Page 1

Motion Control

NI-MotionTM User Manual

NI-Motion User Manual

November 2005

371242B-01

Page 2

support

Worldwide Technical Support and Product Information

ni.com

National Instruments Corporate Headquarters

11500 North Mopac Expressway Austin, Texas 78759-3504 USA Tel: 512 683 0100

Worldwide Offices

Australia 1800 300 800, Austria 43 0 662 45 79 90 0, Belgium 32 0 2 757 00 20, Brazil 55 11 3262 3599,

Canada 800 433 3488, China 86 21 6555 7838, Czech Republic 420 224 235 774, Denmark 45 45 76 26 00,

Finland 385 0 9 725 725 11, France 33 0 1 48 14 24 24, Germany 49 0 89 741 31 30, India 91 80 51190000,

Israel 972 0 3 6393737, Italy 39 02 413091, Japan 81 3 5472 2970, Korea 82 02 3451 3400,

Lebanon 961 0 1 33 28 28, Malaysia 1800 887710, Mexico 01 800 010 0793, Netherlands 31 0 348 433 466,

New Zealand 0800 553 322, Norway 47 0 66 90 76 60, Poland 48 22 3390150, Portugal 351 210 311 210,

Russia 7 095 783 68 51, Singapore 1800 226 5886, Slovenia 386 3 425 4200, South Africa 27 0 11 805 8197,

Spain 34 91 640 0085, Sweden 46 0 8 587 895 00, Switzerland 41 56 200 51 51, Taiwan 886 02 2377 2222,

Thailand 662 278 6777, United Kingdom 44 0 1635 523545

For further support information, refer to the Technical Support and Professional Services appendix. To comment

on National Instruments documentation, refer to the National Instruments Web site at ni.com/info and enter

the info code feedback.

© 2003–2005 National Instruments Corporation. All rights reserved.

Page 3

Important Information

Warranty

The media on which you receive National Instruments software are warranted not to fail to execute programming instructions, due to defects

in materials and workmanship, for a period of 90 days from date of shipment, as evidenced by receipts or other documentation. National

Instruments will, at its option, repair or replace software media that do not execute programming instructions if National Instruments receives

notice of such defects during the warranty period. National Instruments does not warrant that the operation of the software shall be

uninterrupted or error free.

A Return Material Authorization (RMA) number must be obtained from the factory and clearly marked on the outside of the package before

any equipment will be accepted for warranty work. National Instruments will pay the shipping costs of returning to the owner parts which are

covered by warranty.

National Instruments believes that the information in this document is accurate. The document has been carefully reviewed for technical

accuracy. In the event that technical or typographical errors exist, National Instruments reserves the right to make changes to subsequent

editions of this document without prior notice to holders of this edition. The reader should consult National Instruments if errors are suspected.

In no event shall National Instruments be liable for any damages arising out of or related to this document or the information contained in it.

E

XCEPT AS SPECIFIED HEREIN, NATIONAL INSTRUMENTS MAKES NO WARRANTIES, EXPRESS OR IMPLIED, AND SPECIFICALLY DISCLAIMS ANY WAR RANTY OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE . CUSTOMER’S RIGHT TO RECOVER DAMAGES CAUSED BY FAULT OR NEGLIGENCE ON THE PART OF

N

ATIONAL INSTRUMENTS SHALL BE LIMITED TO THE AMOUNT THERETOFORE PAID BY THE CUSTOMER. NATIONAL INSTRUMENTS WILL NOT BE LIABLE FOR

DAMAGES RESULTING FROM LOSS OF DATA, PROFITS, USE OF PRODUCTS, OR INCIDENTAL OR CONSEQUENTIAL DAMAGES, EVEN IF ADVISED OF THE POSS IBILITY

THEREOF. This limitation of the liability of National Instruments will apply regardless of the form of action, whether in contract or tort, including

negligence. Any action against National Instruments must be brought within one year after the cause of action accrues. National Instruments

shall not be liable for any delay in performance due to causes beyond its reasonable control. The warranty provided herein does not cover

damages, defects, malfunctions, or service failures caused by owner’s failure to follow the National Instruments installation, operation, or

maintenance instructions; owner’s modification of the product; owner’s abuse, misuse, or negligent acts; and power failure or surges, fire,

flood, accident, actions of third parties, or other events outside reasonable control.

Copyright

Under the copyright laws, this publication may not be reproduced or transmitted in any form, electronic or mechanical, including photocopying,

recording, storing in an information retrieval system, or translating, in whole or in part, without the prior written consent of National

Instruments Corporation.

Trademarks

National Instruments, NI, ni.com, and LabVIEW are trademarks of National Instruments Corporation. Refer to the Terms of Use section

on

ni.com/legal for more information about National Instruments trademarks.

®

is the registered trademark of Apple Computer, Inc. Other product and company names mentioned herein are trademarks or trade

FireWire

names of their respective companies.

Patents

For patents covering National Instruments products, refer to the appropriate location: Help»Patents in your software, the patents.txt file

on your CD, or ni.com/patents.

WARNING REGARDING USE OF NATIONAL INSTRUMENTS PRODUCTS

(1) NATIONAL INSTRUMENTS PRODUCTS ARE NOT DESIGNED WITH COMPONENTS AND TESTING FOR A LEVEL OF

RELIABILITY SUITABLE FOR USE IN OR IN CONNECTION WITH SURGICAL IMPLANTS OR AS CRITICAL COMPONENTS IN

ANY LIFE SUPPORT SYSTEMS WHOSE FAILURE TO PERFORM CAN REASONABLY BE EXPECTED TO CAUSE SIGNIFICANT

INJURY TO A HUMAN.

(2) IN ANY APPLICATION, INCLUDING THE ABOVE, RELIABILITY OF OPERATION OF THE SOFTWARE PRODUCTS CAN BE

IMPAIRED BY ADVERSE FACTORS, INCLUDING BUT NOT LIMITED TO FLUCTUATIONS IN ELECTRICAL POWER SUPPLY,

COMPUTER HARDWARE MALFUNCTIONS, COMPUTER OPERATING SYSTEM SOFTWARE FITNESS, FITNESS OF COMPILERS

AND DEVELOPMENT SOFTWARE USED TO DEVELOP AN APPLICATION, INSTALLATION ERRORS, SOFTWARE AND

HARDWARE COMPATIBILITY PROBLEMS, MALFUNCTIONS OR FAILURES OF ELECTRONIC MONITORING OR CONTROL

DEVICES, TRANSIENT FAILURES OF ELECTRONIC SYSTEMS (HARDWARE AND/OR SOFTWARE), UNANTICIPATED USES OR

MISUSES, OR ERRORS ON THE PART OF THE USER OR APPLICATIONS DESIGNER (ADVERSE FACTORS SUCH AS THESE ARE

HEREAFTER COLLECTIVELY TERMED “SYSTEM FAILURES”). ANY APPLICATION WHERE A SYSTEM FAILURE WOULD

CREATE A RISK OF HARM TO PROPERTY OR PERSONS (INCLUDING THE RISK OF BODILY INJURY AND DEATH) SHOULD

NOT BE RELIANT SOLELY UPON ONE FORM OF ELECTRONIC SYSTEM DUE TO THE RISK OF SYSTEM FAILURE. TO AVOID

DAMAGE, INJURY, OR DEATH, THE USER OR APPLICATION DESIGNER MUST TAKE REASONABLY PRUDENT STEPS TO

PROTECT AGAINST SYSTEM FAILURES, INCLUDING BUT NOT LIMITED TO BACK-UP OR SHUT DOWN MECHANISMS.

BECAUSE EACH END-USER SYSTEM IS CUSTOMIZED AND DIFFERS FROM NATIONAL INSTRUMENTS' TESTING

PLATFORMS AND BECAUSE A USER OR APPLICATION DESIGNER MAY USE NATIONAL INSTRUMENTS PRODUCTS IN

COMBINATION WITH OTHER PRODUCTS IN A MANNER NOT EVALUATED OR CONTEMPLATED BY NATIONAL

INSTRUMENTS, THE USER OR APPLICATION DESIGNER IS ULTIMATELY RESPONSIBLE FOR VERIFYING AND VALIDATING

THE SUITABILITY OF NATIONAL INSTRUMENTS PRODUCTS WHENEVER NATIONAL INSTRUMENTS PRODUCTS ARE

INCORPORATED IN A SYSTEM OR APPLICATION, INCLUDING, WITHOUT LIMITATION, THE APPROPRIATE DESIGN,

PROCESS AND SAFETY LEVEL OF SUCH SYSTEM OR APPLICATION.

Page 4

Contents

About This Manual

Conventions ...................................................................................................................xiii

Documentation and Examples .......................................................................................xiv

Chapter 1

Introduction to NI-Motion

About NI-Motion ...........................................................................................................1-1

NI-Motion Architecture .................................................................................................1-1

Software and Hardware Interaction.................................................................1-2

NI Motion Controller Architecture..................................................................1-2

NI 73xx Architecture.........................................................................1-2

NI Motion Controller Functional Architecture................................................1-4

NI SoftMotion Controller Architecture.............................................1-7

NI SoftMotion Controller Communication Watchdog ..................................................1-9

PART I

Introduction

Chapter 2

Creating NI-Motion Applications

Creating a Generic NI-Motion Application ...................................................................2-1

Adding Measurements to an NI-Motion Application ....................................................2-2

PART II

Configuring Motion Control

Chapter 3

Tuning Servo Systems

NI SoftMotion Controller Considerations .....................................................................3-1

NI SoftMotion Controller for CANopen .........................................................3-1

NI SoftMotion Controller for Ormec ..............................................................3-1

Using Control Loops to Tune Servo Motors .................................................................3-1

Control Loop ...................................................................................................3-2

PID Loop Descriptions......................................................................3-4

Velocity Feedback ...........................................................................................3-9

NI Motion Controllers with Velocity Amplifiers............................................3-10

© National Instruments Corporation v NI-Motion User Manual

Page 5

Contents

PART III

Programming with NI-Motion

Chapter 4

What You Need to Know about Moves

Move Profiles ................................................................................................................ 4-1

Trapezoidal...................................................................................................... 4-1

S-Curve ........................................................................................................... 4-2

Basic Moves ..................................................................................... 4-2

Coordinate Space.............................................................................. 4-3

Multi-Starts versus Coordinate Spaces............................................. 4-3

Trajectory Parameters ..................................................................................... 4-4

NI 73xx Floating-Point versus Fixed-Point ...................................... 4-4

NI 73xx Time Base ........................................................................... 4-5

NI 73xx Arc Move Limitations ....................................................................... 4-13

Timing Loops ................................................................................................................ 4-14

Status Display ................................................................................................. 4-14

Graphing Data ................................................................................................. 4-14

Event Polling................................................................................................... 4-14

Chapter 5

Straight-Line Moves

Position-Based Straight-Line Moves............................................................................. 5-1

Straight-Line Move Algorithm ....................................................................... 5-1

C/C++ Code ....................................................................................................5-5

1D Straight-Line Move Code ........................................................... 5-5

2D Straight-Line Move Code ........................................................... 5-7

Velocity-Based Straight-Line Moves ............................................................................ 5-10

Algorithm ........................................................................................................ 5-11

LabVIEW Code............................................................................................... 5-13

C/C++ Code ....................................................................................................5-13

Velocity Profiling Using Velocity Override.................................................................. 5-17

Algorithm ........................................................................................................ 5-18

LabVIEW Code............................................................................................... 5-19

C/C++ Code ....................................................................................................5-20

NI-Motion User Manual vi ni.com

Page 6

Chapter 6

Arc Moves

Circular Arcs..................................................................................................................6-1

Arc Move Algorithm .......................................................................................6-3

LabVIEW Code ...............................................................................................6-4

C/C++ Code.....................................................................................................6-4

Spherical Arcs................................................................................................................6-7

Algorithm ........................................................................................................6-9

LabVIEW Code ...............................................................................................6-10

C/C++ Code.....................................................................................................6-10

Helical Arcs ...................................................................................................................6-13

Algorithm ........................................................................................................6-14

LabVIEW Code ...............................................................................................6-15

C/C++ Code.....................................................................................................6-15

Chapter 7

Contoured Moves

Overview........................................................................................................................7-1

Arbitrary Contoured Moves...........................................................................................7-2

Contoured Move Algorithm ............................................................................7-3

LabVIEW Code ...............................................................................................7-5

C/C++ Code.....................................................................................................7-6

Contents

Absolute versus Relative Contouring ...............................................7-4

Chapter 8

Reference Moves

Find Reference Move.....................................................................................................8-1

Reference Move Algorithm.............................................................................8-2

LabVIEW Code ...............................................................................................8-3

C/C++ Code.....................................................................................................8-3

Chapter 9

Blending Moves

Blending.........................................................................................................................9-1

Superimpose Two Moves ................................................................................9-2

Blend after First Move Is Complete ................................................................9-3

Blend after Delay.............................................................................................9-4

Blending Algorithm.........................................................................................9-5

LabVIEW Code ...............................................................................................9-6

C/C++ Code.....................................................................................................9-7

© National Instruments Corporation vii NI-Motion User Manual

Page 7

Contents

Chapter 10

Electronic Gearing and Camming

Gearing .......................................................................................................................... 10-1

Algorithm ........................................................................................................ 10-2

Gear Master ...................................................................................... 10-4

LabVIEW Code............................................................................................... 10-5

C/C++ Code ....................................................................................................10-5

Camming ....................................................................................................................... 10-8

Algorithm ........................................................................................................ 10-11

Camming Table............................................................................................... 10-12

Slave Offset ...................................................................................... 10-15

Master Offset .................................................................................... 10-17

LabVIEW Code............................................................................................... 10-19

C/C++ Code ....................................................................................................10-19

Chapter 11

Acquiring Time-Sampled Position and Velocity Data

Algorithm ......................................................................................................................11-2

LabVIEW Code ............................................................................................................. 11-4

C/C++ Code................................................................................................................... 11-4

Chapter 12

Synchronization

Absolute Breakpoints .................................................................................................... 12-2

Buffered Breakpoints (NI 7350 only) ............................................................. 12-3

Buffered Breakpoint Algorithm........................................................ 12-4

LabVIEW Code ................................................................................12-5

C/C++ Code...................................................................................... 12-5

Single Position Breakpoints ............................................................................ 12-8

Single Position Breakpoint Algorithm ............................................. 12-8

LabVIEW Code ................................................................................12-9

C/C++ Code...................................................................................... 12-10

Relative Position Breakpoints ....................................................................................... 12-12

Relative Position Breakpoints Algorithm ....................................................... 12-13

LabVIEW Code............................................................................................... 12-14

C/C++ Code ....................................................................................................12-14

Periodically Occurring Breakpoints .............................................................................. 12-16

Periodic Breakpoints (NI 7350 only) .............................................................. 12-17

Periodic Breakpoint Algorithm ........................................................ 12-17

LabVIEW Code ................................................................................12-18

C/C++ Code...................................................................................... 12-18

NI-Motion User Manual viii ni.com

Page 8

Modulo Breakpoints (NI 7330, NI 7340 and NI 7390 only) .........................................12-21

Modulo Breakpoints Algorithm ......................................................................12-23

LabVIEW Code ...............................................................................................12-24

C/C++ Code.....................................................................................................12-25

High-Speed Capture.......................................................................................................12-27

Buffered High-Speed Capture (NI 7350 only) ................................................12-27

Buffered High-Speed Capture Algorithm .......................................................12-28

LabVIEW Code ...............................................................................................12-29

C/C++ Code.....................................................................................................12-29

Non-Buffered High-Speed Capture.................................................................12-32

High-Speed Capture Algorithm.......................................................................12-33

LabVIEW Code ...............................................................................................12-34

C/C++ Code.....................................................................................................12-35

Real-Time System Integration Bus (RTSI) ...................................................................12-37

RTSI Implementation on the Motion Controller .............................................12-38

Position Breakpoints Using RTSI ...................................................................12-39

Encoder Pulses Using RTSI ............................................................................12-39

Software Trigger Using RTSI .........................................................................12-39

High-Speed Capture Input Using RTSI...........................................................12-40

Chapter 13

Torque Control

Analog Feedback ...........................................................................................................13-1

Torque Control Using Analog Feedback Algorithm .......................................13-3

LabVIEW Code ...............................................................................................13-4

C/C++ Code.....................................................................................................13-5

Monitoring Force ...........................................................................................................13-8

Torque Control Using Monitoring Force Algorithm.......................................13-9

LabVIEW Code ...............................................................................................13-10

C/C++ Code.....................................................................................................13-11

Speed Control Based on Analog Value .........................................................................13-14

Speed Control Based on Analog Feedback Algorithm....................................13-14

LabVIEW Code ...............................................................................................13-15

C/C++ Code.....................................................................................................13-16

Contents

Chapter 14

Onboard Programs

Using Onboard Programs with the NI SoftMotion Controller ......................................14-1

Using Onboard Programs with NI 73xx Motion Controllers .........................................14-2

Writing Onboard Programs .............................................................................14-3

Algorithm ........................................................................................................14-4

LabVIEW Code ...............................................................................................14-5

© National Instruments Corporation ix NI-Motion User Manual

Page 9

Contents

C/C++ Code ....................................................................................................14-6

Running, Stopping, and Pausing Onboard Programs .................................................... 14-8

Running an Onboard Program ........................................................................ 14-8

Stopping an Onboard Program........................................................................ 14-8

Pausing/Resuming an Onboard Program ........................................................ 14-8

Automatic Pausing............................................................................ 14-9

Single-Stepping Using Pause............................................................ 14-9

Conditionally Executing Onboard Programs................................................................. 14-9

Onboard Program Conditional Execution Algorithm ..................................... 14-11

LabVIEW Code............................................................................................... 14-12

C/C++ Code ....................................................................................................14-12

Using Onboard Memory and Data ................................................................................14-14

Algorithm ........................................................................................................ 14-15

LabVIEW Code............................................................................................... 14-16

C/C++ Code ....................................................................................................14-17

Branching Onboard Programs ....................................................................................... 14-19

Onboard Program Algorithm .......................................................................... 14-20

LabVIEW Code............................................................................................... 14-21

C/C++ Code ....................................................................................................14-22

Math Operations ............................................................................................................ 14-24

Indirect Variables ..........................................................................................................14-24

Onboard Buffers ............................................................................................................ 14-25

Algorithm ........................................................................................................ 14-26

Synchronizing Host Applications with Onboard Programs .......................................... 14-26

LabVIEW Code............................................................................................... 14-28

C/C++ Code ....................................................................................................14-30

Onboard Subroutines ..................................................................................................... 14-34

Algorithm ........................................................................................................ 14-34

LabVIEW Code............................................................................................... 14-35

C/C++ Code ....................................................................................................14-38

Automatically Starting Onboard Programs ................................................................... 14-42

Changing a Time Slice .................................................................................................. 14-42

PART IV

Creating Applications Using NI-Motion

Chapter 15

Scanning

Connecting Straight-Line Move Segments ................................................................... 15-1

Raster Scanning Using Straight Lines Algorithm...........................................15-2

LabVIEW Code............................................................................................... 15-3

C/C++ Code ....................................................................................................15-4

NI-Motion User Manual x ni.com

Page 10

Blending Straight-Line Move Segments........................................................................15-7

Raster Scanning Using Blended Straight Lines Algorithm.............................15-8

LabVIEW Code ...............................................................................................15-9

C/C++ Code.....................................................................................................15-10

User-Defined Scanning Path..........................................................................................15-13

User-Defined Scanning Path Algorithm..........................................................15-15

LabVIEW Code ...............................................................................................15-16

C/C++ Code.....................................................................................................15-17

Chapter 16

Rotating Knife

Solution..........................................................................................................................16-1

Algorithm ........................................................................................................16-3

LabVIEW Code ...............................................................................................16-4

C/C++ Code.....................................................................................................16-5

Appendix A

Sinusoidal Commutation for Brushless Servo Motion Control

Appendix B

Initializing the Controller Programmatically

Contents

Appendix C

Using the Motion Controller with the LabVIEW Real-Time Module

Appendix D

Technical Support and Professional Services

Glossary

Index

© National Instruments Corporation xi NI-Motion User Manual

Page 11

About This Manual

This manual provides information about the NI-Motion driver software,

including background, configuration, and programming information.

The purpose of this manual is to provide a basic understanding of the

NI-Motion driver software, and provide programming steps and examples

to help you develop NI-Motion applications.

This manual is intended for experienced LabVIEW, C/C++, or other

developers. Code instructions and examples assume a working knowledge

of the given programming language. This manual also assumes a general

knowledge of motion control terminology and development requirements.

This manual pertains to all NI motion controllers that use the NI-Motion

driver software.

Conventions

The following conventions appear in this manual:

<> Angle brackets that contain numbers separated by an ellipsis represent a

range of values associated with a bit or signal name—for example,

AO <3..0>.

[ ] Square brackets enclose optional items—for example, [

» The » symbol leads you through nested menu items and dialog box options

to a final action. The sequence File»Page Setup»Options directs you to

pull down the File menu, select the Page Setup item, and select Options

from the last dialog box.

This icon denotes a tip, which alerts you to advisory information.

This icon denotes a note, which alerts you to important information.

This icon denotes a caution, which advises you of precautions to take to

avoid injury, data loss, or a system crash.

bold Bold text denotes items that you must select or click in the software, such

as menu items and dialog box options. Bold text also denotes parameter

names.

© National Instruments Corporation xiii NI-Motion User Manual

response].

Page 12

About This Manual

italic Italic text denotes variables, emphasis, a cross reference, or an introduction

to a key concept. Italic text also denotes text that is a placeholder for a word

or value that you must supply.

monospace Text in this font denotes text or characters that you should enter from the

keyboard, sections of code, programming examples, and syntax examples.

This font is also used for the proper names of disk drives, paths, directories,

programs, subprograms, subroutines, device names, functions, operations,

variables, filenames, and extensions.

monospace bold Monospace bold text indicates a portion of code with structural

significance.

monospace italic Monospace italic text indicates a portion of code that is commented out.

Documentation and Examples

In addition to this manual, NI-Motion includes the following

documentation to help you create motion applications:

• Getting Started with NI-Motion for NI 73xx Motion Controllers—This

document provides installation instructions and general information

about the NI-Motion product.

• Getting Started: NI SoftMotion Controller for Ormec

ServoWire SM Drives—Refer to this document for information about

getting started with the NI SoftMotion Controller for Ormec.

• Getting Started: NI SoftMotion Controller for Copley CANopen

Drives—Refer to this document for information about getting started

with the NI SoftMotion Controller for CANopen.

• NI-Motion VI Help—Refer to this document for specific information

about NI-Motion LabVIEW VIs.

• NI-Motion Function Help—Refer to this document for specific

information about NI-Motion C/C++ functions.

• Measurement & Automation Explorer Help for Motion—Refer to this

document for configuration information.

• NI-Motion ReadMe—Refer to this HTML document for information

about hardware and software installation and information about

changes to the NI-Motion driver software in the current version. This

document also contains last-minute information about NI-Motion.

• Application notes—For information about advanced NI-Motion

concepts and applications, visit

ni.com/appnotes.nsf/.

NI-Motion User Manual xiv ni.com

Page 13

About This Manual

• NI Developer Zone (NIDZ)—Visit the NI Developer Zone, at

ni.com/zone, for example programs, tutorials, technical

presentations, the Instrument Driver Network, a measurement

glossary, an online magazine, a product advisor, and a community area

where you can share ideas, questions, and source code with motion

developers around the world.

• Motion Hardware Advisor—Visit the National Instruments Motion

Hardware Advisor at

ni.com/devzone/advisors/motion/ to

select motors and stages appropriate to the motion control application.

In addition to the NI Developer Zone, you can find NI-Motion C/C++

and Visual Basic programming examples in the

FlexMotion\Examples

default directory is

NI-Motion

.

folder where you installed NI-Motion. The

Program Files\National Instruments\

NI-Motion\

You can find LabVIEW example programs under

examples\Motion

in the directory where you installed LabVIEW. You can find

LabWindows

™

/CVI™ examples under samples\Motion in the directory

where you installed LabWindows/CVI.

You can find the NI-Motion C/C++ and LabVIEW example code

referenced in this manual in the

Examples\NI-Motion User Manual

NI-Motion\Documentation\

folder where you installed

NI-Motion.

© National Instruments Corporation xv NI-Motion User Manual

Page 14

Introduction

This user manual provides information about the NI-Motion driver

software, motion control setup, and specific task-based instructions for

creating motion control applications using the LabVIEW and C/C++

application development environments.

Part I covers the following topics:

• Introduction to NI-Motion

• Creating NI-Motion Applications

Part I

© National Instruments Corporation I-1 NI-Motion User Manual

Page 15

Introduction to NI-Motion

About NI-Motion

NI-Motion is the driver software for National Instruments 73xx motion

controllers and the NI SoftMotion Controller. You can use NI-Motion to

create motion control applications using the included library of LabVIEW

VIs and C/C++ functions.

National Instruments also offers the Motion Assistant and NI-Motion

development tools for Visual Basic.

NI-Motion Architecture

The NI-Motion driver software architecture is based on the interaction

between the NI motion controllers and a host computer. This interaction

includes the hardware and software interface and the physical and

functional architecture of the NI motion controllers.

1

© National Instruments Corporation 1-1 NI-Motion User Manual

Page 16

Chapter 1 Introduction to NI-Motion

Software and Hardware Interaction

NI Motion Assistant

Graphical Prototyping Tool

Creates ADE

Code

Measurement and

Automation Explorer

Configuration Utility

NI-Motion Driver Software

NI Motion Controller

Figure 1-1. NI Motion Control Hardware and Software Interaction

Note

The last block in Figure 1-1 is not applicable to the NI SoftMotion Controller.

NI Motion Controller Architecture

This section includes information about the architecture for both the 73xx

family of NI motion controllers and the NI SoftMotion Controller.

NI 73xx Architecture

NI 73xx controllers use a dual-processor architecture. The two processors,

a central processing unit (CPU) and a digital signal processor (DSP), form

the backbone of the NI motion controller. The controller plugs into a

variety of slots, including PCI slots, or to a PC using a high-speed serial

interface, such as IEEE 1394 (FireWire

Application Development Environments:

LabVIEW, Visual Basic, and C++

®

).

NI-Motion User Manual 1-2 ni.com

Page 17

Chapter 1 Introduction to NI-Motion

The controller CPU is a 32-bit micro-controller running an embedded real

time, multitasking operating system. This CPU offers the performance and

determinism needed to solve most complex motion applications. The CPU

performs command execution, host synchronization, I/O reaction, and

system supervision.

The DSP has the primary responsibility of fast closed-loop control with

simultaneous position, velocity, and trajectory maintenance on multiple

axes. The DSP also closes the position and velocity loops, and directly

commands the torque to the drive or amplifier.

Motion I/O occurs in hardware on an FPGA and consists of

limit/home switch detection, position breakpoint, and high-speed capture.

This ensures very low latencies in the range of hundreds of nanoseconds

for breakpoints and high-speed captures. Refer to Chapter 12,

Synchronization, for information about breakpoints and high-speed

capture.

The motion controller processor is monitored by a watchdog timer, which

is hardware that can be used to automatically detect software anomalies and

reset the processor if any occur. The watchdog timer checks for proper

processor operation. If the firmware on the motion controller is unable to

process functions within 62 ms, the watchdog timer resets the motion

controller and disallows further communications until you explicitly reset

the motion controller. This ensures the real-time operation of the motion

control system. The following functions may take longer than 62 ms to

process.

• Save Defaults

• Reset Defaults

• Enable Auto Start

• Object Memory Management

• Clear Buffer

• End Storage

These functions are marked as non-real-time functions. Refer to the

NI-Motion Function Help or the NI-Motion VI Help for more information.

© National Instruments Corporation 1-3 NI-Motion User Manual

Page 18

Chapter 1 Introduction to NI-Motion

Figure 1-2 illustrates the physical architecture of the NI motion controller

hardware.

Host Computer

Microprocessor

Running a Real-Time

Operating System

PC

Supervisory/

Communications/

User-defined Onboard

Programs

Watchdog

Timer

Figure 1-2. Physical NI Motion Controller Architecture

Because the NI SoftMotion Controller is not a hardware device, information about

Tip

its architecture is not covered in this section. Refer to the NI SoftMotion Controller

Architecture section for information about the functional architecture that is specific to the

NI SoftMotion Controller.

NI Motion Controller Functional Architecture

Functionally, the architecture of the NI 73xx motion controllers and the

NI SoftMotion Controller is generally divided into four components:

supervisory control, trajectory generator, control loop, and motion I/O. For

the NI SoftMotion Controller, the motion I/O component is separate from

the controller. Refer to Figure 1-3 and Figure 1-4 for an illustration of how

the components of the 73xx and NI SoftMotion Controller interact.

NI Motion Controller

Processor (DSP)

Encoders and Motion I/O

Digital Signal

Control Loop and

Trajectory Generation

FPGAs

NI-Motion User Manual 1-4 ni.com

Page 19

Chapter 1 Introduction to NI-Motion

Figure 1-3 shows the components of the NI 73xx motion controllers.

Typical NI 73xx Motion Controller Architecture

Supervisory Control

Host

Host

Bus

Microcontroller running RTOS/DSPs/FPGAs

Trajectory Generation

Figure 1-3. Typical NI 73xx Motion Controller Functional Architecture

Figure 1-4 shows the components of the NI SoftMotion controller.

NI SoftMotion Controller Architecture

Supervisory Control

Trajectory Generation

Bus

Any CPU on a real-time environment

Software is separate from the I/O

Control Loop

Control Loop

To drive

From

feedback

Analog & Digital I/O

& sensors

To drive

From

feedback

Analog & Digital I/O

& sensors

Figure 1-4. NI SoftMotion Controller Functional Architecture

© National Instruments Corporation 1-5 NI-Motion User Manual

Page 20

Chapter 1 Introduction to NI-Motion

Figure 1-5 illustrates the functional architecture of NI motion controllers.

Supervisory Control

(ms)

User API

Interface

Supervisory

Control

Commands for

Trajectory Generator

Trajectory Generation

(ms)

Cruise

Jerk

Accel

Velocity

Time

dt

Set Point

Jerk

Decel

Interpolation

Control Loop (µs)

(with Interpolation)

PID

Output

Event Monitoring Interface

I/O

New

Set Point

Updated

Updates Trajectory

Generator Based on

I/O And User

Response

Feedback

Sensor

Figure 1-5. NI Motion Controller Functional Architecture

The following list describes how each component of the 73xx controllers

and the NI SoftMotion Controller functions:

• Supervisory control—Performs all the command sequencing and

coordination required to carry out the specified operation

– System initialization, which includes homing to a zero position

– Event handling, which includes electronic gearing, triggering

outputs based on position, updating profiles based on user defined

events, and so on

– Fault Detection, which includes stopping moves on a limit switch

encounter, safe system reaction to emergency stop or drive faults,

watchdog, and so on

• Trajectory generator provides path planning based on the profile

specified by the user

• Control loop—Performs fast, closed-loop control with simultaneous

position, velocity, and trajectory maintenance on one or more axes

NI-Motion User Manual 1-6 ni.com

Page 21

Chapter 1 Introduction to NI-Motion

The control loop handles closing the position/velocity loop based on

feedback, and it defines the response and stability of the system. For

stepper systems, the control loop is replaced with a step generation

component. To enable the control loop to execute faster than the

trajectory generation, an interpolation component, or spline engine, the

control loop interpolates between setpoints calculated by the trajectory

generator. Refer to Figure 1-5 for an illustration of the spline engine.

• Motion I/O—Analog and digital I/O that sends and receives signals

from the rest of the motion control system. Typically, the analog output

is used as a command signal for the drive, and the digital I/O is used

for quadrature encoder signals as feedback from the motor. The motion

I/O performs position breakpoint and high speed capture. Also, the

supervisory control uses the motion I/O to achieve certain required

functionality, such as reacting to limit switches and creating the

movement modes needed to initialize the system.

NI SoftMotion Controller Architecture

The NI-Motion architecture for the NI SoftMotion Controller uses standard

PC-based platforms and open standards to connect intelligent drives to a

real-time host. In this architecture, the software components of the motion

controller run on a real-time host and all I/O is implemented in the drives.

This separation of I/O from the motion controller software components

helps to lower system cost and improve reliability by improving

connectivity. Open standards, such as IEEE 1394 and CANopen, are

used to connect these components.

NI SoftMotion Controller for Ormec

When you use the NI SoftMotion Controller with an Ormec device, you can

daisy chain up to 15 drives together and connect them to the real-time host.

The real-time isochronous mode of the IEEE 1394 bus is used to transfer

data between the drives and the host. Figure 1-6 shows the NI SoftMotion

Controller component architecture that applies when the controller is used

with an Ormec device.

The supervisory control and trajectory generation loops execute every

millisecond. If the control loop is configured to execute faster than every

millisecond, the trajectory data is interpolated before the control loop

uses it.

© National Instruments Corporation 1-7 NI-Motion User Manual

Page 22

Chapter 1 Introduction to NI-Motion

Ormec DriveNI SoftMotion Controller on Host Device*

Supervisory

Control

*Host device is a PC or PXI chassis running the

LabVIEW Real-Time Module for RTX Targets

**I/O includes encoder implementation

Figure 1-6. NI SoftMotion Controller Functional Architecture for Ormec

Trajectory

Generation

Control

Loop

I/O**

IEEE 1394 Bus

NI SoftMotion Controller for CANopen

When you use the NI SoftMotion Controller with a CANopen device, you

can daisy chain up to 15 drives together and connect them to the real-time

host. The real-time Process Data Objects (PDOs) defined by the CANopen

protocol are used to transfer data between the drives and host.

All I/O required by the motion controller is implemented by CANopen

drives that support the Device Profile 402 for Motion Control. Currently,

the NI SoftMotion Controller supports only CANopen drives from Copley

Controls Corp. When used with CANopen devices, the Supervisory

Control and Trajectory Generation components of the NI SoftMotion

Controller execute in a real-time environment that is running LabVIEW

Real-Time Module (ETS).

If your motion control system uses 8 axes or fewer, the supervisory control

and trajectory generation loops execute every 10 milliseconds. If your

motion control system uses more than 8 axes, the supervisory control and

trajectory generation loops execute every 20 milliseconds. When you use

the NI SoftMotion Controller with a CANopen drive, the drive implements

the control loop and interpolation.

NI-Motion User Manual 1-8 ni.com

Page 23

Chapter 1 Introduction to NI-Motion

NI SoftMotion Controller

on Host Device*

Supervisory

Control

*Host device is a PC or PXI chassis running the

LabVIEW Real-Time Module

**I/O includes encoder implementation

Figure 1-7. NI SoftMotion Controller Functional Architecture for CANopen

Trajectory

Generation

Spline

Engine

CAN Bus

CANopen Drive

Control

Loop

I/O**

In this configuration, the I/O and the control loop execute on the CANopen

drive. The NI SoftMotion Controller uses an NI-CAN device to

communicate to the CAN bus.

NI SoftMotion Controller Communication Watchdog

The supervisory control in the NI SoftMotion Controller continuously

monitors all communication with the drives connected to the host. If any

drive fails to update its data in the host loop update period, the axis

corresponding to that drive is disabled and the communication watchdog

status bit, which is returned by the Read Per Axis Status function, is set to

TRUE. Similarly, all drives connected to the NI SoftMotion Controller are

configured to go into a fault state if the data from the

NI SoftMotion Controller is not updated every host loop update period on

the drives.

The communication watchdog functionality ensures that the NI SoftMotion

Controller operates in real time.

Tip To get an axis or axes out of the communication watchdog state, reset the

NI SoftMotion Controller.

© National Instruments Corporation 1-9 NI-Motion User Manual

Page 24

Creating NI-Motion Applications

This chapter describes the basic form of an NI-Motion application and its

interaction with other I/O, such as a National Instruments data and/or image

acquisition device.

Creating a Generic NI-Motion Application

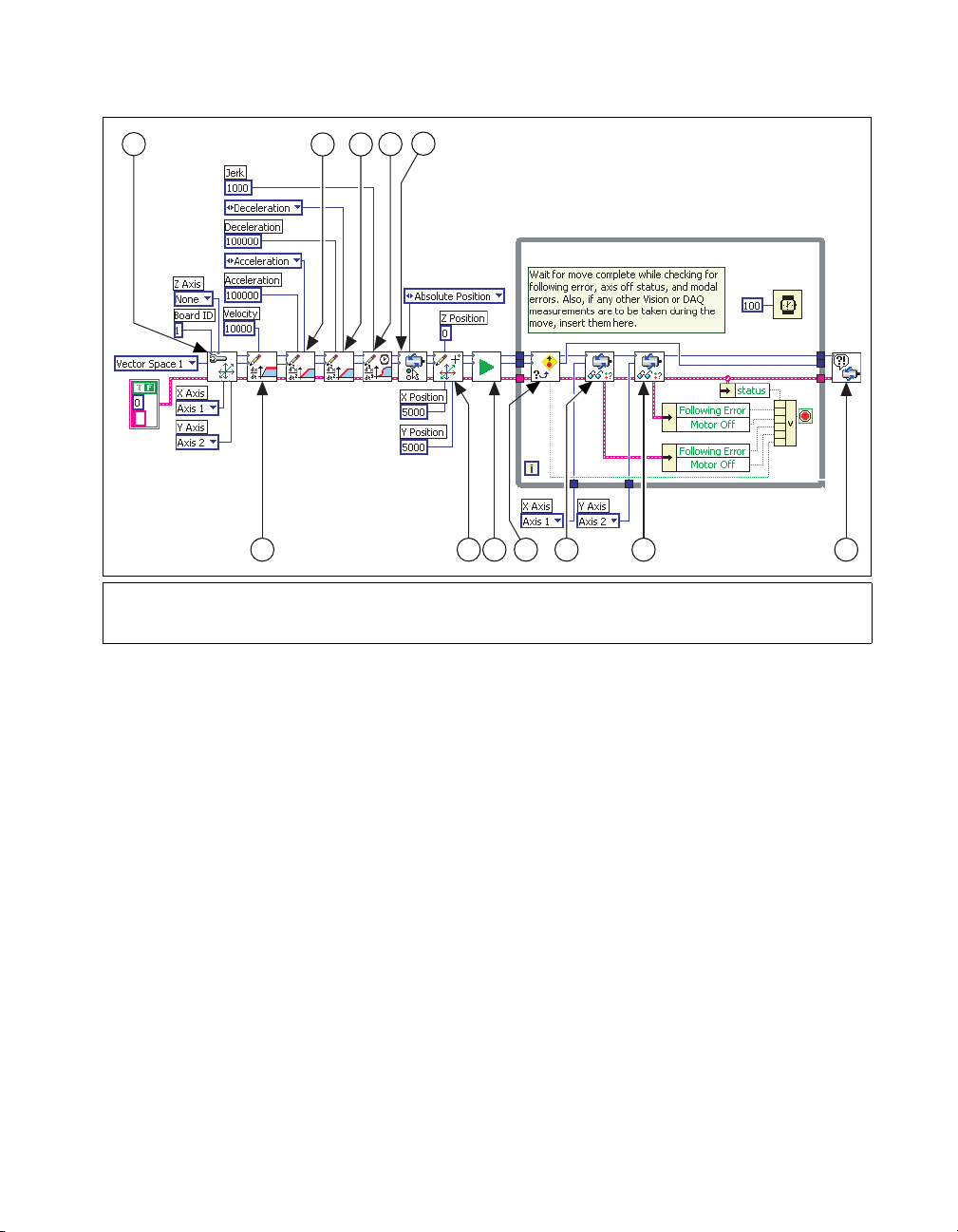

Figure 2-1 illustrates the steps for creating an application with NI-Motion,

and describes the generic steps required to design a motion application.

2

© National Instruments Corporation 2-1 NI-Motion User Manual

Page 25

Chapter 2 Creating NI-Motion Applications

Determine the system requirements

Getting Started with NI-Motion

for NI 73xx Motion Controllers

Measurement & Automation

Explorer Help for Motion

Part III:

Programming with NI-Motion

Determine the

required mechanical system

Connect the hardware

Configure the controller using

MAX

Test the motion system

Plan the moves

Create the moves

Add measurements with data

and/or image acquisition (optional)

Figure 2-1. Generic Steps for Designing a Motion Application

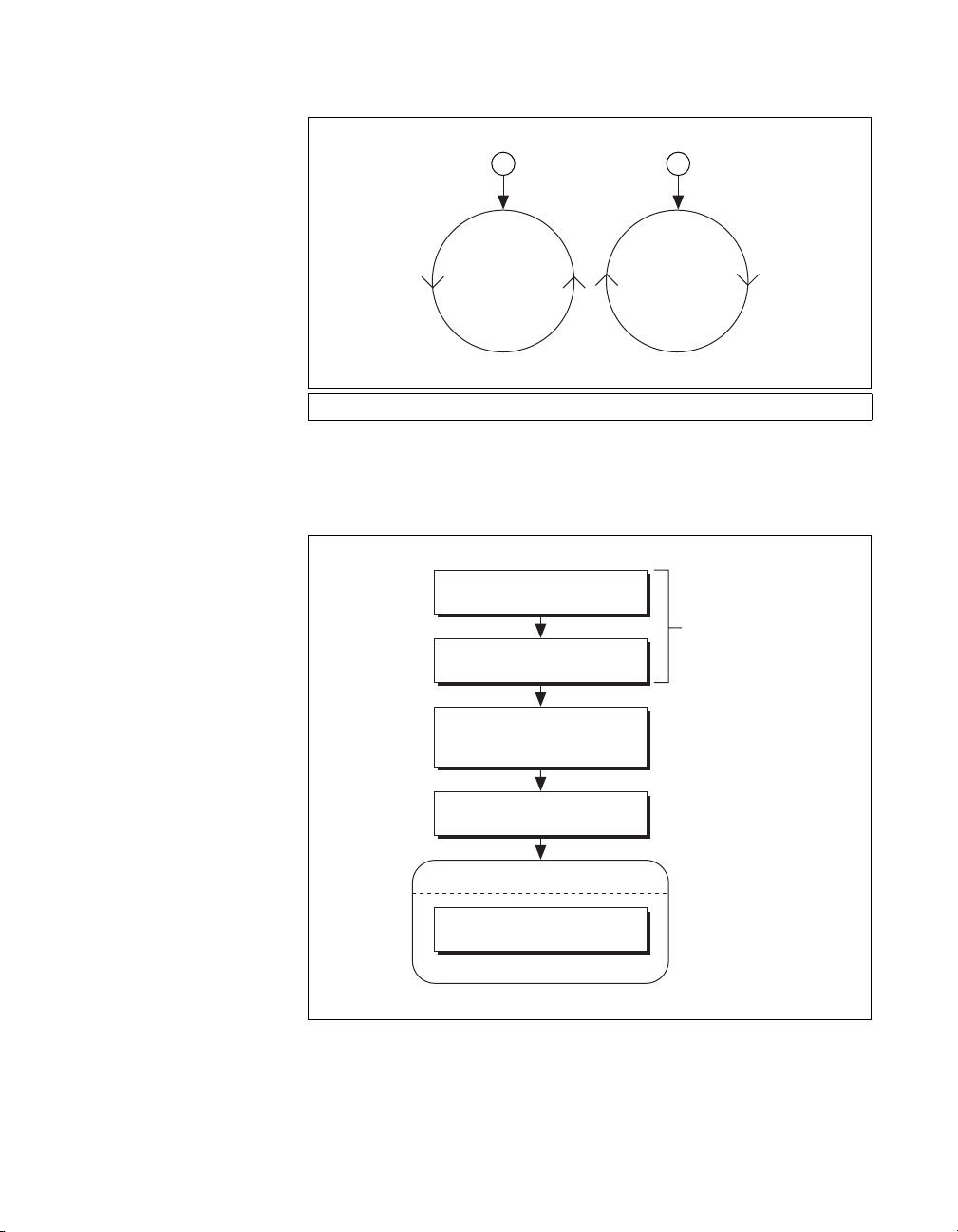

Adding Measurements to an NI-Motion Application

Figure 2-2 illustrates an expanded view of the topics covered in Part III,

Programming with NI-Motion, of this manual. For information about items

in the diagram, refer to Chapter 12, Synchronization.

NI-Motion User Manual 2-2 ni.com

Page 26

Chapter 2 Creating NI-Motion Applications

1

Define control mechanism for I/O

Breakpoints*

2a

Define breakpoint position

Enable a breakpoint

Set data or image acquisition

device to trigger on breakpoint

Re-enable the breakpoint

after each occurrence

(absolute/relative/modulo

breakpoints only)

Synchronization

High-speed capture**

2b

Define triggering input type

Enable high-speed capture

Read the captured position

Re-enable high-speed capture

after each occurrence

(non-buffered high-speed

capture only)

Chapter 12:

* Breakpoints cause a digital output to change state when a specified position is reached

by an encoder. Breakpoints are not supported by the NI SoftMotion Controller when it is

used with an Ormec or CANopen device.

** A high-speed capture records the position of an encoder when a digital line is used as

a trigger. High-speed captures are not supported by NI SoftMotion Controller for

CANopen. You can use two high-speed captures per axis when you are using the

NI SoftMotion Controller with an Ormec device.

Figure 2-2. Input/Output with Data and Image Acquisition

© National Instruments Corporation 2-3 NI-Motion User Manual

Page 27

Chapter 2 Creating NI-Motion Applications

Note If you are using RTSI to connect your motion controller to a National Instruments

data or image acquisition device, be aware that the NI SoftMotion Controller does not

support RTSI.

NI-Motion User Manual 2-4 ni.com

Page 28

Configuring Motion Control

Motion control is divided into two parts: configuration and execution.

Part II of this manual discusses configuring the hardware and software

components of a motion control system using NI-Motion.

Part II covers the following topic:

• Tuning Servo Systems

Part II

© National Instruments Corporation II-1 NI-Motion User Manual

Page 29

Tuning Servo Systems

When your motion control system includes a servo motor, you must tune

and calibrate the system to ensure proper performance. This chapter covers

general information about tuning and calibrating your servo system using

control loop parameters. Refer to Measurement & Automation Explorer

Help for Motion for more information about and instructions for tuning

servo motors in Measurement & Automation Explorer (MAX).

NI SoftMotion Controller Considerations

This section includes information you need if you are using the

NI SoftMotion Controller.

NI SoftMotion Controller for CANopen

This chapter does not apply if you are using the

NI SoftMotion Controller for CANopen because the control loop is

implemented on the drive. Refer to the drive documentation for

information about tuning the servo motors you are using with the CANopen

drive.

3

NI SoftMotion Controller for Ormec

If you are using the NI SoftMotion Controller for Ormec with an Ormec

ServoWire drive in position mode, you must tune the control loop using the

drive configuration utility provided by Ormec.

Using Control Loops to Tune Servo Motors

Tuning maximizes the performance of your servo motors. A servo system

uses feedback to compensate for errors in position and velocity.

For example, when the servo motor reaches the desired position, it cannot

stop instantaneously. There is a normal overshoot that must be corrected.

The controller turns the motor in the opposite direction for the amount of

distance equal to the detected overshoot. However, this corrective move

also exhibits a small overshoot, which must also be corrected in the same

manner as the first overshoot.

© National Instruments Corporation 3-1 NI-Motion User Manual

Page 30

Chapter 3 Tuning Servo Systems

A properly tuned servo system exhibits overshoot as shown in Figure 3-1.

Overshoot

Commanded

Position

Time

0

Settling Time

Figure 3-1. Properly Tuned Servo Motor Behavior

The amount of time required for the motors to settle on the commanded

position is called the settling time. By tuning the servo motors, you can

affect the settling time, the amount of overshoot, and various other

performance characteristics.

Control Loop

NI motion servo control uses control loops to continuously correct errors in

position and velocity. You can configure the control loop to perform a

Proportional, Integral and Derivative (PID) loop or a more advanced

control loop, such as the velocity feedback (PIV) or velocity feedforward

(PIVff) loops.

NI-Motion User Manual 3-2 ni.com

Page 31

Chapter 3 Tuning Servo Systems

Figure 3-2. NI-Motion Servo PID Loop

© National Instruments Corporation 3-3 NI-Motion User Manual

Page 32

Chapter 3 Tuning Servo Systems

PID Loop Descriptions

The following are common variables relating to the PID control loop.

Kp (Proportional Gain)

The proportional gain (Kp) determines the contribution of restoring force

that is directly proportional to the position error. This restoring force

functions in much the same way as a spring in a mechanical system.

Each sample period, the PID loop calculates the position error, which is the

difference between the instantaneous trajectory position and the primary

feedback position, and multiplies the position error by Kp to produce the

proportional component of the 16-bit DAC command output.

An axis with too small a value of Kp is unable to hold the axis in position

and is very soft. Increasing Kp stiffens the axis and improves its disturbance

torque rejection. However, too large a value of Kp often results in

instability.

Ki (Integral Gain)

The integral gain (Ki) determines the contribution of restoring force that

increases with time, ensuring that the static position error in the servo loop

is forced to zero. This restoring force works against constant torque loads

to help achieve zero position error when the axis is stopped.

Each sample period, the position error is added to the accumulation of

previous position errors to form an integration sum. This integration sum is

scaled by dividing by 256 prior to being multiplied by Ki.

In applications with small static torque loads, this value can be left at its

default value of zero (0). For systems having high static torque loads, this

value should be tuned to minimize position error when the axis is stopped.

Although non-zero values of Ki cause reduced static position error, they

tend to cause increased position error during acceleration and deceleration.

This effect can be mitigated through the use of the Integration Limit

parameter. Too high a value of Ki often results in servo loop instability.

National Instruments therefore recommends that you leave Ki at its default

value of zero until the servo system operation is stable. Then you can add a

small amount of Ki to minimize static position errors.

NI-Motion User Manual 3-4 ni.com

Page 33

Chapter 3 Tuning Servo Systems

Kd (Derivative Gain)

The derivative gain (Kd) determines the contribution of restoring force

proportional to the rate of change (derivative) of position error. This force

acts much like viscous damping in a damped spring and mass mechanical

system. A shock absorber is an example of this effect.

The PID loop computes the derivative of position error every derivative

sample period. A non-zero value of Kd is required for all systems that use

torque block amplifiers, where the command output is proportional to

motor torque, for the servo loop operation to be stable. Too small a Kd

value results in servo loop instability.

With velocity block amplifiers, where the command output is proportional

to motor velocity, it is typical to set Kd to zero or a very small positive

value.

Kv (Velocity Feedback)

You can use a primary or secondary feedback encoder for velocity

feedback. Setting the velocity feedback gain (Kv) to a value other than

zero (0) enables velocity feedback using the secondary encoder, if

configured, or the primary encoder if a secondary encoder is not

configured.

Kv is used to scale this velocity feedback before it is added to the other

components in the 16-bit DAC command output. Kv is similar to derivative

gain (Kd) except that it scales the velocity estimated from encoder

resources only. The derivative gain scales the derivative of the position

error, which is the difference between the instantaneous trajectory position

and the primary feedback position. Like the Kd term, the velocity feedback

derivative is calculated every derivative sample period and the contribution

is updated every PID sample period.

Velocity feedback is estimated through a combination of speed-dependent

algorithms. Velocity is measured based on the time elapsed between each

encoder count.

Vff (Velocity Feedforward)

The velocity feedforward gain (Vff) determines the contribution in the

16-bit DAC command output that is directly proportional to the

instantaneous trajectory velocity. This value is used to minimize following

error during the constant velocity portion of a move and can be changed at

any time to tune the PID loop.

© National Instruments Corporation 3-5 NI-Motion User Manual

Page 34

Chapter 3 Tuning Servo Systems

Velocity feedforward is an open-loop compensation technique and cannot

affect the stability of the system. However, if you use too large a value for

Vff, following error can reverse during the constant velocity portion, thus

degrading performance, rather than improving it.

Velocity feedforward is typically used when operating in PIVff mode

with either a velocity block amplifier or substantial amount of velocity

feedback (Kv). In these cases, the uncompensated following error is

directly proportional to the desired velocity. You can reduce this following

error by applying velocity feedforward. Increasing the integral gain (Ki)

also reduces the following error during constant velocity but only at the

expense of increased following error during acceleration and deceleration

and reduced system stability. For these reasons, increasing Ki is not a

recommended solution.

Tip In PIVff mode, the Kd and Kv gains are set to zero.

Velocity feedforward is rarely used when operating in PID mode with

torque block amplifiers. In this case, because the following error is

proportional to the torque required, rather than the velocity, it is typically

much smaller and does not require velocity feedforward.

Aff (Acceleration Feedforward)

The acceleration feedforward gain (Aff) determines the contribution in the

16-bit DAC command output that is directly proportional to the

instantaneous trajectory acceleration. Aff is used to minimize following

error (position error) during acceleration and deceleration and can be

changed at any time to tune the PID loop.

Acceleration feedforward is an open-loop compensation technique and

cannot affect the stability of the system. However, if you use too large a

value of Aff, following error can reverse during acceleration and

deceleration, thus degrading performance, rather than improving it.

Kdac

Kdac is the Digital to Analog Converter (DAC) gain. Use the following

equation to calculate Kdac:

Kdac

20 V represents the ±10 V range in the motion controller.

NI-Motion User Manual 3-6 ni.com

20 V

-----------=

16

2

Page 35

Dual Loop Feedback

Chapter 3 Tuning Servo Systems

Ga

Ga is the Amplifier Gain.

Kt

Kt is the Torque Constant of the motor. Kt is represented in Newton Meters

per Amp.

1/J

1/J represents the motor plus load inertia of the motion system.

Ke

Ke represents the conversion factor to revolutions. This may involve a

scaling factor.

Motion control systems often use gears to increase output torque, increase

resolution, or convert rotary motion to linear motion. The main

disadvantage of using gears is the backlash created between the motor and

the load. This backlash can cause a loss of position accuracy and system

instability.

The control loop on the motion system corrects for errors and maintains

tight control over the trajectory. The control loop consists of three main

parts—proportional, integral and derivative—known as PID parameters.

The derivative part estimates motor velocity by differentiating the

following error (position error) signal. This velocity signal adds, to the

loop, damping and stability. If backlash is present between the motor and

the position sensor, the positions of the motor and the sensor are no longer

the same. This difference causes the derived velocity to become ineffective

for loop damping purposes, which creates inaccuracy in position and

system instability.

Using two position sensors for an axis can help solve the problems caused

by backlash. As shown in Figure 3-3, one position sensor resides on the

load and the other on the motor before the gears. The motor sensor is used

to generate the required damping and the load sensor for position feedback.

The mix of these two signals provides the correct position feedback with

damping and stability.

© National Instruments Corporation 3-7 NI-Motion User Manual

Page 36

Chapter 3 Tuning Servo Systems

ΣΣ

Tip

You can enable dual-loop feedback on the NI motion controller by mapping an

encoder as the secondary feedback for the axis, and then using the velocity feedback gain

instead of the derivative gain to dampen and stabilize the system, as shown in Figure 3-4.

Figure 3-3. Dual Loop Feedback

Figure 3-4. Dual Loop Feedback Algorithm

NI-Motion User Manual 3-8 ni.com

Page 37

Velocity Feedback

Chapter 3 Tuning Servo Systems

You can configure the NI motion controller for velocity feedback using the

Kv (velocity feedback) gain. Using Kv creates a minor velocity feedback

loop. This is very similar to the traditional analog servo control method of

using a tachometer for closing the velocity loop. This type of feedback is

necessary for systems where precise speed control is essential.

You can use a less expensive standard torque, or current mode, amplifier

with the velocity feedback loop on NI motion controllers to achieve the

same results you would get from using velocity amplifiers, as shown in

Figure 3-5.

ΣΣ

Figure 3-5. Velocity Feedback

Setting any non-zero value for Kv allows you to use the Kv term instead of

or in addition to the Kd term to stabilize the system.

Velocity feedback gain (Kv) is similar to derivative gain (Kd) except that it

scales the velocity estimated from encoder resources only. The derivative

gain scales the derivative of the position error, which is the difference

between the instantaneous trajectory position and the primary feedback

position. Like the Kd term, the velocity feedback derivative is calculated

every derivative sample period, and the contribution is updated every PID

sample period, as shown in Figure 3-6.

© National Instruments Corporation 3-9 NI-Motion User Manual

Page 38

Chapter 3 Tuning Servo Systems

in Addition to Kd

Figure 3-6. Alternate Dual-Loop Feedback Algorithm

NI Motion Controllers with Velocity Amplifiers

Velocity amplifiers close the velocity loop using a tachometer on the

amplifier itself, as shown in Figure 3-7. In this case, the controller must

ensure that the voltage output is proportional to the velocity. Use the

velocity feedforward term (Vff) to ensure that there is minimum following

error during the constant velocity profiles.

Figure 3-7. NI Motion Controllers with Velocity Amplifiers

NI-Motion User Manual 3-10 ni.com

Page 39

Chapter 3 Tuning Servo Systems

Figure 3-8 describes how to use NI motion controllers with velocity

amplifiers.

Figure 3-8. NI Motion Controllers with Velocity Amplifiers Algorithm

You typically use velocity feedforward when using controllers with

velocity amplifiers. The uncompensated following error is directly

proportional to the specified velocity. You can reduce the following error

by applying velocity feedforward. Increasing the integral gain (Ki) also

reduces the following error during constant velocity, but at the expense of

increased following error during acceleration and deceleration and reduced

system stability.

Note National Instruments does not recommend increasing Ki.

Velocity feedforward is rarely used when operating in PID mode with

torque block amplifiers. In this case, following error is typically much

smaller because it is proportional to the torque required rather than to the

velocity. When operating in PID mode with torque block amplifiers,

velocity feedforward is not required.

© National Instruments Corporation 3-11 NI-Motion User Manual

Page 40

Programming with NI-Motion

You can use the C/C++ functions and LabVIEW VIs, included with

NI-Motion, to configure and execute motion control applications. Part III

of this manual covers the NI-Motion algorithms you need to use all the

features of NI-Motion.

Each task discussion uses the same structure. First, a generic algorithm

flow chart shows how the component pieces relate to each other. Then, the

task discussion details any aspects of creating the task that are specific to

LabVIEW or C/C++ programming, complete with diagrams and code

examples.

Part III

Note The LabVIEW block diagrams and C/C++ code examples are designed to illustrate

concepts, and do not contain all the logic or safety features necessary for most functional

applications.

Refer to the NI-Motion Function Help or the NI-Motion VI Help for

detailed information about specific functions or VIs.

Part III covers the following topics:

• What You Need to Know about Moves

• Straight-Line Moves

• Arc Moves

• Contoured Moves

• Reference Moves

• Blending Moves

• Electronic Gearing and Camming

• Acquiring Time-Sampled Position and Velocity Data

© National Instruments Corporation III-1 NI-Motion User Manual

Page 41

Part III Programming with NI-Motion

• Synchronization

• Torque Control

• Onboard Programs

NI-Motion User Manual III-2 ni.com

Page 42

What You Need to Know about

Moves

This chapter discusses the concepts necessary for programming motion

control.

Move Profiles

The basic function of a motion controller is to make moves. The trajectory

generator takes in the type of move and the move constraints and generates

points, or instantaneous positions, in real time. Then, the trajectory

generator feeds the points to the control loop.

The control loop converts each instantaneous position to a voltage or to

step-and-direction signals, depending on the type of motor you are using.

Move constraints are the maximum velocity, acceleration, deceleration, and

jerk that the system can handle. The trajectory generator creates a velocity

profile based on these move constraint values.

4

There are two types of profiles that can be generated while making the

move: trapezoidal and s-curve.

Trapezoidal

When you use a trapezoidal profile, the axes accelerate at the acceleration

value you specify, and then cruise at the maximum velocity you load.

Based on the type of move and the distance being covered, it may be

impossible to reach the maximum velocity you set.

The velocity of the axis, or axes, in a coordinate space never exceeds the

maximum velocity loaded. The axes decelerate to a stop at their final

position, as shown in Figure 4-1.

© National Instruments Corporation 4-1 NI-Motion User Manual

Page 43

Chapter 4 What You Need to Know about Moves

Velocity

S-Curve

The acceleration and deceleration portions of an s-curve motion profile are

smooth, resulting in less abrupt transitions, as shown in Figure 4-2. This

limits the jerk in the motion control system, but increases cycle time. The

value by which the profile is smoothed is called the maximum jerk or

s-curve value.

Time

Figure 4-1. Trapezoidal Move Profile

Velocity

Time

Figure 4-2. S-Curve Move Profile

Basic Moves

There are four basic move types:

• Reference Move—Initializes the axes to a known physical reference

such as a home switch or encoder index

• Straight-Line Move—Moves from point A to point B in a straight

line. The move can be based on position or velocity

• Arc Move—Moves from point A to point B in an arc or helix

NI-Motion User Manual 4-2 ni.com

Page 44

Chapter 4 What You Need to Know about Moves

• Contoured Move—Is a user-defined move; you generate the

trajectory, and the points loaded into the motion controller are splined

to create a smooth profile

The motion controller uses the specified move constraints, along with the

move data, such as end position or radius and travel angle, to create a

motion profile in all the moves except the contoured moves. Contoured

moves ignore the move constraints and follow the points you have defined.

Coordinate Space

With the exception of the arc move, you can execute all basic moves on

either a single axis or on a coordinate space. A coordinate space is a logical

grouping of axes, such as the XYZ axis shown in Figure 4-3. Arc moves

always execute on a coordinate space.

If you are performing a move that uses more than one axis, you must

specify a coordinate space made up of the axes the move will use, as shown

in Figure 4-3.

Z

X, Y, Z

Y

X

Figure 4-3. 3D Coordinate Space

Use the Configure Vector Space function to configure a coordinate space.

This function creates a logical mapping of axes and treats the axes as part

of a coordinate space.The function then executes the move generated by the

trajectory generator on the vector, and treats all the move constraints as

vector values.

Multi-Starts versus Coordinate Spaces

Coordinate spaces always start and end the motion of all axes

simultaneously. You can use multi-starts to create a similar effect without

© National Instruments Corporation 4-3 NI-Motion User Manual

Page 45

Chapter 4 What You Need to Know about Moves

grouping axes into coordinate spaces. Using a multi-start automatically

starts all axes virtually simultaneously. To simultaneously end the moves,

you must calculate the move constraints to end travel at the same time. In

coordinate spaces, this behavior is calculated automatically.

Trajectory Parameters

Use trajectory parameters to control the moves you program in NI-Motion.

All trajectory parameters for servo axes are expressed in terms of

quadrature encoder counts. Parameters for open-loop and closed-loop

stepper axes are expressed in steps. For servo axes, the encoder resolution,

which is expressed in counts per revolution, determines the ultimate

positional resolution of the axis.

For stepper axes, the number of steps per revolution depends upon the type

of stepper drive and motor you are using. For example, a stepper motor with

1.8°/step (200 steps/revolution) used in conjunction with a 10X microstep

drive has an effective resolution of 2,000 steps per revolution. Resolution

on closed-loop stepper axes is limited to the steps per revolution or encoder

counts per revolution, whichever value is more coarse.

Floating-point versus fixed-point parameter representation and time base

are two additional factors that affect the way trajectory parameters are

loaded to the NI motion controller as compared to how they are used by the

trajectory generators.