Page 1

Artisan Technology Group is your source for quality

new and certied-used/pre-owned equipment

• FAST SHIPPING AND

DELIVERY

• TENS OF THOUSANDS OF

IN-STOCK ITEMS

• EQUIPMENT DEMOS

• HUNDREDS OF

MANUFACTURERS

SUPPORTED

• LEASING/MONTHLY

RENTALS

• ITAR CERTIFIED

SECURE ASSET SOLUTIONS

SERVICE CENTER REPAIRS

Experienced engineers and technicians on staff

at our full-service, in-house repair center

Instra

Remotely inspect equipment before purchasing with

our interactive website at www.instraview.com

Contact us: (888) 88-SOURCE | sales@artisantg.com | www.artisantg.com

SM

REMOTE INSPECTION

View

WE BUY USED EQUIPMENT

Sell your excess, underutilized, and idle used equipment

We also offer credit for buy-backs and trade-ins

www.artisantg.com/WeBuyEquipment

LOOKING FOR MORE INFORMATION?

Visit us on the web at www.artisantg.com for more

information on price quotations, drivers, technical

specications, manuals, and documentation

Page 2

DAQ M Series

M Series User Manual

NI 622x, NI 625x, and NI 628x Multifunction I/O

Modules and Devices

M Series User Manual

July 2016

371022L-01

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 3

Support

Worldwide Technical Support and Product Information

ni.com

Worldwide Offices

Visit ni.com/niglobal to access the branch office websites, which provide up-to-date

contact information, support phone numbers, email addresses, and current events.

National Instruments Corporate Headquarters

11500 North Mopac Expressway Austin, Texas 78759-3504 USA Tel: 512 683 0100

For further support information, refer to the NI Services appendix. To comment on NI

documentation, refer to the NI website at ni.com/info and enter the Info Code feedback.

© 2004–2016 National Instruments. All rights reserved.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 4

Legal Information

Limited Warranty

This document is provided ‘as is’ and is subject to being changed, without notice, in future editions. For the latest version,

ni.com/manuals. NI reviews this document carefully for technical accuracy; however, NI MAKES NO EXPRESS

refer to

OR IMPLIED WARRANTIES AS TO THE ACCURACY OF THE INFORMATION CONTAINED HEREIN AND

SHALL NOT BE LIABLE FOR ANY ERRORS.

NI warrants that its hardware products will be free of defects in materials and workmanship that cause the product to fail to

substantially conform to the applicable NI published specifications for one (1) year from the date of invoice.

For a period of ninety (90) days from the date of invoice, NI warrants that (i) its software products will perform substantially

in accordance with the applicable documentation provided with the software and (ii) the software media will be free from

defects in materials and workmanship.

If NI receives notice of a defect or non-conformance during the applicable warranty period, NI will, in its discretion: (i) repair

or replace the affected product, or (ii) refund the fees paid for the affected product. Repaired or replaced Hardware will be

warranted for the remainder of the original warranty period or ninety (90) days, whic hever is lon ger. If NI elects to repair or

replace the product, NI may use new or refurbished parts or products that are equivalent to new in performance and reliability

and are at least functionally equivalent to the original part or product.

You must obtain an RMA number from NI before returning any product to NI. NI reserves the right to charge a fee for

examining and testing Hardware not covered by the Limited Warranty.

This Limited Warranty does not apply if the defect of the product resulted from improper or inadequate maintenance,

installation, repair, or calibration (performed by a party other than NI); unauthorized modification; improper environment;

use of an improper hardware or software key; impr oper use or operation outsid e of the specification for the product; improper

voltages; accident, abuse, or neglect; or a hazard such as lightning, flood, or other act of nature.

THE REMEDIES SET FORTH ABOVE ARE EXCLUSIVE AND THE CUSTOMER’S SOLE REMEDIES, AND SHALL

APPLY EVEN IF SUCH REMEDIES FAIL OF THEIR ESSENTI A L PU RPOS E.

EXCEPT AS EXPRESSLY SET FORTH HEREIN, PRODUCTS ARE PROVIDED "AS IS" WITHOUT WARRANTY OF

ANY KIND AND NI DISCLAIMS ALL WARRANTIES, EXPRESSED OR IMPLIED, WITH RESPECT TO THE

PRODUCTS, INCLUDING ANY IMPLIED WARRANTIES OF MERCHANTABILITY, FITNESS FOR A

PARTICULAR PURPOSE, TIT LE OR NON-INFR INGEMENT, AND ANY WARRANTIES T HAT MAY ARISE FROM

USAGE OF TRADE OR COURSE OF DEALING. NI DOES NOT WARRANT, GUARANTEE, OR MAKE ANY

REPRESENTATIONS REGARDING THE USE OF OR THE RESULTS O F THE USE OF THE PRODUCTS IN TERMS

OF CORRECTNESS, ACCURACY, RELIABILITY, OR OTHERWISE. NI DOES NOT WARRANT THAT THE

OPERATION OF THE PRODUCTS WILL BE UNINTERRUPTED OR ERROR FRE E.

In the event that you and NI have a separate signed written agreement with warranty terms covering the products, then the

warranty terms in the separate agreement shall control.

Copyright

Under the copyright laws, this publication may not be reproduced or transmitted in any form, electronic or mechanical,

including photocopying, recording, storing in an information retr ieval system, or translating , in whole or in part, without the

prior written consent of National Instruments Corporation.

National Instruments respects the intellectual property of others, and we ask our users to do the same. NI software is protected

by copyright and other intellectual property laws. Where NI soft ware may be used to reproduce software or other materials

belonging to others, you may use NI software only to reproduce materials that you may reproduce in accordance with the

terms of any applicable license or other legal restriction.

End-User License Agreements and Third-Party Legal Notices

You can find end-user license agreements (EULAs) and third-party legal notices in the following locations:

• Notices are located in the

directories.

• EULAs are located in the

•Review

<National Instruments>\_Legal Information.txt for information on including legal information in

installers built with NI products.

U.S. Government Restricted Rights

If you are an agency, department, or other entity of the United States Government (“Government”), the use, duplication,

reproduction, release, modification, disclosure or transfer of the technical data includ ed in this manual is governed by the

Restricted Rights provisions under Federal Acquisition Regulation 52.227-14 for civilian agencies and Defense Federal

Acquisition Regulation Supplement Section 252.227-7014 and 252 .22 7-7015 fo r military agencies.

Trademarks

Refer to the NI Trademarks and Logo Guidelines at ni.com/trademarks for more information on NI trademarks.

ARM, Keil, and µVision are trademarks or registered of ARM Ltd or its subsidiaries.

LEGO, the LEGO logo, WEDO, and MINDSTORMS are trademarks of the LEGO Group.

TETRIX by Pitsco is a trademark of Pitsco, Inc.

FIELDBUS FOUNDATION

®

EtherCAT

is a registered trademark of and licensed by Beckhoff Automation GmbH.

<National Instruments>\_Legal Information and <National Instruments>

<National Instruments>\Shared\MDF\Legal\license directory.

™

and FOUNDATION™ are trademarks of the Fieldbus Foundation.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 5

CANopen® is a registered Community Trademark of CAN in Automation e.V.

™

DeviceNet

Go!, SensorDAQ, and Vernier are registered trademarks of Vernier Software & Technology. Vernier Software & Technology

and

and EtherNet/IP™ are trademarks of ODVA.

vernier.com are trademarks or trade dress.

Xilinx is the registered trademark of Xilinx, Inc.

Taptite and Trilobular are registered trademarks of Research Engineering & Manufacturing Inc.

®

is the registered trademark of Apple Inc.

FireWire

®

Linux

is the registered trademark of Linus Torvalds in the U.S. and other countries.

Handle Graphics

Simulink Coder

Tektronix

The Bluetooth

The ExpressCard

license.

The mark LabWindows is used under a license from Microsoft Corporation. Windows is a registered trademark of Microsoft

Corporation in the United States and other countries.

®

, MATLAB®, Simulink®, Stateflow®, and xPC TargetBox® are registered trademarks, and

™

, TargetBox™, and Target Language Compiler™ are trademarks of The MathWorks, Inc.

®

, Tek, and Tektronix, Enabling Technology are registered trademarks of Tektronix, Inc.

®

word mark is a registered trademark owned by the Bluetooth SIG, Inc.

™

word mark and logos are owned by PCMCIA and any use of such marks by National Instruments is under

Other product and company names mentioned herein are trademarks or trade names of their respective companies.

Members of the National Instruments Alliance Partner Program are business entities independent from NI and have no

agency, partnership, or joint-venture relationship with NI.

Patents

For patents covering NI products/technology, refer to the appropriate location : Help»Patents in your software,

the patents.txt file on your media, or the National Instruments Patent Notice at ni.com/patents.

Export Compliance Information

Refer to the Export Compliance Information at ni.com/legal/export-compliance for the NI global trade compliance

policy and how to obtain relevant HTS codes, ECCNs, and other import/export data.

WARNING REGARDING USE OF NATIONAL INSTRUMENTS PRODUCTS

YOU ARE ULTIMATELY RESPONSIBLE FOR VERIFYING AND VALIDATING THE SUITABILITY AND

RELIABILITY OF THE PRODUCTS WHENEVE R THE PR ODUCTS AR E INCORPO RATED IN YOUR SYSTE M OR

APPLICATION, INCLUDING THE APPROPRIATE DESIGN, PROCESS, AND SAFETY LEVEL OF SUCH SYSTEM

OR APPLICATION.

PRODUCTS ARE NOT DESIGNED, MANUFACTURED, OR TESTED FOR USE IN LIFE OR SAFETY CRITICAL

SYSTEMS, HAZARDOUS ENVIRONME NTS OR ANY OTHER ENVIRONMENTS REQUIRING FAIL- S AF E

PERFORMANCE, INCLUDING IN TH E OPE RAT ION O F NUCLEAR FACILITIES; AIRCRAFT NAVIGATION; AIR

TRAFFIC CONTROL SYSTEMS; LIFE SAVING OR LIFE SUSTAINING SYSTEMS OR SUCH OTHER MEDICAL

DEVICES; OR ANY OTHER APPLICATION IN WHICH THE FAILURE OF THE PRODUCT OR SERVICE COULD

LEAD TO DEATH, PERSONAL INJURY, SEVERE PROPERTY DAMAGE OR ENVIRONMENTAL HARM

(COLLECTIVELY, “HIGH-RISK USE S”). FURTHER, PRUDENT ST EPS MUST BE TAKEN TO PROTECT AGAINST

FAILURES, INCLUDING P ROVIDING BACK-U P AND SHUT-DOWN ME CHANISMS. NI EXPR ESSLY DISCLAIMS

ANY EXPRESS OR IMPLIED WARRANTY OF FITNESS OF THE PRODUCTS OR SERVICES FOR HIGH-RISK

USES.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 6

Contents

Chapter 1

Getting Started

Safety Guidelines.............................................................................................................. 1-1

Safety Guidelines for Hazardous Voltages...............................................................1-2

Electromagnetic Compatibility Guidelines ......................................................................1-2

Hardware Symbol Definitions.................. ................................................. .......................1-3

Installation ........................................................................................................................ 1-3

Unpacking.........................................................................................................................1-3

Device Self-Calibration ....................................................................................................1-4

Getting Started with M Series PCI Express Devices and the Disk Drive Power

Connector ...................................................................................................................... 1-5

When to Use the Disk Drive Power Connector........................................................1-5

Disk Drive Power Connector Installation................................................................. 1-5

Getting Started with M Series USB Devices.................................................................... 1-6

Applying the Signal Label to USB Screw Terminal Devices ..................................1-6

USB Device Chassis Ground.................................................................................... 1-6

USB Device Panel/Wall Mounting........................................................................... 1-8

USB Device LEDs........................................................................................ ............1-8

USB Cable Strain Relief...........................................................................................1-8

USB Device Fuse Replacement ................................................................................ 1-9

USB Device Security Cable Slot..............................................................................1-12

Installing a Ferrite.....................................................................................................1-13

Pinouts .............................................................................................................................. 1-13

Specifications....................................................................................................................1-13

Accessories and Cables ....................... ............................................................................. 1-13

Chapter 2

DAQ System Overview

DAQ Hardware............................................. ............................................... .....................2-1

DAQ-STC2 and DAQ-6202.....................................................................................2-2

Calibration Circuitry.................................................................................................2-2

Cables and Accessories .................................................................................................... 2-3

68-Pin M Series Cables and Accessories ................................................................. 2-3

68-Pin Cables........ .............................................. .............................................. 2-5

68-Pin BNC Accessories ... ................................................. .............................. 2-6

68-Pin Screw Terminal Accessories................................................................. 2-6

RTSI Cables....... ............................................... ................................................ 2-6

SCC Carriers and Accessories.......................................................................... 2-6

SCXI.................................................................................................................2-7

68-Pin Custom Cabling and Connectivity........................................................ 2-7

USB Device Accessories, USB Cable, and Power Supply...............................2-8

© National Instruments | v

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 7

Contents

37-Pin M Series Cables and Accessories.......................................... ........................2-8

37-Pin Cables................................ ............................................... .....................2-9

37-Pin Screw Terminal Accessories .................................................... .............2-9

RTSI Cables.............................................................................. ........................2-9

37-Pin Custom Cabling.................................................... .................................2-9

Signal Conditioning..........................................................................................................2-10

Sensors and Transducers...........................................................................................2-10

Signal Conditioning Options ....................................................................................2-10

SCXI .................................................................................................................2-10

SCC...................................................................................................................2-11

Programming Devices in Software...................................................................................2-11

Chapter 3

Connector and LED Information

I/O Connector Signal Descriptions...................................................................................3-1

+5 V Power Source...........................................................................................................3-5

USER 1 and USER 2 ........................................................................................................3-5

RTSI Connector Pinout.....................................................................................................3-7

LED Patterns.....................................................................................................................3-7

Chapter 4

Analog Input

Analog Input Range..........................................................................................................4-2

Analog Input Lowpass Filter ............................................................................................4-3

Analog Input Ground-Reference Settings.........................................................................4-4

Configuring AI Ground-Reference Settings in Software .........................................4-6

Multichannel Scanning Considerations ............................................................................4-6

Analog Input Data Acquisition Methods..........................................................................4-9

Software-Timed Acquisitions ...................................................................................4-9

Hardware-Timed Acquisitions............................................. .....................................4-9

Analog Input Triggering...................................................................................................4-10

Connecting Analog Input Signals.....................................................................................4-11

Connecting Floating Signal Sources.................................................................................4-12

What Are Floating Signal Sources?..................................... .....................................4-12

When to Use Differential Connections with Floating Signal Sources......................4-12

When to Use Non-Referenced Single-Ended (NRSE) Connections with

Floating Signal Sources................ .........................................................................4-12

When to Use Referenced Single-Ended (RSE) Connections with Floating

Signal Sources .......................................................................................................4-13

Using Differential Connections for Floating Signal Sources...................................4-13

Using Non-Referenced Single-Ended (NRSE) Connections for

Floating Signal Sources................ .........................................................................4-16

Using Referenced Single-Ended (RSE) Connections for Floating

Signal Sources .......................................................................................................4-17

vi | ni.com

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 8

M Series User Manual

Connecting Ground-Referenced Signal Sources..............................................................4-17

What Are Ground-Referenced Signal Sources? ....................................................... 4-17

When to Use Differential Connections with Ground-Referenced Signal

Sources .................................................................................................................. 4-18

When to Use Non-Referenced Single-Ended (NRSE) Connections with

Ground-Referenced Signal Sources ......................................................................4-18

When to Use Referenced Single-Ended (RSE) Connections with

Ground-Referenced Signal Sources ......................................................................4-19

Using Differential Connections for Ground-Referenced Signal Sources.................4-19

Using Non-Referenced Single-Ended (NRSE) Connections for

Ground-Referenced Signal Sources ......................................................................4-20

Field Wiring Considerations............................................................................................. 4-21

Analog Input Timing Signals ........................................................................................... 4-21

AI Sample Clock Signal ...........................................................................................4-23

Using an Internal Source ..................................................................................4-24

Using an External Source ................................................................................. 4-24

Routing AI Sample Clock Signal to an Output Terminal................................. 4-24

Other Timing Requirements ............................................................................. 4-24

AI Sample Clock Timebase Signal........................................................................... 4-25

AI Convert Clock Signal ..........................................................................................4-25

Using an Internal Source ..................................................................................4-26

Using an External Source ................................................................................. 4-26

Routing AI Convert Clock Signal to an Output Terminal................................4-26

Using a Delay from Sample Clock to Convert Clock ......................................4-27

Other Timing Requirements ............................................................................. 4-27

AI Convert Clock Timebase Signal..........................................................................4-29

AI Hold Complete Event Signal...............................................................................4-29

AI Start Trigger Signal .............................................................................................4-29

Using a Digital Source...................................................................................... 4-29

Using an Analog Source...................................................................................4-30

Routing AI Start Trigger to an Output Terminal..............................................4-30

AI Reference Trigger Signal............... ................................................. .....................4-30

Using a Digital Source...................................................................................... 4-31

Using an Analog Source...................................................................................4-31

Routing AI Reference Trigger Signal to an Output Terminal.......................... 4-31

AI Pause Trigger Signal ...........................................................................................4-31

Using a Digital Source...................................................................................... 4-32

Using an Analog Source...................................................................................4-32

Routing AI Pause Trigger Signal to an Output Terminal.................................4-32

Getting Started with AI Applications in Software........ ................................................... . 4-32

© National Instruments | vii

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 9

Contents

Chapter 5

Analog Output

AO Offset and AO Reference Selection ...........................................................................5-2

Minimizing Glitches on the Output Signal......... ................................................. ... ..........5-3

Analog Output Data Generation Methods ........................................................................5-3

Software-Timed Generations....................................................................................5-3

Hardware-Timed Generations........ ................................................. ..........................5-4

Analog Output Triggering ................................................................................................5-5

Connecting Analog Output Signals ..................................................................................5-5

Analog Output Timing Signals.........................................................................................5-6

AO Start Trigger Signal.......................... ..................................................................5-6

Using a Digital Source......................................................................................5-6

Using an Analog Source ...................................................................................5-7

Routing AO Start Trigger Signal to an Output Terminal.................................5-7

AO Pause Trigger Signal ..........................................................................................5-7

Using a Digital Source......................................................................................5-8

Using an Analog Source ...................................................................................5-8

Routing AO Pause Trigger Signal to an Output Terminal................................5-8

AO Sample Clock Signal.......................... ................................................................5-8

Using an Internal Source...................................................................................5-8

Using an External Source .................................................................................5-8

Routing AO Sample Clock Signal to an Output Terminal...............................5-9

Other Timing Requirements .............................................................................5-9

AO Sample Clock Timebase Signal .........................................................................5-9

Getting Started with AO Applications in Software..........................................................5-10

Chapter 6

Digital I/O

Static DIO .........................................................................................................................6-2

Digital Waveform Triggering ...........................................................................................6-2

Digital Waveform Acquisition..........................................................................................6-3

DI Sample Clock Signal ...........................................................................................6-3

Using an Internal Source...................................................................................6-3

Using an External Source .................................................................................6-4

Routing DI Sample Clock to an Output Terminal............................................6-4

Digital Waveform Generation ..........................................................................................6-4

DO Sample Clock Signal.......................... ................................................................6-4

Using an Internal Source...................................................................................6-5

Using an External Source .................................................................................6-5

Routing DO Sample Clock to an Output Terminal............... .. ..........................6-5

I/O Protection................................................ ............................................... .. ...................6-5

Programmable Power-Up States.......................................................................................6-6

DI Change Detection ........................................................................................................6-7

DI Change Detection Applications...........................................................................6-8

viii | ni.com

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 10

M Series User Manual

Connecting Digital I/O Signals............................................. ............................................ 6-8

Getting Started with DIO Applications in Software............................................. .. ..........6-9

Chapter 7

Counters

Counter Input Applications ................... ............................................... ............................ 7-1

Counting Edges........................................................................................................ . 7-2

Single Point (On-Demand) Edge Counting...................................................... 7-2

Buffered (Sample Clock) Edge Counting.........................................................7-3

Controlling the Direction of Counting.............................................................. 7-3

Pulse-Width Measurement .......................................................................................7-3

Single Pulse-Width Measurement .................................................................... 7-4

Buffered Pulse-Width Measurement ...................................... ..........................7-4

Period Measurement................................................................................................. 7-5

Single Period Measurement.............................................................................. 7-5

Buffered Period Measurement.......................................................................... 7-6

Semi-Period Measurement .......................................................................................7-7

Single Semi-Period Measurement .................................................................... 7-7

Buffered Semi-Period Measurement ................................................................7-7

Frequency Measurement............................................................. .............................. 7-8

Low Frequency with One Counter...................................................................7-8

Low Frequency with One Counter (Averaged)................................................7-9

High Frequency with Two Counters ................................................................7-9

Large Range of Frequencies with Two Counters............................................. 7-10

Choosing a Method for Measuring Frequency.................................................7-11

Position Measurement ..............................................................................................7-14

Measurements Using Quadrature Encoders ..................................................... 7-15

Measurements Using Two Pulse Encoders ...................................................... 7-16

Buffered (Sample Clock) Position Measurement........................ .. ...................7-17

Two-Signal Edge-Separation Measurement.......................... ................................... 7-17

Single Two-Signal Edge-Separation Measurement.......................................... 7-18

Buffered Two-Signal Edge-Separation Measurement......................................7-18

Counter Output Applications............................................................................. ...............7-19

Simple Pulse Generation ..........................................................................................7-19

Single Pulse Generation.................................................................................... 7-19

Single Pulse Generation with Start Trigger...................................................... 7-20

Retriggerable Single Pulse Generation............................................................. 7-20

Pulse Train Generation ............................................................................................. 7-21

Continuous Pulse Train Generation..................................................................7-21

Finite Pulse Train Generation........................................................................... 7-22

Frequency Generation........... .................................................................................... 7-22

Using the Frequency Generator........................................................................7-22

Frequency Division............... ................................................. ................................... 7-23

Pulse Generation for ETS.................................................................. .......................7-23

© National Instruments | ix

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 11

Contents

Counter Timing Signals............................................................. .......................................7-24

Counter n Source Signal ...........................................................................................7-24

Routing a Signal to Counter n Source ..............................................................7-25

Routing Counter n Source to an Output Terminal............................................7-25

Counter n Gate Signal...............................................................................................7-25

Routing a Signal to Counter n Gate........................ ... .......................................7-26

Routing Counter n Gate to an Output Terminal ...............................................7-26

Counter n Aux Signal ...............................................................................................7-26

Routing a Signal to Counter n Aux...................................................................7 -26

Counter n A, Counter n B, and Counter n Z Signals................................................7-27

Routing Signals to A, B, and Z Counter Inputs................................................7-27

Routing Counter n Z Signal to an Output Terminal .........................................7-27

Counter n Up_Down Signal......................................................................................7-27

Counter n HW Arm Signal .......................................................................................7-27

Routing Signals to Counter n HW Arm Input ..................................................7-27

Counter n Internal Output and Counter n TC Signals ..............................................7-28

Routing Counter n Internal Output to an Output Terminal ..............................7-28

Frequency Output Signal .. .. ................................................. .. ...................................7-28

Routing Frequency Output to a Terminal.........................................................7-28

Default Counter/Timer Pinouts.........................................................................................7-28

Counter Triggering ....................... ............................................... .....................................7-29

Other Counter Features.....................................................................................................7-30

Cascading Counters ..................................................................................................7-30

Counter Filters ............................................................................ ..............................7-30

Prescaling..................................................................................................................7-32

Duplicate Count Prevention................................. ............................................... .. ....7-32

Example Application That Works Correctly (No Duplicate Counting)...........7-33

Example Application That Works Incorrectly (Duplicate Counting)...............7-33

Example Application That Prevents Duplicate Count......................................7-34

When To

Enabling Duplicate Count Prevention in NI-DAQmx......................................7-35

Synchronization Modes ............................................................................................7-35

80 MHz Source Mode.......................................................................................7-36

Other Internal Source Mode .............................................................................7-36

External Source Mode ............................. ................................................. ........7-36

Use Duplicate Count

Prevention.......................................................7-34

Chapter 8

PFI

Using PFI Terminals as Timing Input Signals..................................................................8-2

Exporting Timing Output Signals Using PFI Terminals..................................................8-2

Using PFI Terminals as Static Digital I/Os ......................................................................8-3

Connecting PFI Input Signals...................................................... .....................................8-3

PFI Filters ....................................................................... ..................................................8-4

I/O Protection................................................ ............................................... .. ...................8-5

Programmable Power-Up States.......................................................................................8-5

x | ni.com

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 12

M Series User Manual

Chapter 9

Digital Routing and Clock Generation

Clock Routing...................................................................................................................9-1

80 MHz Timebase .................................................................................................... 9-2

20 MHz Timebase .................................................................................................... 9-2

100 kHz Timebase......................... ........................................................................... 9-2

External Reference Clock.........................................................................................9-2

10 MHz Reference Clock ......................................................................................... 9-2

Synchronizing Multiple Devices ...................................................................................... 9-3

PXI/PXI Express Modules........................................................................................ 9-3

PCI/PCI Express Devices ......................................................................................... 9-3

USB Devices................. .............................................. .............................................. 9-3

Real-Time System Integration (RTSI) .................... .........................................................9-4

RTSI Connector Pinout ............................................................................................9-4

Using RTSI as Outputs.............................................................................................9-5

Using RTSI Terminals as Timing Input Signals ...................................................... 9-6

RTSI Filters ................................................................................ .............................. 9-6

PXI Clock and Trigger Signals ......................................................................................... 9-8

PXI_CLK10..............................................................................................................9-8

PXI Triggers ... ............................................... ...........................................................9-8

PXI_STAR Trigger................................................................................................... 9-8

PXI_STAR Filters ....................................................................................................9-8

Chapter 10

Bus Interface

Data Transfer Methods..................................................................................................... 10-1

PCI/PCI Express Device and PXI/PXI Express Module Data Transfer Methods.... 10-1

USB Device Data Transfer Methods............... .........................................................10-2

PXI Considerations.................................................................................... .......................10-3

PXI Clock and Trigger Signals ................................................................................. 10-3

PXI and PXI Express................................................................................................10-3

Using PXI with CompactPCI .................................................................... ...............10-4

Chapter 11

Triggering

Triggering with a Digital Source................ ................................................. .....................11-1

Triggering with an Analog Source ................................................................................... 11-2

APFI <0,1> Terminals..............................................................................................11-2

Analog Input Channels............................................................................................. 11-2

Analog Trigger Actions............................................................................................ 11-3

Routing Analog Comparison Event to an Output Terminal ..................................... 11-3

Analog Trigger Types.......................................................................................................11-3

Analog Trigger Accuracy .................................................................................................11-6

© National Instruments | xi

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 13

Contents

Appendix A

Module/Device-Specific Information

NI 6220.............................................................................................................................A-2

NI 6221 (68-Pin)...............................................................................................................A-4

NI PCI-6221 (37-Pin) .......................................................................................................A-11

NI 6224.............................................................................................................................A-13

NI 6225.............................................................................................................................A-15

NI 6229.............................................................................................................................A-21

NI 6250.............................................................................................................................A-27

NI 6251.............................................................................................................................A-29

NI 6254.............................................................................................................................A-37

6255 .............................................................................................................................A-39

NI

NI 6259.............................................................................................................................A-45

NI 6280.............................................................................................................................A-53

NI 6281.............................................................................................................................A-55

NI 6284.............................................................................................................................A-61

NI 6289.............................................................................................................................A-63

Appendix B

Timing Diagrams

Appendix C

Troubleshooting

Appendix D

Upgrading from E Series to M Series

Appendix E

Where to Go from Here

Appendix F

NI Services

Index

xii | ni.com

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 14

M Series User Manual

Figures

Figure A-1. PCI/PXI-6220 Pinout ............................................................................ A-2

Figure A-2. PCI/PXI-6221 Pinout ............................................................................ A-5

Figure A-3. USB-6221 Screw Terminal Pinout........................................................A-7

Figure A-4. USB-6221 BNC Top Panel and Pinout................................................. A-9

Figure A-5. PCI-6221 (37-Pin) Pinout...................................................................... A-11

Figure A-6. PCI/PXI-6224 Pinout ............................................................................ A-13

Figure A-7. PCI/PXI-6225 Pinout ............................................................................ A-15

Figure A-8. USB-6225 Screw Terminal Pinout........................................................A-17

Figure A-9. USB-6225 Mass Termination Pinout.................................................... A-19

Figure A-10. PCI/PXI-6229 Pinout ............................................................................ A-21

Figure A-11. USB-6229 Screw Terminal Pinout........................................................A-23

Figure A-12. USB-6229 BNC Top Panel and Pinout................................................. A-25

Figure A-13. PCI/PXI-6250 Pinout ............................................................................ A-27

Figure A-14. NI PCI/PCIe/PXI/PXIe-6251 Pinout..................................................... A-29

Figure A-15. USB-6251 Screw Terminal Pinout........................................................A-31

Figure A-16. USB-6251 BNC Top Panel and Pinout................................................. A-33

Figure A-17. USB-6251 Mass Termination Pinout.................................................... A-35

Figure A-18. PCI/PXI-6254 Pinout ............................................................................ A-37

Figure A-19. PCI/PXI-6255 Pinout ............................................................................ A-39

Figure A-20. USB-6255 Screw Terminal Pinout........................................................A-41

Figure A-21. USB-6255 Mass Termination Pinout.................................................... A-43

Figure A-22. NI PCI/PCIe/PXI/PXIe-6259 Pinout..................................................... A-45

Figure A-23. USB-6259 Screw Terminal Pinout........................................................A-47

Figure A-24. USB-6259 BNC Top Panel and Pinout................................................. A-49

t

Figure A-25. USB-6259 Mass Termination Pinou

Figure A-26. PCI/PXI-6280 Pinout ............................................................................ A-53

Figure A-27. PCI/PXI-6281 Pinout ............................................................................ A-55

Figure A-28. USB-6281 Screw Terminal Pinout........................................................A-57

Figure A-29. USB-6281 Mass Termination Pinout.................................................... A-59

Figure A-30. PCI/PXI-6284 Pinout ............................................................................ A-61

Figure A-31. PCI/PXI-6289 Pinout ............................................................................ A-63

Figure A-32. USB-6289 Screw Terminal Pinout........................................................A-65

Figure A-33. USB-6289 Mass Termination Pinout.................................................... A-67

.................................................... A-51

© National Instruments | xiii

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 15

1

Getting Started

The M Series User Manual contains information about using the National Instruments M Series

multifunction I/O data acquisition (DAQ) devices with NI-DAQmx 15.5 and later. M Series

devices feature up to 80 analog input (AI) channels, up to four analog output (AO) channels, up

to 48 lines of digital input/output (DIO), and two counters. This chapter provides basic

information you need to get started using your M Series device.

Safety Guidelines

Operate the NI 62xx M Series devices and modules only as described in this user manual.

Caution NI 62xx devices and modules are not certified for use in hazardous

locations.

Caution Never connect the +5 V power terminals to analog or digital ground or to

any other voltage source on the M Series device or any other device. Doing so can

damage the device and the computer. NI is not liable for damage resulting from such

a connection.

Caution The maximum input voltages rating of AI signals with respect to ground

(and for signal pairs in differential mode with respect to each other) are listed in the

specifications document for your device. Exceeding the maximum input voltage of

AI signals distorts the measurement results. Exceeding the maximum input voltage

rating also can damage the device and the computer . NI is not liable fo r any damage

resulting from such signal connections.

Caution Exceeding the maximum input voltage ratings, which are listed in the

specifications document for each M Series device, can damage the DAQ device and

the computer. NI is not liable for any damage resulting from such signal connections.

Caution Damage can result if these lines are dri ven by the sub-bus. NI is not liable

for any damage resulting from improper signal connections.

© National Instruments | 1-1

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 16

Chapter 1 Getting Started

Safety Guidelines for Hazardous Voltages

If hazardous voltages are connected to the device/module, take the following precautions. A

hazardous voltage is a voltage greater than 42.4 V

Caution Ensure that hazardous voltage wiring is performed only by qualified

personnel adhering to local electrical standards.

Caution Do not mix hazardous voltage circuits and human-accessible circuits on

the same module.

Caution Make sure that chassis and circuits connected to the module are properly

insulated from human contact.

Caution NI 62xx devices and modules provide no isolation.

or 60 VDC to earth ground.

pk

Electromagnetic Compatibility Guidelines

This product was tested and complies with the regulatory requirements and limits for

electromagnetic compatibility (EMC) as stated in the product specifications. These requirements

and limits are designed to provide reasonable protection against harmful interference when the

product is operated in its intended operational electromagnetic environment.

This product is intended for use in industrial locations. There is no guarantee that harmful

interference will not occur in a particular installation, when the product is connected to a test

object, or if the product is used in residential areas. To minimize the potential for the product to

cause interference to radio and television reception or to experience unacceptable performance

degradation, install and use this product in strict accordance with the instructions in the product

documentation.

Furthermore, any changes or modifications to the product not expressly approved by National

Instruments could void your authority to operate it under your local regulatory rules.

Caution To ensure the specified EMC performance, product installation requires

either special considerations or user-installed, add-on devices. Refer to the product

installation instructions for further information.

Caution For compliance with Electromagnetic Comp ati b il ity (EMC)

requirements, this product must be operated with shielded cables and accessories. If

unshielded cables or accessories are used, the EMC specifications are no longer

guaranteed unless all unshielded cables and/or accessories are installe d in a shielde d

enclosure with properly designed and shielded input/output ports.

Caution This product may become more sensitive to electromagnetic disturbances

in the operational environment when test leads are attached or when connected to a

test object.

1-2 | ni.com

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 17

M Series User Manual

⬉ᄤֵᙃѻક∵ᶧࠊㅵ⧚ࡲ⊩ ˄Ё ˅

Ёᅶ᠋

National Instruments

ヺড়Ё⬉ᄤֵᙃѻકЁ䰤ࠊՓ⫼ᶤѯ᳝ᆇ⠽䋼ᣛҸ

(RoHS)

DŽ݇Ѣ

National InstrumentsЁRoHS

ড়㾘ᗻֵᙃˈ䇋ⱏᔩ

ni.com/

environment/rohs_china

DŽ

(For information about China RoHS compliance,

go to

ni.com/environment/rohs_china

.)

Hardware Symbol Definitions

The following symbols are marked on your device or module.

Caution When this symbol is marked on a product, refer to the Safety Guidelines

section for information about precautions to take.

EU Customers At the end of the product life cycle, all products must be sent to

a WEEE recycling center. For more information about WEEE recycling centers,

National Instruments WEEE initiatives, and compliance with WEEE Directive

2002/96/EC on Waste and Electronic Equipment, visit

weee.

ni.com/environment/

Installation

Before installing your multifunction I/O device, you must install the software you plan to use

with the device.

1. Installing application software—Refer to the installation instructions that accompany

your software.

2. Installing NI-DAQmx—The DAQ Getting Started Guide for PXI/PXI Express, DAQ

Getting Started Guide for PCI/PCI Express, or DAQ Getting Started Guide for Externally

Powered USB, packaged with your device or module, and also available on ni.com/

manuals, contain step-by-step instructions for installing software and hardware,

configuring channels and tasks, and getting started developing an application.

3. Installing the hardware—Unpack your M Series device as described in the Unpacking

section. Refer to the DAQ Getting Started Guide for PXI/PXI Express, DAQ Getting Started

Guide for PCI/PCI Express, or DAQ Getting Started Guide for Externally Powered USB

for information how to install your software and device or module. It also describes how to

confirm that your device or module is operating properly, configure your device or module,

run test panels, and take a measurement.

Unpacking

The M Series device ships in an antistatic package to prevent electrostatic discharge (ESD).

ESD can damage several components on the device.

Caution Never touch the exposed pins of connectors.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

© National Instruments | 1-3

Page 18

Chapter 1 Getting Started

To avoid ESD damage in handling the device, take the following precautions:

• Ground yourself with a grounding strap or by touching a grounded object.

• T ouch the antistatic package to a metal part of your computer chassis before removing the

device from the package.

Remove the device from the package and inspect it for loose components or any other signs of

damage. Notify NI if the device appears damaged in any way. Do not install a damaged device

in your computer or chassis.

Store the device in the antistatic package when the device is not in use.

Device Self-Calibration

NI recommends that you self-calibrate your M Series device after installation and whenever the

ambient temperature changes. Self-calibration should be performed after the device has warmed

up for the recommended time period. Refer to the device specifications to find your device

warm-up time. This function measures the onboard reference voltage of the device and adjusts

the self-calibration constants to account for any errors caused by short-term fluctuations in the

environment. Disconnect all external signals when you self-calibrate a device.

Note (NI PCIe-6251/6259 Devices) Connecting or disconnecting the disk drive

power connector on M Series PCI Express devices can affect the analog performance

of your device. To compensate for this, NI recommends that you self-calibrate after

connecting or disconnecting the disk drive power connector, as described in the

Device Self-Calibration section.

You can initiate self-calibration using Measurement & Automation Explorer (MAX), by

completing the following steps.

1. Launch MAX.

2. Select My System»Devices and Interfaces»your device.

3. Initiate self-calibration using one of the following methods:

•Click Self-Calibrate in the upper right corner of MAX.

• Right-click the name of the device in the MAX configuration tree and select

Self-Calibrate from the drop-down menu.

Note You can also programmatically self-calibrate your device with NI-DAQmx,

as described in Device Calibration in the NI-DAQmx Help or the LabVIEW Help.

1-4 | ni.com

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 19

M Series User Manual

1

2

Getting Started with M Series PCI Express

Devices and the Disk Drive Power Connector

(NI PCIe-6251/6259 Devices) The disk drive power connector is a four-pin hard drive

connector on PCI Express devices that, when connected, increases the current the device can

supply on the +5 V terminal.

When to Use the Disk Drive Power Connector

M Series PCI Express devices without the disk drive power connector installed perform

identically to other M Series devices for most applications and with most accessories. For most

applications, it is not necessary to install the disk drive power connector.

However, you should install the disk drive power connector in either of the following situations:

• You need more power than listed in the device specifications

• You are using an SCC accessory without an external power supply, such as the SC-2345

Refer to the specifications document for your device for more information about PCI Express

power requirements and power limits.

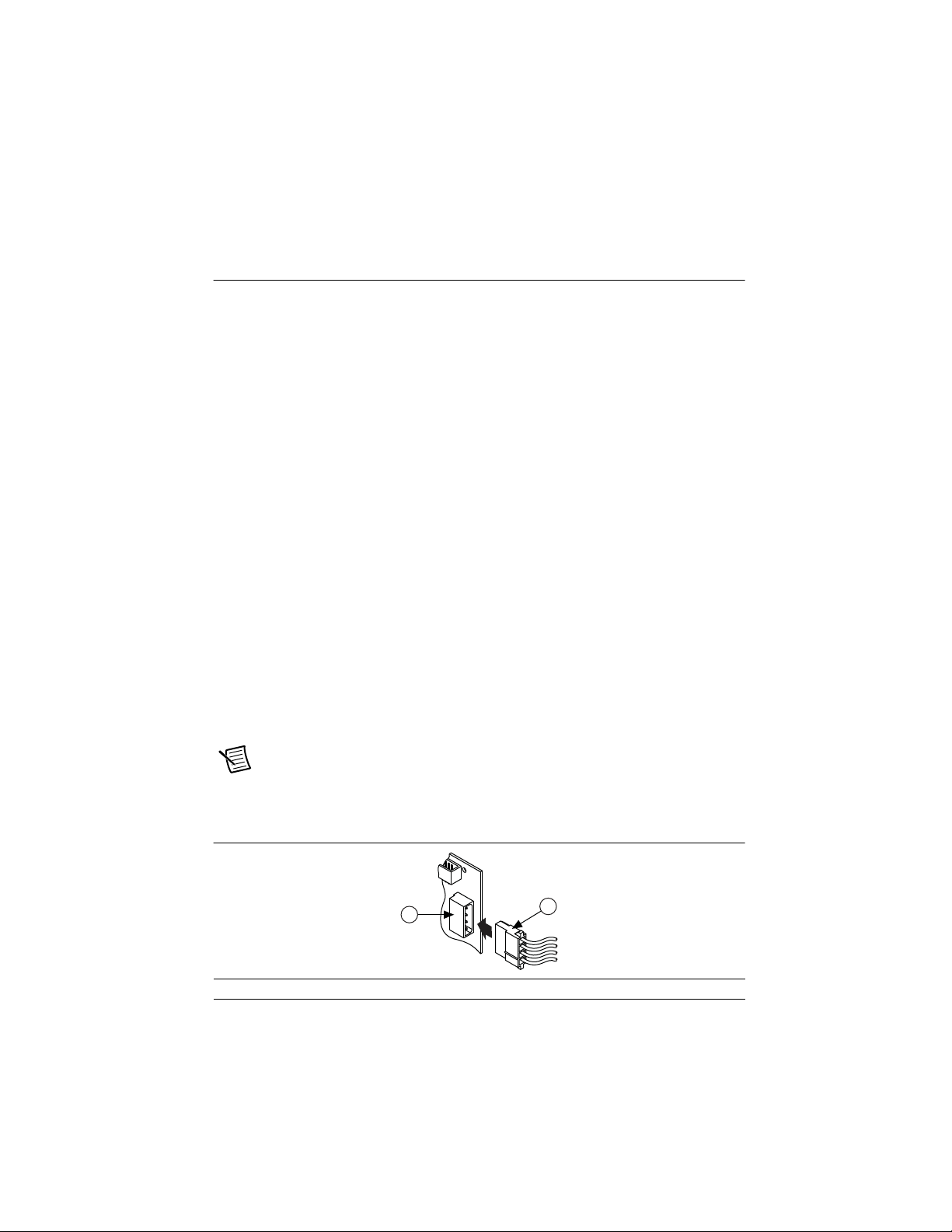

Disk Drive Power Connector Installation

Before installing the disk drive power connector, you must install and set up the M Series PCI

Express device as described in the DAQ Getting Started Guide for PCI/PCI Express. Complete

the following steps to install the disk drive power connector.

1. Power off and unplug the computer.

2. Remove the computer cover.

3. Attach the PC disk drive power connector to the disk drive power connector on the device,

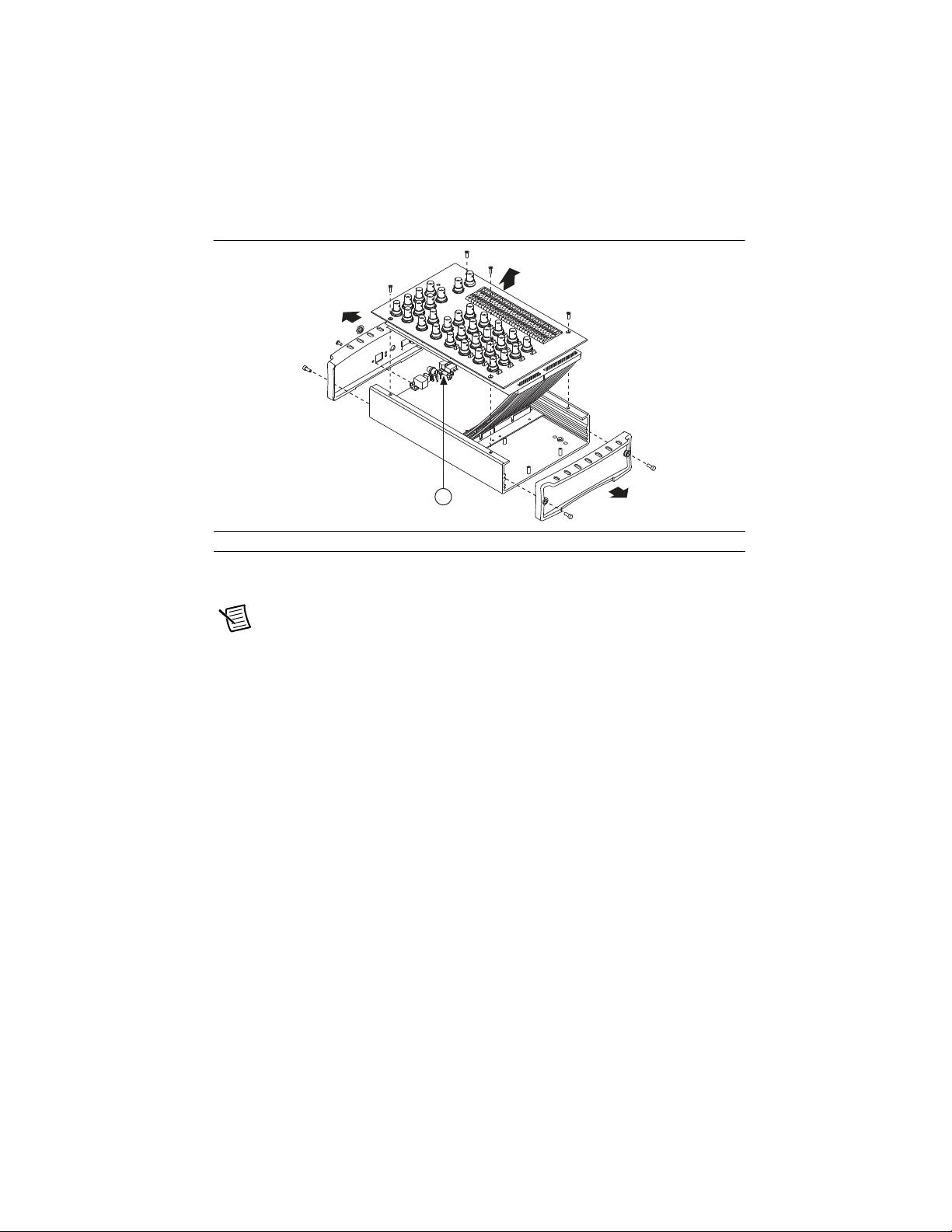

as shown in Figure 1-1.

Note The power available on the disk drive power connectors in a computer can

vary. For example, consider using a disk driv e power connector that is not in the same

power chain as the hard drive.

Figure 1-1. Connecting to the Disk Drive Power Connector

1 Device Disk Drive Power Connector 2 PC Disk Drive Power Connector

© National Instruments | 1-5

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 20

Chapter 1 Getting Started

4. Replace the computer cover, and plug in and power on the computer.

5. Self-calibrate the PCI Express DAQ device in MAX by following the instructions in the

Device Self-Calibration section.

Note Connecting or disconnecting the disk drive power connector can affect the

analog performance of your device. T o compensate for this, NI recommends that you

self-calibrate after connecting or disconnecting the disk drive power connector, as

described in the Device Self-Calibration section.

Getting Started with M Series USB Devices

The following sections contain information about M Series USB device features and best

practices.

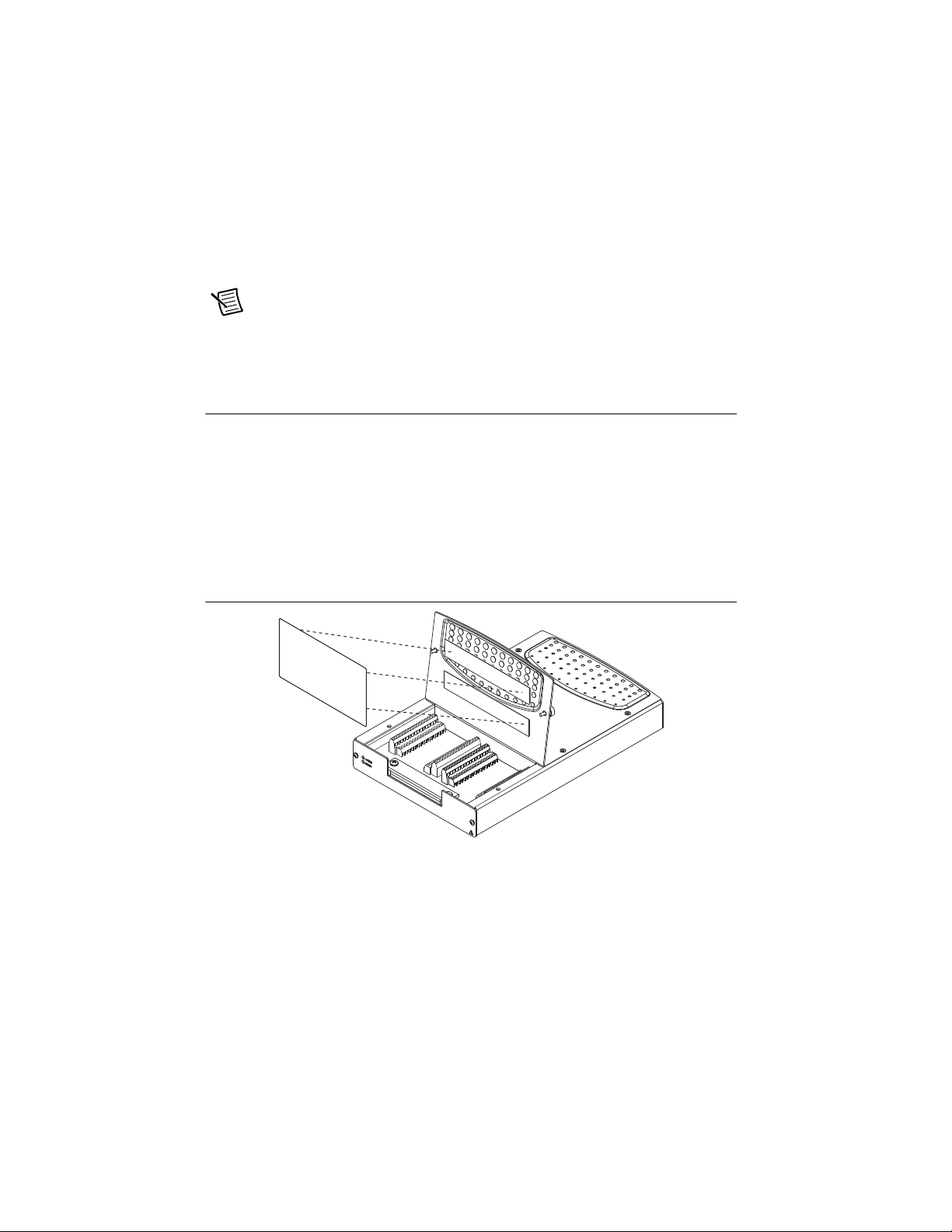

Applying the Signal Label to USB Screw Terminal

Devices

(USB-622x/625x/628x Screw Terminal Devices) The supplied signal label can be adhered to

the inside cover of the USB-62xx Screw Terminal device with supplied velcro strips as shown

in Figure 1-2.

Figure 1-2. Applying the USB-62xx Screw Ter m inal Signal Label

USB Device Chassis Ground

(USB-622x/625x/628x Devices) For EMC compliance, the cha ssis of the USB M Series device

must be connected to earth ground through the chassis ground.

The wire should be A WG 16 or lar ger solid copper wire with a maximu m length of 1.5 m (5 ft).

Attach the wire to the earth ground of the facility’s power system. For more information about

earth ground connections, refer to the KnowledgeBase document, Earth Grounding for Test and

Measurement Devices, by going to

1-6 | ni.com

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

ni.com/info and entering the Info Code earthground.

Page 21

M Series User Manual

NI USB-62xx

Multifunction I/O with

Correlated Digital I/O for USB

ACTIVE

READY

ON OFF

NATIONAL

INSTRUMENTS

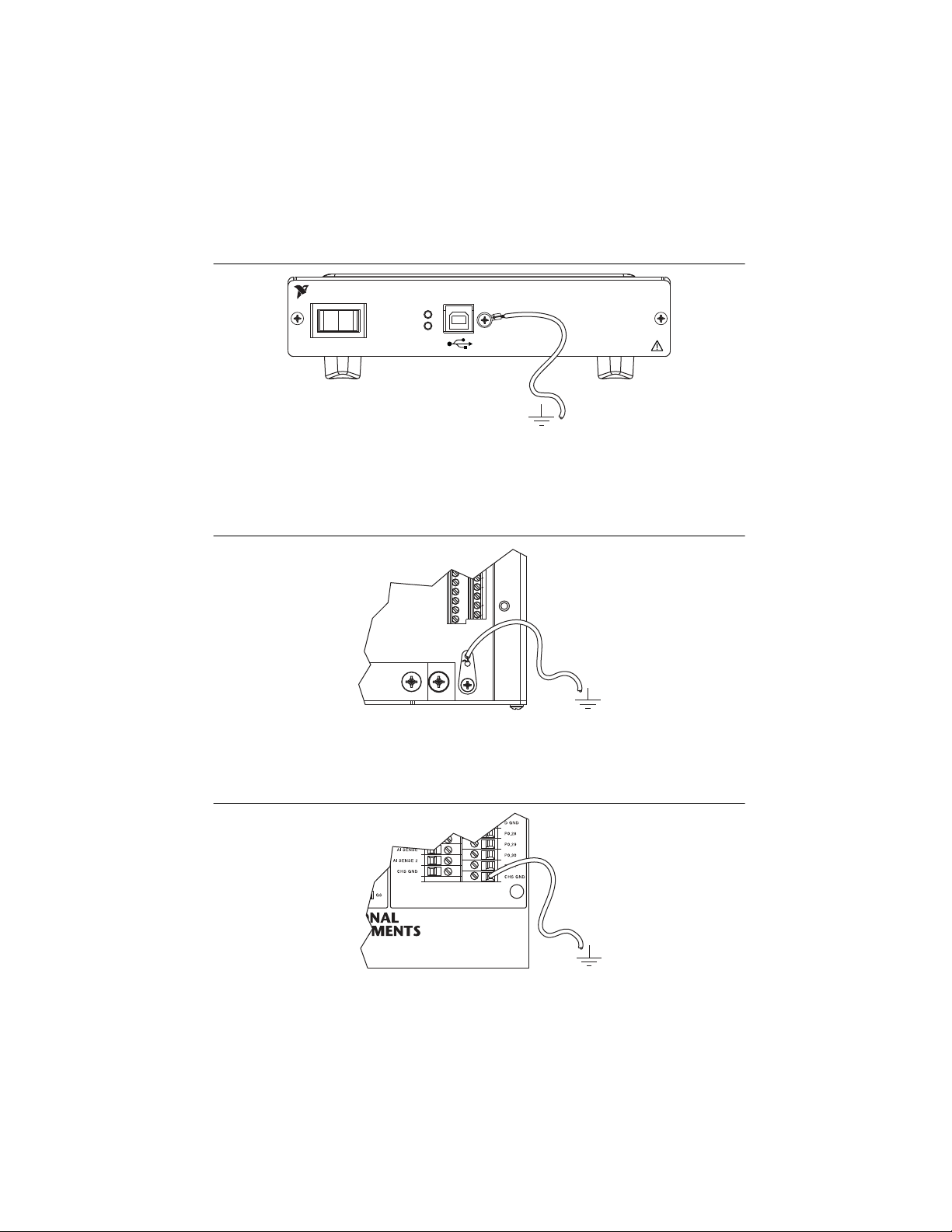

You can attach a wire to the ground lug screw of any USB-62xx device, as shown in Figure 1-3.

Figure 1-3. Grounding a USB-62xx Device through the Ground Lug Screw

(USB-6225/625x/628x Screw Terminal Devices) You can attach and solder a wire to the

chassis ground lug of certain USB-62xx Screw Terminal devices, as shown in Figure 1-4. The

wire should be as short as possible.

Figure 1-4. Grounding a USB-62xx Screw Terminal Device through the Chassis Ground

Lug

(USB-62xx BNC Devices) You can attach a wire to a CHS GND screw terminal of any

USB-62xx BNC device, as shown in Figure 1-5. Use as short a wire as possible. In addition, the

wires in the shielded cable that extend beyond the shield should be as short as possible.

Figure 1-5. Grounding a USB-62xx BNC Device through the CHS GND Screw Terminal

© National Instruments | 1-7

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 22

Chapter 1 Getting Started

USB Device Panel/Wall Mounting

(USB-622x/625x/628x Devices) The Externally Powered USB M Series Panel Mounting Kit

(part number 780214-01, not included in your USB-62xx kit) is an accessory you can use to

mount the USB-62xx family of products to a panel or wall.

USB Device LEDs

(USB-622x/625x/628x Devices) Refer to the LED Patterns section of Chapter 3, Connector

and LED Information, for information about the M Series USB device LEDs.

USB Cable Strain Relief

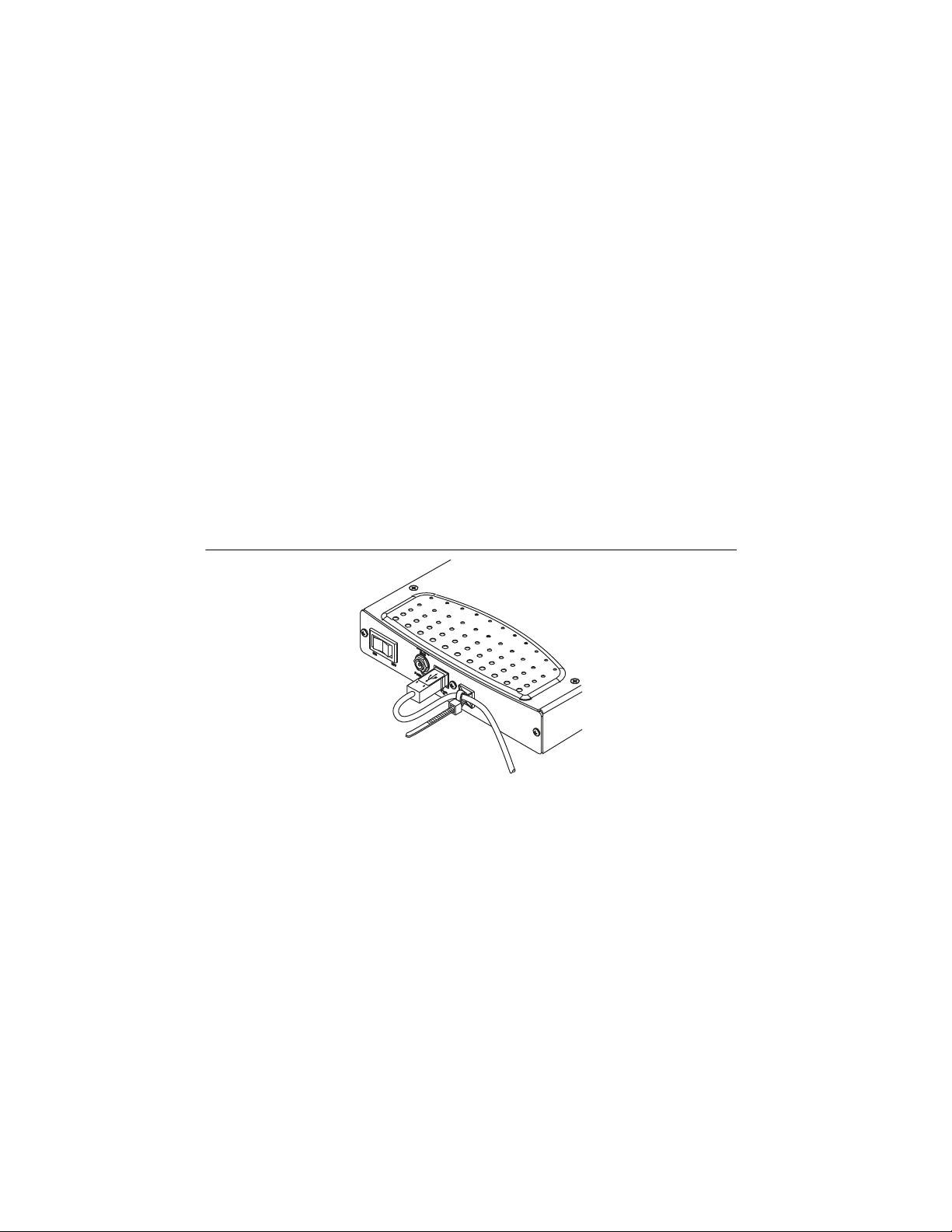

(USB-622x/625x/628x Screw Terminal and USB-622x/625x/628x Mass Termination

Devices) Use the supplied strain relief hardware to provide strain relief for your USB cable.

Adhere the cable tie mount to the rear panel of the USB-62xx Screw Terminal or USB-62xx Mass

Termination device, as shown in Figure 1-6. Thread a zip tie through the cable tie mount and

tighten around the USB cable.

Figure 1-6. USB Cable Strain Relief on USB-62xx Screw Terminal and

USB-62xx Mass Termination Devices

(USB-622x/625x BNC Devices) Thread a zip tie through two of the strain relief holes on the

end cap to provide strain relief for your USB cable as shown in Figure 1-7. The strain relief holes

can also be used as cable management for signal wires to/from the screw terminals and BNC

connectors.

1-8 | ni.com

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 23

Figure 1-7. USB Cable Strain Relief on USB-62xx BNC Devices

1 USB Cable Strain Relief

2 Security Cable Slot

M Series User Manual

3

1

2

3 Signal Wire Strain Relief

USB Device Fuse Replacement

M Series USB devices have a replaceable T 2A 250V (5 × 20 mm) fuse that protects the device

from overcurrent through the power connector.

(USB-6281/6289 Devices) USB-628x devices also have a replaceable Littelfuse 0453002

(F 2A 250V) fuse that protects the device from overcurrent through the +5 V terminal(s).

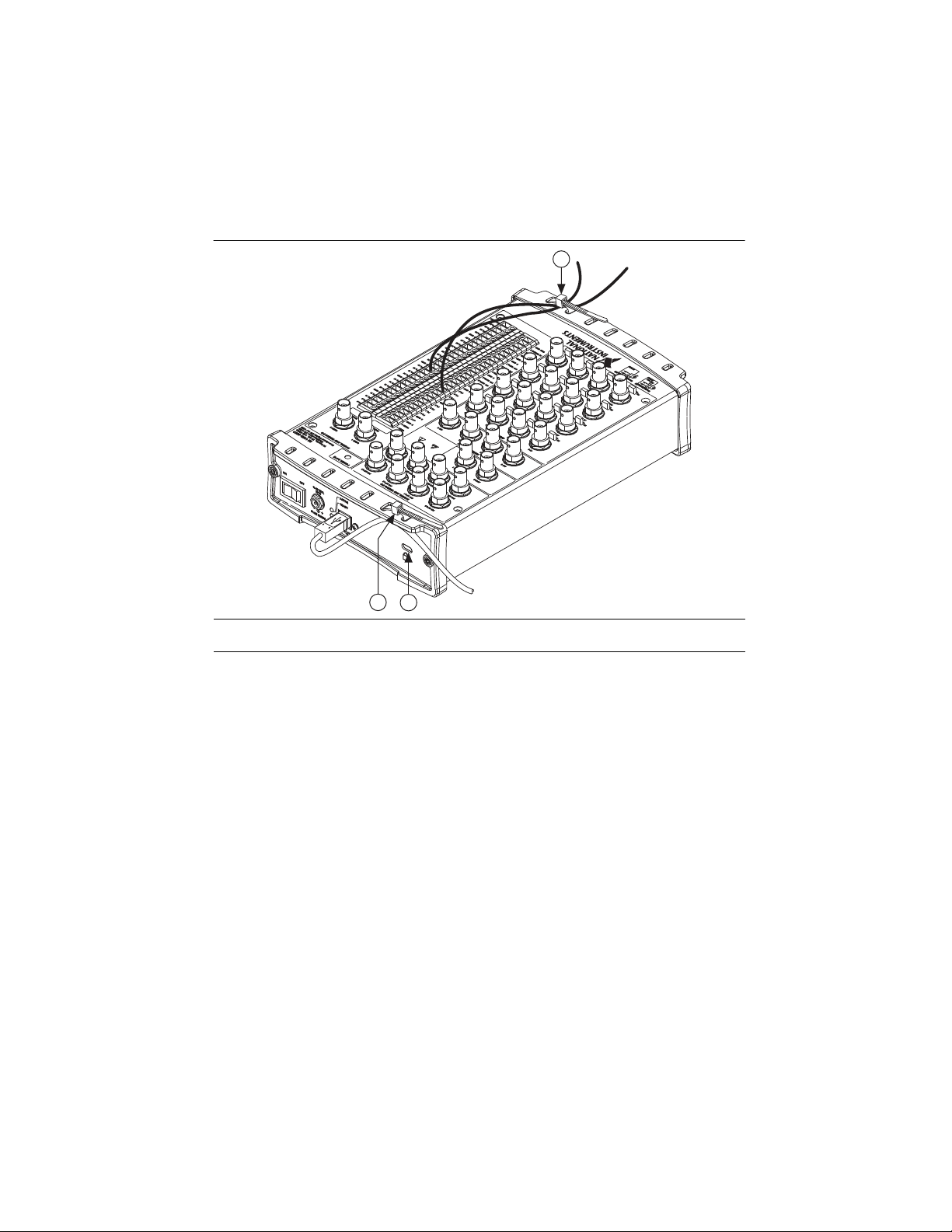

(USB-622x/625x/628x Screw Terminal Devices) To replace a broken fuse in the USB-62xx

Screw T e rminal, complete the following steps.

1. Power down and unplug the device.

2. Remove the USB cable and all signal wires from the device.

3. Loosen the four Phillips screws that attach the back lid to th e enclosure and re move the lid.

4. Replace the broken fuse while referring to Figure 1-8 for the fuse locations.

© National Instruments | 1-9

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 24

Chapter 1 Getting Started

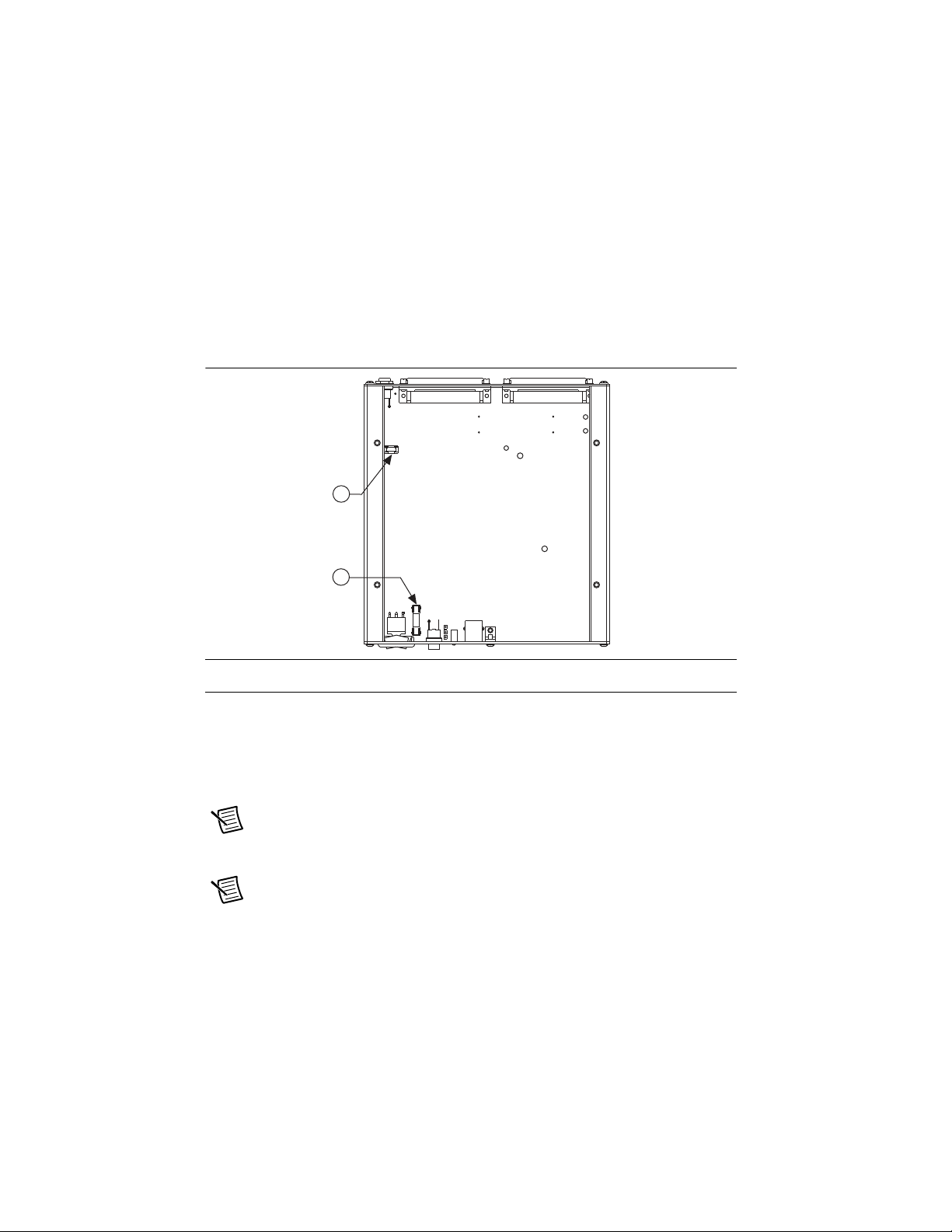

2

1

Figure 1-8. USB-62xx Screw Terminal Fuse Locations

1 T 2A 250V (5 × 20 mm) Fuse 2 Littelfuse 0453002 Fuse on USB-628x Devices

5. Replace the lid and screws.

(USB-622x/625x BNC Devices) T o replace a broken fuse in the USB-62xx BNC, complete the

following steps.

1. Power down and unplug the device.

Note Take proper ESD precautions when handling the device.

2. Remove the USB cable and all BNC cables and signal wires from the device.

1-10 | ni.com

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 25

M Series User Manual

1

Figure 1-9. USB-62xx BNC Fuse Location

1 T 2A 250V (5 × 20 mm) Fuse

3. Remove both end pieces by unscrewing the four sockethead cap screws with a 7/64 in. hex

wrench.

Note The end pieces are attached using self-threading screws. Repeated screwing

and unscrewing of self-threading screws will produce a compromised connection.

4. With a Phillips #2 screwdriver, remove the Phillips 4-40 screw adjacent to the USB

connector.

5. Remove the nut from the power connector.

6. Remove the four Phillips 4-40 screws that attach the top panel to the enclosure and remove

the panel and connector unit.

7. Replace the broken fuse while referring to Figure 1-9 for the fuse location.

8. Replace the top panel, screws, nut, and end pieces.

© National Instruments | 1-11

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 26

Chapter 1 Getting Started

1

2

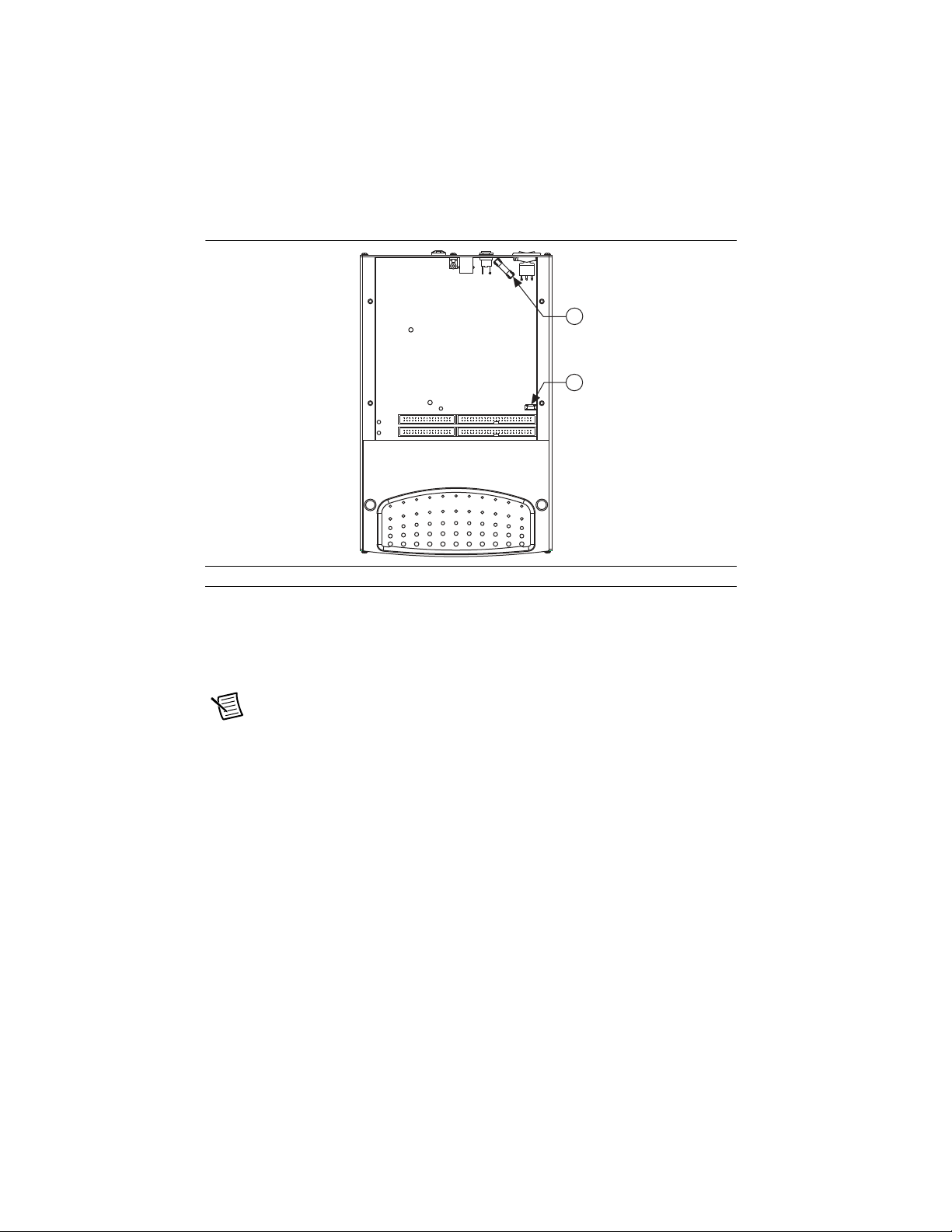

(USB-622x/625x/628x Mass Termination Devices) T o replace a broken fuse in th e USB-62xx

Mass T erm ina tion, com plete the following steps.

1. Power down and unplug the device.

2. Remove the USB cable and signal cable(s) from the device.

3. Loosen the four Phillips screws that attach the lid to the enclosure and remove the lid.

4. Replace the broken fuse while referring to Figure 1-10 for the fuse locations.

Figure 1-10. USB-62xx Mass Termination Fuse Locations

1 T 2A 250V (5 × 20 mm) Fuse

2 Littelfuse 0453002 Fuse on USB-628x Devices

5. Replace the lid and screws.

USB Device Security Cable Slot

(USB-622x/625x BNC Devices) The security cable slot, shown in Figure 1-7, allows you to

attach an optional antitheft device to your USB device.

Note The security cable is designed to ac t as a deterrent, but may not prevent the

device from being mishandled or stolen. For more information, refer to the

documentation that accompanied the security cable.

Note The security cable slot on th e USB-62xx BNC may not be compatible with all

antitheft cables.

1-12 | ni.com

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 27

M Series User Manual

Installing a Ferrite

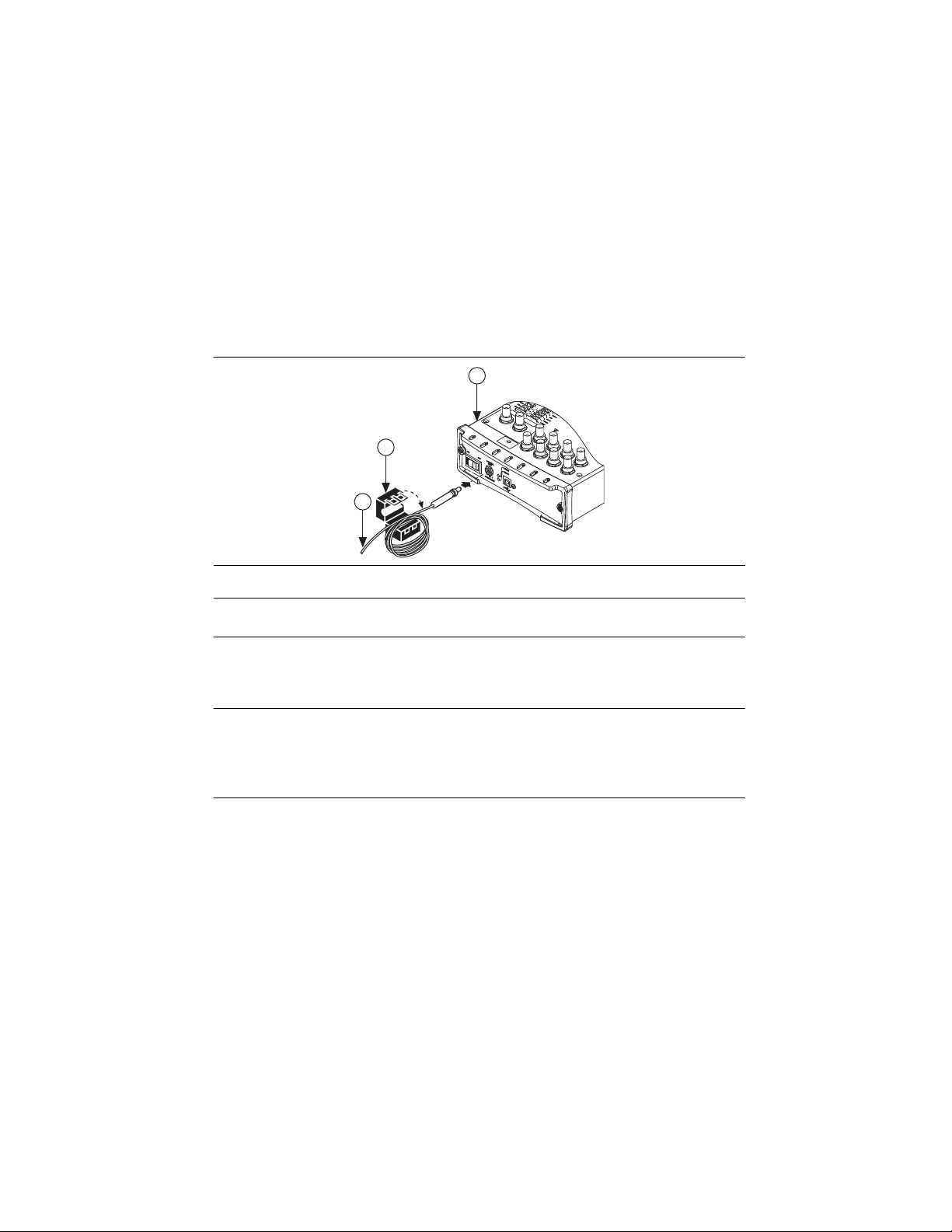

(USB-62221/6229 BNC Devices) To ensure EMC compliance, you must install the ferrite

shipped with the USB-6221/6229 BNC.

Loop the power cabling through the ferrite at least five times. Install the ferrite as close as

possible to the end of the power cable, as shown in Figure 1-11.

Figure 1-11. Installing the Ferrite on the Power Cable

3

2

1

1 Power Cable

2 Ferrite

3 NI USB-6221/6229 BNC Device

Pinouts

Refer to Appendix A, Module/Device-Specific Information, for M Series device pinouts.

Specifications

Refer to the device specifications document for your device. M Series device documentation is

available on ni.com/manuals.

Accessories and Cables

NI offers a variety of accessories and cables to use with your multifunction I/O DAQ module

device. Refer to the Cables and Accessories section of Chapter 2, DAQ System Overview, for

more information.

© National Instruments | 1-13

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 28

2

Analog Output

Digital I/O

Analog Input

Counters

PFI

Digital

Routing

and Clock

Generation

Bus

Interface

Bus

I/O Connector

RTSI

DAQ System Overview

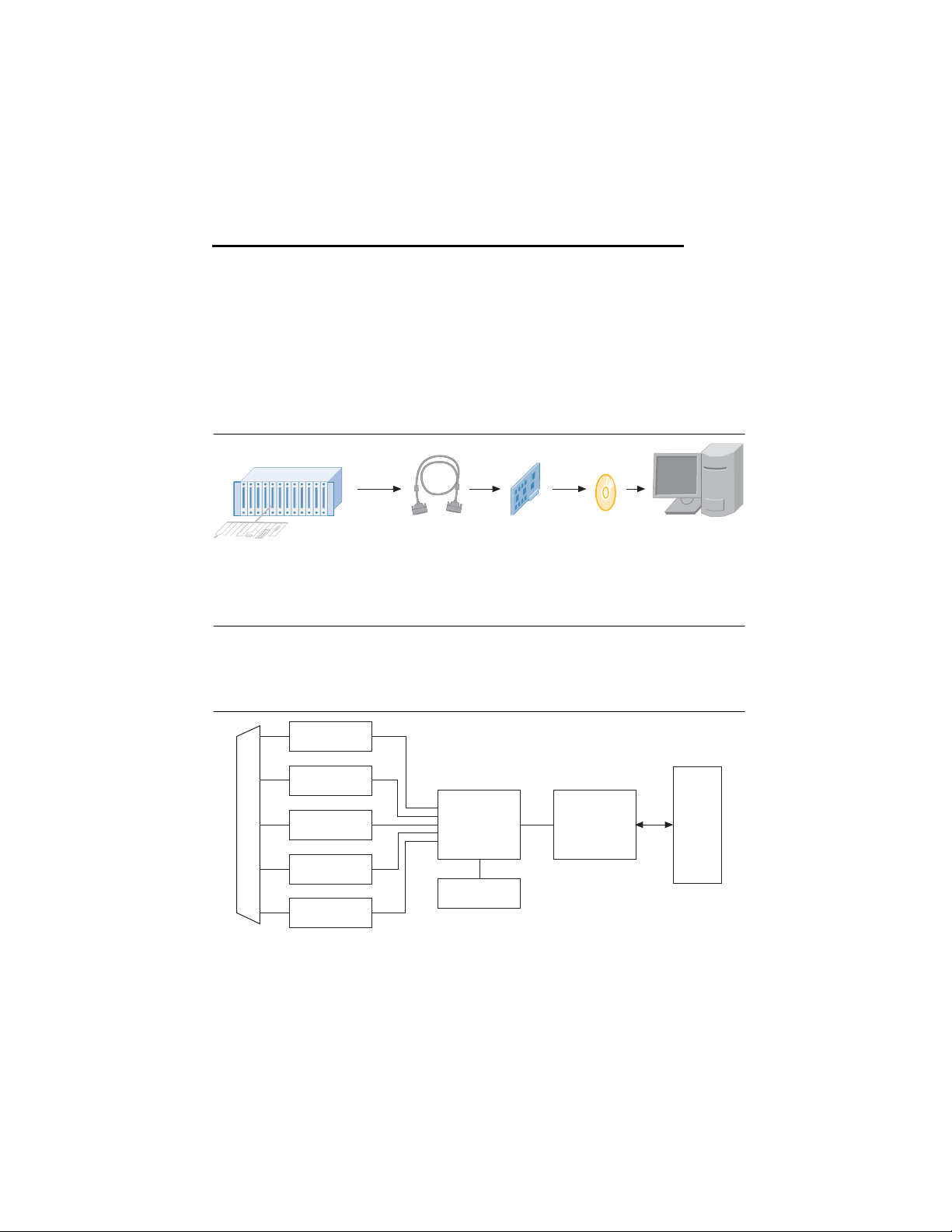

Figure 2-1 shows a typical DAQ system, which includes sensors, transducers, signal

conditioning devices, cables that connect the various devices to the accessories, the M Series

device, programming software, and PC. The following sections cover the components of a

typical DAQ system.

Figure 2-1. Components of a Typical DAQ System

Sensors and

Transducers

Signal

Conditioning

Cables and

Accessories

DAQ

Hardware

DAQ

Software

Personal Computer

or

PXI/PXI Express

Chassis

DAQ Hardware

DAQ hardware digitizes signals, performs D/A conversions to generate analog output signals,

and measures and controls digital I/O signals. Figure 2-2 features components common to all

M Series devices.

Figure 2-2. General M Series Block Diagram

© National Instruments | 2-1

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 29

Chapter 2 DAQ System Overview

DAQ-STC2 and DAQ-6202

The DAQ-STC2 and DAQ-6202 implement a high-performance digital engine for M Series data

acquisition hardware. Some key features of this engine include the following:

• Flexible AI and AO sample and convert timing

• Many triggering modes

• Independent AI, AO, DI, and DO FIFOs

• Generation and routing of RTSI signals for multi-device synchronization

• Generation and routing of internal and external timing signals

• T wo flexible 32-bit counter/timer modules with hardware gating

• Digital waveform acquisition and generation

• Static DIO signals

• True 5 V high current drive DO

• DI change detection

• PLL for clock synchronization

• Seamless interface to signal conditioning accessories

• PCI/PXI interface

• Independent scatter-gather DMA controllers for all acquisition and generation functions

Calibration Circuitry

The M Series analog inputs and outputs have calibration circuitry to correct gain and offset

errors. You can calibrate the device to minimize AI and AO errors caused by time and

temperature drift at run time. No external circuitry is necessary; an internal reference ensures

high accuracy and stability over time and temperature changes.

Factory-calibration constants are permanently stored in an onboard EEPROM and cannot be

modified. When you self-calibrate the device, as described in the Device Self-Calibration

section of Chapter 1, Getting Started, software stores new constants in a user-modifiable section

of the EEPROM. To return a device to its initi al factory calibration settings, software can copy

the factory-calibration constants to the user-modifiable sec tion of the EEPROM. Refer to the

NI-DAQmx Help or the LabVIEW Help for more information about using calibration constants.

For a detailed calibration procedure for M Series devices, refer to the B/E/M/S/X Series

Calibration Procedure available at

2-2 | ni.com

ni.com/manuals.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 30

M Series User Manual

Cables and Accessories

NI offers a variety of products to use with M Series PCI, PCI Express, PXI, PXI Express, USB

devices, including cables, connector blocks, and other accessories, as follows:

• Shielded cables and cable assemblies, and unshielded ribbon cables and cable assemblies

• Screw terminal connector blocks, shielded and unshielded

• RTSI bus cables

• SCXI modules and accessories for isolating, amplifying, exciting, and multiplexing

signals; with SCXI you can condition and acquire up to 3,072 channels

• Low-channel-count signal conditioning modules, devices, and accessories, including

conditioning for strain gauges and RTDs, simultaneous sample and hold circuitry, and

relays

Refer to the appropriate section for your device connector type—68-Pin M Series Cables and

Accessories or 37-Pin M Series Cables and Accessories. For more specific information about

these products, refer to

Note For compliance with Electromagnetic Compatibility (EMC) requirements,

this product must be operated with shielded cables and accessories. If unshielded

cables or accessories are used, the EMC specifications are no longer guaranteed

unless all unshielded cables and/or accessories are installed in a shie lded enclosure

with properly designed and shielded input/output ports.

ni.com.

Refer to the 68-Pin Custom Cabling and Connectivity or 37-Pin Custom Cabling section of this

chapter and the Field Wiring Considerations section of Chapter 4, Analog Input, for information

about how to select accessories for your M Series device.

68-Pin M Series Cables and Accessories

This section describes some cable and accessory options for M Series devices with one or two

68-pin connectors. Refer to the following sections for descriptions of these cables and

accessories. Refer to

ni.com for other accessory options.

© National Instruments | 2-3

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 31

Chapter 2 DAQ System Overview

Table 2-1. 68-Pin M Series Device/Module Cables and Accessories

PCI, PCI Express,

PXI, PXI Express

Devices and Modules

622x/625x/

628x

Connector 0

6224/6229/

Cables and Accessories

Cables

Accessories

* Can only be attached directly to PXI modules front connector only, and does not require a cable.

Type

Shielded SHC68-68-EPM SHC68-68 SC68-68-EPM SHC68-68

Unshielded RC68-68 RC68-68 RC68-68 RC68-68

Screw