• Sample rate: 12.5 GS/s

• Minimum number of samples: 1,048,567

2. Connect the calibrator test head directly to the channel 0, 50 Ω input of the digitizer.

3. Configure the calibrator output impedance to 50 Ω .

4. Configure the calibrator to output a 1.0 GHz leveled sine wave with peak-to-peak voltage

amplitude of 0.90 V.

5. Enable the calibrator output.

6. Wait 2.5 s for settling, then record the measured peak frequency.

7. Use the following formula to calculate the frequency difference:

TBerror = ( f - 1.0E+9)/1.0E+3

where f = measured frequency

8. Compare the error to the Test Limit shown in Table 8.

Note Timebase verification is only required on one channel.

Adjustment

If the PXIe-5185/5186 successfully passed each of the verification procedures within the test

limits, then an adjustment is recommended but not required to warrant the published

specifications for the next year. If the digitizer was not within the test limits for each of the

verification procedures, you can perform the adjustment procedure to improve the accuracy of

the digitizer.

An adjustment is required once a year. Following the adjustment procedure automatically

updates the calibration date and temperature in the EEPROM of the digitizer.

Table 8. PXIe-5185/5186 Timebase Accuracy Limits

Channel Function

Input

Impedance

Range

(V

pk-pk

)

Test Point

(V

pk-pk

) Test Limit

0 Timebase 50 Ω 1.0 0.9 at 1 GHz ±25 ppm

(25.0 kHz)

Page 24

24 | ni.com | PXIe-5185/5186 Calibration Procedure

Complete the following steps to externally adjust the PXIe-5185/5186.

1. Obtain a calibration session handle using the niScope Cal Start VI.

2. Connect the calibrator test head directly to the channel 0, 50 Ω input of the digitizer.

3. Configure the calibrator output impedance to 50 Ω.

4. Configure the calibrator to output the voltage listed under Input (V) in Table 9 for the

current iteration.

5. Enable the calibrator output.

6. Wait 2.5 s for the impedance matching of the calibrator to settle.

7. Adjust the vertical range using the niScope Cal Adjust Range VI.

8. Repeat steps 4 through 7 for each iteration in Table 9.

9. Connect the calibrator test head directly to the channel 1, 50 Ω input of the digitizer and

repeat steps 3 through 8, changing the value of the channels parameter from

"0" to "1".

Note If your module supports 1 MΩ input, follow steps 10 through 22. Otherwise,

jump to step 23 to complete the adjustment. 1 MΩ input available on PXIe-5185

module part number 152962X-0ZL and PXIe-5186 module part number

152961X-0ZL, where X is any letter and Z is any number.

10. Connect the calibrator test head directly to the channel 0, 1 MΩ input of the digitizer.

11. Configure the calibrator output impedance to 1 MΩ.

12. Configure the calibrator to output a 100 kHz symmetrical square wave with peak-to-peak

voltage amplitude of 8.0 V.

LabVIEW VI C/C++ Function Call

Call niScope_CalStart with the

following parameters:

resourceName: The device number

assigned by MAX

password:

"NI"

LabVIEW VI C/C++ Function Call

Call niScope_CalAdjustRange with

the following parameters:

vi: The instrument handle from

niScope_CalStart

channelName: "0"

range: 0

stimulus: The Input (V) value listed in

Table 9 for the current iteration

Page 25

PXIe-5185/5186 Calibration Procedure | © National Instruments | 25

13. Enable the calibrator output.

14. Wait 2.5 s for the impedance matching of the calibrator to settle.

15. Adjust the 1 MΩ compensation attenuator using the niScope Cal Adjust Compensation

Attenuator VI.

16. Configure the calibrator output impedance to 1 MΩ.

17. Configure the calibrator to output the voltage listed under Input (V) in Table 10 for the

current iteration.

18. Enable the calibrator output.

19. Wait 2.5 s for the impedance matching of the calibrator to settle.

20. Adjust the vertical range using the niScope Cal Adjust Range VI.

21. Repeat steps 17 through 20 for each iteration in Table 10.

22. Connect the calibrator test head directly to the channel 1, 1 MΩ input of the digitizer and

repeat steps 11 through 21, changing the value of the channels parameter from

"0" to "1".

23. Connect the calibrator test head directly to the external trigger channel input on the

digitizer.

24. Configure the calibrator output impedance to 50 Ω.

25. Configure the calibrator to output the voltage listed under Input (V) in Table 11 for the

current iteration. Configure the load impedance of the calibrator to 50 Ω.

26. Enable the calibrator output.

LabVIEW VI C/C++ Function Call

Call

niScope_CalAdjustCompensatio

nAttenuator

with the following

parameters:

vi: The instrument handle from

niScope_CalStart

channelName: "0"

range: 8.0

LabVIEW VI C/C++ Function Call

Call niScope_CalAdjustRange with

the following parameters:

vi: The instrument handle from

niScope_CalStart

channelName: "0"

range: 0

stimulus: The Input (V) value listed in

Table 10 for the current iteration

Page 26

26 | ni.com | PXIe-5185/5186 Calibration Procedure

27. Wait 2.5 s for the impedance matching of the calibrator to settle.

28. Adjust the vertical range using the niScope Cal Adjust Range VI.

.

29. Repeat steps 25 through 28 for each iteration in Table 11.

30. Disconnect or disable all inputs to the digitizer.

31. Self-calibrate the digitizer using niScope Cal Self Calibrate VI.

32. End the calibration session by calling the niScope Cal End VI.

You have finished adjusting the PXIe-5185/5186. Repeat the Verification section to reverify the

performance of the digitizer after adjustments.

LabVIEW VI C/C++ Function Call

Call niScope_CalAdjustRange with

the following parameters:

vi: The instrument handle from

niScope_CalStart

channelName:

"NISCOPE_VAL_EXTERNAL"

range: 0

stimulus: The Input (V) value listed in

Table 11 for the current iteration

LabVIEW VI C/C++ Function Call

Call niScope_CalSelfCalibrate

with the following parameters:

vi: The instrument handle from

niScope_CalStart

channelList: VI_NULL

option: VI_NULL

LabVIEW VI C/C++ Function Call

Call niScope_CalEnd with the

following parameters:

sessionHandle: The instrument handle

from

niScope_CalStart

action:

NISCOPE_VAL_ACTION_STORE to

save the results of the calibration

Page 27

PXIe-5185/5186 Calibration Procedure | © National Instruments | 27

Table 9. PXIe-5185/5186 50 Ω Input Parameters for Input Channel

External Adjustment

Iteration Input (V)

1 0.32

2 0.135

3 0.075

4 0.065

5 0.055

6 0.045

7 -0.045

8 -0.055

9 -0.065

10 -0.075

11 -0.135

12 -0.32

13 2.0

14 -2.0

Table 10. PXIe-5185/5186 1 MΩ Input Parameters for Input Channel

External Adjustment

Iteration Input (V)

1 5.0

2 3.0

3 2.0

4 1.0

5 0.75

6 0.5

7 0.32

8 0.135

9 0.075

Page 28

28 | ni.com | PXIe-5185/5186 Calibration Procedure

10 0.065

11 0.055

12 0.045

13 -0.045

14 -0.055

15 -0.065

16 -0.075

17 -0.135

18 -0.32

19 -0.5

20 -0.75

21 -1.0

22 -2.0

23 -3.0

24 -5.0

Table 11. PXIe-5185/5186 Input Parameters for External Trigger Channel

External Adjustment

Iteration Input (V)

1 -5.0

2 0.001

3 5.0

Table 10. PXIe-5185/5186 1 MΩ Input Parameters for Input Channel

External Adjustment (Continued)

Iteration Input (V)

Page 29

© 2011–2018 National Instruments. All rights reserved.

373258F-01

April 24, 2018

Information is subject to change without notice. Refer to the NI Trademarks and Logo Guidelines atni.com/trademarks for more

information on NI trademarks. Other product and company names mentioned herein are trademarks or trade names of their

respective companies. For patents covering NI products/technology, refer to the appropriate location: Help»Patents in your

software, the

patents.txt file on your media, or the National Instruments Patents Notice at ni.com/patents. You can find

information about end-user license agreements (EULAs) and third-party legal notices in the readme file for your NI product. Refer

to the Export Compliance Information at

ni.com/legal/export-compliance for the NI global trade compliance policy and how

to obtain relevant HTS codes, ECCNs, and other import/export data. NI MAKES NO EXPRESS OR IMPLIED WARRANTIES AS

TO THE ACCURACY OF THE INFORMATION CONTAINED HEREIN AND SHALL NOT BE LIABLE FOR ANY ERRORS. U.S.

Government Customers: The data contained in this manual was developed at private expense and is subject to the applicable

limited rights and restricted data rights as set forth in FAR 52.227-14, DFAR 252.227-7014, and DFAR 252.227-7015.

Worldwide Support and Services

The NI website is your complete resource for technical support. At ni.com/support you have

access to everything from troubleshooting and application development self-help resources to

email and phone assistance from NI Application Engineers.

Visit

ni.com/services for NI Factory Installation Services, repairs, extended warranty, and

other services.

Visit

ni.com/register to register your NI product. Product registration facilitates technical

support and ensures that you receive important information updates from NI.

A Declaration of Conformity (DoC) is our claim of compliance with the Council of the European

Communities using the manufacturer’s declaration of conformity. This system affords the user

protection for electromagnetic compatibility (EMC) and product safety. You can obtain the DoC

for your product by visiting

ni.com/certification. If your product supports calibration,

you can obtain the calibration certificate for your product at

ni.com/calibration.

NI corporate headquarters is located at 11500 North Mopac Expressway, Austin, Texas,

78759-3504. NI also has offices located around the world. For telephone support in the United

States, create your service request at

ni.com/support or dial 1 866 ASK MYNI (275 6964).

For telephone support outside the United States, visit the Worldwide Offices section of

ni.com/niglobal to access the branch office websites, which provide up-to-date contact

information, support phone numbers, email addresses, and current events.

Loading...

Loading...