Page 1

CALIBRATION PROCEDURE

NI PXI-5422

This document contains step-by-step instructions for writing a calibration

procedure for the NI PXI-5422 arbitrary waveform generator.

Contents

Conventions ............................................................................................ 1

Introduction.............................................................................................2

What Is Calibration? ........................................................................ 2

Self-Calibration ........................................................................ 2

External Calibration.................................................................. 2

Why Should You Calibrate? ............................................................ 2

How Often Should You Calibrate? .................................................. 3

Software and Documentation Requirements...........................................3

Software ........................................................................................... 3

Documentation.................................................................................5

Self-Calibration Procedures .................................................................... 5

MAX ................................................................................................ 5

FGEN Soft Front Panel.................................................................... 6

NI-FGEN ......................................................................................... 6

External Calibration Options .................................................................. 7

Complete Calibration....................................................................... 7

Optional Calibration ........................................................................ 9

External Calibration Requirements ......................................................... 11

Test Equipment ................................................................................ 11

Test Conditions ................................................................................ 11

External Calibration Procedures ............................................................. 12

Writing Your Calibration Procedure................................................12

Calibration Procedures in LabVIEW........................................ 12

Calibration Procedures in LabWindows/CVI ...........................12

Calibration Procedures in C......................................................12

Verifying NI PXI-5422 Specifications ............................................13

Verifying the Oscillator Frequency Accuracy.......................... 15

Verifying the DC Gain and Offset Accuracy ...........................17

Adjusting the NI PXI-5422.............................................................. 31

Initializing the External Calibration Session ............................35

Page 2

Adjusting the Analog Output ....................................................35

Adjusting the Oscillator Frequency...........................................52

Adjusting the Calibration ADC.................................................55

Closing the External Adjustment Session.................................60

Calibration Utilities .................................................................................61

MAX.................................................................................................61

FGEN SFP........................................................................................61

NI-FGEN ..........................................................................................62

Where to Go for Support .........................................................................63

Conventions

The following conventions are used in this manual:

» The » symbol leads you through nested menu items and dialog box options

to a final action. The sequence File»Page Setup»Options directs you to

pull down the File menu, select the Page Setup item, and select Options

from the last dialog box.

This icon denotes a note, which alerts you to important information.

This icon denotes a caution, which advises you of precautions to take to

avoid injury, data loss, or a system crash. When this symbol is marked on

a product, refer to the Read Me First: Safety and Radio-Frequency

Interference document for information about precautions to take.

bold Bold text denotes items that you must select or click in the software, such

as menu items and dialog box options. Bold text also denotes parameter

names.

italic Italic text denotes variables, emphasis, a cross reference, or an introduction

to a key concept. This font also denotes text that is a placeholder for a word

or value that you must supply.

monospace Text in this font denotes text or characters that you should enter from the

keyboard, sections of code, programming examples, and syntax examples.

This font is also used for the proper names of disk drives, paths, directories,

programs, subprograms, subroutines, device names, functions, operations,

variables, filenames, and extensions.

Introduction

This document contains instructions for calibrating the NI PXI-5422

arbitrary waveform generator. This calibration procedure is intended for

metrology labs. It describes specific programming steps for writing an

external calibration procedure for the NI PXI-5422.

NI PXI-5422 Calibration Procedure 2 ni.com

Page 3

What Is Calibration?

Calibration consists of verifying the output accuracy of a device and

correcting for any output error. Verification is measuring the performance

of a device and comparing the results to the specifications of the device.

NI calibrates every NI PXI-5422 at the factory. During the factory

calibration process, the calibration constants are stored in an onboard

EEPROM. These values are loaded from this EEPROM and used as needed

by the NI PXI-5422.

The NI PXI-5422 supports two types of calibration: self-calibration (or

internal calibration) and external calibration.

Self-Calibration

Self-calibration, also known as internal calibration, uses a software

command and requires no external connections. Self-calibration improves

output accuracy by compensating for variables, such as temperature and

time, that may have changed since the last external calibration.

Self-calibration retains the traceability of the external calibration.

External Calibration

External calibration is generally performed at either NI or a metrology lab.

This procedure replaces all calibration constants in the EEPROM and is

equivalent to a factory calibration at NI. Because the external calibration

procedure changes all EEPROM constants, it invalidates the original

calibration certificate. If an external calibration is done with a traceable

instrument, a new calibration certificate can be issued.

Why Should You Calibrate?

The accuracy of electronic components drifts with time and temperature,

which can affect output accuracy as a device ages. Calibration verifies

that the NI PXI-5422 still meets its specified accuracy and NI standards. If

adjustments are necessary, calibration makes the adjustments to restore

the accuracy.

How Often Should You Calibrate?

Self-calibration can be performed as necessary to compensate for

environmental changes.

Caution Although you can use self-calibration repeatedly, self-calibrating the

NI PXI-5422 more than a few times a day may cause excessive wear on the relays over

time.

© National Instruments Corporation 3 NI PXI-5422 Calibration Procedure

Page 4

The output accuracy requirements of your application determine how often

you should externally calibrate the NI PXI-5422. NI recommends that you

perform a complete external calibration at least once every two years.

You can shorten this interval based on the accuracy demands of your

application. Refer to the External Calibration Options section for more

information.

Software and Documentation Requirements

This section describes the software and documentation required for both

self-calibration and external calibration.

Software

Calibrating the NI PXI-5422 requires installing NI-FGEN version 2.2 or

later on the calibration system. You can download NI-FGEN from the

Instrument Driver Network at

programming the Self-Calibration Procedures and the External

Calibration Procedures in the LabVIEW, LabWindows

application development environments (ADEs). When you install

NI-FGEN, you only need to install support for the ADE that you intend to

use.

NI-FGEN 2.2 or later includes all the functions and attributes necessary for

calibrating the NI PXI-5422. For LabWindows/CVI, the NI-FGEN

function panel (

LabVIEW support is in the

appear in the function palette.

niFgen.fp) provides help about the functions available.

ni.com/idnet. NI-FGEN supports

niFgen.llb file, and all calibration functions

™

/CVI™, and C

Calibration functions are C function calls or LabVIEW VIs in NI-FGEN.

In this document, the C function call is shown first, followed by the

corresponding LabVIEW VI, or NI-FGEN LabVIEW property node,

in parentheses. The C function calls are valid for any compiler capable of

NI PXI-5422 Calibration Procedure 4 ni.com

Page 5

calling a 32-bit DLL. Many of the functions use constants defined in the

niFgen.h file. To use these constants in C, you must include niFgen.h

in your code when you write the calibration procedure. Refer to Table 1

for file locations.

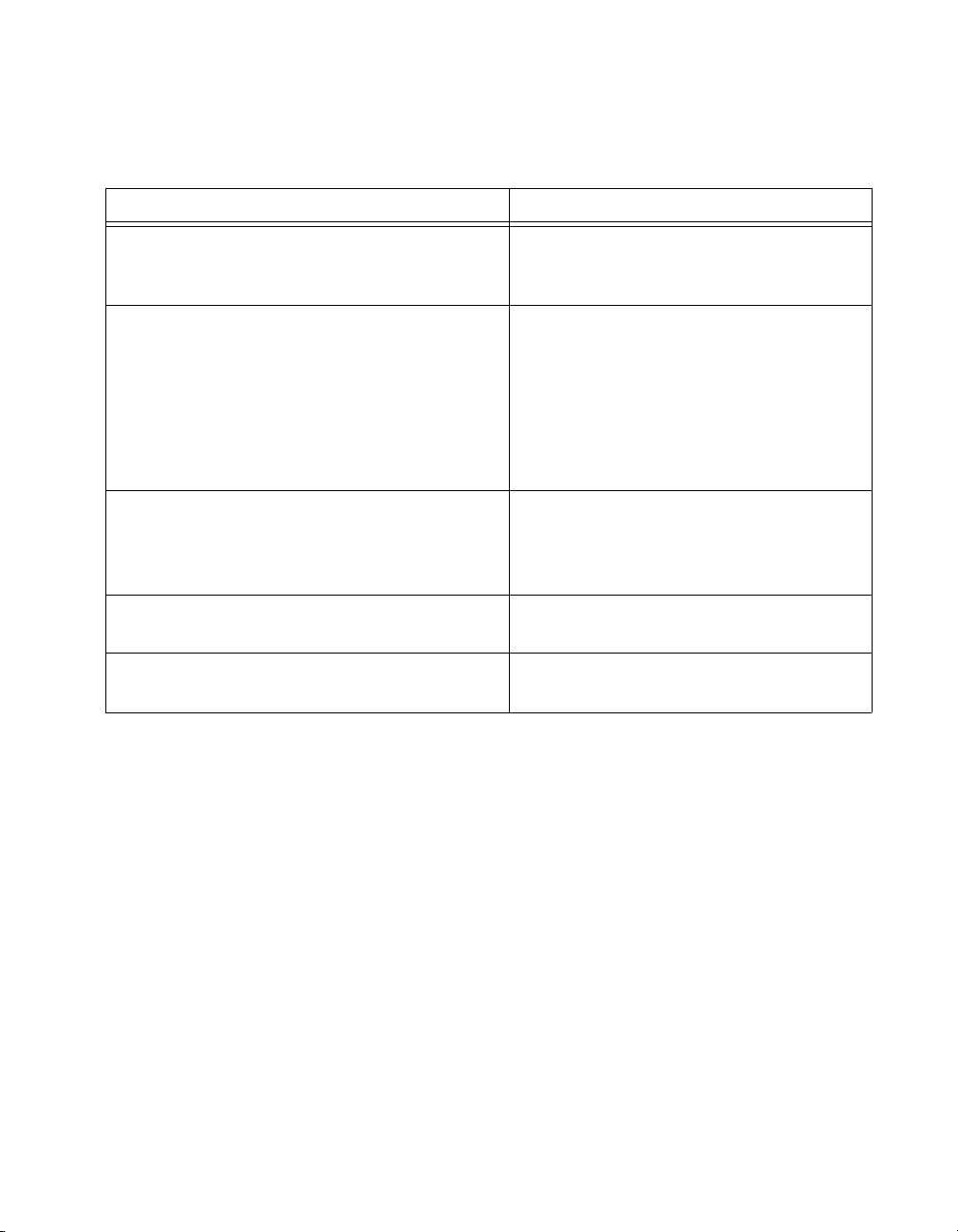

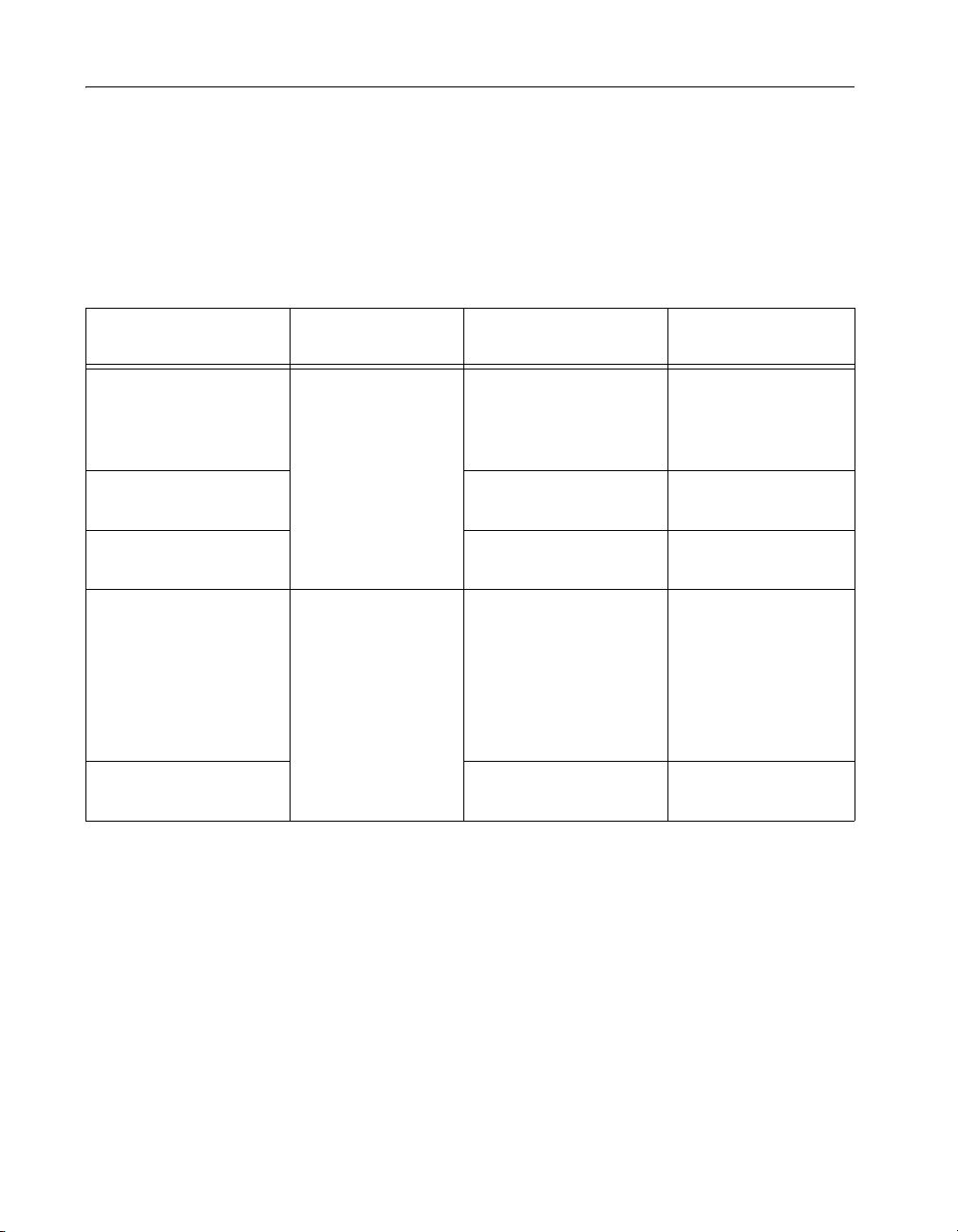

Table 1. Calibration File Locations

File Name and Location Description

IVI\Bin\niFgen_32.dll The NI-FGEN library, which provides the

functionality for calibrating the

NI PXI-5422.

IVI\Lib\msc\niFgen.lib Allows you to create applications that call

functions in the

niFgen_32.dll:

• For Microsoft Visual C/C++, link to

msc\niFgen.lib.

• For LabWindows/CVI, link to the library

appropriate to your current compatibility

mode (

msc for Microsoft Visual C/C++).

IVI\Include\niFgen.h A header file for the accessible functions in

the

niFgen_32.dll. You must include this

file in any C code that you write to call these

functions.

<LabVIEW>\instr.lib\niFgen\niFgen.llb

(LabVIEW)

IVI\Drivers\niFgen\niFgen.fp

(CVI)

The calibration process is described in the Self-Calibration Procedures and

the External Calibration Procedures sections, including step-by-step

instructions on calling the appropriate calibration functions.

Contains VIs that correspond to the functions

in the

niFgen_32.dll.

Contains the function panels for the function

in the

niFgen32.dll.

© National Instruments Corporation 5 NI PXI-5422 Calibration Procedure

Page 6

Documentation

For information about NI-FGEN and the NI PXI-5422, you may find the

following documents helpful:

• NI Signal Generators Getting Started Guide

• NI Signal Generators Help

• NI PXI-5422 Specifications

• NI-FGEN Instrument Driver Quick Reference Guide

The NI Signal Generators Getting Started Guide provides instructions for

installing and configuring NI signal generators.

The NI Signal Generators Help includes detailed information about

the NI PXI-5422 and the NI-FGEN functions. You can access this help file

by selecting Start»Programs»National Instruments»NI-FGEN»

Documentation»NI Signal Generators Help. For the latest versions

of NI documentation, refer to

Self-Calibration Procedures

The NI PXI-5422 is capable of performing self-calibration, which adjusts

the gain and offset of the main and direct analog paths. Self-calibration

exclusively uses an onboard A/D converter (ADC) to measure the output

voltage. You can implement self-calibration on the NI PXI-5422 by

following procedures similar to the Verifying the DC Gain and Offset

Accuracy and the Adjusting the Analog Output procedures. However,

output impedance, oscillator frequency, and the calibration ADC cannot be

adjusted during self-calibration.

ni.com/manuals.

You can initiate self-calibration interactively from Measurement &

Automation Explorer (MAX) or from the FGEN Soft Front Panel (SFP).

Alternately, you can initiate self-calibration programmatically using

NI-FGEN.

MAX

To initiate self-calibration from MAX, complete the following steps:

1. Launch MAX.

2. Select My System»Devices and Interfaces»NI-DAQmx Devices.

NI PXI-5422 Calibration Procedure 6 ni.com

Page 7

3. Select the device that you want to calibrate.

4. Initiate self-calibration in one of the following ways:

FGEN Soft Front Panel

To initiate self-calibration from the FGEN SFP, complete the following

steps:

1. Select the device that you want to calibrate using the Device

2. Open the Calibration dialog box (Utility»Calibration).

3. Click Perform self-calibration.

NI-FGEN

To self-calibrate the NI PXI-5422 programmatically using NI-FGEN,

complete the following steps:

1. Call

2. Call

3. Call

•Click Self-Calibrate in the upper right corner.

• Right-click the device name under Devices and Interfaces,

and select Self-Calibrate from the drop-down menu.

Configuration dialog box (Edit»Device Configuration).

niFgen_init (niFgen Initialize VI) to open an NI-FGEN session

using the following parameters:

• resourceName: The name of the device that you want to calibrate.

You can find this name under Devices and Interfaces in MAX.

• IDQuery:

• resetDevice: VI_TRUE

• vi: A pointer to a ViSession. The variable passed by reference

through this parameter receives the value that identifies the

session created by this function. This value acts as the session

handle and is passed as the first parameter to all subsequent

NI-FGEN functions.

niFgen_SelfCal (niFgen Self Cal VI) using the following

parameter:

• vi: The session handle returned from

niFgen_close (niFgen Close VI) to close the NI-FGEN session

using the following parameter:

• vi: The session handle returned from

VI_TRUE

niFgen_init

niFgen_init

© National Instruments Corporation 7 NI PXI-5422 Calibration Procedure

Page 8

External Calibration Options

External calibration involves both verification and adjustment. Verification

is the process of testing the device to ensure that the output accuracy is

within certain specifications. You can use verification to ensure that the

adjustment process was successful or to determine if the adjustment

process needs to be performed.

Adjustment is the process of measuring and compensating for device

performance to improve the output accuracy. Performing an adjustment

updates the calibration date, resetting the calibration interval. The device is

guaranteed to meet or exceed its published specifications for the duration

of the calibration interval.

This document provides two sets of test limits for most verification stages,

the calibration test limits and the published specifications. The calibration

test limits are more restrictive than the published specifications. If all of

the output errors determined during verification fall within the calibration

test limits, the device is guaranteed to meet or exceed its published

specifications for a full calibration interval (two years). For this reason,

you must verify against the calibration test limits when performing

verification after adjustment.

If all of the output errors determined during verification fall within the

published specifications, but not within the calibration test limits, the

device meets its published specifications. However, the device may not

remain within these specifications for another two years. The device will

meet published specifications for the rest of the current calibration interval.

In this case, you can perform an adjustment if you want to improve

the output accuracy or reset the calibration interval. If some output

errors determined during verification do not fall within the published

specifications, you must perform an adjustment to restore the device

operation to its published specifications.

The Complete Calibration section describes the recommended

calibration procedure. The Optional Calibration section describes

alternate procedures that allow you to skip adjustment if the device

already meets its calibration test limits or published specifications.

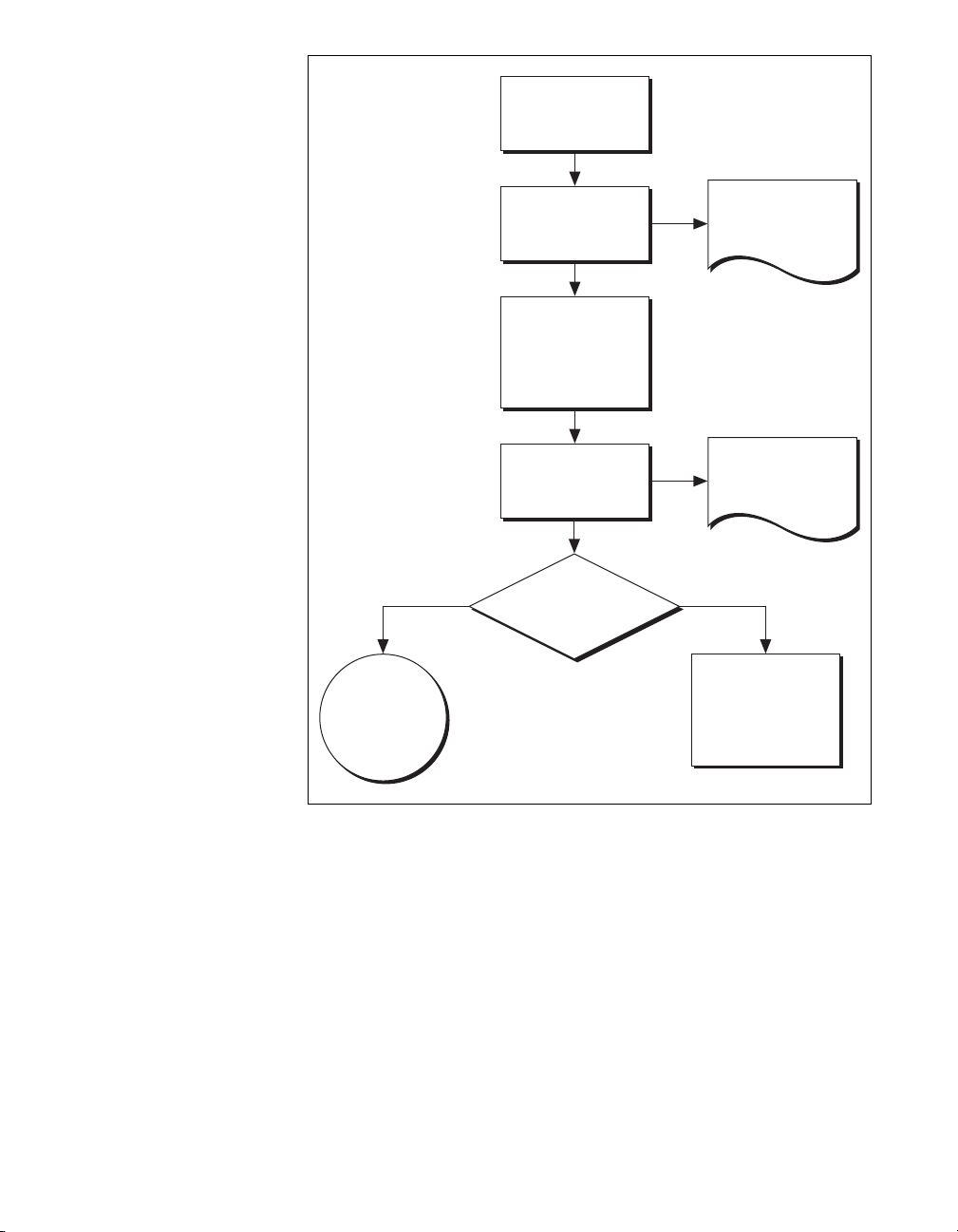

Complete Calibration

Performing a complete calibration is the recommended way to guarantee

that the NI PXI-5422 meets or exceeds its published specifications for a

two-year calibration interval. At the end of the complete calibration

procedure, you verify that the output error falls within the calibration test

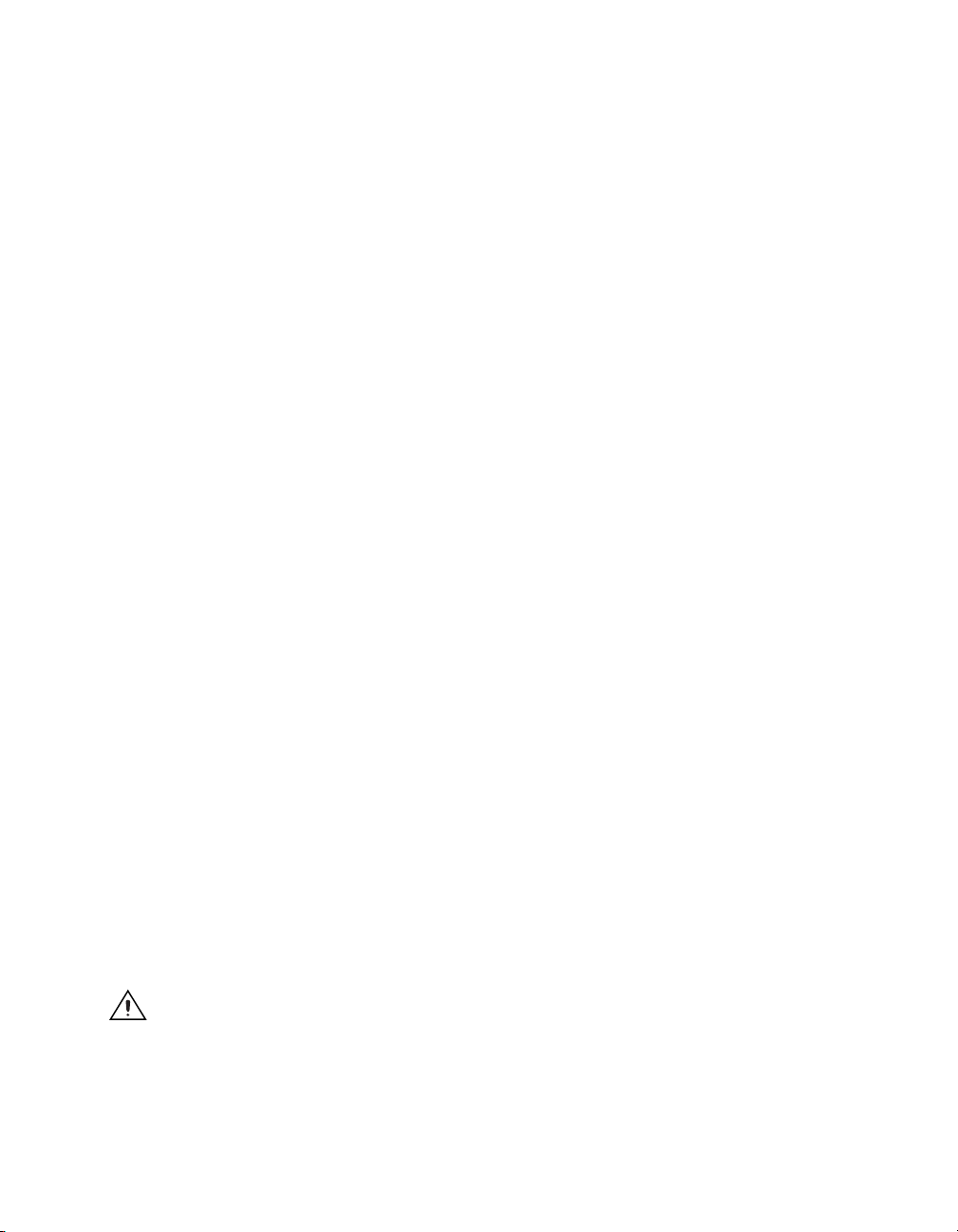

limits. Figure 1 shows the programming flow for complete calibration.

NI PXI-5422 Calibration Procedure 8 ni.com

Page 9

Self-Calibrate

Verify

Adjust

(Cal Dates and

Temperatures

Updated)

Verify

Document

Pre-Adjustment

Results

Document

Post-Adjustment

Results

Calibration/

Verification

Complete

Ye s N o

Meets

Calibration

Test Limits?

Review

Verification/

Adjustment

Procedure or

Return Device

Figure 1. Complete Calibration Programming Flow

© National Instruments Corporation 9 NI PXI-5422 Calibration Procedure

Page 10

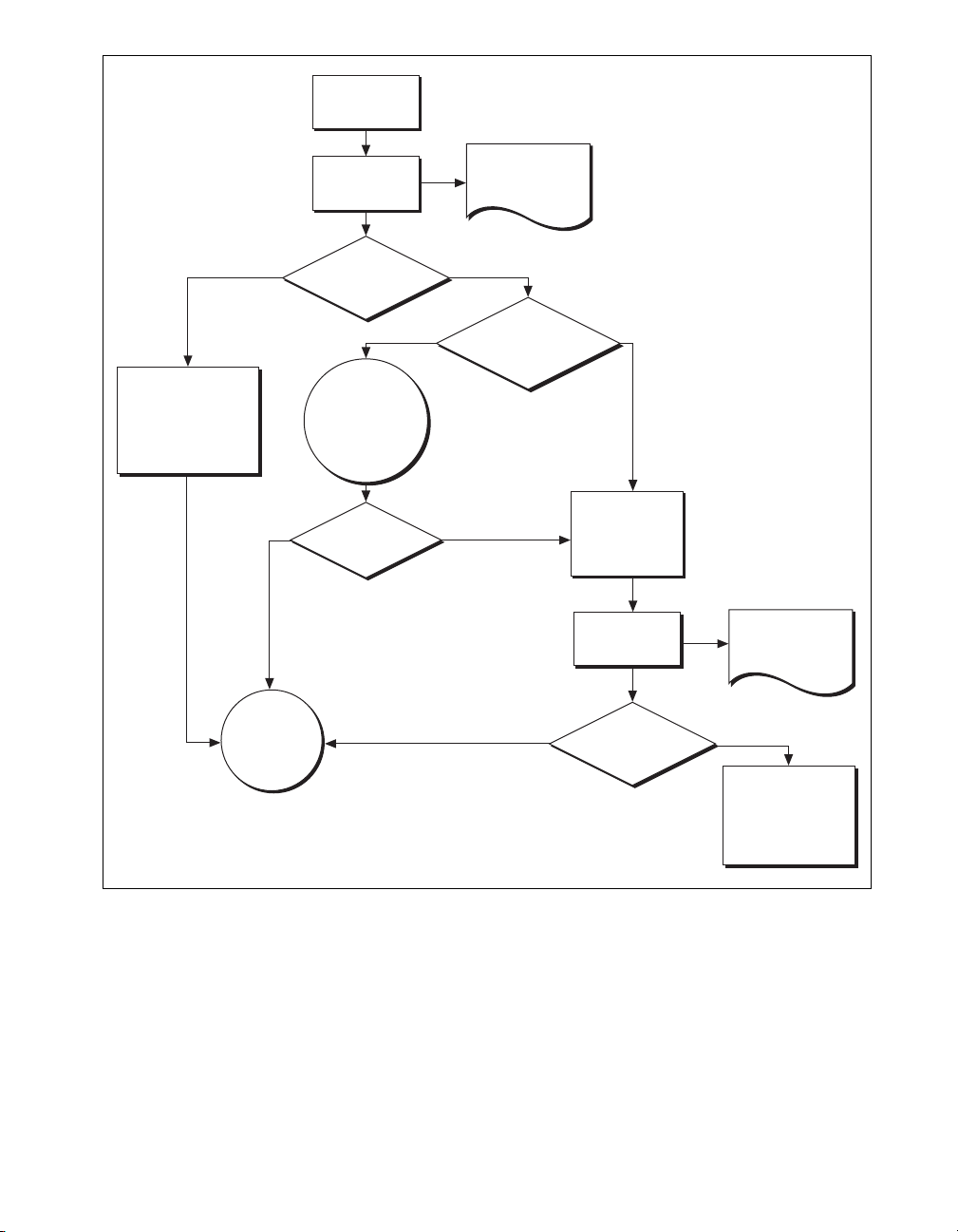

Optional Calibration

Note Regardless of the results of the first verification, if you choose to perform an

adjustment you must verify that the output error falls within the calibration test limits

at the end of the calibration procedure.

You can choose to skip the adjustment steps of the calibration procedure

if the output error is within the calibration test limits or the published

specifications during the first verification. If all of the output errors

determined during the first verification fall within the calibration test

limits, the device is guaranteed to meet or exceed its published

specifications for a full calibration interval. In this case, you can update

the calibration date, effectively resetting the calibration interval, without

actually performing an adjustment. Refer to the Adjusting the NI PXI-5422

section for more information.

If all of the output errors determined during the first verification fall within

the published specifications, but not within the calibration test limits,

adjustment is also optional. However, you cannot update the calibration

date because the device will not necessarily operate within the published

specifications for an additional two years.

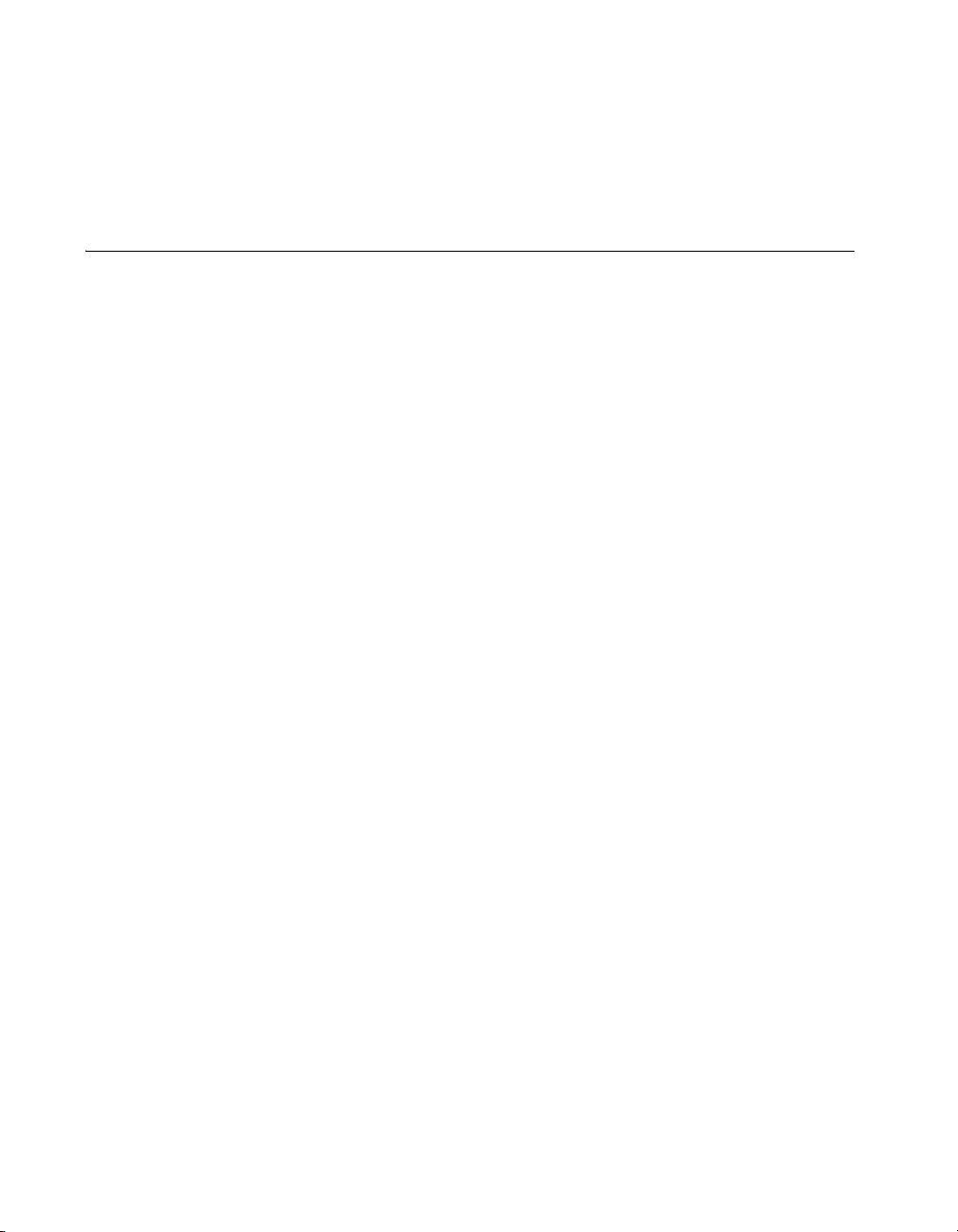

Figure 2 shows the programming flow for the optional calibration.

NI PXI-5422 Calibration Procedure 10 ni.com

Page 11

Self-Calibrate

Verify

Document

Pre-Adjustment

Results

Update Calibration

Dates and

Temperatures

Without Adjusting

Calibration/

Verification

Ye s N o

Complete

Meets

Calibration

Test Limits?

Ye s No

Results

Within

Published Specs

(Adjustment

Optional)

Adjust

Anyway?

Specifications?

Ye sNo

Meets

Published

Ye s

Adjust

(Cal Dates and

Temperatures

Updated)

Verify

Meets

Calibration

Test Limits?

Document

Post-Adjustment

Results

No

Review

Verification/

Adjustment

Procedure or

Return Device

Figure 2. Optional Calibration Programming Flow

© National Instruments Corporation 11 NI PXI-5422 Calibration Procedure

Page 12

External Calibration Requirements

This section describes the test equipment and test conditions required for

calibration.

Test Equipment

External calibration requires different equipment for each applicable

specification. Refer to Table 2 for a list of equipment.

Table 2. Equipment Required for Calibrating the NI PXI-5422

Instrument

Digital multimeter

(DMM)

Male banana to

female BNC adapter

Male BNC to

female SMB cable

Spectrum analyzer or

frequency meter

Male BNC to

female SMB cable

Test Conditions

Applicable

Specification

DC gain and offset DC accuracy ≤ ±50 ppm

Frequency accuracy Ability to measure

Follow these guidelines to optimize the connections and the environment

during calibration:

• Keep connections to the NI PXI-5422 short.

• Keep relative humidity below 80%.

• Maintain a temperature between 18 °C and 28 °C.

• Observe the 15-minute warm-up time.

Minimum

Specifications

Resolution ≤1 µV

— —

50 Ω, RG-223 —

10 MHz or higher

sine waves

Frequency accuracy

to ±500 ppb

50 Ω, RG-223 —

Recommended

Instrument

NI PXI-4070

Agilent HP 34401A

Keithley 2000

NI PXI-5660

Agilent HP 8560E

Agilent HP 53131A

or HP 53132A

with timebase option

001, 010, or 012

NI PXI-5422 Calibration Procedure 12 ni.com

Page 13

External Calibration Procedures

The complete external calibration procedure consists of self-calibrating,

verifying the performance of the NI PXI-5422, adjusting the calibration

constants, and verifying again after the adjustments. In some cases, the

complete calibration procedure may not be required. Refer to the External

Calibration Options section for more information.

The external calibration procedure automatically stores the calibration date

to allow traceability.

Writing Your Calibration Procedure

Before you begin to write your calibration program, review the

programming flows in Figures 1 and 2.

Calibration Procedures in LabVIEW

To write calibration procedures in LabVIEW, you must use the

VIs included in the

appear within the NI-FGEN Calibration palette under Functions»

Instrument I/O»Instruments Drivers»NI-FGEN»Calibration.

Calibration Procedures in LabWindows/CVI

To write calibration procedures in LabWindows/CVI, you must use the

functions included in the

the calibration functions under the Calibration class node.

niFgen.llb file. After installation, these VIs

niFgen.fp file. After installation, you can locate

Calibration Procedures in C

To write calibration procedures in C, you must include the niFgen.h

file in the code that calls the calibration functions, and you must link

the

niFgen.lib file into the build of your executable.

© National Instruments Corporation 13 NI PXI-5422 Calibration Procedure

Page 14

Verifying NI PXI-5422 Specifications

Note Always self-calibrate the NI PXI-5422 before beginning a verification procedure.

This section provides instructions for verifying the NI PXI-5422

specifications. This section also includes instructions for updating the

calibration cycle.

Verification determines whether the device is performing within its

specifications prior to external adjustment. Verification and external

adjustment together comprise a complete calibration. To verify that the

NI PXI-5422 still meets its specifications, you must use NI-FGEN to

control the NI PXI-5422.

The steps in the verification procedures describe the code that you use to

generate the appropriate signals, as well as the NI-FGEN function calls

that you make to verify specifications.

You can verify the following specifications for the NI PXI-5422:

• Oscillator frequency accuracy

• DC gain and offset accuracy

The verification procedure for each of these specifications includes setting

up, programming, and cleaning up.

Note If any of these tests fail immediately after you perform an external adjustment, verify

that you have met the required test conditions before you return the NI PXI-5422 to NI for

repair.

Refer to Table 2 for information about which instrument to use for

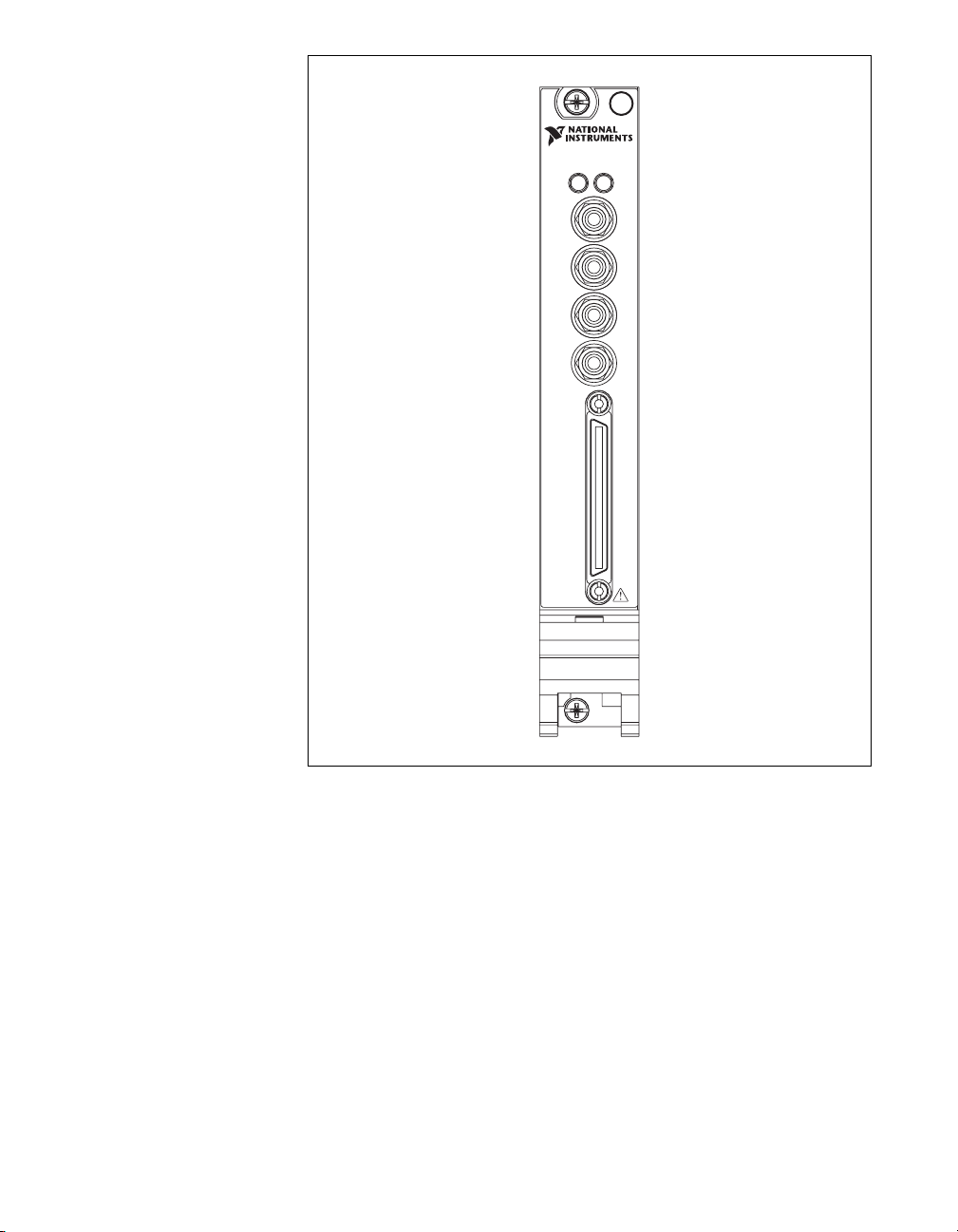

verifying each specification. Refer to Figure 3 for the names and locations

of the NI PXI-5422 front panel connectors.

NI PXI-5422 Calibration Procedure 14 ni.com

Page 15

NI PXI-5422

16-Bit 200 MS/s AWG

ACCESS ACTIVE

CH 0

CLK

IN

PFI 0

PFI 1

DIGITAL DATA & CONTROL

Figure 3. NI PXI-5422 Front Panel Connectors

© National Instruments Corporation 15 NI PXI-5422 Calibration Procedure

Page 16

Verifying the Oscillator Frequency Accuracy

This test verifies the frequency accuracy of the oscillator on the

NI PXI-5422. The verification involves generating a 10 MHz sine wave

with the NI PXI-5422 and measuring the sine wave frequency with one of

the instruments from Table 2.

To verify the frequency accuracy of the oscillator on the NI PXI-5422,

complete the following steps:

1. Connect the NI PXI-5422 CH 0 front panel connector to the instrument

measuring the frequency accuracy with a male BNC to female SMB

cable.

2. Call

3. Call

4. Call niFgen_SetAttributeViReal64 to set the gain (niFgen

niFgen_init (niFgen Initialize VI) using the following

parameters:

• resourceName: The name of the device that you want to verify.

You can find this name under Devices and Interfaces in MAX.

• IDQuery:

VI_TRUE

• resetDevice: VI_TRUE

• vi: A pointer to a ViSession. The variable passed by reference

through this parameter receives the value that identifies the

session created by this function. This value acts as the session

handle and is passed as the first parameter to all subsequent

NI-FGEN functions.

niFgen_SetAttributeViReal64 to set the sample rate

(niFgen property node: Arbitrary Waveform Output»Sample Rate)

using the following parameters:

• vi: The session handle returned from

niFgen_init

• channelName: "0"

• attributeID: NIFGEN_ATTR_ARB_SAMPLE_RATE

• value: 200000000

property node: Arbitrary Waveform Output»Arbitrary Waveform

Gain) using the following parameters:

• vi: The session handle returned from

niFgen_init

• channelName: "0"

• attributeID: NIFGEN_ATTR_ARB_GAIN

• value: 1

Note You can adjust this value based on which measuring device you use.

NI PXI-5422 Calibration Procedure 16 ni.com

Page 17

5. Call niFgen_SetAttributeViReal64 to set the offset (niFgen

property node: Arbitrary Waveform Output»Arbitrary Waveform

Offset) using the following parameters:

• vi: The session handle returned from

niFgen_init

• channelName: "0"

• attributeID: NIFGEN_ATTR_ARB_OFFSET

• value: 0

Note You can adjust this value based on which measuring device you use.

6. Call

niFgen_SetAttributeViBoolean to set the analog filter state

(niFgen property node: Output Attributes»Analog Filter Enabled)

using the following parameters:

• vi: The session handle returned from

niFgen_init

• channelName: "0"

• attributeID: NIFGEN_ATTR_ANALOG_FILTER_ENABLED

• value: VI_TRUE

7. Generate an array of waveform samples. The waveform should have

20 samples per cycle with a total of 500 samples. This configuration

results in 25 sine wave cycles. Because you set the sample rate to 200

MS/s and because you are using 20 samples per cycle, the resulting

waveform is a 10 MHz sine wave.

Note The sample values of this waveform must fall between –1.0 and 1.0.

8. Call

niFgen_CreateArbWaveform (niFgen Create Arbitrary

Waveform VI) using the following parameters:

• vi: The session handle returned from

• wfmSize: The size in samples (

niFgen_init

500) of the waveform you created

in step 7

• wfmData: The array of waveform samples that you created in

step 7

• wfmHandle: The variable passed by reference through this

parameter receives the value (waveform handle) that identifies

the waveform created by this function.

9. Call

niFgen_InitiateGeneration (niFgen Initiate Generation VI)

to initiate the waveform generation using the following parameter:

• vi: The session handle returned from

niFgen_init

10. Measure the frequency out of the NI PXI-5422.

© National Instruments Corporation 17 NI PXI-5422 Calibration Procedure

Page 18

A frequency error of 45 Hz for a 10 MHz signal corresponds to an

error of 4.5 ppm. This limit accounts for the initial accuracy and the

frequency deviation caused by temperature and aging. Refer to Table 3

for frequency ranges.

Table 3. Frequency Ranges

Calibration Test Limit Published Specifications ±25 ppm

Low High Low High

9,999,955 Hz 10,000,045 Hz 9,999,750 Hz 10,000,250 Hz

11. Call

niFgen_AbortGeneration (niFgen Abort Generation VI) to

abort the waveform generation using the following parameter:

• vi: The session handle returned from

niFgen_init

12. Call niFgen_close (niFgen Close VI) to close the instrument

driver session, to destroy the instrument driver session and all of

its properties, and to release any memory resources NI-FGEN uses.

Use the following parameter:

• vi: The session handle returned from

niFgen_init

Verifying the DC Gain and Offset Accuracy

This test verifies the DC gain and offset accuracy of the NI PXI-5422 into

a high-impedance load by generating a number of DC voltages and offsets,

measuring the voltage with a DMM, and comparing the NI PXI-5422 to the

error limits.

The DC gain and offset accuracy verification procedure has three

sub-procedures that verify the following:

• Main analog path gain

• Main analog path offset

• Direct path gain

Verifying the Main Analog Path Gain

To verify the gain of the NI PXI-5422 main analog path, complete the

following steps:

1. Connect the NI PXI-5422 CH 0 front panel connector to the DMM for

measuring DC gain and offset accuracy.

2. Call

niFgen_init (niFgen Initialize VI) using the following

parameters:

• resourceName: The name of the device that you want to verify.

You can find this name under Devices and Interfaces in MAX.

NI PXI-5422 Calibration Procedure 18 ni.com

Page 19

• IDQuery: VI_TRUE

• resetDevice: VI_TRUE

• vi: A pointer to a ViSession. The variable passed by reference

through this parameter receives the value that identifies the

session created by this function. This value acts as the session

handle and is passed as the first parameter to all subsequent

NI-FGEN functions.

3. Call

niFgen_SetAttributeViBoolean to set the analog filter state

(niFgen property node: Output Attributes»Analog Filter Enabled)

using the following parameters:

• vi: The session handle returned from

niFgen_init

• channelName: "0"

• attributeID: NIFGEN_ATTR_ANALOG_FILTER_ENABLED

• value: VI_FALSE

4. Call niFgen_SetAttributeViReal64 to set the load impedance

(niFgen property node: Output Attributes»Load Impedance)

using the following parameters:

• vi: The session handle returned from

niFgen_init

• channelName: "0"

• attributeID:

NIFGEN_ATTR_LOAD_IMPEDANCE

• value: 10000000000

5. Call niFgen_SetAttributeViInt32 to set the analog path (niFgen

property node: Output Attributes»Analog Path) using the following

parameters:

• vi: The session handle returned from

niFgen_init

• channelName: "0"

• attributeID: NIFGEN_ATTR_ANALOG_PATH

• value: NIFGEN_VAL_MAIN_ANALOG_PATH

6. Call niFgen_SetAttributeViReal64 to set the output impedance

(niFgen property node: Basic Operation»Output Impedance) using

the following parameters:

• vi: The session handle returned from

niFgen_init

• channelName: "0"

• attributeID: NIFGEN_ATTR_OUTPUT_IMPEDANCE

• value: 50

© National Instruments Corporation 19 NI PXI-5422 Calibration Procedure

Page 20

7. Call niFgen_SetAttributeViBoolean to enable the analog output

(niFgen property node: Basic Operation»Output Enabled) using

the following parameters:

• vi: The session handle returned from

niFgen_init

• channelName: "0"

• attributeID: NIFGEN_ATTR_OUTPUT_ENABLED

• value: VI_TRUE

8. Create an array of waveform samples for the positive full-scale DC

waveform. This array should contain 500 samples with each sample

having the value

9. Call

niFgen_CreateArbWaveform (niFgen Create Arbitrary

1.0 (representation: double).

Waveform VI) using the following parameters:

• vi: The session handle returned from

• wfmSize: The size in samples (

niFgen_init

500) of the waveform you created

in step 8

• wfmData: The array of waveform samples that you created in

step 8

• wfmHandle: The variable passed by reference through this

parameter receives the value (waveform handle) that identifies the

waveform created by this function (positive full-scale handle).

10. Create an array of waveform samples for the negative full-scale DC

waveform. This array should contain 500 samples with each sample

having the value

11. Call

niFgen_CreateArbWaveform (niFgen Create Arbitrary

–1.0 (representation: double).

Waveform VI) using the following parameters:

• vi: The session handle returned from

• wfmSize: The size in samples (

niFgen_init

500) of the waveform that you

created in step 10

• wfmData: The array of waveform samples that you created in

step 10

• wfmHandle: The variable passed by reference through this

parameter receives the value (waveform handle) that identifies the

waveform created by this function (negative full-scale handle).

NI PXI-5422 Calibration Procedure 20 ni.com

Page 21

12. Call niFgen_SetAttributeViReal64 to set the offset (niFgen

property node: Arbitrary Waveform Output»Arbitrary Waveform

Offset) using the following parameters:

• vi: The session handle returned from

niFgen_init

• channelName: "0"

• attributeID: NIFGEN_ATTR_ARB_OFFSET

• value: 0

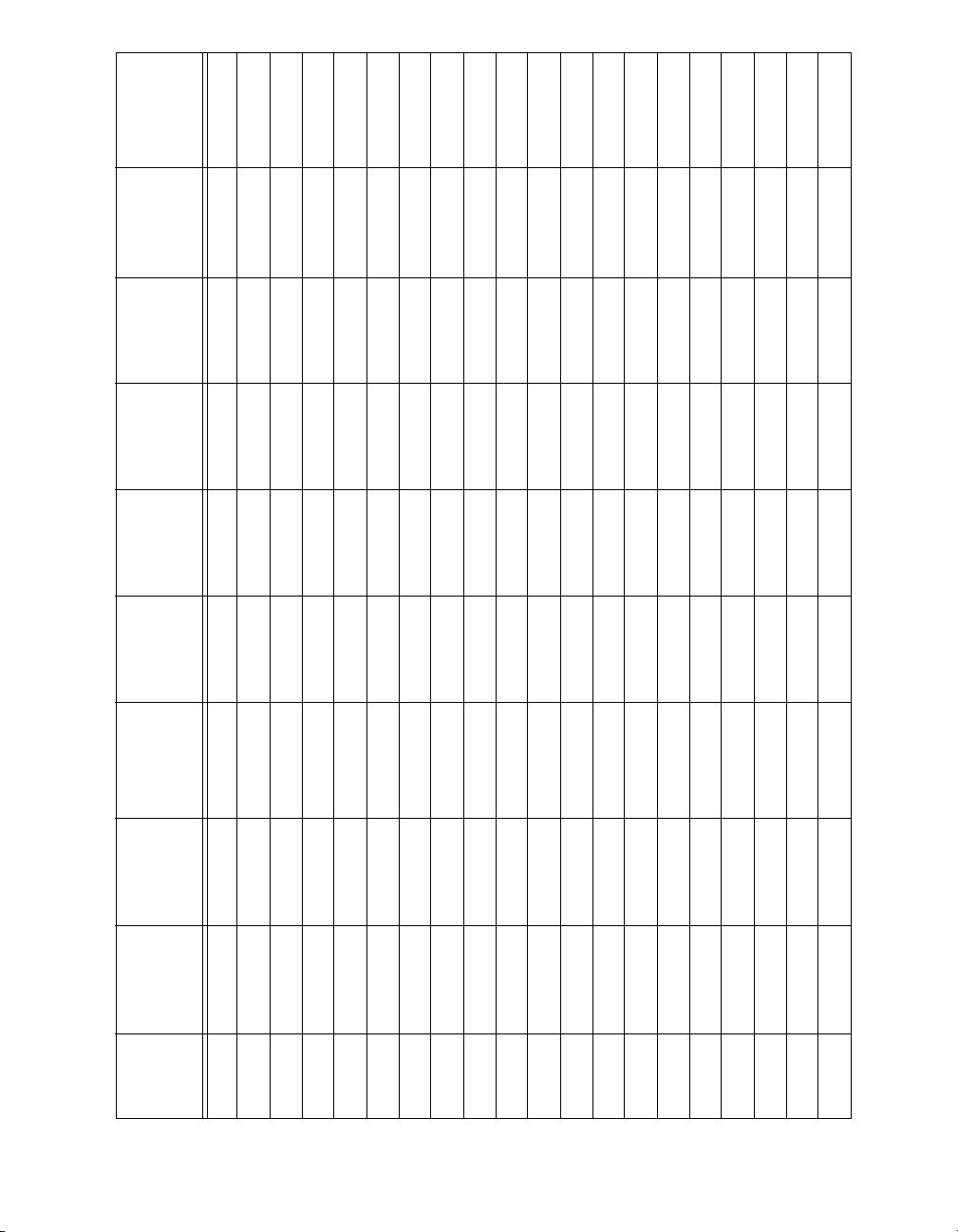

13. Repeat steps 14 through 24 for each of the 24 iterations listed in

Table 4, changing the Gain value for each iteration. You can use

Table 4 to record the results of these steps.

© National Instruments Corporation 21 NI PXI-5422 Calibration Procedure

Page 22

Spec

Published

Test Li mi t

Calibration

Error

Negative

Full-Scale

Error

Positive

Full-Scale

Negative

Measured

Full-Scale

Positive

Measured

Full-Scale

(Volts)

(Volts)

2

(Volts)

1

(Volts)

(Volts)

(Volts)

(Volts)

Ideal Negative

Ideal

Positive

Full-Scale

Full-Scale

(Volts)

1 12.000000 12.000000 –12.000000 ±0.019700 ±0.048500

2 10.000000 10.000000 –10.000000 ±0.016500 ±0.040500

3 7.000000 7.000000 –7.000000 ±0.011700 ±0.028500

4 5.000000 5.000000 –5.000000 ±0.008500 ±0.020500

5 3.500000 3.500000 –3.500000 ±0.006100 ±0.014500

6 2.500000 2.500000 –2.500000 ±0.004500 ±0.010500

7 2.000000 2.000000 –2.000000 ±0.003700 ±0.008500

8 1.650000 1.650000 –1.650000 ±0.003140 ±0.007100

9 1.250000 1.250000 –1.250000 ±0.002500 ±0.005500

10 0.850000 0.850000 – 0.850000 ±0.001860 ±0.003900

11 0.600000 0.600000 – 0.600000 ±0.001460 ±0.002900

12 0.415000 0.415000 – 0.415000 ±0.001164 ±0.002160

13 0.300000 0.300000 – 0.300000 ±0.000980 ±0.001700

14 0.205000 0.205000 – 0.205000 ±0.000828 ±0.001320

15 0.150000 0.150000 – 0.150000 ±0.000740 ±0.001100

16 0.105000 0.105000 – 0.105000 ±0.000668 ±0.000920

17 0.075000 0.075000 – 0.075000 ±0.000620 ±0.000800

18 0.055000 0.055000 – 0.055000 ±0.000588 ±0.000720

19 0.037500 0.037500 – 0.037500 ±0.000560 ±0.000650

Table 4. Values for Verifying the Gain of the Main Analog Path

Iteration Gain

NI PXI-5422 Calibration Procedure 22 ni.com

20 0.026000 0.026000 – 0.026000 ±0.000542 ±0.000604

Page 23

Spec

Published

Test Li mi t

Calibration

Error

Negative

Full-Scale

Error

Positive

Full-Scale

Negative

Measured

Full-Scale

Positive

Measured

Full-Scale

(Volts)

(Volts)

2

(Volts)

1

(Volts)

(Volts)

(Volts)

(Volts)

Full-Scale

Ideal Negative

Table 4. Values for Verifying the Gain of the Main Analog Path (Continued)

Ideal

(Volts)

Positive

Full-Scale

21 0.018500 0.018500 – 0.018500 ±0.000530 ±0.000574

22 0.013000 0.013000 – 0.013000 ±0.000521 ±0.000552

23 0.009000 0.009000 – 0.009000 ±0.000514 ±0.000536

24 0.006500 0.006500 – 0.006500 ±0.000510 ±0.000526

Iteration Gain

© National Instruments Corporation 23 NI PXI-5422 Calibration Procedure

1

Error Positive Full-Scale Value = (Measured Positive Full-Scale Value) – (Ideal Positive Full-Scale Value) 2 Error Negative Full-Scale Value = (Measured Negative Full-Scale Value) – (Ideal Negative Full-Scale Value)

Page 24

14. Call niFgen_SetAttributeViReal64 to set the gain (niFgen

property node: Arbitrary Waveform Output»Arbitrary Waveform

Gain) using the following parameters:

• vi: The session handle returned from

niFgen_init

• channelName: "0"

• attributeID: NIFGEN_ATTR_ARB_GAIN

• value: The Gain value listed in Table 4 for the current iteration

15. Call

niFgen_SetAttributeViInt32 to choose the positive

full-scale DC waveform (niFgen property node: Arbitrary

Waveform Output»Arbitrary Waveform Handle) using

the following parameters:

• vi: The session handle returned from

niFgen_init

• channelName: "0"

• attributeID: NIFGEN_ATTR_ARB_WAVEFORM_HANDLE

• value: The wfmHandle from step 9 (positive full-scale handle)

16. Call

niFgen_InitiateGeneration (niFgen Initiate Generation VI)

to initiate the waveform generation using the following parameter:

• vi: The session handle returned from

niFgen_init

17. Measure the DC voltage out of the NI PXI-5422. Record this value in

the Measured Positive Full-Scale value column of Table 4.

18. Subtract the Ideal Positive Full-Scale value from the Measured

Positive Full-Scale value and record the result under Error Positive

Full-Scale. The Error Positive Full-Scale value should be less than

or equal to the limit you are using.

19. Call

niFgen_AbortGeneration (niFgen Abort Generation VI) to

abort the waveform generation using the following parameter:

• vi: The session handle returned from

niFgen_init

20. Call niFgen_SetAttributeViInt32 to choose the negative

full-scale DC waveform (niFgen property node: Arbitrary

Waveform Output»Arbitrary Waveform Handle) using the

following parameters:

• vi: The session handle returned from

niFgen_init

• channelName: "0"

• attributeID: NIFGEN_ATTR_ARB_WAVEFORM_HANDLE

• value: The wfmHandle from step 11 (negative full-scale handle)

21. Call

niFgen_InitiateGeneration (niFgen Initiate Generation VI)

to initiate the waveform generation using the following parameter:

• vi: The session handle returned from

niFgen_init

22. Measure the DC voltage out of the NI PXI-5422. Record this value in

the Measured Negative Full-Scale column of Table 4.

NI PXI-5422 Calibration Procedure 24 ni.com

Page 25

23. Subtract the Ideal Negative Full-Scale value from the Measured

Negative Full-Scale value and record the result under Error Negative

Full-Scale. The Error Negative Full-Scale value should be less than

or equal to the limit you are using.

24. Call

niFgen_AbortGeneration (niFgen Abort Generation VI) to

abort the waveform generation using the following parameter:

• vi: The session handle returned from

niFgen_init

25. Return to step 14 until iterations are completed.

26. Verify that both the Error Positive Full-Scale value and the Error

Negative Full-Scale value are less than or equal to the limit you are

using. If either of the errors is greater than the Calibration Test Limit

or the Published Specification, perform an external adjustment.

Verifying the Main Analog Path Offset

To verify the offset of the NI PXI-5422 main analog path, complete the

following steps:

1. Create an array of waveform samples for the mid-scale DC waveform

(0 VDC). This array should contain 500 samples with each sample

having the value

2. Call

niFgen_CreateArbWaveform (niFgen Create Arbitrary

Waveform VI) using the following parameters:

• vi: The session handle returned from

• wfmSize: The size in samples (

created in step 1.

• wfmData: The array of waveform samples that you created in

step 1.

• wfmHandle: The variable passed by reference through this

parameter receives the value (waveform handle) that identifies

the waveform created by this function (mid-scale handle).

3. Call

niFgen_SetAttributeViInt32 to choose the mid-scale

handle DC waveform (niFgen property node: Arbitrary Waveform

Output»Arbitrary Waveform Handle) using the following

parameters:

• vi: The session handle returned from

• channelName: "0"

• attributeID: NIFGEN_ATTR_ARB_WAVEFORM_HANDLE

• value: The wfmHandle from step 2 (mid-scale handle)

4. Repeat steps 5 through 15 for each of the 24 iterations listed in Table 5,

changing the Ideal Positive Offset, Ideal Negative Offset, and Gain

values for each iteration. You can use Table 5 to record the results of

these steps.

0.0 (representation: double).

niFgen_init

500) of the waveform that you

niFgen_init

© National Instruments Corporation 25 NI PXI-5422 Calibration Procedure

Page 26

Spec

Published

Test Li mi t

Calibration

Error

Offset

Negative

Error

Offset

Positive

Offset

Negative

Measured

Offset

Positive

Measured

(Volts)

(Volts)

2

(Volts)

1

(Volts)

(Volts)

(Volts)

Ideal

Offset

(Volts)

Negative

Table 5. Values for Verifying the Offset of the Main Analog Path

Ideal

Offset

(Volts)

Positive

1 12.000000 6.000000 – 6.000000 ±0.021500 ±0.051500

2 10.000000 5.000000 –5.000000 ±0.018000 ±0.043000

3 7.000000 3.500000 –3.500000 ±0.012750 ±0.030250

4 5.000000 2.500000 –2.500000 ±0.009250 ±0.021750

5 3.500000 1.750000 –1.750000 ±0.006625 ±0.015375

6 2.500000 1.250000 –1.250000 ±0.004875 ±0.011125

7 2.000000 1.000000 –1.000000 ±0.004000 ±0.009000

8 1.650000 0.825000 – 0.825000 ±0.003388 ±0.007513

9 1.250000 0.625000 – 0.625000 ±0.002688 ±0.005813

10 0.850000 0.425000 – 0.425000 ±0.001988 ±0.004113

11 0.600000 0.300000 – 0.300000 ±0.001550 ±0.003050

12 0.415000 0.207500 – 0.207500 ±0.001226 ±0.002264

13 0.300000 0.150000 – 0.150000 ±0.001025 ±0.001775

14 0.205000 0.102500 – 0.102500 ±0.000859 ±0.001371

15 0.150000 0.075000 – 0.075000 ±0.000763 ±0.001138

16 0.105000 0.052500 – 0.052500 ±0.000684 ±0.000946

17 0.075000 0.037500 – 0.037500 ±0.000631 ±0.000819

18 0.055000 0.027500 – 0.027500 ±0.000596 ±0.000734

19 0.037500 0.018750 – 0.018750 ±0.000566 ±0.000659

Iteration Gain

NI PXI-5422 Calibration Procedure 26 ni.com

20 0.026000 0.013000 – 0.013000 ±0.000546 ±0.000611

Page 27

Spec

Published

Test Li mi t

Calibration

Error

Offset

Negative

Error

Offset

Positive

Offset

Negative

Measured

Offset

Positive

Measured

(Volts)

(Volts)

2

(Volts)

1

(Volts)

(Volts)

(Volts)

Ideal

Offset

(Volts)

Negative

Table 5. Values for Verifying the Offset of the Main Analog Path (Continued)

Ideal

Offset

(Volts)

Positive

21 0.018500 0.009250 – 0.009250 ±0.000532 ±0.000579

22 0.013000 0.006500 – 0.006500 ±0.000523 ±0.000555

23 0.009000 0.004500 – 0.004500 ±0.000516 ±0.000538

24 0.006500 0.003250 – 0.003250 ±0.000511 ±0.000528

Iteration Gain

© National Instruments Corporation 27 NI PXI-5422 Calibration Procedure

1

Error Positive Offset Value = (Measured Positive Offset Value) – (Ideal Positive Offset Value) 2 Error Negative Offset Value = (Measured Negative Offset Value) – (Ideal Negative Offset Value)

Page 28

5. Call niFgen_SetAttributeViReal64 to set the offset (niFgen

property node: Arbitrary Waveform Output»Arbitrary Waveform

Offset) using the following parameters:

• vi: The session handle returned from

niFgen_init

• channelName: "0"

• attributeID: NIFGEN_ATTR_ARB_OFFSET

• value: The Ideal Positive Offset value listed in Table 5 for the

current iteration

6. Call

niFgen_SetAttributeViReal64 to set the gain (niFgen

property node: Arbitrary Waveform Output»Arbitrary Waveform

Gain) using the following parameters:

• vi: The session handle returned from

niFgen_init

• channelName: "0"

• attributeID: NIFGEN_ATTR_ARB_GAIN

• value: The Gain value listed in Table 5 for the current iteration

7. Call

niFgen_InitiateGeneration (niFgen Initiate Generation VI)

to initiate the waveform generation using the following parameter:

• vi: The session handle returned from

niFgen_init

8. Measure the positive DC voltage out of the NI PXI-5422. Record the

positive DC voltage out measurement in the Measured Positive

Offset column of Table 5.

9. Subtract the Ideal Positive Offset from the Measured Positive Offset

and record the result under Error Positive Offset. The Error Positive

Offset should be less than or equal to the limit you are using.

10. Call

niFgen_AbortGeneration (niFgen Abort Generation VI) to

abort the waveform generation using the following parameter:

• vi: The session handle returned from

niFgen_init

11. Call niFgen_SetAttributeViReal64 to set the offset (niFgen

property node: Arbitrary Waveform Output»Arbitrary

Waveform Offset) using the following parameters:

• vi: The session handle returned from

niFgen_init

• channelName: "0"

• attributeID: NIFGEN_ATTR_ARB_OFFSET

• value: The Ideal Negative Offset value listed in Table 5 for the

current iteration

12. Call

niFgen_InitiateGeneration (niFgen Initiate Generation VI)

to initiate the waveform generation using the following parameter:

• vi: The session handle returned from

niFgen_init

NI PXI-5422 Calibration Procedure 28 ni.com

Page 29

13. Measure the negative DC voltage out of the NI PXI-5422. Record

negative DC voltage out measurement in the Measured Negative Offset

column of Table 5.

14. Subtract the Ideal Negative Offset from the Measured Negative Offset

and record the result under Error Negative Offset. The Error Negative

Offset should be less than or equal to the limit you are using.

15. Call

niFgen_AbortGeneration (niFgen Abort Generation VI) to

abort the waveform generation using the following parameter:

• vi: The session handle returned from

16. Return to step 5 until all iterations are completed.

17. Verify that all errors are less than or equal to the limit you are using.

If any of the errors are greater than the Calibration Test Limit or the

Published Specification, perform an external adjustment.

Verifying the Gain of the Direct Path

To verify the gain of the NI PXI-5422 Direct path, complete the following

steps:

Note The offset is not adjustable for the Direct path.

niFgen_init

1. Call

niFgen_SetAttributeViReal64 to set the offset (niFgen

property node: Arbitrary Waveform Output»Arbitrary

Waveform Offset) using the following parameters:

• vi: The session handle returned from

niFgen_init

• channelName: "0"

• attributeID: NIFGEN_ATTR_ARB_OFFSET

• value: 0

2. Call niFgen_SetAttributeViInt32 to set the analog path (niFgen

property node: Output Attributes»Analog Path) using the following

parameters:

• vi: The session handle returned from

niFgen_init

• channelName: "0"

• attributeID: NIFGEN_ATTR_ANALOG_PATH

• value: NIFGEN_VAL_DIRECT_ANALOG_PATH

3. Repeat steps 4 through 15 for each of the seven iterations listed

in Table 6, changing the Gain value for each iteration. You can use

Table 6 to record the results of these steps.

© National Instruments Corporation 29 NI PXI-5422 Calibration Procedure

Page 30

Error

Error

Measured

Spec

Published

Test Li mi t

Calibration

3

Negative

Full-Scale

2

Positive

Full-Scale

Limit

Offset

1

Offset

Negative

Full-Scale

(Volts)

(Volts)

(Volts)

(Volts)

(Volts)

(Volts)

(Volts)

(Volts)

Positive

Measured

Full-Scale

Table 6. Values for Verifying the Gain of the Direct Analog Path

Ideal

(Volts)

Negative

Full-Scale

Ideal

(Volts)

Positive

Full-Scale

1 1.000000 1.000000 –1.000000 ±0.025000 ±0.001600 ±0.004000

2 0.950000 0.950000 – 0.950000 ±0.025000 ±0.001520 ±0.003800

3 0.900000 0.900000 – 0.900000 ±0.025000 ±0.001440 ±0.003600

4 0.850000 0.850000 – 0.850000 ±0.025000 ±0.001360 ±0.003400

5 0.800000 0.800000 – 0.800000 ±0.025000 ±0.001280 ±0.003200

6 0.750000 0.750000 – 0.750000 ±0.025000 ±0.001200 ±0.003000

7 0.710000 0.710000 – 0.710000 ±0.025000 ±0.001136 ±0.002840

Iteration Gain

NI PXI-5422 Calibration Procedure 30 ni.com

Offset = ((Measured Positive Full-Scale Value) + (Measured Negative Full-Scale Value))/2 2 Error Positive Full-Scale Value = (Measured Positive Full-Scale Value) – Offset – (Ideal Positive Full-Scale Value) 3 Error Negative Full-Scale Value = (Measured Negative Full-Scale Value) – Offset – (Ideal Negative Full-Scale Value)

1

Page 31

4. Call niFgen_SetAttributeViReal64 to set the gain (niFgen

property node: Arbitrary Waveform Output»Arbitrary

Waveform Gain) using the following parameters:

• vi: The session handle returned from

niFgen_init

• channelName: "0"

• attributeID: NIFGEN_ATTR_ARB_GAIN

• value: The Gain value listed in Table 6 for the current iteration

5. Call

niFgen_SetAttributeViInt32 to choose the positive

full-scale DC waveform (niFgen property node: Arbitrary

Waveform Output»Arbitrary Waveform Handle) using

the following parameters:

• vi: The session handle returned from

niFgen_init

• channelName: "0"

• attributeID: NIFGEN_ATTR_ARB_WAVEFORM_HANDLE

• value: The wfmHandle from step 9 of the Verifying the Main

Analog Path Gain section (positive full-scale handle)

6. Call

niFgen_InitiateGeneration (niFgen Initiate Generation VI)

to initiate the waveform generation using the following parameter:

• vi: The session handle returned from

niFgen_init

7. Measure the positive DC voltage out of the NI PXI-5422. Record the

positive DC voltage out measurement in the Measured Positive

Full-Scale Value column of Table 6.

8. Call

niFgen_AbortGeneration (niFgen Abort Generation VI)

to abort the waveform generation using the following parameter:

• vi: The session handle returned from

niFgen_init

9. Call niFgen_SetAttributeViInt32 to choose the negative

full-scale DC waveform (niFgen property node: Arbitrary

Waveform Output»Arbitrary Waveform Handle) using

the following parameters:

• vi: The session handle returned from

niFgen_init

• channelName: "0"

• attributeID: NIFGEN_ATTR_ARB_WAVEFORM_HANDLE

• value: The wfmHandle from step 11 of the Verifying the Main

Analog Path Gain section (negative full-scale handle)

10. Call

niFgen_InitiateGeneration (niFgen Initiate Generation VI)

to initiate the waveform generation using the following parameter:

• vi: The session handle returned from

niFgen_init

© National Instruments Corporation 31 NI PXI-5422 Calibration Procedure

Page 32

11. Measure the negative DC voltage out of the NI PXI-5422. Record the

negative DC voltage out measurement in the Measured Negative

Full-Scale Value column of Table 6.

12. Call

niFgen_AbortGeneration (niFgen Abort Generation VI) to

abort the waveform generation using the following parameter:

• vi: The session handle returned from

niFgen_init

13. Average the Measured Positive Full-Scale Value and Measured

Negative Full-Scale Value to calculate the Offset.

14. Verify that the Offset is less than or equal to the Offset Limit listed in

Table 6 for the current iteration.

15. Subtract the Offset and the Ideal Full-Scale Value from the Measured

Full-Scale Value to get the Error Full-Scale Value for both the positive

and negative settings, respectively.

16. Return to step 4 until all iterations are completed.

17. Verify that these errors are less than or equal to the limits you are using.

If any of the errors are greater than the Calibration Test Limit or the

Published Specification, perform an external adjustment.

18. Call

niFgen_close (niFgen Close VI) to close the instrument driver

session, to destroy the instrument driver session and all of its

properties, and to release any memory resources that NI-FGEN

uses. Use the following parameter:

• vi: The session handle returned from

niFgen_init

Adjusting the NI PXI-5422

If the NI PXI-5422 successfully passes all verification within the

calibration test limits, adjustment is recommended, but not required, to

guarantee its published specifications for the next two years. If the

NI PXI-5422 was not within the calibration test limits for each verification

procedure, perform the adjustment procedure to improve the accuracy of

the NI PXI-5422. Refer to the External Calibration Options section to

determine which procedures to perform.

An adjustment is required only once every two years. The adjustment

procedure automatically updates the calibration date and temperature in

the EEPROM of the NI PXI-5422.

If the NI PXI-5422 passed verification within the calibration test limits and

you do not want to do an adjustment, you can update the calibration date

and onboard calibration temperature without making any adjustments by

completing the following steps:

NI PXI-5422 Calibration Procedure 32 ni.com

Page 33

1. Call niFgen_InitExtCal (niFgen Init Ext Cal VI) to open an

NI-FGEN external calibration session using the following parameters:

• resourceName: The name of the device you want to calibrate.

This name can be found under Devices and Interfaces in MAX.

• password: The password required to open an external

calibration session. If this password has not been changed

since manufacturing, the password is

NI.

• vi: A pointer to a ViSession. The variable passed by reference

through this parameter receives the value that identifies the

external calibration session created by this function. This value

acts as the session handle and is passed as the first parameter to

all subsequent NI-FGEN functions.

2. Call

niFgen_CloseExtCal (niFgen Close Ext Cal VI) using the

following parameters:

• vi: The session handle returned from

• action:

NIFGEN_VAL_EXT_CAL_COMMIT

niFgen_InitExtCal

The external calibration procedure adjusts the analog output, the oscillator

frequency, and the calibration ADC. Analog output adjustment

characterizes the DC gains and the offsets of the analog path to ensure

the analog output voltage accuracy. Adjusting the oscillator frequency

adjusts the onboard oscillator to ensure frequency accuracy. Calibration

ADC adjustment characterizes the onboard ADC gain and offset so that

self-calibration results in an accurately calibrated device.

You cannot perform an external calibration using a standard NI-FGEN

session. You must create an external calibration session using

niFgen_InitExtCal (niFgen Init Ext Cal VI). An external calibration

session allows you to use NI-FGEN functions and attributes that are

specifically for external calibration, while still allowing you to use all

the standard NI-FGEN functions and attributes with the external calibration

session.

Along with the standard NI-FGEN attributes, the external calibration

session uses a set of calibration constants that are determined during the

calibration procedure and stored in the device onboard memory when

the session is closed. NI-FGEN uses these calibration constants during

a standard NI-FGEN session to ensure that the device operates within its

specifications.

You must close an external calibration session by using

niFgen_CloseExtCal (niFgen Close Ext Cal VI), as shown in Figure 4.

© National Instruments Corporation 33 NI PXI-5422 Calibration Procedure

Page 34

Initialize Ext Cal Session

Initialize Analog Output Calibration

Adjust Main Path Pre-Amp Offset

Adjust Main Path Pre-Amp Gain

Adjust Main Path Post-Amp

Gain and Offset

Adjust Direct Path Gain

Initialize Oscillator

Frequency Calibration

Adjust Oscillator Frequency

Initialize Calibration

ADC Calibration

Adjust Calibration ADC

Close Ext Cal Session

Figure 4. NI PXI-5422 External Calibration Procedure

NI PXI-5422 Calibration Procedure 34 ni.com

Page 35

Initializing the External Calibration Session

Call niFgen_InitExtCal (niFgen Init Ext Cal VI) to open an NI-FGEN

external calibration session using the following parameters:

• resourceName: The name of the device you want to calibrate.

This name can be found under Devices and Interfaces in MAX.

• password: The password required to open an external calibration

session. If this password has not been changed since manufacturing,

the password is

• vi: A pointer to a ViSession. The variable passed by reference through

this parameter receives the value that identifies the external calibration

session created by this function. This value acts as the session handle

and is passed as the first parameter to all subsequent NI-FGEN

functions.

NI.

Adjusting the Analog Output

The analog output adjustment procedure has several sub-procedures that

adjust the following:

• Main path pre-amplifier offset

• Main path pre-amplifier gain

• Main path post-amplifier gain and offset

• Direct path gain

In each of these sub-procedures, you put the device in several

configurations and take several output measurements. You then pass

these measurements to NI-FGEN, which determines the calibration

constants for the device.

Initializing Analog Output Calibration

1. Call niFgen_InitializeAnalogOutputCalibration (niFgen

Initialize Analog Output Calibration VI) using the following

parameter:

• vi: The session handle returned from

2. Call

© National Instruments Corporation 35 NI PXI-5422 Calibration Procedure

niFgen_WriteBinary16AnalogStaticValue (niFgen Write

Binary 16 Analog Static Value VI) to set the main DAC value using

the following parameters:

• vi: The session handle returned from

• channelName: "0"

• value: 0

niFgen_InitExtCal

niFgen_InitExtCal

Page 36

3. Call niFgen_SetAttributeViInt32 to set the analog path value

(niFgen property node: Output Attributes»Analog Path) using

the following parameters:

• vi: The session handle returned from

niFgen_InitExtCal

• channelName: "0"

• attributeID: NIFGEN_ATTR_ANALOG_PATH

• value: NIFGEN_VAL_FIXED_LOW_GAIN_ANALOG_PATH

4. Call niFgen_SetAttributeViInt32 to set the gain DAC value

(niFgen property node: Calibration»Gain DAC Value) using the

following parameters:

• vi: The session handle returned from

niFgen_InitExtCal

• channelName: "0"

• attributeID: NIFGEN_ATTR_GAIN_DAC_VALUE

• value: 2000

5. Call niFgen_SetAttributeViInt32 to set the offset DAC value

(niFgen property node: Calibration»Offset DAC Value) using the

following parameters:

• vi: The session handle returned from

niFgen_InitExtCal

• channelName: "0"

• attributeID: NIFGEN_ATTR_OFFSET_DAC_VALUE

• value: 32767

6. Call niFgen_SetAttributeViBoolean to set the analog filter state

(niFgen property node: Output Attributes»Analog Filter Enabled)

using the following parameters:

• vi: The session handle returned from

niFgen_InitExtCal

• channelName: "0"

• attributeID: NIFGEN_ATTR_ANALOG_FILTER_ENABLED

• value: VI_FALSE

7. Call niFgen_SetAttributeViReal64 to set the pre-amplifier

attenuation (niFgen property node: Calibration»Pre-Amplifier

Attenuation) using the following parameters:

• vi: The session handle returned from

niFgen_InitExtCal

• channelName: "0"

• attributeID: NIFGEN_ATTR_PRE_AMPLIFIER_ATTENUATION

• value: 0

NI PXI-5422 Calibration Procedure 36 ni.com

Page 37

8. Call niFgen_SetAttributeViReal64 to set the post-amplifier

attenuation (niFgen property node: Calibration»Post-Amplifier

Attenuation) using the following parameters:

• vi: The session handle returned from

niFgen_InitExtCal

• channelName: "0"

• attributeID: NIFGEN_ATTR_POST_AMPLIFIER_ATTENUATION

• value: 0

9. Call niFgen_SetAttributeViReal64 to set the output impedance

(niFgen property node: Basic Operation»Output Impedance) using

the following parameters:

• vi: The session handle returned from

niFgen_InitExtCal

• channelName: "0"

• attributeID: NIFGEN_ATTR_OUTPUT_IMPEDANCE

• value: 50

10. Call niFgen_SetAttributeViBoolean to enable the analog output

(niFgen property node: Basic Operation»Output Enabled) using

the following parameters:

• vi: The session handle returned from

niFgen_InitExtCal

• channelName: "0"

• attributeID: NIFGEN_ATTR_OUTPUT_ENABLED

• value: VI_TRUE

11. Call niFgen_Commit (niFgen Commit VI) to commit the attribute

values to the device using the following parameter:

• vi: The session handle returned from

niFgen_InitExtCal

Adjusting the Main Path Pre-Amplifier Offset

1. Call niFgen_SetAttributeViInt32 to set the analog path value

(niFgen property node: Output Attributes»Analog Path) using

the following parameters:

• vi: The session handle returned from

• channelName: "0"

• attributeID: NIFGEN_ATTR_ANALOG_PATH

• value: NIFGEN_VAL_FIXED_LOW_GAIN_ANALOG_PATH

© National Instruments Corporation 37 NI PXI-5422 Calibration Procedure

niFgen_InitExtCal

Page 38

2. Call niFgen_SetAttributeViReal64 to set the post-amplifier

attenuation (niFgen property node: Calibration»Post-Amplifier

Attenuation) using the following parameters:

• vi: The session handle returned from

niFgen_InitExtCal

• channelName: "0"

• attributeID: NIFGEN_ATTR_POST_AMPLIFIER_ATTENUATION

• value: 0

3. Call niFgen_WriteBinary16AnalogStaticValue (niFgen Write

Binary 16 Analog Static Value VI) to set the main DAC value using

the following parameters:

• vi: The session handle returned from

• channelName:

"0"

niFgen_InitExtCal

• value: 0

4. Repeat steps 5 through 8 for each of the 10 iterations listed in Table 7,

changing the Analog Filter Enable, Pre-Amplifier Attenuation, and

Current Configuration values for each iteration.

Table 7. Attributes and Values for Main Path Pre-Amplifier Offset

Analog Filter

Iteration

1 VI_FALSE 0 NIFGEN_VAL_CAL_CONFIG_MAIN_PATH_FILTER_OFF_0DB

2 VI_FALSE 3 NIFGEN_VAL_CAL_CONFIG_MAIN_PATH_FILTER_OFF_3DB

3 VI_FALSE 6 NIFGEN_VAL_CAL_CONFIG_MAIN_PATH_FILTER_OFF_6DB

4 VI_FALSE 9 NIFGEN_VAL_CAL_CONFIG_MAIN_PATH_FILTER_OFF_9DB

5 VI_FALSE 12 NIFGEN_VAL_CAL_CONFIG_MAIN_PATH_FILTER_OFF_12DB

6 VI_TRUE 0 NIFGEN_VAL_CAL_CONFIG_MAIN_PATH_FILTER_ON_0DB

7 VI_TRUE 3 NIFGEN_VAL_CAL_CONFIG_MAIN_PATH_FILTER_ON_3DB

8 VI_TRUE 6 NIFGEN_VAL_CAL_CONFIG_MAIN_PATH_FILTER_ON_6DB

9 VI_TRUE 9 NIFGEN_VAL_CAL_CONFIG_MAIN_PATH_FILTER_ON_9DB

10 VI_TRUE 12 NIFGEN_VAL_CAL_CONFIG_MAIN_PATH_FILTER_ON_12DB

Enable

Pre-Amplifier

Attenuation

Current Configuration

NI PXI-5422 Calibration Procedure 38 ni.com

Page 39

5. Call niFgen_SetAttributeViBoolean to set the analog filter state

(niFgen property node: Output Attributes»Analog Filter Enabled)

using the following parameters:

• vi: The session handle returned from

niFgen_InitExtCal

• channelName: "0"

• attributeID: NIFGEN_ATTR_ANALOG_FILTER_ENABLED

• value: The Analog Filter Enable value for the current iteration

from Table 7.

6. Call

niFgen_SetAttributeViReal64 to set the pre-amplifier

attenuation (niFgen property node: Calibration»Pre-Amplifier

Attenuation) using the following parameters:

• vi: The session handle returned from

niFgen_InitExtCal

• channelName: "0"

• attributeID: NIFGEN_ATTR_PRE_AMPLIFIER_ATTENUATION

• value: The Pre-Amplifier Attenuation value for the current

iteration from Table 7.

7. Take the following voltage measurements at the NI PXI-5422 CH 0

front panel connector into a high-impedance load:

a. Call

niFgen_SetAttributeViInt32 to set the gain DAC value

(niFgen property node: Calibration»Gain DAC Value) using the

following parameters:

• vi: The session handle returned from

niFgen_InitExtCal

• channelName: "0"

• attributeID: NIFGEN_ATTR_GAIN_DAC_VALUE

• value: 2000

b. Call niFgen_SetAttributeViInt32 to set the offset DAC

value (niFgen property node: Calibration»Offset DAC Value)

using the following parameters:

• vi: The session handle returned from

niFgen_InitExtCal

• channelName: "0"

• attributeID: NIFGEN_ATTR_OFFSET_DAC_VALUE

• value: 50000

c. Call niFgen_Commit (niFgen Commit VI) to commit the

attribute values to the device using the following parameter:

• vi: The session handle returned from

niFgen_InitExtCal

d. Wait 500 ms for the output to settle.

e. Use the DMM to measure the voltage output by the device. This

measurement is

measurement 0, which is used in step 8.

© National Instruments Corporation 39 NI PXI-5422 Calibration Procedure

Page 40

f. Call niFgen_SetAttributeViInt32 to set the gain DAC value

(niFgen property node: Calibration»Gain DAC Value) using the

following parameters:

• vi: The session handle returned from

niFgen_InitExtCal

• channelName: "0"

• attributeID: NIFGEN_ATTR_GAIN_DAC_VALUE

• value: 1000

g. Call niFgen_Commit (niFgen Commit VI) to commit the

attribute values to the device using the following parameter:

• vi: The session handle returned from

niFgen_InitExtCal

h. Wait 500 ms for the output to settle.

i. Use the DMM to measure the voltage output by the device. This

measurement is

j. Call

niFgen_SetAttributeViInt32 to set the offset DAC

measurement 1, which is used in step 8.

value (niFgen property node: Calibration»Offset DAC Value)

using the following parameters:

• vi: The session handle returned from

niFgen_InitExtCal

• channelName: "0"

• attributeID: NIFGEN_ATTR_OFFSET_DAC_VALUE

• value: 15000

k. Call niFgen_Commit (niFgen Commit VI) to commit the

attribute values to the device using the following parameter:

• vi: The session handle returned from

niFgen_InitExtCal

l. Wait 500 ms for the output to settle.

m. Use the DMM to measure the voltage output of the device. This

measurement is

measurement 2, which is used in step 8.

NI PXI-5422 Calibration Procedure 40 ni.com

Page 41

8. Call niFgen_CalAdjustMainPathPreAmpOffset (niFgen Cal

Adjust Main Path Pre Amp Offset VI) using the following parameters:

• vi: The session handle returned from

niFgen_InitExtCal

• channelName: "0"

• configuration: The Current Configuration value for the current

iteration from Table 7.

• gainDACValues: An array containing two elements—the two

values (

2000, 1000) that you set as the gain DAC in the order that

you measured them.

• offsetDACValues: An array containing two elements—the two

values (

50000, 15000) that you set as the offset DAC in the order

that you measured them.

• measuredOutputs: An array containing three elements—the

three output voltages (

measurement 2) that you measured in the order that you

measurement 0, measurement 1,

measured them.

Adjusting the Main Path Pre-Amplifier Gain

1. Call niFgen_SetAttributeViInt32 to set the analog path value

(niFgen property node: Output Attributes»Analog Path) using the

following parameters:

• vi: The session handle returned from

• channelName: "0"

• attributeID: NIFGEN_ATTR_ANALOG_PATH

• value: NIFGEN_VAL_FIXED_LOW_GAIN_ANALOG_PATH

2. Call niFgen_SetAttributeViReal64 to set the post-amplifier

attenuation (niFgen property node: Calibration»Post-Amplifier

Attenuation) using the following parameters:

• vi: The session handle returned from

• channelName: "0"

• attributeID: NIFGEN_ATTR_POST_AMPLIFIER_ATTENUATION

• value: 0

niFgen_InitExtCal

niFgen_InitExtCal

© National Instruments Corporation 41 NI PXI-5422 Calibration Procedure

Page 42

3. Call niFgen_SetAttributeViInt32 to set the offset DAC value

(niFgen property node: Calibration»Offset DAC Value) using the

following parameters:

• vi: The session handle returned from

niFgen_InitExtCal

• channelName: "0"

• attributeID: NIFGEN_ATTR_OFFSET_DAC_VALUE

• value: 32000

4. Repeat steps 5 through 8 for each of the 10 iterations listed in Table 8,

changing the Analog Filter Enable, Pre-Amplifier Attenuation, and

Current Configuration values for each iteration.

Table 8. Attributes and Values for Main Path Pre-Amplifier Gain

Analog Filter

Iteration

1 VI_FALSE 0 NIFGEN_VAL_CAL_CONFIG_MAIN_PATH_FILTER_OFF_0DB

2 VI_FALSE 3 NIFGEN_VAL_CAL_CONFIG_MAIN_PATH_FILTER_OFF_3DB

3 VI_FALSE 6 NIFGEN_VAL_CAL_CONFIG_MAIN_PATH_FILTER_OFF_6DB

4 VI_FALSE 9 NIFGEN_VAL_CAL_CONFIG_MAIN_PATH_FILTER_OFF_9DB

5 VI_FALSE 12 NIFGEN_VAL_CAL_CONFIG_MAIN_PATH_FILTER_OFF_12DB

6 VI_TRUE 0 NIFGEN_VAL_CAL_CONFIG_MAIN_PATH_FILTER_ON_0DB

7 VI_TRUE 3 NIFGEN_VAL_CAL_CONFIG_MAIN_PATH_FILTER_ON_3DB

8 VI_TRUE 6 NIFGEN_VAL_CAL_CONFIG_MAIN_PATH_FILTER_ON_6DB

9 VI_TRUE 9 NIFGEN_VAL_CAL_CONFIG_MAIN_PATH_FILTER_ON_9DB

10 VI_TRUE 12 NIFGEN_VAL_CAL_CONFIG_MAIN_PATH_FILTER_ON_12DB

Enable

Pre-Amplifier

Attenuation

5. Call

niFgen_SetAttributeViBoolean to set the analog filter state

Current Configuration

(niFgen property node: Output Attributes»Analog Filter Enabled)

using the following parameters:

• vi: The session handle returned from

niFgen_InitExtCal

• channelName: "0"

• attributeID: NIFGEN_ATTR_ANALOG_FILTER_ENABLED

• value: The Analog Filter Enable value for the current iteration

from Table 8.

NI PXI-5422 Calibration Procedure 42 ni.com

Page 43

6. Call niFgen_SetAttributeViReal64 to set the pre-amplifier

attenuation (niFgen property node: Calibration»Pre-Amplifier

Attenuation) using the following parameters:

• vi: The session handle returned from

niFgen_InitExtCal

• channelName: "0"

• attributeID: NIFGEN_ATTR_PRE_AMPLIFIER_ATTENUATION

• value: The Pre-Amplifier Attenuation value for the current

iteration from Table 8.

7. Take the following voltage measurements at the NI PXI-5422 CH 0

front panel connector into a high-impedance load:

a. Call

niFgen_SetAttributeViInt32 to set the gain DAC value

(niFgen property node: Calibration»Gain DAC Value) using

the following parameters:

• vi: The session handle returned from

niFgen_InitExtCal

• channelName: "0"

• attributeID: NIFGEN_ATTR_GAIN_DAC_VALUE

• value: 1500

b. Call niFgen_WriteBinary16AnalogStaticValue (niFgen

Write Binary 16 Analog Static Value VI) to set the main DAC

value using the following parameters:

• vi: The session handle returned from

niFgen_InitExtCal

• channelName: "0"

• value: 25233

c. Call niFgen_Commit (niFgen Commit VI) to commit the

attribute values to the device using the following parameter:

• vi: The session handle returned from

niFgen_InitExtCal

d. Wait 500 ms for the output to settle.

e. Use the DMM to measure the voltage output by the device. This

measurement is

f. Call

niFgen_SetAttributeViInt32 to set the gain DAC value

measurement 0, which is used in step 8.

(niFgen property node: Calibration»Gain DAC Value) using the

following parameters:

• vi: The session handle returned from

niFgen_InitExtCal

• channelName: "0"

• attributeID: NIFGEN_ATTR_GAIN_DAC_VALUE

• value: 2000

© National Instruments Corporation 43 NI PXI-5422 Calibration Procedure

Page 44

g. Call niFgen_WriteBinary16AnalogStaticValue (niFgen

Write Binary 16 Analog Static Value VI) to set the main DAC

value using the following parameters:

• vi: The session handle returned from

• channelName:

"0"

niFgen_InitExtCal

• value: –29232

h. Call niFgen_Commit (niFgen Commit VI) to commit the

attribute values to the device using the following parameter:

• vi: The session handle returned from

niFgen_InitExtCal

i. Wait 500 ms for the output to settle.

j. Use the DMM to measure the voltage output by the device. This

8. Call

measurement is

niFgen_CalAdjustMainPathPreAmpGain (niFgen Cal

measurement 1, which is used in step 8.

Adjust Main Path Pre Amp Gain VI) using the following parameters:

• vi: The session handle returned from

niFgen_InitExtCal

• channelName: "0"

• configuration: The Current Configuration value for the current

iteration from Table 8

• mainDACValues: An array containing two elements—the two

values (

25233, –29232) that you set for the main DAC in the

order that you measured them

• gainDACValues: An array containing two elements—the two

values (

1500, 2000) that you set for the gain DAC in the order

that you measured them

• offsetDACValues: An array containing one element—the value

(

32000) that you set for the offset DAC

• measuredOutputs: An array containing two elements—the

two output voltages (

measurement 0, measurement 1) that

you measured in the order that you measured them

NI PXI-5422 Calibration Procedure 44 ni.com

Page 45