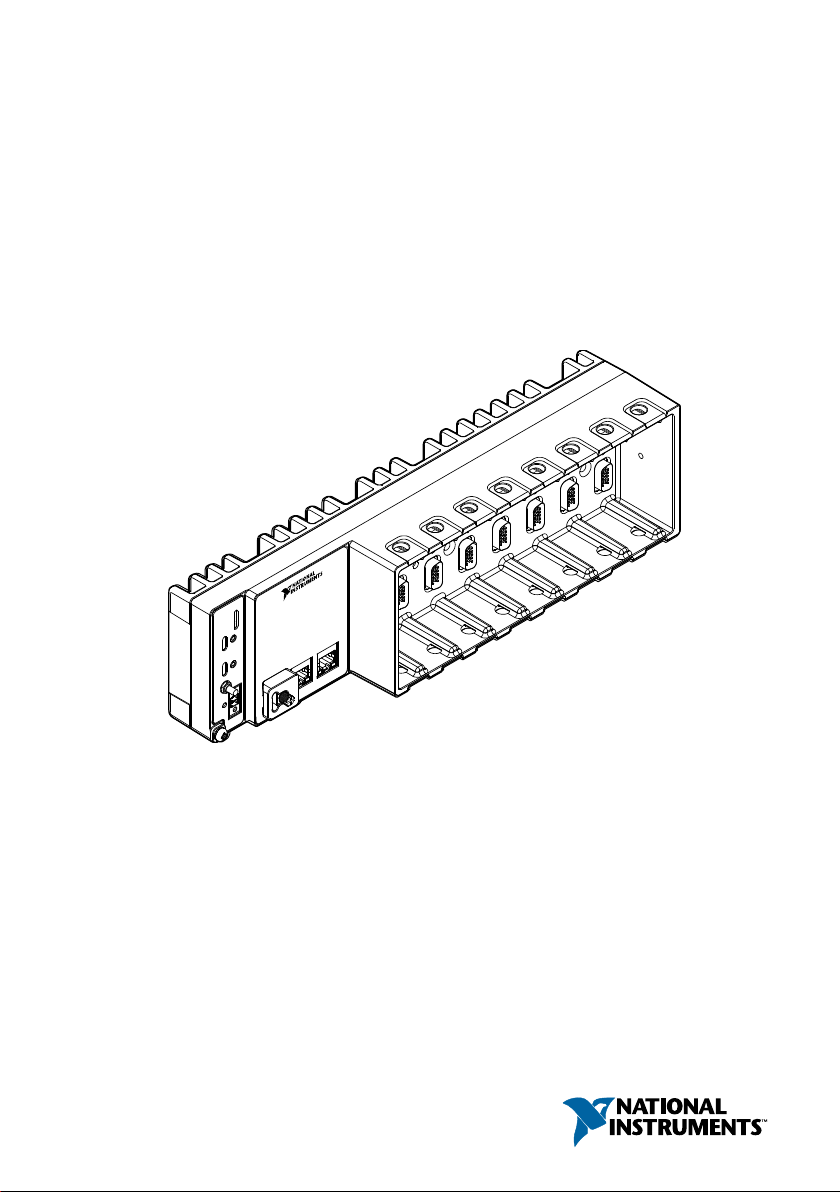

National Instruments NI cRIO-905x, NI cRIO-9053, NI cRIO-9054, NI cRIO-9056, NI cRIO-9057 User Manual

Page 1

USER MANUAL

NI cRIO-905x

Embedded CompactRIO Controller with Real-Time Processor and

Reconfigurable FPGA

This document describes the features of the cRIO-905x and contains information about

mounting and operating the device.

In this document, the NI cRIO-9053, NI cRIO-9054, NI cRIO-9056, NI cRIO-9057 are

referred to collectively as cRIO-905x.

Page 2

Contents

Configuring the cRIO-905x...................................................................................................... 2

Connecting the cRIO-905x to the Host Computer Using USB........................................ 3

Connecting the cRIO-905x to the Host Computer or Network Using Ethernet............... 4

Configuring Startup Options.............................................................................................4

cRIO-905x Features.................................................................................................................. 6

Ports and Connectors........................................................................................................ 6

Buttons............................................................................................................................ 10

LEDs................................................................................................................................11

Chassis Grounding Screw............................................................................................... 14

Internal Real-Time Clock................................................................................................14

Digital Routing................................................................................................................14

Clock Routing................................................................................................................. 15

Synchronization Across a Network.................................................................................16

Battery.............................................................................................................................18

File System......................................................................................................................18

Mounting the Controller..........................................................................................................19

Alternative Mounting Configurations.............................................................................20

Mounting Requirements..................................................................................................20

Dimensions......................................................................................................................21

Front Mounting on a Flat Surface................................................................................... 23

Rear Mounting on a Flat Surface.................................................................................... 25

Mounting the Controller on a Panel ...............................................................................27

Mounting on a DIN Rail ................................................................................................ 31

Mounting on a Rack........................................................................................................33

Mounting the Device on a Desktop.................................................................................33

Choosing Your Programming Mode....................................................................................... 37

Analog Input with NI-DAQmx....................................................................................... 38

Analog Output with NI-DAQmx.................................................................................... 44

Digital Input/Output with NI-DAQmx........................................................................... 50

PFI with NI-DAQmx...................................................................................................... 62

Counters with NI-DAQmx..............................................................................................63

Counter Input Applications.............................................................................................68

Counter Output Applications.......................................................................................... 87

Counter Timing Signals.................................................................................................. 95

Worldwide Support and Services.......................................................................................... 100

Configuring the cRIO-905x

You can connect the cRIO-905x to a host computer or network and configure the startup

options using the USB 2.0 Type-C Device Port with Console Out or the RJ-45 Gigabit

Ethernet port 0.

Tip Refer to the NI cRIO-905x Getting Started Guide for basic configuration

instructions and information about connecting to a host computer using the USB 2.0

2 | ni.com | NI cRIO-905x User Manual

Page 3

Type-C Device Port with Console Out. NI recommends using the USB 2.0 Type-C

Device Port with Console Out for configuration, debugging, and maintenance.

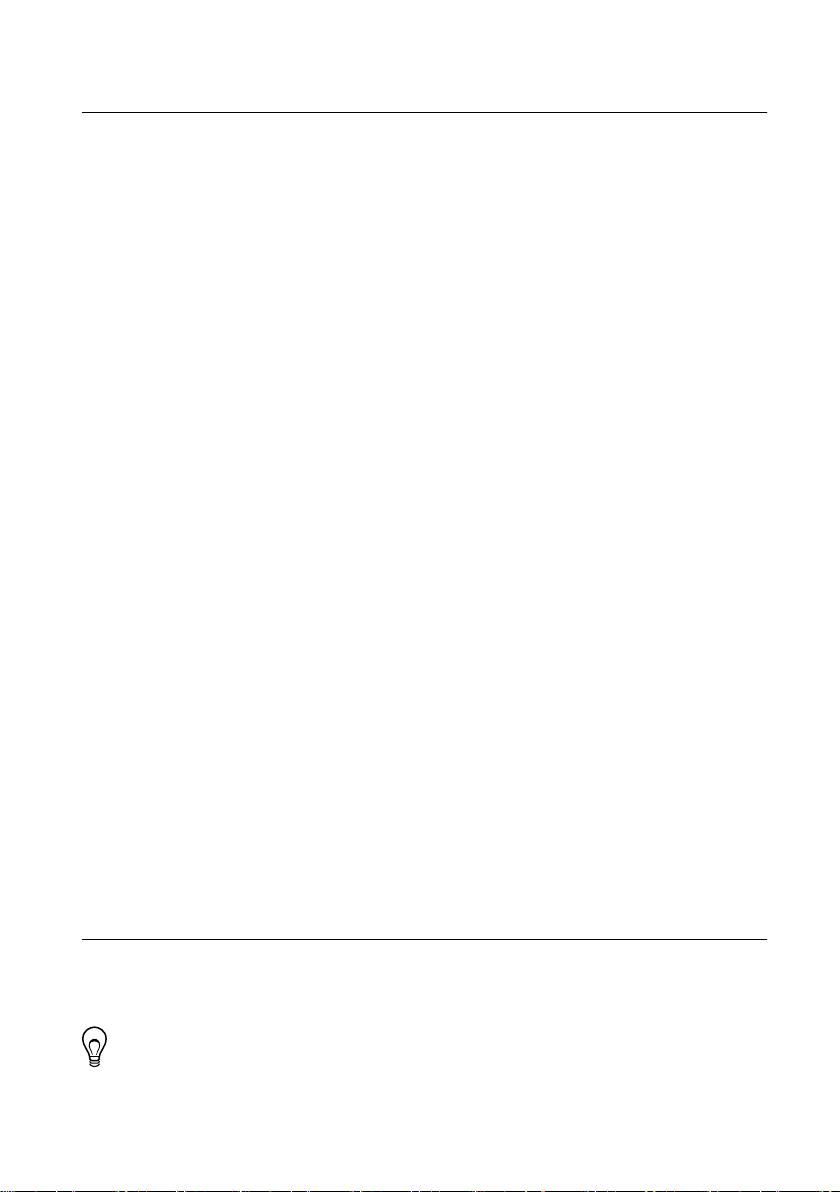

Connecting the cRIO-905x to the Host Computer Using USB

Complete the following steps to connect the cRIO-905x to the host computer using the USB

2.0 Type-C Device Port with Console Out.

1. Power on the host computer.

2. Connect the cRIO-905x to the host computer using the USB Type C to Type A cable

(included in kit), inserting the USB Type-C connector into the USB 2.0 Type-C Device

Port with Console Out.

3. Connect the other end of the USB cable (Type-A) to the host computer.

Note The device driver software automatically detects the cRIO-905x. If the

device driver software does not detect the cRIO-905x, verify that you installed

the appropriate NI software in the correct order on the host computer as

described in Installing Software on the Host Computer in the NI cRIO-905x

Getting Started Guide.

4. Select Configure and install software to this device.

NI cRIO-905x User Manual | © National Instruments | 3

Page 4

Connecting the cRIO-905x to the Host Computer or Network Using Ethernet

Complete the following steps to connect the cRIO-905x to a host computer or Ethernet

network using the RJ-45 Gigabit Ethernet port 0. NI recommends using the RJ-45 Gigabit

Ethernet port 0 for communication with deployed systems.

Note If your controller has the RJ-45 Gigabit Ethernet port 1, you can configure

that port in Measurement & Automation Explorer (MAX) under the Network

Settings tab.

1. Power on the host computer or Ethernet hub.

2. Connect the RJ-45 Gigabit Ethernet port 0 on the cRIO-905x to the host computer or

Ethernet hub using a standard Category 5 (CAT-5) or better shielded, twisted-pair

Ethernet cable.

Notice To prevent data loss and to maintain the integrity of your Ethernet

installation, do not use a cable longer than 100 m (328 ft).

The cRIO-905x attempts to initiate a DHCP network connection the first time you

connect using Ethernet. The cRIO-905x connects to the network with a link-local IP

address with the form 169.254.x.x if it is unable to initiate a DHCP connection.

Finding the cRIO-905x on the Network (DHCP)

Complete the following steps to find the cRIO-905x on a network using DHCP.

1. Disable secondary network interfaces on the host computer, such as a wireless access

card on a laptop.

2. Ensure that any anti-virus and firewall software running on the host computer allows

connections to the host computer.

Note MAX uses UDP on port 44525. Refer to the documentation of your

firewall software for information about configuring the firewall to allow

communication through this port.

3. Launch MAX on the host computer.

4. Expand Remote Systems in the configuration tree and locate your system.

Tip MAX lists the system under the model number followed by the serial

number, such as NI-cRIO-905x-1856AAA.

Tip If you do not see the cRIO-905x under Remote Systems, use the

Troubleshoot Remote System Discovery utility to walk through

troubleshooting steps.

Configuring Startup Options

Complete the following steps to configure the cRIO-905x startup options in MAX.

1. In MAX, expand your system under Remote Systems.

2. Select the Startup Settings tab to configure the startup settings.

4 | ni.com | NI cRIO-905x User Manual

Page 5

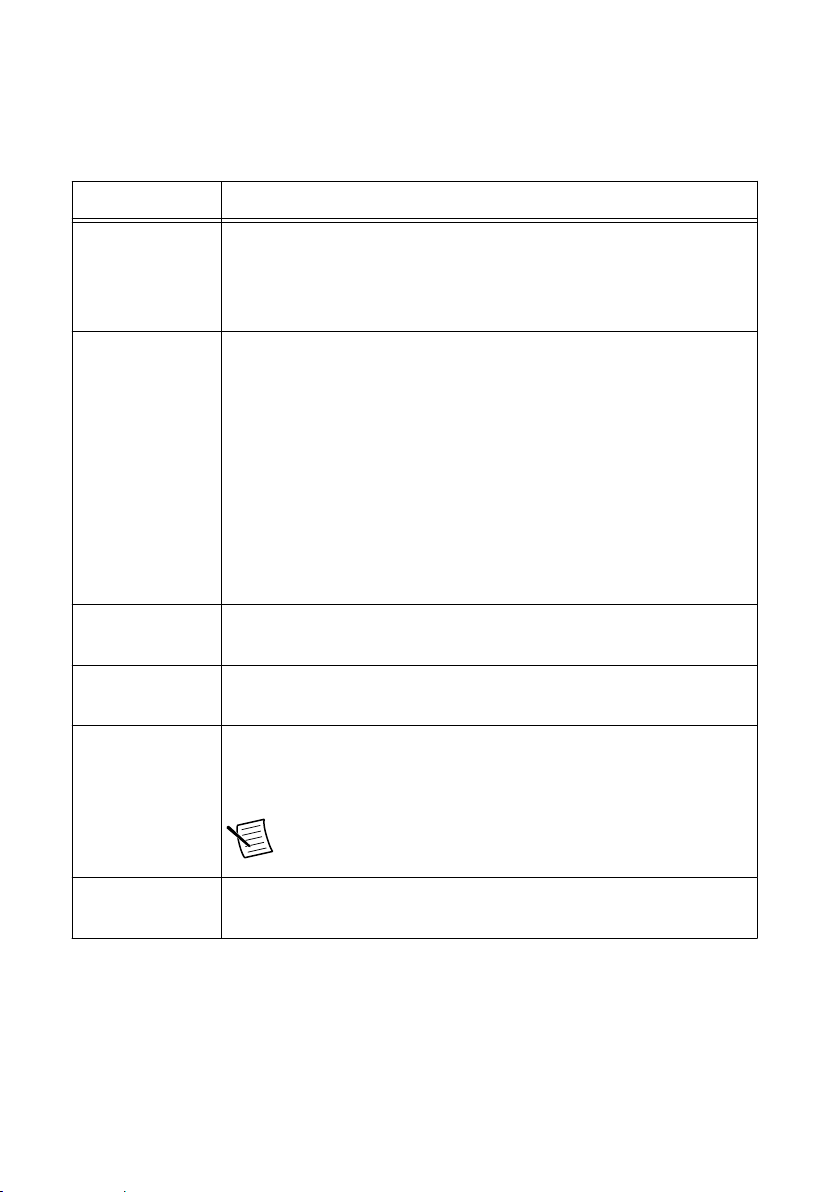

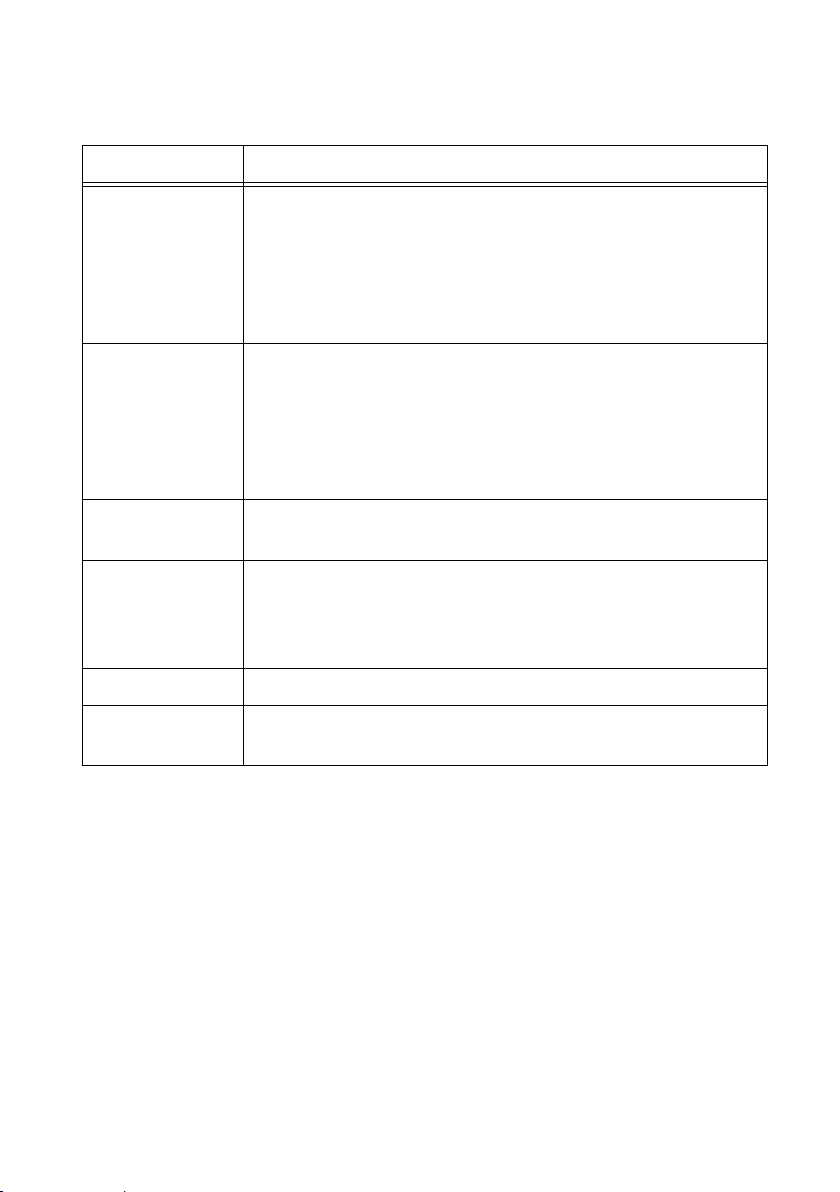

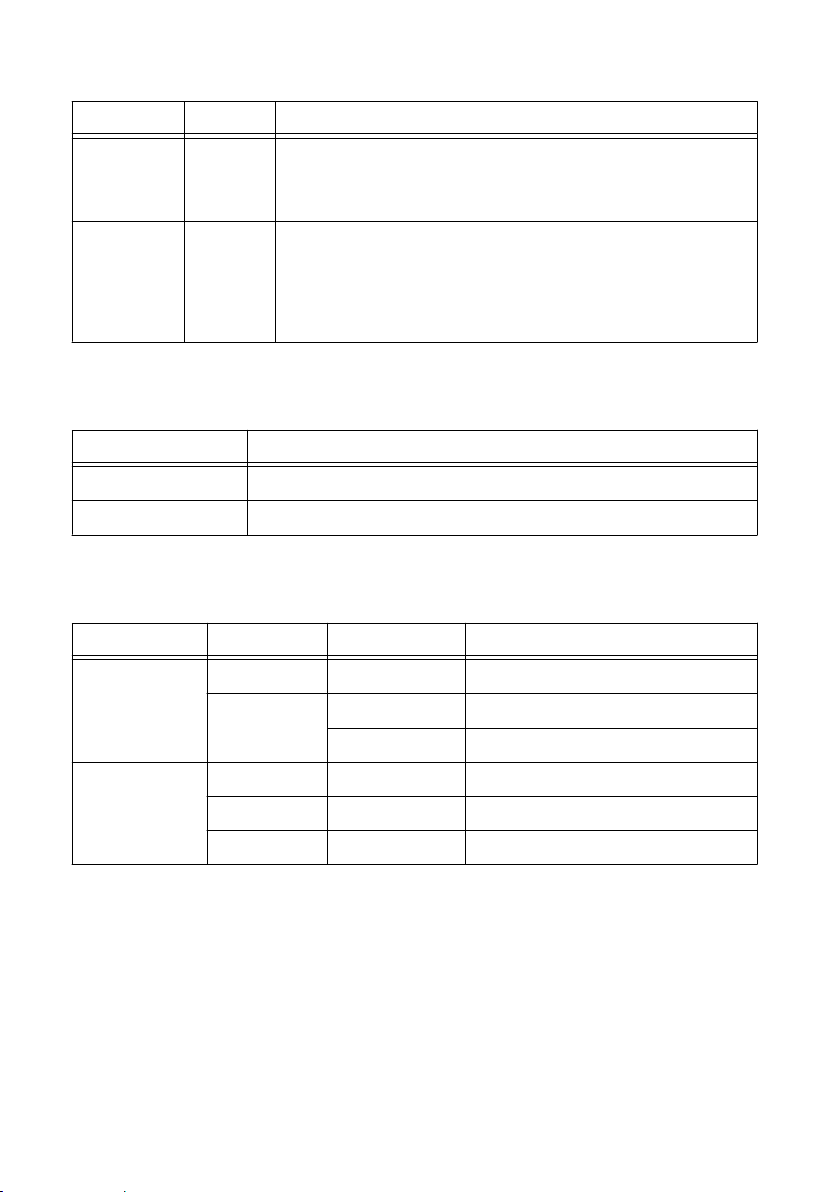

cRIO-905x Startup Options

You can configure the following cRIO-905x startup options.

Table 1. cRIO-905x Startup Options

Startup Option Description

Force Safe Mode Rebooting the cRIO-905x with this setting on starts the cRIO-905x

without launching LabVIEW Real-Time or any startup applications. In

safe mode, the cRIO-905x launches only the services necessary for

updating configuration and installing software.

Enable Console

Out

Disable RT

Startup App

Disable FPGA

Startup App

Enable Secure

Shell (SSH)

Logins

LabVIEW Project

Access

Rebooting the cRIO-905x with this setting on redirects the console

output to the USB 2.0 Type-C Device Port with Console Out. You can

use a serial-port terminal program to read the IP address and firmware

version of the cRIO-905x. Make sure that the serial-port terminal

program is configured to the following settings:

• 115,200 bits per second

• Eight data bits

• No parity

• One stop bit

• No flow control

Rebooting the cRIO-905x with this setting on prevents any LabVIEW

startup applications from running.

Rebooting the cRIO-905x with this setting on prevents autoloading of

any FPGA application.

Rebooting the cRIO-905x with this setting on starts sshd on the

cRIO-905x. Starting sshd enables logins over SSH, an encrypted

communication protocol.

Note Visit ni.com/info and enter the Info Code openssh

for more information about SSH.

Rebooting the cRIO-905x with this setting on enables you to add the

target to a LabVIEW project.

NI cRIO-905x User Manual | © National Instruments | 5

Page 6

cRIO-905x Features

1

2

3

4

5

6

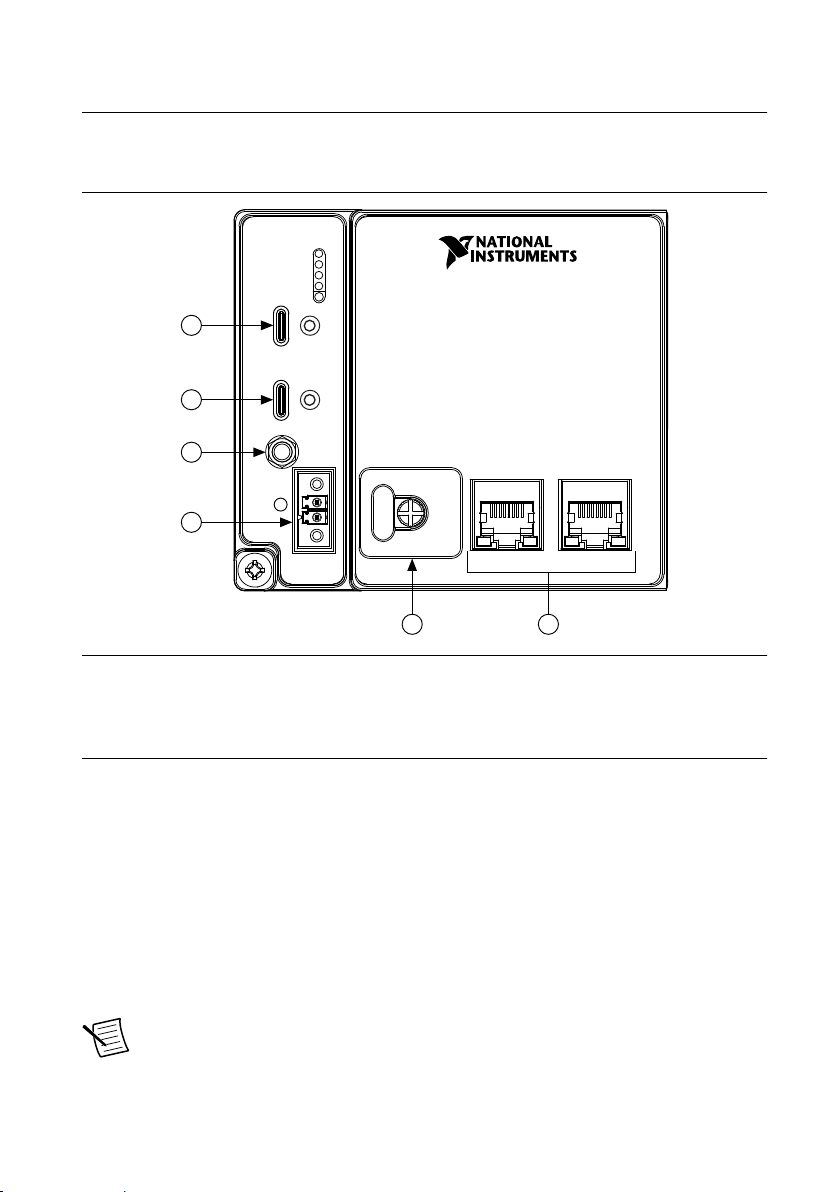

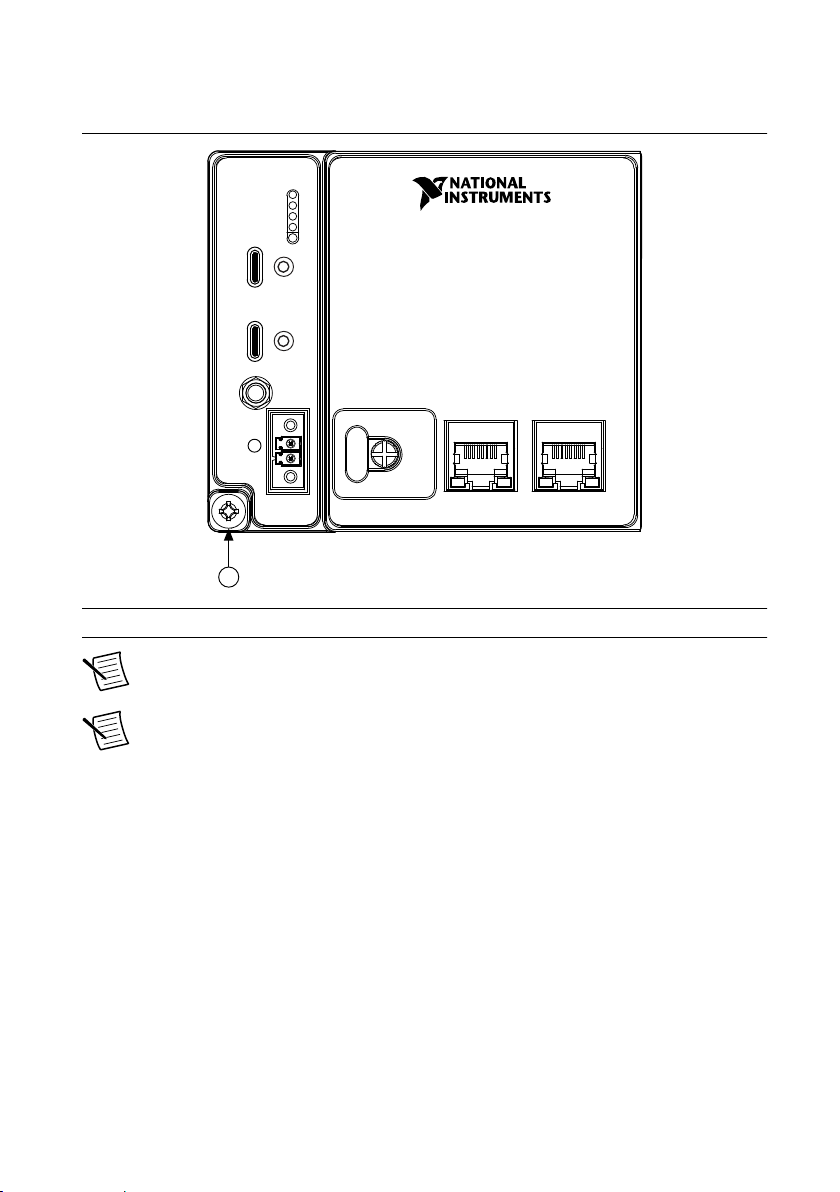

Ports and Connectors

Figure 1. cRIO-905x Ports and Connectors

1. USB 2.0 Type-C Device Port with Console Out

2. USB 3.1 Type-C Host Port

3. PFI 0

4. Power Connector

5. SD Association MicroSD Card Removable

Storage

6. RJ-45 Gigabit Ethernet Ports (one or two,

depending on the model)

USB 2.0 Type-C Device Port with Console Out

When operating a device, use this port to connect the cRIO-905x to a host PC. The USB

device functionality provides an alternate method to connect the controller to a host PC for

configuration, application deployment, debugging, and maintenance.

Console Out over USB requires a virtual COM port driver on the host PC. This driver installs

with CompactRIO 18.1 or later.

You must enable Console Out on the cRIO-905x in Measurement & Automation Explorer

(MAX) or by booting the controller into Safe Mode.

Note This port cannot be accessed by the user application when the Console Out

startup option is enabled.

6 | ni.com | NI cRIO-905x User Manual

Page 7

USB 3.1 Type-C Host Port

V

C

The USB host port on the cRIO-905x support common USB mass-storage devices such as

USB Flash drives, USB-to-IDE adapters, keyboards, mice, and USB cameras.

The following NI USB Type-C adapters are available for the cRIO-905x.

Table 2. NI USB Type-C Adapters for cRIO-905x

Cable Length Part Number

USB Cable with Retention, Type-C Male to Type-A Female, USB

0.5 m 143555-0R5

3.1, 3A

The following NI cables with retention are available for use with the cRIO-905x.

Table 3. NI USB Cables with Retention

Cable Length Part Number

0.3 m 143556-0R3

USB Cable with Retention, Type-C Male to Type-C Male, USB 3.1,

3A

1 m 143556-01

2 m 143556-02

PFI 0

The Programmable Function Interface (PFI) terminal is a SMB connector. You can configure

the PFI terminal as a timing input or timing output signal for AI, AO, DI, DO, or counter/timer

functions.

Note The PFI 0 terminal can only be used while the module is in the Real Time

programmatic mode. For more information about programming modes, refer to

Choosing Your Programming Mode.

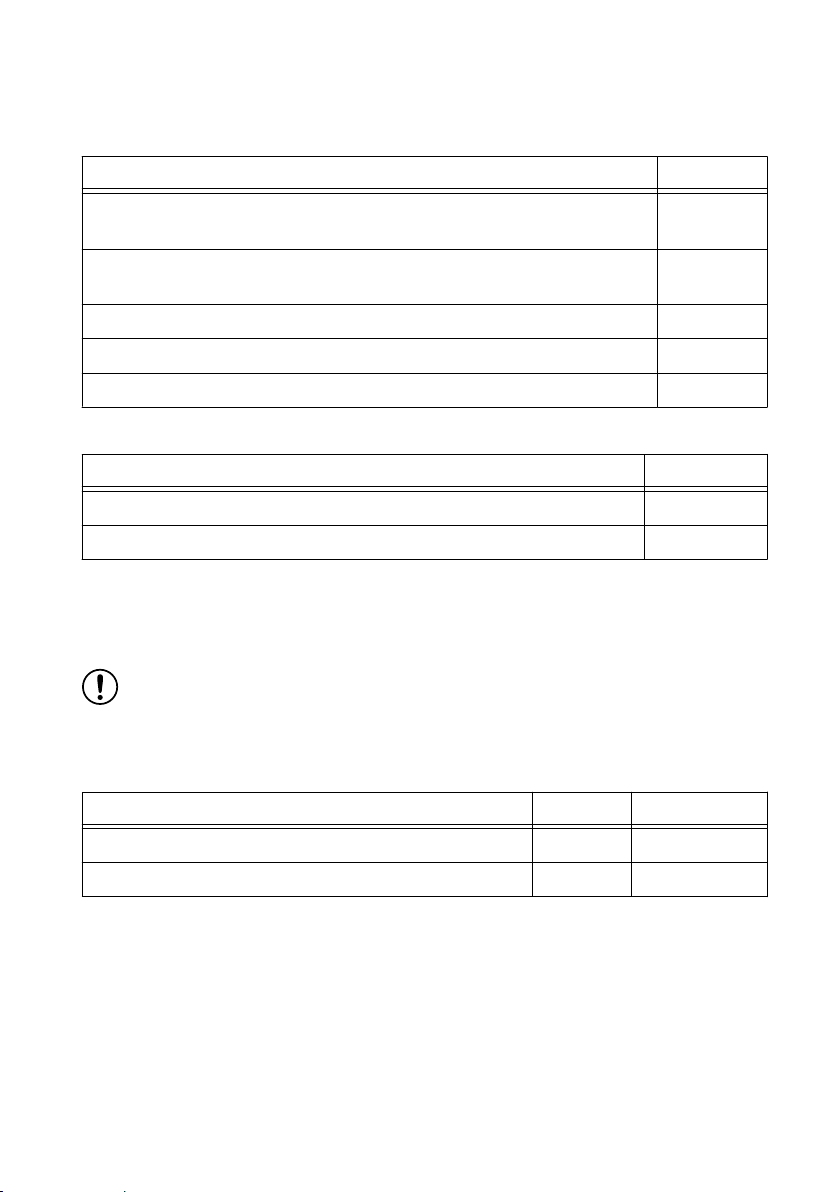

Power Connector

The cRIO-905x has a power connector to which you can connect a power supply.

Table 4. Power Connector Pinout

Pinout Pin Description

V Power input

C Common

NI cRIO-905x User Manual | © National Instruments | 7

Page 8

The cRIO-905x has reverse-voltage protection.

The following NI power supplies and accessories are available for use with the cRIO-905x.

Table 5. Power Supplies

Accessory Part Number

NI PS-10 Desktop Power Supply, 24 V DC, 5 A, 100-120/200-240 V AC

782698-01

Input

NI PS-14 Industrial Power Supply, 24 to 28 V DC, 3.3 A, 100-240 V AC

783167-01

Input

NI PS-15 Industrial Power Supply, 24 to 28 V DC, 5 A, 100/230 V AC Input 781093-01

NI PS-16 Industrial Power Supply, 24 to 28 V DC, 10 A, 115/230 V AC Input 781094-01

NI PS-17 Industrial Power Supply, 24 to 28 V DC, 20 A, 85-276 V AC Input 781095-01

Table 6. Power Accessories

Accessory Part Number

2-Position Screw Terminal Power Connector for cRIO-905x (Qty 4) 786902-01

NI 9971 Backshell for 2-Position Connector Block (Qty 4) 196375-01

MicroSD Card Removable Storage

The cRIO-905x has a microSD card slot that reads from and writes to microSD cards. The slot

supports microSD card interface speeds up to UHS-I DDR50.

Notice Using microSD cards that are not approved by NI might invalidate

specifications and result in unreliable performance.

The following accessories are available for use with the cRIO-905x.

Table 7. MicroSD Storage Accessories

Accessory Capacity Part Number

Industrial microSD card, -40 °C to 85 °C, UHS-I 16 GB 786913-01

MicroSD card slot cover (x3) — 786901-01

8 | ni.com | NI cRIO-905x User Manual

Page 9

MicroSD Card Slot Cover

1

2

3

4

5

6

7

8

You must use the microSD card slot cover to protect the microSD card in hazardous locations.

Do not remove a microSD card while the SD IN USE LED is flashing or solid because file

corruption may result.

Note Screw the slot cover closed completely. Tighten the captive screws to a

maximum torque of 0.75 N · m (6.7 lb · in.) using a #1 Phillips screwdriver. Do not

overtighten.

RJ-45 Gigabit Ethernet Port

The cRIO-905x will have one or two tri-speed RJ-45 Gigabit Ethernet ports. By default, the

Ethernet port is enabled and configured to obtain an IP address automatically. The Ethernet

port can be configured in MAX.

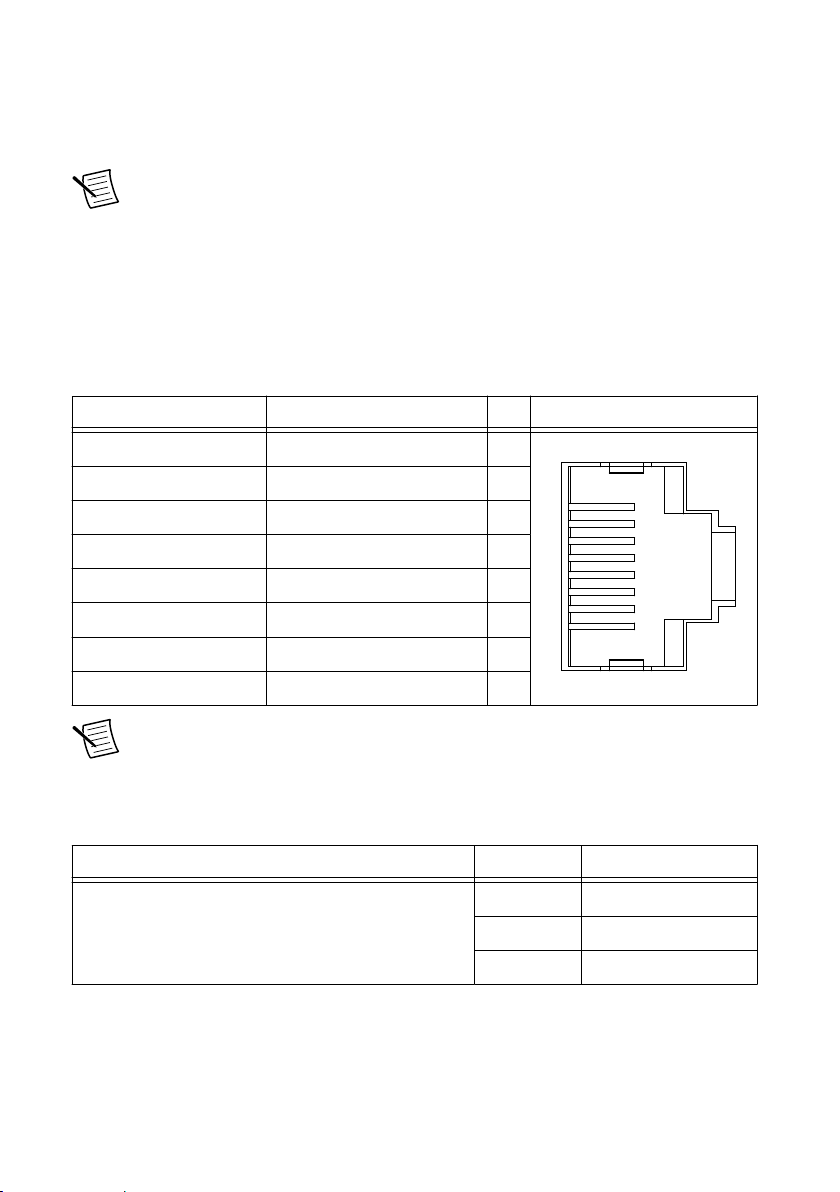

Table 8. RJ-45 Gigabit Ethernet Port Pinout

Fast Ethernet Signal Gigabit Ethernet Signal Pin Pinout

TX+ TX_A+ 1

TX- TX_A- 2

RX+ RX_B+ 3

No Connect TX_C+ 4

No Connect TX_C- 5

RX- RX_B- 6

No Connect RX_D+ 7

No Connect RX_D- 8

Note The Ethernet port performs automatic crossover configuration so you do not

need to use a crossover cable to connect to a host computer.

The following NI Ethernet cables are available for use with the cRIO-905x.

Table 9. RJ-45 Gigabit Ethernet Cables

Cables Length Part Number

2 m 151733-02

CAT-5E Ethernet Cable, shielded

5 m 151733-05

10 m 151733-10

NI cRIO-905x User Manual | © National Instruments | 9

Page 10

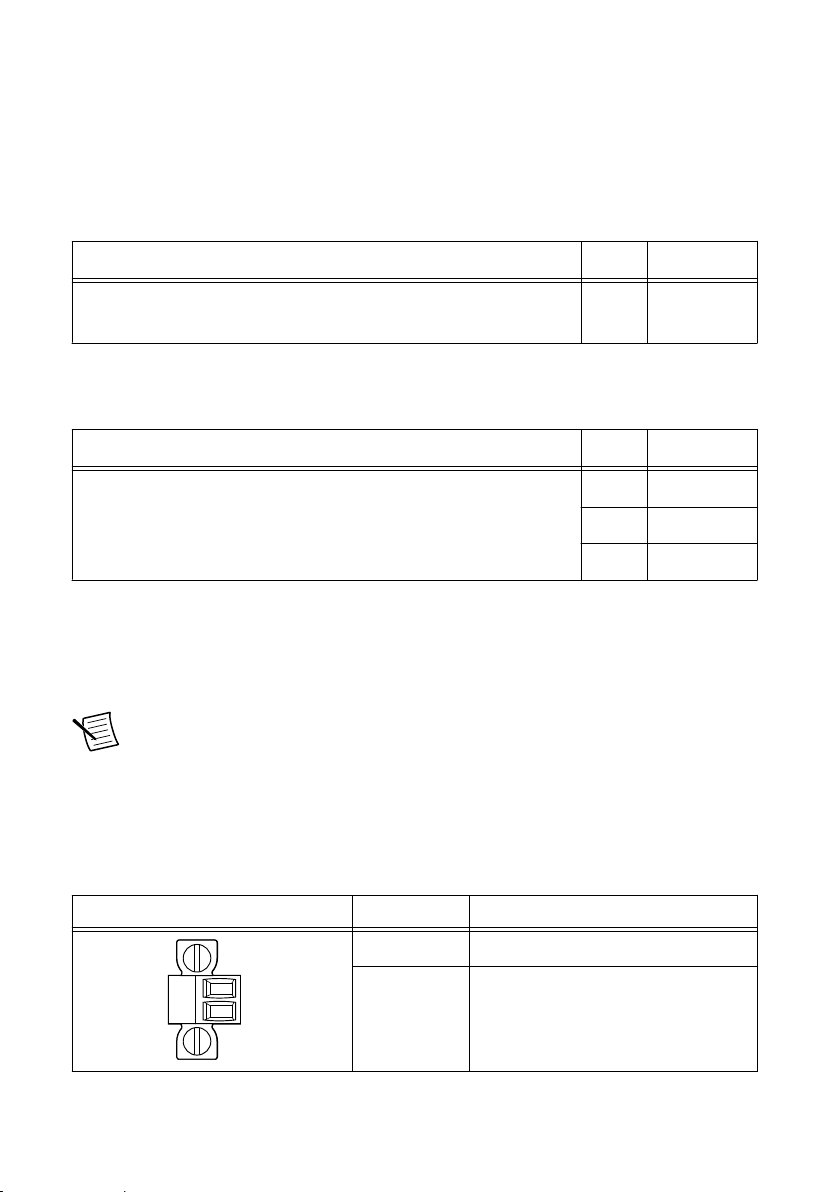

Buttons

1 2 3

4 5 6 7 8

1

2

Press and hold RESET button for ≥ 5 s

Press and hold RESET button for < 5 s

Run Mode

Safe Mode

Press and hold RESET button for < 5 s

Press and hold RESET button for ≥ 5 s

Press and hold

RESET button for ≥ 5 s

Press and hold

RESET button for < 5 s

• Console Out enabled

• Network settings reset

• RT Startup App disabled

• FPGA Startup App disabled

• Console Out enabled

• RT Startup App disabled

• FPGA Startup App disabled

Safe Mode

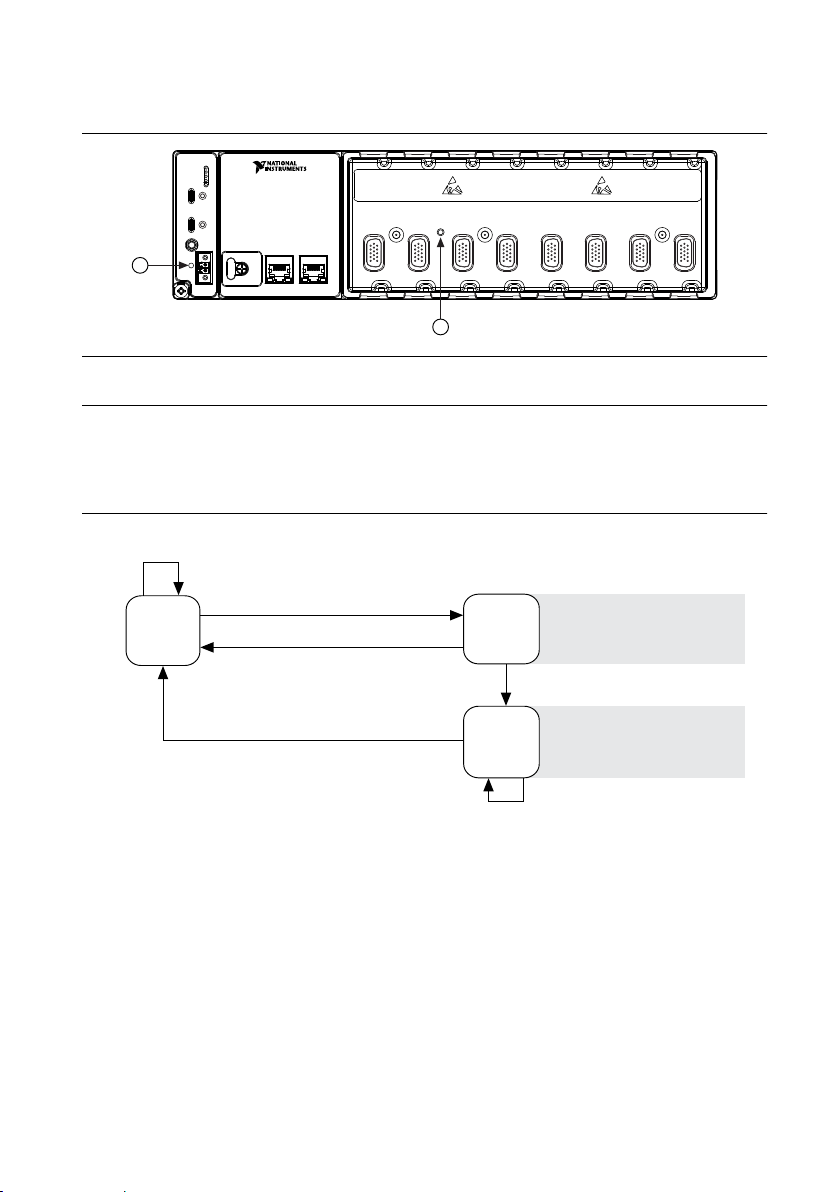

Figure 2. cRIO-905x Buttons

1. RESET Button

2. CMOS Reset Button

RESET Button

Press the RESET button to reset the processor in the same manner as cycling power.

Figure 3. Reset Button Behavior

For more information about using the RESET button for network troubleshooting, see

Troubleshooting Network Connectivity.

Troubleshooting Network Connectivity

You can use the RESET button to troubleshoot network connectivity.

Complete the following steps to reset the network adapters to default settings.

1. Hold the RESET button for 5 seconds, and then release it to boot the controller in safe

mode and enable Console Out.

2. Hold the RESET button again for 5 seconds to boot the controller into safe mode, enable

Console Out, and reset network adapters to default settings.

10 | ni.com | NI cRIO-905x User Manual

Page 11

CMOS Reset Button

1

2

3

4

5

6

The cRIO-905x has a CMOS reset button that you can use to reset the CMOS and the BIOS.

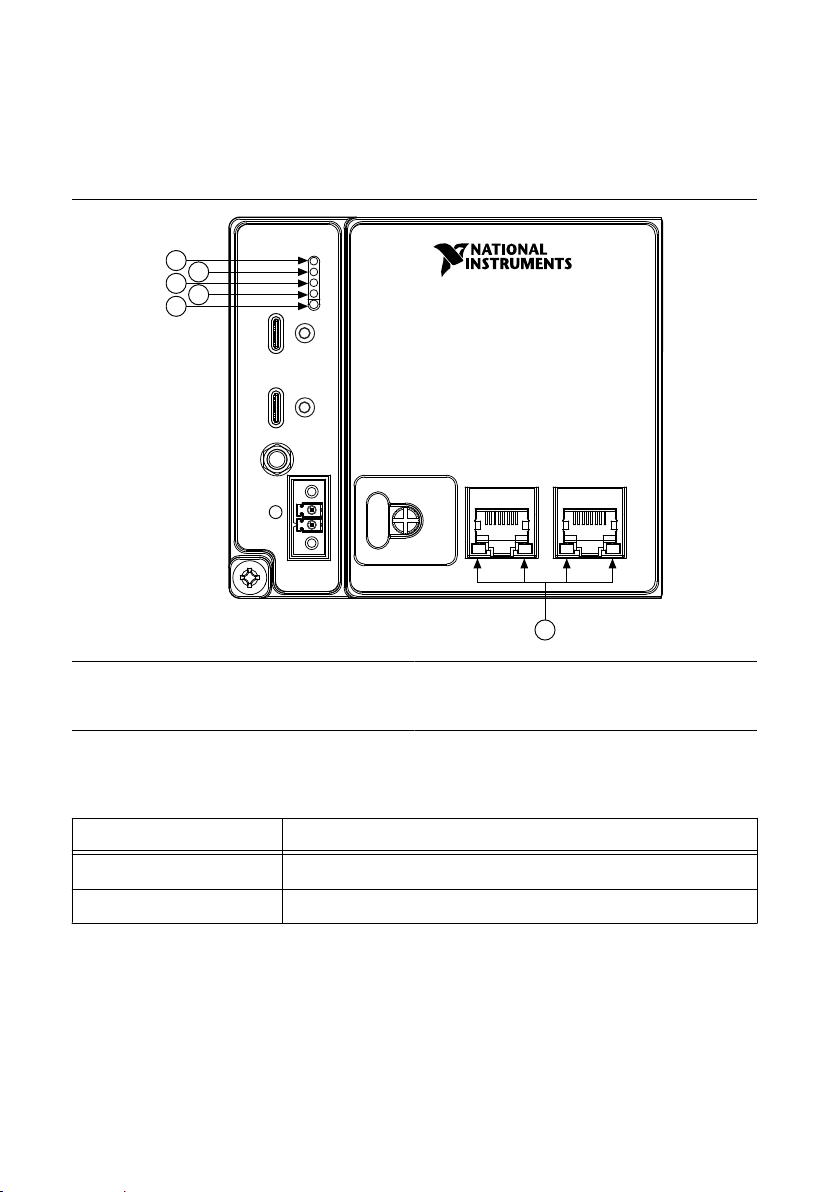

LEDs

Figure 4. cRIO-905x Front Panel LEDs

1. POWER LED

2. STATUS LED

3. SD IN USE LED

4. USER1 LED

5. USER FPGA1 LED

6. Gigabit Ethernet LEDs

POWER LED Indicators

LED Pattern Indication

Solid The cRIO-905x is powered on.

Off The cRIO-905x is powered off.

Table 10. POWER LED Indicators

NI cRIO-905x User Manual | © National Instruments | 11

Page 12

STATUS LED Indicators

Table 11. STATUS LED Indicators

LED Pattern Indication

Blinks twice and

pauses

Blinks three times

and pauses

Blinks four times

and pauses

Continuously blinks The cRIO-905x has not booted into NI Linux Real-Time. The

On momentarily The cRIO-905x is booting. No action required.

Off The cRIO-905x is in run mode. Software is installed and the operating

The cRIO-905x is in safe mode. Software is not installed, which is the

factory default state, or software has been improperly installed on the

cRIO-905x. An error can occur when an attempt to upgrade the

software is interrupted. Reinstall software on the cRIO-905x. Refer to

the Measurement & Automation Explorer (MAX) Help for information

about installing software on the cRIO-905x.

The cRIO-905x is in user-directed safe mode, or the cRIO-905x is in

install mode to indicate that software is currently being installed. This

pattern may also indicate that the user has forced the cRIO-905x to

boot into safe mode by pressing the reset button for longer than five

seconds or by enabling safe mode in MAX. Refer to the Measurement

& Automation Explorer (MAX) Help for information about safe mode.

The cRIO-905x is in safe mode. The software has crashed twice

without rebooting or cycling power between crashes.

cRIO-905x either booted into an unsupported operating system, was

interrupted during the boot process, or detected an unrecoverable

software error. If the problem persists, contact NI for support.

system is running.

User LEDs

You can define the behavior of the USER1 LED and the USER FPGA1 LED to meet the needs

of your application.

12 | ni.com | NI cRIO-905x User Manual

Page 13

Table 12. User LEDs

LED LED Color Description

USER1 Green Use LabVIEW Real-Time to define the USER1 LED with the

RT LEDs VI. For more information about the RT LEDs VI, refer

to the LabVIEW Help.

USER

FPGA1

Green Use the LabVIEW FPGA Module and NI-RIO Device Drivers

software to define the USER FPGA1 LED. Use the USER

FPGA1 LED to help debug your application or retrieve

application status. Refer to the LabVIEW Help for information

about programming this LED.

SD IN USE LED Indicators

Table 13. SD IN USE LED Indicators

LED Pattern Indication

Solid A microSD card is present and mounted.

Off No microSD card is present.

Ethernet LED Indicators

Table 14. Ethernet LED Indicators

LED LED Color LED Pattern Indication

ACT/LINK — Off LAN link not established

Green Solid LAN link established

Flashing Activity on LAN

10/100/1000 Yellow Solid 1,000 Mb/s data rate selected

Green Solid 100 Mb/s data rate selected

— Off 10 Mb/s data rate selected

NI cRIO-905x User Manual | © National Instruments | 13

Page 14

Chassis Grounding Screw

1

Figure 5. cRIO-905x Chassis Grounding Screw

1. Chassis Grounding Screw

Note For information about grounding the cRIO-905x, see Grounding the

Controller in the NI cRIO-905x Getting Started Guide.

Note For more information about ground connections, visit ni.com/info and enter

the Info Code emcground.

Internal Real-Time Clock

The cRIO-905x contains an internal real-time clock that maintains system time when the

cRIO-905x is powered off. The system clock of the cRIO-905x is synchronized with the

internal real-time clock at startup. You can set the real-time clock using the BIOS setup utility

or MAX, or you can set the real-time clock programmatically using LabVIEW.

Refer to the model specifications on ni.com/manuals for the real-time clock accuracy

specifications.

Digital Routing

The digital routing circuitry of the cRIO-905x manages the flow of data between the bus

interface and the acquisition and generation sub-systems when programming C Series modules

in Real-Time (NI-DAQmx) mode. The subsystems include analog input, analog output, digital

14 | ni.com | NI cRIO-905x User Manual

Page 15

I/O, and counters. The digital routing circuitry uses FIFOs (if present) in each sub-system to

Onboard

100 MHz

Oscillator

Clock

Generator

DAQ ASIC

RIO FPGA

cRIO Trigger Bus

80 MHz Timebase

20 MHz Timebase

100 kHz Timebase

13.1072 MHz Timebase

12.8 MHz Timebase

10 MHz Timebase

40 MHz Onboard Clock

÷200

13.1072 MHz Carrier Clock

12.8 MHz Carrier Clock

10 MHz Carrier Clock

÷2

÷4

ensure efficient data movement.

Note When programming C Series modules in FPGA mode, the flow of data

between the modules and the bus interface is programmed using LabVIEW FPGA.

The digital routing circuitry also routes timing and control signals. The acquisition and

generation sub-systems use these signals to manage and synchronize acquisitions and

generations. These signals can come from the following sources:

• C Series modules programmed in Real-Time (NI-DAQmx) mode

• User input through the PFI terminals using parallel digital C Series modules or the

cRIO-905x PFI 0 terminal

• FPGA or DAQ ASIC using the cRIO trigger bus to share hardware triggers and signals

between the LabVIEW FPGA and DAQmx applications

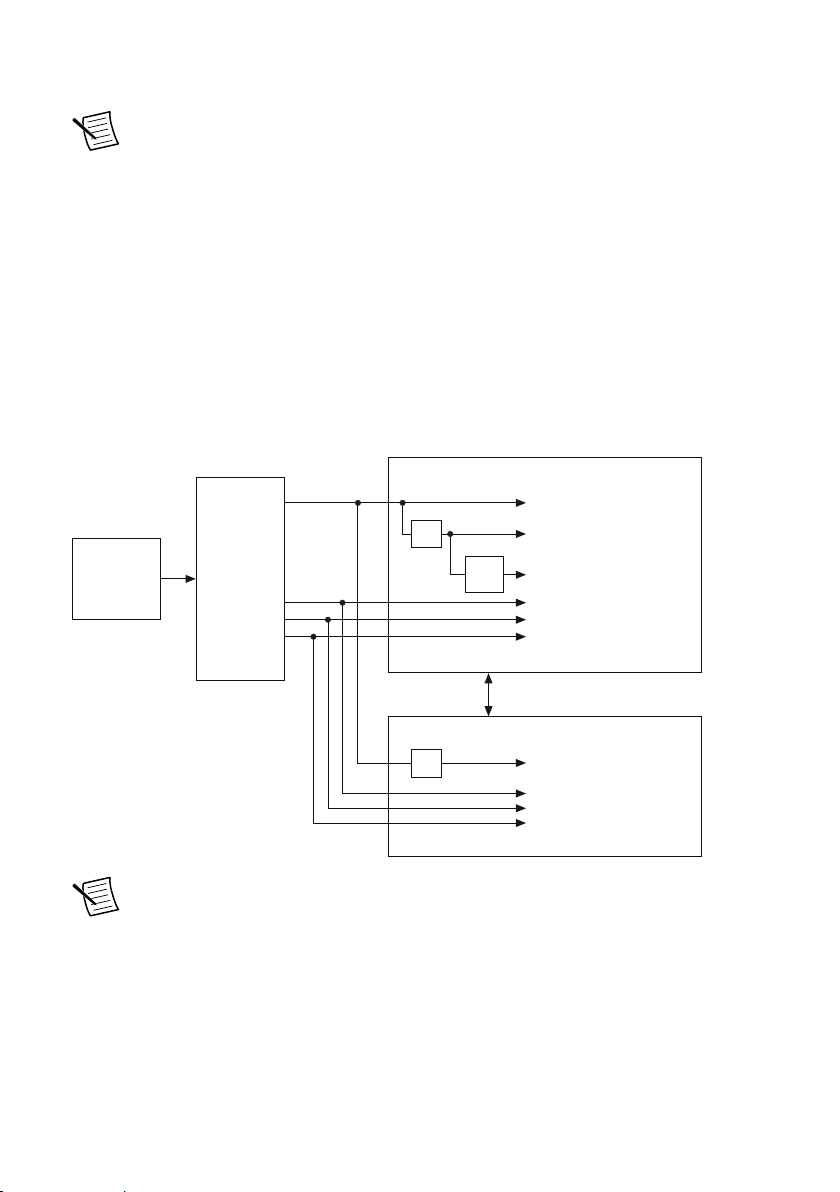

Clock Routing

The following figure shows the clock routing circuitry of the cRIO-905x.

Figure 6. Clock Routing Circuitry of the cRIO-905x

Note When switching between programming modes, you may notice the terms

timebase and clock used interchangeably. This is due to the DAQ ASIC and the RIO

FPGA using different terminology for timing and clock mechanisms. The

documentation will use the term based on the programming mode discussed.

80 MHz Timebase

When programming C Series modules in Real-Time (NI-DAQmx) mode, the 80 MHz

timebase can function as the source input to the 32-bit general-purpose counter/timers. The

80 MHz timebase is generated from the onboard oscillator.

NI cRIO-905x User Manual | © National Instruments | 15

Page 16

20 MHz and 100 kHz Timebases

When programming C Series modules in Real-Time (NI-DAQmx) mode, the 20 MHz and

100 kHz timebases can be used to generate many of the analog input and analog output timing

signals. These timebases can also function as the source input to the 32-bit general-purpose

counter/timers. The 20 MHz and 100 kHz timebases are generated by dividing down the

80 MHz timebase, as shown in the previous figure.

40 MHz Onboard Clock

When programming C Series modules in FPGA mode, the 40 MHz onboard clock is used as

the top-level clock for your LabVIEW FPGA application and C Series module IO nodes. The

40 MHz onboard clock can be used to clock single-cycle timed loops. Derived clocks of

varying frequency can be generated from the 40 MHz onboard clock. The 40 MHz onboard

clock is phase aligned with the incoming 80 MHz clock.

13.1072 MHz, 12.8 MHz, and 10 MHz Timebases and Carrier Clocks

When programming C Series modules in Real-Time (NI-DAQmx) mode, the 13.1072 MHz,

12.8 MHz, and 10 MHz timebases can be used to generate many of the analog input and

analog output timing signals. These timebases can also function as the source input to the 32bit general-purpose counter/timers. The 13.1072 MHz, 12.8 MHz, and 10 MHz timebases are

generated directly from the onboard clock generator.

When programming C Series modules in FPGA mode, the 13.1072 MHz, 12.8 MHz, and

10 MHz carrier clocks can be used as the master clock for C Series analog input and analog

output modules. The 13.1072 MHz, 12.8 MHz, and 10 MHz carrier clocks are available as IO

Nodes in LabVIEW FPGA applications and can be used to correlate the onboard clocks with

self-timed C Series modules containing free-running clocks.

Synchronization Across a Network

Internal Timebase

The onboard 100 MHz oscillator automatically synchronizes to other network-synchronized

devices that are part of the local IEEE 802.1AS or IEEE 1588-2008 subnet, depending on the

active time reference that is being used on the controller.

The 80 MHz, 40 MHz, 20 MHz, 100 kHz, 13.1072 MHz, 12.8 MHz, and 10 MHz timebases

are derived from the onboard oscillator and are synchronized to it. Therefore, the timebases are

also synchronized to other network-synchronized timebases on the IEEE 802.1AS or

IEEE 1588-2008 subnet. This enables analog input, analog output, digital I/O, and counter/

timers to be synchronized to other chassis across a distributed network.

When programming C Series modules in FPGA mode, the Time Synchronization IO Nodes

can be used to synchronize the LabVIEW FPGA application to other network-synchronized

devices.

16 | ni.com | NI cRIO-905x User Manual

Page 17

Network-based Synchronization

IEEE 1588, also known as the precision time protocol (PTP), is an Ethernet-based

synchronization method designed for cabled, local networks. The PTP protocol provides a

fault tolerant method of synchronizing all participating clocks to the highest quality clock in

the network. This method of synchronization between networked devices uses packet-based

communication and is possible over the long distances allowed for each Ethernet link, without

signal propagation impact. IEEE 1588 has many different profiles, such as

IEEE 802.1AS-2011, each of which use different features. Because the profiles are not

interoperable with each other, make sure it is known which profile is implemented on the

device. For devices on the network to synchronize with each other using IEEE 1588, all

devices must be compatible with the desired IEEE 1588 profile and must all be connected

within the selected IEEE 1588 profile-compliant network infrastructure.

The cRIO-905x controllers are compatible with both the IEEE 802.1AS-2011 profile and the

IEEE 1588-2008 (1588v2) Delay Request-Response profile. However, each network port must

be configured individually to the specific profile required for the network.

Differences Between IEEE 802.1AS-2011 and IEEE 1588-2008

IEEE 802.1AS-2011, also known as the generalized precision time protocol (gPTP), is a

profile of IEEE 1588. A cRIO-905x controller can be configured to use either the

IEEE 802.1AS-2011 profile or the IEEE 1588-2008 profile by configuring the port’s time

reference. If a user does not explicitly specify which time reference to use a cRIO-905x

controller will default to use the IEEE 802.1AS-2011 profile. There are some differences

between the IEEE 802.1AS-2011 profile and the IEEE 1588-2008 profile which are called out

below:

• IEEE 802.1AS-2011 assumes all communication between devices is done on the OSI

layer 2, while IEEE 1588-2008 can support various layer 2 and layer 3-4 communication

methods. The IEEE 1588-2008 profile National Instruments implements on the

cRIO-905x only supports layer 3-4 communication methods. Operating on the layer 2

yields better performance for the IEEE 802.1AS-2011.

• IEEE 802.1AS-2011 only communicates gPTP information directly with other

IEEE 802.1AS devices within a system. Therefore, there must be IEEE 802.1AS-2011

support along the entire path from one IEEE 802.1AS-2011 device to another. With

IEEE 1588-2008, it is possible to use non-IEEE 1588-2008 switches between two

IEEE 1588-2008 devices. The benefit of having IEEE 802.1AS-2011 support along the

entire path is a faster performance and lower jitter compared to IEEE 1588-2008.

• With IEEE 802.1AS-2011 there are only two types of time-aware systems: time-aware

end stations and time-aware bridges. Whereas with IEEE 1588-2008, there are the

following: ordinary clock, boundary clock, end-to-end transparent clock and a time-aware

bridges. Based on these factors, IEEE 802.1AS-2011 can reduce complexity and

configuration challenges compared to IEEE 1588-2008. A cRIO-905x controller acts as a

time-aware end station for both protocols.

NI cRIO-905x User Manual | © National Instruments | 17

Page 18

IEEE 1588 External Switch Requirements

To take advantage of the network synchronization features of the cRIO-905x controllers,

ensure that your network infrastructure meets certain requirements depending on which

IEEE 1588 profile is implemented for your application:

• IEEE 802.1AS-2011 support—Automatically enables timebase synchronization and

enables the use of time-based triggers and timestamping between devices across the

network. Synchronization performance will meet NI product specifications.

• IEEE 1588-2008 support—Enables timebase synchronization and enables the use of timebased triggers and timestamping between devices across the network. Synchronization

performance will vary and may not meet NI product specifications. As a default

configuration for IEEE 1588-2008, NI supports the IEEE 1588 Delay Request-Response

profile, using the UDP over IP transport (layer 3-4).

Battery

The cRIO-905x contains a lithium cell battery that stores the system clock information when

the cRIO-905x is powered off. There is only a slight drain on the battery when power is

applied to the cRIO-905x power connector. The rate at which the battery drains when power is

disconnected depends on the ambient storage temperature. For longer battery life, store the

cRIO-905x at a cooler temperature and apply power to the power connector. Refer to the

specifications on ni.com/manuals for the expected battery lifetime.

The battery is not user-replaceable. If you need to replace the battery, contact NI. Refer to the

controller specifications on ni.com/manuals for information about battery disposal.

File System

LabVIEW mounts USB devices and microSD cards to the media/sdx1 directory and creates

symbolic links /u, /v, /w, or /x to the media mount point, starting with /u if it is available.

To prevent any file corruption to external storage devices, verify that any file IO operations

with the specific drive finish before removing the device. Refer to the LabVIEW Help for more

information.

The file system of the cRIO-905x follows conventions established for UNIX-style operating

systems. Other LabVIEW Real-Time targets follow Microsoft Windows-style conventions. In

order to facilitate the porting of applications from those targets, this target supports the

Windows-style /C home directory. This path is bound to the UNIX-style directory /home/

lvuser.

Various LabVIEW Real-Time system files which would be accessible from C: (or /C) on

other LabVIEW Real-Time targets are found in different locations on this target.

UNIX-style file systems support the concept of a symbolic link, which allows access to a file

using an alternative file path. For example, it is possible to link /C/ni-rt/system, where

dynamic libraries are deployed on other LabVIEW Real-Time targets, to /usr/local/lib,

where they are stored on the cRIO-905x, if the application requires this.

For more information, visit ni.com/info and enter the Info Code RT_Paths.

18 | ni.com | NI cRIO-905x User Manual

Page 19

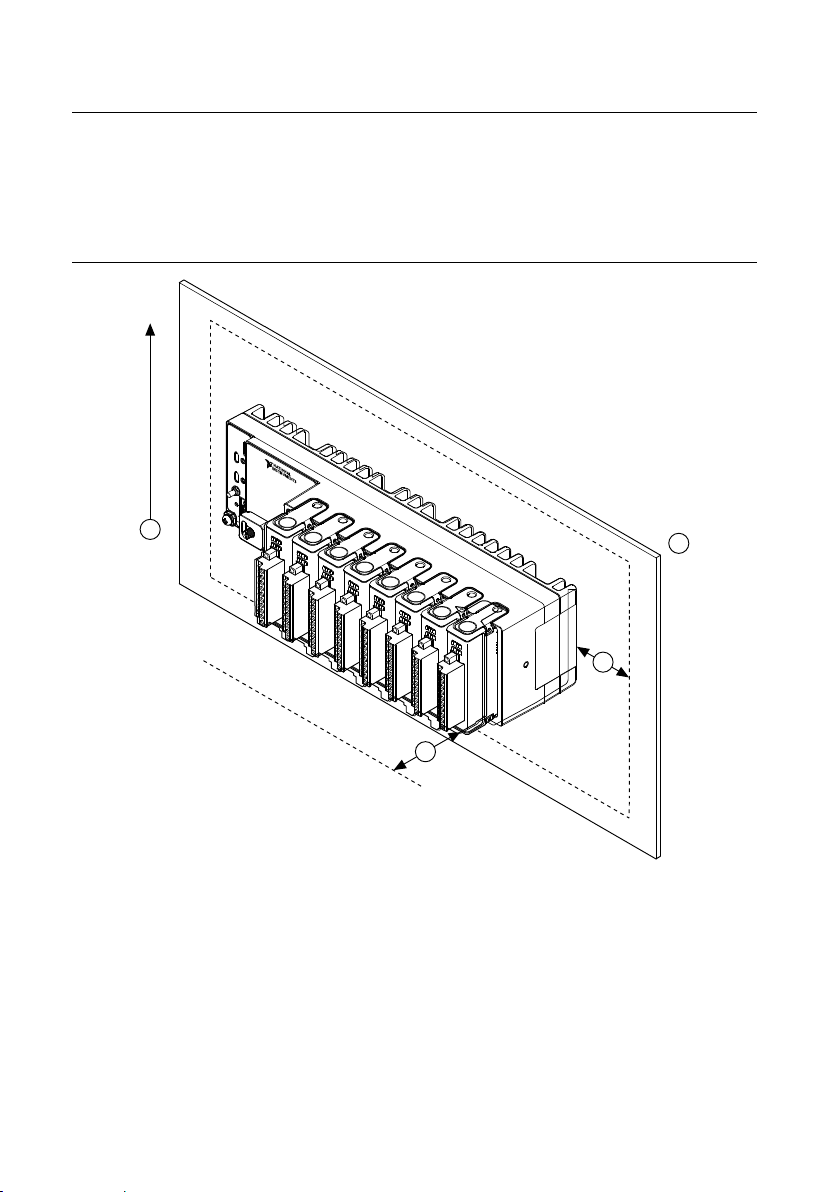

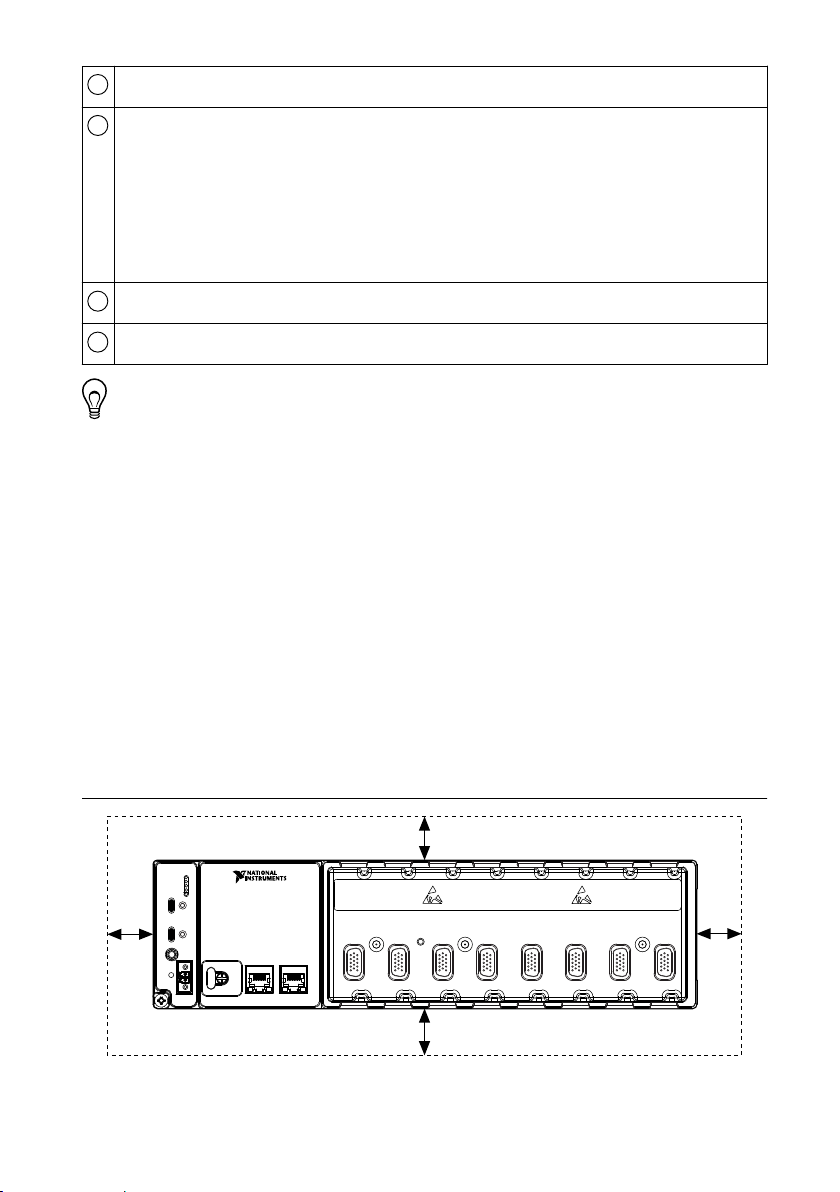

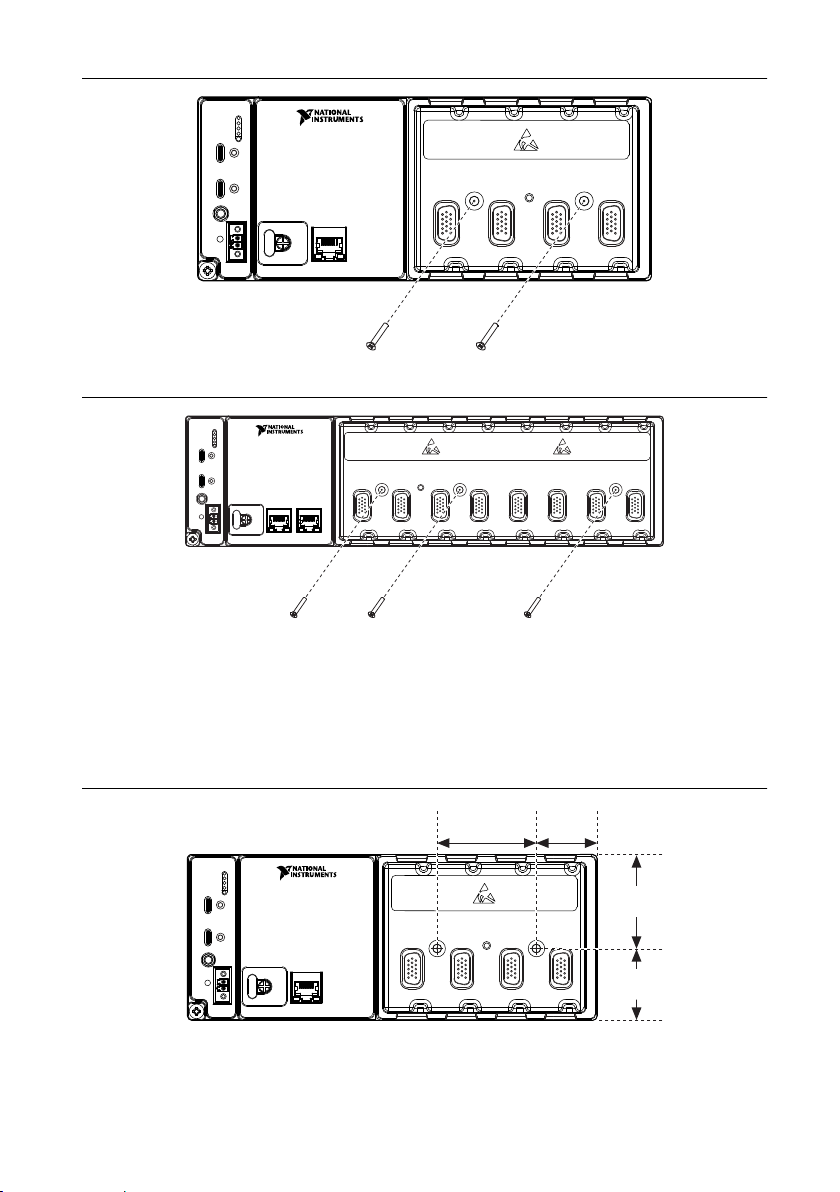

Mounting the Controller

3

4

1

2

To obtain the maximum ambient temperature, you must mount the cRIO-905x in the reference

mounting configuration shown in the following image. Mounting the cRIO-905x in the

reference mounting configuration ensures that your system will operate correctly across the

full operating temperature range and provide optimal C Series module accuracy. Observe the

following guidelines to mount the cRIO-905x in the reference mounting configuration.

Figure 7. System Mounting Configuration

NI cRIO-905x User Manual | © National Instruments | 19

Page 20

1

Vertical mounting orientation.

2

3

4

1 2 3

4 5 6 7 8

25.4 mm

(1.00 in.)

Mounting substrate options:

• Mount the cRIO-905x directly to a metallic surface that is at least 1.6 mm

(0.062 in.) thick and extends a minimum of 101.6 mm (4 in.) beyond all edges of

the device.

• Use the NI Panel Mounting Kit to mount the cRIO-905x to a metallic surface that is

at least 1.6 mm (0.062 in.) thick and extends a minimum of 101.6 mm (4 in.)

beyond all edges of the device.

Observe the minimum spacing dimensions in the Mounting Requirements section.

Allow space for cabling clearance according to the Mounting Requirements section.

Tip Before mounting the controller, record the serial number from the side of the

cRIO-905x so that you can identify the cRIO-905x in MAX. You will be unable to

read the serial number after you mount the controller.

Alternative Mounting Configurations

The maximum operating temperature may be reduced for any mounting configuration other

than the reference mounting configuration. A 10 °C (18 °F) reduction in maximum operating

temperature is sufficient for most alternate mounting configurations. Follow the guidelines

above for all mounting configurations. The published accuracy specifications, although not

guaranteed for alternate mounting configurations, may be met depending on the system power

and the thermal performance of the alternate mounting configuration. Contact NI for further

details regarding the impact of common alternate mounting configurations on maximum

operating temperature and module accuracy.

Contact NI for further details regarding the system impact of common alternative mounting

configurations.

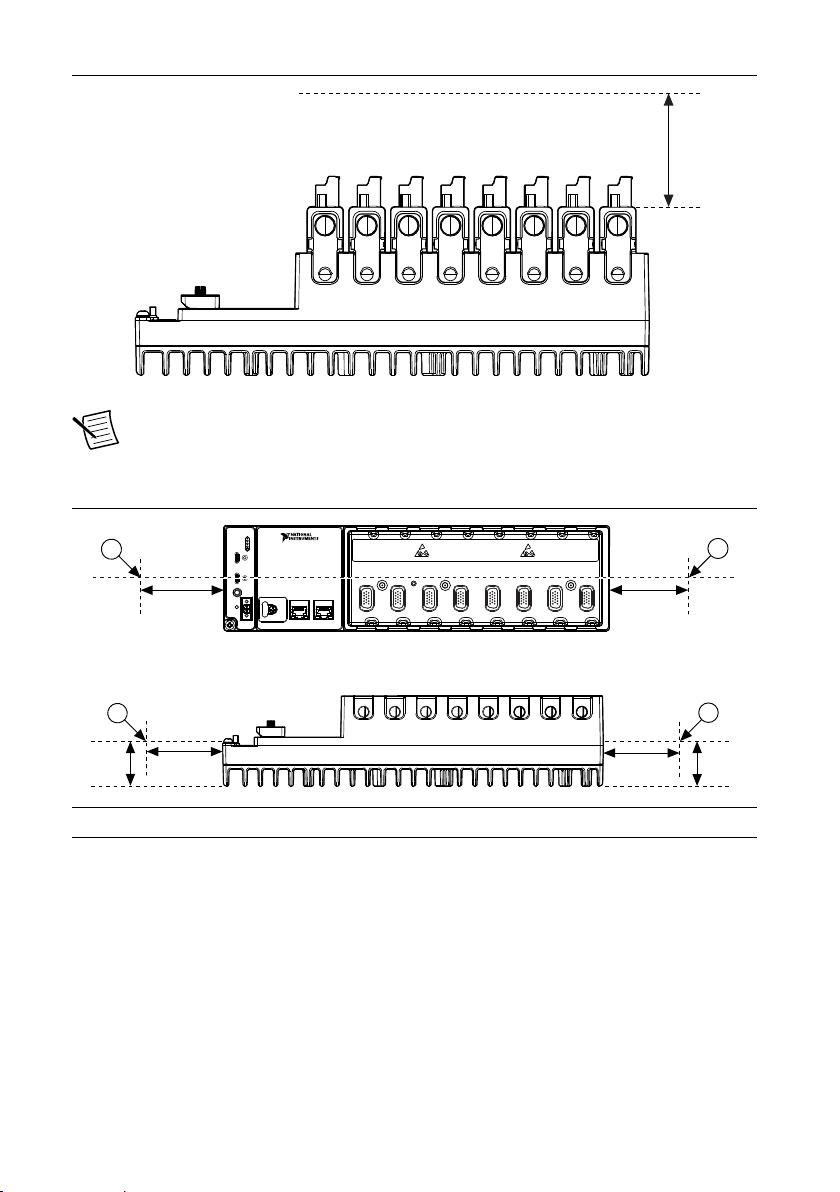

Mounting Requirements

Figure 8. Minimum Spacing Dimensions

20 | ni.com | NI cRIO-905x User Manual

Page 21

Figure 9. Cabling Clearance

1 2 3

4 5 6 7 8

38.1 mm

(1.50 in.)

63.5 mm

(2.50 in.)

63.5 mm

(2.50 in.)

38.1 mm

(1.50 in.)

63.5 mm

(2.50 in.)

63.5 mm

(2.50 in.)

1

1

1

1

Note The various connector types on C Series modules require different cabling

clearances. For a complete list of cabling clearances for C Series modules, visit

ni.com/info and enter the Info Code crioconn.

Figure 10. Ambient Temperature Measurement Location

1. Measure the ambient temperature here.

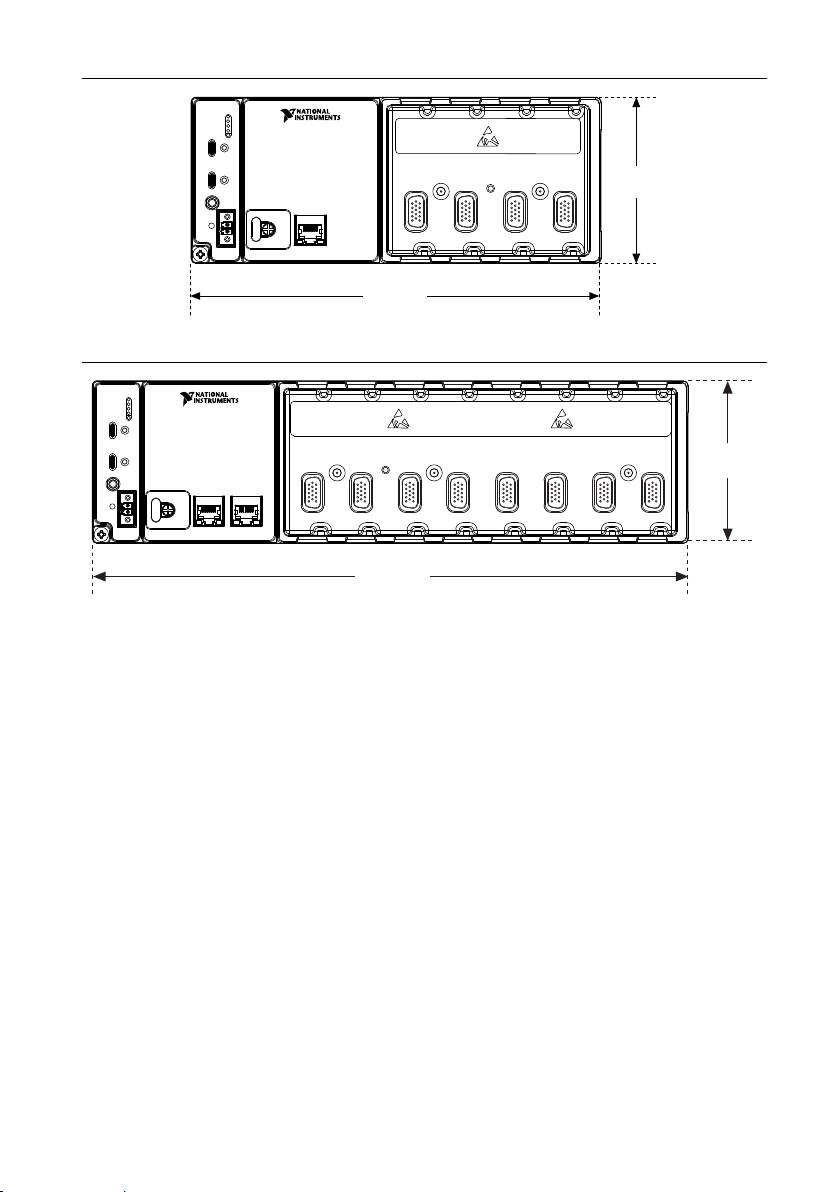

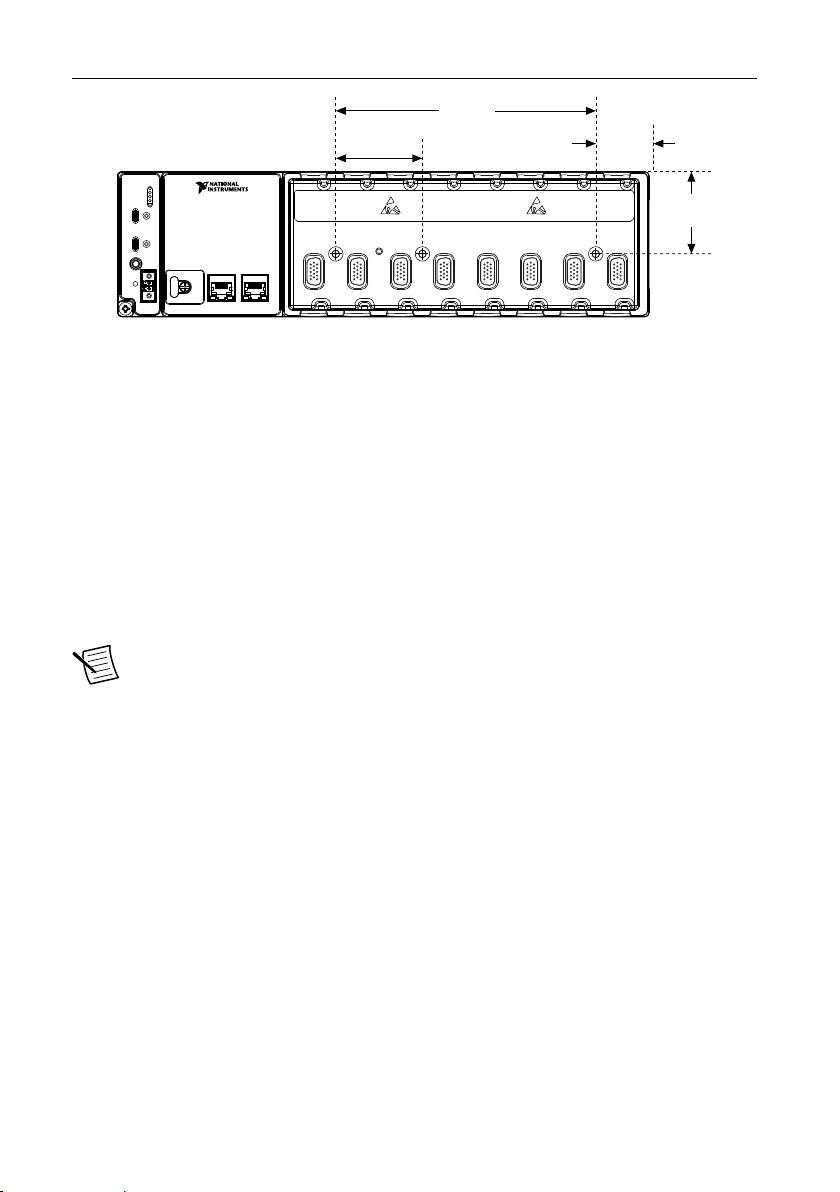

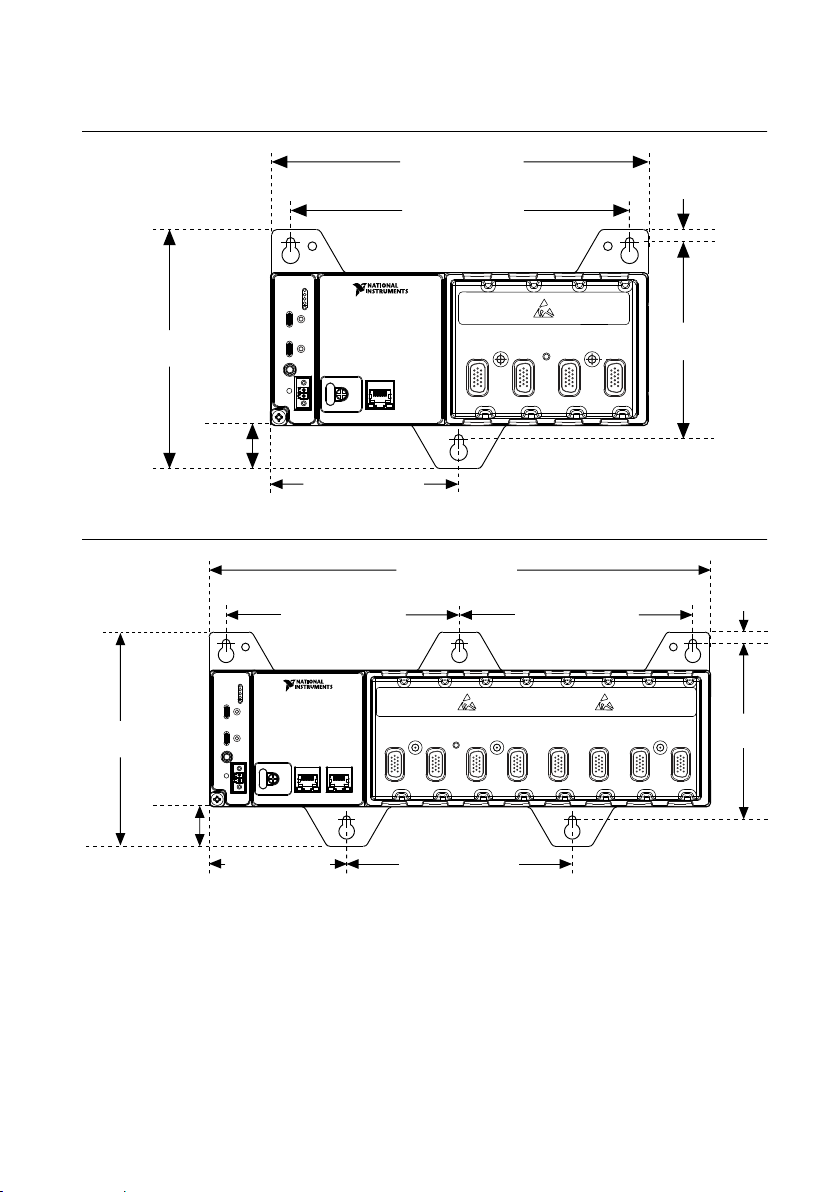

Dimensions

The following dimensional drawings apply to all cRIO-905x controllers. For detailed

dimensional drawings and 3D models, visit ni.com/dimensions and search for the model

number.

NI cRIO-905x User Manual | © National Instruments | 21

Page 22

Figure 11. cRIO-905x 4-slot Controller Front Dimensions

1 2 3

4

221.40 mm

(8.72 in.)

89.61 mm

(3.528 in.)

1 2 3

4 5 6 7 8

328.64 mm

(12.938 in.)

89.61 mm

(3.528 in.)

Figure 12. cRIO-905x 8-slot Controller Front Dimensions

22 | ni.com | NI cRIO-905x User Manual

Page 23

Figure 13. cRIO-905x Side Dimensions

44.81 mm

(1.764 in.)

44.81 mm

(1.764 in.)

53.52 mm

(2.107 in.)

24.35 mm

(0.959 in.)

M4 x 0.7 Thread

5.00 mm (0.20 in.)

Max Insertion Depth

Front Mounting on a Flat Surface

What to Use

• cRIO-905x

• M4 screws, user-provided, length dependent on application

– x2 for 4-slot models

– x3 for 8-slot models

What to Do

Complete the following steps to front mount the cRIO-905x directly on a flat, rigid surface

using the mounting holes.

Note NI recommends surface mounting your system in environments with high

shock and vibration.

NI cRIO-905x User Manual | © National Instruments | 23

Page 24

Figure 14. Front Mounting the 4-slot cRIO-905x Directly on a Flat Surface

1 2 3

4

1 2 3

4 5 6 7 8

1 2 3

4

41.1 mm

(1.62 in.)

47.0 mm

(1.85 in.)

47.2 mm

(1.86 in.)

30.6 mm

(1.20 in.)

Figure 15. Front Mounting the 8-slot cRIO-905x Directly on a Flat Surface

1. Prepare the surface for mounting the cRIO-905x using the Surface Mounting Dimensions.

2. Align the cRIO-905x on the surface.

3. Fasten the cRIO-905x to the surface using the M4 screws appropriate for the surface.

Surface Mounting Front Dimensions

Figure 16. 4-slot cRIO-905x Front Dimensions

24 | ni.com | NI cRIO-905x User Manual

Page 25

Figure 17. 8-slot cRIO-905x Front Dimensions

1 2 3

4 5 6 7 8

47.2 mm

(1.86 in.)

141.7 mm

(5.58 in.)

30.8 mm

(1.21 in.)

47.0 mm

(1.85 in.)

Rear Mounting on a Flat Surface

What to Use

• cRIO-905x

• M4 screws, user provided, which must not exceed 8 mm of insertion into the cRIO-905x

– x4 for 4-slot models

– x6 for 8-slot models

What to Do

Complete the following steps to rear mount the cRIO-905x directly on a flat, rigid surface

using the mounting holes.

Note NI recommends surface mounting your system in environments with high

shock and vibration.

NI cRIO-905x User Manual | © National Instruments | 25

Page 26

Figure 18. Rear Mounting the 4-slot cRIO-905x Directly on a Flat Surface

1

2

3

1

2

3

Figure 19. Rear Mounting the 8-slot cRIO-905x Directly on a Flat Surface

26 | ni.com | NI cRIO-905x User Manual

Page 27

1. Prepare the surface for mounting the cRIO-905x using the Surface Mounting Dimensions.

6x M4 x 0.7

8.0 mm (0.315 in.)

Max Insertion Depth

38.79 mm

(1.527 in.)

24.48 mm

(0.964 in.)

24.49 mm

(0.964 in.)

20.33 mm

(0.800 in.)

20.32 mm

(0.800 in.)

50.82 mm

(2.001 in.)

75.89 mm

(2.988 in.)

116.54 mm

(4.588 in.)

221.4 mm

(8.72 in.)

29 mm

(1.142 in.)

328.6 mm

(12.94 in.)

120 mm

(4.72 in.)

24.5 mm

(0.96 in.)

20.3 mm

(0.80 in.)

20.3 mm

(0.80 in.)

9x M4 x 0.7

8.0 mm (0.32 in.)

Max Insertion Depth

38.8 mm

(1.52 in.)

50.8 mm

(2.00 in.)

73.8 mm

(2.91 in.)

120 mm

(4.72 in.)

2. Align the cRIO-905x on the surface.

3. Fasten the cRIO-905x to the surface using the M4 screws appropriate for the surface.

Note Screws must not exceed 8 mm of insertion into the cRIO-905x. Tighten

the screws to a torque of 1.3 N · m (11.5 lb · in.).

Surface Mounting Rear Dimensions

Figure 20. 4-slot cRIO-905x Rear Dimensions

Figure 21. 8-slot cRIO-905x Rear Dimensions

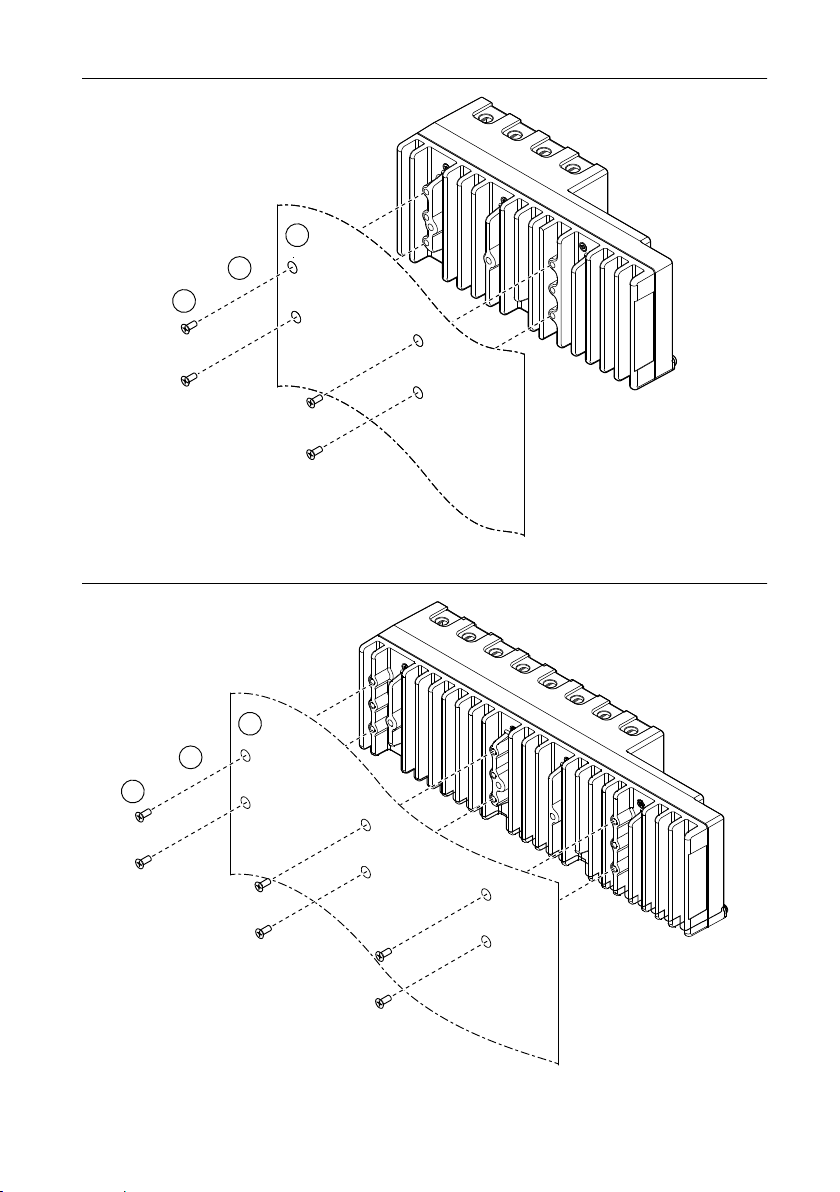

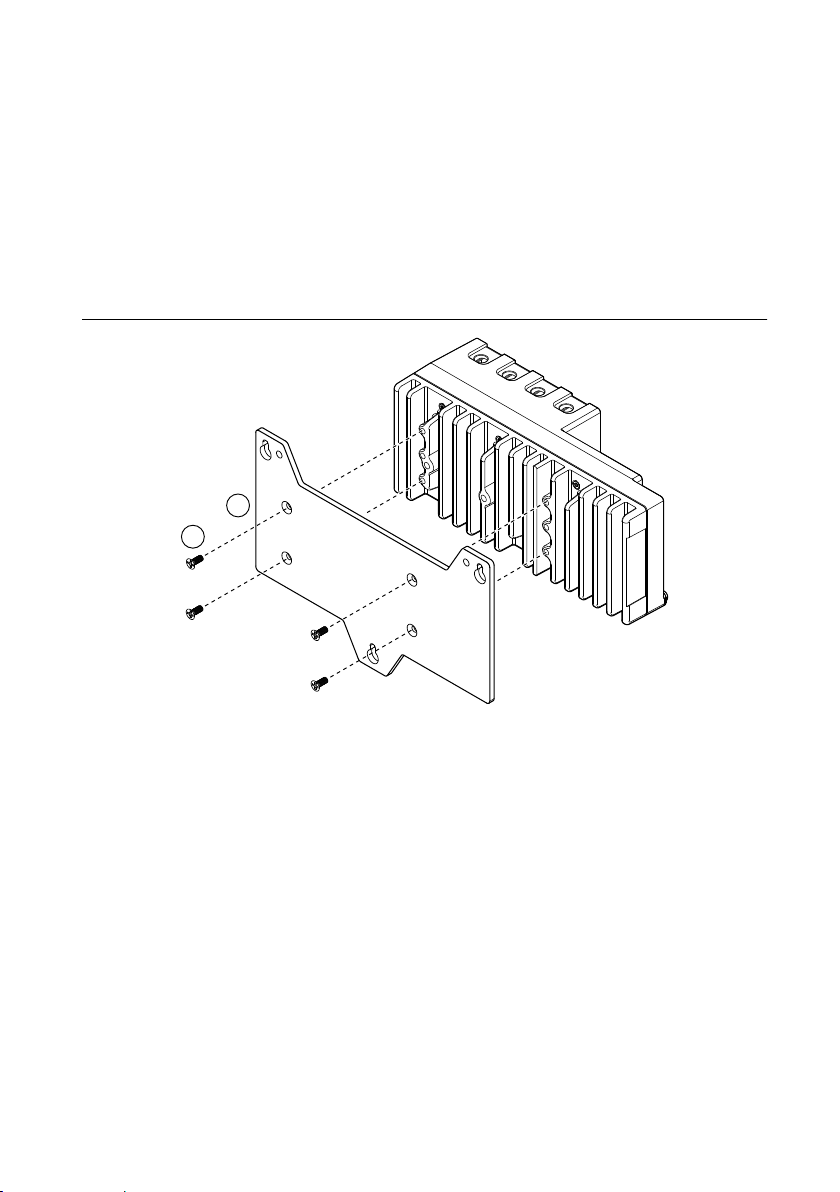

Mounting the Controller on a Panel

What to Use

• cRIO-905x

• Screwdriver, Phillips #2

NI cRIO-905x User Manual | © National Instruments | 27

Page 28

• NI panel mounting kit for 4-slot controllers, 157253-01

1

2

– Panel mounting plate

– M4 x 10 screws (x4)

• NI panel mounting kit for 8-slot controllers, 157267-01

– Panel mounting plate

– M4 x 10 screws (x6)

What to Do

Complete the following steps to mount the cRIO-905x on a panel.

Figure 22. Mounting the 4-slot cRIO-905x on a Panel

28 | ni.com | NI cRIO-905x User Manual

Page 29

Figure 23. Mounting the 8-slot cRIO-905x on a Panel

1

2

1. Align the cRIO-905x and the panel mounting plate.

2. Fasten the panel mounting plate to the cRIO-905x using the screwdriver and M4 x 10

screws.

Note You must use the screws provided with the NI panel mounting kit

because they are the correct depth and thread for the panel mounting plate.

Tighten the screws to a torque of 1.3 N · m (11.5 lb · in.).

3. Fasten the panel mounting plate to the surface using the screwdriver and screws that are

appropriate for the surface. The maximum screw size is M5 or number 10.

NI cRIO-905x User Manual | © National Instruments | 29

Page 30

Panel Mounting Dimensions

108.8 mm (4.26 in.)

217.7 mm (8.57 in.)

199.4 mm (7.85 in.)

138.9 mm

(5.47 in.)

114.3 mm

(4.50 in.)

7.2 mm

(0.29 in.)

25.4 mm

(1.00 in.)

1 2 3

4

89.9 mm (3.54 in.)

147.3 mm (5.80 in.)

327 mm (12.88 in.)

152.4 mm (6.00 in.) 152.4 mm (6.00 in.)

138.9 mm

(5.47 in.)

114.3 mm

(4.50 in.)

7.2 mm

(0.29 in.)

25.4 mm

(1.00 in.)

1 2 3

4 5 6 7 8

Figure 24. 4-slot cRIO-905x Panel Mounting Dimensions

Figure 25. 8-slot cRIO-905x Panel Mounting Dimensions

30 | ni.com | NI cRIO-905x User Manual

Page 31

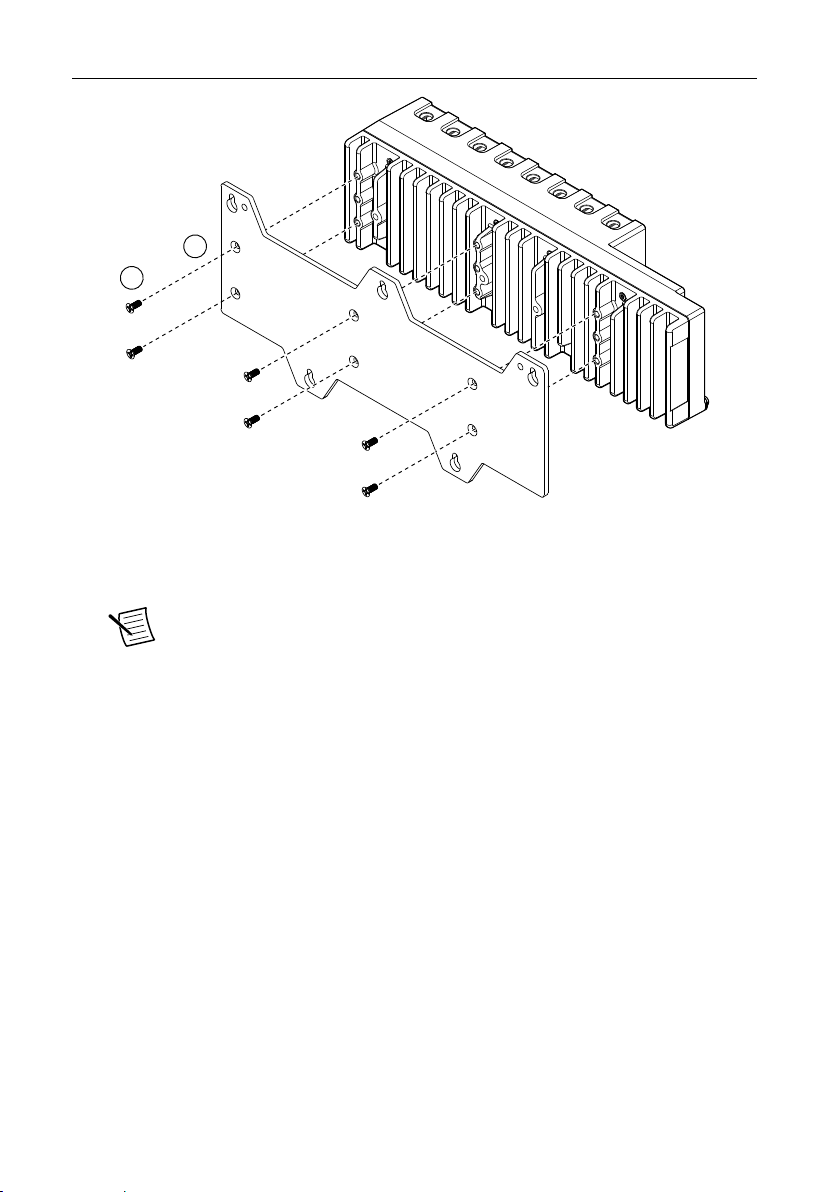

Mounting on a DIN Rail

1

2

What to Use

• cRIO-905x

• Screwdriver, Phillips #2

• NI DIN rail mounting kit

– 4-slot models - 157254-01

• DIN rail clip

• M4 x 10 screws (x2)

– 8-slot models - 157268-01

• DIN rail clip

• M4 x 10 screws (x3)

What to Do

Complete the following steps to mount the cRIO-905x on a standard 35-mm DIN rail.

Figure 26. Mounting the 4-slot cRIO-905x on a DIN Rail

NI cRIO-905x User Manual | © National Instruments | 31

Page 32

Figure 27. Mounting the 8-slot cRIO-905x on a DIN Rail

1

2

1

2

1. Align the DIN rail clip with the mounting holes on the rear of the cRIO-905x.

2. Fasten the DIN rail clip to the cRIO-905x using the screwdriver and M4 x 10 screws.

Note You must use the screws provided with the NI DIN rail kit because they

are the correct depth and thread for the DIN rail clip. Tighten the screws to a

torque of 1.3 N · m (11.5 lb · in.).

Clipping the Controller on a DIN Rail

Figure 28. Clipping the Controller on a DIN Rail

1. Latch the spring side (top) of the DIN clip onto the top edge of the DIN rail.

2. Press down firmly to compress the spring until the clip locks in place on the DIN rail.

Note Ensure that no C Series modules are in the controller before removing it from

the DIN rail.

32 | ni.com | NI cRIO-905x User Manual

Page 33

Mounting on a Rack

2 3

1

You can use the following rack mount kits to mount the controller and other DIN railmountable equipment on a standard 482.6 mm (19 in.) rack.

• Industrial Rack Mount Kit, 786411-01

• NI Rack-Mounting Kit, 781989-01

Note You must use the appropriate NI DIN rail mounting kit for your model in

addition to a rack-mounting kit.

Mounting the Device on a Desktop

What to Use

• cRIO-905x

• Screwdriver, Phillips #1

• Screwdriver, Phillips #2

• Screwdriver, Torx T10

• NI desktop mounting kit, 779473-01

Figure 29. Components of the NI Desktop Mount Kit

1. Desktop mounting brackets (x2)

2. Adapter bracket

3. M3 x 35 screws (x2)

What to Do

Complete the following steps to mount the cRIO-905x on a desktop.

NI cRIO-905x User Manual | © National Instruments | 33

Page 34

Figure 30. Mounting the 4-Slot cRIO-905x on a Desktop

1

4

4

3

3

2

34 | ni.com | NI cRIO-905x User Manual

Page 35

Figure 31. Mounting the 8-Slot cRIO-905x on a Desktop

1

3

4

4

3

2

1. Use the Torx T10 screwdriver to remove the two screws from the back of the chassis on

the controller side.

2. Use the #1 Phillips screwdriver and the two M3 x 35 screws to attach the adapter bracket

to the chassis.

3. Align the desktop mounting brackets with the mounting holes at the end of the chassis

and on the adapter bracket.

4. Use a #2 Phillips screwdriver to tighten the captive screw on the end bracket.

NI cRIO-905x User Manual | © National Instruments | 35

Page 36

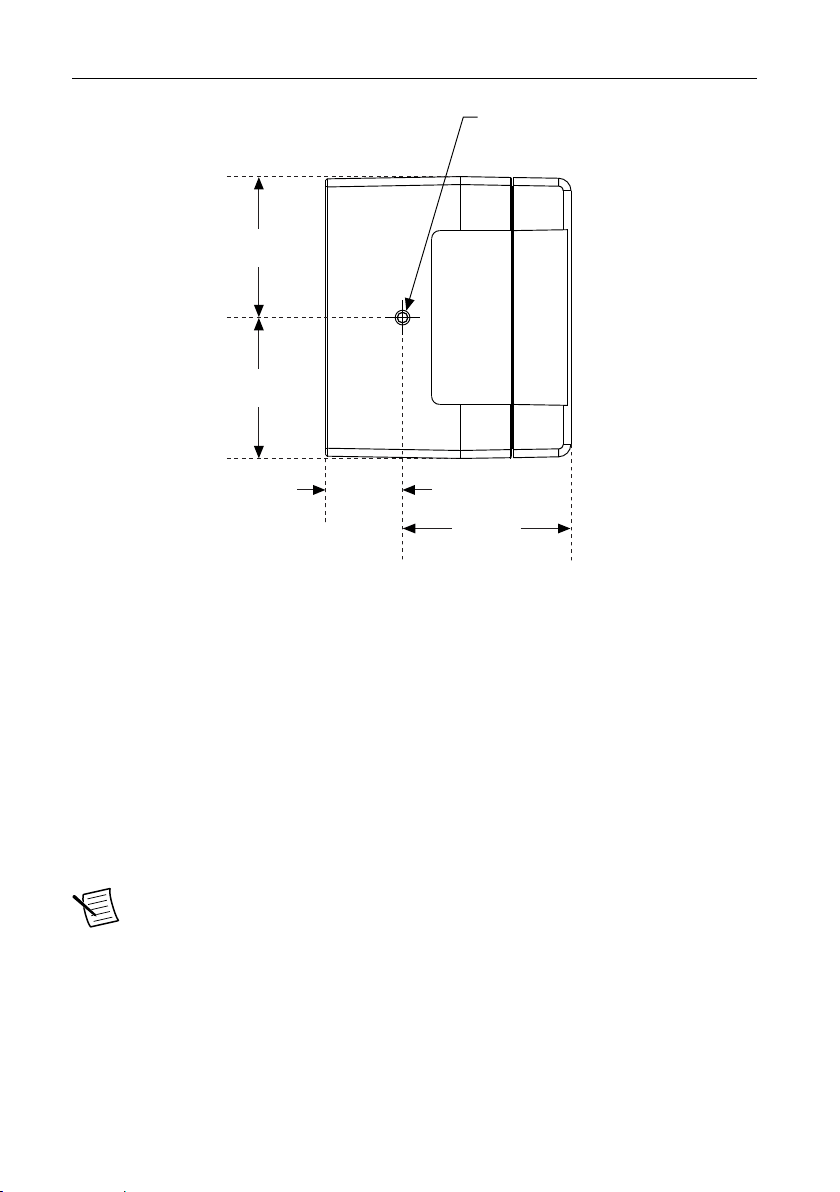

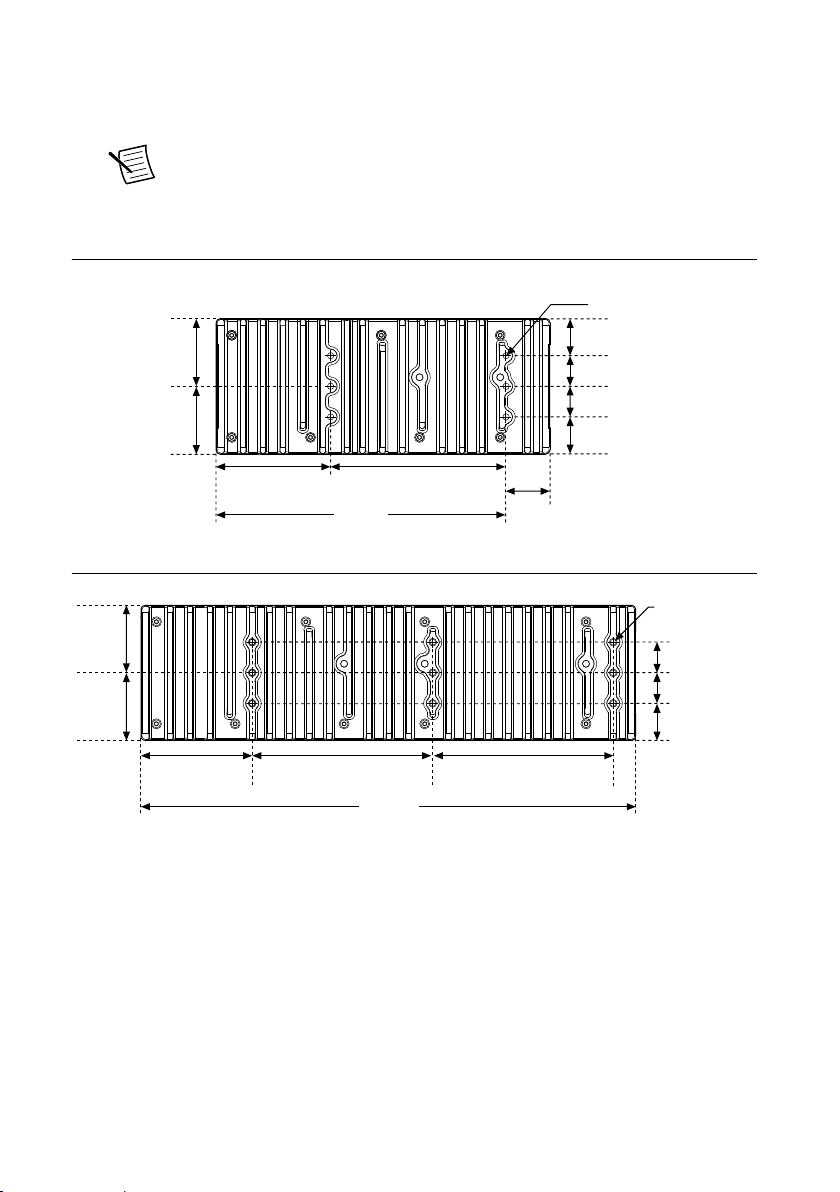

Desktop Mounting Dimensions

1 2 3

4

17.2 mm

(0.68 in.)

39.1 mm

(1.54 in.)

22.9 mm

(1.14 in.)

1 2 3

4 5 6 7 8

17.2 mm

(0.68 in.)

39.1 mm

(1.54 in.)

22.9 mm

(1.14 in.)

127.0 mm

(5.00 in.)

130.0 mm

(5.12 in.)

Figure 32. 4 Slot cRIO-905x Desktop Mounting Front Dimensions

Figure 33. 8 Slot cRIO-905x Desktop Mounting Front Dimensions

Figure 34. cRIO-905x Desktop Mounting Side Dimensions

36 | ni.com | NI cRIO-905x User Manual

Page 37

Choosing Your Programming Mode

The cRIO-905x supports three programming modes on a per slot basis.

RealTime

RealTime

Scan

Enables you to use C Series modules directly from LabVIEW Real-Time,

using NI DAQmx.

C Series modules appear under the Real-Time Resources item in the MAX

Project Explorer window and I/O channels appear as I/O variables under

the modules. To use I/O variables, you drag and drop them from the

Project Explorer window to LabVIEW Real-Time VIs.

Use this mode to make the C Series module behave like it is in a

CompactDAQ controller, using the Real-Time NI-DAQmx and NI-XNET

drivers to communicate, and access the four counter/timers and the PFI

trigger connector on the controller.

Enables you to use C Series modules directly from LabVIEW Real-Time,

using I/O variables.

C Series modules that you use in Scan Interface mode appear under the

Real-Time Scan Resources item in the MAX Project Explorer window

and I/O channels appear as I/O variables under the modules. To use I/O

variables, you drag and drop them from the Project Explorer window to

LabVIEW Real-Time VIs.

In this mode, you do not need to do any LabVIEW FPGA development.

LabVIEW programs the FPGA for you with a fixed FPGA bitfile that

communicates with all the C Series modules that RT Scan mode supports.

LabVIEW also sends C Series data to the Real-Time host to be displayed

in I/O variables. Real-Time Scan mode also enables you to dynamically

detect which types of C Series modules are plugged into chassis slots.

FPGA Enables you to use C Series modules from LabVIEW FPGA VIs.

C Series modules appear directly under the FPGA Target item in the

MAX Project Explorer window and I/O channels appear as FPGA I/O

items under the FPGA Target. To access the I/O channels, you either

configure FPGA I/O Nodes in a LabVIEW FPGA VI or drag and drop the

I/O channels from the Project Explorer window to a LabVIEW FPGA VI

block diagram.

Use this mode to add more flexibility, customization, timing, and

synchronization to your applications. To use the CompactRIO system in

FPGA mode, you must either have the LabVIEW FPGA Module installed

on the host computer, or have access to a compiled bitfile that you can

download to the FPGA. In either case, you use the Open FPGA VI

Reference function in a LabVIEW Real-Time VI to access the FPGA VI

or bitfile.

NI cRIO-905x User Manual | © National Instruments | 37

Page 38

Table 15. Supported Programming Modes for Popular Tasks

Task Real-Time Real-Time Scan FPGA

Control rates up to 1 kHz ■ ■

Control rates between 1 kHz and 2.5 kHz

(application dependent)

Control rates over 2.5 kHz ■

High-speed waveform acquisition ■ ■

Note Some C Series modules can only be used in certain programming modes. For

module-specific software support information, visit ni.com/info and enter the Info

Code swsupport.

To learn more about using the cRIO-905x in Real-Time mode, refer to the following sections:

• Analog Input with NI-DAQmx

• Analog Output with NI-DAQmx

• Digital Input/Output with NI-DAQmx

• PFI with NI-DAQmx

• Counters with NI-DAQmx

■ ■ ■

Analog Input with NI-DAQmx

To perform analog input measurements, install a supported analog input C Series module into

any slot on the cRIO controller and set the programming mode to Real-Time (NI-DAQmx)

mode. The measurement specifications, such as number of channels, channel configuration,

sample rate, and gain, are determined by the type of C Series module used. For more

information and wiring diagrams, refer to the documentation included with your C Series

modules.

The cRIO controller has eight input timing engines, which means that up to eight hardwaretimed analog input tasks can be running at a time on the controller. An analog input task can

include channels from multiple analog input modules. However, channels from a single

module cannot be used in multiple tasks.

Multiple timing engines allow the cRIO controller to run up to eight analog input tasks

simultaneously, each using independent timing and triggering configurations. The eight timing

engines are it0, it1,…it7.

Hardware-Timed Single Point (HWTSP) Mode

In HWTSP mode, samples are acquired or generated continuously using hardware timing and

no buffer. You must use the sample clock or change detection timing types. No other timing

types are supported.

Use HWTSP mode if you need to know if a loop executes in a given amount of time, such as

in a control application. Because there is no buffer, if you use HWTSP mode, ensure that reads

38 | ni.com | NI cRIO-905x User Manual

Page 39

or writes execute fast enough to keep up with hardware timing. If a read or write executes late,

it returns a warning.

Note DSA modules do not support HWTSP mode.

Analog Input Triggering Signal

A trigger is a signal that causes an action, such as starting or stopping the acquisition of data.

When you configure a trigger, you must decide how you want to produce the trigger and the

action you want the trigger to cause. The cRIO controller supports internal software triggering,

external digital triggering, analog triggering, and internal time triggering.

Three triggers are available: Start Trigger, Reference Trigger, and Pause Trigger. An analog or

digital signal can initiate these three trigger actions. C Series Parallel digital input modules and

the controller’s integrated PFI trigger line can be used in any controller slot to supply a digital

trigger. To find your module triggering options, refer to the documentation included with your

C Series modules. For more information about using digital modules for triggering, refer to the

Digital Input/Output with NI-DAQmx section.

Refer to the AI Start Trigger Signal, AI Reference Trigger Signal, and AI Pause Trigger Signal

sections for more information about the analog input trigger signals.

Analog Input Timing Signals

The cRIO controller features the following analog input timing signals:

• AI Sample Clock Signal*

• AI Sample Clock Timebase Signal

• AI Start Trigger Signal*

• AI Reference Trigger Signal*

• AI Pause Trigger Signal*

Signals with an * support digital filtering. Refer to the PFI Filters section for more

information.

Refer to the AI Convert Clock Signal Behavior For Analog Input Modules section for more

information about AI Convert Clock signals and the cRIO controller.

AI Sample Clock Signal

A sample consists of one reading from each channel in the AI task. Sample Clock signals the

start of a sample of all analog input channels in the task. The sample clock can be generated

from external or internal sources as shown in the figure below.

NI cRIO-905x User Manual | © National Instruments | 39

Page 40

Figure 35. AI Sample Clock Timing Options

Programmable

Clock

Divider

Sample Clock

Timebase

PFI

Analog Comparison Event

Ctr n Internal Output

AI Sample

Clock

Sigma-Delta Module Internal Output

Analog Comparison

Event

80 MHz Timebase

20 MHz Timebase

PFI

13.1072 MHz Timebase

12.8 MHz Timebase

10 MHz Timebase

100 kHz Timebase

Routing the Sample Clock to an Output Terminal

You can route Sample Clock to any output PFI terminal. Sample Clock is an active high pulse

by default.

AI Sample Clock Timebase Signal

The AI Sample Clock Timebase signal is divided down to provide a source for Sample Clock.

AI Sample Clock Timebase can be generated from external or internal sources. AI Sample

Clock Timebase is not available as an output from the controller.

AI Start Trigger Signal

Use the Start Trigger signal to begin a measurement acquisition which consists of one or more

samples. Once the acquisition begins, configure the acquisition to stop in one of the following

ways:

• When a certain number of points has been sampled (in finite mode)

• After a hardware reference trigger (in finite mode)

• With a software command (in continuous mode)

An acquisition that uses a start trigger (but not a reference trigger) is sometimes referred to as

a posttriggered acquisition. That is, samples are measured only after the trigger.

When you are using an internal sample clock, you can specify a default delay from the start

trigger to the first sample.

Using a Digital Source

To use the Start Trigger signal with a digital source, specify a source and a rising or falling

edge. Use the following signals as the source:

• Any PFI terminal

• Counter n Internal Output

40 | ni.com | NI cRIO-905x User Manual

Page 41

The source also can be one of several other internal signals on your cRIO controller. Refer to

the "Device Routing in MAX" topic in the NI-DAQmx Help or the LabVIEW Help for more

information.

Using an Analog Source

Some C Series modules can generate a trigger based on an analog signal. In NI-DAQmx, this

is called the Analog Comparison Event. When you use an analog trigger source for Start

Trigger, the acquisition begins on the first rising edge of the Analog Comparison Event signal.

Routing AI Start Trigger to an Output Terminal

You can route the Start Trigger signal to any output PFI terminal. The output is an active high

pulse.

Using a Time Source

To use the Start Trigger signal with a time source, configure a specific time in NI-DAQmx.

Refer to the "Timestamps" and "Time Triggering" topics in the NI-DAQmx Help for more

information on accessing time-based features in the NI-DAQmx API.

AI Reference Trigger Signal

Use a reference trigger to stop a measurement acquisition. To use a reference trigger, specify a

buffer of finite size and a number of pretrigger samples (samples that occur before the

reference trigger). The number of posttrigger samples (samples that occur after the reference

trigger) desired is the buffer size minus the number of pretrigger samples.

Once the acquisition begins, the cRIO controller writes samples to the buffer. After the cRIO

controller captures the specified number of pretrigger samples, the cRIO controller begins to

look for the reference trigger condition. If the reference trigger condition occurs before the

cRIO controller captures the specified number of pretrigger samples, the controller ignores the

condition.

If the buffer becomes full, the cRIO controller continuously discards the oldest samples in the

buffer to make space for the next sample. This data can be accessed (with some limitations)

before the cRIO controller discards it. Refer to the Can a Pretriggered Acquisition be

Continuous? document for more information. To access this document, go to ni.com/info and

enter the Info Code rdcanq.

When the reference trigger occurs, the cRIO controller continues to write samples to the buffer

until the buffer contains the number of posttrigger samples desired. The figure below shows

the final buffer.

NI cRIO-905x User Manual | © National Instruments | 41

Page 42

Figure 36. Reference Trigger Final Buffer

Reference Trigger

Pretrigger Samples

Complete Buffer

Posttrigger Samples

Using a Digital Source

To use a reference trigger with a digital source, specify a source and a rising or falling edge.

Either PFI or one of several internal signals on the cRIO controller can provide the source.

Refer to the "Device Routing in MAX" topic in the NI-DAQmx Help or the LabVIEW Help for

more information.

Using an Analog Source

Some C Series modules can generate a trigger based on an analog signal. In NI-DAQmx, this

is called the Analog Comparison Event.

When you use an analog trigger source, the acquisition stops on the first rising or falling edge

of the Analog Comparison Event signal, depending on the trigger properties.

Routing the Reference Trigger Signal to an Output Terminal

You can route a reference trigger to any output PFI terminal. Reference Trigger is active high

by default.

AI Pause Trigger Signal

You can use the Pause Trigger to pause and resume a measurement acquisition. The internal

sample clock pauses while the external trigger signal is active and resumes when the signal is

inactive. You can program the active level of the pause trigger to be high or low.

Using a Digital Source

To use the Pause Trigger, specify a source and a polarity. The source can be either from PFI or

one of several other internal signals on your cRIO controller. Refer to the "Device Routing in

MAX" topic in the NI-DAQmx Help or the LabVIEW Help for more information.

Using an Analog Source

Some C Series modules can generate a trigger based on an analog signal. In NI-DAQmx, this

is called the Analog Comparison Event.

42 | ni.com | NI cRIO-905x User Manual

Page 43

When you use an analog trigger source, the internal sample clock pauses when the Analog

Comparison Event signal is low and resumes when the signal goes high (or vice versa).

Note Pause triggers are only sensitive to the level of the source, not the edge.

AI Convert Clock Signal Behavior For Analog Input Modules

Refer to the Scanned Modules, Simultaneous Sample-and-Hold Modules, Delta-Sigma

Modules, and Slow Sample Rate Modules sections for information about the AI Convert Clock

signal and C Series analog input modules.

Scanned Modules

Scanned C Series analog input modules contain a single A/D converter and a multiplexer to

select between multiple input channels. When the module interface receives a Sample Clock

pulse, it begins generating a Convert Clock for each scanned module in the current task. Each

Convert Clock signals the acquisition of a single channel from that module. The Convert

Clock rate depends on the module being used, the number of channels used on that module,

and the system Sample Clock rate.

The driver chooses the fastest conversion rate possible based on the speed of the A/D

converter for each module and adds 10 µs of padding between each channel to allow for

adequate settling time. This scheme enables the channels to approximate simultaneous

sampling. If the AI Sample Clock rate is too fast to allow for 10 µs of padding, NI-DAQmx

selects a conversion rate that spaces the AI Convert Clock pulses evenly throughout the

sample. NI-DAQmx uses the same amount of padding for all the modules in the task. To

explicitly specify the conversion rate, use the ActiveDevs and AI Convert Clock Rate

properties using the DAQmx Timing property node or functions.

Simultaneous Sample-and-Hold Modules

Simultaneous sample-and-hold (SSH) C Series analog input modules contain multiple A/D

converters or circuitry that allows all the input channels to be sampled at the same time. These

modules sample their inputs on every Sample Clock pulse.

Delta-Sigma Modules

Delta-sigma C Series analog input modules function much like SSH modules, but use A/D

converters that require a high-frequency oversample clock to produce accurate, synchronized

data. Some delta-sigma modules in the cRIO controller automatically share a single

oversample clock to synchronize data from all the modules that support an external

oversample clock timebase when they all share the same task. (DSA modules are an example).

The oversample clock is used as the AI Sample Clock Timebase. The cRIO controller supplies

10 MHz, 12.8 MHz, and 13.1072 MHz timebases from which software automatically selects

based on the modules in the task. When delta-sigma modules with different oversample clock

frequencies are used in an analog input task, the AI Sample Clock Timebase can use any of the

NI cRIO-905x User Manual | © National Instruments | 43

Page 44

available frequencies; by default, the fastest available is used. The sample rate of all modules

in the task is an integer divisor of the frequency of the AI Sample Clock Timebase.

When one or more delta-sigma modules are in an analog input task, the delta-sigma modules

also provide the signal used as the AI Sample Clock. This signal is used to cause A/D

conversion for other modules in the system, just as the AI Sample Clock does when a deltasigma module is not being used.

When delta-sigma modules are in an AI task, the controller automatically issues a

synchronization pulse to each delta-sigma module so that their ADCs are reset at the same

time. Because of the filtering used in delta-sigma A/D converters, these modules usually

exhibit a fixed input delay relative to non-delta-sigma modules in the system. This input delay

is specified in the C Series module documentation.

When channels from delta-sigma C Series modules are included in a multi-chassis task, please

ensure that the first channel in your channel list is from a delta-sigma module.

Note DSA modules do not support HWTSP mode.

Slow Sample Rate Modules

Some C Series analog input modules are specifically designed for measuring signals that vary

slowly, such as temperature. Because of their slow rate, it is not appropriate for these modules

to constrain the AI Sample Clock to operate at or slower than their maximum rate. When using

such a module in the cRIO controller mixed with a non-slow sample module in the same task,

exceeding the maximum sampling rate of the slow sample module results in the most recently

acquired sample being read multiple times. In this scenario, the first sample of a hardwaretimed acquisition with a slow sampled C Series module is sampled when the task is

committed.

For more information about which C Series modules are compatible with the cRIO controller,

go to ni.com/info and enter the Info Code rdcdaq.

Getting Started with AI Applications in Software

You can use the cRIO controller in the following analog input applications:

• Single-point acquisition

• Hardware-Timed Single Point acquisition

• Finite acquisition

• Continuous acquisition

For more information about programming analog input applications and triggers in software,

refer to the NI-DAQmx Help or the LabVIEW Help for more information.

Analog Output with NI-DAQmx

To generate analog output, install an analog output C Series module in any slot on the cRIO

controller. The generation specifications, such as the number of channels, channel

44 | ni.com | NI cRIO-905x User Manual

Page 45

configuration, update rate, and output range, are determined by the type of C Series module

used. For more information, refer to the documentation included with your C Series module(s).

The cRIO controller has eight output timing engines, which means that up to eight hardwaretimed analog output tasks can be running at a time on the controller. On a single analog output

C Series module, you can assign any number of channels to either a hardware-timed task or a

software-timed (single-point) task. However, you cannot assign some channels to a hardwaretimed task and other channels (on the same module) to a software-timed task.

Multiple timing engines allow the cRIO controller to run up to eight analog output tasks

simultaneously, each using independent timing and triggering configurations. The eight timing

engines are ot0, ot1,… ot7.

Analog Output Data Generation Methods

When performing an analog output operation, you either can perform software-timed

generations or hardware-timed generations.

Software-Timed Generations

With a software-timed generation, software controls the rate at which data is generated.

Software sends a separate command to the hardware to initiate each DAC conversion. In NIDAQmx, software-timed generations are referred to as on-demand timing. Software-timed

generations are also referred to as immediate or static operations. They are typically used for

writing out a single value, such as a constant DC voltage.

The following considerations apply to software-timed generations:

• If any AO channel on a module is used in a hardware-timed (waveform) task, no channels

on that module can be used in a software-timed task

• You can configure software-timed generations to simultaneously update

• Only one simultaneous update task can run at a time

• A hardware-timed AO task and a simultaneous update AO task cannot run at the same

time

Hardware-Timed Generations

With a hardware-timed generation, a digital hardware signal controls the rate of the generation.

This signal can be generated internally on the controller or provided externally.

Hardware-timed generations have several advantages over software-timed acquisitions:

• The time between samples can be much shorter

• The timing between samples is deterministic

• Hardware-timed acquisitions can use hardware triggering

Hardware-Timed Single Point (HWTSP) Mode

In HWTSP mode, samples are acquired or generated continuously using hardware timing and

no buffer. You must use the sample clock or change detection timing types. No other timing

types are supported.

NI cRIO-905x User Manual | © National Instruments | 45

Page 46

Use HWTSP mode if you need to know if a loop executes in a given amount of time, such as

in a control application. Because there is no buffer, if you use HWTSP mode, ensure that reads

or writes execute fast enough to keep up with hardware timing. If a read or write executes late,

it returns a warning.

Note DSA modules do not support HWTSP mode.

Buffered Analog Input

A buffer is a temporary storage in computer memory for generated samples. In a buffered

generation, data is moved from a host buffer to the cRIO controller onboard FIFO before it is

written to the C Series modules.

One property of buffered I/O operations is sample mode. The sample mode can be either finite

or continuous:

• Finite—Finite sample mode generation refers to the generation of a specific,

predetermined number of data samples. After the specified number of samples is written

out, the generation stops.

• Continuous—Continuous generation refers to the generation of an unspecified number of

samples. Instead of generating a set number of data samples and stopping, a continuous

generation continues until you stop the operation. There are three different continuous

generation modes that control how the data is written. These modes are regeneration,

onboard regeneration, and non-regeneration:

– In regeneration mode, you define a buffer in host memory. The data from the buffer

is continually downloaded to the FIFO to be written out. New data can be written to

the host buffer at any time without disrupting the output. There is no limitation on

the number of waveform channels supported by regeneration mode.

– With onboard regeneration, the entire buffer is downloaded to the FIFO and

regenerated from there. After the data is downloaded, new data cannot be written to

the FIFO. To use onboard regeneration, the entire buffer must fit within the FIFO

size. The advantage of using onboard regeneration is that it does not require

communication with the main host memory once the operation is started, which

prevents problems that may occur due to excessive bus traffic or operating system

latency. There is a limit of 16 waveform channels for onboard regeneration.

– With non-regeneration, old data is not repeated. New data must continually be

written to the buffer. If the program does not write new data to the buffer at a fast

enough rate to keep up with the generation, the buffer underflows and causes an

error. There is no limitation on the number of waveform channels supported by nonregeneration.

Analog Output Triggering Signals

A trigger is a signal that causes an action, such as starting or stopping the acquisition of data.

When you configure a trigger, you must decide how you want to produce the trigger and the

46 | ni.com | NI cRIO-905x User Manual

Page 47

action you want the trigger to cause. The cRIO controller supports internal software triggering,

Programmable

Clock

Divider

AO Sample Clock

Timebase

PFI

Analog Comparison Event

Ctr n Internal Output

Sample

Clock

Analog Comparison

Event

80 MHz Timebase

20 MHz Timebase

PFI

13.1072 MHz Timebase

12.8 MHz Timebase

10 MHz Timebase

100 kHz Timebase

external digital triggering, analog triggering, and internal time triggering.

Analog output supports two different triggering actions: AO Start Trigger and AO Pause

Trigger. An analog or digital signal can initiate these actions. C Series parallel digital input

modules and the controller’s integrated PFI trigger line can be used in any controller slot to

supply a digital trigger. An analog trigger can be supplied by some C Series analog modules.

Refer to the AO Start Trigger Signal and AO Pause Trigger Signal sections for more

information about the analog output trigger signals.

Analog Output Timing Signals

The cRIO controller features the following AO (waveform generation) timing signals:

• AO Sample Clock Signal*

• AO Sample Clock Timebase Signal

• AO Start Trigger Signal*

• AO Pause Trigger Signal*

Signals with an * support digital filtering. Refer to the PFI Filters section for more

information.

AO Sample Clock Signal

The AO sample clock signals when all the analog output channels in the task update. AO

Sample Clock can be generated from external or internal sources as shown in the figure below.

Figure 37. Analog Output Timing Options

Routing AO Sample Clock to an Output Terminal

You can route AO Sample Clock to any output PFI terminal. AO Sample Clock is active high

by default.

NI cRIO-905x User Manual | © National Instruments | 47

Page 48

AO Sample Clock Timebase Signal

The AO Sample Clock Timebase signal is divided down to provide a source for AO Sample

Clock. AO Sample Clock Timebase can be generated from external or internal sources, and is

not available as an output from the controller.

Delta-Sigma Modules

The oversample clock is used as the AO Sample Clock Timebase. The cRIO controller

supplies 10 MHz, 12.8 MHz, and 13.1072 MHz timebases. When delta-sigma modules with

different oversample clock frequencies are used in an analog output task, the AO Sample

Clock Timebase can use any of the available frequencies; by default, the fastest available is

used. The update rate of all modules in the task is an integer divisor of the frequency of the

AO Sample Clock Timebase.

Note DSA modules do not support HWTSP mode.

AO Start Trigger Signal

Use the AO Start Trigger signal to initiate a waveform generation. If you do not use triggers,

you can begin a generation with a software command. If you are using an internal sample

clock, you can specify a delay from the start trigger to the first sample. For more information,

refer to the NI-DAQmx Help.

Using a Digital Source

To use AO Start Trigger, specify a source and a rising or falling edge. The source can be one

of the following signals:

• A pulse initiated by host software

• Any PFI terminal

• AI Reference Trigger

• AI Start Trigger

The source also can be one of several internal signals on the cRIO controller. Refer to the

"Device Routing in MAX" topic in the NI-DAQmx Help or the LabVIEW Help for more

information.

You also can specify whether the waveform generation begins on the rising edge or falling

edge of AO Start Trigger.

Routing AO Start Trigger Signal to an Output Terminal

You can route AO Start Trigger to any output PFI terminal. The output is an active high pulse.

Using a Time Source

To use the Start Trigger signal with a time source, configure a specific time in NI-DAQmx.

Refer to the "Timestamps" and "Time Triggering" topics in the NI-DAQmx Help for more

information on accessing time-based features in the NI-DAQmx API.

48 | ni.com | NI cRIO-905x User Manual

Page 49

AO Pause Trigger Signal

Pause Trigger

Sample Clock

Pause Trigger

Sample Clock

Use the AO Pause Trigger signal to mask off samples in a DAQ sequence. When AO Pause

Trigger is active, no samples occur, but AO Pause Trigger does not stop a sample that is in

progress. The pause does not take effect until the beginning of the next sample.

When you generate analog output signals, the generation pauses as soon as the pause trigger is

asserted. If the source of the sample clock is the onboard clock, the generation resumes as soon

as the pause trigger is deasserted, as shown in the following figure.

Figure 38. AO Pause Trigger with the Onboard Clock Source

If you are using any signal other than the onboard clock as the source of the sample clock, the

generation resumes as soon as the pause trigger is deasserted and another edge of the sample

clock is received, as shown in the following figure.

Figure 39. AO Pause Trigger with Other Signal Source

Using a Digital Source

To use AO Pause Trigger, specify a source and a polarity. The source can be a PFI signal or

one of several other internal signals on the cRIO controller.

You also can specify whether the samples are paused when AO Pause Trigger is at a logic high

or low level. Refer to the "Device Routing in MAX" topic in the NI-DAQmx Help or the

LabVIEW Help for more information.

Minimizing Glitches on the Output Signal