Page 1

USER MANUAL

PXIe-1086DC

PXIe, 18-Slot (16 Hybrid Slots, 1 PXI Express Slot), Up to 12 GB/s

PXI Chassis

The manual includes instructions for installing and configuring your PXIe-1086DC chassis

and PXI Express system.

Contents

Getting Started.......................................................................................................................... 2

Unpacking......................................................................................................................... 2

What You Need to Get Started..........................................................................................2

Key Features..................................................................................................................... 2

Chassis Description...........................................................................................................3

Optional Equipment.......................................................................................................... 5

PXIe-1086DC Chassis Backplane Overview....................................................................6

Installation and Configuration................................................................................................ 12

Safety Information.......................................................................................................... 12

Chassis Cooling Considerations......................................................................................13

Fan Access Door Clearance............................................................................................ 16

Rack Mounting................................................................................................................16

Connecting to Safety Ground and Power Source............................................................16

Power-On Test.................................................................................................................18

Installing a PXI Express System Controller................................................................... 18

Installing Peripheral Modules......................................................................................... 20

Remote System Monitoring............................................................................................ 21

LED Indicators................................................................................................................22

Remote Inhibit and Fault Monitoring............................................................................. 24

Inhibit Mode Switch........................................................................................................24

PXI_CLK10 Front Panel Connectors............................................................................. 25

PXI Express System Configuration with MAX..............................................................25

Using System Configuration and Initialization Files......................................................27

Maintenance............................................................................................................................ 28

Service Interval............................................................................................................... 28

Preparation...................................................................................................................... 28

Page 2

Cleaning.......................................................................................................................... 28

Replacing a Modular Power Supply............................................................................... 29

Replacing a Modular Fan Assembly...............................................................................33

Specifications.......................................................................................................................... 35

Environmental.................................................................................................................38

Shock and Vibration........................................................................................................38

Backplane........................................................................................................................39

Mechanical...................................................................................................................... 41

Pinouts.....................................................................................................................................46

System Controller Slot XP1 Connector Pinout...............................................................46

System Controller Slot XP2 Connector Pinout...............................................................46

System Controller Slot XP3 Connector Pinout...............................................................47

System Controller Slot XP4 Connector Pinout...............................................................47

System Timing Slot TP1 Connector Pinout....................................................................48

System Timing Slot TP2 Connector Pinout....................................................................48

System Timing Slot XP3 Connector Pinout....................................................................49

System Timing Slot XP4 Connector Pinout....................................................................49

Hybrid Slot P1 Connector Pinout....................................................................................50

Where to Go for Support.........................................................................................................51

Getting Started

Unpacking

Carefully inspect the shipping container and the chassis for damage. Check for visible damage

to the metal work. Check to make sure all handles, hardware, and switches are undamaged.

Inspect the inner chassis for any possible damage, debris, or detached components. If damage

appears to have been caused during shipment, file a claim with the carrier. Retain the packing

material for possible inspection and/or reshipment.

What You Need to Get Started

The PXIe-1086DC chassis kit contains the following items:

• PXIe-1086DC chassis

• Filler panels

• Power cable

• PXIe-1086DC Safety, Environmental, and Regulatory Information

• Software media with PXI Platform Services 14.0 or newer

• Chassis number labels

• Inhibit fault cable connector

• Ferrite bead for use with redundant power supplies

Key Features

The PXIe-1086DC chassis combines a high-performance 18-slot PXI Express backplane with

a high-output power supply and a structural design that has been optimized for maximum

2 | ni.com | PXIe-1086DC User Manual and Specifications

Page 3

usability in a wide range of applications. The chassis’ modular design ensures a high level of

maintainability, resulting in a very low mean time to repair (MTTR). The chassis also features

redundant power supplies and fans designed to maximize system availability. The

PXIe-1086DC chassis fully complies with the PXI-5 PXI Express Hardware Specification,

offering advanced timing and synchronization features.

The key features of the PXIe-1086DC chassis include the following:

High Performance for Instrumentation Requirements

• Up to 4 GB/s (single direction) per PXI Express slot dedicated bandwidth (Gen-2 x8 PCI

Express).

• 38.25 W per slot cooling meets increased PXI Express cooling requirements

• Low-jitter internal 10 MHz reference clock for PXI slots with ± 25 ppm stability

• Low-jitter internal 100 MHz reference clock for PXI Express slots with ± 25 ppm

stability

• Variable speed fan controller optimizes cooling and acoustic emissions

• Remote power-inhibit control

• Complies with PXI and CompactPCI Specifications

High Reliability

• 0 to 50 °C operating temperature range

• Power supply, temperature, and fan monitoring

• Ethernet interface for remote monitoring

High Availability

• Dual redundant, hot-swappable power supplies

• Redundant, hot-swappable chassis fans

Multi-Chassis Support

• PXI Express System Timing Slot for tight synchronization across chassis

• Front CLK10 I/O connectors

• Switchless CLK10 routing

Optional Features

• Front and rear rack-mount kits

• Replacement power supply

• EMC filler panels

• Slot blockers for improved cooling performance

• Factory installation services

• Replacement fan modules

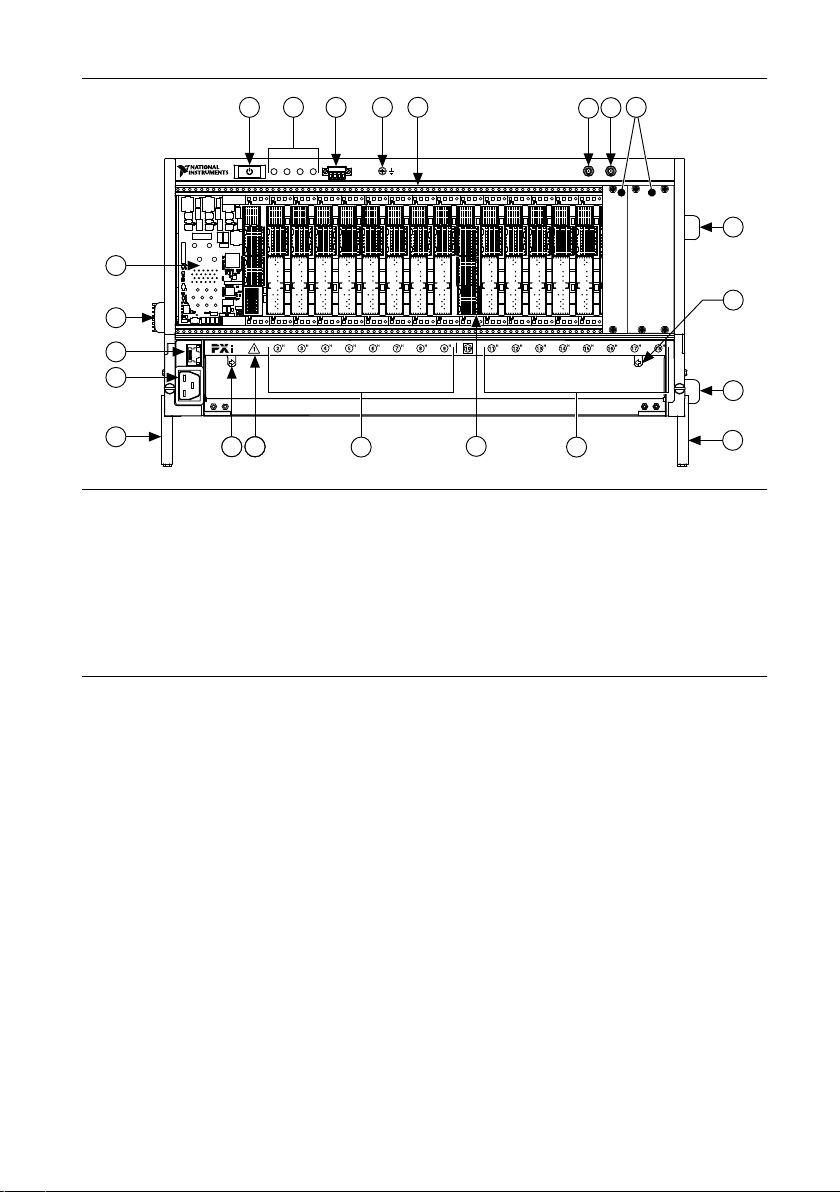

Chassis Description

The following figures show key features of the PXIe-1086DC chassis front and back panels.

PXIe-1086DC User Manual and Specifications | © National Instruments | 3

Page 4

Figure 1. Front View of the PXIe-1086DC

PXIe-1086DC

5

8

4

7

6

3

2

1

9

9

9

10

9

16

17

15

14

814813

11 11

12

810

1. Power Inhibit Switch

2. Status LEDs

3. Inhibit/Fault Connector

4. Ground Terminal

5. Backplane Connectors

6. Clk10 Output

7. Clk10 Input

8. PXI Filler Panels (Optional)

10. Fan Door Latch

11. PXI Express Hybrid Peripheral Slots (16x)

12. PXI Express PXI Express System Timing Slot

13. PXI Express System Controller Slot

14. Chassis Power Connector

15. Ethernet Port

16. Chassis Carry Handle

17. System Controller Expansion Slots

9. Removable Feet

4 | ni.com | PXIe-1086DC User Manual and Specifications

Page 5

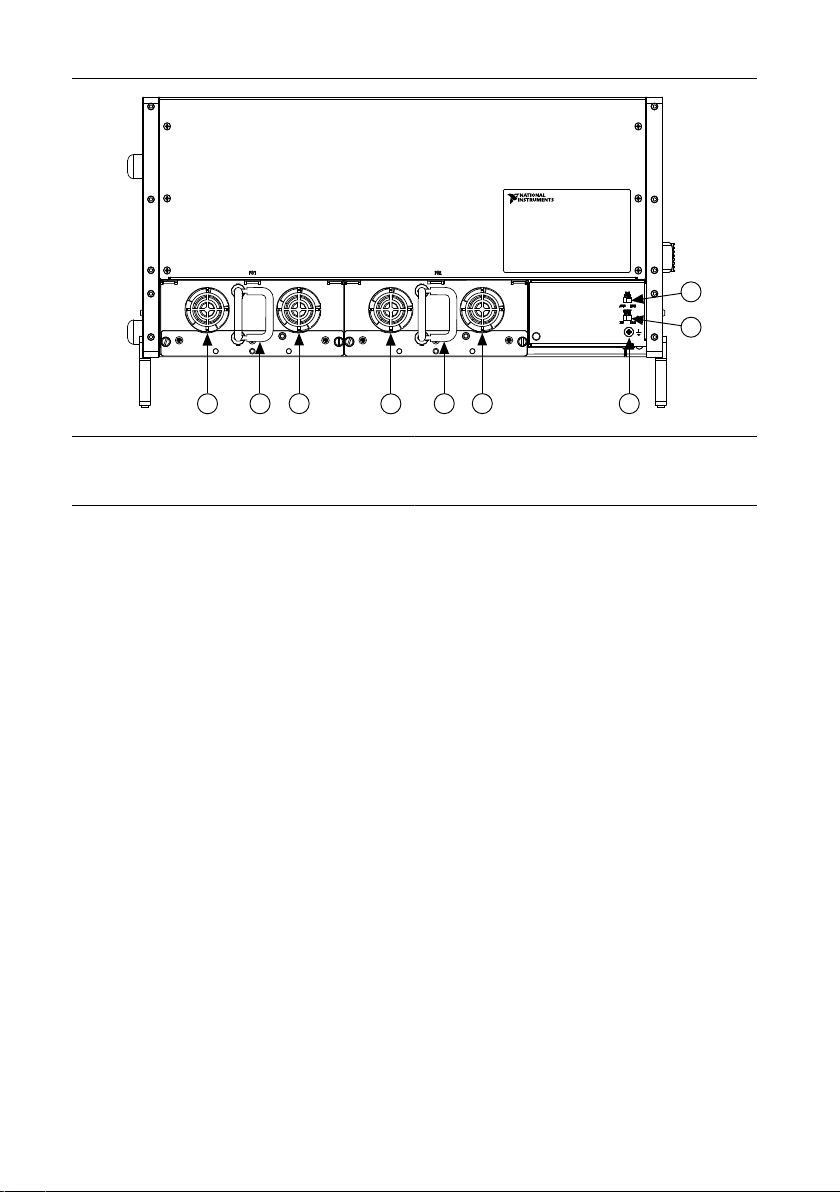

Figure 2. Rear View of the PXIe-1086DC

2

2

1

1

3

1

1

5

4

1. Power Supply Cooling Fan

2. Power Supply Handle

3. Earth Ground Terminal (PE)

4. Inhibit Mode Selector Switch

5. Fan Speed Selector Switch

Optional Equipment

Contact National Instruments to order the following options for the PXIe-1086DC chassis.

EMC Filler Panels

EMC filler panel kits are available from National Instruments.

Power Supply Filler Panels

Optional power supply filler panels are available from National Instruments. Use a power

supply filler panel if you operate the PXIe-1086DC chassis with a single power supply.

Rack Mount Kits

There are two optional kits for mounting the PXIe-1086DC chassis into a rack. The first option

is a pair of mounting brackets for use on the front of the chassis. The second option is a rear

rack mount kit. The rear rack mount kit differs from the front kit to allow for easier installation

into the rack. Refer to NI Chassis Rack Mount Kit Components for more information.

Slot Blockers

PXI Slot Blocker kits are available from National Instruments. Slot Blockers improve cooling

in a chassis by re-routing airflow from empty slots to slots containing PXI modules.

Replacement Power Supply

Replacement power supply kits are available from National Instruments.

PXIe-1086DC User Manual and Specifications | © National Instruments | 5

Page 6

Replacement Fan Modules

Replacement fan modules are available from National Instruments.

PXIe-1086DC Chassis Backplane Overview

Interoperability with CompactPCI

The design of the PXIe-1086DC provides you the flexibility to use the following devices in a

single PXI Express chassis:

• PXI Express compatible products

• CompactPCI Express compatible 2-Link system controller products

• CompactPCI Express compatible Type-2 peripheral products

• PXI peripheral products modified to fit in a hybrid slot

• Standard CompactPCI peripheral products modified to fit in a hybrid slot

System Controller Slot

The system controller slot is Slot 1 of the chassis and is a 2-Link configuration system slot as

defined by the CompactPCI Express and PXI Express specifications. It has three expansion

slots for system controller modules that are wider than one slot. These slots allow the system

controller to expand to the left to prevent it from using peripheral slots.

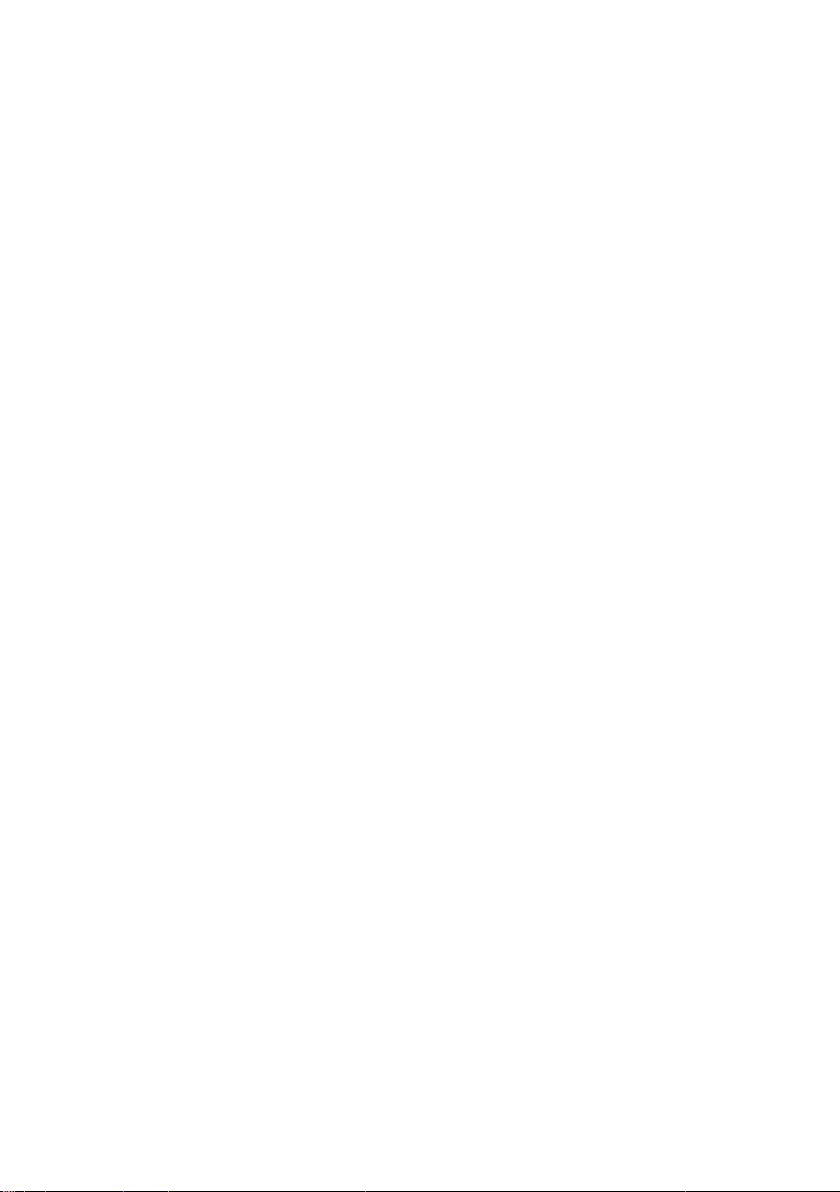

The backplane connects the system slot to two PCI Express switches using a Gen-2 x8 and a

Gen-2 x16 PCI Express link. These switches distribute PCI Express connections to the

peripheral slots and to two PCI Express-to-PCI bridges to provide PCI buses to the hybrid

peripheral slots. Refer to PXIe-1086DC PCI Express Backplane Diagram.

System slot link 1 is a Gen-2 x8 PCI Express link to PCI Express switch 1, providing a

nominal bandwidth of 4 GB/s (single direction) between the system controller and PCI

Express switch 1. PXI Express peripheral slots 2-10 are connected to PCI Express switch 1

with Gen-2 x8 PCI Express links and are downstream of system slot link 1. PCI Express-toPCI bridge 1 is connected to PCI Express switch 1 and provides a 32-bit, 33 MHz PCI bus for

hybrid peripheral slots 2-9. PCI Express switch 1 also is connected to PCI Express switch 2

with a Gen-2 x8 PCI Express link for advanced backplane configurations.

System slot link 2 is a Gen-2 x16 PCI Express link to PCI Express switch 2, providing a

nominal bandwidth of 8 GB/s (single direction) between the system controller slot and PCI

Express switch 2. PXI Express peripheral slots 11-18 are connected to PCI Express switch 2

with Gen-2 x8 PCI Express links and are downstream of system slot link 2. PCI Express-toPCI bridge 2 is connected to PCI Express switch 2 and provides a 32-bit, 33 MHz PCI bus for

hybrid peripheral slots 11-18. PCI Express switch 2 also is connected to PCI Express switch 1

with a Gen-2 x8 PCI Express link for advanced backplane configurations.

The system controller slot also has connectivity to some PXI features such as: PXI_CLK10,

PXI Star, PXI Trigger Bus and PXI Local Bus 6.

6 | ni.com | PXIe-1086DC User Manual and Specifications

Page 7

By default, the system controller will control the power supply with the PS_ON# signal. A

x8

x1

x8

x1

x16

3H2

H

4

H5H6H7H8H9H

11H12H13H14H15H16H17H18

H

PCIe Switch #1

Port 16 Port 17 Port 8 Port 9

PCIe Switch #2

10

1

PCI Bus (32-bit, 33 MHz) to slots 2-9 PCI Bus (32-bit, 33 MHz) to slots 11-18

PCIe-to-

PCI

Bridge #1

Port 0 Port 4 Port 5

Port 17 Port 8 Port 9

Port 12Port 13 Port 20Port 21

Port 16

Port 20

Port 5Port 4Port 1Port 0

Port 21Port 13 Port 12

x8

x8

x8

x8

x8

x8

x8

x8

x8

x8

x8

x8

x8

x8

x8

x8

x8

PCIe-to-

PCI

Bridge #2

logic low on this line will turn the power supply on.

Note The Inhibit Mode switch on the rear of the chassis must be in the Default

position for the system controller to have control of the power supply. Refer to the

Inhibit Mode Switch section for details about the Inhibit Mode switch.

Hybrid Peripheral Slots

The chassis provides 16 hybrid peripheral slots as defined by the PXI-5 PXI Express Hardware

Specification: slots 2 to 9 and slots 11 to 18. A hybrid peripheral slot can accept the following

peripheral modules:

• A PXI Express peripheral with x8, x4, or x1 PCI Express link through a switch to the

system slot. Each PXI Express peripheral slot can link up to a Gen-2 x8 PCI Express,

providing a maximum nominal single-direction bandwidth of 4 GB/s.

• A CompactPCI Express Type-2 Peripheral with x8, x4, or x1 PCI Express link through a

PCI Express switch to the system slot.

• A hybrid-compatible PXI Peripheral module modified by replacing the J2 connector with

an XJ4 connector installed in the upper eight rows of J2. Refer to the PXI Express

Specification for details. The PXI peripheral communicates through the backplane’s 32bit PCI bus.

• A CompactPCI 32-bit peripheral on the backplane’s 32-bit PCI bus.

The hybrid peripheral slots provide full PXI Express functionality and 32-bit PXI functionality

except for PXI Local Bus. The hybrid peripheral slot only connects to PXI Local Bus 6 left

and right.

Figure 3. PXIe-1086DC PCI Express Backplane Diagram

PXIe-1086DC User Manual and Specifications | © National Instruments | 7

Page 8

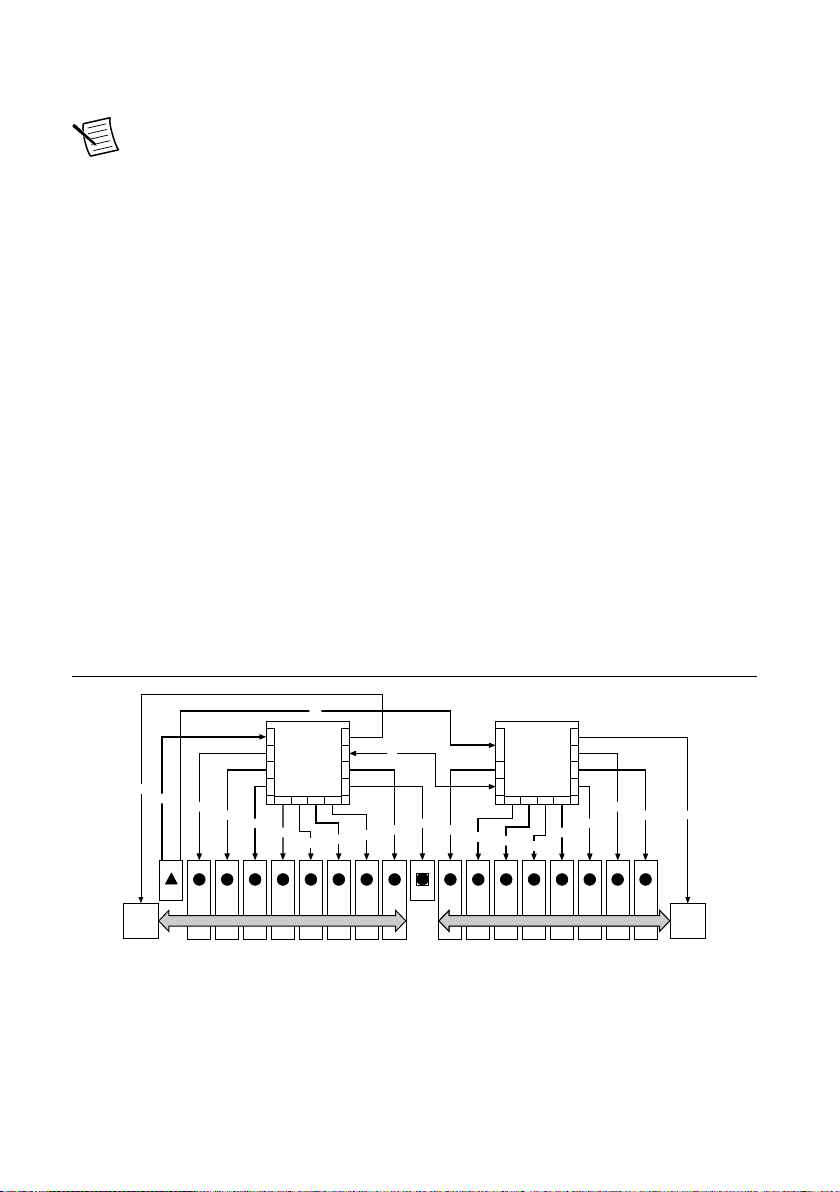

System Timing Slot

1 2H3H4H5H6H7H8H9H10 11H12H13H14H15H16H17H18

H

DSTAR 6

DSTAR 5

DSTAR 7

DSTAR 4

DSTAR 3

DSTAR 2

DSTAR 1

DSTAR 15

DSTAR 14

DSTAR 13

DSTAR 16

DSTAR 12

DSTAR 11

DSTAR 10

STAR 7

STAR 8

STAR 6

STAR 5

STAR 4

STAR 3

STAR 2

STAR 1 STAR 10

STAR 11

STAR 12

STAR 13

STAR 14

STAR 15

STAR 16

DSTAR 8

DSTAR 9

DSTAR 0

STAR 9

STAR 0

The system timing slot is slot 10. The system timing slot accepts the following peripheral

modules:

• A PXI Express System Timing Module with x8, x4, or x1 PCI Express link to the system

slot through a PCI Express switch. Each PXI Express peripheral slot can link up to a

Gen-2 x8 PCI Express, providing a maximum nominal single-direction bandwidth of 4

GB/s.

• A PXI Express Peripheral with x8, x4, or x1 PCI Express link to the system slot through a

PCI Express switch.

• A CompactPCI Express Type-2 Peripheral with x8, x4, or x1 PCI Express link to the

system slot through a PCI Express switch.

The system timing slot has three (3) dedicated differential pairs (PXIe_DSTAR) connected

from the TP1 and TP2 connectors to the XP3 connector for each PXI Express hybrid

peripheral slot, as well as routed back to the XP3 connector of the system timing slot, as

shown in the following figure. You can use the PXIe_DSTAR pairs for high-speed triggering,

synchronization, and clocking. Refer to the PXI Express Specification for details.

The system timing slot also has a single-ended (PXI Star) trigger connected to every slot.

Refer to the following figure for more details.

The system timing slot has a pin (PXI_CLK10_IN) through which a system timing module

may source a 10 MHz clock to which the backplane phase-locks. Refer to the System

Reference Clock section for details.

The system timing slot has a pin (PXIe_SYNC_CTRL) through which a system timing module

can control the PXIe_SYNC100 timing. Refer to the PXI Express Specification and the PXIe

SYNC CTRL section of this chapter for details.

Figure 4. PXIe_DSTAR and PXI Star Connectivity Diagram

8 | ni.com | PXIe-1086DC User Manual and Specifications

Page 9

PXI Local Bus

7H8H9

H

10

11H12

H

PXI Trigger Bus #2

PXI

Trigger

Bridge #2

PXI

Trigger

Bridge #1

1

2H3H4H5H6

H

PXI Trigger Bus #1

13H14H15H16H17H18

H

PXI Trigger Bus #3

The PXI backplane local bus is a daisy-chained bus that connects each peripheral slot with

adjacent peripheral slots to the left and right.

The backplane routes PXI Local Bus 6 between all slots. The left local bus 6 from slot 1 is not

routed anywhere, and the right local bus 6 from slot 18 is not routed anywhere.

Local bus signals may range from high-speed TTL signals to analog signals as high as 42 V.

Initialization software uses the configuration information specific to each adjacent peripheral

module to evaluate local bus compatibility.

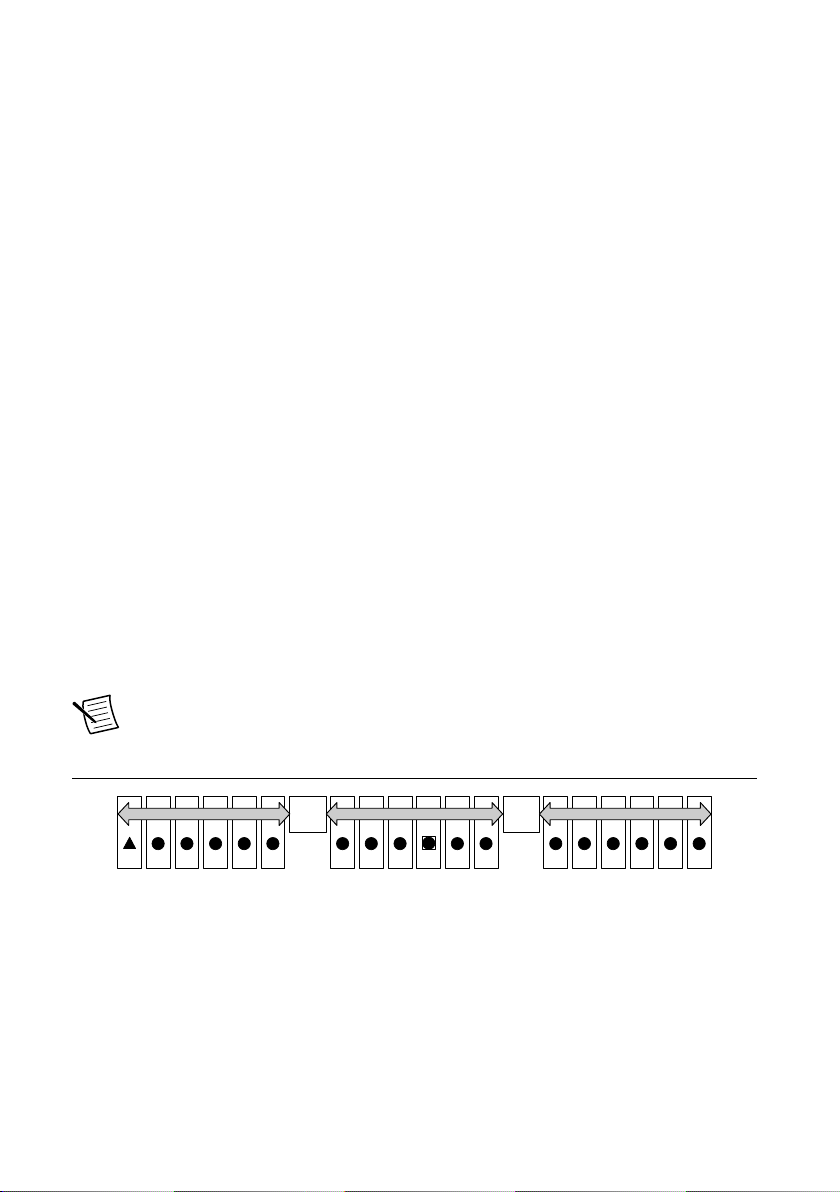

PXI Trigger Bus

All slots on the same PXI bus segment share eight PXI trigger lines. You can use these trigger

lines in a variety of ways. For example, you can use triggers to synchronize the operation of

several different PXI peripheral modules. In other applications, one module located in the

system timing slot can control carefully timed sequences of operations performed on other

modules in the system. Modules can pass triggers to one another on the lines, allowing

precisely timed responses to asynchronous external events the system is monitoring or

controlling.

The PXI trigger lines from adjacent PXI trigger bus segments can be routed in either direction

across the PXI trigger bridges through buffers. This allows you to send trigger signals to, and

receive trigger signals from, every slot in the chassis. Static trigger routing (user-specified line

and directional assignments) can be configured through Measurement & Automation Explorer

(MAX). Dynamic routing of triggers (automatic line assignments) is supported through certain

National Instruments drivers like NI-DAQmx.

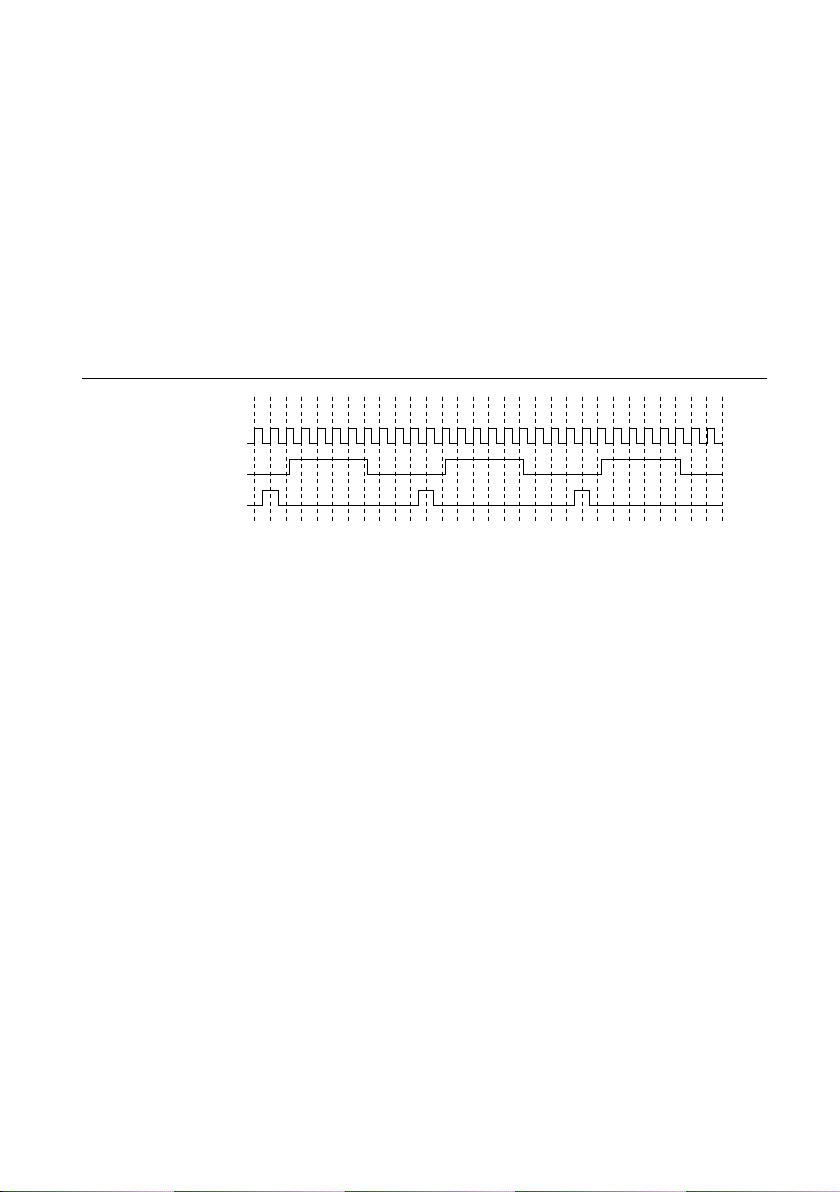

System Reference Clock

The PXIe-1086DC chassis supplies PXI_CLK10, PXIe_CLK100 and PXIe_SYNC100 to

every peripheral slot with an independent driver for each signal.

An independent buffer (having a source impedance matched to the backplane and a skew of

less than 1 ns between slots) drives PXI_CLK10 to each peripheral slot. You can use this

common reference clock signal to synchronize multiple modules in a measurement or control

system.

Note Although any trigger line may be routed in either direction, it cannot be

routed in more than one direction at a time.

Figure 5. PXI Trigger Bus Connectivity Diagram

PXIe-1086DC User Manual and Specifications | © National Instruments | 9

Page 10

An independent buffer drives PXIe_CLK100 to each peripheral slot. These clocks are matched

PXIe_CLK100

PXI_CLK10

PXIe_SYNC100

0 1 2 3 4 5 6 7 8 9 0 1 2 3 4 5 6 7 8 9 0 1 2 3 4 5 6 7 8 9

in skew to less than 100 ps. The differential pair must be terminated on the peripheral with

LVPECL termination for the buffer to drive PXIe_CLK100 so that when there is no peripheral

or a peripheral that does not connect to PXIe_CLK100, there is no clock being driven on the

pair to that slot.

An independent buffer drives PXIe_SYNC100 to each peripheral slot. The differential pair

must be terminated on the peripheral with LVPECL termination for the buffer to drive

PXIe_SYNC100 so that when there is no peripheral or a peripheral that does not connect to

PXIe_SYNC100, there is no SYNC100 signal being driven on the pair to that slot.

PXI_CLK10, PXIe_CLK100 and PXIe_SYNC100 have the default timing relationship

described in the following figure.

Figure 6. System Reference Clock Default Behavior

To synchronize the system to an external clock, you can drive PXI_CLK10 from an external

source through the PXI_CLK10_IN pin on the System Timing Slot. Refer to the System

Timing Slot XP4 Connector Pinout section for the pinout. When a 10MHz clock is detected on

this pin, the backplane automatically phase-locks the PXI_CLK10, PXIe_CLK100, and

PXIe_SYNC100 signals to this external clock and distributes these signals to the slots. Refer

to the Specifications for the specification information for an external clock provided on the

PXI_CLK10_IN pin of the system timing slot.

You also can drive a 10 MHz clock on the 10 MHz REF IN connector on the front of the

chassis. When a 10 MHz clock is detected on this connector, the backplane automatically

phase-locks the PXI_CLK10, PXIe_CLK100, and PXIe_SYNC100 signals to this external

clock and distributes these signals to the slots. Refer to the Specifications section for the

specification information for an external clock provided on the 10 MHz REF IN connector on

the front panel of the chassis.

If the 10 MHz clock is present on both the PXI_CLK10_IN pin of the System Timing Slot and

the 10 MHz REF IN connector on the front of the chassis, the signal on the System Timing

Slot is selected. Refer to the following table which explains how the 10 MHz clocks are

selected by the backplane.

10 | ni.com | PXIe-1086DC User Manual and Specifications

Page 11

Table 1. Backplane External Clock Input Configuration

System Timing Slot

PXI_CLK10_IN

Front Chassis

Panel 10 MHz REF

IN

Backplane PXI_CLK10, PXIe_CLK100

and PXIe_SYNC100

No clock present No clock present Backplane generates its own clocks

No clock present 10 MHz clock

present

PXI_CLK10, PXIe_CLK100 and

PXIe_SYNC100 all phase-locked to front

Chassis Panel—10 MHz REF IN

10 MHz clock present No clock present PXI_CLK10, PXIe_CLK100 and

PXIe_SYNC100 all phase-locked to

System Timing Slot— PXI_CLK10_IN

10 MHz clock present 10 MHz clock

present

PXI_CLK10, PXIe_CLK100 and

PXIe_SYNC100 all phase-locked to

System Timing Slot— PXI_CLK10__IN

A copy of the backplane’s PXI_CLK10 is exported to the 10 MHz REF OUT connector on the

front of the chassis. This clock is driven by an independent buffer.

PXIe_SYNC_CTRL

PXIe_SYNC100 is by default a 10 ns pulse synchronous to PXI_CLK10. The frequency of

PXIe_SYNC100 is 10/n MHz, where n is a positive integer. The default for n is 1, giving

PXIe_SYNC100 a 100 ns period. However, the backplane allows n to be programmed to other

integers. For example, setting n = 3 gives a PXIe_SYNC100 with a 300 ns period while still

maintaining its phase relationship to PXI_CLK10. The value for n can be any positive integer

from 1 to 255.

The system timing slot has a control pin for PXIe_SYNC100 called PXIe_SYNC_CTRL for

use when n > 1. Refer to System Timing Slot XP3 Connector Pinout for the pinout. Refer to the

Specifications for the PXIe_SYNC_CTRL input specifications.

By default, a high-level detected by the backplane on the PXIe_SYNC_CTRL pin causes a

synchronous restart for the PXIe_SYNC100 signal. On the next PXI_CLK10 edge the

PXIe_SYNC100 signal restarts. This allows several chassis to have their PXIe_SYNC100 in

phase with each other. Refer to the following figure for timing details with this method.

PXIe-1086DC User Manual and Specifications | © National Instruments | 11

Page 12

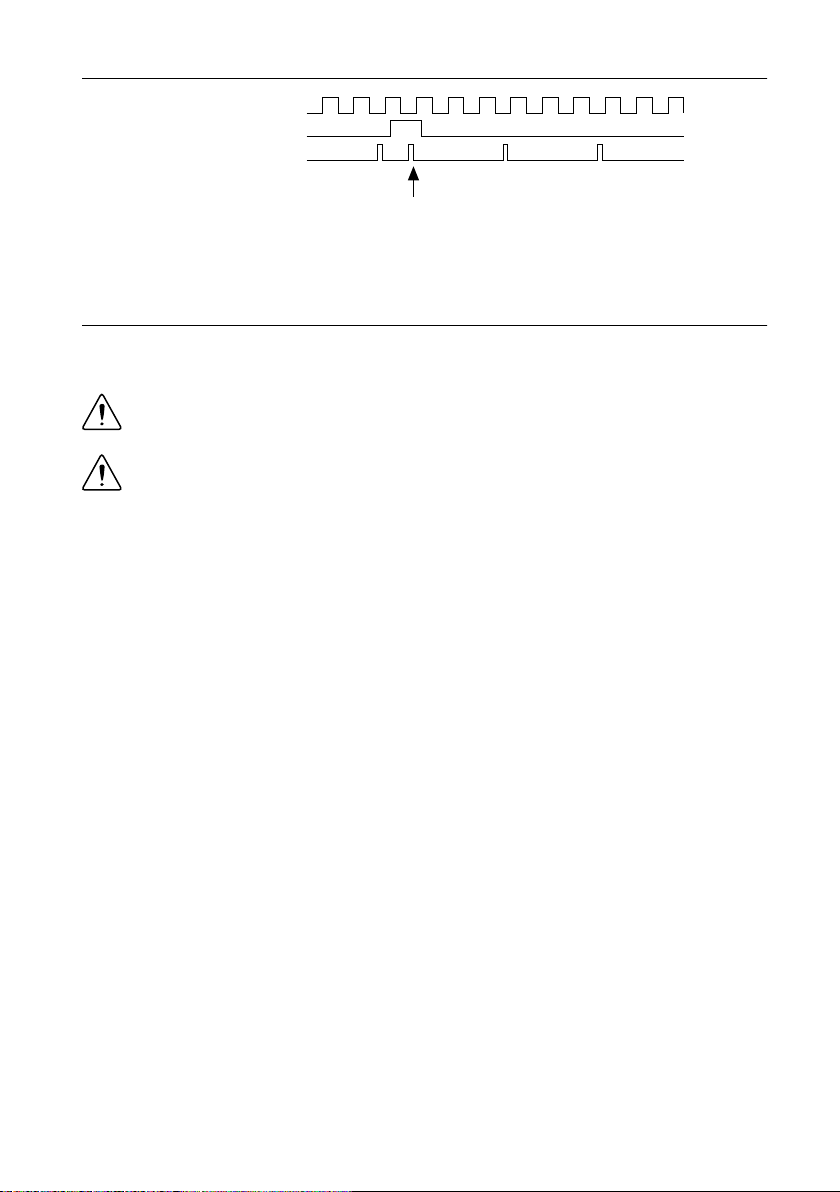

Figure 7. PXIe_SYNC100 at 3.33 MHz Using PXIe_SYNC_CTRL as Restart

PXI_CLK10

PXIe_SYNC_CTRL

PXIe_SYNC100

SYNC100 Divider

Restarted Here

Installation and Configuration

Safety Information

Caution Before undertaking any troubleshooting, maintenance, or exploratory

procedure, carefully read the following caution notices.

Caution Protection may be impaired if equipment is not used in the manner

specified.

This equipment contains voltage hazardous to human life and safety, and is capable of

inflicting personal injury.

• Chassis Grounding—The chassis requires a connection from the premise wire safety

ground to the chassis ground. The earth safety ground must be connected during use of

this equipment to minimize shock hazards. Refer to the Connecting Safety Ground section

for instructions on connecting safety ground.

• Live Circuits—Operating personnel and service personnel must not remove protective

covers when operating or servicing the chassis. Adjustments and service to internal

components must be undertaken by qualified service technicians. During service of this

product, the mains connector to the premise wiring must be disconnected. Dangerous

voltages may be present under certain conditions; use extreme caution.

• Explosive Atmosphere—Do not operate the chassis in conditions where flammable gases

are present. Under such conditions, this equipment is unsafe and may ignite the gases or

gas fumes.

• Part Replacement—Only service this equipment with parts that are exact replacements,

both electrically and mechanically. Contact National Instruments for replacement part

information. Installation of parts with those that are not direct replacements may cause

harm to personnel operating the chassis. Furthermore, damage or fire may occur if

replacement parts are unsuitable.

12 | ni.com | PXIe-1086DC User Manual and Specifications

Page 13

• Modification—Do not modify any part of the chassis from its original condition.

Unsuitable modifications may result in safety hazards.

• Location—The chassis is for use in stationary (non-moveable), restricted access locations

such as a desk or bench, or for installation in a rack only. Installation and maintenance are

to be performed by skilled/trained service persons.

Chassis Cooling Considerations

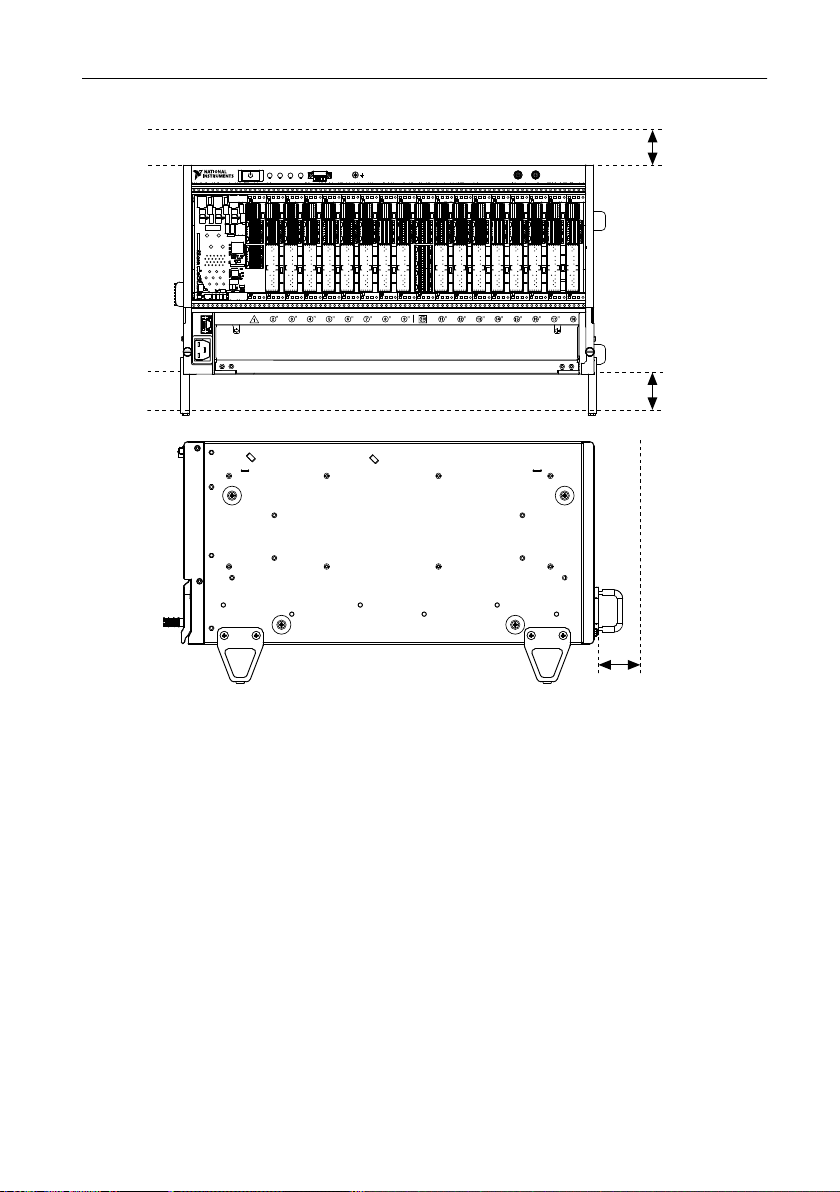

The PXIe-1086DC chassis is designed to operate on a bench or in an instrument rack. The

chassis must be oriented horizontally with the primary exhaust vent at top. Vertical orientation

with the chassis handle up is not a supported configuration. Regardless of the configuration,

you must provide the cooling clearances as outlined in the following sections.

Providing Adequate Clearance

The primary cooling exhaust vent for the PXIe-1086DC is on the top of the chassis. The

primary intake vent is on the bottom of the chassis. The secondary intake vents are located

along on the rear of the chassis. Adequate clearance between the chassis and surrounding

equipment or blockages must be maintained to ensure proper cooling of the chassis power

supply as well as the modules plugged into the chassis. These clearances are outlined in the

following figures. Failure to provide these clearances may result in thermal-related failures in

the chassis or modules.

PXIe-1086DC User Manual and Specifications | © National Instruments | 13

Page 14

1.75

(44.5)

3.00

(76.2)

Dimensions are in inches (millimeters)

1.75

(44.5)

PXIe-1086DC

H

Figure 8. PXIe-1086DC Cooling Clearances

The vent locations are shown in the following figure.

14 | ni.com | PXIe-1086DC User Manual and Specifications

Page 15

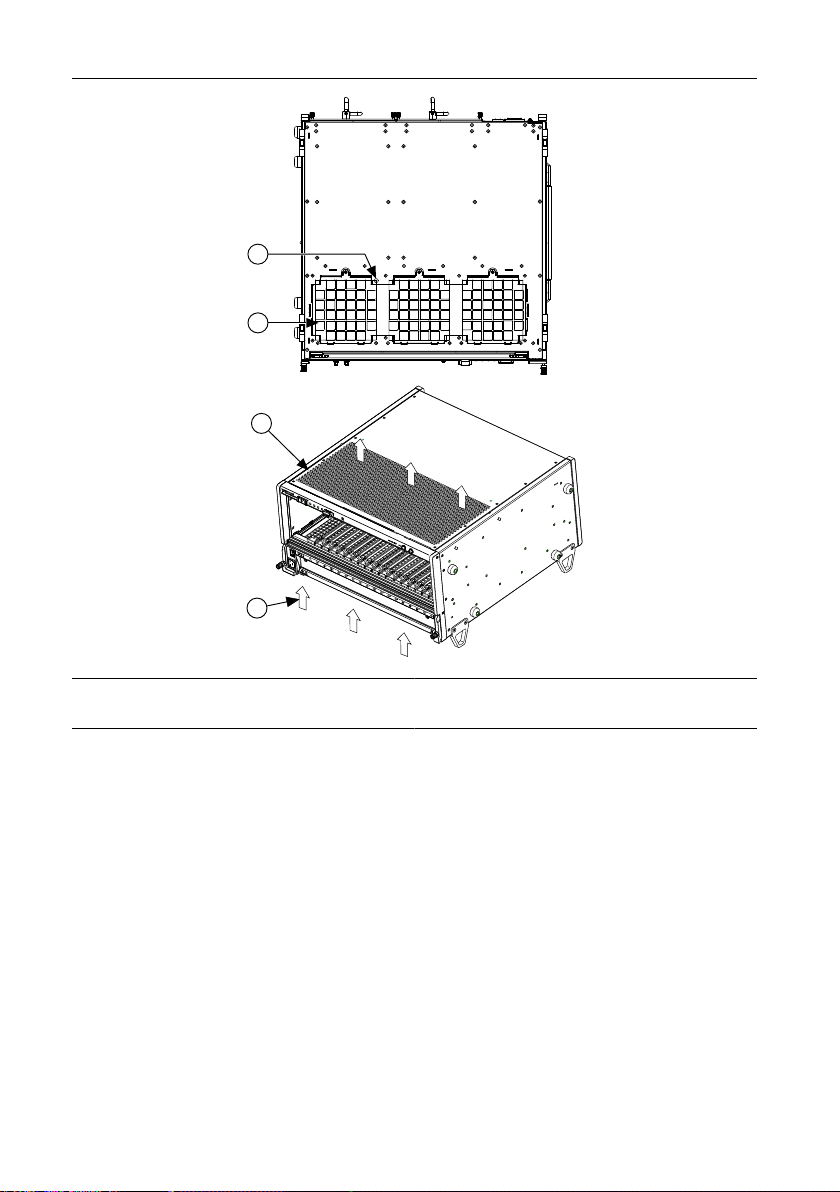

Figure 9. PXIe-1086DC Vents

PXIe-1086DC

4

2

1

3

1. Ambient Temperature Sensor

2. PXI Module Air Intake (3x)

3. PXI Module Air Exhaust Vent

4. Airflow

Chassis Ambient Temperature Definition

The chassis fan control system uses ambient intake air temperatures for controlling fan speeds

when in Auto Fan Speed mode. Because of this, the chassis ambient temperature is defined as

the temperature of the air just outside of the fan intake vents on the bottom of the chassis. Note

that this temperature may be higher than ambient room temperature depending on the

surrounding equipment and/or blockages present. Ensure ambient intake temperatures do not

exceed the ratings in the Operating Environment section of the PXIe-1086DC Specifications.

If the temperature exceeds the stated spec, the front-panel temperature LED blinks red.

Setting Fan Speed

The fan-speed selector switch is on the chassis rear panel. Refer to Rear View of the

PXIe-1086DC to locate the fan-speed selector switch. Select High for maximum cooling

performance or Auto for improved acoustic performance. When set to Auto, the chassis intake

air temperature determines the fan speed.

PXIe-1086DC User Manual and Specifications | © National Instruments | 15

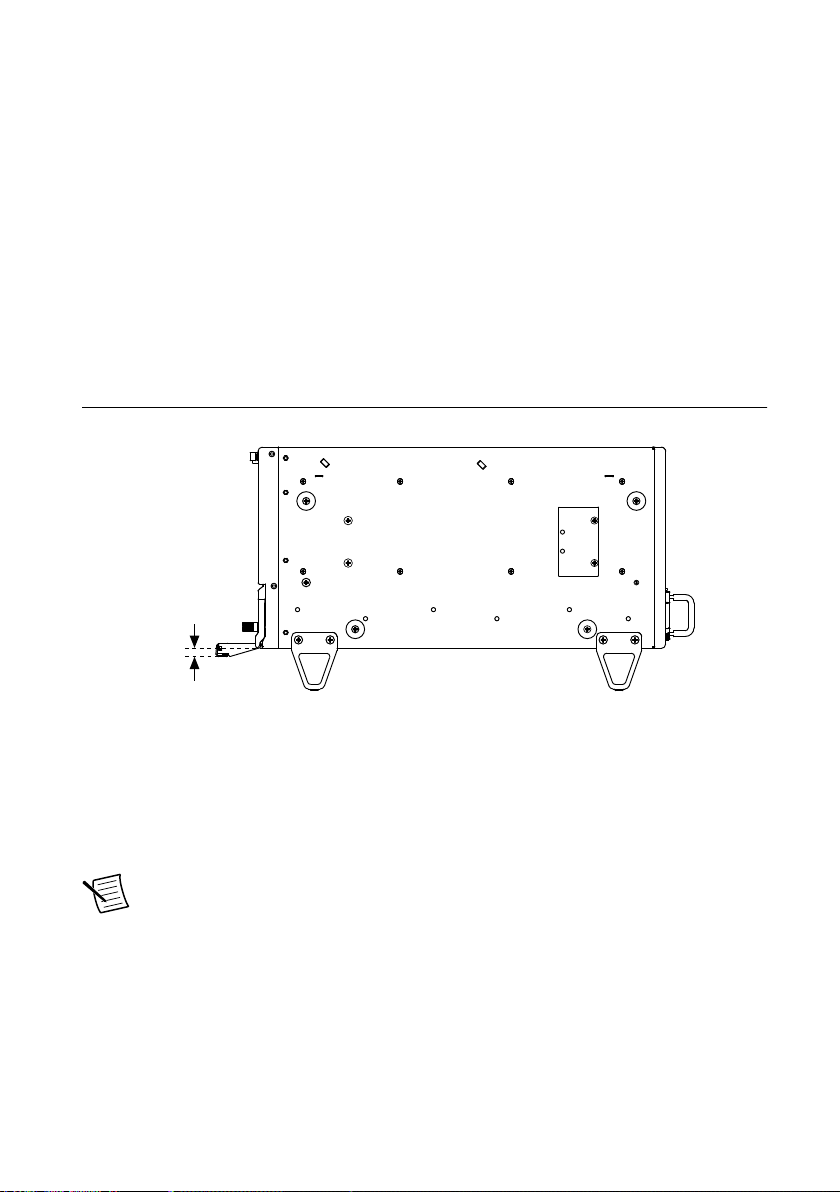

Page 16

Installing Filler Panels

Dimensions are in inches (millimeters)

0.35

(8.9)

To maintain proper module cooling performance, install filler panels (provided with the

chassis) in unused or empty slots. Secure with the captive mounting screws provided.

Installing Slot Blockers

The cooling performance of the chassis can be improved by installing optional slot blockers.

Refer to the National Instruments website at ni.com/info and enter the Info Code

slotblocker for more information about slot blockers.

Fan Access Door Clearance

When installing the PXIe-1086DC chassis, you also must provide the proper clearance for the

fan access door to open fully, as shown in the following figure.

Figure 10. Fan Access Door Clearance

Rack Mounting

Rack mount applications require optional rack mount kits available from National Instruments.

Refer to the instructions supplied with the rack mount kits to install your PXIe-1086DC

chassis in an instrument rack. Refer to NI Chassis Rack Mount Kit Components for more

information.

Note You may want to remove the feet from the PXIe-1086DC chassis when rack

mounting. To do so, remove the screw holding the feet and handle in place.

Connecting to Safety Ground and Power Source

The PXIe-1086DC chassis has a single power connector that supplies input power to both

chassis power supplies. The power connector is on the front panel.

16 | ni.com | PXIe-1086DC User Manual and Specifications

Page 17

The PXIe-1086DC ships with a power cord that has an appliance coupler and leads for

3

2

1

connection to the source. The cord requires custom termination. The following figure shows

the cord connector pinout.

You can order an additional or replacement cord from National Instruments. Part number

782108-01 is a US/CAN approved 3 m, three-conductor, 18 AWG cord with leads and suitable

for use in North America. Part number 785863-01 is an international harmonized power cord,

3 m, three-conductor, 1.0mm2 cord with leads and suitable for use in the EU and

internationally. Installation must be done in accordance with local electric codes.

Caution The PXIe-1086DC chassis must have a safety ground (protective earth),

which is connected by the installer to the premise safety ground system for safe

operation. The supplied power cord has a green ground wire for this purpose. The

safety ground method shall be reliable and meet applicable safety codes.

Attention Pour un fonctionnement en toute sécurité, le châssis PXIe-1086DC doit

disposer d'un fil de protection (mise à la terre) relié par l'installateur au système de

mise à la terre du site. Le cordon d'alimentation fourni dispose d'un fil de protection

vert prévu à cet effet. La méthode de mise à la terre doit être fiable et respecter les

codes de sécurité applicables.

The Earth Ground Terminal on the rear of the chassis must be used where the power cord is

terminated via a standard power plug (for example, IEC 60320, NEMA 5-15). This provides a

supplemental protective earthing connection to prevent shock hazards if the ground in the plug

were to be interrupted. Complete the following steps to connect a protective conductor to this

terminal:

1. Connect a 18 AWG wire to the Earth Ground Terminal using a grounding lug. The wire

must have green insulation with a yellow stripe or must be noninsulated (bare). The lug

must be sized for the M4 x 6 screw.

2. Attach the opposite end of the wire to permanent earth ground using toothed washers or a

toothed lug.

1. Protective Earth (Ground)

2. Power (-, Neutral)

3. Power (+, Hot)

Figure 11. Power Connector

PXIe-1086DC User Manual and Specifications | © National Instruments | 17

Page 18

Notice

To ensure the specified EMC performance with a second chassis power supply,

install a snap-on ferrite bead (NI part number 711849-01) onto the power cord as

close to the input connector as possible. You can order this ferrite bead directly from

NI using the Order By Part Number link on the home page at ni.com. Order the

following part number: 781233-02 EMI suppression ferrite, 10.2 mm (includes NI

part number 711849-01 (Fair-Rite 0443167251, type 43, round cable, 10.2 mm/

0.402 in. ID, 225 Ω @ 100 MHz)).

Power-On Test

Caution Do not install modules prior to performing the following power-on test.

Caution To completely remove power, you must disconnect all power cables.

The PXIe-1086DC chassis has two slots for inserting power supplies on the rear of the chassis.

A power supply must be installed in one or both of these slots to power on the chassis.

Use the Inhibit Mode switch to power on the chassis or place it in standby mode. Set the

Inhibit Mode switch on the back of the chassis to the Manual position. Observe that all fans

become operational and that all chassis LEDs are steady green. Set the Inhibit Mode switch

back to the Default position to allow the system controller to control the power supply.

Installing a PXI Express System Controller

This section contains general installation instructions for installing a PXI Express system

controller in a PXIe-1086DC chassis. Refer to your PXI Express system controller user

manual for specific instructions and warnings. To install a system controller, complete the

following steps:

1. Ensure that the chassis is properly grounded to protect it from electrical damage while

you install the system controller.

2. Install the system controller into the system controller slot (slot 1, indicated by the red

card guides) by first placing the system controller PCB into the front of the card guides

(top and bottom). Slide the system controller to the rear of the chassis, making sure that

the injector/ejector handle is pushed down as shown in the following figure.

18 | ni.com | PXIe-1086DC User Manual and Specifications

Page 19

Figure 12. Installing a PXI Express System Controller

NI PXIe-1086

4

3

2

1

1. Controller Front Panel Mounting Screws (4x)

2. NI PXI Express System Controller

3. Injector/Ejector Handle

4. PXIe-1086DC Chassis

3. When you begin to feel resistance, pull up on the injector/ejector handle to seat the

system controller fully into the chassis frame. Secure the system controller front panel to

the chassis using the system controller front panel mounting screws.

4. Connect the keyboard, mouse, and monitor to the appropriate connectors. Connect

devices to ports as required by your system configuration.

5. Power on the chassis. Verify that the system controller boots. If the system controller does

not boot, refer to your system controller user manual.

The following figure shows a PXI Express system controller installed in the system controller

slot of a PXIe-1086DC chassis. You can place CompactPCI, CompactPCI Express, PXI, or

PXI Express modules in other slots depending on the slot type.

PXIe-1086DC User Manual and Specifications | © National Instruments | 19

Page 20

Figure 13. PXI Express System Controller Installed in an PXIe-1086DC Chassis

NI PXIe-1086

1

2

3

1. PXIe-1086DC chassis

2. PXI Express System Controller

3. Injector/Ejector Rail

Installing Peripheral Modules

Caution The PXIe-1086DC chassis has been designed to accept a variety of

peripheral module types in different slots. To prevent damage to the chassis, ensure

that the peripheral module is being installed into a slot designed to accept it. Refer to

the Getting Started section for a description of the various slot types.

This section contains general installation instructions for installing a peripheral module in a

PXIe-1086DC chassis. Refer to your peripheral module user manual for specific instructions

and warnings. To install a module, complete the following steps:

1. Ensure that the chassis is properly grounded to protect it from electrical damage while

you install the module.

2. Ensure that the chassis is powered off.

3. Install a module into a chassis slot by first placing the module card PCB into the front of

the card guides (top and bottom), as shown in the following figure. Slide the module to

the rear of the chassis, making sure that the injector/ejector handle is pushed down as

shown in the following figure.

4. When you begin to feel resistance, push up on the injector/ejector handle to fully seat the

module into the chassis frame. Secure the module front panel to the chassis using the

module front-panel mounting screws.

20 | ni.com | PXIe-1086DC User Manual and Specifications

Page 21

Figure 14. Installing PXI, PXI Express, or CompactPCI Peripheral Modules

NI PXIe-1086

5

4

6

3

2

1

1. Injector/Ejector Handle

2. PXI Peripheral Module

3. Peripheral Module Front Panel Mounting Screws

(2x)

4. PXI Express System Controller

5. PXIe-1086DC Chassis

6. Injector/Ejector Rail

Remote System Monitoring

The PXIe-1086DC chassis provides an Ethernet port on the front panel of the chassis. You can

use this Ethernet port to monitor the chassis operating parameters remotely over a network.

The Ethernet port on the chassis supports communication speeds of 10 Mbps and 100 Mbps.

Contact your network administrator to determine whether your network supports DHCP. If

your network uses DHCP, the network configuration is performed automatically. Refer to

Front View of the PXIe-1086DC to locate the Ethernet port

To use the remote monitoring interface, connect one end of an Ethernet cable to your

PXIe-1086DC chassis. Connect the other end of the cable to your Ethernet network.

Note The Ethernet controller can perform automatic crossover, thus eliminating the

need for crossover cables.

Through the remote monitoring Ethernet interface of the chassis, you can access a web page

with information about the current chassis operating parameters. You can access this page in

most browsers. Enter the IP address or hostname currently assigned to the chassis into the

browser’s address bar.

PXIe-1086DC User Manual and Specifications | © National Instruments | 21

Page 22

Figure 15. Chassis Configuration Web Page

The Ethernet connector has two LEDs that indicate the current status of the Ethernet link.

Table 2. Ethernet LED Behavior

LED State Description

Off Link is not established.

ACT/Link

10/100

Steady green Link is established.

Blinking green Chassis is communicating with another device on the network.

Off 10 Mbps data rate is selected.

Steady green 100 Mbps data rate is selected.

Default Configuration Settings

The chassis ships from the factory with the following default configuration settings:

• DHCP with Auto IP fallback

• Default hostname as printed on the product label

LED Indicators

The PXIe-1086DC chassis has four main LEDs on the front panel next to the Power Inhibit

switch. Refer to Front View of the PXIe-1086DC to locate these LEDs. You can use the four

main LEDs to determine the chassis operating status quickly.

22 | ni.com | PXIe-1086DC User Manual and Specifications

Page 23

Table 3. Main Chassis LED Behavior

LED State Description

Off Chassis is powered off.

Temperature Status

Fan Status

Power Supply 1 Status

Steady green

Blinking red

Steady red

Air intake temperature is within chassis operating

range.

Air intake temperature is outside of chassis operating

range.

Air intake or exhaust temperature has reached critical

limits.

Off Chassis is powered off.

Steady green All chassis fans are enabled and operating normally.

Blinking red

Steady red

One or more chassis fans have failed, but chassis can

continue to operate.

One or more chassis fans have failed, and chassis

must shut itself down.

Off Power supply is not installed or is in standby.

Steady green

Blinking red

Power supply is active, and all voltages are within

normal operating ranges.

Power supply is active, and at least one voltage is out

of range.

Steady red Power supply has failed.

Off Power supply is not installed or is in standby.

Steady green

Power supply is active, and all voltages are within

normal operating ranges.

Power Supply 2 Status

Blinking red

Power supply is active, and at least one voltage is out

of range.

Steady red Power supply has failed.

Each chassis fan assembly has an LED that shows the current health of that fan.

PXIe-1086DC User Manual and Specifications | © National Instruments | 23

Page 24

Table 4. Chassis Fan LED Behavior

LED State Description

Off Fan is not enabled.

Individual Fan Status

Each power supply also has an LED that shows the power supply’s current health.

LED State Description

Individual Power Supply Status

Steady green Fan is operating normally.

Steady red Fan has failed.

Table 5. Power Supply LED Behavior

Off Power supply is in standby.

Steady green Power supply is operating normally.

Steady red Power supply has failed.

Remote Inhibit and Fault Monitoring

The PXIe-1086DC chassis supports remote inhibit and fault monitoring through a 4-pin

terminal block on the chassis front panel. Refer to Front View of the PXIe-1086DC to locate

this connector.

Table 6. Remote Inhibit and Fault Connector Pinout

Pin Signal

1 Remote Inhibit (active low)

2 Ground

3 Remove Fault (active high)

4 Ground

When the chassis Inhibit Mode switch is in the Manual position, you can use the Remote

Inhibit signal to control the chassis power supplies. Refer to the Inhibit Mode Switch section

for details.

The Remote Fault signal is an output signal that is asserted high when any chassis fault is

detected. You can use this signal to monitor the overall chassis health.

Inhibit Mode Switch

On the rear panel of the chassis there is an Inhibit Mode switch. Refer to Rear View of the

PXIe-1086DC to locate this switch.

24 | ni.com | PXIe-1086DC User Manual and Specifications

Page 25

The Inhibit Mode switch should be in the Default position when normal power inhibit switch

functionality is desired. If the user needs to power on a chassis without a system controller

installed the switch should be in the Manual position.

When the Inhibit Mode switch is set to the Manual position, the power supplies are enabled,

and you can use the Inhibit signal (active low) on pin 1 of the Remote Inhibit and Fault

connector to power off the chassis. To power off the chassis remotely, connect the Inhibit pin

(pin 1) to a Logic Ground pin (pin 2). As long as this connection exists, the chassis will remain

off (standby); when you remove this connection, the chassis turns on.

Note For the Remote Inhibit signal to control the On/Off (standby) state of the

chassis, the Inhibit Mode switch must be in the Manual position.

PXI_CLK10 Front Panel Connectors

There are two SMA connectors on the front of the PXIe-1086DC chassis for PXI_CLK10. The

connectors are labeled IN and OUT. You can use them for supplying the backplane with

PXI_CLK10 or routing the backplane’s PXI_CLK10 to another chassis. Refer to the System

Reference Clock section for details about these signals.

PXI Express System Configuration with MAX

The PXI Platform Services software included with your chassis automatically identifies your

PXI Express system components to generate a pxiesys.ini file. You can configure your

entire PXI system and identify your chassis through Measurement & Automation Explorer

(MAX), included with your system controller. PXI Platform Services creates the

pxiesys.ini and pxisys.ini file, which define your PXI system parameters.

MAX provides the following chassis information:

• Asset information, such as serial number or part number

• Chassis number

• Voltages, temperatures, and fan speeds

• Ethernet monitoring port configuration

• Slot details

• Chassis self-test

• Firmware Update

PXIe-1086DC User Manual and Specifications | © National Instruments | 25

Page 26

Figure 16. MAX Interface

Trigger Configuration in MAX

PXI Platform Services provides an interface to route and reserve triggers so dynamic routing,

through drivers such as NI-DAQmx, avoids double-driving and potentially damaging trigger

lines. For more information about routing and reserving PXI triggers, refer to Info Code

wf17sp at ni.com/support.

Each chassis has one or more trigger buses, each with eight lines numbered 0 through 7 that

can be reserved and routed statically or dynamically. Static reservation pre-allocates a trigger

line to prevent its configuration by a user program. Dynamic reservation/routing/deallocation

is on the fly within a user program based on National Instruments APIs such as NI-DAQmx.

NI recommends dynamic reservations and routing are used whenever possible. If static

reservations are required, static reservation of trigger lines can be implemented by the user in

MAX through the Triggers tab. PXI modules dynamically configured by programs such as

NI-DAQmx will not use reserved trigger lines. This prevents the instruments from doubledriving the trigger lines, possibly damaging devices in the chassis. In the default configuration,

trigger lines on each bus are independent. For example, if trigger line 3 is asserted on trigger

bus 0, by default it is not asserted automatically on any other trigger bus.

Complete the following steps to reserve these trigger lines in MAX.

1. In the Configuration tree, click the PXI chassis branch to configure.

2. In the lower right pane, click the Triggers tab.

3. Select the trigger lines to statically reserve.

4. Click the Save button.

26 | ni.com | PXIe-1086DC User Manual and Specifications

Page 27

PXI Trigger Bus Routing

Some National Instruments chassis, such as the PXIe-1086DC, have the capability to route

triggers from one bus to others within the same chassis using the Trigger Routing tab in

MAX.

Note Selecting any non-disabled routing automatically reserves the line in all

trigger buses being routed to. If you are using NI-DAQmx, it will reserve and route

trigger lines for you, so you won’t have to route trigger lines manually.

Complete the following steps to configure trigger routings in MAX.

1. In the Configuration tree, select the chassis in which you want to route trigger lines.

2. In the right-hand pane, select the Triggers tab near the bottom.

3. For each trigger line, select Route Right, Route Outward From Middle, or Route Left to

route triggers on that line in the described direction, or select Disabled for the default

behavior with no manual routing.

4. Click the Save button.

Figure 17. Trigger Configuration

Using System Configuration and Initialization Files

The PXI Express specification allows many combinations of PXI Express chassis and system

modules. To assist system integrators, the manufacturers of PXI Express chassis and system

modules must document the capabilities of their products. The minimum documentation

requirements are contained in .ini files, which consist of ASCII text. System integrators,

configuration utilities, and device drivers can use these .ini files.

PXIe-1086DC User Manual and Specifications | © National Instruments | 27

Page 28

The capability documentation for the PXIe-1086DC chassis is contained in the chassis.ini

file on the software media that comes with the chassis. The information in this file is combined

with information about the system controller to create a single system initialization file called

pxisys.ini (PXI System Initialization). The system controller manufacturer either provides

a pxisys.ini file for the particular chassis model that contains the system controller or

provides a utility that can read an arbitrary chassis.ini file and generate the corresponding

pxisys.ini file. System controllers from NI provide the pxisys.ini file for the

PXIe-1086DC chassis, so you should not need to use the chassis.ini file. Refer to the

documentation provided with the system controller or to ni.com/support for more

information on pxisys.ini and chassis.ini files.

Device drivers and other utility software read the pxisys.ini file to obtain system

information. The device drivers should have no need to directly read the chassis.ini file.

For detailed information regarding initialization files, refer to the PXI Express specification at

www.pxisa.org.

Maintenance

This section describes basic maintenance procedures you can perform on the PXIe-1086DC

chassis.

Caution Disconnect the power cable prior to servicing your

PXIe-1086DC chassis.

Service Interval

Clean dust from the chassis exterior (and interior) as needed, based on the operating

environment. Periodic cleaning increases reliability

.

Preparation

The information in this section is designed for use by qualified service personnel. Read the

PXIe-1086DC Safety, Environmental, and Regulatory Information document included with

your kit before attempting any procedures in this section.

Caution Many components within the chassis are susceptible to static dischar

damage. Service the chassis only in a static-free environment. Observe standard

handling precautions for static-sensitive devices while servicing the chassis. Always

wear a grounded wrist strap or equivalent while servicing the chassis.

ge

Cleaning

Cleaning procedures consist of exterior and interior cleaning of the chassis. Refer to your

module's user documentation for information about cleaning individual CompactPCI or PXI

Express modules.

Caution Always disconnect the power cable prior to servicing the chassis.

28 | ni.com | PXIe-1086DC User Manual and Specifications

Page 29

Interior Cleaning

Use a dry, low-velocity stream of air to clean the interior of the chassis. Use a soft-bristle

brush for cleaning around components.

Exterior Cleaning

Clean the exterior surfaces of the chassis with a dry, lint-free cloth or a soft-bristle brush. If

any dirt remains, wipe with a cloth moistened in a mild soap solution. Remove any soap

residue by wiping with a cloth moistened with clear water. Do not use abrasive compounds on

any part of the chassis.

Caution Avoid getting moisture inside the chassis during exterior cleaning,

especially through the top vents. Use just enough moisture to dampen the cloth.

Do not wash the front- or rear-panel connectors or switches. Cover these

components while cleaning the chassis.

Do not use harsh chemical cleaning agents; they may damage the chassis. Avoid

chemicals that contain benzene, toluene, xylene, acetone, or similar solvents.

Replacing a Modular Power Supply

This section describes how to remove and install a modular power supply for the

PXIe-1086DC chassis.

Caution Disconnect the power cable prior to replacing the power supply.

Attention Débranchez le câble d'alimentation avant de remplacer le bloc

d'alimentation.

Caution Do not use a power supply from another chassis. Doing so may damage

your chassis and the power supply. You must ensure the chassis is properly grounded

after any maintenance.

Attention N'essayez pas d'utiliser un bloc d'alimentation provenant d'un modèle de

châssis différent du vôtre. Cela pourrait endommager votre châssis et le bloc

d'alimentation.

Refer to Connecting to Safety Ground and Power Source for instructions on connecting safety

ground.

Removal of Power Supply

The PXIe-1086DC power supply (part number 782106-01) is a replacement part for the

PXIe-1086DC chassis. Before attempting to replace a power supply, verify that there is

adequate clearance behind the chassis.

The power supplies for this chassis are redundant and hot swappable. If both power supplies

are installed and functional, you can remove either without disconnecting main AC power

PXIe-1086DC User Manual and Specifications | © National Instruments | 29

Page 30

from the system. If both power supplies are installed, and one has failed, you can remove the

1

2

3

2

failed supply without disconnecting main AC power from the system.

Complete the following steps to remove a power supply from the rear of the chassis:

Caution Before handling the power supply, allow the fan to stop spinning.

1. Disengage the two screws on the rear of the power supply with a flat-blade screwdriver.

2. Extend the collapsible handle and pull the power supply out of the chassis.

Figure 18. Removing Power Supply from the PXIe-1086DC Chassis

1. Power Supply

2. Captive Screw

3. Collapsible Handle

Removal of Power Drawer

If access to the rear of the chassis is not available, you still can remove the power supplies by

removing the entire power drawer from the chassis.

30 | ni.com | PXIe-1086DC User Manual and Specifications

Page 31

Figure 19. PXIe-1086DC Power Drawer

2

1

3

2

1

4

1. Captive Screw

2. Power Drawer Lever

3. Side Latch

4. Power Supply

Caution If you are using the PXIe-1086DC and SC Express modules with front

mounting terminal blocks together, you must remove the SC Express module front

mount terminal blocks to access the power drawer. Refer to your module

documentation for more information about removing the terminal blocks.

Complete the following steps to remove the power drawer:

Caution You must disconnect AC or DC power before removing the power

drawer.

1. Disconnect AC or DC power by pressing the release button on the power cord.

2. Loosen the drawer lever captive screws with a flat-blade screwdriver until the threads

disengage from the chassis frame.

3. Rotate the drawer levers to eject the drawer from the chassis frame.

4. Pull the drawer about halfway out until the side latches engage.

5. Press in the side latches on both sides to release the drawer and continue to pull out the

drawer.

Caution Before handling the power supply, allow the fan to stop spinning.

6. Place the drawer on a table surface to remove the power supply.

7. Disengage the two screws on the rear of the power supply with a flat-blade screwdriver.

Refer to Rear View of the PXIe-1086DC for the location of the screws.

8. Extend the collapsible handle and pull the power supply out of the chassis. Refer to Rear

View of the PXIe-1086DC for the location of the handle.

PXIe-1086DC User Manual and Specifications | © National Instruments | 31

Page 32

Installation of Power Supply

Ensure there is no visible damage to the new power supply before installing it. Verify that

there is no foreign material inside the connector on the new power supply.

The power supplies for this chassis are redundant and hot swappable. If one power supply

already is installed and functional, you can install the second power supply without first

disconnecting main AC power from the system. If no power supplies are installed or

functional in the system, you must remove main power from the system by disconnecting the

power cable from the AC power connector on the chassis front panel.

Complete the following steps to install a power supply from the rear of the chassis:

1. Slide the power supply into an empty slot with the connector facing toward the chassis

until it engages.

2. Fold down the collapsible handle on the power supply.

3. Tighten the two captive screws on the rear of the power supply to 11.5 lb · in. torque with

a flat-blade screwdriver.

Installation of Power Drawer

If access to the rear of the chassis is not available, you still can install power supplies by

removing the entire power drawer from the chassis. The power drawer is shown in

PXIe-1086DC Power Drawer.

Caution If you are using the PXIe-1086DC and SC Express modules with front

mounting terminal blocks together, you must remove the SC Express module front

mount terminal blocks to access the power drawer. Refer to your module

documentation for more information about removing the terminal blocks.

Complete the following steps to remove the power drawer:

Caution You must disconnect AC or DC power before removing the power

drawer.

1. Disconnect AC or DC power by pressing the release button on the power cord.

2. Loosen the drawer lever captive screws with a flat-blade screwdriver until the threads

disengage from the chassis frame.

3. Rotate the drawer levers to eject the drawer from the chassis frame.

4. Pull the drawer about halfway out until the side latches engage.

5. Press in the side latches on both sides to release the drawer and continue to pull out the

drawer.

Caution Before handling the power supply, allow the fan to stop spinning.

6. Place the drawer on a table surface to install the power supply.

7. Slide the power supply into an empty slot with the connector facing toward inside of

drawer until it engages.

32 | ni.com | PXIe-1086DC User Manual and Specifications

Page 33

8. Fold down the collapsible handle on the power supply.

9. Tighten the two captive screws on the rear of the power supply to 11.5 lb · in. torque with

a flat-blade screwdriver.

10. Reinstall the power drawer. When reinstalling the drawer, tighten the drawer lever captive

screws to 11.5 lb · in. torque.

Replacing a Modular Fan Assembly

This section describes how to remove and install a modular fan assembly for the chassis.

Caution Do not use a fan assembly from another chassis. Doing so may damage

your chassis and the fan assembly.

Removal

The fan assembly (part number 782107-01) is a replacement part for the chassis. Before

attempting to replace a fan assembly, verify that there is adequate clearance in front of the

chassis.

The fans for this chassis are redundant and hot swappable. You can remove the fans with main

power connected to the system.

Caution Use care when selecting which fans to remove, as an undesired system

shut down can occur. Do not remove both fans from the same column, as this

triggers a system shutdown.

Caution Likewise, do not remove the working fan from the same column as a

failed fan, as this also triggers a chassis shutdown.

Caution If all fans are installed and operating normally, you can remove any fan

without causing the system to shut down.

The following figure shows the PXIe-1086DC chassis with a fan assembly removed.

PXIe-1086DC User Manual and Specifications | © National Instruments | 33

Page 34

Figure 20. PXIe-1086DC Chassis with Fan Assembly Removed

NI PXIe-1086

2

3

1

1. Modular Fan Assembly

2. Fan Latch

3. Fan Door

Complete the following steps to remove a fan assembly:

1. Open the fan door by sliding the door latches inward and rotating the door down.

2. Locate the fan to be removed. A red LED indicates a failed fan.

Caution If the fan is still spinning, allow the fan to stop before handling. (The

fan will not stop as long as it is in the airflow path.)

3. Slide the fan latch until it disengages and allows removal by pulling the fan module

forward.

Installation

Ensure there is no visible damage to the new fan assembly before installing it. Verify that there

is no foreign material inside the connector on the new fan assembly.

The fans for this chassis are redundant and hot swappable. You can install any fan with main

AC power connected to the system.

Complete the following steps to install a fan assembly:

1. Open the fan door by sliding the door latches inward and rotating the door down.

2. Slide the fan module into an empty fan slot with the connector facing the chassis until it

latches.

34 | ni.com | PXIe-1086DC User Manual and Specifications

Page 35

3. Verify that the fan is properly installed by pulling it forward with a light force without

pressing the latch. If the fan does not slide out without pressing in the latch, it is installed

correctly.

4. Close the fan door.

Specifications

This document contains specifications for the PXIe-1086DC chassis.

Electrical

AC Input

Input rating 210 to 300 VDC, 3.5 to 6 A

100 to 240 VAC, 12 to 6 A

Operating voltage range

Nominal AC input frequency 50/60 Hz

Operating AC frequency range

Efficiency 70% typical

Power disconnect The AC/DC power cable provides main power

1

1

210 to 300 VDC

90 to 264 VAC

47 to 63 Hz

disconnect. Do not position the equipment so

that it is difficult to disconnect the power cord.

The front-panel power switch causes the

internal chassis power supply to provide DC

power to the CompactPCI/PXI Express

backplane. You also can use the front panel

terminal block 4-pin connector and power

mode switch to control the internal chassis

power supply.

DC Output

Table 7. DC Current Capacity (Imp)

Voltage

+3.3 V 50 A 60 A

+5 V 40 A 49 A

1

Maximum Current Single Power

Supply

The operating range is guaranteed by design.

PXIe-1086DC User Manual and Specifications | © National Instruments | 35

Maximum Current Dual Power

Supplies

Page 36

Table 7. DC Current Capacity (Imp) (Continued)

Voltage

Maximum Current Single Power

Supply

Maximum Current Dual Power

Supplies

+12 V 50 A 62 A

-12 V 4 A 4 A

5 V

AUX

1.5 A 1.5 A

Note Maximum total usable power is 855 W.

Note Maximum combined +12 V and -12 V power of a single power supply is

588 W.

Table 8. Backplane Slot Current Capacity

Slot +5 V V (I/O) +3.3 V +12 V -12 V 5 V

System Controller Slot 15 A — 15 A 30 A — 1 A

System Timing Slot — — 6 A 4 A — 1 A

Hybrid Peripheral Slot with PXI-1 Peripheral 6 A 5 A 6 A 1 A 1 A —

Hybrid Peripheral Slot with PXI-5 Peripheral — — 6 A 4 A — 1 A

PXI-1 Peripheral Slot 6 A 11 A 6 A 1 A 1 A —

Note Total system slot current should not exceed 45 A.

Note PCI V(I/O) pins in PXI-1 peripheral slots and hybrid peripheral slots are

connected to +5 V.

Note The maximum power dissipated in the system slot should not exceed 140 W.

AUX

Note The maximum power dissipated in a peripheral slot should not exceed

38.25 W.

36 | ni.com | PXIe-1086DC User Manual and Specifications

Page 37

Table 9. Load Regulation

Voltage Load Regulation

+3.3 V <5%

+12 V <5%

+5 V <5%

-12 V <5%

Table 10. Maximum Ripple and Noise (20 MHz Bandwidth)

Voltage Maximum Ripple and Noise

+3.3 V 50 mV

+12 V 120 mV

+5 V 50 mV

-12 V 120 mV

pp

pp

pp

pp

Over-current protection All outputs protected from short circuit and

overload with automatic recovery

Over-voltage protection, 3.3 V and 5 V Clamped at 25 to 40% above nominal output

voltage

Power supply shuttle MTTR Replacement in under 1 minute

Chassis Cooling

Module cooling system Forced air circulation (positive pressurization)

through six 150 cfm fans (three sets of dual

stacked fans) with High/Auto speed selector

Slot airflow direction Bottom of module to top of module

Module cooling intake Bottom of chassis

Module cooling exhaust Along top of chassis

Power supply cooling system Forced air circulation through integrated fan

Power supply cooling intake Rear of chassis

Power supply cooling exhaust Top of chassis

PXIe-1086DC User Manual and Specifications | © National Instruments | 37

Page 38

Minimum chassis cooling clearances

Above 44.45 mm (1.75 in)

Rear 76.20 mm (3.00 in)

Sides 44.45 mm (1.75 in)

Environmental

Maximum altitude 4,600 m (570 mbar) (at 25 °C ambient)

Note Fan speed selector must be set to High to meet the maximum altitude

specification.

Pollution Degree 2

Indoor use only.

Operating Environment

Ambient temperature range 0 °C to 50 °C

Relative humidity range 10% to 90%, noncondensing

Storage Environment

Ambient temperature range –40 °C to 71 °C

Relative humidity range 5% to 95%, noncondensing

Shock and Vibration

Operational shock 30 g peak, half-sine, 11 ms pulse

Random Vibration Operating 5 to 500 Hz, 0.3 g

Caution When using a single power supply unit, you must use a power supply

filler panel (NI part number 784057-01) in the empty slot to meet operational shock

and vibration specifications.

rms

Acoustic Emissions

Sound Pressure Level (at Operator Position)

Auto fan (up to ~30 °C ambient) 57.0 dBA

High fan 69.0 dBA

38 | ni.com | PXIe-1086DC User Manual and Specifications

Page 39

Sound Power

Auto fan (up to ~30 °C ambient) 63.3 dBA

High fan 79.3 dBA

Caution The protection provided by the PXIe-1086DC can be impaired if it is used

in a manner not described in this document.

Backplane

Size 3U-sized; one system slot (with three system

expansion slots) and 17 peripheral slots.

Compliant with IEEE 1101.10 mechanical

packaging. PXI Express Specification

compliant. Accepts both PXI Express and

CompactPCI (PICMG 2.0 R 3.0) 3U modules.

Backplane bare-board material UL 94 V-0 Recognized

Backplane connectors Conforms to IEC 917 and IEC 1076-4-101, UL

94 V-0 rated

10 MHz System Reference Clock: PXI_CLK10

Maximum slot-to-slot skew 250 ps

Accuracy ±25 ppm max (guaranteed over the operating

temperature range)

Maximum jitter 5 ps RMS phase-jitter (10 Hz–1 MHz range)

Duty-factor 45% to 55%

Unloaded signal swing 3.3 V ±0.3 V

Note For other specifications, refer to the PXI-1 Hardware Specification.

100 MHz System Reference Clock: PXIe_CLK100 and PXIe_SYNC100

Maximum slot-to-slot skew 100 ps

Accuracy ±25 ppm max (guaranteed over the operating

temperature range)

Maximum jitter 3 ps RMS phase-jitter (10 Hz to 12 kHz range),

2 ps RMS phase-jitter (12 kHz to 20 MHz

range)

PXIe-1086DC User Manual and Specifications | © National Instruments | 39

Page 40

Duty-factor for PXIe_CLK100 45% to 55%

Absolute differential voltage (When

terminated with a 50 Ω load to 1.30 V or

Thévenin equivalent)

Note For other specifications, refer to the PXI-5 PXI Express Hardware

Specification

400 to 1000 mV

External 10 MHz Reference Out

(SMA on front panel of chassis)

Accuracy ±25 ppm max (guaranteed over the operating

temperature range)

Maximum jitter 5 ps RMS phase-jitter (10 Hz to 1 MHz range)

Output amplitude 1 VPP ±20% square-wave into 50 Ω, 2 V

unloaded

Output impedance 50 Ω ±5 Ω

PP

External Clock Source

Frequency 10 MHz ±100 ppm

Input amplitude

Front panel SMA 200 mVPP to 5 VPP square-wave or sine-wave

System timing slot PXI_CLK10_IN 5 V or 3.3 V TTL signal

Front-panel SMA input impedance 50 Ω ±5 Ω

Maximum jitter introduced by backplane 1 ps RMS phase-jitter (10 Hz to 1 MHz range)

PXIe_SYNC_CTRL

V

IH

V

IL

2.0 to 5.5 V

0 to 0.8 V

PXI Star Trigger

Maximum slot-to-slot skew 250 ps

Backplane characteristic impedance 65 Ω ±10%

For PXI slot to PXI Star mapping, refer to System Timing Slot.

For other specifications, refer to the PXI-1 Hardware Specification.

40 | ni.com | PXIe-1086DC User Manual and Specifications

Page 41

PXI Differential Star Triggers

(PXIe-DSTARA, PXIe-DSTARB, PXIe-DSTARC)

Maximum slot-to-slot skew 150 ps

Maximum differential skew 25 ps

Backplane differential impedance 100 Ω ±10%

For PXI Express slot to PXI DStar mapping, refer to System Timing Slot.

For other specifications, the PXIe-1086DC complies with the PXI-5 PXI Express Hardware

Specification.

Mechanical

Standard chassis dimensions

Height 10.59 in. (268.7 mm)

Width 18.39 in. (467.1 mm)

Depth 18.76 in. (476.5 mm)

Weight

With two power supplies 37.6 lb. (17.1 kg)

With single power supply 31.5 lb. (14.3 kg)

Chassis materials Sheet Aluminum (5052-H32, 3003-H14, and

6061-T6), Extruded Aluminum (6060-T6), and

Cold Rolled Steel, PC-ABS, Santoprene,

Nylon

Finish Conductive Clear Iridite on Aluminum,

Electroplated Nickel on Cold Rolled Steel,

Polyurethane Enamel

The following figures show the PXIe-1086DC chassis dimensions. The holes shown are for

the installation of the optional rack mount kits. You can install those kits on the front or rear of

the chassis, depending on which end of the chassis you want to face toward the front of the

instrument cabinet. Notice that the front and rear chassis mounting holes (size M4) are

symmetrical.

PXIe-1086DC User Manual and Specifications | © National Instruments | 41

Page 42

Figure 21. PXIe-1086DC Chassis Dimensions (Front and Side)

Dimensions are in inches (millimeters)

0.50

(12.7)

17.50 (444.5)

0.39

(9.9)

1.84

(46.8)

8.73

(221.9)

2.09

(53.2)

1.23

(31.3)

10.70 (271.8)

1.82

(46.3)

1.82

(46.3)

1.84

(46.8)

3.54

(90.0)

5.57

(141.5)

0.84

(21.3)

0.75

(19.1)

2.13

(54.2)

10.10

(256.1)

17.80

(452.7)

14.35 (364.40)

NI PXIe-1086

3.5-6A

210-300VDC

ACT/

LINK

10/100

42 | ni.com | PXIe-1086DC User Manual and Specifications

Page 43

Figure 22. PXIe-1086DC Chassis Dimensions (Bottom)

Dimensions are in inches (millimeters)

0.18

(4.7)

PXIe-1086DC User Manual and Specifications | © National Instruments | 43

Page 44

Figure 23. NI Chassis Rack Mount Kit Components

NI PXIe-1086

COOLING CLEARANCE REQUIRED. SEE MANUAL.

3

2

1

1. Front Rack Mount Kit

2. PXIe-1086DC Chassis

3. Rear Rack Mount Kit

Safety Compliance Standards

This product is designed to meet the requirements of the following electrical equipment safety

standards for measurement, control, and laboratory use:

• IEC 61010-1, EN 61010-1

• UL 61010-1, CSA C22.2 No. 61010-1

Note For UL and other safety certifications, refer to the product label or the

Electromagnetic Compatibility

This product meets the requirements of the following EMC standards for electrical equipment

for measurement, control, and laboratory use:

• EN 61326-1 (IEC 61326-1): Class A emissions; Basic immunity

• EN 55011 (CISPR 11): Group 1, Class A emissions

• AS/NZS CISPR 11: Group 1, Class A emissions

44 | ni.com | PXIe-1086DC User Manual and Specifications

Product Certifications and Declarations section.

Page 45

• FCC 47 CFR Part 15B: Class A emissions

• ICES-003: Class A emissions

Note In the United States (per FCC 47 CFR), Class A equipment is intended for

use in commercial, light industrial, and heavy industrial locations. In Europe,

Canada, Australia, and New Zealand (per CISPR 11), Class A equipment is intended

for use only in heavy industrial locations.

Note Group 1 equipment (per CISPR 11) is any industrial, scientific, or medical

equipment that does not intentionally generate radio frequency energy for the

treatment of material or inspection/analysis purposes.

Note For EMC declarations and certifications and additional information, refer to

the Product Certifications and Declarations section

CE Compliance

This product meets the essential requirements of applicable European Directives, as follows:

• 2014/35/EC; Low-Voltage Directive (safety)

• 2014/13/EC; Electromagnetic Compatibility Directive (EMC)

Product Certifications and Declarations

Refer to the product Declaration of Conformity (DoC) for additional regulatory compliance

information. To obtain product certifications and the DoC for NI products, visit ni.com/

product-certifications, search by model number, and click the appropriate link.

Environmental Management

NI is committed to designing and manufacturing products in an environmentally responsible

manner. NI recognizes that eliminating certain hazardous substances from our products is

beneficial to the environment and to NI customers.