Page 1

DAQ

PCI/PXI™-6703/6704 User Manual

DC Analog Output Devices

for PCI/PXI/CompactPCI Bus Computers

PCI/PXI-6703/6704 User Manual

March 1999 Edition

Part Number 322110B-01

Page 2

Worldwide Technical Support and Product Information

www.natinst.com

National Instruments Corporate Headquarters

11500 North Mopac Expressway Austin, Texas 78759-3504 USA Tel: 512 794 0100

Worldwide Offices

Australia 03 9879 5166, Austria 0662 45 79 90 0, Belgium 02 757 00 20, Brazil 011 284 5011,

Canada (Ontario) 905 785 0085, Canada (Québec) 514 694 8521, China 0755 3904939, Denmark 45 76 26 00,

Finland 09 725 725 11, France 01 48 14 24 24, Germany 089 741 31 30, Hong Kong 2645 3186,

India 91805275406, Israel 03 6120092, Italy 02 413091, Japan 03 5472 2970, Korea 02 596 7456,

Mexico (D.F.) 5 280 7625, Mexico (Monterrey) 8 357 7695, Netherlands 0348 433466, Norway 32 27 73 00,

Singapore 2265886, Spain (Madrid) 91 640 0085, Spain (Barcelona) 93 582 0251, Sweden 08 587 895 00,

Switzerland 056 200 51 51, Taiwan 02 2377 1200, United Kingdom 01635 523545

For further support information, see the Technical Support Resources appendix. To comment on the

documentation, send e-mail to techpubs@natinst.com.

© Copyright 1998, 1999 National Instruments Corporation. All rights reserved.

Page 3

Important Information

Warranty

The PCI-6703, PXI-6703, PCI-6704, and PXI-6704 are warranted against defects in materials and workmanship for a

period of one year from the date of shipment, as evidenced by receipts or other documentation. National Instruments

will, at its option, repair or replace equipment that proves to be defective during the warranty period. This warranty

includes parts and labor.

The media on which you receive National Instruments software are warranted not to fail to execute programming

instructions, due to defects in materials and workmanship, for a period of 90 days from date of shipment, as evidenced

by receipts or other documentation. National Instruments will, at its option, repair or replace software media that do not

execute programming instructions if National Instruments receives notice of such defects during the warranty period.

National Instruments does not warrant that the operation of the software shall be uninterrupted or error free.

A Return Material Authorization (RMA) number must be obtained from the factory and clearly marked on the outside

of the package before any equipment will be accepted for warranty work. National Instruments will pay the shipping costs

of returning to the owner parts which are covered by warranty.

National Instruments believes that the information in this document is accurate. The document has been carefully

reviewed for technical accuracy. In the event that technical or typographical errors exist, National Instruments reserves

the right to make changes to subsequent editions of this document without prior notice to holders of this edition. The

reader should consult National Instruments if errors are suspected. In no event shall National Instruments be liable for

any damages arising out of or related to this document or the information contained in it.

XCEPT AS SPECIFIED HEREIN

E

SPECIFICALLY DISCLAIMS ANY WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE

RIGHT TO RECOVER DAMAGES CAUSED BY FAULT OR NEGLIGENCE ON THE PART OF NATIONAL INSTRUMENTS SHALL BE

LIMITED TO THE AMOUNT THERETOFORE PAID BY THE CUSTOMER

DAMAGES RESULTING FROM LOSS OF DATA, PROFITS, USE OF PRODUCTS, OR INCIDENTAL OR CONSEQUENTIAL DAMAGES

EVEN IF ADVISED OF THE POSSIBILITY THEREOF

regardless of the form of action, whether in contract or tort, including negligence. Any action against National

Instruments must be brought within one year after the cause of action accrues. National Instruments shall not be liable for

any delay in performance due to causes beyond its reasonable control. The warranty provided herein does not cover

damages, defects, malfunctions, or service failures caused by owner’s failure to follow the National Instruments

installation, operation, or maintenance instructions; owner’s modification of the product; owner’s abuse, misuse, or

negligent acts; and power failure or surges, fire, flood, accident, actions of third parties, or other events outside reasonable

control.

ATIONAL INSTRUMENTS MAKES NO WARRANTIES, EXPRESS OR IMPLIED, AND

, N

. This limitation of the liability of National Instruments will apply

USTOMER’S

. C

ATIONAL INSTRUMENTS WILL NOT BE LIABLE FOR

. N

,

Copyright

Under the copyright laws, this publication may not be reproduced or transmitted in any form, electronic or mechanical,

including photocopying, recording, storing in an information retrieval system, or translating, in whole or in part, without

the prior written consent of National Instruments Corporation.

Trademarks

ComponentWorks™, CVI™, LabVIEW™, natinst.com™, NI-DAQ™, PXI™, RTSI™, SCXI™, and VirtualBench™ are

trademarks of National Instruments Corporation.

Product and company names mentioned herein are trademarks or trade names of their respective companies.

WARNING REGARDING MEDICAL AND CLINICAL USE OF NATIONAL INSTRUMENTS PRODUCTS

National Instruments products are not designed with components and testing for a level of reliability suitable for use in

or in connection with surgical implants or as critical components in any life support systems whose failure to perform

can reasonably be expected to cause significant injury to a human. Applications of National Instruments products

involving medical or clinical treatment can create a potential for death or bodily injury caused by product failure, or by

errors on the part of the user or application designer. Because each end-user system is customized and differs from

National Instruments testing platforms and because a user or application designer may use National Instruments products

in combination with other products in a manner not evaluated or contemplated by National Instruments, the user or

application designer is ultimately responsible for verifying and validating the suitability of National Instruments products

whenever National Instruments products are incorporated in a system or application, including, without limitation,

the appropriate design, process and safety level of such system or application.

Page 4

Conventions

The following conventions are used in this manual:

<> Angle brackets that contain numbers separated by an ellipsis represent a

range of values associated with a bit or signal name—for example,

DBIO<3..0>.

♦ The ♦ symbol indicates that the following text applies only to a specific

product, a specific operating system, or a specific software version.

This icon denotes a note, which alerts you to important information.

This icon denotes a caution, which advises you of precautions to take to

avoid injury, data loss, or a system crash.

bold Bold text denotes items that you must select or click on in the software,

such as menu items and dialog box options. Bold text also denotes

parameter names.

italic Italic text denotes variables, emphasis, a cross reference, or an introduction

to a key concept. This font also denotes text that is a placeholder for a word

or value that you must supply.

monospace

NI-DAQ NI-DAQ refers to the NI-DAQ driver software.

Text in this font denotes text or characters that you should enter from the

keyboard, sections of code, programming examples, and syntax examples.

This font is also used for the proper names of disk drives, paths, directories,

programs, subprograms, subroutines, device names, functions, operations,

variables, filenames and extensions, and code excerpts.

Abbreviations, acronyms, definitions, metric prefixes, mnemonics, and

symbols are listed in the Glossary.

Page 5

Contents

Chapter 1

Introduction

About the PCI/PXI-6703/6704 ......................................................................................1-1

What You Need to Get Started ......................................................................................1-2

Unpacking......................................................................................................................1-2

Software Programming Choices ....................................................................................1-3

National Instruments Application Software ....................................................1-3

NI-DAQ Driver Software ................................................................................1-4

Optional Equipment.......................................................................................................1-5

Custom Cabling ...............................................................................................1-5

Chapter 2

Installation and Configuration

Software Installation ......................................................................................................2-1

Hardware Installation.....................................................................................................2-1

Device Configuration.....................................................................................................2-2

Chapter 3

Signal Connections

I/O Connector Pin Assignments ....................................................................................3-1

Signal Connection Descriptions ...................................................................... 3-3

Analog Output Signal Connections ............................................................................... 3-4

Voltage Output ................................................................................................3-4

Power-up Condition ..........................................................................3-4

Current Output for the 6704 ............................................................................3-5

Power-up Condition ..........................................................................3-6

Digital I/O Signal Connections......................................................................................3-6

Power-up Condition.........................................................................................3-7

Power Connections ........................................................................................................3-7

Chapter 4

Hardware Overview

Bus Interface Circuitry...................................................................................................4-2

I/O Connector ................................................................................................................4-2

Nonvolatile RAM/DAC Control....................................................................................4-2

Digital I/O Control......................................................................................................... 4-2

Temperature Sensor ....................................................................................................... 4-2

© National Instruments Corporation v PCI/PXI-6703/6704 User Manual

Page 6

Contents

Chapter 5

Calibration

Self-Calibration ............................................................................................................. 5-1

External Calibration....................................................................................................... 5-1

Voltage Output Calibration ........................................................................................... 5-3

Offset Adjustment ........................................................................................... 5-3

Gain Adjustment ............................................................................................. 5-3

Current Output Calibration for the 6704 ....................................................................... 5-3

Offset Adjustment ........................................................................................... 5-3

Gain Adjustment ............................................................................................. 5-4

Saving Calibration Values............................................................................................. 5-4

Appendix A

Specifications

Appendix B

Common Questions

Appendix C

Technical Support Resources

Glossary

Index

Figures

Figure 1-1. The Relationship between the Programming Environment,

NI-DAQ, and Your Hardware................................................................. 1-4

Figure 3-1. I/O Connector Pin Assignments.............................................................. 3-2

Figure 3-2. VCH Connection as a Voltage Output.................................................... 3-4

Figure 3-3. ICH Connection as a Current Output...................................................... 3-5

Figure 3-4. Example Digital I/O Connections........................................................... 3-6

Figure 4-1. PCI/PXI-6703/6704 Block Diagram....................................................... 4-1

Tables

Table 5-1. 6703 Calibration Channel Numbers........................................................ 5-2

Table 5-2. 6704 Calibration Channel Numbers........................................................ 5-2

PCI/PXI-6703/6704 User Manual vi www.natinst.com

Page 7

Introduction

This manual describes the mechanical and electrical aspects of the 6703

and 6704 devices and contains information concerning their configuration,

installation, and operation. The 6703 and 6704 devices are designed for

precise DC setpoint applications and provide general-purpose digital I/O.

Unless otherwise noted, text applies to all 6703 and 6704 devices: the

PCI-6703, PXI-6703, PCI-6704 and PXI-6704.

This chapter describes the 6703/6704 devices, lists what you need to get

started, describes software programming choices, optional equipment, and

custom cables, and explains how to unpack your device.

About the PCI/PXI-6703/6704

Thank you for purchasing a National Instruments 6703/6704 device. The

6703/6704 devices are precise DC setpoint devices for PCI and PXI. The

6703 devices have 16 voltage output channels. The 6704 devices have

16 voltage output channels and 16 current output channels for a total of 32

analog output channels. Both 6703 and 6704 devices have eight digital I/O

lines.

1

You can use the 6703/6704 devices in a wide variety of DC setpoint and

digital I/O applications. With the 6703/6704 devices, your PC system can

serve as a digital I/O system controller for laboratory testing, production

testing, and industrial process monitoring and control. These devices can

do the following:

• Generate experimental stimuli

• Generate analog functions

• Connect to a variety of signal types, including:

– Electromechanical relays

– LEDs

– Optically isolated, solid-state relays and I/O module mounting

racks

– Voltage and current excitation for precision transducers

– Current excitation for precision transducers (6704 only)

© National Instruments Corporation 1-1 PCI/PXI-6703/6704 User Manual

Page 8

Chapter 1 Introduction

Detailed specifications for the 6703/6704 devices are in Appendix A,

Specifications.

What You Need to Get Started

To set up and use your 6703/6704 device, you will need the following:

❑

One of the following devices:

• PCI-6703

• PXI-6703

• PCI-6704

• PXI-6704

PCI/PXI-6703/6704 User Manual

❑

❑

One of the following software packages and documentation:

• ComponentWorks

• LabVIEW for Windows

• LabWindows/CVI for Windows

• Measure

• NI-DAQ for PC compatibles

• VirtualBench

❑

PC with a free PCI slot or PXI chassis with a free slot

❑

68-pin cable (type SH68-68-D1)

❑

68-pin terminal block (type CB-68)

Unpacking

Your 6703/6704 device is shipped in an antistatic package to prevent

electrostatic damage to the device. Electrostatic discharge can damage

several components on the device. To avoid such damage in handling the

device, take the following precautions:

• Ground yourself via a grounding strap or by holding a grounded

object.

• Touch the antistatic package to a metal part of your PC chassis

before removing the device from the package.

PCI/PXI-6703/6704 User Manual 1-2 www.natinst.com

Page 9

• Remove the device from the package and inspect the device for

loose components or any other sign of damage. Notify National

Instruments if the device appears damaged in any way. Do not

install a damaged device into your computer.

• Never touch the exposed pins of connectors.

Software Programming Choices

There are several options to choose from when programming your National

Instruments DAQ hardware. You can use LabVIEW, LabWindows/CVI,

ComponentWorks, VirtualBench, or other application development

environments in conjunction with NI-DAQ.

National Instruments Application Software

ComponentWorks contains tools for data acquisition and instrument

control built on NI-DAQ driver software. ComponentWorks provides a

higher-level programming interface for building virtual instruments

through standard OLE controls and DLLs. With ComponentWorks, you

can use all of the configuration tools, resource management utilities, and

interactive control utilities included with NI-DAQ.

Chapter 1 Introduction

LabVIEW features interactive graphics, a state-of-the-art user interface,

and a powerful graphical programming language. The LabVIEW Data

Acquisition VI Library, a series of VIs for using LabVIEW with National

Instruments DAQ hardware, is included with LabVIEW. The LabVIEW

Data Acquisition VI Library is functionally equivalent to the NI-DAQ

software.

LabWindows/CVI features interactive graphics, a state-of-the-art user

interface, and uses the ANSI standard C programming language. The

LabWindows/CVI Data Acquisition Library, a series of functions for using

LabWindows/CVI with National Instruments DAQ hardware, is included

with the NI-DAQ software kit. The LabWindows/CVI Data Acquisition

Library is functionally equivalent to the NI-DAQ software.

VirtualBench features VIs that combine DAQ products, software, and your

computer to create a standalone instrument with the added benefit of the

processing, display, and storage capabilities of your computer.

VirtualBench instruments load and save waveform data to disk in the same

forms that can be used in popular spreadsheet programs and word

processors.

© National Instruments Corporation 1-3 PCI/PXI-6703/6704 User Manual

Page 10

Chapter 1 Introduction

Using ComponentWorks, LabVIEW, LabWindows/CVI, or VirtualBench

software will greatly reduce the development time for your data acquisition

and control application.

NI-DAQ Driver Software

The NI-DAQ driver software is included at no charge with all National

Instruments DAQ hardware. NI-DAQ is not packaged with accessory

products. NI-DAQ has an extensive library of functions that you can call

from your application programming environment. These functions include

routines for analog input (A/D conversion), buffered data acquisition

(high-speed A/D conversion), analog output (D/A conversion), waveform

generation, digital I/O, counter/timer operations, SCXI, RTSI,

self-calibration, messaging, and acquiring data to extended memory.

NI-DAQ maintains a consistent software interface among its different

versions so that you can change platforms with minimal modifications to

your code. Whether you are using conventional programing languages or

National Instruments application software, your application uses the

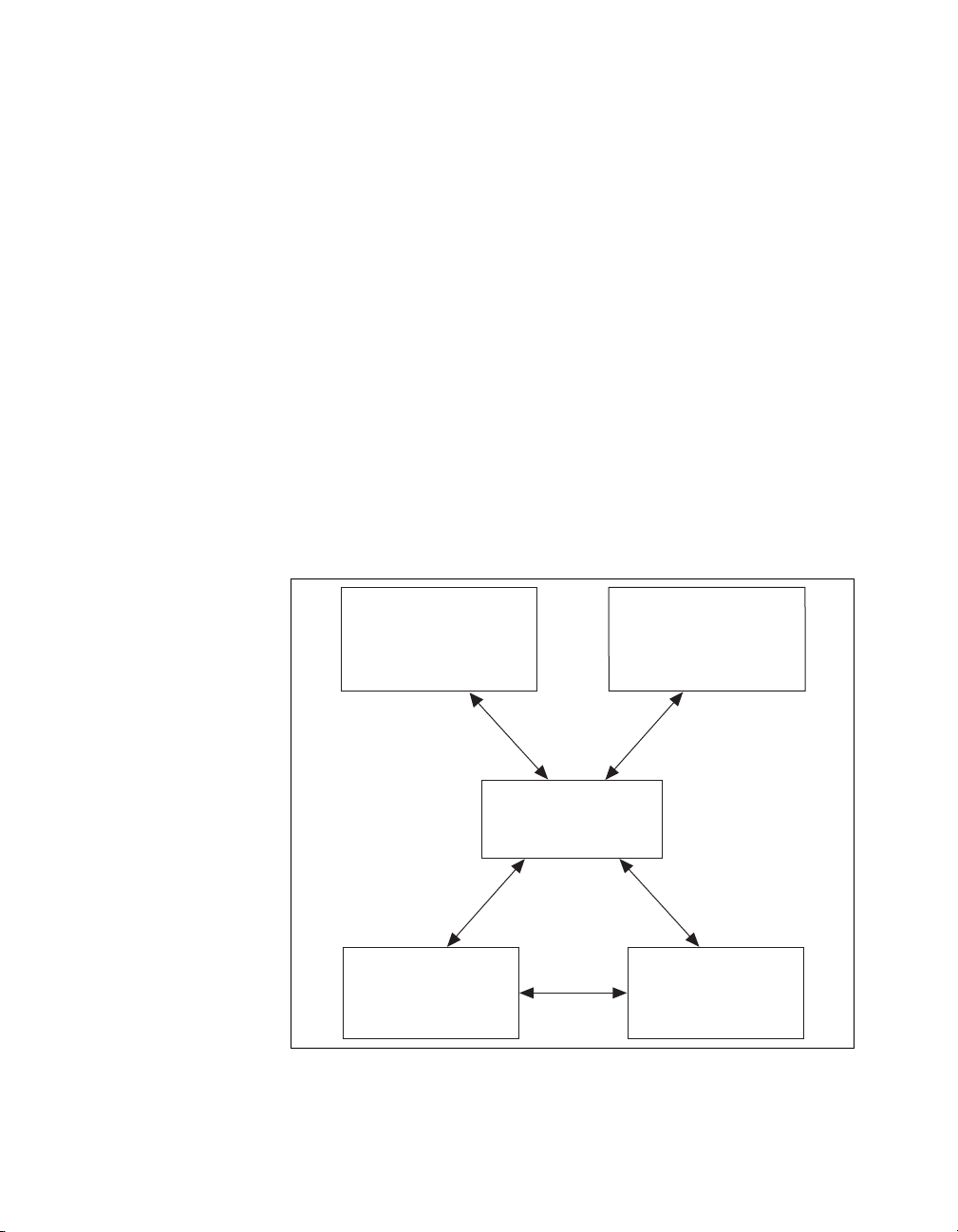

NI-DAQ driver software, as illustrated in Figure 1-1.

Programming Environment

Figure 1-1.

Conventional

NI-DAQ

Driver Software

DAQ or

SCXI Hardware

The Relationship between the Programming Environment, NI-DAQ, and

Your Hardware

ComponentWorks,

LabVIEW,

LabWindows/CVI, or

VirtualBench

Personal

Computer or

Workstation

PCI/PXI-6703/6704 User Manual 1-4 www.natinst.com

Page 11

Optional Equipment

National Instruments offers a variety of products to use with your

6703/6704 device, including cables, connector blocks, and other

accessories, as follows:

• Cables and cable assemblies, shielded and ribbon

• Connector blocks, shielded and unshielded screw terminals

For more information about these products, refer to the National

Instruments catalogue or website or call the office nearest you.

Custom Cabling

National Instruments offers cables and accessories for you to prototype

your application or to use if you frequently change module

interconnections.

If you want to develop your own cable, mating connectors and a backshell

kit for making custom 68-pin cables are available from National

Instruments (part number 776832-01).

Chapter 1 Introduction

Refer to your National Instruments catalogue for specific information.

© National Instruments Corporation 1-5 PCI/PXI-6703/6704 User Manual

Page 12

Installation and Configuration

This chapter explains how to install and configure your 6703/6704 device.

Software Installation

Install your software before you install your 6703/6704 device. Refer to the

appropriate release notes indicated below for specific instructions on the

software installation sequence.

1. Install your application software—If you are using LabVIEW,

LabWindows/CVI, or other National Instruments application software

packages, refer to the appropriate release notes.

2. Install the NI-DAQ driver software—Refer to your NI-DAQ release

notes and follow the instructions given there for your operating system

and application software package.

You can now install your hardware.

Hardware Installation

2

You can install your 6703/6704 device in any available expansion slot in

your computer. However, to achieve best noise performance, leave as much

room as possible between your 6703/6704 device and other boards and

hardware. The following are general installation instructions, but consult

your computer user manual or technical reference manual for specific

instructions and warnings.

♦ PCI-6703/6704

1. Turn off and unplug your computer.

2. Remove the top cover or access port to the I/O channel.

3. Remove the expansion slot cover on the back panel of the computer.

4. Touch any metal part of your computer chassis to discharge any static

electricity that might be on your clothes or body.

5. Insert the PCI-6703/6704 into a 5 V PCI slot. Gently rock the device

to ease it into place. Do not force the device into place.

© National Instruments Corporation 2-1 PCI/PXI-6703/6704 User Manual

Page 13

Chapter 2 Installation and Configuration

6. Screw the mounting bracket of the PCI-6703/6704 device to the back

panel rail of the computer.

7. Visually verify the installation.

8. Replace the cover.

9. Plug in and turn on your computer.

Your PCI-6703/6704 is installed. You are now ready to configure your

hardware and software.

♦ PXI-6703/6704

1. Turn off and unplug your PXI controller.

2. Choose an unused PXI slot in your system.

3. Remove the filler panel for the slot you have chosen.

4. Touch any metal part of your computer chassis to discharge any static

electricity that might be on your clothes or body.

5. Insert the PXI-6703/6704 into a PXI chassis slot. Use the

injector/ejector handle to fully insert the device into the chassis.

6. Screw the front panel of the PXI-6703/6704 to the front panel

mounting rail of the system.

7. Visually verify the installation.

8. Plug in and turn on your computer.

Your PXI-6703/6704 is installed. You are now ready to configure your

hardware and software.

Device Configuration

Due to the National Instruments standard architecture for data acquisition

and the PCI and PXI bus specifications, all 6703 and 6704 devices are

completely software-configurable. Refer to your software documentation

for configuration instructions.

The PCI-6703/6704 are fully compatible with the industry-standard

Local Bus Specification Revision 2.0, and the PXI-6703/6704 are fully

compatible with the PXI Specification Revision 1.0.

allow the PCI and PXI systems to automatically perform all bus-related

configurations and require no user interaction. Bus-related configuration

includes setting the device base memory address and interrupt channel.

PCI/PXI-6703/6704 User Manual 2-2 www.natinst.com

These specifications

PCI

Page 14

Signal Connections

This chapter provides connection instructions for the signals on your

6703/6704 device I/O connector.

3

Warning

on the 6703/6704 device can damage the device and the computer. Maximum input ratings

for each signal are given in this chapter under the discussion of that signal. National

Instruments is

Connections that exceed any of the maximum ratings of input or output signals

liable for any damages resulting from any incorrect signal connections.

NOT

I/O Connector Pin Assignments

Figure 3-1 shows the I/O connector pin assignments for the

6703/6704 devices.

© National Instruments Corporation 3-1 PCI/PXI-6703/6704 User Manual

Page 15

Chapter 3 Signal Connections

+5V

DIO0

DIO1

DIO2

DIO3

DIO4

DIO5

DIO6

DIO7

ICH31*

AGND15/AGND31

VCH14

ICH29*

AGND13/AGND29

VCH12

ICH27*

VCH11

AGND10/AGND26

AGND

AGND9/AGND25

ICH24*

VCH8

ICH23*

AGND7/AGND23

VCH6

ICH21*

AGND5/AGND21

VCH4

ICH19*

AGND3/AGND19

VCH2

ICH17*

AGND1/AGND17

VCH0

135

236

337

438

539

640

741

842

943

10 44

11 45

12 46

13 47

14 48

15 49

16 50

17 51

18 52

19 53

20 54

21 55

22 56

23 57

24 58

25 59

26

60

61

27

62

28

63

29

64

30

65

31

32

66

33

67

34

68

DGND

DGND

DGND

RFU

DGND

RFU

DGND

DGND

AGND

VCH15

ICH30*

AGND14/AGND30

VCH13

ICH28*

AGND12/AGND28

AGND11/AGND27

ICH26*

VCH10

ICH25*

VCH9

AGND8/AGND24

AGND

VCH7

ICH22*

AGND6/AGND22

VCH5

ICH20*

AGND4/AGND20

VCH3

ICH18*

AGND2/AGND18

VCH1

ICH16*

AGND0/AGND16

* No connects on the PCI/PXI 6703

Figure 3-1. I/O Connector Pin Assignments

PCI/PXI-6703/6704 User Manual 3-2 www.natinst.com

Page 16

Chapter 3 Signal Connections

Signal Connection Descriptions

Pin Signal Name Description

<2..9> DIO<0..7> Digital Input/Output lines—Line 7 is the

MSB and Line 0 is the LSB.

<35..37>, 39, 41, 42 DGND Digital Ground—These pins are connected

to the 6703/6704 device digital ground

plane. All 6703/6704 device ground planes

connect to the computer system’s ground

signal.

1 +5V +5 V—This pin is connected to the

computer system’s +5 VDC supply through

a self-resetting circuit breaker.

38, 40 RFU Reserved for future use.

34, 66, 31, 63, 28, 60, 25,

57, 22, 54, 52, 17, 15, 47,

12, 44

67, 32, 64, 29, 61, 26, 58,

23, 21, 53, 51, 16, 48, 13,

45, 10

68, 33, 65, 30, 62, 27, 59,

24, 55, 20, 18, 50, 49, 14,

46, 11

19, 43, 56 AGND Additional pins connected to analog

VCH<0..15> Voltage output channels.

ICH<16..31> Current output channels on the 6704.

No connects on the 6703.

AGND<0/16..15/31> Analog Grounds—Each ground pin is

shared between one voltage and one current

channel. These pins are connected to the

6703/6704 device analog ground plane. All

6703/6704 device ground planes connect to

the computer system’s ground signal.

ground.

© National Instruments Corporation 3-3 PCI/PXI-6703/6704 User Manual

Page 17

Chapter 3 Signal Connections

Analog Output Signal Connections

This section describes how to make connections for voltage and current

outputs. The 6704 has both voltage and current outputs, however, the 6703

has voltage outputs only. A 68-pin cable such as the SH68-68-D1 cable is

required. Figure 3-2 shows how to connect the voltage channel (VCH)

outputs.

VCH

Voltage Output

Warning

load with high common-mode voltages can damage the devices. National Instruments is

liable for any damages resulting from any such signal connections.

NOT

Load

Figure 3-2.

VCH Connection as a Voltage Output

±

10.1 V

AGND

Floating Load

A

PCI/PXI-6703/6704

You can connect a floating load to your 6703/6704 device at the voltage

output channel.

Because 6703/6704 devices are not electrically isolated from high voltages, a

Your 6703/6704 device has a bipolar voltage range of –10.1 to +10.1 V.

Maximum load current is ±10 mA for 16-bit linearity.

Power-up Condition

All voltage outputs are at their user-defined values to full accuracy within

1 s of power-up board reset. Before this time, the voltage outputs can float

to unspecified values. Take this behavior into account when connecting

external devices to the 6703/6704.

PCI/PXI-6703/6704 User Manual 3-4 www.natinst.com

Page 18

Current Output for the 6704

You can connect a floating or grounded load to your 6704 device at the

current output channel. You do not need an external floating power supply

to complete the controlled current loop. You can control the current loop

from 0.1 to 20.2 mA. The compliance for the current loop is 0 V to

10 VDC.

Chapter 3 Signal Connections

Warning

Because 6704 devices are not electrically isolated from high voltages, a load

with high common-mode voltages can damage the 6704 devices. National Instruments is

liable for any damages resulting from any such signal connections.

NOT

Figure 3-3 shows how to connect a current channel (ICH) as a current

output.

ICH

Load

0.1 to 20.2 mA

AGND

PCI/PXI-6704

Figure 3-3.

ICH Connection as a Current Output

Because each current channel shares a ground line with a voltage channel,

you should try to minimize the effect of the return current from your current

channel on the voltage that you are outputting on your voltage channel. For

example, if you output 20 mA on a current channel and return that current

to the 6704 device along the shared ground line in a cable with an

impedance of 0.1 Ω, you will see a 2 mV drop in the voltage output by the

© National Instruments Corporation 3-5 PCI/PXI-6703/6704 User Manual

Page 19

Chapter 3 Signal Connections

voltage channel sharing the ground line. You can approach this problem in

the following ways:

– Use a shorter cable to minimize the impedance of the shared

ground line.

– Use separate wiring for VCH and ICH ground return to minimize

common ground impedance.

– Use different pairs of voltage and current channels to keep your

sensitive voltage outputs separate from your higher output current

channels.

Power-up Condition

All current outputs are within ± 1.1 mA maximum of their user-defined

values within 0.5 s of power-up board reset. The current outputs will settle

to their user-defined values to full accuracy within 7 s of power-up board

reset. Take this behavior into account when connecting external devices to

the 6704.

Digital I/O Signal Connections

+5 V

LED

Figure 3-4 illustrates example signal connections for three typical digital

I/O applications.

+5 V

Line 0

R

TTL Signal

Switch

I/O Connector

Figure 3-4.

Line 1

Line 2

DGND

PCI/PXI-6703/6704

Example Digital I/O Connections

DIO

Line<0..7>

PCI/PXI-6703/6704 User Manual 3-6 www.natinst.com

Page 20

In Figure 3-4, line 0 is configured for digital output; lines 1 and 2 are

configured for digital input.

Digital input applications include receiving TTL signals and sensing

external device states such as the switch in Figure 3-4. Digital output

applications include sending TTL signals and driving external devices such

as the LED shown in Figure 3-4.

Note

The 6703/6704 devices allow line-by-line direction control of digital I/O

connections.

Refer to Appendix A, Specifications, for a list of the digital I/O signal

ratings.

Power-up Condition

At power up, all of the DIO lines on the 6703/6704 devices are configured

as input lines.

Power Connections

Chapter 3 Signal Connections

Pin 1 on the I/O connector is connected to the +5 V supply from the PCI or

PXI bus power supply. This pin is referenced to DGND and can supply

power to external circuitry. The +5 V supply has a total of 0.75 A available.

The +5 V power supply has a self-resetting protection circuit breaker in

series. If the circuit breaker protection is activated, simply remove the

circuit causing the heavy current load and the circuit breaker will reset

itself. For more information on these output pins, see the Digital I/O and

Power Requirement sections in Appendix A, Specifications.

Power rating 0.75 A at +5 V ±10%, +4.55 to

+5.25 VDC at 0.75 A

Warning

ground or to any other voltage source on your 6703/6704 device or any other device. Doing

so can damage your device and your computer system. National Instruments is

for damage resulting from such a connection.

Under no circumstances should you connect these +5 V power pins directly to

liable

NOT

© National Instruments Corporation 3-7 PCI/PXI-6703/6704 User Manual

Page 21

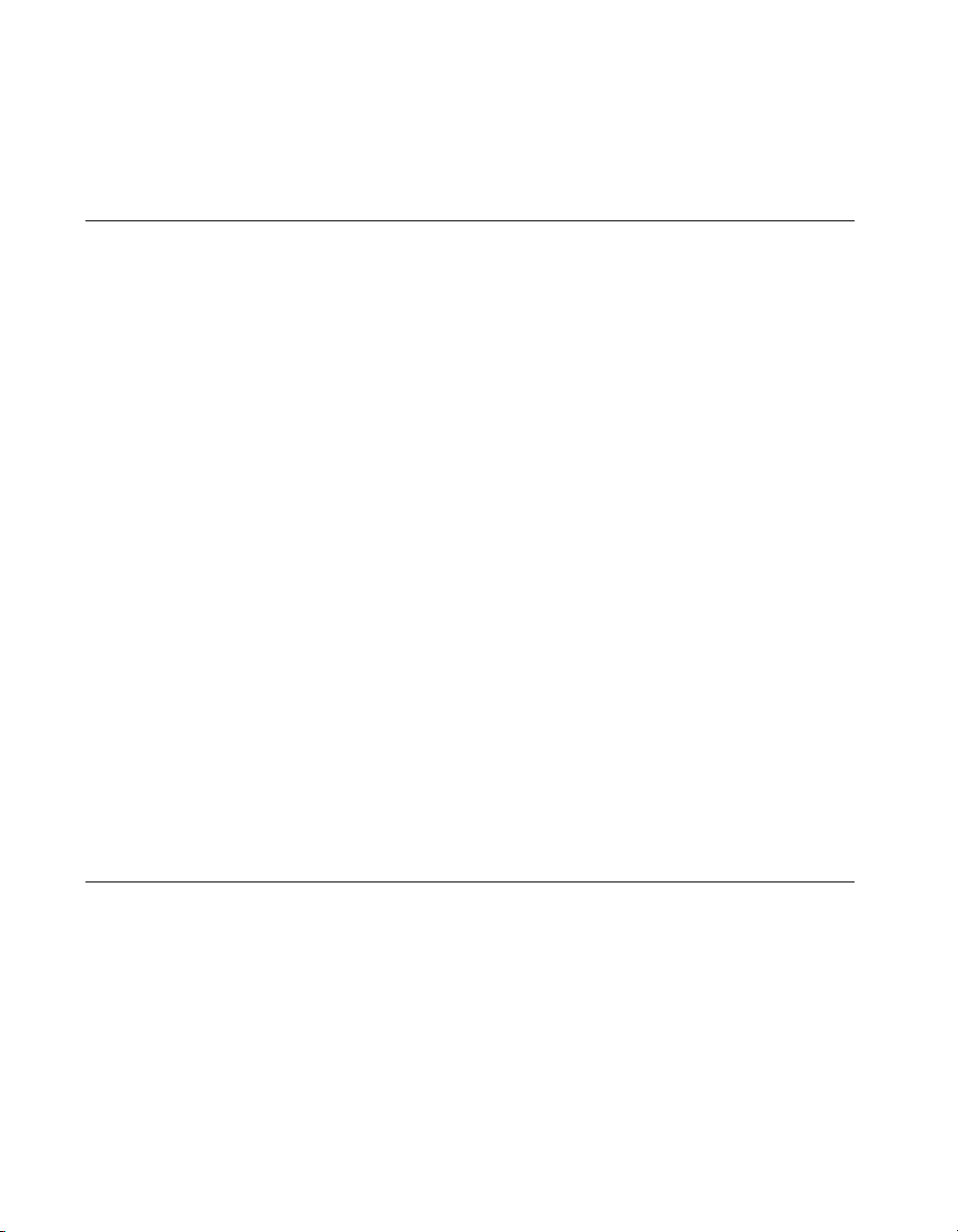

Hardware Overview

This chapter contains a functional overview of the 6703/6704 devices and

explains the operation of each functional unit making up the devices.

The block diagram in Figure 4-1 illustrates the key functional components

of the 6703/6704 devices.

Control

Address

Data

Bus

Interface

Logic

4

Control

Lines

nvRAM/

PCI/PXI Bus

DAC

Control

Digital

I/O

Serial

Number

EEPROM

Temperature

Sensor

*No current circuits present on PCI/PXI-6703

RAM

Addr/Ctrl

nvSRAM

16-Bit

DAC

RAM Data

Figure 4-1.

Main

DAC

Out

Voltage

Circuit

Main

Current

Circuit*

DIO Lines <7..0>

Self-Resetting Circuit Breaker

PCI/PXI-6703/6704 Block Diagram

Voltage

Output

Circuit X 16

Current

Output

Circuit X 16*

0.75 A

16

16

I/O Connector

+5 V

© National Instruments Corporation 4-1 PCI/PXI-6703/6704 User Manual

Page 22

Chapter 4 Hardware Overview

Bus Interface Circuitry

The bus interface circuitry monitors the PCI or PXI bus. If the bus address

matches the 6703/6704 device’s address, the board is enabled and the

corresponding register on the 6703/6704 is accessed.

I/O Connector

All user I/O is transmitted through a 68-pin connector. Refer to the Custom

Cabling section in Chapter 1, Introduction, and to Chapter 3, Signal

Connections, for additional information.

Nonvolatile RAM/DAC Control

The 6703/6704 devices have one 16-bit DAC that is time-division

multiplexed to create all the output channels. Each channel has a

track-and-hold circuit to maintain the channel value between DAC updates.

On the 6703, the DAC is multiplexed to create 16 voltage outputs and two

calibration channels. On the 6704, the DAC is multiplexed to create

16 voltage outputs, 16 current outputs, and four calibration channels.

Data is stored in a nonvolatile RAM (nvRAM). The nvRAM/DAC control

reads the DAC channel data stored in the nvRAM and updates the DAC

periodically. The nvRAM/DAC control also controls the analog

demultiplexing circuits to route the DAC output to the correct analog output

channel. You can choose to save nvRAM data so that the current output

values will become the power-on states.

Digital I/O Control

The 6703/6704 devices have eight digital I/O lines configured as one 8-bit

port. You can configure each line independently as an input or output. The

DIO lines have 16 mA of sink capability and 16 mA of source capability.

All digital lines are TTL compatible. At power up, all digital lines are

configured as inputs.

Temperature Sensor

The onboard temperature sensor measures the air temperature flowing over

the board. This sensor is positioned near the onboard precision voltage

reference, which can be affected by extreme temperatures. This sensor has

a serial digital interface.

PCI/PXI-6703/6704 User Manual 4-2 www.natinst.com

Page 23

Calibration

Self-Calibration

5

This chapter discusses the calibration procedures for your 6703/6704

device. Calibration is the process of minimizing output errors by making

small circuit adjustments. There are two calibration channels used to make

adjustments to the voltage channels on the 6703/6704. On the 6704, there

are two additional channels used to make adjustments to the current

channels.

The 6703/6704 devices perform continuous self-calibration. In addition to

the accessible analog output channels, there are internal calibration

channels that get scanned and refreshed along with all the output channels.

There are two of these calibration channels for the voltage outputs: the

voltage offset channel and the voltage gain channel.

There are also two calibration channels for the current outputs on the 6704:

the current offset channel and the current gain channel. The outputs of these

calibration channels are continuously compared to onboard references, and

the 16-bit DAC offset and gain are adjusted to minimize the errors in the

calibration channels. Since 6703/6704 devices have excellent

channel-to-channel matching of offset and gain errors, minimizing the

errors in the calibration channels also minimizes the errors for all the

voltage and current outputs.

External Calibration

Because of the nature of the 6703/6704 device calibration circuitry, the

only calibration adjustment you must make is to adjust the values of the

calibration channels to account for time- or temperature-related drift of the

onboard reference. These calibration values are loaded into nvRAM at

factory calibration, and you should not need to adjust them for at least one

year after the date of factory calibration, unless you are operating your

device at an extreme temperature.

To perform calibration, you need a voltage and current measuring device

that is much more accurate than your 6703/6704 device. A DMM with an

© National Instruments Corporation 5-1 PCI/PXI-6703/6704 User Manual

Page 24

Chapter 5 Calibration

accuracy of at least 10 ppm will generally suffice, but be sure to check its

specifications. Also, be sure that no other devices are connected to your

6703/6704 when you calibrate it to ensure that no ground loops can corrupt

the calibration.

Your 6703/6704 device contains a calibration enable bit in a control register

to prevent you from accidentally writing to the calibration channels. Before

you can calibrate the board, you must set this bit. If you are using NI-DAQ,

calibration is enabled by calling the NI-DAQ function

Set_DAQ_Device_Info

infoType equal to

ND_YES

AO_VWrite

. You may then write to the calibration channels by calling

(deviceNumber, chan, voltage) where chan is the calibration

(deviceNumber, infoType, infoValue) with

ND_CALIBRATION_ENABLE

and infoValue equal to

channel number, and voltage is the channel value to be written.

Table 5-1 lists the channel numbers of the calibration channels for the 6703.

Table 5-1. 6703 Calibration Channel Numbers

Calibration Channel Channel Number

Voltage offset Channel 16

Voltage gain Channel 17

Table 5-2 lists the channel numbers of the calibration channels for the 6704.

Table 5-2. 6704 Calibration Channel Numbers

Calibration Channel Channel Number

Voltage offset Channel 32

Voltage gain Channel 34

Current offset Channel 33

Current gain Channel 35

PCI/PXI-6703/6704 User Manual 5-2 www.natinst.com

Page 25

Voltage Output Calibration

There are two adjustments to make for the voltage outputs: offset and gain.

You should perform offset adjustment first. It is a good idea to calibrate

twice, because a large change in the voltage gain channel value could

impact the accuracy of the offset calibration.

Offset Adjustment

To calibrate the offset, set one of the voltage output channels to 0 V and

measure it with a precise voltmeter. Then, change the voltage offset

channel value until the output is zero. The voltage you write to the voltage

offset channel will be close to zero, and increasing it will lower the voltage

you measure.

Gain Adjustment

To calibrate the gain, set the voltage output channel to a voltage near

full-scale, such as +10 V. Then, change the voltage gain channel value until

the output that you measure is as close as possible to the voltage that you

wrote to the output channel. The voltage you write to the voltage gain

channel will be close to +10 V, and increasing it will lower the magnitude

of the voltage you measure.

Chapter 5 Calibration

You can also calibrate using several output channels, instead of just one, by

averaging channels together. Do this by writing the values to all the

channels you wish to average and using a resistive averaging circuit to

average the outputs. This will reduce the sensitivity of the calibration

process to interchannel mismatch—the slight differences in the output

characteristics of the channels—by averaging out these differences.

Current Output Calibration for the 6704

There are two adjustments to make for the current outputs: offset and gain.

You should perform offset adjustment first. It is a good idea to calibrate

twice, because a large change in the current gain channel value could

impact the accuracy of the offset calibration.

Offset Adjustment

To calibrate the offset, set one of the current output channels to 100 µA and

measure it with a precise ammeter. Then, change the current offset channel

value until the output is as close as possible to 100 µA. The current you

© National Instruments Corporation 5-3 PCI/PXI-6703/6704 User Manual

Page 26

Chapter 5 Calibration

write to the current offset channel will be close to 10 µA, and increasing it

will lower the current you measure.

Gain Adjustment

To calibrate the gain, set the current output channel to a current near

full-scale, such as 20 mA. Then, change the current gain channel value

until the output that you measure is as close as possible to the current that

you wrote to the output channel. The current you write to the current gain

channel will be close to 19.608 mA, and increasing it will lower the current

you measure.

You can also calibrate using several output channels instead of just one by

adding channels together. Do this by writing the values to all the channels

you wish to add and summing the outputs by connecting them together.

This will reduce the sensitivity of the calibration process to interchannel

mismatch—the slight differences in the output characteristics of the

channels by averaging out these differences.

Saving Calibration Values

When you have finished calibration, you will want to write your calibration

values into nvRAM. This will ensure that your new calibration values are

permanently saved and automatically loaded when the card is powered-on.

Calibration values are saved and restored through the

(deviceNumber, operation, EEPROMloc) function call in NI-DAQ. To

save your calibration values, make the following call:

(deviceNumber, 2, 1), where deviceNumber refers to the device number

assigned by the NI-DAQ Configuration Utility. If you need to restore the

factory calibration values, load them by calling

(deviceNumber, 1, 5). For more information, consult the NI-DAQ

Function Reference Manual.

AO_Calibrate

AO_Calibrate

AO_Calibrate

PCI/PXI-6703/6704 User Manual 5-4 www.natinst.com

Page 27

Specifications

This appendix lists specifications for 6703/6704 devices. These

specifications are valid for an ambient temperature of 0° to 55 °C, unless

otherwise stated.

Analog Output

Number of voltage channels .................. 16

Number of current channels

for the 6704 ............................................ 16

Resolution .............................................. 16-bit

Recommended warm-up time ................ 15 minutes

Transfer Characteristics

A

INL .........................................................±1 LSB max

DNL ....................................................... ±1 LSB max

Monotonicity..........................................16 bits, guaranteed

Voltage Output

Range ..................................................... ±10.1 V

Output coupling......................................DC

Output impedance .................................. 0.1 Ω max

Current drive ..........................................±10 mA max

Load capacitance.................................... 10,000 pF max

Protection ............................................... Short-circuit to ground

© National Instruments Corporation A-1 PCI/PXI-6703/6704 User Manual

Page 28

Appendix A Specifications

Absolute accuracy...................................±1 mV max

Noise.......................................................100 µV rms, DC to 1 MHz

Power-up state ........................................Independent, user-defined values

Current Output, 6704 Only

Range ......................................................0.1 to 20.2 mA

Type ........................................................Source, does not require external

Output impedance...................................1 GΩ min

Output compliance..................................0 to 10 V

Absolute accuracy...................................±2 µA max

Noise.......................................................1 µA rms, DC to 1 MHz

Protection................................................Short-circuit and open circuit

excitation source

Power-up state ........................................Independent, user-defined values

Dynamic Characteristics

Settling time (including channel latency)

Accuracy Time

±0.1% 1.8 ms typ, 5.6 ms max

±0.01% 3.6 ms typ, 11.2 ms max

±0.001% 14.4 ms typ, 48.8 ms max

Stability

Offset temperature coefficient

Voltage ............................................5 µV/ ºC

Current (6704 only) .........................10 nA/ ºC

PCI/PXI-6703/6704 User Manual A-2 www.natinst.com

Page 29

Digital I/O

Appendix A Specifications

Gain temperature coefficient

Voltage............................................ 1 ppm/ ºC

Current (6704 only) ........................2 ppm/ ºC

Number of channels ............................... 8 I/O

Compatibility ......................................... TTL

Power-on state........................................ Input (high impedance)

Digital logic levels

Level Min Max

Input low voltage — 0.8 V

Input high voltage 2.0 V —

Bus Interface

Power Requirement

Output low voltage — 0.45 V, IOL = 16 mA

Output high voltage 2.4 V, IOH = 16 mA —

Input leakage current — 10 µA

Type ....................................................... Slave

+5 V

6703 ................................................ 700 mA

6704 ................................................ 1 A

+12 V...................................................... 70 mA

–12 V...................................................... 70 mA

© National Instruments Corporation A-3 PCI/PXI-6703/6704 User Manual

Page 30

Appendix A Specifications

Note

These power usage figures do not include the power used by external devices that

are connected to the fused supply present on the I/O connector. They assume that all

voltage and current outputs are fully loaded.

Physical

Environment

Dimensions (not including connectors)

PCI-6703/6704 ................................9.9 by 17.5 cm (3.9 by 6.9 in.)

PXI-6703/6704 ................................10 by 16 cm (3.9 by 6.3 in.)

I/O connector ..........................................68-pin male

Operating

Temperature............................................0° to 55 °C ambient

Relative humidity ...................................5% to 90% noncondensing

Storage

Temperature............................................–20° to 70 °C ambient

Relative humidity ...................................5% to 90% noncondensing

PCI/PXI-6703/6704 User Manual A-4 www.natinst.com

Page 31

Common Questions

This appendix contains commonly asked questions and their answers

relating to usage and special features of your 6703/6704 device.

General Information

What if I short-circuit the power supply on the 6703/6704 connector?

Pin 1 of the I/O connector is connected to the +5 V supply from the PCI or

PXI bus power supply. This pin is referenced to GND and can be used to

power external circuitry. The +5 V supply has a total of 0.75 A available.

This power supply has a self-resetting protection circuit breaker in series.

If the circuit breaker protection is activated, simply remove the circuit

causing the heavy current load and the circuit breaker will reset itself. For

more information on this output pin, see the Power Requirement section in

Appendix A, Specifications.

Installation and Configuration

B

Which National Instruments document should I read first to get

started using DAQ software?

The release notes document for your application or driver software is

always the best starting place.

What version of NI-DAQ must I have to program my 6703 device?

You must have NI-DAQ for PC compatibles version 6.6 or higher for your

6703 device.

What version of NI-DAQ must I have to program my 6704 device?

You must have NI-DAQ for PC compatibles version 6.5 or higher for your

6704 device.

© National Instruments Corporation B-1 PCI/PXI-6703/6704 User Manual

Page 32

Appendix B Common Questions

What is the best way to test my device without having to program it?

The Measurement and Automation Explorer has a Test panel with some

excellent tools for doing simple functional tests of the device, such as

testing the digital I/O lines. Also, the Test Configuration button will verify

that the logical address for the device is current.

Timing and Digital I/O

What are the power-on states of the DIO lines on the I/O connector?

At system power-on and reset, all lines are configured as inputs. Refer to

the Digital I/O Control section in Chapter 4, Hardware Overview, for more

information.

Analog Output

What are the power-on states of the voltage and current outputs?

At system power-on and reset, all analog outputs are at the values you last

saved.

How fast do the 6703 devices scan channels?

The 6703 devices have one 16-bit DAC that is time-division multiplexed to

create 16 voltage output and two calibration channels. The channels are

scanned at a rate of 50 µs per channel, thus a channel can change value a

maximum of 0.9 ms after it has been updated by software.

How fast do the 6704 devices scan channels?

The 6704 devices have one 16-bit DAC that is time-division multiplexed to

create 16 voltage output, 16 current output, and four calibration channels.

The channels are scanned at a rate of 50 µs per channel, thus a channel can

change value a maximum of 1.8 ms after it has been updated by software.

PCI/PXI-6703/6704 User Manual B-2 www.natinst.com

Page 33

Technical Support Resources

National Instruments offers technical support through electronic, fax, and

telephone systems. The electronic services include our Web site, an FTP

site, and a fax-on-demand system. If you have a hardware or software

problem, please first try the electronic support systems. If the information

available on these systems does not answer your questions, contact one of

our technical support centers, which are staffed by applications engineers,

for support by telephone and fax. To comment on the documentation

supplied with our products, send e-mail to

Web Site

The InstrumentationWeb address is

From this Web site you can connect to our Web sites around the

world (

www.natinst.com/niglobal/

support (

www.natinst.com/support/

FTP Site

To access our FTP site, log in to our Internet host,

as

anonymous

yourname@anywhere.com

documents are located in the

and use your e-mail address, such as

, as your password. The support files and

www.natinst.com

\support

directories.

) and access technical

).

C

techpubs@natinst.com

.

ftp.natinst.com

.

,

Fax-on-Demand Support

Fax-on-Demand is a 24-hour information retrieval system containing a

library of documents in English on a wide range of technical information.

You can access Fax-on-Demand from a touch-tone telephone at

512 418 1111.

E-Mail Support

You can submit technical support questions to the applications engineering

team through e-mail at

your name, address, and phone number so we can contact you with

solutions and suggestions.

© National Instruments Corporation C-1 PCI/PXI-6703/6704 User Manual

support@natinst.com

. Remember to include

Page 34

Telephone and Fax Support

For telephone support in the United States, dial 512 795 8248. For

telephone support outside the United States, contact your local branch

office:

Australia 03 9879 5166, Austria 0662 45 79 90 0, Belgium 02 757 00 20,

Brazil 011 284 5011, Canada (Ontario) 905 785 0085,

Canada (Québec) 514 694 8521, China 0755 3904939,

Denmark 45 76 26 00, Finland 09 725 725 11, France 01 48 14 24 24,

Germany 089 741 31 30, Hong Kong 2645 3186, India 91805275406,

Israel 03 6120092, Italy 02 413091, Japan 03 5472 2970,

Korea 02 596 7456, Mexico (D.F.) 5 280 7625,

Mexico (Monterrey) 8 357 7695, Netherlands 0348 433466,

Norway 32 27 73 00, Singapore 2265886, Spain (Madrid) 91 640 0085,

Spain (Barcelona) 93 582 0251, Sweden 08 587 895 00,

Switzerland 056 200 51 51, Taiwan 02 2377 1200,

United Kingdom 01635 523545

PCI/PXI-6703/6704 User Manual C-2 www.natinst.com

Page 35

Glossary

Prefix Meaning Value

n- nano- 10

µ- micro- 10

m- milli- 10

k- kilo- 10

M- mega- 10

G- giga- 10

–9

–6

–3

3

6

9

Numbers/Symbols

° degrees

– negative of, or minus

Ω ohms

/per

% percent

± plus or minus

+ positive of, or plus

A

A amperes

A/D analog-to-digital

ANSI American National Standards Institute

© National Instruments Corporation G-1 PCI/PXI-6703/6704 User Manual

Page 36

Glossary

B

bit one binary digit, either 0 or 1

bus the group of conductors that interconnect individual circuitry in a computer.

Typically, a bus is the expansion vehicle to which I/O or other devices are

connected.

C

CCelsius

channel pin or wire lead to which you apply or from which you read the analog or

digital signal. Analog signals can be single-ended or differential. For digital

signals, you group channels to form ports. Ports usually consist of either

four or eight digital channels.

D

D/A digital-to-analog

DAC D/A converter

DAQ data acquisition—(1) collecting and measuring electrical signals from

sensors, transducers, and test probes or fixtures and inputting them to a

computer for processing; (2) collecting and measuring the same kinds of

electrical signals with A/D and/or DIO boards plugged into a computer, and

possibly generating control signals with D/A and/or DIO boards in the

same computer

DC direct current

device (1) a plug-in data acquisition board, card, or pad that can contain multiple

channels and conversion devices. Plug-in boards, PCMCIA cards, and

devices such as the DAQPad-1200, which connects to your computer

parallel port, are all examples of DAQ devices.

DIO digital input/output

PCI/PXI-6703/6704 User Manual G-2 © National Instruments Corporation

Page 37

Glossary

DLL Dynamic Link Library—A software module in Microsoft Windows

containing executable code and data that can be called or used by Windows

applications or by other DLLs. Functions and data in a DLL are loaded and

linked at run time when they are referenced by a Windows application or

other DLLs.

drivers/driver software software that controls a specific hardware device such as a DAQ board

E

EEPROM Electrically Erasable Programmable Read-Only Memory (ROM) that can

be erased (usually by ultraviolet light exposure) and reprogrammed

F

function a set of software instructions executed by a single line of code that may

have input and/or output parameters and returns a value when executed

G

GND ground signal or bit

H

hardware the physical components of a computer system, such as the circuit boards,

plug-in boards, chassis, enclosures, peripherals, cables, and so on

hex hexadecimal

Hz hertz—the number of scans read or updates written per second

I

IC integrated circuit

in. inches

INL Integral Nonlinearity—a measure in LSB of the worst-case deviation from

the ideal A/D or D/A transfer characteristic of the analog I/O circuitry

© National Instruments Corporation G-3 PCI/PXI-6703/6704 User Manual

Page 38

Glossary

interrupt a computer signal indicating that the CPU should suspend its current task

to service a designated activity

interrupt level the relative priority at which a device can interrupt

I/O input/output—the transfer of data to/from a computer system involving

communications channels, operator interface devices, and/or data

acquisition and control interfaces

I

OH

I

OL

current, output high

current, output low

K

KB kilobytes—1,024 bytes when referring to memory

L

LED light-emitting diode

LSB least significant bit

M

m meters

max maximum

min minimum

MSB most significant bit

N

NC not connected

NI-DAQ National Instruments driver software for DAQ hardware

PCI/PXI-6703/6704 User Manual G-4 © National Instruments Corporation

Page 39

Glossary

noise an undesirable electrical signal—Noise comes from external sources such

as the AC power line, motors, generators, transformers, fluorescent lights,

soldering irons, CRT displays, computers, electrical storms, welders, radio

transmitters, and internal sources such as semiconductors, resistors, and

capacitors. Noise corrupts signals you are trying to send or receive.

nvRAM nonvolatile RAM

O

operating system base-level software that controls a computer, runs programs, interacts with

users, and communicates with installed hardware or peripheral devices

P

PC personal computer

port (1) a communications connection on a computer or a remote controller (2)

a digital port, consisting of four or eight lines of digital input and/or output

ppm parts per million

R

RAM random access memory

resolution the smallest signal increment that can be detected by a measurement

system. Resolution can be expressed in bits, in proportions, or in percent of

full scale. For example, a system has 12-bit resolution, one part in 4,096

resolution, and 0.0244% of full scale.

RTSI Real-Time System Integration

S

s seconds

settling time the amount of time required for a voltage to reach its final value within

specified limits

slot a position where a module can be inserted into the PCI bus

© National Instruments Corporation G-5 PCI/PXI-6703/6704 User Manual

Page 40

Glossary

system RAM RAM installed on a personal computer and used by the operating system,

as contrasted with onboard RAM

T

transfer rate the rate, measured in bytes/s, at which data is moved from source to

destination after software initialization and set up operations; the maximum

rate at which the hardware can operate

TTL transistor-transistor logic

typ typical

U

update the output equivalent of a scan. One or more analog or digital output

samples. Typically, the number of output samples in an update is equal to

the number of channels in the output group. For example, one pulse from

the update clock produces one update which sends one new sample to every

analog output channel in the group.

V

V volts

VDC volts direct current

VI Virtual Instrument—(1) a combination of hardware and/or software

elements, typically used with a PC, that has the functionality of a classic

stand-alone instrument (2) a LabVIEW software module (VI), which

consists of a front panel user interface and a block diagram program

W

Wwatts

PCI/PXI-6703/6704 User Manual G-6 © National Instruments Corporation

Page 41

Index

Numbers

+5 V signal

description (table), 3-3

power connections, 3-7

self-resetting protection circuit breaker, 3-7

A

AGND signal (table), 3-3

AGND<0/16..15/31> signals (table), 3-3

analog output signal connections, 3-4 to 3-6

common questions, B-2

current output for 6704 device, 3-5 to 3-6

voltage channel (VCH) outputs (figure), 3-4

voltage output, 3-4 to 3-5

analog output specifications, A-1 to A-3

current output, 6704 only, A-2

dynamic characteristics, A-2

stability, A-2 to A-3

transfer characteristics, A-1

voltage output, A-1 to A-2

B

bus interface

circuitry, 4-2

specifications, A-3

external calibration, 5-1 to 5-2

6703 calibration channel numbers

(table), 5-2

6704 calibration channel numbers

(table), 5-2

saving calibration values, 5-4

self-calibration, 5-1

voltage output calibration

gain adjustment, 5-3

offset adjustment, 5-3

common questions. See questions about

PCI/PXI-6703/6704.

ComponentWorks software, 1-3

configuration

common questions, B-1 to B-2

overview, 2-2

connector. See I/O connector.

conventions used in manual, iv

current output for 6704 device

calibration, 5-3 to 5-4

gain adjustment, 5-4

offset adjustment, 5-4

ICH connection as current output

(figure), 3-5

power-up condition, 3-6

signal connections, 3-5 to 3-6

specifications, A-2

custom cabling, 1-5

C

calibration, 5-1 to 5-4

current output calibration for 6704,

5-3 to 5-4

gain adjustment, 5-4

offset adjustment, 5-4

© National Instruments Corporation I-1 PCI/PXI-6703/6704 User Manual

D

DGND signal (table), 3-3

digital I/O

common questions, B-2

example connections (figure), 3-6

hardware overview, 4-2

power-up condition, 3-7

Page 42

Index

signal connections, 3-6 to 3-7

specifications, A-3

DIO<0..7> signals (table), 3-3

E

e-mail support, C-1

environment specifications, A-4

equipment, optional, 1-5

F

fax and telephone support numbers, C-2

Fax-on-Demand support, C-1

frequently asked questions. See questions

about PCI/PXI-6703/6704.

FTP support, C-1

G

gain adjustment

current output calibration for 6704, 5-4

voltage output calibration, 5-3

I/O connector

overview, 4-2

pin assignments (figure), 3-2

signal connection descriptions (table), 3-3

L

LabVIEW and LabWindows/CVI

software, 1-3

N

National Instruments application software,

1-3 to 1-4

NI-DAQ driver software, 1-4

nonvolatile RAM/DAC control, 4-2

O

offset adjustment

current output calibration for 6704, 5-4

voltage output calibration, 5-3

optional equipment, 1-5

H

hardware

configuration, 2-2

installation, 2-1 to 2-2

overview, 4-1 to 4-2

I

ICH connection as current output (figure), 3-5

ICH<16..31> signals (table), 3-3

installation

common questions, B-1

hardware, 2-1 to 2-2

software, 2-1

unpacking the PCI/PXI-6703/6704,

1-2 to 1-3

PCI/PXI-6703/6704 User Manual I-2 © National Instruments Corporation

P

PCI/PXI-6703/6704

block diagram, 4-1

common questions, B-1 to B-2

custom cabling, 1-5

features, 1-1 to 1-2

hardware overview, 4-1 to 4-2

optional equipment, 1-5

requirements for getting started, 1-2

software programming choices, 1-3 to 1-4

National Instruments application

software, 1-3 to 1-4

NI-DAQ driver software, 1-4

unpacking, 1-2 to 1-3

physical specifications, A-4

pin assignments for I/O connector (figure), 3-2

Page 43

Index

power connections, 3-7

power requirement specifications, A-3 to A-4

power supply, short-circuiting, B-1

power-up condition

current output for 6704 device, 3-6

digital I/O, 3-7

voltage output, 3-4

Q

questions about PCI/PXI-6703/6704,

B-1 to B-2

analog output, B-2

general information, B-1

installation and configuration, B-1 to B-2

timing and digital I/O, B-2

R

requirements for getting started, 1-2

S

self-resetting protection circuit breaker, 3-7

signal connections, 3-1 to 3-7

analog output, 3-4 to 3-6

current output for 6704 device,

3-5 to 3-6

voltage channel (VCH) outputs

(figure), 3-4

voltage output, 3-4 to 3-5

digital I/O, 3-6 to 3-7

I/O connector

pin assignments (figure), 3-2

signal connection descriptions

(table), 3-3

power connections, 3-7

software installation, 2-1

software programming choices, 1-3 to 1-4

National Instruments application

software, 1-3 to 1-4

NI-DAQ driver software, 1-4

specifications, A-1 to A-4

analog output, A-1 to A-3

current output, 6704 only, A-2

dynamic characteristics, A-2

stability, A-2 to A-3

transfer characteristics, A-1

voltage output, A-1 to A-2

bus interface, A-3

digital I/O, A-3

environment, A-4

physical, A-4

power requirements, A-3 to A-4

T

technical support resources, C-1 to C-2

telephone and fax support numbers, C-2

temperature sensor, 4-2

timing, questions about, B-2

U

unpacking the PCI/PXI-6703/6704, 1-2 to 1-3

V

VCH connection as voltage output

(figure), 3-4

VCH<0..15> signals (table), 3-3

VirtualBench software, 1-3

voltage output, 3-4 to 3-5

calibration

gain adjustment, 5-3

offset adjustment, 5-3

power-up condition, 3-4

signal connections, 3-4

specifications, A-1 to A-2

VCH connection as voltage output

(figure), 3-4

© National Instruments Corporation I-3 PCI/PXI-6703/6704 User Manual

Page 44

Index

W

Web site support, C-1

PCI/PXI-6703/6704 User Manual I-4 © National Instruments Corporation

Loading...

Loading...