Page 1

DeviceNet

NI-DNETTM User Manual

NI-DNET User Manual

T

May 2004 Edition

Part Number 370375B-01

Page 2

Support

Worldwide Technical Support and Product Information

ni.com

National Instruments Corporate Headquarters

11500 North Mopac Expressway Austin, Texas 78759-3504 USA Tel: 512 683 0100

Worldwide Offices

Australia 1800 300 800, Austria 43 0 662 45 79 90 0, Belgium 32 0 2 757 00 20, Brazil 55 11 3262 3599,

Canada (Calgary) 403 274 9391, Canada (Ottawa) 613 233 5949, Canada (Québec) 450 510 3055,

Canada (Toronto) 905 785 0085, Canada (Vancouver) 514 685 7530, China 86 21 6555 7838,

Czech Republic 420 224 235 774, Denmark 45 45 76 26 00, Finland 385 0 9 725 725 11,

France 33 0 1 48 14 24 24, Germany 49 0 89 741 31 30, Greece 30 2 10 42 96 427, India 91 80 51190000,

Israel 972 0 3 6393737, Italy 39 02 413091, Japan 81 3 5472 2970, Korea 82 02 3451 3400,

Malaysia 603 9131 0918, Mexico 001 800 010 0793, Netherlands 31 0 348 433 466,

New Zealand 0800 553 322, Norway 47 0 66 90 76 60, Poland 48 22 3390150, Portugal 351 210 311 210,

Russia 7 095 783 68 51, Singapore 65 6226 5886, Slovenia 386 3 425 4200, South Africa 27 0 11 805 8197,

Spain 34 91 640 0085, Sweden 46 0 8 587 895 00, Switzerland 41 56 200 51 51, Taiwan 886 2 2528 7227,

Thailand 662 992 7519, United Kingdom 44 0 1635 523545

For further support information, refer to the Technical Support and Professional Services appendix. To comment

on the documentation, send email to techpubs@ni.com.

© 1998–2004 National Instruments Corporation. All rights reserved.

Page 3

Important Information

Warranty

The CAN/DeviceNet hardware is warranted against defects in materials and workmanship for a period of one year from the date of shipment,

as evidenced by receipts or other documentation. National Instruments will, at its option, repair or replace equipment that proves to be defective

during the warranty period. This warranty includes parts and labor.

The media on which you receive National Instruments software are warranted not to fail to execute programming instructions, due to defects

in materials and workmanship, for a period of 90 days from date of shipment, as evidenced by receipts or other documentation. National

Instruments will, at its option, repair or replace software media that do not execute programming instructions if National Instruments receives

notice of such defects during the warranty period. National Instruments does not warrant that the operation of the software shall be

uninterrupted or error free.

A Return Material Authorization (RMA) number must be obtained from the factory and clearly marked on the outside of the package before

any equipment will be accepted for warranty work. National Instruments will pay the shipping costs of returning to the owner parts which are

covered by warranty.

National Instruments believes that the information in this document is accurate. The document has been carefully reviewed for technical

accuracy. In the event that technical or typographical errors exist, National Instruments reserves the right to make changes to subsequent

editions of this document without prior notice to holders of this edition. The reader should consult National Instruments if errors are suspected.

In no event shall National Instruments be liable for any damages arising out of or related to this document or the information contained in it.

XCEPT AS SPECIFIED HEREIN, NATIONAL INSTRUMENTS MAKES NO WARRANTIES, EXPRESS OR IMPLIED, AND SPECIFICALLY DISCLAIMS ANY WAR RANTY OF

E

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE . CUSTOMER’S RIGHT TO RECOVER DAMAGES CAUSED BY FAULT OR NEGLIGENCE ON THE PART OF

N

ATIONAL INSTRUMENTS SHALL BE LIMITED TO THE AMOUNT THERETOFORE PAID BY THE CUSTOMER. NATIONAL INSTRUMENTS WILL NOT BE LIABLE FOR

DAMAGES RESULTING FROM LOSS OF DATA, PROFITS, USE OF PRODUCTS, OR INCIDENTAL OR CONSEQUENTIAL DAMAGES, EVEN IF ADVISED OF THE POSS IBILITY

THEREOF. This limitation of the liability of National Instruments will apply regardless of the form of action, whether in contract or tort, including

negligence. Any action against National Instruments must be brought within one year after the cause of action accrues. National Instruments

shall not be liable for any delay in performance due to causes beyond its reasonable control. The warranty provided herein does not cover

damages, defects, malfunctions, or service failures caused by owner’s failure to follow the National Instruments installation, operation, or

maintenance instructions; owner’s modification of the product; owner’s abuse, misuse, or negligent acts; and power failure or surges, fire,

flood, accident, actions of third parties, or other events outside reasonable control.

Copyright

Under the copyright laws, this publication may not be reproduced or transmitted in any form, electronic or mechanical, including photocopying,

recording, storing in an information retrieval system, or translating, in whole or in part, without the prior written consent of National

Instruments Corporation.

Trademarks

CVI™, LabVIEW™, National Instruments™, ni.com™, NI-CAN™, and NI-DNET™ are trademarks of National Instruments Corporation.

Product and company names mentioned herein are trademarks or trade names of their respective companies.

Patents

For patents covering National Instruments products, refer to the appropriate location: Help»Patents in your software, the patents.txt file

on your CD, or

ni.com/patents.

WARNING REGARDING USE OF NATIONAL INSTRUMENTS PRODUCTS

(1) NATIONAL INSTRUMENTS PRODUCTS ARE NOT DESIGNED WITH COMPONENTS AND TESTING FOR A LEVEL OF

RELIABILITY SUITABLE FOR USE IN OR IN CONNECTION WITH SURGICAL IMPLANTS OR AS CRITICAL COMPONENTS IN

ANY LIFE SUPPORT SYSTEMS WHOSE FAILURE TO PERFORM CAN REASONABLY BE EXPECTED TO CAUSE SIGNIFICANT

INJURY TO A HUMAN.

(2) IN ANY APPLICATION, INCLUDING THE ABOVE, RELIABILITY OF OPERATION OF THE SOFTWARE PRODUCTS CAN BE

IMPAIRED BY ADVERSE FACTORS, INCLUDING BUT NOT LIMITED TO FLUCTUATIONS IN ELECTRICAL POWER SUPPLY,

COMPUTER HARDWARE MALFUNCTIONS, COMPUTER OPERATING SYSTEM SOFTWARE FITNESS, FITNESS OF COMPILERS

AND DEVELOPMENT SOFTWARE USED TO DEVELOP AN APPLICATION, INSTALLATION ERRORS, SOFTWARE AND

HARDWARE COMPATIBILITY PROBLEMS, MALFUNCTIONS OR FAILURES OF ELECTRONIC MONITORING OR CONTROL

DEVICES, TRANSIENT FAILURES OF ELECTRONIC SYSTEMS (HARDWARE AND/OR SOFTWARE), UNANTICIPATED USES OR

MISUSES, OR ERRORS ON THE PART OF THE USER OR APPLICATIONS DESIGNER (ADVERSE FACTORS SUCH AS THESE ARE

HEREAFTER COLLECTIVELY TERMED “SYSTEM FAILURES”). ANY APPLICATION WHERE A SYSTEM FAILURE WOULD

CREATE A RISK OF HARM TO PROPERTY OR PERSONS (INCLUDING THE RISK OF BODILY INJURY AND DEATH) SHOULD

NOT BE RELIANT SOLELY UPON ONE FORM OF ELECTRONIC SYSTEM DUE TO THE RISK OF SYSTEM FAILURE. TO AVOID

DAMAGE, INJURY, OR DEATH, THE USER OR APPLICATION DESIGNER MUST TAKE REASONABLY PRUDENT STEPS TO

PROTECT AGAINST SYSTEM FAILURES, INCLUDING BUT NOT LIMITED TO BACK-UP OR SHUT DOWN MECHANISMS.

BECAUSE EACH END-USER SYSTEM IS CUSTOMIZED AND DIFFERS FROM NATIONAL INSTRUMENTS' TESTING

PLATFORMS AND BECAUSE A USER OR APPLICATION DESIGNER MAY USE NATIONAL INSTRUMENTS PRODUCTS IN

COMBINATION WITH OTHER PRODUCTS IN A MANNER NOT EVALUATED OR CONTEMPLATED BY NATIONAL

INSTRUMENTS, THE USER OR APPLICATION DESIGNER IS ULTIMATELY RESPONSIBLE FOR VERIFYING AND VALIDATING

THE SUITABILITY OF NATIONAL INSTRUMENTS PRODUCTS WHENEVER NATIONAL INSTRUMENTS PRODUCTS ARE

INCORPORATED IN A SYSTEM OR APPLICATION, INCLUDING, WITHOUT LIMITATION, THE APPROPRIATE DESIGN,

PROCESS AND SAFETY LEVEL OF SUCH SYSTEM OR APPLICATION.

Page 4

Contents

About This Manual

How to Use the Manual Set ...........................................................................................ix

Conventions ...................................................................................................................x

Related Documentation..................................................................................................x

Chapter 1

NI-DNET Software Overview

Installation and Configuration .......................................................................................1-1

Measurement & Automation Explorer (MAX) ...............................................1-1

Verify Installation of Your DeviceNet Hardware ...........................................1-1

Configure DeviceNet Port.................................................................1-3

Change Protocol................................................................................1-3

LabVIEW Real-Time (RT) Configuration ......................................................1-3

Tools ................................................................................................................1-3

NI-Spy...............................................................................................1-4

SimpleWho........................................................................................1-4

NI-DNET Objects ..........................................................................................................1-4

Interface Object ...............................................................................................1-5

Explicit Messaging Object ..............................................................................1-5

I/O Object ........................................................................................................1-6

Example...........................................................................................................1-6

Using NI-CAN with NI-DNET......................................................................................1-7

Chapter 2

NI-DNET Hardware Overview

Types of Hardware.........................................................................................................2-1

Differences Between CAN Kits and DeviceNet Kits ....................................................2-2

Chapter 3

Developing Your Application

Accessing NI-DNET from your Programming Environment........................................3-1

LabVIEW ........................................................................................................3-1

LabWindows/CVI............................................................................................3-2

Microsoft Visual Basic ....................................................................................3-2

Microsoft C/C++ .............................................................................................3-3

Borland C/C++ ................................................................................................3-3

Other Programming Languages.......................................................................3-4

© National Instruments Corporation v NI-DNET User Manual

Page 5

Contents

Programming Model for NI-DNET Applications ......................................................... 3-6

Step 1. Open Objects....................................................................................... 3-8

Step 2. Start Communication .......................................................................... 3-8

Step 3. Run Your DeviceNet Application....................................................... 3-8

Addition of Slave Connections after Communication Start ............. 3-9

Step 4. Stop Communication .......................................................................... 3-10

Step 5. Close Objects ...................................................................................... 3-10

Multiple Applications on the Same Interface................................................................ 3-10

Checking Status in LabVIEW ....................................................................................... 3-11

Checking Status in C, C++, and Visual Basic ............................................................... 3-11

Chapter 4

NI-DNET Programming Techniques

Configuring I/O Connections ........................................................................................ 4-1

Expected Packet Rate...................................................................................... 4-1

Strobed I/O ....................................................................................... 4-2

Polled I/O.......................................................................................... 4-3

Cyclic I/O ......................................................................................... 4-6

Change-of-State (COS) I/O ..............................................................4-7

Automatic EPR Feature .................................................................................. 4-7

Using I/O Data in Your Application .............................................................................4-8

Accessing I/O Members in LabVIEW ............................................................ 4-10

Accessing I/O Members in C .......................................................................... 4-11

Using Explicit Messaging Services............................................................................... 4-12

Get and Set Attributes in a Remote DeviceNet Device .................................. 4-12

Other Explicit Messaging Services ................................................................. 4-13

Handling Multiple Devices............................................................................................ 4-14

Configuration .................................................................................................. 4-14

Object Handles................................................................................................4-15

Main Loop....................................................................................................... 4-16

Appendix A

DeviceNet Overview

History of DeviceNet.....................................................................................................A-1

Physical Characteristics of DeviceNet .......................................................................... A-2

General Object Modeling Concepts .............................................................................. A-2

Object Modeling in the DeviceNet Specification.......................................................... A-3

Explicit Messaging Connections ................................................................................... A-5

I/O Connections............................................................................................................. A-7

Assembly Objects.......................................................................................................... A-11

NI-DNET User Manual vi ni.com

Page 6

Appendix B

Cabling Requirements

Connector Pinouts..........................................................................................................B-1

Power Supply Information for the DeviceNet Ports ......................................................B-3

Cable Specifications ......................................................................................................B-6

Cable Lengths ................................................................................................................B-6

Maximum Number of Devices ......................................................................................B-6

Cable Termination .........................................................................................................B-7

Cabling Example............................................................................................................B-8

Appendix C

Troubleshooting and Common Questions

Troubleshooting with the Measurement & Automation Explorer (MAX) ....................C-1

Troubleshooting Self Test Failures................................................................................C-2

Common Questions........................................................................................................C-3

Appendix D

Hardware Specifications

Contents

Appendix E

Technical Support and Professional Services

Glossary

Index

© National Instruments Corporation vii NI-DNET User Manual

Page 7

About This Manual

This manual describes the basics of DeviceNet and explains how to

develop an application program, including reference to examples. The user

manual also contains hardware information.

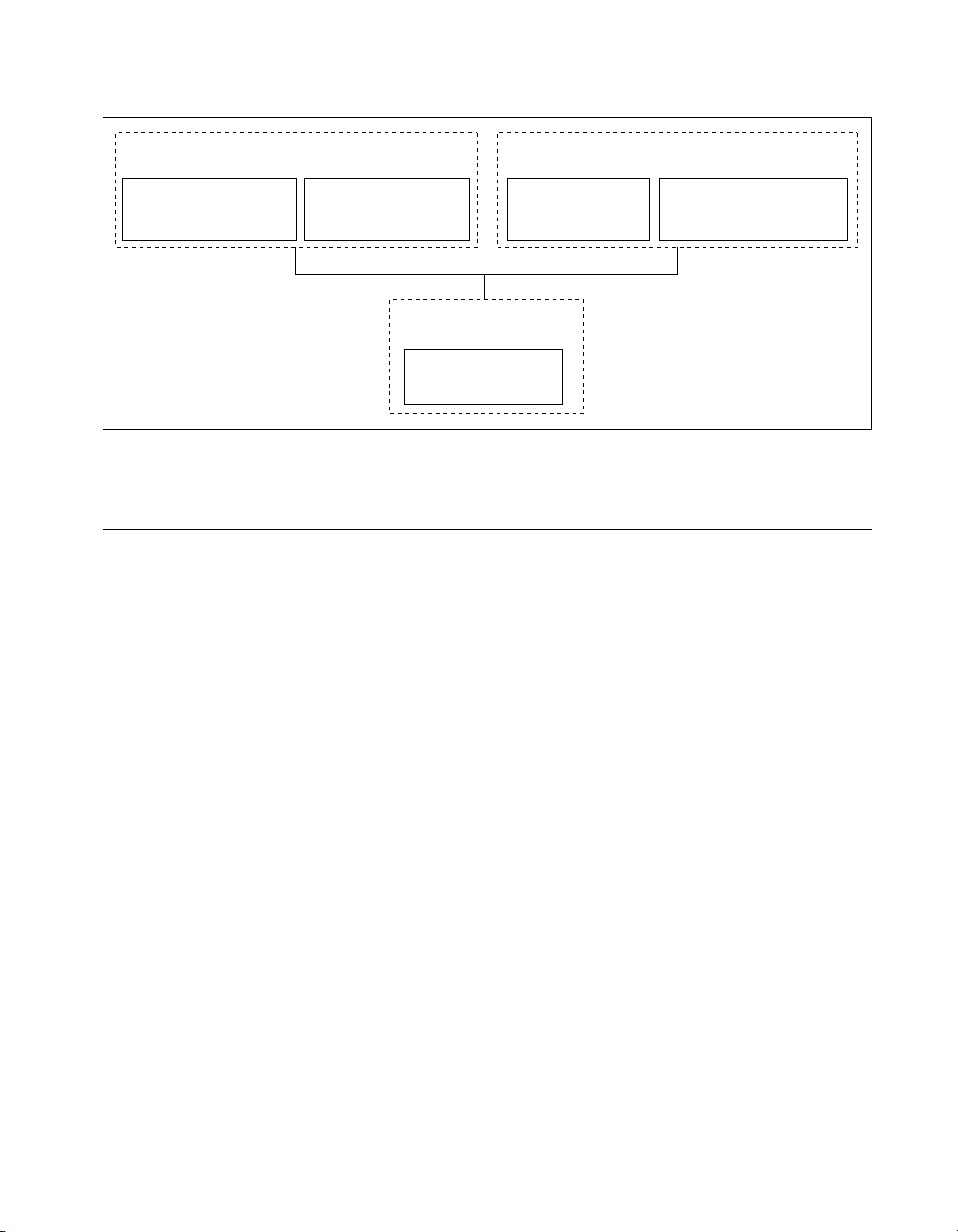

How to Use the Manual Set

Installation Guide

(CD Sleeve)

Software and

Hardware

Installation

NI-DNET Users

NI-DNET

User Manual

First-Time

and Examples

Application

Development

Experienced

NI-DNET Users

NI-DNET

Programmer

Reference Manual

Function

and Object

Descriptions

Use the installation guide to install and configure your DeviceNet hardware

and the NI-DNET software.

Use this NI-DNET User Manual to learn the basics of DeviceNet and how

to develop an application program. The user manual also contains

information on DeviceNet hardware.

Use the NI-DNET Programmer Reference Manual for specific information

about each NI-DNET function and object.

© National Instruments Corporation ix NI-DNET User Manual

Page 8

About This Manual

Conventions

The following conventions appear in this manual:

» The » symbol leads you through nested menu items and dialog box options

to a final action. The sequence File»Page Setup»Options directs you to

open the File menu, select the Page Setup item, and select Options from

the last dialog box.

This icon denotes a note, which alerts you to important information.

bold Bold text denotes items that you must select or click on in the software,

such as menu items and dialog box options. Bold text also denotes

parameter names.

italic Italic text denotes variables, emphasis, a cross reference, or an introduction

to a key concept. This font also denotes text that is a placeholder for a word

or value that you must supply.

monospace Text in this font denotes text or characters that you should enter from the

keyboard, sections of code, programming examples, and syntax examples.

This font is also used for the proper names of disk drives, paths, directories,

programs, subprograms, subroutines, device names, functions, operations,

variables, filenames, and extensions.

Related Documentation

The following documents contain information that you might find helpful

as you read this manual:

• ANSI/ISO Standard 11898-1993, Road Vehicles—Interchange of

Digital Information—Controller Area Network (CAN) for High-Speed

Communication

• DeviceNet Specification, Version 2.0, Open DeviceNet Vendor

Association

• CompactPCI Specification, Revision 2.0, PCI Industrial Computers

Manufacturers Group

• PXI Hardware Specification, Revision 2.1, National Instruments

Corporation

• PXI Software Specification, Revision 2.1, National Instruments

Corporation

NI-DNET User Manual x ni.com

Page 9

About This Manual

• LabVIEW online reference

• ODVA website,

www.odva.org

• Microsoft Win32 Software Development Kit (SDK) online help

© National Instruments Corporation xi NI-DNET User Manual

Page 10

NI-DNET Software Overview

The DeviceNet software provided with National Instruments DeviceNet

hardware is called NI-DNET. This section provides an overview of the

NI-DNET software.

Installation and Configuration

Measurement & Automation Explorer (MAX)

Measurement & Automation Explorer (MAX) provides access to all of

your National Instruments products. Like other NI software products,

NI-DNET uses MAX as the centralized location for all configuration

and tools.

To launch MAX, select the Measurement & Automation shortcut on your

desktop, or within your Windows Programs menu under National

Instruments»Measurement & Automation.

For information about the NI-DNET software within MAX, consult the

MAX online help. A reference is in the MAX Help menu under

Help Topics»NI-DNET.

1

View help for items in the MAX Configuration tree by using the built-in

MAX help pane. If this help pane is not shown on the far right, select the

Show/Hide button in the upper right.

View help for a dialog box by selecting the Help button in the window.

The following sections provide an overview of some common tasks you

can perform within MAX.

Verify Installation of Your DeviceNet Hardware

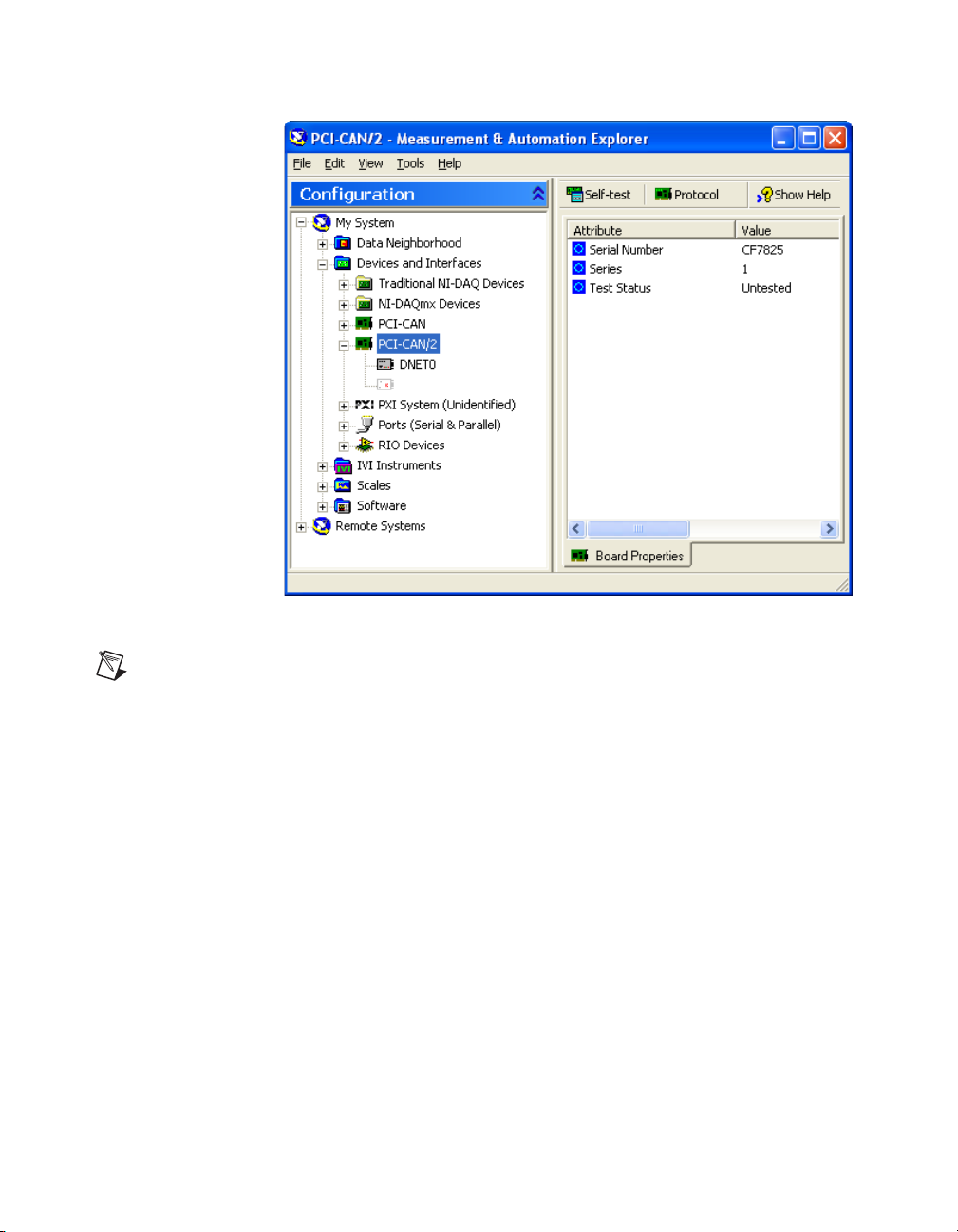

Within the Devices & Interfaces branch of the MAX Configuration tree,

NI DeviceNet cards are listed along with other hardware in the local

computer system, as shown in Figure 1-1.

© National Instruments Corporation 1-1 NI-DNET User Manual

Page 11

Chapter 1 NI-DNET Software Overview

Figure 1-1. NI-DNET Cards Listed in MAX

Note

Each card’s name uses the word CAN, because the Controller Area Network is the

communication protocol upon which DeviceNet is built.

If your NI DeviceNet hardware is not listed here, MAX is not configured

to search for new devices on startup. To search for the new hardware,

press <F5>.

To verify installation of your DeviceNet hardware, right-click the

DeviceNet card, then select Self-test. If the self-test passes, the card icon

shows a checkmark. If the self-test fails, the card icon shows an X mark, and

the Test Status in the right pane describes the problem. Refer to

Appendix C, Troubleshooting and Common Questions, for information

about resolving hardware installation problems.

NI-DNET User Manual 1-2 ni.com

Page 12

Configure DeviceNet Port

The physical port of each DeviceNet card is listed under the card’s name.

To configure software properties, right-click the port and select

Properties.

In the Properties dialog, you assign an interface name to the port, such as

DNET0 or DNET1. The interface name identifies the physical port within

NI-DNET APIs.

Change Protocol

To change the default protocol for the DeviceNet (CAN) card, right-click

the card and select Protocol. In this dialog you can select either DeviceNet

for NI-DNET (default), or CAN for NI-CAN. For more information, refer

to the section Using NI-CAN with NI-DNET.

LabVIEW Real-Time (RT) Configuration

LabVIEW Real-Time (RT) combines easy-to-use LabVIEW programming

with the power of real-time systems. When you use a National Instruments

PXI controller as a LabVIEW RT system, you can install a PXI DeviceNet

card and use the NI-DNET APIs to develop real-time applications. For

example, you can control a network of DeviceNet devices as a master, and

write your control algorithm in LabVIEW.

Chapter 1 NI-DNET Software Overview

When you install the NI-DNET software, the installer checks for the

presence of the LabVIEW RT module. If LabVIEW RT exists, the

NI-DNET installer copies components for LabVIEW RT to your

Windows system. As with any other NI product for LabVIEW RT, you then

download the NI-DNET and NI-CAN software to your LabVIEW RT

system using the Remote Systems branch in MAX. For more information,

refer to the LabVIEW RT documentation.

After you have installed your PXI DeviceNet cards and downloaded the

NI-DNET software to your LabVIEW RT system, you need to verify

the installation. Within the Tools menu in MAX, select NI-DNET»

RT Hardware Configuration. The RT Hardware Configuration tool

provides features similar to Devices & Interfaces on your local system.

Use the RT Hardware Configuration tool to self-test the DeviceNet cards

and assign an interface name to each physical DeviceNet port.

Tools

NI-DNET provides tools that you can launch from MAX.

© National Instruments Corporation 1-3 NI-DNET User Manual

Page 13

Chapter 1 NI-DNET Software Overview

NI-Spy

This tool monitors function calls to the NI-DNET APIs. This tool helps in

debugging programming problems in your application. To launch this tool,

open the Software branch of the MAX Configuration tree, right-click

NI Spy, and select Launch NI Spy.

SimpleWho

To provide valid parameters for the NI-DNET open functions

(

ncOpenDnetIntf, ncOpenDnetExplMsg, and ncDnetOpenIO), you

need to determine some basic information about your DeviceNet devices.

This information includes the MAC ID of each device, the I/O connections

it supports, and the input/output lengths for those I/O connections.

In most cases, the vendor of each DeviceNet device provides this

information, but if not, NI-DNET provides a tool that helps you determine

this information. Searching a DeviceNet network to determine information

about connected devices is often referred to as a network who, and thus the

NI-DNET tool is called SimpleWho. This tool is not a complete network

management or configuration tool. It provides read-only information about

the DeviceNet devices connected to your National Instruments DeviceNet

interface.

To launch SimpleWho, right-click the DeviceNet interface (such as

DNET0) in MAX, and select SimpleWho.

For more information on the SimpleWho tool, refer to the NI-DNET help

file in MAX. This help file can be opened using the Help button in the

SimpleWho tool itself.

NI-DNET Objects

The NI-DNET software, like the DeviceNet Specification, uses

object-oriented concepts to represent components in the DeviceNet system

(for more information about object-oriented concepts in the DeviceNet

Specification, refer to Appendix A, DeviceNet Overview). However,

whereas in the DeviceNet Specification objects represent a multitude of

components in DeviceNet devices, NI-DNET objects represent

components of the Windows device driver software. The NI-DNET device

driver objects do not correspond directly to objects contained in remote

devices. To facilitate access to the DeviceNet network, the NI-DNET

objects provide a more concise representation of various objects defined in

the DeviceNet Specification.

NI-DNET User Manual 1-4 ni.com

Page 14

Interface Object

Chapter 1 NI-DNET Software Overview

Much like any other object-oriented system, NI-DNET device driver

objects use the concepts of class, instance, attribute, and service to describe

their features. The NI-DNET device driver software provides three classes

of objects: Interface Objects, Explicit Messaging Objects, and I/O Objects.

You can open an instance of an NI-DNET object using one of the three

open functions (

ncOpenDnetIO). The services for an NI-DNET object are accomplished

ncOpenDnetExplMsg, ncOpenDnetIntf, or

using the NI-DNET functions, which can be called directly from your

programming environment (such as Microsoft C/C++ or LabVIEW). The

essential attributes of an NI-DNET object are initialized using its open

function; you can access other attributes using

ncSetDriverAttr. The attributes of NI-DNET device driver objects are

ncGetDriverAttr or

called driver attributes, to differentiate them from actual attributes in

remote DeviceNet devices.

For complete information on each NI-DNET object, including its driver

attributes and supported functions (services), refer to your NI-DNET

Programmer Reference Manual.

The Interface Object represents a DeviceNet interface (physical DeviceNet

port on your DeviceNet board). Since this interface acts as a device on the

DeviceNet network much like any other device, it is configured with its

own MAC ID and baud rate.

Use the Interface Object to do the following:

• Configure NI-DNET settings that apply to the entire interface

• Start and stop communication for all NI-DNET objects associated with

the interface

Explicit Messaging Object

The Explicit Messaging Object represents an explicit messaging

connection to a remote DeviceNet device (physical device attached to your

interface by a DeviceNet cable). Since only one explicit messaging

connection is created for a given device, the Explicit Messaging Object is

also used for features that apply to the device as a whole.

Use the Explicit Messaging Object to do the following:

• Execute the DeviceNet Get Attribute Single service on the remote

device (

© National Instruments Corporation 1-5 NI-DNET User Manual

ncGetDnetAttribute)

Page 15

Chapter 1 NI-DNET Software Overview

• Execute the DeviceNet Set Attribute Single service on the remote

device (

• Send any other explicit message request to the remote device and

receive the associated explicit message response

(

• Configure NI-DNET settings that apply to the entire remote device

I/O Object

The I/O Object represents an I/O connection to a remote DeviceNet device

(physical device attached to your interface by a DeviceNet cable). The

I/O Object usually represents I/O communication as a master with a remote

slave device, but it can also be used for I/O communication as a slave.

The I/O Object supports as many master/slave I/O connections as currently

allowed by the DeviceNet Specification. This means that you can use

polled, strobed, and COS/cyclic I/O connections simultaneously for a given

device. As specified by the DeviceNet Specification, only one master/slave

I/O connection of a given type can be used for each device (MAC ID). For

example, you cannot open two polled I/O connections for the same device.

Use the I/O Object to do the following:

• Read data from the most recent message received on the

I/O connection (

• Write data for the next message produced on the I/O connection

(

ncSetDnetAttribute)

ncWriteDnetExplMsg, ncReadDnetExplMsg)

ncReadDnetIO)

ncWriteDnetIO)

Example

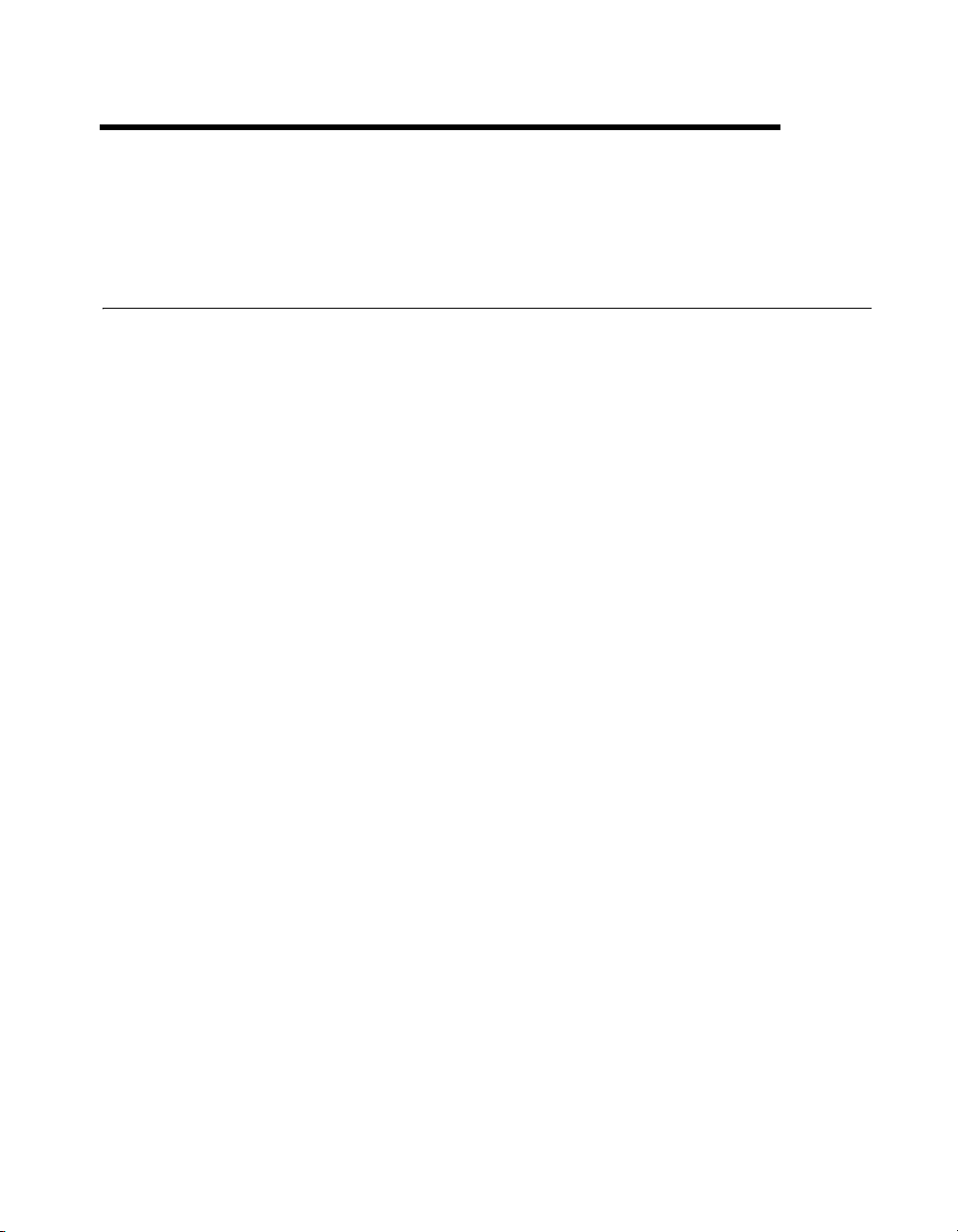

Figure 1-2 shows an example of how NI-DNET objects can be used to

communicate on a DeviceNet network. This example shows three

DeviceNet devices. The first device (at MAC ID 1) is the National

Instruments DeviceNet interface. The second device (at MAC ID 5) uses

NI-DNET to access a polled and a COS I/O connection simultaneously.

The third device (at MAC ID 8) uses NI-DNET to access an explicit

messaging connection and a strobed I/O connection.

NI-DNET User Manual 1-6 ni.com

Page 16

Chapter 1 NI-DNET Software Overview

Access to device at

MAC ID 5

I/O Object

Device MAC ID = 5

Connection Type = COS

I/O Object

Device MAC ID = 5

Connection Type = Poll

Your National Instruments

DeviceNet Interface

Interface Object

Interface MAC ID = 1

Baud Rate = 500K

Figure 1-2. NI-DNET Objects for a Network of Three Devices

Using NI-CAN with NI-DNET

Controller Area Network (CAN) is the low-level protocol used for

DeviceNet communications. In addition to the NI-DNET functions, your

National Instruments DeviceNet hardware can also be used for low-level

access to CAN messages using the NI-CAN software. NI-CAN is intended

primarily for applications that require direct access to CAN messages, such

as test applications for automotive (non-DeviceNet) networks. When

connecting to a DeviceNet network, the NI-CAN capabilities are useful for

the following applications:

• Low-level monitoring of CAN messages to determine conformance to

DeviceNet specifications

• Implementation of sections of the DeviceNet Specification yourself,

such as custom configuration tools

Access to device at

Explicit Messaging

Object

Device MAC ID = 8

MAC ID 8

I/O Object

Device MAC ID = 8

Connection Type = Strobe

NI-CAN uses the same software infrastructure as NI-DNET, so both APIs

can be used with the same CAN card. The general rule is that each CAN

card can only be used for one API at a time.

Use of NI-DNET is restricted to port 1 (top port) of Series 1 CAN cards.

For more information on hardware provided in CAN kits, refer to

Chapter 2, NI-DNET Hardware Overview.

You can view each CAN card in MAX with either DeviceNet or CAN

features. To change the view of a CAN card in MAX, right-click the card

and select Protocol. In this dialog you can select either DeviceNet for

© National Instruments Corporation 1-7 NI-DNET User Manual

Page 17

Chapter 1 NI-DNET Software Overview

NI-DNET (default), or CAN for NI-CAN. When the CAN protocol is

selected, you can access CAN tools in MAX, such as the Bus Monitor tool

that displays CAN messages in their raw form.

In order to develop NI-CAN applications, you must install NI-CAN

components such as documentation and examples. The NI-CAN software

components are available within the NI-DNET installer.

Launch the

manner as your original installation (CD or

setup.exe program for the NI-DNET installer in the same

ni.com download). Within

the installer, select both NI-DNET and NI-CAN components in the

feature tree.

When you right-click a port in MAX and select Properties, the resulting

Interface selection uses the syntax

CAN

x

or DNETx based on your protocol

selection. Regardless of which protocol is selected, the number x is the only

relevant identifier with respect to NI-CAN and NI-DNET functions. For

example, if you select DNET0 as an interface in MAX, you can run an

NI-DNET application that uses DNET0, then you can run an NI-CAN

application that uses CAN0. Both applications refer to the same port,

and can run at different times, but not simultaneously.

NI-DNET User Manual 1-8 ni.com

Page 18

NI-DNET Hardware Overview

Types of Hardware

The National Instruments DeviceNet hardware includes the PCI-CAN,

PXI-8461, and PCMCIA-CAN.

The PCI-CAN is software configurable and compliant with the PCI Local

Bus Specification. It features the National Instruments MITE bus interface

chip that connects the card to the PCI I/O bus. With a PCI-CAN, you can

make your PC-compatible computer with PCI Local Bus slots

communicate with and control DeviceNet devices.

The PXI-8461 is software configurable and compliant with the PXI

Specification and CompactPCI Specification. It features the National

Instruments MITE bus interface chip that connects the card to the PXI or

CompactPCI I/O bus. With a PXI-8461 card, you can make your PXI or

CompactPCI chassis communicate with and control DeviceNet devices.

PCMCIA-CAN hardware is a 16-bit, Type II PC Card that is software

configurable and compliant with the PCMCIA standards for 16-bit PC

cards. With a PCMCIA-CAN card, you can make your PC-compatible

notebook with PCMCIA slots communicate with and control DeviceNet

devices.

2

The PCI-CAN, PXI-8461, or PCMCIA-CAN in your DeviceNet kit is fully

compliant with the DeviceNet Specification.

All of the DeviceNet hardware uses the Intel 386EX embedded processor

to implement time-critical features provided by the NI-DNET software.

The cards communicate with the NI-DNET driver through on-board shared

memory and an interrupt.

The DeviceNet physical communication link protocol is based on the

Controller Area Network (CAN) protocol. The physical layers of the

PCI-CAN, PXI-8461, and PCMCIA-CAN fully conform to the DeviceNet

physical layer requirements. The physical layer is optically isolated to

500 V and is powered from the DeviceNet bus power supply. DeviceNet

interfacing is accomplished using the Intel 82527 CAN controller chip.

© National Instruments Corporation 2-1 NI-DNET User Manual

Page 19

Chapter 2 NI-DNET Hardware Overview

For more information on the DeviceNet physical layer and cables used to

connect to your DeviceNet devices, refer to Appendix B, Cabling

Requirements.

For connection to the network, the PCI-CAN, PXI-8461, and

PCMCIA-CAN for DeviceNet provide combicon-style pluggable screw

terminals, as required by the DeviceNet Specification.

Differences Between CAN Kits and DeviceNet Kits

National Instruments provides hardware/software kits for both CAN and

DeviceNet. Since the CAN kits apply to a broad range of applications such

as automotive testing, the hardware in those kits offers a wide variety of

options. To ensure that the hardware product operates properly on a

DeviceNet network, we recommend that you purchase DeviceNet kits only.

The card provided in your DeviceNet kit can be used with both NI-DNET

and NI-CAN software.

Hardware in CAN kits is referenced as Series 2. Hardware in DeviceNet

kits is referenced as Series 1. Series 2 CAN cards cannot be used with the

NI-DNET software (NI-CAN only). The features of Series 2 CAN cards are

specifically designed for CAN applications, and provide no distinct

advantages for DeviceNet. For more information on Series 2 hardware,

refer to the hardware overview in the NI-CAN Hardware and Software

Manual.

Hardware in CAN kits offers 1-port and 2-port variants. NI-DNET operates

on one port only. If you use NI-DNET on a 2-port Series 1 CAN card, only

the top port can be used.

Hardware in CAN kits offer special transceivers (physical layer) such as

Low-Speed/Fault-Tolerant (LS) and Single-Wire (SW). Hardware in CAN

kits also offer the option to power the transceiver from the card, not the

network. These transceivers cannot be used with DeviceNet. Only

High-Speed (HS) transceivers comply with the DeviceNet specification.

Hardware in CAN kits use the DB-9 D-SUB connector. Hardware in

DeviceNet kits use the combicon-style connector from the DeviceNet

specification.

NI-DNET User Manual 2-2 ni.com

Page 20

Developing Your Application

This chapter explains how to develop an application using the NI-DNET

functions.

Accessing NI-DNET from your Programming Environment

3

LabVIEW

Applications can access the NI-DNET driver software by using either

LabVIEW, LabWindows

C/C++, or Visual Basic. If you are using any other development

environment, you must access the DNET library directly. Each of these

language interface techniques is summarized below.

For applications written in LabVIEW, NI-DNET provides a complete

function library, front panel controls, and examples.

NI-DNET functions and controls are available in the LabVIEW palettes. In

LabVIEW 7.1 or later, the NI-DNET palette is located within the top-level

NI Measurements palette. In earlier LabVIEW versions, the NI-DNET

palette is located at the top-level.

The reference for each NI-DNET function is provided in the NI-DNET

Programmer Reference Manual. To access the reference for a function

from within LabVIEW, press <Ctrl-H> to open the help window, click on

the NI-DNET function, and then follow the link.

The NI-DNET software includes a full set of examples for LabVIEW.

These examples teach basic NI-DNET programming as well as advanced

topics. The example help describes each example and includes a link you

can use to open the VI. The NI-DNET example help is in Help»Find

Examples»Hardware Input and Output»DeviceNet.

™

/CVI™, Microsoft Visual C/C++, Borland

© National Instruments Corporation 3-1 NI-DNET User Manual

Page 21

Chapter 3 Developing Your Application

LabWindows/CVI

Within LabWindows/CVI, the NI-DNET function panel is located in

Library»NI-DNET. Like other LabWindows/CVI function panels, the

NI-DNET function panel provides help for each function and the ability to

generate code.

The reference for each NI-DNET function is provided in the NI-DNET

Programmer Reference Manual. You can access reference for each

function directly from within the function panel.

The header file for NI-DNET is

nidnet.lib.

The NI-DNET software includes a full set of examples for

LabWindows/CVI. The NI-DNET examples are installed in the

LabWindows/CVI directory under samples\nidnet. Each example

provides a complete LabWindows/CVI project (

of each example is provided in comments at the top of the

When you compile your LabWindows/CVI application for NI-DNET,

it is automatically linked with

LabWindows/CVI. When NI-DNET is installed, the installation program

checks to see which compatible C compiler you are using with

LabWindows/CVI (Microsoft or Borland), and copies an appropriate

nidnet.lib for that compiler.

Microsoft Visual Basic

To create an NI-DNET application in Visual Basic, add the nidnet.bas

file to your project. This allows you to call any NI-DNET function file from

your code.

The

NI-DNET folder. The typical path to this folder is \Program Files\

National Instruments\NI-DNET\MS Visual Basic

nidnet.h. The library for NI-DNET is

.prj file). A description

.c file.

nidnet.lib, the link library for

nidnet.bas file is located in the MS Visual Basic folder of the

.

The reference for each NI-DNET function is provided in the NI-DNET

Programmer Reference Manual, which you can open from Start»All

Programs»National Instruments»NI-DNET.

You can find examples for Visual Basic in the

MS Visual Basic folder. Each example is in a separate folder. A .vbp

examples subfolder of the

file with the same name as the example opens the Visual Basic project. A

description of the example is located in a Help form within the project.

NI-DNET User Manual 3-2 ni.com

Page 22

Microsoft C/C++

Chapter 3 Developing Your Application

The NI-DNET software supports Microsoft Visual C/C++ version 6.

The header file and library for Visual C/C++ 6 are in the

folder of the

Files\National Instruments\NI-DNET\MS Visual C

NI-DNET, include the

the

nidnetms.lib library file.

For C applications (files with a

adding a

#include "nidnet.h"

NI-DNET folder. The typical path to this folder is \Program

nidnet.h header file in your code, then link with

.c extension), include the header file by

#include to the beginning of your code, as in:

MS Visual C

. To use

For C++ applications (files with .cpp extension), define _cplusplus

before including the header, such as:

#define _cplusplus

#include "nidnet.h"

The _cplusplus define enables the transition from C++ to the C language

NI-DNET functions.

The reference for each NI-DNET function is provided in the NI-DNET

Programmer Reference Manual, which you can open from Start»All

Programs»National Instruments»NI-DNET. You can find examples for

Visual C++ in the

example is in a separate folder. A

examples subfolder of the MS Visual C folder. Each

.c file with the same name as the

example contains a description the example in comments at the top of the

code. At the command prompt, after setting MSVC environment variables

(such as with MS

vcvars32.bat), you can build each example using a

command such as:

cl –I.. singin.c ..\nidnetms.lib

Borland C/C++

The NI-DNET software supports Borland C/C++ version 5 or later.

The header file and library for Borland C/C++ are in the Borland C folder

of the NI-DNET folder. The typical path to this folder is

Files\National Instruments\NI-DNET\Borland C

To use NI-DNET, include the

with the

© National Instruments Corporation 3-3 NI-DNET User Manual

nidnetbo.lib library file.

nidnet.h header file in your code, then link

\Program

.

Page 23

Chapter 3 Developing Your Application

For C applications (files with .c extension), include the header file by

adding a

#include "nidnet.h"

For C++ applications (files with .cpp extension), define _cplusplus

before including the header, such as:

#define _cplusplus

#include "nidnet.h"

The _cplusplus define enables the transition from C++ to the C language

NI-DNET functions.

The reference for each NI-DNET function is provided in the NI-DNET

Programmer Reference Manual, which you can open from Start»All

Programs»National Instruments»NI-DNET.

#include to the beginning of your code, like this:

You can find examples for Visual C++ in the

Borland C folder. Each example is in a separate folder. A .c file with the

same name as the example contains a description the example in comments

at the top of the code.

Other Programming Languages

You can directly access NI-DNET from any programming environment

that allows you to request addresses of functions that a dynamic link library

(DLL) exports. The functions used to access a DLL in this manner are

provided by the Microsoft Win32 functions of Windows. Using these

Microsoft Win32 functions to access a DLL is often referred to as direct

entry. To use direct entry with NI-DNET, complete the following steps:

1. Load the NI-DNET DLL,

The following C language code fragment illustrates how to call the

Win32

LoadLibrary function and check for an error.

#include <windows.h>

#include "nidnet.h"

HINSTANCE NidnetLib = NULL;

NidnetLib=LoadLibrary("nican.dll");

if (NidnetLib == NULL) {

return FALSE; /*Error*/

}

examples subfolder of the

nican.dll.

NI-DNET User Manual 3-4 ni.com

Page 24

Chapter 3 Developing Your Application

2. Get the addresses for the NI-DNET DLL functions you will use.

Your application must use the Win32

GetProcAddress function to

get the addresses of the NI-DNET functions your application needs.

For each NI-DNET function used by your application, you must define

a direct entry prototype. For the prototypes for each function exported

by

nican.dll, refer to the NI-DNET Programmer Reference Manual.

The following code fragment illustrates how to get the addresses of the

ncOpenDnetIO, ncCloseObject, and ncReadDnetIO functions.

static NCTYPE_STATUS (_NCFUNC_ *PncOpenDnetIO)

(NCTYPE_STRING ObjName,

NCTYPE_OBJH_P ObjHandlePtr);

static NCTYPE_STATUS (_NCFUNC_ *PncCloseObject)

(NCTYPE_OBJH ObjHandle);

static NCTYPE_STATUS (_NCFUNC_ *PncReadDnetIO)

(NCTYPE_OBJH ObjHandle, NCTYPE_UINT32 SizeofData,

NCTYPE_ANY_P Data);

PncOpenDnetIO = (NCTYPE_STATUS (_NCFUNC_ *)

(NCTYPE_STRING, NCTYPE_OBJH_P))

GetProcAddress(NidnetLib,

(LPCSTR)"ncOpenDnetIO");

PncCloseObject = (NCTYPE_STATUS (_NCFUNC_ *)

(NCTYPE_OBJH))

GetProcAddress(NidnetLib,

(LPCSTR)"ncCloseObject");

PncRead = (NCTYPE_STATUS (_NCFUNC_ *)

(NCTYPE_OBJH, NCTYPE_UINT32, NCTYPE_ANY_P))

GetProcAddress(NidnetLib,

(LPCSTR)"ncReadDnetIO");

If GetProcAddress fails, it returns a NULL pointer. The following

code fragment illustrates how to verify that none of the calls to

GetProcAddress failed.

if ((PncOpenDnetIO == NULL) ||

(PncCloseObject == NULL) ||

(PncReadDnetIO == NULL)) {

FreeLibrary(NidnetLib);

printf("GetProcAddress failed");

}

© National Instruments Corporation 3-5 NI-DNET User Manual

Page 25

Chapter 3 Developing Your Application

3. Configure your application to de-reference the pointer to call an

NI-DNET function, as illustrated by the following code.

NCTYPE_STATUS status;

NCTYPE_OBJH MyObjh;

status = (*PncOpenDnetIO) ("DNET0", &MyObjh);

if (status < 0) {

printf("ncOpenDnetIO failed");

}

4. Free nican.dll.

Before exiting your application, you need to free

nican.dll with the

following command.

FreeLibrary(NidnetLib);

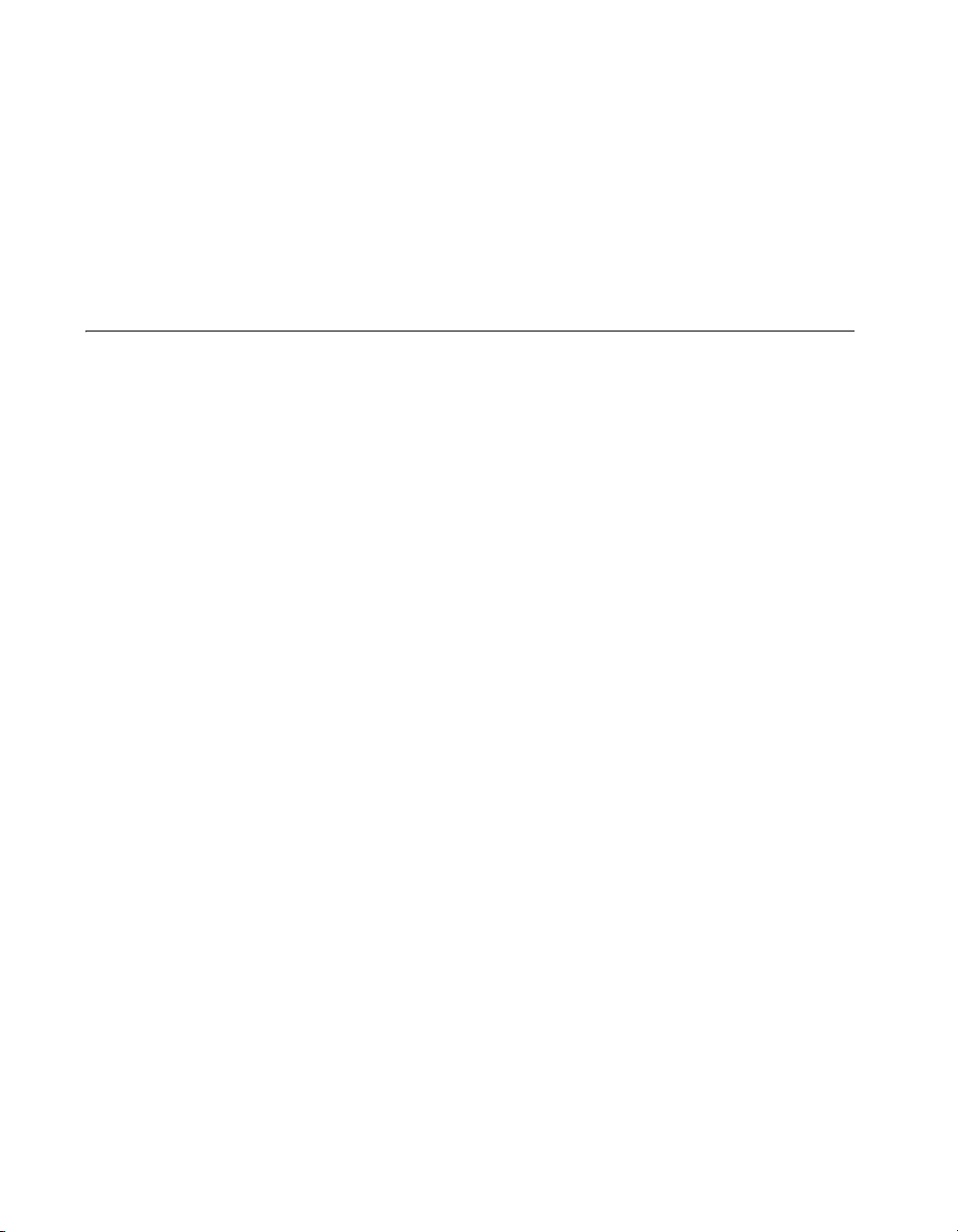

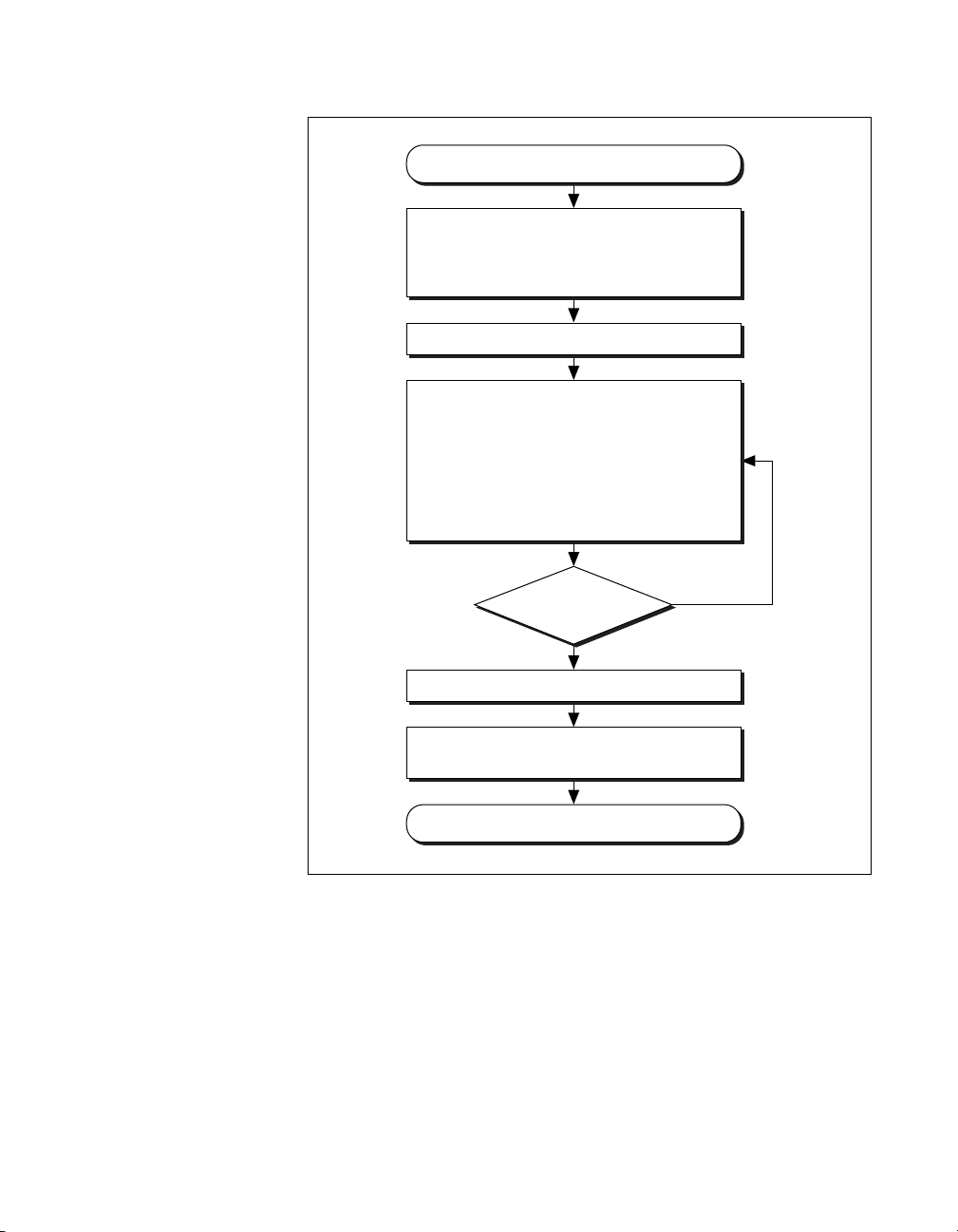

Programming Model for NI-DNET Applications

The following steps provide an overview of how to use the NI-DNET

functions in your application. The steps are shown in Figure 3-1 in

flowchart form. The NI-DNET functions are described in detail in the

NI-DNET Programmer Reference Manual.

NI-DNET User Manual 3-6 ni.com

Page 26

Chapter 3 Developing Your Application

Start

1. Open Interface object

2. Open all I/O and Explicit Messaging (EM)

objects required for your application

3. Call ncSetDriverAttr, if needed

Start communication

Your DeviceNet Application:

• Write output data

• Wait for available input data

• Read input data

• Get or Set DeviceNet Attribute

• Open/Close any new I/O or EM

connection if the interface PollMode

is not equal to NC_POLL_AUTO

Finished?

Yes

Stop communication

1. Close I/O and EM objects.

2. Close the Interface object.

End

No

Figure 3-1. General Programming Steps for an NI-DNET Application

© National Instruments Corporation 3-7 NI-DNET User Manual

Page 27

Chapter 3 Developing Your Application

Step 1. Open Objects

Before you use an NI-DNET object in your application, you must configure

and open it using either

ncOpenDnetIO. These open functions return a handle for use in all

subsequent NI-DNET calls for that object.

The

ncOpenDnetIntf function configures and opens an Interface Object.

Your NI-DNET application uses this Interface Object to start and stop

communication. The Interface Object must be the first NI-DNET object

opened by your application.

The

ncOpenDnetExplMsg function configures and opens an Explicit

Messaging Object, and the

an I/O Object.

Step 2. Start Communication

Start communication to initialize DeviceNet connections to remote

devices. Use the Interface Object to call the

function with the

The following optional steps can be done before you start communication:

• For an I/O Object, if it is not acceptable to send output data of all zeros,

call

ncWriteDnetIO to provide valid output values for the initial

transmission.

• For an I/O Object, if your application is multitasking, call the

ncCreateNotification or ncCreateOccurrence function with

the

DesiredState parameter set to Read Available. This notifies

your application when new input data is received from the remote

device.

• For any NI-DNET object, if any of the Driver attributes needs to be

changed, call

value. The

communication has started.

ncOpenDnetIntf, ncOpenDnetExplMsg, or

ncOpenDnetIO function configures and opens

ncOperateDnetIntf

Opcode parameter set to Start.

ncSetDriverAttr with the attribute Id and attribute

ncSetDriverAttr function cannot be called after the

Step 3. Run Your DeviceNet Application

After you open your NI-DNET objects and start communication, you are

ready to interact with the DeviceNet network.

Complete the following steps with an I/O Object:

1. Call the

transmission on the DeviceNet network.

NI-DNET User Manual 3-8 ni.com

ncWriteDnetIO function to write output data for subsequent

Page 28

Chapter 3 Developing Your Application

2. Call the ncWaitForState function with the DesiredState

parameter set to

Read Available. This function waits for output

data to be transmitted and for new input data to be received. If your

application is multitasking, you might have other tasks to do in your

application while you wait for new input data. If so, use the

ncCreateNotification or ncCreateOccurrence function

instead of

3. Call the

ncWaitForState (refer to Step 2. Start Communication).

ncReadDnetIO function to read input data received from the

DeviceNet network.

4. Loop back to step 1 as needed.

Complete the following steps with an Explicit Messaging Object:

1. Call the

parameter set to

ncWaitForState function with the DesiredState

Established. This ensures that the explicit message

connection is established before you send the first explicit message

request.

2. To get an attribute from a remote DeviceNet device, call the

ncGetDnetAttribute function.

3. To set the value of an attribute in a remote DeviceNet device, call the

ncSetDnetAttribute function.

4. To invoke other explicit message services in a remote DeviceNet

device, use the

request, the

response, and the

ncWriteDnetExplMsg function to write the service

ncWaitForState function to wait for the service

ncReadDnetExplMsg function to read the service

response.

5. Loop back to step 2 as needed.

Addition of Slave Connections after Communication Start

If you need to add I/O and Explicit Messaging connections after the

communication on the network has started, you can call

ncOpenDnetExplMsg and ncOpenDnetIO as long as the Interface

Object’s poll mode had been configured to

NC_POLL_INDIV (Individual). Since the Automatic poll mode

(

NC_POLL_AUTO) calculates the expected packet rate (EPR) based on the

estimated network bandwidth, all the I/O connections have to be opened

before you start the communication if the Automatic mode is selected. The

EPR restrictions due to different values of the

apply to the I/O objects. For details on these requirements, refer to

ncOpenDnetIO and ncOpenDnetIntf function descriptions in the

NI-DNET Programmer Reference Manual.

© National Instruments Corporation 3-9 NI-DNET User Manual

NC_POLL_SCAN (Scanned) or

PollMode parameter still

Page 29

Chapter 3 Developing Your Application

Step 4. Stop Communication

Before you exit your application, stop communication to shut down

DeviceNet connections to remote devices. Use the Interface Object to

call the

to

ncOperateDnetIntf function with the Opcode parameter set

Stop.

Step 5. Close Objects

Before you exit your application, close all NI-DNET objects using the

ncCloseObject function.

Multiple Applications on the Same Interface

The NI-DNET software allows multiple NI-DNET applications to use the

same interface object simultaneously, as long as the interface configuration

remains the same. For example, you can run both the

example and SimpleWho on DNET0 as long as the

BaudRate, and PollMode parameters are the same in both applications

(SimpleWho uses a

two copies of the

different devices as if it were through a single application. These same rules

apply to the I/O Object and the Explicit Messaging Object.

PollMode of Scanned). Similarly, you can open up

SingleDevice example and communicate with two

SingleDevice

Interface MacId,

As long as all the configuration attributes are the same, any object can be

opened multiple times. You can enable only one notification or wait

(through

ncCreateOccurrence functions) for an object, no matter how many

ncWaitForState, ncCreateNotification, or

handles you have opened for that particular object. For example, if you are

running two copies of the

SingleDevice example on the same interface

with the same connection types, the notification triggers in only one

application at a time.

The synchronization of events and the protection of the object I/O data is

the responsibility of the application developer. Similarly, the application

performance might change based on the number of objects open and the

frequency of API calls made in each application. For example, several calls

to

ncGetDnetAttribute in one application might slow down another

application running on the same interface.

To ensure proper clean up of all the objects, each open call to an object

should be matched by a close call to the same object, and each call to

ncOperateDnetIntf with NC_OP_START code should be matched by

a call to the same function with

NI-DNET User Manual 3-10 ni.com

NC_OP_STOP code.

Page 30

If you use two different applications on the same interface and open I/O

connections to different devices, you must set

Scanned or Individual. You cannot use PollMode of Automatic,

because that requires all I/O connections to be open prior to the first start

of communication.

Checking Status in LabVIEW

For applications written in LabVIEW, status checking is handled

automatically. For all NI-DNET functions, the lower left and right

terminals provide status information using LabVIEW Error Clusters.

LabVIEW Error Clusters are designed so that status information flows

from one function to the next, and function execution stops when an error

occurs. For more information, refer to the Error Handling section in the

LabVIEW online reference.

Chapter 3 Developing Your Application

PollMode to either

Within your LabVIEW block diagram, you wire the

Error out terminals of NI-DNET functions together in succession.

When an error is detected in an NI-DNET function (

all NI-DNET functions wired together are skipped except for

ncCloseObject. The ncCloseObject function executes regardless

of whether an error occurred, thus ensuring that all NI-DNET objects are

closed properly when execution stops due to an error. Depending on how

you want to handle errors, you can wire the

terminals together per-object (group a single open/close pair), per-device

(group together Explicit Messaging and I/O Objects for a given device), or

per-network (group all functions for a given interface).

As with any other LabVIEW error cluster, you can view error descriptions

using built-in LabVIEW features such as Explain Error in the Help menu,

or the Simple Error Handler VI in your diagram.

Error in and Error out

Checking Status in C, C++, and Visual Basic

Each C language NI-DNET function returns a value that indicates the status

of the function call. This status value is zero for success, greater than zero

for a warning, and less than zero for an error.

After every call to an NI-DNET function, your program should check to see

if the return status is nonzero. If so, call the

to obtain an ASCII string which describes the error/warning. You can then

use standard C function, such as

printf, to display this ASCII string.

ncStatusToString function

Error in and

status field true),

© National Instruments Corporation 3-11 NI-DNET User Manual

Page 31

Chapter 3 Developing Your Application

Your application code should check the status returned from every

NI-DNET function. If an error is detected, you should close all NI-DNET

handles, then exit the application. If a warning is detected, you can display

a message for debugging purposes, or simply ignore the warning.

For more information on status checking, refer to the

ncStatusToString

function in the NI-DNET Programmer Reference Manual.

NI-DNET User Manual 3-12 ni.com

Page 32

NI-DNET Programming

Techniques

This chapter describes various techniques to help you program your

NI-DNET application. The techniques include configuration of

I/O connection timing, using I/O data (assemblies), using explicit

messaging, and handling multiple devices.

Configuring I/O Connections

This section provides information on how I/O connections relate to one

another and how your configuration of I/O connection timing can affect the

overall performance of your DeviceNet system. The various types of

I/O connections provided by DeviceNet are described in Chapter 1,

NI-DNET Software Overview.

In a master/slave DeviceNet I/O system, the master determines the timing

of all I/O communication. Within your NI-DNET application, the

ncOpenDnetIO function configures the timing for I/O connections in

which your application communicates as master. As you read this section,

you might want to refer to the description of the

in the NI-DNET Programmer Reference Manual.

4

ncOpenDnetIO function

Expected Packet Rate

Each DeviceNet I/O connection contains an attribute called the expected

packet rate, which specifies the expected rate (in milliseconds) of messages

(packets) for the I/O connection. For NI-DNET, you use the

ExpPacketRate parameter of the ncOpenDnetIO function to configure

the expected packet rate.

After you start communication, the embedded microprocessor on your

National Instruments DeviceNet interface transmits messages at the

ExpPacketRate. This means that after the I/O connection is configured,

your NI-DNET application does not need to be concerned with the timing

of messages on the DeviceNet network.

© National Instruments Corporation 4-1 NI-DNET User Manual

Page 33

Chapter 4 NI-DNET Programming Techniques

When you select an ExpPacketRate for an I/O connection, you must

consider all I/O connections in your system. For example, although you

might be able to configure an

I/O connection, you cannot configure a 3 ms

connections because DeviceNet’s bandwidth capabilities cannot support

40 messages in a 3 ms time frame.

The following sections describe how to evaluate system considerations so

that you can configure valid values for

Strobed I/O

For strobed I/O connections, the master broadcasts a single strobe

command message to all strobed slaves. Since all strobed I/O connections

transfer data at the rate of this single strobe command message, the

ExpPacketRate of each strobed I/O connection must be set to the

same value.

ExpPacketRate of 3 ms for a single

ExpPacketRate for 40 I/O

ExpPacketRate.

The common

ExpPacketRate for all strobed I/O connections should

provide enough time for the strobe command and each strobed slave’s

response. You must also allow time for other I/O messages and explicit

messages to occur in the

ExpPacketRate time frame. If you do not know

the time needed, let NI-DNET calculate a safe value for you (refer to the

section Automatic EPR Feature later in this chapter).

Figure 4-1 shows a timing example for four strobed devices at MAC ID 9,

11, 12, and 13. Notice that since MAC ID 11 is slow to respond, the

ExpPacketRate is set to 20 ms to provide additional safety margin for

other messages.

Strobe Command

0 ms 5 ms 10 ms 20 ms15 ms

Strobe Response 9

StrobeResponse 13

Strobe Response 12

Figure 4-1. Strobed I/O Timing Example

Strobe Response 11

Strobe Command

NI-DNET User Manual 4-2 ni.com

Page 34

Chapter 4 NI-DNET Programming Techniques

Polled I/O

Polled I/O connections use a separate poll command and response message

for each device.

The overall scheme that NI-DNET uses to time polled I/O connections is

determined by the

PollMode parameter applies to all polled I/O connections (all calls to

ncOpenDnetIO with ConnectionType of Poll).

The following sections describe different schemes you can use for

polled I/O.

Scanned Polling

You can set the ExpPacketRate of each polled I/O connection to the same

value used for all strobed I/O. Using a common

strobed and polled I/O is referred to as scanned I/O. Scanned I/O is also

referred to as scanned polling with respect to polled I/O connections. When

you use scanned I/O, NI-DNET transmits all strobe and poll command

messages onto the network in quick succession.

Scanned I/O is a simple, efficient way to handle I/O connections that

require similar response rates. With scanned I/O, the master knows that all

strobe and poll commands go out at the same time. Therefore, the master

does not need to manage individual timers, thus optimizing processing

overhead. Scanned I/O also provides overall consistency. If a given

DeviceNet system uses only scanned I/O, you know that all higher level

control algorithms can execute at the single common strobe/poll

ExpPacketRate.

PollMode parameter of ncOpenDnetIntf. This

ExpPacketRate for all

The common

ExpPacketRate for all strobed and polled I/O connections

should provide enough time for all strobe/poll commands and each slave’s

response. You must also allow time for other I/O messages and explicit

messages to occur in the

ExpPacketRate time frame.

NI-DNET provides two different methods you can use to configure

scanned I/O:

• If you set the

Automatic, NI-DNET automatically calculates a valid common

ExpPacketRate value for each strobed and polled I/O connection.

PollMode parameter of ncOpenDnetIntf to

When you use this scheme, you do not need to specify a valid

ExpPacketRate when you open your strobed/polled I/O connections.

For more information, refer to the Automatic EPR Feature section later

in this chapter.

© National Instruments Corporation 4-3 NI-DNET User Manual

Page 35

Chapter 4 NI-DNET Programming Techniques

• If you set the PollMode parameter of ncOpenDnetIntf to Scanned,

to configure scanned I/O you must specify the exact same

ExpPacketRate when you open each of your strobed/polled

I/O connections. Using this scheme, you must determine a valid

ExpPacketRate for your DeviceNet system.

Figure 4-2 shows a scanned polling example for four polled devices at

MAC ID 14, 17, 20, and 30. The shaded areas indicate other message

traffic, such as the strobed I/O messages shown in Figure 4-1.

Poll Cmd 14

Poll Cmd 20

Poll Cmd 17

0 ms 5 ms 10 ms 20 ms15 ms

Poll Cmd 30

Poll Response 30

Poll Response 17

Figure 4-2. Scanned Polling Timing Example

Background Polling

Scanned polling can be less efficient when used with devices with

significantly different response times or devices with significantly different

rates of physical measurement. In the example above (Figure 4-2), consider

what would happen if device 14 took 52 ms to respond and device 20 took

38 ms to respond. In this case, even though device 17 and device 30

respond well within 20 ms, the common

be at least 52 ms. This situation can often be avoided using a special case

of scanned polling called background polling.

Poll Response 14

Poll Response 20

ExpPacketRate would need to

To configure background polling, you first set the

PollMode parameter of

ncOpenDnetIntf to Scanned. Then for each polled I/O connection you

configure (

set

ExpPacketRate to either a foreground rate or a background rate. The

foreground poll rate is the same as the common

ncOpenDnetIO with ConnectionType set to Poll), you must

ExpPacketRate used for

all strobed I/O. Devices in this group generally respond quickly to poll

commands or have data that changes relatively quickly. The background

poll rate must be an exact multiple of the foreground poll rate. Devices in

this group generally respond slowly to poll commands or have data that

changes relatively slowly (such as temperature).

Background polling provides many of the same advantages as scanned

polling. The handling of only two groups optimizes performance. Also,

NI-DNET User Manual 4-4 ni.com

Page 36

Chapter 4 NI-DNET Programming Techniques

background polling maintains overall network consistency because

NI-DNET evenly disperses all background poll commands among multiple

foreground cycles. In other words, all background poll commands are not

sent in quick succession and thus do not generate quick bursts of traffic on

the network.

Figure 4-3 shows a background polling example which resolves the

problem discussed previously. Devices at MAC ID 17 and 30 are

foreground polled every 20 ms (as before). Devices at MAC ID 14 and 20

are background polled every 60 ms (3 times the 20 ms foreground rate).

The shaded areas indicate other message traffic.

Poll Cmd 17

Poll Cmd 30

Bkd Poll Cmd 14

Poll Response 30

Poll Response 17

0 ms 20 ms 40 ms 60 ms

Poll Cmd 17

Poll Cmd 30

Bkd Poll Cmd 20

Poll Response 30

Poll Response 17

Poll Cmd 17

Poll Cmd 30

Poll Response 30

Poll Response 17

Bkd Poll Response 14

Bkd Poll Response 20

Poll Cmd 17

Poll Cmd 30

Blk Poll Cmd 14

Figure 4-3. Background Polling Timing Example

Individual Polling

When the underlying response rates of all polled I/O devices do not fit into

two clear groups, background polling can still be inefficient. For example,

assume you have four different polled I/O sensors capable of updating

measured input at 10 ms, 35 ms, 100 ms, and 700 ms respectively. Each

device responds to its poll command within 1 ms but measures data at a

different rate (such as a pushbutton for 10 ms and a temperature sensor for

700 ms). You could group these into a foreground rate of 10 ms and a

background rate of 700 ms, but then much DeviceNet bandwidth would be

wasted polling the 35 ms and 100 ms devices at the foreground rate. For

this situation, the individual polling scheme is most appropriate.

To configure individual polling, first set the

ncOpenDnetIntf to Individual. Then for each polled I/O connection

you configure (

must set

ncOpenDnetIO with ConnectionType set to Poll), you

ExpPacketRate to the rate desired for that device. Unlike the

scanned polling or background polling scheme, each poll command is no

longer associated with the strobe command’s rate, but instead is solely

based on its

© National Instruments Corporation 4-5 NI-DNET User Manual

ExpPacketRate.

PollMode parameter of

Page 37

Chapter 4 NI-DNET Programming Techniques

Since the poll commands are not synchronized for individual polling, they

can often be scattered relatively randomly. They can be evenly interspersed

for a while, then suddenly occur in bursts of back-to-back messages.

Because of this inconsistency, you should use smaller MAC IDs for smaller

ExpPacketRate values. Since smaller MAC IDs in DeviceNet usually

gain access to the network before larger MAC IDs, this helps to ensure that

smaller rates can be maintained during bursts of increased traffic.

Figure 4-4 shows an individual polling example: MAC ID 3 is polled

every 10 ms, MAC ID 10 every 35 ms, MAC ID 12 every 100 ms, and

MAC ID 13 every 700 ms. Only the poll commands are shown (not poll

responses or other messages).

Poll Cmd 3

Poll Cmd 10

Poll Cmd 3

0 ms 20 ms 40 ms 80 ms60 ms

Poll Cmd 3

Poll Cmd 12

Poll Cmd 3

Figure 4-4. Individual Polling Timing Example

Poll Cmd 3

Poll Cmd 10

Poll Cmd 3

Poll Cmd 13

Poll Cmd 3

Poll Cmd 3

Poll Cmd 3

Poll Cmd 10

Cyclic I/O

Cyclic I/O connections essentially use the same timing scheme as

individually polled I/O connections. Each cyclic I/O connection sends its

data at the configured

cyclic I/O data is transferred from slave to master, rather than from master

to slave.

In the DeviceNet Specification, a poll command message is exactly the

same as a cyclic output message (master to slave data). Since cyclic data

from master to slave can be handled using individual polling, cyclic I/O

connections are more commonly used for input data from slave to master.

For NI-DNET, this means that for cyclic I/O connections,

is normally called with

Just as for individually polled I/O, you should use smaller MAC IDs for

smaller cyclic I/O

I/O traffic is prioritized properly.

NI-DNET User Manual 4-6 ni.com

ExpPacketRate. The main difference is that

ncOpenDnetIO

InputLength nonzero and OutputLength zero.

ExpPacketRate values. Doing so ensures that cyclic

Page 38

Chapter 4 NI-DNET Programming Techniques

Change-of-State (COS) I/O

Change-of-State I/O connections use the same timing scheme as cyclic I/O

connections, but in addition to the

to the master whenever a change is detected.

For COS I/O, the cyclic transmission is used solely to verify that the

I/O connection still exists, so the

value, such as 10,000 (10 seconds). Given such a large

the main performance concerns for COS I/O are an appropriate MAC ID,

and if needed, a nonzero

InhibitTimer.

In many cases, a given COS I/O device cannot detect data changes very

quickly. If a COS device is capable of detecting quickly changing data,

there is a chance that it could transmit many COS messages back-to-back,

precluding other I/O messages and thus dramatically impairing overall

DeviceNet performance. This problem is demonstrated in Figure 4-5.

ExpPacketRate, COS I/O sends data

ExpPacketRate is typically set to a large

ExpPacketRate,

Back to Back

COS I/O Data

COS I/O

0 ms 5 ms 10 ms 20 ms

Figure 4-5. Congestion Due to Back-to-Back COS I/O

Changing Frequently

15 ms

Some of the

Other I/O May

Have Timed Out

This problem can be prevented if you increase the MAC ID of the

frequently changing COS I/O device. If the COS device has a higher

MAC ID than other devices, it cannot preclude their I/O messages.

You can also prevent back-to-back COS I/O messages if you set the

InhibitTimer driver attribute using ncSetDriverAttr. After

transmitting COS data, the I/O connection must wait

InhibitTimer

before it can transmit COS data again. A reasonable value for

InhibitTimer would be the smallest ExpPacketRate of an

I/O connection with a larger MAC ID than the COS I/O device.

Automatic EPR Feature

For cyclic I/O connections, a valid ExpPacketRate is required for

your call to

ExpPacketRate is recommended for your call to ncOpenDnetIO but

can be set to a large value.

ncOpenDnetIO. For COS I/O connections, a nonzero

© National Instruments Corporation 4-7 NI-DNET User Manual

Page 39

Chapter 4 NI-DNET Programming Techniques

For strobed and polled I/O connections, determination of a valid

ExpPacketRate can be somewhat complex. If you have trouble

estimating an

PollMode parameter of your initial call to ncOpenDnetIntf to

Automatic. When you use this automatic EPR feature, the

ExpPacketRate parameter of ncOpenDnetIO is ignored for

strobed/polled I/O (

calculates a safe EPR value for you. This automatic EPR is the same for all

strobed and polled I/O connections (scanned I/O).

ExpPacketRate value for strobed/polled I/O, set the

ConnectionType of Strobe or Poll), and NI-DNET

After you start communication, you can use the

function to determine the value calculated for

value, you can then experiment with other

using

PollMode of Scanned or Individual.

The following information is used by NI-DNET to calculate a safe EPR:

• NI-DNET assumes that it is the only master in your DeviceNet system.

• The

BaudRate parameter of ncOpenDnetIntf determines the time

taken for each message.

• The

InputLength and OutputLength parameters of each

ncOpenDnetIO determine the time needed for each I/O message.

• NI-DNET assumes that each strobed/polled I/O device can respond to

its command within 2 ms.

• NI-DNET sets aside a fixed amount of time for explicit messages. This

time depends on the baud rate.

Using I/O Data in Your Application

Appendix A, DeviceNet Overview, explains that the data transferred to and

from a DeviceNet device on an I/O connection is usually processed by an

Assembly Object within the slave device. Input assemblies represent the