Page 1

TM

LabVIEW

Order Analysis Toolset

User Manual

LabVIEW Order Analysis Toolset User Manual

August 2003 Edition

Part Number 322879B-01

Page 2

Support

Worldwide Technical Support and Product Information

ni.com

National Instruments Corporate Headquarters

11500 North Mopac Expressway Austin, Texas 78759-3504 USA Tel: 512 683 0100

Worldwide Offices

Australia 1800 300 800, Austria 43 0 662 45 79 90 0, Belgium 32 0 2 757 00 20, Brazil 55 11 3262 3599,

Canada (Calgary) 403 274 9391, Canada (Montreal) 514 288 5722, Canada (Ottawa) 613 233 5949,

Canada (Québec) 514 694 8521, Canada (Toronto) 905 785 0085, Canada (Vancouver) 514 685 7530,

China 86 21 6555 7838, Czech Republic 420 2 2423 5774, Denmark 45 45 76 26 00,

Finland 385 0 9 725 725 11, France 33 0 1 48 14 24 24, Germany 49 0 89 741 31 30, Greece 30 2 10 42 96 427,

India 91 80 51190000, Israel 972 0 3 6393737, Italy 39 02 413091, Japan 81 3 5472 2970,

Korea 82 02 3451 3400, Malaysia 603 9131 0918, Mexico 001 800 010 0793, Netherlands 31 0 348 433 466,

New Zealand 0800 553 322, Norway 47 0 66 90 76 60, Poland 48 0 22 3390 150, Portugal 351 210 311 210,

Russia 7 095 783 68 51, Singapore 65 6226 5886, Slovenia 386 3 425 4200, South Africa 27 0 11 805 8197,

Spain 34 91 640 0085, Sweden 46 0 8 587 895 00, Switzerland 41 56 200 51 51, Taiwan 886 2 2528 7227,

Thailand 662 992 7519, United Kingdom 44 0 1635 523545

For further support information, refer to the Technical Support and Professional Services appendix. To comment

on the documentation, send email to techpubs@ni.com.

© 2001–2003 National Instruments Corporation. All rights reserved.

Page 3

Important Information

Warranty

The media on which you receive National Instruments software are warranted not to fail to execute programming instructions, due to defects

in materials and workmanship, for a period of 90 days from date of shipment, as evidenced by receipts or other documentation. National

Instruments will, at its option, repair or replace software media that do not execute programming instructions if National Instruments receives

notice of such defects during the warranty period. National Instruments does not warrant that the operation of the software shall be

uninterrupted or error free.

A Return Material Authorization (RMA) number must be obtained from the factory and clearly marked on the outside of the package before

any equipment will be accepted for warranty work. National Instruments will pay the shipping costs of returning to the owner parts which are

covered by warranty.

National Instruments believes that the information in this document is accurate. The document has been carefully reviewed for technical

accuracy. In the event that technical or typographical errors exist, National Instruments reserves the right to make changes to subsequent

editions of this document without prior notice to holders of this edition. The reader should consult National Instruments if errors are suspected.

In no event shall National Instruments be liable for any damages arising out of or related to this document or the information contained in it.

E

XCEPT AS SPECIFIED HEREIN, NATIONAL INSTRUMENTS MAKES NO WARRANTIES, EXPRESS OR IMPLIED, AND SPECIFICALLY DISCLAIMS ANY WAR RANTY OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE . CUSTOMER’S RIGHT TO RECOVER DAMAGES CAUSED BY FAULT OR NEGLIGENCE ON THE PART OF

N

ATIONAL INSTRUMENTS SHALL BE LIMITED TO THE AMOUNT THERETOFORE PAID BY THE CUSTOMER. NATIONAL INSTRUMENTS WILL NOT BE LIABLE FOR

DAMAGES RESULTING FROM LOSS OF DATA, PROFITS, USE OF PRODUCTS, OR INCIDENTAL OR CONSEQUENTIAL DAMAGES, EVEN IF ADVISED OF THE POSS IBILITY

THEREOF. This limitation of the liability of National Instruments will apply regardless of the form of action, whether in contract or tort, including

negligence. Any action against National Instruments must be brought within one year after the cause of action accrues. National Instruments

shall not be liable for any delay in performance due to causes beyond its reasonable control. The warranty provided herein does not cover

damages, defects, malfunctions, or service failures caused by owner’s failure to follow the National Instruments installation, operation, or

maintenance instructions; owner’s modification of the product; owner’s abuse, misuse, or negligent acts; and power failure or surges, fire,

flood, accident, actions of third parties, or other events outside reasonable control.

Copyright

Under the copyright laws, this publication may not be reproduced or transmitted in any form, electronic or mechanical, including photocopying,

recording, storing in an information retrieval system, or translating, in whole or in part, without the prior written consent of National

Instruments Corporation.

Trademarks

LabVIEW™, National Instruments™, NI™, and ni.com™ are trademarks of National Instruments Corporation.

Product and company names mentioned herein are trademarks or trade names of their respective companies.

Patents

For patents covering National Instruments products, refer to the appropriate location: Help»Patents in your software, the patents.txt file

on your CD, or

ni.com/patents.

WARNING REGARDING USE OF NATIONAL INSTRUMENTS PRODUCTS

(1) NATIONAL INSTRUMENTS PRODUCTS ARE NOT DESIGNED WITH COMPONENTS AND TESTING FOR A LEVEL OF

RELIABILITY SUITABLE FOR USE IN OR IN CONNECTION WITH SURGICAL IMPLANTS OR AS CRITICAL COMPONENTS IN

ANY LIFE SUPPORT SYSTEMS WHOSE FAILURE TO PERFORM CAN REASONABLY BE EXPECTED TO CAUSE SIGNIFICANT

INJURY TO A HUMAN.

(2) IN ANY APPLICATION, INCLUDING THE ABOVE, RELIABILITY OF OPERATION OF THE SOFTWARE PRODUCTS CAN BE

IMPAIRED BY ADVERSE FACTORS, INCLUDING BUT NOT LIMITED TO FLUCTUATIONS IN ELECTRICAL POWER SUPPLY,

COMPUTER HARDWARE MALFUNCTIONS, COMPUTER OPERATING SYSTEM SOFTWARE FITNESS, FITNESS OF COMPILERS

AND DEVELOPMENT SOFTWARE USED TO DEVELOP AN APPLICATION, INSTALLATION ERRORS, SOFTWARE AND

HARDWARE COMPATIBILITY PROBLEMS, MALFUNCTIONS OR FAILURES OF ELECTRONIC MONITORING OR CONTROL

DEVICES, TRANSIENT FAILURES OF ELECTRONIC SYSTEMS (HARDWARE AND/OR SOFTWARE), UNANTICIPATED USES OR

MISUSES, OR ERRORS ON THE PART OF THE USER OR APPLICATIONS DESIGNER (ADVERSE FACTORS SUCH AS THESE ARE

HEREAFTER COLLECTIVELY TERMED “SYSTEM FAILURES”). ANY APPLICATION WHERE A SYSTEM FAILURE WOULD

CREATE A RISK OF HARM TO PROPERTY OR PERSONS (INCLUDING THE RISK OF BODILY INJURY AND DEATH) SHOULD

NOT BE RELIANT SOLELY UPON ONE FORM OF ELECTRONIC SYSTEM DUE TO THE RISK OF SYSTEM FAILURE. TO AVOID

DAMAGE, INJURY, OR DEATH, THE USER OR APPLICATION DESIGNER MUST TAKE REASONABLY PRUDENT STEPS TO

PROTECT AGAINST SYSTEM FAILURES, INCLUDING BUT NOT LIMITED TO BACK-UP OR SHUT DOWN MECHANISMS.

BECAUSE EACH END-USER SYSTEM IS CUSTOMIZED AND DIFFERS FROM NATIONAL INSTRUMENTS' TESTING

PLATFORMS AND BECAUSE A USER OR APPLICATION DESIGNER MAY USE NATIONAL INSTRUMENTS PRODUCTS IN

COMBINATION WITH OTHER PRODUCTS IN A MANNER NOT EVALUATED OR CONTEMPLATED BY NATIONAL

INSTRUMENTS, THE USER OR APPLICATION DESIGNER IS ULTIMATELY RESPONSIBLE FOR VERIFYING AND VALIDATING

THE SUITABILITY OF NATIONAL INSTRUMENTS PRODUCTS WHENEVER NATIONAL INSTRUMENTS PRODUCTS ARE

INCORPORATED IN A SYSTEM OR APPLICATION, INCLUDING, WITHOUT LIMITATION, THE APPROPRIATE DESIGN,

PROCESS AND SAFETY LEVEL OF SUCH SYSTEM OR APPLICATION.

Page 4

Contents

About This Manual

How to Use This Manual ...............................................................................................vii

Conventions ...................................................................................................................vii

Related Documentation..................................................................................................viii

Chapter 1

Introduction to the LabVIEW Order Analysis Toolset

Overview of the LabVIEW Order Analysis Toolset......................................................1-1

Overview of the LabVIEW Order Analysis Start-Up Kit..............................................1-1

Important Considerations for the Analysis of Rotating Machinery...............................1-2

System Requirements ....................................................................................................1-3

Installation .....................................................................................................................1-3

Example VIs ..................................................................................................................1-4

Acquiring Data for Example VIs.....................................................................1-4

Configuring DAQ Hardware Used with Examples .........................................1-4

Acquire Data (Analog Tach) VI........................................................1-5

Acquire Data with PXI 4472 and TIO VI .........................................1-6

Chapter 2

Order Analysis

Order Analysis Definition and Application ...................................................................2-1

Order Analysis Basics....................................................................................................2-1

Effect of Rotational Speed on Order Identification .......................................................2-4

Constant Rotational Speed ..............................................................................2-4

Variable Rotational Speed...............................................................................2-6

Harmonic Analysis ..........................................................................................2-9

Order Analysis.................................................................................................2-9

Order Analysis Methods ................................................................................................2-9

Gabor Transform .............................................................................................2-10

Resampling ......................................................................................................2-13

Adaptive Filter.................................................................................................2-15

© National Instruments Corporation v LabVIEW Order Analysis Toolset User Manual

Page 5

Contents

Chapter 3

Gabor Transform-Based Order Tracking

Overview of Gabor Order Analysis............................................................................... 3-1

Extracting the Order Components ................................................................................. 3-3

Masking .........................................................................................................................3-5

Extracting Orders ............................................................................................ 3-6

Reconstructing the Signal ............................................................................... 3-7

Displaying Spectral Maps.............................................................................................. 3-8

Calculating Waveform Magnitude ................................................................................ 3-10

Chapter 4

Resampling-Based Order Analysis

LabVIEW Order Analysis Toolset Resampling Method............................................... 4-1

Determining the Time Instance for Resampling ........................................................... 4-2

Resampling Vibration Data ........................................................................................... 4-4

Slow Roll Compensation............................................................................................... 4-5

Chapter 5

Calculating Rotational Speed

Digital Differentiator Method........................................................................................ 5-1

Averaging Pulses ........................................................................................................... 5-3

Appendix A

Gabor Expansion and Gabor Transform

Appendix B

References

Appendix C

Technical Support and Professional Services

Glossary

Index

LabVIEW Order Analysis Toolset User Manual vi ni.com

Page 6

About This Manual

This manual provides information about the LabVIEW Order Analysis

Toolset, including system requirements, installation, and suggestions

for getting started with order analysis and the toolset. The manual also

provides a brief discussion of the order analysis process and the algorithm

used by the LabVIEW Order Analysis Toolset.

How to Use This Manual

If you are just beginning to gain experience with order analysis, read

Chapter 2, Order Analysis, of this manual and experiment with the

Order Analysis Start-Up Kit. Refer to Chapter 1, Introduction to the

LabVIEW Order Analysis Toolset, for information about the Order

Analysis Start-Up Kit.

If you have experience with order analysis, use the example VIs to

learn about how to use the LabVIEW Order Analysis Toolset. Refer

to Chapter 1, Introduction to the LabVIEW Order Analysis Toolset,

for information about the example VIs.

If you want to learn more about the algorithm used in the LabVIEW

Order Analysis Toolset, refer to Chapter 3, Gabor Transform-Based Order

Tracking, and Chapter 4, Resampling-Based Order Analysis.

For information about individual VIs, refer to the Order Analysis Toolset

Help, available in LabVIEW 6.1 by selecting Help»Order Analysis.

In LabVIEW 7.0 and later, Order Analysis Toolset Help is part of the

LabVIEW Help, which is available by selecting Help»VI, Function,

& How-To Help.

Conventions

The following conventions appear in this manual:

» The » symbol leads you through nested menu items and dialog box options

to a final action. The sequence File»Page Setup»Options directs you to

pull down the File menu, select the Page Setup item, and select Options

from the last dialog box.

This icon denotes a note, which alerts you to important information.

© National Instruments Corporation vii LabVIEW Order Analysis Toolset User Manual

Page 7

About This Manual

bold Bold text denotes items that you must select or click in the software, such

as menu items and dialog box options. Bold text also denotes the names of

parameters, dialog boxes, sections of dialog boxes, windows, menus,

palettes, and front panel controls and buttons.

italic Italic text denotes variables or cross references.

monospace Text in this font denotes text or characters that you should enter from the

keyboard, sections of code, programming examples, and syntax examples.

This font is also used for the proper names of disk drives, paths, directories,

programs, subprograms, subroutines, device names, functions, operations,

variables, filenames and extensions, and code excerpts.

Platform Text in this font denotes a specific platform and indicates that the text

following it applies only to that platform.

Related Documentation

The following documents contain information that you might find helpful

as you read this manual:

• LabVIEW Order Analysis Toolset Help

• Getting Started with LabVIEW

• LabVIEW User Manual

• LabVIEW Help

LabVIEW Order Analysis Toolset User Manual viii ni.com

Page 8

Introduction to the

LabVIEW Order Analysis Toolset

This chapter introduces the LabVIEW Order Analysis Toolset and the

Order Analysis Start-Up Kit, outlines system requirements, and gives

installation instructions.

Overview of the LabVIEW Order Analysis Toolset

The LabVIEW Order Analysis Toolset is a collection of virtual instruments

(VIs) for LabVIEW. These VIs help you measure and analyze noise or

vibration signals generated by rotating machinery by enabling you to

perform the following analysis operations:

• Calculation and examination of rotational speed

• Measurement of the power distribution in the frequency domain or

in the order domain as a function of either time or rotational speed

• Extraction of the order components from the original noise or vibration

signal

• Measurement of the magnitude and phase of any order component as

a function of rotational speed

• Presentation of data in a waterfall, orbit, or polar plot

1

The LabVIEW Order Analysis Toolset includes easy and advanced VIs.

Use the easy VIs to perform simple tasks in just a few steps. The advanced

VIs provide flexibility and increased control of the analysis process. Refer

to the LabVIEW Order Analysis Toolset Help for information about

individual VIs.

Overview of the LabVIEW Order Analysis Start-Up Kit

The Order Analysis Start-Up Kit is automatically installed when you install

the LabVIEW Order Analysis Toolset. To open the Order Analysis

Start-Up Kit, select Start»Programs»National Instruments»Order

Analysis»Order Analysis Start-Up. The Order Analysis Start-Up Kit

includes a LabVIEW application for order analysis. The order analysis

© National Instruments Corporation 1-1 LabVIEW Order Analysis Toolset User Manual

Page 9

Chapter 1 Introduction to the LabVIEW Order Analysis Toolset

application is built with components found in the LabVIEW Order

Analysis Toolset.

The order analysis application provides an example of how the LabVIEW

Order Analysis Toolset can help you successfully complete analysis

projects. The simple processes included in the order analysis application

enable you to perform data acquisition, tachometer analysis, tachless speed

profile generation, order analysis, and online monitoring of noise or

vibration signals generated by rotating machinery. You also can use the

order analysis application as a simple order analysis VI in projects or as

a tool to learn the basics of building and using LabVIEW Order Analysis

Tools e t VI s.

Important Considerations for the Analysis of Rotating Machinery

Order analysis is a powerful tool for analyzing rotating machinery when the

rotational speed might change over time. However, to successfully use the

LabVIEW Order Analysis Toolset, you must observe the following

condition and restriction:

• Provide a signal directly related to the position of the shaft, such as a

pulse train from a tachometer or key phasor. Although the LabVIEW

Order Analysis Toolset can measure the magnitude of the order

components without a tachometer signal, the measurement of the

phase of the order components requires a tachometer signal.

• Do not use the LabVIEW Order Analysis Toolset for analysis of

frequencies that are not excited by a fundamental frequency, such as

the modes encountered in modal analysis. Although you can observe

the different modes in the frequency domain, no simple relationship

exists among those different modes. Usually, the frequencies of

different modes are not simply a multiple of a fundamental frequency

over time.

LabVIEW Order Analysis Toolset User Manual 1-2 ni.com

Page 10

System Requirements

You must have LabVIEW 6.1 or later Full Development System or

Professional Development System installed to run the LabVIEW Order

Analysis Toolset.

Note Refer to the LabVIEW Release Notes for the required system configuration for

LabVIEW.

Note Order analysis is a memory-intensive task, especially when you display spectral

maps. Increasing the amount of RAM in your system can significantly increase system

performance.

Installation

This section provides instructions for installing the LabVIEW Order

Analysis Toolset.

Note Some virus detection programs interfere with the installer. Disable any automatic

virus detection programs before you install. After installation, check your hard disk for

viruses and enable any virus detection programs you disabled.

Chapter 1 Introduction to the LabVIEW Order Analysis Toolset

(Windows 2000/NT/XP) Complete the following steps to install the LabVIEW

Order Analysis Toolset.

1. Log on as an administrator or as a user with administrator privileges.

2. Insert the LabVIEW Order Analysis Toolset 2.0 installation CD into

the CD-ROM drive and follow the instructions that appear on the

screen. If the startup screen does not appear, select Start»Run,

navigate to the

Toolset 2.0 installation CD, and double-click

(Windows Me/98) Insert the LabVIEW Order Analysis Toolset 2.0

installation CD and follow the instructions that appear on the screen. If the

startup screen does not appear, select Start»Run, navigate to the

folder on the LabVIEW Order Analysis Toolset 2.0 installation CD, and

double-click

© National Instruments Corporation 1-3 LabVIEW Order Analysis Toolset User Manual

Setup folder on the LabVIEW Order Analysis

OAT.exe.

Setup

OAT.exe.

Page 11

Chapter 1 Introduction to the LabVIEW Order Analysis Toolset

Example VIs

If you have experience with order analysis, the example VIs, located in

the

examples\Order Analysis directory, can help you learn how to use

the LabVIEW Order Analysis Toolset. The example VIs illustrate the

following LabVIEW Order Analysis Toolset functions for both analog

and digital tachometer signal processing:

• Acquiring data

• Presenting data

• Gabor order tracking

• Resample order tracking

The example VIs use VIs found on the LabVIEW Order Analysis Toolset

palettes and illustrate the basic capabilities of the LabVIEW Order

Analysis Toolset.

Acquiring Data for Example VIs

For most of the example VIs, you can use prerecorded data or data you

acquire with data acquisition (DAQ) hardware. The example VIs that

accept either prerecorded data or acquired data have a Boolean control

named Data Source. The Data Source control has two choices, Example

and DAQ. When you choose Example, the VI uses prerecorded data

generated during a fan run-up as the data source. When you choose DAQ,

the VI uses data you acquire with DAQ hardware.

When acquiring data through DAQ hardware, National Instruments

recommends you follow the following guidelines:

• Use an anti-aliasing filter before data acquisition to avoid the

frequency alias.

• Sample the data from different channels simultaneously to maintain

the phase relationship between channels, such as a tachometer signal

and a vibration signal.

Configuring DAQ Hardware Used with Examples

The example VIs that accept both prerecorded data and acquired data use

either an analog tachometer signal or a digital tachometer signal. The front

panel of the example VI specifies the type of tachometer signal the VI uses,

for example, Gabor Order Tracking (Analog Tach) or Gabor Order

Tracking (Digital Tach). Depending on whether the example is an analog

tachometer example or a digital tachometer example, when Data Source is

LabVIEW Order Analysis Toolset User Manual 1-4 ni.com

Page 12

Chapter 1 Introduction to the LabVIEW Order Analysis Toolset

set to DAQ and you click the Run button on the front panel of the

example VI, one of the following VIs opens:

• Acquire Data (Analog Tach) VI

• Acquire Data with PXI 4472 and TIO VI

Refer to the Acquire Data (Analog Tach) VI section for information about

the Acquire Data (Analog Tach) VI and the Acquire Data with PXI 4472

and TIO VI section for information about the Acquire Data with PXI 4472

and TIO VI.

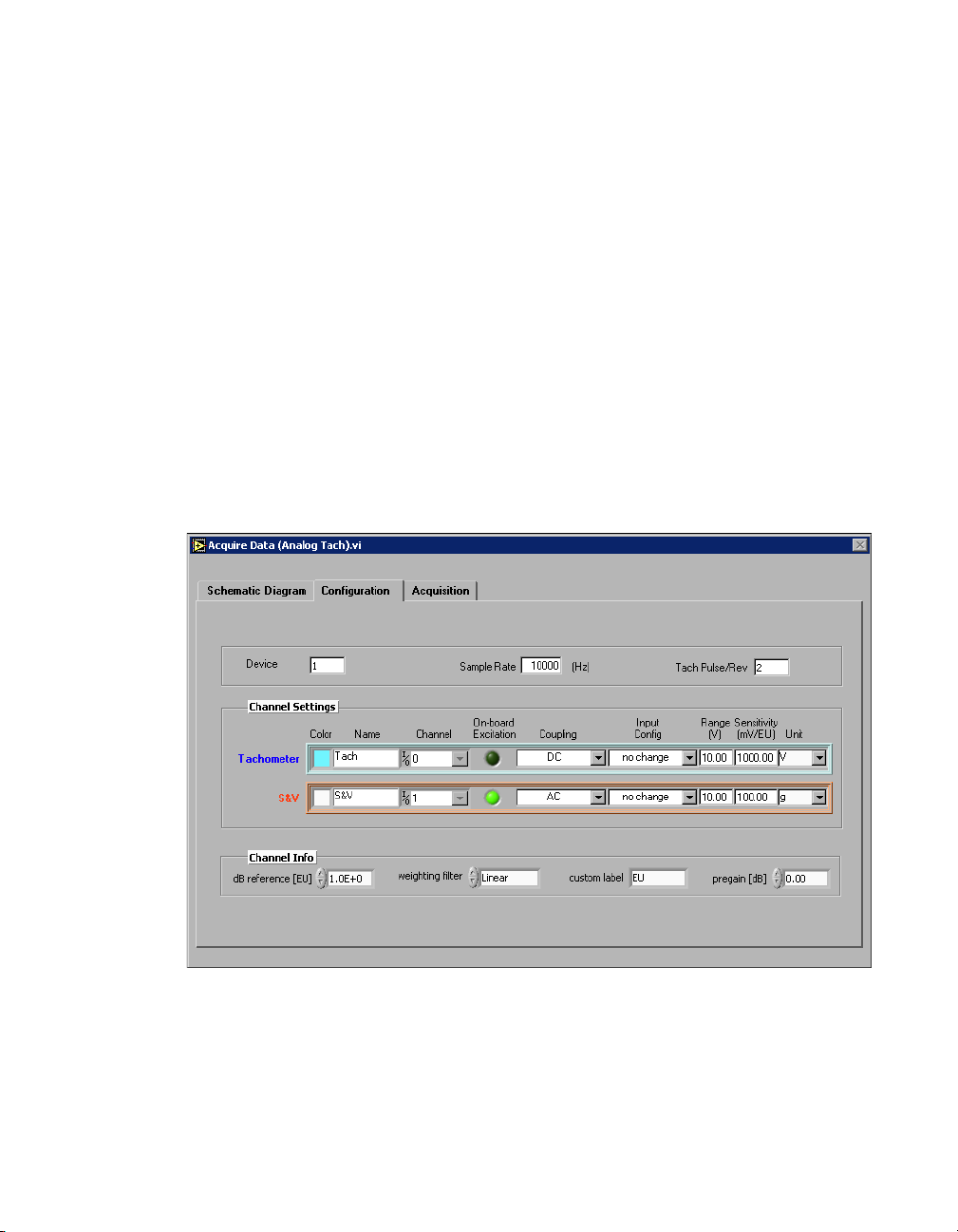

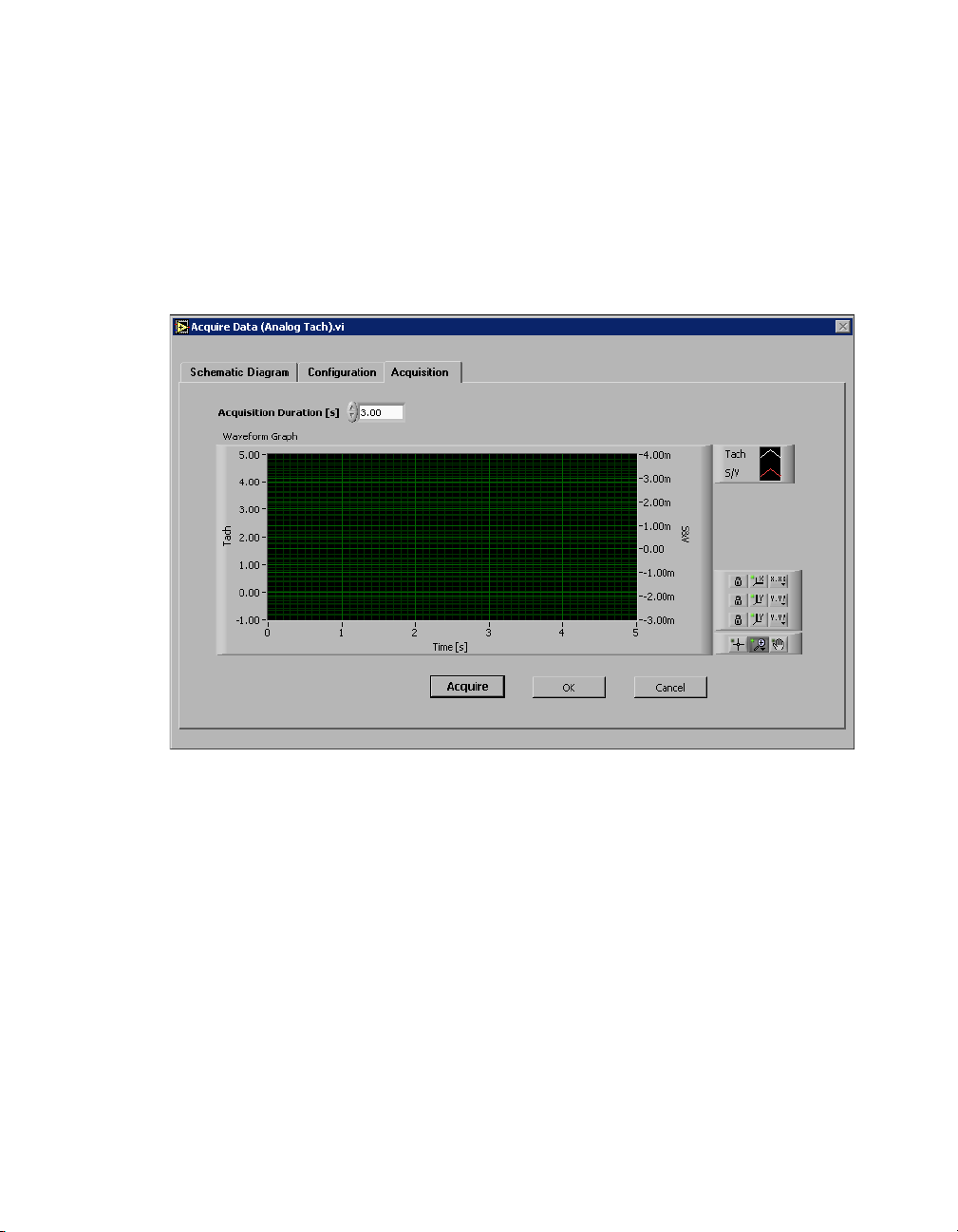

Acquire Data (Analog Tach) VI

In analog tachometer examples, setting Data Source to DAQ and clicking

the Run button opens the Acquire Data (Analog Tach) VI. The Acquire

Data (Analog Tach) VI helps you acquire vibration data with a digital

tachometer signal. Figure 1-1 shows the Configuration tab of the Acquire

Data (Analog Tach) VI.

Figure 1-1. Acquire Data (Analog Tach) VI Configuration Tab

You must configure two channels of the DAQ device before you acquire

data. Use the Configuration tab of the Acquire Data (Analog Tach) VI,

shown in Figure 1-1, to configure your DAQ device. In the Channel

Settings section of the Configuration tab, use Tachometer for the

© National Instruments Corporation 1-5 LabVIEW Order Analysis Toolset User Manual

Page 13

Chapter 1 Introduction to the LabVIEW Order Analysis Toolset

tachometer signal and S&V for the sound or vibration sensor. After

choosing data acquisition settings, enter the number of pulses you want the

tachometer to generate per revolution in the Tach Pulse/Rev text box.

Use the controls in the Channel Info section of the Configuration tab to

specify the channel information for the sound or vibration sensor.

After configuring the DAQ device, click the Acquisition tab, shown in

Figure 1-2.

Figure 1-2. Acquire Data (Analog Tach) VI Acquisition Tab

The Acquisition tab, shown in Figure 1-2, allows you to acquire and

observe data. Click the Acquire button to acquire data. Continue to

configure the data acquisition and acquire data until you acquire the data

you want. Click the OK button to return to the front panel of the example

VI to analyze the data.

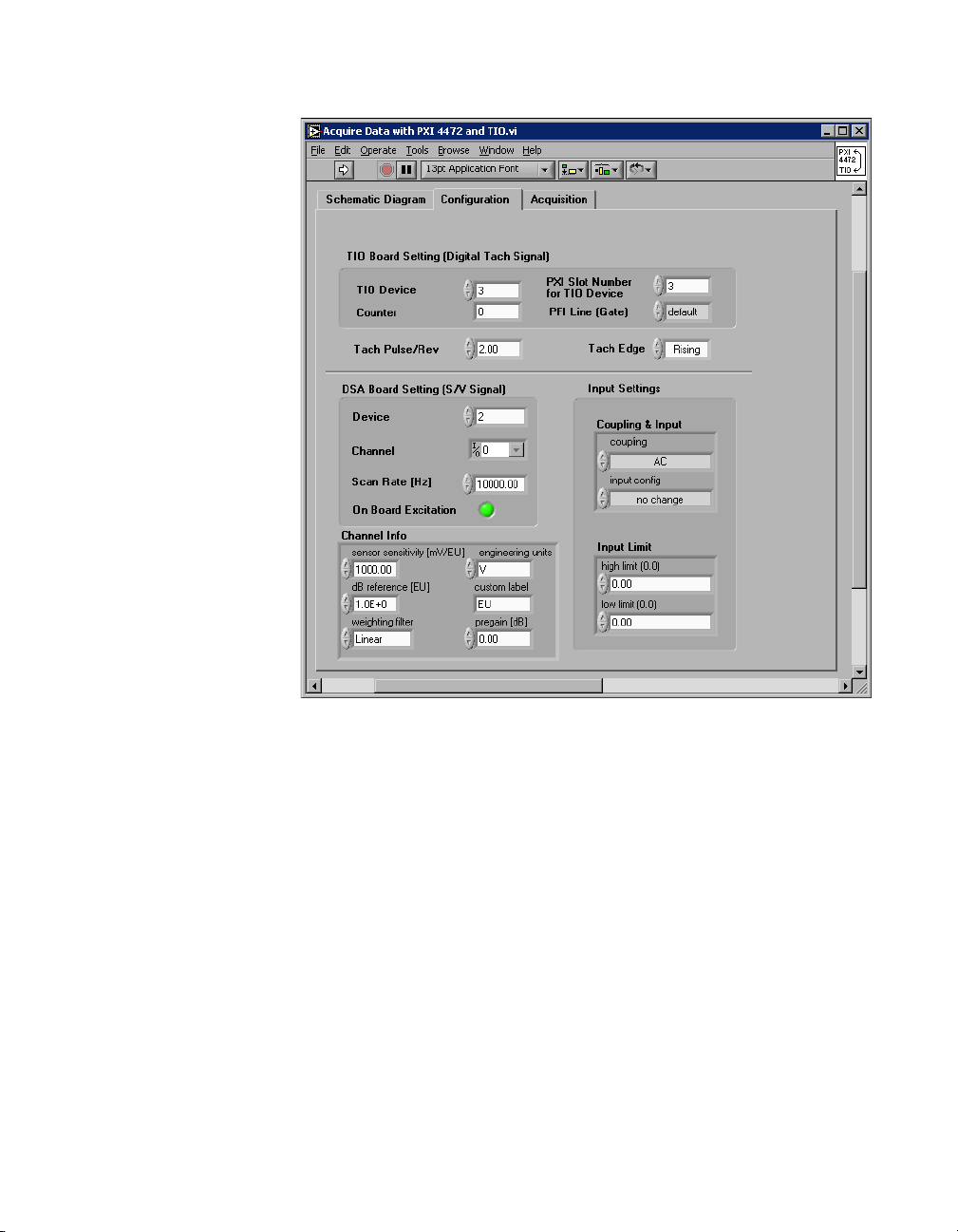

Acquire Data with PXI 4472 and TIO VI

In digital tachometer examples, setting Data Source to DAQ and clicking

the Run button opens the Acquire Data with PXI 4472 and TIO VI. The

Acquire Data with PXI 4472 and TIO VI helps you acquire vibration data

with a digital tachometer signal. Figure 1-3 shows the Configuration tab

of the Acquire Data with PXI 4472 and TIO VI.

LabVIEW Order Analysis Toolset User Manual 1-6 ni.com

Page 14

Chapter 1 Introduction to the LabVIEW Order Analysis Toolset

Figure 1-3. Acquire Data with PXI 4472 and TIO VI Configuration Tab

Use the Configuration tab of the Acquire Data with PXI 4472 and TIO VI,

shown in Figure 1-3, to configure the DAQ devices. Use one of the

counters on a TIO device to receive TTL-compatible tachometer pulses.

Use the controls in the TIO Board Setting (Digital Tach Signal) section

of the Configuration tab to configure the TIO device. Use an NI PXI-4472

to acquire the data from the sound or vibration sensor. Use the controls in

the DSA Board Setting (S/V Signal) and Input Settings sections of the

Configure tab to configure the NI PXI-4472. After configuring the DAQ

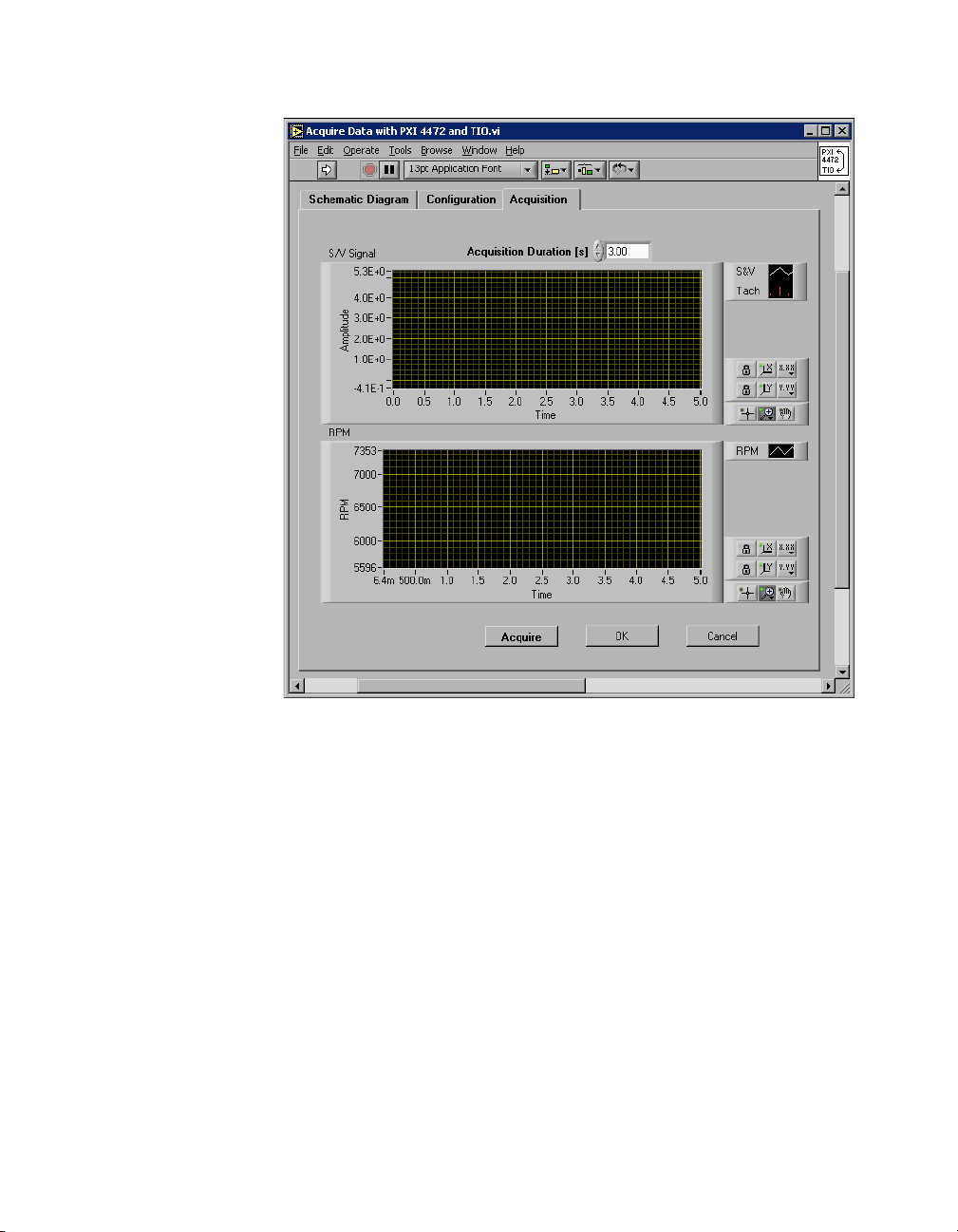

devices, click the Acquisition tab, shown in Figure 1-4.

© National Instruments Corporation 1-7 LabVIEW Order Analysis Toolset User Manual

Page 15

Chapter 1 Introduction to the LabVIEW Order Analysis Toolset

Figure 1-4. Acquire Data with PXI 4472 and TIO VI Acquisition Tab

The Acquisition tab, shown in Figure 1-4, allows you to acquire and

observe data. Click the Acquire button to acquire data. Continue to

configure the data acquisition and acquire data until you acquire the

data you want. Click the OK button to return to the front panel of the

example VI to analyze the data.

LabVIEW Order Analysis Toolset User Manual 1-8 ni.com

Page 16

Order Analysis

This chapter gives brief descriptions of the need for order analysis, the

basic concepts of order analysis, the effect of rotational speed on order

identification, and the different order analysis methods.

Order Analysis Definition and Application

When it is impossible or undesirable to physically open up a system and

study it, you often can gain knowledge about the system by measuring and

analyzing signals associated with the system. For example, physicists and

chemists use the spectrum generated by a prism to distinguish between

different types of matter. Astronomers apply spectra, as well as the Doppler

effect, to determine distances between planets. Physicians use the

electrocardiograph (ECG), which traces the electrical activity of the heart,

as a nonsurgical means of diagnosing heart problems.

You can use order analysis to study, design, and monitor rotating

machinery. By measuring and analyzing sound or vibration signals

generated by a system with rotational components, you can gain a better

understanding of the system, associate features of noise and vibration

with the physical characteristics of the system, and identify system

characteristics that change with time and operating conditions.

Systems with rotational components include automobiles, airplanes,

air conditioners, and PC hard drives.

2

Order Analysis Basics

Order analysis and harmonic analysis have much in common. The term

harmonic refers to frequencies that are integer or fractional multiples of

a fundamental frequency.

When dealing with rotating machinery, you often can hear noise and feel

vibration created by the parts associated with the rotating components.

Parts associated with rotating components include bearings, gears, and

blades. Vibration of the rotating components creates noise and vibration

signals. The machine rotational speed is the source of the noise and

© National Instruments Corporation 2-1 LabVIEW Order Analysis Toolset User Manual

Page 17

Chapter 2 Order Analysis

vibration signals. The frequency-domain representations of noise and

vibration behave as harmonics of the machine rotational speed.

In many industries, the harmonics related to the rotational speed are

referred to as orders. The corresponding harmonic analysis is called order

analysis. The harmonic at the same frequency as that of the rotational speed

is the first

order; the harmonic at twice the frequency of the rotational speed

is the second order and so on. Therefore, you can think of order analysis as

an application of harmonic analysis for rotating machinery.

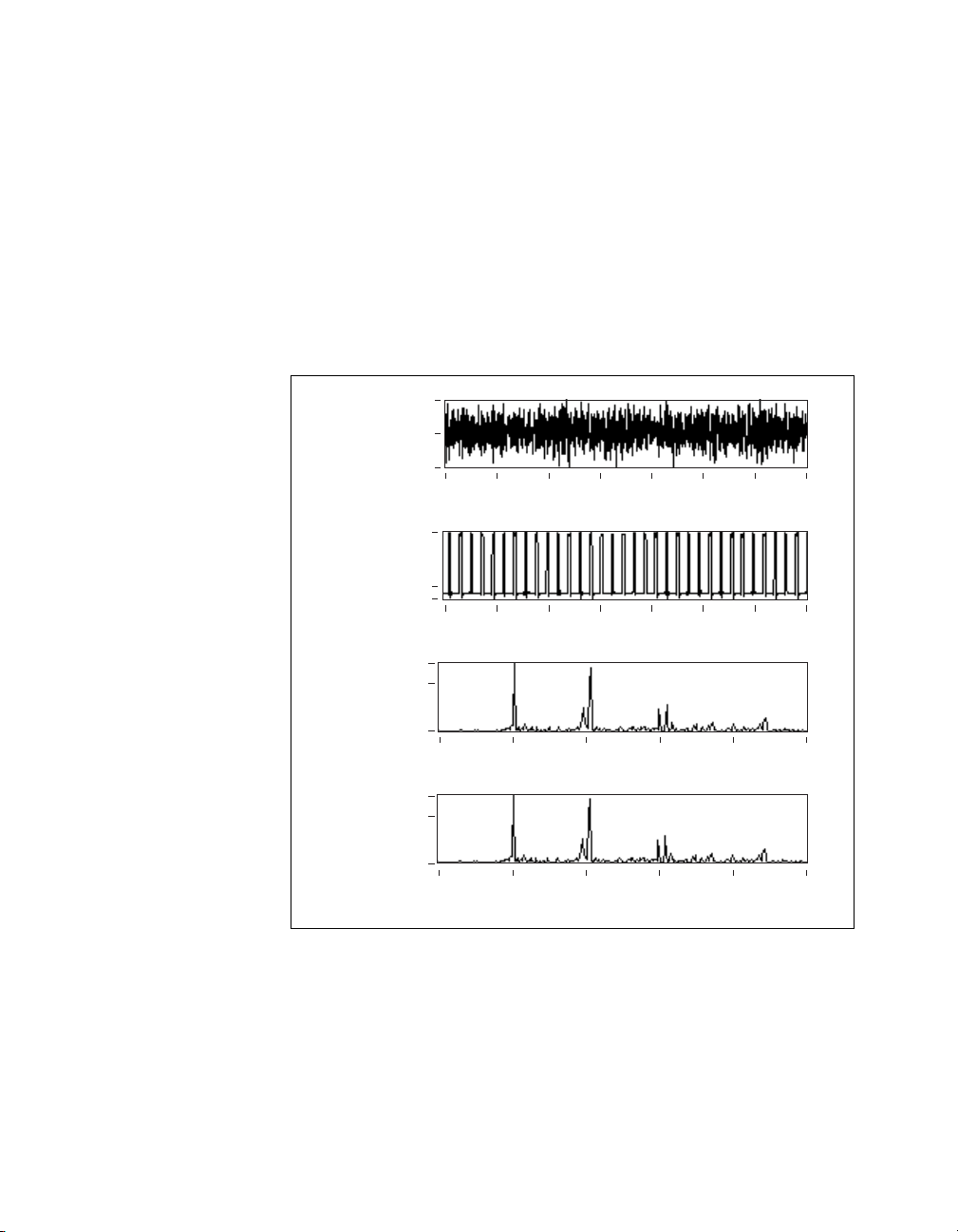

Figure 2-1 shows the relationship between frequency and order spectra.

1.7E+4

0.0E+0

VibrationTachometer

–1.9E+4

–2.5E+4

3.0E+6

2.0E+6

0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7

Time (s)

1.1E+3

0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7

Time (s)

Spectrum

Frequency

3.3E–2

0.0 100.0 200.0 300.0 400.0 500.0

Frequency (Hz)

3.0E+6

2.0E+6

Order

Spectrum

3.3E–2

0.0 2.0 4.0 6.0 8.0 10.0

Order

Figure 2-1. Order and Frequency Domain Display of a Shaft Rotating at 3,000 rpm

The top graph in Figure 2-1 shows a vibration signal from a machine

running at 3,000 revolutions per minute (rpm). The rotational speed is

computed from the tachometer signal, which is shown as the second graph

in Figure 2-1. The frequency domain and order domain plots of the signal

are shown in the third and fourth graphs, respectively, in Figure 2-1.

LabVIEW Order Analysis Toolset User Manual 2-2 ni.com

Page 18

Chapter 2 Order Analysis

Assuming that speed remains constant during data acquisition, you can use

the following equations to switch between the frequency domain and the

order domain.

RPM

Frequency

Order Frequency

-------------

60

Order×=

×=

60

-------------

RPM

Orders often reflect the physical characteristics of rotating machines. As in

classical harmonic analysis, by analyzing the phase and amplitude

relationships between different orders, you often can discover a great deal

about the system in which you are interested. For example, order analysis

has enabled the observation of the following relationships:

• Imbalance results in a spectral peak at the first order.

• Misalignment or bending of the shaft generates a large second order.

• Oil whirl might lead to strong fractional orders.

• Gears, belts, and blades might enhance high orders.

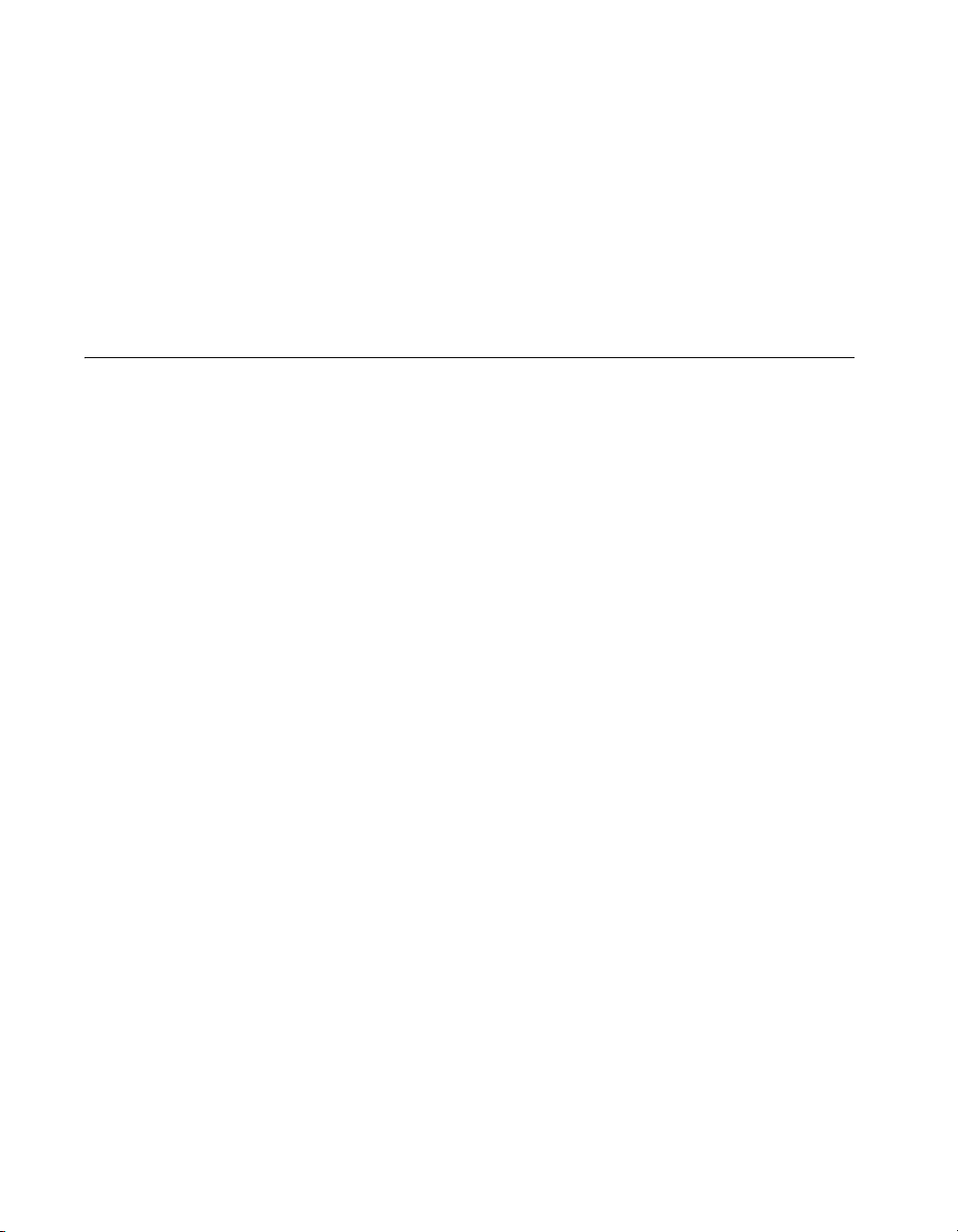

Figure 2-2 shows the order spectrum of the vibration signal measured from

a PC fan with seven blades and four coils.

4 Coils 7 Blades

0.0 2.0 4.0 6.0 8.0 10.0

Orders

Figure 2-2. Order Spectrum of a PC Fan with Seven Blades and Four Coils

12.0 14.0 16.0

The vibration signal depicted in Figure 2-2 contains strong fourth and

seventh orders. The four coils inside the fan drag and push the shaft

four times per revolution, causing the strong fourth order. The seven blades

of the fan pass the position of the sensor seven times per revolution and

cause the strong seventh order.

© National Instruments Corporation 2-3 LabVIEW Order Analysis Toolset User Manual

Page 19

Chapter 2 Order Analysis

Like classical harmonic analysis, order analysis is a powerful tool for

gaining a better understanding of the condition of rotating machinery.

However, compared to harmonic analysis, order analysis is more effective

for the analysis of rotating machinery because you can use order analysis

when a machine runs at a constant speed and when the rotational speed

varies. As described in the Effect of Rotational Speed on Order

Identification section, harmonic analysis is effective only when the

rotational speed remains constant.

Effect of Rotational Speed on Order Identification

The ability to make a reliable identification of individual orders from the

conventional power spectrum depends on whether rotational speed remains

constant or varies. This section discusses the effect rotational speed has on

the conventional power spectrum and discusses classical harmonic analysis

and order analysis in relation to rotational speed.

Constant Rotational Speed

At a constant rotational speed, you can identify orders from both the

conventional power spectrum and the frequency-time spectral map.

Figure 2-3 illustrates the analysis of a vibration signal acquired from

a PC fan running at a constant speed.

LabVIEW Order Analysis Toolset User Manual 2-4 ni.com

Page 20

570

500

450

400

350

300

250

200

Frequency (Hz)

150

100

50

0

Chapter 2 Order Analysis

STFTSpectrum

31.9 31.9 31.9

Figure 2-3. PC Fan Running at Constant Speed

The bottom plot in Figure 2-3 depicts the tachometer pulses and the signal

from an accelerometer mounted on the PC fan. The plot on the left in

Figure 2-3 illustrates a conventional power spectrum based on the fast

Fourier transform (FFT). The upper-right plot in Figure 2-3 shows the

frequency-time spectral map computed from the short-time Fourier

transform (STFT) with a 1,024-point Hanning window. Because of the

constant rotational speed of the fan during data acquisition, you can

identify several peaks in both the power spectrum and the frequency-time

spectral map. The peaks indicate different orders and appear in the

frequency-time spectral map as white lines.

© National Instruments Corporation 2-5 LabVIEW Order Analysis Toolset User Manual

Page 21

Chapter 2 Order Analysis

Variable Rotational Speed

In addition to testing rotating machinery running at a constant speed,

researchers often perform tests involving run-up and run-down. Like a

swept-sine stimulus, testing run-up and run-down provides a stimulus over

a wide range of frequencies.

According to Fourier analysis theory, the frequency bandwidth of a signal

is proportional to the change in the frequency and amplitude of the signal.

The faster the frequency changes, the wider the overall frequency

bandwidth becomes, as measured from the power spectrum.

Figure 2-4 illustrates a conventional power spectrum on the left and the

frequency-time spectral map on the right for a signal with constant

frequency and amplitude.

Spectrum Frequency-Time Spectral Map

0.5

0.4

0.3

0.2

Frequency

0.1

0.0

Time Waveform

1.0

0.5

0.0

–0.5

–1.0

0 50 100 150 200 255

Time

Figure 2-4. Constant Frequency

In Figure 2-4, the overall frequency bandwidth is proportional to the

change in frequencies. When the frequency and amplitude are constant over

LabVIEW Order Analysis Toolset User Manual 2-6 ni.com

Page 22

time, the overall frequency bandwidth, as measured from the conventional

power spectrum, is the minimum.

Figure 2-5 depicts a signal whose frequency changes as a function of time.

Spectrum Frequency-Time Spectral Map

0.5

0.4

0.3

0.2

Frequency

0.1

0.0

Time Waveform

1.0

0.5

0.0

–0.5

–1.0

0 50 100 150 200 255

Chapter 2 Order Analysis

Overall

Bandwidth

Becomes

Wide as the

Frequency

Changes

Time

Figure 2-5. Frequency Changes Over Time

Although the signals in Figures 2-4 and 2-5 have similar frequency

bandwidths at each time instant, the overall frequency bandwidths shown

in their corresponding power spectra are rather different. As you can see

from the two FFT-based power spectra in Figures 2-4 and 2-5, the overall

frequency bandwidth of the signal whose frequency increases with time in

Figure 2-5 is much wider than that of the signal whose frequency is

constant in Figure 2-4. When frequency or amplitude vary with time,

the corresponding overall frequency bandwidth, as measured from the

conventional power spectrum, becomes wide.

When the frequency bandwidth of the fundamental component widens, the

bandwidths of the associated harmonics also widen. The widening of the

bandwidths of the harmonics eventually causes the frequency bandwidth of

the harmonics to overlap in the conventional power spectrum. When the

© National Instruments Corporation 2-7 LabVIEW Order Analysis Toolset User Manual

Page 23

Chapter 2 Order Analysis

harmonics overlap in the conventional power spectrum, you are unable to

identify different harmonics by using the conventional power spectrum.

Figure 2-6 shows the signal from the same PC fan as the one depicted in

Figure 2-3. However, in Figure 2-6, the rotational speed of the fan increases

with time.

1500

1250

1000

750

Frequency (Hz)

500

250

0

STFTSpectrum

31.9 31.9 31.9

Time (sec.)

Figure 2-6. Fan Run-Up

In Figure 2-6, as the rotational speed increases, both the fundamental

frequency bandwidth and the frequency bandwidths of related orders

widen, causing orders to overlap. Whether you can separate nearby orders

in a power spectrum depends on the rate of change in the rotational speed,

the window used, and the highest order of interest. In Figure 2-6, the power

spectrum is measured over the entire duration of the fan run-up and does

not really show any distinguishable orders. When the change of speed is

large enough, the spectra of orders eventually overlap. When the spectra of

LabVIEW Order Analysis Toolset User Manual 2-8 ni.com

Page 24

Harmonic Analysis

Order Analysis

Chapter 2 Order Analysis

orders overlap, you are unable to derive meaningful information about the

individual orders.

Harmonic analysis is suitable for the analysis of rotating machinery only

when the rotational speed remains constant. In classical harmonic analysis,

the fundamental frequency does not change over time. Although the phases

and amplitudes of the individual harmonics can vary over time, the center

frequencies of all the harmonics remain constant.

When using the Fourier transform, you obtain the best results with the

machine running at a constant rotational speed while taking measurements.

If you want to take measurements at a different rotational speed, you have

to run the machine to that rotational speed and take another measurement.

Testing with discrete rotational speed increments is time consuming.

Testing with discrete rotational speed increments also can be inaccurate or

impossible if you cannot control the rotational speed of the system well or

the system is not allowed to run at the critical rotational speed for a

sufficient length of time.

An important goal of order analysis is to uncover information about the

orders that might become buried in the power spectrum due to a change

in rotational speed. While the orders are hidden in the overall power

spectrum in Figure 2-6, the orders have distinguishable features in the

frequency-time spectral map. The observation that orders have

distinguishable features in the frequency-time spectral map serves as the

starting point for uncovering information about orders that are difficult to

see in the power spectrum.

Order Analysis Methods

The basic technique of order analysis involves obtaining the instantaneous

speed of the rotating shaft of a machine from a tachometer or encoder

signal. The speed is then correlated to the noise or vibration signal

produced by the machine to obtain information about the order

components, such as waveforms, magnitudes, and phases. In order

analysis, revolutions, rather than time, serve as the basis for signal analysis.

Thus, in the spectrum domain, the focus is on orders instead of frequency

components.

© National Instruments Corporation 2-9 LabVIEW Order Analysis Toolset User Manual

Page 25

Chapter 2 Order Analysis

Gabor Transform

Currently, the following methods generally are used to perform order

analysis:

• Gabor transform

• Resampling

• Adaptive filter

The LabVIEW Order Analysis Toolset provides the

Gabor-transform-based method and the resampling method of order

analysis.

The Gabor transform is one of the invertible joint time-frequency

transforms. With invertible joint time-frequency transforms, you can

recover any time-domain input signal or an approximation of the signal by

applying an inverse transform to the transform of the signal. The Gabor

transform result is called a Gabor coefficient. The inverse Gabor transform

is known as the Gabor expansion. You can think of the Gabor transform as

a specific STFT. Even though you can recover a signal from its Gabor

transform by using a Gabor expansion, you cannot reconstruct the general

STFT using an inverse Fourier transform.

You can compute the Gabor transform by either STFT or windowed Fourier

transform. However, to ensure reconstruction of the signal, you have to

carefully manage the ratio of the analysis window to the window shift step

and the capture of information at signal edges. Use the following methods

to ensure reconstruction of the signal.

• Make sure that the ratio between the length of the analysis window and

the window shift step is greater than or equal to 1. The ratio between

the length of the analysis window and the window shift step determines

the time overlap. By default in the LabVIEW Order Analysis Toolset,

the ratio is set to 4. For example, if the window length is 2,048, the

window shift is 512.

• Move the analysis window in such way that no information is missed,

especially at the beginning and the end of the data samples. Zero

padding and wrap padding are two commonly used methods for

dealing with the edge data. Figure 2-7 illustrates zero padding and

wrap padding.

LabVIEW Order Analysis Toolset User Manual 2-10 ni.com

Page 26

Chapter 2 Order Analysis

Windows

Data Blocks

Zeros 1 2 n–1 n Zeros

(a) Zero Padding

Windows

Data Blocks

n–1 n 1 2

In zero padding, shown in Figure 2-7(a), the first window and the last

window only cover one data block each. The remaining area in the

range of the window is filled with zeros. Thus, extra data samples are

added. After Gabor expansion, the reconstructed data is longer than the

original data.

To avoid the reconstructed data being longer than the original data,

consider the signal as periodic and use wrap padding, shown in

Figure 2-7(b). In wrap padding, when the first few data blocks are

analyzed, data blocks at the end of the data samples are wrapped ahead

to fill the windows. You also can wrap data blocks backward from the

beginning of the data sample to the end.

n–1 n 1

(b) Wrap Padding

Figure 2-7. Padding Schemes

© National Instruments Corporation 2-11 LabVIEW Order Analysis Toolset User Manual

Page 27

Chapter 2 Order Analysis

0.4

0.2

0.0

–0.2

Amplitude

–0.4

–384 –300 –200 –100 128 8064 8200 8300 8400 8500 8576

0.4

0.2

0.0

–0.2

Amplitude

–0.4

–256 –100 0 200 7808 7900 8000 8100 8200 8320

Figure 2-8 shows two examples of padding.

Time

(a) Zero Padding

100 256

Time

(b) Wrap Padding

Figure 2-8. Padding Examples

Refer to Appendix A, Gabor Expansion and Gabor Transform, for more

information about the Gabor transform and the Gabor expansion.

Refer to Chapter 3, Gabor Transform-Based Order Tracking, for

information about how the LabVIEW Order Analysis Toolset uses a

method based on the Gabor transform for order tracking.

LabVIEW Order Analysis Toolset User Manual 2-12 ni.com

Page 28

Resampling

Chapter 2 Order Analysis

Resampling is a widely used method of order analysis. Figure 2-9

illustrates the resampling method.

Sample at Constant Time Frequency

Sample at Constant Angle Order

Figure 2-9. Resampling

In the resampling method, time-samples are converted to angle samples.

The time-samples are samples of the physical signal that are equally spaced

in time. The angle samples are samples that are equally spaced in the

rotation angle.

You can acquire angle samples with either hardware or software. The

hardware solution uses an encoder or a multiplied tachometer signal to

trigger the analog-to-digital conversion, which ensures a sampling process

spaced equally in the rotation angle. The hardware solution requires

additional hardware devices and a tracking anti-aliasing filter.

Software programs designed to acquire angle samples complete the

following steps to acquire the angle samples.

1. Collects the measured signal and the tachometer signal at some

constant rate.

2. Uses interpolation or curve fitting to determine the instantaneous shaft

angle at intermediate points between the tachometer pulses.

3. Calculates the sampling time at the desired shaft-angular increment.

4. Uses interpolation to obtain new samples at the desired time.

© National Instruments Corporation 2-13 LabVIEW Order Analysis Toolset User Manual

Page 29

Chapter 2 Order Analysis

After acquiring angle samples with either hardware or software, you can

perform a Fourier transform on the angle samples to analyze them. Because

the time domain has changed into the angle domain, the frequency domain

now becomes the order domain. You can separate and observe the order

components through either the STFT spectrum or the order spectrum,

which is actually the FFT spectrum.

Figure 2-10 shows the spectrum of angle samples.

10

8

6

Order

4

2

0

Order Spectrum

Order vs. Rev

Angle Samples

1.0

0.5

0.0

Amplitude

–0.5

–1.0

0 200 400 600 800 1000 1200 1400

Revolution

Figure 2-10. Spectrum of Angle Samples

In Figure 2-10, the Angle Samples plot shows the signal sampled at a

constant angle-interval. The Order Spectrum plot shows the order spectrum

obtained by performing a FFT on the angle samples. In the Order Spectrum

plot, significant peaks appear at each order. The Order vs. Rev plot shows

the result of a STFT on the angle samples, where an order axis is used

instead of a frequency axis. Each horizontal white line in the Order vs. Rev

plot indicates the strong power at an integer order.

LabVIEW Order Analysis Toolset User Manual 2-14 ni.com

Page 30

Adaptive Filter

Chapter 2 Order Analysis

After the resampling process takes place, recovering a time waveform at a

specific order might be difficult.

Refer to Chapter 4, Resampling-Based Order Analysis, for information

about how the LabVIEW Order Analysis Toolset uses software-based

resampling for order analysis.

Although the frequencies of the order components change as the rotational

speed changes, you can consider the rotational speed and the frequency of

order components to remain constant in a relatively short time interval.

The adaptive filter method of order analysis filters out the desired order by

using a bandpass filter whose passband frequency shifts according to the

rotational speed.

The Vold-Kalman Order Tracking Filter is an example of the successful

application of the adaptive filter method. With an accurate instantaneous

speed signal as a guide, the Vold-Kalman Order Tracking Filter can extract,

without ambiguity, two orders that are in close proximity to each other.

© National Instruments Corporation 2-15 LabVIEW Order Analysis Toolset User Manual

Page 31

Gabor Transform-Based Order

Tracking

This chapter discusses a new order analysis method based on the Gabor

transform and provided by the LabVIEW Order Analysis Toolset that

enables you to complete the following tasks:

• Analyze the order components of a noise or vibration signal

• Reconstruct the desired order components in the time domain

Overview of Gabor Order Analysis

The Gabor transform can give the power distribution of the original signal

as the function of both time and frequency. Figure 3-1 shows a

frequency-time spectral map computed by performing a Gabor transform

on a sample vibration signal from a rotating machine.

500

450

400

350

300

250

200

Frequency (Hz)

150

100

50

0

0124681012357911131415

Time (s)

3

Figure 3-1. Frequency-Time Spectral Map of a Vibration Signal

© National Instruments Corporation 3-1 LabVIEW Order Analysis Toolset User Manual

Page 32

Chapter 3 Gabor Transform-Based Order Tracking

In Figure 3-1, the magnitudes of coefficients are shown as gray scale, with

full white indicating a maximal magnitude and full black indicating a

minimal magnitude.

Because the rotational speed changes little in each time portion of the

frequency-time spectral map, the spectrum of each order is clearly

distinguishable. As the rotational speed varies over time, the frequency of

one certain order component changes. Thus, the order component forms a

curve with a large magnitude in the frequency-time spectral map, as shown

in Figure 3-1. The white curves have magnitudes larger than the

magnitudes in local neighborhoods off the curves. The white curves

indicate the order components and are referred to as order curves.

From the frequency-time spectral map, you can separate the order curves,

or any other part of the signal in which you are interested, from the intact

original signal. You then can use Gabor expansion to reconstruct time

waveforms of the orders.

Figure 3-2 illustrates the Gabor order analysis process provided by the

LabVIEW Order Analysis Toolset.

Step 1:

Data

Acquisition

Vibration

Signal

Tachometer

Signal

Step 2:

Gabor

Transform

Step 3:

Tachometer

Processing

Gabor

Coefficients

Step 5:

Mask

Operation

Step 4:

Display

2D Spectral

Map

Modified

Coefficients

Figure 3-2. Gabor Order Analysis Diagram

Step 6:

Gabor

Expansion

Order

Wavefo rm

Step 7:

Compute

Magnitude

and Phase

LabVIEW Order Analysis Toolset User Manual 3-2 ni.com

Page 33

Chapter 3 Gabor Transform-Based Order Tracking

Complete the following steps to perform Gabor order analysis.

1. Acquire data samples from the tachometer and noise or vibration

sensors synchronously at some constant sample rate.

2. Use the LabVIEW Order Analysis Toolset VIs to complete the

following steps.

a. Perform a Gabor transform on the noise or vibration samples to

produce an initial Gabor coefficient array.

b. Calculate the rotational speed from the tachometer signal. Refer to

Chapter 5, Calculating Rotational Speed, for information about

calculating rotational speed.

c. Generate a 2D spectral map from the initial coefficient array to

observe the whole signal over frequency-time, frequency-rpm,

order-rpm, or rpm-order.

d. Generate a modified coefficient array, based on the rotational

speed and the order of interest, from the initial array by

performing a masking operation.

e. Generate a time domain signal from the modified coefficient array

by performing Gabor expansion.

f. Calculate the waveform magnitude and phase.

Refer to the Important Considerations for the Analysis of Rotating

Machinery section of Chapter 1, Introduction to the LabVIEW Order

Analysis Toolset, for information about a condition and restriction for using

the LabVIEW Order Analysis Toolset to analyze rotating machinery.

Extracting the Order Components

After generating the initial Gabor coefficient array through a Gabor

transform, you can select one or more order components for analysis. You

can convert the coefficient corresponding to the selected order component

back into a time domain signal. The resulting time domain signal contains

information only about the selected order component.

You select order components by including the coefficients along the

corresponding order curves. Therefore, you must determine the position

index of the coefficient on each order curve. Because the frequency of an

order component is an integer or fractional multiple of the fundamental

frequency, such as the rotational speed, the position index of a given order

curve at each time interval is calculated by multiplying the order number

and the fundamental frequency index at the time interval. If a signal is

© National Instruments Corporation 3-3 LabVIEW Order Analysis Toolset User Manual

Page 34

Chapter 3 Gabor Transform-Based Order Tracking

f

f

processed by a Gabor transform, the index of the nth order is given by the

following equation.

500–

400–

300–

200–

Frequency (Hz)

100–

=

index round

RPM

-------------

60

N

----

n××

,

f

s

where RPM is the averaged instantaneous rotational speed in the time

interval, N is the number of frequency bins, and f

is the sampling

s

frequency. In the LabVIEW Order Analysis Toolset, the number of

frequency bins N equals the length of the window.

Each order component in the order domain, as well as each harmonic in

the frequency domain, has a side band. Thus, in the joint time-frequency

domain, each order component contains the coefficients along the order

curve and some coefficients in the neighborhood. You must include the

coefficients in the neighborhood when selecting the order component.

Constant frequency bandwidth and constant order bandwidth are two ways

to define the bandwidth of the neighborhood for an order curve. Figure 3-3

illustrates constant frequency bandwidth and constant order bandwidth.

500–

400–

300–

200–

Frequency (Hz)

100–

0–

0 5 25 30 3510 15 20 39

Time (s)

(a) Constant Frequency Bandwidth

Figure 3-3. Constant Frequency Bandwidth and Constant Order Bandwidth

0–

0 5 25 30 3510 15 20 39

Time (s)

(b) Constant Order Bandwidth

Figure 3-3(a) illustrates constant frequency bandwidth. The neighborhood

RPM

is considered as the region between and , where

n

-------------

60

∆

-----+ n

2

RPM

-------------

60

∆

-----–

2

∆ f is a constant frequency. The frequency of the bandwidth ∆ f remains

constant over time.

LabVIEW Order Analysis Toolset User Manual 3-4 ni.com

Page 35

Chapter 3 Gabor Transform-Based Order Tracking

ˆ

Figure 3-3(b) illustrates constant order bandwidth. The neighborhood is

Masking

RPM

k

considered as the region between and .

While the frequency bandwidth varies in time, the order bandwidth

n

RPM

-------------

k

60

-------------

× n

---+

60

2

RPM

k

-------------

×

---–

60

2

k remains constant.

You can use the Gabor Order Analysis VIs to determine the frequency

bandwidth or order bandwidth automatically or in response to your input.

For example, you can automatically determine a bandwidth for the

time-frequency neighborhood based on an estimate of minimum

order-distance to nearest neighbor order-components. Normally, the

bandwidth should not exceed the distance between two nearby orders,

which is the fundamental frequency, or first order.

After you determine the coefficient positions and the bandwidth of the

selected order curves, select a subset of the initial Gabor coefficient array.

The subset of the initial Gabor coefficient array contains only the

coefficients in the neighborhood of the selected order curves. You can

generate the subset by performing a mask operation on the initial Gabor

coefficient array.

To perform the mask operation, you must construct a mask array. The mask

array is a 2D array the same size as the coefficient array. However, the mask

array contains only Boolean elements. When masking is performed, the

coefficients at value TRUE are kept unchanged, while the coefficients at

value FALSE are set to zero. The following equation represents the mask

operation.

c

where c

is the original coefficient array, is the masked coefficient

m, n

array, and mask

ˆ

c

=

mn,

is the mask array.

m, n

0 mask

mn,

mask

TRUE=

mn,

FALSE=

mn,

c

mn,

,

You can build a mask array according to the order number you want to

analyze. In each row, elements within the bandwidth of the designated

order number are set to either TRUE or FALSE. Use the Template to Mask

© National Instruments Corporation 3-5 LabVIEW Order Analysis Toolset User Manual

Page 36

Chapter 3 Gabor Transform-Based Order Tracking

VI to perform the mask operation. Refer to the LabVIEW Order Analysis

Toolset Help for information about the Template to Mask VI.

You can consider the mask operation a time-variant bandpass filter in the

joint time-frequency domain. The center frequency of the passband equals

the frequency of the order curve. The number of elements set to TRUE

determines the bandwidth of the passband.

Extracting Orders

Figure 3-4 illustrates the order extraction and signal reconstruction

process.

500–

400–

300–

200–

Frequency (Hz)

100–

0–

02 468101215 02 468101215

Time (s) Time (s)

(a) Original Signal (b) Mask

500–

400–

300–

200–

Frequency (Hz)

100–

0–

Time (s) Time (s)

(c) Masked Coefficients (d) Gabor Coefficients of the

500–

400–

300–

200–

Frequency (Hz)

100–

0–

500–

400–

300–

200–

Frequency (Hz)

100–

0–

02 46810121502 468101215

Reconstructed Signal

Figure 3-4. Gabor Coefficients

Figure 3-4(a) shows a frequency-time spectral map after the Gabor

transform.

LabVIEW Order Analysis Toolset User Manual 3-6 ni.com

Page 37

Figure 3-4(b) shows a mask array around the fourth order with a constant

frequency bandwidth. The TRUE values comprise the white area, while the

FALSE values comprise the black areas.

Figure 3-4(c) shows the masked coefficients. The black areas indicate

values set to zero and correspond to the FALSE values in the mask array.

The white area contains values copied from the original coefficient array

and corresponds to the TRUE values in the mask array.

Figure 3-4(d) shows the frequency-time spectral map of the reconstructed

signal.

Reconstructing the Signal

Figure 3-5 shows the fourth-order time waveform that was reconstructed

by performing a Gabor expansion on the masked coefficients from

Figure 3-4.

1.0–

)

2

0.5–

0.0–

Chapter 3 Gabor Transform-Based Order Tracking

Extracted 4th Order

Original Signal

–0.5–

Vibration (m/s

–1.0–

10.0 12.04.00.0 2.0 6.0 8.0 14.6

Time (s)

Figure 3-5. Original Signal and Extracted Order Component

Unlike the reverse discrete Fourier transform, the Gabor expansion, in

general, is not a one-to-one mapping. A Gabor coefficient is the subspace

of a two-dimensional function. An arbitrary two-dimensional function,

such as the masked coefficient array, might not have a corresponding time

waveform. Usually, the Gabor coefficients of the reconstructed time

waveform are not exactly the same as the desired coefficients you mask.

However, in terms of the least mean square error (LMSE), the Gabor

coefficients of the reconstructed time waveform are the coefficients closest

to the desired coefficients you mask.

Like conventional time-invariant filters, the time-variant filters

implemented by the Gabor expansion have a certain passband and

attenuation. The extracted time waveform is only a part of the original

signal whose frequencies fall into the passband determined by the Gabor

© National Instruments Corporation 3-7 LabVIEW Order Analysis Toolset User Manual

Page 38

Chapter 3 Gabor Transform-Based Order Tracking

time-variant filters. Figure 3-6 shows an original signal and the spectrum of

the reconstructed signal.

–49.1–

–100.0–

dB

–150.0–

–179.0–

Original Signal

Reconstructed Order

Expected Pass Band

250 300 3501000 50 150 200 408

Frequency (Hz)

Figure 3-6. Spectrum of Reconstructed Signal

In Figure 3-6, one row is selected from the joint time-frequency coefficient

array. The selected row is nothing more than a windowed FFT power

spectrum in the time interval. The original Gabor coefficients comprise the

solid line in Figure 3-6. When performing a mask operation, coefficients

outside the expected passband are set to zero.

After reconstruction, the spectrum of the reconstructed signal is formed.

In Figure 3-6, the dashed line represents the spectrum of the reconstructed

signal. Within the passband, the reconstructed signal keeps the same

magnitude as the original signal. While outside the passband, the

magnitude of the reconstructed signal is no longer zero. Instead,

the magnitude does have some certain value. However, the value of

the magnitude quickly decreases as the frequency leaves the passband.

Displaying Spectral Maps

Before extracting order components from the joint time-frequency domain,

you might want to identify the order components in which you are most

interested, such as which order is the most significant or which order

contributes the most at a certain rotational speed. However, by using order

extraction and reconstruction, you might have to process a large number of

order components before you can obtain this information.

The LabVIEW Order Analysis Toolset provides several methods of

obtaining a 2D spectral map over the whole signal in the frequency-time,

frequency-rpm, and order-rpm domains. Figure 3-7 shows the three types

of spectral maps for a vibration signal.

LabVIEW Order Analysis Toolset User Manual 3-8 ni.com

Page 39

Chapter 3 Gabor Transform-Based Order Tracking

5000

4000

3000

2000

1000

0

0 5 10 15 20 25 30 36 0.0 5.0 10.0 15.0 20.0 25.0 30.0 36.0

Time (s)

5000

4000

3000

2000

Frequency Frequency

1000

(a) Frequency-Time Spectral Map

0

991 1250 1500 1750 2000 2250 2500 2774

RPM

(c) Frequency-RPM Spectral Map

3000

2500

2000

1500

1000

500

0

Time (s)

(b) RPM vs. Time

150

125

100

75

Order RPM

50

25

0

991 1250 1500 1750 2000 2250 2500 2774

RPM

(d) Order-RPM Spectral Map

Figure 3-7. 2D Spectral Maps

Figure 3-7(a) is the frequency-time spectral map generated directly from

the Gabor coefficients. The magnitudes of coefficients are shown as gray

scale, with full white indicating a maximal magnitude and full black

indicating a minimal magnitude. Order components are shown as curves.

Because the frequency of each order component shifts as the rotational

speed varies over time, the outline of each curve is similar to the rpm-time

function shown in Figure 3-7(b).

In Figure 3-7(a), notice the horizontal white lines. The horizontal white

lines indicate the large power around the resonance frequencies. The

physical characteristics of the system containing the rotating machinery

determine the resonance frequency. The resonance frequency does not

change as the rotational speed changes.

© National Instruments Corporation 3-9 LabVIEW Order Analysis Toolset User Manual

Page 40

Chapter 3 Gabor Transform-Based Order Tracking

Figure 3-7(c) shows the frequency-rpm spectral map. The horizontal axis

represents rpm, or rotational speed. You can map the rpm axis from the time

axis in the frequency-time spectral map by the rpm-time function. The

frequency of each order component is calculated by the following equation.

Because the relationship between rpm and frequency is a linear function,

order components appear as lines with a slope of in Figure 3-7(c).

The resonance beams appear as horizontal lines.

Applying a frequency-to-order-number transform to the frequency-rpm

spectral map generates the order-rpm spectral map, shown in Figure 3-7(d).

The order-rpm spectral map displays the order components as horizontal

lines and the resonance beams as hyperbolas.

Using the frequency-time spectral map, the frequency-rpm spectral map,

and the order-rpm spectral map, you can clearly and efficiently observe all

the order components in the entire time and rpm ranges.

Frequency

RPM

-------------

60

Order×=

RPM

-------------

60

Calculating Waveform Magnitude

The reconstructed time waveform of the selected order contains only a few

frequency components in a relatively short time interval. Therefore, the

reconstructed time waveform of the selected order displays like a sine

waveform in which the frequency and magnitude have been modulated.

In practical applications such as product testing for comparison with

reference curves, calculating the waveform magnitude as a function of rpm

is useful. The LabVIEW Order Analysis Toolset uses the root mean square

(RMS) of the time waveform to calculate the waveform magnitude and

correlate the sine waveform with the tachometer pulses to obtain the

waveform phase. Both the magnitude and the phase are computed in a short

time interval. By means of the time-rpm function, the LabVIEW Order

Analysis Toolset performs a time-to-rpm mapping operation to obtain the

waveform magnitude and phase as a function of rpm.

LabVIEW Order Analysis Toolset User Manual 3-10 ni.com

Page 41

4

Resampling-Based Order

Analysis

This chapter describes the resampling method provided by the LabVIEW

Order Analysis Toolset, determining the time instance for resampling,

resampling vibration data, and slow roll compensation.

LabVIEW Order Analysis Toolset Resampling Method

With software resampling, the LabVIEW Order Analysis Toolset enables

you to complete the following tasks:

• Resample even time-space samples to even angle-spaced samples

• Obtain magnitude and phase information for each order

Figure 4-1 illustrates the resampling-based order analysis process provided

by the LabVIEW Order Analysis Toolset.

Tachometer

Signal

Step 1:

Data

Acquisition

Vibration

Signal

© National Instruments Corporation 4-1 LabVIEW Order Analysis Toolset User Manual

Step 2:

Determine the

Time Instant

for Resampling

Time

Instant

Step 3:

Resample the

Vibration Data

Step 4(a):

Compute

Order

Spectrum

Step 4(b):

Track Magnitude

Resampled

Signal

Figure 4-1. Resampling-Based Order Analysis Diagram

and Phase of

Individual Orders

Magnitude

and Phase

Step 5:

Slow Roll

Compensation

Page 42

Chapter 4 Resampling-Based Order Analysis

Complete the following steps to perform resampling-based order analysis.

1. Acquire data samples from tachometer and noise or vibration sensors

synchronously at some constant sample rate.

2. Use the LabVIEW Order Analysis Toolset VIs to complete the

following steps:

a. Determine the pulse edges from the tachometer signal and

interpolate the pulse edges to get the time instance for resampling.

b. Perform software resampling on the vibration signal according

to the time instance determined in step a and generate the

angle-samples.

c. Perform one of the following analyses:

• Obtain the order spectrum of the signal by performing a FFT

• Track the magnitude and phase of each individual order along

d. Perform slow roll compensation to the order magnitudes and

phases, if necessary.

Refer to the Important Considerations for the Analysis of Rotating

Machinery section of Chapter 1, Introduction to the LabVIEW Order

Analysis Toolset, for information about a condition and restriction for using

the LabVIEW Order Analysis Toolset to analyze rotating machinery.

on the angle-samples.

time, revolution, or rpm.

Determining the Time Instance for Resampling

To software resample even time spaced samples into even angle spaced

samples, you first must know at what time a certain angle is reached, that

is, the time instance for resample. After processing either an analog or

digital tachometer signal, you obtain a time sequence that indicates the time

when the shaft rotates at a certain angle. For example, if a tachometer

generates N pulses in one revolution, you can express the time sequence as

a function of angle, as shown in the following equation.

2kπ

=

k

---------

t

N

th

order,

t

When you use even angle-samples to study orders, you also need to follow

the Nyquist sampling theorem. That is, if you want to study the K

resample at least 2K samples in one revolution. However, you usually need

LabVIEW Order Analysis Toolset User Manual 4-2 ni.com

Page 43

Chapter 4 Resampling-Based Order Analysis

a larger margin of samples for analysis and need to resample 2.5K samples

in one revolution.

Most of the time, a tachometer does not produce enough pulses in one

revolution. Therefore, you need to multiply the number of pulses generated

by the tachometer, that is, interpolate the time sequence for a smaller angle

interval. When you interpolate the time sequence for a smaller angle

interval, you need a constant rate integer factor interpolation filter. The

LabVIEW Order Analysis Toolset uses a cascaded integrator-comb (CIC)

filter when interpolating the time sequence for a smaller angle. The transfer

function of the CIC filter is given by the following equation.

n

L

–

1 z

-------------

n

1 z–

,

Hz()

1

-----

=

L

where L is the interpolation factor and n is the order.

The CIC filter has the advantage of only using a few samples in the original

time sequence to obtain a single, resampled point, while maintaining good

accuracy when the original signal is a narrow-band signal. Rotational speed

usually does not change very quickly in a couple of revolutions. Therefore,

the original time sequence is an exactly narrow-band signal and suitable for

interpolating with the CIC filter. You can implement the CIC filter using

only addition and subtraction operations, which makes the CIC filter very

efficient for online processing. Figure 4-2 shows the power spectrum of the

original time sequence and the CIC interpolation filter with an interpolation

factor of eight.

© National Instruments Corporation 4-3 LabVIEW Order Analysis Toolset User Manual

Page 44

Chapter 4 Resampling-Based Order Analysis

Figure 4-2. Original Time Sequence and CIC Interpolation Filter with

an Interpolation Factor of Eight

Resampling Vibration Data

The resampling operation converts a vibration signal from the time domain

into the angle domain. To resample vibration data into even angle spaced

samples, you must be able to calculate the value of the vibration signal at

any time instance.

According to the Nyquist sampling theorem, you can exactly reconstruct

the signal for all time instances using band-limited interpolation if and only

if the original signal is band limited to half of the sampling rate.

For example, a continuous time signal x(t) that is band limited to f

sampled at a sampling rate of f

samples/second yields a discrete sample

s

given by the following equation.

x

= x(nTs),

n

where T

LabVIEW Order Analysis Toolset User Manual 4-4 ni.com

= 1/fs and is the sampling time interval.

s

/2 Hz and

s

Page 45

Chapter 4 Resampling-Based Order Analysis

According to the Nyquist sampling theorem, you can exactly reconstruct

the time signal x(t) from samples x(nT

) with the following equation.

s

π f

π f

(4-1)

t()sin

s

t

s

=

where h

xˆt() xnT

is a sinc function defined by .

s

∑

Figure 4-3 shows the plot of h

Figure 4-3. hs(t) with fs = 1

()hsnTst–()

s

n

h

t() sinc fst()

s

(t) with fs = 1.

s

----------------------==

You can resample the signal at the equal angle interval time instance by

evaluating Equation 4-1 at the desired time. Before resampling, you might

need a lowpass anti-aliasing filter if the new sampling rate is lower that the

previous sampling rate.

The LabVIEW Order Analysis Toolset uses a digital adaptive-interpolation

filter to complete the entire resample process. The bandwidth of the

adaptive-interpolation filter automatically changes according to the

new sampling rate to prevent the aliasing phenomenon. The stopband

attenuation of the interpolation filter controls the accuracy of the

resampling. As the stopband attenuation becomes higher, the accuracy

of the resampled signal improves.

Slow Roll Compensation

In machine condition monitoring applications, engineers often use a

proximity probe to measure the movement of a shaft. The proximity probe

can convert the distance between the probe and the shaft into an electrical

signal.