Page 1

USER MANUAL

NI roboRIONI roboRIO

POWERPOWER

STATUSSTATUS

RADIORADIO

SPISPI

CS0CS0

CS1CS1

5V5V

CS2CS2

CS3CS3

SCLKSCLK

MOSIMOSI

INPUTINPUT

CANCAN

7-16 V7-16V

45W

MA

X45W

M

A

X

L (GRN)L (GRN)

H (YEL)H (YEL)

I2C

SCLSCL

3.3V SDA3.3V SDA

RS-232RS-232

TXDTXD

RXDRXD

RSLRSL

MISOMISO

3.3V3.3V

COMMCOMM

MODEMODE

RSLRSL

RELAYRELAY

0 1

FWDFWD

5V5V

S

S

REVREV

2 3 0 1

133

33

2 3

3

2 1

0

79 8

6 5

4

4 5 6

7 8 9

0 1

2

3

ANALOG INANALOG IN

RESETRESET

ACCELEROMETERACCELEROMETER

PWMPWM

DIODIO

Y

Z

X

USERUSER

S

5V5V

S

6V

6V

5

6 7 8

14

9 10

15

161718

12

1

2

3

4

13

11

NI roboRIO

RIO Device for Robotics

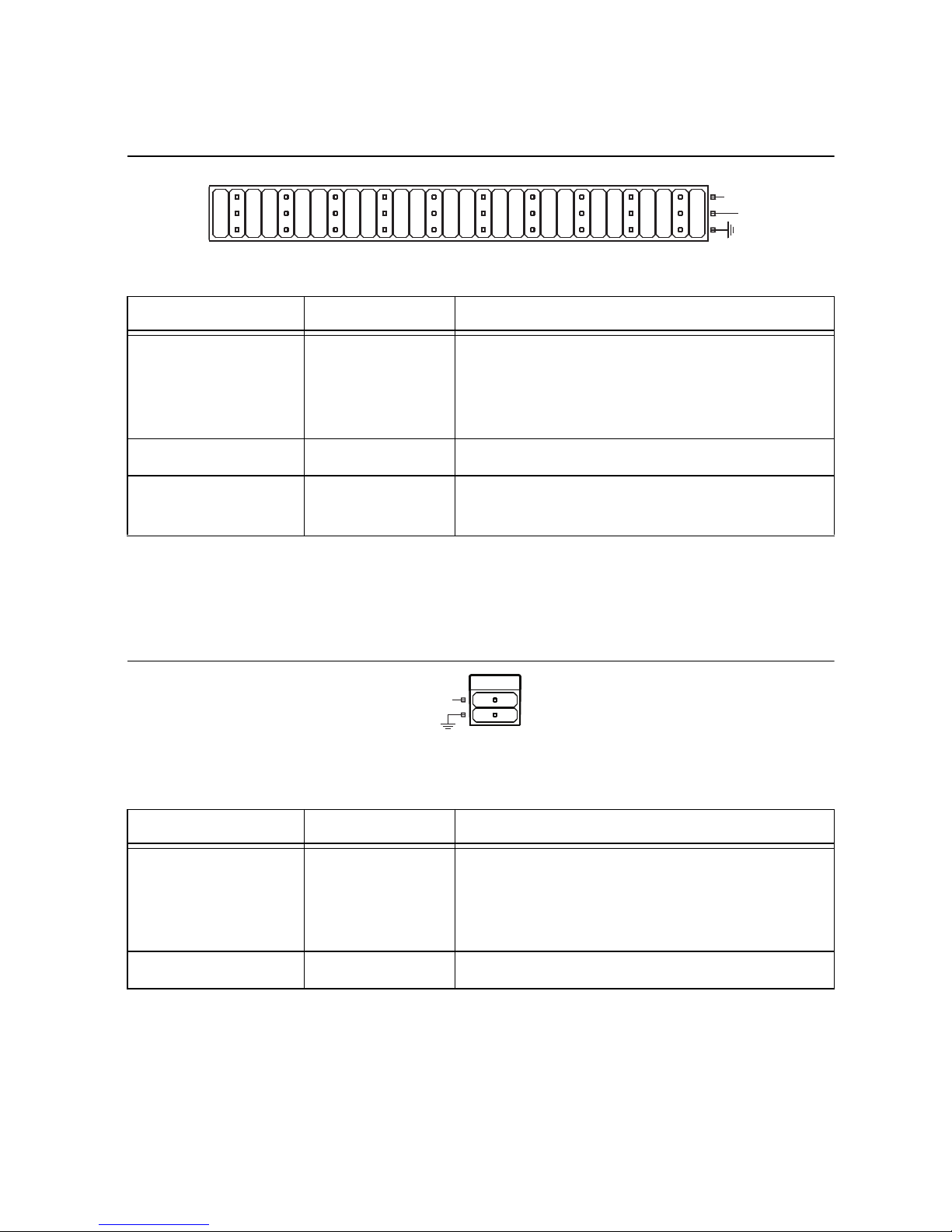

The NI roboRIO is a portable reconfigurable I/O (RIO) device that students can use to design

control, robotics, and mechatronics systems used in the FIRST Robotics Competition (FRC).

This document contains pinouts, connectivity information, dimensions, and mounting

instructions for the NI roboRIO. The NI roboRIO provides the I/O shown in Figure 1 and

connects to a host computer over USB and 10/100 Ethernet.

Figure 1. NI roboRIO Features

1 Digital input and output (DIO) port

2 RS-232 port

3I

4CAN port

5 Power connector

6USB Device port

7 USB Host retention mount

8 USB Host ports

9 Ethernet port

2

C port

10 Serial peripheral interface bus (SPI) port

11 LEDs

12 Pulse-width modulation (PWM) port

13 myRIO Expansion Port (MXP)

14 MXP retention mount

15 User and Reset buttons

16 Analog input (AI) port

17 Relay port

18 Robot signal light (RSL) port

Page 2

Contents

Safety Information .................................................................................................................... 3

Electromagnetic Compatibility Guidelines............................................................................... 3

Hardware Block Diagram ......................................................................................................... 4

Setting Up the NI roboRIO.......................................................................................................5

Wiring Power to the NI roboRIO ..................................................................................... 5

Powering On the NI roboRIO ........................................................................................... 5

Connecting the NI roboRIO to a Network........................................................................6

Preparing the NI roboRIO for Competition ...................................................................... 6

User Power........................................................................................................................ 6

Pinouts ...................................................................................................................................... 8

MXP.................................................................................................................................. 8

CAN Port .......................................................................................................................... 9

2

C Port .............................................................................................................................10

I

RS-232 Port....................................................................................................................... 10

DIO Port............................................................................................................................ 11

RSL Port ...........................................................................................................................11

Relay Port ......................................................................................................................... 12

AI Port...............................................................................................................................12

PWM Port ......................................................................................................................... 13

SPI Port .............................................................................................................................13

Signal Ground References ........................................................................................................14

Interfaces................................................................................................................................... 14

AI Channels ...................................................................................................................... 14

AO Channels.....................................................................................................................14

DIO, PWM, and Relay Lines............................................................................................ 15

UART and RS-232 Lines.................................................................................................. 16

SPI Lines...........................................................................................................................16

2

C Lines ........................................................................................................................... 16

I

USB Device Port............................................................................................................... 16

USB Host Port .................................................................................................................. 16

Accelerometer ........................................................................................................................... 17

Converting Raw Data Values to Voltage.................................................................................. 17

Front Panel Buttons .................................................................................................................. 17

Reset Button...................................................................................................................... 17

User Button ....................................................................................................................... 18

LED Indications ........................................................................................................................ 18

Power LED .......................................................................................................................18

Status LED ........................................................................................................................ 19

Radio LED ........................................................................................................................ 19

Comm LED....................................................................................................................... 20

Mode LED ........................................................................................................................20

RSL (Safety) LED ............................................................................................................ 21

Physical Dimensions................................................................................................................. 22

2 | ni.com | NI roboRIO User Manual

Page 3

Mounting the NI roboRIO ........................................................................................................ 25

Method One: Using Cable Ties to Secure One Edge of the

NI roboRIO to Perfboard............................................................................................... 25

Method Two: Using Cable Ties to Secure One Corner of the

NI roboRIO to Perfboard............................................................................................... 27

Method Three: Using Screws to Secure the Bottom of the

NI roboRIO to a Metal Plate ......................................................................................... 30

Compatible USB and Ethernet Cables...................................................................................... 30

Warranty ................................................................................................................................... 31

Worldwide Support and Services ............................................................................................. 31

Safety Information

Caution Do not operate the hardware in a manner not specified in the user

documentation. Misuse of the hardware can result in a hazard. You can compromise

the safety protection if the hardware is damaged in any way. If the hardware is

damaged, contact National Instruments for repair.

Clean the hardware with a soft, nonmetallic brush. Make sure that the hardware is completely

dry and free from contaminants before returning it to service.

Electromagnetic Compatibility Guidelines

This product was tested and complies with the regulatory requirements and limits for

electromagnetic compatibility (EMC) stated in the product specifications. These requirements

and limits provide reasonable protection against harmful interference when the product is

operated in the intended operational electromagnetic environment.

This product is intended for use in industrial locations. However, harmful interference may

occur in some installations, when the product is connected to a peripheral device or test object,

or if the product is used in residential or commercial areas. To minimize interference with radio

and television reception and prevent unacceptable performance degradation, install and use this

product in strict accordance with the instructions in the product documentation.

Furthermore, any modifications to the product not expressly approved by National Instruments

could void your authority to operate it under your local regulatory rules.

Caution To ensure the specified EMC performance, the maximum length for DIO,

2

RS-232, I

The maximum length for USB cables is 5.0 m (16.40 ft). The maximum length for

Ethernet cables is 30.0 m (98.43 ft). Refer to the Compatible USB and Ethernet

Cables section of this document for information about compatible USB and Ethernet

cables.

C, CAN, SPI, PWM, AI, Relay, and RSL signal wires is 2.0 m (6.56 ft).

NI roboRIO User Manual | © National Instruments | 3

Page 4

Hardware Block Diagram

CAN

Port

Xilinx Zynq-7020

Processor/FPGA

(LabVIEW RT)

USB

Device

Port

USB

Hosts

Port

10/100

Ethernet

Port

Status LED

Comm LED

Radio LED

Mode LED

R

SL LED

Power LED

+

3.3 V

+5.0 V

16 16

2

4

UART

DIO

Analog Out

Analog In

myRIO

Expansion

Port (MXP)

User

Button

Reset

Button

PWM

Port

10

10

+6.0 V

PWM

SPI

SPI Port

+5.0 V

+3.3 V

7

7

2

RS-232

RS-232

Port

2

I2C

I2C

Port

2

+3.3 V

DIO

Port

DIO

10 10

+5.0 V

Watchdog

Nonvolantile

Memory

DDR3

Acceler-

ometer

RSL

RSL

Port

Relay

8

8

RELAY

Port

4

+5.0 V

AI

ANALOG IN

Port

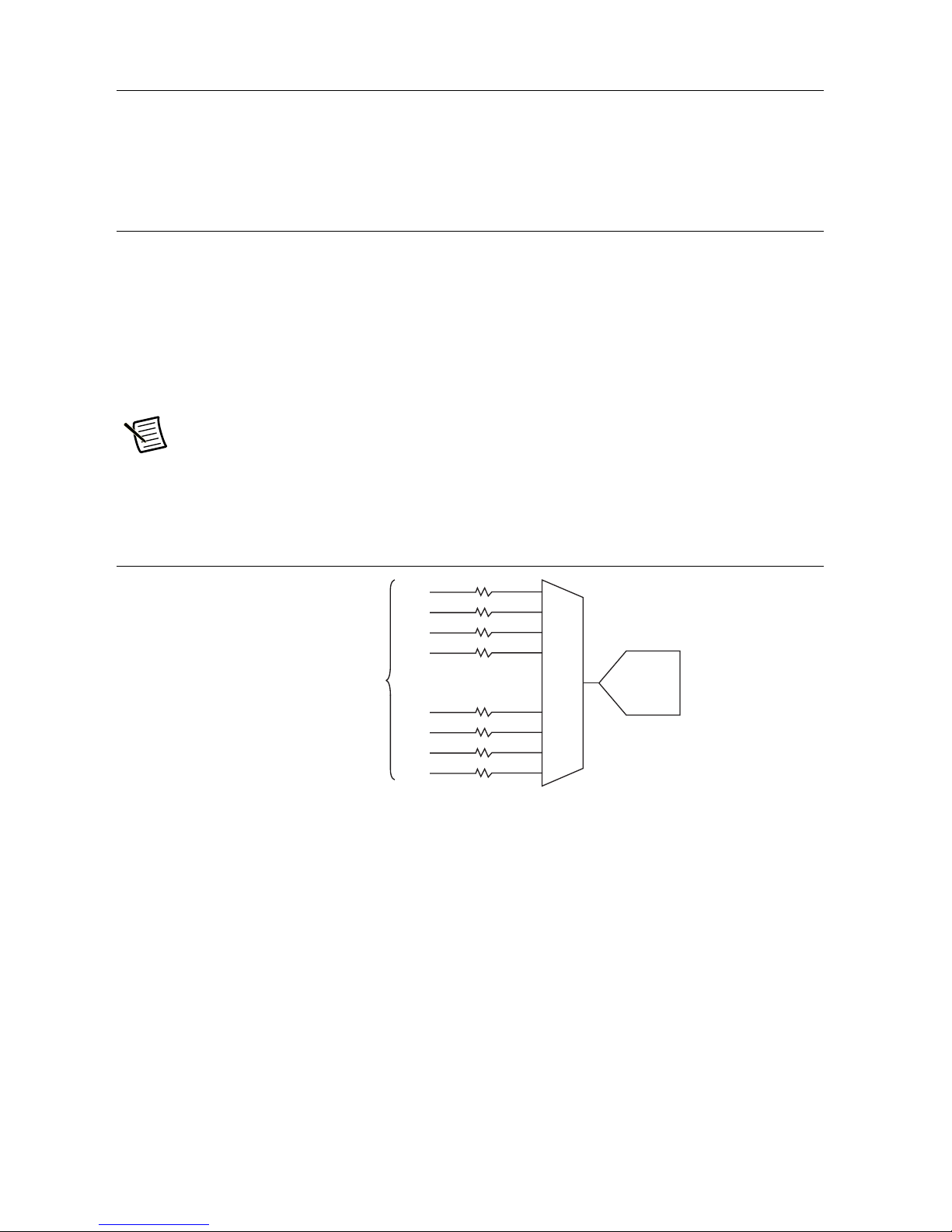

Figure 2 shows the arrangement and functions of NI roboRIO components.

Figure 2. NI roboRIO Hardware Block Diagram

4 | ni.com | NI roboRIO User Manual

Page 5

Setting Up the NI roboRIO

Wiring Power to the NI roboRIO

The NI roboRIO requires an external power supply that meets the specifications in the Power

Requirements section of the NI roboRIO Specifications. The NI roboRIO filters and regulates

the supplied power and provides power for all of the I/O and user voltage. The NI roboRIO has

one layer of reverse-voltage protection. Complete the following steps to connect a power supply

to the chassis.

1. Ensure that the power supply is turned off.

Caution Do not install or remove the power connector from the front panel of the

NI roboRIO while power is applied.

2. Connect the positive lead of the power supply to the V terminal of the COMBICON power

connector shipped with the NI roboRIO, and tighten the terminal screw. Figure 3 shows the

terminal screws, which secure the wires in the screw terminals, and the connector screws,

which secure the power connector on the front panel.

Figure 3. NI roboRIO COMBICON Power Connector

2

1

1 Terminal Screws 2 Connector Screws

3. Connect the negative lead of the power supply to the C terminal of the power connector and

tighten the terminal screw.

4. Install the power connector on the front panel of the NI roboRIO and tighten the connector

screws.

5. Turn on the power supply.

V

C

2

Powering On the NI roboRIO

When you apply power, the NI roboRIO runs a power-on self test (POST). During the POST,

the Power and Status LEDs turn on. The Status LED turns off, indicating that the POST is

complete. If the LEDs do not behave in this way when the system powers on, refer to the LED

Indications section.

NI roboRIO User Manual | © National Instruments | 5

Page 6

Connecting the NI roboRIO to a Network

Connect the NI roboRIO to an Ethernet network using the Ethernet port. Use a standard

Category 5 (CAT-5) or better shielded, twisted-pair Ethernet cable to connect the NI roboRIO

to an Ethernet hub, router, or directly to a computer.

Caution To prevent data loss and to maintain the integrity of your Ethernet

installation, do not use a cable longer than 30 m.

The first time you power up the chassis, it attempts to initiate a DHCP network connection. If

the chassis is unable to initiate a DHCP connection, it connects to the network with a link-local

IP address with the form

169.254.x.x.

Preparing the NI roboRIO for Competition

For information about configuring the controller for competitive use, refer to the Tutorials tab

in the Getting Started window of LabVIEW for FRC.

User Power

Table 1 describes the user voltage rails for powering external sensors and peripherals. The rails

are independent from the power supplies of internal systems, such as the processor and memory.

Table 1. NI roboRIO Voltage Rails

Voltage Rail Description

+6 V Power from PWM ports for use with servos.

+5 V Power for DIO and AI ports for sensors, and power for the MXP for

powering expansion circuits.

+3.3 V Power for I2C, SPI, and the MXP.

6 | ni.com | NI roboRIO User Manual

Page 7

Input Voltage Brownout Behavior

The NI roboRIO input voltage range is 7 V to 16 V. The input voltage monitoring circuit

monitors the voltage on the input voltage pin. When the input voltage drops to between 4.5 V

and 6.8 V, the NI roboRIO enters brownout mode with a staged response, as Table 2 describes.

Table 2. NI roboRIO Input Voltage Brownout Behavior

Input Voltage

Stage

Range

1 6.3 V to 6.8 V The +6 V voltage rail starts to drop.

2 4.5 V to 6.3 V The NI roboRIO enters a brownout fault condition and the

following precautions are taken:

• User voltage rails become disabled.

• All PWM generation stops at the conclusion of the current

cycle.

• GPIOs configured as outputs go to High-Z.

• Relay control outputs are driven low.

• CAN-based motor controllers become disabled.

Behavior

The following systems continue to function normally with

valid data and communication:

• FPGA, processor, RAM, disk, and user code

• USB power and communication

• Radio, if powered by USB

• Ethernet

•CAN

• AI and AO

2

C

•I

•SPI

• RS-232 serial

• LED and RSL status lights

Stage 2 continues until the input voltage rises to greater than

7.5 V or drops to less than 4.5 V.

3 Less than 4.5 V All controller functions cease and the controller state is lost.

This condition continues until the input voltage rises to greater

than 4.65 V, at which point the controller starts the normal

booting sequence. At startup, the controller remains in Stage 2

until the input voltage rises to greater than 7.5 V.

NI roboRIO User Manual | © National Instruments | 7

Page 8

Pinouts

AO0

AO1

AGND

DGND

UART.RX

DGND

UART.TX

DGND

DIO11 / PWM7

DGND

DIO12 / PWM8

DGND

DIO13 / PWM9

DGND

DGND

DIO14 / I2C SCL

DIO15 / I2C SDA

+5V

AI1

AI3

AI2

DIO1 / PWM1

DIO2 / PWM2

DIO3 / PWM3

DIO4 / SPICS

AI0

DIO0 / PWM0

DIO5 / SPI CLK

DIO6 / SPI MISO

DIO7 / SPI MOSI

DIO8 / PWM4

DIO9 / PWM5

DIO10 / PWM6

+3.3V

3433323130292827262524

23222120191817

1615141312111098

7

6

5

4

3

2

1

The following describe the pins and signals on the NI roboRIO ports.

MXP

Figure 4 and Table 3 describe the MXP pins and signals. Note that some pins carry both primary

and secondary functions.

Figure 4. MXP Pinout

Signal Name Reference Direction Description

+5V DGND Output +5 V power output.

AI <0..3> AGND Input 0 to 5 V, referenced, single-ended AI

AO <0..1> AGND Output 0 to 5 V referenced, single-ended AO.

8 | ni.com | NI roboRIO User Manual

AGND — — Reference for AI and AO.

+3.3V DGND Output +3.3 V power output.

Table 3. MXP Signal Descriptions

channels. Refer to the AI Channels

section for more information.

Refer to the AO Channels section for

more information.

Page 9

Table 3. MXP Signal Descriptions (Continued)

Signal Name Reference Direction Description

DIO <0..15> DGND Input or

Output

General-purpose digital lines with

3.3 V output, 3.3 V/5 V-compatible

input. Refer to the DIO, PWM, and

Relay Lines section for more

information.

UART.RX DGND Input UART receive input. UART lines are

electrically identical to DIO lines.

UART.TX DGND Output UART transmit output. UART lines are

electrically identical to DIO lines.

DGND — — Reference for digital signals, +5 V,

and +3.3 V.

CAN Port

Figure 5 and Table 4 describe the CAN port pins and signals.

Figure 5. CAN Port Pinout

L (GRN)

H (YEL)

Table 4. CAN Port Signal Descriptions

Signal Name Direction Description

L (GRN) Input/Output CAN bus differential low signal.

H (YEL) Input/Output CAN bus differential high signal.

Note The NI roboRIO contains an internal 120 W termination resistor between

L (GRN) and H (YEL).

NI roboRIO User Manual | © National Instruments | 9

Page 10

I2C Port

RXD

TXD

Figure 6 and Table 5 describe the I2C port pins and signals.

Figure 6. I

Table 5. I

2

C Port Signal Descriptions

2

C Port Pinout

SDA

3.3V

SCL

Signal Name Direction Description

GND — Reference for digital lines and +3.3 V power

output.

3.3V Output +3.3 V power output.

SCL Input or Output I2C lines with 3.3 V output, 3.3 V/

5 V-compatible input. Refer to the I

SDA Input or Output

section for more information.

RS-232 Port

2

C Lines

Figure 7 and Table 6 describe the RS-232 port pins and signals.

Figure 7. RS-232 Serial Port Pinout

Table 6. RS-232 Serial Port Signal Descriptions

Signal Name Direction Description

TXD Output Serial transmit output with ±5 V to ±15 V signal

levels. Refer to the UART and RS-232 Lines

section for more information.

RXD Input Serial receive input with ±15 V input voltage

range. Refer to the UART and RS-232 Lines

section for more information.

GND — Reference for digital lines.

10 | ni.com | NI roboRIO User Manual

Page 11

DIO Port

1

2

3

5

6

7

4

8

0

9

S

5V

Figure 8 and Table 7 describe the DIO port pins and signals.

Figure 8. DIO Port Pinout

Table 7. DIO Port Signal Descriptions

Signal Name Direction Description

S (DIO) <0..9> Input/Output General-purpose digital lines with 3.3 V output,

3.3 V/5 V-compatible input. Refer to the DIO,

PWM, and Relay Lines section for more

information.

5V Output +5 V power output.

GND — Reference for digital lines and +5 V power

output.

RSL Port

Figure 9 and Table 8 describe the RSL port pins and signals.

Figure 9. RSL Port Pinout

S

Table 8. RSL Port Signal Descriptions

Signal Name Direction Description

S Output Switched power output to drive RSL when

RSLis enabled. The voltage level depends on the

connected input voltage. RSL current is limited

at 120 mA.

GND — Reference for S.

NI roboRIO User Manual | © National Instruments | 11

Page 12

Relay Port

S

5V

1

2

03

Figure 10 and Table 9 describe the Relay port pins and signals.

Figure 10. Relay Port Pinout

1

FWD

REV

2

30

Table 9. Relay Port Signal Descriptions

Signal Name Direction Description

FWD <0..3> Output Relay digital lines with 5 V output.

REV <0..3> Output Relay digital lines with 5 V output.

GND — Reference for digital lines.

AI Port

Figure 11 and Table 10 describe the AI port pins and signals.

Figure 11. AI Port Pinout

Table 10. AI Port Signal Descriptions

Signal Name Direction Description

S (AI) <0..3> Input 0 V to 5 V referenced, single-ended AI channels.

Refer to the AI Channels section for more

information.

5V Output +5 V power output.

GND — Reference for AI and +5 V power.

12 | ni.com | NI roboRIO User Manual

Page 13

PWM Port

Figure 12 and Table 11 describe the PWM port pins and signals.

Figure 12. PWM Port Pinout

6V

S

9

8

7

6

5

4

3

2

Table 11. PWM Port Signal Descriptions

Signal Name Direction Description

S (PWM) <0..9> Output PWM digital lines with 5 V output.

6V Output +6 V power output for servos only.

GND — Reference for digital lines and +6 V power

output.

SPI Port

Figure 13 and Table 12 describe the SPI port pins and signals.

Figure 13. SPI Port Pinout

1

0

CS0

SCLK

MOSI

MISO

3.3V

CS1

5V

CS2

CS3

Table 12. SPI Port Signal Descriptions

Signal Name Direction Description

3.3V Output +3.3 V power output.

5V Output +5 V power output.

CS <0..3> Output SPI with 3.3 V output, 3.3 V/5 V-compatible

input. Refer to the SPI Lines section for more

SCLK Output

information.

MOSI Output

MISO Input

GND — Reference for digital lines and +3.3 V and

+5.5 V power output.

NI roboRIO User Manual | © National Instruments | 13

Page 14

Signal Ground References

To minimize noise on analog measurement channels, use the ground reference of the

corresponding port. For example, when you are using AI, the measurement should reference the

GND of the AI port.

Interfaces

AI Channels

The NI roboRIO has AI channels on the MXP and on the AI port. The channels are multiplexed

to a single analog-to-digital converter (ADC) that samples all channels.

The MXP and the AI port each has four single-ended AI channels, AI0-AI3, which you can use

to measure 0-5 V signals.

Note For important information about improving measurement accuracy by

reducing noise, visit

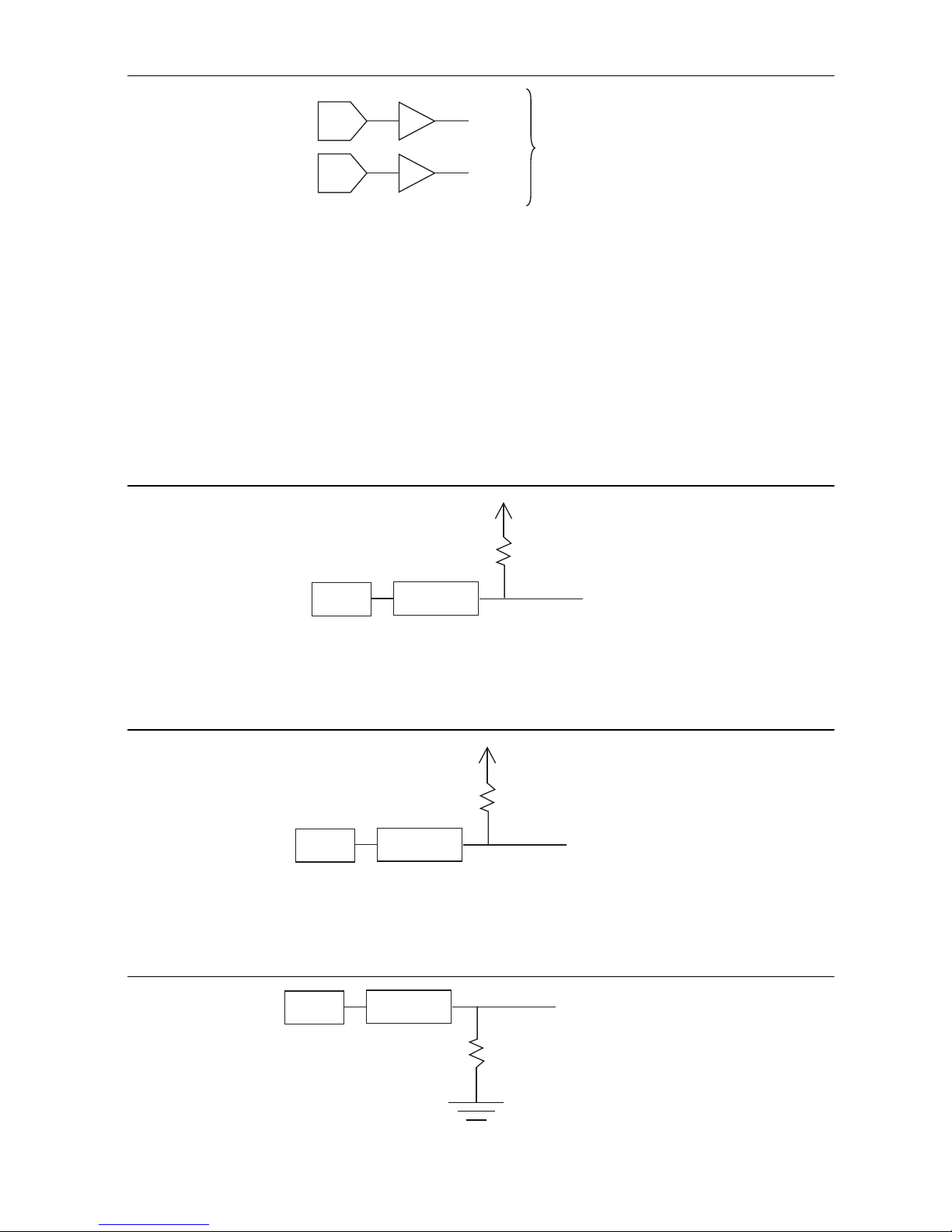

Figure 14 shows the AI topology of the NI roboRIO.

ni.com/info and enter the Info Code analogwiring.

Figure 14. NI roboRIO AI Circuitry

AI0

Expansion port

0–5 V

Integrated AI port

AI1

AI2

AI3

AI0

AI1

AI2

AI3

MUX

ADC

AO Channels

The NI roboRIO MXP has two AO channels, AO0 and AO1, which you can use to generate

signals of 0 V to 5 V. Each channel has a dedicated digital-to-analog converter (DAC), which

allows all AO channels to update simultaneously. The maximum update rate is specified as an

aggregate rate in the Analog Output section of the NI roboRIO Specifications.

Figure 15 shows the AO topology of the NI roboRIO.

14 | ni.com | NI roboRIO User Manual

Page 15

Figure 15. NI roboRIO AO Circuitry

40 kΩ

FPGA

Bus Switch

DIO/CS

+3.3 V

40 kΩ

FPGA

Bus Switch

DIO or Other Line

DAC

DAC

AO0

AO1

Expansion port

0–5 V

DIO, PWM, and Relay Lines

The NI roboRIO provides the following DIO lines:

• 3.3 V general-purpose DIO lines on the MXP

• 3.3 V digital lines on the DIO, I

• 5 V digital lines on the PWM and Relay ports.

DIO <9..0> on the DIO port, CS <3..0> on the SPI port, and DIO <13..0> on the MXP all have

40 kΩ pullup resistors to 3.3 V, as shown in Figure 16.

Figure 16. DIO Lines with 40 kΩ Pullup Resistors to 3.3 V

2

C, and SPI ports

DIO <15..14> on the MXP and the two lines on the I2C port all have 2.2 kΩ pullup resistors to

3.3 V, as shown in Figure 17.

Figure 17. DIO Lines with 2.2 kΩ Pullup Resistors to 3.3 V

+3.3 V

2.2 kΩ

FPGA

Bus Switch

DIO/SCL/SDA

<SCLK, MOSI, MISO> on the SPI port and the lines on the PWM and Relay ports all have

40 kΩ pulldown resistors to ground, as shown in Figure 18.

Figure 18. DIO Lines with 40 kΩ Pulldown Resistors to Ground

NI roboRIO User Manual | © National Instruments | 15

Page 16

You can program all MXP DIO lines and on-board DIO lines individually as inputs or outputs.

2

Secondary digital functions include SPI, I

NI roboRIO software documentation for information about configuring the behavior of the DIO

lines.

When a DIO line is floating, it floats in the direction of the pull resistor. A DIO line may be

floating in any of the following conditions:

• When the NI roboRIO device is starting up

• When the line is configured as an input

• When the NI roboRIO device is powering down

You can add a stronger resistor to a DIO line to cause it to float in the opposite direction.

C, PWM, and quadrature encoder input. Refer to the

UART and RS-232 Lines

The NI roboRIO has one UART connected to the UART lines on the MXP and one UART

connected to the RS-232 port.

The UART lines on the MXP are electrically identical to DIO lines 0 to 13 on the MXP. Like

those lines, UART.RX and UART.TX have 40 kΩ pullup resistors to 3.3 V.

The RS-232 lines are compliant with TIA/EIA-232-F voltage levels.

SPI Lines

The SPI port can support up to four devices by using each of the four Chip Select (CS) lines.

I2C Lines

The I2C lines can be used to connect to a network of I2C slave devices..

USB Device Port

You can deploy and debug code by connecting a USB cable from the USB device port on the

NI roboRIO to a computer.

USB Host Port

The NI roboRIO USB host port supports the following devices:

• Web cameras that conform to the USB Video Device Class (UVC) protocol.

• Machine vision cameras that conform to the USB3 Vision standard and are backward

compatible with the USB 2.0 specification.

• Basler ace USB3 cameras.

• USB Flash drives.

• USB-to-IDE adapters formatted with FAT16 and FAT32 file systems.

LabVIEW usually maps USB devices to the

if it is available.

16 | ni.com | NI roboRIO User Manual

/U, /V, /W, or /X drive, starting with the /U drive

Page 17

Accelerometer

The NI roboRIO contains a three-axis accelerometer, MMA8452Q. Refer to the Accelerometer

section of the NI roboRIO Specifications for the accelerometer sample rates.

Converting Raw Data Values to Voltage

You can use the following equations to convert raw data values to volts:

V = Raw Data Value * LSB Weight

LSB Weight = Nominal Range ÷ 2

where Raw Data Value is the value returned by reading in the input channel,

LSB Weight is the value in volts of the increment between data values,

Nominal Range is the absolute value in volts of the full, peak-to-peak nominal range

of the channel,

and ADC Resolution is the resolution of the ADC in bits. (ADC Resolution = 12.)

• For AI and AO channels on the MXP,

LSB Weight = 5 V ÷ 2

Maximum reading = 4095 * 1.221 mV = 4.999 V

• For the accelerometer,

LSB Weight = 16 g ÷ 2

Maximum Positive Reading = +2047 * 3.906 mg = +7.996 g

Maximum Negative Reading = -2048 * 3.906 mg = -8.000 g

12

12

ADC Resolution

= 1.221 mV

= 3.906 mg

Front Panel Buttons

Reset Button

Pressing and releasing the Reset button restarts the processor and the FPGA.

Pressing and holding the Reset button until the status LED lights (about five seconds) and then

releasing the Reset button restarts the processor and the FPGA and forces the NI roboRIO into

safe mode. In safe mode, the NI roboRIO launches only the services necessary for updating

configuration and installing software.

When the NI roboRIO is in safe mode, you can communicate with it by using the serial lines on

the RS-232 serial port. You must configure your serial-port terminal program with the following

settings:

• 115,200 bits per second

• Eight data bits

NI roboRIO User Manual | © National Instruments | 17

Page 18

• No parity

• One stop bit

• No flow control

User Button

The User Button produces a logic TRUE when depressed and a logic FALSE when not

depressed. The User Button is not debounced in hardware.

LED Indications

Power LED

The Power LED is a tri-color red/green/yellow LED that indicates specific conditions, as shown

in Table 13.

Table 13. Power LED Indications

Color State Indication

Off Off Power is outside valid input range.

Green Solid Power is valid with no fault condition.

Red Solid Fault condition detected. One or more user voltage rails are

in short-circuit or overcurrent condition.

Red Flashing The input voltage is too high (greater than 16 V) and all

outputs, including the RSL output, are disabled.

Ye ll o w Solid Brownout condition detected. The 6 V user rail and

outputs are disabled.

18 | ni.com | NI roboRIO User Manual

Page 19

Status LED

The Status LED is a single-color yellow LED. The Status LED is off during normal operation.

The NI roboRIO runs a power-on self test (POST) when you apply power to the device. During

the POST, the Power and Status LEDs turn on. When the Status LED turns off, the POST is

complete. The NI roboRIO indicates specific error conditions by flashing the Status LED a

certain number of times every few seconds, as shown in Table 14.

Table 14. Status LED Indications

Number of Flashes

Every Few Seconds

2 The device has detected an error in its software. This usually

occurs when an attempt to upgrade the software is interrupted.

Reinstall software on the device.

3 The device is in safe mode.

4 The software has crashed twice without rebooting or cycling

power between crashes. This usually occurs when the device runs

out of memory. Review your RT VI and check the memory usage.

Modify the VI as necessary to solve the memory usage issue.

Indication

Continuously flashing

or solid

The device has detected an unrecoverable error. Contact National

Instruments.

Radio LED

The Radio LED is a tri-color red/green/yellow LED that indicates specific conditions for an

USB-connected radio, as shown in Table 15.

Table 15. Radio LED Indications

Color State Indication

Off Off No connection detected.

Ye ll o w Blinking Booting as access point. Radio is enabled and access point

is being constructed.

Ye ll o w Solid Access point active. Radio is enabled and in access point

mode.

Green Blinking Booting as bridge. Radio is enabled and bridging is in

progress.

Green Solid Bridge active. Radio is enabled and has bridge configured

Red Any Reserved.

with SSID settings.

NI roboRIO User Manual | © National Instruments | 19

Page 20

Other LED states may indicate other, undetermined radio issues or failures. This LED is

undefined if a USB radio is not used.

Comm LED

The Comm LED is a tri-color red/green/yellow LED that indicates robot communication

conditions, as shown in Table 16.

Table 16. Comm LED Indications

Color State Indication

Off Off No communication detected. No heartbeat detected.

Red Solid No code. The protocol indicates that no user code has been

loaded.

Red Blinking E-Stop. The protocol indicates that the driver station has

E-Stopped the robot.

Green Solid Active. The protocol is active and the driver station is in

control of the robot.

Ye ll o w Any Reserved.

Mode LED

The Mode LED is a tri-color red/green/yellow LED that indicates the mode of the NI roboRIO

outputs, as shown in Table 17.

Table 17. Mode LED Indications

Color State Indication

Off Off Outputs disabled.

Green Solid Outputs enabled. Autonomous mode.

Ye ll o w Solid Outputs enabled. TeleOperated mode.

Red Solid Outputs unknown, undetermined, or in test mode.

20 | ni.com | NI roboRIO User Manual

Page 21

RSL (Safety) LED

The RSL LED is a single-color yellow LED that functions identically to the RSL, which is an

external indicator connected to the NI roboRIO using a dedicated connector, and indicates

specific conditions, as shown in Table 18.

Table 18. RSL LED Indications

Color State Indication

Off Off Outputs disabled. No power.

Ye ll o w Solid Outputs disabled. Robot is powered.

Ye ll o w Blinking Outputs enabled. Robot is powered.

NI roboRIO User Manual | © National Instruments | 21

Page 22

Physical Dimensions

NI roboRIO

PO

W

E

R

STAT

US

R

ADIO

SPI

C

S0

C

S1

5V

CS2

CS3

SCLK

MOSI

CAN

L (GR

N)

H (YE

L)

I

2

C

SC

L

3.3

V SDA

RS-

232

TXD

RX

D

R

S

L

MISO

3.3

V

CO

M

M

M

O

D

E

RSL

RELAY

0 1

FWD

5V

S

S

REV

2 3 0 1

1

33

2 3

3

2 1

0

79 8 6 5

4

4 5 6

7 8 9

0 1

2

3

ANALOG IN

RESET

ACCELEROMETER

PWM

DIO

Y

Z

X

USER

S

5V

S

6V

INPUT

7-16V

45W

M

A

X

Figures 19 through 22 describe the physical dimensions of the NI roboRIO enclosure and its

features.

Figure 19. NI roboRIO Dimensions, Primary Side

135.47 mm (5.333 in.)

132.61 mm (5.221 in.)

130.72 mm (5.147 in.)

123.43 mm (4.860 in.)

110.96 mm (4.368 in.)

99.54 mm (3.919 in.)

88.10 mm (3.469 in.)

80.48 mm (3.169 in.)

72.86 mm (2.869 in.)

65.24 mm (2.569 in.)

57.62 mm (2.269 in.)

50.00 mm (1.969 in.)

42.38 mm (1.669 in.)

34.76 mm (1.369 in.)

27.14 mm (1.069 in.)

19.52 mm (0.769 in.)

8.42 mm (0.332 in.)

7.16 mm (0.282 in.)

0.0 mm (0 in.)

8.93 mm (0.352 in.)

8.44 mm (0.332 in.)

INPUT

7-16 V

45W MAX

CAN

L (GRN)

H (YEL)

RS-232

DIO

5V

29.58 mm (1.164 in.)

9.71 mm (0.382 in.)

3.3V SDA

SCL

TXD

RXD

SL

R

FWD

REV

49.45 mm (1.947 in.)

74.55 mm (2.935 in.)

NI roboRIO

33

RELAY

ANALOG IN

94.67 mm (3.727 in.)

CLK

S

MOSI

MISO

3.3V

ACCELEROMETER

5V

116.64 mm (4.592 in.)

R

E

POW

STATUS

SPI

RADIO

COMM

S0

C

S1

C

MODE

5V

S2

C

CS3

RSL

PWM

RESET

USER

6V

129.83 mm (5.111 in.)

129.21 mm (5.087 in.)

126.94 mm (4.998 in.)

88.50 mm (3.484 in.)

80.88 mm (3.184 in.)

74.70 mm (2.941 in.)

65.64 mm (2.584 in.)

58.02 mm (2.284 in.)

54.40 mm (1.984 in.)

42.78 mm (1.684 in.)

42.58 mm (1.677 in.)

35.16 mm (1.384 in.)

27.54 mm (1.084 in.)

19.92 mm (0.784 in.)

8.09 mm (0.319 in.)

0.0 mm (0 in.)

8.44 mm (0.332 in.)

22 | ni.com | NI roboRIO User Manual

22.26 mm (0.876 in.)

60.38 mm (2.377 in.)

52.76 mm (2.077 in.)

45.14 mm (1.777 in.)

93.39 mm (3.677 in.)

85.77 mm (3.377 in.)

78.15 mm (3.077 in.)

73.08 mm (2.877 in.)

68.00 mm (2.677 in.)

101.01 mm (3.977 in.)

117.85 mm (4.64 in.)

137.72 mm (5.422 in.)

128.01 mm (5.040 in.)

Page 23

Figure 20. NI roboRIO Dimensions, Primary Side LEDs

NI roboRIONI roboRIO

POW

E

RPOWER

STATUSSTAT

US

RADIORAD

IO

SPISPI

CS0CS0

CS1C

S1

5V5V

CS2C

S2

CS3CS3

S

CLK

S

CLK

MOSIMOSI

CANCAN

L (GRN)L (GRN)

H (YEL)H (YE

L)

I

2

C

SCLSC

L

3.3V SDA3.3V SD

A

RS-232RS-

232

TXDTXD

RXDRX

D

RSLR

S

L

MISOMISO

3.3V3.3

V

COMMCO

M

M

MODEMO

D

E

RSLR

S

L

RELAYRELAY

0 1

FWDFWD

S

S

REVREV

2 3 0 1

133

33

2 3

3

2 1

0

79 8

6 5

4

4 5 6

7 8 9

0 1

2

3

ANALOG INANALOG IN

RESETRESET

ACCELEROMETERACCELEROMETER

PWMPWM

DIODIO

Y

Z

X

USERUSER

S

S

5V5V

5V5V

6V6V

INPUTINPUT

7-16 V7-16V

45W MAX45

W MA

X

146.15 mm (5.754 in.)

0.0 mm (0 in.)

0.0 mm (0 in.)

143.18 mm (5.637 in.)

128.51 mm (5.059 in.)

143.68 (5.657 in.)

123.51 mm (4.862 in.)

116.01 mm (4.567 in.)

111.01 mm (4.370 in.)

106.01 mm (4.173 in.)

98.51 mm (3.878 in.)

NI roboRIO User Manual | © National Instruments | 23

Page 24

Figure 21. NI roboRIO Dimensions, Secondary Side

22.28 mm (0.877 in.)

0.0 mm (0 in.)

122.39 mm (4.819 in.)

20.79 mm (0.819 in.)

135.09 mm (5.319 in.)

8.09 mm (0.319 in.)

0.0 mm (0 in.)

3.84 mm (0.151 in.)

142.31 mm (5.603 in.)

4-40 Screw Insert

24 | ni.com | NI roboRIO User Manual

Page 25

20.91 mm (0.823 in.)

Figure 22. NI roboRIO Dimensions, Side

34.43 mm (1.355 in.)

32.19 mm (1.267a in.)

22.76 mm (0.

896 in.)

6.03 mm (0.238 in.)

0.0 mm (0 in.)

0.0 mm (0 in.)

20.79 mm (0.819 in.)

13.59 mm (0.535 in.)

129.59 mm (5.102 in.)

122.39 mm (4.819 in.)

5.71 mm (0.225 in.)

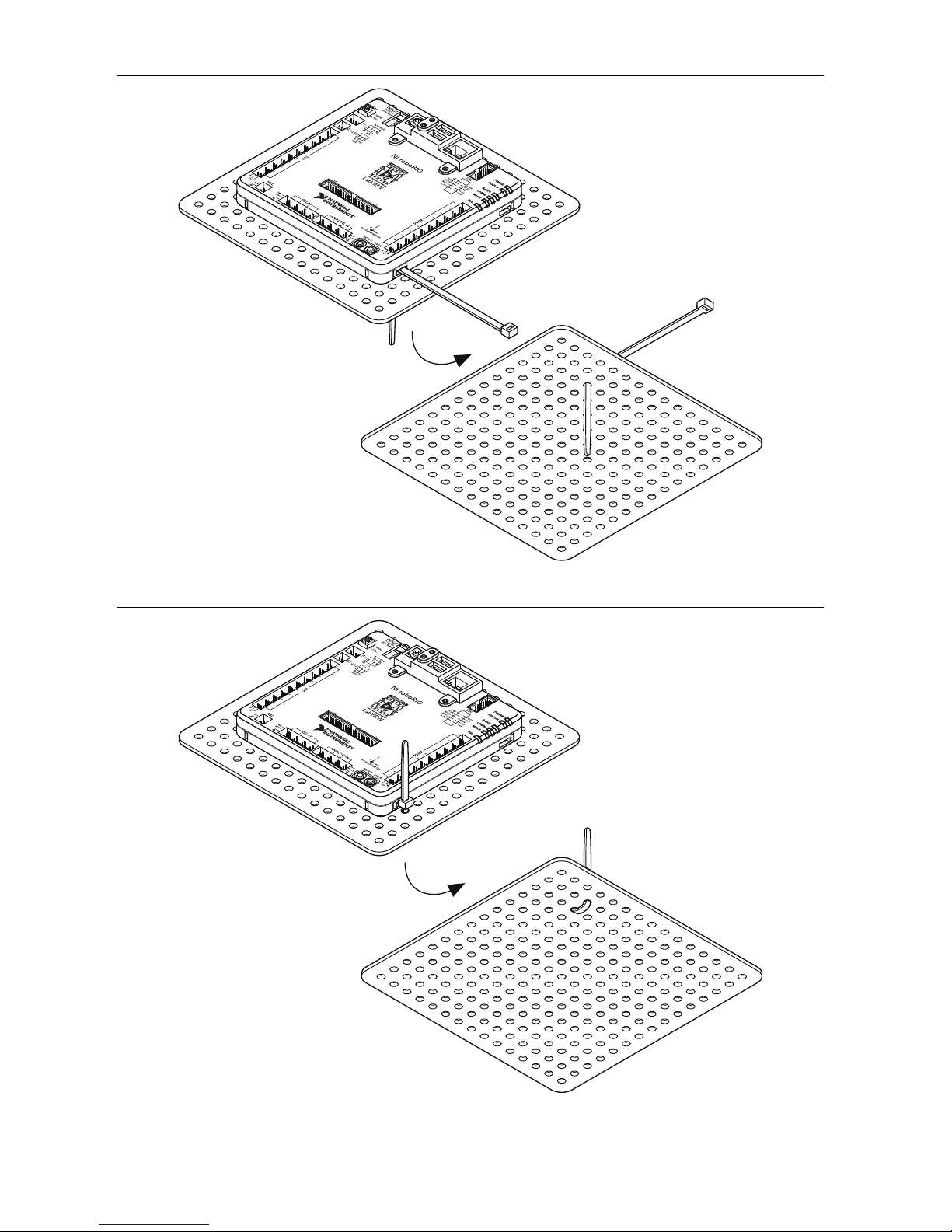

Mounting the NI roboRIO

You can mount the NI roboRIO in the following ways:

• Using cable ties to secure one edge of the NI roboRIO to perfboard with 6.35 mm (0.25 in.)

diameter holes on 12.7 mm (0.5 in.) straight centers, such as AndyMark part number

am-0836.

• Using cable ties to secure one corner of the NI roboRIO to perfboard.

• Using screws to secure the bottom of the NI roboRIO to a metal plate.

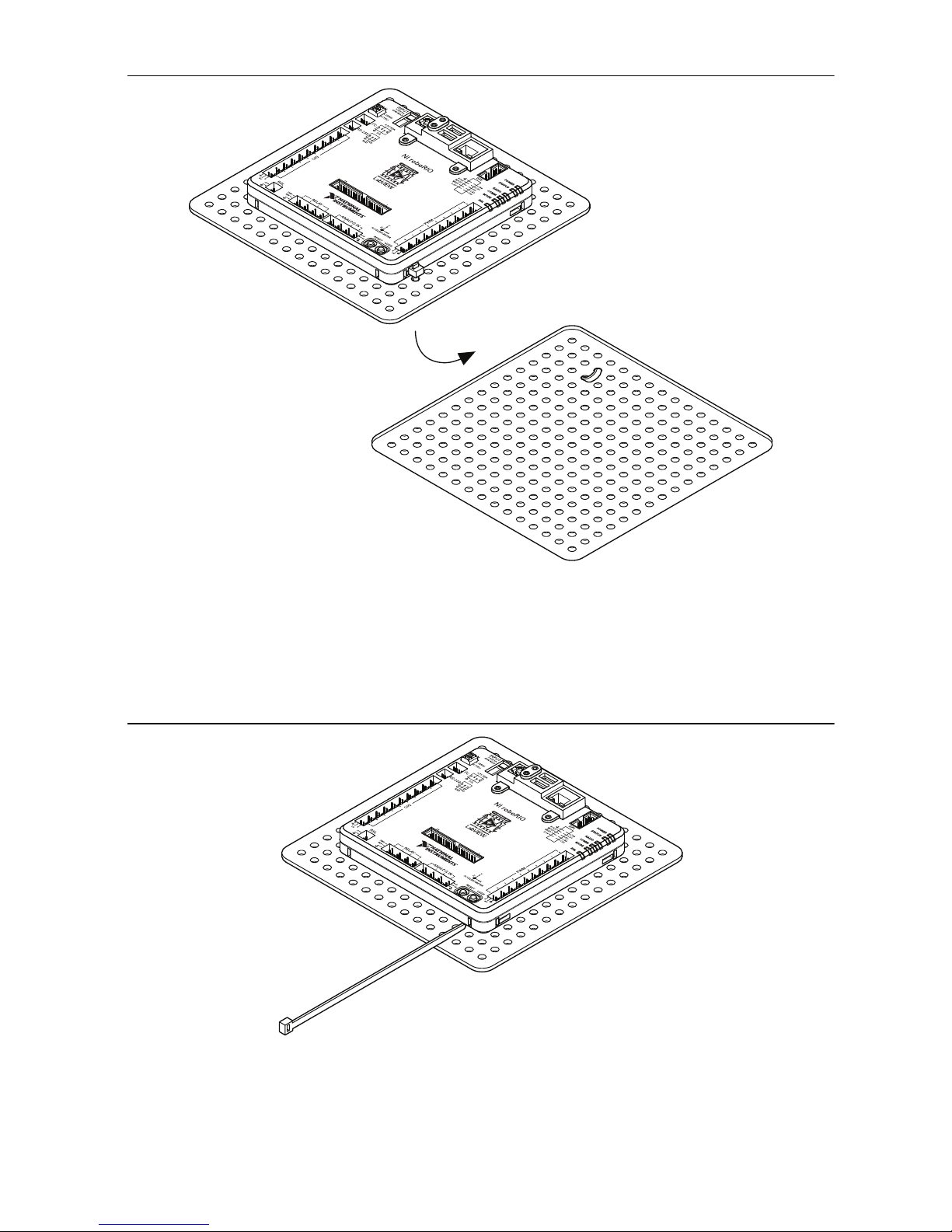

Method One: Using Cable Ties to Secure One Edge of

the NI roboRIO to Perfboard

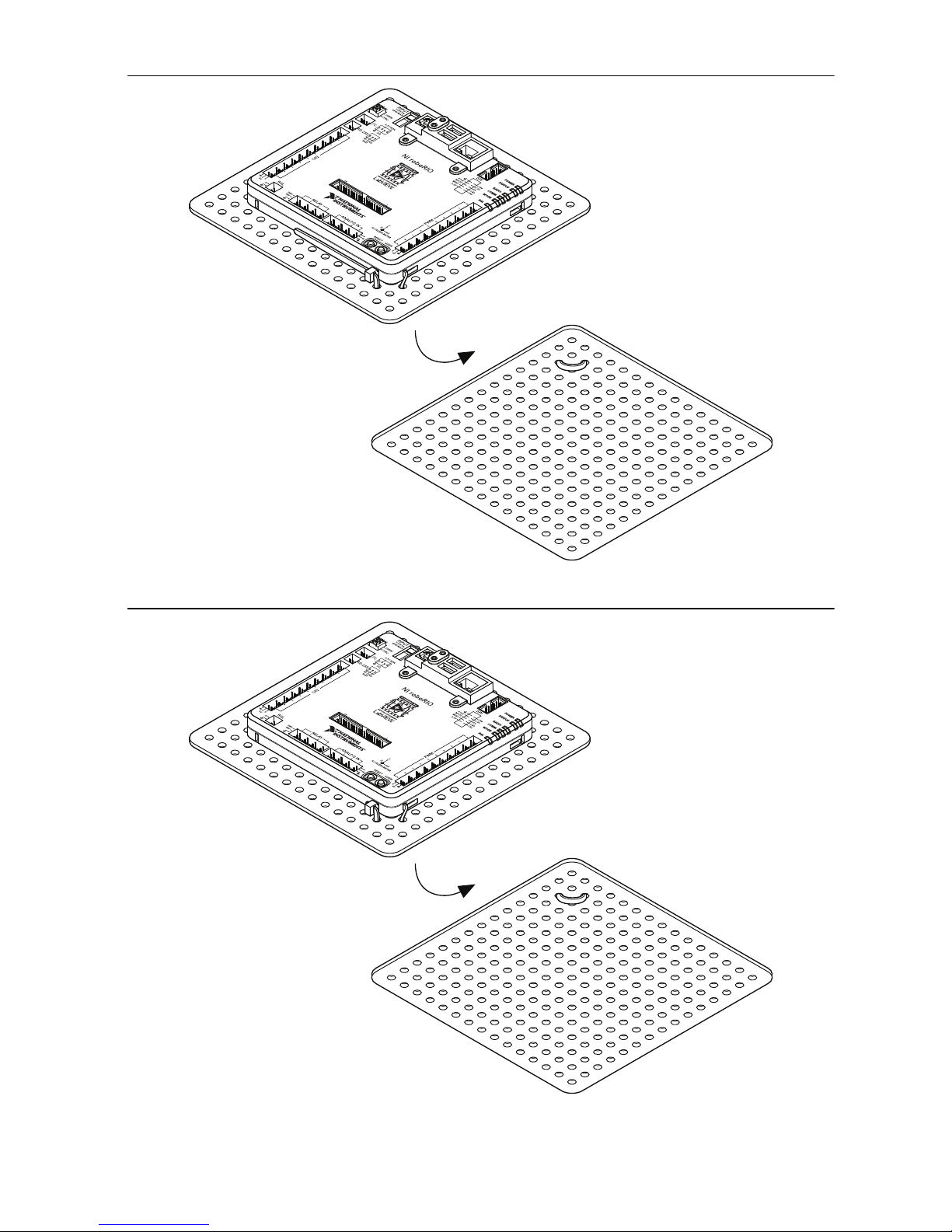

Figures 23 through 26 show how to secure one edge of the NI roboRIO to perfboard.

Figure 23. Cable Ties, Method One, Step One

NI roboRIO User Manual | © National Instruments | 25

Page 26

Figure 24. Cable Ties, Method One, Step Two

Figure 25. Cable Ties, Method One, Step Three

26 | ni.com | NI roboRIO User Manual

Page 27

Figure 26. Cable Ties, Method One, Step Four

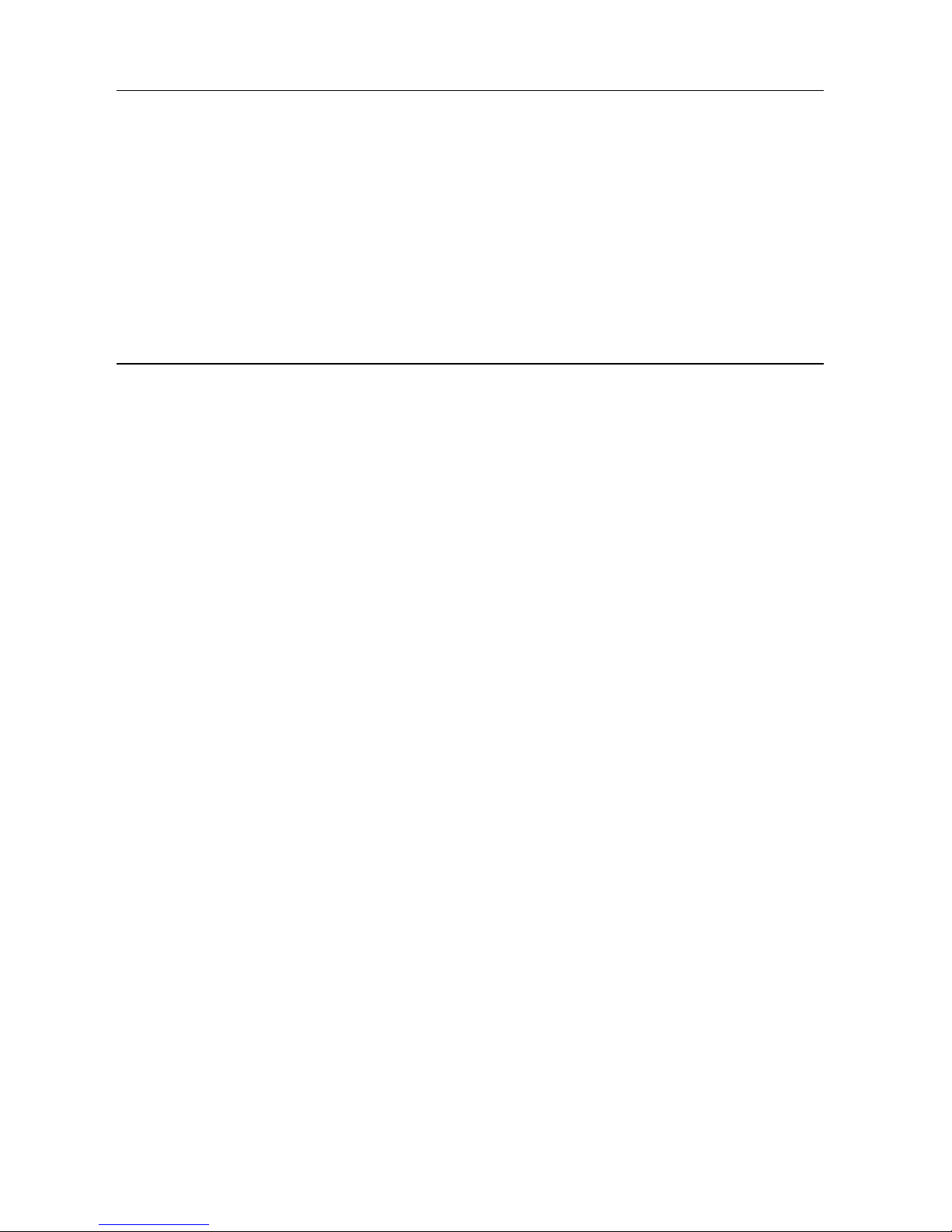

Method Two: Using Cable Ties to Secure One Corner of

the NI roboRIO to Perfboard

Figures 27 through 31 show how to secure one corner of the NI roboRIO to perfboard.

Figure 27. Cable Ties, Method Two, Step One

NI roboRIO User Manual | © National Instruments | 27

Page 28

Figure 28. Cable Ties, Method Two, Step Two

Figure 29. Cable Ties, Method Two, Step Three

28 | ni.com | NI roboRIO User Manual

Page 29

Figure 30. Cable Ties, Method Two, Step Four

Figure 31. Cable Ties, Method Two, Step Five

NI roboRIO User Manual | © National Instruments | 29

Page 30

Method Three: Using Screws to Secure the Bottom of

2

1

the NI roboRIO to a Metal Plate

Figure 32 shows how to secure the bottom of the NI roboRIO to a metal plate using the built-in

4-40 screw holes. The length of the screws required depends on the thickness of the plate you

use. For example, if the plate is 4.76 mm (0.188 in.) thick, the recommended screw length is

7.94 mm (0.313 in.).

Figure 32. Mounting NI roboRIO Using Screws

1 Metal Mounting Plate 2 4-40 Screws x 4

Compatible USB and Ethernet Cables

Table 19 lists the USB and Ethernet cables available from NI that you can use with the

NI roboRIO.

Table 19. Compatible USB and Ethernet Cables Available from NI

Cable Description NI Part Number

USB cable USB 2.0 A/B, black, 2 m 192256A-01

Peripheral USB cable USB 2.0 A/A, locking, black, 2 m 152166A-01

Ethernet cable CAT-5E, thin profile, 2 m 151733A-01

30 | ni.com | NI roboRIO User Manual

Page 31

Warranty

For customers other than private individual users in the EU: The NI roboRIO is warranted

against defects in materials and workmanship for a period of three years from the date of

shipment, as evidenced by receipts or other documentation. National Instruments will, at its

option, repair or replace equipment that proves to be defective during the warranty period. This

warranty includes parts and labor.

For private individual users in the EU: Based on your statutory rights, National Instruments

will—through its distributor—cure defects in materials and workmanship within two years from

delivery.

Worldwide Support and Services

The National Instruments website is your complete resource for technical support. At ni.com/

support

self-help resources to email and phone assistance from NI Application Engineers.

Visit

other services.

you have access to everything from troubleshooting and application development

ni.com/services for NI Factory Installation Services, repairs, extended warranty, and

Visit ni.com/register to register your National Instruments product. Product registration

facilitates technical support and ensures that you receive important information updates from NI.

A Declaration of Conformity (DoC) is our claim of compliance with the Council of the European

Communities using the manufacturer’s declaration of conformity. This system affords the user

protection for electromagnetic compatibility (EMC) and product safety. You can obtain the DoC

for your product by visiting

you can obtain the calibration certificate for your product at

ni.com/certification. If your product supports calibration,

ni.com/calibration.

National Instruments corporate headquarters is located at 11500 North Mopac Expressway,

Austin, Texas, 78759-3504. National Instruments also has offices located around the world. For

telephone support in the United States, create your service request at

ni.com/support or dial

1 866 ASK MYNI (275 6964). For telephone support outside the United States, visit the

Worldwide Offices section of

ni.com/niglobal to access the branch office websites, which

provide up-to-date contact information, support phone numbers, email addresses, and current

events.

Refer to the NI Trademarks and Logo Guidelines at ni.com/trademarks for more information on National Instruments trademarks. Other

product and company names mentioned herein are trademarks or trade names of their respective companies. For patents covering National

Instruments products/technology, refer to the appropriate location: Help»Patents in your software, the patents.txt file on your media, or the

National Instruments Patents Notice at ni.com/patents. You can find information about end-user license agreements (EULAs) and third-party

legal notices in the readme file for your NI product. Refer to the Export Compliance Information at ni.com/legal/export-compliance

for the National Instruments global trade compliance policy and how to obtain relevant HTS codes, ECCNs, and other import/export data. NI MAKES

NO EXPRESS OR IMPLIED WARRANTIES AS TO THE ACCURACY OF THE INFORMATION CONTAINED HEREIN AND SHALL NOT BE LIABLE FOR

ANY ERRORS. U.S. Government Customers: The data contained in this manual was developed at private expense and is subject to the applicable

limited rights and restricted data rights as set forth in FAR 52.227-14, DFAR 252.227-7014, and DFAR 252.227-7015.

© 2014 National Instruments. All rights reserved.

374474A-01 Oct14

Loading...

Loading...