Page 1

USER MANUAL

NI SMD-7613/7614/7615/7616

This manual contains information about the configuration and use of the National

Instruments SMD-7613, SMD-7614, SMD-7615, and SMD-7616. They are referred to

inclusively in this manual as the NI SMD-761x.

Note This manual is not applicable for NI SMD-7610/7611/7612 devices. Refer to

to the unique documentation for information related to the NI SMD-7610/7611/7612.

Functionality on these devices are roughly equivalent. The NI SMD-7613/7615 operates from

18 to 53 VDC, and has a running current of up to 5 A per phase. The SMD-7614/7616 operates

from 18 to 88 VDC, and runs current up to 10 A per phase. The SMD-7615/7616 features

encoder feedback.

Contents

Safety Information .................................................................................................................... 2

Block Diagram.......................................................................................................................... 3

Getting Started .......................................................................................................................... 4

Mounting the Drive .................................................................................................................. 4

Connecting the Power Supply .................................................................................................. 5

Choosing a Power Supply......................................................................................................... 5

Voltage.............................................................................................................................. 5

Current .............................................................................................................................. 6

Regeneration ..................................................................................................................... 7

Connecting the Drive Using Ethernet....................................................................................... 7

Motor Wiring Recommendations ............................................................................................. 12

Four Lead Motors ............................................................................................................. 13

Six Lead Motors ............................................................................................................... 13

Eight Lead Motors ............................................................................................................ 14

Connecting Input Signals.......................................................................................................... 15

STEP and DIR Inputs ....................................................................................................... 17

Single Ended Inputs.......................................................................................................... 19

Connecting Limit Switches and Sensors .......................................................................... 21

Analog Inputs ................................................................................................................... 22

Programmable Outputs ............................................................................................................. 23

Connecting an Encoder (SMD-7615/7616).............................................................................. 25

Configuring the Drive............................................................................................................... 28

Motor ................................................................................................................................ 28

Control .............................................................................................................................. 29

I/O Configuration ............................................................................................................. 31

Self Test ............................................................................................................................ 31

Page 2

Torque Speed Curves................................................................................................................ 32

Motor Heating...........................................................................................................................38

Drive Heating............................................................................................................................ 46

Mechanical Outline................................................................................................................... 48

Technical Specifications ........................................................................................................... 48

Alarm Codes ............................................................................................................................. 50

Safety Information

Only qualified personnel are permitted to transport, assemble, commission, and maintain this

equipment. Properly qualified personnel are persons who are familiar with the transport,

assembly, installation, commissioning and operation of motors, and who have the appropriate

qualifications for their jobs. The qualified personnel must know and observe the following

standards and regulations:

• IEC 364 resp. CENELEC HD 384 or DIN VDE 0100

• IEC report 664 or DIN VDE 0110

• National regulations for safety and accident prevention or VBG 4

To minimize the risk of potential safety problems, you should follow all applicable local and

national codes that regulate the installation and operation of your equipment. These codes vary

from area to area and it is your responsibility to determine which codes should be followed, and

to verify that the equipment, installation, and operation are in compliance with the latest revision

of these codes.

Equipment damage or serious injury to personnel can result from the failure to follow all

applicable codes and standards. We do not guarantee the products described in this publication

are suitable for your particular application, nor do we assume any responsibility for your product

design, installation, or operation.

• Read all available documentation before assembly and commissioning. Incorrect handling

of products in this manual can result in injury and damage to persons and machinery.

Strictly adhere to the technical information on the installation requirements.

• It is vital to ensure that all system components are connected to earth ground. Electrical

safety is impossible without a low-resistance earth connection.

• The SMD-761x contains electrostatically sensitive components that can be damaged by

incorrect handling. Discharge yourself before touching the product. Avoid contact with

high insulating materials (artificial fabrics, plastic film, etc.). Place the product on a

conductive surface.

• During operation keep all covers and cabinet doors shut. Otherwise, there are deadly

hazards that could possibility cause severe damage to health or the product.

• In operation, depending on the degree of enclosure protection, the product can have bare

components that are live or have hot surfaces. Control and power cables can carry a high

voltage even when the motor is not rotating.

2 | ni.com | NI SMD-7613/7614/7615/7616 User Manual

Page 3

• Never pull out or plug in the product while the system is live. There is a danger of electric

INPUT X3

OUTPUT Y3

OUTPUT Y4

ANALOG IN1

ANALOG IN2

Ethernet

INPUT X1

External Power Supply

7613/7615: 24-48 VDC

7614/7616: 24-80 VDC

INPUT X2

INPUT X4

INPUT X5

INPUT X6

X7/CWLIM

X8/CCWLIM

OUTPUT Y1

OUTPUT Y2

Optical

Isolation

DSP

Internal

Logic Supply

MOSFET

PWM

Power

Amplifier

Motor

Encoder

Status

7615/7616

Only

arcing and danger to persons and contacts.

• After powering down the product, wait at least ten minutes before touching live sections of

the equipment or undoing connections (e.g., contacts, screwed connections). Capacitors

can store dangerous voltages for long periods of time after power has been switched off. To

be safe, measure the contact points with a meter before touching.

Be alert to the potential for personal injury. Follow the recommended precautions and safe

operating practices. Safety notices in this manual provide important information. Read and be

familiar with these instructions before attempting installation, operation, or maintenance. The

purpose of this section is to alert users to possible safety hazards associated with this equipment

and the precautions that need to be taken to reduce the risk of personal injury and damage to the

equipment. Failure to observe these precautions could result in serious bodily injury, damage to

the equipment, or operational difficulty.

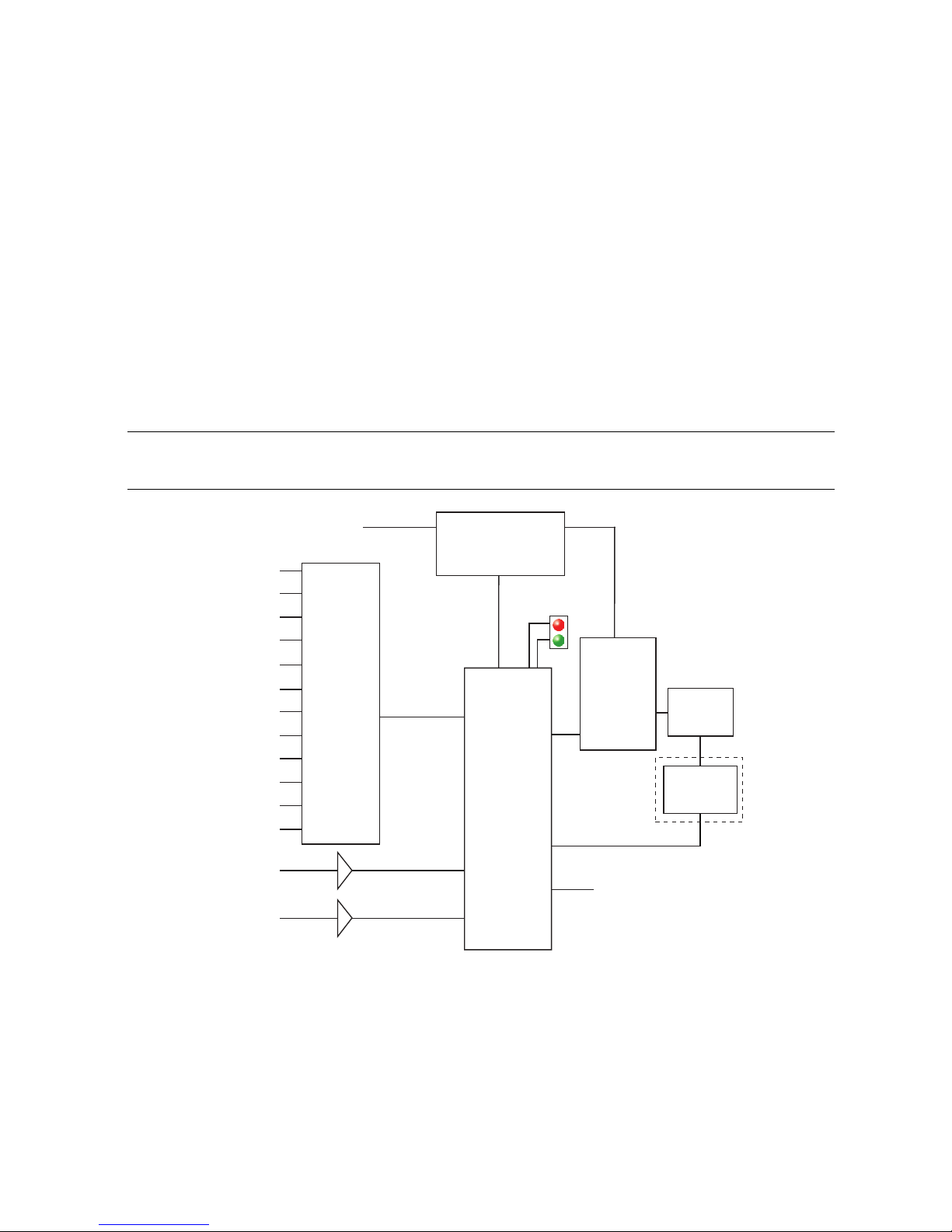

Block Diagram

Figure 1. NI SMD-761x Block Diagram

NI SMD-7613/7614/7615/7616 User Manual | © National Instruments | 3

Page 4

Getting Started

1

2 3 4

5 6

7

You need the following to use your NI SMD-761x stepper drive:

a 24 to 48 VDC power supply (80 V max for NI SMD-7614/7616). Refer to Choosing a

Power Supply for help in choosing the right power supply.

one of the recommended motors

a small flathead screwdriver for tightening the connectors

a source of step signals, such as a motion controller

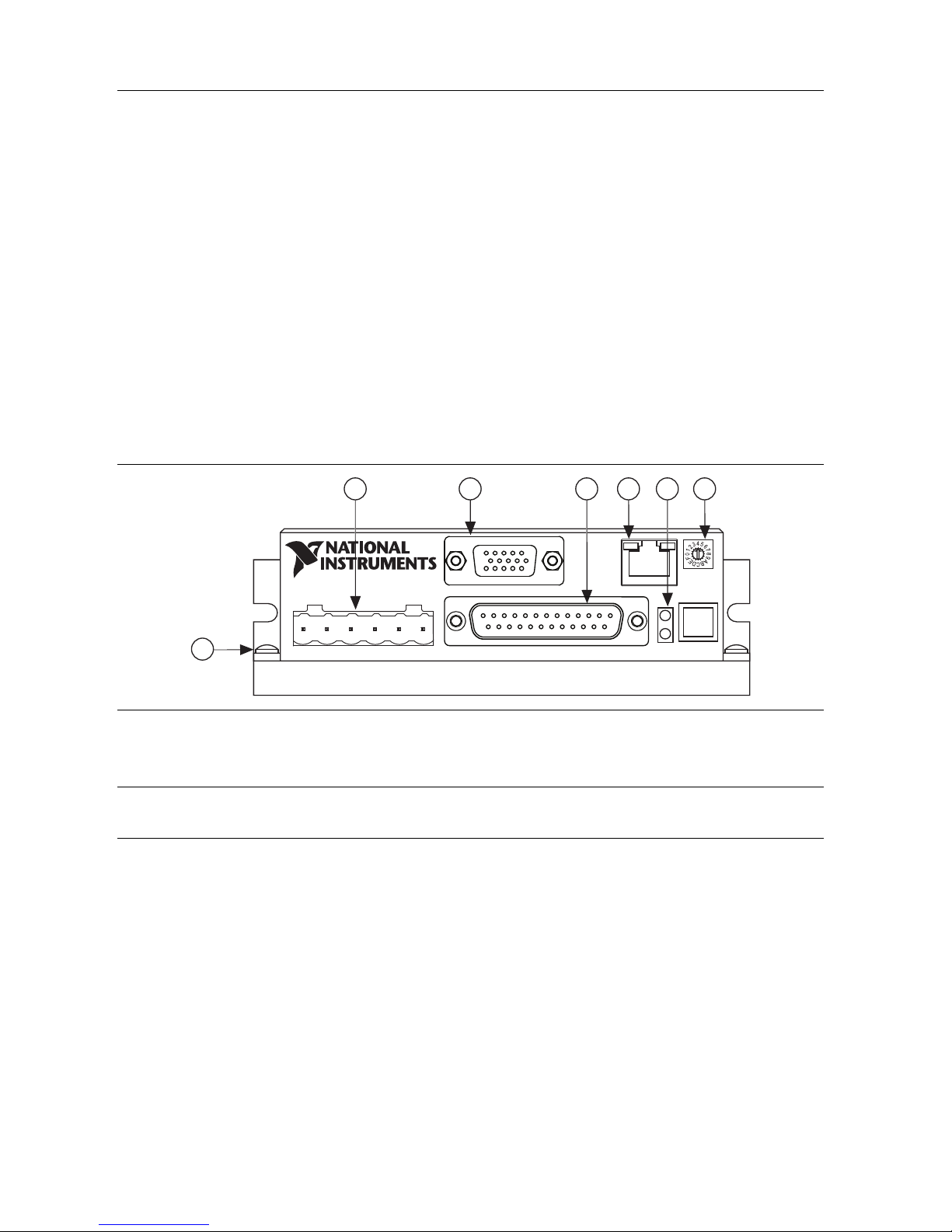

The connectors are illustrated below. These are detailed later in the manual.

Figure 2 shows an overview of the connectors on the NI SMD-7613/7614/7615/7616 stepper

drive.

Figure 2. NI SMD-7613/7614/7615/7616 Stepper Drive Connectors

1 Chassis Grounding Screw

2 Motor and Power Supply Connector

3 Encoder Feedback (SMD-7615/7616)

4 Input and Output Signals

5 Ethernet Connector

6 Drive Status LEDs

7 Rotary Switch

Mounting the Drive

You can mount your drive on the wide or the narrow side of the chassis using #6 screws. If

possible, the drive should be securely fastened to a smooth, flat metal surface that will help

conduct heat away from the chassis. If this is not possible, then forced airflow from a fan may

be required to prevent the drive from overheating. Refer to Drive Heating for more information.

• Never use your drive in a space where there is no air flow or where other devices cause the

surrounding air to be more than 50 °C.

• Never put the drive where it can get wet or where metal or other electrically conductive

particles can get on the circuitry.

• Always provide air flow around the drive. When mounting multiple drives near each other,

maintain at least one and a half inch of space between drives.

4 | ni.com | NI SMD-7613/7614/7615/7616 User Manual

Page 5

Connecting the Power Supply

If you need information about choosing a power supply, refer to Choosing a Power Supply.

• Connect the power supply “+” terminal to the connector terminal labeled “V+”.

• Connect power supply “-” to the connector terminal labeled “V-”.

• The green ground screw on the corner of the chassis should be connected to earth ground.

• Use 18 or 20 gauge wire.

The NI SMD-761x drives contain an internal fuse that connects to the power supply + terminal.

This fuse is not user replaceable. If you want to install a user serviceable fuse in your system,

install a fast acting, 7 A fuse in line with the + power supply lead.

Caution Do not reverse the wires. Reversing the connection will destroy your drive

and void your warranty.

If you plan to use a regulated power supply you may encounter a problem with regeneration. If

you rapidly decelerate a load from a high speed, much of the kinetic energy of that load is

transferred back to the power supply. This can trip the overvoltage protection of a switching

power supply, causing it to shut down. NI offers the SMD-7700 regeneration clamp to solve this

problem. If in doubt, buy an SMD-7700 for your first installation. If the regen LED on the

SMD-7700 never flashes, you do not need the clamp.

Choosing a Power Supply

When choosing a power supply, there are many things to consider. If you are manufacturing

equipment that will be sold to others, you probably want a supply with all the safety agency

approvals. If size and weight are an issue, get a switching supply.

You must decide what size of power supply (in terms of voltage and current) is needed for your

application.

National Instruments offers two power supplies that are excellent matches for the NI SM D-761x

drives: PS-12 24V, 6.3A) and PS-13 (48V, 6.7A).

Voltage

The motor can provide more torque at higher speeds if a higher power supply voltage is used.

Refer to the Torque Speed Curves section for guidance.

If you choose an unregulated power supply, make sure the no load voltage of the supply does not

exceed the drive’s maximum input voltage specification.

NI SMD-7613/7614/7615/7616 User Manual | © National Instruments | 5

Page 6

Current

The maximum supply current you need is two times the motor current. However, you will

generally need a lot less than that, depending on the motor type, voltage, speed and load

conditions. That is because the NI SMD-761x uses a switching amplifier, converting a high

voltage and low current into lower voltage and higher current. The more the power supply

voltage exceeds the motor voltage, the less current you will need from the power supply. A

motor running from a 48 volt supply can be expected to draw only half the supply current that it

would with a 24 volt supply.

We recommend the following selection procedure:

1. If you plan to use only a few drives, get a power supply with at least twice per phase current

rating of the step motor. Example: for a motor that is rated for 2 A/phase use a 4 A power

supply.

2. If you are designing for mass production and must minimize cost, get one power supply

with more than twice the rated current of the motor. Install the motor in the application and

monitor the current coming out of the power supply and into the drive at various motor

loads. This will tell you how much current you really need so you can design in a lower cost

power supply.

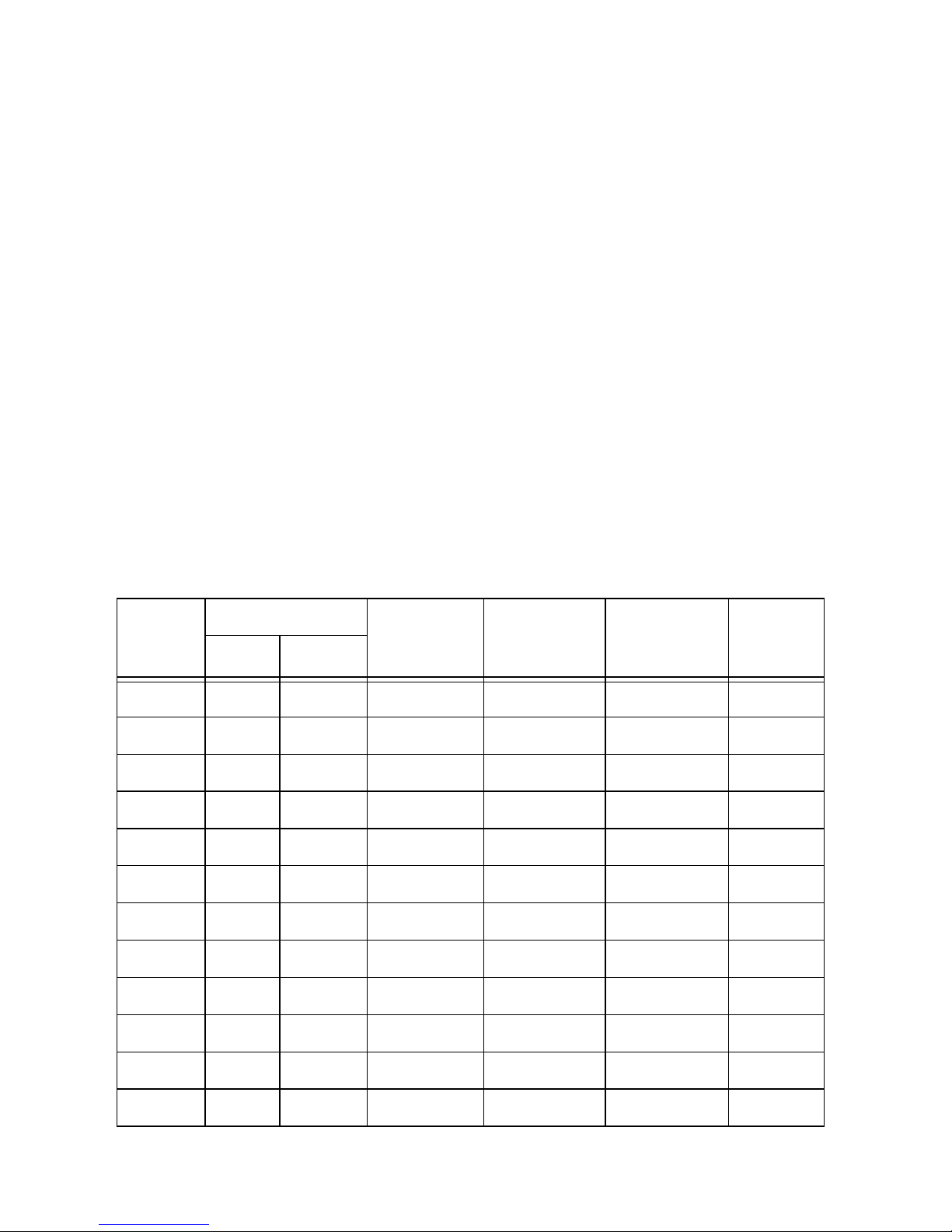

Table 1 lists the relevant specifications for suggested motors. Please consider this information

when choosing a power supply.

Table 1. NI SMD-7613/7615 Power Supply Current

Motor

Holding Torque Drive

Current

Setting (A)

Resistance

(Ω)

Inductance

(mH)

Rotor

Inertia

· cm

(g

ST11-1 7.0 0.50 1.2 1.4 1.4 8

ST11-2 15.0 1.08 1.2 2.0 2.6 18

ST14-1 26.0 1.87 1.2 4.3 5.5 20

ST17-1 31.4 2.26 1.6 2.1 2.8 35

ST17-2 51.0 3.67 2.0 1.7 3.6 54

ST17-3 62.8 4.52 2.0 1.7 3.0 68

ST23-1 76.6 5.52 3.4 0.7 1.4 120

ST23-4 177 12.7 5.0 0.4 1.2 300

ST23-6 264 19.0 5.0 0.5 1.6 480

2

)oz · in kg · cm

ST23-8 354 25.48 6.0 0.5 2.2 750

ST24-1 123.2 8.87 3.36 0.73 1.6 260

ST24-2 177 12.74 4.8 0.43 1.1 450

6 | ni.com | NI SMD-7613/7614/7615/7616 User Manual

Page 7

Table 1. NI SMD-7613/7615 Power Supply Current (Continued)

Motor

Holding Torque Drive

Current

Setting (A)

Resistance

(Ω)

Inductance

(mH)

Rotor

Inertia

· cm

(g

ST24-3 354 24.48 4.8 0.65 2.4 900

ST34-2 650 46.8 10.0 0.19 1.3 1400

ST34-5 1200 86.4 9.7 0.27 2.2 2680

ST34-8 1845 133 10.0 0.27 2.4 4000

ST34-1 396.5 28.55 7.56 0.24 1.7 1100

ST34-4 849.6 61.18 7.56 0.33 2.7 1850

ST34-7 1260 90.75 6.72 0.63 5.4 2750

Regeneration

When a motor rapidly decelerates from high speed under load, the kinetic energy may be

reconverted into electrical energy and transferred back to the power supply. When using

regulated power supplies, this can trip the overvoltage protection and lead to a shutdown, or

cause damage to the system. Unregulated power supplies do not typically have overvoltage

protection, and may store regenerated energy in capacitors.

2

)oz · in kg · cm

Connecting the Drive Using Ethernet

The drive requires only a CAT5 Ethernet cable connection to connect to your PC. You can

connect the drive directly to your PC’s network card, to an auxiliary network card in your PC,

or to a router or network switch.

1. Physically connect the device to your network (or directly to the PC).

2. Set the drive IP address.

3. Set the appropriate networking properties on your PC.

NI SMD-7613/7614/7615/7616 User Manual | © National Instruments | 7

Page 8

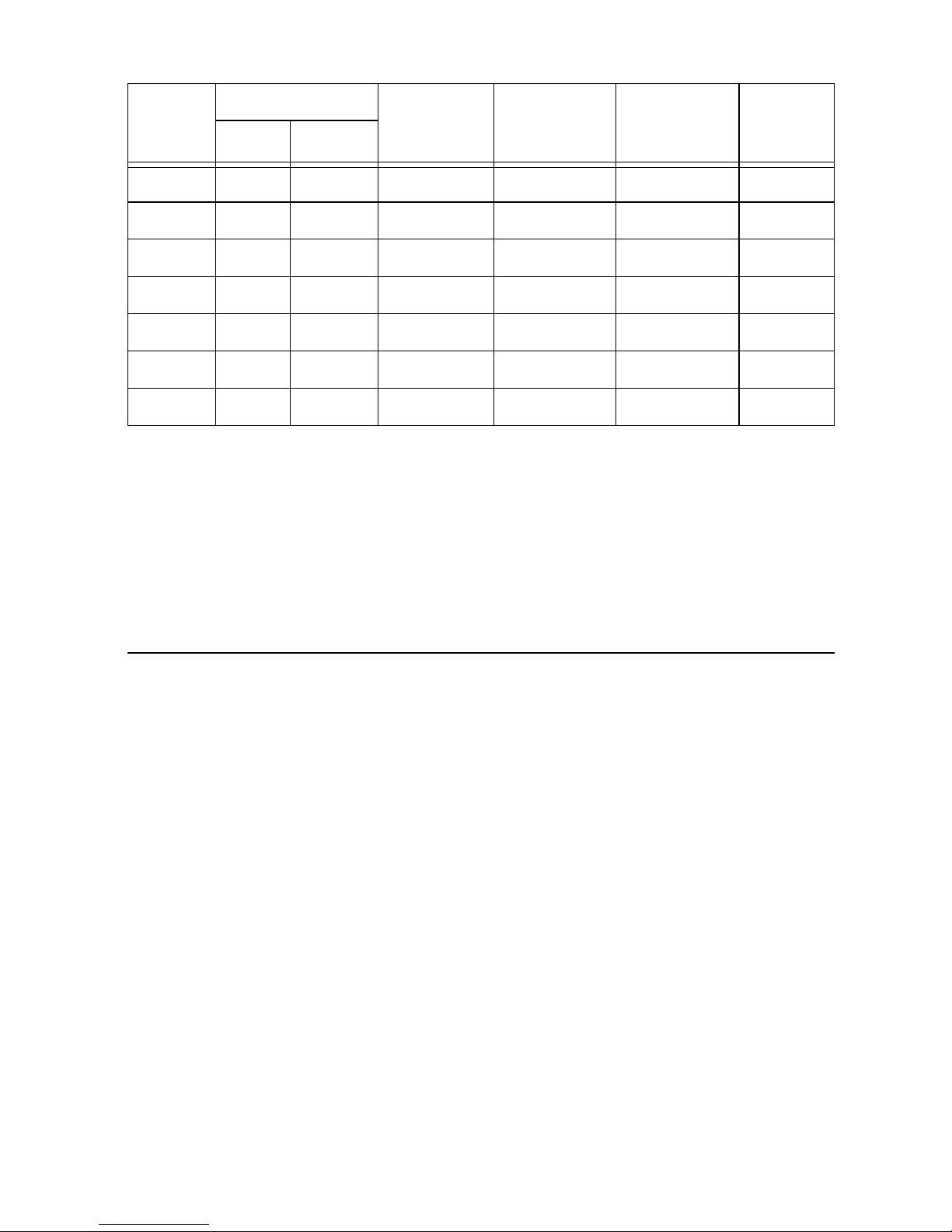

Your device includes a 16 position rotary switch for setting its IP address. The factory default

address for each switch setting is shown in the table below.

Table 2. IP Address Rotary Switch Settings

Position IP Address

0 10.10.10.10

1 192.168.1.10

2 192.168.1.20

3 192.168.1.30

4 192.168.0.40

5 192.168.0.50

6 192.168.0.60

7 192.168.0.70

8 192.168.0.80

9 192.168.0.90

A 192.168.0.100

B 192.168.0.110

C 192.168.0.120

D 192.168.0.130

E 192.168.0.140

F DHCP

The IP address corresponding to positions 1 through E can be changed using the NI Stepper

Configuration Utility software. Setting 0 is always 10.10.10.10, the universal recovery address.

Setting F is DHCP, which commands the device to get an IP address from a DHCP server on the

network. The IP address automatically assigned by the DHCP server may be dynamic or static

depending on how the administrator has configured DHCP. The DHCP setting is reserved for

advanced users.

Your PC, or any other equipment that you use to communicate with the device, will also have

a unique address.

On the device switch settings 1 through E use the standard class B subnet mask (i.e., 255.255.0.0).

The mask for the universal recovery address is the standard class A (i.e., 255.0.0.0).

8 | ni.com | NI SMD-7613/7614/7615/7616 User Manual

Page 9

Option 1: Connect a Drive to Your LAN

NIC PC

LAN Drive

Switch

or

Router

If you have a spare port on a switch or router and if you are able to set your device to an IP

address that is compatible with your network, and not used by anything else, this is a simple way

to get connected. This technique also allows you to connect multiple devices to your PC. If you

are on a corporate network, check with your system administrator before connecting anything

new to the network. He or she should be able assign you a suitable address and help you get

going.

Figure 3. Example Network Configuration

Many networks use dynamic addressing where a DHCP server assigns addresses on demand.

The address you choose for your device might get assigned to something else by the DHCP

server at another time.

Once you have chosen an appropriate IP address for your device, set the rotary switch according

to the address table above. If none of the default addresses are acceptable for your network, you

can enter a new table of IP addresses using the NI Stepper Configuration Utility. If your network

uses addresses starting with

192.168.0, the most common subnet, you will want to choose

an address from switch settings 4 through E. Another common subnet is 192.168.1. If your

network uses addresses in this range, the compatible default selections are 1, 2 and 3. If your PC

address is not in one of the above private subnets, you will have to change your subnet mask to

255.255.0.0 in order to communicate with your device. To change your subnet mask:

1. Open Network Connections.

a.

(Windows 8.1/8/7/Vista) Open Control Panel. From the icon view, open Network

and Sharing Center, then click Change Adapter Settings.

b.

(Windows XP) Right-click My Network Places and select Properties.

2. Right-click your network interface card (NIC) and select Properties.

a.

(Windows 8.1/8/7/Vista) Scroll down and select (TCP/IPv4), then click Properties.

b.

(Windows XP) Scroll down and select Internet Properties (TCP/IP), then click

Properties.

3. If the Obtain an IP address automatically option is selected, your PC is getting an IP

address and a subnet mask from the DHCP server. Cancel this dialog and proceed to the

Using DHCP section.

4. If the option Use the following IP address is selected, change the subnet mask to

255.255.0.0 and click OK.

NI SMD-7613/7614/7615/7616 User Manual | © National Instruments | 9

Page 10

Using DHCP

If you want to use your device on a network where all or most of the devices use dynamic IP

addresses supplied by a DHCP server, set the rotary switch to “F”. When the device is connected

to the network and powered on, it will obtain an IP address and a subnet mask from the server

that is compatible with your PC. However, you will not know what address the server assigns to

the device. The NI Stepper Configuration Utility can find your device using the Drive Discovery

feature, as long as your network is not too large. When the device connected to the network is

powered on, select Drive Discovery from the Drive menu to launch the Network Interface

Dialog dialog box.

Figure 4. Network Interface Dialog Box

Normally, Drive Discovery only detects one network interface card (NIC), and selects it

automatically. If you are using a laptop and have both wireless and wired network connections,

a second NIC may appear. Please select the NIC that you use to connect to the network to which

you have connected your device. Then click OK. Drive Discovery notifies you as soon as it has

detected a device.

If you think this is the correct device, click Yes. If you are not sure, click Not Sure and Drive

Discovery will look for additional devices on you network. Once you have told Drive Discovery

which device is yours, it automatically enters the device IP address in the IP address text box so

that you are ready to communicate.

Option 2: Connect a device Directly to Your PC

1. Connect one end of a CAT5 Ethernet cable into the LAN card (NIC) on your PC and the

other into the device. You do not need a special crossover cable; the device automatically

detects the direct connection and make the necessary physical layer changes.

2. Set the IP address on the device to 10.10.10.10 by setting the rotary switch to position 0.

3. To set the IP address of your PC:

a.

(Windows 8.1/8/7/Vista) Open Control Panel. From the icon view, open Network

and Sharing Center, then click Change Adapter Settings.

b. (Windows XP) Right-click My Network Places and select Properties.

10 | ni.com | NI SMD-7613/7614/7615/7616 User Manual

Page 11

4. Right-click your network interface card (NIC) and select Properties.

a.

(Windows 8.1/8/7/Vista) Scroll down and select (TCP/IPv4), then click Properties.

b.

(Windows XP) Scroll down and select Internet Properties (TCP/IP), then click

Properties.

5. Select Use the following IP address and enter the address 10.10.10.11. This assigns

your PC an IP address that is on the same subnet as the device. Windows directs any traffic

intended for the device’s IP address to this interface card.

6. Next, enter the subnet mask as 255.255.255.0.

7. Leave Default gateway blank. This prevents your PC from looking for a router on this

subnet.

Note Because you are connected directly to the device, anytime the device is not

powered you will receive a small message bubble in the corner of your screen saying

“The network cable is unplugged.”

Option 3: Use Two Network Interface Cards (NICs)

This technique allows you to keep your PC connected to your LAN, but keeps the device off the

LAN, preventing possible IP conflicts or excessive traffic.

1. If you use a desktop PC and have a spare card slot, install a second NIC and connect it

directly to the device using a CAT5 cable. You do not need a special “crossover cable”; the

device will automatically detect the direct connection and make the necessary physical

layer changes.

2. If you use a laptop and only connect to your LAN using wireless networking, you can use

the built-in RJ45 Ethernet connection as your second NIC.

3. Set the IP address on the device to 10.10.10.10 by setting the rotary switch to position 0.

4. To set the IP address of your PC:

a.

(Windows 8.1/8/7/Vista) Open Control Panel. From the icon view, open Network

and Sharing Center, then click Change Adapter Settings.

(Windows XP) Right-click My Network Places and select Properties.

b.

5. Right-click your network interface card (NIC) and select Properties.

a.

(Windows 8.1/8/7/Vista) Scroll down and select (TCP/IPv4), then click Properties.

b.

(Windows XP) Scroll down and select Internet Properties (TCP/IP), then click

Properties.

6. Select Use the following IP address and enter the address 10.10.10.11. This assigns

your PC an IP address that is on the same subnet as the device. Windows directs any traffic

intended for the device’s IP address to this interface card.

7. Next, enter the subnet mask as

8. Leave Default gateway blank. This prevents your PC from looking for a router on this subnet.

Note Because you are connected directly to the device, anytime the device is not

powered you will receive a small message bubble in the corner of your screen saying

“The network cable is unplugged.”

255.255.255.0.

NI SMD-7613/7614/7615/7616 User Manual | © National Instruments | 11

Page 12

Motor Wiring Recommendations

This section explains how to connect motors to the NI SMD-761x. Refer to your motor

documentation for any special considerations that may affect your configuration.

Maintain at least 2 in. separation between the power supply cable and input lines or encoder

feedback. All power supply cables should be properly shielded, and the shield grounded at the

power supply. Signal cables should be shielded, and grounded as close as possible to the signal

source.

Caution Never connect or disconnect the motor while the system is powered on.

Note Ensure any shield or grounding strap on the motor is connected to the chassis

ground screw located near the motor/power connector.

Figure 5. Motor/Power Connector

Figure 6. Grounding Screw on the Chassis

12 | ni.com | NI SMD-7613/7614/7615/7616 User Manual

Page 13

Four Lead Motors

Phase A+

Phase A–

Phase B+

Phase B–

Red

Blue

Yellow

White

Four lead motors can only be configured according to the following diagram.

Note Motor wire colors are correct for NI stepper motors compatible with the

NI SMD-761x. These wire colors may not match a third-party stepper motor.

Figure 7. Four Lead Motor Connection

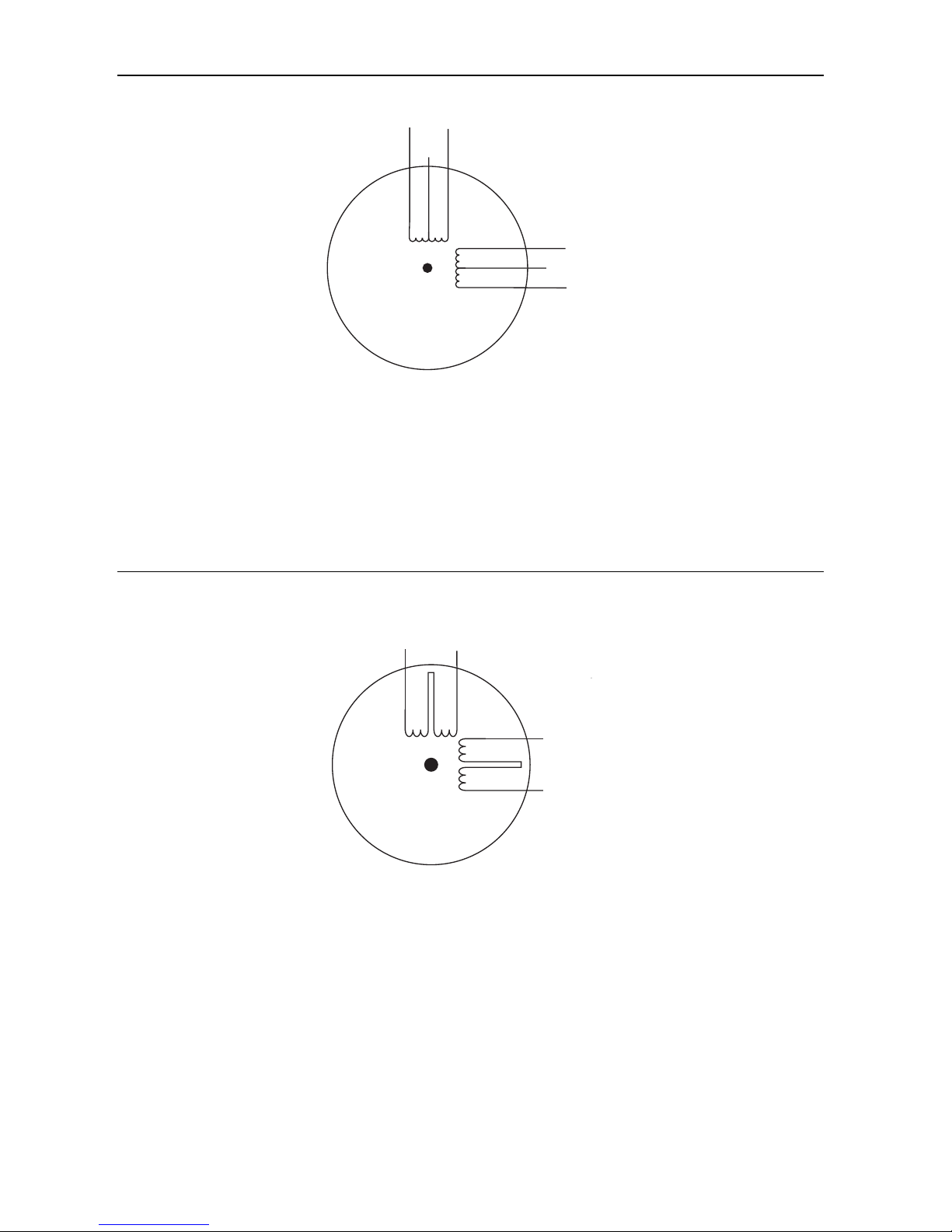

Six Lead Motors

Six lead motors can be connected in series or center tap. A series connected motor produces

more torque but it will not be able to run as fast as a motor in center tap configuration. In series

operation, the motor should be operated at 30% less than the rated current to prevent

overheating. Refer to the wiring diagrams below to connect a six lead motor.

Figure 8. Six Lead Motor Connected in Series

No connect

Phase A+

Green

White

Phase A–Grn/Wht

Black

Red

Phase B+Red/Wht

No connect

Phase B–

NI SMD-7613/7614/7615/7616 User Manual | © National Instruments | 13

Page 14

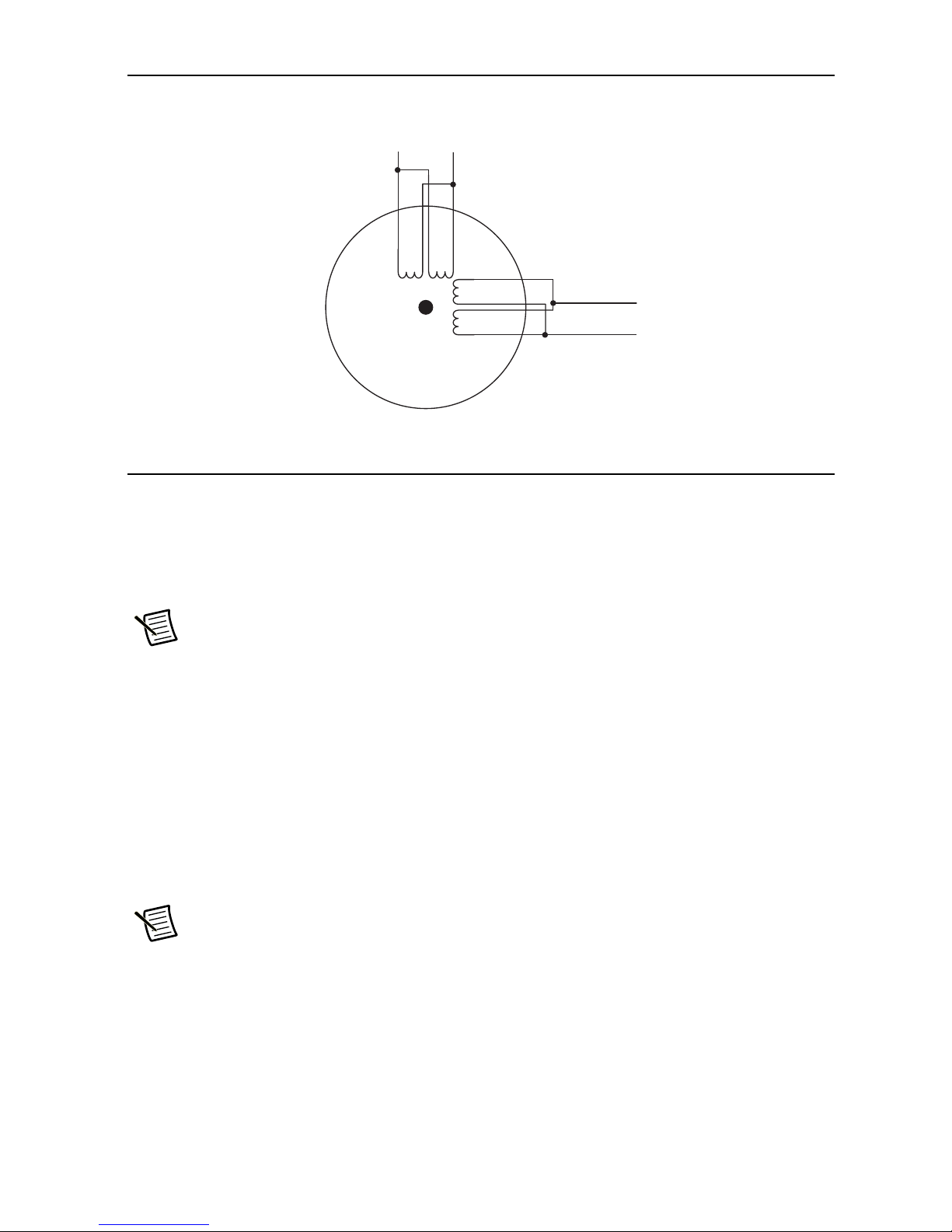

Figure 9. Six Lead Motor Connected in Center Tap

No connectGreen

White

Phase A+

Phase B+

Phase A–Grn/Wht

No connectRed/Wht

Red

Black

Phase B–

Phase B–

Phase A+

Phase A–

Phase B+

Orange

Org/Wht

Blk/Wht

Black

Red

Red/Wht

Yel/Wht

Yellow

Eight Lead Motors

Eight lead motors can be connected in series or parallel. A series connected motor needs less

current than one that is connected in parallel but it will not be able to run as fast. In series

operation, the motor should be operated at 30% less than the rated current to prevent

overheating. Refer to the wiring diagrams below to connect an eight lead motor.

Figure 10. Eight Lead Motor Connected in Series

14 | ni.com | NI SMD-7613/7614/7615/7616 User Manual

Page 15

Figure 11. Eight Lead Motor Connected in Parallel

Phase B–

Phase A+

Phase A–

Phase B+

Orange

Red

Yel/Wht

Red/Wht

Yellow

Black

Org/Wht

Blk/Wht

Connecting Input Signals

The NI SMD-761x has three types of input:

• High speed digital inputs for step and direction commands/encoder use 5 V logic.

• Digital inputs for other signals use 12 to 24 V logic.

• Analog inputs are reserved for furture use.

All drives include eight digital inputs and two analog inputs:

• CW & CCW Limit: These are optional input that can be used to inhibit motion in a given

• IN1/STEP & IN2/DIR: These are digital signals that can be used for commanding a

• IN3, IN4, IN5, IN6: These are software-prgrammable inputs that can be used for motor

Note All inputs except STEP and DIR use 12 to 24 VDC logic.

direction, forcing the motor and the load to travel within mechanical limits. It can be

configured as active closed or active open.

position. Quadrature signals from encoders can also be used. These inputs can also be

connected to sensors and switches.

enable, alarm reset, or jogging. These inputs can also be connected to sensors and switches.

Note These drives can use input signals from a motion controller or accept ethernet

streaming commands. For more information on commanding the drive using

Ethernet, see the Working with Ethernet Steppers page in SoftMotion help.

NI SMD-7613/7614/7615/7616 User Manual | © National Instruments | 15

Page 16

Figure 12. Input Connector Pin Diagram

8

5

7

6

4

23

22

24

25

2200

Ω

2200

Ω

2200

Ω

2200

Ω

2200

Ω

2200

Ω

XCOM

X3/EN

x4/RST

X5

X6

X7/CWLIM+

X7/CWLIM

–

X8/CCWLIM+

X8/CCWLIM-

13

X8/CCWLIMIT–

X8CCWLIMIT+

X7/CWLIMIT–

X7/CWLIMIT+

Y4–

Y4+

GND

+5V OUT

Y COMMON

Y3/FAULT

Y2/MOTION

Y1/BRAKE

25

24

23

22

21

20

19

18

17

16

15

14

GND

12

X1/STEP+

11

X1/STEP–

10

X2/DIR+

9

X2/DIR–

8

X COMMON

7

X3/ENABLE

6

X4/ALARM RESET

5

X5/CWJOG

4

X6/CCWJOG

3

2

ANALOG IN2

1

ANALOG IN1

Figure 13. ISelect Internal Circuitry of the I/O Connector

16 | ni.com | NI SMD-7613/7614/7615/7616 User Manual

Page 17

STEP and DIR Inputs

Indexer

with

Sourcing

Outputs

STEP

DIR

+5V OUT

IN/OUT 1

X2/DIR–

X2/DIR+

X1/STEP–

X1/STEP+

The drive includes two high speed inputs called STEP and DIR. They accept 5 volt single-ended

or differential signals, up to 2 MHz. Normally these inputs connect to an external controller that

provides step & direction command signals. You can also connect a master encoder to the inputs

for following applications. The following section demonstrates example signal connections.

Refer to Motor Wiring Recommendations for cable instructions.

Figure 14. Connecting to Indexer with Sourcing Outputs

Figure 15. Connecting to Indexer with Sinking Outputs

Indexer

with

Sinking

Outputs

+5V OUT

DIR

STEP

X2/DIR+

X2/DIR–

IN/OUT 1

X1/STEP+

X1/STEP–

Figure 16. Connecting to Indexer with Differential Outputs

Indexer

with

Differential

Outputs

DIR+

DIR–

STEP+

STEP-

X2/DIR+

X2/DIR–

IN/OUT 1

X1/STEP+

X1/STEP–

NI SMD-7613/7614/7615/7616 User Manual | © National Instruments | 17

Page 18

Figure 17. Connecting for Encoder Following

X1/STEP+

X1/STEP–

X2/DIR+

X2/DIR–

GND

IN/OUT 1

Indexer

with

Differential

Outputs

A+

A–

B+

B-

GND

Using 12 to 24 Volt Signals

Most controllers do not use 5 V signals. Use external dropping resistors to connect signals up to

24 V to the STEP and DIR inputs. For 12 V logic, use 820 Ω, 1/4 W resistors. For 24 V logic,

use 2,200 Ω, 1/4 W resistors.

Caution Do not exceed an input voltage of 24 VDC. Never apply AC power to an

input terminal.

Connect the resistors according to the following diagrams:

Figure 18. Connecting to the controller with Sourcing (PNP) Outputs

+12-24V

X2/DIR+

X1/STEP–

X1/STEP+

X2/DIR–

761x

PLC

with

Sourcing

Outputs

OUT1

OUT2

GND

18 | ni.com | NI SMD-7613/7614/7615/7616 User Manual

Page 19

Figure 19. Connecting to the controller with Sinking (NPN) Outputs

Sinking

Outputs

+24 VDC

Power

Supply

+12-24V

DIR

PLC

with

STEP

X2/DIR+

X2/DIR–

X1/STEP+

X1/STEP–

Figure 20. Using Mechanical Switches at 24 Volts

+

Direction Switch

X2/DIR+

X2/DIR–

X1/STEP+

761x

Drive

–

Run/Stop Switch

(closed=run)

X1/STEP–

Single Ended Inputs

The SMD-761x includes four single ended, optically isolated input circuits that can be used with

sourcing or sinking signals. These inputs can be used with controllers, sensors, relays, or

mechanical switches. These inputs require an external power supply.

Note COM, or common, refers to a connection to a common voltage. This is often

ground, but not always.If using sourcing (PNP) signals, connect COM to the negative

terminal of the power supply. When using sinking (NPN) signals, connect COM to

the positive terminal of the power supply.

NI SMD-7613/7614/7615/7616 User Manual | © National Instruments | 19

Page 20

Refer to the following diagrams for examples of how to connect the drive to commonly used

Drive

12-24 VDC

Power

Supply

OUT+

XCOM

X3..X6

IN/OUT1

+

OUT–

–

12-24 VDC

Power

Supply

-

+

Output

+

NPN

Proximity

Sensor

-

XCOM

X3..X6

Drive

devices:

Figure 21. Connecting to Input Switch or Relay

12-24 VDC

Power

Supply

Figure 22. Connecting Multiple Drives

+

-

Switch or Relay

(closed = logic low)

XCOM

Drive

X3..X6

Figure 23. Connecting an NPN Type Proximity Sensor to an Input

20 | ni.com | NI SMD-7613/7614/7615/7616 User Manual

Page 21

Figure 24. Connecting a PNP Type Proximity Sensor to an Input

12-24 VDC

Power

Supply

-

+

XCOM

X3..X6

Output

+

PNP

Proximity

Sensor

-

Drive

Drive

12-24 VDC

Power

Supply

+

–

CCWLIMIT–

CWLIMIT–

CCWLIMIT+

CWLIMIT+

Connecting Limit Switches and Sensors

The CWLIMIT and CCWLIMIT differential inputs can be used to connect end of travel sensors.

You can use signals that are sinking (NPN), sourcing (PNP) or differential (line driver). By

connecting switches or sensors that are triggered by the motion of the motor or load, you can

force the motor to operate within certain limits, preventing damage to your system by traveling

too far.

The limit inputs are optically isolated, allowing you to choose a voltage for your limit circuits of

12 to 24 VDC. This also allows you to have long wires on limit sensors that may be far from the

drive with less risk of introducing noise to the drive electronics.

Refer to the following diagrams for help connecting limit switches and sensors:

Figure 25. Wiring a Mechanical Limit Switch

NI SMD-7613/7614/7615/7616 User Manual | © National Instruments | 21

Page 22

Figure 26. Wiring a Sinking Output Limit Sensor

DC

Power

Supply

–

+

CW LIMIT+

CW LIMIT–

Output

+

Limit

Sensor

–

Drive

Figure 27. Wiring a Sourcing Output Proximity Sensor

+

DC

Power

Supply

-

+

Proximity

Sensor

-

Output

CW LIMIT+

CW LIMT–

Drive

Analog Inputs

The device features two analog inputs. Each input can accept a signal range of 0-VDC, ±5 VDC,

0 to 10 VDC or ±10 VDC. These inputs are present for future feature expansion, as SoftMotion

does not currently access the analog inputs on the drive.

The following figure represents the internal circuitry of the analog inputs:

Figure 28. Internal Circuitry of Analog Inputs

1

AIN1

Signal

Conditioning

2

13

Use the NI Stepper Configuration Utility to configure settings such as signal range, offset,

deadband, and filter frequency.

22 | ni.com | NI SMD-7613/7614/7615/7616 User Manual

AIN2

GND

Signal

Conditioning

Page 23

Programmable Outputs

Y1

YCOM

Y3

Y2

Y4+

Y4

–

14

17

16

15

20

21

5-24 VDC

Power

Supply

–

+

YCOM

Y1/2/3

Load

IN/OUT1

The drive features four digital outputs. These outputs are present for future feature expansion,

as SoftMotion does not currently set the state of the digital outputs on the drive. Refer to the

diagram below for a representation of the internal cirtcuitry of the digital outputs:

Figure 29. Internal circuitry of the digital outputs

The outputs can be used to drive LEDs, relays, and the inputs of other electronic devices like

controllers and counters. For Y4, the “+” (collector) and “-” (emitter) terminals of each

transistor are available at the connector. This allows you to configure this output for current

sourcing or sinking. The Y1 to 3 outputs can only sink current. The Y COM terminal must be

tied to power supply (-).

Diagrams of each type of connection follow.

Caution Do not connect outputs to more than 30 VDC.

Caution The current through an output terminal must not exceed 100 mA.

Figure 30. Sinking Output Using Y1, Y2, or Y3

NI SMD-7613/7614/7615/7616 User Manual | © National Instruments | 23

Page 24

Figure 31. Sinking Output Using Y4

PLC

5-24 VDC

Power

Supply

Y1/2/3

COM

IN

IN/OUT1

+

YCOM

–

5-24 VDC

Power

Supply

Figure 32. Sourcing Output Using Y1, Y2, or Y3

+

–

Load

Y4 +

IN/OUT1

Y4 –

IN/OUT1

Y4+

Y4–

Figure 33. Sourcing Output Using Y4

5-24 VDC

Power

Supply

+

–

PLC

COM

IN

24 | ni.com | NI SMD-7613/7614/7615/7616 User Manual

Page 25

Figure 34. Driving a Relay Using Y1, Y2, or Y3

Relay

5-24 VDC

Power

Supply

+

1N4935 suppression diode

–

Y1/2/3

IN/OUT1

YCOM

Figure 35. Driving a Relay Using Y4

Relay

5-24 VDC

Power

Supply

+

1N4935 suppression diode

–

Y4+

IN/OUT1

Y4–

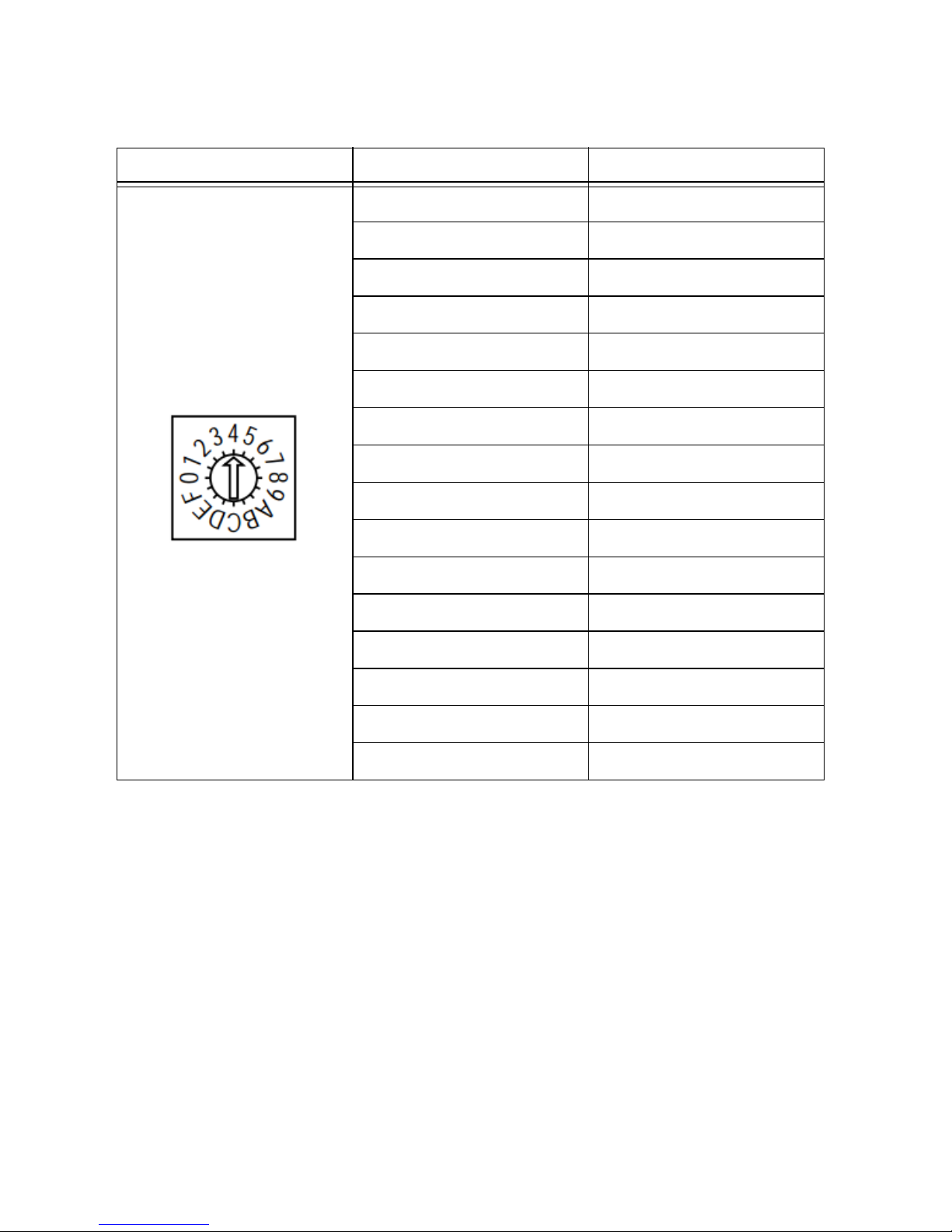

Connecting an Encoder (SMD-7615/7616)

The encoder connections use a HD-15 connector, which you must connect to your encoder as

shown below.

If your encoder is single ended, connect the encoder outputs to the A+, B+ and Z+ inputs. Leave

A-, B- and Z- unconnected. (Z is the encoder index signal and is optional.)

Figure 36. Encoder Connection Pin Numbering

1

5

6

15

NI SMD-7613/7614/7615/7616 User Manual | © National Instruments | 25

Page 26

Table 3. Encoder Connection Pin Definition

Pin Function

1 Encoder A+

2 Encoder A-

3 Encoder B+

4 Encoder B-

5 Encoder Z+

6 Encoder Z-

7 +5 VDC, 200 mA

8 GND

9 No Connect

10 No Connect

11 No Connect

12 No Connect

13 No Connect

14 No Connect

15 Shield

26 | ni.com | NI SMD-7613/7614/7615/7616 User Manual

Page 27

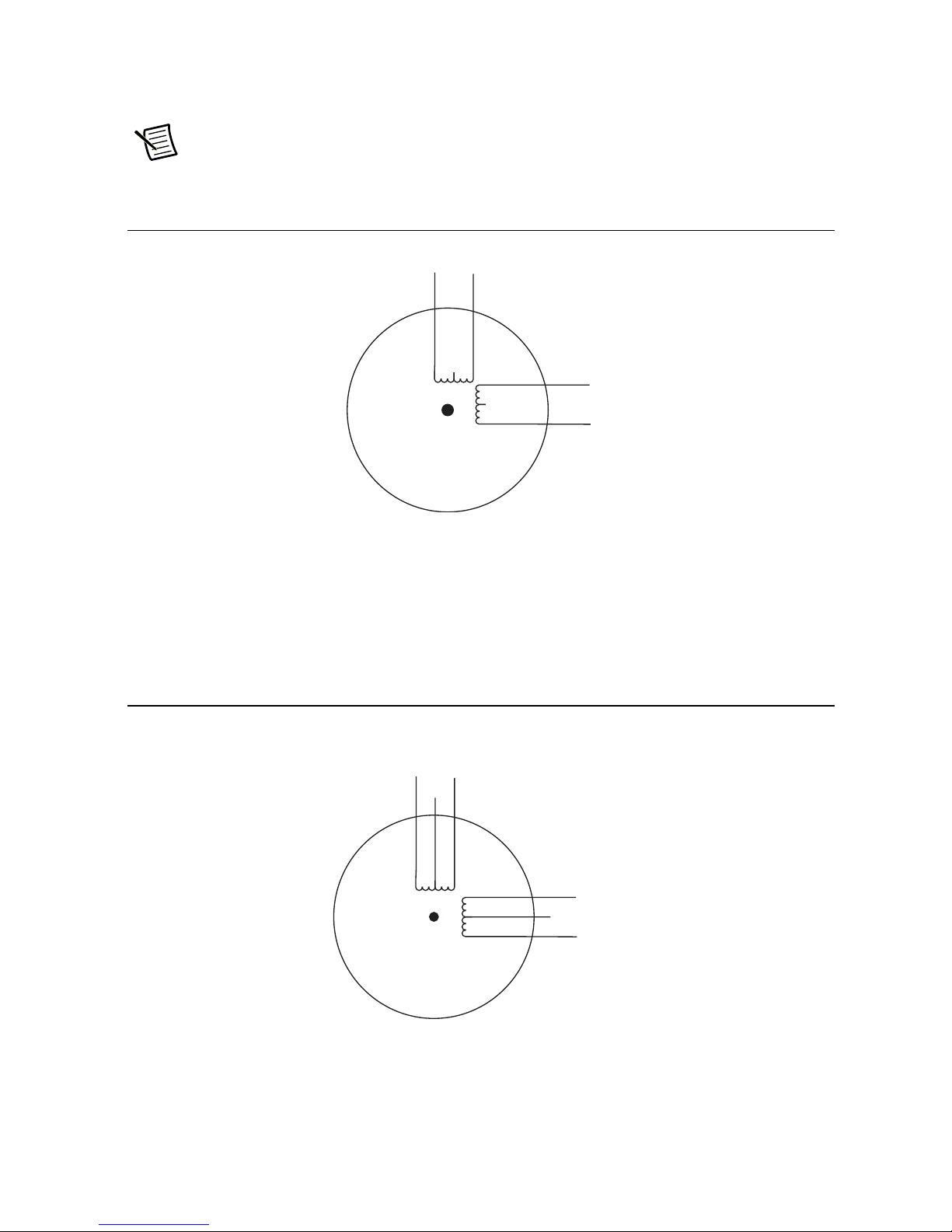

The internal circuitry of the encoder connection is depicted below:

Figure 37. Encoder Connection Pin Numbering

Ω

Ω

5K

12.5 K

Ω

Ω

Ω

5 K

12.5 K

Ω

7

1

2

3

4

5

6

+5V

A+

A

–

B+

B

–

Z+

Z–

Ω

Ω

5 K

12.5 K

Ω

8

GND

8.3 K

8.3 K

8.3 K

NI SMD-7613/7614/7615/7616 User Manual | © National Instruments | 27

Page 28

Configuring the Drive

The drive is configured with the NI Stepper Configuration Utility, available at ni.com/

downloads

aspects of the motor performance and control for your application.

Motor

From the NI Stepper Configuration Utility home screen, click the Motor icon to open the

configuration window.

. When you have located your device with the utility, you can configure various

Figure 38. NI Stepper Configuration Utility Configuration Window

The drive works best with the specially matched motors selectable from the Standard Motor list.

Select the motor you will use and configure the following settings:

Running Current

Set the Running Current to 100% to achieve maximum torque. However, under some conditions

you might want to reduce the current to save power or lower motor temperature. This is

important if the motor is not mounted to a surface that will help it conduct heat away or if you

expect the ambient temperature to be high.

Step motors produce torque in direct proportion to current, but the amount of heat generated

is roughly proportional to the square of the current. If you operate the motor at 90% of rated

current, the motor provides 90% of the rated torque and approximately 81% as much heat.

At 70% current, the torque is reduced to 70% and the heating to about 50%.

28 | ni.com | NI SMD-7613/7614/7615/7616 User Manual

Page 29

Idle Current/Idle Current Delay

You can reduce motor heating and power consumption by lowering the motor current when it is

not moving. The drive automatically lowers the motor current when it is idle for longer than the

time specified by Idle Current Delay.

The default 50% idle current setting lowers the holding torque to 50% of the specified Running

Current, which is enough to prevent the load from moving in most applications. You can adjust

this value to account for your load and heating requirements.

Load Inertia

The drive includes anti-resonance and electronic damping features which greatly improve

motor performance. To perform optimally, the drive must understand the electromechanical

characteristics of the motor and load. Most of this is completed automatically in the factory

during motor and drive assembly. To further enhance performance, you must specify the innertia

of the load. If you are unsure of this value, you can experimentally find an acceptable value by

entering a multiplier of the rotor inertia.

Control

From the NI Stepper Configuration Utility home screen, click Motion icon to open the Motion

Control Mode Window. Select Pulse & Direction Mode button to configure the following

settings:

Figure 39. NI Stepper Configuration Utility Configuration Window

Steps/Rev

You can configure the number of steps per revolution to match the details of your application.

A higher value provides smoother motion, though you may want to configure this value to match

the phsyical parameters of the system such as gearing or screw pitch.

Step Smoothing Filter

At lower step resolutions such as 200 steps per revolution (full step) and 400 steps per revolution

(half step) motors produce more audible noise than when they are microstepped (2,000 steps per

revolution and beyond). The drive includes a feature called microstep emulation, also called step

smoothing, that can provide smooth motion when using full and half steps. If the Steps/Rev setting

is 2,000 or higher, this feature is not needed and can be set to the highest possible value, 2,500.

NI SMD-7613/7614/7615/7616 User Manual | © National Instruments | 29

Page 30

The step smoothing process uses a command filter which causes a slight delay, or lag in the

Rev/Sec

Seconds

0

2

6

8

4

–2

10

0.1 0.2 0.40.3 0.5 0.7 0.80.6 0.9

12

0

–4

On

Off

Motion Profile with Step Smoothing Filter

revs

ondsec

------------------- 20 000

steps

revs

----------------,× 800

kHz

=

motion. The following figure shows an example of the delay that can occur from using the step

smoothing filter.

Figure 40. Delay Due to Filtering

Input Noise Filter

Electrical noise can negatively affect the STEP signal by causing the drive to interpret one

step pulse as two or more pulses. This results in extra motion and inaccurate motor and load

positioning. To solve this problem, the drive includes a digital noise filter on the STEP and

DIR inputs. The default factory setting of this filter is 7.5 MHz, which is suitable for most

applications.

Your maximum pulse rate equals the highest motor speed multiplied by the number of steps per

revolution. For example:

Consider the maximum pulse rate when deciding whether you must increase the filter frequency.

30 | ni.com | NI SMD-7613/7614/7615/7616 User Manual

Page 31

I/O Configuration

From the NI Stepper Configuration Utility home screen, click I/O icon to open the Motion I/O

Configuration window to configure the following settings:

Figure 41. NI Stepper Configuration Utility Configuration Window

Fault Output

The fault output will be triggered if there is a fault condition. This may be a fault within the

drive or a system fault. Not all faults will cause the drive to be disabled. If you are running the

NI Stepper Configuration Utility while an alarm condition develops, a dialog box will give you

details of the fault. Alarms and faults are also displayed by a pattern of red and green flashes on

the drive's front panel LED. Refer to the Alarm Code section for code definitions.

Alarm Reset Input

This parameter allows you to configure an input to reset any alarms that result from a fault. If this

is not enabled, you must reset alarms by cycling power to the drive.

Brake Output

If your motor features a brake, you can configure an output to release the brake when the motor

is enabled. You can configure the delay settings to ensure the brake is fully applied before

disabling the motor.

Motor Enable Input

The Motor Enable input toggles the power stage of the drive. This allows the drive to be powered

on while the motor is inactive.

Self Test

If you are having trouble getting your motor to turn, use the built-in self test from the NI Stepper

Configuration Utility home page. Select the Drive menu item and choose Self Test. Use this

feature to confirm that the motor is wired correctly, selected, and otherwise operational.

NI SMD-7613/7614/7615/7616 User Manual | © National Instruments | 31

Page 32

Torque Speed Curves

Oz-in

ST11, ST14

24 VDC Power Supply, 20000 Steps/Rev

Rev/Sec

5

10

15

20

5 10 15 20

30

3525 40

25

0

0

ST14-1 (1.2 A/Phase)

ST11-2 (1.2 A/Phase)

ST11-1 (1.2 A/Phase)

Oz-in

ST17

24 VDC Power Supply, 20000 Steps/Rev, All Motors Connected in Parallel

Rev/Sec

20

40

60

80

90

70

50

30

10

5 10 15 20 30 3525 40

100

0

0

ST17-3 (2.0 A/Phase)

ST17-2 (2.0 A/Phase)

ST17-1 (1.6 A/Phase)

Figure 42. SMD-761x Torque Curve for ST11 & ST14, 24 V Power Supply

Figure 43. SMD-761x Torque Curve for ST17, 24 V Power Supply

32 | ni.com | NI SMD-7613/7614/7615/7616 User Manual

Page 33

Figure 44. SMD-761x Torque Curve for ST17, 48 V Power Supply

Oz-in

ST17

48 VDC Power Supply, 20000 Steps/Rev, All Motors Connected in Parallel

Rev/Sec

20

10

30

50

70

90

40

60

80

5 10 15 20

30

3525 40

100

0

0

ST17-3 (2.0 A/Phase)

ST17-2 (2.0 A/Phase)

ST17-1 (1.6 A/Phase)

Figure 45. SMD-761x Torque Curve for ST23, 24V Power Supply

ST23

24 VDC Power Supply, 20000 Steps/Rev, All Motors Connected in Parallel

350

300

250

200

Oz-in

150

100

50

0

0

5 10 15 20 30 3525 40

Rev/Sec

ST23-8 (6.0 A/Phase)

ST23-6 (5.0 A/Phase)

ST23-4 (5.0 A/Phase)

ST23-1 (3.4 A/Phase)

NI SMD-7613/7614/7615/7616 User Manual | © National Instruments | 33

Page 34

Figure 46. SMD-761x Torque Curve for ST23, 48 V Power Supply

ST23

48 VDC Power Supply, 20000 Steps/Rev, All Motors Connected in Parallel

350

ST23-8 (6.0 A/Phase)

300

250

200

Oz-in

150

100

50

0

0

5 10 15 20

Rev/Sec

ST23-6 (5.0 A/Phase)

ST23-4 (5.0 A/Phase)

ST23-1 (3.4 A/Phase)

30

3525 40

Figure 47. SMD-761x Torque Curve for ST24, 24V Power Supply

ST24

24 VDC Power Supply, 20000 Steps/Rev

350

ST24-3 (4.80 A/Phase)

300

250

200

Oz-in

150

100

50

0

0

5 10 15 20 30 3525 40

Rev/Sec

ST24-2 (4.80 A/Phase)

ST24-1 (3.36 A/Phase)

34 | ni.com | NI SMD-7613/7614/7615/7616 User Manual

Page 35

Figure 48. SMD-761x Torque Curve for ST24, 48V Power Supply

Oz-in

ST34-2/5/8 with SMD-7614/7616

24 VDC Power Supply, 20000 Steps/Rev, All Motors Connected in Parallel

Rev/Sec

200

400

1000

600

800

1200

5 10 15 20

30

3525 40

1400

0

0

ST34-8 (10 A/Phase)

ST34-5 (9.7 A/Phase)

ST34-2 (10 A/Phase)

ST24

48 VDC Power Supply, 20000 Steps/Rev

350

ST24-3 (4.80 A/Phase)

Oz-in

300

250

200

150

100

50

0

0

5 10 15 20 30 3525 40

Rev/Sec

ST24-2 (4.80 A/Phase)

ST24-1 (3.36 A/Phase)

Figure 49. SMD-7614/7616 Torque Curve for ST34-2/5/8, 48V Power Supply

NI SMD-7613/7614/7615/7616 User Manual | © National Instruments | 35

Page 36

Figure 50. SMD-7614/7616 Torque Curve for ST34-2/5/8, 48V Power Supply

Oz-in

ST34-2/5/8 with SMD-7614/7616

48 VDC Power Supply, 20000 Steps/Rev, All Motors Connected in Parallel

Rev/Sec

200

600

800

1200

1000

400

5 10 15 20 30 3525 40

1400

0

0

ST34-8 (10 A/Phase)

ST34-5 (9.7 A/Phase)

ST34-2 (10 A/Phase)

Oz-in

ST34-2/5/8 with SMD-7614/7616

80 VDC Power Supply, 20000 Steps/Rev, All Motors Connected in Parallel

Rev/Sec

400

600

800

200

1200

1000

5 10 15 20 30 3525 40

1400

0

0

ST34-8 (10 A/Phase)

ST34-5 (9.7 A/Phase)

ST34-2 (10 A/Phase)

Figure 51. SMD-7614/7616 Torque Curve for ST34-2/5/8, 80V Power Supply

36 | ni.com | NI SMD-7613/7614/7615/7616 User Manual

Page 37

Figure 52. SMD-7614/7616 Torque Curve for ST34-1/4/7, 24V Power Supply

ST34-1/4/7 with SMD-7614/7616

24 VDC Power Supply, 20000 Steps/Rev, All motors Connected in Parallel

1000

ST34-7 (6.72 A/Phase)

ST34-4 (7.56 A/Phase)

ST34-1 (7.56 A/Phase)

30

3525 40

Oz-in

900

800

700

600

500

400

300

200

100

0

0

5 10 15 20

Rev/Sec

Figure 53. SMD-7614/7616 Torque Curve for ST34-1/4/7, 48V Power Supply

ST34-1/4/7 with SMD-7614/7616

48 VDC Power Supply, 20000 Steps/Rev, All Motors Connected in Parallel

1000

ST34-7 (6.72 A/Phase)

ST34-4 (7.56 A/Phase)

ST34-1 (7.56 A/Phase)

Oz-in

900

800

700

600

500

400

300

200

100

0

0

5 10 15 20 30 3525

Rev/Sec

40

NI SMD-7613/7614/7615/7616 User Manual | © National Instruments | 37

Page 38

Figure 54. SMD-7614/7616 Torque Curve for ST34-1/4/7, 60V Power Supply

Oz-in

ST34-1/4/7 with SMD-7614/7616

60 VDC Power Supply, 20000 Steps/Rev, All Motors Connected in Parallel

Rev/Sec

200

100

400

600

800

5 10 15 20 30 3525 40

1000

900

700

500

300

0

0

ST34-7 (6.72 A/Phase)

ST34-4 (7.56 A/Phase)

ST34-1 (7.56 A/Phase)

Motor Heating

Step motors convert electrical power from the driver into mechanical power to move a load.

Because step motors are not perfectly efficient, some of the electrical power turns into heat on

its way through the motor. This heating is not so much dependent on the load being driven but

rather the motor speed and power supply voltage. There are certain combinations of speed and

voltage at which a motor cannot be continuously operated without damage.

The following table and figures show the maximum duty cycle versus speed for each motor at

commonly used power supply voltages. Please refer to this information when planning your

application.

A step motor typically reaches maximum temperature after 30 to 45 minutes of operation. If

you run the motor for one minute then let it sit idle for one minute, that is a 50% duty cycle.

Five minutes on and five minutes off is also 50% duty. However, one hour on and one hour off

has the effect of 100% duty because during the first hour the motor will reach full (and possibly

excessive) temperature.

The actual temperature of the motor depends on how much heat is conducted, convected, or

radiated out of it. Our measurements were made in a 40 °C (104 °F) environment with the motor

mounted to an aluminum plate sized to provide a surface area consistent with the motor power

dissipation. Your results may vary.

38 | ni.com | NI SMD-7613/7614/7615/7616 User Manual

Page 39

Table 4. SMD-761x Maximum Motor Duty Cycle

010203040 50

% Duty Cycle

ST14-1 Max Duty Cycle vs Speed

24 VDC, 1.2A, 40°C Ambient

Mounted on 4.75" x 4.75" x .25" Aluminum Plate

Speed (RPS)

0

20

40

60

80

100

Max Duty Cycle at 40 °C

24 VDC 48 VDC

Motor

Drive Current (A),

peak of sine

ST11-1 1.2 100%

ST11-2 1.2 100%

ST14-1 1.2 See chart

ST17-1 1.6 100% See chart

ST17-2 2.0 100% See chart

ST17-3 2.0 100% See chart

ST23-1 3.4 100% See chart

ST23-4 5.0 See chart See chart

ST23-6 5.0 See chart See chart

ST34-2 10.0 See chart See chart

ST34-5 9.7 See chart See chart

ST34-8 10.0 See chart See chart

Figure 55. Duty Cycle for the ST17-1 with the SMD-761x, 24 VDC

NI SMD-7613/7614/7615/7616 User Manual | © National Instruments | 39

Page 40

Figure 56. Duty Cycle for the ST17-1 with the SMD-761x, 48 VDC

010203040 50

% Duty Cycle

ST17-1 Max Duty Cycle vs Speed

48 VDC, 1.60 Amps 40°C Ambient

on 4.75 x 4.75 x .25 Aluminum Plate

Speed (RPS)

0

20

40

60

80

100

010203040 50

% Duty Cycle

ST17-2 Max Duty Cycle vs Speed

48 VDC, 2.0 Amps 40°C Ambient

on 4.75 x 4.75 x .25 Aluminum Plate

Speed (RPS)

0

20

40

60

80

100

Figure 57. Duty Cycle for the ST17-2 with the SMD-761x, 48 VDC

40 | ni.com | NI SMD-7613/7614/7615/7616 User Manual

Page 41

Figure 58. Duty Cycle for the ST17-3 with the SMD-761x, 48 VDC

010203040 50

% Duty Cycle

ST17-2 Max Duty Cycle vs Speed

48 VDC, 2.0 Amps 40°C Ambient

on 4.75 x 4.75 x .25 Aluminum Plate

Speed (RPS)

0

20

40

60

80

100

010203040 50

% Duty Cycle

ST23-1 Max Duty Cycle vs Speed

48 VDC, 3.4 Amps, 40°C Ambient

on 6.4 x 6.4 x .25 Aluminum Plate

Speed (RPS)

0

20

40

60

80

100

Figure 59. Duty Cycle for the ST23-1 with the SMD-761x, 48 VDC

NI SMD-7613/7614/7615/7616 User Manual | © National Instruments | 41

Page 42

Figure 60. Duty Cycle for the ST23-4 with the SMD-761x, 24 VDC

010203040 50

% Duty Cycle

ST23-4 Max Duty Cycle vs Speed

24VDC, 5.0A, 40°C Ambient

on 6.4 x 6.4 x .25 Aluminum Plate

Speed (RPS)

0

20

40

60

80

100

010203040 50

% Duty Cycle

ST23-4 Max Duty Cycle vs Speed

48VDC, 5.0A, 40°C Ambient

on 6.4 x 6.4 x .25 Aluminum Plate

Speed (RPS)

0

20

40

60

80

100

Figure 61. Duty Cycle for the ST23-4 with the SMD-761x, 48 VDC

42 | ni.com | NI SMD-7613/7614/7615/7616 User Manual

Page 43

Figure 62. Duty Cycle for the ST23-6 with the SMD-761x, 24 VDC

010203040 50

% Duty Cycle

ST23-6 Max Duty Cycle vs Speed

24 VDC, 5.0 Amps, 40°C Ambient

on 6.4 x 6.4 x .25 Aluminum Plate

Speed (RPS)

0

20

40

60

80

100

010203040 50

% Duty Cycle

ST23-6 Max Duty Cycle vs Speed

48 VDC, 5.0 Amps 40°C Ambient

on 6.4 x 6.4 x .25 Aluminum Plate

Speed (RPS)

0

20

40

60

80

100

Figure 63. Duty Cycle for the ST23-6 with the SMD-761x, 48 VDC

NI SMD-7613/7614/7615/7616 User Manual | © National Instruments | 43

Page 44

Figure 64. Duty Cycle for the ST34-2 with the SMD-761x, 48 VDC

010203040 50

% Duty Cycle

ST34-2 Max Duty Cycle vs Speed

48 VDC, 10.0 Amps 40°C Ambient

on 10 x 10 x .5 Aluminum Plate

Speed (RPS)

0

20

40

60

80

100

010203040 50

% Duty Cycle

ST34-2 Max Duty Cycle vs Speed

80 VDC, 10.0 Amps 40°C Ambient

on 10 x 10 x .5 Aluminum Plate

Speed (RPS)

0

20

40

60

80

100

Figure 65. Duty Cycle for the ST34-2 with the SMD-761x, 80 VDC

44 | ni.com | NI SMD-7613/7614/7615/7616 User Manual

Page 45

Figure 66. Duty Cycle for the ST34-5 with the SMD-761x, 48 VDC

010203040 50

% Duty Cycle

ST34-5 Max Duty Cycle vs Speed

48 VDC, 10.0 Amps 40°C Ambient

on 10 x 10 x .5 Aluminum Plate

Speed (RPS)

0

20

40

60

80

100

010203040 50

% Duty Cycle

ST34-5 Max Duty Cycle vs Speed

80 VDC, 10.0 Amps 40°C Ambient

on 10 x 10 x .5 Aluminum Plate

Speed (RPS)

0

20

40

60

80

100

Figure 67. Duty Cycle for the ST34-5 with the SMD-761x, 80 VDC

NI SMD-7613/7614/7615/7616 User Manual | © National Instruments | 45

Page 46

Figure 68. Duty Cycle for the ST34-8 with the SMD-761x, 48 VDC

010203040 50

% Duty Cycle

ST34-8 Max Duty Cycle vs Speed

48 VDC, 10.0 Amps 40°C Ambient

on 10 x 10 x .5 Aluminum Plate

Speed (RPS)

0

20

40

60

80

100

01020

3040 50

% Duty Cycle

ST34-8 Max Duty Cycle vs Speed

80 VDC, 10.0 Amps 40°C Ambient

on 10 x 10 x .5 Aluminum Plate

Speed (RPS)

0

20

40

60

80

100

Figure 69. Duty Cycle for the ST34-8 with the SMD-761x, 80 VDC

Drive Heating

While NI SMD-7613/7614/7615/7616 devices efficiently transmit power between the power

supply and motor, they do generate some heat in the process. This will cause the temperature of

the drive to rise above the surrounding air temperature and may also require that the drive be

mounted to a heat conducting metal surface.

46 | ni.com | NI SMD-7613/7614/7615/7616 User Manual

Page 47

To calculate the power dissipation and temperature rise, the following information is provided.

SMD-7611/7612 Drive Losses

Motor Current (A)

Driver Loss (W)

0

5

10

15

20

25

123 45678

60V

24V

48V

Given:

drive power dissipation P

drive thermal constant R

versus motor (refer to the figures below)

d

Q

The final drive case temperature is given by:

T

= Ta + RQ* P

C

d

where Ta is the ambient temperature of the surrounding air. The case of the drive should not be

allowed to exceed 70 °C or the life of the product could be reduced.

Drive thermal constant:

Narrow side of drive mounted on a 3.5” × 13.5” steel plate, 0.070 in. thick: Rθ = 1.0 °C/W

Narrow side of drive mounted on a non-heat conducting surface: R

Figure 70. Drive Thermal Losses

= 2.1 °C/W

θ

NI SMD-7613/7614/7615/7616 User Manual | © National Instruments | 47

Page 48

Mechanical Outline

0.663

5.0

1.775

1.98

0.61

4.74

6X SLOT 0.16

WIDE, FULL R

3.00

Figure 71. Mechanical Dimensions

Technical Specifications

Amplifier

Features .....................................................Digital MOSFET. 20 kHz PWM. Suitable for

driving step motors with four, six, or eight leads.

SMD-7613/7615

Supply voltage ..................................12 to 53 VDC

Motor current .................................... 0.1 to 5.0 A/phase peak of sine

SMD-7614/7616

Supply voltage ..................................18 to 88 VDC

Motor current .................................... 0.5 to 10.0 A/phase peak of sine

48 | ni.com | NI SMD-7613/7614/7615/7616 User Manual

Page 49

Digital inputs

Step & Direction

Isolation ............................................ Optically isolated, 5 V logic

Digital logic ...................................... 5 V, differential

Internal resistance ............................. 330 Ω

Minimum pulse width....................... 0.5 µsec

Minimum set-up, direction ............... 2 µsec

Other inputs

Isolation ............................................ Optically isolated, 12 V logic

Digital logic ...................................... 12 to 24 V, differential

Internal resistance ............................. 2,200 Ω

Analog inputs

Input voltage ............................................. ±10 VDC

Internal resistance ..................................... 100 kΩ

Output ............................................................... Photodarlington, 100 mA, 30 VDC max.

Voltage drop.............................................. 1.2 V max at 100 mA

+5V Output ....................................................... 5 VDC

Max current............................................... 100 mA

Dimensions ....................................................... 1.775 × 3.0 × 5.0 in. (45 × 76.2 × 127 mm)

Weight............................................................... 10 oz (280 g)

Operating temperature range ............................ 0 °C to 40 °C

Mating connectors

Motor/power supply ................................. Phoenix Contact 1757051 (included)

IN/OUT1................................................... DB-25 male (included)

Encoder feedback ..................................... HD-15 male

Accessories

Regeneration clamp .................................. NI SMD-7700, NI part number 748908-01

NI SMD-7613/7614/7615/7616 User Manual | © National Instruments | 49

Page 50

Alarm Codes

In the event of an error, the green LED on the main board will flash one or two times, followed

by a series of red flashes. The pattern repeats until the alarm is cleared.

Table 5. Status LED Blink Code Definitions

Blink sequence Code Error

G Solid green No alarm, motor disabled

GG (slow) Flashing green No alarm, motor enabled

RG 1 red, 1 green Motor stall (encoder-equipped only)

RGG 1 red, 2 green Move attempted, drive disabled

RRG 2 red, 1 green CCW limit

RRGG 2 red, 2 green CW limit

RRRG 3 red, 1 green Drive overheating

RRRGG 3 red, 2 green Internal voltage out of range

RRRRG 4 red, 1 green Power supply overvoltage

RRRRGG 4 red, 2 green Power supply underoltage

RRRRRG 5 red, 1 green Over current /short circuit

RRRRRGG 5 red, 2 green Motor resistance out of range

RRRRRRG 6 red, 1 green Open motor winding

RRRRRRGG 6 red, 2 green Bad encoder signal

RRRRRRRG 7 red, 1 green Serial communication error

RRRRRRRRG 8 red, 1 green Internal voltage out of range

Refer to the NI Trademarks and Logo Guidelines at ni.com/trademarks for more information on National Instruments trademarks. Other

product and company names mentioned herein are trademarks or trade names of their respective companies. For patents covering National

Instruments products/technology, refer to the appropriate location: Help»Patents in your software, the patents.txt file on your media, or the

National Instruments Patents Notice at ni.com/patents. You can find information about end-user license agreements (EULAs) and third-party

legal notices in the readme file for your NI product. Refer to the Export Compliance Information at ni.com/legal/export-compliance

for the National Instruments global trade compliance policy and how to obtain relevant HTS codes, ECCNs, and other import/export data. NI MAKES

NO EXPRESS OR IMPLIED WARRANTIES AS TO THE ACCURACY OF THE INFORMATION CONTAINED HEREIN AND SHALL NOT BE LIABLE FOR

ANY ERRORS. U.S. Government Customers: The data contained in this manual was developed at private expense and is subject to the applicable

limited rights and restricted data rights as set forth in FAR 52.227-14, DFAR 252.227-7014, and DFAR 252.227-7015.

© 2014–2017 National Instruments. All rights reserved.

374809B-01 Jul17

Loading...

Loading...