Page 1

DAQ

PCI-4451/4452 User Manual

Dynamic Signal Acquisition Device for PCI

April 1998 Edition

Part Number 321891A-01

Page 2

Internet Support

E-mail: support@natinst.com

FTP Site: ftp.natinst.com

Web Address: http://www.natinst.com

Bulletin Board Support

BBS United States: 512 794 5422

BBS United Kingdom: 01635 551422

BBS France: 01 48 65 15 59

Fax-on-Demand Support

512 418 1111

Telephone Support (USA)

Tel: 512 795 8248

Fax: 512 794 5678

International Offices

Australia 03 9879 5166, Austria 0662 45 79 90 0, Belgium 02 757 00 20, Brazil 011 288 3336,

Canada (Ontario) 905 785 0085, Canada (Québec) 514 694 8521, Denmark 45 76 26 00, Finland 09 725 725 11,

France 01 48 14 24 24, Germany 089 741 31 30, Hong Kong 2645 3186, Israel 03 6120092, Italy 02 41 3091,

Japan 03 5472 2970, Korea 02 596 7456, Mexico 5 520 2635, Netherlands 0348 433466, Norway 32 84 84 00,

Singapore 2265886, Spain 91 640 0085, Sweden 08 730 49 70, Switzerland 056 200 51 51, Taiwan 02 377 1200,

United Kingdom 01635 523545

National Instruments Corporate Headquarters

6504 Bridge Point Parkway Austin, Texas 78730-5039 USA Tel: 512 794 0100

© Copyright 1998 National Instruments Corporation. All rights reserved.

Page 3

Important Information

Warranty

The PCI-4451/4452 is warranted against defe cts in mate ria l s and workmanship for a period of one year from the date of

shipment, as evidenced by receipts or other documentation. National Instruments will, at its option, repair or replace

equipment that proves to be defective during the warranty period. This warranty includes parts and labor.

The media on which you receive National Instruments software are warranted not to fail to execute programming

instructions, due to defects in materials and workmanship, for a period of 90 days from date of shipment, as evidenced

by receipts or other documentation. National Instruments will, at its option, repair or replace software media that do not

execute programming instructions if National Instruments receives notice of such defects during the warranty period.

National Instruments does not warrant that the operation of the software shall be uninterrupted or error free.

A Return Material Authorization (RMA) number must be obtained from the factory and clearly marked on the outside

of the package before any equipment will be accepted for warranty wo rk. National Instru ments will pay the shippi ng costs

of returning to the owner part s which are c overed by warranty.

National Instruments believes that the informatio n in this manual is accurate. The document ha s been careful ly reviewed

for technical accurac y. In the even t that te chn ical or t ypograp hic al errors ex ist, Nation al Inst rumen ts res erves the righ t to

make changes to subsequent editions of this document without prior notice to holders of this edition. The reader should

consult National Instruments if errors are suspected. In no event shall National Instruments be liable for any damages

arising out of or related to this document or the information contained in it.

XCEPT AS SPECIFIED HEREIN

E

ANY WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE

BY FAULT OR NEGLIGENCE ON THE PART OF NATIONAL INSTRUMENTS SHALL BE LIMITED TO THE AMOUNT THERETOFORE PAID BY THE

CUSTOMER

OR INCIDENTAL OR CONSEQUENTIAL DAMAGES, EVEN IF ADVISED OF THE POSSIBILITY THEREOF

National Instruments will apply regardless of the form of action, whether in contract or tort, including negligence.

Any action against National Instruments must be brought within one year after the cause of action accrues. National

Instruments shall not be liable for any delay in performance due to causes beyond its reasonable control. The warranty

provided herein does not cover damages, defects, malfunctions, or service failures caused by owner’s failure to follow

the National Instruments installation, operation, or maintenance instructions; owner’s modification of the product;

owner’s abuse, misuse, or negligent acts; and power failure or surges, fire, flood, accident, actions of third parties,

or other events outside reasonable control.

ATIONAL INSTRUMENTS WILL NOT BE LIABLE FOR DAMAGES RESULTING FROM LOSS OF DATA, PROFITS, USE OF PRODUCTS

. N

ATIONAL INSTRUMENTS MAKES NO WARRANTIES, EXPRESS OR IMPLIED, AND SPECIFICALLY DISCLAIMS

, N

Copyright

Under the copyright laws, this publication may not be reproduced or transmitted in any form, electronic or mechanical,

including photocopyi ng, recordi ng, sto ring in an inform ati on retriev al syste m, or translat ing , in whole or in part, with out

the prior written consent of National Instruments Corporation.

USTOMER’S RIGHT TO RECOVER DAMAGES CAUSED

. C

. This limitation of the liability of

,

Trademarks

ComponentWorks™, CVI™, LabVIEW™, Measure™, NI-DAQ™, and VirtualBench™ are trademarks of Nationa l

Instruments Corporation.

Product and company names listed are trademarks or trade names of their respective companies.

WARNING REGARDING MEDICAL AND CLINICAL USE OF NATIONAL INSTRUMENTS PRODUCTS

National Instruments products are not designed with components and testing intended to ensure a level of reliability

suitable for use in treatment and diagnosis of humans. Applications of National Instruments products involving medical

or clinical treatment can create a potential for accidental injury caused by product failure, or by errors on the part of the

user or application des igner. An y use or ap plica tion of Na tiona l Instrume nts p roducts for or inv olvi ng medic al or c linica l

treatment must be performed by properly trained and qualifie d medic al pe rsonnel, an d all traditio nal med ical sa feguards,

equipment, and p roce dures tha t ar e a ppropria te in th e pa rticula r s itua tion to p revent s erious inju ry or d eath shou ld alway s

continue to be used whe n National Instruments pro ducts are being use d. Nation al Instrumen ts product s are NOT inte nded

to be a substitute for any fo rm of establis hed process, pro cedure, or e quipment us ed to monito r or safeguard h uman heal th

and safety in medical or clinical treatment.

Page 4

Contents

About This Manual

Organization of This Manual.........................................................................................ix

Conventions Used in This Manual.................................................................................x

National Instruments Documentation............. ...... ..... ........................................ ............xi

Related Documentation..................................................................................................xi

Customer Communication.............................................................................................xi

Chapter 1

Introduction

What You Need to Get Started......................................................................................1-2

Unpacking......................................................................................................................1-2

Software Programming Choices....................................................................................1-3

National Instruments Application Software....................................................1 -3

Optional Equipment.......................................................................................................1-4

Custom Cabling .............................................................................................................1-4

Chapter 2

Installation and Configuration

Software Installation......................................................................................................2-1

Hardware Installation.....................................................................................................2-1

Device Configuration................................................................................... ..................2-2

Chapter 3

Hardware Overview

Analog Input..................................................................................................................3-3

Input Mode ............................................................................... .......................3-3

Input Coupling......................................................... ..... ...................................3-3

Input Polarity and Input Range........................................................................3-3

Considerations for Selecting Input Ranges.....................................................3-4

Analog Output................................................................................................................3-5

Output Mode....................................................................................................3-5

Output Polarity and Output Range..................................................................3-5

Trigger ...........................................................................................................................3-6

RTSI Triggers ..................................................................................................3-9

Digital I/O......................................................................................................................3-10

Timing Signal Routing...................................................................................................3-11

Programmable Function Inputs....................................................................... 3 -11

©

National Instruments Corporation v PCI-4451/4452 User Manual

Page 5

Contents

Device and RTSI Clocks.................................................................................3-11

Selecting Sample/Update Clock Frequency..................................................................3-12

Device Configuration Issues......................... ...... ...... ....................................... ..............3-13

Chapter 4

Signal Connections

I/O Connectors...............................................................................................................4-1

Analog I/O Connector Signal Descriptions ....................................................4-2

Digital I/O Connector Signal Descriptions.....................................................4-5

Analog Input Signal Connections..................................................................................4-9

Types of Signal Sources................................................................................................4-10

Floating Signal Sources ..................................................................................4-10

Ground-Referenced Signal Sources................................................................4-10

Analog Output Signal Connections...............................................................................4-11

Analog Power Connections........................................................................................... 4-12

Digital I/O Signal Connections ..................................................................................... 4-12

Digital Power Connections............................................................................................ 4-14

Timing Connections...................................................................................................... 4-14

Programmable Function Input Connections ...................................................4-14

Acquisition Timing Connections.......................... ...... ..... ...............................4-15

Waveform Generation Timing Connections...................................................4-18

General-Purpose Timing Signal Connections.................................................4-19

Field Wiring Considerations..........................................................................................4-24

PFI0/TRIG1 (EXT_TRIG) Signal....................................................4-16

PFI1/TRIG2 (PRETRIG) Signal ...................................................... 4-17

CONVERT* Signal..........................................................................4-17

EXTSTROBE* Signal......................................................................4-18

WFTRIG Signal................................................................................4-18

UPDATE* Signal .............................................................................4-18

GPCTR0_SOURCE Signal ..............................................................4-19

GPCTR0_GATE Signal ........................................................... ...... ..4-20

GPCTR0_OUT Signal......................................................................4-20

GPCTR0_UP_DOWN Signal...........................................................4-20

GPCTR1_SOURCE Signal ..............................................................4-21

GPCTR1_GATE Signal ........................................................... ...... ..4-21

GPCTR1_OUT Signal......................................................................4-22

GPCTR1_UP_DOWN Signal...........................................................4-22

FREQ_OUT Signal....................................... ..... ...... .........................4-24

PCI-4451/4452 User Manual vi

©

National Instruments Corporation

Page 6

Chapter 5

Calibration

Loading Calibration Constants......................................................................................5-1

Self-Calibration..............................................................................................................5-2

External Calibration.......................................................................................................5-2

Traceable Recalibration.................................................................................................5-3

Chapter 6

Theory of Analog Operation

Functional Overview......................................................................................................6-1

Analog Input Circuitry................................................................................................... 6 -1

Input Coupling......................................................... ..... ...................................6-2

Calibration............ ...... ....................................... ..............................................6-2

Antialias Filtering........................................ ...... ...... ....................................... .6-3

The ADC .........................................................................................................6-8

Noise................................................................................................................6-9

Analog Output Circuitry................................................................................................6-10

Anti-Image Filtering........................................................................................6-10

The DAC .........................................................................................................6-12

Calibration.......................................................................................................6-12

Mute Feature........................................... ..... ...... ........................................ ......6-13

Contents

Appendix A

Specifications

Appendix B

Pin Connections

Appendix C

Customer Communication

Glossary

Index

©

National Instruments Corporation vii PCI-4451/4452 User Manual

Page 7

Contents

Figures

Figure 3-1. Digital Function Block Diagram...........................................................3-1

Figure 3-2. Analog Function Block Diagram..........................................................3-2

Figure 3-3. Below-Low-Level Triggering Mode.....................................................3-7

Figure 3-4. Above-High-Level Triggering Mode.................................................. ..3-8

Figure 3-5. Inside-Region Triggering Mode ...........................................................3-8

Figure 3-6. High-Hysteresis Triggering Mode........................................................ 3-8

Figure 3-7. Low-Hysteresis Triggering Mode.........................................................3-9

Figure 3-8. RTSI Bus Signal Connection................................................................3-10

Figure 4-1. Analog Pin Connections .......................................................................4-2

Figure 4-2. Digital Pin Connections........................................................................4-5

Figure 4-3. Analog Input Stage ...............................................................................4-9

Figure 4-4. Analog Output Channel Block Diagram............................................... 4-11

Figure 4-5. Digital I/O Connections........................................................................4-13

Figure 4-6. Typical Posttriggered Acquisition ........................................................4-15

Figure 4-7. Typical Pretriggered AcquisitionPFI1.................................................. 4-16

Figure 4-8. EXTSTROBE* Signal Timing .............................................................4-18

Figure 4-9. GPCTR0_SOURCE Signal Timing......................................................4-19

Figure 4-10. GPCTR0_OUT Signal Timing .............................................................4-20

Figure 4-11. GPCTR1_SOURCE Signal Timing......................................................4-21

Figure 4-12. GPCTR1_OUT Signal Timing .............................................................4-22

Figure 4-13. GPCTR Timing Summary ....................................................................4-23

Figure 6-1. Input Frequency Response....................................................................6-5

Figure 6-2. Input Frequency Response Near the Cutoff..........................................6-6

Figure 6-3. Alias Rejection at the Oversample Rate...............................................6-7

Figure 6-4. Comparison of a Clipped Signal to a Proper Signal .............................6-8

Figure 6-5. Signal Spectra in the DAC....................................................................6-11

Figure A-1. Idle Channel Noise (Typical)................................................................A-4

Figure B-1. 68-Pin Digital Connector for any Digital Accessory............................B-2

Tables

Table 3-1. Actual Range and Measurement Precision...........................................3-4

Table 3-2. Actual Range and Measurement Precision...........................................3-6

Table 4-1. Analog I/O Connector Pin Assignment................................................4-3

Table 4-2. Analog I/O Signal Summary.................................................................4-4

Table 4-3. Digital I/O Connector Pin Assignment................................................. 4-6

Table 4-4. Digital I/O Signal Summary .................................................................4-8

PCI-4451/4452 User Manual viii

©

National Instruments Corporation

Page 8

About This Manual

This manual describes the electrical and mechanical aspects of the

PCI-4451 and PCI-4452 devices and cont ains information co ncerning their

operation. Unless otherwise noted, the text applies to both devices.

The PCI-4451 and PCI-4452 are high-performance, high-accuracy analog

input/output (I/O) devices for the PCI bus. These devices also support

digital I/O (DIO) functions, counter/timer functions, and external trigger

functions.

Organization of This Manual

The PCI-4451/4452 User Manual is organized as follows:

• Chapter 1, Introduction, describes the PCI-4451 and PCI-4452

devices, lists what yo u need to get start ed, explains how to u npack your

devices, and describes the optional software and optional equipment.

• Chapter 2, Installation and Configuration, explains how to install and

configure your PCI-4451/4452 device.

• Chapter 3, Hardware Overview, presents an overview of the hardware

functions on your PCI-4451/4452 device.

• Chapter 4, Signal Connections, describes how to make input and

output connections to your PCI-4451/4452 device via the analog I/O

and digital I/O connectors of the device.

• Chapter 5, Calibration, discusses the calibration procedures for your

PCI-4451/4452 device.

• Chapter 6, Theory of Analog Operation, contains a functional

overview and explains the operation of each analog functional unit

making up the PCI-4451/4452.

• Appendix A, Specifications, lists the specifications of the

PCI-4451/4452.

• Appendix B, Pin Connections, describes the pin connections on the

optional 68-pin digital accessories for the PCI-4451/4452 devices.

• Appendix C, Customer Communication, contains forms you can use to

request help from National I nstruments or to comment on our products

and manuals.

©

National Instruments Corporation ix PCI-4451/4452 User Manual

Page 9

About This Manual

•The Glossary contains an alphabetical list and description of terms

used in this manual, including abbreviations, acronyms, metric

prefixes, mnemonics, and symbols.

•The Index contains an alphabetical list of key terms and topics in this

manual, including the page where you can find each one.

Conventions Used in This Manual

The following conventions are used in this manual:

<> Angle brackets enclose the name of a key on the keyboard—for example,

<shift>. Angle brackets containing numbers separated by an ellipsis

represent a range of values associated with a bit or signal name—for

example, DBIO<3..0>.

♦ The ♦ symbol indicates that the text following it applies only to a specific

product, a specific operating system, or a specific software version.

* An asterisk following a signal name denotes an ACTIVE LOW signal.

This icon to the left of bold italicized text denotes a note, which alerts you

to important information.

!

bold italic Bold italic text denotes an activity objective, note, caution, or warning.

DSA DSA refers to dynamic signal acquisition.

italic Italic text denotes v ariables, emphasis, a cross reference, or an introduction

SE SE means referenced single ended (RSE). SE and RSE are equivilant.

PCI-4451/4452 User Manual x

This icon to the left of bold italicized text denotes a caution, which advises

you of precautions to take to avoid injury, data loss, or a system crash.

to a key concept. This font also denotes text from which you supply the

appropriate word or value, as in NI-DAQ 6.x.

©

National Instruments Corporation

Page 10

National Instruments Documentation

The PCI-4451/4452 User Manual is one piece of the documentation set

for your DAQ system. You could have any of several types of manuals

depending on the hardware and software in your system. Use the manuals

you have as follows:

• Software documentation—You may have both application software

and NI-DAQ software documentation. National Instruments

application software includes ComponentWorks, LabVIEW,

LabWindows/CVI, Measure, and VirtualBench. After you set up your

hardware system, use either your application softw are do cumen t ation

or the NI-DAQ documentation to help you write your application. If

you have a large, complicated system, it is worthwhile to look through

the software documentation before you configure your hardware.

• Accessory installation guides or manuals—If you are using accessory

products, read the terminal block and cable assembly installation

guides. They explain how to physically connect the relevant pieces

of the system. Consult these guides when you are making your

connections.

About This Manual

Related Documentation

The following documents contain information you may find helpful:

• BNC-2140 User Manual

• National Instruments Application Note 025, Field Wiring and Noise

Considerations for Analog Signals

• PCI Local Bus Specification Revision 2.0

Customer Communication

National Instruments wants to receive your comments on our products

and manuals. We are interest ed in the applications you develop with our

products, and we want to help if you have problems with them. To make it

easy for you to contact us, thi s manual contains comment and conf iguration

forms for you to complete. These forms are in Appendix C, Customer

Communication, at the end of this manual.

©

National Instruments Corporation xi PCI-4451/4452 User Manual

Page 11

Introduction

This chapter describes the PC I-445 1 and PCI -4452 d evices , lists what you

need to get started, explains how to unpack you r devices, and describes the

optional software and optional equipment.

The PCI-4451/4452 are high-performance, high-accuracy analog I/O

devices for the PCI bus. These de vices are members of the PCI-DSA series

and are specifically designed for demanding dynamic signal acquisition

applications. The PCI-4451 has two channels of 16-bit simultaneously

sampled input at 204.8 kS/s and two channels of 16-bit simultaneously

updated output at 51.2 kS/s, while the PC I-4452 has four chan nels of 16-bit

simultaneously sampled analog input at 204.8 kS/s. Inf ormation on anal og

output applies only to the PCI-4451, where as information on anal og input

applies to both the PCI-4451 and the PCI-4452.

Both the analog input and the analog output circuitry have oversampling

delta-sigma modulating converters. Delta-sigma converters are inherently

linear, provide built-in brick-wall anti-aliasing/imaging filters, and have

specifications that exceed other conventional technology for this

application with regard to THD, SNR, and amplitude flatness. You can use

these high-quality specifications and features to acquire or generate signals

with high-accuracy and fidelity without introducing n oise or out-of-band

aliases.

1

Applications include audio signal processing and analysis, acoustics and

speech research, sonar, audio frequency test and measurement, vibration

and modal analysis, or any application requ iring high-fidelity signal

acquisition with a bandwidth up to 95 kHz or signal generation with a

bandwidth up to 23 kHz.

©

National Instruments Corporation 1-1 PCI-4451/4452 User Manual

Page 12

Chapter 1 Introduction

What You Need to Get Started

To set up and use your PCI-4451 or PCI-4452, you will need the following:

❑ One of the following devices:

PCI-4451

PCI-4452

❑ PCI-4451/4452 Series User Manual

❑ You may have one or more of the following software packages and

documentation:

LabVIEW for Windows

LabWindows/CVI for Windows

NI-DAQ for PC Compatibles

VirtualBench-DSA

ComponentWorks

Measure

❑ Your co mputer

Unpacking

❑

SHC68-C68-A1

analog cable

❑ BNC-2140 accessory

Your PCI-4451/4452 is shipped in an antistatic plastic package to prevent

electrostatic damage to the device. Electrostatic discharge can damage

components on the instrument. To avoid such damage in handling the

device, take the following precautions:

• Ground yourself vi a a grounding strap or by hold ing a grounded obj ect.

• Touch the plastic package to a metal part of your computer chassis

before removing the device from the package.

• Remove the device from the package and inspect the device for loose

components or any other si gn of damage. Notify National In struments

if the device appears damaged in any way. Do not install a damaged

device into your computer.

• Never touch the exposed pins of connectors.

PCI-4451/4452 User Manual 1-2

©

National Instruments Corporation

Page 13

Software Programming Choices

There are several options to choose from to program and use your

National Instruments device. You can use LabVIEW for Windows,

LabWindows/CVI for Windows, VirtualBench-DSA, ComponentWorks,

and Measure.

National Instruments Application Software

LabVIEW and LabWindows/CVI are innovative program development

software packages for data acquisition and control applications. LabVIEW

uses graphical programming, whereas LabWindows/CVI enhances

traditional programing languages. Both packages include extensive

libraries for data acquisition, instrument control, data analysis, and

graphical data presentation.

LabVIEW features interactive graphics, a state-of-the-art user interface,

and a powerful graphical programming language. The LabVIEW Data

Acquisition VI Library, a series of VIs for using LabVIEW with National

Instruments device hardware, is included with LabVIEW. The LabVIEW

Data Acquisition VI Library is functionally equivalent to the NI-DAQ

software.

Chapter 1 Introduction

LabWindows/CVI features interactive graphics, a state-of-the-art user

interface, and uses the ANSI C programming language. The

LabWindows/CVI Data Acquisition, a series of functions for using

LabWindows/CVI with National Instruments device hardware, is included

with the NI-DAQ software kit. The LabWindows/CVI Data Acquisition

library is functionally equivalent to the NI-DAQ software.

VirtualBench is a suite of VIs that allows you to use your data acquisition

products just as you use stand-alone instruments, but you benefit from

processing, display, and storage capabilities of PCs. VirtualBench

instruments load and save waveform data to disk in the same forms used in

popular spreadsheet programs and word processors. A report generation

capability complements the raw data storage by adding timestamps,

measurements, user name, and comments.

The complete VirtualBench suite contains VirtualBench-Scope,

VirtualBench-DSA, VirtualBench-Function Generator, VirtualBench-FG,

VirtualBench-Arb, VirtualBench-AODC, VirtualBench-DIO,

VirtualBench-DMM, and VitualBench-Logger. Your PCI 4451/4452

comes with VirtualBench-DSA. VirtualBench-DSA is a turnkey

©

National Instruments Corporation 1-3 PCI-4451/4452 User Manual

Page 14

Chapter 1 Introduction

application you can use to make measurements as you would with a

standard dynamic analyzer.

ComponentWorks contains tools for data acquisition and instrument

control built on NI-DAQ driver software. ComponentWorks provides a

higher-level programming interface for building virtual instruments with

Visual Basic, V isual C++, Borland Delphi, and Microsoft Internet Explorer .

With Com ponentW orks, you can use al l of the configurat ion tools, resource

management utilities, and interactive control utilities included in NI-DAQ.

Measure is a data acquisition and instrument control add-in for Microsoft

Excel. With Measure, you can acquire data directly from plug-in DAQ

boards, GPIB instruments, or serial (RS-232) devices. Measure has

easy-to-use dialogs for configurin g your measurements. Your data is placed

directly into Excel worksheet cells, from which you can perform your

analysis and report generations using the full power and flexibility of Excel.

Optional Equipment

National Instruments offers a variety of products to use with your

PCI-4451/4452 series devices, including cables and connector blocks as

follows:

•

SHC50-68 digital cable

•

Shielded and DIN rail mountable 68-pin connector blocks

•

RTSI cables

Custom Cabling

National Instruments offers cable s of different l engths and the BNC-2140

DSA accessory to connect your analog I/O to the PCI-4451/4452. National

Instruments recommends you do not develop your own cabling solution

due to the difficulty of working with the high-density connector and the

need to maintain high signal integrity . Howeve r, if your application

requires that you develop your own cable use the following guidelines:

• Use shielded twisted-pair wires for each differential analog input or

output channel pair. Since the signals are differential, using this type

of wire yields the best results.

• When connecting the cable shields, be sure to connect the analog input

grounds to the AIGND pins and the analog output grounds to the

AOGND pins. For a conne ctor pin assignment, refer to Table 4- 1,

Analog I/O Connector Pin Assignment.

PCI-4451/4452 User Manual 1-4

©

National Instruments Corporation

Page 15

Chapter 1 Introduction

• To create your own accessories, you can use an AMP 68-pin

right-angle PWB receptacle header, part number 787254-1.

• Recommended manufacturer part numbers for the 68-pin mating

connector for the cable assembly are as follows:

– AMP 68-position straight cable plug, part number 787131-3

– AMP 68-position backshell with jackscrews, part number

787191-1

National Instruments also offers cables of differ ent lengths and accessories

to connect your digital I/O si gn als to th e PC I-4451/4452. To develop your

own cable, the mating connector for the digital I/O is a 50-position

receptacle. For a connector pinout assignment, refer to Table 4-3, Digital

I/O Connector Pin Assignment. Recommended manufacturer part numbers

for this mating connector are as follows:

• 50-position straight cable plug, part number 787131-1

• 50-position backshell with jackscrews, part number 787233-1

Refer to Appendix B, Pin Connections , for pin assign ments of digital

accessories and cables.

©

National Instruments Corporation 1-5 PCI-4451/4452 User Manual

Page 16

Installation and Configuration

This chapter explains how to install and configure your PCI-4451/4452

device.

Software Installation

2

Note

Install your software before you install your PCI-4451/4452 device.

If you are using NI-DAQ, refer to your NI-DAQ release notes. Find the

installation section for your operating system and follow the instructions

given there. If you are using LabVIEW, LabWindows/CVI, or other

National Instruments application software, refer to the appropriate release

notes. After you have installed your application software, refer to your

NI-DAQ release notes and follow the instructions given there for your

operating system and application software package.

Hardware Installation

You can install the PCI-4451/4452 device in any available PCI expansion

slot in your computer. However, to achieve the best noise performance,

leave as much room as possible between the PCI-4451/4452 device and

other devices and hardware. The following are general installation

instructions, but consult your computer user manual or techn ical reference

manual for specific instructions and warnings:

1. Write down the PCI-4451/4452 device serial number in the

PCI-4451/4452 Hardware and Software Configuration Form in

Appendix C, Customer Communication, of this manual.

2. Turn off and unplug your computer.

3. Remove the top cover or access port to the I/O channel.

4. Remove the expansion slot cover on the back panel of the computer.

5. Insert the PCI-4451/4452 device into a 5 V PCI slot. It should fit

snugly, but do not force the device into place.

6. Screw the mounting bracket of the PCI-4451/4452 device to the back

panel rail of the computer.

©

National Instruments Corporation 2-1 PCI-4451/4452 User Manual

Page 17

Chapter 2 Installation and Configuration

7. Check the installation.

8. Replace the cover.

9. Plug in and turn on your computer.

The PCI-4451/4452 de vice is now installe d. Y ou are now ready t o configure

your software.

Device Configuration

The PCI-4451/4452 devices are completely software configurable.

However, you must perform two types of configuration—bus-related and

data acquisition-related.

The PCI-4451/4452 devices are fully compatible with the industry

standard PCI Local Bus Specification Revision 2.0. The PCI system

automatically performs all bus-related configurations and requires no

interaction from you. Bus-related configuration includes setting the device

base memory address and interrupt channel.

Data acquisition related configuration includes such setting s as an alog

input polarity and range, analog input mode, and others. You can modify

these settings through National Instruments application level software,

such as ComponentWorks, LabVIEW, LabWindows/CVI, and

VirtualBench or driver software such as NI-DAQ.

PCI-4451/4452 User Manual 2-2

©

National Instruments Corporation

Page 18

Hardware Overview

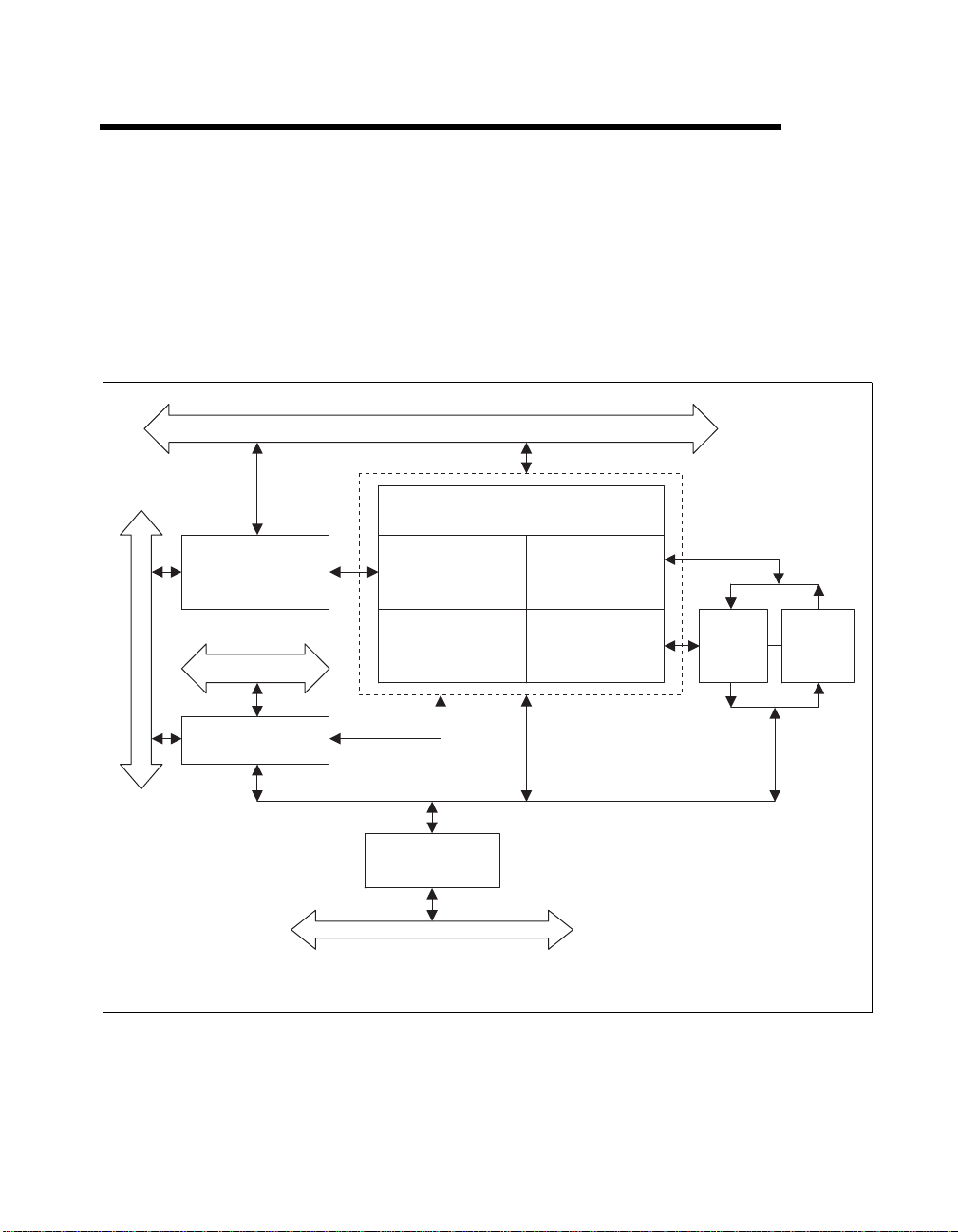

This chapter presents an overview of the hardware functions on your

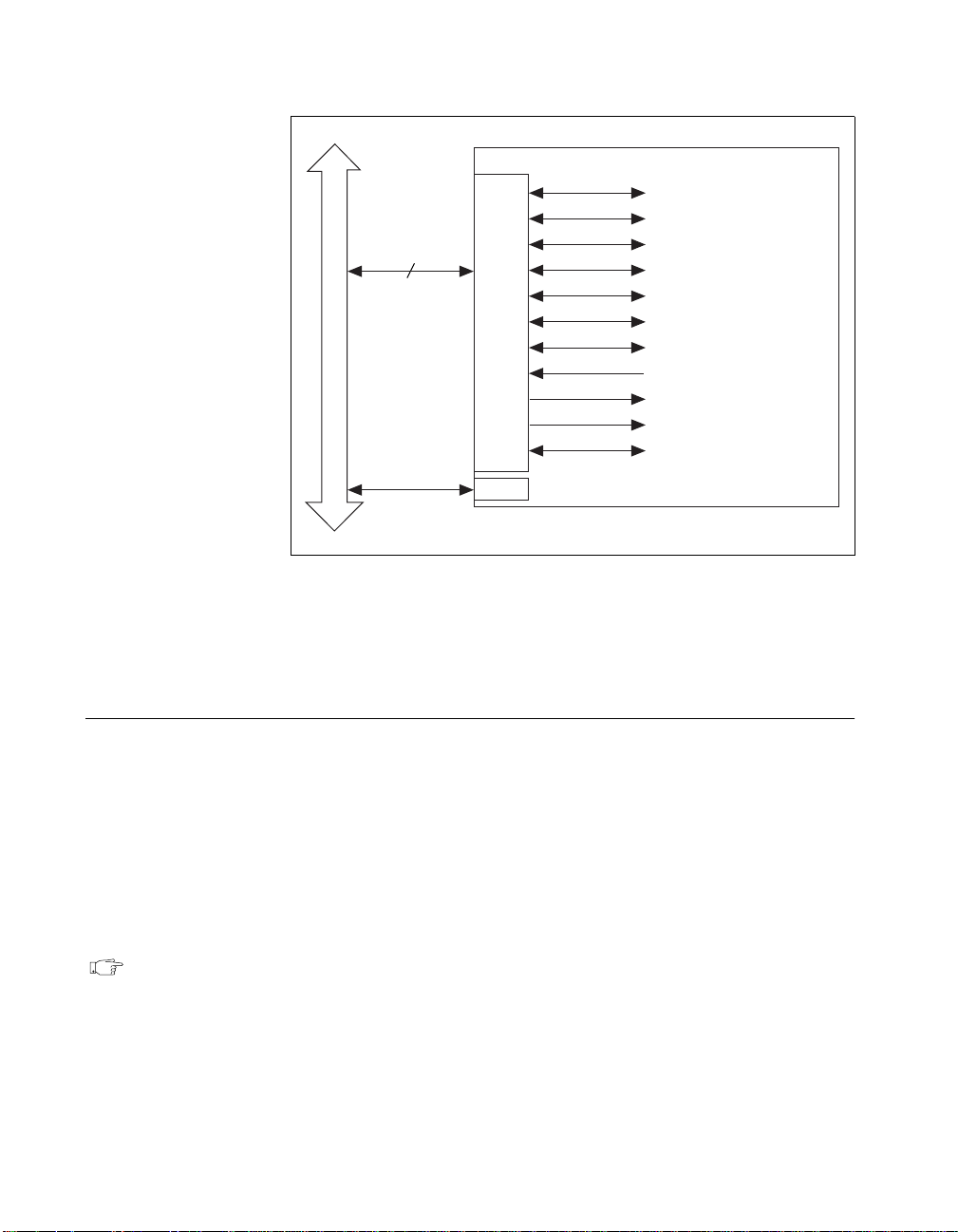

PCI-4451/4452 device. Figure 3-1 shows a block diagram of the digital

functions. Figure 3-2 shows a block diagram of the analog functions.

The two function blocks connect through the analog mezzanine bus.

Analog Mezzanine Bus (to Analog Section)

Analog Mezzanine Control

3

Clock Generator

Digital I/O Bus

RTSI Bus

†

PCI-4451 only

Direct Digital

Synthesis

DAQ-STC

Clock Control

General Control

Functions

MITE

PCI Controller

PCI Bus

Figure 3-1.

Parallel <-> Serial

Converter

FIFO and DMA

Control

Digital Function Block Diagram

AI FIFO

AO FIFO

†

©

National Instruments Corporation 3-1 PCI-4451/4452 User Manual

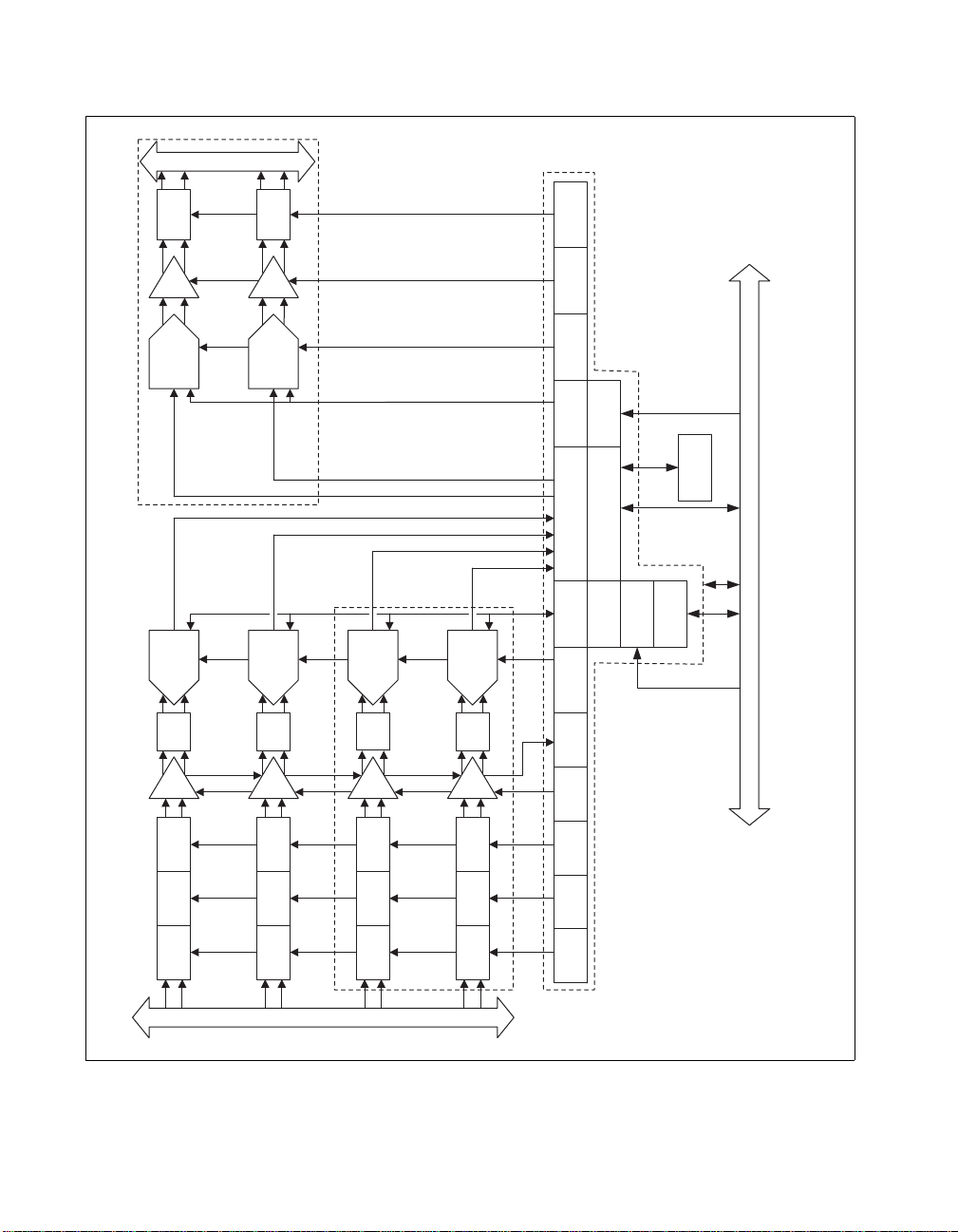

Page 19

Chapter 3 Hardware Overview

Analog Bus

ENABLE0

ENABLE1

Output

Enable

DIFF

ATTEN

††

DAC0

ADC0

LP

DIFF

Gain

Filter

AMP

AMP

DIFF

ATTEN

††

DAC1

ADC1

LP

DIFF

Gain

Filter

AMP

AMP

†

ADC2

LP

Filter

DIFF

Gain

AMP

†

LP

DIFF

Gain

ADC3

Filter

AMP

Control

Attenuation

Calibration

Gain/Offset

Manager

DAC Clock

DAC Control

General Control

Serial Data Manager

Digital

Detect

Overrange

ADC Control

Calibration

Gain/Offset

Detect

Analog

Overrange

Gain

Control

ADC Clock

Manager

Trigger

EEPROM

Control

Analog Mezzanine Bus (to Digital Section)

MUX0

ATTEN

0 dB/20 dB

MUX0

AC/DC

Coupling

MUX0

INPUT/CAL

MUX1

ATTEN

0 dB/20 dB

MUX1

AC/DC

Coupling

MUX1

INPUT/CAL

MUX2

ATTEN

0 dB/20 dB

MUX2

AC/DC

Coupling

MUX2

INPUT/CAL

Analog Bus

Figure 3-2.

PCI-4451/4452 User Manual 3-2

MUX3

ATTEN

0 dB/20 dB

MUX3

AC/DC

Coupling

MUX3

INPUT/CAL

MUX

ATTEN

Control

MUX

AC/DC

Control

MUX

Control

INPUT/CAL

Analog Function Block Diagram

PCI-4451 only

††

PCI-4452 only

†

©

National Instruments Corporation

Page 20

Analog Input

Input Mode

Input Coupling

Chapter 3 Hardware Overview

The analog input section of each PCI-4451/4452 device is software

configurable. You can select di fferent anal og input con figuratio ns through

application software. The following sections describe in detail each of the

analog input categories.

The PCI-4451/4452 devices use differential (DIFF) inputs. You can

configure the input as a referenced single ended (SE) channel using the

BNC-2140 DSA accessory. For more information, please refer to the

BNC-2140 Use r Manual. In DIFF mode, one line connects to the positive

input of the channel, and the other connects to the negative inp ut of the

same channel. You can connect the differential input to SE or DIFF signals,

either floating or ground-referenced. However, grounding the negative

input from floating sources may impr ove the measurement quality by

removing the common-mode noise.

The PCI-4451/4452 has a software-programmable switch that determines

whether a capacitor is placed in the signal path. If the switch is set for DC,

the capacitor is bypassed and any DC offset present in the source signal is

passed to the ADC. If the source has a significant amount of unwanted

offset (bias voltage), you must set the switch for AC coupling to place the

capacitor in the signal path and take full advantage of the input signal

range.

Input Polarity and Input Range

The PCI-4451/4452 devices operate in bipolar mode. Bipolar input

means that the input voltage range is between –V

The PCI-4451/4452 has a bipolar input range of 20 V (±10 V) for a

gain of 1.0 (0 dB).

You can program the range settings on a per channel basis so that you can

configure each input channel uniquely. The software-programmable gain

on these devices increases their overall flexibility by matching the input

signal ranges to those that the ADC can accommodate. With the proper gain

setting, you can use the full resolution of the ADC to measure the input

signal. Table 3-1 shows the overall input range and precision according to

the input range configuration and gain used.

©

National Instruments Corporation 3-3 PCI-4451/4452 User Manual

/2 and +V

ref

/2.

ref

Page 21

Chapter 3 Hardware Overview

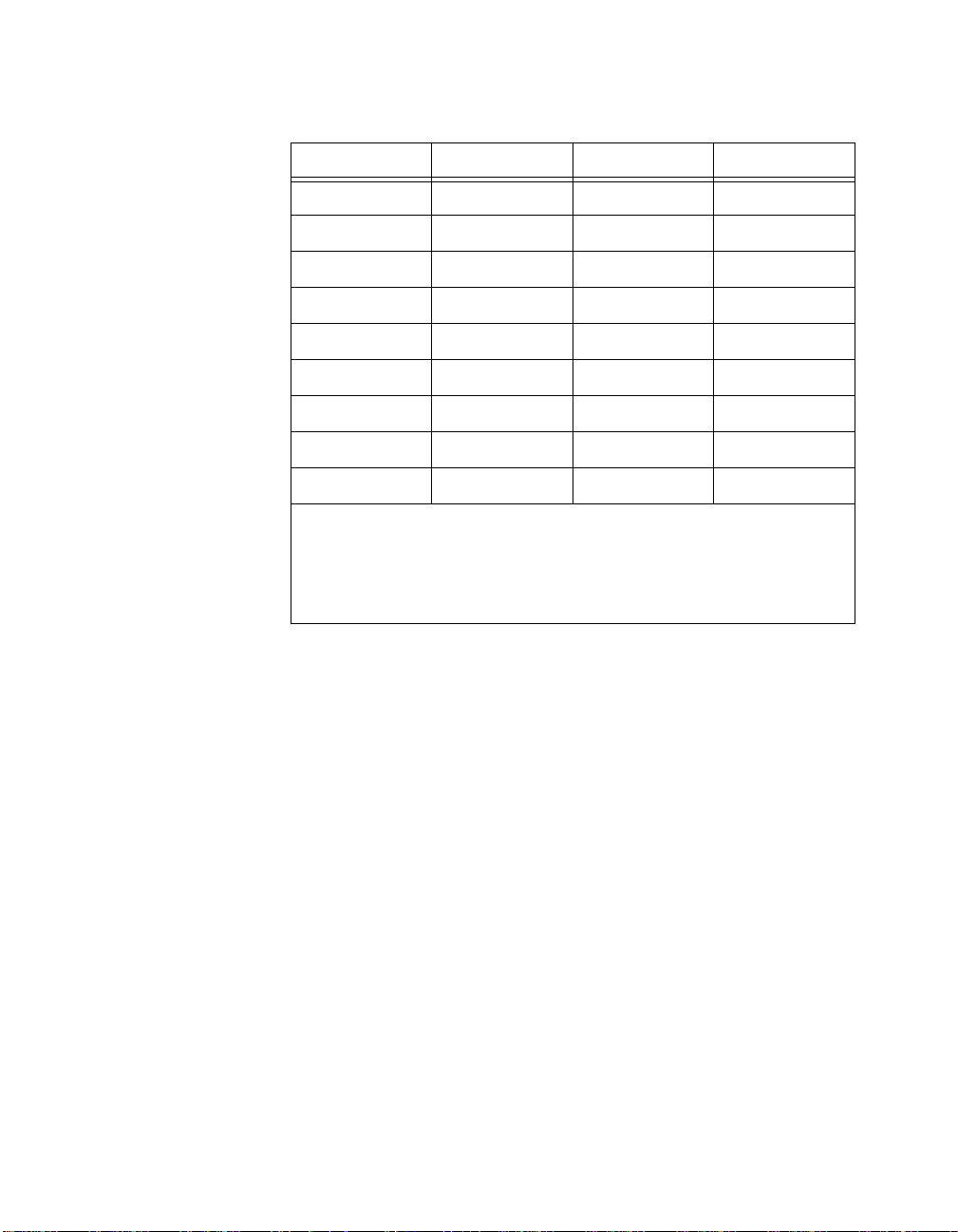

Table 3-1.

Linear Gain Gain Input Range Precision

0.1 –20 dB ±42.4 V

Actual Range and Measurement Precision

2

3.0518 mV

1

2

0.316 –10 dB ±31.6 V 965.05 µV

1.0 0 dB ±10.0 V 305.18 µV

3.16 10 dB ±3.16 V 96.505 µV

10 20 dB ±1.00 V 30.518 µV

31.6 30 dB ±0.316 V 9.6505 µV

100 40 dB ±0.100 V 3.0518 µV

316 50 dB ±31.6 mV 965.05 nV

1000 60 dB ±10.0 mV 305.18 nV

1

The value of 1 LSB of the 16-bit ADC; that is, the voltage increment corresponding to a

change of one count in t h e ADC 16-bit count.

2

The actual input range is by design ±100 V; howe ver, the device is not tested or certified

to operate in this range.

See Appendix A,

Specifications

, for absolute ma ximum ratings.

All data read from the ADC is interpreted as two’s complement format. In

two’s complement mode, digital data values read from the analog input

channel are either positive or negative.

Considerations for Selecting Input Ranges

The input range you select depends on the expected range of the incoming

signal. A large input range can accommodate a large signal variation but

reduces the voltage resolution. Choosing a smaller input range improves

the voltage resolution but can result in the input signal going out of range.

For best results, match the input range as closely as possible to the expected

range of the input signal.

If the input range is not appropriately chosen, an input signal can be clipped

and introduce large errors that are easily identified in the frequency

spectrum. The PCI-4451/4452 is equipped with overrange detection

circuits in both the analog and digital sections of each input channel. These

circuits determine if an input signal has exceeded the selected input

voltage. Chapter 6, Theory of Analog Operation, provides a m ore in-depth

explanation of how overranges can occur.

PCI-4451/4452 User Manual 3-4

©

National Instruments Corporation

Page 22

Chapter 3 Hardware Overview

Caution If you exceed the rated input voltages, you can damage the computer and the

!

connected equipment.

Analog Output

The analog output section of t he PCI-4451 device is software-con figurable.

You can select different analog output configurations through application

software designed to control the PCI-4451. The followi ng sections describe

in detail each of the analog output categories. Th e PCI-4451 device has two

channels of analog output voltage at the I/O connector.

Output Mode

The PCI-4451 device uses DIFF outputs. You can configure the outputs as

an SE channel using the BNC-21 40 DSA accessory. For more information,

please refer to the BNC-2140 User Manual. In DIFF mode, one line

connects to the positive input of the channel, and the other connects to the

negative input of that same channel. You can connect the differential output

to either SE or DIFF loads, either floating or gro und-referenced. Howev er,

grounding the ne gative output is recommended w hen driving floating

single-ended loads.

Output Polarity and Output Range

The PCI-4451 device operates in bipolar mode. Bipolar outp ut means that

the output voltage range is between –V

a bipolar output range of 20 V (±10 V) for an attenuation of 1.0 (0 dB).

You can program the range settings on a per channel basis so that you can

configure each output channel uniquely. The software-programmable

attenuation on these devices increases their overall flexibility by matching

the output signal ranges to the your application. Table 3-2 shows the overall

output range and precision according to the attenuation used.

©

National Instruments Corporation 3-5 PCI-4451/4452 User Manual

/2 and +V

ref

/2. The PCI-4451 has

ref

Page 23

Chapter 3 Hardware Overview

Table 3-2.

Attenuation

Linear

Actual Range and Measurement Precision

Attenuation

dB

1.0 0 dB ±10.0 V 305.18 µV

10 20 dB ±1.00 V 30.158 µV

100 40 dB ±0.100 V 3.0518 µV

∞ ∞ dB 0 V 0 V

1

The value of 1 LSB of the 16-bit DAC; that is, the voltage increment corresponding to a

change of one count in the DAC 16-bit count.

See Appendix A,

Note The device boots in a m ode with the outputs disabled

Specifications

, for absolute ma ximum ratings.

Although these functions appear similar, they are quite distinct and are

implemented to protect your external equipment from startup transients.

When the DACs no longer have data written to them, they automatically

retransmit the last data point they received. If you are expecting the data to return

to 0 V or any other voltage level, you

append the data to make it do so.

MUST

All data written to the DACs are interpreted as two’s complement format.

In two’s complement mode, data values written to the analog output

channel are either positive or negative.

Range Precision

infinitely (∞) attenuated.

AND

1

Trigger

In addition to supporting internal software tri ggering and external digital

triggering to initiate a data acquisition sequence, the PCI-44 51/4452 also

supports analog level triggering. You can configure the trigger circuit to

monitor any one of the analog input channels to generate the level trigger.

Choosing an input channel as the level trigger channel does not influence

the input channel capabilities. The level trigger circuit compares the full

16 bits of the programmed trigger level with the digitized 16-bit sample.

The trigger-level range is identical to the analog input voltage range. The

trigger-level resolution is the same as the precision for a given input range.

Refer to Table 3-1.

The trigger circuit generates an internal digital trigger based on the input

signal and the user-defined trigger levels. Any of the timing sections of the

DAQ-STC can use th is level trigger, including the analog input, analog

output, RTSI, and general-purpose counter/timer sections. For example,

PCI-4451/4452 User Manual 3-6

©

National Instruments Corporation

Page 24

Chapter 3 Hardware Overview

you can configure the analog input section to acquire a given number of

samples after the analog input signal crosses a specific threshold. As

another example, you can configure the analog output section to generate

an output waveform whenever the analog input signal crosses a specific

threshold.

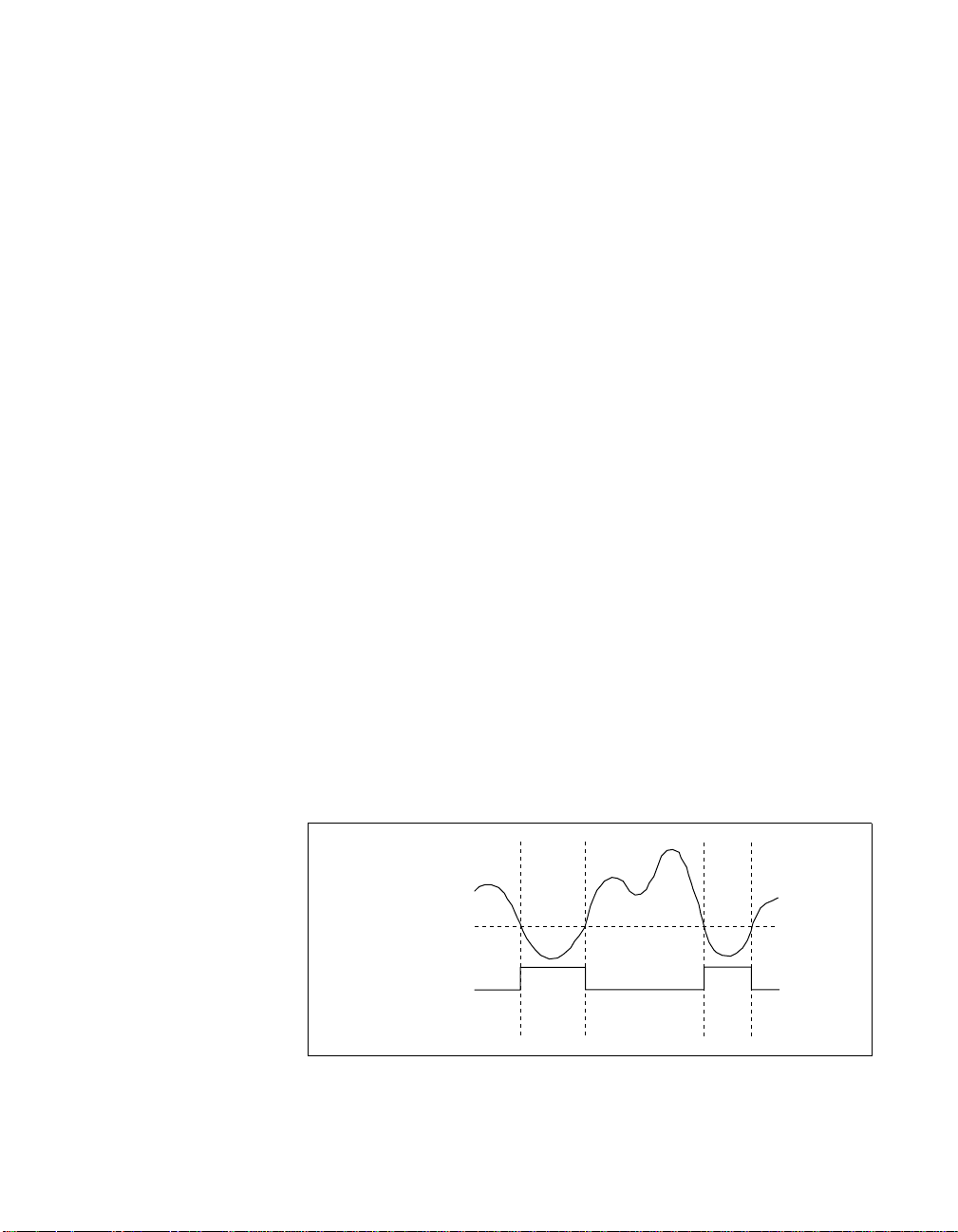

Due to the nature of delta-sigma con v er ters, the triggering cir cuits o perate

on the digital output of the converter. Since the trigger is generated at the

output of the converter, triggers can occur only when a sample is actually

generated. Placing the triggering circuits on the digital side of the converter

does not affect most measurements unless an analog output is generated

based on the input trigger. In this case, you must be aware of the inheren t

delays of the finite impulse response (FIR) filters internal to the delta-sigma

conv erters and you must accoun t for the delays. The delay through th e input

converter is 42 sample periods, while the delay through the output converter

is 34.6 ±0.5 sample periods.

During repetitive sampling of a waveform, you may observe jitter due to the

uncertainty of where a trigger level falls compared to the actual digitized

data. Although this trigger jitter is never greater than one sample period, it

can seem quite bad when the sample rate is only twice the bandwid th of

interest. This jitter has no effect on the processing of the data, and you can

decrease this jitter by oversampling.

There are five analog level triggering modes available, as shown in

Figures 3-3 throug h 3-7. You can set lowValue and highValue

independently in the software.

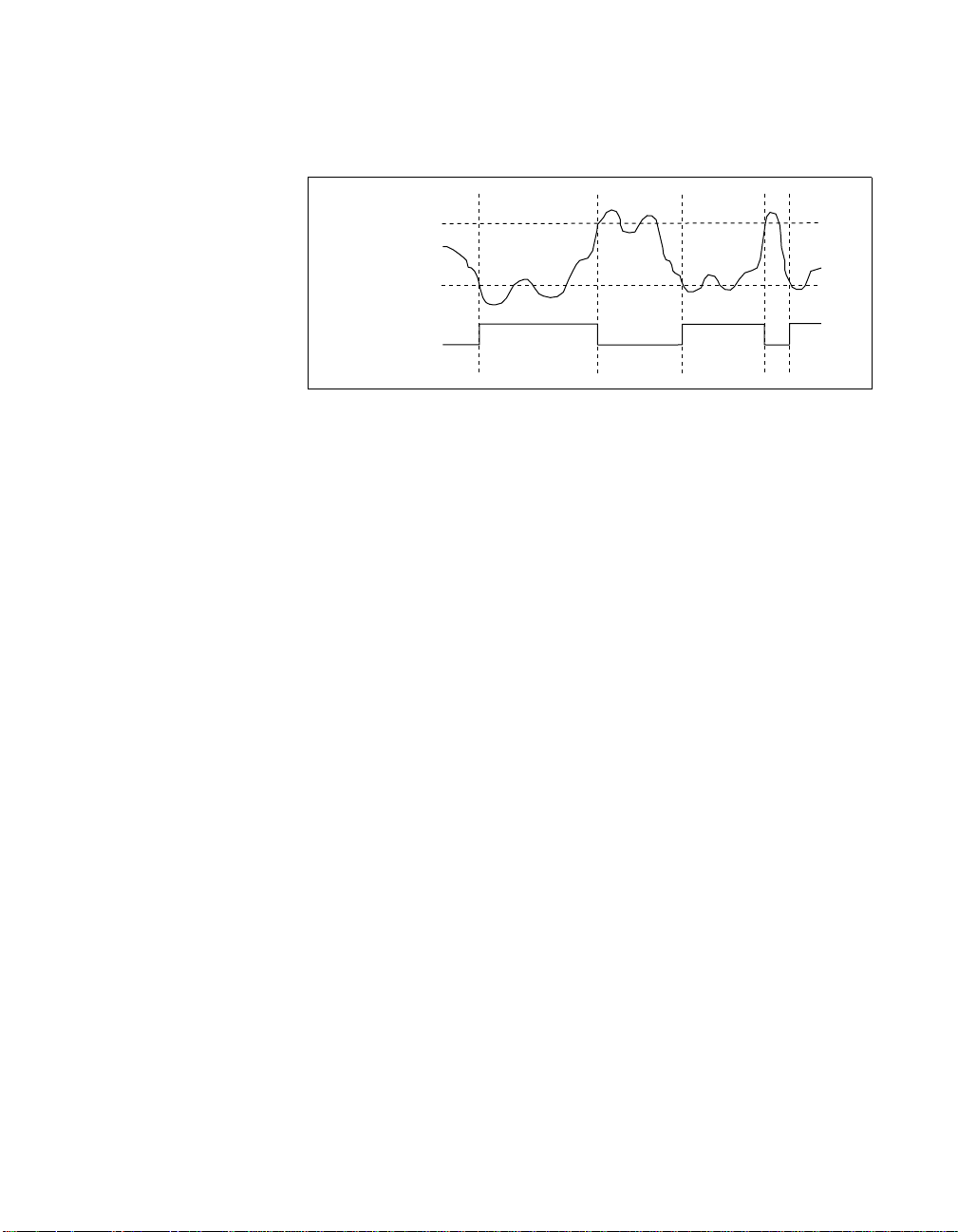

In below-low-level triggering mode, shown in Figure 3-3, the trigger is

generated when the signal value is less than lowValue. HighValue is

unused.

lowValue

Trigger

Figure 3-3.

©

National Instruments Corporation 3-7 PCI-4451/4452 User Manual

Below-Low-Level Triggering Mode

Page 25

Chapter 3 Hardware Overview

In above-high-level triggering mode, the trigger is generated when the

signal value is greater than highValue. LowValue i s unu sed .

highValue

Trigger

Figure 3-4.

Above-High-Level Triggering Mode

In inside-region triggering mode, the trigger is generated when the signal

value is between the lowValue and the highValue.

highValue

lowValue

Trigger

Figure 3-5.

Inside-Region Triggering Mode

In high-hysteresi s trigger ing mode, the trigger i s generated when the signal

value is greater than highValue, with the hysteresis specified by lowValue.

highValue

lowValue

Trigger

Figure 3-6.

PCI-4451/4452 User Manual 3-8

High-Hysteresis Triggering Mode

©

National Instruments Corporation

Page 26

Chapter 3 Hardware Overview

In low-hysteresis triggering mode, the trigger is generated when the signal

value is less than lowValue, with the hysteresis specified by highValue.

highValue

lowValue

Trigger

RTSI Triggers

Figure 3-7.

Low-Hysteresis Triggering Mode

Y o u can use digital triggering through the RTSI bus and the external digital

50-pin connector using any one of the eight available programmable

function input (PFI) pi ns. PFI0/TRIG1 (EXT_TRIG) is the pin dedicated to

external digital triggering.

You can trigger the PCI-DSA devices from any other PCI-DSA device or

any National Instruments device that has the RTSI bus feature. You can

connect the devices through the RTSI bus cable. An external digital trigger

can also trigger multiple devices simultaneously by distributing that trigger

through the RTSI bus. You can select the polarity of the external digital

trigger.

The seven RTSI trigger lines on the RTSI bus provide a very flexible

interconnection scheme for any PCI-4451/4452 device sharing the RTSI

bus. These bidirectional lines can drive any of eight timing signals onto the

RTSI bus and can receive any of these timing signals. This signal

connection scheme is shown in Figure 3-8.

©

National Instruments Corporation 3-9 PCI-4451/4452 User Manual

Page 27

Chapter 3 Hardware Overview

Trigger 7

RTSI Bus Connector

Clock

RTSI Switch

switch

DAQ-STC

TRIG1

TRIG2

CONVERT*

UPDATE*

WFTRIG

GPCTR0_SOURCE

GPCTR0_GATE

GPCTR0_OUT

GPCTR1_SOURCE

GPCTR1_GATE

RTSI_OSC (20 MHz)

Figure 3-8.

RTSI Bus Signal Connection

Refer to the Chapter 4, Signal Connections for a des c ript i on of the signals

shown in Figure 3-8.

Digital I/O

The PCI-4451/4452 devices contain eight lines of digital I/O for

general-purpose use through the 50-pin connector. You can individually

software-configure each line for either input or output.

The hardware up/down control for general-purpose counters 0 and 1 are

connected onboard to DIO6 and DIO7, respectively. Thus, you can use

DIO6 and DIO7 to control the general-purpose counters. The up/down

control signals are input only and do not affect the operation of the DIO

lines.

Note At system power-on and reset, the hardware sets both the PFI and DIO lines to

high impedance. This means that the device circuitry is not actively driving the

output either high or low. F or example, DIO(0) will be in the high impedance state

after power on, and Table 4-4, Digital I/O Signal Summary, shows that there is a

50 kΩ pull-up resistor. This pull-up resistor sets the DIO(0) pin to a logic high

when the output is in a high-impedance state. Take careful consideration of the

power-on state of the system to prevent any damage to external equipment.

PCI-4451/4452 User Manual 3-10

©

National Instruments Corporation

Page 28

Timing Signal Routing

The DAQ-STC provides a flexible interface for connecting timing signals

to other devices or to external circuitry. Your PCI-4451/4452 device uses

the RTSI bus to interconnect timing signals between devices, and uses the

PFI pins on the I/O connector to connect the device to external circuitry.

These connections enable the PCI-4 451/4452 device to both control and be

controlled by other devices and circuits.

There are a total of 13 timing signals internal to the DAQ-STC that you can

control by an external source. You can also control these timing signals by

signals generated internally to the DAQ-STC, and these selections are fully

software configurable. Many of these timing signals are also available as

outputs on the RTSI pins, as indicated in the RTSI Triggers section earlier

in this chapter, and on the PFI pins, as indicated in Chapter 4, Signal

Connections.

Programmable Function Inputs

The 10 PFIs are connected to the signal routing multiplexer for each timing

signal, and software can select one of the PFIs as the external source for a

given timing signal . It is im portant to note that you can use any of th e PFIs

as an input by any of the timing signals and that multiple timing signals can

use the same PFI simultaneously. This flexible routing scheme reduces the

need to change physical connections to the I/O connector for different

applications. You can also individually enable each of the PFI pins to

output a specific internal timing signal. For example, if you need the

GPCTR0_SOURCE signal as an output on the I/O connector, software can

turn on the output driver for the PFI8/GPCTR0_SOURCE pin.

Chapter 3 Hardware Overview

Note

Two o f the 10 PF I pi n s are n ot avai l ab le for general-purpose input on the di git a l

connector . You can confi gure PFI2/C ONVERT * and PFI5 /UPD A TE * as output s

only.

Device and RTSI Clocks

Some PCI-4451/4452 device functions require a frequency timebase to

generate the necessary timing signals for controlling general-purpose

signals at the 50-pin digital I/O connector. You canno t use these signals for

the generating the frequency of sample rates or update rates. Refer to

Selecting Sample/Update Cl ock Freq uency section for information on

sample/update clock generation.

©

National Instruments Corporation 3-11 PCI-4451/4452 User Manual

Page 29

Chapter 3 Hardware Overview

A PCI-4451/4452 device can use either its internal 20 MHz timebase or a

timebase received over the RTSI bus. In addition, if you configure the

device to use the internal timebase, you can pr ogram the de vi ce to dri v e its

internal timebase o ver the RTSI bus to anot her device that you program to

receive this timebase signal. The default configuration at startup is to use

the internal timebase without driving the RTSI bus timebase signal. This

timebase is software-selectable.

Selecting Sample/Update Clock Frequency

The two analog input channels of the PCI-4451 and the four inputs of the

PCI-4452 are simultaneously sampled at any software-programmable rate

from 5.0 kS/s to 204.8 kS/s in 190.7 µS/s increments (worst case). The

devices use direct digital synthesis (DDS) technology so that you can

choose the correct sample rate required for your application. All the input

channels acquire data at the same rate. One input channel cannot acquire

data at a different rate from another input channel.

The two analog output channels of the PCI-4451 are updated

simultaneously at any software programmable rate from 1.25 kS/s to

51.2 kS/s in 47.684 µS/s increments (worst case). The input sample rate

and output update rate on the PCI-4451 are synchronized and deri ved fro m

the same DDS clock. The input and output clocks may differ from each

other by a factor of 2 (1, 2, 4, 8, …, 128) while still maintaining their

synchronization as lon g as the lower bounds for update and sample rate are

maintained. All the output channels update data at the same rate. One

output channel cannot update data at a different rate from another output

channel.

The DDS clock signal and the synchronization start signal are transmitted

to other PCI-DSA devices via the RTSI bus. The PCI-4451/4452 can also

receive these signals to syn chronize the acquisition or wa veform generation

with other devices. In a multidevice system, a master device would drive

the clock and synchronization signal to other slave or receiving devices.

PCI-4451/4452 User Manual 3-12

©

National Instruments Corporation

Page 30

Device Configuration Issues

Selecting a sample rate that is less than two times the frequency of a band

of interest can lead you to believe the board is functioning improperly. By

undersampling the signal, you could receive what appears to be a DC

signal. This situation is due to the sharp antialiasing filters that remove

frequency components above the sampling frequency. If you have a

situation where this occurred, simply increase the sample rate until it meets

the requirements of the Shannon Sampling Theorem. For more information

on the filters and aliasing, refer to Chapter 6, Theory of Analog Opera tio n.

Unlike other converter technologies, delta-sigma converters must be run

continuously and at a minimum clock rate. To operate within guaranteed

specifications, the A/D con verters should operate at a minimum sample rate

of 5.0 kS/s and the D/A converters should operate at a minimum update rate

of 1.25 kS/s. This minimum rate is required to keep the internal circuitry of

the converters running within specifications. You are responsible for

selecting sample and update rates that fall within the specified limits.

Failure to do so could greatly affect the specifications.

Chapter 3 Hardware Overview

©

National Instruments Corporation 3-13 PCI-4451/4452 User Manual

Page 31

Signal Connections

This chapter describes how to make input and output connections to your

PCI-4451/4452 device via th e analog I/O and digital I/ O connectors of t he

device.

The analog I/O connector for the PCI-4451/4452 connects to the

BNC-2140 DSA accessory through the SHC68-C68-A1 shielded cable.

You can access the analog I/O of the PCI-4451/4452 using standard BNC

connectors on the BNC-2140. Y ou can connect the analog I/O sign als to the

shielded cable through a single 68-pin connector.

The digital I/O connector for the PCI-4451/4452 has 50 pins that you can

connect to generic 68-pi n t erm inal blocks through the SHC 50-68 shielded

cable. You can connect the digital I/O signals to the shielded cable through

a single 50-pin connector.

I/O Connectors

Table 4-1 describes the pin assignments for the 68-pin analog I/O

connector. Ta ble 4-3 describes the 50 -pin digital connec tor on the

PCI-4451/4452 devices. A signal description follows the connector

pinouts.

4

Caution

!

©

National Instruments Corporation 4-1 PCI-4451/4452 User Manual

Connections that exceed any of the maximum ratings of input or output signals

on the PCI-4451/4452 devices can damage the PCI-4451/4452 device, the

computer , and associated accessories. Maximum input ratings for each signal are

given in the Protection column of Table 4-2 and 4-4. National Instruments is not

liable for any damages resulting from s uch signal connections.

Page 32

Chapter 4 Signal Connections

Analog I/O Connector Signal Descriptions

Figure 4-1 shows the analog pin connections for the PCI-4451/4452.

-ACH0

NC

-ACH1

NC

ACH2-

NC

-ACH3

NC

NC

NC

NC

NC

NC

NC

NC

NC

NC

NC

NC

NC

NC

NC

NC

NC

-DAC0 OUT

NC

-DAC1 OUT

NC

NC

NC

NC

NC

+5 V

GND

135

236

337

438

539

640

741

842

943

10 44

11 45

12 46

13 47

14 48

15 49

16 50

17 51

18 52

19 53

20 54

21 55

22 56

23 57

24 58

25 59

26 60

27 61

28 62

29 63

30 64

31 65

32 66

33 67

34 68

+ACH0

GND

+ACH1

GND

+ACH2

GND

+ACH3

GND

NC

NC

NC

NC

NC

NC

NC

NC

NC

NC

NC

NC

NC

NC

NC

NC

+DAC0 OUT

GND

+DAC1 OUT

GND

NC

NC

NC

NC

+5 V

GND

Figure 4-1.

PCI-4451/4452 User Manual 4-2

Analog Pin Connections

©

National Instruments Corporation

Page 33

Chapter 4 Signal Connections

Table 4-1.

Signal Name Reference Direction Description

+ACH<0..3> AIGND Input +Analog Input Channel 0 throu gh 3—The PCI-4451 uses

−ACH<0..3>

AIGND Input

Analog I/O Connector Pin Assignment

+ACH<0..1> and the PCI-4452 uses +ACH<0..3>.

−Analog Input Channel 0 through 3—The PCI-4451 uses

−ACH<0..1> and the PCI-445 2 uses −ACH<0..3>.

AIGND — — Ana log Input Ground—These pins are the reference point for

single-ended measure m ents in SE configuration and t he bias

current return point for di fferential measurement s . Al l three

ground references—AIGND, AOGND, and DGND—are

connected together on your PCI-4451/4452 device, but each

serves a separate purpose.

+DAC0OUT

−DAC0OUT

+DAC1OUT

−DAC1OUT

AOGND — — Analog Output Ground—The anal og output voltages are

+5 V DGND Output +5 VDC Source—These pins are fused for up to 0. 5 A and

DGND — — Dig it al Ground—This pin supplies the reference for the +5

−DAC0OUT

+DAC0OUT Output

−DAC1OUT

+DAC1OUT Output

Output +Analog Output Channel 0—T hi s pin supplies the analog

non-inverting output channel 0. This pin is available only on

the PCI-4451.

−Analog Output Channel 0—This pin supplies the an al og

inverting output channel 0. This pin is available only on the

PCI-4451.

Output +Analog Output Channel 1—T hi s pin supplies the analog

non-inverting output channel 1. This pin is only available on

the PCI-4451.

−Analog Output Channel 1—This pin supplies the an al og

inverting output channel 1. This pin is only available on the

PCI-4451.

ultimately refere nc ed to this node. All three ground

references—AIGND, AOGND, and DGND—are connected

together on your PCI-4451/4 452 device, but each serves a

separate purpose.

supply power to the DSA signal conditioning accessories.

The fuse is s elf resetting.

VDC supply. All three ground references—AIGND, AOGND,

and DGND—are connected together on your PCI-4451/4452

device, but each serves a sep ara te purpose.

©

National Instruments Corporation 4-3 PCI-4451/4452 User Manual

Page 34

Chapter 4 Signal Connections

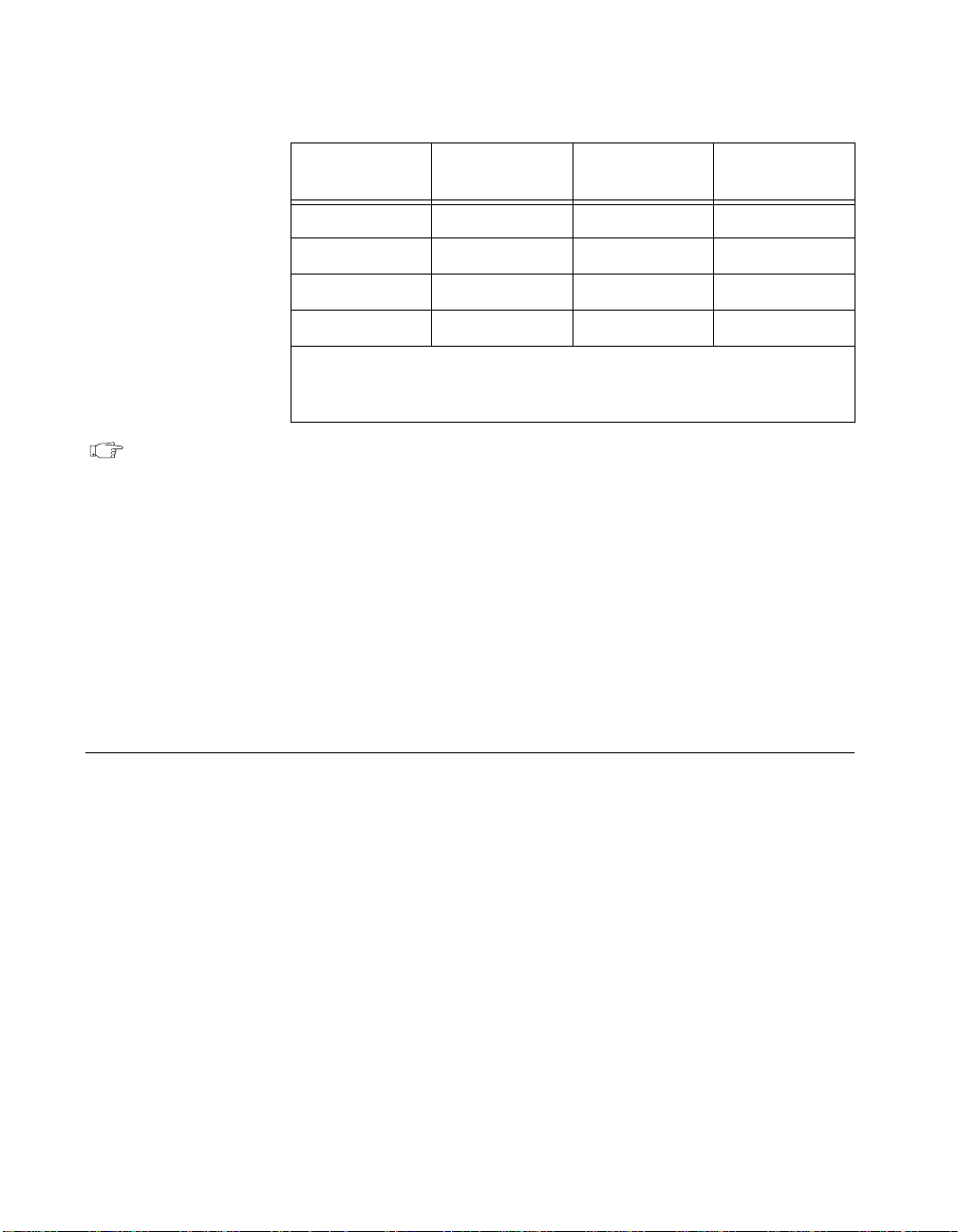

Table 4-2.

Signal

Signal Name

+ACH<0..3>

ACH<0..3>

−

AIGND

+DAC0OUT

DAC0OUT

−

+DAC1OUT

DAC1OUT

−

AOGND

DGND

+5 V

AI = Analog Input DIO = Digital Input/Outpu t

AO = Analog Output DO = Digital Output

†

±400 V/±400 V guarantee d by de sign, but not tested or certi fied to operate beyond ± 42. 4 V

Type and

Direction

AI

AI

AI — — — — — —

AO

AO

AO

AO

AO — — — — — —

DIO — — — — — —

DO

Impedance

Input/

Output

1 MΩ

in parallel

with

50 pF to

AIGND

1 MΩ

in parallel

with

50 pF to

AIGND

22 Ω to

DAC0OUT,

−

4.55 kΩ to

AOGND

22 Ω to

+DAC0OUT,

4.55 kΩ to

AOGND

22 Ω to

DAC1OUT,

−

4.55 kΩ to

AOGND

22 Ω to

+DAC1OUT,

4.55 kΩ to

AOGND

0.7 Ω Short-circuit to

Analog I/O Signal Summary

Protection

(V olts)

On/Off

±42.4 V/±42.4 V

±42.4 V/±42.4 V

Short-circuit to

DAC0OUT,

−

ground

Short-circuit to

+DAC0OUT,

ground

Short-circuit to

DAC1OUT,

−

ground

Short-circuit to

+DAC1OUT,

ground

ground

Source

(mA at V)

†

— — —

†

— — —

16.7 mA at

10 V

16.7 mA at

10 V

16.7 mA at

10 V

16.7 mA at

10 V

0.5A

Sink

(mA at

V)

— — —

— — —

— — —

— — —

— — —

Rise

Time

(ns)

Bias

±100 pA

±100 pA

PCI-4451/4452 User Manual 4-4

©

National Instruments Corporation

Page 35

Digital I/O Connector Signal Descriptions

Figure 4-2 shows the digital pin connections for the PCI-4451/4452.

Chapter 4 Signal Connections

FREQ_OUT

GPCTR0_OUT

PFI8/GPCTR0_SOURCE

PFI6/WFTRIG

PFI7

GPCTR1_OUT

PFI3/GPCTR1_SOURCE

PFI1/TRIG2 (PRETRIG)

CONVERT*

DIO(7)

DIO(6)

DIO(0)

DIO(2)

DIO(4)

DIO(3)

+5 V

+5 V

+5 V

N/C

N/C

N/C

N/C

N/C

N/C

N/C

126

227

328

429

530

631

732

833

934

10 35

11 36

12 37

13 38

14 39

15 40

16 41

17 42

18 43

19 44

20 45

21 46

22 47

23 48

24 49

25 50

DGND

PFI9/GPCTR0_GATE

DGND

UPDATE*

DGND

PFI4/GPCTR1_GATE

DGND

PFI0/TRIG1(EXT_TRIG)

DGND

RESERVED1

DGND

DIO(1)

DGND

EXTSTROBE*

DGND

DIO(5)

N/C

+5 V

DGND

N/C

DGND

N/C

DGND

N/C

DGND

Figure 4-2.

Digital Pin Connections

Refer to Appendix B, Pin Connections , for the digital pin connections of

the 68-pin connector.

©

National Instruments Corporation 4-5 PCI-4451/4452 User Manual

Page 36

Chapter 4 Signal Connections

Table 4-3.

Signal Name Reference Direction De scription

DIO<0..7> DGND Input or

DGND — — Digital Ground—This pin supplies the reference for the digital

+5 V DGND Output +5 VDC Source—These pins are fused for up to 1 A of +5 V

RESERVED1 DGND Output RESERVED—This pin is reserved. This signal is always high.

EXTSTROBE* DGND Output Externa l Strobe—This signal can be toggled under software

PFI0/TRIG1 (EXT_TRIG) DGND Input

PFI1/TRIG2 (PRETRIG) DGND Input

CONVERT* DGND Output A high-to-low edge on CONVERT* indicates that an A/D

PFI3/GPCTR1_SOURCE DGND Input

Digital I/O Connector Pin Assignment

Output

Output

Output

Digital I/O channels 0 through 7—Channels 6 and 7 can

control the up/down signal of general-purpose counters 0

and 1, respectivel y.

signals at the I/O connector as we ll as the +5 VDC supply.

supply. The fuse is self-resetting.

control to latch sign al s or trigger events on external devices.

TRIG1—As an input, this is a source for the data acquisition

trigger.

As an output, this signa l can drive external applications to

indicate that a trigger on the device has occurred. TRIG1 is the

start acquisi tion signal.

In LabVIEW, referred to as AI Start Trigger for both input and

output.

PFI1/TRIG2 (PRETRIG)—As an in put , this is one of the

PFIs.

As an output, this is the TRIG2 sig nal . In pre tri gger

applications, a low-to-high transition indicates the initiation of

the posttrigger conversi ons. TR IG2 is not used in posttrigger

applications.

In LabVIEW, referred to as AI Stop Trigger for both input and

output.

conversion is oc curring.

In LabVIEW, referred to as AI Convert.

PFI3/Counter 1 Source— As an input, this is one of the PFIs.

Output

PFI4/GPCTR1_GATE DGND Input

Output

UPDATE* DGND Output A high-to-low edge on UPDATE* indicates that a D/A

PCI-4451/4452 User Manual 4-6

As an output, this is the GPCTR1_SOURCE signal. This signal

reflects the actua l source connected to th e general-purpose

counter 1.

PFI4/Counter 1 G ate—As an input , th is is one of the PFIs.

As an output, this is the GPCTR1_GATE signal. This signal

reflects the actual gate signal connected to the general-purpose

counter 1.

conversion is oc curring.

In LabVIEW, referred to as AO Upda te.

©

National Instruments Corporation

Page 37

Chapter 4 Signal Connections

Table 4-3.

Signal Name Reference Direction De scription

GPCTR1_OUT DGND Out put General-Purpose Counter 1 Output

PFI6/WFTRIG DGND Input

PFI7 DGND Input PFI7—This is one of the PFIs.

PFI8/GPCTR0_SOURCE DGND Input

PFI9/GPCTR0_GATE DGND Input

GPCTR0_OUT DGND Out put General-Purpose Counter 0 Output

FREQ_OUT DGND Output Frequency Output—This output is from the frequency

Digital I/O Connector Pin Assignment (Continued)

PFI6/Waveform Trigger—As an input, this is one of the PFIs.

Output

Output

Output

As an output, this is the WFTRIG signal. In timed analog

output sequences, a low-to-high tran s ition indicates the

initiation of the wave form generation.

In LabVIEW, referred to as AO Start Trigger for both input

and output.

PFI8/Counter 0 Source—As an input, this is one of the

PFIs.

As an output, this is the GPCTR0_SOURCE signal. This signal

reflects the actua l source connected to th e general-purpose

counter 0.

PFI9/Counter 0 Gate—As a n input, this is one of the PFIs.

As an output, this is the GPCTR0_GATE signal. This signal

reflects the actual gate signal connected to the general-purpose

counter 0.

generator output.

©

National Instruments Corporation 4-7 PCI-4451/4452 User Manual

Page 38

Chapter 4 Signal Connections

Table 4-4.

Signal

Signal Name

DGND

+5 V

DIO<0..7>

RESERVED1

EXTSTROBE*

PFI0/TRIG1 (EXT_TRIG)

PFI1/TRIG2 (PRETRIG)

CONVERT*

PFI3/GPCTR1_SOURCE

PFI4/GPCTR1_GATE

GPCTR1_OUT

UPDATE*

PFI6/WFTRIG

PFI7

PFI8/GPCTR0_SOURCE

PFI9/GPCTR0_GATE

GPCTR0_OUT

FREQ_OUT

DIO = Digital Input/Output pu = pullup

DO = Digital Output DI = Digital Input

Note: The tolerance on the 50 kΩ pullup and pulldown resistors is very large. Actual value may range between 17 and 100 kΩ.

Type and

Direction

DIO —

DIO 0.15 Ω

DIO —

DO —

DO —

DIO —

DIO —

DO —

DIO —

DIO —

DO —

DO —

DIO —

DI —

DIO —

DIO —

DO —

DO —

Digital I/O Signal Summary

Impedance

Input/

Output

Protection

(V olts)

On/Off

— — —

Short-circuit

to ground

Vcc +0.5 13 at

— — —

— 3.5 at

Vcc +0.5 3.5 at

Vcc +0.5 3.5 at

— 3.5 at

Vcc +0.5 3.5 at

Vcc +0.5 3.5 at

— 3.5 at

— 3.5 at

Vcc +0.5 3.5 at

Vcc +0.5 — —

Vcc +0.5 3.5 at

Vcc +0.5 3.5 at

— 3.5 at

— 3.5 at

Source

(mA at V)

1A —

24 at 0.4

(Vcc

0.4)

−

5 at 0.4

(Vcc

0.4)

−

5 at 0.4

(Vcc

0.4)

−

5 at 0.4

(Vcc

0.4)

−

5 at 0.4

(Vcc

0.4)

−

5 at 0.4

(Vcc

0.4)

−

5 at 0.4

(Vcc

0.4)

−

5 at 0.4

(Vcc

0.4)

−

5 at 0.4

(Vcc

0.4)

−

5 at 0.4

(Vcc -0.4)

5 at 0.4

(Vcc

0.4)

−

5 at 0.4

(Vcc

0.4)

−

5 at 0.4

(Vcc

0.4)

−

5 at 0.4

(Vcc

0.4)

−

Sink

(mA at

V)

Rise

Time

(ns)

—

—

1.1

—

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

—

1.5

1.5

1.5

1.5

Bias

—

—

50 kΩ pu

50 kΩ pu

50 kΩ pu

50 kΩ pu

50 kΩ pu

50 kΩ pu

50 kΩ pu

50 kΩ pu

50 kΩ pu

50 kΩ pu

50 kΩ pu

50 kΩ pu

50 kΩ pu

50 kΩ pu

50 kΩ pu

50 kΩ pu

PCI-4451/4452 User Manual 4-8

©

National Instruments Corporation

Page 39

Analog Input Signal Connections

The analog input signals for the PCI-4451 /4452 d evices are +ACH<0..3>,

−ACH<0..3>, and AIGND. The +

analog input channels of your PCI-4451, and ±ACH<0..3> are tied to the

four analog input channels of your PCI-4452 device.

Chapter 4 Signal Connections

ACH<0..1> signals are tied to the two

!

+ACH

-ACH

AIGND

Caution

x

Calibration

Multiplexer

x

Exceeding the differential and common-mode input ranges distorts your input

signals.

AIGND is an analog input common signal that connects directly to the

ground system on the PCI -4451/44 52 de vices. You can use t his sign al for a

general analog ground tie point to your PCI-4451/4452 de vice if necessary ,

but connecting AIGND to other earth-connected grounds is not

recommended. AIGND is not directly available if you are using a

BNC-2140 accessory.