Page 1

PC-OPDIO-16

User Manual

Optically Isolated Digital I/O Board for the PC

May 1995 Edition

Part Number 320937A-01

© Copyright 1995 National Instruments Corporation.

All Rights Reserved.

Page 2

National Instruments Corporate Headquarters

6504 Bridge Point Parkway

Austin, TX 78730-5039

(512) 794-0100

Technical support fax: (800) 328-2203

(512) 794-5678

Branch Offices:

Australia (03) 879 9422, Austria (0662) 435986, Belgium 02/757.00.20, Canada (Ontario) (519) 622-9310,

Canada (Québec) (514) 694-8521, Denmark 45 76 26 00, Finland (90) 527 2321, France (1) 48 14 24 24,

Germany 089/741 31 30, Hong Kong 02 2637 5019, Italy 02/48301892, Japan (03) 3788-1921, Korea 02 596-7456,

Mexico 05 202 2544, Netherlands 03480-33466, Norway 32-84 84 00, Singapore 2265886, Spain (1) 640 0085,

Sweden 08-730 49 70, Switzerland 056/20 51 51, Taiwan 62 377 1200, U.K. 1635 523545

Page 3

Limited Warranty

The PC-OPDIO-16 is warranted against defects in materials and workmanship for a period of one year from the date

of shipment, as evidenced by receipts or other documentation. National Instruments will, at its option, repair or

replace equipment that proves to be defective during the warranty period. This warranty includes parts and labor.

The media on which you receive National Instruments software are warranted not to fail to execute programming

instructions, due to defects in materials and workmanship, for a period of 90 days from date of shipment, as

evidenced by receipts or other documentation. National Instruments will, at its option, repair or replace software

media that do not execute programming instructions if National Instruments receives notice of such defects during

the warranty period. National Instruments does not warrant that the operation of the software shall be uninterrupted

or error free.

A Return Material Authorization (RMA) number must be obtained from the factory and clearly marked on the

outside of the package before any equipment will be accepted for warranty work. National Instruments will pay the

shipping costs of returning to the owner parts which are covered by warranty.

National Instruments believes that the information in this manual is accurate. The document has been carefully

reviewed for technical accuracy. In the event that technical or typographical errors exist, National Instruments

reserves the right to make changes to subsequent editions of this document without prior notice to holders of this

edition. The reader should consult National Instruments if errors are suspected. In no event shall National

Instruments be liable for any damages arising out of or related to this document or the information contained in it.

EXCEPT AS SPECIFIED HEREIN, NATIONAL INSTRUMENTS MAKES NO WARRANTIES, EXPRESS OR IMPLIED,

AND SPECIFICALLY DISCLAIMS ANY WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE

OF

NATIONAL INSTRUMENTS WILL NOT BE LIABLE FOR DAMAGES RESULTING FROM LOSS OF DATA, PROFITS,

USE OF PRODUCTS, OR INCIDENTAL OR CONSEQUENTIAL DAMAGES, EVEN IF ADVISED OF THE POSSIBILITY

THEREOF

whether in contract or tort, including negligence. Any action against National Instruments must be brought within

one year after the cause of action accrues. National Instruments shall not be liable for any delay in performance due

to causes beyond its reasonable control. The warranty provided herein does not cover damages, defects,

malfunctions, or service failures caused by owner’s failure to follow the National Instruments installation, operation,

or maintenance instructions; owner’s modification of the product; owner’s abuse, misuse, or negligent acts; and

power failure or surges, fire, flood, accident, actions of third parties, or other events outside reasonable control.

. CUSTOMER’S RIGHT TO RECOVER DAMAGES CAUSED BY FAULT OR NEGLIGENCE ON THE PART

NATIONAL INSTRUMENTS SHALL BE LIMITED TO THE AMOUNT THERETOFORE PAID BY THE CUSTOMER.

. This limitation of the liability of National Instruments will apply regardless of the form of action,

Copyright

Under the copyright laws, this publication may not be reproduced or transmitted in any form, electronic or

mechanical, including photocopying, recording, storing in an information retrieval system, or translating, in whole

or in part, without the prior written consent of National Instruments Corporation.

Trademarks

®

LabVIEW

Product and company names listed are trademarks or trade names of their respective companies.

,

NI-DAQ®, RTSI®, and DAQPad™ are trademarks of National Instruments Corporation.

Page 4

WARNING REGARDING MEDICAL AND CLINICAL USE

OF NATIONAL INSTRUMENTS PRODUCTS

National Instruments products are not designed with components and testing intended to ensure a level of reliability

suitable for use in treatment and diagnosis of humans. Applications of National Instruments products involving

medical or clinical treatment can create a potential for accidental injury caused by product failure, or by errors on

the part of the user or application designer. Any use or application of National Instruments products for or involving

medical or clinical treatment must be performed by properly trained and qualified medical personnel, and all

traditional medical safeguards, equipment, and procedures that are appropriate in the particular situation to prevent

serious injury or death should always continue to be used when National Instruments products are being used.

National Instruments products are NOT intended to be a substitute for any form of established process, procedure, or

equipment used to monitor or safeguard human health and safety in medical or clinical treatment.

Page 5

Contents

____________________________________________________

About This Manual.............................................................................................................ix

Organization of This Manual.........................................................................................ix

Conventions Used in This Manual................................................................................. x

National Instruments Documentation ........................................................................... xi

Related Documentation.................................................................................................. xi

Customer Communication............................................................................................. xi

Chapter 1

Introduction

About Your PC-OPDIO-16 Board.................................................................................1-1

What You Need to Get Started ......................................................................................1-1

Software Programming Choices....................................................................................1-2

Optional Equipment.......................................................................................................1-3

Cabling...........................................................................................................................1-4

Unpacking......................................................................................................................1-4

..........................................................................................................................1-1

LabVIEW and LabWindows/CVI Application Software..................................1-2

NI-DAQ Driver Software...................................................................................1-2

Register-Level Programming.............................................................................1-3

Chapter 2

Installation and Configuration

Hardware Installation.....................................................................................................2-1

Hardware Configuration ................................................................................................2-2

Bus-Related Configuration ................................................................................2-2

Plug and Play Mode...............................................................................2-2

Switchless Mode....................................................................................2-2

Base I/O Address Selection....................................................................2-2

Data Acquisition-Related Configuration ...........................................................2-3

NI-DAQ Software Installation.......................................................................................2-3

NI-DAQ Installation for DOS............................................................................2-3

NI-DAQ Installation for LabVIEW...................................................................2-3

NI-DAQ Installation for LabWindows/CVI......................................................2-4

NI-DAQ Installation for Windows ....................................................................2-5

Software Configuration..................................................................................................2-5

Configuring Your PC-OPDIO-16......................................................................2-5

Using DAQCONF..............................................................................................2-6

NI-DAQ Configuration File...................................................................2-6

Device Configuration in DAQCONF ....................................................2-7

DAQCONF Command-Line Flags........................................................2-8

Using WDAQCONF..........................................................................................2-8

.......................................................................................2-1

© National Instruments Corporation v PC-OPDIO-16 User Manual

Page 6

Contents

Chapter 3

Signal Connections

I/O Connectors...............................................................................................................3-2

Signal Connection Descriptions.........................................................................3-3

Optically Isolated Digital Output ..................................................................................3-4

Output Channels.................................................................................................3-4

Optically Isolated Digital Input......................................................................................3-6

Input Channels...................................................................................................3-6

Sensing DC Voltages.........................................................................................3-7

Sensing AC Voltages.........................................................................................3-7

Signal Isolation ..................................................................................................3-7

Signal Connection Example...............................................................................3-7

Reducing the Forward Current for 24 V Inputs.................................................3-8

Power-on Condition...........................................................................................3-8

.............................................................................................................3-1

Signal Isolation ......................................................................................3-4

Signal Connection Example...................................................................3-5

Increasing Switching Frequency for TTL Loads...................................3-6

Power-on Condition...............................................................................3-6

Chapter 4

Fundamentals of Building Applications with NI-DAQ

Building DOS Applications with NI-DAQ....................................................................4-1

Creating a DOS Application Using Microsoft C...............................................4-1

Example Programs.................................................................................4-2

Creating a DOS Application Using Visual Basic..............................................4-2

Running Your Application Inside the Visual Basic Environment.........4-4

Compiling and Running Your Visual Basic Application from the

DOS Prompt...........................................................................................4-4

Example Programs.................................................................................4-5

Creating a DOS Application Using Borland Turbo C++ or Borland C++ ........4-5

Example Programs.................................................................................4-6

Creating a DOS Application Using Borland Turbo Pascal................................4-6

Memory Requirement............................................................................4-7

Example Programs.................................................................................4-7

Building Windows Applications with NI-DAQ.............................................................4-7

The NI-DAQ Libraries.......................................................................................4-8

NI-DAQ Programming Considerations .............................................................4-8

Buffer Allocation...............................................................................................4-8

Huge (Greater Than 64 KB) Buffer Access...........................................4-9

String Passing.........................................................................................4-9

Parameter Passing..................................................................................4-9

Creating a Windows Application Using Borland C++......................................4-9

Example Programs.................................................................................4-10

Special Considerations...........................................................................4-10

Creating a Windows Application Using Microsoft Visual C++........................4-11

Special Considerations...........................................................................4-11

Creating a Windows Application Using Turbo Pascal......................................4-11

Example Programs.................................................................................4-12

Special Considerations...........................................................................4-12

PC-OPDIO-16 User Manual vi © National Instruments Corporation

Page 7

Creating a Windows Application Using Microsoft Visual Basic......................4-14

Example Programs.................................................................................4-14

Special Considerations...........................................................................4-14

Chapter 5

Theory of Operation

Functional Overview......................................................................................................5-1

Theory of Operation.......................................................................................................5-2

I/O Channel Interface Circuitry.........................................................................5-2

Digital I/O Circuitry...........................................................................................5-2

Optical Isolation Circuitry .................................................................................5-3

Using NI-DAQ Functions for Isolated Digital I/O............................................5-4

Using LabVIEW Data Acquisition Library for Digital I/O...............................5-5

Easy I/O VIs...........................................................................................5-5

Advanced VIs.........................................................................................5-5

Chapter 6

NI-DAQ Function Reference

Using NI-DAQ Functions..............................................................................................6-1

Status Codes.......................................................................................................6-1

Variable Data Types...........................................................................................6-1

Primary Types........................................................................................6-2

Programming Language Considerations............................................................6-2

Visual BASIC for DOS..........................................................................6-3

Borland Turbo Pascal.............................................................................6-3

Visual BASIC for Windows ..................................................................6-3

NI-DAQ for LabWindows/CVI.........................................................................6-4

Device Numbers.................................................................................................6-5

Function Descriptions....................................................................................................6-5

DIG_In_Line......................................................................................................6-5

DIG_In_Port.......................................................................................................6-6

DIG_Out_Line...................................................................................................6-7

DIG_Out_Port....................................................................................................6-8

Get_DAQ_Device_Info.....................................................................................6-9

Get_NI_DAQ_Version......................................................................................6-10

Init_DA_Brds.....................................................................................................6-11

Contents

Appendix A

Specifications

........................................................................................................................A-1

Appendix B

CP Clare LDA210 Data Sheet

........................................................................................B-1

Appendix C

Register-Level Programming

.........................................................................................C-1

Appendix D

Status Codes

© National Instruments Corporation vii PC-OPDIO-16 User Manual

..........................................................................................................................D-1

Page 8

Contents

Appendix E

Customer Communication

...............................................................................................E-1

Glossary......................................................................................................................Glossary-1

Index ................................................................................................................................. Index-1

Figures

Figure 1-1. The Relationship between the Programming Environment, NI-DAQ, and

Your Hardware......................................................................................................1-3

Figure 3-1. PC-OPDIO-16 I/O Connector Pin Assignments....................................................3-2

Figure 3-2. Signal Connection Example for Isolated Output....................................................3-5

Figure 3-3. Resistor in Parallel to Increase the Switching Frequency......................................3-6

Figure 3-4. Signal Connection Example for Isolated Input......................................................3-8

Figure 3-5. Reducing Input Current for 24 V Signals...............................................................3-8

Figure 5-1. PC-OPDIO-16 Block Diagram...............................................................................5-1

Figure 5-2. PC I/O Interface Circuitry Block Diagram of PC-OPDIO-16...............................5-2

Figure 5-3. Optical Isolation Circuitry for Input.......................................................................5-3

Figure 5-4. Optical Isolation Circuitry for Output....................................................................5-3

Tables

Table 6-1. Status Values...........................................................................................................6-1

Table 6-2. Primary Type Names...............................................................................................6-2

Table 6-3. LabWindows/CVI Function Tree for Data Acquisition

Using the PC-OPDIO-16 .........................................................................................6-4

PC-OPDIO-16 User Manual viii © National Instruments Corporation

Page 9

About This Manual

____________________________________________________

This manual describes the electrical and mechanical aspects of the PC-OPDIO-16 and contains

information concerning its installation, operation, and programming. The PC-OPDIO-16 is fully

compatible with industry standard Intel-Microsoft Plug and Play specification Version 1.0a.

The PC-OPDIO-16 is an optically isolated digital I/O board for PC/XT/AT and IBM Personal

System 2 (PS/2) models 25 and 30 computers. This board is designed for low-cost data

acquisition and control for applications in laboratory testing, production testing, and industrial

process monitoring and control.

Organization of This Manual

The PC-OPDIO-16 User Manual is organized as follows:

• Chapter 1, Introduction, describes the PC-OPDIO-16; lists what you need to get started;

describes the optional software and optional equipment; and explains how to unpack your

PC-OPDIO-16.

• Chapter 2, Installation and Configuration, contains instructions for installing the

PC-OPDIO-16, installing the NI-DAQ software, configuring your PC-OPDIO-16 board, and

cabling.

• Chapter 3, Signal Connections, describes the pin arrangement, signal names, and signal

connections on the PC-OPDIO-16.

• Chapter 4, Fundamentals of Building Applications with NI-DAQ, contains general

information about building NI-DAQ applications that run in DOS and Windows and explains

the nature of the files needed and the basics of making applications. You can skip this

chapter if you are an experienced NI-DAQ user.

• Chapter 5, Theory of Operation, describes the theory of operation for optically isolated

digital I/O on the PC-OPDIO-16. This chapter also discusses using NI-DAQ functions with

the PC-OPDIO-16 board.

• Chapter 6, NI-DAQ Function Reference, contains important information about how to apply

the NI-DAQ function descriptions in this manual to your programming language and

environment. This chapter also includes a detailed description of each NI-DAQ function that

supports the PC-OPDIO-16. You can skip this chapter if you are an experienced NI-DAQ

user.

• Appendix A, Specifications, lists the specifications of the PC-OPDIO-16.

• Appendix B, LDA210 Data Sheet, contains a manufacturer data sheet for the LDA210 solid

state current sensor (CP Clare Corporation). This sensor is used on the PC-OPDIO-16

isolated input port.

• Appendix C, Register-Level Programming, describes in detail the address and function of

each PC-OPDIO-16 register.

© National Instruments Corporation ix PC-OPDIO-16 User Manual

Page 10

About This Manual

• Appendix D, Status Codes, lists the status codes returned by NI-DAQ, including the name

and description.

• Appendix E, Customer Communication, contains forms you can use to request help from

National Instruments or to comment on our products.

• The Glossary contains an alphabetical list and description of terms used in this manual,

including abbreviations, acronyms, metric prefixes, mnemonics, and symbols.

• The Index alphabetically lists the topics in this manual, including the page where you can

find the topic.

Conventions Used in This Manual

The following conventions are used in this manual:

bold Bold text denotes menus, menu items, or dialog box buttons or options.

bold italic Bold italic text denotes a note, caution, or warning.

italic Italic text denotes emphasis on a specific board or on other important

information, a cross reference, or an introduction to a key concept.

monospace Text in this font denotes text or characters that are to be literally input

from the keyboard, sections of code, programming examples, and syntax

examples. This font is also used for the proper names of disk drives,

paths, directories, programs, subprograms, subroutines, device names,

functions, variables, filenames, and extensions, and for statements and

comments taken from program code.

NI-DAQ NI-DAQ refers to the NI-DAQ software for PC compatibles unless

otherwise noted.

PC PC refers to PC/XT/AT and IBM PS/2 models 25 and 30 computers.

Port A Port A refers to port A or port 0 (as in the NI-DAQ software portions of

this manual).

Port B Port B refers to port B or port 1 (as in the NI-DAQ software portions of

this manual).

< > Angle brackets containing numbers separated by an ellipsis represent a

range of values associated with a bit, port, or signal name (for example,

ACH<0..7> stands for ACH0 through ACH7).

Abbreviations, acronyms, metric prefixes, mnemonics, symbols, and terms are listed in the

Glossary.

PC-OPDIO-16 User Manual x © National Instruments Corporation

Page 11

About This Manual

National Instruments Documentation

The PC-OPDIO-16 User Manual is one piece of the documentation set for your data acquisition

system. You could have any of several types of manuals depending on the hardware and

software in your system. Use the manuals you have as follows:

• Your DAQ hardware user manuals—These manuals have detailed information about the

DAQ hardware that plugs into or is connected to your computer. Use these manuals for

hardware installation and configuration instructions, specification information about your

DAQ hardware, and application hints.

• Software manuals—Examples of software manuals you may have are the LabVIEW and

LabWindows

application software (LabVIEW or LabWindows/CVI) manuals or the NI-DAQ chapters in

this manual to help you write your application. If you have a large and complicated system,

it is worthwhile to look through the software manuals before you configure your hardware.

• Accessory manuals—If you are using accessory products, read the terminal block and cable

assembly installation guides. They explain how to physically connect the relevant pieces of

the system. Consult these guides when you are making your connections.

®

/CVI manual sets. After you set up your hardware system, use either the

Related Documentation

The following documents contain information that you may find helpful as you read this manual:

• IBM Personal Computer AT Technical Reference manual

• IBM Personal Computer XT Technical Reference manual

Customer Communication

National Instruments wants to receive your comments on our products and manuals. We are

interested in the applications you develop with our products, and we want to help if you have

problems with them. To make it easy for you to contact us, this manual contains comment and

configuration forms for you to complete. These forms are in Appendix E, Customer

Communication, at the end of this manual.

© National Instruments Corporation xi PC-OPDIO-16 User Manual

Page 12

Chapter 1 Introduction

This chapter describes the PC-OPDIO-16; lists what you need to get started; describes the

optional software and optional equipment; and explains how to unpack your PC-OPDIO-16.

About Your PC-OPDIO-16 Board

Thank you for purchasing the PC-OPDIO-16, which is an optically isolated digital I/O board for

PC/XT/AT and IBM Personal System 2 (PS/2) models 25 and 30 computers. Each board has

eight optically isolated digital inputs and eight optically isolated digital outputs. You can control

and sense digital levels up to 24 VDC. You can install the PC-OPDIO-16 in any 8-bit or 16-bit

expansion slot on a PC.

The low cost of a system based on the PC-OPDIO-16 makes it ideal for laboratory work in

industrial and academic environments. You can use the optically isolated digital I/O lines to

switch external devices, such as transistors and solid-state relays, and to read the status of

external digital logic. Because the PC-OPDIO-16 is optically isolated, you can decouple the

noise and harsh ground of the PC from the real-world signals and vice versa.

Your PC-OPDIO-16 board, used in conjunction with the PC, is a versatile, cost-effective

platform for laboratory test, measurement, and control.

Detailed specifications of the PC-OPDIO-16 are in Appendix A, Specifications.

What You Need to Get Started

To set up and use your PC-OPDIO-16, you will need the following:

PC-OPDIO-16 board

PC-OPDIO-16 User Manual

One of the following software packages and documentation:

LabVIEW

LabWindows/CVI

NI-DAQ software for PC compatibles, version 4.8 or later

CB-50 LP (low cost) or CB-50 I/O connector block with 0.5 or 1.0 m NB1 connector cable

Your computer

© National Instruments Corporation 1-1 PC-OPDIO-16 User Manual

Page 13

Introduction Chapter 1

Software Programming Choices

There are several options to choose from when programming your National Instruments DAQ

and SCXI hardware. You can use LabVIEW, LabWindows/CVI, or NI-DAQ.

LabVIEW and LabWindows/CVI Application Software

LabVIEW and LabWindows/CVI are innovative program development software packages for

data acquisition and control applications. LabVIEW uses graphical programming, whereas

LabWindows/CVI enhances traditional programming languages. Both packages include

extensive libraries for data acquisition, instrument control, data analysis, and graphical data

presentation.

LabVIEW features interactive graphics, a state-of-the-art user interface, and a powerful graphical

programming language. The LabVIEW Data Acquisition VI Library, a series of VIs for using

LabVIEW with National Instruments DAQ hardware, is included with LabVIEW. The

LabVIEW Data Acquisition VI Libraries are functionally equivalent to the NI-DAQ software.

LabWindows/CVI features interactive graphics, a state-of-the-art user interface, and uses the

ANSI standard C programming language. The LabWindows/CVI Data Acquisition Library, a

series of functions for using LabWindows/CVI with National Instruments DAQ hardware, is

included with the NI-DAQ software kit. The LabWindows/CVI Data Acquisition libraries are

functionally equivalent to the NI-DAQ software.

Using LabVIEW or LabWindows/CVI software will greatly reduce the development time for

your data acquisition and control application.

NI-DAQ Driver Software

The NI-DAQ driver software is included at no charge with all National Instruments DAQ

hardware. NI-DAQ is not packaged with SCXI or accessory products, except for the SCXI-1200.

NI-DAQ has an extensive library of functions that you can call from your application

programming environment. These functions include routines for analog input (A/D conversion),

buffered data acquisition (high-speed A/D conversion), analog output (D/A conversion),

waveform generation, digital I/O, counter/timer operations, SCXI, RTSI, self-calibration,

messaging, and acquiring data to extended memory.

NI-DAQ has both high-level DAQ I/O functions for maximum ease of use and low-level DAQ

I/O functions for maximum flexibility and performance. Examples of high-level functions are

streaming data to disk or acquiring a certain number of data points. An example of a low-level

function is writing directly to registers on the DAQ device. NI-DAQ does not sacrifice the

performance of National Instruments DAQ devices because it lets multiple devices operate at

their peak performance.

NI-DAQ also internally addresses many of the complex issues between the computer and the

DAQ hardware such as programming interrupts and DMA controllers. NI-DAQ maintains a

consistent software interface among its different versions so that you can change platforms with

PC-OPDIO-16 User Manual 1-2 © National Instruments Corporation

Page 14

Chapter 1 Introduction

minimal modifications to your code. Figure 1-1 illustrates the relationship between NI-DAQ and

LabVIEW and LabWindows/CVI. You can see that the data acquisition parts of LabVIEW and

LabWindows/CVI are functionally equivalent to the NI-DAQ software.

Conventional

Programming

Environment

(PC, Macintosh, or

Sun SPARCstation)

DAQ or

SCXI Hardware

LabVIEW

(PC, Macintosh, or

Sun SPARCstation)

NI-DAQ

Driver Software

LabWindows/CVI

(PC or Sun

SPARCstation)

Personal

Computer or

Workstation

Figure 1-1. The Relationship between the Programming Environment,

NI-DAQ, and Your Hardware

Register-Level Programming

The final option for programming any National Instruments DAQ hardware is to write registerlevel software. Writing register-level programming software can be very time-consuming and

inefficient and is not recommended for most users.

Even if you are an experienced register-level programmer, consider using NI-DAQ, LabVIEW,

or LabWindows/CVI to program your National Instruments DAQ hardware. Using the NI-DAQ,

LabVIEW, or LabWindows/CVI software is as easy and as flexible as register-level

programming and can save weeks of development time.

Optional Equipment

You can use the following National Instruments product with your PC-OPDIO-16.

• CB-50 LP (low cost) or CB-50 I/O connector block with 0.5 or 1.0 m NB1 connector cable

For more information about optional equipment available from National Instruments, refer to

your National Instruments catalog or call the office nearest you.

© National Instruments Corporation 1-3 PC-OPDIO-16 User Manual

Page 15

Introduction Chapter 1

Cabling

National Instruments offers two cable termination accessory kits, the CB-50 and CB-50 LP, for

use with the PC-OPDIO-16. These kits include a terminated, 50-conductor, flat ribbon cable and

a connector block. You can attach signal input and output wires to screw terminals on the

connector blocks and connect to your PC-OPDIO-16 board I/O connector.

You can use the CB-50 or the CB-50 LP for initial prototyping of an application or in situations

where you frequently change your PC-OPDIO-16 board interconnections. When you develop a

final field wiring scheme, however, you may want to develop your own cable. This section

contains information and guidelines for designing custom cables.

The PC-OPDIO-16 I/O connector is a 50-pin male ribbon cable header. The manufacturer part

numbers of the headers National Instruments uses are as follows:

• Electronic Products Division/3M (part number 3596-5002)

• T&B/Ansley Corporation (part number 609-500)

The mating connector for the PC-OPDIO-16 is a 50-position, polarized, ribbon socket connector

with strain relief. National Instruments uses a polarized (keyed) connector to prevent inadvertent

upside-down connection to the PC-OPDIO-16. Recommended manufacturer part numbers for

this mating connector are as follows:

• Electronic Products Division/3M (part number 3425-7650)

• T&B/Ansley Corporation (part number 609-5041CE)

The following are the standard ribbon cables (50-conductor, 28 AWG, stranded) that can be used

with these connectors:

• Electronic Products Division/3M (part number 3365/50)

• T&B/Ansley Corporation (part number 171-50)

Unpacking

Your PC-OPDIO-16 board is shipped in an antistatic envelope to prevent electrostatic damage.

Several components on the board can be damaged by electrostatic discharge. To avoid damage

in handling the board, take the following precautions:

• Ground yourself via a grounding strap or by holding a grounded object.

• Touch the package to a metal part of your computer chassis before removing the board from

the package.

• Never attempt to touch the pins of the connectors.

• Remove the board from the package and inspect the board for loose components or any other

sign of damage. Notify National Instruments if the board appears damaged in any way. Do

not install a damaged board into your computer.

•Store your PC-OPDIO-16 board in the antistatic envelope when not in use.

PC-OPDIO-16 User Manual 1-4 © National Instruments Corporation

Page 16

Chapter 2 Installation and Configuration

This chapter contains instructions for installing the PC-OPDIO-16, installing the NI-DAQ

software, configuring your PC-OPDIO-16 board, and cabling.

Hardware Installation

You can install the PC-OPDIO-16 in any available 8-bit or 16-bit expansion slot in your

computer. The following are general installation instructions, but consult your PC user manual

or technical reference manual for specific instructions and warnings.

1. Turn off your computer.

2. Remove the top cover or access port to the I/O channel.

3. Remove the expansion slot cover on the back panel of the computer.

4. Record the PC-OPDIO-16 serial and revision numbers on the Hardware and Software

Configuration form in Appendix E, Customer Communication. You will need these numbers

when you install and configure your board.

5. Insert the PC-OPDIO-16 into an 8-bit or a 16-bit slot.

6. Screw the mounting bracket of the PC-OPDIO-16 to the back panel rail of the computer.

7. Check the installation.

8. Replace the cover.

The PC-OPDIO-16 board is installed. Follow the instructions in the NI-DAQ Software

Installation section to install NI-DAQ in your computer. If NI-DAQ is already installed, skip

that section and continue with the Software Configuration section later in this chapter.

If you are using LabVIEW, the software installation instructions are in your LabVIEW release

notes.

If you are using LabWindows/CVI, the software installation instructions are in Part 1,

Introduction to LabWindows/CVI, of the Getting Started with LabWindows/CVI manual.

© National Instruments Corporation 2-1 PC-OPDIO-16 User Manual

Page 17

Installation and Configuration Chapter 2

Hardware Configuration

The PC-OPDIO-16 is completely software configurable. Typically, two types of configuration

are performed on a DAQ board—bus related and data acquisition related. To configure the

PC-OPDIO-16 bus, you only have to set the base address.

Bus-Related Configuration

The PC-OPDIO-16 works in either a Plug and Play mode or a switchless mode. These modes

dictate how the base I/O address is determined and assigned to the board.

Plug and Play Mode

The PC-OPDIO-16 is fully compatible with the industry-standard Intel/Microsoft Plug and Play

Specification version 1.0. A Plug and Play system arbitrates and assigns resources through

software, freeing you from manually setting switches and jumpers. These resources include the

board base I/O address. The PC-OPDIO-16 is configured at the factory to request these

resources from the Plug and Play Configuration Manager.

The Configuration Manager receives all of the resource requests at start up, compares the

available resources to those requested, and assigns the available resources as efficiently as

possible to the Plug and Play boards. Application software can query the Configuration Manager

to determine the resources assigned to each board without your involvement. The Plug and Play

software is installed as a device driver or as an integral component of the computer BIOS.

Switchless Mode

You can use the PC-OPDIO-16 in a non-Plug and Play system as a switchless data acquisition

(DAQ) board. A non-Plug and Play system is a system in which the Configuration Manager has

not been installed and which does not contain any non-National Instruments Plug and Play

products. You use a configuration utility to enter the base address, and the application software

assigns it to the board.

Note: Avoid resource conflicts with non-National Instruments boards. For example, do not

configure two boards for the same base address.

Base I/O Address Selection

You can configure the PC-OPDIO-16 to use base addresses in the range of 100 to 3E0 hex. The

PC-OPDIO-16 occupies 8 bytes of address space and must be located on an 8-byte boundary.

Valid addresses include 100, 108, 110, ..., 3D8, 3E0 hex. This selection is software configured

and does not require you to manually change any settings on the board.

PC-OPDIO-16 User Manual 2-2 © National Instruments Corporation

Page 18

Chapter 2 Installation and Configuration

Data Acquisition-Related Configuration

The PC-OPDIO-16 supplies eight channels of optically isolated digital input and eight channels

of optically isolated digital output at the I/O connector.

NI-DAQ Software Installation

This following sections describe the installation of NI-DAQ on different platforms, including

DOS, LabVIEW, LabWindows/CVI, and Windows. Refer to the appropriate section and follow

the instructions to install the NI-DAQ software.

NI-DAQ Installation for DOS

The NI-DAQ distribution diskettes contain the installation utility SETUPDOS.EXE. Running

this installation utility copies the appropriate files to your computer. For example, if your

installation diskette is in drive A, type the following:

a:\setupdos

After installing NI-DAQ, continue by reading the Software Configuration section later in this

chapter to configure your PC-OPDIO-16.

NI-DAQ Installation for LabVIEW

The LabVIEW installation program may have installed the NI-DAQ software for you. However,

the NI-DAQ software that is included with your DAQ hardware may be a more recent revision

than the NI-DAQ software that LabVIEW installed.

After you have installed LabVIEW, you should run the NI-DAQ Windows installer

SETUPWIN.EXE, which will check the NI-DAQ version that LabVIEW installed against this

NI-DAQ version to ensure that the newest version is installed.

Note: You need NI-DAQ Version 4.8 or later to use your PC-OPDIO-16. Since LabVIEW

Version 3.1 installs NI-DAQ Version 4.6.1, you will need to install the NI-DAQ

software included with your PC-OPDIO-16 board if you are using LabVIEW Version

3.1 or earlier.

To upgrade NI-DAQ for LabVIEW, run the SETUPWIN program on Disk 1. One way to do this

is to select the File menu from the Program Manager Window, then select Run... and type in

a:\setupwin, assuming a: is the floppy disk drive containing Disk 1. When prompted, select

the Upgrade NI-DAQ for LabVIEW option.

Depending on your LabVIEW version, it may be necessary for NI-DAQ to update some of the

LabVIEW data acquisition VIs. If so, carefully follow the instructions given in the NI-DAQ

installer and the README.DAQ file.

© National Instruments Corporation 2-3 PC-OPDIO-16 User Manual

Page 19

Installation and Configuration Chapter 2

LabVIEW users are encouraged to use the Easy I/O VIs in LabVIEW. These VIs allow full

access to the PC-OPDIO-16 board functionality. For specific information on the VIs and on how

to write LabVIEW data acquisition applications, refer to your LabVIEW for Windows Data

Acquisition VI Reference Manual. The PC-OPDIO-16 boards may not be specifically mentioned

in your version of the LabVIEW manuals.

The following LabVIEW VIs are supported for the PC-OPDIO-16.

• Easy I/O VIs

– Read from Digital Line

– Read from Digital Port

– Write to Digital Line

– Write to Digital Port

• Configuration VIs

– Device Reset

– Get Device Information

– Set Device Information

• Advanced Digital I/O VIs

– DIO Port Read

– DIO Port Write

– DIO Single Read/Write

Follow instructions in the Software Configuration section later in this chapter to configure your

PC-OPDIO-16.

NI-DAQ Installation for LabWindows/CVI

To install NI-DAQ for LabWindows/CVI, run the SETUPWIN program on Disk 1. One way to

do this is to select the File menu from the Program Manager Window, then select Run... and

type in a:\setupwin, assuming a: is the floppy disk drive containing Disk 1. When

prompted, select the Install NI-DAQ for LabWindows/CVI option.

The NI-DAQ example programs for LabWindows/CVI are installed in the CVI\SAMPLES\DAQ

directory.

For LabWindows/CVI, the defined constants that several NI-DAQ functions use are in the

include file DATAACQ.H.

After installing NI-DAQ, continue by reading the Software Configuration section later in this

chapter to configure your PC-OPDIO-16.

PC-OPDIO-16 User Manual 2-4 © National Instruments Corporation

Page 20

Chapter 2 Installation and Configuration

NI-DAQ Installation for Windows

To install NI-DAQ for Windows, run the SETUPWIN program on Disk 1. One way to do this is

to select the File menu from the Program Manager Window, then select Run... and type in

a:\setupwin, assuming a: is the floppy disk drive containing Disk 1. When prompted, select

the Install/Upgrade NI-DAQ for Windows option.

Setupwin will install examples programs and support files for a variety of languages and

compilers. Choose all of the languages/compilers you plan to use. The NI-DAQ installer

examines your computer system to determine the system-dependent files that you need.

After installing NI-DAQ, continue by reading the Software Configuration section to configure

your PC-OPDIO-16.

Software Configuration

Before you begin your NI-DAQ application development, you must configure your

PC-OPDIO-16. NI-DAQ needs the device configuration information to program your hardware

properly.

You can configure your PC-OPDIO-16 board using DAQCONF or WDAQCONF. DAQCONF and

WDAQCONF are applications that you can use to view and configure your DAQ boards and SCXI

hardware for NI-DAQ to use. DAQCONF is a DOS-based application while WDAQCONF is

Windows-based. If you are using NI-DAQ in DOS, you need to run DAQCONF. If you are using

NI-DAQ in Windows or LabWindows/CVI, you should run WDAQCONF. Refer to the

appropriate section that follows according to the system you are using.

Configuring Your PC-OPDIO-16

The National Instruments switchless devices support switchless and jumperless configuration in

DOS and Windows. All resources including base address on these devices are fully software

configurable. No jumpers or DIP switches are needed to configure any of these resources.

The NI-DAQ installer will install a standalone executable called NI-PNP.EXE in the boot

directory of your root drive. This program detects and configures any switchless devices you

have in your computer. The program will run every time you boot from your autoexec.bat

file. After configuring your switchless hardware in the system, the program will generate an

NI-PNP.INI file in the same directory. This file contains information about the National

Instruments devices in your system, including switchless devices.

The DAQ configuration utility (WDAQCONF or DAQCONF) will read the NI-PNP.INI for

information and will automatically configure any switchless devices you have in your computer.

The utility will also deconfigure any previously configured switchless device that you have

removed from your computer. Running the configuration utility after installing a new switchless

device is important because you will be able to obtain a mapping for the newly installed device

into an NI-DAQ device number.

© National Instruments Corporation 2-5 PC-OPDIO-16 User Manual

Page 21

Installation and Configuration Chapter 2

When the configuration utility finds a new switchless device in your computer, it assigns the first

available device number to the new device. The utility also assigns default resources such as I/O

address. When you remove the device from your computer, the utility deallocates these resources

and the device number will contain an “empty device.”

Note: You must run the DAQ configuration utility after you install or remove any National

Instruments switchless devices such as the PC-OPDIO-16.

If you have plug and play software in your system, the behavior of the DAQ configuration utility

may change significantly. If the plug and play software in your system has its own separate

configuration utility, you must use the system configuration utility to configure all National

Instruments devices in your system. Subsequently, you must run the DAQ configuration utility

in order to assign NI-DAQ device numbers to any new devices. If you do not run the DAQ

configuration utility in this case, you will be unable to assign the base address for your

PC-OPDIO-16. The configuration utility that comes with your plug and play software is

responsible for assigning system resources to your National Instruments device. You will not be

able to change the I/O base address using WDAQCONF if you are using other Plug and Play

software to configure your PC-OPDIO-16.

Examples of plug and play software are a Plug and Play BIOS or the Intel Plug and Play Kit,

which includes the Intel Configuration Manager with its own configuration utility.

WDAQCONF performs a full set of tests before saving the device configuration to ensure the

device will operate correctly. If the device fails any of the tests, WDAQCONF reports the errors

and does not save the configuration.

DAQCONF does not perfom any such tests. The only way to find out if the configuration is

100 percent successful in DOS is to run a few NI-DAQ calls on the device.

Using DAQCONF

DAQCONF is a DOS-based application that you can use to view and configure your DAQ devices

for NI-DAQ to use. You need to run DAQCONF if you are using NI-DAQ in DOS. If you are

using NI-DAQ in Windows or LabWindows/CVI, you should skip to the Using WDAQCONF

section later in this chapter.

Locate DAQCONF in the same directory you installed NI-DAQ using the installation program.

Run the configuration utility by typing DAQCONF at the DOS prompt.

NI-DAQ Configuration File

The NI-DAQ configuration file holds all configuration information for your DAQ hardware.

The NI-DAQ configuration file in DOS is named ATBRDS.CFG. The first time you run

DAQCONF, it will create ATBRDS.CFG in your root directory. If you wish to create the

configuration file in a different directory, provide a path name when you run DAQCONF as in the

following example:

DAQCONF\PROJ_X

PC-OPDIO-16 User Manual 2-6 © National Instruments Corporation

Page 22

Chapter 2 Installation and Configuration

With this option, you can create multiple configuration files for different NI-DAQ applications

or projects; simply use the appropriate path name when you want to create a new configuration

file or view an existing one. Be sure to enter only the path name; the file will automatically be

created as ATBRDS.CFG in the specified directory.

When you run an NI-DAQ DOS application, NI-DAQ will look for the configuration file in the

current directory first. If NI-DAQ cannot find ATBRDS.CFG, it will look in the root directory of

the current drive. NI-DAQ will also read the device configuration that was stored in the EISA

system configuration utility.

DAQCONF takes a long time to start up. If you are not planning to use switchless devices with

NI-DAQ, you can start DAQCONF with the -x command-line option. This will disable autodetection of switchless devices in your computer.

Device Configuration in DAQCONF

DAQCONF opens with the board configuration panel. Perform the following steps to configure

your board.

1. Select a Device Number for your device. Use the F5 and F6 keys to scroll through the

choices. If the device number selected has a device assigned to it, you will see the current

settings for that device. To add a device, select a number without any device assigned to it.

You will use the device number in your NI-DAQ function calls to identify which device you

want to use.

2. Use the down arrow key to highlight the Device selection. Use the F5 and F6 keys to find

the correct device type.

3. You need to select the correct I/O base address. Use the up/down arrow keys to highlight the

fields, and then use the F5 and F6 keys to select the settings you wish to use.

4. You must save the configuration for this device before advancing to the next device number.

Press F10 to save. DAQCONF will test the configuration parameters before saving. If the test

fails, DAQCONF will not save the settings. You can disable the automatic test feature by

using the -t option on the command line when you invoke DAQCONF as in the following

example:

DAQCONF -t

© National Instruments Corporation 2-7 PC-OPDIO-16 User Manual

Page 23

Installation and Configuration Chapter 2

DAQCONF Command-Line Flags

You can use the following command-line flags with DAQCONF:

Command-Line Flag Description

-t Disable auto tests

-i Assume ISA bus computer

-e Assume EISA bus computer

-a Auto test for bus type

-u Usage

-x Disable auto-detection of switchless devices

-le Display in English (default)

-lj Display in Japanese (you must have a Japanese operating system)

You should enter multiple flags separately. For example:

daqconf -t -i

Using WDAQCONF

WDAQCONF is a Windows-based application that you can use to configure and view National

Instruments DAQ device settings for NI-DAQ Windows and LabWindows/CVI.

Locate WDAQCONF in the NI-DAQ Program Group in Windows. Run WDAQCONF by doubleclicking on its icon. If other NI-DAQ applications are running when you launch WDAQCONF,

you can only view your configuration.

When WDAQCONF starts, it tries to retrieve the current configuration from the WDAQCONF.CFG

file in the Windows directory. If WDAQCONF does not locate the file, WDAQCONF will create a

file.

When WDAQCONF starts, it also runs NI-PnP to find any Plug and Play boards in the system.

After WDAQCONF retrieves the current configuration, it displays all the devices installed in a

scrollable window. On the right of the window, you will see the current setting of the

highlighted device.

Perform the following steps to view and test your board. Press the F1 key any time to access the

online help.

1. Select a device number for your PC-OPDIO-16 by highlighting it in the scrollable window.

On the right side of the WDAQCONF window, you can see the current setting of the

PC-OPDIO-16. The device number you selected is the number you use to refer to the

PC-OPDIO-16 in your NI-DAQ applications.

2. Click on the Configure/Test Device #n button to bring out the configuration/test window.

PC-OPDIO-16 User Manual 2-8 © National Instruments Corporation

Page 24

Chapter 2 Installation and Configuration

3. Select the Device menu item to select your device type. Device type is the name of your

device. After you select the device type, you can see the default settings for your device.

4. Modify the base address if the default setting is not acceptable.

By default, WDAQCONF does not allow you to configure the same resource to different

devices. To disable this feature, go to the WDAQCONF main window and uncheck Resource

Checks under the Options menu item.

You cannot change the Resource Checks option if you are currently changing the

configuration of any devices. Make sure all your Device #n windows are closed before you

try to select this option.

5. To save your device setting, go to the File Configuration menu item in the configuration

window and select save. Before WDAQCONF saves your configuration, WDAQCONF runs

through a resource detection test for your configuration. It makes sure you have selected the

correct settings. WDAQCONF will not save the configuration if the test fails. You can disable

the feature by unchecking the Auto Test option under the Options menu item in the main

window.

When you save your device setting, WDAQCONF runs NI-PnP to check the Plug and Play

cards.

6. After saving your configuration, you can run simple tests on your PC-OPDIO-16. Under the

Test menu item in your configuration window, you can see all the tests you can perform.

• Configuration initiates the same test Auto Test uses.

• Digital I/O performs digital input read and digital output write operations.

7. After making sure all your DAQ device configurations are correct, you are ready to begin

your NI-DAQ development.

The Resources menu has an option called Write to Text File. Clicking on this option produces a

file named WDAQCONF.TXT in your Windows directory. This file, which describes your current

configuration, is useful when you call National Instruments technical support for assistance.

Your PC-OPDIO-16 is configured and ready for use.

© National Instruments Corporation 2-9 PC-OPDIO-16 User Manual

Page 25

Chapter 3 Signal Connections

This chapter describes the pin arrangement, signal names, and signal connections on the

PC-OPDIO-16.

Warning: Connections that exceed any of the maximum ratings of input or output signals

on the PC-OPDIO-16 may damage your PC-OPDIO-16 board and your

computer. This warning includes connecting any power signals to ground and

vice versa. National Instruments is

any such signal connections.

NOT liable for any damages resulting from

© National Instruments Corporation 3-1 PC-OPDIO-16 User Manual

Page 26

Signal Connections Chapter 3

I/O Connectors

Figure 3-1 shows the pin assignments for the PC-OPDIO-16 I/O connector.

VCCO0 1 2 VOUT0

COM0 3 4 VCCO1

VOUT1 5 6 COM1

VCCO2 7 8 VOUT2

COM2 9 10 VCCO3

VOUT3 11 12 COM3

VCCO4 13 14 VOUT4

COM4 15 16 VCCO5

VOUT5 17 18 COM5

VCCO6 19 20 VOUT6

COM6 21 22 VCCO7

VOUT7 23 24 COM7

IGND0 25 26 VIN0

IGND1 27 28 VIN1

IGND2 29 30 VIN2

IGND3 31 32 VIN3

IGND4 33 34 VIN4

IGND5 35 36 VIN5

IGND6 37 38 VIN6

IGND7 39 40 VIN7

NC 41 42 NC

NC 43 44 NC

NC 45 46 NC

NC 47 48 DGND

+5 V 49 50 DGND

Figure 3-1. PC-OPDIO-16 I/O Connector Pin Assignments

You can use the CB-50 LP (low cost) or CB-50 I/O connector block and the NB1 cable with the

PC-OPDIO-16 for your prototyping needs. The following table describes the connector pins on

the PC-OPDIO-16 I/O connector.

PC-OPDIO-16 User Manual 3-2 © National Instruments Corporation

Page 27

Chapter 3 Signal Connections

Signal Connection Descriptions

Pin Signal Name Description

1, 4, 7, 10,

13, 16, 19,

22

2, 5, 8, 11,

14, 17, 20,

23

3, 6, 9, 12,

15, 18, 21,

24

25. 27, 29,

31, 33, 35,

37, 39

26, 28, 30,

32, 34, 36,

38, 40

41–47 NC These pins are not connected.

48, 50 DGND Digital Ground—These pins are connected to the internal ground signal of the

49 +5 V +5 V—This output signal carries 1 A maximum output. It is referenced to

VCCO<0..7>

VOUT<0..7> Isolated Output, channels 0 through 7—This signal is the optically isolated

COM<0..7> Common, channels 0 through 7—This signal is the reference level from which

IGND<0..7> Isolated Input Ground, channels 0 through 7—This signal is the optically

VIN<0..7> Isolated Input Voltage, channels 0 through 7—This signal is the optically

Isolated Vcc for Output, channels 0 through 7—This signal is the Vcc for the

output channels. Range: +5 V to +24 V.

digital output line. VOUT7 is the MSB; VOUT0 is the LSB.

VOUTx is measured. It may be the isolated GND at the user end.

isolated ground for the input channels. The input signal will be referenced to

this ground.

isolated digital input line. VIN7 is the MSB; VIN0 is the LSB.

PC-OPDIO-16 board. This is not an isolated ground.

DGND.

© National Instruments Corporation 3-3 PC-OPDIO-16 User Manual

Page 28

Signal Connections Chapter 3

Optically Isolated Digital Output

I/O connector pins 1 through 24 shown in Figure 3-1 represent the optically isolated output

signal pins.

Output Channels

The optically isolated outputs of the PC-OPDIO-16 consist of a photo coupler and a load resistor.

The PC-OPDIO-16 has eight isolated output channels. Each channel has its own isolated ground

(COM), supply (VCCO), and output signal (VOUT). Figure 3-2 shows signal connection

examples for isolated output.

The maximum power ratings for the PC-OPDIO-16 are as follows:

• Maximum supply voltage (VCCO), 24 VDC

• Maximum output high current (IOH) = 250 µA

(VOUT = 3 V when VCCO = 5 V, or at VOUT = 22 V when VCCO = 24 V)

(shown in Figure 3-2a)

• Maximum output low current (I

Note: The data rate at the output is limited by the hardware. The maximum data rate

achievable with the PC-OPDIO-16 is 5 kHz. But the data rate may be slower than

5 kHz, depending on your software and CPU speed.

Signal Isolation

The COM, VCCO and VOUT signals of each channel are isolated from outputs of other channels

and also isolated from the PC-OPDIO-16 internal power and ground signals. These barriers

provide an isolation for voltages upto +24 VDC and protect the PC-OPDIO-16. Common-mode

voltages higher than the +24 VDC may damage your equipment.

Warning: You must not exceed the voltage limit of the VCCO referenced to their respective

COM signals. National Instruments is

signal connections that exceed these limits.

) = 7.0 mA at supply = 5 to 24 V (shown in Figure 3-2b)

OL

NOT liable for any damages resulting from

PC-OPDIO-16 User Manual 3-4 © National Instruments Corporation

Page 29

Chapter 3 Signal Connections

Signal Connection Example

Figure 3-2 shows signal connections for the load connected to an isolated output.

PC-OPDIO-16

5.6 kΩ5.6 kΩ5.6 kΩ

5.6 kΩ

VCCO

VOUT

COM

I

OH

Load

Isolated Ground

+

-

Supply

5–24 VDC

Digital Logic

+5 V

470 Ω

TLP121

Isolation

a. Load sinking current

Digital Logic

PC-OPDIO-16

5.6 kΩ5.6 kΩ5.6 kΩ

+5 V

470 Ω

Isolation

5.6 kΩ

VCCO

VOUT

COM

I

OL

Load

Isolated Ground

b. Load sourcing current

Figure 3-2. Signal Connection Example for Isolated Output

+

-

Supply

5–24 VDC

© National Instruments Corporation 3-5 PC-OPDIO-16 User Manual

Page 30

Signal Connections Chapter 3

Increasing Switching Frequency for TTL Loads

You can increase the switching frequency for the TTL loads by putting a resistor in parallel to

VCCO and VOUT. This parallel arrangement will reduce load resistance and increase switching

frequency. You can choose a value of Ro, as shown in Figure 3-3, in such a way that the

effective resistance from the parallel combination of 5.6 kΩ and Ro is about 1 kΩ. This

resistance will increase the switching frequency at the output to about 8 kHz, depending on your

software and the computer used.

PC-OPDIO-16

5.6 kΩ5.6 kΩ5.6 kΩ

TLP121

5.6 kΩ

VCC0

VOUT

COM

Ro

Load

5 V

+

Supply

-

Isolated Ground

Figure 3-3. Resistor in Parallel to Increase the Switching Frequency

Power-on Condition

At power up, VOUT will be high if the supply is connected to the VCCO terminal.

Optically Isolated Digital Input

I/O connector pins 25 through 40 shown in Figure 3-1 represent the optically isolated input

signal pins.

Input Channels

The optically isolated inputs of the PC-OPDIO-16 consist of a bidirectional light-emitting diode

and a resistor for current limiting. The PC-OPDIO-16 has eight isolated input channels. Each

channel has its own isolated ground and input signal.

Maximum input voltage (VIN) +24 VDC or 24 VAC

Note: Maximum data rate that can be sensed at the input is limited by the hardware to 1 kHz.

But the data rate that can be sensed at input may be slower than 1 kHz depending on

your software and CPU speed.

PC-OPDIO-16 User Manual 3-6 © National Instruments Corporation

Page 31

Chapter 3 Signal Connections

Sensing DC Voltages

When a positive or negative DC voltage with a magnitude of at least 2 V is referenced to the

IGND of a channel and is applied to an input of that channel, the PC-OPDIO-16 registers a logic

high for that input. If no voltage is present, the PC-OPDIO-16 will register a logic low for that

input. Thus, you can use the PC-OPDIO-16 to sense a wide range of DC signals—from digital

logic levels to DC power supply levels up to 24 V.

Sensing AC Voltages

The PC-OPDIO-16 senses a wide range of AC signals by registering a constant high while an

AC voltage (referenced to IGND) is present at an input. Signals with low amplitude and low

frequency appear as signals that are alternately turned on and off; therefore, the PC-OPDIO-16

alternately registers logic highs and logic lows for that signal. For sinusoidal signals, a 1 kHz

and higher frequency signal with a voltage of at least 4 Vrms returns a constant logic high level.

Signal Isolation

The VIN and IGND signals of each channel are isolated from the inputs of other channels and

are also isolated from the PC-OPDIO-16 internal power and ground signals. These barriers

provide an isolation for voltages up to +24 V and protect the PC-OPDIO-16. Voltages higher

than the +24 VDC may damage your equipment.

Warning: You must not exceed the voltage limit of the VIN signals referenced to their

respective IGND signals. National Instruments is

NOT liable for any damages

resulting from signal connections that exceed these limits.

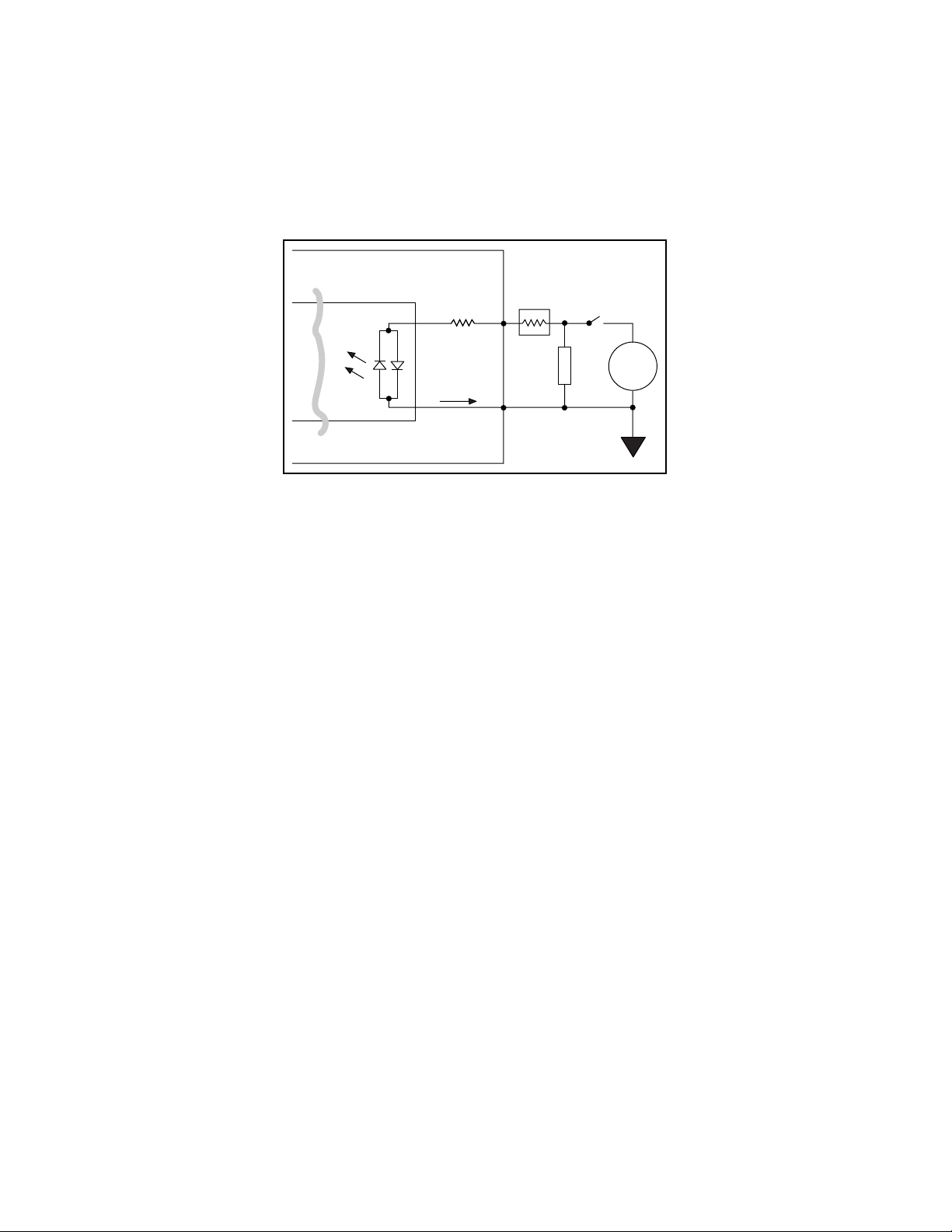

Signal Connection Example

Figure 3-4 shows signal connections for the load connected to an isolated input. In this figure,

the PC-OPDIO-16 is being used to sense that a load is being powered. The load is connected to

the power supply by means of a switch. This power supply can be AC or DC and can be any

voltage within the PC-OPDIO-16 range. When the switch is open, no current flows through the

load and no voltage is applied to the load or to the PC-OPDIO-16 input. The digital logic of the

PC-OPDIO-16 then registers a logic low for that channel. When the switch is closed, current

flows through the LED and the PC-OPDIO-16 registers a logic high for that channel.

+5 V

LDA210 (1/2)

2.7 kΩ

Digital Logic

Isolation

PC-OPDIO-16

3.3 kΩ

0.5 W

VIN

Supply

Load

IGND

Isolated Ground

Figure 3-4. Signal Connection Example for Isolated Input

© National Instruments Corporation 3-7 PC-OPDIO-16 User Manual

Page 32

Signal Connections Chapter 3

Reducing the Forward Current for 24 V Inputs

You can reduce the forward current, I

for 24 V input signals by adding a series resistance with

f

,

the 3.3 kΩ current-limiting resistor, as shown in Figure 3-5. The value of resistance should be

such that at least 1 mA flows through the LED. You can choose a value close to 20 kΩ for R

PC-OPDIO-16

Isolation

3.3 kΩ

0.5 W

I

f

IGND

VIN

R

s

Load

Isolated Ground

Supply

Figure 3-5. Reducing Input Current for 24 V Signals

Power-on Condition

At power up, the PC-OPDIO-16 will register a logic low if nothing is connected to the inputs.

.

s

PC-OPDIO-16 User Manual 3-8 © National Instruments Corporation

Page 33

Chapter 4 Fundamentals of Building Applications with NI-DAQ

_____________________________________________________________________________

This chapter contains general information about building NI-DAQ applications that run in DOS

and Windows and explains the nature of the files needed and the basics of making applications.

You can skip this chapter if you are an experienced NI-DAQ user.

Building DOS Applications with NI-DAQ

This section contains general information about building NI-DAQ applications that run in DOS

and explains the nature of the files needed and the basics of making applications using the

following compilers:

• Microsoft C

• Microsoft Visual Basic

• Turbo C++ and Borland C++

• Borland Turbo Pascal

In the DOS environment, a set of function libraries provides the NI-DAQ functions. You

compile and then link an application that makes calls to these functions to the appropriate library

for that compiler.

Creating a DOS Application Using Microsoft C

The NI-DAQ library for Microsoft C (NIDAQMSC.LIB) is compiled using the large memory

model. It is therefore essential that you install the large memory model of your Microsoft C

Compiler. If you have the files llibce.lib and llibc7.lib in the LIB directory of your

C compiler, you have the large memory model installed. Perform the following steps:

1. Create your source code. Follow the instructions in this manual and the NI-DAQ Function

Reference Manual for PC Compatibles when making calls to NI-DAQ functions. Be sure to

use the functional prototypes by including NIDAQ.H in your source file. You can find the

file NI_DAQ.H in the C_EX subdirectory under your NI-DAQ directory.

Note: You must call the USE function in your application before calling any other

NI-DAQ functions. This function causes portions of the NI-DAQ library that are

required to use your DAQ product to be included in your application. If you do not

call the appropriate USE function, your other NI-DAQ functions will return error -

421 (functionNotLinkedErr).

© National Instruments Corporation 4-1 PC-OPDIO-16 User Manual

Page 34

The Fundamentals of Building Applications with NI-DAQChapter 4

2. Compile your source code with the Microsoft C Compiler (Version 8.0 or later) and use the

large memory model, which you select when you include the /AL flag in the command line.

For example, to compile diginout.c and its support files, use the following commands:

cl /c /AL diginout.c

cl /c /AL getdev.c

cl /c /AL errprint.c

The /c flag directs the compiler to compile only.

3. Link your object file or files (using Microsoft Overlay Linker Version 3.61 or later) with the

NIDAQMSC.LIB library to create the executable application. For example, to link the

diginout.obj, getdev.obj, and errprint.obj files produced in step 2, use the

following command:

link /SEG:250 diginout getdev errprint,,,NIDAQMSC;

This link command will produce an diginout.exe executable.

Example Programs

You can find a set of example programs and the necessary header files in the NIDAQDOS\C_EX

directory.

Creating a DOS Application Using Visual Basic

To create an application that calls NI-DAQ functions, first create a source file for your

application using the following guidelines:

1. Add the following line to the beginning of the source file:

REM $INCLUDE: 'NIDAQ.INC'

This statement declares all of the NI-DAQ functions in the NI-DAQ library.

Note: If you are using NI-DAQ memory management functions, use the include file

called NIDAQR.INC, which has less restrictive prototypes.

PC-OPDIO-16 User Manual 4-2 © National Instruments Corporation

Page 35

Chapter 4 The Fundamentals of Building Applications with NI-DAQ

2. NI-DAQ library needs to allocate some memory for internal use. Therefore, you need to set

aside memory using the SETMEM statement. The amount of memory you need will depend

on which NI-DAQ functions you are using. If you have not set aside sufficient memory,

NI-DAQ functions will return a memory error (error code -98). For a description of the

SETMEM statement, refer to your BASIC manual. In the NI-DAQ Basic example programs,

a number between -2,000 and -10,000 is generally used as follows:

heap.size=SETMEM (-8000)

3. Follow the instructions in this chapter when making calls to the NI-DAQ functions.

Remember to substitute a period (.) wherever you see an underscore (_) in a function name.

For example, the function AO_Configure should be entered as AO.Configure in Visual

Basic applications.

Note: You must call the USE function in your application before calling any other

NI-DAQ functions. This function causes portions of the NI-DAQ library that

are required to use your DAQ product to be included in your application. If you

do not call the appropriate USE function, your other NI-DAQ functions will

return error -421 (functionNotLinkedErr).

Next, you can use either of the following approaches to run your application:

1. Run your application inside the Visual Basic environment. To do so, you must first create

and then load a Quick library of NI-DAQ functions when you enter Visual Basic

environment. The only case in which this approach will not work is when Visual Basic

returns out-of-memory error; in that case, use the second approach.

Note: Visual Basic returns an out-of-memory error either when you try to load the Quick

library or when you try to run your application. You may try to free up memory by

removing as many TSRs or device drivers as possible before entering the Visual

BasicC environment.

2. Compile and run your application from the DOS prompt. To do so, you use the BASIC

command-line compiler and linker.

These approaches are explained in detail in the following sections.

© National Instruments Corporation 4-3 PC-OPDIO-16 User Manual

Page 36

The Fundamentals of Building Applications with NI-DAQChapter 4

Running Your Application Inside the Visual Basic Environment

First, you must create an NI-DAQ Quick library.

MAKEQLB.BAT in the QLBUTIL subdirectory is useful for creating Quick libraries for Visual

Basic.

The steps for making a Quick library are as follows:

1. Edit NIDAQ.BAS. Remove the keyword REM from functions you want to include in the

Quick library.

2. Run this batch file by using the following command:

MAKEQLB VB

3. If all files needed to build the Quick library are found, and the linking was successful, the

batch file creates a Quick library in the NI-DAQ LIB subdirectory with a .QLB extension.

Next, load the Quick library when you enter the environment by using the following

command:

vbdos /l NIDAQVB

Note: Visual Basic returns an out-of-memory error either when you try to load the Quick

library or when you try to run your application. You may try to free up memory by

removing as many TSRs or device drivers as possible before entering the Visual Basic

environment.

After you are inside the environment, you can load the source file of your application and run it.

Compiling and Running Your Visual Basic Application from the DOS Prompt

The steps to run your application outside Visual Basic environment are as follows:

1. Compile your source code with the Visual Basic compiler. For example:

bc /O diginout.bas;

Note: NOT ENOUGH MEMORY—If the Visual Basic compiler does not have enough

memory to compile your application, you should first try to make available as much