Page 1

Motion Control

NI PCI-7342 Hardware User Manual

NI PCI-7342 Hardware User Manual

October 2002 Edition

Part Number 373454A-01

Page 2

Support

Worldwide Technical Support and Product Information

ni.com

National Instruments Corporate Headquarters

11500 North Mopac Expressway Austin, Texas 78759-3504 USA Tel: 512 683 0100

Worldwide Offices

Australia 03 9879 5166, Austria 0662 45 79 90 0, Belgium 02 757 00 20, Brazil 55 11 3262 3599,

Canada (Calgary) 403 274 9391, Canada (Montreal) 514 288 5722, Canada (Ottawa) 613 233 5949,

Canada (Québec) 514 694 8521, Canada (Toronto) 905 785 0085, China 86 21 6555 7838,

Czech Republic 02 2423 5774, Denmark 45 76 26 00, Finland 09 725 725 11, France 01 48 14 24 24,

Germany 089 741 31 30, Greece 01 42 96 427, Hong Kong 2645 3186, India 91 80 4190000,

Israel 03 6393737, Italy 02 413091, Japan 03 5472 2970, Korea 02 3451 3400, Malaysia 603 9596711,

Mexico 001 800 010 0793, Netherlands 0348 433466, New Zealand 09 914 0488, Norway 32 27 73 00,

Poland 22 3390 150, Portugal 210 311 210, Russia 095 238 7139, Singapore 65 6 226 5886,

Slovenia 3 425 4200, South Africa 11 805 8197, Spain 91 640 0085, Sweden 08 587 895 00,

Switzerland 056 200 51 51, Taiwan 02 2528 7227, United Kingdom 01635 523545

For further support information, refer to the Technical Support and Professional Services appendix. To comment

on the documentation, send email to techpubs@ni.com.

© 2002 National Instruments Corporation. All rights reserved.

Page 3

Important Information

Warranty

The NI PCI-7342 controller is warranted against defects in materials and workmanship for a period of one year from the date of shipment, as

evidenced by receipts or other documentation. National Instruments will, at its option, repair or replace equipment that proves to be defective

during the warranty period. This warranty includes parts and labor.

The media on which you receive National Instruments software are warranted not to fail to execute programming instructions, due to defects

in materials and workmanship, for a period of 90 days from date of shipment, as evidenced by receipts or other documentation. National

Instruments will, at its option, repair or replace software media that do not execute programming instructions if National Instruments receives

notice of such defects during the warranty period. National Instruments does not warrant that the operation of the software shall be

uninterrupted or error free.

A Return Material Authorization (RMA) number must be obtained from the factory and clearly marked on the outside of the package before

any equipment will be accepted for warranty work. National Instruments will pay the shipping costs of returning to the owner parts which are

covered by warranty.

National Instruments believes that the information in this document is accurate. The document has been carefully reviewed for technical

accuracy. In the event that technical or typographical errors exist, National Instruments reserves the right to make changes to subsequent

editions of this document without prior notice to holders of this edition. The reader should consult National Instruments if errors are suspected.

In no event shall National Instruments be liable for any damages arising out of or related to this document or the information contained in it.

XCEPT AS SPECIFIED HEREIN, NATIONAL INSTRUMENTS MAKES NO WARRANTIES, EXPRESS OR IMPLIED, AND SPECIFICALLY DISCLAIMS ANY WARRANTY OF

E

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE . CUSTOMER’S RIGHT TO RECOVER DAMAGES CAUSED BY FAULT OR NEGLIGENCE ON THE PART OF

N

ATIONAL INSTRUMENTS SHALL BE LIMITED TO THE AMOUNT THERETOFORE PAID BY THE CUSTOMER. NATIONAL INSTRUMENTS WILL NOT BE LIABLE FOR

DAMAGES RESULTING FROM LOSS OF DATA, PROFITS, USE OF PRODUCTS, OR INCIDENTAL OR CONSEQUENTIAL DAMAGES, EVEN IF ADVISED OF THE PO SSIBILITY

THEREOF. This limitation of the liability of National Instruments will apply regardless of the form of action, whether in contract or tort, including

negligence. Any action against National Instruments must be brought within one year after the cause of action accrues. National Instruments

shall not be liable for any delay in performance due to causes beyond its reasonable control. The warranty provided herein does not cover

damages, defects, malfunctions, or service failures caused by owner’s failure to follow the National Instruments installation, operation, or

maintenance instructions; owner’s modification of the product; owner’s abuse, misuse, or negligent acts; and power failure or surges, fire,

flood, accident, actions of third parties, or other events outside reasonable control.

Copyright

Under the copyright laws, this publication may not be reproduced or transmitted in any form, electronic or mechanical, including photocopying,

recording, storing in an information retrieval system, or translating, in whole or in part, without the prior written consent of National

Instruments Corporation.

Trademarks

CVI™, LabVIEW™, National Instruments™, NI™, ni.com™, NI-Motion™, and RTSI™ are trademarks of National Instruments Corporation.

Product and company names mentioned herein are trademarks or trade names of their respective companies.

WARNING REGARDING USE OF NATIONAL INSTRUMENTS PRODUCTS

(1) NATIONAL INSTRUMENTS PRODUCTS ARE NOT DESIGNED WITH COMPONENTS AND TESTING FOR A LEVEL OF

RELIABILITY SUITABLE FOR USE IN OR IN CONNECTION WITH SURGICAL IMPLANTS OR AS CRITICAL COMPONENTS IN

ANY LIFE SUPPORT SYSTEMS WHOSE FAILURE TO PERFORM CAN REASONABLY BE EXPECTED TO CAUSE SIGNIFICANT

INJURY TO A HUMAN.

(2) IN ANY APPLICATION, INCLUDING THE ABOVE, RELIABILITY OF OPERATION OF THE SOFTWARE PRODUCTS CAN BE

IMPAIRED BY ADVERSE FACTORS, INCLUDING BUT NOT LIMITED TO FLUCTUATIONS IN ELECTRICAL POWER SUPPLY,

COMPUTER HARDWARE MALFUNCTIONS, COMPUTER OPERATING SYSTEM SOFTWARE FITNESS, FITNESS OF COMPILERS

AND DEVELOPMENT SOFTWARE USED TO DEVELOP AN APPLICATION, INSTALLATION ERRORS, SOFTWARE AND

HARDWARE COMPATIBILITY PROBLEMS, MALFUNCTIONS OR FAILURES OF ELECTRONIC MONITORING OR CONTROL

DEVICES, TRANSIENT FAILURES OF ELECTRONIC SYSTEMS (HARDWARE AND/OR SOFTWARE), UNANTICIPATED USES OR

MISUSES, OR ERRORS ON THE PART OF THE USER OR APPLICATIONS DESIGNER (ADVERSE FACTORS SUCH AS THESE ARE

HEREAFTER COLLECTIVELY TERMED “SYSTEM FAILURES”). ANY APPLICATION WHERE A SYSTEM FAILURE WOULD

CREATE A RISK OF HARM TO PROPERTY OR PERSONS (INCLUDING THE RISK OF BODILY INJURY AND DEATH) SHOULD

NOT BE RELIANT SOLELY UPON ONE FORM OF ELECTRONIC SYSTEM DUE TO THE RISK OF SYSTEM FAILURE. TO AVOID

DAMAGE, INJURY, OR DEATH, THE USER OR APPLICATION DESIGNER MUST TAKE REASONABLY PRUDENT STEPS TO

PROTECT AGAINST SYSTEM FAILURES, INCLUDING BUT NOT LIMITED TO BACK-UP OR SHUT DOWN MECHANISMS.

BECAUSE EACH END-USER SYSTEM IS CUSTOMIZED AND DIFFERS FROM NATIONAL INSTRUMENTS' TESTING

PLATFORMS AND BECAUSE A USER OR APPLICATION DESIGNER MAY USE NATIONAL INSTRUMENTS PRODUCTS IN

COMBINATION WITH OTHER PRODUCTS IN A MANNER NOT EVALUATED OR CONTEMPLATED BY NATIONAL

INSTRUMENTS, THE USER OR APPLICATION DESIGNER IS ULTIMATELY RESPONSIBLE FOR VERIFYING AND VALIDATING

THE SUITABILITY OF NATIONAL INSTRUMENTS PRODUCTS WHENEVER NATIONAL INSTRUMENTS PRODUCTS ARE

INCORPORATED IN A SYSTEM OR APPLICATION, INCLUDING, WITHOUT LIMITATION, THE APPROPRIATE DESIGN,

PROCESS AND SAFETY LEVEL OF SUCH SYSTEM OR APPLICATION.

Page 4

Compliance

FCC/Canada Radio Frequency Interference Compliance

Determining FCC Class

The Federal Communications Commission (FCC) has rules to protect wireless communications from interference. The FCC

places digital electronics into two classes. These classes are known as Class A (for use in industrial-commercial locations only)

or Class B (for use in residential or commercial locations). Depending on where it is operated, this product could be subject to

restrictions in the FCC rules. (In Canada, the Department of Communications (DOC), of Industry Canada, regulates wireless

interference in much the same way.)

Digital electronics emit weak signals during normal operation that can affect radio, television, or other wireless products. By

examining the product you purchased, you can determine the FCC Class and therefore which of the two FCC/DOC Warnings

apply in the following sections. (Some products may not be labeled at all for FCC; if so, the reader should then assume these are

Class A devices.)

FCC Class A products only display a simple warning statement of one paragraph in length regarding interference and undesired

operation. Most of our products are FCC Class A. The FCC rules have restrictions regarding the locations where FCC Class A

products can be operated.

FCC Class B products display either a FCC ID code, starting with the letters EXN,

or the FCC Class B compliance mark that appears as shown here on the right.

Consult the FCC Web site at

FCC/DOC Warnings

This equipment generates and uses radio frequency energy and, if not installed and used in strict accordance with the instructions

in this manual and the CE Marking Declaration of Conformity*, may cause interference to radio and television reception.

Classification requirements are the same for the Federal Communications Commission (FCC) and the Canadian Department

of Communications (DOC).

Changes or modifications not expressly approved by National Instruments could void the user’s authority to operate the

equipment under the FCC Rules.

http://www.fcc.gov for more information.

Class A

Federal Communications Commission

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to part 15 of the FCC

Rules. These limits are designed to provide reasonable protection against harmful interference when the equipment is operated

in a commercial environment. This equipment generates, uses, and can radiate radio frequency energy and, if not installed and

used in accordance with the instruction manual, may cause harmful interference to radio communications. Operation of this

equipment in a residential area is likely to cause harmful interference in which case the user will be required to correct

the interference at his own expense.

Canadian Department of Communications

This Class A digital apparatus meets all requirements of the Canadian Interference-Causing Equipment Regulations.

Cet appareil numérique de la classe A respecte toutes les exigences du Règlement sur le matériel brouilleur du Canada.

Class B

Federal Communications Commission

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to part 15 of the

FCC Rules. These limits are designed to provide reasonable protection against harmful interference in a residential installation.

This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance with the

instructions, may cause harmful interference to radio communications. However, there is no guarantee that interference will not

occur in a particular installation. If this equipment does cause harmful interference to radio or television reception, which can

be determined by turning the equipment off and on, the user is encouraged to try to correct the interference by one or more of

the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

• Consult the dealer or an experienced radio/TV technician for help.

Page 5

Canadian Department of Communications

This Class B digital apparatus meets all requirements of the Canadian Interference-Causing Equipment Regulations.

Cet appareil numérique de la classe B respecte toutes les exigences du Règlement sur le matériel brouilleur du Canada.

Compliance to EU Directives

Readers in the European Union (EU) must refer to the Manufacturer’s Declaration of Conformity (DoC) for information*

pertaining to the CE Marking compliance scheme. The Manufacturer includes a DoC for most every hardware product except

for those bought for OEMs, if also available from an original manufacturer that also markets in the EU, or where compliance is

not required as for electrically benign apparatus or cables.

To obtain the DoC for this product, click Declaration of Conformity at

by product family. Select the appropriate product family, followed by your product, and a link to the DoC appears in Adobe

Acrobat format. Click the Acrobat icon to download or read the DoC.

* The CE Marking Declaration of Conformity will contain important supplementary information and instructions for the user

or installer.

ni.com/hardref.nsf/. This Web site lists the DoCs

Page 6

Contents

About This Manual

Conventions ................................................................................................................... ix

Related Documentation..................................................................................................x

Chapter 1

Introduction

About the NI PCI-7342.................................................................................................. 1-1

Hardware .........................................................................................................1-1

RTSI ................................................................................................................1-1

PCI-7342 Features ........................................................................................... 1-2

Servo and Stepper Fundamentals .................................................................... 1-2

Getting Started ...............................................................................................................1-3

Software Programming Choices ....................................................................................1-3

National Instruments Application Software ..................................................................1-3

Optional Equipment.......................................................................................................1-4

Motion I/O Connections ................................................................................................1-4

Chapter 2

Configuration and Installation

Software Installation ......................................................................................................2-1

Controller Configuration................................................................................................2-1

Unpacking......................................................................................................................2-1

Safety Information .........................................................................................................2-2

Hardware Installation.....................................................................................................2-4

Chapter 3

Hardware Overview

User Connectors.............................................................................................................3-2

Chapter 4

Functional Overview

Dual Processor Architecture ..........................................................................................4-1

Embedded Real-Time Operating System (RTOS) .......................................... 4-2

Trajectory Generators......................................................................................4-2

Analog Feedback.............................................................................................4-2

Flash Memory..................................................................................................4-3

© National Instruments Corporation vii NI PCI-7342 Hardware User Manual

Page 7

Contents

Axes and Motion Resources.......................................................................................... 4-3

Axes ................................................................................................................ 4-3

Motion Resources ........................................................................................... 4-4

Host Communications ................................................................................................... 4-5

Chapter 5

Signal Connections

Motion I/O Connector ................................................................................................... 5-2

Motion Axis Signals........................................................................................ 5-5

Limit and Home Inputs ................................................................................... 5-6

Encoder Signals............................................................................................... 5-8

Analog Inputs.................................................................................................. 5-13

Other Motion I/O Connection ......................................................................... 5-15

Digital I/O Connector .................................................................................................... 5-16

PWM Features.................................................................................................5-17

RTSI Connector............................................................................................................. 5-17

RTSI Signal Considerations............................................................................ 5-17

Wiring Concerns............................................................................... 5-7

Limit and Home Input Circuit .......................................................... 5-7

Encoder <1..2> Phase A/Phase B ..................................................... 5-8

Encoder <1..2> Index ....................................................................... 5-9

Wiring Concerns............................................................................... 5-10

Encoder Input Circuit ....................................................................... 5-11

Trigger Inputs, Shutdown Input, and Breakpoint Outputs ............... 5-11

Wiring Concerns............................................................................... 5-12

Trigger Input, Shutdown Input, and Breakpoint Output Circuits..... 5-12

Wiring Concerns............................................................................... 5-15

Appendix A

Specifications

Appendix B

Cable Connector Descriptions

Appendix C

Technical Support and Professional Services

Glossary

Index

NI PCI-7342 Hardware User Manual viii ni.com

Page 8

About This Manual

This manual provides guidelines for programming and operating the

National Instruments PCI-7342 motion controller and includes controller

specifications and descriptions of electrical and mechanical features.

Refer to the Glossary for definitions of selected related terms.

Conventions

The manual uses the following conventions:

<> Angle brackets that contain numbers separated by an ellipsis represent a

range of values associated with a bit or signal name—for example,

DBIO<3..0>.

This icon denotes a note, which alerts you to important information.

This icon denotes a caution, which advises you of precautions to take to

avoid injury, data loss, or a system crash.

bold Bold text denotes items that you must select or click in the software, such

as menu items and dialog box options. Bold text also denotes parameter

names.

italic Italic text denotes variables, emphasis, a cross reference, or an introduction

to a key concept. This font also denotes text that is a placeholder for a word

or value that you must supply.

monospace Text in this font denotes text or characters that you should enter from the

keyboard, sections of code, programming examples, and syntax examples.

This font is also used for the proper names of disk drives, paths, directories,

programs, subprograms, subroutines, device names, functions, operations,

variables, filenames and extensions, and code excerpts.

© National Instruments Corporation ix NI PCI-7342 Hardware User Manual

Page 9

About This Manual

Related Documentation

The following documents contain information pertaining to the PCI-7342

motion controller:

• NI-Motion Release Notes

• NI-Motion Software Reference Manual

• NI-Motion Software Reference online help

• NI-Motion VIs online help

• PCI Local Bus Specification, Revision 2.1

• Your computer’s technical reference manual

NI PCI-7342 Hardware User Manual x ni.com

Page 10

Introduction

This chapter describes the features and functionality of the National

Instruments PCI-7342 motion controller. It includes a list of items

necessary for getting started with your controller, software choices,

and optional equipment.

About the NI PCI-7342

The NI PCI-7342 motion controller features advanced motion control with

easy-to-use software tools and add-on motion VI libraries for use with

LabVIEW. The PCI-7342 controller provides dedicated motion I/O for

limit and home switches and additional I/O for general-purpose functions.

The following sections describe the features of the PCI-7342.

Hardware

The PCI-7342 controller has high-performance capabilities because of the

advanced dual-processor architecture that uses a Motorola MC68331

real-time 32-bit CPU, combined with an Analog Devices ADSP-2185

digital signal processor (DSP) and custom field programmable gate arrays

(FPGAs). The first-in-first-out (FIFO) bus interface and powerful function

set provide high-speed communications while offloading complex motion

functions from the host PC for optimum command throughput and system

performance.

1

Each axis has motion I/O for end-of-travel limit and home switch inputs,

breakpoint output, trigger input, and encoder feedback rates up to 20 MHz.

The PCI-7342 controller also has nondedicated user I/O, including 32 bits

of digital I/O and two analog inputs for ±10 V signals, joystick inputs, or

monitoring of analog sensors. Additionally, the analog inputs can provide

feedback for loop closure.

RTSI

The PCI-7342 controller supports the National Instruments Real-Time

System Integration (RTSI) bus. RTSI is a dedicated, high-speed digital bus

that facilitates low-level, high-speed, real-time communication between

© National Instruments Corporation 1-1 NI PCI-7342 Hardware User Manual

Page 11

Chapter 1 Introduction

Note Seven of the 34 pins on the RTSI connector are available for user signals. You can

use the software-configurable RTSI switch to accommodate more than seven signal options

for each device. With this many-to-few selector switch, any available signal can be routed

to any RTSI pin. You can also route more than one signal to a single RTSI pin or connect

two RTSI pins to the same signal.

National Instruments devices. The RTSI bus provides high-speed

connectivity between National Instruments products, including image

acquisition (IMAQ) and data acquisition (DAQ) devices. With RTSI, you

can easily synchronize several functions to a common trigger or timing

event across multiple motion, IMAQ, and DAQ devices.

RTSI requires no external cabling and does not consume host bus

bandwidth. Additionally, the RTSI bus features built-in switching that you

can control with software to route signals to and from the bus on the fly.

The bus interface on PCI devices is an internal 34-pin connector. Signals

are shared through a ribbon cable inside the PC enclosure. RTSI cables are

available for chaining two, three, four, or five devices together.

Refer to the National Instruments Developer Zone at

more information about RTSI, including tutorials, examples, and

configuration guidelines.

PCI-7342 Features

The PCI-7342 controller combines servo and stepper functionality for PCI

bus computers. It provides motion control for up to two independent or

coordinated axes of motion.

You can use the PCI-7342 motion controller for point-to-point

and straight-line vector moves for stepper and servo motor applications.

Servo and Stepper Fundamentals

Servo axes can control servo motors, servo hydraulics, servo valves, and

other servo devices. Servo axes always operate in closed-loop mode. These

axes use quadrature encoders or analog inputs for position and velocity

feedback and provide analog command outputs with an industry-standard

range of ±10 V.

Stepper axes control stepper motors and operate in open- or closed-loop

mode. They use quadrature encoders or analog inputs for position and

velocity feedback (closed-loop only), and provide step/direction or

ni.com/zone for

NI PCI-7342 Hardware User Manual 1-2 ni.com

Page 12

Getting Started

Chapter 1 Introduction

clockwise (CW) /counter-clockwise (CCW) digital command outputs. All

stepper axes support full, half, and microstepping applications.

The following items are necessary for setting up and getting started with

your motion controller:

❑ PCI-7342 motion controller

❑ A computer with an available PCI slot

❑ One of the following software packages and documentation:

– LabVIEW

™

– LabWindows

– NI-Motion

/CVI

™

❑ NI PCI-7342 Hardware User Manual

❑ NI-Motion Software Reference Manual

Software Programming Choices

The simple but powerful high-level function set application programming

interface (API) makes programming your controller easy. All setup and

motion control functions are easily executed by calling into either a static

or dynamic link library (DLL). These libraries are callable from C, Visual

Basic, and other high-level languages. Full function set implementations

are available for LabVIEW, LabWindows/CVI, and other

industry-standard software programs.

National Instruments Application Software

LabVIEW is based on the graphical programming language G and features

interactive graphics and a state-of-the-art user interface. In LabVIEW,

you can create 32-bit compiled programs and stand-alone executables

for custom automation, data acquisition, test, measurement, and control

solutions. National Instruments offers the NI-Motion VI Library, a series

of virtual instruments (VIs) for using LabVIEW with the National

Instruments motion control hardware. The NI-Motion VI library

implements the full function set API and a powerful set of demo functions,

example programs, and fully operational, high-level application routines.

© National Instruments Corporation 1-3 NI PCI-7342 Hardware User Manual

Page 13

Chapter 1 Introduction

ANSI C-based LabWindows/CVI also features interactive graphics and a

state-of-the-art user interface. Using LabWindows/CVI, you can generate

C code for custom data acquisition, test, and all measurement and

automation solutions.

NI-Motion is the motion control software and virtual instruments (VIs) for

interfacing with all National Instruments motion controllers.

Optional Equipment

The following optional products are available for use with the National

Instruments motion controllers:

• Cables and cable assemblies for motion and digital I/O

• RTSI bus cables

• UMI wiring connectivity blocks with integrated motion signal

conditioning and motion inhibit functionality

• Stepper and servo motor compatible driver amplifier units with

integrated power supply and wiring connectivity

• Connector blocks, shielded and unshielded 68-pin screw terminal

wiring aids

For specific information about these products, refer to the National

Instruments catalog, the National Instruments Web site at

your National Instruments sales representative.

ni.com, or call

Motion I/O Connections

The external motion I/O and digital I/O connectors are high-density, 68-pin

female VHDCI connectors. Refer to the User Connectors section of

Chapter 3, Hardware Overview, for more information about these

connectors.

For custom cables, use the AMP mating connector (part number

787801-01).

NI PCI-7342 Hardware User Manual 1-4 ni.com

Page 14

Configuration and Installation

This chapter describes how to configure, unpack, and install the National

Instruments PCI-7342 motion controller.

Software Installation

Before installing your controller, install the NI-Motion driver software and,

if appropriate, the Motion VI libraries.

Note You must install the NI-Motion driver software before installing your motion

controller.

Refer to the Release Notes included with the controller for specific

instructions on the software installation sequence for your host PC.

Controller Configuration

Because motion I/O-related configuration is performed entirely with

software, it is not necessary to set jumpers for motion I/O configuration.

2

The PCI-7342 controller is fully compatible with the PCI Local Bus

Specification, Revision 2.1. It is not necessary to configure jumpers for

bus-related configuration.

Unpacking

The PCI-7342 motion controller ships in an antistatic package to prevent

electrostatic discharge from damaging board components. To avoid such

damage in handling the controller, take the following precautions:

1. Ground yourself via a grounding strap or by holding a grounded object,

such as your computer chassis.

2. Touch the antistatic package to a metal part of your computer chassis

before removing the controller from the package.

3. Remove the controller from the package and inspect it for loose

components or any other signs of damage. Notify National Instruments

© National Instruments Corporation 2-1 NI PCI-7342 Hardware User Manual

Page 15

Chapter 2 Configuration and Installation

if the controller appears damaged in any way. Do not install a damaged

controller in your computer.

Caution Never touch the exposed connector pins.

Safety Information

Caution The following paragraphs contain important safety information you must follow

when installing and operating the device.

Do not operate the device in a manner not specified in the documentation.

Misuse of the device may result in a hazard and may compromise the safety

protection built into the device. If the device is damaged, turn it off and do

not use it until service-trained personnel can check its safety. If necessary,

return the device to National Instruments for repair.

Keep away from live circuits. Do not remove equipment covers or shields

unless you are trained to do so. If signal wires are connected to the device,

hazardous voltages can exist even when the equipment is turned off. To

avoid a shock hazard, do not perform procedures involving cover or shield

removal unless you are qualified to do so. Disconnect all field power prior

to removing covers or shields.

If the device is rated for use with hazardous voltages (>30 V

or 60 V

), it may require a safety earth-ground connection wire. See the

dc

, 42.4 Vpk,

rms

device specifications for maximum voltage ratings.

Because of the danger of introducing additional hazards, do not install

unauthorized parts or modify the device. Use the device only with the

chassis, modules, accessories, and cables specified in the installation

instructions. All covers and filler panels must be installed while operating

the device.

Do not operate the device in an explosive atmosphere or where flammable

gases or fumes may be present. Operate the device only at or below the

pollution degree stated in the specifications. Pollution consists of any

foreign matter—solid, liquid, or gas—that may reduce dielectric strength

or surface resistivity. Pollution degrees are listed below:

• Pollution Degree 1—No pollution or only dry, nonconductive

pollution occurs. The pollution has no effect.

NI PCI-7342 Hardware User Manual 2-2 ni.com

Page 16

Chapter 2 Configuration and Installation

• Pollution Degree 2—Normally only nonconductive pollution occurs.

Occasionally, nonconductive pollution becomes conductive because of

condensation.

• Pollution Degree 3—Conductive pollution or dry, nonconductive

pollution occurs. Nonconductive pollution becomes conductive

because of condensation.

Clean the device and accessories by brushing off light dust with a soft,

nonmetallic brush. Remove other contaminants with a stiff, nonmetallic

brush. The unit must be completely dry and free from contaminants before

returning it to service.

Yo u must insulate signal connections for the maximum voltage for which

the device is rated. Do not exceed the maximum ratings for the device.

Remove power from signal lines before connection to or disconnection

from the device.

Operate this device only at or below the installation category stated in the

specifications. Installation categories are listed below:

• Installation CAT IV—for measurements performed at the source of the

low-voltage (<1000 V) installation. Examples include electricity

meters, measurements on primary overcurrent protection devices,

and ripple-control units.

• Installation CAT III—for measurements performed in the building

installation. Examples include measurements on distribution boards,

circuit-breakers, wiring (including cables), bus bars, junction boxes,

switches, socket outlets in the fixed installation, equipment for

industrial use, and some other types of equipment, such as stationary

motors permanently connected to the fixed installation.

• Installation CAT II—for measurements performed on circuits directly

connected to the low-voltage installation. Examples include

measurements on household appliances, portable tools, and other

similar equipment.

• Installation CAT I—for measurements performed on circuits not

directly connected to mains

1

. Examples include measurements on

circuits not derived from mains, and specially-protected (internal)

mains-derived circuits.

1

Mains is defined as the electricity supply system to which the equipment concerned is designed to be connected for either

powering the equipment or for measurement purposes.

© National Instruments Corporation 2-3 NI PCI-7342 Hardware User Manual

Page 17

Chapter 2 Configuration and Installation

Figure 2-1 illustrates a sample installation.

Hardware Installation

Install your PCI-7342 controller in any open compatible expansion slot in

your computer. Appendix A, Specifications, lists the power requirements

for the PCI-7342 controller.

Figure 2-1. Sample Installation

The following instructions are for general installation. Consult your

computer user manual or technical reference manual for specific

instructions and warnings.

Caution Observe precautions for handling electrostatic-sensitive devices. Refer to the

Unpacking section of this chapter for information about handling the controller.

1. Verify that the NI-Motion software is installed on your computer.

2. Power off and unplug your computer.

Caution To protect yourself and the computer from electrical hazards, the computer

should remain off until you finish installing the controller.

3. Remove the top cover or access port to the PCI expansion slots in

your computer.

4. Wait for any motherboard LEDs to turn off to ensure system power

has dissipated.

5. Remove the expansion slot connector port cover on the back panel

of your computer.

NI PCI-7342 Hardware User Manual 2-4 ni.com

Page 18

Chapter 2 Configuration and Installation

6. Insert the controller into a +3.3 V or +5 V PCI slot. Gently rock the

device to ease it into place. It may be a tight fit, but do not force the

device into place.

7. If available, screw the controller mounting bracket to the back panel

rail of the computer.

8. Replace the cover.

9. Plug in the 68-pin cable for motion I/O to the controller.

10. Plug in and turn on your computer.

Your PCI controller is installed.

© National Instruments Corporation 2-5 NI PCI-7342 Hardware User Manual

Page 19

Hardware Overview

This chapter provides an overview of the PCI-7342 motion controller

hardware functionality.

Figure 3-1 shows the PCI-7342 parts locator diagram.

6 7

5

3

1

C

2

3

2001

PCI-7342

4

1 RTSI Connector

2 Assembly Number Label

3 Serial Number Label

© National Instruments Corporation 3-1 NI PCI-7342 Hardware User Manual

4 68-Pin Digital I/O Connector

5 68-Pin Motion I/O Connector

Figure 3-1. PCI-7342 Parts Locator Diagram

6 MC68331 CPU

7 ADSP 2185 DSP

Page 20

Chapter 3 Hardware Overview

User Connectors

The 68-pin motion I/O connector provides all the signals for two axes of

closed-loop motion control, including encoder feedback, limit and home

inputs, breakpoint outputs, trigger inputs, and analog-to-digital (A/D)

converter signals. Refer to Chapter 5, Signal Connections, for details about

motion I/O connector signals.

The 68-pin digital I/O connector provides 32 bits of user-configurable

digital I/O. Refer to Chapter 5, Signal Connections, for details about the

digital I/O connector signals.

The RTSI connector provides up to seven triggers and one high-speed clock

signal to facilitate synchronization between multiple National Instruments

products. Typical applications of the RTSI bus include triggering an image

acquisition or DAQ measurement based on motion events, or capturing

current motion positions based on events external to the motion controller.

The RTSI bus can also be used for general-purpose I/O. Refer to Chapter 5,

Signal Connections, for details about RTSI connector signals.

NI PCI-7342 Hardware User Manual 3-2 ni.com

Page 21

Functional Overview

This chapter provides an overview of the motion control algorithms and

controller capabilities.

Dual Processor Architecture

With the PCI-7342 controller, you can perform one or two axes of

simultaneous, coordinated motion control in a preemptive, multitasking,

real-time environment.

An advanced dual-processor architecture that uses a Motorola MC68331

real-time 32-bit CPU combined with an Analog Devices ADSP 2185 DSP

and custom FPGAs give the PCI-7342 controller high-performance

capabilities. The FIFO bus interface and powerful function set provide

high-speed communications while offloading complex motion functions

from the host PC for optimized system performance.

The PCI-7342 controller uses the digital signal processor for all

closed-loop control, including position tracking, PID control closed-loop

computation, and motion trajectory generation. The DSP chip is supported

by custom FPGAs that perform the high-speed encoder interfacing,

position capture and breakpoint functions, motion I/O processing, and

stepper pulse generation for hard real-time functionality.

4

The embedded, multitasking real-time CPU handles host communications,

command processing, multi-axis interpolation, onboard program

execution, error handling, general-purpose digital I/O, and overall motion

system integration functions.

© National Instruments Corporation 4-1 NI PCI-7342 Hardware User Manual

Page 22

Chapter 4 Functional Overview

Embedded Real-Time Operating System (RTOS)

The embedded firmware is based upon an embedded RTOS kernel and

provides optimum system performance in varying motion applications.

Motion tasks are prioritized, and task execution order depends on the

priority of each task, the state of the entire motion system, I/O or other

system events, and the real-time clock.

The DSP chip is a separate processor that operates independently from

the CPU but is closely synchronized by an internal packet-based command,

data, and messaging event structure. The PCI-7342 controller is a true

multiprocessing and multitasking embedded controller.

The advanced architecture of the PCI-7342 controller enables advanced

motion features, such as enhanced PID functions. Refer to the NI-Motion

Software Reference Manual for more information about the features

available on the PCI-7342 controller.

Trajectory Generators

The trajectory generators on the PCI-7342 controller calculate the

instantaneous position command that controls acceleration and velocity

while moving the axis to its target position. Depending on how you

configure the axis, this command is sent to the PID servo loop or stepper

pulse generator.

To implement infinite trajectory control, the PCI-7342 controller has

four trajectory generators (two per axis) implemented in the DSP chip.

Each generator calculates an instantaneous position each PID update

period. While simple point-to-point moves require only one trajectory

generator, blended moves and infinite trajectory control processing require

two simultaneous generators.

Analog Feedback

The PCI-7342 controller has two multiplexed, 12-bit ADC channels

available for analog feedback. The converted analog values transmit to

both the DSP and CPU through a dedicated internal high-speed serial bus.

The multiplexer scan rate is approximately 50 µs per enabled ADC channel,

which provides the high sampling rates required for feedback loop closure,

joystick inputs, and monitoring analog sensors.

NI PCI-7342 Hardware User Manual 4-2 ni.com

Page 23

Flash Memory

Flash ROM implements the nonvolatile memory on the PCI-7342

controller, which enables the controllers to electrically erase and reprogram

its ROM. Flash memory stores all the embedded firmware, including the

RTOS and DSP code, enabling you to upgrade the onboard firmware

contents in the field for support and new feature enhancement.

Flash memory also allows objects such as programs and data arrays to be

stored in nonvolatile memory. It is possible to save the entire parameter

state of the controller to the flash memory. On the next power cycle, the

controller automatically loads and returns the configuration to these new

saved default values.

Flash ROM also stores the FPGA configuration programs. At power-up, the

FPGAs are booted with these programs, which means that updates to the

FPGA programs can be performed in the field.

Note A flash memory download utility is included with the NI-Motion software that ships

with the controller.

Axes and Motion Resources

Chapter 4 Functional Overview

The PCI-7342 controller can control one or two axes of motion. The axes

can be completely independent, simultaneously coordinated, or mapped in

multidimensional groups called vector spaces. You can also synchronize

vector spaces for multi-vector space coordinated motion control.

Axes

An axis consists of a trajectory generator, a PID (for servo axes) or stepper

control block, and at least one output resource—either a DAC output (for

servo axes) or a stepper pulse generator output. Servo axes must have either

an encoder or ADC channel feedback resource. Closed-loop stepper axes

also require a feedback resource, while open-loop stepper axes do not.

Figures 4-1 and 4-2 show these axis configurations.

You can map one or two feedback resources and one or two output

resources to the axis. An axis with its primary output resource mapped to

a stepper output is by definition a stepper axis. An axis with its primary

output resource mapped to a DAC is by definition a servo axis.

© National Instruments Corporation 4-3 NI PCI-7342 Hardware User Manual

Page 24

Chapter 4 Functional Overview

øA

øB

Index

øA

øB

Index

32-Bit

Encoder

Interface

0101011101101 11101101100

101100111

PID

Servo

Loop

101100111

16-Bit

D/A

Converter

±10 V

Figure 4-1. Servo Axis Resources

32-Bit

Encoder

Interface

01011010 010010110

101100111

Stepper

Control

Loop

101100111

Stepper

Pulse

Generator

Figure 4-2. Stepper Axis Resources

The PCI-7342 controller supports axes with secondary output resources

(DACs for servo axes or stepper outputs). Defining two output resources is

useful when controlling axes with multiple motors, such as gantry systems

in which two DAC outputs can be configured with different torque limits

and/or offsets.

The PCI-7342 controller supports secondary feedback resources (encoders)

for axes defined as servo. Two feedback resources are necessary when

implementing dual-loop control, such as in backlash compensation,

which reduces the number of encoders available for other axes.

Note Refer to the Axis and Resource Configuration section of the NI-Motion Software

Reference Manual for more information about configuring axes.

Motion Resources

Encoder, DAC, ADC, and motion I/O resources that are not used by an axis

are available for nonaxis- or nonmotion-specific applications. You can

directly control an unmapped DAC as a general-purpose analog output

(±10 V). Similarly, you can use any ADC channel to measure

potentiometers or other analog sensors.

NI PCI-7342 Hardware User Manual 4-4 ni.com

Page 25

If an encoder resource is not needed for axis control, you can use it for any

number of other functions, including position or velocity monitoring, as a

digital potentiometer encoder input, or as a master encoder input for

master/slave (electronic gearing) applications.

Each axis also has an associated forward and reverse limit input, a home

input, a high-speed capture trigger input, a breakpoint output, and an inhibit

output. These signals can be used for general-purpose digital I/O when not

being used for their motion-specific purpose.

Note Once mapped to an axis, all features and functions of a resource are available as part

of the axis. It is not necessary to remember or use the resource number directly when

accessing these features. Resources are referenced by axis number once assigned to that axis.

Host Communications

The host computer communicates with the controller through a number of

memory port addresses on the host bus.

The primary bi-directional data transfer port is at the base address of the

controller. This port supports FIFO data passing in both send and readback

directions. The PCI-7342 controller has both a command buffer for

incoming commands and a return data buffer (RDB) for readback data.

Chapter 4 Functional Overview

Two read-only status registers are at offsets from the base address.

The communications status register (CSR) provides bits for

communications handshaking as well as real-time error reporting and

general status feedback to the host PC. The move complete status (MCS)

register provides instantaneous motion status of all axes.

© National Instruments Corporation 4-5 NI PCI-7342 Hardware User Manual

Page 26

Signal Connections

This chapter describes how to send input and output signal connections

directly to the controller and briefly describes the associated I/O circuitry.

The PCI-7342 controller has three connectors that handle all signals to and

from the external motion system:

• 68-pin motion I/O connector

• 68-pin digital I/O connector

• RTSI connector

You can connect to your motion system with cables and accessories,

varying from simple screw terminal blocks to enhanced UMI units and

drives.

Caution Power off all devices when connecting or disconnecting the motion I/O and

auxiliary digital I/O cables. Failure to do so may damage the controller.

Figure 5-1 shows the connectors on the PCI-7342 controller. Refer to

Figure 3-1, PCI-7342 Parts Locator Diagram, to locate the RTSI

connector.

5

DIGITAL I/O MOTION I/O

Figure 5-1. PCI-7342 Motion Controller Connectors

© National Instruments Corporation 5-1 NI PCI-7342 Hardware User Manual

Page 27

Chapter 5 Signal Connections

Motion I/O Connector

The motion I/O connector contains all signals necessary for controlling

axes of servo and stepper motion, including the following features:

• Encoder feedback inputs

• Forward, home, and reverse limit inputs

• Trigger inputs

• Motor command analog and stepper outputs

• Breakpoint outputs

• Inhibit outputs

The motion I/O connector also contains two channels of 12-bit A/D inputs

for analog feedback or general-purpose analog input.

Figure 5-2 shows the pin assignments for the 68-pin motion I/O connector

on the PCI-7342 controller. Refer to Table 5-1 for a description of each

motion I/O signal.

Note Lines above signal names indicate that the signal is active-low.

NI PCI-7342 Hardware User Manual 5-2 ni.com

Page 28

Axis 1 Dir (CCW)

Digital Ground

Digital Ground

Axis 1 Home Switch

Trigger 1

Axis 1 Inhibit

Axis 2 Dir (CCW)

Digital Ground

Digital Ground

Axis 2 Home Switch

Trigger 2

Axis 2 Inhibit

NC

Digital Ground

Digital Ground

NC

NC

NC

NC

NC

Digital Ground

Digital Ground

NC

NC

Digital Ground

Breakpoint 1

NC

Digital Ground

Analog Output 1

NC

Analog Output Ground

Analog Input 1

NC

Analog Reference (Output)

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

Chapter 5 Signal Connections

35

1

2

3

4

5

6

7

8

9

Axis 1 Step (CW)

36

Axis 1 Encoder Phase A

37

Axis 1 Encoder Phase B

38

Axis 1 Encoder Index

39

Axis 1 Forward Limit Switch

40

Axis 1 Reverse Limit Switch

41

Axis 2 Step (CW)

42

Axis 2 Encoder Phase A

43

Axis 2 Encoder Phase B

44

Axis 2 Encoder Index

45

Axis 2 Forward Limit Switch

46

Axis 2 Reverse Limit Switch

47

NC

48

NC

49

NC

50

NC

51

NC

52

NC

53

NC

54

NC

55

NC

56

NC

57

NC

58

NC

59

Host +5 V

60

Breakpoint 2

61

NC

62

Shutdown

63

Analog Output 2

64

NC

65

NC

66

Analog Input 2

67

NC

68

Analog Input Ground

Figure 5-2. 68-Pin Motion I/O Connector Pin Assignment

Caution

Do not connect NC (not connected) signals. Connecting these signals could cause

permanent damage to your motion controller.

© National Instruments Corporation 5-3 NI PCI-7342 Hardware User Manual

Page 29

Chapter 5 Signal Connections

Table 5-1 describes the signals on the motion I/O connector.

Table 5-1. Motion I/O Signal Connections

Signal Name Reference Direction Description

Axis <1..2> Dir (CCW) Digital Ground Output Motor direction or

counter-clockwise control

Axis <1..2> Step (CW) Digital Ground Output Motor step or clockwise control

Axis <1..2> Encoder Phase A Digital Ground Input Closed-loop only—phase A encoder

input

Axis <1..2> Encoder Phase B Digital Ground Input Closed-loop only—phase B encoder

input

Axis<1..2> Encoder Index Digital Ground Input Closed-loop only—index encoder

input

Axis <1..2> Home Switch Digital Ground Input Home switch

Axis <1..2> Forward Limit Switch Digital Ground Input Forward/clockwise limit switch

Axis <1..2> Reverse Limit Switch Digital Ground Input Reverse/counter-clockwise limit

switch

Axis <1..2> Inhibit Digital Ground Output Drive inhibit

Trigger <1..2> Digital Ground Input High-speed position capture trigger

Breakpoint <1..2> Digital Ground Output Breakpoint output <1..2>

Host +5 V Digital Ground Output +5 V—host computer +5 V supply

Analog Input Ground — — Reference for analog inputs

Analog Input <1..2> Analog Input Ground Input 12-bit analog input

Analog Output <1..2> Analog Output Ground Output 16-bit analog output

Analog Output Ground — — Reference for analog outputs

Shutdown Digital Ground Input Controlled device shutdown

Analog Reference (Output) Analog Input Ground Output +7.5 V—analog reference level

Digital Ground — — Reference for digital I/O

input <1..2>

NI PCI-7342 Hardware User Manual 5-4 ni.com

Page 30

Motion Axis Signals

Chapter 5 Signal Connections

The following signals control the servo amplifier or stepper driver:

• Analog Output <1..2>—These 16-bit DAC outputs are typically

the servo command outputs for each axis. They can drive

the industry-standard ±10 V output, and you can limit them to

any positive or negative voltage range desired. They also feature

a software-programmable voltage offset.

Although typically used as the command output of an axis control

loop, unused DACs can also function as independent analog outputs

for general-purpose control.

• Analog Output Ground—This separate return connection is

available to help keep digital noise separate from the analog DAC

outputs. Use this analog ground connection and not Digital Ground

(digital I/O reference) as the reference for the DAC outputs when

connecting to servo amplifiers.

• Axis <1..2> Step (CW) and Dir (CCW)—These open-collector

signals are the stepper command outputs for each axis. The PCI-7342

controller supports both major industry standards for stepper

command signals: step and direction, or independent CW and CCW

pulse outputs.

The output configuration and signal polarity is software programmable

for compatibility with various third-party drives, as follows:

– When step and direction mode is configured, each commanded

step (or microstep) produces a pulse on the step output. The

direction output signal level indicates the command direction of

motion, either forward or reverse.

– CW and CCW mode produces pulses (steps) on the CW output for

forward-commanded motion and pulses on the CCW output for

reverse-commanded motion.

In either case, you can set the active polarity of both outputs to

active-low (inverting) or active-high (non-inverting). For example,

with step and direction, you can make a logic high correspond to either

forward or reverse direction.

The Step (CW) and Dir (CCW) outputs are driven by high-speed

open-collector transistor-to-transistor (TTL) buffers that feature

64 mA sink current capability and built-in 3.3 kΩ pull-up resistors

to +5 V.

Caution Do not connect these outputs to anything other than a +5 V circuit. The output

buffers will fail if subjected to voltages in excess of +5.5 V.

© National Instruments Corporation 5-5 NI PCI-7342 Hardware User Manual

Page 31

Chapter 5 Signal Connections

• Axis <1..2> Inhibit—Use the inhibit output signals to control the

enable/inhibit function of a servo amplifier or stepper driver. When

properly connected and configured, the inhibit function de-energizes

the connected motor its shaft turns freely. These open-collector inhibit

signals feature 64 mA current sink capability with built-in 3.3 kΩ

pull-up resistors to +5 V, and can directly drive most driver/amplifier

inhibit input circuits.

While the industry standard for inhibits is active-low (inverting), these

outputs have programmable polarity and can be set to active-high

(non-inverting) for increased flexibility and unique drive

compatibility.

Inhibit output signals can automatically activate upon a Kill Motion

command or any motion error that causes a kill motion condition—a

following error trip, for example. You can also directly control the

inhibit output signals to enable or disable a driver or amplifier.

Figure 5-3 shows a simplified schematic diagram of the step, direction,

and inhibit output.

Vcc

3.3 kΩ

To the External

Connector Step,

Direction, or Inhibit Pins

74AS760

From the

Step, Direction,

or Inhibit Circuits

Figure 5-3. Step, Direction, and Inhibit Output

Limit and Home Inputs

The following signals control limit and home inputs:

• Axis <1..2> Forward Limit Input

• Axis <1..2> Home Input

• Axis <1..2> Reverse Limit Input

These inputs are typically connected to limit switches located at physical

ends of travel and/or at a specific home position. You can use software to

enable or disable limit and home inputs at any time. Enabling an active

transition on a limit or home input causes a full torque halt stop of the

associated motor axis. In addition, an active forward or reverse limit input

impedes future commanded motion in that direction for as long as the

signal is active.

NI PCI-7342 Hardware User Manual 5-6 ni.com

Page 32

Chapter 5 Signal Connections

Note Limit and home inputs are digitally filtered and must remain active for at least 1 ms

to be recognized. Active signals should remain active to prevent motion from proceeding

further into the limit. Pulsed limit signals stop motion but do not prevent further motion in

that direction if another move is started.

The input polarity of these signals is software programmable for active-low

(inverting) or active-high (non-inverting).

You can use software disabled limit and home inputs as general-purpose

inputs. You can read the status of these inputs at any time and set and

change their polarity as required.

Limit and home inputs are a per-axis enhancement and are not required for

basic motion control. These inputs are part of a system solution for

complete motion control.

Wiring Concerns

For the end of travel limits to function correctly, the forward limit must be

at the forward or positive end of travel, and the reverse limit at the negative

end of travel.

Caution Failure to follow these guidelines may result in motion that stops at a limit but

then travels through the limit, which could damage the motion system. Miswired limits

could prevent motion from occurring at all.

Keep limit and home switch signals and their ground connections wired

separately from the motor driver/amplifier signal and encoder signal

connections.

Caution Wiring these signals near each other can cause faulty motion system operation

due to signal noise and crosstalk.

Limit and Home Input Circuit

All limit and home inputs are digitally filtered and must be active for at

least 1 ms. Figure 5-4 shows a simplified schematic diagram of the circuit

the limit and home switch inputs use for input signal buffering and

detection.

© National Instruments Corporation 5-7 NI PCI-7342 Hardware User Manual

Page 33

Chapter 5 Signal Connections

From the External

Connector Limit

and Home Switch Pins

3.3 kΩ

Vcc

1 kΩ

1/8 W

74HC244

DGND

Figure 5-4. Limit and Home Input Circuit

To the Limit and

Home Switch

Circuits

Caution

Excessive input voltages can cause erroneous operation and/or component

failure. Verify that your input voltage is within the specification range.

Encoder Signals

The PCI-7342 controller offers two channels of single-ended quadrature

encoder inputs. All National Instruments power drives and UMI

accessories provide built-in circuitry that converts differential encoder

signals to single-ended encoder signals. Each channel consists of a

Phase A, Phase B, and Index input, as described in the following sections.

Encoder <1..2> Phase A/Phase B

The encoder inputs provide position and velocity feedback for absolute

and relative positioning of axes in any motion system configuration.

If you do not need an encoder resource for axis control, you can use it for

other functions, including position or velocity monitoring, digital

potentiometer encoder inputs, or as a master encoder input for master/slave

(electronic gearing) applications.

A field-programmable gate array (FPGA) implements the encoder channels

(Encoder <1..2>). The encoders are high-performance with extended input

frequency response and advanced features, such as high-speed position

capture inputs and breakpoint outputs. Their maximum count frequency is

20 MHz.

An encoder input channel converts quadrature signals on Phase A and

Phase B into 32-bit up/down counter values. Quadrature signals are

generated by optical, magnetic, laser, or electronic devices that provide

two signals, Phase A and Phase B, that are 90° out of phase. The leading

phase, A or B, determines the direction of motion. The four transition states

of the relative signal phases provide distinct pulse edges that cause count

up or count down pulses in the direction determined by the leading phase.

NI PCI-7342 Hardware User Manual 5-8 ni.com

Page 34

Chapter 5 Signal Connections

A typical encoder with a specification of N (N = number) lines per unit

of measure (revolutions or linear distance) produces 4 × N quadrature

counts per unit of measure. The count is the basic increment of position

in National Instruments motion systems.

Note Determine quadrature counts by multiplying the encoder resolution in encoder lines

by 4. The encoder resolution is the number of encoder lines between consecutive encoder

indexes (marker or Z-bit). If the encoder does not have an index output, the resolution is

referred to as lines per revolution, or lines per unit of measure—inch, centimeter,

millimeter, and so on.

Encoder <1..2> Index

The Index input works primarily with the Find Index function. This

function uses the number of counts per revolution, or linear distance, to

initiate a search move that locates the index position. When a valid Index

signal transition occurs during a Find Index sequence, the position of the

Index signal is captured very accurately. Use this captured position to

establish a reference zero position for absolute position control or any other

motion system position reference required. Figure 5-5 shows the

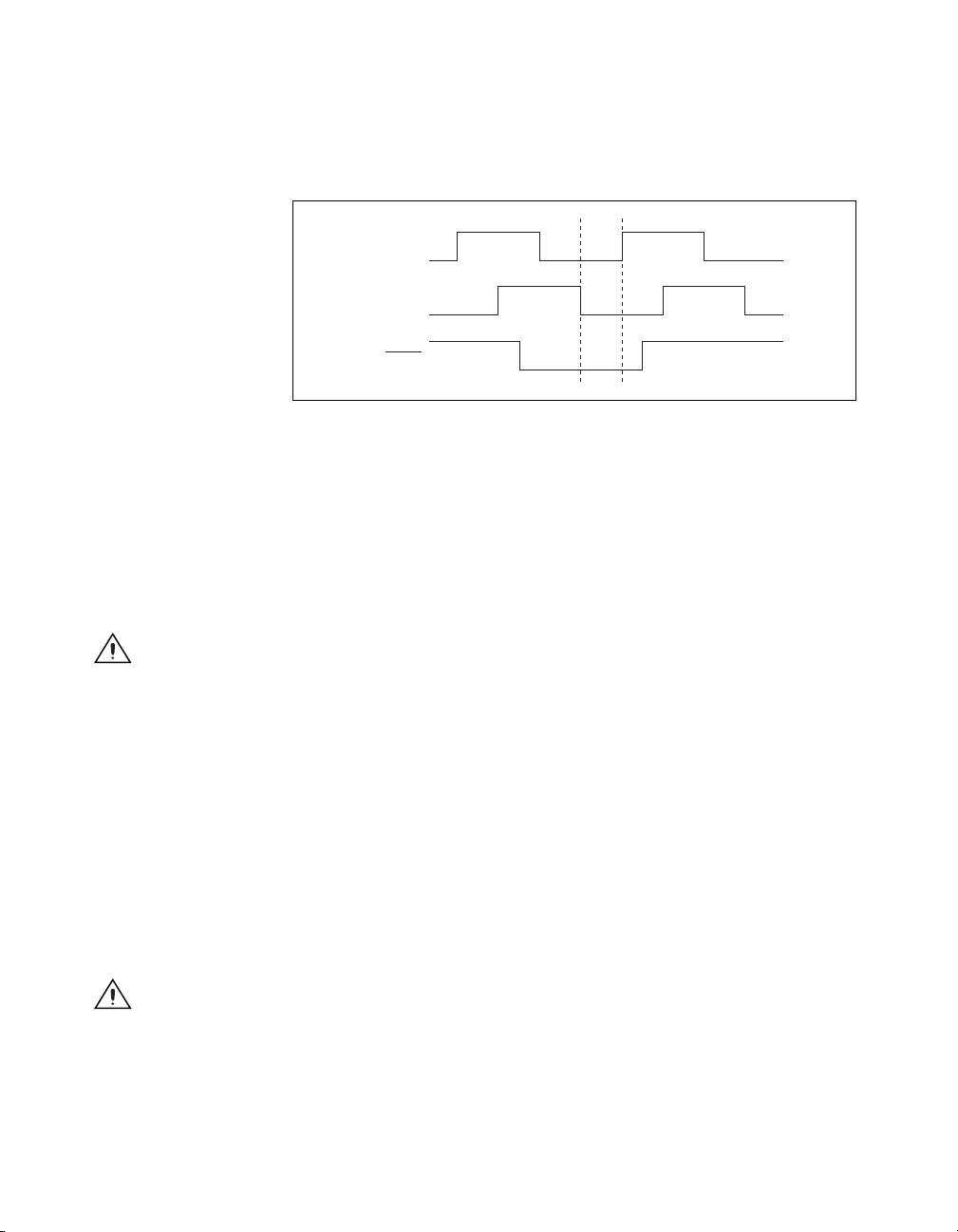

quadrature encoder phasing diagram when using a UMI or drive accessory.

Phase A

Phase B

Index

Figure 5-5. Quadrature Encoder Phasing with a UMI or Drive Accessory

© National Instruments Corporation 5-9 NI PCI-7342 Hardware User Manual

Page 35

Chapter 5 Signal Connections

Figure 5-6 shows the quadrature encoder phasing diagram when

interfacing directly to the PCI-7342 without using a UMI or drive

accessory.

Phase A

Phase B

Index

Figure 5-6. Quadrature Encoder Phasing without a UMI or Drive Accessory

Wiring Concerns

The encoder inputs are connected to quadrature decoder/counter circuits.

It is very important to minimize noise at this interface. Excessive noise on

these encoder input signals may result in loss of counts or extra counts and

erroneous closed-loop motion operation. Verify the encoder connections

before powering up the system.

Caution Wire encoder signals and their ground connections separately from all other

connections. Wiring these signals near the motor drive/amplifier or other signals can cause

positioning errors and faulty operation.

National Instruments recommends using encoders with differential line

driver outputs for all applications. If the encoder cable length is longer than

3.05 m (10 ft), you must use encoders with differential line driver outputs.

Shielded 24 AWG wire is the minimum recommended size for the encoder

cable. For optimized noise immunity, use cables with twisted pairs and an

overall shield.

All National Instruments power drives and UMI accessories provide

built-in circuitry that converts differential encoder signals to single-ended

encoder signals.

Caution Unshielded cable can cause noise to corrupt the encoder signals, resulting in lost

counts and reduced motion system accuracy.

NI PCI-7342 Hardware User Manual 5-10 ni.com

Page 36

3.3 kΩ

From the External

Connector Encoder

Input Pins

Chapter 5 Signal Connections

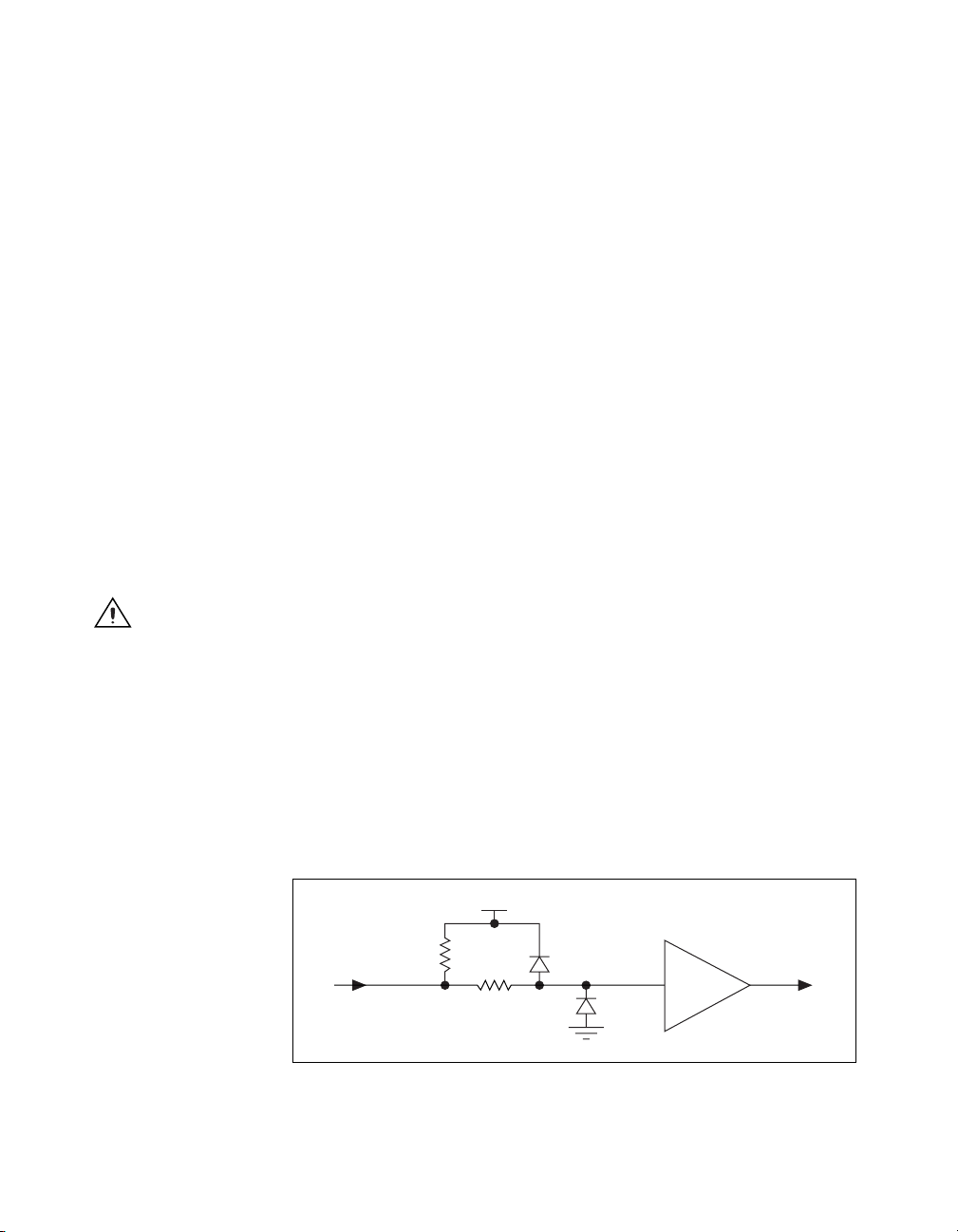

Encoder Input Circuit

Figure 5-7 shows a simplified schematic diagram of the circuit used for

the Phase A, Phase B, and Index encoder inputs. Both Phases A and B are

required for proper encoder counter operation, and the signals must support

the 90° phase difference within system tolerance. The encoder and Index

signals are conditioned by a software-programmable digital filter inside

the FPGA. The Index signal is optional but highly recommended and

required for initialization functionality with the Find Index function.

Vcc

1 kΩ

74HC244

1/8 W

DGND

Figure 5-7. Encoder Input Circuit

To the Quadrature

Decoder Circuit

Trigger Inputs, Shutdown Input, and Breakpoint Outputs

The PCI-7342 controller offers additional high-performance features in the

encoder FPGA. The encoder channels have high-speed position capture

trigger inputs and breakpoint outputs. These signals are useful for

high-speed synchronization of motion with actuators, sensors, and other

parts of the complete motion system:

• Trigger Input <1..2>—When enabled, an active transition on a

high-speed position capture input causes instantaneous position

capture (<100 ns latency) of the corresponding encoder count value.

You can use this high-speed position capture functionality for

applications ranging from simple position tagging of sensor data

to complex camming systems with advance/retard positioning and

registration.

The polarity of the trigger input is programmable in software as

active-low (inverting) or active-high (non-inverting), rising or falling

edge. You can also use a trigger input as a latching general-purpose

digital input by simply ignoring the captured position.

• Shutdown Input—When enabled in software, the shutdown input

signal can be used to kill all motion by asserting the controller inhibits,

setting the analog outputs to 0 V, and stopping any stepper pulse

© National Instruments Corporation 5-11 NI PCI-7342 Hardware User Manual

Page 37

Chapter 5 Signal Connections

generation. To activate shutdown, the signal must transition from a low

to high state (rising edge). Shutdown occurs when a rising edge is

detected on the shutdown line.

• Breakpoint Output <1..2>—You can program a breakpoint output to

transition when the associated encoder value equals the breakpoint

position. You can use a breakpoint output to directly control actuators

or as a trigger to synchronize data acquisition or other functions in the

motion control system.

You can program breakpoints as either absolute, modulo, or relative

position. You can preset breakpoint outputs to a known state so that

when the breakpoint occurs the transition is low to high, high to low,

or toggled.

Open-collector TTL buffers drive the breakpoint outputs. These

buffers feature 64 mA sink current capability and built-in 3.3 kΩ

pull-up resistors to +5 V.

You can directly set and reset breakpoint outputs to use as

general-purpose digital outputs.

Wiring Concerns

Caution Keep trigger input, shutdown input, and breakpoint output signals and their

ground connections wired separately from the motor driver/amplifier signal and encoder

signal connections. Wiring these signals near each other can cause faulty operation.

Excessive input voltages can cause erroneous operation and/or component failure.

Trigger Input, Shutdown Input, and Breakpoint Output Circuits

Figures 5-8, 5-9, and 5-10 show a simplified schematic diagram of the

circuits trigger inputs, shutdown inputs, and breakpoint outputs use for

signal buffering.

Vcc

3.3 kΩ

From the External

Connector

Trigger Pins

1 kΩ

1/8 W

DGND

Figure 5-8. Trigger Input Circuit

74HC244

To the Trigger

Circuits

NI PCI-7342 Hardware User Manual 5-12 ni.com

Page 38

3.3 kΩ

From the External

Connector

Shutdown Pin

To the External

Connector Step,

Direction, or Inhibit Pins

Figure 5-10. Breakpoint Output Circuit

Chapter 5 Signal Connections

Vcc

74HC244

1 kΩ

1/8 W

DGND

Figure 5-9. Shutdown Input Circuit

Vcc

3.3 kΩ

74AS760

To the

Shutdown

Circuits

From the

Step, Direction,

or Inhibit Circuits

Analog Inputs

The PCI-7342 controller has the following ADC input signals:

• Analog Input <1..2>—The PCI-7342 controller includes an

8-channel multiplexed, 12-bit ADC capable of measuring ±10 V, ±5 V,

0–10 V, and 0–5 V inputs. ADC channels 1 and 2 are brought out

externally on the 68-pin motion I/O connector. ADC channels 5

through 8 connect internally, as shown in Table 5-2. You can use these

signals for ADC testing.

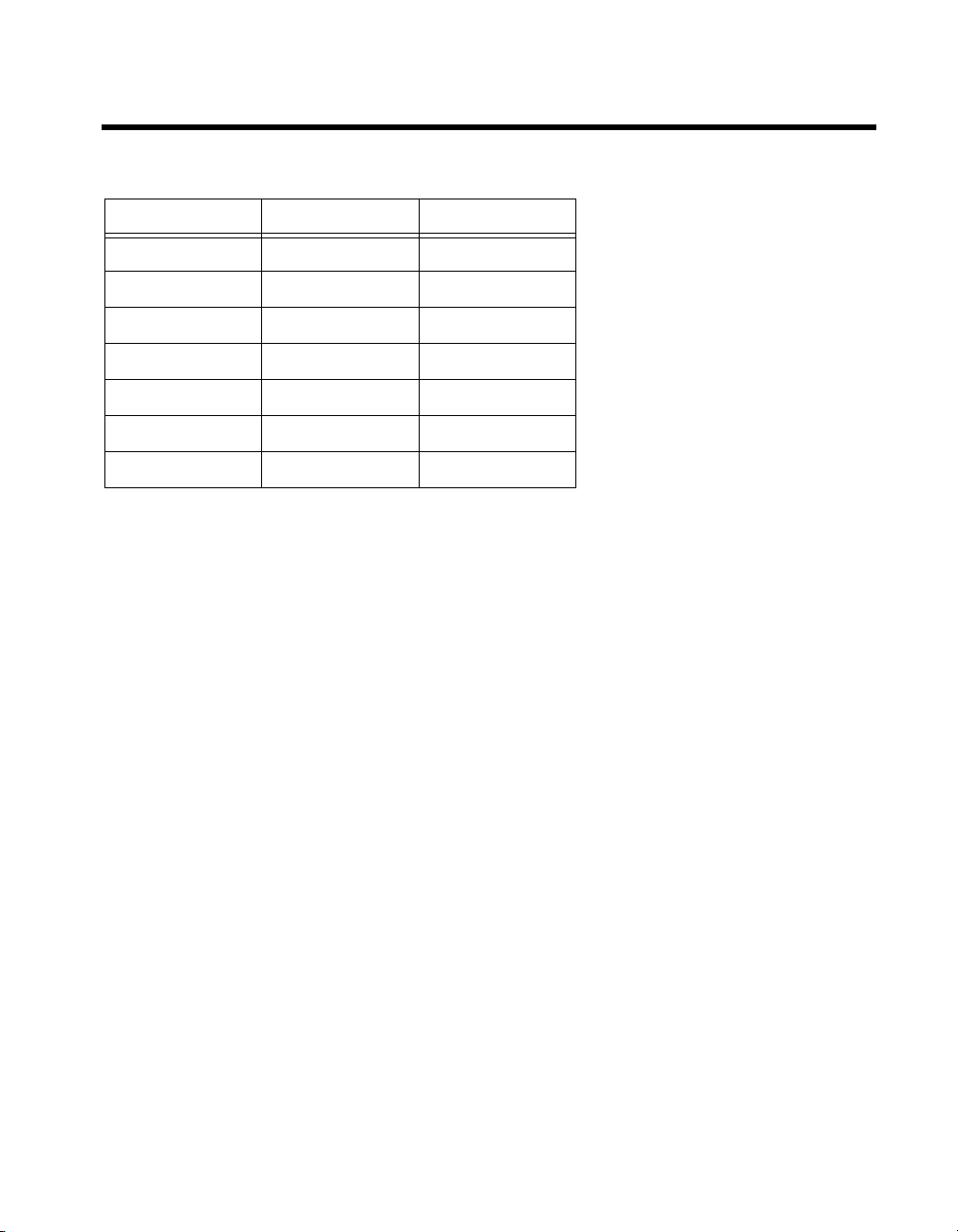

Table 5-2. Internal ADC Channels

ADC Input Signal

3 Unavailable

4 Unavailable

5 Filtered +5 V

6 Floating (NC)

7 Analog Reference (7.5 V)

8 Analog Input Ground

© National Instruments Corporation 5-13 NI PCI-7342 Hardware User Manual

Page 39

Chapter 5 Signal Connections

You can configure each ADC channel for motion feedback, simple

A/D conversion, or both.

You can use the Read ADC function to read the digital value of analog

voltage on any of the eight ADC channels on the controller. Table 5-3

shows the range of values read back and the voltage resolution for each

setting. The voltage resolution is in volts per least significant bit

(V/LSB).

Table 5-3. Analog Input Voltage Ranges

Input Range Binary Values Resolution

±10 V –2,048 to 2,047 0.0049 V/LSB

±5 V –2,048 to 2,047 0.0024 V/LSB

0–10 V 0 to 4,095 0.0024 V/LSB

0–5V 0 to 4,095 0.0012 V/LSB

As indicated in Figure 5-3, when configured as analog feedback, an

analog sensor acts like a limited range absolute position device with a

full-scale position range. You can map any ADC channel as feedback

to any axis.

You can enable and disable individual ADC channels in software.

Disable unused ADC channels for the highest multiplexer scan rate

performance. Properly enabled, the scan rate is high enough to support

analog feedback at the highest PID sample rate.

• Analog Reference—For convenience, 7.5 V (nominal) analog

reference voltage is available. You can use this output as a low-current

supply to sensors that require a stable reference.

• Analog Input Ground—This separate return connection is available

to help keep digital noise out of the analog input. Use this reference

ground connection and not Digital Ground (digital I/O reference) or

Analog Output Ground as the reference for the analog inputs.

NI PCI-7342 Hardware User Manual 5-14 ni.com

Page 40

Wiring Concerns

For proper use of each ADC input channel, connect the analog signal to be

measured to the channel input, and connect its ground reference to the

Analog Input Ground.

Note The analog reference output is an output signal only and must not connect to an

external reference voltage. Connect the common of the external reference to the Analog

Input Ground pin for proper A/D reference and improved voltage measurement.

Other Motion I/O Connection

The PCI-7342 controller provides the following other motion I/O

connection:

• Host +5 V—This signal is the internal +5 V supply of the host

computer. The typical uses of this signal are to detect when the host

computer is powered on and to shut down external motion system

components when the host computer is turned off or disconnected from

the motion accessory.

Caution The host +5 V signal is limited to <100 mA. Do not use this signal to power any

external devices, except those intended in the host bus monitor circuits on the UMI and

drive products.

Chapter 5 Signal Connections

© National Instruments Corporation 5-15 NI PCI-7342 Hardware User Manual

Page 41

Chapter 5 Signal Connections

Digital I/O Connector

All the general-purpose digital I/O lines are available on a separate 68-pin

digital I/O connector. Figure 5-11 shows the pin assignments for this

connector.

+5 V

PCLK

Reserved

Reserved

PWM1

Reserved

Reserved

Reserved

PWM2

Port 1:bit 0

Digital Ground

Port 1:bit 3

Port 1:bit 4

Digital Ground

Port 1:bit 7

Port 2:bit 0

Port 2:bit 1

Digital Ground

Digital Ground

Digital Ground

Port 2:bit 6

Port 2:bit 7

Port 3:bit 0

Digital Ground

Port 3:bit 3

Port 3:bit 4

Digital Ground

Port 3:bit 7

Port 4:bit 0

Digital Ground

Port 4:bit 3

Port 4:bit 4

Digital Ground

Port 4:bit 7

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

1

2

3

4

5

6

7

8

9

Digital Ground

36

Digital Ground

37

Digital Ground

38

DPull

39

Digital Ground

40

Reserved

41

Digital Ground

42

Digital Ground

43

Digital Ground

44

Port 1:bit 1

45

Port 1:bit 2

46

Digital Ground

47

Port 1:bit 5

48

Port 1:bit 6

49

Digital Ground

50

Digital Ground

51

Port 2:bit 2

52

Port 2:bit 3

53

Port 2:bit 4

54

Port 2:bit 5

55

Digital Ground

56

Digital Ground

57

Port 3:bit 1

58

Port 3:bit 2

59

Digital Ground

60

Port 3:bit 5

61

Port 3:bit 6

62

Digital Ground

63

Port 4:bit 1

64

Port 4:bit 2

65

Digital Ground

66

Port 4:bit 5

67

Port 4:bit 6

68

Digital Ground

Figure 5-11. 68-Pin Digital I/O Connector Pin Assignments

NI PCI-7342 Hardware User Manual 5-16 ni.com

Page 42

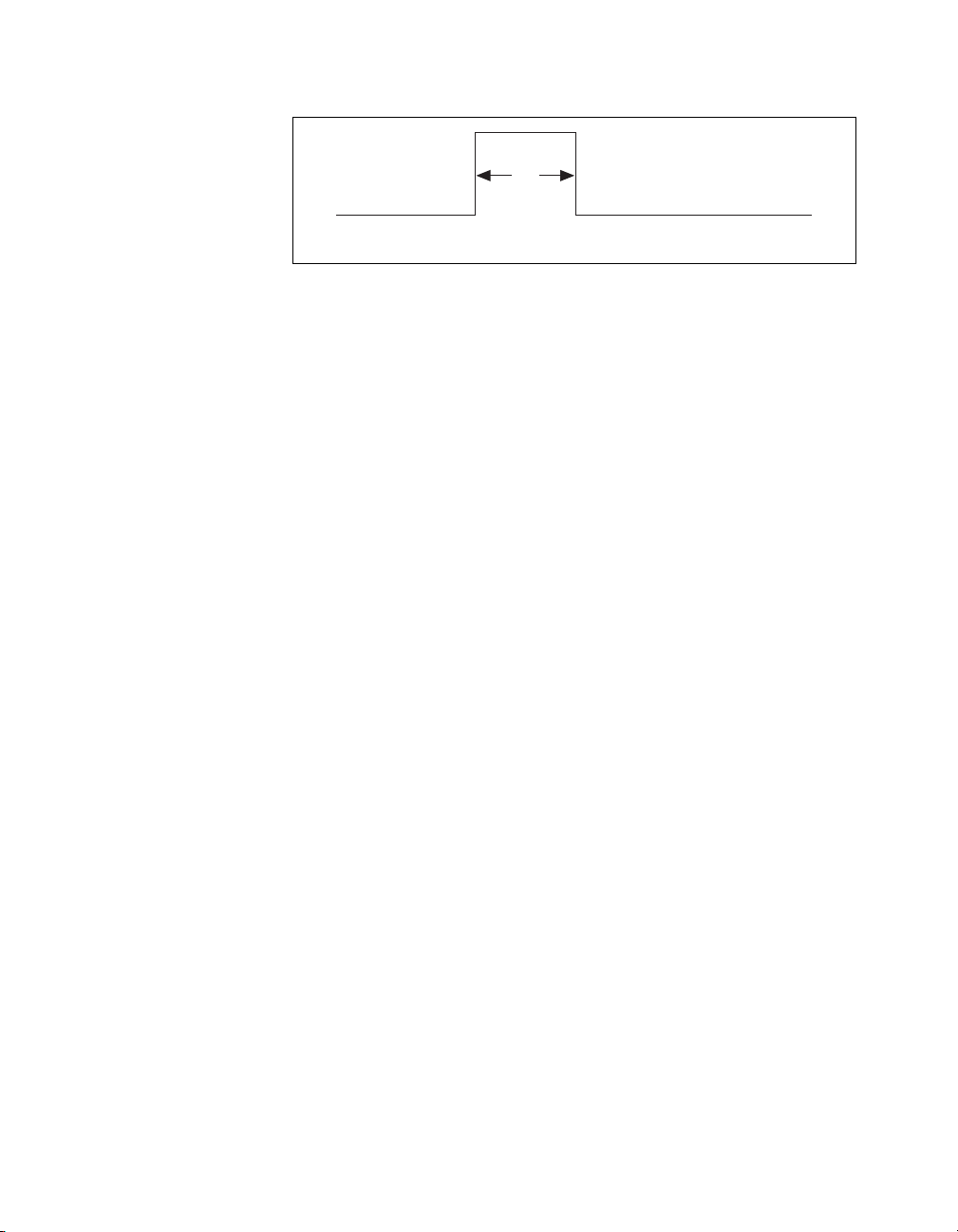

PWM Features

Chapter 5 Signal Connections

The 32-bit digital I/O port is configured in hardware as four 8-bit digital I/O

ports. The bits in a port are typically controlled and read with byte-wide

bitmapped commands.

All digital I/O lines have programmable direction and polarity. Each output

circuit can sink and source 24 mA.

The DPull pin controls the state of the input pins at power-up. Connecting