Page 1

NI UES-3880

Hardware Installation Guide

First Edition, Sept 2007

P/N: 1802003080110

Page 2

Overview

The NI UES-3880 is a smart Ethernet switch that provides an economical

solution for your Ethernet connections. As an added bonus, the built-in smart

alarm function helps system maintainers monitor the health of your Ethernet

network.

The NI UES-3880 has a wide operating temperature range of -40 to 75ºC, and

is designed to withstand a high degree of vibration and shock. The rugged

hardware design makes either model perfect for ensuring that your Ethernet

equipment can withstand critical industrial applications, and complies with

FCC and CE Standards.

Package Checklist

Your NI UES-3880 is shipped with the following items. If any of these items

are missing or damaged, please contact your customer service representative

for assistance.

y NI UES-3880 Switch

y Hardware Installation Guide

y Protective caps for unused ports

Features

High Performance Network Switching Technology

y 10/100BaseT(X) (RJ45)

y IEEE802.3/802.3u/802.3x

y Store and Forward switching process type, with 1024 address entries

y 10/100M, Full/Half-Duplex, MDI/MDIX auto-sensing

Industrial Grade Reliability

y Power failure, port break alarm by relay output

y Redundant dual DC power inputs

Rugged Design

y Operating temperature range from -40 to 75ºC

y IP30, rugged high-strength case

y DIN-rail or panel mounting ability

WARNING

The power for this product is intended to be supplied by a Listed

Power Supply, with output marked LPS, and rated to deliver 12 to

48 VDC at a maximum of 0.6A.

The DC jack should be used with an LPS unit that is rated to

deliver 12 to 48 VDC at a minimum of 1.1A. The product should

not be disassembled by operators or service people.

— 1 —

Page 3

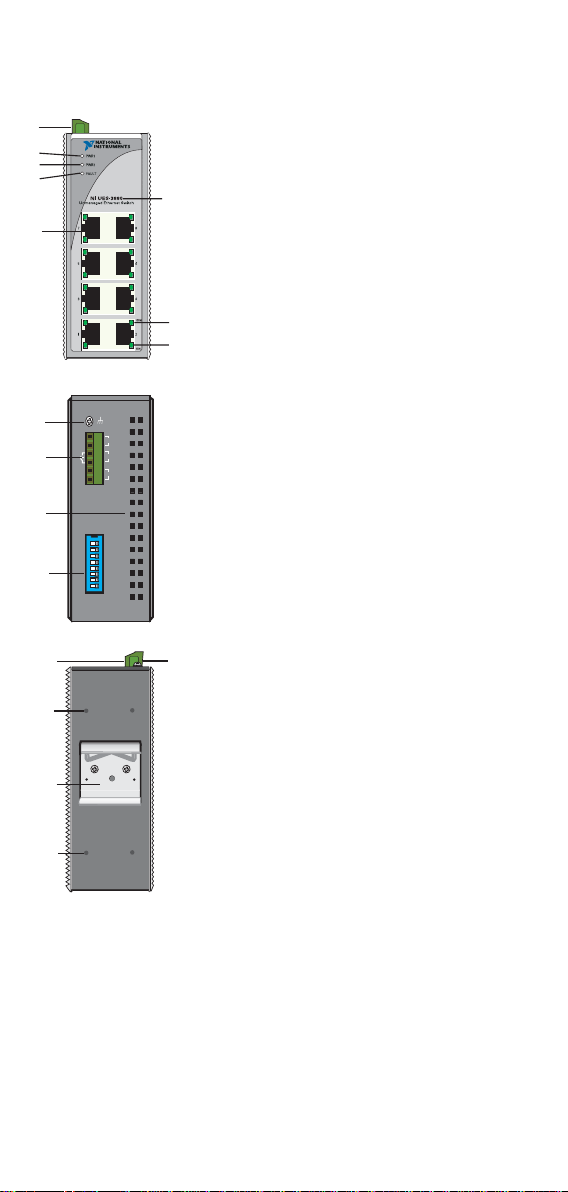

Panel Layout

Front Panel View

2

5

6

7

8

Top Panel View

1

2

3

4

V2+

V2-

V1+

V1-

V1 V2 INPUTS: 24 VDC

PORT ALARM

12345678

ON DIP

11

9

10

PWR2

FAULT

PWR1

1. Grounding screw

2. Terminal block for power inputs

PWR1/PWR2 and relay output

3. Heat dissipation orifices

4. DIP switches

5. Power input PWR1 LED

6. Power input PWR2 LED

7. Fault LED

8. 10/100BaseT(X) Port

9. TP port’s 100 Mbps LED

10. TP port’s 10 Mbps LED

11. Model Name

12. Screw holes for wall mounting kit

13. DIN-rail Kit

Rear Panel View

2

12

13

12

1

— 2 —

Page 4

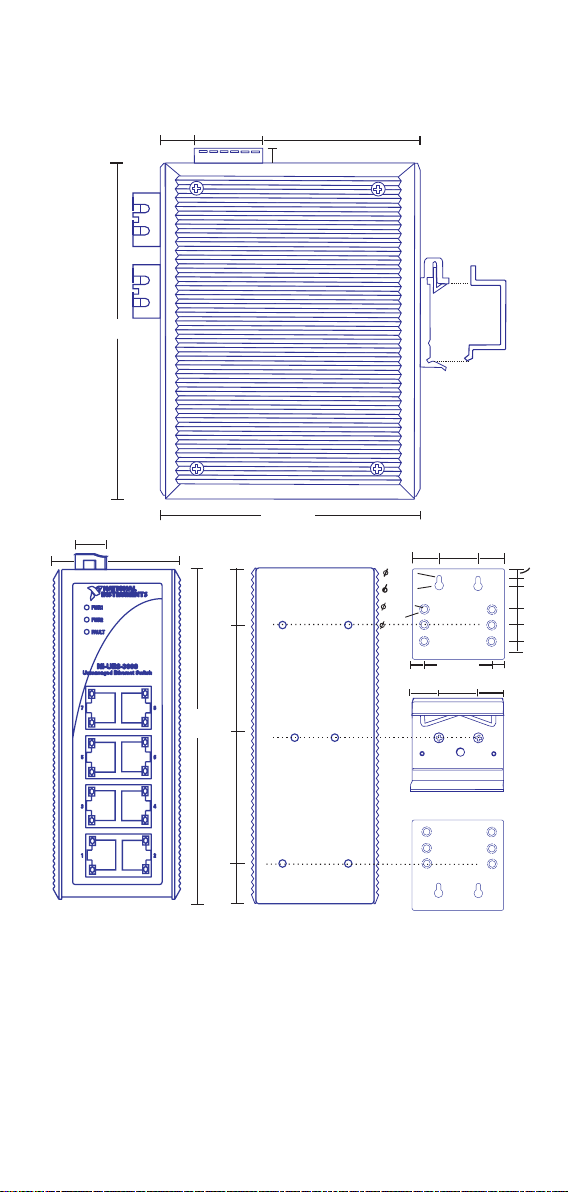

Mounting Dimensions (unit = mm)

30.00

21.00

135.00

54.00

9.50

Side View

(unit = mm)

13.10

15.10

25.40

Front View

135.00

25.7123.15

39.3746.77

105.00

+

+

Rear View

3.50

6.00

3.50

6.00

+

7.75

+

13.90

13.90

18.20

+

+

+

+

+

+

+

+

+

+

30.50

+

+

+

+

+

131813

+

+

+

+

+

Panel Mount Kit

7.75

9.75

26

10

10

6

5

— 3 —

Page 5

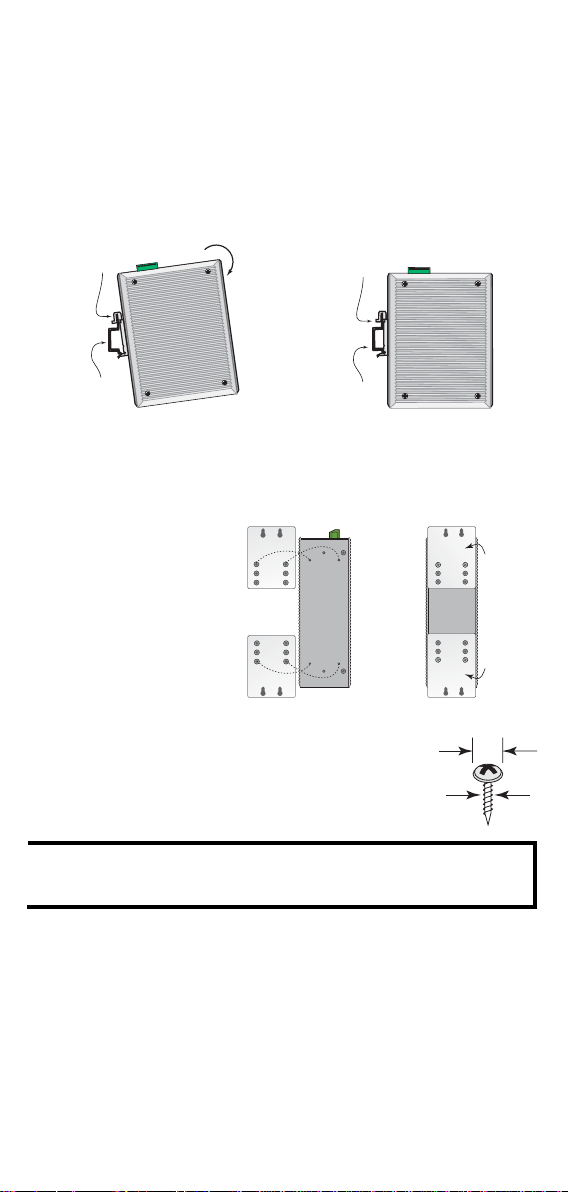

DIN-rail Mounting

The aluminum DIN-rail attachment plate should already be fixed to the back

panel of the switch when you take it out of the box. If you need to reattach the

DIN-rail attachment plate, make sure the stiff metal spring is situated towards

the top, as shown in the figures below.

STEP 1:

Insert the top of the DIN-rail into the

slot just below the stiff metal spring.

metal

spring

STEP 2:

The DIN-rail attachment unit will

snap into place as shown below.

metal

spring

DIN-Rail

To remove the switch from the DIN-rail, simply reverse Steps 1 and 2 above.

DIN-Rail

Wall Mounting (optional)

For some applications, you will find it convenient to mount the NI UES-3880

on the wall, as illustrated below.

STEP 1:

Remove the aluminum

DIN-rail attachment plate

from the NI UES-3880’s rear

panel, and then attach the

wall mount plates, as shown

in the diagram below.

STEP 2:

Mounting the NI UES-3880 on the wall requires 4 screws.

Use the switch, with wall mount plates attached, as a guide

to mark the correct locations of the 4 screws. The heads of

the screws should be less than 6.0 mm in diameter, and the

shafts should be less than 3.5 mm in diameter, as shown in

the figure at the right.

Before tightening the screws into the wall, make sure the screw head

NOTE

and shank size are suitable by inserting the screw into one of the

keyhole-shaped apertures of the Wall Mounting Plates.

Do not screw the screws in all the way—leave about 2 mm to allow room for

sliding the wall mount panel between the wall and the screws.

⇒

3.5 mm

top

plate

bottom

plate

6.0 mm

— 4 —

Page 6

STEP 3:

Once the screws are fixed in the

wall, insert the four screw heads

through the large parts of the

keyhole-shaped apertures, and then

slide the NI UES-3880

downwards, as indicated. Tighten

the four screws for added stability.

Wiring Requirements

WARNING

Do not disconnect modules or wires unless the power supply has

been switched off or the area is known to be non-hazardous. The

devices may only be connected to the supply voltage shown on

the type plate.

The devices are designed for operation with a Safety Extra-Low

Voltage. Thus, they may only be connected to the supply voltage

connections and to the signal contact with the Safety Extra-Low

Voltages (SELV) in compliance with IEC950/ EN60950/

VDE0805.

WARNING

Substitution of components may impair suitability for Class I,

Division 2, and Zone 2. These devices must be supplied by an

SELV source as defined in Low Voltage Directive 73/23/EEC

and 93/68/EEC.

WARNING

This unit is a built-in type. When the unit is installed in another

piece of equipment, the equipment enclosing the unit must

comply with fire enclosure regulation IEC 60950/EN60950 (or

similar regulation).

WARNING

Safety First!

Be sure to disconnect the power cord before installing and/or

wiring your Switch.

Calculate the maximum possible current in each power wire and

common wire. Observe all electrical codes dictating the

maximum current allowable for each wire size.

If the current goes above the maximum ratings, the wiring could

overheat, causing serious damage to your equipment.

⇒

— 5 —

Page 7

You should also pay attention to the following items:

y Use separate paths to route wiring for power and devices. If power wiring

and device wiring paths must cross, make sure the wires are perpendicular

at the intersection point.

y NOTE: Do not run signal or communications wiring and power wiring in

the same wire conduit. To avoid interference, wires with different signal

characteristics should be routed separately.

y You can use the type of signal transmitted through a wire to determine

which wires should be kept separate. The rule of thumb is that wiring that

shares similar electrical characteristics can be bundled together.

y Keep input wiring and output wiring separated.

y It is strongly advised that you label wiring to all devices in the system when

necessary.

Grounding the Switch

Grounding and wire routing help limit the effects of noise due to

electromagnetic interference (EMI). Run the ground connection from the

ground screw to the grounding surface prior to connecting devices.

ATTENTION

This product is intended to be mounted to a well-grounded

mounting surface, such as a metal panel.

Wiring the Alarm Contact

The Alarm Contact consists of the two middle contacts of the terminal block on

the NI UES-3880’s top panel. You may refer to the next section for detailed

instructions on how to connect the wires to the terminal block connector, and

how to attach the terminal block connector to the terminal block receptor. In

this section, we explain the meaning of the two contacts used to connect the

Alarm Contact.

FAULT

Top View

FAULT

Front View

FAULT: The two middle contacts of the

6-contact terminal block connector are used to

detect both power faults and port faults. The two

wires attached to the Fault contacts form an open

circuit when:

1. The NI UES-3880 has lost power from one of

the DC power inputs.

OR

2. One of the ports for which the corresponding

PORT ALARM DIP Switch is set to ON is

not properly connected.

If neither of these two conditions is satisfied, the

Fault circuit will be closed.

Wiring the Redundant Power Inputs

The top two contacts and the bottom two contacts of the 6-contact terminal

block connector on the NI UES-3880’s top panel are used for the NI

UES-3880’s two DC inputs. Top and front views of one of the terminal block

connectors are shown here.

— 6 —

Page 8

STEP 1: Insert the negative/positive DC wires

r

Top View

Front View

into the V-/V+ terminals.

STEP 2: To keep the DC wires from pulling

loose, use a small flat-blade screwdriver to

tighten the wire-clamp screws on the front of the

terminal block connector.

STEP 3: Insert the plastic terminal block

connector prongs into the terminal block

receptor, which is located on the NI UES-3880’s

top panel.

ATTENTION

Before connecting the NI UES-3880 to the DC power inputs,

make sure the DC power source voltage is stable.

10/100BaseT(X) Ethernet Port Connection

The 10/100BaseT(X) ports located on the NI UES-3880’s front panel are used

to connect to Ethernet-enabled devices.

Below we show pinouts for both MDI (NIC-type) ports and MDI-X

(HUB/Switch-type) ports, and also show cable wiring diagrams for

straight-through and cross-over Ethernet cables.

MDI Port Pinouts MDI-X Port Pinouts 8-pin RJ45

Pin Signal Pin Signal

1 Tx+ 1 Rx+

2 Tx- 2 Rx 3 Rx+ 3 Tx+

6 Rx- 6 Tx-

RJ45 (8-pin) to RJ45 (8-pin) Straight-Through Cable Wiring

Switch Port

RJ45

Connector

Tx+

TxRx+

Rx-

Straight-Through Cable

RJ45 Plug Pin 1

Cable Wiring

3 3

6 6

1 1

2 2

1

8

NIC Port

RJ45

Connecto

Rx+

RxTx+

Tx-

— 7 —

Page 9

RJ45 (8-pin) to RJ45 (8-pin) Cross-Over Cable Wiring

Switch Port

(NIC Port)

RJ45

Connector

Tx+

(Rx+)

Tx-

(Rx-)

Rx+

(Tx+)

Rx-

(Tx-)

3 1

6 2

1 3

2 6

Cross-Over Cable

RJ45 Plug Pin 1

Cable Wiring

Switch Port

(NIC Port)

RJ45

Connector

(Tx+)

Rx+

(Tx-)

Rx-

(Rx+)

Tx+

(Rx-)

Tx-

Redundant Power Inputs

Both power inputs can be connected simultaneously to live DC power sources.

If one power source fails, the other live source acts as a backup, and

automatically supplies all of the NI UES-3880’s power needs.

Alarm Contact

The NI UES-3880 has one Alarm Contact located on the top panel. For detailed

instructions on how to connect the Alarm Contact power wires to the two

middle contacts of the 6-contact terminal block connector, see the Wiring the

Alarm Contact section. A typical scenario would be to connect the Fault circuit

to a warning light located in the control room. The light can be set up to switch

on when a fault is detected.

The Alarm Contact has two terminals that form a Fault circuit for connecting to

an alarm system. The two wires attached to the Fault contacts form an open

circuit when (1) the NI UES-3880 has lost power from one of the DC power

inputs, or (2) one of the ports for which the corresponding PORT ALARM DIP

Switch is set to ON is not properly connected.

If neither of these two conditions occurs, the Fault circuit will be closed.

DIP Switch Settings

ON DIP

12345678

ON: Enables the corresponding PORT Alarm. If the port’s link fails, the relay

will form an open circuit and the fault LED will light up.

Off: Disables the corresponding PORT Alarm. The relay will form a closed

circuit and the Fault LED will never light up.

— 8 —

Page 10

LED Indicators

The front panel of the NI Switch contains several LED indicators. The function

of each LED is described in the table below.

LED Color State Description

Power is being supplied to power input

On

PWR1

PWR2

FAULT

10M

100M

AMBER

AMBER

RED

GREEN

GREEN

Blinking Data is being transmitted at 10 Mbps

Blinking Data is being transmitted at 100 Mbps

PWR1

Power is not being supplied to power

Off

input PWR1

Power is being supplied to power input

On

PWR2

Power is not being supplied to power

Off

input PWR2

When the corresponding PORT alarm is

On

enabled, and the port’s link is inactive.

When the corresponding PORT alarm is

enabled and the port’s link is active, or

Off

when the corresponding PORT alarm is

disabled.

On TP port’s 10 Mbps link is active

Off TP Port’s 10 Mbps link is inactive

On TP port’s 100 Mbps link is active

Off TP Port’s 100 Mbps link is inactive

Auto MDI/MDI-X Connection

The Auto MDI/MDI-X function allows users to connect the NI UES-3880’s

10/100BaseTX ports to any kind of Ethernet device, without needing to pay

attention to the type of Ethernet cable being used for the connection. This

means that you can use either a straight-through cable or cross-over cable to

connect the NI UES-3880 to Ethernet devices.

Dual Speed Functionality and

Switching

The NI UES-3880’s 10/100 Mbps switched RJ45 port auto-negotiates with the

connected device for the fastest data transmission rate supported by both

devices. The NI UES-3880 is a plug-and-play devices, so that software

configuration is not required at installation, or during maintenance. The

half/full duplex mode for the switched RJ45 ports is user dependent and

changes (by auto-negotiation) to full or half duplex, depending on which

transmission speed is supported by the attached device.

Switching, Filtering, and Forwarding

Each time a packet arrives at one of the switched ports, a decision is made to

either filter or forward the packet. Packets with source and destination

addresses belonging to the same port segment will be filtered, constraining

those packets to one port, and relieving the rest of the network from the need to

process them. A packet with destination address on another port segment will

be forwarded to the appropriate port, and will not be sent to the other ports

— 9 —

Page 11

where it is not needed. Packets that are used in maintaining the operation of the

network (such as the occasional multi-cast packet) are forwarded to all ports.

The NI UES-3880 operates in the store-and-forward switching mode, which

eliminates bad packets and enables peak performance to be achieved when

there is heavy traffic on the network.

Switching and Address Learning

The NI UES-3880 has an address table that can hold up to 1K node addresses,

which makes it suitable for use with large networks. The address tables are

self-learning, so that as nodes are added or removed, or moved from one

segment to another, the NI UES-3880 automatically keeps up with new node

locations. An address-aging algorithm causes the least-used addresses to be

deleted in favor of newer, more frequently used addresses. To reset the address

buffer, power down the unit and then power it back up.

Auto-Negotiation and Speed Sensing

The NI UES-3880 is a RJ45 Ethernet ports independently support

auto-negotiation for speeds in the 10BaseT and 100BaseTX modes, with

operation according to the IEEE 802.3u standard. This means that some nodes

could be operating at 10 Mbps, while at the same time, other nodes are

operating at 100 Mbps.

Auto-negotiation takes place when an RJ45 cable connection is made, and then

each time a LINK is enabled. The NI UES-3880 advertises its capability for

using either 10 Mbps or 100 Mbps transmission speeds, with the device at the

other end of the cable expected to similarly advertise. Depending on what type

of device is connected, this will result in agreement to operate at a speed of

either 10 Mbps or 100 Mbps.

If the NI UES-3880 RJ45 Ethernet port is connected to a non-negotiating

device, it will default to 10 Mbps speed and half-duplex mode, as required by

the IEEE 802.3u standard.

— 10 —

Page 12

Specifications

Technology

Standards IEEE802.3, 802.3u, 802.3x

Forward and Filtering

Rate

Packet Buffer Memory 256 KB

Processing Type

Address Table Size 1K uni-cast addresses

Latency Less than 5 μs

Interface

RJ45 Ports

LED Indicators Power, Fault, 10M, 100M

DIP Switch Port break alarm mask

Alarm Contact

Power

Input Voltage 12 to 48 VDC, redundant inputs

Input Current @ 24VDC 0.25 A

Connection Removable “6-pin” Terminal Block

Overload Current

Protection

Reverse Polarity

Protection

Mechanical

Casing IP30 protection, metal case

Dimensions

Weight 0.63 kg

Installation DIN-rail, Wall Mounting

Environmental

Operating Temperature -40 to 75ºC (-40 to 167ºF)

Storage Temperature -40 to 85ºC (-40 to 185ºF)

Ambient Relative

Humidity

Regulatory Approvals

Safety

Hazardous Location UL/cUL Class I, Division 2, Groups A, B, C, and D

EMI FCC Part 15, CISPR (EN55022) class A

EMS

Operating Shock 15g, half-sine, 11 ms pulse

Operating Vibration 10 Hz to 150 Hz, 1 grms

148810 pps

Store and Forward, with IEEE802.3x full duplex,

back pressure flow control

10/100BaseT(X) auto negotiation speed, F/H duplex

mode, and auto MDI/MDI-X connection

One relay output with current carrying capacity of

1A @ 24 VDC

1.1 A

Present

53.6 × 135 × 105 mm (W × H × D)

5 to 95% (non-condensing)

UL60950-1, CSA C22.2 No. 60950-1, EN60950-1,

TUV

EN61000-4-2 (ESD), Level 3

EN61000-4-3 (RS), Level 3

EN61000-4-4 (EFT), Level 3

EN61000-4-5 (Surge), Level 3

EN61000-4-6 (CS), Level 3

— 11 —

Page 13

Technical Support and Professional

Services

Visit the following sections of the National Instruments Web site at ni.com for

technical support and professional services:

• Support— Online technical support resources at ni.com/support include

the following:

Self-Help Resources— For answers and solutions, visit the

award-winning National Instruments Web site for software drivers and

updates, a searchable KnowledgeBase, product manuals, step-by-step

troubleshooting wizards, thousands of example programs, tutorials,

application notes, instrument drivers, and so on.

Free Technical Support— All registered users receive free Basic

Service, which includes access to hundreds of Application Engineers

worldwide in the NI Discussion Forums at ni.com/forums. National

Instruments Application Engineers make sure every question receives

an answer.

For information about other technical support options in your area, visit

ni.com/services or contact your local office at ni.com/contact.

• Training and Certification— Visit ni.com/training for self-paced training,

eLearning virtual classrooms, interactive CDs, and Certification program

information. You also can register for instructor-led, hands-on courses at

locations around the world.

• System Integration— If you have time constraints, limited in-house

technical resources, or other project challenges, National Instruments

Alliance Partner members can help. To learn more, call your local NI office

or visit ni.com/alliance.

• Declaration of Conformity (DoC)— A DoC is our claim of compliance

with the Council of the European Communities using the manufacturer’s

declaration of conformity. This system affords the user protection for

electronic compatibility (EMC) and product safety. You can obtain the DoC

for your product by visiting ni.com/certification.

• Calibration Certificate— If your product supports calibration, you can

obtain the calibration certificate for your product at ni.com/calibration.

If you searched ni.com and could not find the answers you need, contact your

local office or NI corporate headquarters. Phone numbers for our worldwide

offices are listed at the front of this manual. You also can visit the Worldwide

Offices section of ni.com/niglobal to access the branch office Web sites, which

provide up-to-date contact information, support phone numbers, email

addresses, and current events.

— 12 —

Page 14

Worldwide Technical Support and Product Information

ni.com

National Instruments Corporate Headquarters

11500 North Mopac ExpresswayAustin, Texas 78759-3504USATel: 512 683

0100

Worldwide Offices

Australia 1800 300 800, Austria 43 662 457990-0, Belgium 32 (0) 2 757 0020,

Brazil 55 11 3262 3599, Canada 800 433 3488, China 86 21 5050 9800, Czech

Republic 420 224 235 774, Denmark 45 45 76 26 00, Finland 358 (0) 9 725

72511, France 01 57 66 24 24, Germany 49 89 7413130, India 91 80 41190000,

Israel 972 3 6393737, Italy 39 02 413091, Japan 81 3 5472 2970, Korea 82 02

3451 3400, Lebanon 961 (0) 1 33 28 28, Malaysia 1800 887710, Mexico 01

800 010 0793, Netherlands 31 (0) 348 433 466, New Zealand 0800 553 322,

Norway 47 (0) 66 90 76 60, Poland 48 22 3390150, Portugal 351 210 311 210,

Russia 7 495 783 6851, Singapore 1800 226 5886, Slovenia 386 3 425 42 00,

South Africa 27 0 11 805 8197, Spain 34 91 640 0085, Sweden 46 (0) 8 587

895 00, Switzerland 41 56 2005151, Taiwan 886 02 2377 2222, Thailand 662

278 6777, Turkey 90 212 279 3031, United Kingdom 44 (0) 1635 523545

For further support information, refer to the Cross referenceolor:Blueparatext

appendix. To comment on National Instruments documentation, refer to the

National Instruments Web site at ni.com/info and enter the info code feedback.

© 2007 National Instruments Corporation. All rights reserved.

— 13 —

Loading...

Loading...