Page 1

USER GUIDE AND SPECIFICATIONS

NI USB-6509

This document contains information about using the National Instruments

USB-6509 data acquisition (DAQ) device with NI-DAQmx 8.7 and later.

The NI USB-6509 is a bus-powered 96-channel, digital input/output (I/O)

device. The NI USB-6509 features 96 TTL/CMOS-compatible digital I/O

lines, a watchdog timer, digital input filtering and change detection, and

output programmable power-up states. The NI USB-6509 also features an

optional external DC power supply that can increase the I/O drive strength.

Contents

Getting Started ........................................................................................2

Installing Software........................................................................... 2

Installing the Hardware.................................................................... 3

USB Cable Strain Relief .................................................................. 3

Mounting the NI USB-6509 ............................................................3

Desktop Use.............................................................................. 3

DIN Rail Mounting................................................................... 4

Panel Mounting.........................................................................5

Hardware Overview ................................................................................ 6

Programming Devices in Software .........................................................7

Related Documentation.................................................................... 8

I/O Connector.......................................................................................... 8

Pin Assignments .............................................................................. 8

SH100-100-F Pin Assignments ................................................ 8

R1005050 Pin Assignments...................................................... 10

Signal Descriptions ..........................................................................11

Digital I/O ............................................................................................... 12

Static DIO on NI USB-6509 Devices ..............................................12

Digital I/O Circuitry......................................................................... 12

I/O Protection................................................................................... 12

I/O State at Power-On/Power-Off/Suspend..................................... 13

I/O Pull-Up/Pull-Down Resistor...................................................... 13

High DIO State ......................................................................... 13

Low DIO State.......................................................................... 14

Increasing Current Drive on NI USB-6509 Devices ....................... 15

Page 2

Getting Started

DIO Signal Connection ....................................................................16

Protecting Inductive Loads...............................................................17

Sinking and Sourcing Examples.......................................................17

Driving a Relay <24 mA ...........................................................17

Driving a Relay >24 mA ...........................................................18

Driving SSRs.............................................................................19

LED Indicator...................................................................................19

Power Connection....................................................................................19

Optional +12 VDC Power Supply Installation.................................19

+5 V Power Available at I/O Connector ..........................................20

Industrial DIO Features ...........................................................................20

Digital Filtering ................................................................................20

Digital Filtering Example..........................................................21

Programmable Power-Up States.......................................................22

Change Detection .............................................................................22

Change Detection Example.......................................................23

Watchdog Timer...............................................................................23

Cables and Accessories ...........................................................................24

Specifications...........................................................................................24

Safety Guidelines.....................................................................................29

Where to Go for Support .........................................................................31

NI USB-6509 devices feature up to 96 bidirectional per-port static DIO

lines. If you have not already installed your device, refer to the NI-DAQmx

for USB Devices Getting Started Guide.

Before installing your DAQ device, you must install the software you plan

to use with the device.

Installing Software

Software support for the NI USB-6509 for Windows is provided by

NI-DAQmx.

The NI-DAQmx CD contains example programs that you can use to get

started programming with the NI USB-6509. Refer to the NI-DAQmx for

USB Devices Getting Started Guide, that shipped with your device and

is also accessible from Start»All Programs»National Instruments»

NI-DAQ, for more information.

Note For information about non-Windows operating system support, refer to

ni.com/info and enter rddqld.

NI 6509 User Guide and Specifications 2 ni.com

Page 3

Installing the Hardware

The NI-DAQmx for USB Devices Getting Started Guide contains

non-software-specific information about how to install USB devices.

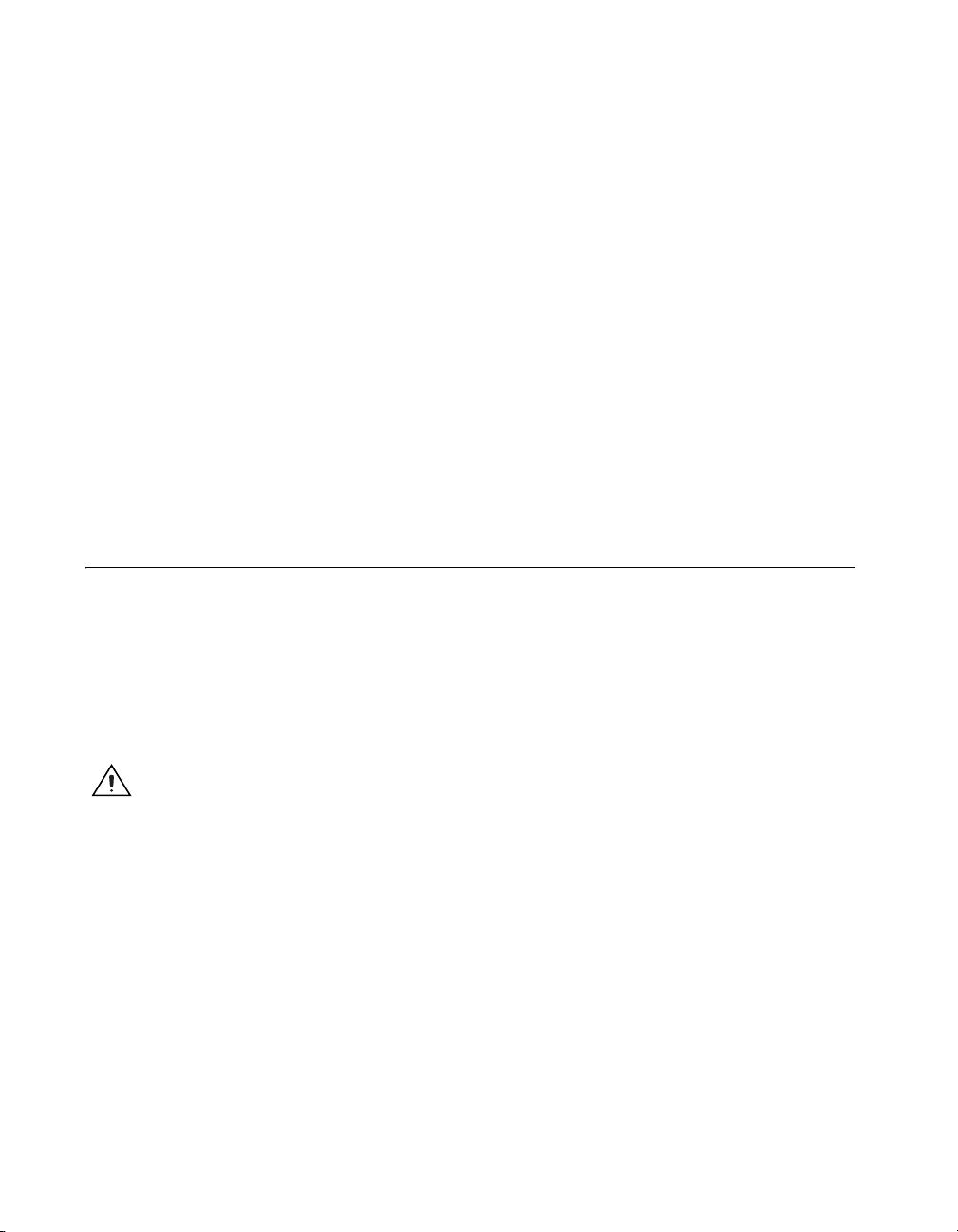

USB Cable Strain Relief

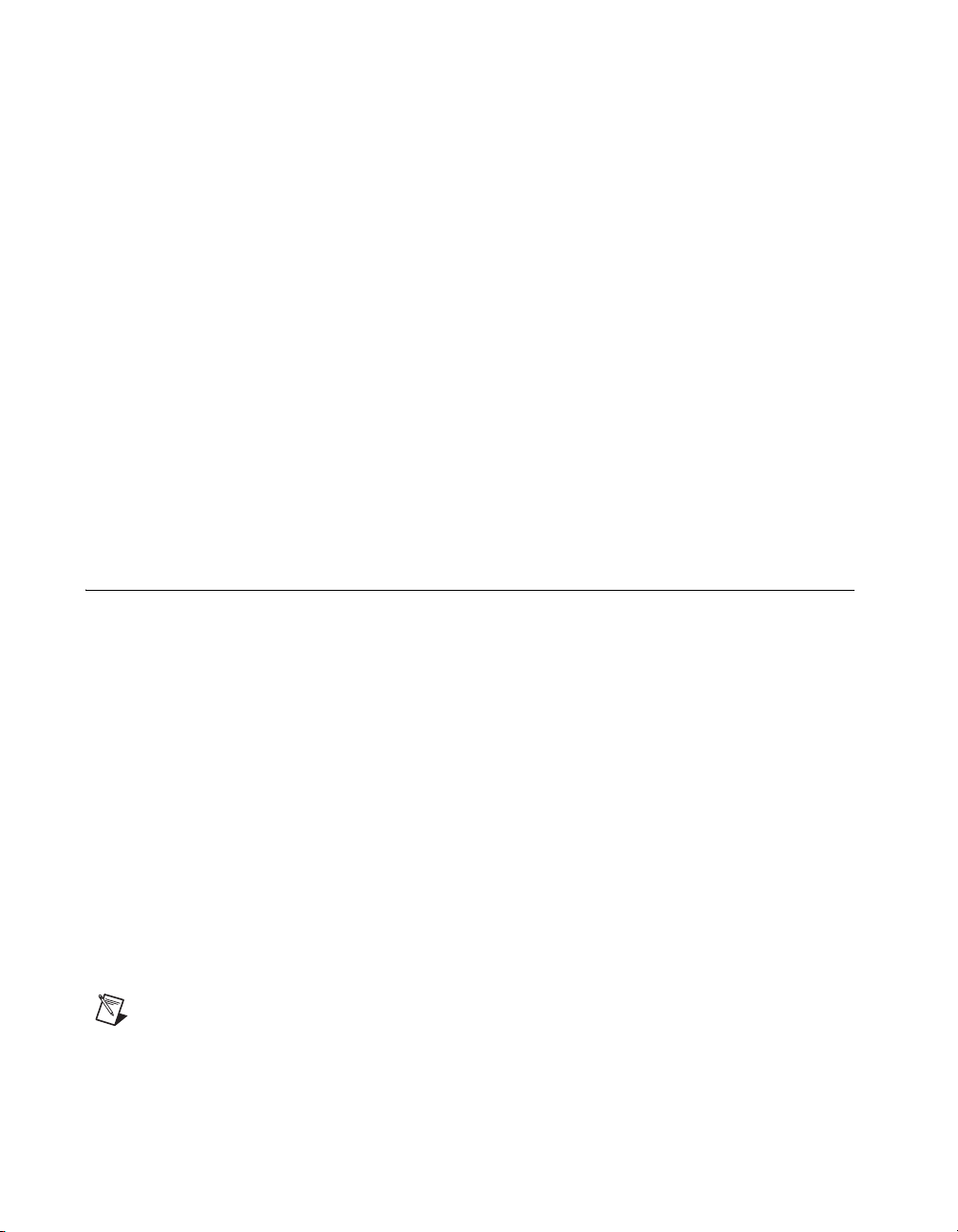

The two strain relief options for your USB cable are as follows:

• Cable Strain Relief Groove Method—Press the USB cable into one

of the two grooves on the underside of the NI USB-6509. Choose the

USB cable groove that matches your USB cable size, as shown in

Figure 1.

• Zip Tie Method—Thread a zip tie through the zip tie bar on the

underside of the NI USB-6509 and tighten around the USB cable,

as shown in Figure 1.

1

1 USB Cable Strain Relief Groove (Large)

2 USB Cable Strain Relief Groove (Small)

3 USB Cable

Mounting the NI USB-6509

You can use the NI USB-6509 on a desktop or mount it to a standard DIN

rail or a panel.

Desktop Use

You can use the NI USB-6509 on a desktop. The NI USB-6509 has grooves

on the underside that allow it to be stacked on top of other NI USB-6509

devices.

3

3

2

4 Zip Tie

5 Zip Tie Bar

Figure 1. USB Cable Strain Relief Options

4

5

© National Instruments Corporation 3 NI 6509 User Guide and Specifications

Page 4

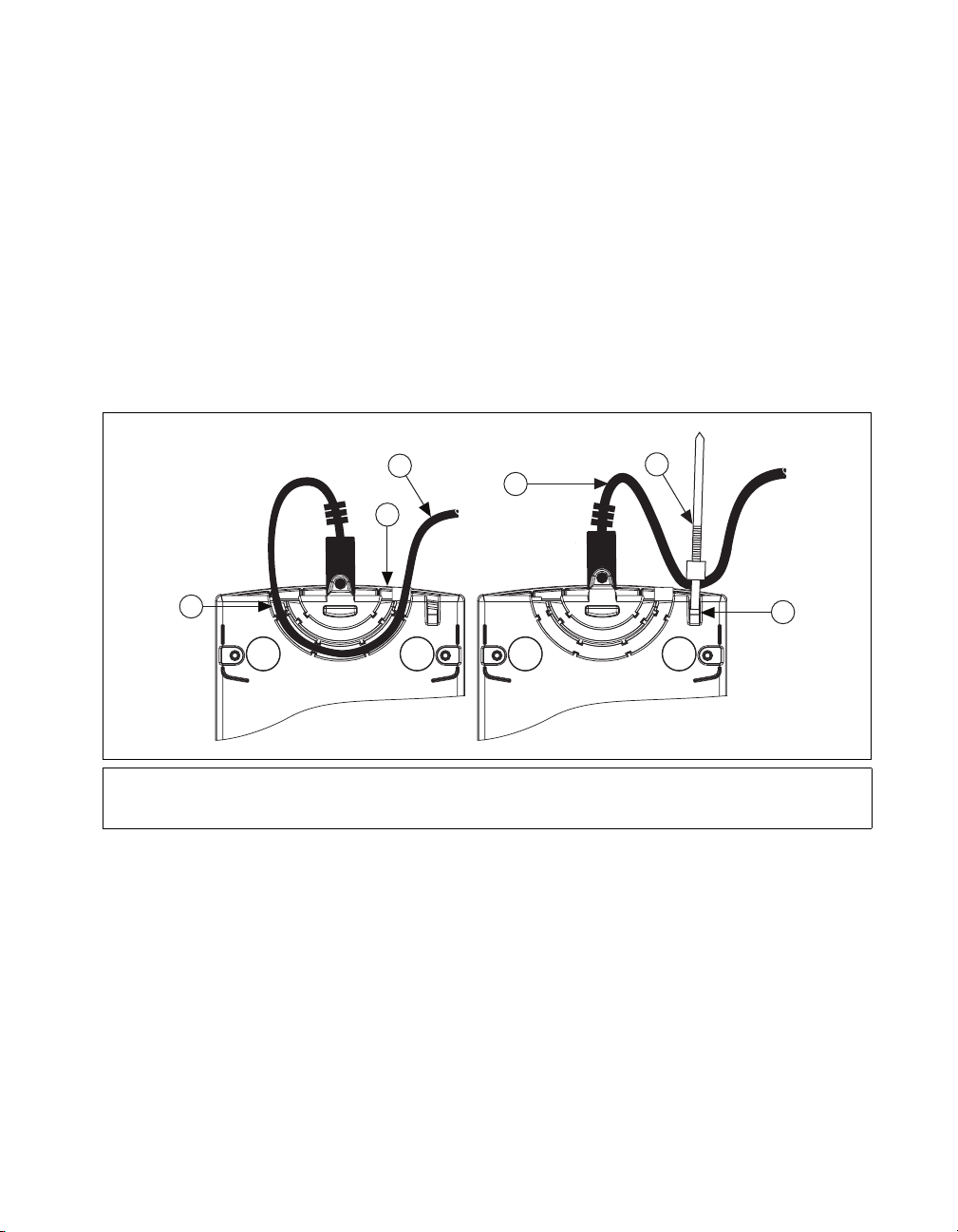

For secure desktop use, you can adhere the supplied rubber non-skid feet to

the underside of the device, as shown in Figure 2.

Note Do not apply the rubber feet if you are panel mounting the NI USB-6509 or stacking

multiple NI USB-6509 devices.

Figure 2. Applying Rubber Feet to the NI USB-6509

DIN Rail Mounting

The DIN rail mounting kit (part number 779689-01, not included in your

NI USB-6509 kit) is an accessory you can use to mount the NI USB-6509

to a standard DIN rail.

Note Apply strain relief, as described in the USB Cable Strain Relief section, before

mounting the NI USB-6509 to a DIN rail.

NI 6509 User Guide and Specifications 4 ni.com

Page 5

Panel Mounting

To mount the NI USB-6509 to a board or panel, complete the following

steps while referring to Figure 3.

Figure 3. Mounting the NI USB-6509 on a Panel

Do not apply the rubber feet to the NI USB-6509 when panel mounting the device.

Notes

Apply strain relief, as described in the USB Cable Strain Relief section, before panel

mounting the NI USB-6509.

1. Go to ni.com/info and enter the info code rd3233 to download and

print the panel mounting template PDF.

2. Using the template, mark the bottom point and top point on the panel.

The points will be 162 mm (6.375 in.) from each other.

3. Remove the USB cable from the connector on the NI USB-6509.

4. Screw a #8 or M4 screw into the bottom point on the panel.

5. Set the NI USB-6509 on the screw by fitting it into the bottom screw

notch on the underside of the NI USB-6509.

6. Screw a #8 or M4 screw through the NI USB-6509 top screw hole into

the panel.

© National Instruments Corporation 5 NI 6509 User Guide and Specifications

Page 6

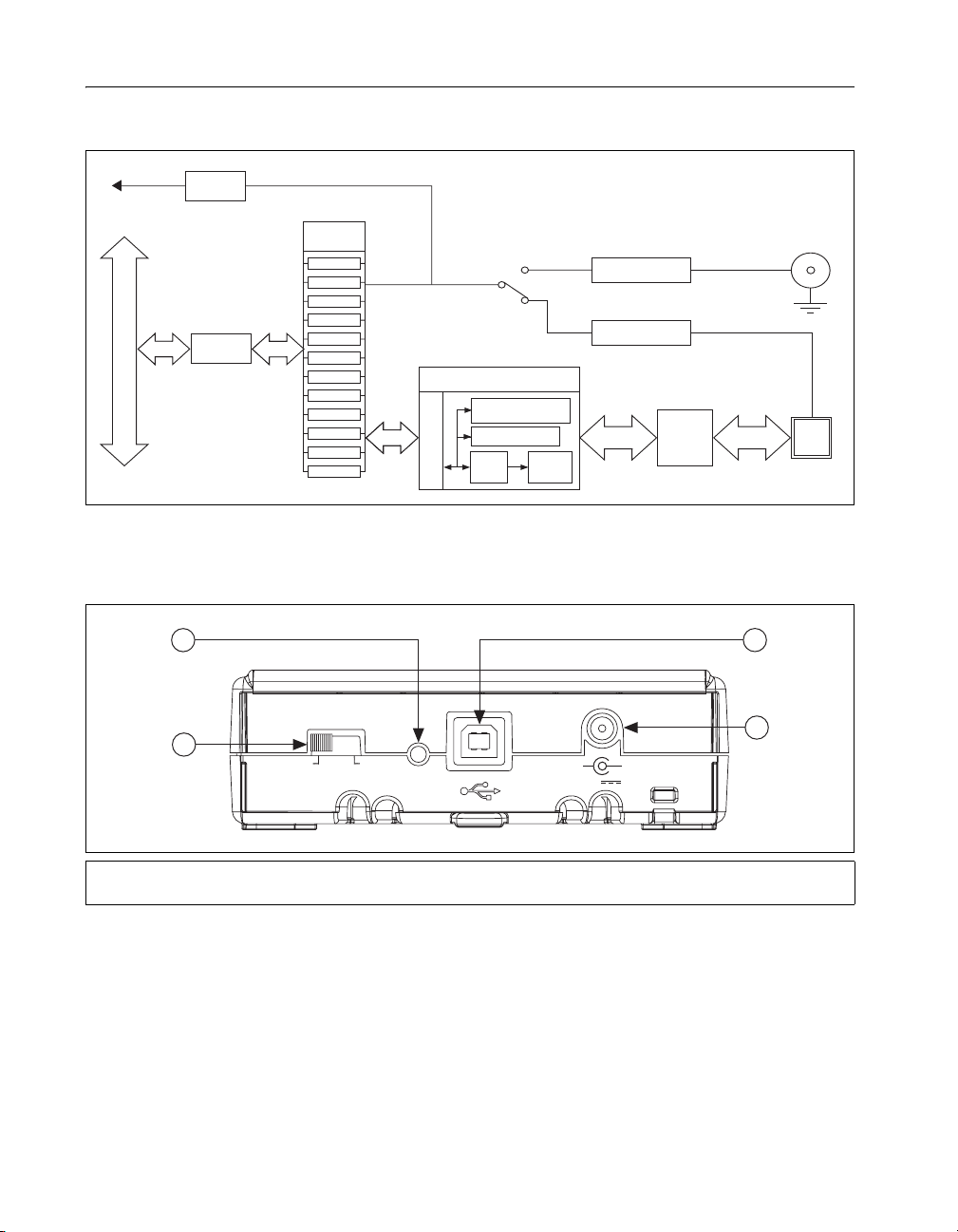

Hardware Overview

Figure 4 shows the key functional components of the NI USB-6509.

+5 V

I/O Connector

96 DIO96 DIO

Fuse and

2

1

Filter

I/O

Protection

24 mA DIO

Tranceivers

Por t 0

Por t 1

Por t 2

96 DIO96 DIO

Por t 3

Por t 4

Por t 5

Por t 6

Por t 7

Por t 8

Por t 9

Por t 10

Por t 11

96 DIO96 DIO96 DIO96 DIO

Industrial Digital

I/O Control FPGA

DIO Lines

Filtering

Programmable

Power-Up States

Watchdog Timer

Digital

Change

Detection

VBUS Current

Data/Control

Figure 4. NI USB-6509 Block Diagram

Figure 5 shows the back panel of the NI USB-6509.

I/O LINE PULL

HIGH

LOW

12VDC

12 V to 5 V

Regulation

Sense

+–

, 1A

USB

Interface

External Power

VBUS Power

USB Data

3

4

12 VDC Input

USB

Por t

1 I/O Line Pull Switch

2LED

3 Recessed USB Port

4 DC Power Jack

Figure 5. NI USB-6509 Back Panel

Refer to the Safety Guidelines section of this document for important safety

information.

NI 6509 User Guide and Specifications 6 ni.com

Page 7

Programming Devices in Software

National Instruments measurement devices for USB are packaged with

NI-DAQ driver software, an extensive library of functions and VIs you

can call from your application software, such as LabVIEW or

LabWindows

devices. Driver software has an application programming interface (API),

which is a library of VIs, functions, classes, attributes, and properties for

creating applications for your device.

NI-DAQ 8.x includes NI-DAQmx, which has its own API, hardware

configuration, and software configuration. Refer to the NI-DAQmx for USB

Getting Started Guide for more information.

NI-DAQmx includes a collection of programming examples to help you get

started developing an application. You can modify example code and save

it in an application. You can use examples to develop a new application or

add example code to an existing application.

To locate LabVIEW and LabWindows/CVI examples, open the National

Instruments Example Finder:

• In LabVIEW, select Help»Find Examples.

• In LabWindows/CVI, select Help»NI Example Finder.

Measurement Studio, Visual Basic, and ANSI C examples are in the

following directories:

• NI-DAQmx examples for Measurement Studio-supported languages

are in the following directories:

–

– MeasurementStudio\DotNET\Examples\NIDaq

• NI-DAQmx examples for ANSI C are in the NI-DAQ\Examples\

DAQmx ANSI C Dev directory

™

/CVI™, to program all the features of your NI measurement

MeasurementStudio\VCNET\Examples\NIDaq

For additional examples, refer to

© National Instruments Corporation 7 NI 6509 User Guide and Specifications

zone.ni.com.

Page 8

Related Documentation

The following documents contain information that you may find helpful as

you use this user guide:

• NI-DAQmx for USB Getting Started Guide—This guide describes how

to install the NI-DAQmx software, the DAQ device, and how to

confirm that the device is operating properly.

• NI-DAQmx Help—This help file contains information about using

NI-DAQmx to program National Instruments devices. NI-DAQmx

is the software you use to communicate with and control NI DAQ

devices.

• Measurement & Automation Explorer Help for NI-DAQmx—This

help file contains information about configuring and testing DAQ

devices using Measurement & Automation Explorer (MAX) for

NI-DAQmx, and information about special considerations for

operating systems.

• DAQ Assistant Help—This help file contains information about

creating and configuring channels, tasks, and scales using the DAQ

Assistant.

I/O Connector

The 100-pin high-density SCSI connector on the NI USB-6509 provides

access to 96 digital inputs and outputs. Use this connector to connect to

external devices, such as solid-state relays (SSRs) and LEDs. For easy

connection to the digital I/O connector, use the National Instruments

SH100-100-F shielded digital I/O cable with the SCB-100 connector block,

or use the R1005050 ribbon cable with the CB-50 or CB-50LP connector

block.

Caution Do not make connections to the digital I/O that exceed the maximum I/O

specifications. Doing so may permanently damage the NI USB-6509 device and the

computer. Refer to the Signal Descriptions and Specifications sections for information

about maximum input ratings.

Pin Assignments

SH100-100-F Pin Assignments

Figure 6 shows the pin assignments for the NI USB-6509 using the

SH100-100-F cable. The naming convention for each pin is PX.Y, where X

is the port (P) number, and Y is the line number or name.

NI 6509 User Guide and Specifications 8 ni.com

Page 9

P2.7

P5.7

P2.6

P5.6

P2.5

P5.5

P2.4

P5.4

P2.3

P5.3

P2.2

P5.2

P2.1

P5.1

P2.0

P5.0

P1.7

P4.7

P1.6

P4.6

P1.5

P4.5

P1.4

P4.4

P1.3

P4.3

P1.2

P4.2

P1.1

P4.1

P1.0

P4.0

P0.7

P3.7

P0.6

P3.6

P0.5

P3.5

P0.4

P3.4

P0.3

P3.3

P0.2

P3.2

P0.1

P3.1

P0.0

P3.0

+5 V

GND

51

P8.7

1

52

2

P11.7

53

3

P8.6

54

4

P11.6

55

5

P8.5

6

56

P11.5

7

57

P8.4

8

58

P11.4

9

59

100

P8.3

60

P11.3

61

P8.2

62

P11.2

63

P8.1

64

P11.1

65

P8.0

66

P11.0

67

P7.7

68

P10.7

69

P7.6

70

P10.6

71

P7.5

72

P10.5

73

P7.4

74

P10.4

75

P7.3

P10.3

76

P7.2

77

P10.2

78

P7.1

79

P10.1

80

P7.0

81

P10.0

82

P6.7

83

P9.7

84

P6.6

85

P9.6

86

P6.5

87

P9.5

88

P6.4

89

P9.4

90

P6.3

91

P9.3

92

P6.2

93

P9.2

94

P6.1

95

P9.1

96

P6.0

97

P9.0

98

99

+5 V

GND

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

Figure 6. Pin Assignments for the NI USB-6509 using the SH100-100-F

Refer to the Signal Descriptions section for information about the signals

available on this connector.

© National Instruments Corporation 9 NI 6509 User Guide and Specifications

Page 10

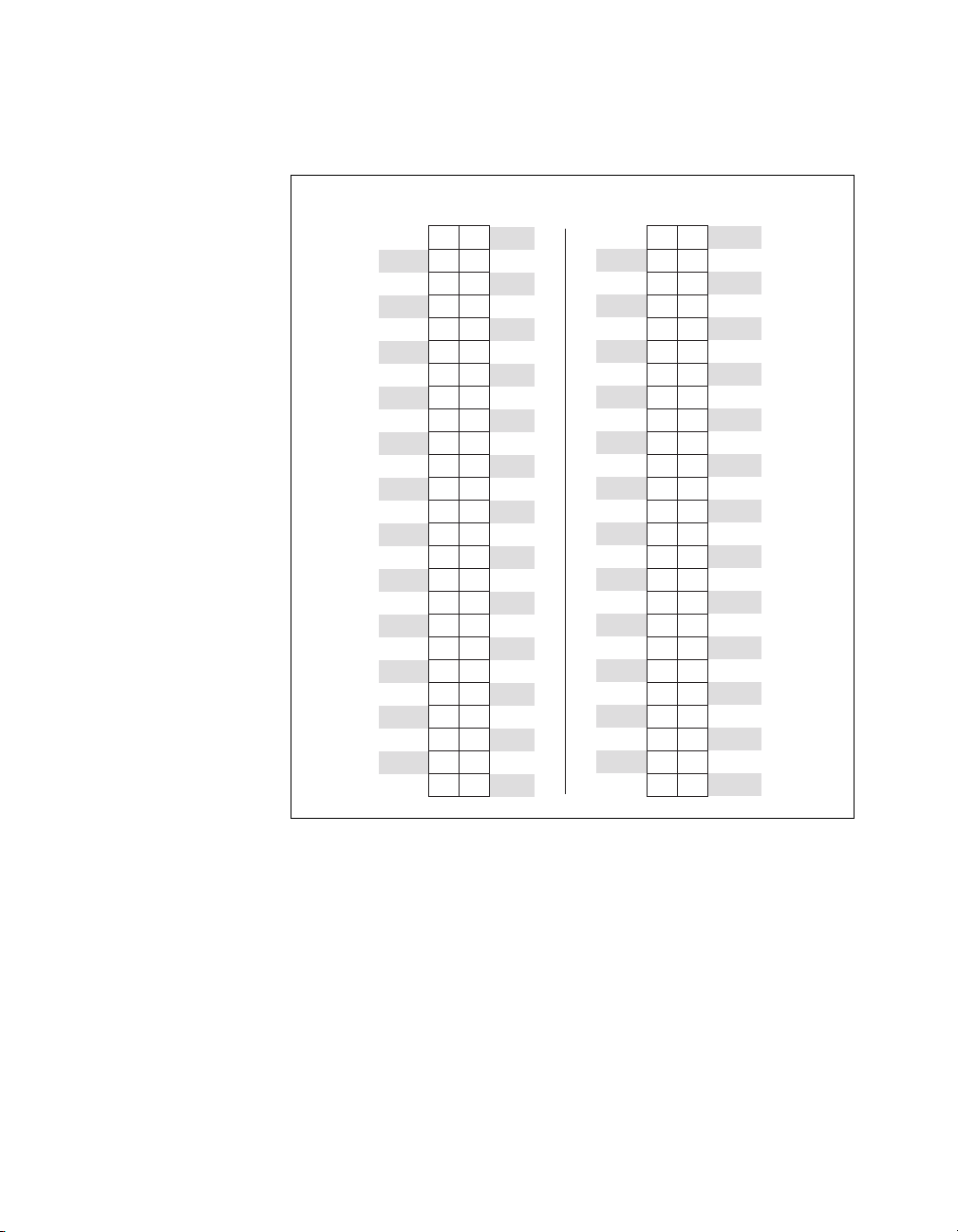

R1005050 Pin Assignments

Figure 6 shows the pin assignments for the NI USB-6509 using the

R1005050 cable. The naming convention for each pin is PX.Y, where X is

the port (P) number, and Y is the line number or name.

Positions 1 through 50 Positions 51 through 100

P2.7

P2.6

P2.5

P2.4

P2.3

P2.2

P2.1

P2.0

P1.7

P1.6

P1.5

P1.4

P1.3

P1.2

P1.1

P1.0

P0.7

P0.6

P0.5

P0.4

P0.3

P0.2

P0.1

P0.0

+5 V

12

3 4

56

78

910

11 12

13 14

15 16

17 18

19 20

21 22

23 24

25 26

27 28

29 30

31 32

33 34

35 36

37 38

3940

41 42

43 44

45 46

47 48

49 50

P5.7

P5.6

P5.5

P5.4

P5.3

P5.2

P5.1

P5.0

P4.7

P4.6

P4.5

P4.4

P4.3

P4.2

P4.1

P4.0

P3.7

P3.6

P3.5

P3.4

P3.3

P3.2

P3.1

P3.0

GND

P8.7

P8.6

P8.5

P8.4

P8.3

P8.2

P8.1

P8.0

P7.7

P7.6

P7.5

P7.4

P7.3

P7.2

P7.1

P7.0

P6.7

P6.6

P6.5

P6.4

P6.3

P6.2

P6.1

P6.0

+5 V

12

3 4

56

78

910

11 12

13 14

15 16

17 18

19 20

21 22

23 24

25 26

27 28

29 30

31 32

33 34

35 36

37 38

3940

41 42

43 44

45 46

47 48

49 50

P11.7

P11.6

P11.5

P11.4

P11.3

P11.2

P11.1

P11.0

P10.7

P10.6

P10.5

P10.4

P10.3

P10.2

P10.1

P10.0

P9.7

P9.6

P9.5

P9.4

P9.3

P9.2

P9.1

P9.0

GND

Figure 7. Pin Assignments for the NI USB-6509 using the R1005050

Refer to the Signal Descriptions section for information about the signals

available on this connector.

NI 6509 User Guide and Specifications 10 ni.com

Page 11

Signal Descriptions

Pin Signal Name Description MSB LSB

Table 1 lists the signals and descriptions for all signals available on the

NI USB-6509 device.

Table 1. NI USB-6509 Signal Descriptions

1, 3, 5, 7, 9, 11, 13, 15 P2.<7..0> Bi-directional data lines for

port 2

2, 4, 6, 8, 10, 12, 14, 16 P5.<7..0> Bi-directional data lines for

port 5

17, 19, 21, 23, 25, 27,

29, 31

18, 20, 22, 24, 26, 28,

30, 32

33, 35, 37, 39, 41, 43,

45, 47

34, 36, 38, 40, 42, 44,

46, 48

49, 99 +5 V supply +5 Volts; provide +5 V power

50, 100 GND Ground; connected to the

51, 53, 55, 57, 59, 61,

63, 65

52, 54, 56, 58, 60, 62,

64, 66

P1.<7..0> Bi-directional data lines for

port 1

P4.<7..0> Bi-directional data lines for

port 4

P0.<7..0> Bi-directional data lines for

port 0

P3.<7..0> Bi-directional data lines for

port 3

source

computer ground signal

P8.<7..0> Bi-directional data lines for

port 8

P11.<7..0> Bi-directional data lines for

port 11

P2.7 P2.0

P5.7 P5.0

P1.7 P1.0

P4.7 P4.0

P0.7 P0.0

P3.7 P3.0

— —

— —

P8.7 P8.0

P11.7 P11.0

67, 69, 71, 73, 75, 77,

79, 81

68, 70, 72, 74, 76, 78,

80, 82

83, 85, 87, 89, 91, 93,

95, 97

84, 86, 88, 90, 92, 94,

96, 98

© National Instruments Corporation 11 NI 6509 User Guide and Specifications

P7.<7..0> Bi-directional data lines for

port 7

P10.<7..0> Bi-directional data lines for

port 10

P6.<7..0> Bi-directional data lines for

port 6

P9.<7..0> Bi-directional data lines for

port 9

P7.7 P7.0

P10.7 P10.0

P6.7 P6.0

P9.7 P9.0

Page 12

Digital I/O

Static DIO on NI USB-6509 Devices

You can use each of the NI USB-6509 DIO lines as a static digital

input (DI) or digital output (DO) line. You can use static DIO lines to

monitor or control digital signals. Each DIO port can be configured as a

DI or DO port.

All samples of static DI lines and updates of DO lines are software-timed.

Digital I/O Circuitry

The NI USB-6509 provides 96 lines of bidirectional DIO signals,

P<0..11>.<0..7>. You can configure the direction as input or output on a

per-port basis. Each I/O line has a 100 kΩ I/O pull resistor. For more

information on the I/O pull resistor, refer to the I/O Pull-Up/Pull-Down

Resistor section.

Figure 8 shows the circuitry of one DIO line.

+5 V

GND

Tr ansceiver

Figure 8. NI USB-6509 Digital I/O Circuitry

The voltage input and output levels and the current drive levels of the DIO

lines are listed in the Specifications section.

100 kΩ

I/O Protection

PX.Y

I/O Protection

You should avoid ESD events and overvoltage, undervoltage, and

overcurrent fault conditions by following these guidelines.

• If you configure a DIO line as an output, do not connect it to any

external signal source, ground signal, or power supply.

• If you configure a DIO line as an output, understand the current

requirements of the load connected to these signals. Do not exceed the

specified current output limits of the DAQ device. NI has several signal

NI 6509 User Guide and Specifications 12 ni.com

Page 13

conditioning solutions for digital applications requiring high current

drive.

• If you configure a DIO line as an input, do not drive the line with

voltages outside of its normal operating range.

• Treat the DAQ device as you would treat any static sensitive device.

Always properly ground yourself and the equipment when handling

the DAQ device or connecting to it.

I/O State at Power-On/Power-Off/Suspend

After the device is powered on, the default state of all I/O lines is input.

Using the I/O line pull switch located on the back panel, you can select to

pull all I/O lines high or low. The pull-up or pull-down resistor provides a

weak pull-high or pull-low logic level, respectively, on every I/O line. The

selected I/O line pull setting takes effect regardless of the I/O direction. For

more information about this feature, refer to the I/O Pull-Up/Pull-Down

Resistor section.

You can also configure the power-up state in software using the

programmable power-up state feature. Each individual I/O line can be

independently configured for high-impedance input, high output, or low

output after power-up. For more information, refer to the Programmable

Power-Up States section.

When the device is powered off or in suspend state, all I/O lines are

powered off.

I/O Pull-Up/Pull-Down Resistor

The NI USB-6509 facilitates user-configurable pull-up or pull-down tasks.

Each DIO channel is connected to a 100 kΩ resistor and can be pulled high

or low using the back-panel switch, shown in Figure 5. Using this switch

pulls all 96 DIO lines high when set to HIGH or low when set to LOW.

However, if all lines are high, you might want to pull some lines low. To

do this properly, you must understand the nature of the drive current on

those lines and adhere to TTL-logic levels.

High DIO State

If you select the pulled-high mode, each DIO line is pulled to Vcc (+5 V)

with a 100 kΩ resistor. To pull a specific line low, connect a pull-down

resistor (R

and ground. Use the largest possible resistor so that you do not use more

current than necessary to perform the pull-down task. Also, make sure the

resistor value is not so large that leakage current from the DIO line drives

the voltage at the resistor above a TTL low level of 0.8 V.

© National Instruments Corporation 13 NI 6509 User Guide and Specifications

) whose value gives you a maximum of 0.8 V between the line

L

Page 14

NI USB-6509

Tr ansceiver

Figure 9. DIO Channel Configured for High DIO State with External Load

100 kΩ

+5 V

GND

Digital I/O Line

R

L

Example:

At power up, the device is configured for input and, by default, all DIO

lines are high. To pull one channel low, complete the following steps:

1. Install a load (R

). Remember that the smaller the resistance, the

L

greater the current consumption and the lower the voltage (V).

2. Using the following formula, calculate the largest possible load to

maintain a logic low level of 0.8 V and supply the maximum driving

current (I).

V = I * R

⇒ RL = V / I

L

where:

V= 0.8 V is the voltage across R

L

I = 91 μA is the maximum leakage current from the device at low

input

therefore:

R

= 8.8 kΩ is the 0.8 V / 91 μA

L

This resistor value, 8.8 kΩ, provides a maximum of 0.8 V on the DIO line.

You can substitute smaller resistor values, but they draw more current,

leaving less drive current for other circuitry connected to this line.

Low DIO State

If you select pulled-low mode, each DIO line is pulled to GND (0 V) using

a 100 kΩ resistor. If you want to pull a specific line high, connect a pull-up

resistor that gives you a minimum of 2 V. Use the largest possible

resistance value so that you do not use more current than necessary to

perform the pull-up task.

NI 6509 User Guide and Specifications 14 ni.com

Page 15

Also, make sure the pull-up resistor value is not so large that leakage

current from the DIO line brings the voltage at the resistor below a

TTL-high level of 2 V.

NI USB-6509

Tr ansceiver

100 kΩ

GND

Figure 10. DIO Channel Configured for Low DIO State with External Load

+5 V

R

L

Digital I/O Line

Example:

The switch is set in the low DIO state, which means all DIO lines are pulled

low. If you want to pull one channel high, complete the following steps:

1. Install a load (R

). Remember that the smaller the resistance, the

L

greater the current consumption and the lower the voltage (V).

2. Using the following formula, calculate the largest possible load to

maintain a logic high level of 2 V and supply the maximum sink

current (I).

V = I * R

⇒ RL = V / I

L

where:

V = 5 V – 2 V = 3 V is the voltage across R

L

I = 91 μA is the maximum leakage current to the device at high

input

therefore:

R

= 33 kΩ is the 3 V / 91 μA

L

This resistor value, 33 kΩ, provides a minimum of 2 V on the DIO line. You

can substitute smaller resistor values, but they draw more current, leaving

less sink current for other circuitry connected to this line.

Increasing Current Drive on NI USB-6509 Devices

Based on the USB specification, the maximum current that a bus-powered

USB device can draw is limited to 500 mA. Consequently, when the

NI USB-6509 is powered only from a USB port, the current drive capacity

at output channels is limited.

© National Instruments Corporation 15 NI 6509 User Guide and Specifications

Page 16

The NI USB-6509 has a current-sense circuit on VBUS (USB power rail).

If the output channels source more than the specified current, the current is

limited. The two following occurrences indicate an overcurrent condition:

• The inputs/outputs are disabled

• The LED on the back panel is blinking

If you want to increase the current drive capacity on the NI USB-6509, you

can use an optional external +12 VDC power supply. For more information,

refer to the Optional +12 VDC Power Supply Installation section.

DIO Signal Connection

Figure 11 shows an example of signal connections for three typical digital

I/O applications. Port 0 is configured for digital output, and port 7 is

configured for digital input. Digital input applications include receiving

TTL signals and sensing external device states such as the state of the

switch in the figure. Digital output applications include sending TTL

signals and driving external devices such as the LED shown in Figure 11.

+5 V

LED

+5 V

TTL Signal

41

43

45

47

67

69

71

73

Por t 0

P0.<3..0>

Por t 7

P7.<7..4>

50, 100

GND

NI USB-6509

Figure 11. NI USB-6509 Signal Connections

NI 6509 User Guide and Specifications 16 ni.com

Page 17

Protecting Inductive Loads

When inductive loads are connected to outputs, a large

counter-electromotive force may occur at switching time because of the

energy stored in the inductive load. These flyback voltages can damage the

outputs and/or the power supply.

To limit these flyback voltages at the inductive load, install a flyback diode

across the inductive load. For best results, mount the flyback diode within

18 inches of the load. Figure 12 shows an example of using an external

flyback diode to protect inductive loads.

NI USB-6509

Figure 12. Limiting Flyback Voltages at the Inductive Load

Sinking and Sourcing Examples

The following sections provide examples of driving a relay less than

24 mA, driving a relay greater than 24 mA, and driving solid-state relays.

PX.Y

Load

GND

Flyback Diode for

Inductive Loads

Driving a Relay <24 mA

Figures 13 and 14 show examples of connecting the NI USB-6509 to a

relay that does not require more than 24 mA of current.

Vcc

PX.Y

GND

NI USB-6509

Figure 13. NI USB-6509 Sinking Connection Example, <24 mA

© National Instruments Corporation 17 NI 6509 User Guide and Specifications

Page 18

PX.Y

GND

NI USB-6509

Figure 14. NI USB-6509 Sourcing Connection Example, <24 mA

Driving a Relay >24 mA

Figures 15 and 16 are examples of connecting the NI USB-6509 to a relay

that requires more than 24 mA of current. These examples use an additional

transistor circuit.

Vcc

PX.Y

GND

NI USB-6509

Figure 15. NI USB-6509 Sinking Connection Example, >24 mA

Vcc

PX.Y

GND

NI USB-6509

Figure 16. NI USB-6509 Sourcing Connection Example, >24 mA

NI 6509 User Guide and Specifications 18 ni.com

Page 19

Driving SSRs

Figure 17 shows an example of connecting the NI USB-6509 to a

solid-state relay (SSR).

+

or

_

ACDC

Load

SSR

Figure 17. NI USB-6509 SSR Connection Example

PX.Y

GND

NI USB-6509

LED Indicator

The LED indicator, located on the device back panel, indicates device

status. Table 2 shows the behavior of the LED.

Table 2. PWR/ACT LED Status

LED State Device Status

Not lit Device not powered or in suspend state

On, not blinking Operating normally

Blinking Device error—USB power budget possibly exceeded

Power Connection

Optional +12 VDC Power Supply Installation

To install a +12 VDC power supply into the NI USB-6509, complete the

following steps:

1. Ensure that the device is powered off by unplugging the USB cable

from the device.

2. After the device is powered off and unplugged, remove the plastic cap

on the DC jack, located on the device back panel.

3. Plug the +12 VDC power supply into the DC jack.

Caution Do not remove external +12 VDC power supply when the device is powered on.

Doing so may reboot the NI USB-6509 and cause device damage.

© National Instruments Corporation 19 NI 6509 User Guide and Specifications

Page 20

+5 V Power Available at I/O Connector

Pins 49 and 99 supply +5 V power to the I/O connector. The power drawn

from these two pins shares the power consumption with the transceivers.

The I/O connector power has a fuse for overcurrent protection. This fuse is

not customer replaceable. If the fuse is blown, return the device to NI for

repair.

Caution The power pins, +5V and GND, connect to the computer power supply and are

not isolated. Do not connect a +5V power pin directly to GND or connect a +5V or GND

pin to any other voltage source. Doing so may cause injury or permanently damage the

NI USB-6509 components. National Instruments is not liable for any damage or injury

resulting from such a connection.

For more information on maximum power ratings and overcurrent limits,

refer to the Specifications section.

Industrial DIO Features

The NI USB-6509 features digital filtering, programmable power-up

states, change detection, and a watchdog timer.

Digital Filtering

Use the digital filter option available on the NI USB-6509 input lines to

eliminate glitches on input data. When used with change detection, filtering

can also reduce the number of changes to examine and process.

You can configure the digital input channels to pass through a digital filter,

and you can control the timing interval the filter uses. The filter blocks

pulses that are shorter than half of the specified timing interval and passes

pulses that are longer than the specified interval. Intermediate-length

pulses—pulses longer than half of the interval but less than the

interval—may or may not pass the filter.

Table 3 lists the pulse widths guaranteed to be passed and blocked.

Table 3. NI USB-6509 Digital Filtering

Pulse Width Passed Pulse Width Blocked

Filter Interval

t

interval

Low Pulse High Pulse Low Pulse High Pulse

t

interval

t

interval

t

/2 t

interval

interval

/2

You can enable filtering on as many input lines as is necessary for your

application. All filtered lines share the same timing interval, which ranges

from 200 ns to 200 ms.

NI 6509 User Guide and Specifications 20 ni.com

Page 21

External

Signal

Filter

Clock

Sample Clock (20.83 ns)

External

Signal

Sampled

Filtered

Signal

Internally, the filter uses two clocks: the sample clock and the filter clock.

The sample clock has a frequency of 48 MHz that corresponds to a period

of 20.83 ns. The filter clock is generated by a counter and has a period equal

to one half of the specified timing interval. The input signal is sampled on

each rising edge of the sample clock. However, a change in the input signal

is recognized only if it maintains its new state for at least two consecutive

rising edges of the filter clock.

The filter clock is programmable and allows you to control how long a

pulse must last to be recognized. The sample clock provides a fast sample

rate to ensure that input pulses remain constant between filter clocks.

Digital Filtering Example

Figure 18 shows a filter configuration with an 208 ns filter interval

(104 ns filter clock).

HL L L H

HLL L H

H

A

H

B

HH HH H

H

C

Figure 18. Digital Filtering Example

In periods A and B, the filter blocks the glitches because the external signal

does not remain steadily high from one rising edge of the filter clock to the

next. In period C, the filter passes the transition because the external signal

remains steadily high. Depending on when the transition occurs, the filter

may require up to two filter clocks—one full filter interval—to pass a

transition. Figure 18 shows a rising (0 to 1) transition. The same filtering

applies to falling (1 to 0) transitions.

© National Instruments Corporation 21 NI 6509 User Guide and Specifications

Page 22

Programmable Power-Up States

At power-up, the output drives on the NI USB-6509 are disabled. All lines

are user-configurable for high-impedance input, high output, or low output.

User-configurable power-up states are useful for ensuring that the

NI USB-6509 powers up in a known state.

To use MAX (recommended) to program the power-up states, select

the device and click the Properties button. Refer to the software

documentation for information about how to program the power-up states

using NI-DAQ with LabVIEW or other National Instruments application

development environments (ADEs).

Note Using the programmable power-up states feature overrides the state configured

using the I/O pull-up/pull-down switch.

Change Detection

You can program the NI USB-6509 to send an interrupt when a change

occurs on any input line.

The NI USB-6509 can monitor changes on selected input lines or on all

input lines. It can monitor for rising edges (0 to 1), falling edges (1 to 0),

or both. When an input change occurs, the NI USB-6509 generates an

interrupt, and the NI-DAQ driver then notifies the software.

Note Excessive change detections can affect system performance. Use digital filtering to

minimize the effects of noisy input lines.

The NI USB-6509 sends a change detection when any one of the changes

occurs, but it does not report which line changed or if the line was rising or

falling. After a change, you can read the input lines to determine the current

line states. The maximum rate of change detection is determined by the

software response time, which varies from system to system.

An overflow bit indicates that an additional rising or falling edge has been

detected before the software could process the previous change.

Refer to the software documentation for information about how to set up

and implement the change detection.

NI 6509 User Guide and Specifications 22 ni.com

Page 23

Change Detection Example

Table 4 shows a change detection example for six bits of one port.

Table 4. Change Detection Example

Bit

7 6 5 4 3 2 1 0

Changes to detect — —

Enable rising-edge

detection

Enable falling-edge

detection

Watchdog Timer

yes yes yes yes no no yes no

yes yes yes yes no no no yes

This example assumes the following line connections:

• Bits 7, 6, 5, and 4 are connected to data lines from a four-bit TTL

output device. The NI USB-6509 detects any change in the input data

so you can read the new data value.

• Bit 1 is connected to a limit sensor. The NI USB-6509 detects rising

edges on the sensor, which correspond to over-limit conditions.

• Bit 0 is connected to a switch. The software can react to any switch

closure, which is represented by a falling edge. If the switch closure is

noisy, enable digital filtering for this line.

In this example, the NI USB-6509 reports rising edges only on bit 1, falling

edges only on bit 0, and rising and falling edges on bits 7, 6, 5, and 4.

The NI USB-6509 reports no changes for bits 3 and 2. After receiving

notification of a change, you can read the port to determine the current

values of all eight lines. You cannot read the state of any lines that are

configured for change detection until the change detection interrupt occurs.

The watchdog timer is a software configurable feature used to set critical

outputs to safe states in the event of a software failure, a system crash, or

any other loss of communication between the application and the

NI USB-6509.

When the watchdog timer is enabled, if the NI USB-6509 does not receive

a watchdog reset software command within the time specified for the

watchdog timer, the outputs go to a user-defined safe state and remain in

that state until the watchdog timer is disarmed by the application and new

values are written, the NI USB-6509 is reset, or the computer is restarted.

© National Instruments Corporation 23 NI 6509 User Guide and Specifications

Page 24

The expiration signal that indicates an expired watchdog continues to assert

until the watchdog is disarmed. After the watchdog timer expires, the

NI USB-6509 ignores any writes until the watchdog timer is disarmed.

Note When the watchdog timer is enabled and the computer enters a fault condition, ports

that are set to tri-state remain tri-stated and do not go to user-defined safe states.

You can set the watchdog timer timeout period to specify the amount of

time that must elapse before the watchdog timer expires. The counter on the

watchdog timer is configurable up to (2

1.5 minutes) before it expires.

Cables and Accessories

Table 5 lists the products available for use with the NI USB-6509.

Table 5. NI USB-6509 Connectivity Options

Cable Accessory

SH100-100-F shielded cable—part number 185095-01 (1 m)

or 185095-02 (2 m)

R1005050 ribbon cable—part number 182762-0R5 (0.5 m),

182762-01 (1 m), or 182762-02 (2 m)

— CB-100 I/O kit (cable included in kit)

— +12 VDC power supply—part number 780308-0x (where

32

– 1) × 20.83 ns (approximately

SCB-100 connector block—part number 776990-01

CB-50 connector block, DIN-rail

mount—part number 776164-90

CB-50LP connector block, panel

mount—part number 777101-01

(unshielded)—part number 777812-01

the x indicates different regions or cable options)

For more information about optional equipment available from National

Instruments, visit

ni.com.

Specifications

This section lists the specifications of the NI USB-6509 devices. These

specifications are typical at 25 °C, unless otherwise stated.

Number of channels................................96 input/output

Compatibility ..........................................TTL/CMOS, single-ended

GND referenced

NI 6509 User Guide and Specifications 24 ni.com

Page 25

Power-on state........................................ Configured as inputs,

Pull-up/pull-down resistor...................... 100 kΩ ±5%

Data transfers ......................................... Programmed I/O

Digital Input Characteristics

Input voltage 0 V 5.0 V

pull-up/pull-down (selectable on

the back panel switch)

Level Min Max

Input low voltage

Input high voltage

Input low current (V

Input high current (V

Digital Output Characteristics

Low-level output current (IOL) — — 24 mA

High-level output current (IOH) — — –24 mA

Output low voltage (VOL), at 100 μA

Output high voltage (VOH), at –100 μA

—

2.0 V

= 0 V)

in

= 5 V)

in

Level Min Typ Max

at 2 mA

at 12 mA

at 24 mA

at –2 mA

at –12 mA

—

—

—

—

—

—

4.3 V

—

—

0.0 V

0.1 V

0.5 V

1.0 V

5.0 V

4.9 V

4.5 V

0.8 V

—

–91.0 μA

91.0 μA

0.2 V

—

—

1.4 V

—

—

—

at –24 mA

© National Instruments Corporation 25 NI 6509 User Guide and Specifications

2.8 V

4.0 V

—

Page 26

Note The I/O connector power has a fuse for overcurrent protection. This fuse is not

customer replaceable. If the fuse is blown, return the device to NI for repair.

Bus Interface

Power Requirement

The total current sinking/sourcing from one port cannot exceed 100 mA.

Total current sourced by all DO lines simultaneously should not exceed

215 mA for bus-powered configuration. If more sourcing current is

required, use an optional external power supply

+5V power available at

I/O connector (pins 49 and 99) ...............+4.1 to +5.2 V;

215 mA, maximum

(Bus-powered);

0.5 A, maximum (with

external power supply)

USB ........................................................USB 2.0 Hi-Speed or full-speed

USB

Input voltage....................................4.5 to 5.25 V in configured state

No load current ................................150 mA, max

Maximum load current ....................500 mA, max

Suspend current ...............................250 μA, typical

(no external supply)

External DC supply

Input voltage range ..........................+12 V ±20%

Maximum input current...................1 A

Power input connector.....................DC input jack with threaded

locking ring, 0.08 in. (2 mm)

center pin

Power input mating connector.........Switchcraft S760K

1

Physical

Dimensions .............................................17.78 × 10.30 × 3.34 cm

(7.0 × 4.1 × 1.3 in.)

I/O connector ..........................................100-pin female 0.050 series SCSI

Weight ....................................................Approx. 239 g (8.4 oz)

1

If you are using the NI USB-6509 in full-speed mode, device performance is lower.

NI 6509 User Guide and Specifications 26 ni.com

Page 27

Safety

Note For UL and other safety certifications, refer to the product label or visit ni.com/

certification

in the Certification column.

Environmental

This product is designed to meet the requirements of the following

standards of safety for electrical equipment for measurement, control,

and laboratory use:

• IEC 61010-1, EN 61010-1

• UL 61010-1, CSA 61010-1

, search by model number or product line, and click the appropriate link

Hazardous Locations

The NI USB-6509 is not certified for use in hazardous locations.

The NI USB-6509 device is intended for indoor use only.

Operating temperature

(IEC 60068-2-1 and IEC 60068-2-2) ..... 0 to 55 °C

Operating humidity

(IEC 60068-2-56)...................................10 to 90% RH, noncondensing

Maximum altitude .................................. 2,000 m (at 25 °C ambient

temperature)

Storage temperature

(IEC 60068-2-1 and IEC 60068-2-2) ..... – 40 to 85 °C

Storage humidity

(IEC 60068-2-56)...................................5 to 90% RH, noncondensing

Pollution Degree (IEC 60664) ............... 2

Electromagnetic Compatibility

This product is designed to meet the requirements of the following

standards of EMC for electrical equipment for measurement, control,

and laboratory use:

• EN 61326 EMC requirements; Minimum Immunity

• EN 55011 Emissions; Group 1, Class A

• CE, C-Tick, ICES, and FCC Part 15 Emissions; Class A

Note For EMC compliance, operate this device according to product documentation.

© National Instruments Corporation 27 NI 6509 User Guide and Specifications

Page 28

CE Compliance

⬉ᄤֵᙃѻક∵ᶧࠊㅵ⧚ࡲ⊩ ˄Ё

˅

Ёᅶ᠋

This product meets the essential requirements of applicable European

Directives, as amended for CE marking, as follows:

• 2006/95/EC; Low-Voltage Directive (safety)

• 2004/108/EC; Electromagnetic Compatibility Directive (EMC)

Note Refer to the Declaration of Conformity (DoC) for this product for any additional

regulatory compliance information. To obtain the DoC for this product, visit

certification

, search by model number or product line, and click the appropriate link

in the Certification column.

Environmental Management

NI is committed to designing and manufacturing products in an

environmentally responsible manner. NI recognizes that eliminating

certain hazardous substances from our products is beneficial not only to the

environment but also to NI customers.

For additional environmental information, refer to the NI and the

Environment web page at

environmental regulations and directives with which NI complies, as well

as other environmental information not included in this document.

ni.com/

ni.com/environment. This page contains the

Waste Electrical and Electronic Equipment (WEEE)

EU Customers At the end of their life cycle, all products must be sent to a WEEE recycling

center. For more information about WEEE recycling centers and National Instruments

WEEE initiatives, visit

ni.com/environment/weee.htm.

RoHS

National Instruments

݇Ѣ

National InstrumentsЁRoHS

(For information about China RoHS compliance, go to

NI 6509 User Guide and Specifications 28 ni.com

ヺড়Ё⬉ᄤֵᙃѻકЁ䰤ࠊՓ⫼ᶤѯ᳝ᆇ⠽䋼ᣛҸ

ড়㾘ᗻֵᙃˈ䇋ⱏᔩ

ni.com/environment/rohs_china

ni.com/environment/rohs_china

(RoHS)

DŽ

DŽ

.)

Page 29

Safety Guidelines

Caution Operate the hardware only as described in these operating instructions.

The following section contains important safety information that you must

follow when installing and using the NI USB-6509.

Do not operate the NI USB-6509 in a manner not specified in this

document. Misuse of the device can result in a hazard. You can compromise

the safety protection built into the device if the device is damaged in any

way. If the device is damaged, contact National Instruments for repair.

Do not substitute parts or modify the device except as described in this

document. Use the device only with the chassis, modules, accessories, and

cables specified in the installation instructions. You must have all covers

and filler panels installed during operation of the device.

Do not operate the device in an explosive atmosphere or where there may

be flammable gases or fumes. If you must operate the device in such an

environment, it must be in a suitably rated enclosure.

If you need to clean the device, use a dry cloth. Make sure that the device

is completely dry and free from contaminants before returning it to service.

Operate the device only at or below Pollution Degree 2. Pollution is foreign

matter in a solid, liquid, or gaseous state that can reduce dielectric strength

or surface resistivity. The following is a description of pollution degrees:

• Pollution Degree 1 means no pollution or only dry, nonconductive

pollution occurs. The pollution has no influence.

• Pollution Degree 2 means that only nonconductive pollution occurs in

most cases. Occasionally, however, a temporary conductivity caused

by condensation must be expected.

• Pollution Degree 3 means that conductive pollution occurs, or dry,

nonconductive pollution occurs that becomes conductive due to

condensation.

You must insulate signal connections for the maximum voltage for which

the device is rated. Do not exceed the maximum ratings for the device. Do

not install wiring while the device is live with electrical signals. Do not

remove or add connector blocks when power is connected to the system.

Avoid contact between your body and the connector block signal when hot

swapping modules. Remove power from signal lines before connecting

them to or disconnecting them from the device.

© National Instruments Corporation 29 NI 6509 User Guide and Specifications

Page 30

Operate the device at or below the Measurement Category I1. Measurement

circuits are subjected to working voltages

2

and transient stresses

(overvoltage) from the circuit to which they are connected during

measurement or test. Measurement categories establish standard impulse

withstand voltage levels that commonly occur in electrical distribution

systems. The following is a description of measurement categories:

• Measurement Category I is for measurements performed on circuits

not directly connected to the electrical distribution system referred to

as MAINS

3

voltage. This category is for measurements of voltages

from specially protected secondary circuits. Such voltage

measurements include signal levels, special equipment, limited-energy

parts of equipment, circuits powered by regulated low-voltage sources,

and electronics.

• Measurement Category II is for measurements performed on circuits

directly connected to the electrical distribution system. This category

refers to local-level electrical distribution, such as that provided by a

standard wall outlet (for example, 115 V for U.S. or 230 V for Europe).

Examples of Measurement Category II are measurements performed

on household appliances, portable tools, and similar E Series devices.

• Measurement Category III is for measurements performed in the

building installation at the distribution level. This category refers to

measurements on hard-wired equipment such as equipment in fixed

installations, distribution boards, and circuit breakers. Other examples

are wiring, including cables, bus-bars, junction boxes, switches,

socket-outlets in the fixed installation, and stationary motors with

permanent connections to fixed installations.

Measurement Category IV is for measurements performed at the primary

electrical supply installation (<1,000 V). Examples include electricity

meters and measurements on primary overcurrent protection devices and

on ripple control units.

1

Measurement Category as defined in electrical safety standard IEC 61010-1. Measurement Category is also referred to as

Installation Category.

2

Working Voltage is the highest rms value of an AC or DC voltage that can occur across any particular insulation.

3

MAINS is defined as a hazardous live electrical supply system that powers equipment. Suitably rated measuring circuits may

be connected to the MAINS for measuring purposes.

NI 6509 User Guide and Specifications 30 ni.com

Page 31

Where to Go for Support

The National Instruments Web site is your complete resource for technical

support. At

troubleshooting and application development self-help resources to email

and phone assistance from NI Application Engineers.

A Declaration of Conformity (DoC) is our claim of compliance with the

Council of the European Communities using the manufacturer’s

declaration of conformity. This system affords the user protection for

electronic compatibility (EMC) and product safety. You can obtain the DoC

for your product by visiting

supports calibration, you can obtain the calibration certificate for your

product at

National Instruments corporate headquarters is located at

11500 North Mopac Expressway, Austin, Texas, 78759-3504.

National Instruments also has offices located around the world to help

address your support needs. For telephone support in the United States,

create your service request at

instructions or dial 512 795 8248. For telephone support outside the United

States, contact your local branch office:

Australia 1800 300 800, Austria 43 662 457990-0,

Belgium 32 (0) 2 757 0020, Brazil 55 11 3262 3599,

Canada 800 433 3488, China 86 21 5050 9800,

Czech Republic 420 224 235 774, Denmark 45 45 76 26 00,

Finland 358 (0) 9 725 72511, France 01 57 66 24 24,

Germany 49 89 7413130, India 91 80 41190000, Israel 972 3 6393737,

Italy 39 02 41309277, Japan 0120-527196, Korea 82 02 3451 3400,

Lebanon 961 (0) 1 33 28 28, Malaysia 1800 887710,

Mexico 01 800 010 0793, Netherlands 31 (0) 348 433 466,

New Zealand 0800 553 322, Norway 47 (0) 66 90 76 60,

Poland 48 2 2 3390150 , Portugal 351 210 311 210, Russia 7 495 783 6851,

Singapore 1800 226 5886, Slovenia 386 3 425 42 00,

South Africa 27 0 11 805 8197, Spain 34 91 640 0085,

Sweden 46 (0) 8 587 895 00, Switzerland 41 56 2005151,

Taiwan 886 02 2377 2222, Thailand 662 278 6777,

Turkey 90 212 279 3031, United Kingdom 44 (0) 1635 523545

ni.com/support you have access to everything from

ni.com/calibration.

ni.com/certification. If your product

ni.com/support and follow the calling

National Instruments, NI, ni.com, and LabVIEW are trademarks of National Instruments Corporation.

Refer to the Terms of Use section on ni.com/legal for more information about National

Instruments trademarks. Other product and company names mentioned herein are trademarks or trad e

names of their respective companies. For patents covering National Instruments products, refer to the

appropriate location: Help»Patents in your software, the patents.txt file on your CD, or

ni.com/patents.

© 2008 National Instruments Corporation. All rights reserved.

372136A-01 Mar08

Loading...

Loading...