Page 1

PXI

NI PXI-8183 User Manual

NI PXI-8183 User Manual

February 2008

372512A-01

Page 2

Support

Worldwide Technical Support and Product Information

ni.com

National Instruments Corporate Headquarters

11500 North Mopac Expressway Austin, Texas 78759-3504 USA Tel: 512 683 0100

Worldwide Offices

Australia 1800 300 800, Austria 43 662 457990-0, Belgium 32 (0) 2 757 0020, Brazil 55 11 3262 3599,

Canada 800 433 3488, China 86 21 5050 9800, Czech Republic 420 224 235 774, Denmark 45 45 76 26 00,

Finland 358 (0) 9 725 72511, France 01 57 66 24 24, Germany 49 89 7413130, India 91 80 41190000,

Israel 972 3 6393737, Italy 39 02 41309277, Japan 0120-527196, Korea 82 02 3451 3400,

Lebanon 961 (0) 1 33 28 28, Malaysia 1800 887710, Mexico 01 800 010 0793, Netherlands 31 (0) 348 433 466,

New Zealand 0800 553 322, Norway 47 (0) 66 90 76 60, Poland 48 22 3390150, Portugal 351 210 311 210,

Russia 7 495 783 6851, Singapore 1800 226 5886, Slovenia 386 3 425 42 00, South Africa 27 0 11 805 8197,

Spain 34 91 640 0085, Sweden 46 (0) 8 587 895 00, Switzerland 41 56 2005151, Taiwan 886 02 2377 2222,

Thailand 662 278 6777, Turkey 90 212 279 3031, United Kingdom 44 (0) 1635 523545

For further support information, refer to the Technical Support and Professional Services appendix. To comment

on National Instruments documentation, refer to the National Instruments Web site at

the info code

feedback.

ni.com/info and enter

© 2008 National Instruments Corporation. All rights reserved.

Page 3

Important Information

Warranty

The NI PXI-8183 is warranted against defects in materials and workmanship for a period of one year from the date of shipment, as evidenced

by receipts or other documentation. National Instruments will, at its option, repair or replace equipment that proves to be defective during the

warranty period. This warranty includes parts and labor.

The media on which you receive National Instruments software are warranted not to fail to execute programming instructions, due to defects in

materials and workmanship, for a period of 90 days from date of shipment, as evidenced by receipts or other documentation. National Instruments

will, at its option, repair or replace software media that do not execute programming instruc tions if National Instruments receives notice of such defects

during the warranty period. National Instruments does not warrant that the operation of the software shall be uninterrupted or error free.

A Return Material Authorization (RMA) number must be obtained from the factory and clearly marked on the outside of the package before any

equipment will be accepted for warranty work. National Instruments will pay the shipping costs of returning to the owner parts which are covered by

warranty.

National Instruments believes that the information in this document is accurate. The document has been carefully reviewed for technical accuracy. In

the event that technical or typographical errors exist, National Instruments reserves the right to make changes to subsequent editions of this document

without prior notice to holders of this edition. The reader should consult National Instruments if errors are suspected. In no event shall National

Instruments be liable for any damages arising out of or related to this document or the information contained in it.

E

XCEPT AS SPECIFIED HEREIN, NATIONAL INSTRUMENTS MAKES NO WARRANTIES, EXPRESS OR IMPLIED, AND SPECIFICALLY DISCLAIMS ANY WARRANTY OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. CUSTOMER’S RIGHT TO RECOVER DAMAGES CAUSED BY FAULT OR NEGLIGENCE ON THE PART OF NATIONAL

I

NSTRUMENTS SHALL BE LIMITED TO THE AMOUNT THERETOFORE PAID BY THE CUSTOMER. NATIONAL INSTRUMENTS WILL NOT BE LIABLE FOR DAMAGES RESULTING

FROM LOSS OF DATA, PROFITS, USE OF PRODUCTS, OR INCIDENTAL OR CONSEQUENTIAL DAMAGES, EVEN IF ADVISED OF THE POSSIBILITY THEREOF. This limitation of

the liability of National Instruments will apply regardless of the form of action, whether in contract or tort, including negligence. Any action against

National Instruments must be brought within one year after the cause of action accrues. National Instruments shall not be liable for any delay in

performance due to causes beyond its reasonable control. The warranty provided herein does not cover damages, defects, malfunctions, or service

failures caused by owner’s failure to follow the National Instruments installation, operation, or maintenance instructions; owner’s modification of the

product; owner’s abuse, misuse, or negligent acts; and power failure or surges, fire, flood, accident, actions of third parties, or other events outside

reasonable control.

Copyright

Under the copyright laws, this publication may not be reproduced or transmitted in any form, electronic or mechanical, including photocopying,

recording, storing in an information retrieval system, or translating, in whole or in part, without the prior written consent of National

Instruments Corporation.

National Instruments respects the intellectual property of others, and we ask our users to do the same. NI software is protected by copyright and other

intellectual property laws. Where NI software may be used to reproduce software or other materials belonging to others, you may use NI software only

to reproduce materials that you may reproduce in accordance with the terms of any applicable license or other legal restriction.

Trademarks

National Instruments, NI, ni.com, and LabVIEW are trademarks of National Instruments Corporation. Refer to the Terms of Use section

on

ni.com/legal for more information about National Instruments trademarks.

Other product and company names mentioned herein are trademarks or trade names of their respective companies.

Members of the National Instruments Alliance Partner Program are business entities independent from National Instruments and have no agency,

partnership, or joint-venture relationship with National Instruments.

Patents

For patents covering National Instruments products, refer to the appropriate location: Help»Patents in your software, the patents.txt file

on your CD, or ni.com/patents.

WARNING REGARDING USE OF NATIONAL INSTRUMENTS PRODUCTS

(1) NATIONAL INSTRUMENTS PRODUCTS ARE NOT DESIGNED WITH COMPONENTS AND TESTING FOR A LEVEL OF

RELIABILITY SUITABLE FOR USE IN OR IN CONNECTION WITH SURGICAL IMPLANTS OR AS CRITICAL COMPONENTS IN

ANY LIFE SUPPORT SYSTEMS WHOSE FAILURE TO PERFORM CAN REASONABLY BE EXPECTED TO CAUSE SIGNIFICANT

INJURY TO A HUMAN.

(2) IN ANY APPLICATION, INCLUDING THE ABOVE, RELIABILITY OF OPERATION OF THE SOFTWARE PRODUCTS CAN BE

IMPAIRED BY ADVERSE FACTORS, INCLUDING BUT NOT LIMITED TO FLUCTUATIONS IN ELECTRICAL POWER SUPPLY,

COMPUTER HARDWARE MALFUNCTIONS, COMPUTER OPERATING SYSTEM SOFTWARE FITNESS, FITNESS OF COMPILERS

AND DEVELOPMENT SOFTWARE USED TO DEVELOP AN APPLICATION, INSTALLATION ERRORS, SOFTWARE AND HARDWARE

COMPATIBILITY PROBLEMS, MALFUNCTIONS OR FAILURES OF ELECTRONIC MONITORING OR CONTROL DEVICES,

TRANSIENT FAILURES OF ELECTRONIC SYSTEMS (HARDWARE AND/OR SOFTWARE), UNANTICIPATED USES OR MISUSES, OR

ERRORS ON THE PART OF THE USER OR APPLICATIONS DESIGNER (ADVERSE FACTORS SUCH AS THESE ARE HEREAFTER

COLLECTIVELY TERMED “SYSTEM FAILURES”). ANY APPLICATION WHERE A SYSTEM FAILURE WOULD CREATE A RISK OF

HARM TO PROPERTY OR PERSONS (INCLUDING THE RISK OF BODILY INJURY AND DEATH) SHOULD NOT BE RELIANT SOLELY

UPON ONE FORM OF ELECTRONIC SYSTEM DUE TO THE RISK OF SYSTEM FAILURE. TO AVOID DAMAGE, INJURY, OR DEATH,

THE USER OR APPLICATION DESIGNER MUST TAKE REASONABLY PRUDENT STEPS TO PROTECT AGAINST SYSTEM FAILURES,

INCLUDING BUT NOT LIMITED TO BACK-UP OR SHUT DOWN MECHANISMS. BECAUSE EACH END-USER SYSTEM IS

CUSTOMIZED AND DIFFERS FROM NATIONAL INSTRUMENTS' TESTING PLATFORMS AND BECAUSE A USER OR APPLICATION

DESIGNER MAY USE NATIONAL INSTRUMENTS PRODUCTS IN COMBINATION WITH OTHER PRODUCTS IN A MANNER NOT

EVALUATED OR CONTEMPLATED BY NATIONAL INSTRUMENTS, THE USER OR APPLICATION DESIGNER IS ULTIMATELY

RESPONSIBLE FOR VERIFYING AND VALIDATING THE SUITABILITY OF NATIONAL INSTRUMENTS PRODUCTS WHENEVER

NATIONAL INSTRUMENTS PRODUCTS ARE INCORPORATED IN A SYSTEM OR APPLICATION, INCLUDING, WITHOUT

LIMITATION, THE APPROPRIATE DESIGN, PROCESS AND SAFETY LEVEL OF SUCH SYSTEM OR APPLICATION.

Page 4

Compliance

Compliance with FCC/Canada Radio Frequency Interference

Regulations

Determining FCC Class

The Federal Communications Commission (FCC) has rules to protect wireless communications from interference. The FCC

places digital electronics into two classes. These classes are known as Class A (for use in industrial-commercial locations only)

or Class B (for use in residential or commercial locations). All National Instruments (NI) products are FCC Class A products.

Depending on where it is operated, this Class A product could be subject to restrictions in the FCC rules. (In Canada, the

Department of Communications (DOC), of Industry Canada, regulates wireless interference in much the same way.) Digital

electronics emit weak signals during normal operation that can affect radio, television, or other wireless products.

All Class A products display a simple warning statement of one paragraph in length regarding interference and undesired

operation. The FCC rules have restrictions regarding the locations where FCC Class A products can be operated.

Consult the FCC Web site at

FCC/DOC Warnings

This equipment generates and uses radio frequency energy and, if not installed and used in strict accordance with the instructions

in this manual and the CE marking Declaration of Conformity*, may cause interference to radio and television reception.

Classification requirements are the same for the Federal Communications Commission (FCC) and the Canadian Department

of Communications (DOC).

Changes or modifications not expressly approved by NI could void the user’s authority to operate the equipment under the

FCC Rules.

Class A

Federal Communications Commission

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to part 15 of the FCC

Rules. These limits are designed to provide reasonable protection against harmful interference when the equipment is operated

in a commercial environment. This equipment generates, uses, and can radiate radio frequency energy and, if not installed and

used in accordance with the instruction manual, may cause harmful interference to radio communications. Operation of this

equipment in a residential area is likely to cause harmful interference in which case the user is required to correct the interference

at their own expense.

www.fcc.gov for more information.

Canadian Department of Communications

This Class A digital apparatus meets all requirements of the Canadian Interference-Causing Equipment Regulations.

Cet appareil numérique de la classe A respecte toutes les exigences du Règlement sur le matériel brouilleur du Canada.

Compliance with EU Directives

Users in the European Union (EU) should refer to the Declaration of Conformity (DoC) for information* pertaining to the

CE marking. Refer to the Declaration of Conformity (DoC) for this product for any additional regulatory compliance

information. To obtain the DoC for this product, visit

and click the appropriate link in the Certification column.

* The CE marking Declaration of Conformity contains important supplementary information and instructions for the user or

installer.

ni.com/certification, search by model number or product line,

Page 5

Contents

About This Manual

How to Use the Documentation Set...............................................................................vii

Conventions ...................................................................................................................vii

Related Documentation..................................................................................................viii

Chapter 1

Introduction

Benefits of PXI ..............................................................................................................1-1

NI PXI-8183 ..................................................................................................................1-2

Description ......................................................................................................1-2

Modules ...........................................................................................................1-2

Functional Overview .......................................................................................1-2

National Instruments Software ......................................................................................1-4

Chapter 2

Installation and Configuration

Installing the NI PXI-8183 ............................................................................................2-1

How to Remove the Controller from the PXI Chassis ....................................2-4

BIOS Setup ....................................................................................................................2-4

Entering BIOS Setup .......................................................................................2-4

Main Setup Menu ............................................................................................2-5

Advanced Setup Menu ....................................................................................2-6

PXI Setup Menu ..............................................................................................2-8

LabVIEW RT Setup Menu..............................................................................2-9

Security Setup Menu .......................................................................................2-9

Boot Setup Menu.............................................................................................2-10

Exiting BIOS Setup .........................................................................................2-11

System CMOS ...............................................................................................................2-12

LabVIEW RT Configuration Switches..........................................................................2-13

Drivers and Software .....................................................................................................2-15

Files and Directories Installed on Your Hard Drive........................................2-15

PXI Features ..................................................................................................................2-15

PXI Trigger Connectivity................................................................................2-15

Upgrading RAM ............................................................................................................2-16

Hard Drive Recovery .....................................................................................................2-17

Installing an OS .............................................................................................................2-17

Installing from a CD-ROM .............................................................................2-17

Installing from a Network ...............................................................................2-18

© National Instruments Corporation v NI PXI-8183 User Manual

Page 6

Contents

Chapter 3

I/O Information

Front Panel Connectors ................................................................................................. 3-1

Front Panel.....................................................................................................................3-2

VGA ................................................................................................................ 3-3

COM1.............................................................................................................. 3-4

Ethernet ........................................................................................................... 3-5

Parallel Port..................................................................................................... 3-6

Universal Serial Bus........................................................................................ 3-8

PS/2 ................................................................................................................. 3-9

Trigger............................................................................................................. 3-10

Front Panel Features ...................................................................................................... 3-11

Data Storage .................................................................................................................. 3-11

Chapter 4

Common Configuration Questions

General Questions ......................................................................................................... 4-1

Boot Options..................................................................................................................4-2

Cables and Connections ................................................................................................ 4-3

Operating System and Software Driver Installation...................................................... 4-4

Chassis Configuration ................................................................................................... 4-5

Basic PXI System Configuration .................................................................... 4-6

Upgrade Information ..................................................................................................... 4-7

PXI Configuration ......................................................................................................... 4-8

Chapter 5

Troubleshooting

Appendix A

Specifications

Appendix B

Technical Support and Professional Services

Glossary

Index

NI PXI-8183 User Manual vi ni.com

Page 7

About This Manual

This manual contains detailed instructions for installing and configuring

your National Instruments NI PXI-8183 embedded computer kit.

How to Use the Documentation Set

Begin by reading the NI PXI-8183 Installation Guide, a brief quick-start

guide that describes how to install and get started with your controller.

This manual contains more details about changing the installation or

configuration from the defaults and using the hardware.

Conventions

The following conventions appear in this manual:

» The » symbol leads you through nested menu items and dialog box options

to a final action. The sequence File»Page Setup»Options directs you to

pull down the File menu, select the Page Setup item, and select Options

from the last dialog box.

This icon denotes a note, which alerts you to important information.

This icon denotes a caution, which advises you of precautions to take to

avoid injury, data loss, or a system crash.

bold Bold text denotes items that you must select or click in the software, such

as menu items and dialog box options. Bold text also denotes parameter

names.

italic Italic text denotes variables, emphasis, a cross-reference, or an introduction

to a key concept. Italic text also denotes text that is a placeholder for a word

or value that you must supply.

monospace Text in this font denotes text or characters that you should enter from the

keyboard, sections of code, programming examples, and syntax examples.

This font is also used for the proper names of disk drives, paths, directories,

programs, subprograms, subroutines, device names, functions, operations,

variables, filenames, and extensions.

© National Instruments Corporation vii NI PXI-8183 User Manual

Page 8

About This Manual

monospace bold Bold text in this font denotes the messages and responses that the computer

automatically prints to the screen. This font also emphasizes lines of code

that are different from the other examples.

Related Documentation

The following documents contain information you may find helpful as you

read this manual:

• PICMG 2.0 R3.0 CompactPCI Specification, PCI Industrial

Computers Manufacturers Group

• IEEE Standard P1284.1-1997 (C/MM) Standard for Information

Technology for Transport Independent Printer/System Interface

• PCI Local Bus Specification, Revision 2.2, PCI Special Interest Group

• PXI Hardware Specification, Revision 2.2, PXI Systems Alliance

• PXI Software Specification, Revision 2.3, PXI Systems Alliance

• Serialized IRQ Support for PCI Systems Specification, Revision 6.0,

Compaq Computer et al.

NI PXI-8183 User Manual viii ni.com

Page 9

Introduction

Benefits of PXI

The PXIbus specification defines a compact modular PC platform for

industrial instrumentation. PXI leverages the PCI bus, which is the de facto

standard for today’s desktop computer software and hardware designs. As

a result, PXI users receive all the benefits of PCI within an architecture that

supports mechanical, electrical, and software features tailored to industrial

instrumentation, data acquisition, and automation applications.

Well-suited for industrial applications, PXI leverages from the

CompactPCI specification, which defines a rugged form factor for PCI that

offers superior mechanical integrity and easy installation and removal of

hardware components. PXI products offer higher and more carefully

defined levels of environmental performance required by the vibration,

shock, temperature, and humidity extremes of industrial environments.

PXI adds mandatory environmental testing and active cooling to the

CompactPCI mechanical specification to ease system integration and

ensure multivendor interoperability.

1

Additionally, PXI meets the more specific needs of instrumentation users

by adding an integrated trigger bus and reference clock for multiple-board

synchronization, a star trigger bus for very precise timing, and local buses

for side-band communication between adjacent peripherals.

© National Instruments Corporation 1-1 NI PXI-8183 User Manual

Page 10

Chapter 1 Introduction

NI PXI-8183

Description

The NI PXI-8183 PXI/CompactPCI embedded computer is a

high-performance PXI/CompactPCI-compatible system controller. The

NI PXI-8183 controller integrates standard I/O features in a single unit by

using state-of-the-art packaging. Combining a NI PXI-8183 embedded

controller with a PXI-compatible chassis, such as the PXI-1036, results in

a fully PC-compatible computer in a compact, rugged package.

Modules

The standard I/O on this module includes video, RS-232 serial port, parallel

port, two USB ports, 10/100 ENET, PS/2 mouse and keyboard port, Reset

button, PXI Trigger, an 850 MHz processor, and a 40 GB (or larger) hard

drive.

Functional Overview

This section contains functional descriptions of each major logic block on

the NI PXI-8183 embedded computer.

NI PXI-8183 User Manual 1-2 ni.com

Page 11

Chapter 1 Introduction

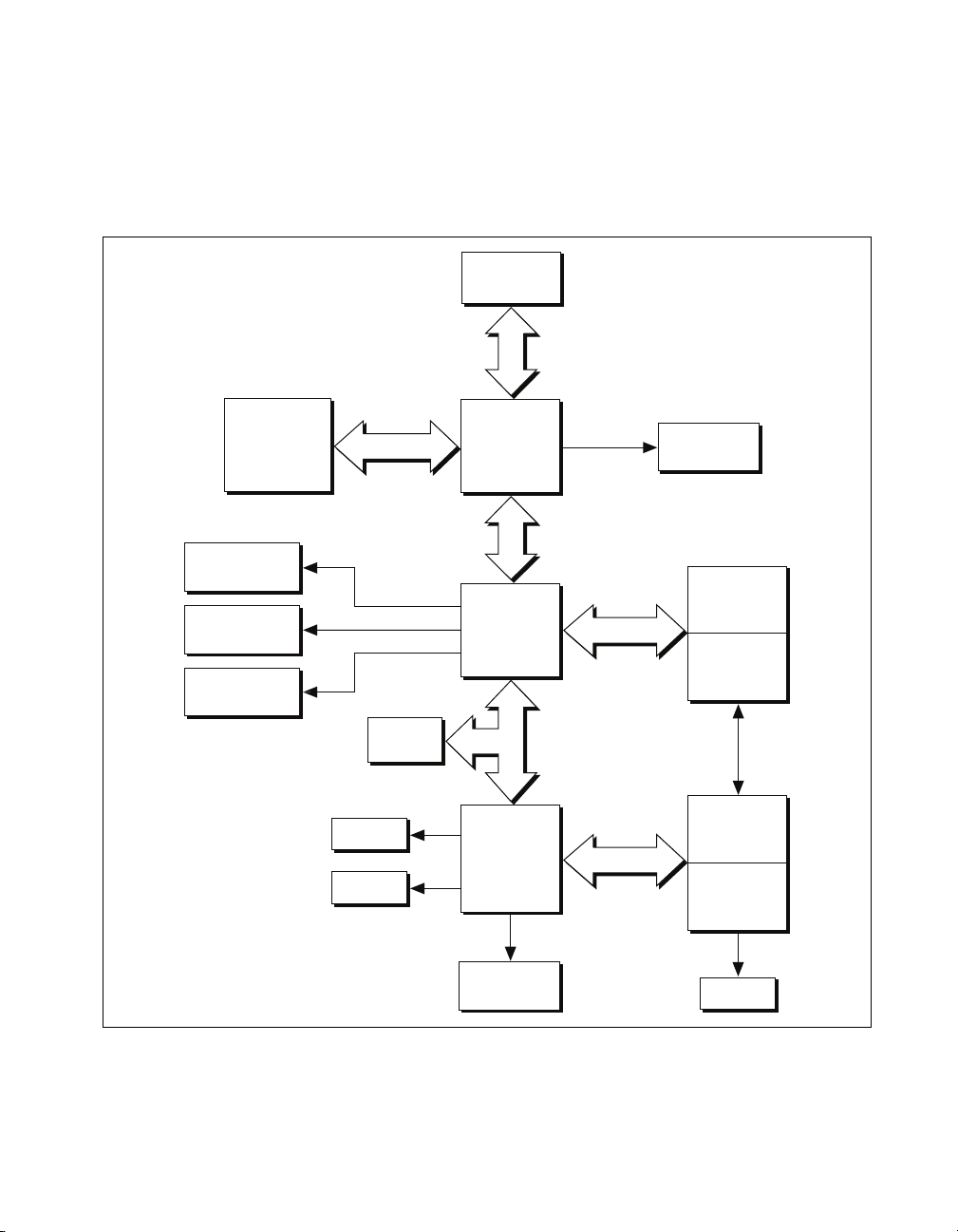

NI PXI-8183 Functional Description

The NI PXI-8183 is a modular PC in a PXI 3U-size form factor. Figure 1-1

is a functional block diagram of the NI PXI-8183. Following the diagram

is a description of each logic block shown.

Socket 370

CPU

SO-DIMM

SDRAM

PC 100

ATA 100

IDE Interface

2 USB

Connectors

10/100BaseT

Ethernet

LPT 1

COM 1

Flash

ROM

Chip Set

Graphics

Memory

Controller

Hub

Chip Set

I/O

Controller

Hub

Super I/O

PS/2

VGA

Connector

Hub Interface

PXI

Connector

PCI Bus

PXI

Triggers

LPC Bus

SMB to

PXI Trigger

PCI Bus

Watchdog

Keyboard/

Mouse

SMB

Figure 1-1. NI PXI-8183 Block Diagram

© National Instruments Corporation 1-3 NI PXI-8183 User Manual

Page 12

Chapter 1 Introduction

The NI PXI-8183 consists of the following logic blocks on the

CPU module:

• The Socket 370 CPU is the socket definition for the Intel Pentium III

processor families.

• The SO-DIMM block consists of a 64-bit SDRAM socket that can hold

up to 512 MB.

• The Chip Set GMCH connects to the CPU, SDRAM, and video.

• The SMB to PXI Trigger provides a routable connection of the

PXI triggers to/from the SMB on the front panel.

• The Watchdog Timer block consists of a watchdog timer that can reset

the controller or generate a trigger.

• The Chip Set ICH2 connects to the PCI bus USB, IDE, LPC, and

Ethernet ports.

• The USB Connector connects the chip set to the Universal Serial Bus

interface.

• The PXI Connector connects the NI PXI-8183 to the PXI/CompactPCI

backplane.

• The Keyboard/Mouse block contains the PS/2 keyboard and mouse

interface.

• The Super I/O block represents the other peripherals supplied by the

NI PXI-8183. The NI PXI-8183 has one serial port and an ECP/EPP

parallel port.

• The IDE block is dedicated PCI-IDE circuitry providing fast ATA-100

transfers to the internal hard drive. The IDE feature is built into the

chip set.

• The 10/100 Enet connects to either 10 Mbit or 100 Mbit Ethernet

interfaces.

• The 2.5 in. hard drive is 40 GB or larger.

National Instruments Software

National Instruments has developed several software kits you can use

with the NI PXI-8183. The software is already installed on your hard drive.

NI-DAQ has an extensive library of functions that you can call from your

application programming environment. These functions include routines

for analog input (A/D conversion), buffered data acquisition (high-speed

A/D conversion), analog output (D/A conversion), waveform generation,

NI PXI-8183 User Manual 1-4 ni.com

Page 13

Chapter 1 Introduction

digital I/O, counter/timer operations, SCXI, RTSI, self-calibration,

messaging, and acquiring data to extended memory.

NI-VISA is the National Instruments implementation of the VISA

specification. VISA is a uniform API for communicating and controlling

Serial, GPIB, PXI, VXI, and various other types of instruments. This API

aids in the creation of more portable applications and instrument drivers.

For information on writing your own PXI instrument driver with NI-VISA,

refer to the NI-VISA Getting Started manual and the

the

NI-VISA directory.

readme.txt file in

You also can use the National Instruments LabVIEW and Measurement

Studio application programs and instrument drivers to ease your

programming task. These standardized programs match the modular

virtual instrument capability of PXI and can reduce your PXI software

development time. These programs feature extensive libraries of GPIB,

Serial, and VXI instrument drivers written to take full advantage of direct

PXI control. LabVIEW and Measurement Studio include all the tools

needed for instrument control, data acquisition, analysis, and presentation.

LabVIEW is an easy-to-use, graphical programming environment you can

use to acquire data from thousands of different instruments, including

IEEE 488.2 devices, VXI devices, serial devices, PLCs, and plug-in data

acquisition boards. After you have acquired raw data, you can convert it

into meaningful results using the powerful data analysis routines in

LabVIEW. LabVIEW also comes with hundreds of instrument drivers,

which dramatically reduce software development time, because you do not

have to spend time programming the low-level control of each instrument.

Measurement Studio allows you to choose from standard environments

such as Microsoft Visual Basic, Visual C++, and Visual Studio .NET to

create your application, using tools specific for each language. With

Measurement Studio, you can write programs quickly and easily and

modify them as your needs change.

LabWindows

™

/CVI™ is an interactive ANSI C programming

environment designed for building virtual instrument applications.

LabWindows/CVI delivers a drag-and-drop editor for building user

interfaces, a complete ANSI C environment for building your test program

logic, and a collection of automated code generation tools, as well as

utilities for building automated test systems, monitoring applications,

or laboratory experiments.

© National Instruments Corporation 1-5 NI PXI-8183 User Manual

Page 14

Installation and Configuration

This chapter contains information about installing and configuring your

NI PXI-8183 controller.

Installing the NI PXI-8183

This section contains general installation instructions for the NI PXI-8183.

Consult your PXI chassis user manual for specific instructions and

warnings.

1. Plug in your chassis before installing the NI PXI-8183. The power cord

grounds the chassis and protects it from electrical damage while you

install the module. (Make sure the power switch is turned off.)

Caution To protect both yourself and the chassis from electrical hazards, leave the chassis

powered off until you finish installing the NI PXI-8183 module.

2. Remove any filler panels blocking access to the system controller slot

(Slot 1) in the chassis.

3. Touch the metal part of the case to discharge any static electricity that

might be on your clothes or body.

2

© National Instruments Corporation 2-1 NI PXI-8183 User Manual

Page 15

Chapter 2 Installation and Configuration

4. Remove the protective plastic covers from the four bracket-retaining

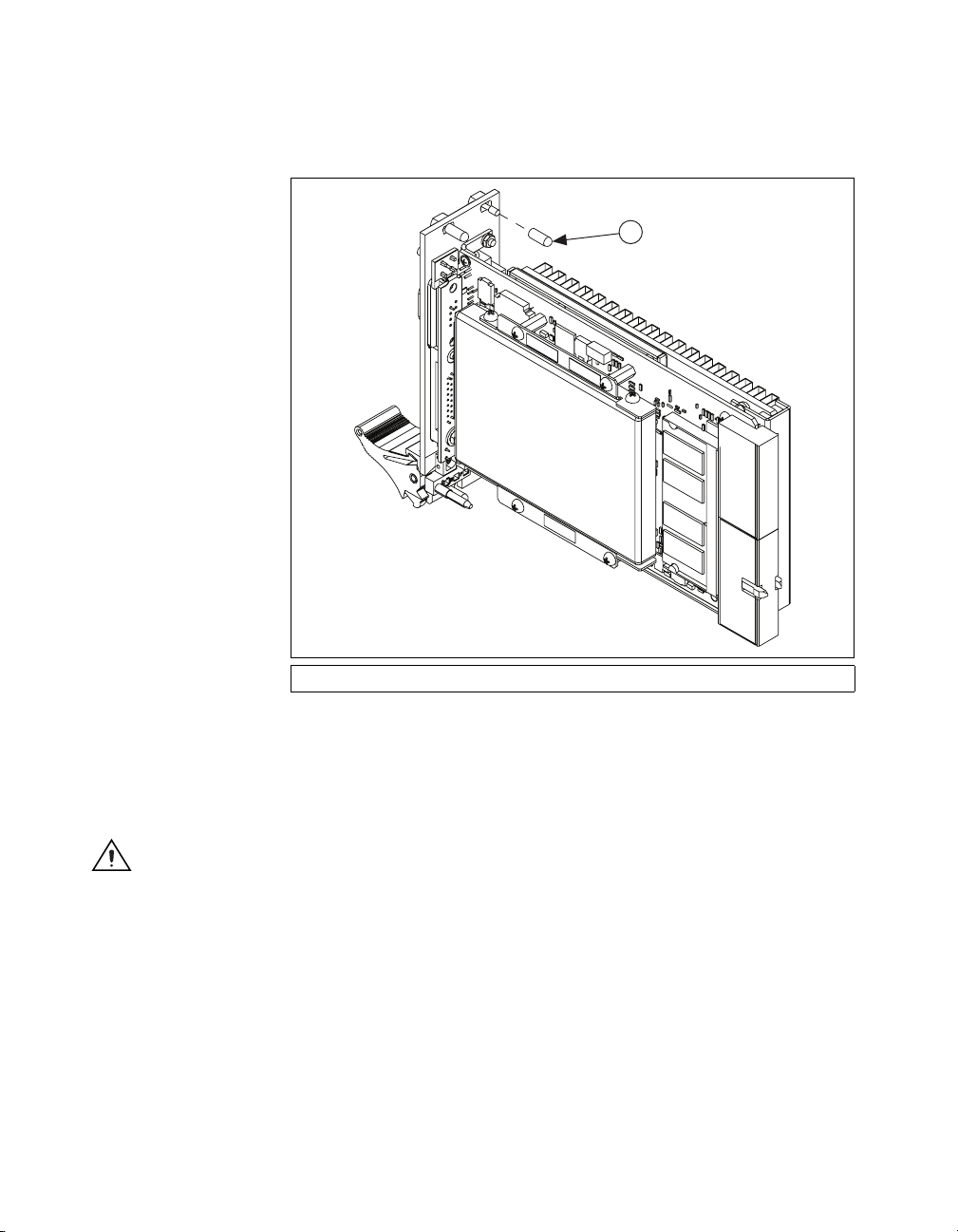

screws as shown in Figure 2-1.

1

1Protective Screw Cap (4X)

Figure 2-1. Removing Protective Screw Caps

5. Make sure the injector/ejector handle is in its downward position.

Align the NI PXI-8183 with the card guides on the top and bottom of

the system controller slot.

Caution Do not raise the injector/ejector handle as you insert the NI PXI-8183. The

module will not insert properly unless the handle is in its downward position so that it does

not interfere with the injector rail on the chassis.

6. Hold the handle as you slowly slide the module into the chassis until

the handle catches on the injector/ejector rail.

7. Raise the injector/ejector handle until the module firmly seats

into the backplane receptacle connectors. The front panel of the

NI PXI-8183 should be even with the front panel of the chassis.

8. Tighten the four bracket-retaining screws on the top and bottom of the

front panel to secure the NI PXI-8183 to the chassis.

NI PXI-8183 User Manual 2-2 ni.com

Page 16

Chapter 2 Installation and Configuration

9. Check the installation.

10. Connect the keyboard and mouse to the appropriate connectors. If you

are using a PS/2 keyboard and a PS/2 mouse, use the Y-splitter adapter

(refer to Figure 4-1, Y-Splitter Cable) included with your controller to

connect both to the PS/2 connector.

11. Connect the VGA monitor video cable to the VGA connector.

12. Connect devices to ports as required by your system configuration.

13. Power on the chassis.

14. Verify that the controller boots. If the controller does not boot, refer to

the What if the NI PXI-8183 does not boot? section of Chapter 5,

Troubleshooting.

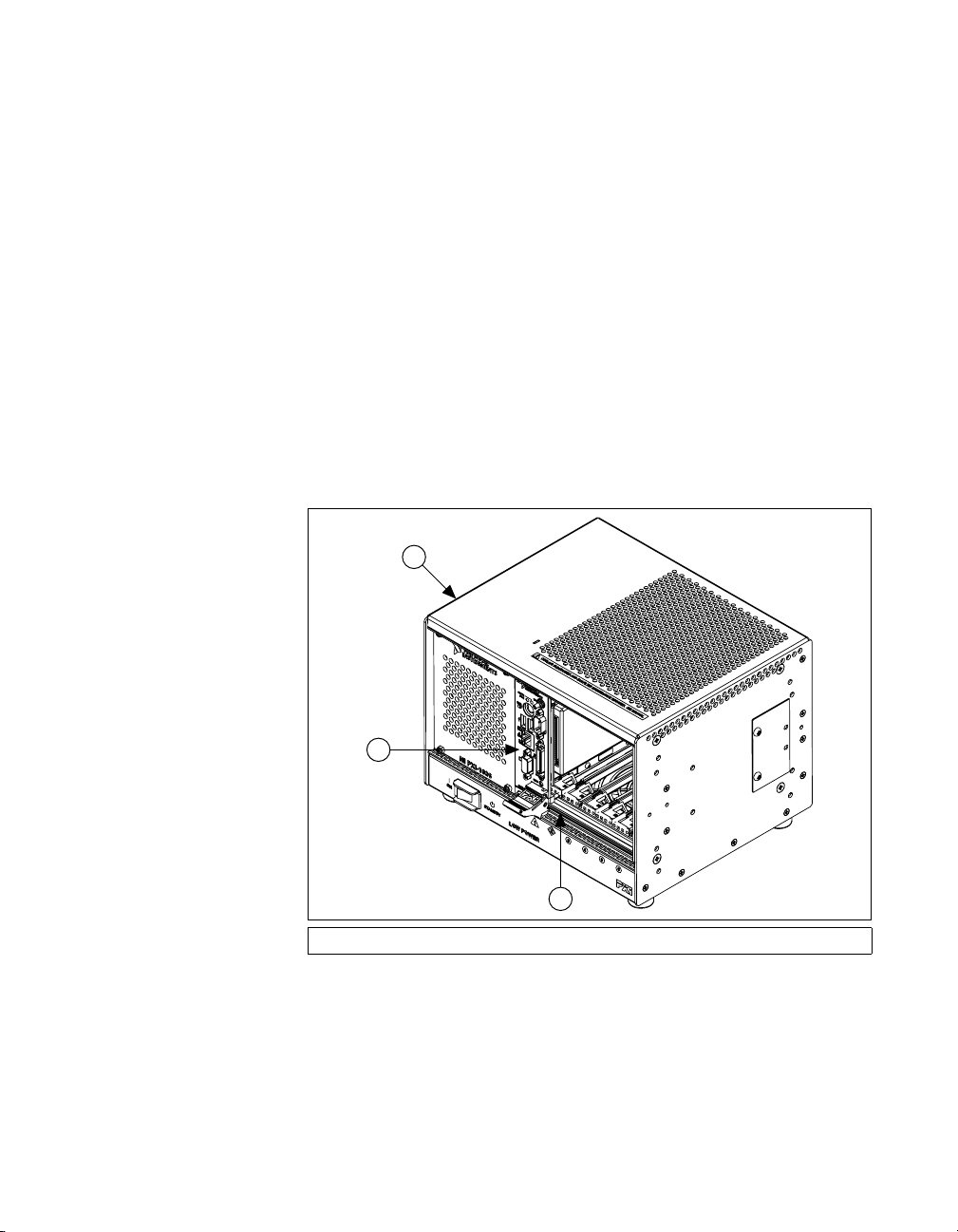

Figure 2-2 shows an NI PXI-8183 installed in the system controller slot of

a National Instruments PXI-1036 chassis. You can place PXI devices in any

other slot.

1

2

3

1PXI-1036 Chassis 2 NI PXI-8183 Controller 3 Injector/Ejector Rail

Figure 2-2. NI PXI-8183 Controller Installed in a PXI Chassis

© National Instruments Corporation 2-3 NI PXI-8183 User Manual

Page 17

Chapter 2 Installation and Configuration

How to Remove the Controller from the PXI Chassis

The NI PXI-8183 controllers are designed for easy handling. To remove

the unit from the PXI chassis, complete the following steps:

1. Power off the chassis.

2. Remove the bracket-retaining screws in the front panel.

3. Press the injector/ejector handle down.

4. Slide the unit out of the chassis.

BIOS Setup

You can change the NI PXI-8183 configuration settings in the BIOS setup.

The BIOS is the low-level interface between the hardware and PC software

that configures and tests your hardware when you boot the system. The

BIOS setup program includes menus for configuring settings and enabling

NI PXI-8183 controller features.

Most users do not need to use the BIOS setup program, as the NI PXI-8183

controller ships with default settings that work well for most

configurations.

Caution Changing BIOS settings may lead to incorrect controller behavior and possibly

an unbootable controller. If this happens, follow the instructions for restoring default

settings in the System CMOS section. In general, do not change a setting unless you are

absolutely certain what it does.

Entering BIOS Setup

To start the BIOS setup utility, complete the following steps:

1. Power on or reboot your NI PXI-8183 controller.

2. When the message

<Delete> or <Del> on the numeric keypad. The message

Setup…

3. When you first enter the BIOS setup program, it displays the Main

menu.

Use the following keys to navigate through the BIOS setup.

• Left Arrow, Right Arrow—Use these keys to move between the

different setup menus. If you are in a submenu, these keys have no

effect, and you need to press <Esc> to leave the submenu first. (To use

the arrows on the numeric keypad, you must turn off Num Lock.)

NI PXI-8183 User Manual 2-4 ni.com

appears, and the setup program is loaded after a short delay.

Press <DEL> to enter SETUP appears, press

Entering

Page 18

Main Setup Menu

Chapter 2 Installation and Configuration

• Up Arrow, Down Arrow—Use these keys to move between the

options within a setup menu. (To use the arrows on the numeric

keypad, you must turn off Num Lock.)

• <Enter>—Use this key either to enter a submenu or display all

available settings for a highlighted configuration option.

• <Esc>—Use this key to return the parent menu of a submenu. At the

top-level menus, this key serves as a shortcut to the Exit menu.

• <+> and <–>—Use these keys to cycle between all available settings

for a selected configuration option.

The most commonly accessed and modified BIOS settings are in the Main

setup menu. The Main setup menu includes the following settings:

• System Time & Date—This setting controls the time of day, which is

stored in a battery-backed real-time clock. Most operating systems

also include a way to change this setting. Use <+> and <–> in

conjunction with <Enter> to change these values.

• DMI Event Logging—This setting brings up the DMI Event

Logging submenu. (Refer to the DMI Event Logging Submenu

section.)

• Require Keyboard to Boot—When Yes, a missing or malfunctioning

keyboard causes the BIOS to halt with an error. When No, the BIOS

allows booting without a keyboard. If you are using a USB keyboard,

you may attach it at any time during the powered up state. If you are

using a PS/2 keyboard, you must power down the controller and then

attach the keyboard. To use this controller in a “headless” mode, you

must set this option to No. The default value is Yes.

• Num Lock—This setting indicates whether you turn on Num Lock at

boot time. The default value is On.

• Primary/Secondary Master/Slave—These items display the

IDE/ATA devices detected in the system. Normally, you do not

need to modify these items. However, if an IDE/ATA device is not

autodetected properly, you can specify it manually by pressing

<Enter> on an item.

• System Information—This setting displays a screen containing

important system information about the NI PXI-8183 controller.

© National Instruments Corporation 2-5 NI PXI-8183 User Manual

Page 19

Chapter 2 Installation and Configuration

DMI Event Logging Submenu

Major errors that occur during the BIOS booting process are stored in

battery-backed memory on the controller, and remain there until you view

and clear them using this submenu. This logging capability allows a system

administrator to detect the historical occurrence of faults on a controller.

This submenu includes the following items:

• View DMI Event Log—This setting displays a window containing

all logged system errors and the time at which they occurred.

• Mark Events as Read—This setting prevents any current logged

entries from being displayed again. However, all entries remain in

battery-backed memory, and you can retrieve them using other

DMI software that is beyond the scope of this document.

• Clear All Events—When set to Yes, this setting clears all entries from

the DMI event log on reboot.

• Event Logging—This setting controls whether events are logged.

Disabling logging has no impact on system performance. The default

is Enabled.

Advanced Setup Menu

This menu contains BIOS settings that normally do not require

modification. If you have specific problems such as unbootable disks

or resource conflicts, you may need to examine these settings.

Caution Changing settings in this menu may result in an unstable or unbootable controller.

If this happens, follow the procedures outlined in the System CMOS section to restore

BIOS settings to their factory defaults.

The Advanced setup menu includes the following settings:

• Reset Configuration Data—A portion of the EEPROM on the

controller is designated as the Extended System Configuration Data

region (ESCD). The BIOS and Plug-and-Play operating systems use

this table to store the Last Known Good configuration of system

peripherals. If you experience resource conflicts or peripheral

malfunction, set this setting to Yes to force the BIOS to recreate the

ESCD on the next reboot. This is rarely necessary.

• Integrated Peripherals—Use this setting to bring up the Integrated

Peripherals submenu. (Refer to the Integrated Peripherals Submenu

section.)

NI PXI-8183 User Manual 2-6 ni.com

Page 20

Chapter 2 Installation and Configuration

• Local Bus IDE Adapter—The NI PXI-8183 controller has

two integrated IDE/ATA channels (Primary and Secondary), each

capable of supporting two ATA devices (Master and Slave). Use this

setting to disable one or more of these integrated channels. You should

modify this setting only if specified in other sections of this manual.

The default is Both.

• Quick Boot Mode—When you enable this option, certain lengthy

BIOS tests that rarely fail are skipped to shorten controller boot time.

The default is Enabled.

• Summary Screen—This setting controls the display of the summary

screen shown after BIOS completes its initialization, but before

booting takes place. You can disable this screen in the interest of

shortening controller boot time. The default is Disabled.

• PXE Network Boot—This setting enables the option for booting from

a network PXE server on the subnet. The default is Disabled.

Integrated Peripherals Submenu

Use this submenu to apply nondefault configurations to the front panel

peripherals of an NI PXI-8183 controller. Normally, you do not need to

modify these settings, as the factory default settings provide the most

compatible and optimal configuration possible.

• Serial Port A & B—This setting enables or disables COM1 and

COM2. You also can change this setting to Enabled and modify

the base address and Interrupt Request Level (IRQ) of a port. The

NI PXI-8183 does not have a COM2, so Serial Port B is always

disabled. The default is Auto, which places COM1 at 0x3F8 IRQ 4

and COM2 at 0x2F8 IRQ 3.

• Parallel Port—Use this setting to enable or disable LPT1. You also

can change this setting to Enabled and modify the base address,

IRQ level, and ISA Direct Memory Access (DMA) channel of the

port. The default is Auto, which places LPT1 at 0x378, IRQ 7, using

ISA DMA Channel 3 if necessary.

• Parallel Port Mode—The PC industry has created several different

modes of operation for this port over the years. Usually, the default

setting works for all applications. However, if a parallel port device

specifically requires a nondefault setting, you can change it here.

The default is Bidirectional, for full IEEE 1284 capabilities.

© National Instruments Corporation 2-7 NI PXI-8183 User Manual

Page 21

Chapter 2 Installation and Configuration

• Floppy Drive—You can route the internal signals used for the

3.5 in. floppy drive operation through the pins on the parallel port

connector. Use this setting to operate the NI PXI-8183 controller with

a specialized external floppy drive. Normally, using a Universal Serial

Bus (USB) floppy drive is preferable to this option, which requires a

specially designed drive and cable. (Refer to the Parallel Port section

of Chapter 3, I/O Information, for pinout information.) Setting this

option to Parallel Port disables normal LPT1 functionality. The

default is Disabled.

• Legacy USB Support—Use this setting to use a USB keyboard and

mouse as if they were standard PS/2-style peripherals. You must enable

this setting to use these devices in operating systems with no USB

support and to boot from a USB floppy or CD-ROM. The BIOS setup

screen always works with USB keyboards regardless of this setting.

Certain real-time applications may require you to disable this setting

to reduce loop time jitter. The default is Enabled.

PXI Setup Menu

Use this menu to control and route certain signals on the PXI backplane.

Normally, you do not need to modify these settings. However, other

sections of this manual may indicate that modifications are necessary

and may lead to unpredictable behavior.

• INTP Routing—You can route INTP to ISA IRQ 14, for use by a

PXI device functioning as a Primary IDE Controller. The default

setting is Not Routed.

• INTS Routing—You can route INTS to ISA IRQ 15, for use by a

PXI device functioning as a Secondary IDE Controller. You also can

route it to the controller’s 21-frame serialized IRQ input, for use by

certain PXI carrier cards. The default setting is Not Routed.

Note If INTS or INTP is routed to an ISA IRQ, you must disable one or both channels of

the integrated IDE/ATA controller for correct operation of this routing.

NI PXI-8183 User Manual 2-8 ni.com

Page 22

LabVIEW RT Setup Menu

Note This menu is visible only if the controller supports LabVIEW RT.

Use this menu to configure boot options for LabVIEW RT if it is installed

on the controller. If you are not using LabVIEW RT, you should leave these

settings as default.

Note These settings override the behavior of the switches on SW1. Refer to the LabVIEW

RT Configuration Switches section for more information. To use the settings from the

switches, select Use Hardware Switch for each option.

• Boot Configuration—This setting selects whether the controller

should boot LabVIEW RT, LabVIEW RT Safe Mode, or an installed

OS such as Windows XP. The default is Use Hardware Switch.

• Disable Startup VI—If the controller becomes inaccessible because

of a startup VI, this switch can prevent VIs from automatically running

at startup. The default is Use Hardware Switch.

• Reset IP Address—If the controller is deployed to a different subnet

from which it was originally configured, or if the current IP address

is invalid, use this switch to reset the IP address to

LabVIEW RT startup. The default is Use Hardware Switch.

Chapter 2 Installation and Configuration

0.0.0.0 during

Security Setup Menu

Use this menu to apply system-level passwords to the NI PXI-8183

controller. With these passwords, you can restrict access to the BIOS

setup program, floppy drives, and operating systems installed on bootable

devices. If you forget any password, you can restore the CMOS contents to

the factory default as described in the System CMOS section.

Note In most chassis configurations, an unauthorized user has easy access to the jumper

that resets the CMOS contents to the factory default. For a secure setup of this controller,

National Instruments recommends further provisions that are beyond the scope of this

document.

The Security setup menu includes the following settings:

• Set Supervisor Password—This setting sets the password that

governs supervisor-level access to the BIOS setup screen and booting.

The default is no password.

© National Instruments Corporation 2-9 NI PXI-8183 User Manual

Page 23

Chapter 2 Installation and Configuration

• Set User Password—This setting sets the password that governs

user-level access to the BIOS setup screen and booting. If you enter

BIOS setup using the user password, the only BIOS setting you can

modify is the user password. The default is no password.

• Password on Boot—This setting controls whether the controller

requires a supervisor or user password to boot an operating system. If

you enter the supervisor password on boot, you have supervisor-level

diskette access. If you enter the user password on boot, you have

user-level diskette access.

• Write Protect Boot Sector—When set to Yes, this setting prevents

modification of a hard disk boot sector through INT 13h services,

which may help prevent certain computer viruses from infecting the

controller. This setting does not prevent boot sector modification

by 32-bit operating system drivers that access the hard disk directly.

The default is No.

Note To disable a current password, leave the new password field blank by pressing

<Enter> on the field.

Boot Setup Menu

This screen displays the boot order of devices associated with the

controller. The BIOS proceeds down this list in search of a bootable device.

If the BIOS fails to find any bootable device, the message

System Not Found

• Removable Devices—The boot list includes floppy drives, ZIP drives,

and some USB-based devices.

• Hard Drive—The boot list includes all IDE/ATA and USB hard disks

detected on the system. Press <Enter> on this entry to expand it to

select the boot priority of individual IDE/ATA hard drives.

• CD-ROM Drive—The boot list includes all classes of CD-ROM

drive, including USB drives.

Operating

is displayed, and the system halts.

Notes If an SCSI host adapter exists in the system, this menu has an additional entry for

SCSI devices.

If PXE Network Boot is enabled, this menu has an additional entry for the Ethernet

interface.

NI PXI-8183 User Manual 2-10 ni.com

Page 24

Exiting BIOS Setup

Chapter 2 Installation and Configuration

The Exit setup menu includes all available options for exiting, saving, and

loading the BIOS default configuration. As an alternative to this screen,

press <F9> to load BIOS default settings and <F10> to save changes and

exit setup.

The Exit setup menu includes the following settings:

• Exit Saving Changes—Any changes made to BIOS settings are stored

in the battery-backed System CMOS. The setup program then exits

and reboots the controller.

• Exit Discarding Changes—Any changes made to BIOS settings

during this session of the BIOS setup program are discarded. The setup

program then exits and boots the controller without rebooting first.

• Load Setup Defaults—This setting restores all BIOS settings to the

factory default. This is useful if the controller exhibits unpredictable

behavior due to an incorrect or inappropriate BIOS setting. Notice

that any nondefault settings such as boot order, passwords, and

keyboardless operation are restored to their factory defaults. This

may produce undesirable behavior, and in heavily customized cases,

may cause the controller to malfunction or fail to boot.

• Discard Changes—Any changes made to BIOS settings during this

session of the BIOS setup program are discarded. Unlike Exit

Discarding Changes, however, the BIOS setup continues to be active.

• Save Changes—Changes made to BIOS settings during this session

are committed to battery-backed System CMOS. The setup program

remains active, allowing further changes.

© National Instruments Corporation 2-11 NI PXI-8183 User Manual

Page 25

Chapter 2 Installation and Configuration

System CMOS

The NI PXI-8183 contains a backed-up memory used to store

BIOS configuration information.

Complete the following steps to clear the CMOS contents:

1. Power off the chassis.

2. Remove the controller from the chassis.

3. Move the jumper on J1 from pins 1–2 to pins 2–3, as shown in

Figure 2-3.

4. Wait one second. Move the jumper back to pins 1–2.

5. Reinstall the controller in the chassis.

Caution Do not leave the jumper on pins 2-3. Doing so decreases battery life.

3

1

1Normal Operation (Default) 2Clear CMOS Contents 3 Pin 1

Figure 2-3. Clearing the CMOS Contents (NI PXI-8183 Shown)

NI PXI-8183 User Manual 2-12 ni.com

2

Page 26

LabVIEW RT Configuration Switches

Note These switches are functional only if the controller supports LabVIEW RT.

Use the LabVIEW RT configuration switches to configure LabVIEW RT

if it is installed on the controller. If you are not using LabVIEW RT, these

switches should remain in the OFF position. The controller reads these

switches only after a system reset. You must reboot the controller for any

changes to take place.

The NI PXI-8183 controller includes the following LabVIEW RT

configuration switches:

• Switch 1—Reset IP Address: Set this switch to ON to reset the

IP address to

Use this switch if moving the controller to a different subnet or if

the current TCP/IP settings are invalid.

• Switch 2—Disable Startup VI: Set this switch to ON to prevent

VIs from automatically running at startup if the controller becomes

inaccessible because of a startup VI.

• Switch 3—Boot Safe Mode: Set this switch to ON to boot

LabVIEW RT into safe mode to reconfigure TCP/IP settings and

to download or update software from a host computer. This switch

overrides the behavior of Switch 1. Booting the controller into safe

mode does not start the embedded LabVIEW RT engine. After

changing the settings or software, reboot the controller with this switch

OFF to resume normal operation.

• Switch 4—Boot LabVIEW RT: Set this switch to ON to boot

LabVIEW RT.

0.0.0.0 and other TCP/IP settings to their defaults.

Chapter 2 Installation and Configuration

© National Instruments Corporation 2-13 NI PXI-8183 User Manual

Page 27

Chapter 2 Installation and Configuration

Figure 2-4 shows the location of the LabVIEW RT configuration switches.

The switches are shown in the OFF position.

4

3

2

1

1 Switch 1—Reset IP Address

2 Switch 2—Disable Startup VI

3Switch 3—Boot Safe Mode

4 Switch 4—Boot LabVIEW RT

Figure 2-4. LabVIEW RT Configuration Switches

NI PXI-8183 User Manual 2-14 ni.com

Page 28

Chapter 2 Installation and Configuration

Drivers and Software

Files and Directories Installed on Your Hard Drive

Your hard drive includes a directory called images in its root that

contains software and soft copies of manuals for the peripherals. The

directory structure under the

into several levels.

In the

images directory, you will find a manuals directory,

an

os directory, and directories for each computer peripheral.

The

manuals directory contains quick reference guides, technical

reference manuals, and National Instruments software manuals, all in

Adobe Acrobat format. To access any manual, change your directory to

c:\images\pxi-8180\manuals and list the contents of that directory.

You will see several files, one corresponding to each peripheral.

The

os directory contains a subdirectory corresponding to the operating

system installed on your computer.

The rest of the directories correspond to each peripheral in your system.

Within each of these directories are the drivers for the peripherals. These

files and directories are copied exactly from the manufacturer distribution

disks, so the naming conventions vary from peripheral to peripheral.

images directory is logically organized

Because the naming conventions may not be completely straightforward,

National Instruments provides a text file named

c:\images\pxi-8180 directory. The drivers.txt file explains how

to install support for each peripheral. You may want to print this file for

reference when you install your peripheral device drivers.

drivers.txt in the

PXI Features

PXI Trigger Connectivity

The SMB connector on the NI PXI-8183 front panel can connect to or from

any PXI backplane trigger line through software. A trigger allocation

process is needed to prevent two resources from connecting to the same

trigger line, resulting in the trigger being double-driven and possibly

damaging the hardware. At the time of this manual’s publication, this

software is not yet available; however, an interim trigger routing software

utility is available from National Instruments. Contact National

Instruments at

© National Instruments Corporation 2-15 NI PXI-8183 User Manual

ni.com/support for more information.

Page 29

Chapter 2 Installation and Configuration

Upgrading RAM

You can change the amount of installed RAM on the NI PXI-8183 by

upgrading the SO-DIMM.

To upgrade the RAM, remove the NI PXI-8183 from the PXI chassis.

Remove the old SO-DIMM module and install the new SO-DIMM in the

socket as shown in Figure 2-5.

National Instruments offers the following types of SO-DIMMs for use with

the NI PXI-8183 controller.

• 256 MB, 32 MB × 64, 7.5 ns, 1.05 in. max

• 512 MB, 64 MB × 64, 7.5 ns, 1.05 in. max

Note National Instruments has tested and verified that the SO-DIMMs we sell work with

the NI PXI-8183. We recommend you purchase your SO-DIMM modules from National

Instruments. Other off-the-shelf SO-DIMM modules are not guaranteed to work properly.

1

2

1 SO-DIMM Module 2 SO-DIMM Socket

Figure 2-5. Installing a SO-DIMM in an NI PXI-8183 Controller

(NI PXI-8183 Shown)

NI PXI-8183 User Manual 2-16 ni.com

Page 30

Hard Drive Recovery

NI PXI-8183 controllers include Phoenix Technologies Ltd. Firstware

tools, either Recover or Vault, or both. These tools allow you to recover the

original factory condition of the hard disk from a small protected area of

your hard drive. This protected area contains an image of the hard disk

provided to you at the time of shipment. Should you need to restore your

software to its original condition, you can access that image by pressing a

hot key during the initial boot process. For more information regarding

these tools, refer to the documentation on your hard drive in the

c:\Images\Firstware directory.

Note Your system hot key is <Alt>. To access the Phoenix Firstware Recover tool, press

and hold <Alt> when video first appears during the boot process.

If you need to recover your factory-installed operating system from a CD,

you can use the included OS installation CD with an external CD-ROM

drive such as a USB CD-ROM drive. Boot the PXI controller using the

OS installation CD to recover the OS. You also may need to reinstall other

software after using the CD to recover the OS.

Chapter 2 Installation and Configuration

Note Recovering the OS using Firstware or the recovery CD erases the contents of your

hard disk. Back up any files you want to keep.

Installing an OS

NI PXI-8183 controllers include a preinstalled OS. In some cases, you may

want to reinstall the OS or install a different OS. When doing so, consider

the following guidelines.

Installing from a CD-ROM

The NI PXI-8183 supports the installation of Windows XP from a USB

CD-ROM. However, many other operating systems do not support

installation from a USB CD-ROM. For example, Windows 2000 aborts

during the install process because it does not have drivers for the CD-ROM

device.

With DOS drivers, you can install Windows 9x operating systems.

However, only a few USB CD-ROM drives have DOS drivers.

As an alternative to a USB CD-ROM drive, you can use an external SCSI

CD-ROM with a PXI-SCSI adapter.

© National Instruments Corporation 2-17 NI PXI-8183 User Manual

Page 31

Chapter 2 Installation and Configuration

Installing from a Network

Complete the following steps to install an OS from a network:

1. Create a network bootdisk. (Refer to the

netboot folder on your OS installation CD.)

2. Use another PC on the network with a CD-ROM drive. Share the drive

and load the OS installation CD.

3. Boot your NI PXI-8183 using the network boot disk.

4. Run the net utility from the

(for example, drive

5. Run

Notes To launch the installation in unattended mode, type:

z:\os\i386\winnt.exe /u:z:\os\pxi8180.txt /s:z:\os\i386

For additional assistance with installing or changing an operating system, refer to

KnowledgeBase 2ZKC02OK at

readme.txt file in the

a: drive. Map the shared CD-ROM

z:).

winnt.exe from the \os\i386 directory.

ni.com/support.

NI PXI-8183 User Manual 2-18 ni.com

Page 32

I/O Information

Front Panel Connectors

Table 3-1 lists various peripherals and their corresponding NI PXI-8183

external connectors, bus interfaces, and functions.

Table 3-1. NI PXI-8183 Peripherals Overview

External

Peripheral

Connector

3

Function

Video 15-pin D-SUB

(standard VGA)

Serial COM1 RS-232 Serial

Port (9-pin D-SUB)

10/100 Ethernet Ethernet Ethernet network connection

Parallel Parallel Port

(IEEE 1284)

USB 4-pin Series A

receptacle

Keyboard/mouse PS/2 PS/2-style keyboard and mouse

PXI trigger Trigger Routing PXI triggers to or from the backplane

Integrated with Dynamic Video Memory

16550 serial port

Extended capabilities

Universal Serial Bus

(two ports on all models)

(mouse requires PS/2 Y splitter)

trigger bus

© National Instruments Corporation 3-1 NI PXI-8183 User Manual

Page 33

Chapter 3 I/O Information

Front Panel

Figure 3-1 shows the front panel layout and dimensions of the

NI PXI-8183. Dimensions are in inches [millimeters].

.00 [0]

1.20 [30.4]

0.34 [8.7]

0.95 [24.2]

0.86 [21.9]

.00 [0]

.68 [17.1]

1.25 [31.8]

1.52 [38.5]

1.85 [47.1]

2.49 [63.3]

3.00 [76.3]

3.46 [87.9]

NI PXI-8183

Embedded Controller

0.97 [24.6]

0.34 [8.7]

0.94 [23.9]

Figure 3-1. NI PXI-8183 Front Panel Layout and Dimensions

NI PXI-8183 User Manual 3-2 ni.com

Page 34

VGA

Chapter 3 I/O Information

Figure 3-2 shows the location and pinouts for the VGA connector on

the NI PXI-8183. Table 3-2 lists and describes the VGA connector signals.

AMP manufactures a mating connector with part numbers 748364-1

(housing) and 748333-2 (pin contact).

11 6 1

VGA

15 10 5

Figure 3-2. VGA Connector Location and Pinout

Table 3-2. VGA Connector Signals

NI PXI-8183

Embedded Controller

Pin Signal Name Signal Description

1 R Red

2 G Green

3 B Blue

4 NC Not Connected

5 GND Ground

6 GND Ground

7 GND Ground

8 GND Ground

9 +5V 5 V

10 GND Ground

© National Instruments Corporation 3-3 NI PXI-8183 User Manual

Page 35

Chapter 3 I/O Information

COM1

Table 3-2. VGA Connector Signals (Continued)

Pin Signal Name Signal Description

11 NC Not Connected

12 SD Serial Data

13 HSync Horizontal Sync

14 VSync Vertical Sync

15 SC Serial Clock

Figure 3-3 shows the location and pinouts for the COM1 connector on the

NI PXI-8183. Table 3-3 lists and describes the COM1 connector signal.

AMP manufactures a serial port mating connector, part number 745491-5.

5

9

COM1

6

1

NI PXI-8183

Embedded Controller

Figure 3-3. COM1 Connector Location and Pinout

Table 3-3. COM1 Connector Signals

Pin Signal Name Signal Description

1 DCD* Data Carrier Detect

2 RXD* Receive Data

3 TXD* Transmit Data

4 DTR* Data Terminal Ready

NI PXI-8183 User Manual 3-4 ni.com

Page 36

Ethernet

Chapter 3 I/O Information

Table 3-3. COM1 Connector Signals (Continued)

Pin Signal Name Signal Description

5 GND Ground

6 DSR* Data Set Ready

7 RTS * Ready to Send

8 CTS* Clear to Send

9 RI* Ring Indicator

Figure 3-4 shows the location and pinouts for the Ethernet connector on the

NI PXI-8183. Table 3-4 lists and describes the Ethernet connector signals.

AMP manufactures a mating connector, part number 554739-1.

1

Ethernet

8

NI PXI-8183

Embedded Controller

Figure 3-4. Ethernet Connector Location and Pinout

Table 3-4. Ethernet Connector Signals

Pin Signal Description

1 Differential Transmit

2 Differential Transmit

3 Differential Receive

4 NC

© National Instruments Corporation 3-5 NI PXI-8183 User Manual

Page 37

Chapter 3 I/O Information

Parallel Port

Table 3-4. Ethernet Connector Signals (Continued)

Pin Signal Description

5 NC

6 Differential Receive

7 NC

8 NC

Figure 3-5 shows the location and pinouts for the IEEE 1284 (parallel)

connector on the NI PXI-8183. Table 3-5 lists and describes the IEEE 1284

connector signals.

Parallel port adapter cables are available from National Instruments,

part number 777169-01.

NI PXI-8183

Embedded Controller

1

18

19

Parallel Port

36

Figure 3-5. Parallel Port Connector Location and Pinout

NI PXI-8183 User Manual 3-6 ni.com

Page 38

Table 3-5. Parallel Port Connector Signals

Chapter 3 I/O Information

1

Pin

Default Configuration (LPT) Floppy Configuration

Signal Name Signal Description Signal Name Signal Description

1 BUSY* Device Busy MTR1* Motor on Disk 1

2 SLCTIN* Select Input Step* Step Pulse

3 ACK* Acknowledge DS1* Drive Select 1

4 FAULT* Fault WDATA* Write Disk Data

5 ERROR Error HDSEL* Head Select

6 PD0 Data Bit 0 Index* Index Pulse Input

7 PD1 Data Bit 1 TRK0* Track 0

8 PD 2 Data Bit 2 WRTPRT* Write Protected

9 PD3 Data Bit 3 RDATA* Read Disk Data

10 PD4 Data Bit 4 DSKCHG* Disk Change

11 PD5 Data Bit 5 Not Used —

12 PD6 Data Bit 6 MTR0* Motor on Disk 0

13 PD7 Data Bit 7 Not Used —

14 INIT* Initialize Printer DIR* Step Direction

15 STROBE* Strobe DS0* Drive Select 0

16 SLCT Select WGATE* Write Gate

17 AUTOFD Auto Line Feed DRVDEN0* Density Select

18 +5V +5 V +5V +5 V

19–35 GND Ground GND Ground

36 NC Not Connected NC Not Connected

1

Refer to the BIOS Setup section of Chapter 2, Installation and Configuration.

© National Instruments Corporation 3-7 NI PXI-8183 User Manual

Page 39

Chapter 3 I/O Information

Universal Serial Bus

Figure 3-6 shows the location and pinouts for the Universal Serial Bus

(USB) connector on the NI PXI-8183. Table 3-6 lists and describes the

USB connector signals.

AMP manufactures a USB mating connector, part number 787633.

NI PXI-8183

Embedded Controller

4

1

USB

Figure 3-6. USB Connector Location and Pinout

Table 3-6. USB Connector Signals

Pin Signal Name Signal Description

1 VCC Cable Power (+5 V)

2 –Data USB Data–

3 +Data USB Data+

4 GND Ground

NI PXI-8183 User Manual 3-8 ni.com

Page 40

PS/2

Chapter 3 I/O Information

Figure 3-7 shows the location and pinouts for the PS/2 connector on the

NI PXI-8183. Table 3-7 lists and describes the PS/2 connector signals.

To connect both a PS/2 keyboard and PS/2 mouse to the NI PXI-8183,

use the Y-splitter adapter cable included with your controller (refer to

Figure 4-1, Y-Splitter Cable).

Replacement Y-splitter cables are available from National Instruments,

part number 778713-01.

3

5

1

PS/2

2

6

4

NI PXI-8183

Embedded Controller

Figure 3-7. PS/2 Connector Location and Pinout

Table 3-7. PS/2 Connector Signals

Pin Signal Name Signal Description

Y-Splitter

Keyboard

Y-Splitter

Mouse

1 DATA Data Keyboard Data Keyboard Data Mouse

2 NC Data Mouse NC NC

3 GND Ground GND GND

4 +5V +5 V + 5 + 5

5 CLK Clock Keyboard Clock Keyboard Clock Mouse

6 NC Clock Mouse NC NC

© National Instruments Corporation 3-9 NI PXI-8183 User Manual

Page 41

Chapter 3 I/O Information

Trigger

The TRG connector is the software-controlled trigger connection for

routing PXI triggers to or from the backplane trigger bus.

Figure 3-8 shows the TRG connector location on the NI PXI-8183.

Table 3-8 lists and describes the trigger connector signals.

2

NI PXI-8183

Embedded Controller

1

Figure 3-8. TRG Connector Location and Pinout

Table 3-8. TRG Connector Signals

Pin Signal Name Signal Description

1 TRIG Trigger

2 (Shield) GND Ground

NI PXI-8183 User Manual 3-10 ni.com

Page 42

Front Panel Features

The NI PXI-8183 have the following front-panel features:

• A system reset pushbutton (hold the button for at least two seconds to

generate a reset to the controller).

• Two front-panel LEDs that show PC status.

– The POWER OK LED indicates that the power is on and reset is

no longer asserted.

– The DRIVE LED indicates when an access to the internal hard

disk is occurring.

Data Storage

The NI PXI-8183 have the following data storage features:

• Internal IDE hard drive

– 2.5 in. notebook hard drive

– Supports up to ATA-5 (UDMA 100)

• USB storage support—USB CD-ROM, floppy drive, or mass storage

device

Chapter 3 I/O Information

© National Instruments Corporation 3-11 NI PXI-8183 User Manual

Page 43

Common Configuration

Questions

This chapter answers common configuration questions you may have when

using the NI PXI-8183 embedded controller.

General Questions

What do the LEDs on the NI PXI-8183 front panel mean?

The green LED indicates the power supplies to/on the NI PXI-8183 are

within spec. The supplies monitored are 3.3 V, 5 V, +12 V, and the internally

regulated processor core voltage. The hard drive LED lights when there is

hard drive activity on the NI PXI-8183.

How do I check the configuration of the memory, hard drive,

time/date, and so on?

You can view these parameters in the BIOS setup. To enter the BIOS setup,

reboot the NI PXI-8183 and press <Delete> during the memory tests. Refer

to the Entering BIOS Setup section of Chapter 2, Installation and

Configuration, for more information.

4

Can I use the internal IDE drive and an external SCSI hard drive at

the same time?

Ye s.

© National Instruments Corporation 4-1 NI PXI-8183 User Manual

Page 44

Chapter 4 Common Configuration Questions

Boot Options

What devices can I boot from?

The NI PXI-8183 can boot from the following devices:

• The internal IDE hard drive

• An external SCSI hard drive or CD-ROM if an SCSI adapter, such as

the PXI-8214, is used

• An external USB mass storage device such as a USB hard drive or

CD-ROM

• An external USB floppy drive

Note There are some limitations when booting from a USB device. Windows XP

can be installed from a USB CD-ROM, but earlier versions of Windows cannot.

The NI PXI-8183 BIOS configures the USB devices so that they will work

in a DOS environment.

How do I configure the controller to boot from these devices?

There are two methods:

• Enter Setup and select the Boot menu. You will see a list of all bootable

devices, ordered by device type. You can set the boot order pressing

<+> and <–>. Set the order by device type and set the order for the

devices listed within the device type.

• To boot from a different device without permanently changing the boot

order, press <Esc> during POST. After the BIOS completes the POST

and just before the controller boots the OS, the Boot menu is displayed.

You can select the device type you want to boot from.

Note Two devices cannot share the same IDE channel, and doing so may damage the

hardware. If you configure the PC Card ATA drive for the primary channel, you must

physically remove the internal IDE drive.

NI PXI-8183 User Manual 4-2 ni.com

Page 45

Cables and Connections

How do I plug both a PS/2 mouse and PS/2 keyboard into the

controller?

The NI PXI-8183 has a combined PS/2 mouse and PS/2 keyboard

connector, so you need to use the PS/2 Y-splitter cable shipped with the

NI PXI-8183, shown in Figure 4-1, to connect both a PS/2 mouse and PS/2

keyboard.

How do I get a replacement Y-splitter cable?

Chapter 4 Common Configuration Questions

Figure 4-1. Y-Splitter Cable

Y-splitter cables, part number 778713-01, are available through the online

catalog at

What if I don’t have a Y-splitter cable? Can I still use a mouse and

keyboard?

If you do not have a Y-splitter cable, plug a PS/2 keyboard into the

PS/2 combo connector. However, you cannot use a PS/2 mouse without

the Y-splitter, so use a serial or USB mouse.

How do I connect a standard 25-pin LPT cable to the NI PXI-8183?

The NI PXI-8183 uses a type C LPT connector. Most parallel port devices

use a type A connector. To use a device with a standard type A LPT

connector, you need to use a type C-to-type A LPT adapter. Parallel port

adapter cables, part number 777169-01, are available through the online

catalog at

© National Instruments Corporation 4-3 NI PXI-8183 User Manual

ni.com/products.

ni.com/products.

Page 46

Chapter 4 Common Configuration Questions

Operating System and Software Driver Installation

How do I install or reinstall the video driver?

Refer to the

How do I install or reinstall the Ethernet driver?

Refer to the

How do I install software from a CD?

The compact size of the NI PXI-8183 does not allow for an integrated

CD-ROM drive. If you are using Windows XP, you have the following

options:

• USB CD-ROM—Windows XP supports installing from a USB

CD-ROM using a bootable installation CD.

• SCSI, LPT, or PC Card-based CD-ROM—Other types of CD-ROM

drives are available. Check with the vendor to make sure Windows XP

supports the drive.

• Mapped network drive—You can use the Ethernet to connect to

another computer. If you share the CD-ROM drive on the other

computer, you can map the shared CD-ROM drive to a drive letter

on the NI PXI-8183.

Drivers.txt file on the hard drive or recovery CD-ROM.

Drivers.txt file on the hard drive or recovery CD-ROM.

NI PXI-8183 User Manual 4-4 ni.com

Page 47

Chassis Configuration

How do I set up the NI PXI-8183 to work with my chassis?

Configuration of the PXI system is handled through Measurement &

Automation Explorer (MAX), included with the software pre-installed on

your controller. MAX creates the

layout and parameters of your PXI system.

The configuration steps for single or multiple-chassis systems are the same.

Chapter 4 Common Configuration Questions

pxisys.ini file, which defines the

Figure 4-2. Multichassis Configuration in MAX

© National Instruments Corporation 4-5 NI PXI-8183 User Manual

Page 48

Chapter 4 Common Configuration Questions

Basic PXI System Configuration

1. Launch MAX.

2. In the Configuration tree, click the Devices and Interfaces branch to

expand it.

3. If the PXI system controller has not yet been configured, it is labeled

PXI System (Unidentified). Right-click this entry to display the

pop-up menu, then select the appropriate controller model from the

Identify As submenu.

4. Click the PXI System controller. The chassis (or multiple chassis, in a

multichassis configuration) is listed below it. Identify each chassis by

right-clicking its entry, then selecting the appropriate chassis model

through the Identify As submenu. Further expanding the PXI System

branch shows all devices in the system that can be recognized by

NI-VISA. When your controller and all your chassis are identified, the

required

The PXI specification allows many combinations of PXI chassis and

system modules. To assist system integrators, the manufacturers of

PXI chassis and system modules must document the capabilities of their

products. The minimum documentation requirements are contained in

.ini files, which consist of ASCII text. System integrators, configuration

utilities, and device drivers can use these

pxisys.ini file is complete.

.ini files.

The capability documentation for the chassis is contained in a

chassis.ini file provided by the chassis manufacturer. The information

in this file is combined with information about the system controller to

create a single system initialization file called

Initialization). The NI PXI-8183 uses MAX to generate the

file from the

chassis.ini file.

Device drivers and other utility software read the

pxisys.ini (PXI System

pxisys.ini

pxisys.ini file to

obtain system information. For detailed information regarding initialization

files, refer to the PXI specification at

NI PXI-8183 User Manual 4-6 ni.com

www.pxisa.org.

Page 49

Upgrade Information

How do I upgrade system memory?

You can change the amount of installed RAM on the NI PXI-8183 by

upgrading the SO-DIMM.

To upgrade the RAM, remove the NI PXI-8183 from the PXI chassis.

Remove the old SO-DIMM module and install the new SO-DIMM in the

socket as shown in Figure 4-3.

National Instruments offers the following types of SO-DIMMs for use with

the NI PXI-8183 controller.

• 256 MB, 32 MB × 64, 7.5 ns, 1.05 in. max

• 512 MB, 64 MB × 64, 7.5 ns, 1.05 in. max

Note National Instruments has tested and verified that the SO-DIMMs we sell work with

the NI PXI-8183. We recommend you purchase your SO-DIMM modules from National

Instruments. Other off-the-shelf SO-DIMM modules are not guaranteed to work properly.

Chapter 4 Common Configuration Questions

1

2

1 SO-DIMM Module 2 SO-DIMM Socket

Figure 4-3. Installing a SO-DIMM in an NI PXI-8183 Controller

© National Instruments Corporation 4-7 NI PXI-8183 User Manual

Page 50