Page 1

CAN

Getting Started with Your PXI-8461 or PXI-8460 and the NI-CAN™ Software for Windows NT

PXI-8461 or PXI-8460 and NI-CAN for Windows NT

September 1999 Edition

Part Number 322006B-01

Page 2

Worldwide Technical Support and Product Information

www.natinst.com

National Instruments Corporate Headquarters

11500 North Mopac Expressway Austin, Texas 78759-3504 USA Tel: 512 794 0100

Worldwide Offices

Australia 03 9879 5166, Austria 0662 45 79 90 0, Belgium 02 757 00 20, Brazil 011 284 5011,

Canada (Calgary) 403 274 9391, Canada (Ontario) 905 785 0085, Canada (Québec) 514 694 8521,

China 0755 3904939, Denmark 45 76 26 00, Finland 09 725 725 11, France 01 48 14 24 24,

Germany 089 741 31 30, Greece 30 1 42 96 427, Hong Kong 2645 3186, India 91805275406,

Israel 03 6120092, Italy 02 413091, Japan 03 5472 2970, Korea 02 596 7456, Mexico (D.F.) 5 280 7625,

Mexico (Monterrey) 8 357 7695, Netherlands 0348 433466, Norway 32 27 73 00, Singapore 2265886,

Spain (Barcelona) 93 582 0251, Spain (Madrid) 91 640 0085, Sweden 08 587 895 00,

Switzerland 056 200 51 51, Taiwan 02 2377 1200, United Kingdom 01635 523545

For further support information, see the Technical Support Resources appendix. To comment on the

documentation, send e-mail to techpubs@natinst.com.

© Copyright 1998, 1999 National Instruments Corporation. All rights reserved.

Page 3

Important Information

Warranty

The PXI hardware is warranted against defects in materials and workmanship for a period of one year from the date of

shipment, as evidenced by receipts or other documentation. National Instruments will, at its option, repair or replace equipmen t

that proves to be defective during the warranty period. Th is warrant y in cludes parts and labor.

The media on which you receive National Instruments software are warranted not to fail to execute programming i nstructions,

due to defects in materials and workmanship, for a period of 90 days from date of shipment, as evidenced by receipt s or other

documentation. National Instruments will, at its op ti on, repai r or repl ace soft ware me dia th at do not ex ecu te prog ram mi ng

instructions if National Instruments receives notice of such defects during the warrant y period. Nati onal Inst rume nt s does not

warrant that the operation of the software shall be uninterrup ted or error free.

A Return Material Authorization (RMA) number must be obtained from the factory and clearly marked on the outside of

the package before any equipment will be accepted for warranty work. National Instruments will pay the shipping costs of

returning to the owner parts which are covered by warrant y.

National Instruments believes that the information in this document is accurate. The document has been carefully reviewed

for technical accuracy. In the event that technical or typographical errors exist, National Instruments reserves the right to

make changes to subsequent editions of this document without prior notice to holders of this edition. The reader should consult

National Instruments if errors are suspected. In no even t shall Nati on al Inst rum ents be l iable fo r any dama ges aris in g o ut of

or related to this document or the information contained in it.

XCEPT AS SPECIFIED HEREIN

E

WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE

OR NEGLIGENCE ON THE PART OF NATIONAL INSTRUMENTS SHALL BE LIMITED TO THE AMOUNT THERETOFORE PAID BY THE CUSTOMER

ATIONAL INSTRUMENTS WILL NOT BE LIABLE FOR DAMAGES RESULTING FROM LOSS OF DATA, PROFITS, USE OF PRODUCTS, OR INCIDENTAL

N

OR CONSEQUENTIAL DAMAGES, EVEN IF ADVISED OF THE POSSIBILITY THEREOF

will apply regardless of the form of action, whether in contract or tort, including negligence. Any action against National

Instruments must be brought within one year after the cause of action accrues. National Instruments shall not be liable for

any delay in performance due to causes beyond its reasonable control. The warranty provided herein does not cover damages,

defects, malfunctions, or service failures caused by owner’s failure to follow the National Instruments installation, operation,

or maintenance instructions; owner’s modification of the product; owner’s abuse, misuse, or negligent acts; and power failure

or surges, fire, flood, accident, actions of third part ies, o r other eve nts o ut side reasonab le co ntrol .

ATIONAL INSTRUMENTS MAKES NO WARRANTIES, EXPRESS OR IMPLIED, AND SPECIFICALLY DISCLAIMS ANY

, N

Copyright

Under the copyright laws, this publication may not be reproduced or transmitted in any form, electronic or mechanical,

including photocopying, recording, sto rin g in an i nform atio n ret rieval s ystem , o r t ranslati ng , i n w hole o r in part, w it ho ut

the prior written consent of National Instruments Corporation.

USTOMER’S RIGHT TO RECOVER DAMAGES CAUSED BY FAULT

. C

. This limitation of the liability of National Instruments

.

Trademarks

BridgeVIEW™, CVI™, LabVIEW™, natinst.com™, National Instruments™, and NI-CAN™ are trademarks of

National Instruments Corporation.

Product and company names mentioned herein are trademarks or trade names of their respective companies.

WARNING REGARDING USE OF NATIONAL INSTRUMENTS PRODUCTS

(1) NATIONAL INSTRUMENTS PRODUCTS ARE NOT DESIGNED WITH COMPONENTS AND TESTING

FOR A LEVEL OF RELIABILITY SUITABLE FOR USE IN OR IN CONNECTION WITH SURGICAL IMPLANT S

OR AS CRITICAL COMPONENTS IN ANY LIFE SUPPORT SYSTEMS WHOSE FAILURE TO PERFORM CAN

REASONABLY BE EXPECTED TO CAUSE SIGNIFICANT INJURY TO A HUMAN.

(2) IN ANY APPLICATION, INCLUDING THE ABOVE, RELIABILITY OF OPERATION O F THE SOFTWARE

PRODUCTS CAN BE IMPAIRED BY ADVERSE FACTORS, INCLUDING BUT NOT LIMITED TO FLUCTUATIONS

IN ELECTRICAL POWER SUPPLY, COMPUTER HARDWARE MALFUNCTIONS, COMPUTER OPERATING

SYSTEM SOFTWARE FITNESS, FITNESS OF COMPILERS AND DEVELOPMENT SOFTWARE USED TO DEVELOP

AN APPLICATION, INSTALLATION ERRORS, SOFTWARE AND HARDWARE COMPATIBILITY PROBLEMS,

MALFUNCTIONS OR FAILURES OF ELECTRONIC MONITORING OR CONTROL DEVICES, TRANSIENT

FAILURES OF ELECTRONIC SYSTEMS (HARDWARE AND/OR SOFTWARE), UNANTICIPATED USES OR

MISUSES, OR ERRORS ON THE PART OF THE USER OR APPLICATIONS DESIGNER (ADVERSE FACTORS SUCH

AS THESE ARE HEREAFTER COLLECTIVELY TERMED “SYSTEM FAILURES”). AN Y A PPLICATION WHE RE A

SYSTEM FAILURE WOULD CREATE A RISK OF HARM TO PROPERTY OR PERSONS (INCLUDING THE RISK OF

BODILY INJURY AND DEATH) SHOULD NOT BE RELIANT SOLELY UPON ONE FORM OF ELECTRONIC SYSTEM

DUE TO THE RISK OF SYSTEM FAILURE. TO AVOID DAMAGE, INJURY, OR DEATH , TH E U SER OR

APPLICATION DESIGNER MUST TAKE REASONABLY PRUDENT STEPS TO PROTECT AGAINST SYSTEM

FAILURES, INCLUDING BUT NOT LIMITED TO BACK-UP OR SHUT DOWN MECHANISMS. BECAUSE EACH

END-USER SYSTEM IS CUSTOMIZED AND DIFFERS FROM NATIONAL INSTRUMENTS' TESTING PLATFORMS

AND BECAUSE A USER OR APPLICATION DESIGNER MAY USE NATIONAL INSTRUMENTS PRODUCTS IN

COMBINATION WITH OTHER PRODUCTS IN A MANNER NOT EVALUATED OR CONTEMPLATED BY

NATIONAL INSTRUMENTS, THE USER OR APPLICATION DESIGNER IS ULTIMATELY RESPONSIBL E FOR

VERIFYING AND VALIDATING THE SUITABILITY OF NATIONAL INSTRUMENT S PRODUCTS WHENEVE R

NATIONAL INSTRUMENTS PRODUCTS ARE INCORPORATED IN A SYSTEM OR A PPLICATION, INCL UDING ,

WITHOUT LIMITATION, THE APPROPRIATE DESIGN, PROCESS AND SAFETY LEVEL OF SUCH SYSTEM OR

APPLICATION.

Page 4

Compliance

FCC/DOC Radio Frequency Interference

Class A Compliance

This equipment generates and uses radio frequency energy and, if not installed and used in strict accordance

with the instructions in this manual, may cause interference to radio and television reception. Classification

requirements are the same for the Federal Communications Commission (FCC) and the Canadian

Department of Communications (DOC). This equipment has been tested and found to comply with the

following two regulatory agencies:

Federal Communications Commission

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant

to part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial environment. This equipment generates,

uses, and can radiate radio frequency energy and, if not installed and used in accordance with the instruction

manual, may cause harmful interference to radio communications. Operation of this equipment in a

residential area is likely to cause harmful interference in which case the user will be required to correct the

interference at his own expense.

Notices to User: Changes or modifications not expressly approved by National Instruments could void

If necessary, consult National Instruments or an experienced radio/television technician for additional

suggestions. The following booklet prepared by the FCC may also be helpful: Interference to Home

Electronic Entertainment Equipment Handbook. This booklet is available from the U.S. Government

Printing Office, Washington, DC 20402.

the user’s authority to operate the equipment under the FCC Rules.

This device complies with the FCC rules only if used with shielded interface cables

of suitable quality and construction. National Instruments used such cables to test

this device and provides them for sale to the user. The use of inferior or nonshielded

interface cables could void the user’s authority to operate the equipment under the

FCC rules.

Canadian Department of Communications

This Class A digital apparatus meets all requirements of the Canadian Interference-Causing Equipment

Regulations.

Cet appareil numérique de la classe A respecte toutes les exigences du Règlement sur le matériel brouilleur

du Canada.

Page 5

Contents

About This Manual

How To Use the Manual Set..........................................................................................ix

Conventions ...................................................................................................................x

Related Documentation........................................... .......................................................xi

Chapter 1

Introduction

What You Need to Get Started...................................................................................... 1-1

Hardware Overview.......................................................................................................1-1

NI-CAN Software Overview ...................................................... ...................................1-2

Optional Programming Tools ........................... .............................................................1-3

Chapter 2

Installation and Configuration

Install the NI-CAN Software.........................................................................................2-1

Installation for Windows NT 3.51...................................................................2-1

Installing for Windows NT 4.0........................................................................2-1

Install the Hardware.......................................................................................................2-3

Check the Configuration of Your PXI-8461 or PXI-8460..............................2-3

Install Your PXI-8461 or PXI-8460................................................................2-3

Connect the Cables..........................................................................................2-4

Configure the NI-CAN Software...................................................................................2-5

Chapter 3

Verify the Installation

Chapter 4

Begin to Use the NI-CAN Software

Using the NI-CAN Software..........................................................................................4-1

General Programming Considerations...........................................................................4-2

Appendix A

Uninstalling the Hardware and Software

Uninstalling the Hardware from Windows NT..............................................................A-1

Uninstalling the NI-CAN Software from Windows NT................................................A-1

© National Instruments Corporation v PXI-8461 or PXI-8460 and NI-CAN for Windows NT

Page 6

Contents

Appendix B

Cabling Requirements for PXI-8461 High-Speed CAN

Connector Pinouts ............................... ..........................................................................B-1

Power Supply Information for the High-Speed CAN Ports..........................................B-2

Bus Power Supply Requirements..................................................................................B-4

Cable Specifications......................................................................................................B-5

Cable Lengths................................................................................................................B-5

Number of Devices........................................................................................................B-6

Cable Termination.........................................................................................................B-6

Cabling Example...........................................................................................................B-7

Appendix C

Cabling Requirements for PXI-8460 Low-Speed CAN

Connector Pinouts ............................... ..........................................................................C-1

Power Supply Information for the Low-Speed CAN Ports...........................................C-2

Bus Power Supply Requirements..................................................................................C-3

Cable Specifications......................................................................................................C-4

Number of Devices........................................................................................................C-4

Low-Speed Termination................................................................................................C-5

Determining the Necessary Termination Resistance for Your Board.............C-5

Replacing the Termination Resistors..............................................................C-7

Cabling Example...........................................................................................................C-8

Appendix D

Troubleshooting and Common Questions

Missing Board in the NI-CAN Configuration Utility....................................................D-1

Diagnostic Utility Failures ............................................................................................ D-1

Resource Errors................................. ..............................................................D-1

NI-CAN Software Problem Encountered ....................................................... D-2

Missing Board in Diagnostic Utility...............................................................D-2

Hardware Problem Encountered.....................................................................D-2

Common Questions.......................................................................................................D-2

Appendix E

Specifications

Appendix F

Technical Support Resources

PXI-8461 or PXI-8460 and NI-CAN for Windows NT vi www.natinst.com

Page 7

Glossary

Figures

Figure 2-1. Add/Remove Programs Properties Dialog Box.....................................2-2

Figure 2-2. Installing the PXI Hardware..................................................................2-4

Figure 2-3. PXI-8461 That Is Working Properly.....................................................2-5

Figure 2-4. NI-CAN Hardware Settings Dialog Box...............................................2-6

Figure 3-1. NI-CAN Diagnostic Utility after Testing..............................................3-1

Figure A-1. Add/Remove Programs Properties Dialog Box.....................................A-2

Figure B-1. Pinout for 9-Pin D-Sub Connector ........................................................B-1

Figure B-2. Pinout for 5-Pin Combicon-Style Pluggable Screw Terminal ..............B-2

Figure B-3. PXI-8461 Part Locator Diagram ...........................................................B-3

Figure B-4. Power Source Jumpers ..........................................................................B-4

Figure B-5. Termination Resistor Placement ...........................................................B-6

Figure B-6. Cabling Example ...................................................................................B-7

Figure C-1. Pinout for 9-Pin D-Sub Connector ........................................................C-1

Figure C-2. PXI-8460 Parts Locator Diagram..........................................................C-2

Figure C-3. Power Source Jumpers ..........................................................................C-3

Figure C-4. Termination Resistor Placement for Low-Speed CAN.........................C-5

Figure C-5. Location of Termin ation Resistors on a PXI-8460 ...............................C-7

Figure C-6. Preparing Lead Wires of Replacement Resistors..................................C-7

Figure C-7. Cabling Example ...................................................................................C-8

Contents

Tables

Table B-1. Power Requirements for the CAN Physical Layer for

Bus-Powered Versions ..........................................................................B-4

Table B-2. ISO 11898 Specifications for Characteristics of a CAN_H and

CAN_L Pair of Wires............................................................................B-5

Table B-3. DeviceNet Cable Length Specifications................................................B-5

Table C-1. Power Requirements for the Low-Speed CAN Physical Layer for

Bus-Powered Versions ..........................................................................C-3

Table C-2. ISO 11519-2 Specifications for Characteristics of a CAN_H and

CAN_L Pair of Wires............................................................................C-4

© National Instruments Corporation vii PXI-8461 or PXI-8460 and NI-CAN for Windows NT

Page 8

About This Manual

This manual contains instructions to help you install and configure your

PXI-8461 (one port and two port) or PXI-8460 (one port or two port) and

the NI-CAN software for Windows NT. This manual uses PXI-8461 or

PXI-8460 to refer to both the one port and two port versions of the boards.

This manual assumes that you are already familiar with Windows NT.

How To Use the Manual Set

Getting Started

Manual

Novice

Users

NI-CAN

User Manual

Application

Development

and Examples

Installation and

Configuration

Experienced

Users

NI-CAN Programmer

Reference Manual

Function

and Object

Descriptions

Use this getting started manual to install and configure your PXI-8461 or

PXI-8460 and the NI-CAN software for Windows NT.

Use the NI-CAN User Manual to learn the basics of CAN and how to

develop an application program. The user manual also contains debugging

information and detailed examples.

© National Instruments Corporation ix PXI-8461 or PXI-8460 and NI-CAN for Windows NT

Page 9

About This Manual

Use the NI-CAN Programmer Reference Manual for specific information

about each NI-CAN function and object, including format, parameters, and

possible errors.

Conventions

The following conventions appear in this manual:

» The » symbol leads you through nested menu items and dialog box options

to a final action. The sequence File»Page Setup»Options directs you to

pull down the File menu, select the Page Setup item, and select Options

from the last dialog box.

This icon denotes a note, which alerts you to important information.

This icon denotes a caution, which advises you of precautions to take to

avoid injury, data loss, or a system crash.

bold Bold text denotes items that you must select or click on in the software,

such as menu items and dialog box options. Bold text also denotes

parameter names.

italic Italic text denotes variables, emphasis, a cross reference, or an introduction

to a key concept. This font also denotes text that is a placeholder for a w ord

or value that you must supply.

monospace Text in this font denotes text or characters that you should enter from the

keyboard, sections of code, programming examples, and syntax examples.

This font is also used for the proper names of disk drives, paths, directories,

programs, subprograms, subroutines, device names, functions, operations,

variables, filenames and extensions, and code excerpts.

monospace italic

PXI-8461 or PXI-8460 and NI-CAN for Windows NT x www.natinst.com

Italic text in this font denotes text that is a placeholder for a word or value

that you must supply.

Page 10

Related Documentation

The following documents contain information that you may find helpful as

you read this manual:

• ANSI/ISO Standard 11898-1993, Road Vehicles—Interchange of

Digital Information—Controller Area Network (CAN) for High-Speed

Communication

• ANSI/ISO Standard 11519-2-1994, Road Vehicles—Low-Speed

Serial Data Communication—Part 2: Low-Speed Controller Area

Network (CAN)

• CAN Specification Version 2.0, 1991, Robert Bosch Gmbh.,

Postfach 500, D-7000 Stuttgart 1

• CiA Draft Standard 102, Version 2.0, CAN Physical Layer for

Industrial Applications

• CompactPCI Specification, Revision 2.0, PCI Industrial Computers

Manufacturers Group

• DeviceNet Specification, Version 2.0, Open DeviceNet Vendor

Association

• PXI Specification, Revision 1.0, National Instruments Corporation

About This Manual

© National Instruments Corporation xi PXI-8461 or PXI-8460 and NI-CAN for Windows NT

Page 11

Introduction

This chapter lists what you need to get started, provides an overview of the

PXI hardware and the NI-CAN software for Windows NT, and describes

optional equipment you can order.

What You Need to Get Started

Make sure you have all of the following items before you attempt to install

the hardware and software:

❑ Windows NT 3.51 or later installed on your computer

– PXI-8461 one port

– PXI-8461 two port

– PXI-8460 one port

– PXI-8460 two port

❑ 3.5 in., high-density (1.44 MB) disks, which are included in your kit:

– NI-CAN Software for Windows 95/98/NT

Version 1.3

(Disk x of 3)

1

❑ CAN interface cables that meet the requirements in Appendix B,

Cabling Requirements for PXI-8461 High-Speed CAN or Appendix C,

Cabling Requirements for PXI-8460 Low-Speed CAN.

Hardware Overview

The PXI-8461 and PXI-8460 (one port and two port) are software

configurable and compliant with the PXI Specification and CompactPCI

Specification. With a PXI-8461 or PXI-8460 board, you can make your

PXI or CompactPCI chassis communicate with and control CAN devices.

The PXI-8461 physical layer fully conforms to the ISO 11898

physical layer specification for CAN and is optically isolated to 500 V.

The PXI-8460 physical layer conforms to the ISO 11519-2 physical layer

© National Instruments Corporation 1-1 PXI-8461 or PXI-8460 and NI-CAN for Windows NT

Page 12

Chapter 1 Introduction

specification for CAN and is also optically isolated to 500 V. CAN

interfacing is accomplished using the Intel 82527 CAN controller chip.

The PXI-8461 supports a wide variety of transfer rates up to 1 Mb/s.

The PXI-8460 supports rates up to 125 kb/s. The CAN physical layer on the

PXI-8461 and PXI-8460 can be powered either internally (from the board)

or externally (from the bus cable power). The power source for the CAN

physical layer for each port is configured with a jumper.

PXI-8461 boards are available with two physical connector types:

• DB-9 D-Sub

• Combicon-style pluggable screw terminals

PXI-8460 boards are available with DB-9 D-Sub connectors.

The PXI-8461 and PXI-8460 use the Intel 386EX embedded processor

to implement time-critical features provided by the NI-CAN software.

The PXI-8461 and PXI-8460 communicate with the NI-CAN driver

through on-board shared memory and an interrupt.

NI-CAN Software Overview

The NI-CAN software includes a native, 32-bit multitasking Windows NT

kernel driver. The NI-CAN software is fully integrated into the

Windows NT operating system. You can configure it through the

Windo ws NT Control Panel and uninstall it through the Add/Remove

Programs applet of the Control Panel.

The NI-CAN software for Windows NT supports the concurrent use of

multiple CAN boards. For example, you can use both a PXI-8461 and

PCMCIA-CAN in the same system at the same time.

The NI-CAN software, along with the PXI hardware, transforms your

computer into a CAN interface with complete communications and bus

management capability. The NI-CAN software includes the following

components:

• Firmware (runs on embedded Intel 386EX)

• Device driver

• Diagnostic test utility

• Configuration utility

PXI-8461 or PXI-8460 and NI-CAN for Windows NT 1-2 www.natinst.com

Page 13

• Language interface libraries for Microsoft Visual C/C++ 2.0 or later,

LabWindows/CVI 4.0 or later, and LabVIEW 4.0 or later

• Example programs that use NI-CAN functions

Optional Programming Tools

Your kit includes the NI-CAN software for Windows NT. In addition,

you can order the LabWindows/CVI, LabVIEW, or BridgeVIEW software

from National Instruments.

LabWindows/CVI is an interactive ANSI C development environment for

building test and measurement and instrument control systems. It includes

interactive code-generation tools and a graphical editor for b uilding custom

user interfaces. It also includes built-in libraries for IEEE 488.2, VXI,

RS-232 control, and plug-in data acquisition. When you order

LabWindows/CVI, you also get hundreds of complete instrument drivers,

which are modular, source-code programs that handle the communication

with your instrument so that you do not have to learn the programming

details.

LabVIEW is a complete programming environment that departs from the

sequential nature of traditional programming languages and features a

graphical programming environment. It includes all the tools needed for

instrument control, data acquisition, analysis, and presentation. LabVIEW

also includes an extensive instrument driver library.

Chapter 1 Introduction

BridgeVIEW is a radical departure from traditional automation software

that provides a flexible program development system for a variety of

DeviceNet applications including general manufacturing, test, and control.

Leveraging National Instruments patented graphical programming

language G (otherwise known as LabVIEW), BridgeVIEW gives you the

ability to integrate functionality in a way that is not possible with traditional

automation software. In addition to the programming advantages of G,

BridgeVIEW also provides a number of powerful features for the

development of your industrial automation application: graphical HMI

(Human Machine Interface); ease of use; fill-in-the-blank configuration

utilities; HMI G Wizard for simplified HMI development; historical data

collection and trending; alarm and event reporting and logging; security;

and connectivity to PLCs and industrial device networks like DeviceNet.

For more information about LabWindows/CVI , LabVIEW, and

BridgeVIEW, contact National Instruments.

© National Instruments Corporation 1-3 PXI-8461 or PXI-8460 and NI-CAN for Windows NT

Page 14

Installation and Configuration

This chapter describes how to install and configure the NI-CAN software

for Windows NT and the PXI-8461 or PXI-8460 hardware.

Install the NI-CAN Software

Install the NI-CAN software for Windows NT before you install your

hardware.

Installation for Windows NT 3.51

1. Log on as Administrator or as a user with Administrator privileges.

The NI-CAN setup program must have

because the program modifies the configuration registry of your

system.

2. Insert the NI-CAN Software for Windows 95/98/NT (Disk 1 of 3) into

an unused drive.

3. In the Run dialog box, type the following:

x

:\setup

where x is the letter of the drive containing the disk (usually a or b).

4. Shut down Windo ws NT and turn off your computer when the setup is

complete.

5. Proceed to the section Install the Hardware.

2

Administrator privileges

Installing for Windows NT 4.0

1. Log on as Administrator or as a user with Administrator privileges.

The NI-CAN setup program must have

because the program modifies the configuration registry of your

system.

2. Select Start»Settings»Control Panel.

© National Instruments Corporation 2-1 PXI-8461 or PXI-8460 and NI-CAN for Windows NT

Administrator privileges

Page 15

Chapter 2 Installation and Configuration

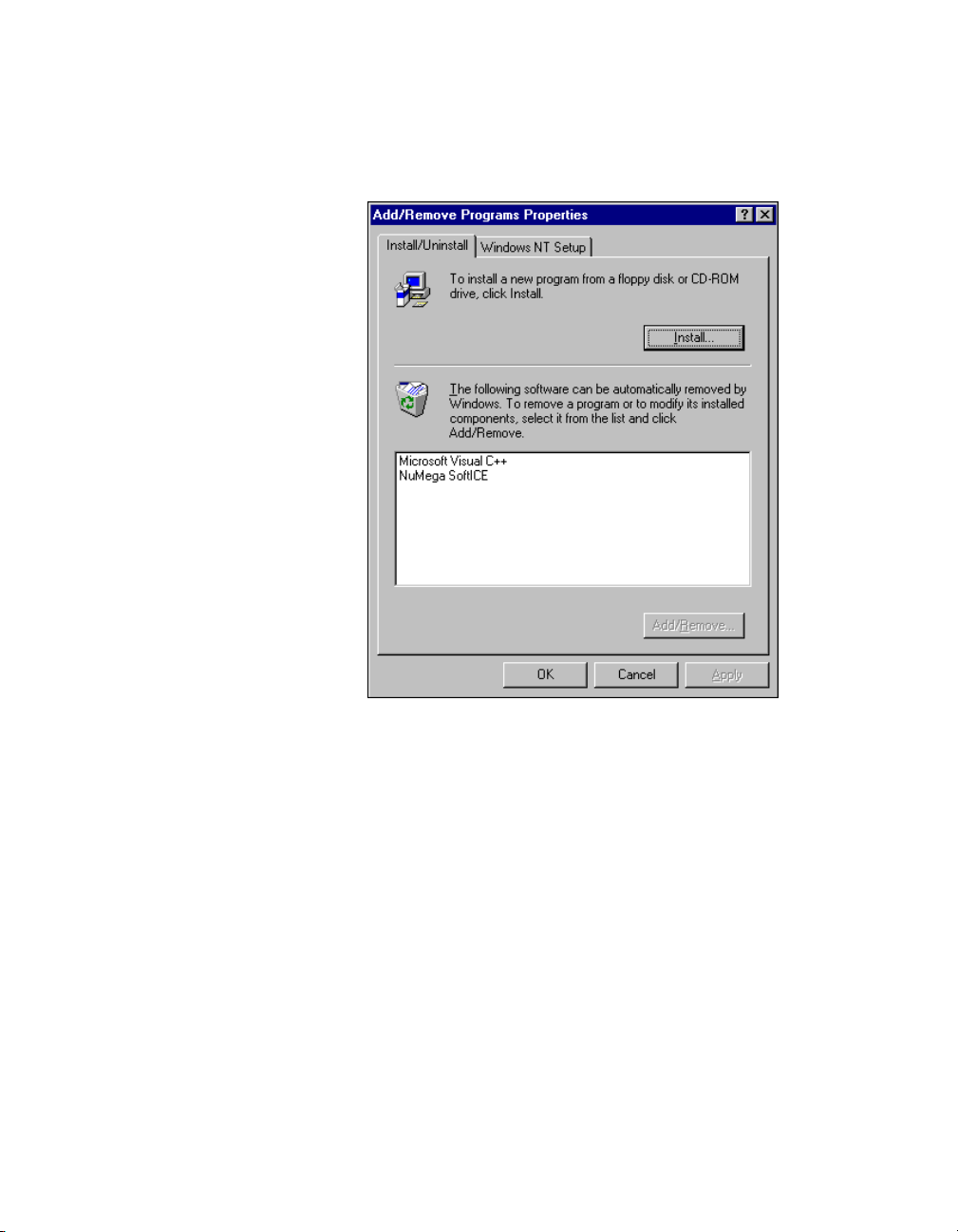

3. Double-click on the Add/Remove Programs icon in the Control Panel

to launch the Add/Remove Programs applet. A dialog box similar to

the one in Figure 2-1 appears.

Figure 2-1. Add/Remove Programs Properties Dialog Box

You can use this same applet to uninstall the NI-CAN software

at a later time. Refer to Appendix A, Uninstalling the Hardware

and Software, for more information.

4. Click on the Install button.

5. When prompted, insert the NI-CAN Software for Windows 95/98/NT

(Disk 1 of 3), and click on the Next button to proceed.

6. The setup wizard guides you through the necessary steps to install

the NI-CAN software. You may go back and change values where

appropriate by clicking on the Back button. If at any time you want to

exit the setup, click on the Cancel button.

7. Shut down Windo ws NT and turn off your computer when the setup is

complete.

PXI-8461 or PXI-8460 and NI-CAN for Windows NT 2-2 www.natinst.com

Page 16

Chapter 2 Installation and Configuration

Install the Hardware

This section describes how to install your PXI-8461or PXI-8460 hardware.

Check the Configuration of Your PXI-8461 or PXI-8460

If you plan to use your CAN board in a system where bus power is

available, you may want to configure the power supply jumpers on your

board. See Appendix B, Cabling Requirements for PXI-8461 High-Speed

CAN, for more information.

If you are installing a low-speed CAN board, you may need to change the

power supply jumpers or termination resistors. See Appendix C, Cabling

Requirements for PXI-8460 Low-Speed CAN, for more information.

Install Your PXI-8461 or PXI-8460

Caution

metal part of your system chassis to discharge electrostatic energy, which can damage

several components on your board.

Before you remove the board from the package, touch the antistatic package to a

1. Make sure that your PXI or CompactPCI chassis is turned off. Keep the

PXI or CompactPCI chassis plugged in so that it remains grounded

while you install the PXI board.

2. Choose an unused PXI or CompactPCI 5 V peripheral slot.

3. Remove the filler panel for the peripheral slot you have chosen.

4. Touch a metal part on your chassis to discharge any static electricity

that might be on your clothes or body.

© National Instruments Corporation 2-3 PXI-8461 or PXI-8460 and NI-CAN for Windows NT

Page 17

Chapter 2 Installation and Configuration

5. Insert the PXI board into the selected 5 V slot. Use the injector/ejector

handle to fully inject the device into place. Figure 2-2 shows how to

install the PXI board into a PXI or CompactPCI chassis.

3

2

ON STANDBY

1

2

3

4

5

6

7

8

4

1

1 Injector/Ejector Handle (In Down Position)

2 PXI Board

3 PXI Chassis

4 Injector/Ejector Rail

Figure 2-2. Installing the PXI Hardware

6. Screw the front panel of the PXI board to the front panel mounting rail

of the PXI or CompactPCI chassis.

7. Turn on your PXI or CompactPCI chassis and start Windows NT.

Connect the Cables

After you have installed your board, connect the CAN cables to your PXI

board. Because exact cabling requirements vary for each application,

National Instruments does not provide cables. Refer to Appendix B,

Cabling Requirements for PXI-8461 High-Speed CAN , or Appendix C,

Cabling Requirements for PXI-8460 Low-Speed CAN, for information

about the cabling requirements of the CAN hardware.

PXI-8461 or PXI-8460 and NI-CAN for Windows NT 2-4 www.natinst.com

Page 18

Configure the NI-CAN Software

The NI-CAN Configuration utility is located in the Windows NT Control

Panel. You can use it to examine or modify the configuration of the

NI-CAN software. The context-sensitive online help, available by

right-clicking on any of the controls on the configuration utility buttons,

includes all the information you need to configure the NI-CAN software.

To use the NI-CAN Configuration utility, you must first log in as

Administrator or as a user with Administrator privileges. To configure

the NI-CAN software, double-click on the NI-CAN Configuration icon in

the Control Panel:

• Windo ws NT 3.51—Open the Control Panel in the Main group of the

Program Manager.

• Windows NT 4.0 or later—Select Start»Settings»Control Panel.

Figure 2-3 shows a CAN interface that is working properly . If no interfaces

are listed under NI-CAN Configuration, refer to the Missing Board in the

NI-CAN Configuration Utility section in Appendix D,

Common Questions,

to resolve the problem.

Chapter 2 Installation and Configuration

Troubleshooting and

Figure 2-3.

To select a particular interface, click on that interface in the list.

When you install a PXI-8461 or PXI-8460, your computer automatically

assigns valid resources to it. Because this resource assignment is automatic,

you do not need to use the Resources dialog box for the PXI hardware, and

you do not need to restart Windows NT.

© National Instruments Corporation 2-5 PXI-8461 or PXI-8460 and NI-CAN for Windows NT

PXI-8461 That Is Working Properly

Page 19

Chapter 2 Installation and Configuration

To view information about the NI-CAN software configuration for the

PXI-8461 or PXI-8460, click on the Settings button. Figure 2-4 shows

the Settings dialog box.

Figure 2-4. NI-CAN Hardware Settings Dialog Box

Each port of the PXI-8461 or PXI-8460 is configured from this tab. Use the

drop-down box nearest the top of the tab to select the physical port number

to configure. For each port, use the

for the CAN Network Interface Object (

drop-down box to select the name

Name

CAN0, CAN1, and so on). You use

this name to refer to the physical port from within your NI-CAN

application.

To access online help for the NI-CAN Configuration utility, click on the

Help button. You can also right-click on a specific control and select

What’s This? from the pop-up menu to see context-sensitive help for the

item you have clicked on.

When you have finished configuring the NI-CAN software, proceed to

Chapter 3, Verify the Installation.

PXI-8461 or PXI-8460 and NI-CAN for Windows NT 2-6 www.natinst.com

Page 20

Verify the Installation

This chapter describes how to verify the hardware and software

installation.

You can use the NI-CAN Diagnostic utility, installed with your NI-CAN

software, to test the hardware and software installation. The utility verifies

that your hardware and software are functioning properly and that the

configuration of your hardware does not conflict with anything else in your

system.

To run the utility, select the NI-CAN Diagnostic item:

• Windo ws NT 3.51—Double-click on the

NI-CAN Software

the

• Windows NT 4.0 or later—Select

Instruments CAN»NI-CAN Diagnostic

When you have started the NI-CAN Diagnostic utility, test your CAN

interfaces by clicking on the

interface by highlighting it and clicking on the

NI-CAN Diagnostic is successful, it puts a checkmark next to the interface

and changes its status from

fails, it puts an X next to the interface, and changes its status from

Failed

to

tested some CAN interfaces.

. Figure 3-1 shows the NI-CAN Diagnostic utility after it has

group of the

Test All

Untested

to

3

NI-CAN Diagnostic

Program Manager

Start»Programs»National

.

button. You can also test one CAN

Test One

Passed

. If the NI-CAN Diagnostic

button. If the

icon in

.

Untested

Figure 3-1.

© National Instruments Corporation 3-1 PXI-8461 or PXI-8460 and NI-CAN for Windows NT

NI-CAN Diagnostic Utility after Testing

Page 21

Chapter 3 Verify the Installation

You can get details about any tested CAN interface by selecting the

interface and clicking on the Details button. F or each failed CAN interface,

select it and click on the Details button to get a description of the failure.

Use that information and the information in Appendix D, Troubleshooting

and Common Questions, to troubleshoot th e problem. Troubleshooting

information is also available in the online help for the NI-CAN Diagnostic

utility, which you can access by clicking on the Help button.

PXI-8461 or PXI-8460 and NI-CAN for Windows NT 3-2 www.natinst.com

Page 22

Begin to Use the

NI-CAN Software

This chapter helps you get started with the NI-CAN software for

Windows NT.

Using the NI-CAN Software

The functions provided by the NI-CAN software are similar to those

provided by many other device drivers. For example, NI-CAN has open,

close, read, and write functions. NI-CAN provides two different levels of

access to a CAN network: the CAN Network Interface Object and CAN

Objects. Both forms of access support timestamping of incoming data and

various forms of queuing.

The CAN Network Interface Object provides low-level access to a CAN

network. Each CAN Network Interface Object maps to a specific CAN

port, with no limitation on the maximum number of ports or boards you can

use (for example, two PXI-8461 two-port interfaces would provide

through

frames. For example, to transmit a CAN frame, you would specify the

outgoing arbitration ID, frame type (data or remote), data length, and data.

CAN3). You can use this object to transmit and receive entire CAN

4

CAN0

The CAN Objects provide higher level access to a CAN network. Each

CAN Object maps to a specific data item (arbitration ID), and you can use

multiple CAN Objects for a given port. When configuring a CAN Object

for use, you specify the arbitration ID, direction of data transfer, data

length, and how you want the data to be accessed (such as periodically).

For example, you could configure a CAN Object to transmit an outgoing

data frame for a specific arbitration ID every 100 ms. After opening this

CAN Object, you use the write function to provide data to transmit, and the

NI-CAN embedded firmware handles all periodic timing.

For detailed information about the NI-CAN software and functions, refer

to the NI-CAN User Manual and the NI-CAN Programmer Reference

Manual.

© National Instruments Corporation 4-1 PXI-8461 or PXI-8460 and NI-CAN for Windows NT

Page 23

Chapter 4 Begin to Use the NI-CAN Software

General Programming Considerations

As you begin developing your Win32 NI-CAN application, remember the

following points:

• For your LabVIEW or BridgeVIEW application, you must use the

NI-CAN LabVIEW functions in

• For your C/C++ application, you must include the NI-CAN header file,

nican.h, in your source code.

• The NI-CAN software is accessed through the 32-bit DLL,

nican.dll, either by linking with one of the language interfaces

provided with the NI-CAN software, or by using direct DLL entry

from other programming environments.

• Several sample CAN applications are included with the NI-CAN

software. Use these as a guide for your own application development.

For information about developing your application, refer to the NI-CAN

User Manual. For detailed information about NI-CAN functions and

objects, refer to the NI-CAN Programmer Reference Manual.

nican.llb.

PXI-8461 or PXI-8460 and NI-CAN for Windows NT 4-2 www.natinst.com

Page 24

A

Uninstalling the Hardware

and Software

This appendix describes how to uninstall the PXI-8461 or PXI-8460

hardware and the NI-CAN software from Windows NT.

Uninstalling the Hardware from Windows NT

Because Windo ws NT 3.51 and 4.0 do not maintain hardware information

for the board, you just need to physically remove your PXI hardware from

your computer. To do so, shut down Windows NT, power off your PXI or

CompactPCI chassis, remove any cables attached to your board, and

physically remove the board.

Uninstalling the NI-CAN Software from Windows NT

Note

The following instructions apply to Windows NT 4.0 only . If you are using W indows

NT 3.51, refer to the

to uninstall the NI-CAN software.

readme.txt file in your NI-CAN directory for information on how

Before uninstalling the NI-CAN software, you should remove the PXI

boards from your computer, as explained in the previous section.

© National Instruments Corporation A-1 PXI-8461 or PXI-8460 and NI-CAN for Windows NT

Page 25

Appendix A Uninstalling the Hardware and Software

Complete the following steps to remove the NI-CAN software from

Windows NT 4.0:

1. Select the Add/Remove Programs icon under Start»Settings»

Control Panel

This dialog box lists the software available for removal.

A dialog box similar to the one in Figure A-1 appears.

.

Figure A-1. Add/Remove Programs Properties Dialog Box

2. Select the NI-CAN software you want to remove and click on the

Add/Remove button. The uninstall program runs and removes all

folders, utilities, device drivers, DLLs, and registry entries associated

with the NI-CAN software.

The uninstall program removes only items that the installation program

installed. If you add anything to a directory that was created by the

installation program, the uninstall program does not delete that directory

because the directory is not empty after the uninstallation. You need to

remove any remaining components yourself.

If you want to reinstall the hardware and software, refer to Chapter 2,

Installation and Configuration.

PXI-8461 or PXI-8460 and NI-CAN for Windows NT A-2 www.natinst.com

Page 26

Cabling Requirements for

PXI-8461 High-Speed CAN

This appendix describes the cabling requirements for the hardware.

Cables should be constructed to meet these requirements and the

requirements of the other CAN or DeviceNet devices in the network.

Connector Pinouts

Depending on the type of PXI board you are installing, it either has DB-9

D-Sub connector(s) or Combicon-style pluggable screw terminal

connector(s).

The 9-pin D-Sub follows the pinout recommended by CiA Draft

Standard 102. Figure B-1 shows the pinout for this connector.

B

1 2345

Optional Ground (V–)

CAN_H

No Connection

V+

Figure B-1.

© National Instruments Corporation B-1 PXI-8461 or PXI-8460 and NI-CAN for Windows NT

Pinout for 9-Pin D-Sub Connector

6

789

No Connection

CAN_L

V–

No Connection

Shield

Page 27

Appendix B Cabling Requirements for PXI-8461 High-Speed CAN

The 5-pin Combicon-style pluggable screw terminal follows the pinout

required by the DeviceNet Specification. Figure B-2 shows the pinout for

this connector.

V–

12345

Figure B-2. Pinout for 5-Pin Combicon-Style Pluggable Screw Terminal

CAN_H and CAN_L are signal lines that carry the data on the CAN

network. These signals should be connected using twisted-pair cable.

The V+ and V– pins are used to supply bus power to the CAN physical

layer if external power is required for the CAN physical layer . If internal

power for the CAN physical layer is used, the V– pin serves as the refe rence

ground for CAN_H and CAN_L. See the next section, Power Supply

Information for the High-Speed CAN Ports, for more information.

CAN_L

Shield

CAN_H

V+

Power Supply Information for the High-Speed CAN Ports

For the PXI-8461, a jumper controls the source of power for the CAN

physical layer. F or the one-port boards and port one of the two-port boards,

power is configured with jumper J5. For port two of the two-port boards,

power is configured with jumper J6. The location of these jumpers is shown

in Figure B-3.

PXI-8461 or PXI-8460 and NI-CAN for Windows NT B-2 www.natinst.com

Page 28

Appendix B Cabling Requirements for PXI-8461 High-Speed CAN

3 4

2

1

5

1 Power Supply Jumper J6

2 Power Supply Jumper J5

3 Assembly Number

4 Product Name

5 Serial Number

Figure B-3. PXI-8461 Part Locator Diagram

Connecting pins 1 and 2 of a jumper configures the CAN physical layer to

be powered externally (from the bus cable po wer). In this configuration, the

power must be supplied on the V+ and V– pins on the port connector.

Connecting pins 2 and 3 of a jumper configures the CAN physical layer to

be powered internally (from the board). In this configuration, the V– signal

serves as the reference ground for the isolated signals.

© National Instruments Corporation B-3 PXI-8461 or PXI-8460 and NI-CAN for Windows NT

Page 29

Appendix B Cabling Requirements for PXI-8461 High-Speed CAN

Figure B-4 shows how to configure your jumpers for internal or external

power supplies.

INT EXT

123123

a. Internal Power Mode

Figure B-4. Power Source Jumpers

The CAN physical layer is still isolated regardless of the power source

chosen.

Bus Power Supply Requirements

If the CAN physical layer is powered from a bus power supply, the power

supply should be a DC power supply with an output of 10 V to 30 V. The

power requirements for the CAN ports for bus-powered conf igurations are

shown in T able B-1. You should take these requirements into account when

determining requirements of the bus power supply for the system.

Table B-1. Power Requirements for the CAN Physical Layer for

Bus-Powered Versions

Characteristic Specification

INT EXT

b. External Power Mode

Voltage requirement V+ 10 to 30 VDC

Current requirement 40 mA typical

100 mA maximum

PXI-8461 or PXI-8460 and NI-CAN for Windows NT B-4 www.natinst.com

Page 30

Cable Specifications

Cables should meet the physical medium requirements specified in

ISO 11898, shown in Table B-2.

Belden cable (3084A) meets all of those requirements and should be

suitable for most applications.

Appendix B Cabling Requirements for PXI-8461 High-Speed CAN

Cable Lengths

Table B-2.

Impedance 108 Ω minimum, 120 Ω nominal,

Length-related resistance 70 mΩ/m nominal

Specific line delay 5 ns/m nominal

The allowable cable length is affected b y the characteristics of the cabling

and the desired bit transmission rates. Detailed cable length requirements

can be found in ISO 11898, CiA Draft Standard 102, and the DeviceNet

Specification.

ISO 11898 specifies 40 m total cable length with a maximum stub length

of 0.3 m for a bit rate of 1 Mb/s. The ISO 11898 specification says that

significantly longer cable lengths may be allowed at lower bit rates, but

each node should be analyzed for signal integrity problems.

Table B-3 lists the DeviceNet cable length specifications.

ISO 11898 Specifications for Characteristics of a CAN_H and

CAN_L Pair of Wires

Characteristic Value

132 Ω maximum

Table B-3.

Baud Rate Trunk Length

500 kb/s 100 m (328 ft) 6 m (20 ft) 39 m (128 ft)

250 kb/s 250 m (820 ft) 6 m (20 ft) 78 m (256 ft)

125 kb/s 500 m (1640 ft) 6m (20ft) 156 m (512 ft)

© National Instruments Corporation B-5 PXI-8461 or PXI-8460 and NI-CAN for Windows NT

DeviceNet Cable Length Specifications

Drop Length

Maximum

Drop Length

Cumulative

Page 31

Appendix B Cabling Requirements for PXI-8461 High-Speed CAN

Number of Devices

The maximum number of devices that you can connect to a CAN port

depends on the electrical characteristics of the devices on the network. If all

of the devices meet the requirements of ISO 11898, at least 30 devices may

be connected to the bus. Higher numbers of devices may be connected if the

electrical characteristics of the devices do not degrade signal quality below

ISO 11898 signal level specifications. If all of the devices on the network

meet the DeviceNet specifications, 64 devices may be connected to the

network.

Cable Termination

The pair of signal wires (CAN_H and CAN_L) constitutes a transmission

line. If the transmission line is not terminated, each signal change on the

line causes reflections that may cause communication failures.

Because communication flows both ways on the CAN bus, CAN requires

that both ends of the cable be terminated. However, this requirement does

not mean that every de vice should have a termination resistor. If multiple

devices are placed along the cable, only the devices on the ends of the cable

should have termination resistors. See Figure B-5 for an example of where

termination resistors should be placed in a system with more than two

devices.

CAN

Device

CAN

Device

Figure B-5.

CAN_H

CAN_L

Termination Resistor Placement

CAN

Device

CAN

Device

The termination resistors on a cable should match the nominal impedance

of the cable. ISO 11898 requires a cable with a nominal impedance of

120 Ω; therefore, a 120

Ω resistor should be used at each end of the cable.

Each termination resistor should be capable of dissipating at least 0.25 W

of power.

PXI-8461 or PXI-8460 and NI-CAN for Windows NT B-6 www.natinst.com

Page 32

Cabling Example

Figure B-6 shows an example of a cable to connect two CAN devices. For

the internal power configuration, no V+ connection is required.

Appendix B Cabling Requirements for PXI-8461 High-Speed CAN

5-Pin

Combicon

9-Pin

D-Sub

Pin 7Pin 4 Pin 7 Pin 4

Pin 2Pin 2

Pin 5Pin 3

Pin 9Pin 5

Pin 3Pin 1

CAN_H

120Ω 120Ω

CAN_L

Shield

V+

V–

Power

Connector

V+

V–

Figure B-6.

Cabling Example

9-Pin

D-Sub

Pin 2 Pin 2

Pin 5 Pin 3

Pin 9 Pin 5

Pin 3 Pin 1

5-Pin

Combicon

© National Instruments Corporation B-7 PXI-8461 or PXI-8460 and NI-CAN for Windows NT

Page 33

Cabling Requirements for

PXI-8460 Low-Speed CAN

This appendix describes the cabling requirements for the PXI-8460

hardware.

Cables should be constructed to meet these requirements, as well as the

requirements of the other CAN devices in the network.

Connector Pinouts

The PXI-8460 has DB-9 D-Sub connector(s). The 9-pin D-Sub follows the

pinout recommended by CiA DS 102. Figure C-1 shows the pinout for this

connector.

C

1 2345

Optional Ground (V–)

CAN_H

No Connection

V+

Figure C-1.

© National Instruments Corporation C-1 PXI-8461 or PXI-8460 and NI-CAN for Windows NT

Pinout for 9-Pin D-Sub Connector

6

789

No Connection

CAN_L

V–

No Connection

Shield

Page 34

Appendix C Cabling Requirements for PXI-8460 Low-Speed CAN

CAN_H and CAN_L are signal lines that carry the data on the CAN

network. These signals should be connected using twisted-pair cable.

The V+ and V– pins are used to supply bus power to the CAN physical

layer if external power is required for the CAN physical layer . If internal

power for the CAN physical layer is used, the V- pin serves as the reference

ground for CAN_H and CAN_L. See the next section, Power Supply

Information for the Low-Speed CAN Ports, for more information.

Power Supply Information for the Low-Speed CAN Ports

For port one of the PXI-8460, power is configured with jumper J5. For port

two of the PXI-8460, power is configured with jumper J6. These jumpers

are shown in Figure C-2.

3 4

2

1

1 Power Supply Jumper J6

2 Power Supply Jumper J5

6

3 Assembly Number

4 Product Name

Figure C-2.

PXI-8460 Parts Locator Diagram

5

5 Serial Number

6 Termination Resistor Sockets

Connecting pins 1 and 2 of a jumper configures the CAN physical layer to

be powered externally (from the bus cable po wer). In this configuration, the

power must be supplied on the V+ and V– pins on the port connector.

PXI-8461 or PXI-8460 and NI-CAN for Windows NT C-2 www.natinst.com

Page 35

Appendix C Cabling Requirements for PXI-8460 Low-Speed CAN

Connecting pins 2 and 3 of a jumper configures the CAN physical layer to

be powered internally (from the card). In this configuration, the V– signal

serves as the reference ground for the isolated signals. Even if the CAN

physical layer is powered internally , the fault-tolerant CAN transceiv er still

requires bus power to be supplied in order for it to monitor the power

supply (battery) voltage.

Figure C-3 shows how to configure your jumpers for internal or external

power supplies.

INT EXT

123123

a. Internal Power Mode

Figure C-3. Power Source Jumpers

The CAN physical layer is still isolated regardless of the power source

chosen.

Bus Power Supply Requirements

If the CAN physical layer is powered from a bus power supply, the power

supply should be a DC power supply with an output of 8 V to 27V. The

power requirements for the CAN ports for Bus-Powered configurations are

shown in Table C-1. You should take these requirements into account when

determining requirements of the bus power supply for the system.

Table C-1. Power Requirements for the Low-Speed CAN Physical Layer for

Bus-Powered Versions

Characteristic Specification

Voltage requirement V+ 8–27 VDC

INT EXT

b. External Power Mode

Current requirement 40 mA typical

100 mA maximum

© National Instruments Corporation C-3 PXI-8461 or PXI-8460 and NI-CAN for Windows NT

Page 36

Appendix C Cabling Requirements for PXI-8460 Low-Speed CAN

Cable Specifications

Cables should meet the physical medium requirements specified in

ISO 11519-2, shown in Table C-2.

Belden cable (3084A) meets all of those requirements, and should be

suitable for most applications.

Table C-2.

Length-related resistance 90 mΩ/m nominal

Length-related capacitance:

CAN_L and ground, CAN_H and

ground, CAN_L and CAN_H

Number of Devices

The maximum number of devices depends on the electrical characteristics

of the devices on the network. If all of the devices meet the requirements

of ISO 11519-2, at least 20 devices may be connected to the bus. Higher

numbers of devices may be connected if the electrical characteristics of

the devices do not degrade signal quality below ISO 11519-2 signal level

specifications.

ISO 11519-2 Specifications for Characteristics of a CAN_H and

CAN_L Pair of Wires

Characteristic Value

30 pF/m nominal

PXI-8461 or PXI-8460 and NI-CAN for Windows NT C-4 www.natinst.com

Page 37

Low-Speed Termination

Every device on the low-speed CAN network requires a termination

resistor for each CAN data line: R

Figure C-4 shows termination resistor placement in a low-speed CAN

network.

Appendix C Cabling Requirements for PXI-8460 Low-Speed CAN

for CAN_H and R

RTH

for CAN_L.

RTL

Low-speed

CAN Device

RTL CAN_L RTH CAN_H

CAN_H

CAN_L

Figure C-4.

Low-speed

CAN Device

RTL CAN_L RTH CAN_H

Termination Resistor Placement for Low-Speed CAN

Low-speed

CAN Device

RTL CAN_L RTH CAN_H

The following sections explain ho w to determine the correct resistor values

for your PXI-8460, and how to replace those resistors, if necessary.

Determining the Necessary Termination Resistance for Your Board

Unlike high-speed CAN, low-speed CAN requires termination at the

low-speed CAN transceiver instead of on the cable. The termination

requires one resistor for each CAN line. This configuration allows the

Philips fault-tolerant CAN transceiver to detect any of seven network

faults. You can use your PXI-8460 to connect to a low-speed CAN network

having from two to 32 nodes as specified by Philips (including the port on

the PXI-8460 as a node). You can also use the PXI-8460 to communicate

with individual low-speed CAN devices. It is important to determine the

overall termination of your existing network, or the termination of your

individual device, before connecting it to a PXI-8460 port. Philips

recommends an overall RTH and RTL termination of 100 to 500 Ω (each)

for a properly terminated low-speed network. The ov erall network

termination may be determined as follows:

1

------------------------- -

R

RTH overall

© National Instruments Corporation C-5 PXI-8461 or PXI-8460 and NI-CAN for Windows NT

†

1

------------------------

R

RTH node 1

1

------------------------

R

RTH node 2

1

------------------------

R

RTH node 3

1

------------------------------- -+++=

R

RTH or node n...

Page 38

Appendix C Cabling Requirements for PXI-8460 Low-Speed CAN

Philips also recommends an individual device R TH and R TL termination of

500 Ω to 16 kΩ. The PXI-8460 board ships with mounted RTH and RTL

values of 510 Ω ±5% per port. The PXI-8460 kit also includes a pair of

15 kΩ ±5% resistors for each port. After determining the termination of

your existing network or device, you can use the following formula to

indicate which value should be placed on your PXI-8460 board in order to

produce the proper overall R TH and R TL termination of 100 to 500 Ω upon

connection of the board:

R

RTH overall*

------------------------------------------------------------------------------------------------------------------------------- ------------=

†

*R

RTH overall

**R

RTH of low-speed CAN interface

†R

RTH

should be between 100 and 500 Ω

= R

RTL

---------------------------------------------------------------- -

R

RTH of low-speed CAN interface**

1

= 510 Ω ±5% (mounted) or 15 kΩ ±5% (in kit)

1

--------------------------------------------------------------+

R

RTH of existing network or device

1

As the formula indicates, the 510 Ω ±5% shipped on your board will work

with properly terminated networks having a total RTH and RTL

termination of 125 to 500 Ω, or individual devices having an RTH and RTL

termination of 500 Ω to 16 kΩ. F or communication with a network having

an overall RTH and RTL termination of 100 to 125 Ω, you will need to

replace the 510 Ω resistors with the 15 kΩ resistors in the kit. Please refer

to the next section, Replacing the Termination Resistors.

PXI-8461 or PXI-8460 and NI-CAN for Windows NT C-6 www.natinst.com

Page 39

Appendix C Cabling Requirements for PXI-8460 Low-Speed CAN

Replacing the Termination Resistors

Follow these steps to replace the termination resistors, after you have

determined the correct value in the previous section, Determining the

Necessary Termination Resistance for Your Board.

1. Remove the termination resistors on your PXI-8460. Figure C-5 shows

the location of the termination resistor sockets on a PXI-8460.

1

2

1 Port 1 Termination Resistors 2 Port 2 Termination Resistors

Figure C-5.

Location of Termination Resistors on a

PXI-8460

2. Cut and bend the lead wires of the resistors you want to install. Refer

to Figure C-6.

0.5 in

(13 mm)

0.165 in

(4 mm)

Figure C-6.

© National Instruments Corporation C-7 PXI-8461 or PXI-8460 and NI-CAN for Windows NT

Preparing Lead Wires of Replacement Resistors

Page 40

Appendix C Cabling Requirements for PXI-8460 Low-Speed CAN

3. Insert the replacement resistors into the empty sockets.

4. Refer to Install the Hardware, in Chapter 2, Installation and

Configuration, to complete the hardware installation.

Cabling Example

Figure C-7 shows an example of a cable to connect two low-speed CAN

devices. For the internal power configuration, the V+ connection is

required for the low-speed transceiv er to operate as specif ied in the Philips

data sheet.

5-Pin

Combicon

9-Pin

D-Sub

Pin 7Pin 4 Pin 7 Pin 4

Pin 2Pin 2

Pin 5Pin 3

Pin 9Pin 5

Pin 3Pin 1

CAN_H

CAN_L

GND

V+

V–

Power

Connector

V+

V–

Figure C-7.

Cabling Example

9-Pin

D-Sub

Pin 2 Pin 2

Pin 5 Pin 3

Pin 9 Pin 5

Pin 3 Pin 1

5-Pin

Combicon

PXI-8461 or PXI-8460 and NI-CAN for Windows NT C-8 www.natinst.com

Page 41

Troubleshooting and

Common Questions

This appendix describes how to troubleshoot problems and answers some

common questions.

Missing Board in the NI-CAN Configuration Utility

The NI-CAN Configuration utility contains configuration information for

all of the CAN hardware it is aware of that is installed in your system. To

start the NI-CAN Configuration utility, double-click on the NI-CAN

Configuration icon in the Control Panel:

• Windows NT 3.51–Open the Control Panel in the Main group of

the Program Manager.

• Windows NT 4.0 or later–Select Start»Settings»Control Panel.

If your board is not listed under NI-CAN Configuration, the board is not

properly installed. For the PXI-8461 or PXI-8460, this means that the board

is not physically present in the system. If your board is firmly plugged into

its slot and the problem persists, contact National Instruments.

D

Diagnostic Utility Failures

The following sections explain common error messages generated by the

NI-CAN Diagnostic utility.

Resource Errors

This error occurs if the memory resource or interrupt resource assigned to

a board conflicts with the resources being used by other hardware in the

system. If a resource error occurs, click on the Resources button in the

NI-CAN Configuration utility to view the board resources. For the

PXI-8461 or PXI-8460, if legacy hardware in your system is using the

resources, change the resource configuration of the legacy hardware. If you

need help, refer to the documentation that came with your hardware. If the

problem persists, contact National Instruments.

© National Instruments Corporation D-1 PXI-8461 or PXI-8460 and NI-CAN for Windows NT

Page 42

Appendix D Troubleshooting and Common Questions

NI-CAN Software Problem Encountered

This error occurs if the NI-CAN Diagnostic utility detects that it is unable

to communicate correctly with the hardware using the installed NI-CAN

software. If you get this error, shut down your computer , restart it, and run

the NI-CAN Diagnostic utility again. If the problem persists, try

reinstalling the NI-CAN software for Windows NT.

Missing Board in Diagnostic Utility

If your board is physically installed in your system, but is not listed in the

NI-CAN Diagnostic utility , check to see if the NI-CAN Configuration

utility has detected the board. For more information, refer to the Missing

Board in the NI-CAN Configuration Utility section earlier in this appendix.

Hardware Problem Encountered

This error occurs if the NI-CAN Diagnostic utility detects a defect in the

hardware. If you get this error, write do wn the numeric code shown with the

error and contact National Instruments. Depending on the cause of the

hardware failure, you may need to repair or replace your board.

Common Questions

How can I determine which type of CAN hardware I have installed?

Run the NI-CAN Configuration utility. To run the utility, select

Start»Settings»Control Panel»NI-CAN Configuration. If any hardware

is correctly installed, it is listed under National Instruments CAN

Interfaces.

How can I determine which version of the NI-CAN software I have

installed?

Run the NI-CAN Diagnostic utility. To run the utility, select the NI-CAN

Diagnostic item under Start»Programs»National Instruments CAN.

The NI-CAN Diagnostic utility displays information about the version of

the NI-CAN software currently installed.

How many PXI-8461 or PXI-8460 boards can I configure for use with

my NI-CAN software?

The NI-CAN software for Windo ws NT can be configured to communicate

with up to 10 boards.

PXI-8461 or PXI-8460 and NI-CAN for Windows NT D-2 www.natinst.com

Page 43

Appendix D Troubleshooting and Common Questions

How do I connect a CAN cable to my CAN port?

You will need to use an appropriate cable. For information about cabling

requirements for National Instruments CAN hardware, refer to

Appendix B, Cabling Requirements for PXI-8461 High-Speed CAN or

Appendix C, Cabling Requirements for PXI-8460 Low-Sp eed CAN.

Are interrupts required for the PXI-8461 and PXI-8460?

Yes, one interrupt per board is required.

What do I do if the NI-CAN Diagnostic utility fails with an error?

Refer to the Diagnostic Utility Failures section in this appendix for specific

information about what might cause the NI-CAN Diagnostic utility to fail.

If you have already completed the troubleshooting steps, contact National

Instruments.

How do I use an NI-CAN language interface?

For information about using NI-CAN language interfaces, refer to

Chapter 3, Developing Your Application

,

in the NI-CAN User Manual.

How do I use NI-CAN from within LabVIEW or BridgeVIEW?

For information about using NI-CAN from within LabVIEW or

BridgeVIEW, refer to Chapter 3, Developing Your Application

,

in the

NI-CAN User Manual.

Why does the uninstall program leave some components installed?

The uninstall program removes only items that the installation program

installed. If you add anything to a directory that was created by the

installation program, the uninstall program does not delete that directory

because the directory is not empty after the uninstallation. You must

remove any remaining components yourself.

© National Instruments Corporation D-3 PXI-8461 or PXI-8460 and NI-CAN for Windows NT

Page 44

Specifications

This appendix describes the physical characteristics of the hardware and

the recommended operating conditions.

PXI-8461 One Port and Two Port

Dimensions.............................................PXI 3U Module

Power requirement.................................+5 VDC 500 mA typical

I/O connector.......................................... 9-pin D-Sub for each port

Operating environment

Component temperature..................0 to 55 °C

Relative humidity............................10% to 90%, noncondensing

E

100 by 160 mm

(3.94 by 6.30 in.)

(standard)

or

5-pin Combicon-style pluggable

DeviceNet screw terminal

Storage environment

Temperature....................................–20 to 70 °C

Relative humidity............................10% to 90%, noncondensing

PXI-8460 One Port and Two Port

Dimensions.............................................PXI 3U Module

100 by 160 mm

(3.94 by 6.30 in.)

Power requirement.................................+5 VDC 500 mA typical

I/O connector.......................................... 9-pin D-Sub for each port

© National Instruments Corporation E-1 PXI-8461 or PXI-8460 and NI-CAN for Windows NT

Page 45

Appendix E Specifications

Operating environment

Component temperature ..................0 to 55 °C

Relative humidity ............................10% to 90%, noncondensing

Storage environment

Temperature.....................................–20 to 70 °C

Relative humidity ............................10% to 90%, noncondensing

High-Speed CAN Port Characteristics for Bus-Powered Ports

Power requirement..................................10–30 V, 40 mA typical

100 mA maximum

Isolation ..................................................500 VDC optical

Low-Speed CAN Port Characteristics for Bus-Powered Ports

Power requirement..................................8–27 V, 40 mA typical

100 mA maximum

Isolation ..................................................500 VDC optical

PXI-8461 or PXI-8460 and NI-CAN for Windows NT E-2 www.natinst.com

Page 46

Technical Support Resources

This appendix describes the comprehensive resources available to you in

the Technical Support section of the National Instruments Web site and

provides technical support telephone numbers for you to use if you have

trouble connecting to our We b site or if you do not have internet access.

NI Web Support

To provide you with immediate answers and solutions 24 hours a day,

365 days a year, National Instruments maintains extensi ve online technical

support resources. They are available to you at no cost, are updated daily,

and can be found in the Technical Support section of our Web site at

www.natinst.com/support.

Online Problem-Solving and Diagnostic Resources

• KnowledgeBase—A searchable database containing thousands of

frequently asked questions (F A Qs) and their corresponding answers or

solutions, including special sections devoted to our newest products.

The database is updated daily in response to new customer experiences

and feedback.

• Troubleshooting Wizards—Step-by-step guides lead you through

common problems and answer questions about our entire product line.

Wizards include screen shots that illustrate the steps being described

and provide detailed information ranging from simple getting started

instructions to advanced topics.

• Product Manuals—A comprehensive, searchable library of the latest

editions of National Instruments hardware and software product

manuals.

• Hardware Reference Database—A searchable database containing

brief hardware descriptions, mechanical drawings, and helpful images

of jumper settings and connector pinouts.

• Application Notes—A library with more than 100 short papers

addressing specific topics such as creating and calling DLLs,

developing your own instrument driver software, and porting

applications between platforms and operating systems.

F

© National Instruments Corporation F-1 PXI-8461 or PXI-8460 and NI-CAN for Windows NT

Page 47

Appendix F Technical Support Resources

Software-Related Resources

• Instrument Driver Network—A library with hundreds of instrument

drivers for control of standalone instruments via GPIB, VXI, or serial

interfaces. You also can submit a request for a particular instrument

driver if it does not already appear in the library.

• Example Programs Database—A database with numerous,

non-shipping example programs for National Instruments

programming environments. You can use them to complement the

example programs that are already included with National Instruments

products.

• Software Library—A library with updates and patches to application

software, links to the latest versions of driver software for National

Instruments hardware products, and utility routines.

Worldwide Support

National Instruments has offices located around the globe. Many branch

offices maintain a Web site to provide information on local services. You

can access these Web sites from

www.natinst.com/worldwide.

If you have trouble connecting to our Web site, please contact your local

National Instruments office or the source from which you purchased your

National Instruments product(s) to obtain support.

For telephone support in the United States, dial 512 795 8248. For

telephone support outside the United States, contact your local branch

office:

Australia 03 9879 5166, Austria 0662 45 79 90 0, Belgium 02 757 00 20,

Brazil 011 284 5011, Canada (Calgary) 403 274 9391,

Canada (Ontario) 905 785 0085, Canad a (Québec) 514 694 8521,

China 0755 3904939, Denmark 45 76 26 00, Finland 09 725 725 11,

France 01 48 14 24 24, Germany 089 741 31 30, Greece 30 1 42 96 427

Hong Kong 2645 3186, India 91805275406, Israel 03 6120092,

Italy 02 41309 1, Japan 03 5472 2970, Korea 02 596 7456,

Mexico (D.F.) 5 280 7625, Mexico (Monterrey) 8 357 7695,

Netherlands 0348 433466, Norway 32 27 73 00, Singapore 2265886,

Spain (Barcelona) 93 582 025 1, Spain (Madrid) 91 640 0085,

Sweden 08 58 7 895 00, Switzerland 056 200 51 51,

Taiwan 02 2377 1200, United Kingdom 01635 523545

PXI-8461 or PXI-8460 and NI-CAN for Windows NT F-2 www.natinst.com

Page 48

Glossary

Prefix Meaning Value

n- nano- 10

m- milli- 10

k- kilo- 10

M- mega- 10

° degrees

Ω ohms

% percent

A amperes

ANSI American National Standards Institute

bbits

Bbytes

–9

–3

3

6

C Celsius

CAN Controller Area Network

CiA CAN in Automation

DC direct current

DLL dynamic link library

FCC Federal Communications Commission

ft feet

HMI Human Machine Interface

Hz hertz

IEEE Institute of Electrical and Electronic Engineers

in. inches

IRQ interrupt request

© National Instruments Corporation G-1 PXI-8461 or PXI-8460 and NI-CAN for Windows NT

Page 49

Glossary

ISO International Standards Organization

LED light-emitting diode

m meters

PC personal computer

PCI peripheral component interconnect

PCMCIA Personal Computer Memory Card International Association

PLC Programmable Logic Controller

RAM random-access memory

resource hardware settings used by National Instruments CAN hardware, including

an interrupt request level (IRQ) and an 8 KB physical memory range (such

as D0000 to D1FFF hex)

s seconds

V volts

VDC volts direct current

VXI VME eXtensions for Instrumentation

Wwatts

PXI-8461 or PXI-8460 and NI-CAN for Windows NT G-2 www.natinst.com

Loading...

Loading...