National Instruments NI Vision 1722, NI Vision 1744, NI Vision 1762, NI Vision 1764, NI Vision 1742 User Manual

Page 1

NI Vision

NI 17xx Smart Camera User Manual

For NI 1722/1742/1744/1762/1764 Smart Cameras

NI 17xx Smart Camera User Manual

September 2013

374174A-01

Page 2

Support

Worldwide Technical Support and Product Information

ni.com

Worldwide Offices

Visit

ni.com/niglobal to access the branch office Web sites, which provide up-to-date

contact information, support phone numbers, email addresses, and current events.

National Instruments Corporate Headquarters

11500 North Mopac Expressway Austin, Texas 78759-3504 USA Tel: 512 683 0100

For further support information, refer to the Technical Support and Professional Services

appendix. To comment on National Instruments documentation, refer to the National

Instruments Web site at ni.com/info and enter the Info Code feedback.

© 2013 National Instruments. All rights reserved.

Page 3

Important Information

Warranty

NI 17xx Smart Cameras are warranted against defects in materials and workmanship for a period of one year from the date

of shipment, as evidenced by receipts or other documentation. National Instruments will, at its option, repair or replace

equipment that proves to be defective during the warranty period. This warranty includes parts and labor.

The media on which you receive National Instruments software are warranted not to fail to execute programming instructions,

due to defects in materials and workmanship, for a period of 90 days from date of shipment, as evidenced by receipts or other

documentation. National Instruments will, at its option, repair or replace software media that do not execute programming

instructions if National Instruments receives notice of such defects during the warranty period. National Instruments does not

warrant that the operation of the software shall be uninterrupted or error free.

A Return Material Authorization (RMA) number must be obtained from the factory and clearly marked on the outside of the

package before any equipment will be accepted for warranty work. National Instruments will pay the shipping costs of

returning to the owner parts which are covered by warranty.

National Instruments believes that the information in this document is accurate. The document has been carefully reviewed

for technical accuracy. In the event that technical or typographical errors exist, National Instruments reserves the right to

make changes to subsequent editions of this document without prior notice to holders of this edition. The reader should

consult National Instruments if errors are suspected. In no event shall National Instruments be liable for any damages arising

out of or related to this document or the information contained in it.

XCEPT AS SPECIFIED HEREIN, NATIONAL INSTRUMENTS MAKES NO WARRANTIES, EXPRESS OR IMPLIED, AND SPECIFICALLY DISCLAIMS ANY

E

WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. CUSTOMER’S RIGHT TO RECOVER DAMAGES CAUSED BY FAULT

OR NEGLIGENCE ON THE PART OF NATIONAL INSTRUMENTS SHALL BE LIMITED TO THE AMOUNT THERETOFORE PAID BY THE CUSTOMER.

ATIONAL INSTRUMENTS WILL NOT BE LIABLE FOR DAMAGES RESULTING FROM LOSS OF DATA, PROFITS, USE OF PRODUCTS, OR INCIDENTAL

N

OR CONSEQUENTIAL DAMAGES, EVEN IF ADVISED OF THE POSSIBILITY THEREOF. This limitation of the liability of National Instruments

will apply regardless of the form of action, whether in contract or tort, including negligence. Any action against National

Instruments must be brought within one year after the cause of action accrues. National Instruments shall not be liable for any

delay in performance due to causes beyond its reasonable control. The warranty provided herein does not cover damages,

defects, malfunctions, or service failures caused by owner’s failure to follow the National Instruments installation, operation,

or maintenance instructions; owner’s modification of the product; owner’s abuse, misuse, or negligent acts; and power failure

or surges, fire, flood, accident, actions of third parties, or other events outside reasonable control.

Copyright

Under the copyright laws, this publication may not be reproduced or transmitted in any form, electronic or mechanical,

including photocopying, recording, storing in an information retrieval system, or translating, in whole or in part, without the

prior written consent of National Instruments Corporation.

National Instruments respects the intellectual property of others, and we ask our users to do the same. NI software is protected

by copyright and other intellectual property laws. Where NI software may be used to reproduce software or other materials

belonging to others, you may use NI software only to reproduce materials that you may reproduce in accordance with the

terms of any applicable license or other legal restriction.

End-User License Agreements and Third-Party Legal Notices

You can find end-user license agreements (EULAs) and third-party legal notices in the following locations:

• Notices are located in the

directories.

• EULAs are located in the

•Review

<National Instruments>\_Legal Information.txt for more information on including legal

information in installers built with NI products.

Trademarks

Refer to the NI Trademarks and Logo Guidelines at ni.com/trademarks for more information on National Instruments

trademarks.

ARM, Keil, and µVision are trademarks or registered of ARM Ltd or its subsidiaries.

LEGO, the LEGO logo, WEDO, and MINDSTORMS are trademarks of the LEGO Group. ©2013 The LEGO Group.

TETRIX by Pitsco is a trademark of Pitsco, Inc.©2013

FIELDBUS FOUNDATION

EtherCAT

CANopen

DeviceNet

Go!, SensorDAQ, and Vernier are registered trademarks of Vernier Software & Technology. Vernier Software & Technology

and

Xilinx is the registered trademark of Xilinx, Inc.

Taptite and Trilobular are registered trademarks of Research Engineering & Manufacturing Inc.

FireWire

Linux

®

is a registered trademark of and licensed by Beckhoff Automation GmbH.

®

is a registered Community Trademark of CAN in Automation e.V.

™

and EtherNet/IP™ are trademarks of ODVA.

vernier.com are trademarks or trade dress.

®

is the registered trademark of Apple Inc.

®

is the registered trademark of Linus Torvalds in the U.S. and other countries.

<National Instruments>\_Legal Information and <National Instruments>

<National Instruments>\Shared\MDF\Legal\license directory.

™

and FOUNDATION™ are trademarks of the Fieldbus Foundation.

Page 4

Handle Graphics®, MATLAB®, Real-Time Workshop®, Simulink®, Stateflow®, and xPC TargetBox® are registered

trademarks, and TargetBox

Tektronix

The Bluetooth

The ExpressCard

®

, Tek, and Tektronix, Enabling Technology are registered trademarks of Tektronix, Inc.

®

word mark is a registered trademark owned by the Bluetooth SIG, Inc.

™

word mark and logos are owned by PCMCIA and any use of such marks by National Instruments is under

™

and Target Language Compiler™ are trademarks of The MathWorks, Inc.

license.

The mark LabWindows is used under a license from Microsoft Corporation. Windows is a registered trademark of Microsoft

Corporation in the United States and other countries.

Other product and company names mentioned herein are trademarks or trade names of their respective companies.

Members of the National Instruments Alliance Partner Program are business entities independent from National Instruments

and have no agency, partnership, or joint-venture relationship with National Instruments.

Patents

For patents covering National Instruments products/technology, refer to the appropriate location: Help»Patents in your

software, the patents.txt file on your media, or the National Instruments Patent Notice at ni.com/patents.

Export Compliance Information

Refer to the Export Compliance Information at ni.com/legal/export-compliance for the National Instruments

global trade compliance policy and how to obtain relevant HTS codes, ECCNs, and other import/export data.

WARNING REGARDING USE OF NATIONAL INSTRUMENTS PRODUCTS

(1) NATIONAL INSTRUMENTS PRODUCTS ARE NOT DESIGNED WITH COMPONENTS AND TESTING FOR A

LEVEL OF RELIABILITY SUITABLE FOR USE IN OR IN CONNECTION WITH SURGICAL IMPLANTS OR AS

CRITICAL COMPONENTS IN ANY LIFE SUPPORT SYSTEMS WHOSE FAILURE TO PERFORM CAN

REASONABLY BE EXPECTED TO CAUSE SIGNIFICANT INJURY TO A HUMAN.

(2) IN ANY APPLICATION, INCLUDING THE ABOVE, RELIABILITY OF OPERATION OF THE SOFTWARE

PRODUCTS CAN BE IMPAIRED BY ADVERSE FACTORS, INCLUDING BUT NOT LIMITED TO FLUCTUATIONS

IN ELECTRICAL POWER SUPPLY, COMPUTER HARDWARE MALFUNCTIONS, COMPUTER OPERATING

SYSTEM SOFTWARE FITNESS, FITNESS OF COMPILERS AND DEVELOPMENT SOFTWARE USED TO

DEVELOP AN APPLICATION, INSTALLATION ERRORS, SOFTWARE AND HARDWARE COMPATIBILITY

PROBLEMS, MALFUNCTIONS OR FAILURES OF ELECTRONIC MONITORING OR CONTROL DEVICES,

TRANSIENT FAILURES OF ELECTRONIC SYSTEMS (HARDWARE AND/OR SOFTWARE), UNANTICIPATED

USES OR MISUSES, OR ERRORS ON THE PART OF THE USER OR APPLICATIONS DESIGNER (ADVERSE

FACTORS SUCH AS THESE ARE HEREAFTER COLLECTIVELY TERMED “SYSTEM FAILURES”). ANY

APPLICATION WHERE A SYSTEM FAILURE WOULD CREATE A RISK OF HARM TO PROPERTY OR PERSONS

(INCLUDING THE RISK OF BODILY INJURY AND DEATH) SHOULD NOT BE RELIANT SOLELY UPON ONE

FORM OF ELECTRONIC SYSTEM DUE TO THE RISK OF SYSTEM FAILURE. TO AVOID DAMAGE, INJURY, OR

DEATH, THE USER OR APPLICATION DESIGNER MUST TAKE REASONABLY PRUDENT STEPS TO PROTECT

AGAINST SYSTEM FAILURES, INCLUDING BUT NOT LIMITED TO BACK-UP OR SHUT DOWN MECHANISMS.

BECAUSE EACH END-USER SYSTEM IS CUSTOMIZED AND DIFFERS FROM NATIONAL INSTRUMENTS'

TESTING PLATFORMS AND BECAUSE A USER OR APPLICATION DESIGNER MAY USE NATIONAL

INSTRUMENTS PRODUCTS IN COMBINATION WITH OTHER PRODUCTS IN A MANNER NOT EVALUATED

OR CONTEMPLATED BY NATIONAL INSTRUMENTS, THE USER OR APPLICATION DESIGNER IS

ULTIMATELY RESPONSIBLE FOR VERIFYING AND VALIDATING THE SUITABILITY OF NATIONAL

INSTRUMENTS PRODUCTS WHENEVER NATIONAL INSTRUMENTS PRODUCTS ARE INCORPORATED IN A

SYSTEM OR APPLICATION, INCLUDING, WITHOUT LIMITATION, THE APPROPRIATE DESIGN, PROCESS

AND SAFETY LEVEL OF SUCH SYSTEM OR APPLICATION.

Page 5

Compliance

Electromagnetic Compatibility Information

This hardware has been tested and found to comply with the applicable regulatory requirements and limits

for electromagnetic compatibility (EMC) as indicated in the hardware’s Declaration of Conformity (DoC)

These requirements and limits are designed to provide reasonable protection against harmful interference

when the hardware is operated in the intended electromagnetic environment. In special cases, for example

when either highly sensitive or noisy hardware is being used in close proximity, additional mitigation

measures may have to be employed to minimize the potential for electromagnetic interference.

While this hardware is compliant with the applicable regulatory EMC requirements, there is no guarantee

that interference will not occur in a particular installation. To minimize the potential for the hardware to

cause interference to radio and television reception or to experience unacceptable performance degradation,

install and use this hardware in strict accordance with the instructions in the hardware documentation and

the DoC

If this hardware does cause interference with licensed radio communications services or other nearby

electronics, which can be determined by turning the hardware off and on, you are encouraged to try to correct

the interference by one or more of the following measures:

• Reorient the antenna of the receiver (the device suffering interference).

• Relocate the transmitter (the device generating interference) with respect to the receiver.

• Plug the transmitter into a different outlet so that the transmitter and the receiver are on different branch

Some hardware may require the use of a metal, shielded enclosure (windowless version) to meet the EMC

requirements for special EMC environments such as, for marine use or in heavy industrial areas. Refer to

the hardware’s user documentation and the DoC

When the hardware is connected to a test object or to test leads, the system may become more sensitive to

disturbances or may cause interference in the local electromagnetic environment.

Operation of this hardware in a residential area is likely to cause harmful interference. Users are required to

correct the interference at their own expense or cease operation of the hardware.

Changes or modifications not expressly approved by National Instruments could void the user’s right to

operate the hardware under the local regulatory rules.

1

.

circuits.

1

for product installation requirements.

1

.

1

The Declaration of Conformity (DoC) contains important EMC compliance information and instructions

for the user or installer. To obtain the DoC for this product, visit

model number or product line, and click the appropriate link in the Certification column.

ni.com/certification, search by

Page 6

Contents

About This Manual

Related Documentation .................................................................................................... xi

Hardware Documents ............................................................................................... xi

NI Vision Builder for Automated Inspection Documents ........................................ xi

LabVIEW and NI Vision Development Module Documents................................... xii

NI Vision Acquisition Software Documents ............................................................ xii

Chapter 1

NI Smart Camera Overview

Hardware Overview.......................................................................................................... 1-1

Software Overview ........................................................................................................... 1-3

NI Vision Builder for Automated Inspection ........................................................... 1-3

LabVIEW.................................................................................................................. 1-3

LabVIEW Real-Time Module .......................................................................... 1-4

NI Vision Development Module ...................................................................... 1-4

NI Vision Acquisition Software ....................................................................... 1-4

Chapter 2

Power and I/O

POWER-I/O Connector.................................................................................................... 2-1

NI Smart Camera Power Requirements............................................................................ 2-2

Isolated Inputs................................................................................................................... 2-3

Isolated Outputs ................................................................................................................2-4

Protecting Against Inductive Loads ......................................................................... 2-5

Connecting to Serial Devices ........................................................................................... 2-5

Communicating with the Console ............................................................................ 2-6

Connecting to a Quadrature Encoder................................................................................ 2-6

Chapter 3

NI Smart Camera Image Sensor

Field of View .................................................................................................................... 3-1

Image Sensor Spectral Response ...................................................................................... 3-3

Partial Scan Mode............................................................................................................. 3-3

Binning ............................................................................................................................. 3-4

Gain .................................................................................................................................. 3-4

Hardware Binarization...................................................................................................... 3-5

© National Instruments | vii

Page 7

Contents

Chapter 4

Lighting

Lighting Connector ........................................................................................................... 4-1

Direct Drive Lighting Controller ......................................................................................4-2

Lighting Files ............................................................................................................ 4-3

Selecting a Light ....................................................................................................... 4-4

Connecting a Light to the Direct Drive Lighting Controller .................................... 4-5

External Lighting Controllers ...........................................................................................4-6

Connecting an External Lighting Controller to the NI Smart Camera ..................... 4-7

Chapter 5

Image Acquisition

Exposure ........................................................................................................................... 5-1

Acquiring Images.............................................................................................................. 5-2

Internal Timing ......................................................................................................... 5-2

External Trigger ........................................................................................................ 5-2

Maximum Frame Rate ...................................................................................................... 5-5

Determining the Maximum Frame Rate ................................................................... 5-5

Determining the Scan Mode ..................................................................................... 5-6

Determining the Exposure Time............................................................................... 5-6

Determining the Lighting Mode ............................................................................... 5-6

Determining the Trigger Delay ................................................................................. 5-7

Calculating the Minimum Frame Period .................................................................. 5-7

Chapter 6

LEDs and DIP Switches

Understanding the LED Indicators ................................................................................... 6-1

Device Initialization.................................................................................................. 6-1

POWER LED............................................................................................................ 6-2

STATUS LED........................................................................................................... 6-2

IMG ACQ LED ........................................................................................................ 6-3

PASS LED ................................................................................................................6-3

FAIL LED................................................................................................................. 6-4

Configuring DIP Switches ................................................................................................ 6-4

SAFE MODE Switch................................................................................................ 6-4

IP RESET Switch...................................................................................................... 6-5

NO APP Switch ........................................................................................................ 6-5

CONSOLE Switch .................................................................................................... 6-6

viii | ni.com

Page 8

NI 17xx Smart Camera User Manual

Chapter 7

Ethernet Ports

Ethernet LEDs .................................................................................................................. 7-2

ACTIVITY/LINK LED ............................................................................................ 7-2

SPEED LED ............................................................................................................. 7-2

DHCP and Static IP Address Assignment ........................................................................ 7-3

Firewall Considerations ............................................................................................ 7-3

Subnet Considerations .............................................................................................. 7-4

Chapter 8

Thermal Considerations and Mounting

Thermal Considerations.................................................................................................... 8-1

Mounting the NI Smart Camera ....................................................................................... 8-2

Appendix A

Specifications

Appendix B

Troubleshooting

Appendix C

Maintenance

Appendix D

Technical Support and Professional Services

Glossary

Index

© National Instruments | ix

Page 9

About This Manual

This manual describes the electrical and mechanical aspects of the National Instruments 17xx

Smart Camera. Refer to Getting Started with the NI 17xx Smart Camera for smart camera and

accessory installation information.

Related Documentation

The following documents contain information that you may find helpful as you read this manual:

Hardware Documents

• Getting Started with the NI 17xx Smart Camera—Contains important safety information

and information about installing and configuring NI Smart Cameras and accessories. You

can access this manual by navigating to Start»All Programs»National Instruments»

Vision»Documentation»NI-IMAQ.

• NI Developer Zone—Contains example programs, tutorials, technical presentations, the

Instrument Driver Network, a measurement glossary, an online magazine, a product

advisor, and a community area where you can share ideas, questions, and source code with

developers around the world. The NI Developer Zone is located on the National

Instruments Web site at

NI Developer Zone:

ni.com/zone. You can find the following documents in the

– Using the NI 17xx Smart Camera Direct Drive Lighting Controller—Demonstrates

how to utilize the Direct Drive lighting controller feature on the NI 17xx Smart

Camera with LabVIEW or Vision Builder for Automated Inspection.

– A Practical Guide to Machine Vision Lighting—Explains machine vision lighting

concepts and theories.

NI Vision Builder for Automated Inspection Documents

• NI Vision Builder for Automated Inspection Tutorial—Describes Vision Builder for

Automated Inspection and provides step-by-step instructions for solving common visual

inspection tasks, such as inspection, gauging, part presence, guidance, and counting.

• NI Vision Builder for Automated Inspection: Configuration Help—Contains information

about using the Vision Builder for Automated Inspection Configuration Interface to create

a machine vision application.

• NI Vision Builder for Automated Inspection: Inspection Help—Contains information about

running applications created with Vision Builder for Automated Inspection in the Vision

Builder Automated Inspection Interface.

© National Instruments | xi

Page 10

About This Manual

LabVIEW and NI Vision Development Module

Documents

• LabVIEW Help—Includes information about LabVIEW programming concepts,

step-by-step instructions for using LabVIEW, and reference information about LabVIEW

VIs, functions, palettes, menus, and tools.

• Getting Started with LabVIEW—Use this manual as a tutorial to familiarize yourself with

the LabVIEW graphical programming environment and the basic LabVIEW features you

use to build data acquisition and instrument control applications.

• Getting Started with the LabVIEW Real-Time Module—Use this manual as a tutorial to

familiarize yourself with the LabVIEW Real-Time Module and the basic Real-Time

Module features you use to build real-time applications.

• NI Vision Concepts Manual—Describes the basic concepts of image analysis, image

processing, and machine vision. This document also contains in-depth discussions about

imaging functions for advanced users.

• NI Vision for LabVIEW Help—Describes how to create machine vision and image

processing applications in LabVIEW using the Vision Development Module. The help file

guides you through tasks beginning with setting up your imaging system to taking

measurements. It also describes how to create a real-time vision application using NI Vision

with the LabVIEW Real-Time Module and contains reference information about NI Vision

for LabVIEW palettes and VIs.

NI Vision Acquisition Software Documents

• NI-IMAQ VI Reference Help—Contains reference information about the LabVIEW VIs

and properties for NI-IMAQ driver software.

• Measurement & Automation Explorer Help for NI-IMAQ—Describes how to configure

NI-IMAQ driver software, NI image acquisition devices, and NI Smart Cameras using

Measurement & Automation Explorer.

xii | ni.com

Page 11

1

NI Smart Camera Overview

This chapter provides an overview of the features and components of the National Instruments

Smart Camera. Refer to Getting Started with the NI 17xx Smart Camera for smart camera and

accessory installation information.

Hardware Overview

The NI Smart Camera is available in several different configurations. When a feature pertains

only to specific smart camera models, a list at the beginning of the section shows which smart

camera models support the feature.

All smart camera models incorporate an image sensor, processor, and digital I/O in a compact,

rugged housing.

Table 1-1 shows the differentiating features for each smart camera model.

Table 1-1. NI Smart Camera Models

NI Smart

Camera

Model Processor Image Sensor

NI 1722 400 MHz PowerPC 1/3 inch Sony ICX424AL

CCD Monochrome

640 × 480 pixels (VGA)

NI 1742 533 MHz PowerPC 1/3 inch Sony ICX424AL

CCD Monochrome

640 × 480 pixels (VGA)

NI 1744 533 MHz PowerPC 1/2 inch Sony ICX205AL

CCD Monochrome

1,280 × 1,024 pixels (SXGA)

NI 1762 533 MHz PowerPC

and 720 MHz DSP

NI 1764 533 MHz PowerPC

and 720 MHz DSP

1/3 inch Sony ICX424AL

CCD Monochrome

640 × 480 pixels (VGA)

1/2 inch Sony ICX205AL

CCD Monochrome

1,280 × 1,024 pixels (SXGA)

Direct Drive

Lighting

Controller

No No

Ye s Ye s

Ye s Ye s

Ye s Ye s

Ye s Ye s

Quadrature

Encoder

Support

© National Instruments | 1-1

Page 12

Chapter 1 NI Smart Camera Overview

For more information about the image sensors, refer to Chapter 3, NI Smart Camera Image

Sensor. For complete smart camera specifications, refer to Appendix A, Specifications.

All smart cameras have an RS-232 serial port, Gigabit Ethernet ports, and use a standard

C-mount lens. Some smart camera models also include the Direct Drive lighting controller and

support for quadrature encoders. The Direct Drive lighting controller is an integrated controller

to directly power a variety of third-party current-controlled lights. Refer to Chapter 4, Lighting,

for more information about the Direct Drive lighting controller. The smart camera also has

one 5 V TTL strobe output and one unregulated 24 V strobe output for lighting control.

The smart camera also includes LEDs for communicating system status, four DIP switches to

specify startup options, isolated inputs, and isolated outputs for connecting to external devices.

Refer to Chapter 6, LEDs and DIP Switches, for more information about the LEDs and DIP

switches. Refer to Chapter 2, Power and I/O, for more information about the digital I/O

capabilities of the smart camera.

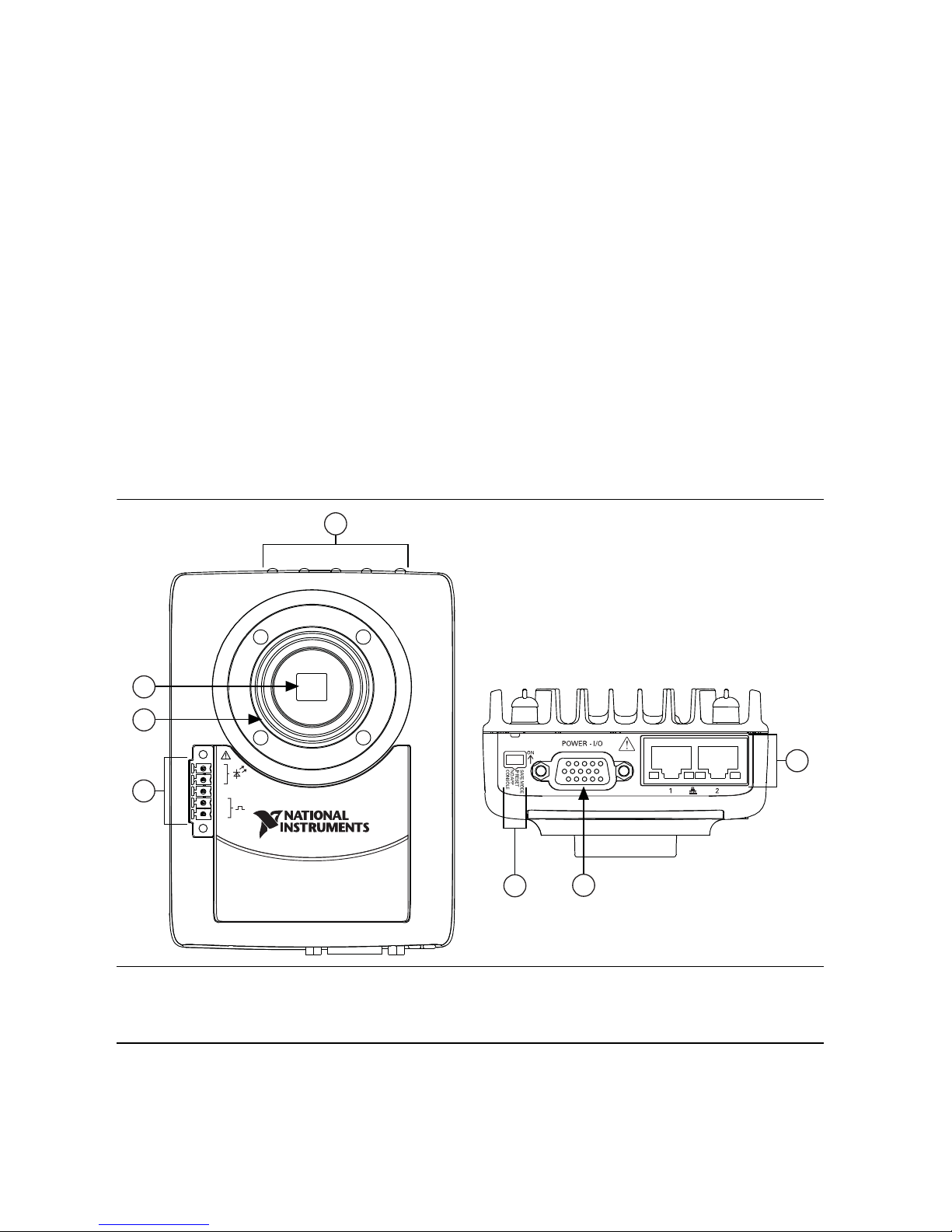

Figure 1-1 shows the smart camera.

Figure 1-1. NI Smart Camera

4

1

2

-

+

3

GND

5V

24V

NI 17XX SMART CAMERA

5

6

7

1 Image Sensor

2 Standard C Lens Mount

3 Lighting Connector

4LEDs

1-2 | ni.com

5 DIP Switches

6 POWER-I/O Connector

7 Ethernet Ports

Page 13

NI 17xx Smart Camera User Manual

Vision Builder

for

Automated Inspection

LabVIEW

LabVIEW Real-Time Module

NI Vision Development Module

NI Vision Acquisition Software

or

Software Overview

Developing applications with the NI Smart Camera requires one of the following software

options:

The installation and configuration process for each development environment is different. Refer

to Getting Started with the NI 17xx Smart Camera for installation and configuration instructions.

The following sections describe the software options. For detailed information about individual

software packages, refer to the documentation specific to the package.

Note Vision Builder for Automated Inspection and NI Vision Acquisition Software

are included with the smart camera. LabVIEW, the LabVIEW Real-Time Module,

and the NI Vision Development Module are sold separately.

NI Vision Builder for Automated Inspection

Vision Builder for Automated Inspection (Vision Builder AI) is configurable machine vision

software you can use to configure the NI Smart Camera and prototype, benchmark, and deploy

machine vision applications.

Creating applications in Vision Builder AI does not require programming. Vision Builder AI

allows you to easily configure and benchmark a sequence of visual inspection steps, as well as

deploy the visual inspection system for automated inspection. With Vision Builder AI, you can

perform powerful visual inspection tasks and make decisions based on the results of individual

tasks. You can also migrate your configured inspection to LabVIEW, extending the capabilities

of your applications if necessary.

LabVIEW

LabVIEW is a graphical programming environment for developing flexible and scalable

applications. To develop machine vision applications with the NI Smart Camera and LabVIEW,

you must have the following add-on modules: LabVIEW Real-Time Module, NI Vision

Development Module, and Vision Acquisition Software.

© National Instruments | 1-3

Page 14

Chapter 1 NI Smart Camera Overview

LabVIEW Real-Time Module

The LabVIEW Real-Time Module combines LabVIEW graphical programming with the power

of Real-Time (RT) hardware, enabling you to build deterministic, real-time systems. You

develop VIs in LabVIEW and embed the VIs on RT targets, such as the NI Smart Camera. The

RT target runs VIs without a user interface and offers a stable platform for real-time VIs. For

more information about the LabVIEW Real-Time Module, refer to the LabVIEW Help.

NI Vision Development Module

The NI Vision Development Module is an image acquisition, processing, and analysis library of

hundreds of functions for the following common machine vision tasks:

• Pattern matching

• Particle analysis

• Gauging

• Taking measurements

• Grayscale, color, and binary image display

With the NI Vision Development Module you can acquire, display, and store images as well as

perform image analysis and processing. Using the NI Vision Development Module, imaging

novices and experts can program the most basic or complicated image applications without

knowledge of particular algorithm implementations.

For information about how to use the NI Vision Development Module with the

LabVIEW Real-Time Module, refer to the NI Vision for LabVIEW Help.

NI Vision Acquisition Software

The NI Vision Acquisition Software CD contains Measurement & Automation Explorer (MAX)

configuration software and NI-IMAQ driver software.

Use MAX to configure the NI Smart Camera. You can set the IP address, update software on the

smart camera, configure triggering, and set up the lighting features. For more information about

MAX, refer to the Measurement & Automation Explorer Help for NI-IMAQ

NI-IMAQ is the interface path between the application software and the smart camera.

NI-IMAQ also controls the I/O and image acquisition on the smart camera.

NI-IMAQ includes an extensive library of VIs you can call from LabVIEW. These VIs include

routines for video configuration, continuous and single-shot image acquisition, and trigger

control.

The NI-IMAQ driver software performs all functions necessary for acquiring and saving images

but does not perform image analysis. NI-IMAQ features both high-level and low-level functions.

A function that acquires images in single-shot or continuous mode is an example of a high-level

function. A function that requires advanced understanding of image acquisition, such as

configuring an image sequence, is an example of a low-level function.

For information about using NI-IMAQ to configure an acquisition, refer to the NI-IMAQ VI

Reference Help.

1-4 | ni.com

Page 15

2

Power and I/O

This chapter provides information about the NI Smart Camera POWER-I/O connector,

connecting isolated inputs and isolated outputs, and connecting to serial devices and to

quadrature encoders.

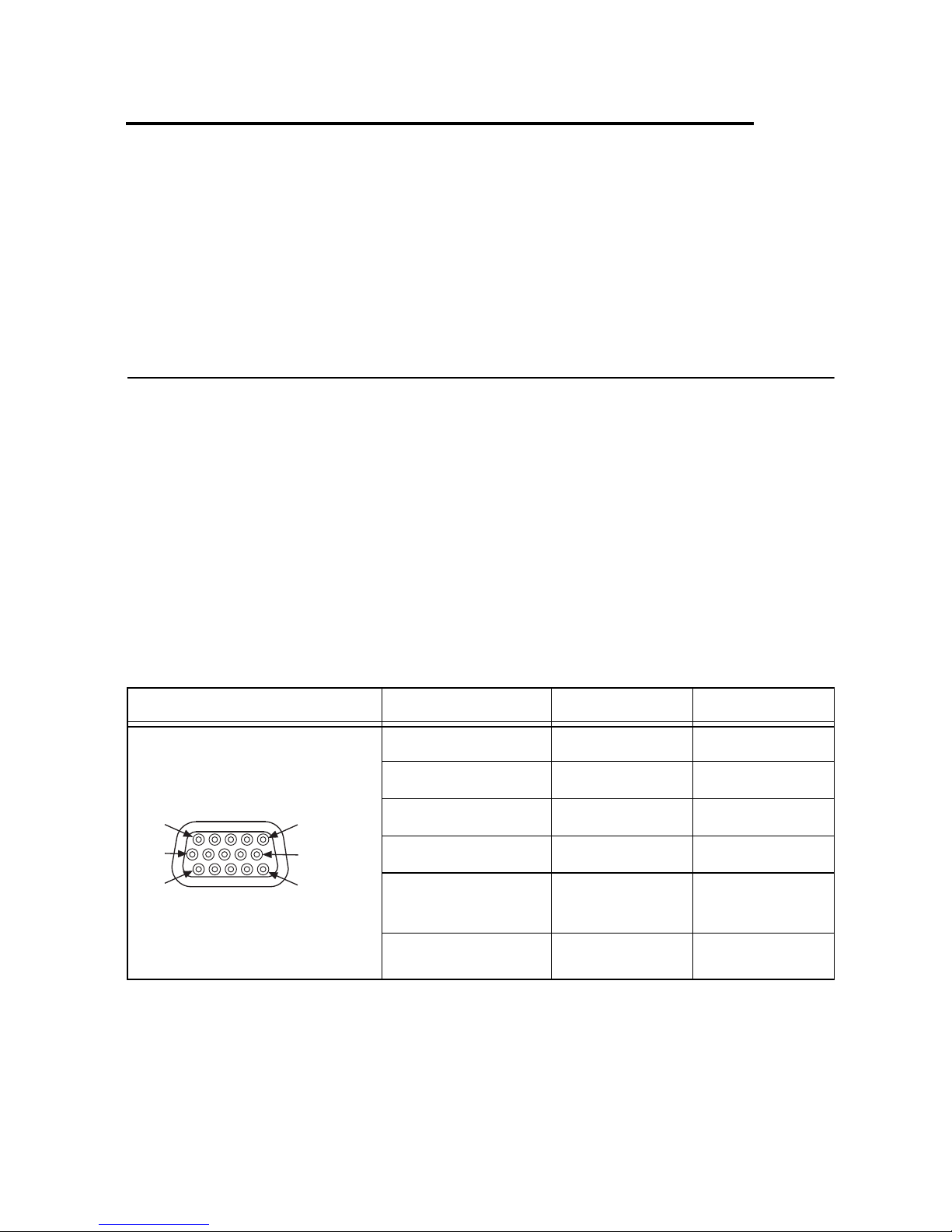

POWER-I/O Connector

The POWER-I/O connector provides signal connections for power and I/O, including isolated

inputs and outputs, quadrature encoders, and serial devices. The POWER-I/O connector is a

standard female high-density 15-pin D-SUB connector. Table 2-1 shows the pin organization for

the POWER-I/O connector. The two pins used to connect to a power supply, pin 15 and pin 5,

are also shown in the table. Refer to Getting Started with the NI 17xx Smart Camera for

information about connecting a power supply to the NI Smart Camera.

Table 2-1 lists the signal names and pin numbers for the 15-pin POWER-I/O connector. The

table also lists the wire colors for the 15-pin D-SUB pigtail cable (part number 197818-05), sold

separately by National Instruments. Cables sold by other manufacturers could have different

wire colors.

Table 2-1. POWER-I/O Connector Signal Descriptions

Connector Diagram Signal Name Pin Number Wire Color

+24 V 5 Red

COM 15 Black

11

15 (COM)

6

1

10

5 (+24 V)

RS232_TXD 10 Pink

RS232_RXD 14 Black/White

TrigIn+

IsoIn(0)+

IsoIn(1)+ 8 Orange

2 Brown

© National Instruments | 2-1

Page 16

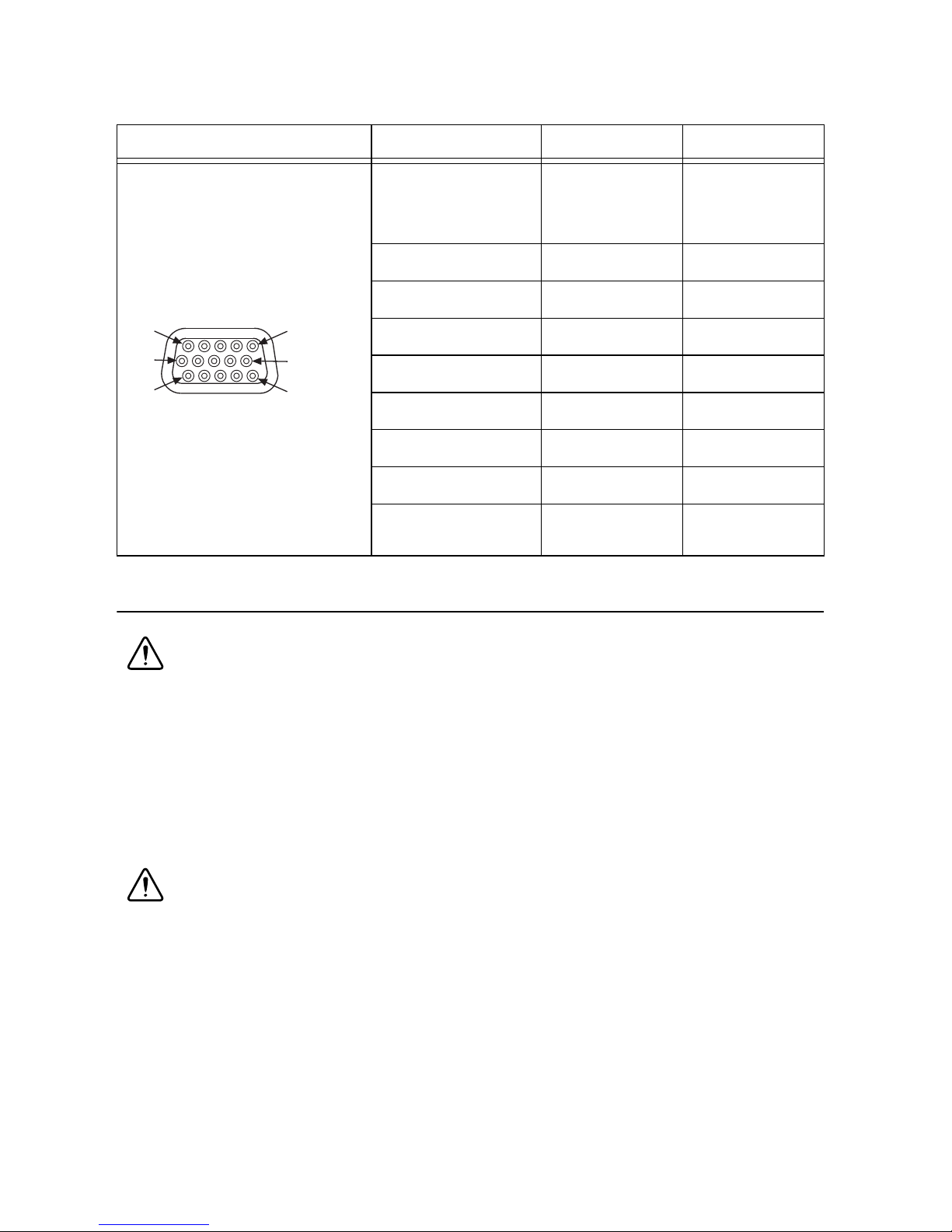

Chapter 2 Power and I/O

Table 2-1. POWER-I/O Connector Signal Descriptions (Continued)

Connector Diagram Signal Name Pin Number Wire Color

TrigIn-

12 Light Green

IsoIn(0)IsoIn(1)-

IsoOut(0)+ 6 Yel l ow

IsoOut(0)- 1 Green

11

6

15 (COM)

10

IsoOut(1)+ 11 Light Blue

IsoOut(1)- 7 Gray

1

5 (+24 V)

PhaseA+ 3 Blue

PhaseA- 13 Brown/White

PhaseB+ 9 Purple

PhaseB- 4 White

NI Smart Camera Power Requirements

Caution Use the NI Smart Camera only with a 24 VDC, UL listed, limited power

source (LPS) supply. The power supply should bear the UL listed mark, LPS. The

power supply must meet any safety and compliance requirements for the country

of use.

The smart camera uses a nominal 24 VDC power source. The smart camera accepts power within

the range of the industry standard IEC 1311 input power specification (24 V +20%/-15% with

an additional allowance for an AC peak of +5%). Refer to Appendix A, Specifications, for

complete power requirement specifications.

Caution The 24 V external lighting strobe is an unregulated output dependent on

the range of the power supply provided to the smart camera. If the power provided to

the smart camera is +20%/-15% with +5% AC ripple, the external lighting strobe

output could be as high as 30 V. If the provided power exceeds the input voltage

specifications of the third-party lighting controller, do not connect the 24 V lighting

strobe output to the controller to prevent damage to the controller. Use a power

supply with tolerances that meet the requirements of the controller, or use the 5 V

external lighting strobe.

2-2 | ni.com

Page 17

NI 17xx Smart Camera User Manual

Sensor

Power

Sensor

Common

PNP (Sourcing)

Output Device

NI 17xx

TrigIn+

IsoIn(0)+

IsoIn(1)+

TrigIn–

IsoIn(0)–

IsoIn(1)–

If you are using the Direct Drive lighting controller, the power supply wattage must be sufficient

to power both the camera and the light. The power required by the light can be significantly more

than the power required by the smart camera.

Note The NI Smart Camera will revert to the default timestamp if power is

interrupted and the device is not connected to a network. Ensure your power supply

is not interrupted, or the device is connected to a networked or local SMTP server, to

maintain accurate timestamps.

Isolated Inputs

Caution Do not apply a voltage greater than 30 VDC to the isolated inputs.

Voltages greater than 30 VDC may damage the NI Smart Camera.

Caution The isolated inputs and outputs on the smart camera provide an easy

means for preventing ground loops that could degrade signal integrity. The isolation

on the smart camera is not safety isolation.

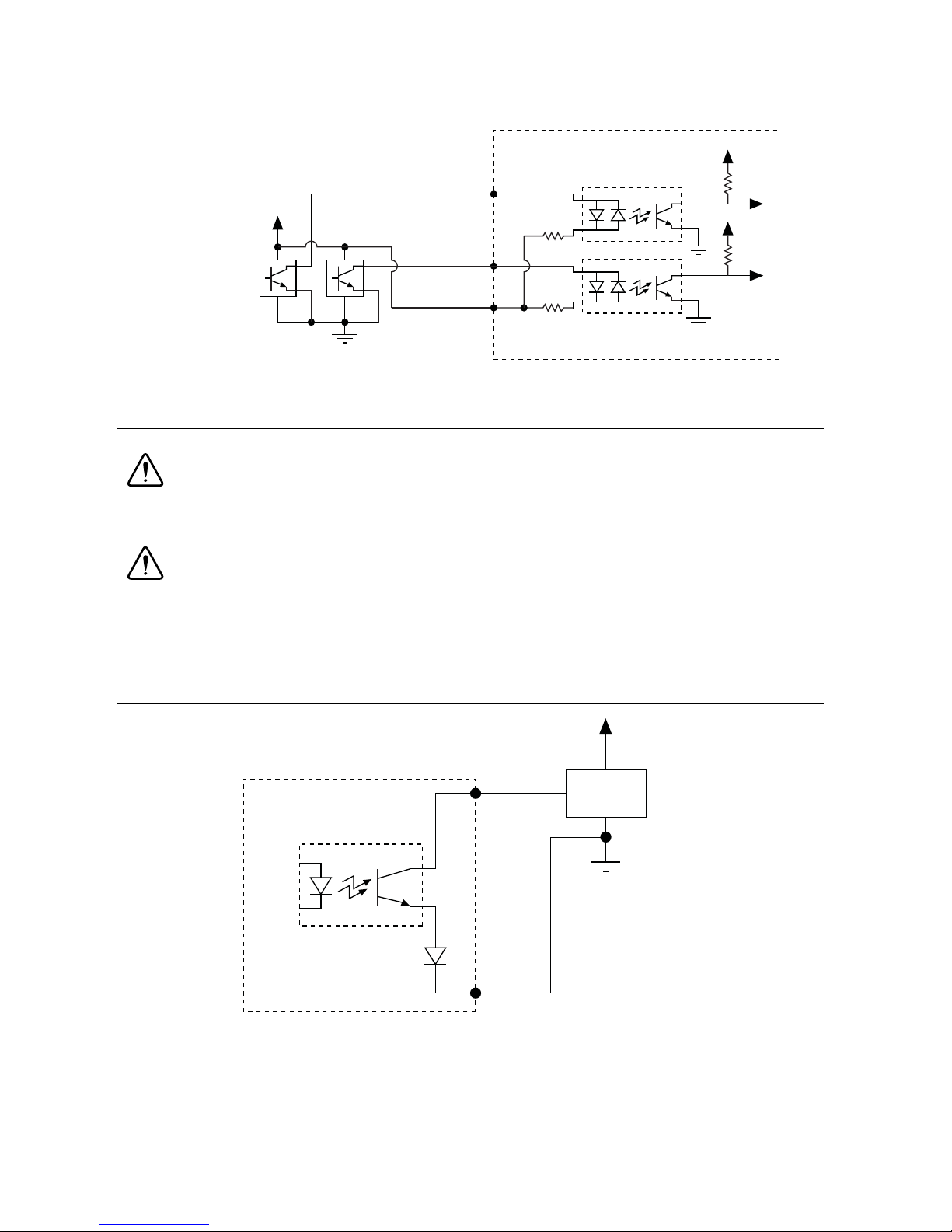

You can wire an isolated input to both sourcing and sinking output devices. Refer to Figures 2-1

and 2-2 for wiring examples by output type. Refer to Appendix A, Specifications, for current

requirements.

Isolated inputs are not compatible with 5 V logic.

Figure 2-1. Connecting External Sourcing Output Sensors to Isolated Inputs

© National Instruments | 2-3

Page 18

Chapter 2 Power and I/O

Sensor

Power

Sensor

Common

NI 17xx

NPN (Sinking)

Output Device

TrigIn+

IsoIn(0)+

IsoIn(1)+

TrigIn–

IsoIn(0)–

IsoIn(1)–

Sourcing

Load

IsoOut+

IsoOut–

NI 17xx

Sensor

Power

Sensor

Common

Figure 2-2. Connecting External Sinking Output Sensors to Isolated Inputs

Isolated Outputs

Caution Do not power the load connected to the isolated outputs with any external

power supply greater than 30 VDC. Voltages greater than 30 VDC may damage the

NI Smart Camera.

Caution The isolated inputs and outputs on the smart camera provide an easy

means for preventing ground loops that could degrade signal integrity. The isolation

on the smart camera is not safety isolation.

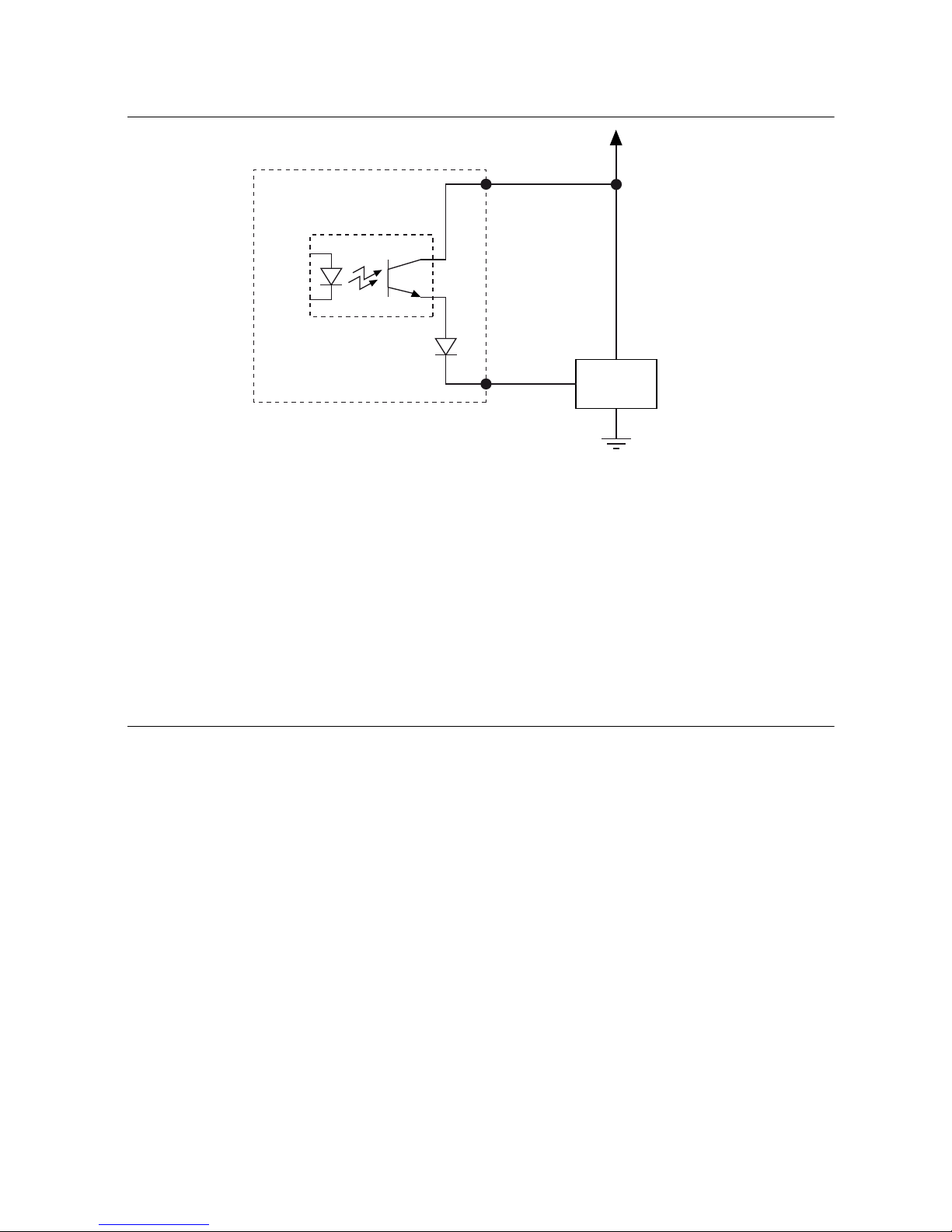

The isolated outputs can be used to drive external loads, as shown in Figures 2-3 and 2-4.

Figure 2-3. Connecting an Isolated Output to a Sourcing External Load

2-4 | ni.com

Page 19

Figure 2-4. Connecting an Isolated Output to a Sinking External Load

IsoOut+

IsoOut–

NI 17xx

Sensor

Power

Sensor

Common

Sinking

Load

Protecting Against Inductive Loads

NI 17xx Smart Camera User Manual

When an inductive load, such as a relay or solenoid, is connected to an output, a large

counter-electromotive force may occur at switching time due to energy stored in the inductive

load. This flyback voltage can damage the outputs and the power supply.

To limit flyback voltages at the inductive load, install a flyback diode across the load. Mount the

flyback diode as close to the load as possible. Use this protection method if you connect any of

the isolated outputs to an inductive load.

Connecting to Serial Devices

Use the RS232_RXD and RS232_TXD signals on the POWER-I/O connector for serial

communication. Connect the RS232_RXD signal on the NI Smart Camera to the Tx signal on

your serial device. Connect the RS232_TXD signal on the smart camera to the Rx signal on your

serial device. Connect COM on the smart camera to the ground of your serial device.

When the CONSOLE DIP switch is in the OFF position, you can use the NI-Serial driver for

serial communication. You must install the NI-Serial software on the smart camera; it is not

installed by default. Refer to the Serial Hardware and Software Help for information about

installing the NI-Serial software on LabVIEW Real-Time targets, such as the smart camera. To

open this document, navigate to Start»All Programs» National Instruments»NI-Serial»

NI-Serial Help.

© National Instruments | 2-5

Page 20

Chapter 2 Power and I/O

Communicating with the Console

When the CONSOLE DIP switch is in the ON position, you can read device information from

the NI Smart Camera during startup, such as the IP address and firmware version, through a

serial port terminal program. Ensure that the serial port terminal program is configured to the

following settings:

• 9,600 bits per second

• Eight data bits

• No parity

• One stop bit

• No flow control

Connecting to a Quadrature Encoder

This section applies only to the following NI Smart Cameras:

• NI 1742

• NI 1744

• NI 1762

• NI 1764

Connect RS-422 compatible differential quadrature encoders to the NI 17xx Smart Camera to

provide positional information. A quadrature encoder uses two output channels, Phase A and

Phase B, to track the position of a rotary shaft. Generally, the shaft is coupled to a motor drive

that controls the movement of an object. By providing Phase A and Phase B signals to the smart

camera, you can obtain a precise measurement of the object position. Using a quadrature encoder

gives you the ability to specify your trigger delay in terms of positional units—such as inches or

centimeters, after applying the resolution information of your encoder—rather than time.

National Instruments does not recommend the use of single-ended encoders with the smart

camera. This configuration would require the ground for a single-ended encoder to be connected

to the COM pin of the smart camera, and the PhaseA- and PhaseB- signals would be left

unconnected. In this configuration, the system is susceptible to significant noise that would be

eliminated by using a differential encoder.

Shielded encoder cables are recommended for all applications. Unshielded cables are more

susceptible to noise and can corrupt the encoder signals.

Refer to the External Trigger section of Chapter 5, Image Acquisition, for information about

using a quadrature encoder to delay a trigger.

2-6 | ni.com

Page 21

NI 17xx Smart Camera User Manual

Phase A+

Phase A–

Phase A–

Phase A

Phase B+

Phase B–

Phase B–

Phase B

Encoder NI 17xx

Tw isted

Pair

Tw isted

Pair

+

–

Phase A–

Phase A+

+

–

Phase B–

Phase B+

+3.3 V

10 kΩ 10 kΩ 10 kΩ 10 kΩ

7.5 kΩ 7.5 kΩ 7.5 kΩ 7.5 kΩ

NI 17xx

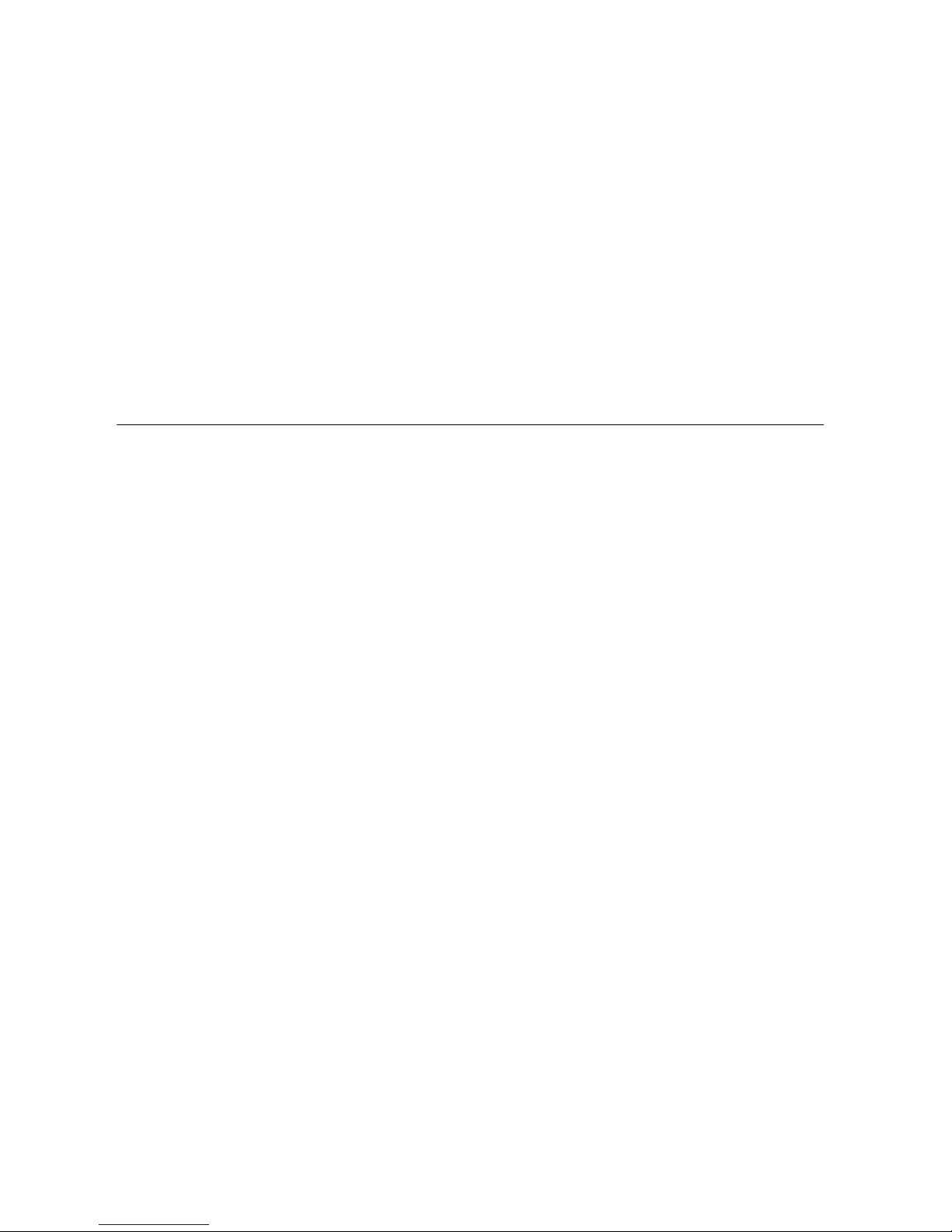

Figure 2-5 shows an example of connecting the quadrature encoder differential line drivers.

Figure 2-5. Connecting Differential Line Drivers

Figure 2-6 shows the internal quadrature encoder/RS-422 input circuit.

Figure 2-6. NI Smart Camera Quadrature Encoder Input Circuit

© National Instruments | 2-7

Page 22

3

FOV

Pixel Pitch Active Pixels× Working Distance×

Focal Length

-----------------------------------------------------------------------------------------------------------------=

NI Smart Camera Image

Sensor

This chapter provides an overview of the NI Smart Camera image sensors, field of view, spectral

response, partial scan mode, binning, gain, and hardware binarization. NI 1722/1742/1762

Smart Cameras use a VGA sensor. NI 1744/1764 Smart Cameras use an SXGA sensor. Refer to

Appendix A, Specifications, for information about your smart camera image sensor.

Field of View

The field of view is the area under inspection that will be imaged by the NI Smart Camera. It is

critical to ensure that the field of view of your system includes the object you want to inspect.

To calculate the horizontal and vertical field of view (FOV) of your imaging system, use

Equation 3-1 and the specifications for the image sensor of your smart camera, as listed in

Appendix A, Specifications.

where FOV is the field of view in either the horizontal or vertical direction,

Pixel Pitch measures the distance between the centers of adjacent pixels in either the

horizontal or vertical direction,

Active Pixels is the number of pixels in either the horizontal or vertical direction,

Working Distance is the distance from the front element (external glass) of the lens to

the object under inspection, and

Focal Length measures how strongly a lens converges (focuses) or diverges (diffuses)

light.

(3-1)

© National Instruments | 3-1

Page 23

Chapter 3 NI Smart Camera Image Sensor

FOV

horizontal

0.0074 mm 640× 100 mm×

8 mm

-------------------------------------------------------------------- - 59.2 mm==

FOV

vertical

0.0074 mm 480× 100 mm×

8 mm

-------------------------------------------------------------------- - 44.4 mm==

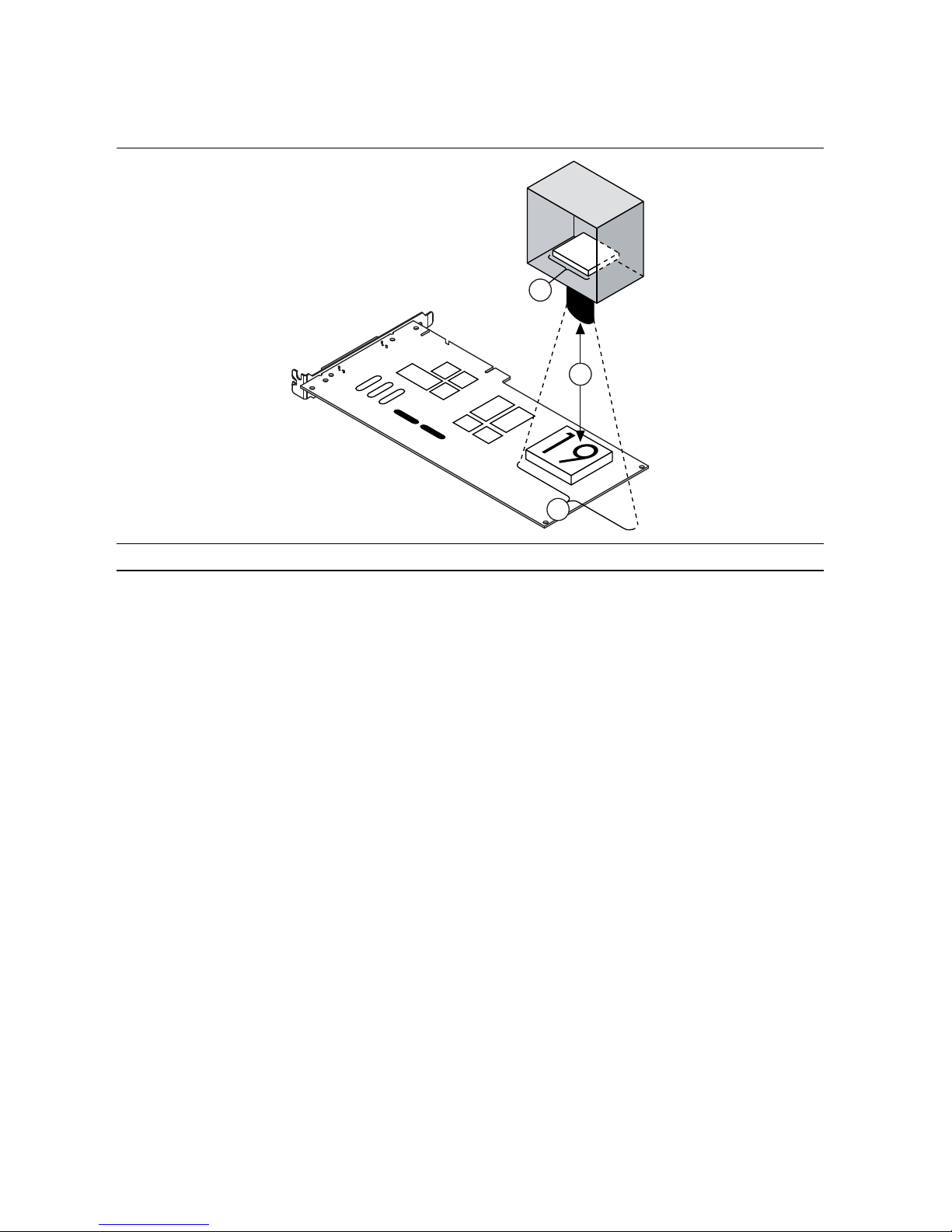

Figure 3-1 illustrates horizontal field of view and working distance.

Figure 3-1. Parameters of an Imaging System

1

2

3

1 Horizontal Imaging Width 2 Working Distance 3 Horizontal Field of View

For example, if the working distance of your imaging setup is 100 mm, and the focal length of

the lens is 8 mm, then the field of view in the horizontal direction of a smart camera using the

VGA sensor in full scan mode is

(3-2)

Similarly, the field of view in the vertical direction is

(3-3)

Based on the result of Equations 3-2 and/or 3-3, you can see that you might need to adjust the

various parameters in the FOV equation until you achieve the right combination of components

that match your inspection needs. This might include increasing your working distance,

choosing a lens with a shorter focal length, or changing to a high resolution camera.

3-2 | ni.com

Page 24

NI 17xx Smart Camera User Manual

abc

Image Sensor Spectral Response

The spectral response curve describes the relative sensitivity of the sensor to different

wavelengths of light. The peak responsiveness of the VGA and SXGA sensors is to light with a

wavelength of approximately 500 nm. If you are imaging a dim scene, this information can be

useful when selecting a light source to use in your application as the camera is most sensitive at

its peak responsiveness. It also helps determine what, if any, filters your application might

require to remove undesired wavelengths of light from the scene.

Refer to Appendix A, Specifications, to find the normalized spectral response curves for the

VGA and SXGA sensors.

Partial Scan Mode

Partial scan mode is a method of obtaining higher frame rates by reading out only a portion of

the image from the sensor. Partial scan is frequently used when an application requires higher

speed but less resolution than the sensor offers in full scan mode. The NI Smart Camera supports

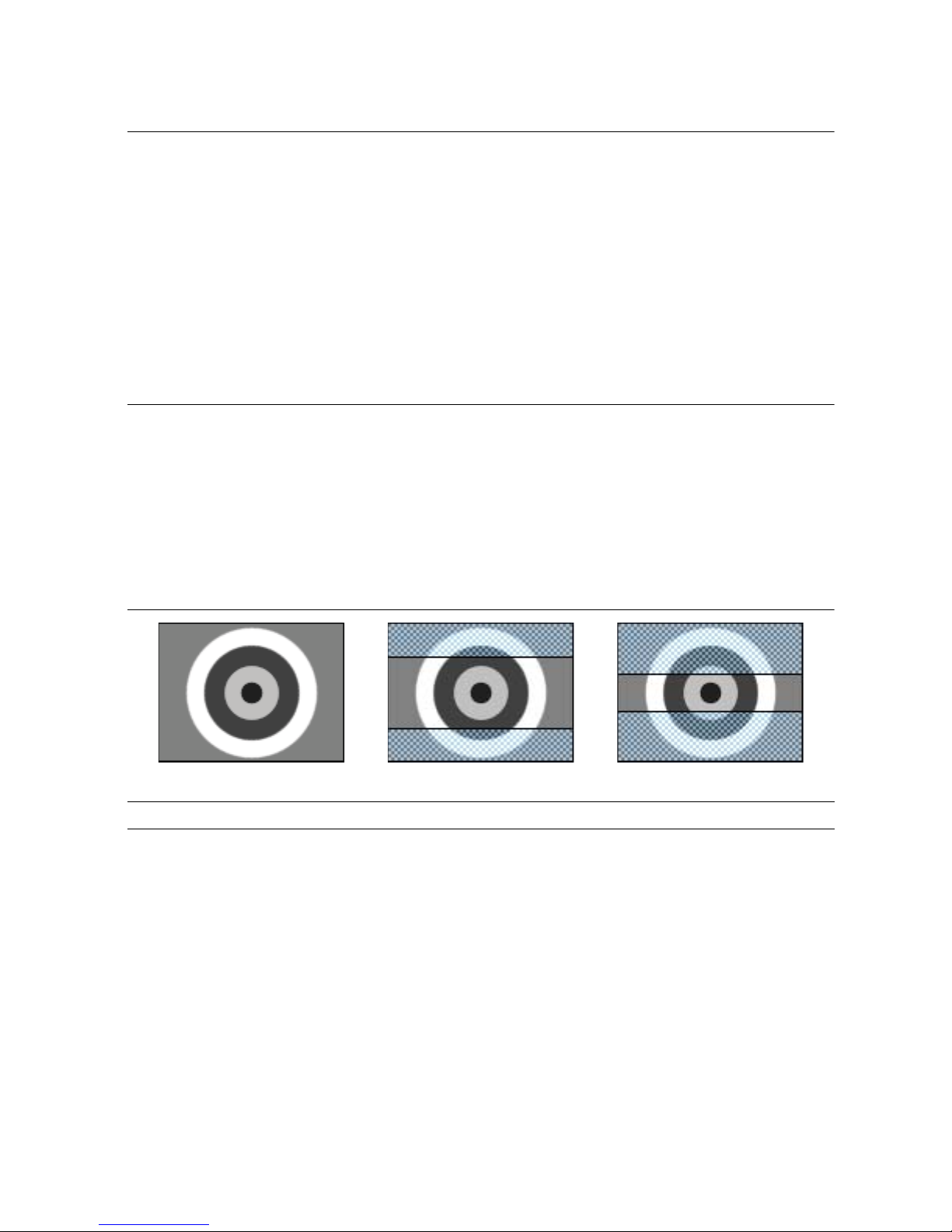

1/2 scan and 1/4 scan. In 1/2 scan, shown in Figure 3-2b, one half of the image is read out from

the center of the sensor and the rest of the image is discarded to enable a faster start of the next

frame. In 1/4 scan, only one quarter of the image is read out. Figure 3-2 illustrates the portion of

the sensor exposed during partial scanning.

Figure 3-2. Partial Scan Modes

a Full Scan b 1/2 Scan c 1/4 Scan

© National Instruments | 3-3

Page 25

Chapter 3 NI Smart Camera Image Sensor

ab

Binning

Binning can improve the light sensitivity of the sensor by treating adjacent pixels as a single

pixel. Binning allows the image sensor to collect more electrons per pixel, which reduces the

amount of required light and exposure time. Binning results in higher frame rates and lower

spatial resolution in the vertical direction. The NI Smart Camera supports 1 × 2 binning.

Figure 3-3 illustrates what happens to the sensor output during binning.

Figure 3-3. Binning

a No Binning b Binning

Gain

Gain is a multiplier applied to the analog signal prior to digitization. Increasing the gain

increases the amplitude of the signal. Gain allows you to trade off between making smaller

signals more visible at the cost of increased noise and no longer being able to differentiate

between larger signals. For most applications, the NI Smart Camera default gain setting

optimizes the balance between small signals and large signals.

Figure 3-4 shows what happens when gain is applied to a signal.

Figure 3-4. Effect of Gain on the Video Signal

255

Pixel Value

a

a Low Gain b Medium Gain c High Gain

255

255

Pixel Value

b

Pixel Value

c

In Figure 3-4a, low gain has been applied to the signal. The pixel values in the image are grouped

close together. In Figure 3-4b, medium gain has been applied to the signal; there are now more

notable differences in pixel value within the image. In Figure 3-4c, high gain has been applied

to the signal; at high gain, mid-range and bright portions of the image are now both represented

3-4 | ni.com

Page 26

NI 17xx Smart Camera User Manual

NORMAL

Stored Value

Sampled Data

INVERSE

Stored Value

Sampled Data

as white, the highest pixel value. In Figure 3-4c, several bright areas of the image have been

clipped to the maximum pixel value, and you can no longer distinguish subtle shading in the

brightest areas of the image.

Gain can be useful when there is not enough available light and you need to increase the

brightness of your images. However, increasing gain multiplies both the signal and noise. When

possible, it is preferable to add additional lighting.

Hardware Binarization

The NI Smart Camera supports binarization and inverse binarization of acquired images.

Binarization and inverse binarization segment an image into two regions—a particle region and

a background region. Use binarization and inverse binarization to isolate objects of interest in an

image.

To separate objects under consideration from the background, select a pixel value range. This

pixel value range is known as the gray-level interval, or the threshold interval. When enabled,

binarization sets all image pixels that fall within the threshold interval to the image white value

and sets all other image pixels to black. Pixels inside the threshold interval are considered part

of the particle region. Pixels outside the threshold interval are considered part of the background

region.

Inverse binarization reverses the assigned bit numbers of the particle region and the background

region. All pixels that belong in the threshold interval, or the particle region, are set to black, and

all pixels outside the threshold interval, or the background region, are set to the image white

value.

Figure 3-5 illustrates binarization and inverse binarization.

Figure 3-5. Binarization and Inverse Binarization

© National Instruments | 3-5

Page 27

Chapter 3 NI Smart Camera Image Sensor

You can enable hardware binarization in the following ways:

• In Vision Builder AI, configure the Lookup Table attribute on the Advanced tab of the

Acquire Image (Smart Camera) step. Refer to the NI Vision Builder for Automated

Inspection: Configuration Help for more information.

• In MAX, use the Lookup Table drop-down box on the LUT tab of the smart camera

configuration page to enable hardware binarization. Refer to the Measurement &

Automation Explorer Help for NI-IMAQ for more information.

3-6 | ni.com

Page 28

4

GND

5V

24V

1

2

3

4

5

Lighting

One of the most important aspects of setting up your imaging environment is proper

illumination. Images acquired under proper lighting conditions make your image processing

software development easier and overall processing time faster. The following sections describe

how to use the Direct Drive lighting controller and the strobe outputs of the NI Smart Camera to

control a light.

Lighting Connector

Figure 4-1 shows the lighting connector on the NI Smart Camera.

Caution All signals on the lighting connector are outputs from the smart camera.

Do not connect any external voltage or current source to any pin on the lighting

connector.

Note The NI 1722 does not offer the Direct Drive lighting controller. Do not

connect to the LED+ and LED- connectors on the NI 1722.

Figure 4-1. NI Smart Camera Lighting Connector

1 LED- Output (Not Available on the NI 1722)

2 LED+ Output (Not Available on the NI 1722)

3 Ground Output

Note Additional/replacement plugs for use with the lighting connector, part

number 780260-01, are available from NI.

4 5 V TTL Strobe Output

5 24 V Strobe Output

© National Instruments | 4-1

Page 29

Chapter 4 Lighting

Direct Drive Lighting Controller

This section applies only to the following NI Smart Cameras:

• NI 1742

• NI 1744

• NI 1762

• NI 1764

The NI Smart Camera offers an innovative lighting controller that directly powers third-party

current controlled lights. With other smart cameras, a lighting controller that drives a light must

be purchased separately. The Direct Drive lighting controller is capable of powering a variety of

third-party lights.

For a current controlled light, higher current produces more light, up to the maximum current

rating of the light. The maximum current rating of the light is specified by the manufacturer and

based on the average amount of power that can be safely dissipated by the light.

The Direct Drive controller can operate in continuous or strobed mode. When operating in

strobed mode, the controller can provide more current to the light than in continuous mode. The

average power dissipated while strobing the light for a short period of time at a higher current

can be comparable to the average power dissipated while running the light continuously at a

lower current. Table 4-1 shows the maximum allowed current for continuous mode and strobed

mode.

Table 4-1. Maximum Allowed Current for Direct Drive Lighting Controller

Maximum Strobed Current Maximum Continuous Current

1 A 500 mA

For applications with a pause between exposures while new parts move into position, you can

strobe the light, which allows the use of higher current and produces more light; thus you can

reduce the exposure time. A shorter exposure time decreases the time it takes to acquire an image

and potentially increases the total throughput of the system. Refer to the Exposure section of

Chapter 5, Image Acquisition, for more information about exposure control.

The smart camera automatically synchronizes the lighting strobe with the image sensor

exposure. The smart camera always turns the light on before an exposure starts and turns the

light off once the exposure completes. The duration of the light strobe is dictated by the exposure

time. Refer to Chapter 5, Image Acquisition, for more information.

When operating in strobed mode, it is important that the strobe duty cycle and strobe duration

are within the specified limits of both the light and the Direct Drive lighting controller. The

strobe duration is the amount of time that the light remains on. The strobe duration limit is the

maximum amount of time that the light can remain on when being driven at the maximum

4-2 | ni.com

Page 30

NI 17xx Smart Camera User Manual

current. The duty cycle is the ratio of the strobe duration to the frame period, expressed as a

percentage. Refer to the Maximum Frame Rate section of Chapter 5, Image Acquisition, for

more information about the frame period.

By default, you can set the exposure time to any setting within the range supported by your smart

camera. However, if the smart camera is configured to use the Direct Drive lighting controller

in strobed mode, care must be taken to ensure that the resulting strobe duty cycle and strobe

duration do not violate the limits of the Direct Drive lighting controller or the limits of the light.

For your convenience, the software calculates the resulting strobe duration and duty cycle for

your configured frame rate and exposure time. It then compares them to the limits of the Direct

Drive lighting controller and the limits specified in the associated lighting file. Refer to the

Lighting Files section of this chapter or the Maximum Frame Rate section of Chapter 5, Image

Acquisition, for more information.

If the requested exposure time violates the limits of the Direct Drive lighting controller or the

limits for your light as specified in the associated lighting file, the smart camera can use the

requested exposure time, but requires the configured current to be at or below the maximum

continuous current.

Caution If you are using the 5 V strobe output or the 24 V strobe output, the

software does not impose any limits on the duration or the duty cycle of the strobe

output. You must ensure that your requested exposure time and the frame rate result

in duration and duty cycle that do not violate the limits of the external controller

and/or light(s). Refer to the Maximum Frame Rate section of Chapter 5, Image

Acquisition, for more information.

Lighting Files

A lighting file is a text file that contains information about a light, such as the type and color of

the light, maximum current limit, and maximum strobe duty cycle. Lighting files have the

extension .ild. MAX and Vision Builder AI use lighting files to ensure that the current limits

and duty cycle of your light are not exceeded when the light is used with the Direct Drive lighting

controller. Lighting files exist in four levels of certification:

• Digitally Signed by National Instruments—The information contained within the

lighting file has been verified as correct and safe by National Instruments. Contact National

Instruments for support regarding this lighting data file or the light to which it refers.

• Digitally Signed by a Third-Party Company—The information contained within the

lighting file has been verified as correct and safe by the specified third-party company.

Contact the third-party company for support regarding this lighting data file or the light to

which it refers.

© National Instruments | 4-3

Page 31

Chapter 4 Lighting

• Not Digitally Signed—The information contained within the lighting file meets the

requirements of Direct Drive lighting; however, it has not been verified that the information

is safe to use with the specified light. Use this file at your own risk.

• Invalid—The information contained within the lighting file is unusable because the data

does not meet the requirements of Direct Drive lighting, the data describing the light is not

in the proper syntax, or the digital signature has been altered.

In digitally signed lighting files, the current limit and duty cycle limit are encoded as part of the

signing process. The limits in signed lighting files are not human-readable. Modifying a signed

lighting file will invalidate the signature and render the file unusable.

To use a light that has a lighting file, you can select the lighting data in MAX or Vision

Builder AI:

• In MAX—Select the Lighting tab of the NI Smart Camera configuration page. Click

Configure Light, and select Select Light.

• In Vision Builder AI—Select the Lighting tab of the Acquire Image (Smart Camera)

step. Click Configure Light Source, and select Select Light.

To use a light that does not have a lighting file, you can enter the lighting data manually in MAX

or Vision Builder AI:

• In MAX—Select the Lighting tab of the NI Smart Camera configuration page. Click

Configure Light, and select Enter Lighting Data Manually.

• In Vision Builder AI—Select the Lighting tab of the Acquire Image (Smart Camera)

step. Click Configure Light Source, and select Enter Lighting Data Manually.

Lighting files are installed to the following locations when you install NI-IMAQ.

X represents

the letter of the CD drive:

• Windows Vista—X:\Users\Public\Documents\National Instruments\

NI-IMAQ\Data

• Windows XP/2000—X:\Documents and Settings\All Users\Documents\

National Instruments\NI-IMAQ\Data

Selecting a Light

This section applies only to the following NI Smart Cameras:

• NI 1742

• NI 1744

• NI 1762

• NI 1764

National Instruments software provides support for a variety of lights from major machine vision

lighting companies. However, if your light is not in the list of supported lights, you may still be

able to use your light with the Direct Drive lighting controller.

4-4 | ni.com

Page 32

NI 17xx Smart Camera User Manual

To determine if your light is compatible with the NI Smart Camera, verify the following:

• The light is current controlled and not voltage controlled.

• The smart camera can provide enough current to obtain the desired illumination from the

light.

• The maximum voltage drop specified for the light does not exceed the specified range of

the smart camera. Under some circumstances, some LEDs, particularly certain lights with

white and blue LEDs, require a higher voltage drop than usual to turn on or reach full

brightness. Such lights may be incompatible with the smart camera. These lights may need

to be reconfigured by the manufacturer to bring the voltage drop within the specified range

of the smart camera.

• The minimum voltage drop specified for the light does not fall below the specified range of

the smart camera. Under some circumstances some LEDs, particularly certain lights with

infrared LEDs and lights with only one LED per string, present a lower voltage drop than

usual and may be incompatible with the smart camera. These lights may need to be

reconfigured by the manufacturer to bring the voltage drop within the specified range of the

smart camera.

Note The voltage drop of a light can vary significantly with environmental

conditions, such as ambient temperature, current supplied, and strobe time.

Refer to Appendix A, Specifications, for complete specifications for the Direct Drive lighting

controller.

Connecting a Light to the Direct Drive Lighting

Controller

This section applies only to the following NI Smart Cameras:

• NI 1742

• NI 1744

• NI 1762

• NI 1764

© National Instruments | 4-5

Page 33

Chapter 4 Lighting

LED

–

LED

+

LED

NI 17xx

Direct

Drive

Figure 4-2 illustrates how to connect a light to the Direct Drive lighting controller. Do not use

the GND signal when connecting a light to the Direct Drive lighting controller.

Figure 4-2. Connecting a Light to the Direct Drive Lighting Controller

The Direct Drive controller performs an initialization sequence to achieve the requested current

output prior to acquiring the first image. You may notice a sequence of short flashes from the

light when the application initializes or shuts down.

External Lighting Controllers

While the Direct Drive lighting controller is designed to handle common machine vision lighting

requirements, some applications require the use of a light with current or voltage requirements

beyond those supported by the Direct Drive. Other applications require more than one light. All

NI Smart Cameras support connections to third-party lighting controllers to solve these

applications.

The smart camera provides two types of external lighting outputs for synchronizing third-party

controllers to the exposure of the smart camera: a 5 V TTL strobe output and a 24 V strobe

output. The 5 V TTL strobe output is available for connecting to devices that require a 5 V signal.

The 24 V strobe output is powered by the voltage from the smart camera power supply and is

available for controllers that require higher voltage inputs. The 24 V strobe output is nominally

a 24 V output if 24 V power is supplied to the smart camera.

Caution The 24 V external lighting strobe is an unregulated output dependent on

the range of the power supply provided to the smart camera. If the power provided to

the smart camera is +20%/-15% with +5% AC ripple, the output could be as high as

30 V. If the provided power exceeds the input voltage specifications of the third-party

lighting controller, do not connect the 24 V lighting strobe output to the controller to

prevent damage to the controller. Use a power supply with tolerances that meet the

requirements of the controller, or use the 5 V external lighting strobe.

When enabled, the 5 V and 24 V external strobe outputs create a strobe pulse that can be used

as a level-sensitive signal by third-party controllers to strobe the light simultaneously with the

image exposure. Alternatively, if the third-party lighting controller supports a programmable

4-6 | ni.com

Page 34

NI 17xx Smart Camera User Manual

5 V TTL Strobe Output

GND Output

LED

External

Lighting

Controller

NI 17xx

strobe time, the controller can be programmed for any arbitrary strobe duration, and the assertion

edge of the smart camera output can start the strobe timer in the controller.

Caution If you are using the 5 V strobe output or the 24 V strobe output, the

software does not impose any limits on the duration or the duty cycle of the strobe

output. You must ensure that your requested exposure time and the frame rate result

in duration and duty cycle that do not violate the limits of the external controller

and/or light(s). Refer to the Maximum Frame Rate section of Chapter 5, Image

Acquisition, for more information.

Enable the 5 V and 24 V lighting outputs as follows:

• In Vision Builder AI, enable the 5 V TTL Strobe and/or 24 V Strobe controls on the

Lighting tab of the Acquire Image (Smart Camera) step. Refer to the NI Vision Builder

for Automated Inspection: Configuration Help for more information about configuring the

5 V TTL and 24 V strobe outputs.

• In LabVIEW, configure the 24V Strobe and 5V Strobe lighting properties. Refer to the

NI-IMAQ VI Reference Help for more information about configuring the 5 V TTL and 24 V

strobe outputs.

• In MAX, select the 5 V TTL Strobe and/or 24 V Strobe checkboxes on the Lighting tab

of the smart camera configuration page. Refer to the Measurement & Automation Explorer

Help for NI-IMAQ for more information about configuring the 5 V TTL and 24 V strobe

outputs.

Connecting an External Lighting Controller to the

NI Smart Camera

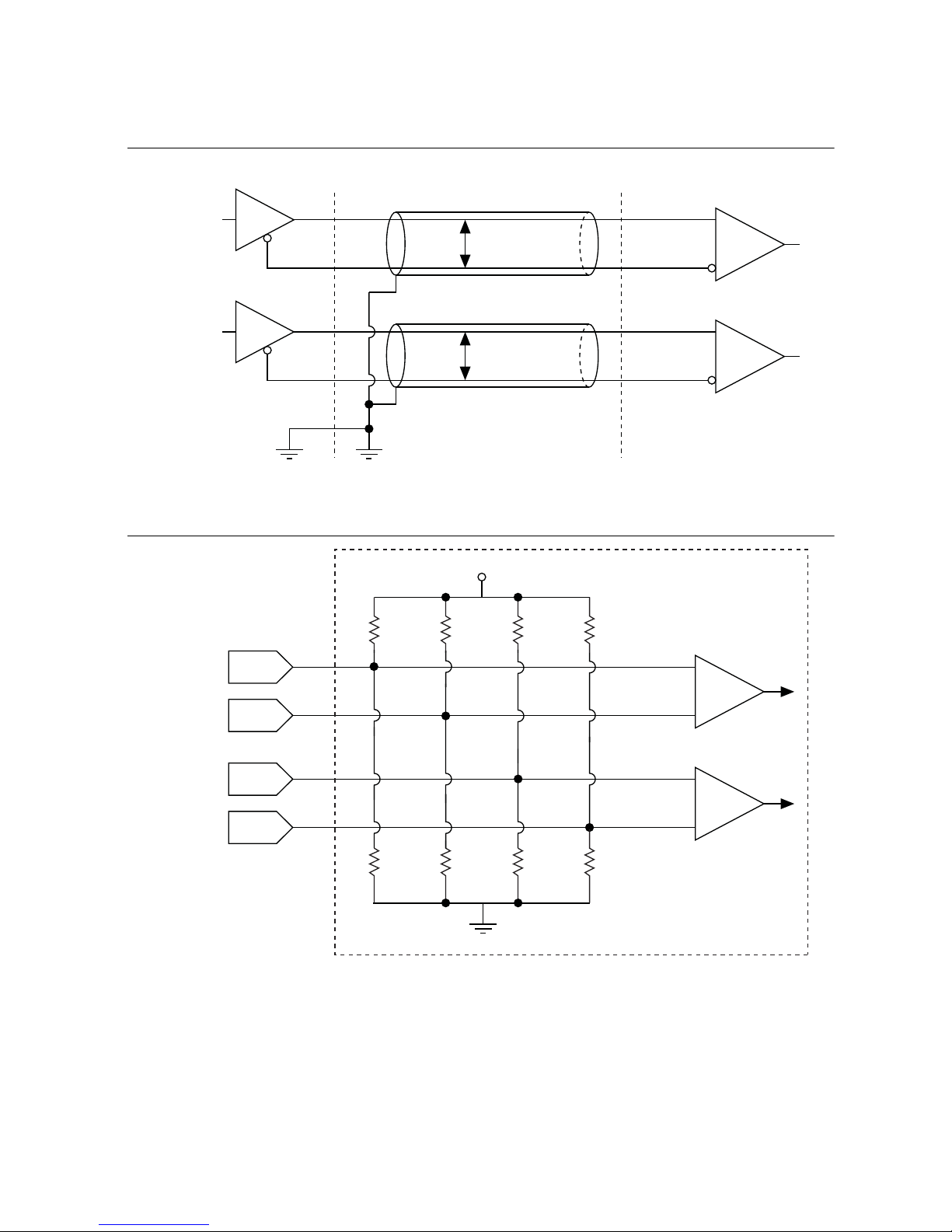

Figure 4-3 illustrates how to connect an external lighting controller to the 5 V TTL output on the

NI Smart Camera.

Figure 4-3. Connecting an External Lighting Controller to the 5 V TTL Strobe Output

© National Instruments | 4-7

Page 35

Chapter 4 Lighting

Figure 4-4 illustrates how to connect an external lighting controller to the 24 V output on the

NI Smart Camera.

Figure 4-4. Connecting an External Lighting Controller to the 24 V Strobe Output

24 V Strobe Output

(~ 18 V – 30 V)

NI 17xx

GND Output

External

Lighting

Controller

LED

4-8 | ni.com

Page 36

5

Image Acquisition

This chapter contains information about acquiring images with the NI Smart Camera and

explains the relationships between triggering, lighting, and exposure.

Exposure

The NI Smart Camera provides control of the image sensor exposure time through software. The

exposure time is the amount of time that light is allowed to strike the sensor to produce an image.

When light strikes the surface of the sensor, it dislodges electrons. As more light strikes the

sensor, more electrons are freed, creating a charge on the sensor.

For a given amount of light, the sensor collects more charge during a longer exposure time than

a shorter exposure time. Because the charge is what is read out to produce the image, it is

important to have an optimal amount of light and exposure time for your application.

Exposing the image sensor for too short of a time relative to the amount of light in the

environment results in a dark, low contrast image. Exposing the image sensor for too long of a

time relative to the amount of light in the environment results in a bright, low contrast image.

When the image sensor is exposed for an appropriate amount of time relative to the light in the

environment, acquired images will exhibit appropriate contrast to easily distinguish both dark

and light features. Contrast is a key factor in obtaining good results from image processing

algorithms.

In applications where the object under inspection is moving, the exposure time must be carefully

considered. If the object moves significantly during the exposure, the resulting image is blurry

and unsuitable for processing.

The maximum exposure time for imaging a moving object without blurring depends on the per

pixel spatial resolution and the rate of motion of the object. The per pixel spatial resolution is the

field of view, calculated in the Field of View section of Chapter 3, NI Smart Camera Image

Sensor, divided by the number of pixels in the sensor. Together, this information can be used to

calculate the maximum exposure. Assuming the object is moving horizontally across the field

of view, use Equation 5-1 to calculate the maximum exposure time.

© National Instruments | 5-1

Page 37

Chapter 5 Image Acquisition

E

max

R

Horizontal

2×

FOV

Horizontal

()N

Horizontal

()⁄

---------------------------------------------------------------------------- -=

(5-1)

where E

is the maximum exposure time without blurring,

max

R is the rate of motion of the object either horizontally or vertically,

FOV is the field of view in the direction of motion, and

N is the number of sensor pixels in the direction of motion

For many applications that include moving objects, additional lighting is necessary to achieve

good image contrast due to the short exposure time required to avoid motion blur.

Additionally, in many environments, the ambient light conditions vary too significantly to obtain

consistent results without adding dedicated lighting. For example, in a building with windows,

the ambient light can vary significantly with weather. Also, standard fluorescent lighting flickers

at a rate that is perceivable by the smart camera. In these situations, the ambient light must be

overridden with a dedicated light source to ensure reproducible results.

Acquiring Images

You can configure the NI Smart Camera to acquire images based on internal timing or an

external trigger signal. In both cases, the smart camera can acquire full frame images at the

camera’s maximum frame rate. If partial scanning or binning are enabled, the smart camera can

acquire images faster than the full frame maximum frame rate. Refer to the Maximum Frame

Rate section for information about factors that affect the maximum frame rate.

Internal Timing

The NI Smart Camera features two types of internally-timed modes: free-run mode and

fixed-frame-rate mode.

In free-run mode, the smart camera acquires images at the maximum frame rate allowed by the

configuration.

In fixed-frame-rate mode, you can specify a frame rate that is less than or equal to the maximum

frame rate by setting the Frame Rate property in LabVIEW. Setting the Frame Rate property

will implicitly take you out of free-run mode and into fixed-frame-rate mode. To return to

free-run mode, set the Fixed-Frame-Rate Mode property in LabVIEW to FALSE.

Note Vision Builder AI and MAX do not support fixed-frame-rate mode.

5-2 | ni.com

Page 38

NI 17xx Smart Camera User Manual

Trigger

Lighting Strobe

Exposure

Image Readout

3

2

1

External Trigger

Use the trigger input to synchronize the NI Smart Camera with an external event, such as the

assertion of a signal generated by a proximity sensor. You can trigger the smart camera at rates

up the maximum frame rate. Refer to the Maximum Frame Rate section for information about

factors that affect the maximum frame rate.

To use an external trigger, the trigger signal must be provided on the TrigIn/IsoIn(0)+ and

TrigIn/IsoIn(0)- inputs to the camera and triggering must be enabled in the software. Refer to the

Isolated Inputs section of Chapter 2, Power and I/O, for information about connecting external

signals.

You can enable triggering in the following software programs:

• Vision Builder AI—Select the Triggered Acquisition checkbox on the Trigger tab of the

Acquire Image (Smart Camera) step.

• LabVIEW—Use the IMAQ Configure Trigger 3 VI.

• MAX—Select the Enable Trigger checkbox on the Triggering tab of the smart camera

configuration page.

Figure 5-1 illustrates the relationship between an external trigger, a lighting strobe, and the

exposure time.

Figure 5-1. Externally Triggered Mode

1 User-Configurable Trigger Delay

2 Lighting Turn-On Time

3 Beginning of Image Readout

The trigger shown in Figure 5-1 represents an external trigger, configured to use the rising edge

as the active edge. The time between the active edge of the trigger and the assertion of the

lighting strobe is a user-configurable trigger delay. The trigger delay can be configured in either

milliseconds or quadrature encoder counts. The NI 1722 does not support quadrature encoders.

© National Instruments | 5-3

Page 39

Chapter 5 Image Acquisition

The incoming trigger is synchronized to the line rate of the smart camera. This adds an additional

delay that can vary on a frame by frame basis. The maximum variability is shown in Table 5-1.

Table 5-1. Trigger Synchronization Variability

Smart Camera Model Trigger Synchronization Variability

NI 1722

31.2 μs

NI 1742

NI 1762

NI 1744

71.6 μs

NI 1764

The amount of time required from the assertion of a trigger to the start of the light strobe and

image exposure varies by application. For example, if a sensor that detects the presence of a part

is positioned before the smart camera on a conveyor belt, a trigger delay will be necessary so

that the smart camera waits to expose the image until the part to be inspected passes in front of

the smart camera. In this case, specifying the trigger delay in terms of quadrature encoder counts