Page 1

PC-DIO-24

User Manual

Digital I/O Board for the IBM PC/XT/AT

September 1995 Edition

Part Number 320288B-01

© Copyright 1989, 1995 National Instruments Corporation.

All Rights Reserved.

Page 2

National Instruments Corporate Headquarters

6504 Bridge Point Parkway

Austin, TX 78730-5039

(512) 794-0100

Technical support fax: (800) 328-2203

(512) 794-5678

Branch Offices:

Australia 03 9 879 9422, Austria 0662 45 79 90 0, Belgium 02 757 00 20, Canada (Ontario) 519 622 9310,

Canada (Québec) 514 694 8521, Denmark 45 76 26 00, Finland 90 527 2321, France 1 48 14 24 24,

Germany 089 741 31 30, Hong Kong 2645 3186, Italy 02 48301892, Japan 03 5472 2970, Korea 02 596 7456,

Mexico 5 202 2544, Netherlands 03480 33466, Norway 32 84 84 00, Singapore 2265886, Spain 91 640 0085,

Sweden 08 730 49 70, Switzerland 056 20 51 51, Taiwan 02 377 1200, U.K. 01635 523545

Page 3

Limited Warranty

The PC-DIO-24 is warranted against defects in materials and workmanship for a period of one year from the date of

shipment, as evidenced by receipts or other documentation. National Instruments will, at its option, repair or replace

equipment that proves to be defective during the warranty period. This warranty includes parts and labor.

The media on which you receive National Instruments software are warranted not to fail to execute programming

instructions, due to defects in materials and workmanship, for a period of 90 days from date of shipment, as

evidenced by receipts or other documentation. National Instruments will, at its option, repair or replace software

media that do not execute programming instructions if National Instruments receives notice of such defects during

the warranty period. National Instruments does not warrant that the operation of the software shall be uninterrupted

or error free.

A Return Material Authorization (RMA) number must be obtained from the factory and clearly marked on the

outside of the package before any equipment will be accepted for warranty work. National Instruments will pay the

shipping costs of returning to the owner parts which are covered by warranty.

National Instruments believes that the information in this manual is accurate. The document has been carefully

reviewed for technical accuracy. In the event that technical or typographical errors exist, National Instruments

reserves the right to make changes to subsequent editions of this document without prior notice to holders of this

edition. The reader should consult National Instruments if errors are suspected. In no event shall National

Instruments be liable for any damages arising out of or related to this document or the information contained in it.

EXCEPT AS SPECIFIED HEREIN, NATIONAL INSTRUMENTS MAKES NO WARRANTIES, EXPRESS OR

IMPLIED, AND SPECIFICALLY DISCLAIMS ANY WARRANTY OF MERCHANTABILITY OR FITNESS

FOR A PARTICULAR PURPOSE. CUSTOMER'S RIGHT TO RECOVER DAMAGES CAUSED BY FAULT

OR NEGLIGENCE ON THE PART OF NATIONAL INSTRUMENTS SHALL BE LIMITED TO THE AMOUNT

THERETOFORE PAID BY THE CUSTOMER. NATIONAL INSTRUMENTS WILL NOT BE LIABLE FOR

DAMAGES RESULTING FROM LOSS OF DATA, PROFITS, USE OF PRODUCTS, OR INCIDENTAL OR

CONSEQUENTIAL DAMAGES, EVEN IF ADVISED OF THE POSSIBILITY THEREOF. This limitation of the

liability of National Instruments will apply regardless of the form of action, whether in contract or tort, including

negligence. Any action against National Instruments must be brought within one year after the cause of action

accrues. National Instruments shall not be liable for any delay in performance due to causes beyond its reasonable

control. The warranty provided herein does not cover damages, defects, malfunctions, or service failures caused by

owner's failure to follow the National Instruments installation, operation, or maintenance instructions; owner's

modification of the product; owner's abuse, misuse, or negligent acts; and power failure or surges, fire, flood,

accident, actions of third parties, or other events outside reasonable control.

Copyright

Under the copyright laws, this publication may not be reproduced or transmitted in any form, electronic or

mechanical, including photocopying, recording, storing in an information retrieval system, or translating, in whole or

in part, without the prior written consent of National Instruments Corporation.

Trademarks

LabVIEW® and NI-DAQ® are trademarks of National Instruments Corporation.

Product and company names listed are trademarks or trade names of their respective companies.

Page 4

WARNING REGARDING MEDICAL AND CLINICAL USE

OF NATIONAL INSTRUMENTS PRODUCTS

National Instruments products are not designed with components and testing intended to ensure a level of reliability

suitable for use in treatment and diagnosis of humans. Applications of National Instruments products involving

medical or clinical treatment can create a potential for accidental injury caused by product failure, or by errors on the

part of the user or application designer. Any use or application of National Instruments products for or involving

medical or clinical treatment must be performed by properly trained and qualified medical personnel, and all

traditional medical safeguards, equipment, and procedures that are appropriate in the particular situation to prevent

serious injury or death should always continue to be used when National Instruments products are being used.

National Instruments products are NOT intended to be a substitute for any form of established process, procedure, or

equipment used to monitor or safeguard human health and safety in medical or clinical treatment.

Page 5

FCC/DOC Radio Frequency Interference Compliance

This equipment generates and uses radio frequency energy and, if not installed and used in strict accordance with the

instructions in this manual, may cause interference to radio and television reception. This equipment has been tested

and found to comply with the following two regulatory agencies:

Federal Communications Commission

This device complies with Part 15 of the Federal Communications Commission (FCC) Rules for a Class A digital

device. Operation is subject to the following two conditions:

1. This device may not cause harmful interference in commercial environments.

2. This device must accept any interference received, including interference that may cause undesired operation.

Canadian Department of Communications

This device complies with the limits for radio noise emissions from digital apparatus set out in the Radio

Interference Regulations of the Canadian Department of Communications (DOC).

Le présent appareil numérique n’émet pas de bruits radioélectriques dépassant les limites applicables aux appareils

numériques de classe A prescrites dans le règlement sur le brouillage radioélectrique édicté par le ministère des

communications du Canada.

Instructions to Users

These regulations are designed to provide reasonable protection against harmful interference from the equipment to

radio reception in commercial areas. Operation of this equipment in a residential area is likely to cause harmful

interference, in which case the user will be required to correct the interference at his own expense.

There is no guarantee that interference will not occur in a particular installation. However, the chances of

interference are much less if the equipment is installed and used according to this instruction manual.

If the equipment does cause interference to radio or television reception, which can be determined by turning the

equipment on and off, one or more of the following suggestions may reduce or eliminate the problem.

• Operate the equipment and the receiver on different branches of your AC electrical system.

• Move the equipment away from the receiver with which it is interfering.

• Reorient or relocate the receiver’s antenna.

• Be sure that the equipment is plugged into a grounded outlet and that the grounding has not been defeated with a

cheater plug.

Notice to user: Changes or modifications not expressly approved by National Instruments could void the user’s

authority to operate the equipment under the FCC Rules.

If necessary, consult National Instruments or an experienced radio/television technician for additional suggestions.

The following booklet prepared by the FCC may also be helpful: How to Identify and Resolve Radio-TV

Interference Problems. This booklet is available from the U.S. Government Printing Office, Washington, DC

20402, Stock Number 004-000-00345-4.

Page 6

Contents

About This Manual............................................................................................................. xi

Organization of This Manual ......................................................................................... xi

Conventions Used in This Manual................................................................................. xii

National Instruments Documentation ............................................................................ xii

Related Documentation.................................................................................................. xiii

Customer Communication ............................................................................................. xiii

Chapter 1

Introduction

About the PC-DIO-24 .................................................................................................... 1-1

What You Need to Get Started ...................................................................................... 1-2

Software Programming Choices .................................................................................... 1-2

Optional Equipment ....................................................................................................... 1-4

Unpacking ...................................................................................................................... 1-6

.......................................................................................................................... 1-1

LabVIEW and LabWindows/CVI Application Software .................................. 1-2

NI-DAQ Driver Software................................................................................... 1-3

Register-Level Programming............................................................................. 1-4

Custom Cables ................................................................................................... 1-4

Chapter 2

Configuration and Installation

Board Configuration ...................................................................................................... 2-1

Base I/O Address Settings.................................................................................. 2-2

Interrupt Selection.............................................................................................. 2-4

Interrupt Enable Settings........................................................................ 2-4

Interrupt Level Settings.......................................................................... 2-4

Installation...................................................................................................................... 2-5

Signal Connections ........................................................................................................ 2-6

I/O Connector Pin Description........................................................................... 2-6

Signal Connection Descriptions......................................................................... 2-7

Port C Pin Assignments ......................................................................... 2-7

Timing Specifications ........................................................................................ 2-8

Mode 1 Input Timing ............................................................................. 2-9

Mode 1 Output Timing .......................................................................... 2-10

Mode 2 Bidirectional Timing................................................................. 2-11

Chapter 3

Theory of Operation

Address Decoder............................................................................................................ 3-2

Bus Transceivers............................................................................................................ 3-2

PC I/O Channel Control Circuitry ................................................................................. 3-2

82C55A Programmable Peripheral Interface ................................................................ 3-2

Interrupt Control Circuitry............................................................................................. 3-2

Digital I/O Connector..................................................................................................... 3-2

.......................................................................................................... 3-1

...................................................................................... 2-1

© National Instruments Corporation vii PC-DIO-24 User Manual

Page 7

Contents

Chapter 4

Register-Level Programming

Introduction.................................................................................................................... 4-1

82C55A Modes of Operation......................................................................................... 4-1

Mode 0 ............................................................................................................... 4-2

Mode 1 ............................................................................................................... 4-2

Mode 2 ............................................................................................................... 4-2

Single Bit Set/Reset Feature .............................................................................. 4-2

Register Map.................................................................................................................. 4-3

Register Descriptions ..................................................................................................... 4-3

Single Bit Set/Reset Feature .............................................................................. 4-4

Programming Considerations......................................................................................... 4-5

Mode 0–Basic I/O .............................................................................................. 4-5

Mode 0 Programming Example ............................................................. 4-6

Mode 1–Strobed Input ....................................................................................... 4-7

Mode 1 Input Programming Example.................................................... 4-9

Mode 1–Strobed Output..................................................................................... 4-9

Mode 1 Output Programming Example................................................. 4-11

Mode 2–Bidirectional Bus ................................................................................. 4-12

Mode 2 Programming Example ............................................................. 4-13

Interrupt Programming Examples...................................................................... 4-14

Interrupt Handling.......................................................................................................... 4-15

......................................................................................... 4-1

Appendix A

Specifications

........................................................................................................................ A-1

Appendix B

I/O Connector

....................................................................................................................... B-1

Appendix C

OKI 82C55A Data Sheet

................................................................................................... C-1

Appendix D

Customer Communication

............................................................................................... D-1

Glossary............................................................................................................................ Glossary-1

Index .................................................................................................................................. Index-1

PC-DIO-24 User Manual viii © National Instruments Corporation

Page 8

Contents

Figures

Figure 1-1. The Relationship between the Programming Environment, NI-DAQ, and

Your Hardware................................................................................................... 1-3

Figure 2-1. PC-DIO-24 Parts Locator Diagram ................................................................... 2-2

Figure 2-2. Example Base I/O Address Switch Settings ..................................................... 2-3

Figure 2-3. Jumper Settings–PC6, PC4, PC2, and N/C........................................................ 2-4

Figure 2-4. Interrupt Jumper Setting for IRQ5 (Factory Setting) ........................................ 2-4

Figure 2-5. Digital I/O Connector Pin Assignments ............................................................ 2-6

Figure 3-1. PC-DIO-24 Block Diagram ............................................................................... 3-1

Figure 4-1. Control-Word Formats....................................................................................... 4-4

Figure B-1. PC-DIO-24 I/O Connector................................................................................. B-1

Tables

Table 2-1. PC-DIO-24 Factory-Set Jumper and Switch Settings........................................ 2-1

Table 2-2. Port C Signal Assignments ............................................................................... 2-7

Table 4-1. PC-DIO-24 Address Map................................................................................... 4-3

Table 4-2. Port C Set/Reset Control Words ........................................................................ 4-5

Table 4-3. Mode 0 I/O Configurations................................................................................ 4-6

Table 4-4. Interrupt Enable Signals for All Mode Combinations ....................................... 4-16

Table A-1. Maximum Average Transfer Rates for the PC-DIO-24..................................... A-2

© National Instruments Corporation ix PC-DIO-24 User Manual

Page 9

About This Manual

This manual describes the mechanical and electrical aspects of the PC-DIO-24 and contains

information concerning its operation and programming. The PC-DIO-24 is a 24-bit parallel,

digital I/O interface designed around an 82C55A programmable peripheral interface (PPI). The

PC-DIO-24 is a member of the National Instruments PC Series of PC I/O Channel expansion

boards for the IBM PC computer family. These boards are designed for low-cost data acquisition

and control for applications in laboratory testing, production testing, and industrial process

monitoring and control.

This manual describes installation, basic programming considerations, and theory of operation

for the PC-DIO-24. The example programs included are written in C.

Organization of This Manual

The PC-DIO-24 User Manual is organized as follows:

• Chapter 1, Introduction, describes the PC-DIO-24, lists what you need to get started,

describes software programming choices, optional equipment, and custom cables, and

explains how to unpack the PC-DIO-24.

• Chapter 2, Configuration and Installation, describes how to configure and install the

PC-DIO-24, including I/O connector signal descriptions, handshake timing diagrams, and

cabling instructions.

• Chapter 3, Theory of Operation, contains a functional overview of the PC-DIO-24 board and

explains the operation of each functional unit making up the PC-DIO-24.

• Chapter 4, Register-Level Programming, describes in detail the address and function of each

of the PC-DIO-24 control and status registers. This chapter also includes important

information related to register-level programming the PC-DIO-24.

• Appendix A, Specifications, lists the specifications for the PC-DIO-24 board.

• Appendix B, I/O Connector, describes the pinout and signal names for the I/O connector on

the PC-DIO-24.

• Appendix C, OKI 82C55A Data Sheet, contains the manufacturer data sheet for the

OKI 82C55A (OKI Semiconductor) CMOS programmable peripheral interface. This

interface is used on the PC-DIO-24 board.

• Appendix D, Customer Communication, contains forms you can use to request help from

National Instruments or to comment on our products.

• The Glossary contains an alphabetical list and description of terms used in this manual,

including abbreviations, acronyms, metric prefixes, mnemonics, symbols, and terms.

© National Instruments Corporation xi PC-DIO-24 User Manual

Page 10

About This Manual

• The Index alphabetically lists the topics in this manual, including the page where you can

find each one.

Conventions Used in This Manual

The following conventions are used in this manual.

bold Bold text denotes menus, menu items, or dialog box buttons or options.

bold italic Bold italic text denotes a note, caution, or warning.

italic Italic text denotes emphasis, a cross reference, or an introduction to a key

concept.

monospace Lowercase text in this font denotes text or characters that are to be literally

input from the keyboard, sections of code, programming examples, and

syntax examples. This font is also used for the proper names of disk

drives, paths, directories, programs, subprograms, subroutines, device

names, functions, variables, filenames, and extensions, and for statements

and comments taken from program code.

NI-DAQ NI-DAQ refers to the NI-DAQ software for PC compatibles unless

otherwise noted.

PC PC refers to the IBM PC/XT, the IBM PC AT, and compatible computers

unless otherwise noted.

SCXI SCXI stands for Signal Conditioning eXtensions for Instrumentation and

is a National Instruments product line designed to perform front-end signal

conditioning for National Instruments plug-in DAQ boards.

< > Angle brackets containing numbers separated by an ellipses represent a

range, signal, or port (for example, ACH<0..7> stands for ACH0 through

ACH7).

Abbreviations, acronyms, metric prefixes, mnemonics, and symbols are listed in the Glossary.

National Instruments Documentation

The PC-DIO-24 User Manual is one piece of the documentation set for your data acquisition

(DAQ) system. You could have any of several types of manuals, depending on the hardware and

software in your system. Use the different types of manuals you have as follows:

• Getting Started with SCXI—If you are using SCXI, this is the first manual you should read.

It gives an overview of the SCXI system and contains the most commonly needed

information for the modules, chassis, and software.

PC-DIO-24 User Manual xii © National Instruments Corporation

Page 11

About This Manual

• Your SCXI hardware user manuals—If you are using SCXI, read these manuals next for

detailed information about signal connections and module configuration. They also explain

in greater detail how the module works and contain application hints.

• Your DAQ hardware user manuals—These manuals have detailed information about the

DAQ hardware that plugs into or is connected to your computer. Use these manuals for

hardware installation and configuration instructions, specification information about your

DAQ hardware, and application hints.

• Software manuals—Examples of software manuals you may have are the LabVIEW and

LabWindows

NI-DAQ supports LabWindows for DOS). After you set up your hardware system, use either

the application software (LabVIEW or LabWindows/CVI) manuals or the NI-DAQ manuals

to help you write your application. If you have a large and complicated system, it is

worthwhile to look through the software manuals before you configure your hardware.

• Accessory installation guides or manuals—If you are using accessory products, read the

terminal block and cable assembly installation guides or accessory board user manuals. They

explain how to physically connect the relevant pieces of the system. Consult these guides

when you are making your connections.

®

/CVI manual sets and the NI-DAQ manuals (a 4.6.1 or earlier version of

• SCXI chassis manuals—If you are using SCXI, read these manuals for maintenance

information on the chassis and installation instructions.

Related Documentation

The following documents contain information that you may find helpful as you read this manual:

• IBM Personal Computer AT Technical Reference manual

• IBM Personal Computer XT Technical Reference manual

Customer Communication

National Instruments wants to receive your comments on our products and manuals. We are

interested in the applications you develop with our products, and we want to help if you have

problems with them. To make it easy for you to contact us, this manual contains comment and

configuration forms for you to complete. These forms are in Appendix D, Customer

Communication, at the end of this manual.

© National Instruments Corporation xiii PC-DIO-24 User Manual

Page 12

Chapter 1 Introduction

This chapter describes the PC-DIO-24, lists what you need to get started, describes software

programming choices, optional equipment, and custom cables, and explains how to unpack the

PC-DIO-24.

About the PC-DIO-24

Thank you for purchasing the National Instruments PC-DIO-24. The PC-DIO-24 is a low cost,

24-bit parallel, digital I/O interface for the PC. An OKI 82C55A PPI controls the 24 bits of

digital I/O. The 82C55A is very flexible and powerful when interfacing with peripheral

equipment, can operate in either a unidirectional or bidirectional bus mode, and can generate

interrupt request outputs. The 82C55A can be programmed for almost any 8-bit or 16-bit digital

I/O application. All digital I/O is through a standard 50-pin male connector. The pin

assignments for this connector are compatible with standard 24-channel digital I/O applications.

The PC-DIO-24 can be used in a wide range of digital I/O applications. With the PC-DIO-24, a

PC can be interfaced to any of the following.

• Other computers

- Another PC with a National Instruments PC-DIO-24 or AT-DIO-32F

- IBM Personal System/2 with a National Instruments MC-DIO-24 or MC-DIO-32F

- Apple Macintosh II with a National Instruments NB-DIO-24 or NB-DIO-32F

- Any other computer with an 8-bit or 16-bit parallel interface

• Centronics-compatible printers and plotters

• Panel meters

• Instruments and test equipment with BCD readouts and/or controls

• Opto-isolated solid-state relays (SSRs) and I/O module mounting racks

Note: The PC-DIO-24 cannot sink sufficient current to drive the SSR-OAC-5 and

SSR-OAC-5A output modules. However, it can drive the SSR-ODC-5 output module

and all SSR input modules available from National Instruments.

If you need to drive a SSR-OAC-5 or SSR-OAC-5A, you can either use a non-inverting

digital buffer chip between the PC-DIO-24 and the SSR backplane, or you can use a

DIO-23F or MIO Series board with appropriate connections (e.g., SC-205X and

cables).

© National Instruments Corporation 1-1 PC-DIO-24 User Manual

Page 13

Introduction Chapter 1

With the PC-DIO-24, the PC can serve as a digital I/O system controller for laboratory testing,

production testing, and industrial process monitoring and control.

Detailed specifications of the PC-DIO-24 are in Appendix A, Specifications.

What You Need to Get Started

To set up and use your PC-DIO-24, you will need the following:

PC-DIO-24 board

PC-DIO-24 User Manual

One of the following software packages and documentation:

NI-DAQ for PC compatibles

LabVIEW for Windows

LabWindows/CVI for Windows

Your computer

Software Programming Choices

There are several options to choose from when programming your National Instruments DAQ

and SCXI hardware. You can use LabVIEW, LabWindows/CVI, or NI-DAQ. A 4.6.1 or earlier

version of NI-DAQ supports LabWindows for DOS.

LabVIEW and LabWindows/CVI Application Software

LabVIEW and LabWindows/CVI are innovative program development software packages for

data acquisition and control applications. LabVIEW uses graphical programming, whereas

LabWindows/CVI enhances traditional programming languages. Both packages include

extensive libraries for data acquisition, instrument control, data analysis, and graphical data

presentation.

LabVIEW features interactive graphics, a state-of-the-art user interface, and a powerful graphical

programming language. The LabVIEW Data Acquisition VI Library, a series of VIs for using

LabVIEW with National Instruments DAQ hardware, is included with LabVIEW. The LabVIEW

Data Acquisition VI Libraries are functionally equivalent to the NI-DAQ software.

LabWindows/CVI features interactive graphics, a state-of-the-art user interface, and uses the

ANSI standard C programming language. The LabWindows/CVI Data Acquisition Library, a

series of functions for using LabWindows/CVI with National Instruments DAQ hardware, is

included with the NI-DAQ software kit. The LabWindows/CVI Data Acquisition libraries are

functionally equivalent to the NI-DAQ software.

Using LabVIEW or LabWindows/CVI software will greatly reduce the development time for

your data acquisition and control application.

PC-DIO-24 User Manual 1-2 © National Instruments Corporation

Page 14

Chapter 1 Introduction

NI-DAQ Driver Software

The NI-DAQ driver software is included at no charge with all National Instruments DAQ

hardware. NI-DAQ is not packaged with SCXI or accessory products, except for the SCXI-1200.

NI-DAQ has an extensive library of functions that you can call from your application

programming environment. These functions include routines for analog input (A/D conversion),

buffered data acquisition (high-speed A/D conversion), analog output (D/A conversion),

waveform generation, digital I/O, counter/timer operations, SCXI, RTSI, self-calibration,

messaging, and acquiring data to extended memory.

NI-DAQ has both high-level DAQ I/O functions for maximum ease of use and low-level DAQ

I/O functions for maximum flexibility and performance. Examples of high-level functions are

streaming data to disk or acquiring a certain number of data points. An example of a low-level

function is writing directly to registers on the DAQ device. NI-DAQ does not sacrifice the

performance of National Instruments DAQ devices because it lets multiple devices operate at

their peak performance.

NI-DAQ also internally addresses many of the complex issues between the computer and the

DAQ hardware such as programming interrupts and DMA controllers. NI-DAQ maintains a

consistent software interface among its different versions so that you can change platforms with

minimal modifications to your code. Figure 1-1 illustrates the relationship between NI-DAQ and

LabVIEW and LabWindows/CVI.

Conventional

Programming

Environment

(PC, Macintosh, or

Sun SPARCstation)

DAQ or

SCXI Hardware

LabVIEW

(PC, Macintosh, or

Sun SPARCstation)

NI-DAQ

Driver Software

LabWindows/CVI

(PC or Sun

SPARCstation)

Personal

Computer or

Workstation

Figure 1-1. The Relationship between the Programming Environment,

NI-DAQ, and Your Hardware

© National Instruments Corporation 1-3 PC-DIO-24 User Manual

Page 15

Introduction Chapter 1

Register-Level Programming

The final option for programming any National Instruments DAQ hardware is to write registerlevel software. Writing register-level programming software can be very time-consuming and

inefficient, and is not recommended for most users.

Even if you are an experienced register-level programmer, consider using NI-DAQ, LabVIEW,

or LabWindows/CVI to program your National Instruments DAQ hardware. Using the NI-DAQ,

LabVIEW, or LabWindows/CVI software is easier than, and as flexible as, register-level

programming, and can save weeks of development time.

Optional Equipment

National Instruments offers a variety of products to use with your PC-DIO-24 board, including

cables, connector blocks, and other accessories, as follows:

• Cables and cable assemblies, shielded and ribbon

• Connector blocks, shielded and unshielded 50-pin screw terminals

• Signal conditioning eXtensions for Instrumentation (SCXI) modules and accessories for

isolating, amplifying, exciting, and multiplexing signals for relays and analog output. With

SCXI you can condition and acquire up to 3,072 channels.

• Low channel count signal conditioning modules, boards, and accessories, including

conditioning for strain gauges and RTDs, simultaneous sample and hole, and relays.

For more specific information about these products, refer to your National Instruments catalog or

call the office nearest you.

Custom Cables

National Instruments offers cables and accessories for you to prototype your application or to use

if you frequently change board interconnections.

If you want to develop your own cable, however, the following guidelines may be useful:

The PC-DIO-24 I/O connector is a 50-pin male ribbon-cable header. The manufacturer part

numbers used by National Instruments for this header are as follows:

• Electronic Products Division/3M (part number 3596-5002)

• T&B/Ansley Corporation (part number 609-5007)

The mating connector for the PC-DIO-24 is a 50-position, polarized, ribbon socket connector

with strain relief. National Instruments uses a polarized (keyed) connector to prevent inadvertent

upside-down connection to the PC-DIO-24. Recommended manufacturer part numbers for this

mating connector are as follows:

PC-DIO-24 User Manual 1-4 © National Instruments Corporation

Page 16

Chapter 1 Introduction

• Electronic Products Division/3M (part number 3425-7650)

• T&B/Ansley Corporation (part number 609-5041CE)

The standard ribbon cable (50-conductor, 28 AWG, stranded) that can be used with these

connectors is as follows:

• Electronic Products Division/3M (part number 3365/50)

• T&B/Ansley Corporation (part number 171-50)

Recommended manufacturer part numbers for the 50-pin edge connector for connecting to a

module rack with an edge connector are as follows:

• Electronic Products Division/3M (part number 3415-0001)

• T&B Ansley Corporation (part number 609-5015M)

A polarizing key can be plugged into these edge connectors to prevent inadvertent upside-down

connection to the I/O module rack. The location of this key varies from rack to rack. Consult

the specification for the rack you intend to use for the location of any polarizing key. The

recommended manufacturer part numbers for this polarizing key are as follows:

• Electronic Products Division/3M (part number 3439-2)

• T&B Ansley Corporation (part number 609-0005)

If you plan to use the PC-DIO-24 for a communications application, you may need shielded

cables to meet FCC requirements. The PC-DIO-24 I/O bracket has been designed so that the

shield of the I/O cable can be grounded through the computer chassis when a mating connector

such as the following is used:

• AMP Special Industries (part number 2-746483-2)

Many varieties of shielded ribbon cable are available to work with the mating connector listed

previously. One type of shielded cable encloses a standard ribbon cable with a shielded jacket.

Recommended manufacturers and the appropriate part numbers for this type of cable are as

follows:

• Belden Electronic Wire and Cable (part number 9L28350)

• T&B/Ansley Corporation (part number 187-50)

© National Instruments Corporation 1-5 PC-DIO-24 User Manual

Page 17

Introduction Chapter 1

Unpacking

Your PC-DIO-24 board is shipped in an antistatic package to prevent electrostatic damage to the

board. Electrostatic discharge can damage several components on the board. To avoid such

damage in handling the board, take the following precautions:

• Ground yourself via a grounding strap or by holding a grounded object.

• Touch the antistatic package to a metal part of your PC chassis before removing the board

from the package.

• Remove the board from the package and inspect the board for loose components or any other

sign of damage. Notify National Instruments if the board appears damaged in any way. Do

not install a damaged board into your computer.

• Never touch the exposed pins of connectors.

PC-DIO-24 User Manual 1-6 © National Instruments Corporation

Page 18

Chapter 2 Configuration and Installation

This chapter describes how to configure and install the PC-DIO-24, including I/O connector

signal descriptions, handshake timing diagrams, and cabling instructions.

Board Configuration

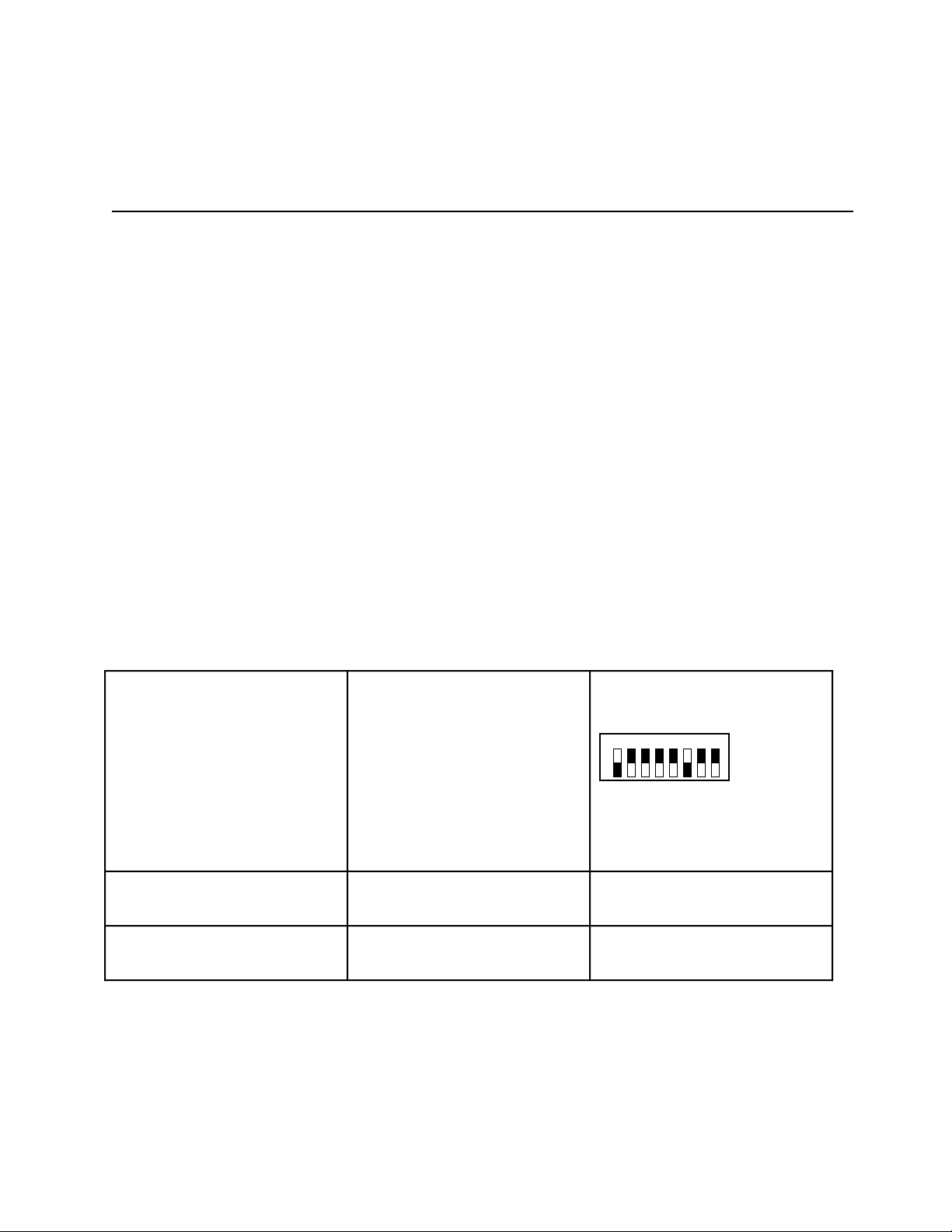

The PC-DIO-24 contains one DIP switch and two jumpers to configure the base I/O address and

interrupts, respectively. The PC-DIO-24 also contains one fuse to protect the +5 V power

output. Figure 2-1 shows the location of jumper sets W1 and W2, DIP switch U2, and the

fuse F1.

The PC-DIO-24 is configured at the factory to a base I/O address of hex 210, to use interrupt

enable line PC4, and to use interrupt level 5. These settings (shown in Table 2-1) are suitable for

most systems. However, if your system has other hardware at this base I/O address, interrupt

enable line, or interrupt level, you need to change these settings on the PC-DIO-24 (as described

in the following pages) or on the other hardware. Record your settings in the PC-DIO-24

Hardware and Software Configuration Form in Appendix D, Customer Communication.

Table 2-1. PC-DIO-24 Factory-Set Jumper and Switch Settings

Base I/O Address Hex 210

(factory setting)

Interrupt Enable Line PC4

(factory setting)

Interrupt Level Interrupt level 5 selected

(factory setting)

A9A8A7A6A5A4A3

1 2 3 4 5 6 7 8

U2

(The black side indicates the side that

is pushed down.)

W1: Row PC4

W2: IRQ5

A2

© National Instruments Corporation 2-1 PC-DIO-24 User Manual

Page 19

Configuration and Installation Chapter 2

21

NATIONAL

INSTRUMENTS

4 3

1U2

2W1

3F1

4W2

Figure 2-1. PC-DIO-24 Parts Locator Diagram

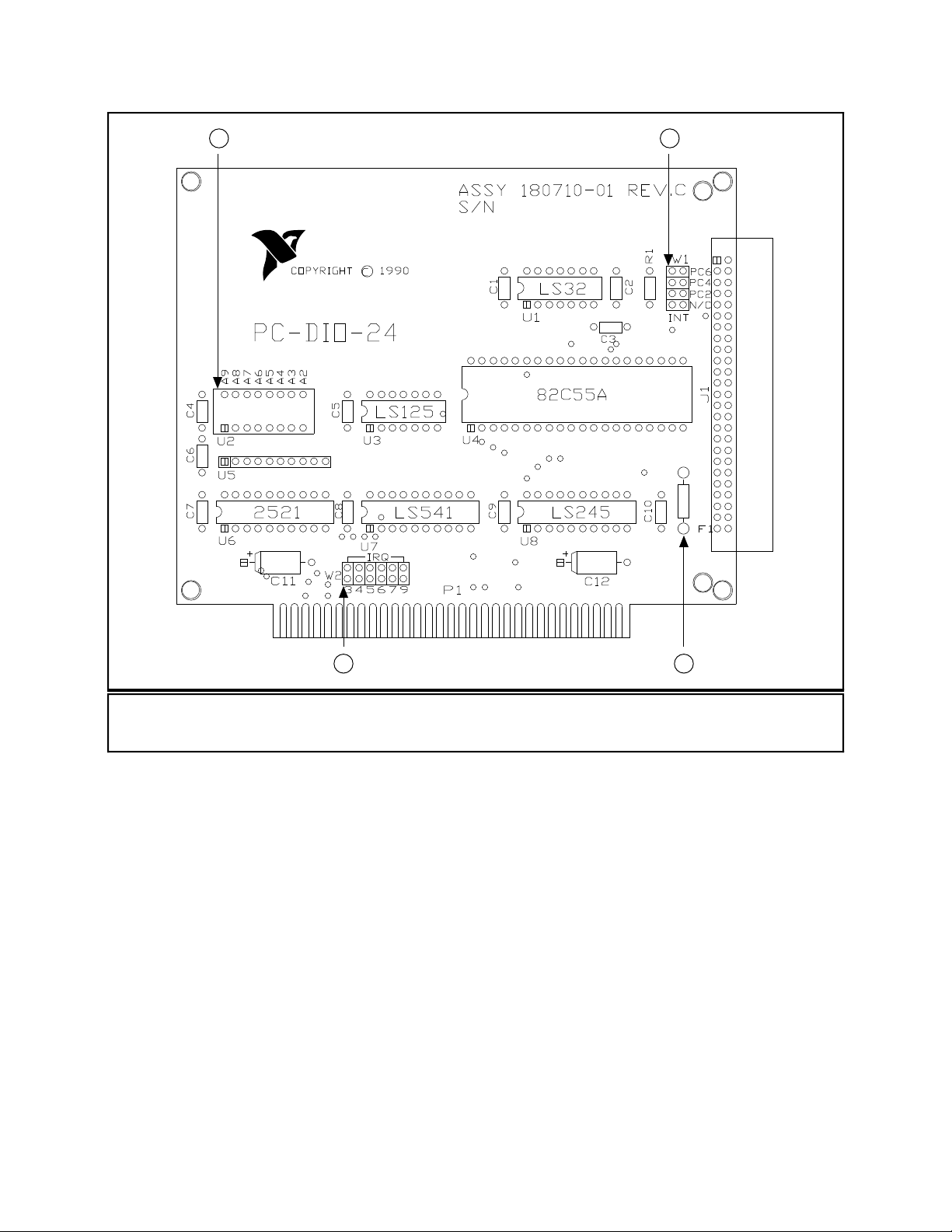

Base I/O Address Settings

The base I/O address for the PC-DIO-24 is determined by the switches at position U2 (see

Figure 2-1). The switches are set at the factory for the I/O address hex 210. With this default

setting, the PC-DIO-24 uses the I/O address space hex 210 through 213.

Note: Verify that this space is not already used by other equipment installed in your

computer. If any equipment in your computer uses this I/O address space, you must

change the base I/O address for the PC-DIO-24 or for the other device.

Each switch in U2 corresponds to one of the address lines A9 through A2. Thus, the range for

possible base I/O address settings is hex 000 through 3FC. Base I/O address values hex 000

through 0FF are reserved for system use. Base I/O values hex 100 through 3FF are available on

the I/O channel. A1 and A0 are used by the PC-DIO-24 to decode the onboard registers. On the

PC-DIO-24 User Manual 2-2 © National Instruments Corporation

Page 20

Chapter 2 Configuration and Installation

U2 DIP switches, press the side marked OFF to select a binary value of 1 for the corresponding

address bit. Press the other side of the switch to select a binary value of 0 for the corresponding

address bit. Figure 2-2 shows two possible switch settings. The black side indicates the side that

is pushed down.

A9

A8

A7

A6

A5

A4

A3

A2

12345678

O

N

O

F

F

U2

A. Switches Set to Default Setting (Base I/O Address Hex 210)

A8

A7

A6

U2

A5

A4

A3

A2

A9

12345678

O

N

O

F

F

B. Switches Set to Base I/O Address Hex 278

Figure 2-2. Example Base I/O Address Switch Settings

© National Instruments Corporation 2-3 PC-DIO-24 User Manual

Page 21

Configuration and Installation Chapter 2

Interrupt Selection

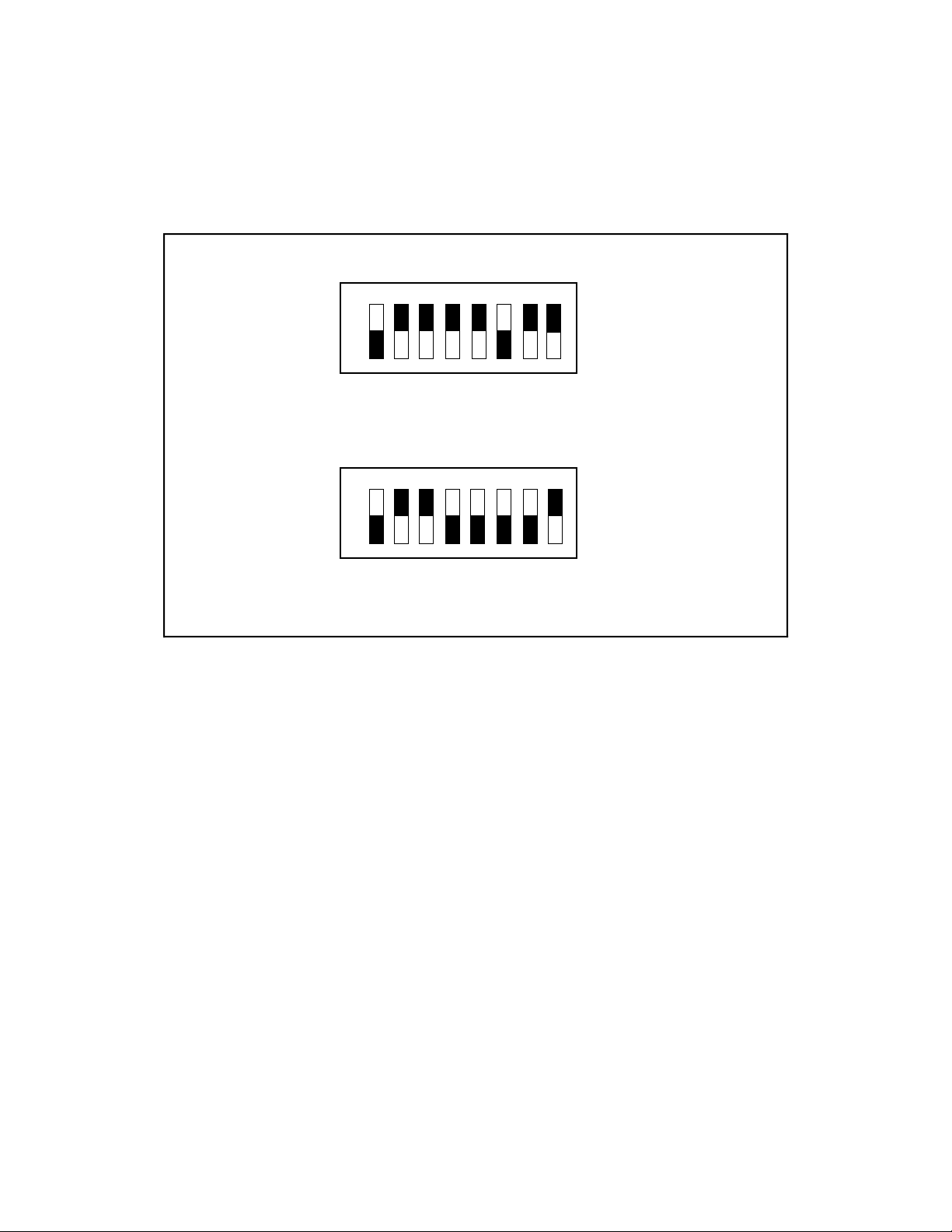

There are two sets of jumpers for interrupt selection on the PC-DIO-24 board. W1 is used for

selecting the interrupt enable line. W2 is for selecting the interrupt level. The location of these

jumpers is shown in Figure 2-1.

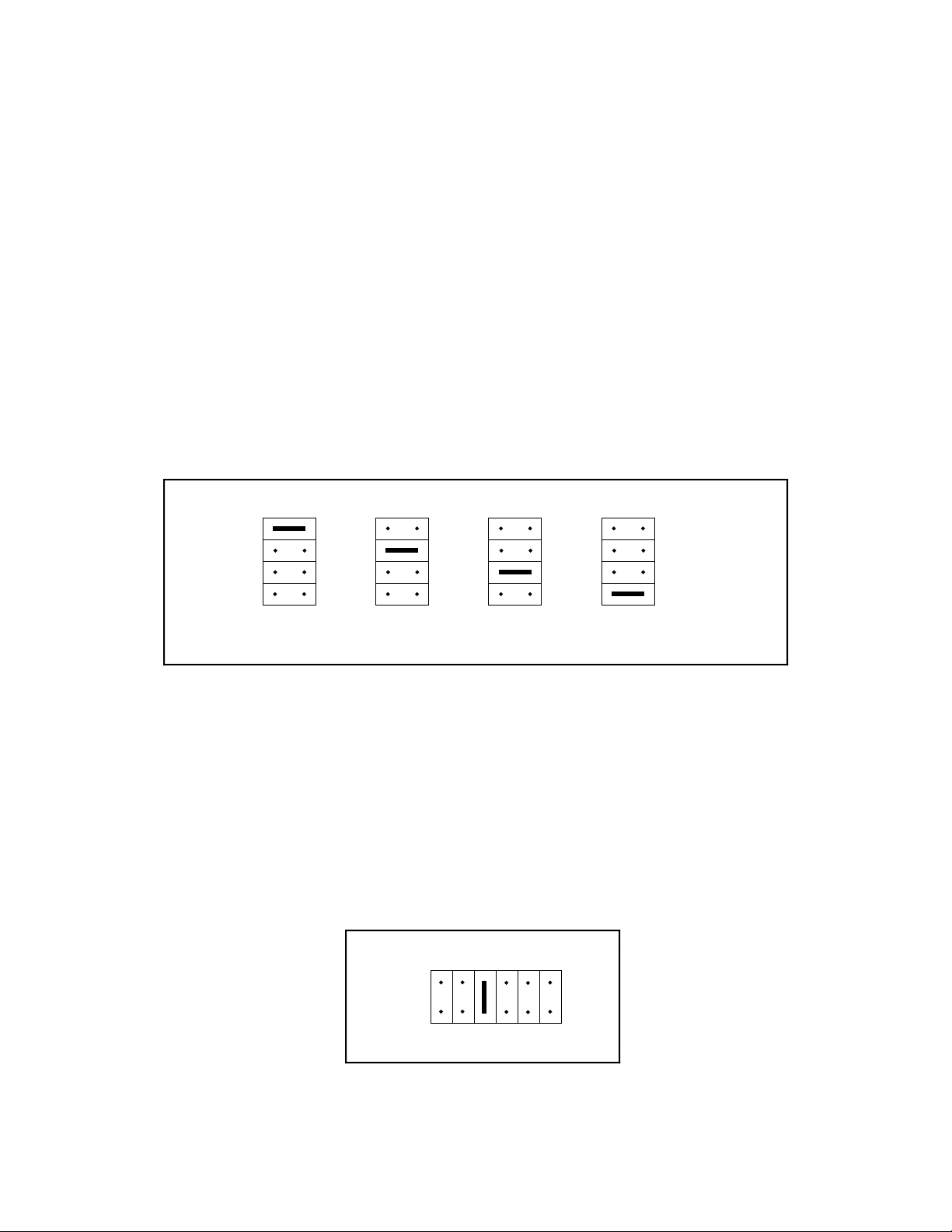

Interrupt Enable Settings

To enable interrupt requests from the PC-DIO-24, you must set jumper W1 to select PC2, PC4,

or PC6 as the active low interrupt enable line. When the interrupt enable line is logic low,

interrupts are enabled from the PC-DIO-24 board. Refer to Chapter 4, Register-Level

Programming, for the suggested interrupt enable line setting for each digital I/O mode of

operation. If W1 is set to N/C, all interrupt requests from the PC-DIO-24 are disabled.

Figure 2-3 shows the possible jumper settings for W1. The board is shipped with this jumper set

to PC4; therefore, interrupt requests from the board are enabled and controlled by PC4.

W1

PC6

PC4

PC2

N/C

INT

(Default Factory Setting)

W1

INT

PC6

PC4

PC2

N/C

W1

INT

PC6

PC4

PC2

N/C

W1

PC6

PC4

PC2

N/C

INT

Figure 2-3. Jumper Settings–PC6, PC4, PC2, and N/C

Interrupt Level Settings

The PC-DIO-24 board can connect to any one of the six interrupt lines of the PC I/O Channel:

IRQ3, IRQ4, IRQ5, IRQ6, IRQ7, or IRQ9. You select the interrupt line by setting a jumper on

W2. To use the interrupt capability of the board, you must select an interrupt line and place the

jumper in the appropriate position. The default interrupt line is IRQ5. To change to another line,

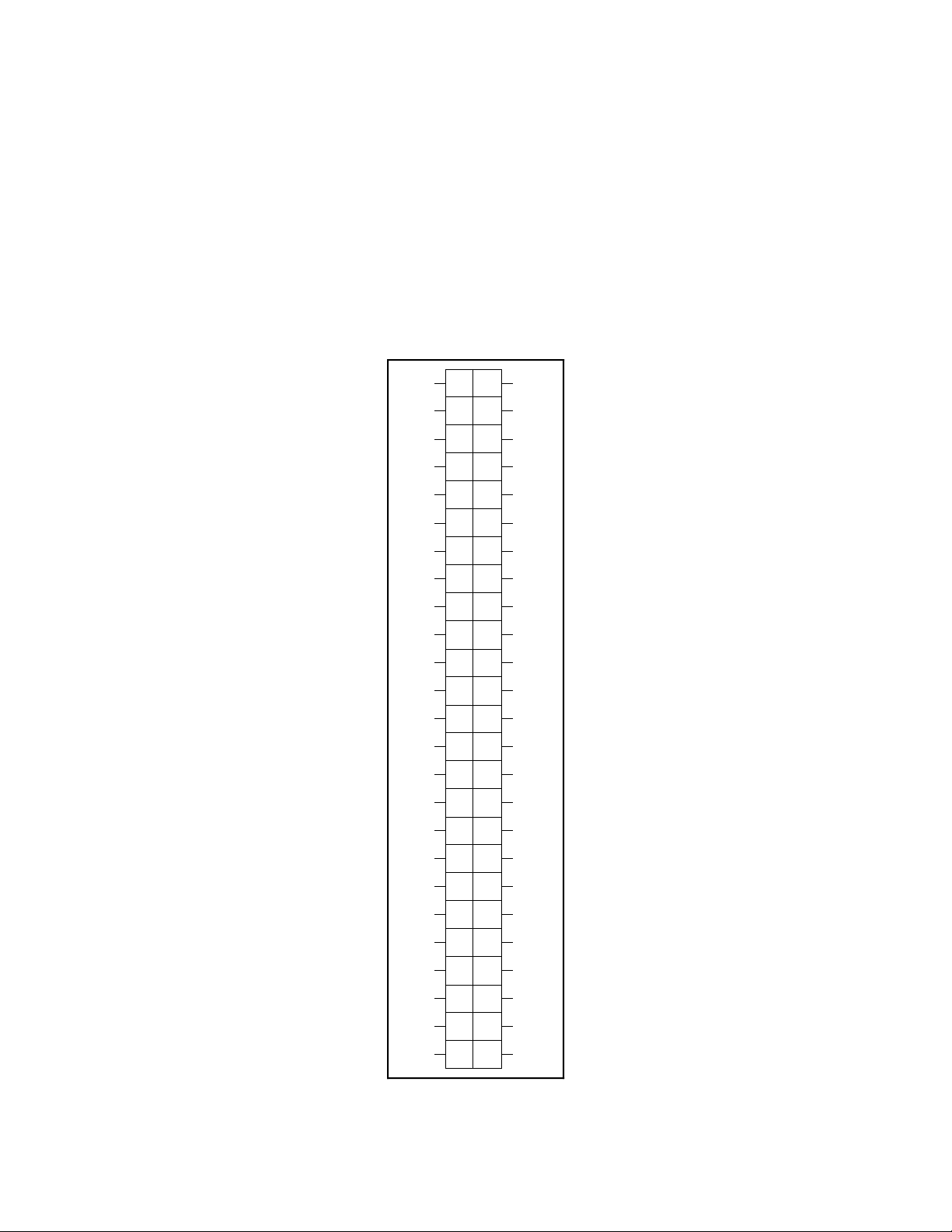

remove the jumper from IRQ5 and place it on the pins for another request line. Figure 2-4 shows

the default factory setting for IRQ5.

IRQ

W2

345679

Figure 2-4. Interrupt Jumper Setting for IRQ5 (Factory Setting)

PC-DIO-24 User Manual 2-4 © National Instruments Corporation

Page 22

Chapter 2 Configuration and Installation

The PC-DIO-24 can share interrupt lines with other devices by using a tristate driver to drive its

selected interrupt lines.

Installation

The PC-DIO-24 can be installed in any unused 8-bit or 16-bit expansion slot in your computer.

After you make any necessary changes and verify the switch and jumper settings, record the

settings in the PC-DIO-24 Hardware and Software Configuration Form in Appendix D,

Customer Communication. You are now ready to install the PC-DIO-24.

The following are general installation instructions, but consult the user manual or technical

reference manual of your personal computer for specific instructions and warnings.

1. Turn off your computer.

2. Remove the top cover or access port to the I/O channel.

3. Remove the expansion slot cover on the back panel of the computer.

4. Insert the PC-DIO-24 in an unused 8-bit or 16-bit slot. It may be a tight fit, but do not force

the board into place.

5. Screw the mounting bracket of the PC-DIO-24 to the back panel rail of the computer.

6. Check the installation.

7. Replace the cover to the computer.

The PC-DIO-24 board is now installed and ready for operation.

© National Instruments Corporation 2-5 PC-DIO-24 User Manual

Page 23

Configuration and Installation Chapter 2

Signal Connections

I/O Connector Pin Description

Figure 2-5 shows the pin assignments for the PC-DIO-24 digital I/O connector.

Warning: Connections that exceed any of the maximum ratings of input or output signals on

the PC-DIO-24 may result in damage to the PC-DIO-24 board and to the PC.

Maximum ratings for each signal are given in this chapter under the discussion of

that signal. National Instruments is not liable for any damages resulting from any

such signal connections.

PC7

PC6

PC5

PC4

PC3

PC2

PC1

PC0

PB7

PB6

PB5

PB4

PB3

PB2

PB1

PB0

PA7

12

34

56

78

9

10

11 12

13

14

15 16

17 18

19 20

21 22

23 24

25 26

27 28

29 30

31 32

33 34

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

PA6

PA5

PA4

PA3

PA2

PA1

PA0

+5V

35 36

37 38

39 40

41 42

43 44

45 46

47 48

49 50

GND

GND

GND

GND

GND

GND

GND

GND

Figure 2-5. Digital I/O Connector Pin Assignments

PC-DIO-24 User Manual 2-6 © National Instruments Corporation

Page 24

Chapter 2 Configuration and Installation

Signal Connection Descriptions

Pin Signal Name Description

1, 3, 5, 7, 9, 11, 13,15PC<7..0> Port C—Bidirectional data lines for port C. PC7 is the MSB,

PC0 the LSB.

17, 19, 21, 23, 25,

27, 29, 31

33, 35, 37, 39, 41,

43, 45, 47

49 (see note below) +5 V +5 Volts—This pin provides +5 VDC.

All even-numbered

pins

Note: Pin 49 is connected to the +5 V PC power supply via a 1 A fuse. A replacement fuse is available from

Allied Electronics, part number 845-2007, or Littelfuse, part number 251001.

PB<7..0> Port B—Bidirectional data lines for port B. PB7 is the MSB,

PB0 the LSB.

PA<7..0> Port A—Bidirectional data lines for port B. PA7 is the MSB,

PA0 the LSB.

GND Ground—These signals are connected to the PC ground signal.

The absolute maximum voltage input rating is -0.5 to +5.5 V with respect to GND.

Port C Pin Assignments

The signals assigned to port C depend on the mode in which the 82C55A is programmed. In

mode 0, port C is considered two 4-bit I/O ports. In modes 1 and 2, port C is used for status and

handshaking signals with two or three I/O bits mixed in. Table 2-2 summarizes the signal

assignments of port C for each programmable mode. See Chapter 4, Register-Level

Programming, for register-level programming information.

Warning: During programming, note that each time a port is configured, output ports A

and C are reset to 0, and output port B is undefined.

Table 2-2. Port C Signal Assignments

Programming Mode Group A Group B

PC7 PC6 PC5 PC4 PC3 PC2 PC1 PC0

Mode 0

Mode 1 Input

Mode 1 Output

Mode 2

© National Instruments Corporation 2-7 PC-DIO-24 User Manual

I/O I/O I/O I/O I/O I/O I/O I/O

I/O I/O IBF

OBFA* ACKA* I/O I/O INTR

OBFA* ACKA* IBF

* Indicates that the signal is active low.

STBA* INTR

A

STBA* INTR

A

STBB* IBFB

A

ACKB* OBFB* INTR

A

I/O I/O I/O

A

INTR

B

B

B

Page 25

Configuration and Installation Chapter 2

Timing Specifications

This section lists the timing specifications for handshaking with the PC-DIO-24. The

handshaking lines STB* and IBF synchronize input transfers. The handshaking lines OBF* and

ACK* synchronize output transfers.

The following signals are used in the timing diagrams on the subsequent pages.

Name Signal

Direction

STB* Input Strobe Input—A low signal on this handshaking line loads data into the input

IBF Output Input Buffer Full—A high signal on this handshaking line indicates that data

ACK* Input Acknowledge Input—A low signal on this handshaking line indicates that

OBF* Output Output Buffer Full—A low signal on this handshaking line indicates that

INTR Output Interrupt Request—This signal becomes high when the 82C55A is

RD* Internal Read Signal—This signal is the read signal generated from the control lines

WR* Internal Write Signal—This signal is the write signal generated from the control lines

DATA Bidirectional Data Lines at the Selected Port—This signal indicates when the data on the

Description

latch.

has been loaded into the input latch. This is an input acknowledge signal.

the data written from the selected port has been accepted. This signal is a

response from the external device that it has received the data from the

PC-DIO-24.

data has been written from the selected port.

requesting service during a data transfer. The appropriate interrupt enable

bits must be set to generate this signal.

of the PC.

of the PC.

data lines at a selected port is or should be available.

PC-DIO-24 User Manual 2-8 © National Instruments Corporation

Page 26

Chapter 2 Configuration and Installation

Mode 1 Input Timing

The following figure illustrates the timing specifications for an input transfer in mode 1.

T1

T2

STB*

T4

T7

IBF

INTR

RD*

DATA

T3

T5

T6

Name Description Minimum Maximum

T1 STB* pulse width 100 –

T2 STB* = 0 to IBF = 1 – 150

T3 Data before STB* = 1 20 –

T4 STB* = 1 to INTR = 1 – 150

T5 Data after STB* = 1 50 –

T6 RD* = 0 to INTR = 0 – 200

T7 RD* = 1 to IBF = 0 – 150

All timing values are in nanoseconds.

© National Instruments Corporation 2-9 PC-DIO-24 User Manual

Page 27

Configuration and Installation Chapter 2

Mode 1 Output Timing

The following figure illustrates the timing specifications for an output transfer in mode 1.

T3

WR*

T4

OBF*

T1

INTR

T6

ACK*

DATA

T2

Name Description Minimum Maximum

T1 WR* = 0 to INTR = 0 – 250

T2 WR* = 1 to output – 200

T3 WR* = 1 to OBF* = 0 – 150

T4 ACK* = 0 to OBF* = 1 – 150

T5 ACK* pulse width 100 –

T6 ACK* = 1 to INTR = 1 – 150

All timing values are in nanoseconds.

T5

PC-DIO-24 User Manual 2-10 © National Instruments Corporation

Page 28

Chapter 2 Configuration and Installation

Mode 2 Bidirectional Timing

The following figure illustrates the timing specifications for bidirectional transfers in mode 2.

T1

WR*

T6

OBF*

INTR

T7

ACK*

STB*

IBF

RD*

T3

T4

T2

T5

T8

T9

T10

DATA

Name Description Minimum Maximum

T1 WR* = 1 to OBF* = 0 – 150

T2 Data before STB* = 1 20 –

T3 STB* pulse width 100 –

T4 STB* = 0 to IBF = 1 – 150

T5 Data after STB* = 1 50 –

T6 ACK* = 0 to OBF = 1 – 150

T7 ACK* pulse width 100 –

T8 ACK* = 0 to output – 150

T9 ACK* = 1 to output float 20 250

T10 RD* = 1 to IBF = 0 – 150

All timing values are in nanoseconds.

© National Instruments Corporation 2-11 PC-DIO-24 User Manual

Page 29

Chapter 3 Theory of Operation

This chapter contains a functional overview of the PC-DIO-24 board and explains the operation

of each functional unit making up the PC-DIO-24.

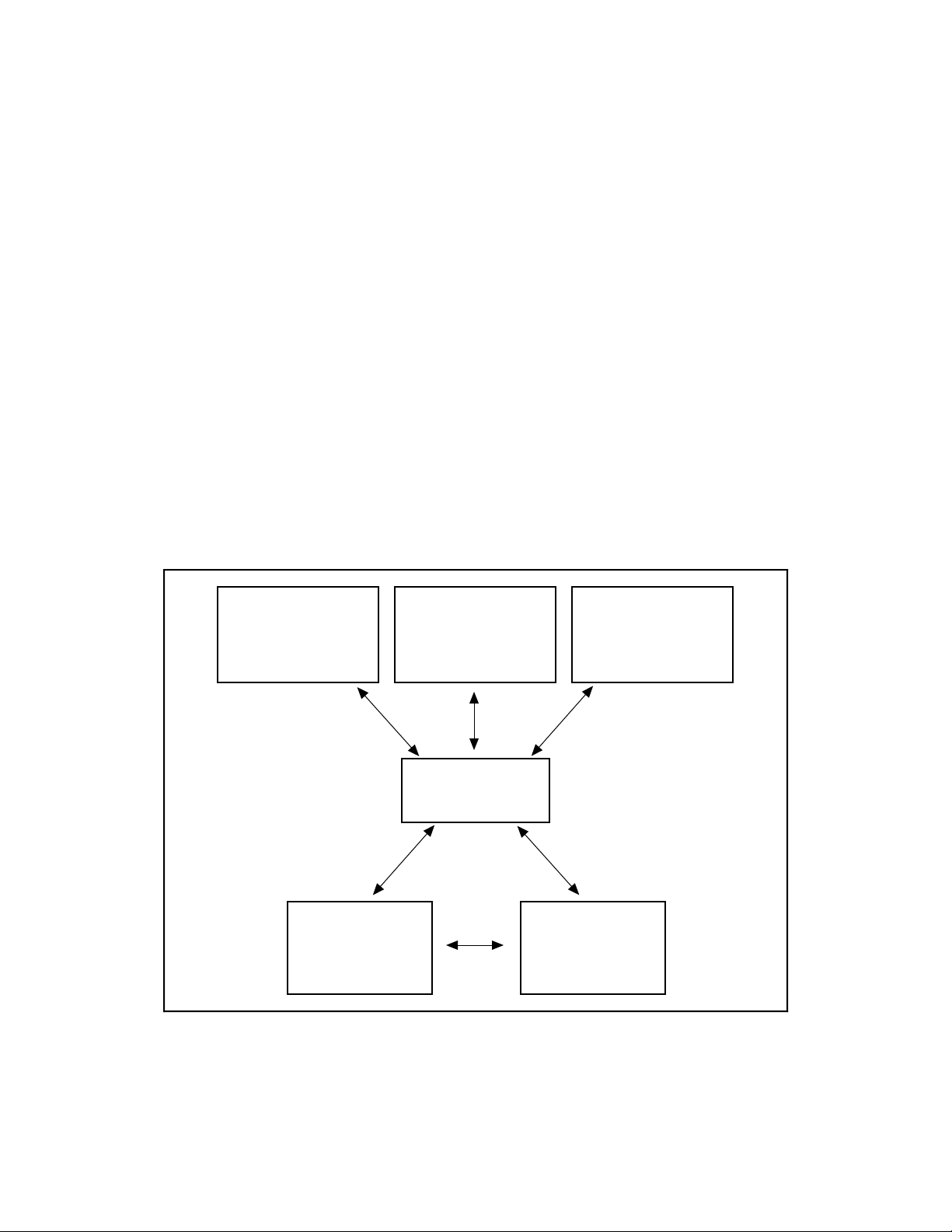

The block diagram in Figure 3-1 illustrates the key functional components of the PC-DIO-24

board.

Address

Decoder

PA

Bus

Transceivers

82C55A

PPI

/

8

PB

/

8

PC

/

8

I/O Connector

PC3

PC0

PC I/O Channel

+5 V

PC I/O

Channel

Control

Circuitry

Interrupt

Control

Circuitry

1 A Fuse

Figure 3-1. PC-DIO-24 Block Diagram

The PC I/O Channel consists of an address bus, a data bus, interrupt lines, and several control

and support signals. Control and data transfers to the system microprocessor are asynchronous.

© National Instruments Corporation 3-1 PC-DIO-24 User Manual

Page 30

Theory of Operation Chapter 3

Address Decoder

The base address used by the board is determined by an onboard switch setting. The address on

the PC I/O Channel bus is monitored by the address decoder. If the address on the bus matches

the selected I/O base address of the board, the board is enabled and the corresponding register on

the PC-DIO-24 is accessed.

Bus Transceivers

The bus transceivers control the sending and receiving of data lines to and from the PC I/O

Channel.

PC I/O Channel Control Circuitry

This circuitry monitors and transmits the PC I/O Channel control and support signals. The

control signals identify transfers as read or write, configuration or I/O, and 8-bit or 16-bit. The

PC-DIO-24 only uses 8-bit transfers.

82C55A Programmable Peripheral Interface

The 82C55A PPI is the heart of the PC-DIO-24. This chip has 24 programmable I/O pins that

represent three 8-bit ports—PA, PB, and PC. Each port can be programmed as an input or an

output port. The 82C55A has three modes of operation—simple I/O (mode 0), strobed I/O

(mode 1), and bidirectional I/O (mode 2). In modes 1 and 2, the three ports are divided into two

groups—group A and group B. Each group has eight data bits and four control and status bits

from port C (PC). Modes 1 and 2 use handshaking signals from port C to synchronize data

transfers. Refer to Chapter 4, Register-Level Programming, or to Appendix C, OKI 82C55A

Data Sheet, for more detailed information.

Interrupt Control Circuitry

The interrupt level used by the PC-DIO-24 is selected by the onboard jumper W2. Another

onboard jumper, W1, is used to enable interrupts from the PC-DIO-24. The setting for W1

selects PC2, PC4, or PC6 as the active low interrupt enable signal. Selecting N/C for W1

disables interrupts from the PC-DIO-24. When the onboard jumpers are set to enable interrupts,

the 82C55A can be programmed to generate an interrupt request by setting INTRA for group A

or INTRB for group B. When interrupts are enabled for group A, an active high signal on the

PC3 line generates an interrupt request. When interrupts are enabled for group B, an active high

signal on the PC0 line generates an interrupt request.

Digital I/O Connector

All digital I/O is transmitted through a standard 50-pin male connector. The pin assignments for

the I/O connector are compatible with standard 24-channel digital I/O applications. All even

pins on this connector are attached to logic ground, and pin 49 is connected to +5 V through a

protection fuse (F1), which is often required to operate I/O module mounting racks. See

Chapter 2, Configuration and Installation, for additional information.

PC-DIO-24 User Manual 3-2 © National Instruments Corporation

Page 31

Chapter 4 Register-Level Programming

This chapter describes in detail the address and function of each of the PC-DIO-24 control and

status registers. This chapter also includes important information related to register-level

programming the PC-DIO-24.

The PC-DIO-24 is a parallel, digital I/O board designed around the OKI 82C55A integrated

circuit. The 82C55A is a general-purpose peripheral interface containing 24 programmable I/O

pins. These pins represent the three 8-bit I/O ports (A, B, and C) of the 82C55A. These ports

can be programmed as two groups of 12 signals or as three individual 8-bit ports. This chapter

includes register-level programming information for the PC-DIO-24, along with program examples

written in C.

Note: If you plan to use a programming software package such as LabWindows/CVI or

NI-DAQ with your PC-DIO-24 board, you need not read this chapter.

Introduction

The three 8-bit ports are divided into two groups—group A and group B (two groups of 12

signals). One 8-bit configuration (or control) word determines the mode of operation for each

group. The group A control bits configure port A<0..7> and the upper 4 bits (nibble) of

port C<4..7>. The group B control bits configure port B<0..7> and the lower nibble of

port C<0..3>. These configuration bits are defined later in this chapter.

82C55A Modes of Operation

The three basic modes of operation for the 82C55A are as follows:

• Mode 0 – Basic I/O

• Mode 1 – Strobed I/O

• Mode 2 – Bidirectional bus

The 82C55A also has a single bit set/reset feature for port C. The 8-bit control word also

programs this function. For additional information, refer to Appendix C, OKI 82C55A Data

Sheet.

© National Instruments Corporation 4-1 PC-DIO-24 User Manual

Page 32

Register-Level Programming Chapter 4

Mode 0

This mode can be used for simple input and output operations for each of the ports. No

handshaking is required; data is simply written to or read from a selected port.

Mode 0 has the following features:

• Two 8-bit ports (A and B) and two 4-bit ports (upper and lower nibble of port C).

• Any port can be input or output.

• Outputs are latched, but inputs are not latched.

Mode 1

This mode transfers data that is synchronized by handshaking signals. ports A and B use the

eight lines of port C to generate or receive the handshake signals. This mode divides the ports

into two groups (group A and group B):

• Each group contains one 8-bit data port (port A or port B) and one 4-bit control/data port

(upper or lower nibble of port C).

• The 8-bit data ports can be either input or output, both of which are latched.

• The 4-bit ports are used for control and status of the 8-bit data ports.

• Interrupt generation and enable and/or disable functions are available.

Mode 2

This mode can be used for communication over a bidirectional 8-bit bus. Handshaking signals

are used in a manner similar to mode 1. Interrupt generation and enable and/or disable functions

are also available. Other features of this mode include the following:

• Used in group A only (port A and upper nibble of port C).

• One 8-bit bidirectional port (port A) and a 5-bit control status port (port C).

• Latched inputs and outputs.

Single Bit Set/Reset Feature

Any of the eight bits of port C can be set or reset with one control word. This feature generates

status and control for port A and port B when operating in mode 1 or mode 2.

PC-DIO-24 User Manual 4-2 © National Instruments Corporation

Page 33

Chapter 4 Register-Level Programming

Register Map

The following table lists the address map for the PC-DIO-24. The registers PORTA, PORTB,

PORTC, and CNFG are 8-bit registers in the 82C55A.

Table 4-1. PC-DIO-24 Address Map

Register Offset Address

(Hex)

PORTA

PORTB

PORTC

CNFG

Note: A number preceded by 0x is a hexadecimal number.

0x00

0x01

0x02

0x03

Size Type

8-bit

8-bit

8-bit

8-bit

Read-and-write

Read-and-write

Read-and-write

Write-Only

Register Descriptions

Figure 4-1 shows the two control-word formats used to completely program the 82C55A. The

Control Word Flag determines which control-word format is being programmed. When the

Control Word Flag is 1, bits 0 through 6 determine the I/O characteristics of the 82C55A ports

and the mode in which they are operating (that is, mode 0, mode 1, or mode 2). When the

Control Word Flag is 0, bits 3 through 0 determine the bit set/reset format of port C.

Warning: During programming, note that each time a port is configured, output ports A

and C are reset to 0, and output port B is undefined.

© National Instruments Corporation 4-3 PC-DIO-24 User Manual

Page 34

Register-Level Programming Chapter 4

Group A Group B

D2 D1 D0D5 D4 D3D7 D6

Control Word

Flag

1 = mode set

Mode Selection

00 = mode 0

01 = mode 1

1X = mode 2

Port A

1 = input

0 = output

Port C

(high nibble)

1 = input

0 = output

Control Word

Flag

0 = bit set/reset

a. Mode Set Word Format

D2 D1 D0XXD3D7 X

Bit Select

(000)

(001)

(010)

:

:

(111)

b. Bit Set/Reset Word Format

Port C

(low nibble)

1 = input

0 = output

Port B

1 = input

0 = output

Mode Selection

0 = mode 0

1 = mode 1

Bit Set/Reset

1 = set

0 = reset

Figure 4-1. Control-Word Formats

Single Bit Set/Reset Feature

Table 4-2 shows the control words for setting or resetting each bit in port C. Notice that bit 7 of

the control word is cleared when programming the set/reset option for the bits of port C.

PC-DIO-24 User Manual 4-4 © National Instruments Corporation

Page 35

Chapter 4 Register-Level Programming

Table 4-2. Port C Set/Reset Control Words

Number Bit Set Bit Reset Bit Set or

Control Word Control Word Reset in Port C

0 0xxx0001 0xxx0000 xxxxxxxn

1 0xxx0011 0xxx0010 xxxxxxnx

2 0xxx0101 0xxx0100 xxxxxnxx

3 0xxx0111 0xxx0110 xxxxnxxx

4 0xxx1001 0xxx1000 xxxnxxxx

5 0xxx1011 0xxx1010 xxnxxxxx

6 0xxx1101 0xxx1100 xnxxxxxx

7 0xxx1111 0xxx1110 nxxxxxxx

Programming Considerations

Mode 0–Basic I/O

Mode 0 can be used for simple I/O functions for each of the three ports with no handshaking.

Each port can be assigned as an input or an output port. The 16 possible I/O configurations are

shown in Table 4-3. Notice that bit 7 of the control word is set when programming the mode of

operation for each port.

© National Instruments Corporation 4-5 PC-DIO-24 User Manual

Page 36

Register-Level Programming Chapter 4

Table 4-3. Mode 0 I/O Configurations

Control Word Group A Group B

Number Bit Port A Port C

1

Port B Port C

76543210

0 10000000 Output Output Output Output

1 10000001 Output Output Output Input

2 10000010 Output Output Input Output

3 10000011 Output Output Input Input

4 10001000 Output Input Output Output

5 10001001 Output Input Output Input

6 10001010 Output Input Input Output

7 10001011 Output Input Input Input

8 10010000 Input Output Output Output

9 10010001 Input Output Output Input

10 10010010 Input Output Input Output

11 10010011 Input Output Input Input

12 10011000 Input Input Output Output

13 10011001 Input Input Output Input

14 10011010 Input Input Input Output

15 10011011 Input Input Input Input

1

Upper nibble of port C

2

Lower nibble of port C

2

Mode 0 Programming Example

Main() {

#define BASE_ADDRESS 0x210 /* Board located at address 210 */

#define PORTAoffset 0x00 /* Offset for port A */

#define PORTBoffset 0x01 /* Offset for port B */

#define PORTCoffset 0x02 /* Offset for port C */

#define CNFGoffset 0x03 /* Offset for CNFG */

register unsigned int porta, portb, portc, cnfg;

char valread; /* Variable to store data read from a

port */

/* Calculate register addresses. */

porta = BASE_ADDRESS + PORTAoffset;

portb = BASE_ADDRESS + PORTBoffset;

portc = BASE_ADDRESS + PORTCoffset;

cnfg = BASE_ADDRESS + CNFGoffset;

PC-DIO-24 User Manual 4-6 © National Instruments Corporation

Page 37

Chapter 4 Register-Level Programming

/* EXAMPLE 1*/

outp(cnfg,0x80); /* Ports A, B, and C are outputs. */

outp(porta,0x12); /* Write data to port A. */

outp(portb,0x34); /* Write data to port B. */

outp(portc,0x56); /* Write data to port C. */

/* EXAMPLE 2*/

outp(cnfg,0x90); /* Port A is input; ports B and C are

outputs. */

outp(portb,0x22); /* Write data to port B. */

outp(portc,0x55); /* Write data to port C. */

valread = inp(porta); /* Read data from port A. */

/* EXAMPLE 3 */

outp(cnfg,0x82); /* Ports A and C are outputs; port B

is an input. */

/* EXAMPLE 4 */

outp(cnfg,0x89); /* Ports A and B are outputs; port C

is an input. */

}

Mode 1–Strobed Input

In mode 1, the digital I/O bits are divided into two groups—group A and group B. Each of these

groups contains one 8-bit port and one 4-bit control/data port. The 8-bit port can be either an

input or an output, and the 4-bit port is used for control and status information for the 8-bit port.

The transfer of data is synchronized by handshaking signals in the 4-bit port.

The control word written to the CNFG Register to configure port A for input in mode 1 is shown

as follows. Bits PC6 and PC7 of port C can be used as extra input or output lines.

7654 3210

1 0 1 1 1/0 XXX

Port C bits PC6 and PC7

1 = input

0 = output

The control word written to the CNFG Register to configure port B for input in mode 1 is shown

as follows. Notice that port B does not have extra input or output lines from port C.

76543210

1 X X X X11X

© National Instruments Corporation 4-7 PC-DIO-24 User Manual

Page 38

Register-Level Programming Chapter 4

During a mode 1 data read transfer, the status of the handshaking lines and interrupt signals can

be obtained by reading port C. The port C status-word bit definitions for an input transfer are

shown as follows.

The following are the port C status-word bit definitions for input (port A and port B).

76543210

I/O I/O IBFA INTEA INTRA INTEB IBFB INTRB

Bit Name Description

7–6 I/O Input/Output—Extra I/O status lines when port A is in mode 1

input.

5 IBFA Input Buffer Full for Port A—High indicates that data has been

loaded into the input latch for port A.

4 INTEA Interrupt Enable Bit for Port A—Enables interrupts from the

82C55A for port A. Controlled by bit set/reset of PC4.

3 INTRA Interrupt Request Status for Port A—When INTEA is high and

IBFA is high, this bit is high, indicating that an interrupt request is

asserted.

2 INTEB Interrupt Enable Bit for Port B—Enables interrupts from the

82C55A for port B. Controlled by bit set/reset of PC2.

1 IBFB Input Buffer Full for Port B—High indicates that data has been

loaded into the input latch for port B.

0 INTRB Interrupt Request Status for Port B—When INTEB is high and

IBFB is high, this bit is high, indicating that an interrupt request is

asserted.

At the digital I/O connector, port C has the following pin assignments when in mode 1 input.

Notice that the status of STBA* and STBB* are not included in the port C status word.

Group A

Group B

PC7

PC6

PC5

PC4

PC3

PC2

PC1

PC0

I/O

I/O

IBFA

STBA*

INTRA

STBB*

IBFB

INTRB

PC-DIO-24 User Manual 4-8 © National Instruments Corporation

Page 39

Chapter 4 Register-Level Programming

Mode 1 Input Programming Example

Main() {

#define BASE_ADDRESS 0x210 /* Board located at address 210. */

#define PORTAoffset 0x00 /* Offset for port A */

#define PORTBoffset 0x01 /* Offset for port B */

#define PORTCoffset 0x02 /* Offset for port C */

#define CNFGoffset 0x03 /* Offset for CNFG */

register unsigned int porta, portb, portc, cnfg;

char valread; /* Variable to store data read from a

port */

/* Calculate register addresses. */

porta = BASE_ADDRESS + PORTAoffset;

portb = BASE_ADDRESS + PORTBoffset;

portc = BASE_ADDRESS + PORTCoffset;

cnfg = BASE_ADDRESS + CNFGoffset;

/* EXAMPLE 1–port A input */

outp(cnfg,0xB0); /* Port A is an input in mode 1. */

while (!(inp(portc) & 0x20)); /* Wait until IBFA is set, indicating that

data has been loaded in port A. */

valread = inp(porta); /* Read the data from port A. */

/* EXAMPLE 2–port B input */

outp(cnfg,0x86); /* Port B is an input in mode 1. */

while (!(inp(portc) & 0x02)); /* Wait until IBFB is set, indicating that

data has been loaded in port B. */

valread = inp(portb);

}

Mode 1–Strobed Output

The control word written to the CNFG Register to configure port A for output in mode 1 is

shown as follows. Bits PC4 and PC5 of port C can be used as extra input or output lines when

port A uses mode 1 output.

7654 3210

1 0 1 0 1/0 XXX

Port C bits PC4 and PC5

1 = input

0 = output

© National Instruments Corporation 4-9 PC-DIO-24 User Manual

Page 40

Register-Level Programming Chapter 4

The control word written to the CNFG Register to configure port B for output in mode 1 is

shown as follows. Notice that port B does not have extra input or output lines from port C.

76543210

1 X X X X10X

During a mode 1 data write transfer, the status of the handshaking lines and interrupt signals can

be obtained by reading port C. Notice that the bit definitions are different for a write and a read

transfer.

The following are the port C status-word bit definitions for output (port A and port B).

7 6543210

OBFA* INTEA I/O I/O INTRA INTEB OBFB* INTRB

Bit Name Description

7 OBFA* Output Buffer Full for Port A—Low indicates that the CPU has

written data to port A.

6 INTEA Interrupt Enable Bit for Port A—If this bit is high, interrupts are

enabled from the 82C55A for port A. Controlled by bit set/reset of

PC6.

5–4 I/O Input/Output—Extra I/O status line when port A is in mode 1

output.

3 INTRA Interrupt Request Status for Port A—When INTEA is high and

OBFA* is high, this bit is high, indicating that an interrupt request

is asserted.

2 INTEB Interrupt Enable Bit for Port B—If this bit is high, interrupts are

enabled from the 82C55A for port B. Controlled by bit set/reset of

PC2.

1 OBFB* Output Buffer Full for Port B—Low indicates that the CPU has

written data out to port B.

0 INTRB Interrupt Request Status for Port B—When INTEB is high and

OBFB* is high, this bit is high, indicating that an interrupt request

is asserted.

PC-DIO-24 User Manual 4-10 © National Instruments Corporation

Page 41

Chapter 4 Register-Level Programming

At the digital I/O connector, port C has the following pin assignments when in mode 1 output.

Notice that the status of ACKA* and ACKB* is not included when port C is read.

Group A

Group B

PC7

PC6

PC5

PC4

PC3

PC2

PC1

PC0

OBFA*

ACKA*

I/O

I/O

INTRA

ACKB*

OBFB*

INTRB

Mode 1 Output Programming Example

Main() {

#define BASE_ADDRESS 0x210 /* Board located at address 210. */

#define PORTAoffset 0x00 /* Offset for port A */

#define PORTBoffset 0x01 /* Offset for port B */

#define PORTCoffset 0x02 /* Offset for port C */

#define CNFGoffset 0x03 /* Offset for CNFG */

register unsigned int porta, portb, portc, cnfg;

char valread; /* Variable to store data read from a

port */

/* Calculate register addresses. */

porta = BASE_ADDRESS + PORTAoffset;

portb = BASE_ADDRESS + PORTBoffset;

portc = BASE_ADDRESS + PORTCoffset;

cnfg = BASE_ADDRESS + CNFGoffset;

/* EXAMPLE 1–port A output */

outp(cnfg,0xA0); /* Port A is an output in mode 1.*/

while (!(inp(portc) & 0x80)); /* Wait until OBFA* is set, indicating

that the data last written to port A

has been read.*/

outp(porta,0x12); /* Write data to port A. */

/* EXAMPLE 2–port B output */

outp(cnfg,0x84); /* Port B is an output in mode 1.*/

while (!(inp(portc) & 0x02)); /* Wait until OBFB* is set, indicating

that the data last written to port B

has been read.*/

outp(portb,0x34); /* Write the data to port B. */

}

© National Instruments Corporation 4-11 PC-DIO-24 User Manual

Page 42

Register-Level Programming Chapter 4

Mode 2–Bidirectional Bus

Mode 2 has an 8-bit bus that can transfer both input and output without changing the

configuration. The data transfers are synchronized with handshaking lines in port C. This mode

uses only port A; however, port B can be used in either mode 0 or mode 1 while port A is

configured for mode 2.

The control word written to the CNFG Register to configure port A as a bidirectional data bus in

mode 2 is shown as follows. If port B is configured for mode 0, then PC2, PC1, and PC0 of

port C can be used as extra input or output lines.

76543210

1 1 X X X 1/0 1/0 1/0

Port C bits PC2,PC1,PC0

1 = input

0 = output

Port B direction

1 = input

0 = output

Group B Mode

0 = mode 0

1 = mode 1

During a mode 2 data transfer, the status of the handshaking lines and interrupt signals can be

obtained by reading port C. The port C status-word bit definitions for a mode 2 transfer are

shown as follows.

The following are the port C status-word bit definitions for bidirectional data path (port A only).

76543210

OBFA* INTE1 IBFA INTE2 INTRA I/O I/O I/O

Bit Name Description

7 OBFA* Output Buffer Full—Low indicates that the CPU has written data

to port A.

6 INTE1 Interrupt Enable Bit for Output—If this bit is set, interrupts are

enabled from the 82C55A for OBFA*. Controlled by bit set/reset of

PC6.

5 IBFA Input Buffer Full—High indicates that data has been loaded into

the input latch of port A.

(continues)

PC-DIO-24 User Manual 4-12 © National Instruments Corporation

Page 43

Chapter 4 Register-Level Programming

Bit Name Description (continued)

4 INTE2 Interrupt Enable Bit for Input—If this bit is set, interrupts are

enabled from the 82C55A for IBFA. Controlled by bit set/reset of

PC4.

3 INTRA Interrupt Request Status—If INTE1 is high and IBFA is high, this

bit is high, indicating that an interrupt request is asserted for input

transfers. If INTE2 is high and OBFA* is high, this bit is high,

indicating that an interrupt request is asserted for output transfers.

2–0 I/O Input/Output—Extra I/O status lines available if port B is not

configured for mode 1.

At the digital I/O connector, port C has the following pin assignments when in mode 2.

Group A

Group B

PC7

PC6

PC5

PC4

PC3

PC2

PC1

PC0

OBFA*

ACKA*

IBFA

STBA*

INTRA

I/O

or

Hand-

shaking

Mode 2 Programming Example

Main() {

#define BASE_ADDRESS 0x210 /* Board located at address 210. */

#define PORTAoffset 0x00 /* Offset for port A */

#define PORTBoffset 0x01 /* Offset for port B */

#define PORTCoffset 0x02 /* Offset for port C */

#define CNFGoffset 0x03 /* Offset for CNFG */

register unsigned int porta, portb, portc, cnfg;

char valread; /* Variable to store data read from a

port */

/* Calculate register addresses. */

porta = BASE_ADDRESS + PORTAoffset;

portb = BASE_ADDRESS + PORTBoffset;

portc = BASE_ADDRESS + PORTCoffset;

cnfg = BASE_ADDRESS + CNFGoffset;

© National Instruments Corporation 4-13 PC-DIO-24 User Manual

Page 44

Register-Level Programming Chapter 4

/* EXAMPLE 1*/

outp(cnfg,0xC0); /* Port A is in mode 2. */

while (!(inp(portc) & 0x80)); /* Wait until OBFA* is set,