Page 1

NI Vision

NI PCI-8254R User Manual

IEEE 1394a Interface Device with Reconfigurable I/O

NI PCI-8254R User Manual

February 2007

371578D-01

Page 2

Support

Worldwide Technical Support and Product Information

ni.com

National Instruments Corporate Headquarters

11500 North Mopac Expressway Austin, Texas 78759-3504 USA Tel: 512 683 0100

Worldwide Offices

Australia 1800 300 800, Austria 43 0 662 45 79 90 0, Belgium 32 0 2 757 00 20, Brazil 55 11 3262 3599,

Canada 800 433 3488, China 86 21 6555 7838, Czech Republic 420 224 235 774, Denmark 45 45 76 26 00,

Finland 385 0 9 725 725 11, France 33 0 1 48 14 24 24, Germany 49 0 89 741 31 30, India 91 80 41190000,

Israel 972 0 3 6393737, Italy 39 02 413091, Japan 81 3 5472 2970, Korea 82 02 3451 3400,

Lebanon 961 0 1 33 28 28, Malaysia 1800 887710, Mexico 01 800 010 0793, Netherlands 31 0 348 433 466,

New Zealand 0800 553 322, Norway 47 0 66 90 76 60, Poland 48 22 3390150, Portugal 351 210 311 210,

Russia 7 495 783 68 51, Singapore 1800 226 5886, Slovenia 386 3 425 42 00, South Africa 27 0 11 805 8197,

Spain 34 91 640 0085, Sweden 46 0 8 587 895 00, Switzerland 41 56 200 51 51, Taiwan 886 02 2377 2222,

Thailand 662 278 6777, Turkey 90 212 279 3031, United Kingdom 44 0 1635 523545

For further support information, refer to the Technical Support and Professional Services appendix. To comment

on National Instruments documentation, refer to the National Instruments Web site at

the info code

feedback.

ni.com/info and enter

© 2005-2007 National Instruments Corporation. All rights reserved.

Page 3

Important Information

Warranty

The NI PCI-8254R is warranted against defects in materials and workmanship for a period of one year from the date of shipment, as evidenced

by receipts or other documentation. National Instruments will, at its option, repair or replace equipment that proves to be defective during the

warranty period. This warranty includes parts and labor.

The media on which you receive National Instruments software are warranted not to fail to execute programming instructions, due to defects in

materials and workmanship, for a period of 90 days from date of shipment, as evidenced by receipts or other documentation. National Instruments

will, at its option, repair or replace software media that do not execute programming instruc tions if National Instruments receives notice of such defects

during the warranty period. National Instruments does not warrant that the operation of the software shall be uninterrupted or error free.

A Return Material Authorization (RMA) number must be obtained from the factory and clearly marked on the outside of the package before any

equipment will be accepted for warranty work. National Instruments will pay the shipping costs of returning to the owner parts which are covered by

warranty.

National Instruments believes that the information in this document is accurate. The document has been carefully reviewed for technical accuracy. In

the event that technical or typographical errors exist, National Instruments reserves the right to make changes to subsequent editions of this document

without prior notice to holders of this edition. The reader should consult National Instruments if errors are suspected. In no event shall National

Instruments be liable for any damages arising out of or related to this document or the information contained in it.

E

XCEPT AS SPECIFIED HEREIN, NATIONAL INSTRUMENTS MAKES NO WARRANTIES, EXPRESS OR IMPLIED, AND SPECIFICALLY DISCLAIMS ANY WARRANTY OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. CUSTOMER’S RIGHT TO RECOVER DAMAGES CAUSED BY FAULT OR NEGLIGENCE ON THE PART OF NATIONAL

INSTRUMENTS SHALL BE LIMITED TO THE AMOUNT THERETOFORE PAID BY THE CUSTOMER. NATIONAL INSTRUMENTS WILL NOT BE LIABLE FOR DAMAGES RESULTING

FROM LOSS OF DATA, PROFITS, USE OF PRODUCTS, OR INCIDENTAL OR CONSEQUENTIAL DAMAGES, EVEN IF ADVISED OF THE POSSIBILITY THEREOF. This limitation of

the liability of National Instruments will apply regardless of the form of action, whether in contract or tort, including negligence. Any action against

National Instruments must be brought within one year after the cause of action accrues. National Instruments shall not be liable for any delay in

performance due to causes beyond its reasonable control. The warranty provided herein does not cover damages, defects, malfunctions, or service

failures caused by owner’s failure to follow the National Instruments installation, operation, or maintenance instructions; owner’s modification of the

product; owner’s abuse, misuse, or negligent acts; and power failure or surges, fire, flood, accident, actions of third parties, or other events outside

reasonable control.

Copyright

Under the copyright laws, this publication may not be reproduced or transmitted in any form, electronic or mechanical, including photocopying,

recording, storing in an information retrieval system, or translating, in whole or in part, without the prior written consent of National

Instruments Corporation.

National Instruments respects the intellectual property of others, and we ask our users to do the same. NI software is protected by copyright and other

intellectual property laws. Where NI software may be used to reproduce software or other materials belonging to others, you may use NI software only

to reproduce materials that you may reproduce in accordance with the terms of any applicable license or other legal restriction.

Trademarks

National Instruments, NI, ni.com, and LabVIEW are trademarks of National Instruments Corporation. Refer to the Terms of Use section

on

ni.com/legal for more information about National Instruments trademarks.

®

is the registered trademark of Apple Computer, Inc. Other product and company names mentioned herein are trademarks or trade names of

FireWire

their respective companies.

Members of the National Instruments Alliance Partner Program are business entities independent from National Instruments and have no agency,

partnership, or joint-venture relationship with National Instruments.

Patents

For patents covering National Instruments products, refer to the appropriate location: Help»Patents in your software, the patents.txt file

on your CD, or

ni.com/patents.

WARNING REGARDING USE OF NATIONAL INSTRUMENTS PRODUCTS

(1) NATIONAL INSTRUMENTS PRODUCTS ARE NOT DESIGNED WITH COMPONENTS AND TESTING FOR A LEVEL OF

RELIABILITY SUITABLE FOR USE IN OR IN CONNECTION WITH SURGICAL IMPLANTS OR AS CRITICAL COMPONENTS IN

ANY LIFE SUPPORT SYSTEMS WHOSE FAILURE TO PERFORM CAN REASONABLY BE EXPECTED TO CAUSE SIGNIFICANT

INJURY TO A HUMAN.

(2) IN ANY APPLICATION, INCLUDING THE ABOVE, RELIABILITY OF OPERATION OF THE SOFTWARE PRODUCTS CAN BE

IMPAIRED BY ADVERSE FACTORS, INCLUDING BUT NOT LIMITED TO FLUCTUATIONS IN ELECTRICAL POWER SUPPLY,

COMPUTER HARDWARE MALFUNCTIONS, COMPUTER OPERATING SYSTEM SOFTWARE FITNESS, FITNESS OF COMPILERS

AND DEVELOPMENT SOFTWARE USED TO DEVELOP AN APPLICATION, INSTALLATION ERRORS, SOFTWARE AND HARDWARE

COMPATIBILITY PROBLEMS, MALFUNCTIONS OR FAILURES OF ELECTRONIC MONITORING OR CONTROL DEVICES,

TRANSIENT FAILURES OF ELECTRONIC SYSTEMS (HARDWARE AND/OR SOFTWARE), UNANTICIPATED USES OR MISUSES, OR

ERRORS ON THE PART OF THE USER OR APPLICATIONS DESIGNER (ADVERSE FACTORS SUCH AS THESE ARE HEREAFTER

COLLECTIVELY TERMED “SYSTEM FAILURES”). ANY APPLICATION WHERE A SYSTEM FAILURE WOULD CREATE A RISK OF

HARM TO PROPERTY OR PERSONS (INCLUDING THE RISK OF BODILY INJURY AND DEATH) SHOULD NOT BE RELIANT SOLELY

UPON ONE FORM OF ELECTRONIC SYSTEM DUE TO THE RISK OF SYSTEM FAILURE. TO AVOID DAMAGE, INJURY, OR DEATH,

THE USER OR APPLICATION DESIGNER MUST TAKE REASONABLY PRUDENT STEPS TO PROTECT AGAINST SYSTEM FAILURES,

INCLUDING BUT NOT LIMITED TO BACK-UP OR SHUT DOWN MECHANISMS. BECAUSE EACH END-USER SYSTEM IS

CUSTOMIZED AND DIFFERS FROM NATIONAL INSTRUMENTS' TESTING PLATFORMS AND BECAUSE A USER OR APPLICATION

DESIGNER MAY USE NATIONAL INSTRUMENTS PRODUCTS IN COMBINATION WITH OTHER PRODUCTS IN A MANNER NOT

EVALUATED OR CONTEMPLATED BY NATIONAL INSTRUMENTS, THE USER OR APPLICATION DESIGNER IS ULTIMATELY

RESPONSIBLE FOR VERIFYING AND VALIDATING THE SUITABILITY OF NATIONAL INSTRUMENTS PRODUCTS WHENEVER

NATIONAL INSTRUMENTS PRODUCTS ARE INCORPORATED IN A SYSTEM OR APPLICATION, INCLUDING, WITHOUT

LIMITATION, THE APPROPRIATE DESIGN, PROCESS AND SAFETY LEVEL OF SUCH SYSTEM OR APPLICATION.

Page 4

Compliance

Compliance with FCC/Canada Radio Frequency Interference

Regulations

Determining FCC Class

The Federal Communications Commission (FCC) has rules to protect wireless communications from interference. The FCC

places digital electronics into two classes. These classes are known as Class A (for use in industrial-commercial locations only)

or Class B (for use in residential or commercial locations). All National Instruments (NI) products are FCC Class A products.

Depending on where it is operated, this Class A product could be subject to restrictions in the FCC rules. (In Canada, the

Department of Communications (DOC), of Industry Canada, regulates wireless interference in much the same way.) Digital

electronics emit weak signals during normal operation that can affect radio, television, or other wireless products.

All Class A products display a simple warning statement of one paragraph in length regarding interference and undesired

operation. The FCC rules have restrictions regarding the locations where FCC Class A products can be operated.

Consult the FCC Web site at

FCC/DOC Warnings

This equipment generates and uses radio frequency energy and, if not installed and used in strict accordance with the instructions

in this manual and the CE marking Declaration of Conformity*, may cause interference to radio and television reception.

Classification requirements are the same for the Federal Communications Commission (FCC) and the Canadian Department

of Communications (DOC).

Changes or modifications not expressly approved by NI could void the user’s authority to operate the equipment under the

FCC Rules.

Class A

Federal Communications Commission

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to part 15 of the FCC

Rules. These limits are designed to provide reasonable protection against harmful interference when the equipment is operated

in a commercial environment. This equipment generates, uses, and can radiate radio frequency energy and, if not installed and

used in accordance with the instruction manual, may cause harmful interference to radio communications. Operation of this

equipment in a residential area is likely to cause harmful interference in which case the user is required to correct the interference

at their own expense.

www.fcc.gov for more information.

Canadian Department of Communications

This Class A digital apparatus meets all requirements of the Canadian Interference-Causing Equipment Regulations.

Cet appareil numérique de la classe A respecte toutes les exigences du Règlement sur le matériel brouilleur du Canada.

Compliance with EU Directives

Users in the European Union (EU) should refer to the Declaration of Conformity (DoC) for information* pertaining to the

CE marking. Refer to the Declaration of Conformity (DoC) for this product for any additional regulatory compliance

information. To obtain the DoC for this product, visit

and click the appropriate link in the Certification column.

* The CE marking Declaration of Conformity contains important supplementary information and instructions for the user or

installer.

ni.com/certification, search by model number or product line,

Page 5

Conventions

The following conventions are used in this manual:

» The » symbol leads you through nested menu items and dialog box options

to a final action. The sequence File»Page Setup»Options directs you to

pull down the File menu, select the Page Setup item, and select Options

from the last dialog box.

This icon denotes a note, which alerts you to important information.

This icon denotes a caution, which advises you of precautions to take to

avoid injury, data loss, or a system crash.

bold Bold text denotes items that you must select or click in the software, such

as menu items and dialog box options. Bold text also denotes parameter

names.

italic Italic text denotes variables, emphasis, a cross-reference, or an introduction

to a key concept. Italic text also denotes text that is a placeholder for a word

or value that you must supply.

monospace Text in this font denotes text or characters that you should enter from the

keyboard, sections of code, programming examples, and syntax examples.

This font is also used for the proper names of disk drives, paths, directories,

programs, subprograms, subroutines, device names, functions, operations,

variables, filenames, and extensions.

NI 8254R NI 8254R refers to the NI PCI-8254R interface device.

Page 6

Contents

Chapter 1

Introduction

Software Overview ........................................................................................................1-1

Vision Builder for Automated Inspection .......................................................1-2

Vision Development Module ..........................................................................1-2

IEEE 1394 and NI 8254R ..............................................................................................1-3

Functional Overview......................................................................................................1-3

Start Conditions .............................................................................................................1-4

Acquisition Window Control.........................................................................................1-4

Chapter 2

Hardware Overview

Digital I/O ......................................................................................................................2-1

RIO and The LabVIEW FPGA Module ........................................................................2-1

TTL Inputs and Outputs.................................................................................................2-2

Isolated Inputs and Outputs ...........................................................................................2-3

I/O for Normal Operation ..............................................................................................2-4

Trigger Inputs ..................................................................................................2-5

Timed Pulse Output.........................................................................................2-5

Trigger Change Detectors................................................................................2-8

Quadrature Encoder.........................................................................................2-8

Product Selection Port ..................................................................................... 2-8

General-Purpose I/O........................................................................................2-9

I/O for Fault Conditions ..................................................................................2-10

Initiating a Timed Pulse ....................................................................2-5

Pulse Modes ......................................................................................2-6

Pulse Delay ....................................................................................... 2-6

Pulse Width .......................................................................................2-7

Trigger Polarity .................................................................................2-7

Using ISO Input 5 as a Latch............................................................ 2-9

General-Purpose Inputs..................................................................... 2-10

General-Purpose Outputs ..................................................................2-10

Shutdown .......................................................................................... 2-11

Watchdog Timer ...............................................................................2-11

© National Instruments Corporation vii NI PCI-8254R User Manual

Page 7

Contents

Considerations When Connecting the Digital I/O......................................................... 2-12

Wiring an Isolated Input to a Sourcing Output Device................................... 2-12

Wiring an Isolated Output to an External Load .............................................. 2-13

Protecting Inductive Loads .............................................................................2-14

Transmission Line Effects .............................................................................. 2-15

Chapter 3

Signal Connections

Connectors..................................................................................................................... 3-2

2-Position Isolated Outputs Power Connector ................................................ 3-2

IEEE 1394a Connector.................................................................................... 3-3

General-Purpose Digital I/O ...........................................................................3-3

Cabling .......................................................................................................................... 3-8

IEEE 1394 Camera Cables.............................................................................. 3-8

I/O Terminal Block ......................................................................................... 3-8

NI Vision I/O Terminal Block and Prototyping Accessory............................ 3-9

Power Requirements...................................................................................................... 3-9

Isolated Outputs Power Connector ................................................................. 3-9

Appendix A

Technical Support and Professional Services

Glossary

Index

NI PCI-8254R User Manual viii ni.com

Page 8

Introduction

The NI PCI-8254R is a OHCI compliant IEEE 1394a interface device with

reconfigurable I/O (RIO).

The NI 8254R device ships with NI Vision Acquisition Software, which

contains all of the drivers in the NI Vision product line. With NI Vision

Acquisition Software, you can quickly and easily start your applications

without having to program the device at the register level.

The NI 8254R includes TTL inputs and outputs for triggering, and isolated

inputs and outputs for connecting to external devices, such as lighting

controllers, proximity sensors, and quadrature encoders.

Behind the digital I/O of the NI 8254R is an FPGA which has been

preconfigured with the functionality required for most common machine

vision tasks. However, if the factory configured functionality does not

fulfill your requirements, the FPGA is user-configurable using the

LabVIEW FPGA Module. The NI 8254R provides a convenient 44-pin

D-SUB connector on its front panel to access the digital I/O.

1

For detailed specifications of the NI 8254R, refer to the Specifications

section of Getting Started with the NI PCI-8254R.

Software Overview

Programming the NI 8254R requires two drivers to control the hardware:

NI-IMAQdx and NI-IMAQ I/O. Both drivers are included with the

NI Vision Acquisition Software.

NI-IMAQdx has an extensive library of functions you can call and handles

communication between the computer and the image acquisition device,

such as programming interrupts and camera control. NI-IMAQ I/O

provides functions to control the I/O on the NI 8254R.

National Instruments also offers the following application software

packages for analyzing and processing your acquired images. For detailed

information about individual software packages, refer to the documentation

specific to each package.

© National Instruments Corporation 1-1 NI PCI-8254R User Manual

Page 9

Chapter 1 Introduction

Vision Builder for Automated Inspection

NI Vision Builder for Automated Inspection (Vision Builder AI) is

configurable machine vision software that you can use to prototype,

benchmark, and deploy applications. Vision Builder AI does not require

programming, but is scalable to powerful programming environments.

Vision Builder AI allows you to easily configure and benchmark a

sequence of visual inspection steps, as well as deploy the visual inspection

system for automated inspection. With Vision Builder AI, you can perform

powerful visual inspection tasks and make decisions based on the results

of individual tasks. You also can migrate the configured inspection to

LabVIEW, extending the capabilities of the applications if necessary.

Vision Development Module

The NI Vision Development Module, which consists of NI Vision and

NI Vision Assistant, is an image acquisition, processing, and analysis

library of more than 270 functions for the following common machine

vision tasks:

• Pattern matching

• Particle analysis

•Gauging

• Taking measurements

• Grayscale, color, and binary image display

You can use the Vision Development Module functions individually or

in combination. With the Vision Development Module, you can acquire,

display, and store images, as well as perform image analysis and

processing. Using the Vision Development Module, imaging novices and

experts can program the most basic or complicated image applications

without knowledge of particular algorithm implementations.

As a part of the Vision Development Module, NI Vision Assistant is an

interactive prototyping tool for machine vision and scientific imaging

developers. With Vision Assistant, you can prototype vision applications

quickly and test how various image processing functions work.

Vision Assistant generates a Builder file, which is a text description

containing a recipe of the machine vision and image processing functions.

This Builder file provides a guide you can use for developing applications

in any ADE, such as LabWindows

Vision Assistant machine vision and image processing libraries. Using the

NI PCI-8254R User Manual 1-2 ni.com

™

/CVI™ or Visual Basic, using the

Page 10

LabVIEW VI creation wizard, Vision Assistant can create LabVIEW VI

diagrams that perform the prototype you created in Vision Assistant.

You can then use LabVIEW to add functionality to the generated VI.

IEEE 1394 and NI 8254R

The NI 8254R uses FireWire® (IEEE 1394) technology. FireWire is a

cross-platform implementation of the high-speed serial data bus—defined

by the IEEE 1394-1995 and IEEE 1394a-2000 standards—that can move

large amounts of data between computers and peripheral devices. It

features simplified cabling using twisted pairs, hot swapping, and transfer

speeds of up to 400 megabits per second. You can support up to 63 devices

on the high-speed bus with IEEE 1394.

The IEEE 1394a standard offers up to 400 Mb/s bandwidth. The NI 8254R

provides two direct-connect IEEE 1394a ports, but more IEEE 1394

devices can be added using IEEE 1394 hubs. The NI 8254R can acquire

images from IEEE 1394 cameras conforming to the IIDC 1394-based

Digital Camera Specification, Version 1.30 and later.

The IEEE 1394 bus provides a fixed amount of bandwidth that is shared

between the two IEEE 1394a ports on the NI 8254R. These ports provide

direct connection for up to two DCAM-compliant IEEE 1394 cameras,

depending on the amount of bandwidth each camera requires. Higher frame

rates and larger image sizes require a higher data transfer rate and use more

bandwidth.

Chapter 1 Introduction

Functional Overview

The NI 8254R features a high-speed data path optimized for receiving and

formatting video data from IEEE 1394 cameras.

Figure 1-1 illustrates the key functional components of the NI 8254R.

© National Instruments Corporation 1-3 NI PCI-8254R User Manual

Page 11

Chapter 1 Introduction

PCI

CONN

PCI

Bridge

Start Conditions

The NI 8254R can start acquisitions in the following ways:

• Software control—The NI 8254R supports software control of

• Trigger control—You can start an acquisition by enabling external

ISO In

TTL In

TTL OutCPLD

ISO Out

ISO Power

Connection

Powe r

Supply

+5 V, +1.5 V

DSUB

Dust

MITE

1394A

Controller

V2 FPGA

Config ROM

1394

Conns

1394

Power Conn

Figure 1-1. NI 8254R Block Diagram

acquisition start. You can configure the NI 8254R to capture a fixed

number of frames. Use this configuration for capturing a single frame

or a sequence of frames.

trigger lines. Each of these inputs can start a video acquisition on a

rising or falling edge.

Acquisition Window Control

You can configure the following parameter on the NI 8254R to control the

video acquisition window:

• Acquisition window—The NI 8254R and the IIDC 1394-based

Digital Camera Specification allow you to specify a particular region

of active pixels and lines on a camera to acquire. In many cases,

specifying a smaller acquisition window will increase the maximum

frame rate of the camera. Valid acquisition windows, and their

corresponding frame rates, are defined by the camera.

NI PCI-8254R User Manual 1-4 ni.com

Page 12

Hardware Overview

Digital I/O

The digital I/O functions on the NI 8254R are accessible through 2 TTL

inputs, 10 TTL outputs, 13 isolated inputs, and 4 isolated outputs.

You can use input signals as triggers, product selection ports, change

detectors, or to read quadrature encoders. Uses for output signals include

controlling camera reset and exposure, controlling strobe lighting,

outputting inspection results, or communicating with PLCs. You can also

define the functions of digital input and output signals.

For information about how to use LabVIEW to implement specific digital

I/O functions, refer to the examples at

IMAQ IO.llb

installed. For information about how to use C or Visual Basic to implement

specific digital I/O functions, refer to the examples at

<National Instruments>\NI-IMAQ IO\Examples\.

, where <LabVIEW> is the location in which LabVIEW is

2

<LabVIEW>\examples\IMAQ\

For more information about using the LabVIEW FPGA Module to

implement custom FPGA logic, refer to the examples at

examples\IMAQ\IMAQ IO FPGA.llb

to which you installed LabVIEW.

, where <LabVIEW> is the location

<LabVIEW>\

RIO and The LabVIEW FPGA Module

Behind the digital I/O of the NI 8254R is an FPGA which has been

preconfigured with the functionality required for most common machine

vision tasks. If the factory configured functionality does not fulfill your

requirements, the FPGA is user-configurable with the LabVIEW FPGA

Module. RIO allows you to develop custom FPGA logic to add triggering,

pulse-width modulation signals, or custom communications protocols to

your machine vision application.

© National Instruments Corporation 2-1 NI PCI-8254R User Manual

Page 13

Chapter 2 Hardware Overview

Using National Instruments RIO hardware and the LabVIEW FPGA

Module, you can define your hardware without in-depth knowledge of

hardware design tools or hardware description languages (HDL). When the

signal requirements change, the LabVIEW code can be modified and

downloaded to the FPGA to change the I/O mix or type. This flexibility

allows you to reuse the same hardware and software at no extra expense.

NI-IMAQ I/O devices such as the such as the NI 8254R, the NI 8255R, and

the NI CVS-1450 Series have 29 digital I/O lines with built-in functionality

for communicating with external devices, such as reading quadrature

encoder inputs, generating strobe pulses, and writing to or reading from

digital lines.

NI-IMAQ I/O devices have 15 digital input lines—13 isolated 24 V lines

and two dedicated TTL lines. There are 14 digital output lines—four

isolated 24 V lines and 10 dedicated TTL lines. Using these signals, you

can dynamically control your lighting or cameras, synchronize with a

conveyor belt, or communicate with relays that control solenoids and other

actuators.

TTL Inputs and Outputs

TTL is a fast-switching 5 V digital signaling standard commonly used for

applications that require high precision, such as camera triggering. TTL

inputs and outputs do not require a separate power supply.

Caution Do not connect voltage or current sources to TTL outputs. Doing so could

damage the NI 8254R.

NI PCI-8254R User Manual 2-2 ni.com

Page 14

Primary

Function

Input

or

Output

Chapter 2 Hardware Overview

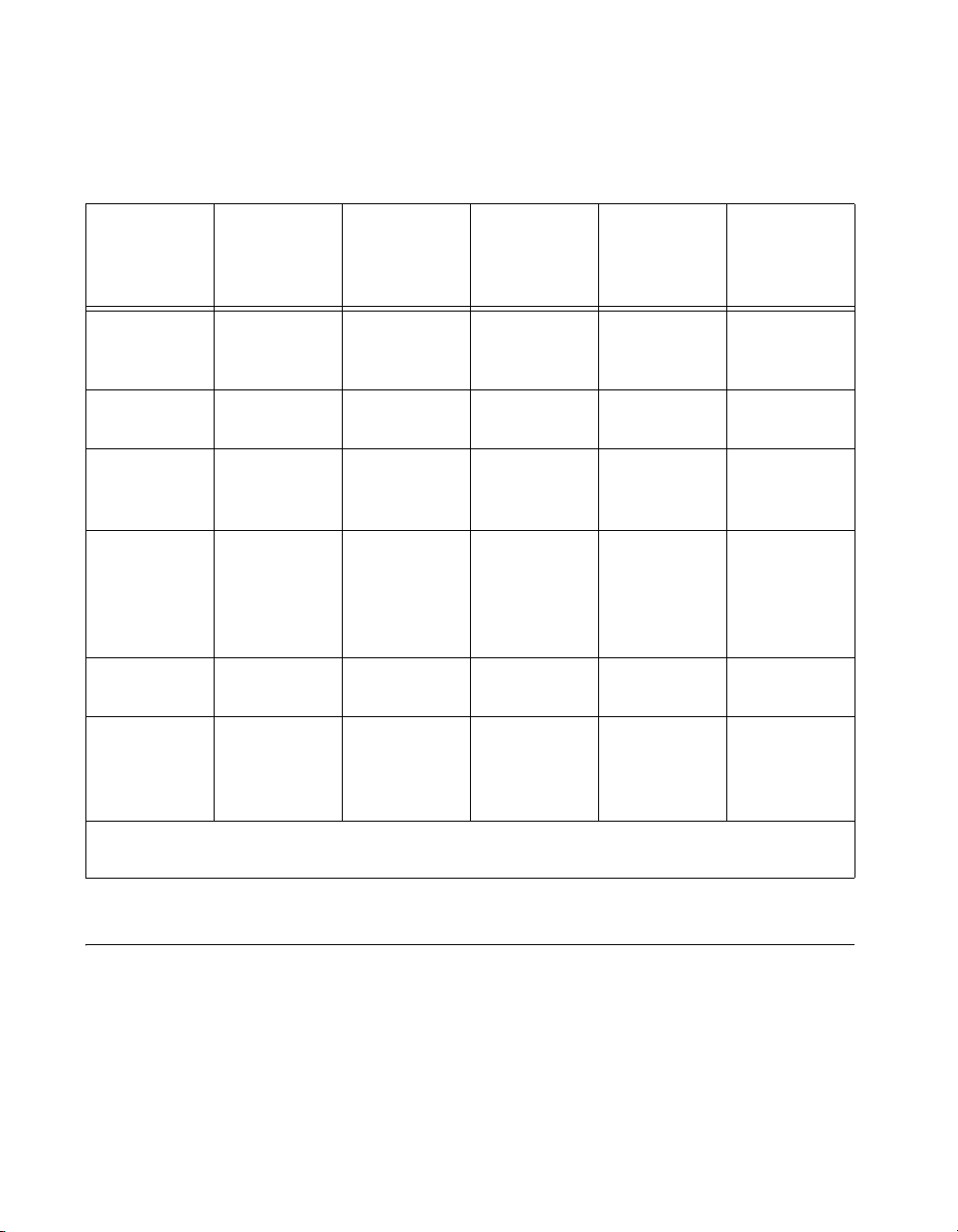

Table 2-1 summarizes the TTL inputs and outputs available on the

NI 8254R.

Table 2-1. NI 8254R TTL Inputs and Outputs

44-Pin

Number

Available

Signal Names

D-SUB on

NI 8254R

Pin

Number

37-Pin

Terminal

Block

Number

Trigger Input 2 TTL Input 0,

General Purpose

TTL Input 1,

General Purpose

Timed

Pulse

Output 6 TTL Output 1, Pulse 1

TTL Output 2, Pulse 2

TTL Output 3, Pulse 3

TTL Output 4, Pulse4

TRIG 1, Pulse 5

TRIG 2, Pulse 6

*

*

1

16

4

6

7

18

24

9

Watchdog Output 1 TTL Output 0 3 4

General

Purpose

* TTL Input 0 and TTL Input 1 can also function as trigger change detectors.

Output 3 TTL Output 5

TTL Output 6

TTL Output 7

19

21

22

Isolated Inputs and Outputs

The isolated inputs and outputs on the NI 8254R have a separate ground

reference from the main NI 8254R supply, providing an easy means to

prevent ground loops that can introduce noise into a system. You can apply

signals up to 30 V to the isolated inputs. The voltage swing of the isolated

outputs is determined by the voltage you supply on the 2-position isolated

outputs power connector.

1

2

5

7

8

20

—

—

21

23

24

Note V

is referred to as V, and C

iso

is referred to as C on the 2-position isolated outputs

iso

power connector on the NI 8254R.

Note The isolated outputs have current-limiting protection circuitry. If this circuitry is

tripped, you can re-enable the outputs by removing the fault and restarting your computer.

© National Instruments Corporation 2-3 NI PCI-8254R User Manual

Page 15

Chapter 2 Hardware Overview

Table 2-2 summarizes the isolated inputs and outputs available on the

NI 8254R.

Table 2-2. NI 8254R Isolated Inputs and Outputs

44-Pin

D-SUB on

Pin Number

†

*

NI 8254R

11

35

40

37

38

Primary

Function

Input or

Output

Number

Available

Signal

Names

Trigger Input 3 TRIG 0

ISO Input 5

ISO Input 8

Quadrature

Encoder

External

Input 1 ISO Input 6

ISO Input 7

Input 1 ISO Input 11 44 31

*

Shutdown

Control

Product

Selection

†

Port

General

Purpose

General

Purpose

*

TRIG 0, ISO Input 8, ISO Input 9, and ISO Input 10 can also function as trigger change detectors.

†

ISO Input 5 can also function as a latch for the product selection port.

Input 1 ISO Input 0

ISO Input 1

ISO Input 2

ISO Input 3

ISO Input 4

Input 2 ISO Input 9*

ISO Input 10

Output 4 ISO Output 0

ISO Output 1

ISO Output 2

ISO Output 3

15

30

31

32

34

41

*

43

12

13

27

28

37-Pin

Terminal

Block

Number

—

15

27

25

26

9

10

11

13

14

29

30

198

35

36

37

I/O for Normal Operation

The following sections describe I/O functions that are available on the

NI 8254R during normal operation.

NI PCI-8254R User Manual 2-4 ni.com

Page 16

Trigger Inputs

Timed Pulse Output

Chapter 2 Hardware Overview

Trigger inputs are available from both TTL inputs and isolated inputs. You

can use these trigger inputs to synchronize the NI 8254R with an external

event, such as the assertion of a signal generated by a proximity sensor or

a PLC, to indicate that an inspection item is passing in front of the camera.

The NI 8254R uses this input to initiate a timed pulse that can be used for

camera control, lighting control, encoder pulse counting, and result output

timing.

For more information about creating a timed pulse output, refer to the

Timed Pulse Output section.

TTL Input 0, TTL Input 1, TRIG 0, ISO Input 6, ISO Input 7, ISO Input 8,

and ISO Input 11 can alternatively function as general-purpose inputs.

ISO Input 5 can alternatively function as a latch for the product selection

port.

The NI 8254R is capable of timed pulse output on six different digital

outputs, which provides precise control over time-critical signals, such as

camera exposure. This section describes the various uses for the timed

pulse output and the parameters you can set to control these outputs.

Uses for timed pulse output include controlling camera reset and exposure,

controlling strobe lighting, operating plungers on an assembly line, and

communicating with PLCs. You can configure the start of the pulse output

generation to occur from software or from a rising or falling edge of a

trigger input.

In addition to controlling the timing of pulse output, you can also configure

the polarity of the output signal, resulting in a high-true or low-true signal.

Based on the polarity setting, the output signal asserts after the appropriate

delay time and de-asserts after the configured pulse width. You can set the

delay time in microseconds or in quadrature encoder counts from the start

signal—either a hardware trigger or a software command. Width is always

configured in microseconds.

Initiating a Timed Pulse

Each timed pulse generator has a trigger input that specifies whether to wait

on a particular trigger input to generate the pulse or to immediately

generate the pulse when software sets the pulse mode to Start in LabVIEW

or imaqIOPulseStart in C and Visual Basic.

© National Instruments Corporation 2-5 NI PCI-8254R User Manual

Page 17

Chapter 2 Hardware Overview

If the trigger input is set to Immediate in LabVIEW or using a None status

signal in C and Visual Basic, the pulse generation occurs as soon as the

pulse mode is set to Start in LabVIEW or imaqIOPulseStart in C and

Visual Basic. After generating a pulse, it immediately generates another

pulse until the pulse generation is stopped. If the trigger input is set to one

of the hardware trigger inputs, the timed pulse output waits for an assertion

edge on the appropriate trigger input. After generating a pulse it waits for

another trigger before generating another pulse. The assertion edge is

configurable based on the trigger polarity parameter. It then generates one

pulse and rearms to wait for the next trigger. In either case, the pulse output

generation stops and resets if the pulse mode parameter is set to Stop in

LabVIEW or imaqIOPulseStop in C and Visual Basic.

Figure 2-1 shows an output pulse when a trigger is selected.

Trigger

Input

Output

Pulse

Figure 2-1. Output pulse resulting from trigger selection

Pulse Modes

Each pulse generator has a Start, Single Shot, and Stop mode. Configure

the pulse generator when in Stop mode. Then, set the pulse generator to

Start mode for continuous or rearmed pulses, and set it to Single Shot for a

pulse that should assert only once.

Pulse Delay

Pulse delay is the amount of time between a trigger and the first (assertion)

edge of an output pulse. The pulse delay is configurable in units of

microseconds or quadrature encoder counts. If configured for

microseconds, available values are between 1 µs and 4,294,967,295 µs,

which is 4,294 seconds, or approximately 71 minutes. If the delay is

configured for quadrature encoder counts, the range of choices is 0 counts

to 4,294,967,295 counts.

NI PCI-8254R User Manual 2-6 ni.com

Page 18

Chapter 2 Hardware Overview

Pulse Width

Pulse width is the amount of time between the first (assertion) edge of a

pulse and the second (deassertion) edge. Pulse width is configurable only

in microseconds from 1 µs to 4,294,967,295 µs.

Trigger Polarity

Each pulse generator can be individually configured for rising or falling

edge triggering. Even if multiple pulse generators are using the same

trigger, each can have different polarities.

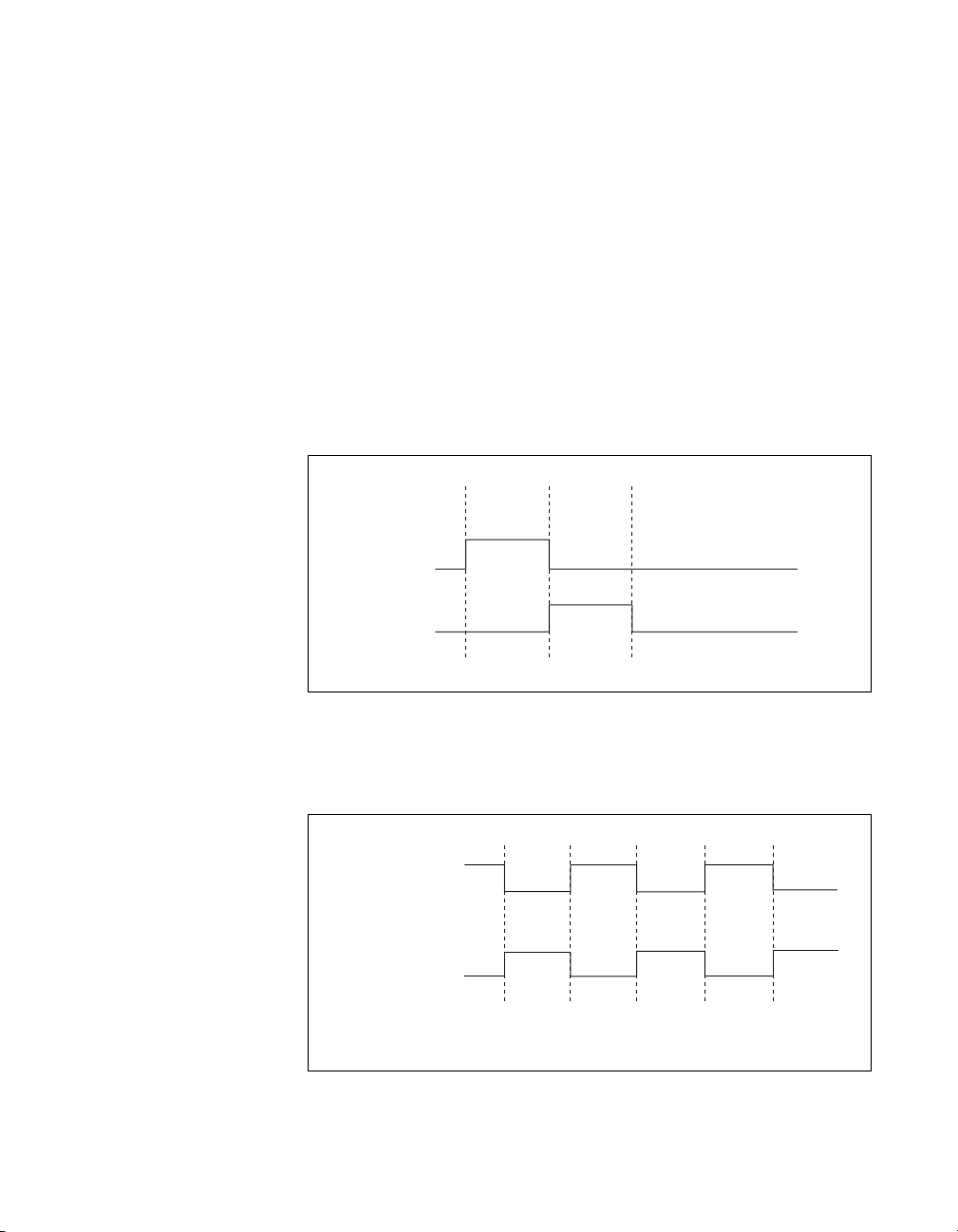

Figure 2-2 shows the output of a pulse generator configured to look for a

rising edge trigger and output a high pulse with a microsecond width and

delay.

Delay Width

Trigger

Pulse

Figure 2-2. Output pulse generator

Figure 2-3 shows how to create a high and low pulse train with a

microsecond delay and width.

High Pulse Train

Delay Width

Low Pulse Train

Software

Start

Figure 2-3. High and low pulse train

© National Instruments Corporation 2-7 NI PCI-8254R User Manual

WidthDelay

Page 19

Chapter 2 Hardware Overview

Trigger Change Detectors

The NI 8254R is capable of detecting edges on various trigger lines and

latching this information for future retrieval. This feature is useful for

high-precision hardware-monitoring of the presence of external events

without the need for software polling. You can arm for the detection of a

rising edge, falling edge, or both on a supported trigger input line.

Supported trigger input lines include TTL Input 0, TTL Input 1,

ISO Input 8, ISO Input 9, ISO Input 10, and TRIG 0.

Quadrature Encoder

The quadrature encoder uses ISO Input 6 for its Phase A input and

ISO Input 7 for its Phase B input. Encoder speed is limited by the speed of

the isolated inputs. Each isolated input can change at a maximum rate of

100 kHz, making the maximum encoder rate 400,000 counts/s.

The quadrature encoder can also be used as a timebase for the pulse

generation delay.

Figure 2-4 shows a rising edge trigger and a low pulse with a quadrature

encoder delay and a microsecond width.

Trigger

Low Pulse

Delay Width

Phase A

Phase B

Figure 2-4. Rising edge trigger and low pulse

Product Selection Port

The product selection port consists of a group of five isolated digital inputs

that the software running on the NI 8254R reads simultaneously. You can

program the NI 8254R to switch between up to 32 (2

sequences for different parts on an assembly line.

NI PCI-8254R User Manual 2-8 ni.com

5

) inspection

Page 20

Chapter 2 Hardware Overview

Based on the input to the product selection port, you can configure the

application software to run the appropriate inspection sequence. For

example, an upstream NI 8254R programmed for part classification might

drive the product selection port of a downstream NI 8254R. Alternatively,

a PLC with information about which part is being inspected can drive the

product selection port of the NI 8254R.

Using ISO Input 5 as a Latch

You can configure the product selection port to use ISO Input 5 as a latch.

A rising edge on ISO Input 5 can latch the data into a data register on the

NI 8254R. Before each inspection, the software checks the status of the

product select inputs and reads the most recent value latched into the

register. If ISO Input 5 is not used as a latch, it can be used as an extra bit

of data.

Note In Vision Builder AI, ISO Input 5 is always designated as a latch.

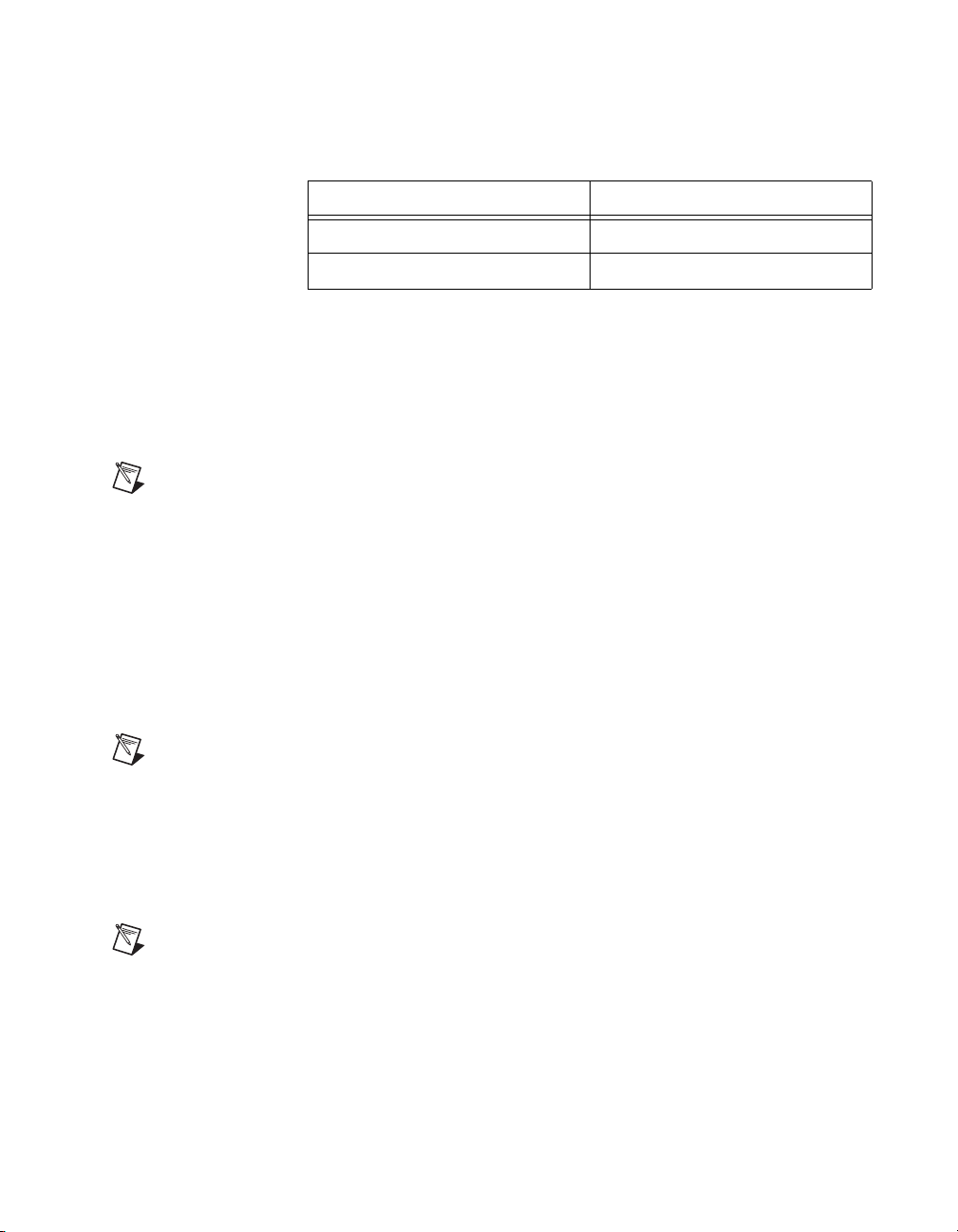

Table 2-3 lists the product selection ports.

Table 2-3. NI 8254R Product Selection Ports

Function External Connection

Data(5), rising edge latch ISO Input 5

Data(4) ISO Input 4

Data(3) ISO Input 3

Data(2) ISO Input 2

Data(1) ISO Input 1

Data(0) ISO Input 0

General-Purpose I/O

General-purpose inputs and outputs are available as both TTL and isolated

connections. The software running on the NI 8254R can read the inputs and

drive the outputs high or low at any time.

© National Instruments Corporation 2-9 NI PCI-8254R User Manual

Page 21

Chapter 2 Hardware Overview

General-Purpose Inputs

The primary difference between general-purpose inputs and trigger inputs

is that you cannot use general-purpose inputs to initiate a timed pulse

generator. In an application, use the general-purpose inputs to get the status

of the inputs at a given point and not to synchronize the NI 8254R with an

external event.

An example of how to use general-purpose inputs is reading the status of a

general-purpose input as the first step in your inspection sequence and

recording that value as part of your inspection.

General-Purpose Outputs

The primary difference between general-purpose outputs and timed pulse

outputs is that the timing of general-purpose outputs is controlled by

software rather than hardware. As a result, timing of general-purpose

outputs changes as the inspection algorithm changes, which makes

general-purpose outputs less appropriate than timed outputs for camera

control, strobe light control, and other applications that require precise

timing.

An example of using general-purpose outputs is driving a relay that turns

on an Inspection in Progress light for an operator to see while the

inspection sequence is running.

I/O for Fault Conditions

The NI 8254R recognizes the following fault conditions:

• External shutdown, when Shutdown mode is enabled

• Watchdog timer expiration

In the event of a fault condition, the behavior of the NI 8254R is dependent

on configuration settings of the software-enabled Shutdown mode. To

resume operation, address the fault condition and cycle power on your

computer.

Table 2-4 summarizes how user configuration affects the behavior of the

NI 8254R in the event of a fault condition.

NI PCI-8254R User Manual 2-10 ni.com

Page 22

Table 2-4. Fault Condition Behavior

Fault Condition Shutdown Enabled

Chapter 2 Hardware Overview

Outputs Change to

User-Defined States

External Shutdown On

Off

Watchdog On

Off

The following sections describe each fault condition.

Shutdown

Shutdown mode is a software-enabled feature that, when activated, allows

an external device to halt the NI 8254R processing operations.

Additionally, Shutdown mode allows you to specify user-defined

shutdown states for all fault conditions.

When Shutdown mode is enabled and the shutdown input signal,

ISO Input 11, turns off, the NI 8254R registers an external shutdown

condition. When a fault occurs, outputs operate according to user-defined

shutdown states. Each TTL output is configurable to drive high, drive low,

or tri-state, and each isolated output is on/off configurable.

Note For prototyping when equipment is unavailable, you can wire from V to

ISO Input 11 to simulate external equipment that indicates to the NI 8254R to operate

normally.

Ye s

No

Ye s

No

Watchdog Timer

The watchdog timer is a software configurable feature that can monitor

software on the NI 8254R and take action if the software is unresponsive.

The millisecond counter on the watchdog timer is configurable up to

65,534 ms, in 1 ms increments, before it expires.

Configure the watchdog timer to take one of the following actions when it

expires.

© National Instruments Corporation 2-11 NI PCI-8254R User Manual

Page 23

Chapter 2 Hardware Overview

Caution Use the Indicator Only option only to test the watchdog timer. If software

becomes unresponsive, it cannot be relied upon to send notification to the host.

• Indicator Only—This option sends the expiration signal back to the

development machine through software. Tru e indicates an expired

watchdog timer. False indicates an unexpired watchdog timer. The

expiration signal that indicates an expired watchdog timer continues to

assert until the watchdog timer is disarmed. Disarming the watchdog

timer resets the software indicator.

• TTL Output 0—This option outputs a signal on TTL Output 0. High

indicates that the watchdog timer has expired. Low indicates that the

watchdog timer has not expired. If the watchdog timer has expired, the

expiration signal continues to assert until the watchdog timer is

disarmed.

• Shutdown—If Shutdown mode is enabled, the outputs go to the

user-defined shutdown states.

Considerations When Connecting the Digital I/O

The isolated trigger inputs on the NI 8254R are current sinking and

optically isolated. The following are considerations you need to make when

connecting the digital I/O.

Wiring an Isolated Input to a Sourcing Output Device

You can wire an isolated input to a sourcing output device, as shown in the

following figure. Refer to Getting Started with the NI PCI-8254R for

switching thresholds and current requirements.

Caution Do not apply a voltage greater than 30 VDC to the isolated inputs. Doing so could

damage the NI 8254R.

Figure 2-5 shows an example of connecting an isolated input to a sourcing

output device.

NI PCI-8254R User Manual 2-12 ni.com

Page 24

Sourcing

Output

Device

Chapter 2 Hardware Overview

V

Input

C

Current

Limiter

NI 8254R

Figure 2-5. Connecting isolated input to a sourcing output device

Wiring an Isolated Output to an External Load

The digital output circuit sources current to external loads, as shown in

Figure 2-6.

Caution Do not draw more than 100 mA from 24 V or 30 V isolated outputs. Do not draw

more than 50 mA from 5 V isolated outputs.

Vcc

Vcc

V

Digital Output

Load

C

NI 8254R

Figure 2-6. Digital output sources current to external loads

© National Instruments Corporation 2-13 NI PCI-8254R User Manual

Page 25

Chapter 2 Hardware Overview

Protecting Inductive Loads

When an inductive load, such as a relay or solenoid, is connected to an

output, a large counter-electromotive force may occur at switching time

due to energy stored in the inductive load. This flyback voltage can damage

the outputs and the power supply.

To limit flyback voltages at the inductive load, install a flyback diode across

the load. Mount the flyback diode as close to the load as possible. Use this

protection method if you connect any of the isolated outputs on the

NI 8254R to an inductive load.

Figure 2-7 shows an example of using an external flyback diode to protect

inductive loads.

Vcc

V

Digital

Output

Load

C

External

NI 8254R

Figure 2-7. External flyback diode to protect inductive loads

NI PCI-8254R User Manual 2-14 ni.com

Flyback

Diode for

Inductive Loads

Page 26

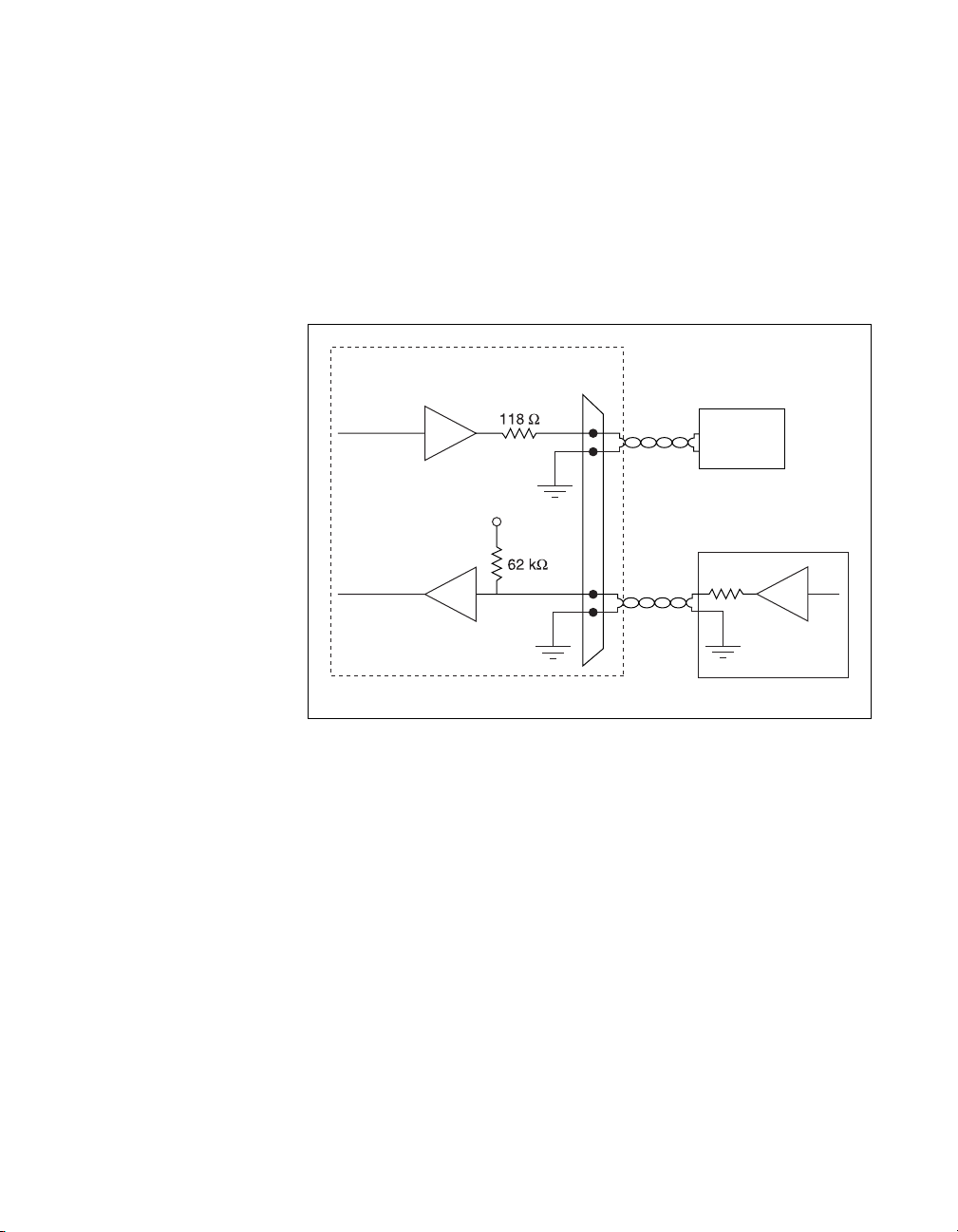

Transmission Line Effects

Transmission line effects can degrade the signals on the I/O cables and

cause instability. To minimize transmission line effects, use twisted pair

wires with a characteristic impedance of 118 Ω to connect external signals

to the 44-pin I/O D-SUB connector.

Figure 2-8 shows connections to the 44-pin D-SUB connector that

minimize transmission line effects.

Chapter 2 Hardware Overview

44-Pin

DSUB

TTL OUT(0)

+5 V

TTL IN(0)

NI 8254R

16

17

3

2

Receiving

Equipment

R

S

Transmitting

Equipment

Figure 2-8. Connections to the 44-pin D-SUB connector

When connecting to TTL inputs on the NI 8254R, match the output

impedance of the transmitting device to the characteristic impedance of the

cable. For example, if the cable characteristic impedance is 118 Ω, make R

equal to 118 Ω, as shown in the figure above.

s

© National Instruments Corporation 2-15 NI PCI-8254R User Manual

Page 27

Signal Connections

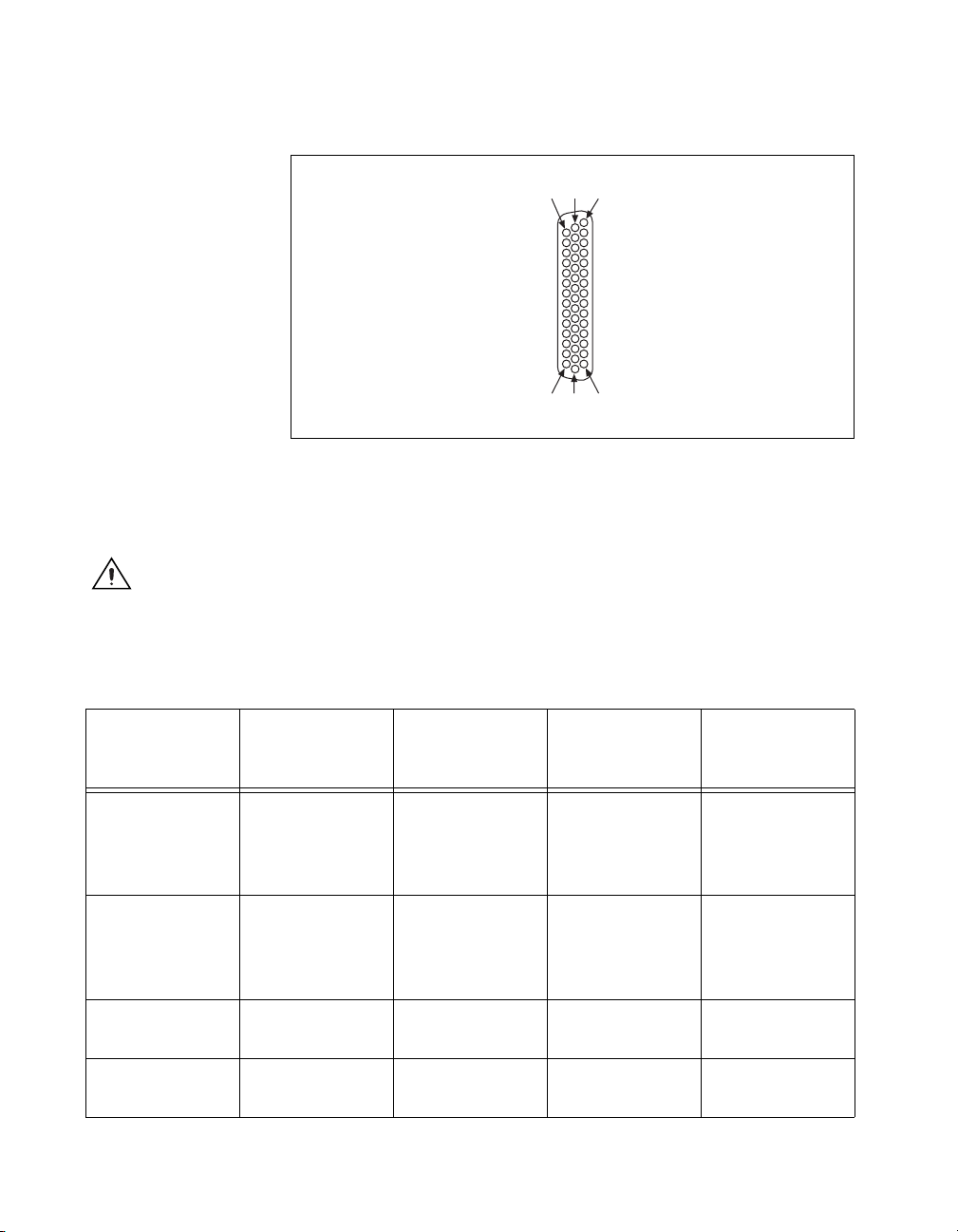

The following diagram shows the connectors on the NI 8254R.

3

NI PCI-8254R

1

IEEE-1394

2

1 IEEE 1394a Connector

2 IEEE 1394a Connector

3

4

3 2-Position Isolated Outputs Power Connector

4 Digital I/O Connector

V

C

5–30V

DIGITAL I/O

© National Instruments Corporation 3-1 NI PCI-8254R User Manual

Page 28

Chapter 3 Signal Connections

Peripheral Connector Function

Table 3-1 summarizes the functions of the connectors on the NI 8254R.

Table 3-1. NI 8254R Connector Functions

Isolated Output Power 2-position isolated outputs

power connector

IEEE 1394 6-pin IEEE 1394a connector Power and data connection to

Digital Input/Output 44-pin female high-density

D-SUB

Camera Power 4-pin computer power Power from PC power supply

Power for isolated outputs

IEEE 1394 cameras

External TTL I/O; External

isolated I/O

to IEEE 1394a connector

Connectors

This section describes the connectors on the NI 8254R and includes pinouts

and signal descriptions for each connector.

2-Position Isolated Outputs Power Connector

The isolated outputs power connector on the NI 8254R accommodates one

power supply. The V terminal provides the isolated output circuitry (5 to

30 VDC) for the NI 8254R. The C terminal provides the common-mode

signal for the NI 8254R.

Figure 3-1 illustrates the isolated outputs power connector on the

NI 8254R.

VC

Figure 3-1. NI 8254R Isolated Power Connector

NI PCI-8254R User Manual 3-2 ni.com

Page 29

Table 3-2 summarizes the functions of the power connector terminals.

IEEE 1394a Connector

The IEEE 1394a connectors on the NI 8254R provide a reliable,

high-frequency connection between the NI 8254R and up to

two DCAM-compliant IEEE 1394 cameras. To access the IEEE 1394a

connectors on the NI 8254R, use any standard 6-pin IEEE 1394 cable.

Note You can use a 4-pin to 6-pin converter cable with cameras that have their own

external power supply and do not require power from the IEEE 1394 bus.

General-Purpose Digital I/O

The 44-pin D-SUB connector provides access to the general-purpose

digital inputs and outputs. The general-purpose digital I/O available on this

connector includes 2 TTL inputs, 9 TTL outputs, 13 isolated inputs, and

4 isolated outputs. For easy connection to the digital I/O connector, use the

National Instruments digital I/O cable and the NI Vision I/O Terminal

Block and Prototyping Accessory.

Chapter 3 Signal Connections

Table 3-2. Power Connector Terminals

Terminal Description

V Isolated power (5 to 30 VDC)

C Isolated common-mode signal

Note The accessories available for use with the NI 8254R do not provide access to all

available I/O on the NI 8254R. To access this I/O, you can create a custom cable using a

standard male 44-pin D-SUB connector.

For more information about the National Instruments digital I/O cable and

terminal block, refer to the Optional Equipment section of Getting Started

with the NI PCI-8254R.

Note Isolated inputs are compatible with 5 V logic if the external circuit meets the voltage

and current requirements listed in the Specifications section of Getting Started with the

NI PCI-8254R.

© National Instruments Corporation 3-3 NI PCI-8254R User Manual

Page 30

Chapter 3 Signal Connections

Caution Do not draw more than 500 mA combined from the V pins on the 44-pin D-SUB

connector. Do not draw more than 100 mA from 24 V or 30 V isolated outputs. Do not draw

more than 50 mA from 5 V isolated outputs.

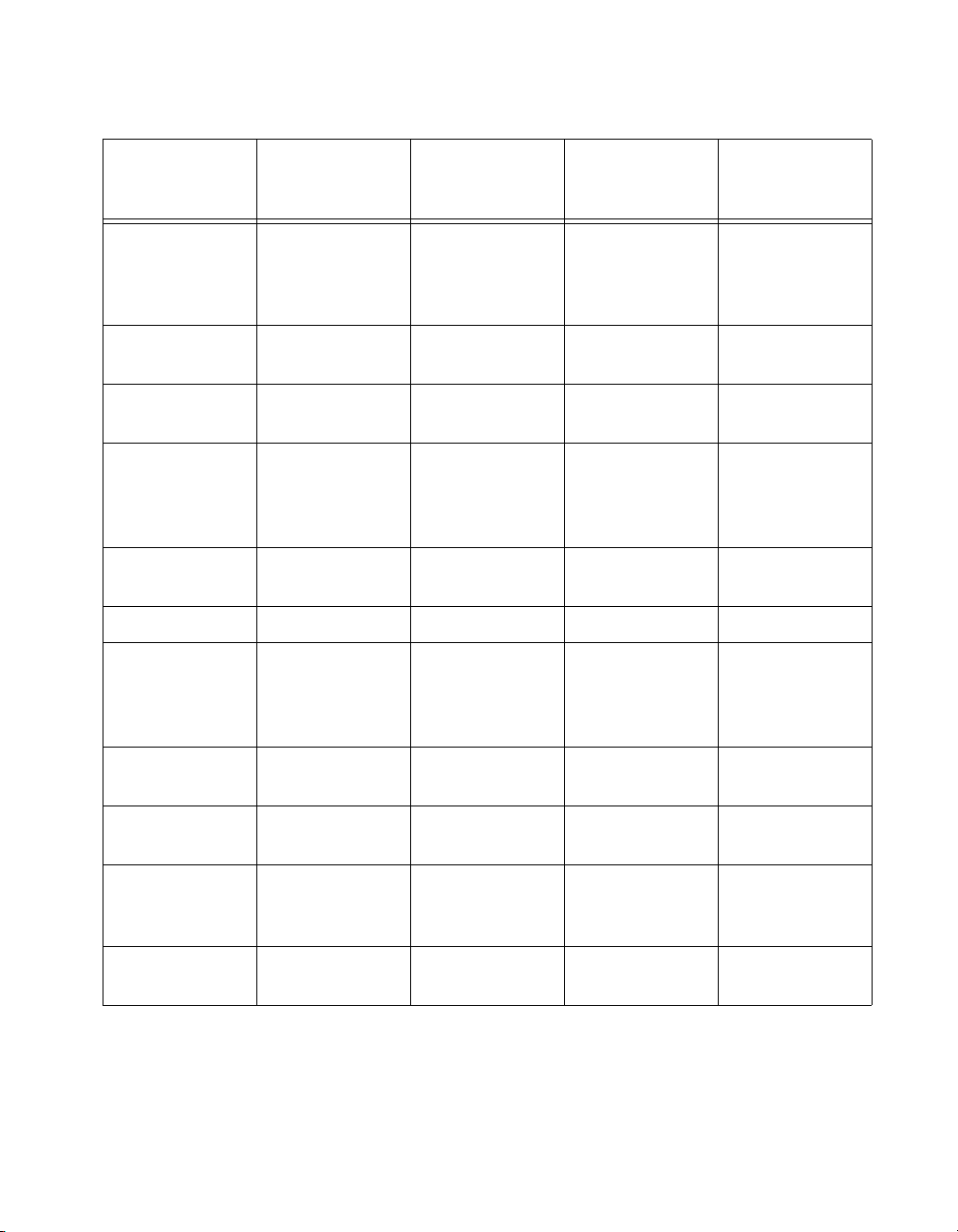

Figure 3-2 illustrates the 44-pin D-SUB connector on the NI 8254R.

153044

11631

Figure 3-2. NI 8254R 44-Pin D-SUB Connector

Table 3-3 lists pin numbers, signal names, and signal descriptions for the

44-pin D-SUB connector on the NI 8254R and the 37-pin terminal block.

Table 3-3. Signal Connections

44-Pin D-SUB

on NI 8254R

Pin Number

1 1 TTL Input 0 Pulse generator

37-Pin Terminal

Block Number

Signal Name

Primary

Function

trigger input

Alternate

Function

Trigger Change

Detector,

General-purpose

input

2 3 C Common-mode

—

signal of the

NI 8254R main

power

3 4 TTL Output 0 Watchdog timer

output

4 5 TTL Output 1 Pulse generator

output

NI PCI-8254R User Manual 3-4 ni.com

General-purpose

output

General-purpose

output

Page 31

44-Pin D-SUB

on NI 8254R

Pin Number

Table 3-3. Signal Connections (Continued)

37-Pin Terminal

Block Number

Signal Name

Primary

Function

Chapter 3 Signal Connections

Alternate

Function

5 6 C Common-mode

signal of the

NI 8254R main

power

6 7 TTL Output 2 Pulse generator

output

7 8 TTL Output 3 Pulse generator

output

8 6 C Common-mode

signal of the

NI 8254R main

power

9 NC TRIG 2*/TTL

Output 8

10 17 V

iso

11 NC TRIG 0*/ISO

Input 12

Pulse generator

output

Isolated power —

Pulse generator

trigger input

12 19 ISO Output 0 General-purpose

output

—

General-purpose

output

General-purpose

output

—

General-purpose

output

Trigger Change

Detector,

General-purpose

input

—

13 35 ISO Output 1 General-purpose

—

output

14 34 C

iso

Isolated

—

common-mode

signal

15 9 ISO Input 0 Input port,

—

Data(0)

© National Instruments Corporation 3-5 NI PCI-8254R User Manual

Page 32

Chapter 3 Signal Connections

44-Pin D-SUB

on NI 8254R

Pin Number

37-Pin Terminal

Block Number

Table 3-3. Signal Connections (Continued)

Primary

Signal Name

Function

Alternate

Function

16 2 TTL Input 1 Pulse generator

trigger input

17 3 C Common-mode

signal of the

NI 8254R main

power

18 20 TTL Output 4 Pulse generator

output

19 21 TTL Output 5 General-purpose

output

20 22 C Common-mode

signal of the

NI 8254R main

power

21 23 TTL Output 6 General-purpose

output

22 24 TTL Output 7 General-purpose

output

23 22 C Common-mode

signal of the

NI 8254R main

power

Trigger Change

Detector,

General-purpose

input

—

General-purpose

output

—

—

—

—

—

24 NC TRIG 1*/TTL

Output 9

25 33 V

26 34 C

iso

iso

Pulse generator

output

General-purpose

output

Isolated power —

Isolated

—

common-mode

signal

NI PCI-8254R User Manual 3-6 ni.com

Page 33

44-Pin D-SUB

on NI 8254R

Pin Number

Table 3-3. Signal Connections (Continued)

37-Pin Terminal

Block Number

Signal Name

Primary

Function

Chapter 3 Signal Connections

Alternate

Function

27 36 ISO Output 2 General-purpose

output

28 37 ISO Output 3 General-purpose

output

29 12 C

iso

Isolated

common-mode

signal

30 10 ISO Input 1 Input port,

Data(1)

31 11 ISO Input 2 Input port,

Data(2)

32 13 ISO Input 3 Input port,

Data(3)

33 16 C

iso

Isolated

common-mode

signal

34 14 ISO Input 4 Input port,

Data(4)

35 15 ISO Input 5 Input port latch,

Data(5)

—

—

—

—

—

—

—

—

Pulse generator

trigger input

36 28 C

iso

Isolated

—

common-mode

signal

37 25 ISO Input 6 Quadrature

encoder Phase A

38 26 ISO Input 7 Quadrature

encoder Phase B

39 28 C

iso

Isolated

General-purpose

input

General-purpose

input

—

common-mode

signal

© National Instruments Corporation 3-7 NI PCI-8254R User Manual

Page 34

Chapter 3 Signal Connections

44-Pin D-SUB

on NI 8254R

Pin Number

37-Pin Terminal

Block Number

Table 3-3. Signal Connections (Continued)

Primary

Signal Name

Function

Alternate

Function

40 27 ISO Input 8 Pulse generator

trigger input

41 29 ISO Input 9 General-purpose

input

42 32 C

43 30 ISO Input 10 General-purpose

44 31 ISO Input 11 User shutdown General-purpose

* TRIG 0, TRIG 1, and TRIG 2 are not available on the 37-pin terminal block or the signal accessory. If you need access to

these signals, you can get them directly from the 44-pin D-SUB connector.

iso

Isolated

common-mode

signal

input

Trigger Change

Detector,

General-purpose

input

Trigger Change

Detector,

General-purpose

input

—

Trigger Change

Detector,

General-purpose

input

input

Cabling

IEEE 1394 Camera Cables

You can connect cameras to the NI 8254R using standard IEEE 1394

cables. IEEE 1394 cables provide both a data path and power to your

camera.

I/O Terminal Block

National Instruments provides an I/O terminal block with the NI 8254R,

which can be mounted either horizontally or vertically. The I/O terminal

block breaks the signals out into easy-to-use screw terminals and comes

with a cable that connects directly to the 44-pin D-SUB connector on the

NI 8254R.

NI PCI-8254R User Manual 3-8 ni.com

Page 35

Chapter 3 Signal Connections

Note TRIG 0, TRIG 1, and TRIG 2 signals are not accessible through the standard 44- to

37-pin cable and I/O terminal block.

NI Vision I/O Terminal Block and Prototyping Accessory

Use the NI Vision I/O Terminal Block and Prototyping Accessory to

troubleshoot and prototype digital I/O applications for the NI 8254R, the

NI 8255R, and the NI CVS-1450 Series compact vision system. The

NI Vision I/O Terminal Block and Prototyping Accessory provides screw

terminals for easy connections and LEDs for each signal.

Note TRIG 0, TRIG 1, and TRIG 2 signals are not accessible through the standard 44 to

37-pin cable and NI Vision I/O Terminal Block and Prototyping Accessory.

Power Requirements

This section describes the power requirements of the NI 8254R.

Isolated Outputs Power Connector

Figure 3-3 illustrates the isolated outputs power connector on the

NI 8254R.

VC

Figure 3-3. NI 8254R Isolated Power Connector

The isolated outputs power connector on the NI 8254R accommodates one

power supply. The V terminal provides the isolated output circuitry (5 to

30 VDC) for the NI 8254R. The C terminal provides the common-mode

signal for the NI 8254R, as shown in Table.

Table 3-4. Power Connector Terminals

Terminal Description

V Isolated power (5 to 30 VDC)

C Isolated common-mode signal

© National Instruments Corporation 3-9 NI PCI-8254R User Manual

Page 36

Technical Support and

Professional Services

Visit the following sections of the National Instruments Web site at

ni.com for technical support and professional services:

• Support—Online technical support resources at

include the following:

– Self-Help Resources—For answers and solutions, visit the

award-winning National Instruments Web site for software drivers

and updates, a searchable KnowledgeBase, product manuals,

step-by-step troubleshooting wizards, thousands of example

programs, tutorials, application notes, instrument drivers, and

so on.

– Free Technical Support—All registered users receive free Basic

Service, which includes access to hundreds of Application

Engineers worldwide in the NI Discussion Forums at

ni.com/forums. National Instruments Application Engineers

make sure every question receives an answer.

For information about other technical support options in your

area, visit

ni.com/contact.

• Training and Certification—Visit

self-paced training, eLearning virtual classrooms, interactive CDs,

and Certification program information. You also can register for

instructor-led, hands-on courses at locations around the world.

• System Integration—If you have time constraints, limited in-house

technical resources, or other project challenges, National Instruments

Alliance Partner members can help. To learn more, call your local

NI office or visit

• Declaration of Conformity (DoC)—A DoC is our claim of

compliance with the Council of the European Communities using

the manufacturer’s declaration of conformity. This system affords

the user protection for electronic compatibility (EMC) and product

safety. You can obtain the DoC for your product by visiting

ni.com/certification.

ni.com/services or contact your local office at

ni.com/alliance.

A

ni.com/support

ni.com/training for

© National Instruments Corporation A-1 NI PCI-8254R User Manual

Page 37

Appendix A Technical Support and Professional Services

• Calibration Certificate—If your product supports calibration,

you can obtain the calibration certificate for your product at

ni.com/calibration.

If you searched

ni.com and could not find the answers you need, contact

your local office or NI corporate headquarters. Phone numbers for our

worldwide offices are listed at the front of this manual. You also can visit

the Worldwide Offices section of

ni.com/niglobal to access the branch

office Web sites, which provide up-to-date contact information, support

phone numbers, email addresses, and current events.

NI PCI-8254R User Manual A-2 ni.com

Page 38

Glossary

A

ADE Application development environment such as LabVIEW, Visual Basic, or

Microsoft Visual C.

B

bandwidth The range of frequencies present in a signal, or the range of frequencies to

which a measuring device can respond.

C

current The rate of flow of electric charge measured in amperes.

D

D-SUB A serial connector.

DCAM Digital camera.

development machine Machine used to develop an application. A development machine usually

has and ADE installed on it.

E

exposure The amount of time that light reaches the image sensor.

F

falling edge An edge trigger occurs when the trigger signal passes through a specified

threshold. A slope that is negative to the trigger is specified as the falling

edge.

© National Instruments Corporation G-1 NI PCI-8254R User Manual

Page 39

Glossary

FireWire A high-speed serial interface invented by Apple Computer in 1989, also

known as IEEE 1394 or iLink.

FPGA Field-programmable gate array. An FPGA is a semi-conductor device

which contains a large quantity of gates (logic devices), which are not

interconnected, and whose function is determined by a wiring list, which is

downloaded to the FPGA. The wiring list determines how the gates are

interconnected, and this interconnection is performed dynamically by

turning semiconductor switches on or off to enable the different

connections.

H

HDL Hardware description language. An example of an HDL is VHDL—a

language used to design digital circuitry.

hot swapping The act of removing or swapping a device when the computer is still on.

I

IEEE Institute of Electrical and Electronics Engineers. A standard-setting body

IIDC IEEE 1394 Trade Association Instrumentation and Industrial Control

Working Group, Digital Camera Sub Working Group.

isolated A signal which has no electrical connection to the overall system power.

N

NI-IMAQdx Driver software for National Instruments IEEE 1394 and Gigabit Ethernet

interface devices.

P

pixel The fundamental picture element in a digital image. The smallest

resolvable rectangular area of an image, either on a screen or stored in

memory. Each pixel has its own brightness and color, usually represented

as red, green, and blue intensities.

NI PCI-8254R User Manual G-2 ni.com

Page 40

Glossary

PLC Programmable Logic Controller. An industrial computer used for factory

automation, process control, and manufacturing systems.

proximity sensor Optical sensor which toggles an electrical signal when an object passes

near it.

Q

quadrature encoder An encoding technique for a rotating device where two tracks of

information are placed on the device, with the signals on the tracks offset

by 90 degrees from each other. This makes it possible to detect the direction

of the motion.

R

RIO Reconfigurable inputs and outputs.

rising edge An edge trigger occurs when the trigger signal passes through a specified

threshold. A slope that is positive to the trigger is specified as the rising

edge.

T

trigger Any event that causes or starts some form of data capture.

TTL Transistor-transistor logic. A digital circuit composed of bipolar transistors

wired in a certain manner. A typical medium-speed digital technology.

Nominal TTL logic levels are 0 and 5 V.

V

VDC Volts direct current.

voltage The electromotive force.

© National Instruments Corporation G-3 NI PCI-8254R User Manual

Page 41

Index

A

acquisition window control, 1-4

C

cabling, 3-8

calibration certificate (NI resources), A-2

connector functions, 3-2

connectors, 3-2

2-position isolated output power, 3-2

general-purpose digital I/O, 3-3

IEEE 1394a, 3-3

conventions used in the manual, v

D

Declaration of Conformity (NI resources), A-1

diagnostic tools (NI resources), A-1

digital I/O

connection considerations, 2-12

overview, 2-1

documentation

conventions used in the manual, v

NI resources, A-1

drivers (NI resources), A-1

G

general purpose outputs, 2-10

general-purpose I/O, 2-9

general-purpose inputs, 2-10

H

help, technical support, A-1

I

I/O for fault conditions, 2-10

I/O for normal operation, 2-4

I/O terminal block, 3-8

IEEE 1394, 1-3

camera cables, 3-8

IEEE 1394a

connector, 3-3

instrument drivers (NI resources), A-1

isolated inputs, 2-3

list of, 2-4

isolated outputs, 2-3

list of, 2-4

power connector, 3-9

K

E

examples (NI resources), A-1

KnowledgeBase, A-1

L

F

FireWire, 1-3

FPGA, 2-1

© National Instruments Corporation I-1 NI PCI-8254R User Manual

LabVIEW FPGA Module, 2-1

LabVIEW, Vision Builder AI, 1-2

latch, 2-9

Page 42

Index

N

National Instruments support and

services, A-1

NI 1427

software programming choices

NI Vision Builder for Automated

Inspection, 1-2

NI Vision Development Module, 1-2

NI 8254R

acquisition window control, 1-4

cabling, 3-8

connection considerations, 2-12

connector functions, 3-2

connectors, 3-2

digital I/O, 2-1

functional overview, 1-3

general-purpose I/O, 2-9

I/O for fault conditions, 2-10

I/O for normal operation, 2-4

IEEE 1394, 1-3

isolated inputs, 2-3

isolated outputs, 2-3

LabVIEW FPGA Module, 2-1

power requirements, 3-9

product selection port, 2-8

quadrature encoder, 2-8

reconfigurable I/O, 2-1

signal connections, 3-1

software overview, 1-1

start conditions, 1-4

timed pulse output, 2-5

trigger change detectors, 2-8

trigger inputs, 2-5

TTL inputs, 2-2

TTL outputs, 2-2

NI 8255R

NI Vision Terminal Block and

Prototyping Accessory, 3-9

NI support and services, A-1

NI Vision Assistant, 1-2

NI Vision Terminal Block and Prototyping

Accessory, 3-9

P

power connector terminals, 3-9

power requirements, 3-9

product selection port, 2-8

programming examples (NI resources), A-1

protecting inductive loads, 2-14

pulse delay, 2-6

pulse modes, 2-6

pulse width, 2-7

Q

quadrature encoder, 2-8

R

reconfigurable I/O, 2-1

RIO. See reconfigurable I/O

S

shutdown, 2-11

signal connections, 3-1

software

NI resources, A-1

overview, 1-1

software programming choices

NI Vision Builder for Automated

Inspection, 1-2

NI Vision Development Module, 1-2

start conditions, 1-4

support, technical, A-1

NI PCI-8254R User Manual I-2 ni.com

Page 43

Index

T

technical support, A-1

timed pulse output

initiating, 2-5

overview, 2-5

training and certification (NI resources), A-1

transmission line effects, 2-15

trigger change detectors, 2-8

trigger inputs, 2-5

trigger polarity, 2-7

troubleshooting (NI resources), A-1

TTL inputs, 2-2

list of, 2-3

TTL outputs, 2-2

list of, 2-3

W

watchdog timer, 2-11

Web resources, A-1

wiring

isolated input to sourcing output device,

2-12

isolated output to external load, 2-13

© National Instruments Corporation I-3 NI PCI-8254R User Manual

Loading...

Loading...