Page 1

PXI Express

NI PXIe-6672 User Manual

Timing and Synchronization Module for PXI Express

NI PXIe-6672 User Manual

June 2008

372185F-01

Page 2

Support

Worldwide Technical Support and Product Information

ni.com

National Instruments Corporate Headquarters

11500 North Mopac Expressway Austin, Texas 78759-3504 USA Tel: 512 683 0100

Worldwide Offices

Australia 1800 300 800, Austria 43 662 457990-0, Belgium 32 (0) 2 757 0020, Brazil 55 11 3262 3599,

Canada 800 433 3488, China 86 21 5050 9800, Czech Republic 420 224 235 774, Denmark 45 45 76 26 00,

Finland 358 (0) 9 725 72511, France 01 57 66 24 24, Germany 49 89 7413130, India 91 80 41190000,

Israel 972 3 6393737, Italy 39 02 41309277, Japan 0120-527196, Korea 82 02 3451 3400,

Lebanon 961 (0) 1 33 28 28, Malaysia 1800 887710, Mexico 01 800 010 0793, Netherlands 31 (0) 348 433 466,

New Zealand 0800 553 322, Norway 47 (0) 66 90 76 60, Poland 48 22 3390150, Portugal 351 210 311 210,

Russia 7 495 783 6851, Singapore 1800 226 5886, Slovenia 386 3 425 42 00, South Africa 27 0 11 805 8197,

Spain 34 91 640 0085, Sweden 46 (0) 8 587 895 00, Switzerland 41 56 2005151, Taiwan 886 02 2377 2222,

Thailand 662 278 6777, Turkey 90 212 279 3031, United Kingdom 44 (0) 1635 523545

For further support information, refer to the Technical Support and Professional Services appendix. To comment

on National Instruments documentation, refer to the National Instruments Web site at

the info code

feedback.

ni.com/info and enter

© 2007–2008 National Instruments Corporation. All rights reserved.

Page 3

Important Information

Warranty

The NI PXIe-6672 is warranted against defects in materials and workmanship for a period of one year from the date of shipment, as evidenced

by receipts or other documentation. National Instruments will, at its option, repair or replace equipment that proves to be defective during the

warranty period. This warranty includes parts and labor.

The media on which you receive National Instruments software are warranted not to fail to execute programming instructions, due to defects in

materials and workmanship, for a period of 90 days from date of shipment, as evidenced by receipts or other documentation. National Instruments

will, at its option, repair or replace software media that do not execute programming instruc tions if National Instruments receives notice of such defects

during the warranty period. National Instruments does not warrant that the operation of the software shall be uninterrupted or error free.

A Return Material Authorization (RMA) number must be obtained from the factory and clearly marked on the outside of the package before any

equipment will be accepted for warranty work. National Instruments will pay the shipping costs of returning to the owner parts which are covered by

warranty.

National Instruments believes that the information in this document is accurate. The document has been carefully reviewed for technical accuracy. In

the event that technical or typographical errors exist, National Instruments reserves the right to make changes to subsequent editions of this document

without prior notice to holders of this edition. The reader should consult National Instruments if errors are suspected. In no event shall National

Instruments be liable for any damages arising out of or related to this document or the information contained in it.

E

XCEPT AS SPECIFIED HEREIN, NATIONAL INSTRUMENTS MAKES NO WARRANTIES, EXPRESS OR IMPLIED, AND SPECIFICALLY DISCLAIMS ANY WARRANTY OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. CUSTOMER’S RIGHT TO RECOVER DAMAGES CAUSED BY FAULT OR NEGLIGENCE ON THE PART OF NATIONAL

I

NSTRUMENTS SHALL BE LIMITED TO THE AMOUNT THERETOFORE PAID BY THE CUSTOMER. NATIONAL INSTRUMENTS WILL NOT BE LIABLE FOR DAMAGES RESULTING

FROM LOSS OF DATA, PROFITS, USE OF PRODUCTS, OR INCIDENTAL OR CONSEQUENTIAL DAMAGES, EVEN IF ADVISED OF THE POSSIBILITY THEREOF. This limitation of

the liability of National Instruments will apply regardless of the form of action, whether in contract or tort, including negligence. Any action against

National Instruments must be brought within one year after the cause of action accrues. National Instruments shall not be liable for any delay in

performance due to causes beyond its reasonable control. The warranty provided herein does not cover damages, defects, malfunctions, or service

failures caused by owner’s failure to follow the National Instruments installation, operation, or maintenance instructions; owner’s modification of the

product; owner’s abuse, misuse, or negligent acts; and power failure or surges, fire, flood, accident, actions of third parties, or other events outside

reasonable control.

Copyright

Under the copyright laws, this publication may not be reproduced or transmitted in any form, electronic or mechanical, including photocopying,

recording, storing in an information retrieval system, or translating, in whole or in part, without the prior written consent of National

Instruments Corporation.

National Instruments respects the intellectual property of others, and we ask our users to do the same. NI software is protected by copyright and other

intellectual property laws. Where NI software may be used to reproduce software or other materials belonging to others, you may use NI software only

to reproduce materials that you may reproduce in accordance with the terms of any applicable license or other legal restriction.

Trademarks

National Instruments, NI, ni.com, and LabVIEW are trademarks of National Instruments Corporation. Refer to the Terms of Use section

on

ni.com/legal for more information about National Instruments trademarks.

Other product and company names mentioned herein are trademarks or trade names of their respective companies.

Members of the National Instruments Alliance Partner Program are business entities independent from National Instruments and have no agency,

partnership, or joint-venture relationship with National Instruments.

Patents

For patents covering National Instruments products, refer to the appropriate location: Help»Patents in your software, the patents.txt file

on your media, or ni.com/patents.

WARNING REGARDING USE OF NATIONAL INSTRUMENTS PRODUCTS

(1) NATIONAL INSTRUMENTS PRODUCTS ARE NOT DESIGNED WITH COMPONENTS AND TESTING FOR A LEVEL OF

RELIABILITY SUITABLE FOR USE IN OR IN CONNECTION WITH SURGICAL IMPLANTS OR AS CRITICAL COMPONENTS IN

ANY LIFE SUPPORT SYSTEMS WHOSE FAILURE TO PERFORM CAN REASONABLY BE EXPECTED TO CAUSE SIGNIFICANT

INJURY TO A HUMAN.

(2) IN ANY APPLICATION, INCLUDING THE ABOVE, RELIABILITY OF OPERATION OF THE SOFTWARE PRODUCTS CAN BE

IMPAIRED BY ADVERSE FACTORS, INCLUDING BUT NOT LIMITED TO FLUCTUATIONS IN ELECTRICAL POWER SUPPLY,

COMPUTER HARDWARE MALFUNCTIONS, COMPUTER OPERATING SYSTEM SOFTWARE FITNESS, FITNESS OF COMPILERS

AND DEVELOPMENT SOFTWARE USED TO DEVELOP AN APPLICATION, INSTALLATION ERRORS, SOFTWARE AND HARDWARE

COMPATIBILITY PROBLEMS, MALFUNCTIONS OR FAILURES OF ELECTRONIC MONITORING OR CONTROL DEVICES,

TRANSIENT FAILURES OF ELECTRONIC SYSTEMS (HARDWARE AND/OR SOFTWARE), UNANTICIPATED USES OR MISUSES, OR

ERRORS ON THE PART OF THE USER OR APPLICATIONS DESIGNER (ADVERSE FACTORS SUCH AS THESE ARE HEREAFTER

COLLECTIVELY TERMED “SYSTEM FAILURES”). ANY APPLICATION WHERE A SYSTEM FAILURE WOULD CREATE A RISK OF

HARM TO PROPERTY OR PERSONS (INCLUDING THE RISK OF BODILY INJURY AND DEATH) SHOULD NOT BE RELIANT SOLELY

UPON ONE FORM OF ELECTRONIC SYSTEM DUE TO THE RISK OF SYSTEM FAILURE. TO AVOID DAMAGE, INJURY, OR DEATH,

THE USER OR APPLICATION DESIGNER MUST TAKE REASONABLY PRUDENT STEPS TO PROTECT AGAINST SYSTEM FAILURES,

INCLUDING BUT NOT LIMITED TO BACK-UP OR SHUT DOWN MECHANISMS. BECAUSE EACH END-USER SYSTEM IS

CUSTOMIZED AND DIFFERS FROM NATIONAL INSTRUMENTS' TESTING PLATFORMS AND BECAUSE A USER OR APPLICATION

DESIGNER MAY USE NATIONAL INSTRUMENTS PRODUCTS IN COMBINATION WITH OTHER PRODUCTS IN A MANNER NOT

EVALUATED OR CONTEMPLATED BY NATIONAL INSTRUMENTS, THE USER OR APPLICATION DESIGNER IS ULTIMATELY

RESPONSIBLE FOR VERIFYING AND VALIDATING THE SUITABILITY OF NATIONAL INSTRUMENTS PRODUCTS WHENEVER

NATIONAL INSTRUMENTS PRODUCTS ARE INCORPORATED IN A SYSTEM OR APPLICATION, INCLUDING, WITHOUT

LIMITATION, THE APPROPRIATE DESIGN, PROCESS AND SAFETY LEVEL OF SUCH SYSTEM OR APPLICATION.

Page 4

Contents

About This Manual

Conventions ...................................................................................................................vii

National Instruments Documentation ............................................................................viii

Related Documentation..................................................................................................viii

Chapter 1

Introduction

What You Need to Get Started ......................................................................................1-1

Unpacking......................................................................................................................1-2

Software Programming Choices ....................................................................................1-2

Safety Information .........................................................................................................1-3

Chapter 2

Installing and Configuring

Installing the Software ...................................................................................................2-1

Installing the Hardware..................................................................................................2-1

Configuring the Module.................................................................................................2-2

Chapter 3

Hardware Overview

NI PXIe-6672 Front Panel .............................................................................................3-3

Access LED .....................................................................................................3-4

Active LED......................................................................................................3-4

Connectors.......................................................................................................3-5

Hardware Features .........................................................................................................3-5

Clock Generation ...........................................................................................................3-7

Direct Digital Synthesis (DDS) .......................................................................3-7

PXI_CLK10 and TCXO..................................................................................3-8

Routing Signals..............................................................................................................3-9

Determining Sources and Destinations ...........................................................3-11

Using Front Panel PFIs As Inputs.....................................................3-12

Using Front Panel PFIs As Outputs ..................................................3-13

Using the PXI Triggers .....................................................................3-14

Using the PXI Star Triggers..............................................................3-15

© National Instruments Corporation v NI PXIe-6672 User Manual

Page 5

Contents

Choosing the Type of Routing ........................................................................ 3-15

Asynchronous Routing ..................................................................... 3-16

Synchronous Routing ....................................................................... 3-17

Generating a Single Pulse (Global Software Trigger) .................................... 3-18

Using the PXI_CLK10 PLL .......................................................................................... 3-19

Chapter 4

Calibration

Factory Calibration........................................................................................................ 4-1

TCXO Frequency............................................................................................ 4-1

PXI_CLK10 Phase.......................................................................................... 4-1

DDS Start Trigger Phase................................................................................. 4-1

DDS Initial Phase............................................................................................ 4-2

Additional Information.................................................................................................. 4-2

Appendix A

Specifications

Appendix B

Technical Support and Professional Services

Glossary

Index

NI PXIe-6672 User Manual vi ni.com

Page 6

About This Manual

Thank you for purchasing the National Instruments NI PXIe-6672 Timing

and Synchronization Module. The NI PXIe-6672 enables you to pass

PXI timing and trigger signals between two or more PXI Express chassis.

The NI PXIe-6672 can generate and route clock signals between devices in

multiple chassis, providing a method to synchronize multiple devices

in a multichassis PXI Express system.

This manual describes the electrical and mechanical aspects of the

NI PXIe-6672 and contains information concerning its operation and

programming.

Conventions

The following conventions appear in this manual:

<> Angle brackets that contain numbers separated by an ellipsis represent

a range of values associated with a bit or signal name—for example,

AO <3. .0>.

» The » symbol leads you through nested menu items and dialog box options

to a final action. The sequence File»Page Setup»Options directs you to

pull down the File menu, select the Page Setup item, and select Options

from the last dialog box.

This icon denotes a tip, which alerts you to advisory information.

This icon denotes a note, which alerts you to important information.

This icon denotes a caution, which advises you of precautions to take to

avoid injury, data loss, or a system crash. When this symbol is marked on

the product, refer to the Safety Information section of Chapter 1,

Introduction, for precautions to take.

bold Bold text denotes items that you must select or click in the software, such

as menu items and dialog box options. Bold text also denotes parameter

names and hardware labels.

italic Italic text denotes variables, emphasis, a cross-reference, or an introduction

to a key concept. Italic text also denotes text that is a placeholder for a word

or value that you must supply.

© National Instruments Corporation vii NI PXIe-6672 User Manual

Page 7

About This Manual

monospace Text in this font denotes text or characters that you should enter from the

keyboard, sections of code, programming examples, and syntax examples.

This font is also used for the proper names of disk drives, paths, directories,

programs, subprograms, subroutines, device names, functions, operations,

variables, filenames, and extensions.

NI PXIe-6672 This phrase refers to the NI PXIe-6672 module for the PXI Express bus.

National Instruments Documentation

The NI PXIe-6672 User Manual is one piece of the documentation set for

your measurement system. You could have any of several other documents

describing your hardware and software. Use the documentation you have

as follows:

• Measurement hardware documentation—This documentation contains

detailed information about the measurement hardware that plugs into

or is connected to the computer. Use this documentation for hardware

installation and configuration instructions, specifications about the

measurement hardware, and application hints.

• Software documentation—Refer to the NI-Sync User Manual,

available at

ni.com/manuals.

You can download NI documentation from

ni.com/manuals.

Related Documentation

The following documents contain information that you might find helpful

as you read this manual:

• PICMG 2.0 R3.0, CompactPCI Core Specification, available from

PICMG at

• PXI-5 PXI Express Hardware Specification, Revision 1.0, available

from

• NI-VISA User Manual, available from ni.com/manuals

• NI-VISA Help, included with the NI-VISA software

• NI-Sync User Manual, available from

NI PXIe-6672 User Manual viii ni.com

www.picmg.org

www.pxisa.org

ni.com/manuals

Page 8

Introduction

The NI PXIe-6672 timing and triggering module enables you to pass

PXI timing signals between two or more PXI Express chassis. The

NI PXIe-6672 module generates and routes clock signals between devices

in multiple chassis, providing a method for synchronizing multiple devices

in a PXI Express system.

What You Need to Get Started

To set up and use the NI PXIe-6672, you need the following items:

❑ NI PXIe-6672 Timing and Triggering Module

❑ NI PXIe-6672 User Manual

❑ NI-Sync CD

❑ An Application Development Environment such as:

–LabVIEW

– LabWindows

– Microsoft Visual C++ (MSVC)

™

/CVI

1

™

❑ PXI Express chassis

❑ PXI Express embedded controller or a desktop computer connected to

the PXI Express chassis using MXI-Express hardware

For information on using the driver software for synchronization, refer

to the NI-Sync User Manual, which you can find on the NI-Sync CD or

download from

© National Instruments Corporation 1-1 NI PXIe-6672 User Manual

ni.com/manuals.

Page 9

Chapter 1 Introduction

Unpacking

Caution Never touch the exposed pins of connectors.

The NI PXIe-6672 is shipped in an antistatic package to prevent

electrostatic damage to the module. Electrostatic discharge (ESD)

can damage several components on the module.

To avoid such damage in handling the module, take the following

precautions:

• Ground yourself using a grounding strap or by touching a grounded

object.

• Touch the antistatic package to a metal part of the computer chassis

before removing the module from the package.

Remove the module from the package and inspect the module for loose

components or any sign of damage. Notify NI if the module appears

damaged in any way. Do not install a damaged module into the computer.

Store the NI PXIe-6672 in the antistatic envelope when not in use.

Software Programming Choices

When programming the NI PXIe-6672, you can use NI application

development environment (ADE) software such as LabVIEW or

LabWindows/CVI, or you can use other ADEs such as Visual C/C++.

LabVIEW features interactive graphics, a state-of-the-art interface,

and a powerful graphical programming language. The LabVIEW Data

Acquisition VI Library, a series of virtual instruments for using LabVIEW

with National Instruments DAQ hardware, is included with LabVIEW.

LabWindows/CVI is a complete ANSI C ADE that features an interactive

user interface, code generation tools, and the LabWindows/CVI Data

Acquisition and Easy I/O libraries.

NI PXIe-6672 User Manual 1-2 ni.com

Page 10

Safety Information

The following section contains important safety information that you must

follow when installing and using the product.

Do not operate the product in a manner not specified in this document.

Misuse of the product can result in a hazard. You can compromise the

safety protection built into the product if the product is damaged in any

way. If the product is damaged, return it to National Instruments for repair.

Do not substitute parts or modify the product except as described in this

document. Use the product only with the chassis, modules, accessories, and

cables specified in the installation instructions. You must have all covers

and filler panels installed during operation of the product.

Do not operate the product in an explosive atmosphere or where there may

be flammable gases or fumes. If you must operate the product in such an

environment, it must be in a suitably rated enclosure.

If you need to clean the product, use a soft, nonmetallic brush. The product

must be completely dry and free from contaminants before you return it to

service.

Chapter 1 Introduction

Operate the product only at or below Pollution Degree 2. Pollution is

foreign matter in a solid, liquid, or gaseous state that can reduce dielectric

strength or surface resistivity. The following is a description of pollution

degrees:

• Pollution Degree 1 means no pollution or only dry, nonconductive

pollution occurs. The pollution has no influence.

• Pollution Degree 2 means that only nonconductive pollution occurs in

most cases. Occasionally, however, a temporary conductivity caused

by condensation must be expected.

• Pollution Degree 3 means that conductive pollution occurs, or dry,

nonconductive pollution occurs that becomes conductive due to

condensation.

You must insulate signal connections for the maximum voltage for which

the product is rated. Do not exceed the maximum ratings for the product.

Do not install wiring while the product is live with electrical signals. Do not

remove or add connector blocks when power is connected to the system.

Avoid contact between your body and the connector block signal when hot

swapping modules. Remove power from signal lines before connecting

them to or disconnecting them from the product.

© National Instruments Corporation 1-3 NI PXIe-6672 User Manual

Page 11

Chapter 1 Introduction

Operate the product at or below the installation category1 marked on the

hardware label. Measurement circuits are subjected to working voltages

2

and transient stresses (overvoltage) from the circuit to which they are

connected during measurement or test. Installation categories establish

standard impulse withstand voltage levels that commonly occur in

electrical distribution systems. The following is a description of installation

categories:

• Installation Category I is for measurements performed on circuits not

directly connected to the electrical distribution system referred to as

MAINS

3

voltage. This category is for measurements of voltages from

specially protected secondary circuits. Such voltage measurements

include signal levels, special equipment, limited-energy parts of

equipment, circuits powered by regulated low-voltage sources,

and electronics.

• Installation Category II is for measurements performed on circuits

directly connected to the electrical distribution system. This category

refers to local-level electrical distribution, such as that provided by a

standard wall outlet (for example, 115 V for U.S. or 230 V for Europe).

Examples of Installation Category II are measurements performed on

household appliances, portable tools, and similar products.

• Installation Category III is for measurements performed in the building

installation at the distribution level. This category refers to

measurements on hard-wired equipment such as equipment in fixed

installations, distribution boards, and circuit breakers. Other examples

are wiring, including cables, bus-bars, junction boxes, switches,

socket-outlets in the fixed installation, and stationary motors with

permanent connections to fixed installations.

• Installation Category IV is for measurements performed at the primary

electrical supply installation (<1,000 V). Examples include electricity

meters and measurements on primary overcurrent protection devices

and on ripple control units.

1

Installation categories, also referred to as measurement categories, are defined in electrical safety standard IEC 61010-1.

2

Working voltage is the highest rms value of an AC or DC voltage that can occur across any particular insulation.

3

MAINS is defined as a hazardous live electrical supply system that powers equipment. Suitably rated measuring circuits may

be connected to the MAINS for measuring purposes.

NI PXIe-6672 User Manual 1-4 ni.com

Page 12

Installing and Configuring

This chapter describes how to install the NI PXIe-6672 hardware and

software and how to configure the device.

Installing the Software

Refer to the readme.htm file that accompanies the NI-Sync CD for

software installation directions.

Note Be sure to install the driver software before installing the NI PXIe-6672 hardware.

Installing the Hardware

The following are general installation instructions. Consult the chassis

user manual or technical reference manual for specific instructions and

warnings about installing new modules.

1. Power off and unplug the chassis.

2. Locate the System Timing Slot in your chassis. It is marked by either

a square glyph shown in Figure 2-1, or a square glyph with a circle

inside of it, as shown in Figure 2-2.

2

Figure 2-1. System Timing Device Slot Indicator Glyph without Circle

Figure 2-2. System Timing Device Slot Indicator Glyph on the NI PXIe-1062Q Chassis

© National Instruments Corporation 2-1 NI PXIe-6672 User Manual

Page 13

Chapter 2 Installing and Configuring

Note The slot number printed on the glyph may vary from chassis to chassis.

The circle inside of the square indicates that the slot may also be used as a PXI Express

peripheral slot.

3. Remove the filler panel for the PXI slot you located in step 2.

4. Ground yourself using a grounding strap or by holding a grounded

5. Remove any packing material from the front panel screws and

6. Insert the NI PXIe-6672 into the PXI Express slot. Use the

7. Screw the front panel of the device to the front panel mounting rail of

8. Visually verify the installation. Make sure the module is not touching

9. Plug in and power on the chassis.

The NI PXIe-6672 is now installed.

object. Follow the ESD protection precautions described in the

Unpacking section of Chapter 1, Introduction.

backplane connectors.

injector/ejector handle to fully insert the module into the chassis.

the chassis.

other modules or components and is fully inserted into the slot.

Configuring the Module

The NI PXIe-6672 is completely software configurable. The system

software automatically allocates all module resources.

The two LEDs on the front panel provide information about module status.

The front panel description sections of Chapter 3, Hardware Overview,

describe the LEDs in greater detail.

NI PXIe-6672 User Manual 2-2 ni.com

Page 14

Hardware Overview

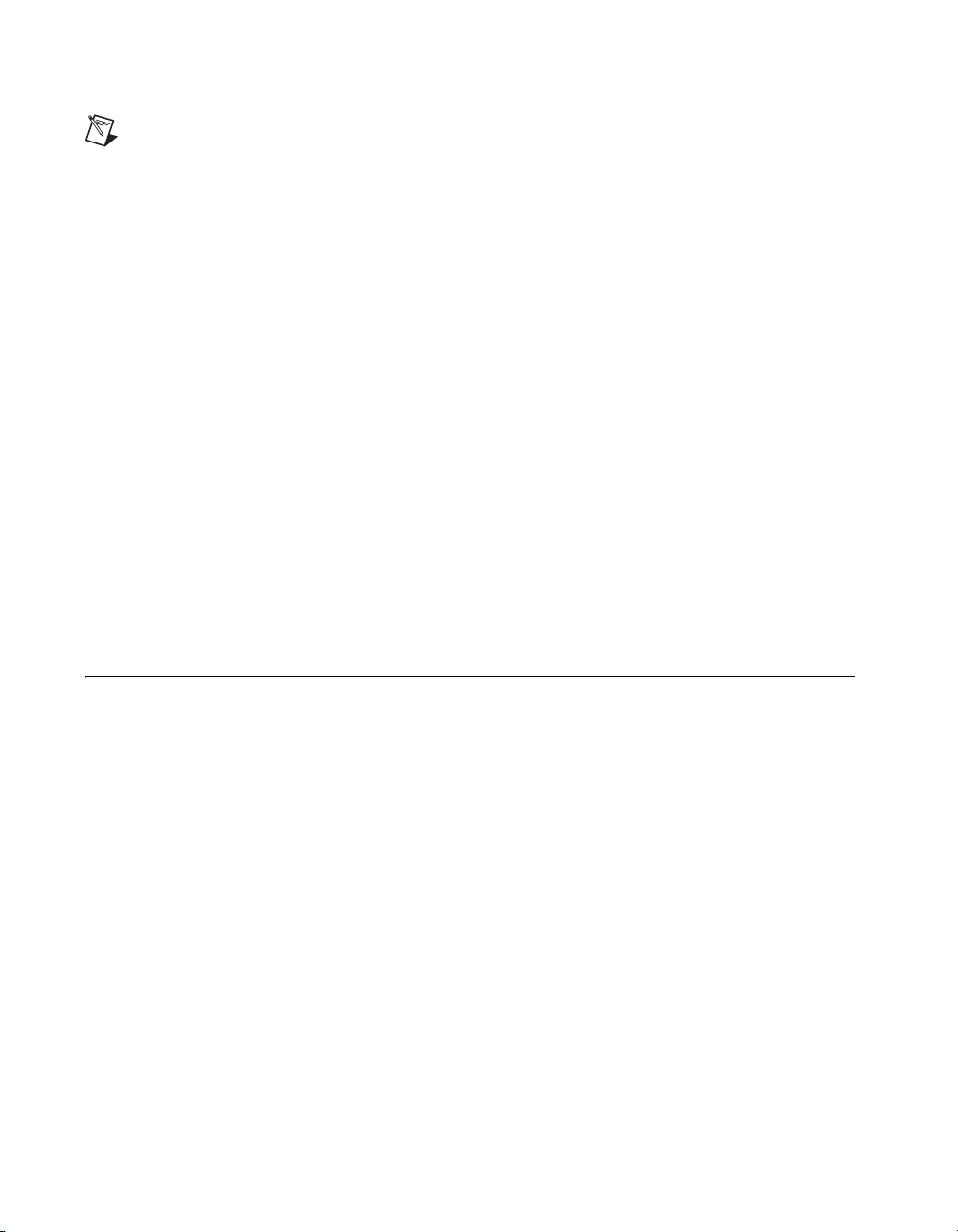

This chapter presents an overview of the hardware functions of

the NI PXIe-6672. Figure 3-1 provides a functional overview of

the NI PXIe-6672 hardware.

3

© National Instruments Corporation 3-1 NI PXIe-6672 User Manual

Page 15

Chapter 3 Hardware Overview

CLKIN

CLKOUT

PFI 0

PFI 1

PFI 2

PFI 3

PFI 4

PFI 5

AC Coupled

Clock Detector

TCXO

Clock

Driver/

Comparator

PFI 0

Threshold

DAC

Driver/

Comparator

PFI 1

Threshold

DAC

Driver/

Comparator

PFI 2

Threshold

DAC

Driver/

Comparator

PFI 3

Threshold

DAC

Driver/

Comparator

PFI 4

Threshold

DAC

Driver/

Comparator

PFI 5

Threshold

DAC

PLL

TCXO

Calibration

DAC

DDS

DDS Clock

TCXO

CLKIN

CLOCK and

TRIGGER

Routing

PCI Interface

PXI_CLK10_IN

PXI_CLK10

PXIPCI

PXI_STAR<0..16>

PXI_TRIG<0..7>

Figure 3-1. Functional Overview of the NI PXIe-6672

NI PXIe-6672 User Manual 3-2 ni.com

Page 16

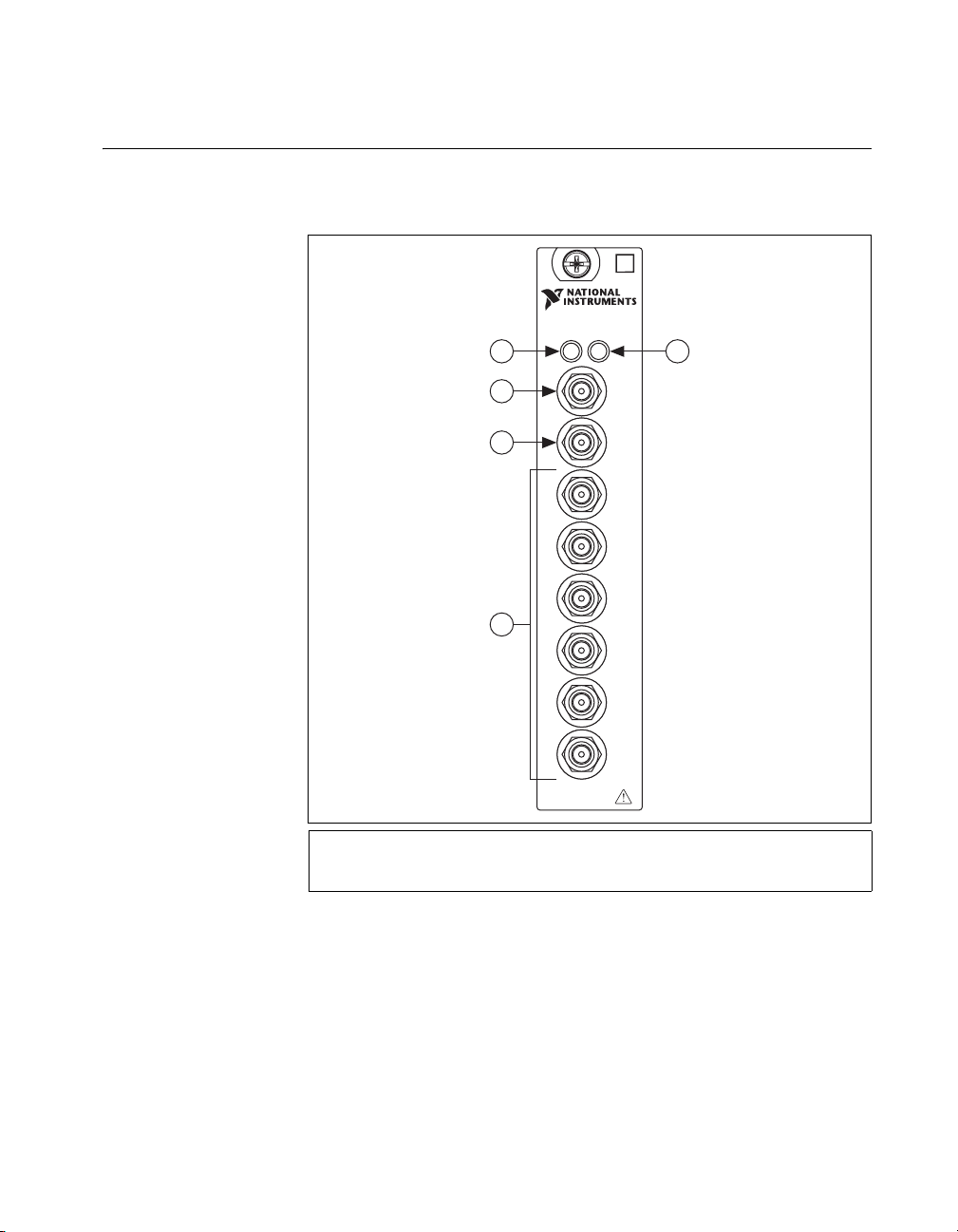

NI PXIe-6672 Front Panel

Figure 3-2 shows the connectors and LEDs on the front panel of the

NI PXIe-6672.

NI PXIe-6672

Timing Module

1 2

ACCESS ACTIVE

3

CLK

OUT

Chapter 3 Hardware Overview

1Access LED

2 Active LED

3 CLKOUT Connector

4

CLK

IN

PFI 0

PFI 1

PFI 2

5

PFI 3

PFI 4

PFI 5

4 CLKIN Connector

5 PFI <0..5> Connectors

Figure 3-2. NI PXIe-6672 Front Panel

© National Instruments Corporation 3-3 NI PXIe-6672 User Manual

Page 17

Chapter 3 Hardware Overview

Access LED

Active LED

The Access LED indicates the communication status of the NI PXIe-6672.

Refer to Figure 3-2 for the location of the Access LED.

Table 3-1 summarizes what the Access LED colors represent.

Table 3-1. Access LED Color Indication

Color Status

Off Module is not yet functional.

Green Driver has initialized the module.

Amber Module is being accessed. The Access LED

flashes amber for 50 ms when the module is

accessed.

The Active LED can indicate an error or phase-locked loop (PLL) activity.

You can change the Active LED to amber, unless an error overrides the

selection. Refer to Figure 3-2 for the location of the Active LED.

Tip Changing the Active LED color to amber is helpful when you want to identify devices

in a multichassis situation or when you want an indication that your application has

reached a predetermined section of the code.

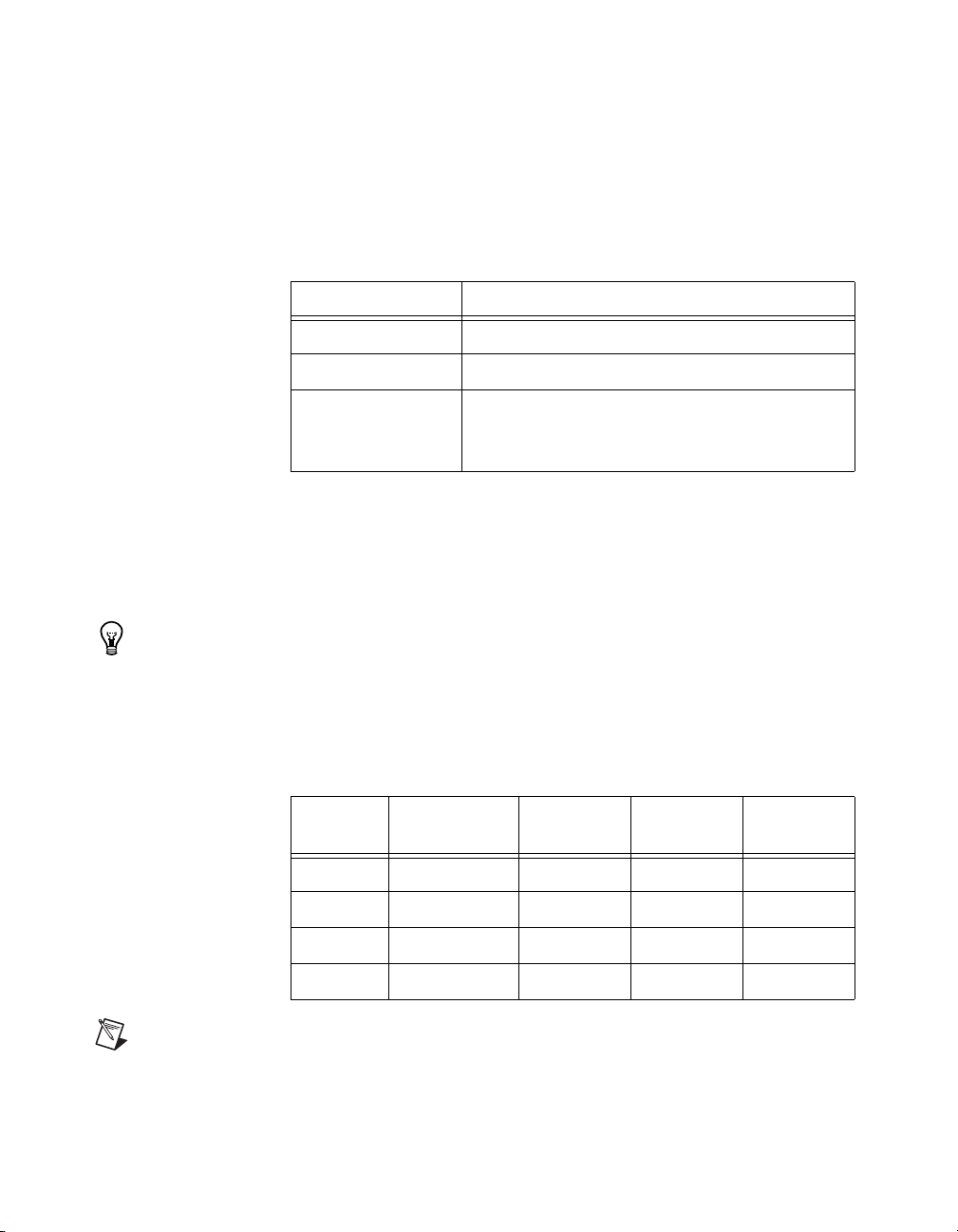

Table 3-2 illustrates the meaning of each Active LED color.

Table 3-2. Active LED Color Quick Reference Table

PXI_CLK10

Color

Red Ye s Ye s — —

Amber No No Ye s —

Green No No No Ye s

Off No No No No

Note A red Active LED can indicate that either PXI_CLK10 has stopped or that there is

a PLL error.

NI PXIe-6672 User Manual 3-4 ni.com

Stopped

PLL

Error

User

Setting

PLL

Active

Page 18

Connectors

Chapter 3 Hardware Overview

This section describes the connectors on the front panel of the

NI PXIe-6672.

• CLKIN—Clock Input. This connector supplies the module with

a clock that can be programmatically routed to the onboard PLL

for use as a reference or routed directly to the PXI backplane

(PXI_CLK10_IN) for distribution to the other modules in the chassis.

• CLKOUT—Clock Output. This connector is used to source

a clock that can be routed programmatically from the

temperature-compensated crystal oscillator (TCXO), direct

digital synthesis (DDS), or backplane clock (PXI_CLK10).

• PFI <0..5>—Programmable Function Interface <0..5>. These

connectors can be used for either input or output. Additionally, PFI 0

can be used as a clock input for internally synchronizing other signals.

Refer to the Synchronous Routing section for more information about

this functionality. You can program the behavior of these PFI

connections individually.

Refer to Figure 3-2 for a diagram showing the locations of these

connections on the NI PXIe-6672 front panel.

Caution Connections that exceed any of the maximum ratings of input or output signals

on the NI PXIe-6672 can damage the module and the computer. NI is not liable for any

damage resulting from such signal connections.

Hardware Features

The NI PXIe-6672 perform two broad functions:

• Generating clock and trigger signals

• Routing internally or externally generated signals from one location

to another

© National Instruments Corporation 3-5 NI PXIe-6672 User Manual

Page 19

Chapter 3 Hardware Overview

Table 3-3 outlines the function and direction of the signals discussed in

detail in the remainder of this chapter.

Table 3-3. Signal Descriptions

Signal Name Direction Description

PXI_CLK10_IN Out This is a signal that can replace the native 10 MHz oscillator

on the PXI backplane. PXI_CLK10_IN may originate from

the onboard TCXO or from an external source.

PXI_CLK10 In This signal is the PXI 10 MHz backplane clock. By default,

this signal is the output of the native 10 MHz oscillator in the

chassis. An NI PXIe-6672 in the System Timing Slot can

replace this signal with PXI_CLK10_IN.

TCXO Clock Out This is the output of the 10 MHz TCXO. The TCXO is an

extremely stable and accurate frequency source.

CLKIN In CLKIN is a signal connected to the SMB input pin of the

same name. CLKIN can serve as PXI_CLK10_IN, a phase

lock reference for the TCXO, or as a source for routing to

PXI_STAR.

CLKOUT Out CLKOUT is the signal on the SMB output pin of the same

name. Either the TCXO clock, DDS clock, or PXI_CLK10

may be routed to this location.

DDS Clock Out This is the output of the DDS. The DDS frequency can be

programmed with fine granularity from 1 Hz to 105 MHz.

The DDS chip automatically phase-locks to PXI_CLK10.

PXI_STAR <0..16> In/Out The PXI star trigger bus connects the System Timing Slot to

all other slots in a star configuration. The electrical paths of

each star line are closely matched to minimize intermodule

skew. An NI PXIe-6672 in System Timing Slot can route

signals to all other slots using the star trigger bus.

PFI <0..5> In/Out The Programmable Function Interface pins on the

NI PXIe-6672 route timing and triggering signals between

multiple PXI chassis. A wide variety of input and output

signals can be routed to or from the PFI lines.

PXI_TRIG <0..7> In/Out The PXI trigger bus consists of eight digital lines shared

among all slots in the PXI chassis. The NI PXIe-6672 can

route a wide variety of signals to and from these lines.

NI PXIe-6672 User Manual 3-6 ni.com

Page 20

The remainder of this chapter describes how these signals are used,

acquired, and generated by the NI PXIe-6672 hardware, and explains

how you can route the signals between various locations to synchronize

multiple measurement devices and PXI chassis.

Clock Generation

The NI PXIe-6672 can generate two types of clock signals. The first clock

is generated using the onboard DDS chip, and the second is generated with

a precise 10 MHz oscillator. The following sections describe the two types

of clock generation and explain the considerations for choosing either type.

Direct Digital Synthesis (DDS)

DDS is a method of generating a clock with programmable frequency.

DDS consists of a frequency tuning word, an accumulator, a sine-lookup

table, a D/A converter (DAC), and a comparator.

The frequency tuning word is a number that specifies the desired

frequency. Each master clock cycle, the frequency tuning word is added to

the accumulator, which rolls over when it gets to its maximum value. The

accumulator value is used to get a point in the sine-lookup table, which is

converted to an analog voltage by the DAC. For example, if the sine table

is 128 points long, and the frequency tuning word is one, the accumulator

takes 128 clock cycles to output one sine wave. If you change the frequency

tuning word to 3, the accumulator steps through the sine table three times

as fast, and outputs a sine wave in 128/3, or 42.6, clock cycles.

Chapter 3 Hardware Overview

The output of the DAC is run through an analog filter to smooth the sine

wave. The filtered output is then run through a comparator, which changes

the output to a square wave with the specified frequency.

You can specify the programmable DDS frequency on the NI PXIe-6672

with a precision of approximately .07 Hz within the range 1 Hz to

105 MHz. The accuracy of the frequency depends on the PXI_CLK10

reference clock, so a precise 10 MHz source improves the accuracy of the

DDS output. You can replace the 10 MHz clock with the TCXO for more

accurate DDS timing.

When the DDS is programmed an update signal must be sent to it before it

will begin operating as programmed. The source for this update signal is

either immediate (DDS starts outputting the programmed frequency as

soon as software programs it) or one of the eight PXI triggers. When one

© National Instruments Corporation 3-7 NI PXIe-6672 User Manual

Page 21

Chapter 3 Hardware Overview

Note NI-Sync software defaults to an immediate update. If a PXI trigger is used instead,

the user must specify the update signal source before setting any of the other DDS

properties.

of the PXI trigger lines is used as the source for the update, frequency

generation will not start until a rising edge occurs on the PXI trigger

selected.

When more then one NI PXIe-6672 is used in a multiple chassis setup, the

DDS frequency of both boards can be synchronized. The DDS system

clock is phase locked to PXI_CLK10, when two or more chassis share a

common 10 MHz clock, the DDS outputs will also be phase locked (refer

to the Using the PXI_CLK10 PLL section for information on how to ensure

that two or more chassis have close PXI_CLK10 phase alignment). To fully

synchronize the DDS outputs a common update signal source must be used

and routed to the selected PXI trigger. A synchronous route to PXI_CLK10

provides the best results. Refer to the Routing Signals section for details on

routing trigger signals.

The NI PXIe-6672 DDS can adjust the phase of the generated clock by up

to ±5 ns. This may be used to tighten the synchronization between two or

more DDS devices in a multi-chassis setup, or to compensate for delays

caused by different cable lengths.

PXI_CLK10 and TCXO

The NI PXIe-6672 features a precision 10 MHz TCXO. The frequency

accuracy of this clock is several orders of magnitude greater than the

frequency accuracy of the native 10 MHz PXI backplane clock

(PXI_CLK10).

The TCXO contains circuitry to measure the temperature of the oscillator.

It uses the temperature to adjust its frequency output according to the

crystal’s known frequency variation across its operating temperature range.

An NI PXIe-6672 module in the System Timing Slot of a PXI Express

chassis can replace the native PXI 10 MHz backplane frequency reference

clock (PXI_CLK10) with the more stable and accurate output of the

TCXO. All other PXI modules in the chassis that reference the 10 MHz

backplane clock benefit from this more accurate frequency reference.

Furthermore, the DDS chip on the NI PXIe-6672 references its output to

the backplane clock and also takes advantage of the superior TCXO

accuracy. The TCXO does not automatically replace the native 10 MHz

NI PXIe-6672 User Manual 3-8 ni.com

Page 22

clock; this feature must be explicitly enabled in software. The TCXO

output also can be routed out to the CLKOUT connector.

In addition to replacing the native backplane clock directly, the TCXO can

phase lock to an external frequency source. This operation is discussed in

detail in the Using the PXI_CLK10 PLL section.

Routing Signals

The NI PXIe-6672 has versatile trigger routing capabilities. It can

route signals to and from the front panel, the PXI triggers, and the PXI star

triggers.

The CLKIN SMB input on the NI PXIe-6672 may be used for PXI_CLK10

replacement by either routing a 10 MHz signal directly from the CLKIN

input to PXI_CLK10_IN, or by using the CLKIN input as a phase lock

reference for the TCXO. When phase locking the TCXO to CLKIN,

CLKIN may be any multiple of 1 MHz to 105 MHz. In addition, CLKIN is

a valid source for PXI_Star.

The CLKOUT SMB on the NI PXIe-6672 may also be used to route the

TCXO, PXI_CLK10, or DDS Clock.

Chapter 3 Hardware Overview

© National Instruments Corporation 3-9 NI PXIe-6672 User Manual

Page 23

Chapter 3 Hardware Overview

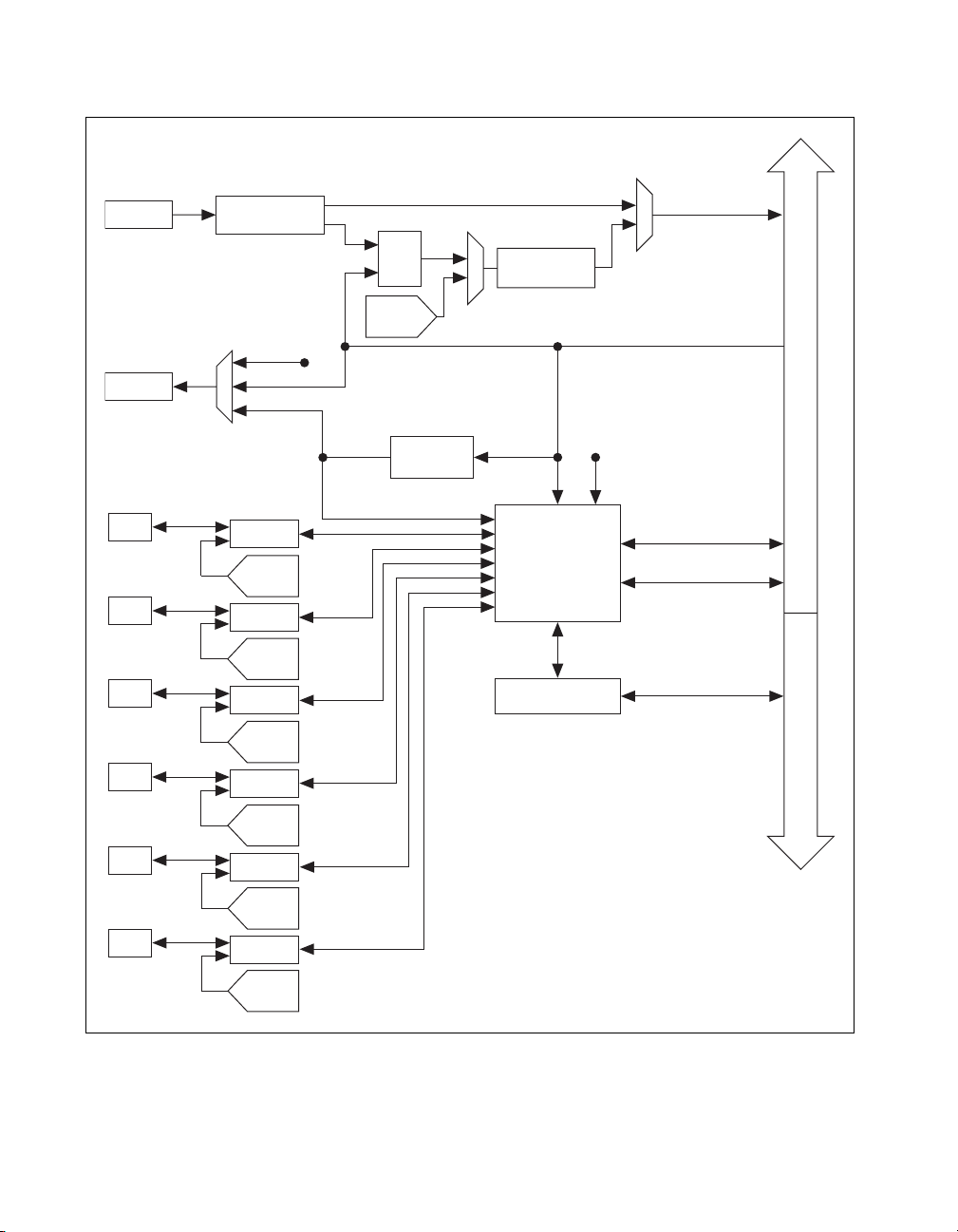

Figures 3-3 and 3-4 summarize the routing features of the NI PXIe-6672.

The remainder of this chapter details the capabilities and constraints of

the routing architecture.

PFI 0

PFI 1

PFI 5

Selection

Circuitry

Selection

Circuitry

Selection

Circuitry

PFI 0

DDS

PXI_CLK10

PFI 0

DDS

PXI_CLK10

PXI_STAR<0..16>,

*

PXI_TRIG<0..7>,

PFI<0..5>, and

Software Trigger are

routed to SOURCE

of each Selection

Circuitry block.

3

SYNCHRONIZATION

CLOCKS for PFI<0..5>

N

÷2

M

÷2

N

÷2

M

÷2

28

*

SOURCE

CLKIN

SYNCHRONIZATION

CLOCKS for

PXI_STAR<0..16> and

PXI_TRIG<0..7>

3

Selection

Circuitry

Selection

Circuitry

Selection

Circuitry

Selection

Circuitry

Selection

Circuitry

Selection

Circuitry

PXI_STAR 0

PXI_STAR 1

PXI_STAR 16

PXI_TRIG 0

PXI_TRIG 1

PXI_TRIG 7

Figure 3-3. High-Level Schematic of NI PXIe-6672 Signal Routing Architecture

NI PXIe-6672 User Manual 3-10 ni.com

Page 24

PXI_TRIG<0..7>

PXI_STAR<0..16>

SOURCE

Software Trigger

Chapter 3 Hardware Overview

Figure 3-4 provides a more detailed view of the Selection Circuitry

referenced in Figure 3-3.

CLKIN*

PFI<0..5>

GND

CLK

CLK/N

CLOCKS

SYNCHRONIZATION

* CLKIN only valid for PXI_STAR

CLK/M

Figure 3-4. Signal Selection Circuitry Diagram

Determining Sources and Destinations

All signal routing operations can be characterized by a source (input) and

a destination. In addition, synchronous routing operations must also define

a third signal known as the synchronization clock. Refer to the Choosing

the Type of Routing section for more information on synchronous versus

asynchronous routing.

DESTINATION

© National Instruments Corporation 3-11 NI PXIe-6672 User Manual

Page 25

Chapter 3 Hardware Overview

Table 3-4 summarizes the sources and destinations of the NI PXIe-6672.

The destinations are listed in the horizontal heading row, and the sources

are listed in the column at the far left. A ✓ in a cell indicates that the source

and destination combination defined by that cell is a valid routing

combination.

Table 3-4. Sources and Destinations for NI PXIe-6672 Signal Routing Operations

Destinations

Front Panel Backplane Onboard

CLKOUT PFI <0..5> PXI_

CLK10_IN

CLKIN ✓

Front Panel

PFI <0..5> ✓ ✓ ✓

PXI_ CLK10 ✓ ✓

Sources

*

Can be accomplished in two stages by routing source to PXI_CLK10_IN, replacing PXI_CLK10 with PXI_CLK10_IN

(occurs automatically in most chassis), and then routing PXI_CLK10 to the destination. The source must be 10 MHz.

†

Routing PXI_CLK10 or DDS to PFI, PXI_Star, or PXI_Trigger is accomplished by setting PXI_CLK10 or DDS to be the

synchronization clock (NI-Sync Property Node) and then routing the synchronization clock as the source.

PXI_STAR

<0..16>

Backplane

PXI TRIG

<0..7>

TCXO ✓ ✓

DDS ✓ ✓

Global

Onboard

Software

Trigger

*

*

✓

†

✓ ✓ ✓

✓ ✓ ✓

✓ ✓ ✓

*

†

✓ ✓

✓ ✓ ✓

PXI_Star

Trigger

<0..16>

†

✓

*

†

✓

PXI TRIG

<0..7>

*

†

✓

*

✓

†

✓

Reference

TCXO

PLL

✓

Using Front Panel PFIs As Inputs

The front-panel PFIs can receive external signals from 0 to +5 V. They can

be terminated programmatically with 50 Ω resistances to match the cable

impedance and minimize reflections.

Note Terminating the signals with a 50 Ω resistance is recommended when the source is

another NI PXIe-6672 or any other source with a 50 Ω output.

The voltage thresholds for the front-panel PFI inputs are programmable.

The input signal is generated by comparing the input voltage on the

NI PXIe-6672 User Manual 3-12 ni.com

Page 26

Chapter 3 Hardware Overview

PFI connectors to the voltage output of software-programmable DACs.

The thresholds for the PFI lines are individually programmable, which is

useful if you are importing signals from multiple sources with different

voltage swings. The front panel PFI inputs can be routed to any PXI_Star

triggers, PXI triggers, or other front panel PFI outputs.

Using Front Panel PFIs As Outputs

The front panel PFI outputs are +3.3 V drivers with 50 Ω output

impedance. The outputs can drive 50 Ω loads, such as a 50 Ω coaxial cable

with a 50 Ω receiver. This cable configuration is the recommended setup to

minimize reflections. With this configuration, the receiver sees a single

+1.6 V step—a +3.3 V step split across the 50 Ω resistors at the source and

the destination.

You also can drive a 50 Ω cable with a high-impedance load. The

destination sees a single step to +3.3 V, but the source sees a reflection.

This cable configuration is acceptable for low-frequency signals or short

cables. You can select the signal source from the front panel triggers

(PFI <0..5>), the PXI star triggers, the PXI triggers, or the synchronization

clock (PXI_CLK10, the DDS clock, or PFI 0). The synchronization clock

concept is explained in more detail in the Choosing the Type of Routing

section.

You can independently select the output signal source for each PFI line

from one of the following sources:

• Another PFI <0..5>

• PXI triggers <0..7> (PXI_TRIG <0..7>)

• PXI_STAR <0..16>

• Global software trigger

• PFI synchronization clock

The PFI synchronization clock may be any of the following signals:

• DDS clock

•PXI_CLK10

• PFI 0 Input

• Any of the previously listed signals divided by the first frequency

divider (2

n

, up to 512)

• Any of the previously listed signals divided by the second frequency

divider (2

© National Instruments Corporation 3-13 NI PXIe-6672 User Manual

m

, up to 512)

Page 27

Chapter 3 Hardware Overview

Note The PFI synchronization clock is the same for all routing operations in which

PFI <0..5> is defined as the output, although the divide-down ratio for this clock (full rate,

first divider, second divider) may be chosen on a per route basis.

Refer to the Choosing the Type of Routing section for more information on

the synchronization clock.

Using the PXI Triggers

The PXI triggers go to all the slots in the chassis. All modules receive the

same PXI triggers, so PXI trigger 0 is the same for Slot 2 as it is for Slot 3,

and so on. This feature makes the PXI triggers convenient in situations

where you want, for instance, to start an acquisition on several devices at

the same time because all modules will receive the same trigger.

The frequency on the PXI triggers should not exceed 20 MHz to preserve

signal integrity. The signals do not reach each slot at precisely the same

time. A difference of several nanoseconds between slots can occur in an

eight-slot chassis. However, this delay is not a problem for many

applications. You can route signals to the PXI triggers from PFI <0..5>,

from the PXI star triggers, or from other PXI triggers. You also can route

PXI_CLK10 or the DDS clock to a PXI trigger line (PXI_TRIG <0..7>)

using the synchronization clock.

You can independently select the output signal source for each PXI trigger

line from one of the following sources:

• PFI <0..5>

• Another PXI trigger <0..7> (PXI_TRIG <0..7>)

• PXI_STAR <0..16>

• Global software trigger

• PXI_Trig/PXI_Star synchronization clock

The PXI_Trig/PXI_Star synchronization clock may be any of the following

signals:

• DDS clock

•PXI_CLK10

• PFI 0 Input

• Any of the previously listed signals divided by the first frequency

divider (2

n

, up to 512)

• Any of the previously listed signals divided by the second frequency

divider (2

NI PXIe-6672 User Manual 3-14 ni.com

m

, up to 512)

Page 28

Chapter 3 Hardware Overview

Refer to the Choosing the Type of Routing section for more information

about the synchronization clock.

Note The PXI_Trig/PXI_Star synchronization clock is the same for all routing operations

in which PXI_TRIG <0..7> or PXI_STAR <0..16> is defined as the output, although the

divide-down ratio for this clock (full rate, first divider, second divider) may be chosen on

a per route basis.

Using the PXI Star Triggers

There are up to 17 PXI star triggers per chassis. Each trigger line

is a dedicated connection between the System Timing Slot and one other

slot. The PXI Specification, Revision 2.1, requires that the propagation

delay along each star trigger line be matched to within 1 ns. A typical upper

limit for the skew in most NI PXI chassis is 500 ps. The low skew of the

PXI star trigger bus is useful for applications that require triggers to arrive

at several modules nearly simultaneously.

The star trigger lines are bidirectional, so signals can be sent to System

Timing Slot from a module in another slot or from System Timing Slot to

the other module.

You can independently select the output signal source for each PXI star

trigger line from one of the following sources:

• PFI <0..5>

• PXI triggers <0..7> (PXI_TRIG <0..7>)

• Another PXI star trigger line (PXI_STAR <0..16>)

• Global software trigger

• PXI_Trig/PXI_Star synchronization clock

•CLKIN

Refer to the Using the PXI Triggers section for more information on the

PXI_Trig/PXI_Star synchronization clock.

Choosing the Type of Routing

The NI PXIe-6672 routes signals in one of two ways: asynchronously or

synchronously. The following sections describe the two routing types and

the considerations for choosing each type.

© National Instruments Corporation 3-15 NI PXIe-6672 User Manual

Page 29

Chapter 3 Hardware Overview

Asynchronous Routing

Asynchronous routing is the most straightforward method of routing

signals. Any asynchronous route can be defined in terms of two signal

locations: a source and a destination. A digital pulse or train comes in on

the source and is propagated to the destination. When the source signal

goes from low to high, this rising edge is transferred to the destination after

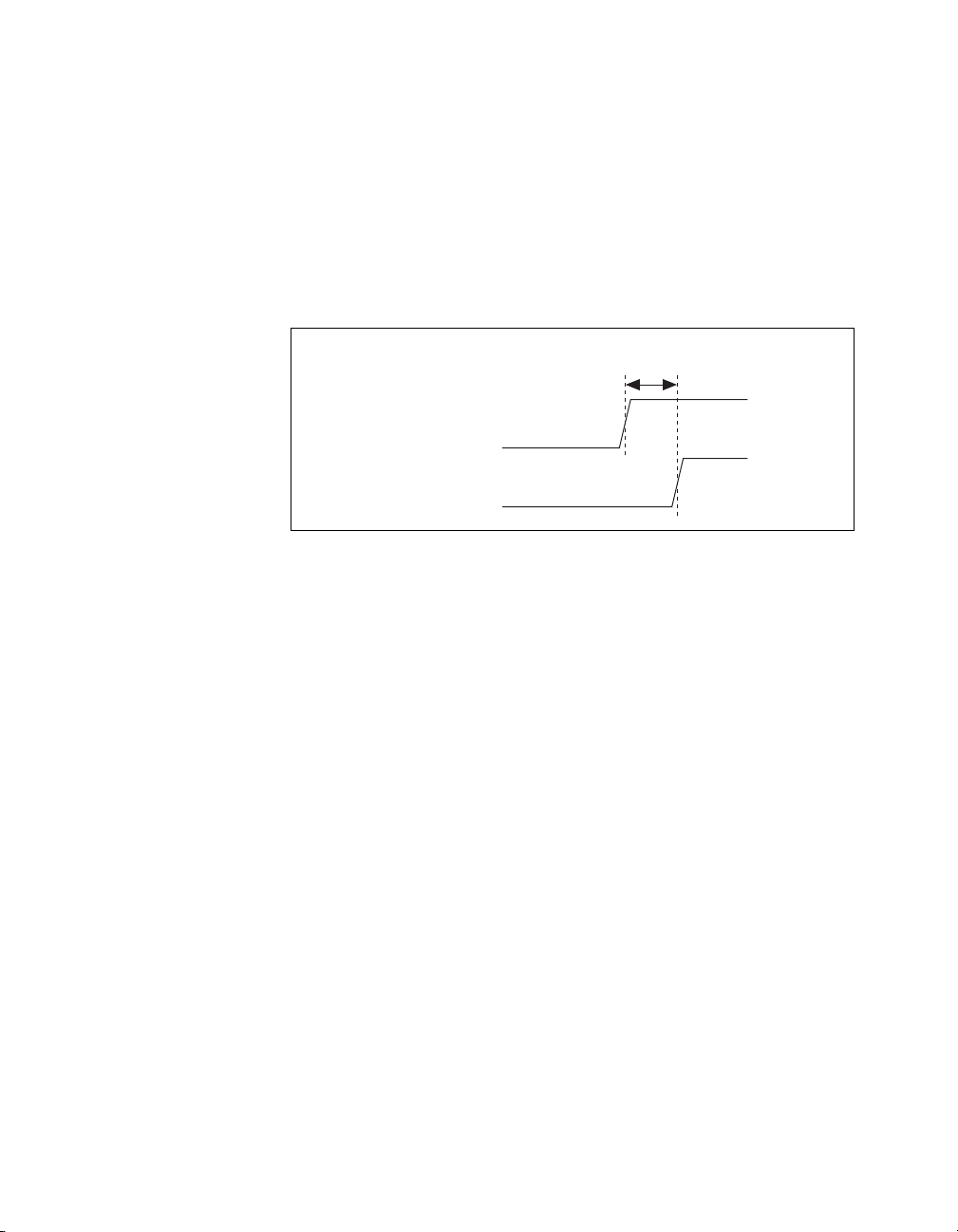

a propagation delay through the module. Figure 3-5 illustrates an

asynchronous routing operation.

Propagation Delay

t

pd

Trigger Input

Trigger Output

Figure 3-5. Asynchronous Routing Operation

Some delay is always associated with an asynchronous route, and this

delay varies among NI PXIe-6672 modules, depending on variations in

temperature and chassis voltage. Typical delay times in the NI PXIe-6672

for asynchronous routes between various sources and destinations are

given in Appendix A, Specifications.

Asynchronous routing works well if the total system delays are not too long

for the application. Propagation delay could be caused by the following

reasons:

• Output delay on the source

• Propagation delay of the signal across the backplane(s) and cable(s)

• Propagation delay of the signal through the NI PXIe-6672

• Time for the receiver to recognize the signal

Both the source and the destination of an asynchronous routing operation

on the NI PXIe-6672 can be any of the following lines:

• Any front panel PFI pin (PFI <0..5)

• Any PXI star trigger line (PXI_STAR <0..16>)

• Any PXI trigger line (PXI_TRIG <0..7>)

NI PXIe-6672 User Manual 3-16 ni.com

Page 30

Chapter 3 Hardware Overview

Synchronous Routing

A synchronous routing operation is defined in terms of three signal

locations: a source, a destination, and a synchronization clock. A digital

signal comes in on the source and is propagated to the destination after

the edge has been realigned with the synchronization clock.

Unlike asynchronous routing, the output of a synchronous routing

operation does not directly follow the input after a propagation delay.

Instead, the output waits for the next rising edge of the clock before it

follows the input. Thus, the output is said to be “synchronous” with this

clock.

Figure 3-6 shows a timing diagram that illustrates synchronous routing.

Setup

Hold

Time

Time

t

t

setup

hold

Trigger Input

Synchronization

Trigger Output

Clock

Figure 3-6. Synchronous Routing Operation

Clock to Output

Time, t

CtoQ

Synchronous routing can send triggers to several places in the same clock

cycle or send the trigger to those same places after a deterministic skew of

a known number of clock cycles. If a signal arrives at two chassis within

the same clock cycle, each NI PXIe-6672 realigns the signal with the

synchronization clock and distributes it to the modules in each chassis at

the same time. Synchronous routing can thus remove uncertainty about

when triggers are received. If the delays through the system are such that

an asynchronous trigger might arrive near the edge of the receiver clock,

the receiver might see the signal in the first clock cycle, or it might see it in

© National Instruments Corporation 3-17 NI PXIe-6672 User Manual

Page 31

Chapter 3 Hardware Overview

Note The possible destinations for a synchronous route are identical to those for an

asynchronous route. The destinations include any front panel PFI pin, any PXI star trigger

line, or any PXI trigger line.

the second clock cycle. However, by synchronizing the signal, you can

eliminate the ambiguity, and the signal will always be seen in the second

clock cycle.

One useful feature of synchronous routing is that the signal can be

propagated on either the rising or falling edge of the synchronization clock.

In addition, the polarity of the destination signal can be inverted, which is

useful when handling active-low digital signals.

Possible sources for synchronous routing include the following sources:

• Any front panel PFI pin

• Any PXI star trigger line (PXI_STAR <0..16>)

• Any PXI trigger line (PXI_TRIG <0..7>)

• Global software trigger

• The synchronization clock itself

The synchronization clock for a synchronous route can be any of the

following signals:

• 10 MHz PXI backplane clock signal

• DDS clock on the NI PXIe-6672

• Front panel PFI 0 Input

• One of two “divided copies” of any of the previously listed three

signals. The NI PXIe-6672 includes two clock-divider circuits that can

divide the synchronization clock signals by any power of 2 up to 512.

Refer to Figures 3-3 and 3-4 for an illustration of how the NI PXIe-6672

performs synchronous routing operations.

Generating a Single Pulse (Global Software Trigger)

The global software trigger is a single pulse with programmable delay that

is fired on a software command. This signal is always routed synchronously

with a clock. Therefore, asynchronous routing is not supported when the

signal source is the global software trigger.

The software trigger can be delayed by up to 15 clock cycles on a per route

basis. This feature is useful if a single pulse must be sent to several

NI PXIe-6672 User Manual 3-18 ni.com

Page 32

destinations with significantly different propagation delays. By delaying

the pulse on the routes with shorter paths, you can compensate for the

propagation delay. An example of such a situation would be when a trigger

pulse must arrive nearly simultaneously at the local backplane and the

backplane of another chassis separated by 50 m of coaxial cable.

Using the PXI_CLK10 PLL

A module in System Timing Slot of a PXI Express chassis can replace the

PXI_CLK10 reference clock. The NI PXIe-6672 offers three options for

this replacement. This section describes each option.

• The first option is to replace PXI_CLK10 directly with the TCXO

output on the NI PXIe-6672. This oscillator is a more stable and

accurate reference than the native backplane clock.

• The second option is to route a 10 MHz clock directly from CLKIN on

the front panel to PXI_CLK10_IN, which is the pin on the backplane

that will replace PXI_CLK10. There is a delay through the module, as

well as a distribution delay on the backplane. These delays tend to

be similar for chassis of the same model, so routing the same clock

to a pair of chassis usually matches PXI_CLK10 to within a few

nanoseconds.

• The third option is to employ the NI PXIe-6672 PLL circuitry for the

TCXO. As in option 1, the output of the TCXO replaces the native

10 MHz signal. However, this scheme also requires an input signal

on CLKIN. This signal must be a stable clock, and its frequency must

be a multiple of 1 MHz (5 MHz or 13 MHz, for example) between

1 MHz and 105 MHz. The PLL feedback circuit generates a voltage

proportional to the phase difference between the reference input on

PXI_CLK10 and the output of the TCXO. This PLL voltage output

then tunes the output frequency of the TCXO. As long as the incoming

signal is a stable 1 MHz frequency multiple, the PLL circuit quickly

locks the TCXO to the reference, eliminating all phase drift between

the two signals.

Chapter 3 Hardware Overview

Using the PLL provides several advantages over the other two options for

replacing the PXI backplane clock:

• CLKIN is not required to be 10 MHz. If you have a stable reference

that is a multiple of 1 MHz, such as 13 or 5 MHz, you can

frequency-lock the chassis to it.

• If CLKIN stops or becomes disconnected, PXI_CLK10 is still present

in the chassis.

© National Instruments Corporation 3-19 NI PXIe-6672 User Manual

Page 33

Chapter 3 Hardware Overview

• If CLKIN is 10 MHz, the NI PXIe-6672 can compensate for

distribution delays in the backplane. The feedback in the PLL comes

from PXI_CLK10. This PLL makes it possible for the NI PXIe-6672

to align clock edges at CLKIN with the edges of PXI_CLK10 that the

modules receive. If you split an external (accurate) 10 MHz reference

and route it to two chassis, they can both lock to it. The result is a

tighter synchronization of PXI_CLK10 on the chassis.

NI PXIe-6672 User Manual 3-20 ni.com

Page 34

Calibration

This chapter discusses the calibration of the NI PXIe-6672.

Calibration consists of verifying the measurement accuracy of a device

and correcting for any measurement error. The NI PXIe-6672 is factory

calibrated before shipment at approximately 25 °C to the levels indicated

in Appendix A, Specifications. The associated calibration constants—the

corrections that were needed to meet specifications—are stored in the

onboard nonvolatile memory (EEPROM). The driver software uses these

stored values.

Factory Calibration

The factory calibration of the NI PXIe-6672 involves calculating and

storing four calibration constants. These values control the accuracy of

four features of the device, which are discussed in the following sections.

TCXO Frequency

The TCXO frequency can be varied over a small range. The output

frequency of the TCXO is adjusted using this constant to meet the

specification listed in Appendix A, Specifications. This calibration

applies only to the NI PXIe-6672.

4

PXI_CLK10 Phase

When using the PLL to lock PXI_CLK10 to an external reference clock, the

phase between the clocks can be adjusted. The time between rising edges

of PXI_CLK10 and the input clock is minimized using this constant.

DDS Start Trigger Phase

To start the DDS reliably, the DDS start trigger must arrive within a certain

window of time. The phase of the DDS start trigger is controlled by this

constant to meet the setup and hold-time requirements of the DDS.

© National Instruments Corporation 4-1 NI PXIe-6672 User Manual

Page 35

Chapter 4 Calibration

DDS Initial Phase

The phase of the DDS output is adjusted using this constant so that the

DDS outputs from multiple NI PXIe-6672 modules are aligned.

Additional Information

Refer to ni.com/calibration for additional information on

NI calibration services.

NI PXIe-6672 User Manual 4-2 ni.com

Page 36

Specifications

CLKIN Characteristics

CLKIN fundamental

frequency range

Input impedance..................................... 50 Ω , nominal

Input coupling ........................................AC

Voltage range

DC................................................... ±20 V

AC................................................... 400 mV

Absolute maximum input voltage2......... ±26 V, max

CLKIN to PXI_CLK10_IN delay

without PLL ...........................................14 ns to 14.7 ns, typical

1

.................................... 1 MHz to 105 MHz,

sine or square wave

to 5 V

p-p

A

p-p

CLKIN to PXI_CLK10 delay

with PLL ................................................ ±1 ns, max

CLKIN frequency accuracy requirement

For PLL and TCXO ........................ ±5.0 ppm

For replacing PXI_CLK10

(no PLL).......................................... ±100 ppm

1

CLKIN fundamental frequency can be any multiple of 1 MHz within the range specified when the PLL is engaged and

PXI_CLK10 is locking to it. The frequency must be 10 MHz when replacing PXI_CLK10 without the PLL.

2

Stresses beyond those listed can cause permanent damage to the device. Exposure to absolute maximum rated conditions for

extended periods of time can affect device reliability. Functional operation of the device outside the conditions indicated in

the operational parts of the specification is not implied.

3

This is a requirement of the PXI specification.

© National Instruments Corporation A-1 NI PXIe-6672 User Manual

3

Page 37

Appendix A Specifications

Jitter added to CLKIN

Without PLL....................................0.5 ps

With PLL .........................................0.6 ps

Duty cycle distortion of CLKIN to

PXI_CLK10_IN without PLL ................±1%, max

Required input duty cycle

when using PLL......................................45 to 55%

CLKOUT Characteristics

Output frequency

From PXI_CLK10...........................10 MHz

From TCXO.....................................10 MHz

From DDS .......................................1 MHz

typical

typical

, 10 Hz to 100 kHz,

rms

, 10 Hz to 100 kHz,

rms

1

to 105 MHz

Duty cycle...............................................43 to 55%

2

Output impedance...................................50 Ω, nominal

Output coupling ......................................AC

Amplitude, software configurable to two voltage levels

(low and high drive)

Open Load Square Wave

Low Drive 2.0 V

High Drive 5.0 V

, typical

p-p

, typical

p-p

50 Ω Load Square Wave

Low Drive 1.0 V

High Drive 2.5 V

1

The lower limit is load dependent because of the AC coupling. This limit is less than 1 MHz for high-impedance loads.

2

The duty cycle specification covers both DDS range and TCXO.

, typical

p-p

, typical

p-p

NI PXIe-6672 User Manual A-2 ni.com

Page 38

PFI <0..5>

Appendix A Specifications

Square wave rise/fall time (10 to 90%)

Low drive........................................ 0.5 ns min,

2.5 ns max

High drive ....................................... 0.5 ns min,

2.5 ns max

Input Characteristics

Frequency range..................................... DC to 105 MHz

Input impedance..................................... 50 Ω , nominal, or 1 kΩ ±10%,

|| 35 pF, software-selectable

Input coupling ........................................DC

Voltage level ..........................................0 to 5 V

Absolute maximum input voltage

1

......... ±5.25 V, max

Input threshold

Voltage level ................................... 0 to 4.3 V, software-selectable

Voltage resolution........................... 16.8 mV (8 bits)

Error ................................................ ±40 mV

Hysteresis ............................................... 50 mV

Asynchronous delay, t

pd

PFI <0..5> to

PXI_TRIG <0..7> output................ 19 to 26 ns, typical

PFI <0..5> to

PXI_STAR <0..12> output ............. 10 to 19 ns, typical

Synchronized trigger

input setup time, t

2

...........................16.5 ns, typical

setup

Synchronized trigger

input hold time, t

1

Stresses beyond those listed can cause permanent damage to the device. Exposure to absolute maximum rated conditions for

extended periods of time can affect device reliability. Functional operation of the device outside the conditions indicated in

the operational parts of the specifications is not implied.

2

Relative to PXI_CLK10 at the backplane connector. When PLL is used to route CLKIN to PXI_CLK10_IN, CLKIN and

PXI_CLK10 are phase locked with ±1 ns max phase difference. Refer to the Synchronous Routing section of Chapter 3,

Hardware Overview, for more details.

2

..............................–9.9 ns, typical

hold

© National Instruments Corporation A-3 NI PXIe-6672 User Manual

Page 39

Appendix A Specifications

Output Characteristics

Frequency range .....................................DC to 105 MHz

Output impedance...................................50 Ω, nominal

Output coupling ......................................DC

Voltage level...........................................0 to 1.6 V into 50 Ω;

0 to 3.3 V into open circuit,

typical

Absolute maximum applied voltage

PXI_CLK10 synchronized trigger clock

to out time, t

2

....................................10.7 ns, typical

CtoQ

Output-to-output skew, synchronous......500 ps, typical

PXI_STAR Trigger Characteristics

PXI_STAR <0..16> to

PXI_STAR <0..16> output skew

at NI PXIe-6672 backplane connector....300 ps

Asynchronous delays, t

PXI_STAR <0..16> to

PFI <0..5> output.............................13 to 17 ns, typical

PXI_STAR <0..16> to

PXI_TRIG <0..7> output.................18 to 24 ns, typical

1

......±5.25 V, max

3

, typical

pd

1

Stresses beyond those listed can cause permanent damage to the device. Exposure to absolute maximum rated conditions for

extended periods of time can affect device reliability. Functional operation of the device outside the conditions indicated in

the operational parts of the specifications is not implied.

2

Relative to PXI_CLK10 at backplane connector.

3

This specification applies to all synchronous routes to the PXI_Star lines, as well as asynchronous routes from the PFI inputs

to the PXI_Star lines.

NI PXIe-6672 User Manual A-4 ni.com

Page 40

PXI Trigger Characteristics

PXI_TRIG <0..7> to

PXI_TRIG <0..7> output skew

at NI PXIe-6672 backplane connector ... 5 ns, typical

Appendix A Specifications

Asynchronous delay, t

TCXO Characteristics

Frequency............................................... 10 MHz

Initial accuracy....................................... ±2.5 ppm

Long-term stability (1 year)

Temperature stability (0 to 55 °C)

DDS Characteristics

Frequency range..................................... 1 Hz to 105 MHz

Frequency resolution.............................. < 0.075 Hz

Frequency accuracy................................ Equivalent to PXI_CLK10

Physical

Chassis requirement ............................... One 3U PXI Express

pd

PXI_TRIG <0..7> to

PFI <0..5> output............................ 15 to 22 ns, typical

1

.................. ±1 ppm

2

........ ±2 ppm

accuracy

3

System Timing Slot

Front panel connectors ........................... SMB male, 50 Ω

Front panel indicators............................. Two tricolor LEDs

(green, red, and amber)

1

Includes stability of TCXO and supporting circuitry.

2

Includes temperature stability of TCXO and supporting circuitry.

3

The DDS frequency inherits the relative frequency of PXI_CLK10. For example, if you route the TCXO to PXI_CLK10,

the DDS output inherits the same relative frequency accuracy as the TCXO output.

© National Instruments Corporation A-5 NI PXIe-6672 User Manual

Page 41

Appendix A Specifications

Recommended maximum cable length

Weight ....................................................0.459 lb (208 g)

Power Requirements

+3.3 V .....................................................800 mA, max

+12 V ......................................................700 mA, max

Environment

Maximum altitude...................................2,000 m (800 mbar)

Pollution Degree .....................................2

Indoor use only.

Caution When required, clean the NI PXIe-6672 with a soft nonmetallic brush. Make sure

that the device is completely dry and free from contaminants before returning it to service.

1

PFI/CLKOUT, DC to 10 MHz ........200 m

CLKOUT High Gain, 105 MHz......80 m

PFI/CLKOUT Low Gain,

105 MHz..........................................30 m

(at 25 °C ambient temperature)

2

3

Operating Environment

Ambient temperature range ....................0 to 55 °C (Tested in accordance

with IEC-60068-2-1 and

IEC-60068-2-2. Meets

MIL-PRF-28800F Class 3

low temperature limit and

MIL-PRF-28800F Class 2

high temperature limit.)

Relative humidity range..........................10% to 90%, noncondensing

(Tested in accordance with

IEC-60068-2-56.)

1

Cable length measurements were made with an RG 58 cable. Maximum cable length performance will vary depending on the

cable type used.

2

Maximum cable length with a direct cable connection. Loss from a signal splitter would reduce maximum cable length.

3

Maximum cable length with a direct cable connection. Loss from a signal splitter would reduce maximum cable length.

NI PXIe-6672 User Manual A-6 ni.com

Page 42

Shock and Vibration

Appendix A Specifications

Storage Environment

Ambient temperature range.................... –40 to 71 °C (Tested in

accordance with IEC-60068-2-1

and IEC-60068-2-2. Meets

MIL-PRF-28800F Class 3

low temperature limit.)

Relative humidity range ......................... 5% to 95% noncondensing

(Tested in accordance with

IEC-60068-2-56.)

Operational shock .................................. 30 g peak, half-sine, 11 ms pulse

(Tested in accordance with

IEC-60068-2-27. Meets

MIL-PRF-28800F Class 2 limits.)

Random vibration

Operating ........................................ 5 to 500 Hz, 0.3 g

Nonoperating .................................. 5 to 500 Hz, 2.4 g

(Tested in accordance with

IEC-60068-2-64. Nonoperating

test profile exceeds the

requirements of

MIL-PRF-28800F, Class 3.)

rms

rms

Note Specifications are subject to change without notice.

Safety

This product is designed to meet the requirements of the following

standards of safety for electrical equipment for measurement, control, and

laboratory use:

• • IEC 61010-1, EN 61010-1

• • UL 61010-1, CSA 61010-1

Note For UL and other safety certifications, refer to the product label or visit ni.com/

certification

in the Certification column.

© National Instruments Corporation A-7 NI PXIe-6672 User Manual

, search by model number or product line, and click the appropriate link

Page 43

Appendix A Specifications

Electromagnetic Compatibility

This product is designed to meet the requirements of the following

standards of EMC for electrical equipment for measurement, control, and

laboratory use:

• EN 61326 EMC requirements; Minimum Immunity

• EN 55011 Emissions; Group 1, Class A

• CE, C-Tick, ICES, and FCC Part 15 Emissions; Class A

Note For EMC compliance, operate this device according to printed documentation.

CE Compliance

This product meets the essential requirements of applicable European

Directives, as amended for CE marking, as follows:

• 2006/95/EC; Low-Voltage Directive (safety)

• 2004/108/EC; Electromagnetic Compatibility Directive (EMC)

Note Refer to the Declaration of Conformity (DoC) for this product for any additional

regulatory compliance information. To obtain the DoC for this product, visit

certification

in the Certification column.

, search by model number or product line, and click the appropriate link

ni.com/

Environmental Management

National Instruments is committed to designing and manufacturing

products in an environmentally responsible manner. NI recognizes that

eliminating certain hazardous substances from our products is beneficial

not only to the environment but also to NI customers.

For additional environmental information, refer to the NI and the

Environment Web page at

environmental regulations and directives with which NI complies, as well

as other environmental information not included in this document.

NI PXIe-6672 User Manual A-8 ni.com

ni.com/environment. This page contains the

Page 44

Appendix A Specifications

⬉ᄤֵᙃѻક∵ᶧࠊㅵ⧚ࡲ⊩ ˄Ё

˅

Ёᅶ᠋

Waste Electrical and Electronic Equipment (WEEE)

EU Customers At the end of their life cycle, all products must be sent to a WEEE recycling

center. For more information about WEEE recycling centers and National Instruments

WEEE initiatives, visit

ni.com/environment/weee.htm.

RoHS

National Instruments

݇Ѣ

National InstrumentsЁRoHS

(For information about China RoHS compliance, go to

ヺড়Ё⬉ᄤֵᙃѻકЁ䰤ࠊՓ⫼ᶤѯ᳝ᆇ⠽䋼ᣛҸ

ড়㾘ᗻֵᙃˈ䇋ⱏᔩ

ni.com/environment/rohs_china

ni.com/environment/rohs_china

(RoHS)

DŽ

DŽ

.)

© National Instruments Corporation A-9 NI PXIe-6672 User Manual

Page 45

Technical Support and

Professional Services

Visit the following sections of the award-winning National Instruments

Web site at

• Support—Technical support resources at

• Training and Certification—Visit

• System Integration—If you have time constraints, limited in-house

ni.com for technical support and professional services:

the following:

– Self-Help Technical Resources—For answers and solutions,

visit

ni.com/support for software drivers and updates, a

searchable KnowledgeBase, product manuals, step-by-step

troubleshooting wizards, thousands of example programs,

tutorials, application notes, instrument drivers, and so on.

Registered users also receive access to the NI Discussion Forums

at

ni.com/forums. NI Applications Engineers make sure every

question submitted online receives an answer.

– Standard Service Program Membership—This program