Page 1

USER GUIDE AND SPECIFICATIONS

NI cDAQ-9172

DeutschFrançais

ni.com/manuals

Contents

Introduction.............................................................................................4

Safety Guidelines .................................................................................... 5

Safety Guidelines for Hazardous Voltages...................................... 5

Related Documentation........................................................................... 6

Device Documentation and Specifications ...................................... 9

Training Courses.............................................................................. 9

Technical Support on the Web......................................................... 9

Installing the Software ............................................................................ 10

Installing NI-DAQmx ...................................................................... 10

Installing Other Software................................................................. 10

Installing the NI cDAQ-9172.................................................................. 11

Mounting the NI cDAQ-9172.......................................................... 12

NI 9901 Desktop Mounting Kit................................................ 12

NI 9910 DIN-Rail Kit............................................................... 13

NI 9905 Panel Mount Kit ......................................................... 13

Setting Up the NI cDAQ-9172................................................................15

Understanding LED Indications.............................................................. 17

Active LED ...................................................................................... 17

Ready LED ...................................................................................... 17

Using the NI cDAQ-9172 ....................................................................... 18

C Series I/O Modules....................................................................... 18

Correlated vs. Static DIO Modules...........................................19

cDAQ Module Interface .................................................................. 19

USB-STC2 ....................................................................................... 19

AI and AO Sample Timing....................................................... 19

Triggering Modes .....................................................................19

Independent Data Streams ........................................................19

PFI Signals................................................................................ 20

Flexible Counter/Timers........................................................... 20

Page 2

Analog Input ............................................................................................20

Analog Input Triggering...................................................................20

AI Start Trigger Signal..............................................................21

AI Reference Trigger Signal .....................................................22

AI Pause Trigger Signal ............................................................24

Analog Input Timing Signals ...........................................................24

AI Sample Clock .......................................................................24

AI Sample Clock Timebase.......................................................25

Convert Behavior For Analog Input Modules...........................25

Getting Started with AI Applications in Software ...........................28

Analog Output .........................................................................................28

Analog Output Data Generation Methods ........................................28

Software-Timed Generations ....................................................29

Hardware-Timed Generations ...................................................29

Analog Output Triggering ................................................................30

Analog Output Timing Signals.........................................................31

AO Sample Clock......................................................................31

AO Start Trigger Signal ............................................................31

AO Pause Trigger Signal...........................................................33

Minimizing Glitches on the Output Signal.......................................34

Getting Started with AO Applications in Software..........................34

Digital I/O................................................................................................35

Correlated vs. Static DIO Modules ..................................................35

Static DIO.........................................................................................36

Digital Waveform Acquisition (Correlated Input) ...........................36

DI Sample Clock Signal............................................................36

Digital Waveform Generation (Correlated Output) .........................37

Buffered Digital Waveform Generation....................................38

Change Detection Event ...................................................................39

Routing Change Detection Event to an Output Terminal .........39

Change Detection Acquisition..........................................................39

Digital Input/Output Configuration for NI 9401 ..............................39

PFI ...........................................................................................................40

Counters...................................................................................................40

Counter Input Applications ..............................................................42

Counting Edges .........................................................................42

Pulse-Width Measurement ........................................................44

Period Measurement..................................................................46

Semi-Period Measurement ........................................................48

Frequency Measurement ...........................................................49

Position Measurement ...............................................................54

Two-Signal Edge-Separation Measurement..............................57

Counter Output Applications............................................................59

Simple Pulse Generation ...........................................................59

Pulse Train Generation..............................................................61

Frequency Generation ...............................................................62

Frequency Division ...................................................................63

NI cDAQ-9172 User Guide and Specifications 2 ni.com

Page 3

Counter Timing Signals................................................................... 63

Counter n Source Signal ........................................................... 64

Counter n Gate Signal............................................................... 65

Counter n Aux Signal ............................................................... 65

Counter n A, Counter n B, and Counter n Z Signals ................ 66

Counter n Up_Down Signal ..................................................... 66

Counter n HW Arm Signal .......................................................66

Counter n Internal Output and Counter n TC Signals ..............67

Frequency Output Signal .......................................................... 67

Default Counter/Timer Routing.......................................................68

Counter Triggering .......................................................................... 68

Other Counter Features.................................................................... 69

Cascading Counters .................................................................. 69

Counter Filters .......................................................................... 69

Prescaling.................................................................................. 70

Duplicate Count Prevention...................................................... 71

Synchronization Modes ............................................................73

Digital Routing and Clock Generation.................................................... 75

Clock Routing .................................................................................. 76

80 MHz Timebase .................................................................... 76

20 MHz Timebase .................................................................... 76

100 kHz Timebase .................................................................... 76

Specifications .......................................................................................... 77

Analog Input .................................................................................... 77

Analog Output.................................................................................. 77

Digital Waveform Characteristics (Slots 1 through 4 Only) ........... 78

PFI Characteristics (Slots 5 and 6 Only) ......................................... 78

General-Purpose Counter/Timers (Slots 5 and 6 Only)................... 79

Frequency Generator (Slots 5 and 6 Only) ...................................... 80

External Digital Triggers (Slots 5 and 6 or with Some

AI Modules) .................................................................................. 80

Module I/O States ............................................................................ 80

Power Requirements ........................................................................ 80

Bus Interface ....................................................................................81

Physical Characteristics ................................................................... 81

Safety ...............................................................................................81

Environmental..................................................................................82

Shock and Vibration ........................................................................82

Electromagnetic Compatibility ........................................................ 83

CE Compliance ................................................................................ 83

Environmental Management............................................................ 83

Where to Go for Support......................................................................... 84

© National Instruments Corporation 3 NI cDAQ-9172 User Guide and Specifications

Page 4

Introduction

This user guide describes how to use the National Instruments cDAQ-9172

chassis and lists specifications. For an interactive demonstration of how to

install the NI cDAQ-9172, go to

ni.com/info and enter daqinstall.

The NI cDAQ-9172 is an eight-slot USB chassis designed for use

with C Series I/O modules. The NI cDAQ-9172 chassis is capable of

measuring a broad range of analog and digital I/O signals and sensors using

a Hi-Speed USB 2.0 interface. For module specifications, refer to the

documentation included with your C Series I/O module(s) or go to

ni.com/manuals.

1

2

NI cDAQ-9172

Ready

Active

3

11-30 VDC

15 W

1 Power Switch

2 Ready/Active LEDs

3 Power Connector

4 USB Connector

ON

OFF

12345

4 5 6

5 Empty Module Slots

6 Installed C Series I/O Modules

7 Screw for Ground Connection

Figure 1. NI cDAQ-9172 Chassis

7

NI cDAQ-9172 User Guide and Specifications 4 ni.com

Page 5

Safety Guidelines

Operate the NI cDAQ-9172 chassis only as described in this user guide.

Note Because some C Series I/O modules may have more stringent certification standards

than the NI cDAQ-9172 chassis, the combined system may be limited by individual

component restrictions. Refer to the Using the NI cDAQ-9172 section of this document for

more details.

Caution The NI cDAQ-9172 chassis is not certified for use in hazardous locations.

Hot Surface This icon denotes that the component may be hot. Touching this component

may result in bodily injury.

Safety Guidelines for Hazardous Voltages

If hazardous voltages are connected to the module, take the following

precautions. A hazardous voltage is a voltage greater than 42.4 V

60 VDC to earth ground.

Caution Ensure that hazardous voltage wiring is performed only by qualified personnel

adhering to local electrical standards.

Caution Do not mix hazardous voltage circuits and human-accessible circuits on the same

module.

or

pk

Caution Make sure that chassis and circuits connected to the module are properly

insulated from human contact.

Caution The NI cDAQ-9172 chassis provides no isolation, but some modules offer

isolation. Follow the safety guidelines for each module when using hazardous voltage.

© National Instruments Corporation 5 NI cDAQ-9172 User Guide and Specifications

Page 6

Related Documentation

Each application software package and driver includes information about

writing applications for taking measurements and controlling measurement

devices. Check

documentation, and refer to Table 1 for a list of locations for driver and

application software documentation. The following document location

references assume you have NI-DAQmx 8.8 or later, and where applicable,

version 7.1 or later of the NI application software.

Table 1. NI Driver and Application Software Documentation

Software Document/Description Location/Topic

ni.com/manuals for the most recent hardware

NI-DAQmx for Windows DAQ Getting Started

Guide—describes how to

install and use the

NI-DAQmx driver software

for Windows and your data

acquisition (DAQ) device,

how to confirm the device is

operating properly, and how

to take an NI-DAQmx

measurement.

NI-DAQ Readme—includes

information about

NI-DAQmx and Traditional

NI-DAQ (Legacy).

Describes how to choose

the API to use, new

features, and a list of known

issues, supported devices,

and devices not supported.

Also provides details about

system requirements.

NI-DAQmx Help—explains

how to get started in your

OS and ADE; provides an

NI-DAQmx overview;

includes information about

programming the most

common measurement

tasks with references to

examples in CVI/C, C++,

.NET.

Start»Programs»

National Instruments»

NI-DAQ»DAQ Getting Started

Guide

Start»Programs»

National Instruments»

NI-DAQ»NI-DAQ Readme

Start»Programs»

National Instruments»

NI-DAQ»NI-DAQmx Help

NI cDAQ-9172 User Guide and Specifications 6 ni.com

Page 7

Table 1. NI Driver and Application Software Documentation (Continued)

Software Document/Description Location/Topic

LabVIEW Getting Started with

LabVIEW—describes the

LabVIEW graphical

programming environment

and the basic LabVIEW

features you use to build

data acquisition and

instrument control

application.

LabVIEW Help—provides

information about

LabVIEW programming

concepts, step-by-step

instructions for using

LabVIEW, and reference

information about

LabVIEW VIs, functions,

palettes, menus, and tools.

LabVIEW Help Topics Specific to NI-DAQmx

Includes overview

information and a tutorial to

learn how to take an

NI-DAQmx measurement

in LabVIEW using the

DAQ Assistant.

Start»All Programs»

National Instruments»

LabVIEW»LabVIEW Manuals or

navigate to the

labview\manuals

directory and opening

LV_Getting_Started.pdf

Help»Search the LabVIEW Help

From the Contents tab, Getting

Started»Getting Started with DAQ

Describes the LabVIEW

NI-DAQmx VIs and

properties.

From the Contents tab, VI and

Function Reference»

Measurement I/O VIs and

Functions

Contains the conceptual

and how-to information you

From the Contents tab, Taking

Measurements

need to acquire and analyze

measurement data in

LabVIEW, including

common measurements,

measurement

fundamentals, NI-DAQmx

key concepts, and device

considerations.

© National Instruments Corporation 7 NI cDAQ-9172 User Guide and Specifications

Page 8

Table 1. NI Driver and Application Software Documentation (Continued)

Software Document/Description Location/Topic

LabWindows™/CVI

™

LabWindows/CVI Help

Data Acquisition

book—contains

NI-DAQmx measurement

concepts and step-by-step

Help»Contents, then select Using

LabWindows/CVI»

Data Acquisition»Taking an

NI-DAQmx Measurement in

LabWindows/CVI

instructions about creating

a measurement task using

the DAQ Assistant.

Measurement

Studio/Microsoft Visual

Studio .NET

ANSI C without

NI Application Software

LabWindows/CVI Help

NI-DAQmx Library

LibraryReference»

NI-DAQmx Library

book—contains

NI-DAQmx API overviews

and function reference.

Microsoft Visual Studio

.NET Help/NI

Measurement Studio

Help—contains

NI-DAQmx methods and

Measurement Studio»

NI Measurement Studio Help and

select NI-DAQmx .NET Class

Library or NI-DAQmx Visual C++

Class Library

properties.

NI-DAQmx Help Start»All Programs»

National Instruments»

NI-DAQ»NI-DAQmx Help

NI-DAQmx C Reference

Help—describes the

NI-DAQmx Library

functions.

Start»All Programs»

National Instruments»

NI-DAQ»NI-DAQmx C Reference

Help

NI cDAQ-9172 User Guide and Specifications 8 ni.com

Page 9

Table 1. NI Driver and Application Software Documentation (Continued)

Software Document/Description Location/Topic

.NET Languages without

NI Application Software

NI-DAQmx .NET

*

Help—contains conceptual

topics for using NI-DAQmx

with Visual C# and Visual

Basic .NET.

Start»All Programs»

National Instruments»

NI-DAQ»NI-DAQmx .NET

Reference Help. Expand

NI Measurement Studio Help»

NI Measurement Studio .NET

Class Library»Reference to view

the function reference. Expand

NI Measurement Studio Help»

NI Measurement Studio .NET

Class Library»Using the

Measurement Studio .NET Class

Libraries

Visual Studio .NET

Help—contains conceptual

topics for using NI-DAQmx

with Visual C# and Visual

Basic .NET.

*

With the Microsoft .NET Framework version 1.1 or later, you can use NI-DAQmx to create applications using Visual C#

and Visual Basic .NET without Measurement Studio. You need Microsoft Visual Studio .NET 2003 or Microsoft Visual

Studio 2005 for the API documentation to be installed.

Help»Contents. Select

Measurement Studio from the

Filtered By drop-down list and

follow the location instructions for

the NI-DAQmx .NET Help.

Device Documentation and Specifications

Check ni.com/manuals for the most recent device and software

documentation. If you do not have Web access, NI-DAQmx includes a

Documentation CD that includes documentation available when

NI-DAQmx released.

Training Courses

If you need more help getting started developing an application with

NI products, NI offers training courses. To enroll in a course or obtain

a detailed course outline, refer to

ni.com/training.

Technical Support on the Web

For additional support, refer to ni.com/support or zone.ni.com.

© National Instruments Corporation 9 NI cDAQ-9172 User Guide and Specifications

Page 10

Installing the Software

Installing NI-DAQmx

The DAQ Getting Started Guide, which you can download at ni.com/

manuals

software and hardware, configuring channels and tasks, and getting started

developing an application.

Installing Other Software

If you are using other software, refer to the installation instructions that

accompany your software.

, offers NI-DAQmx users step-by-step instructions for installing

NI cDAQ-9172 User Guide and Specifications 10 ni.com

Page 11

Installing the NI cDAQ-9172

Figure 2 shows the dimensions of the NI cDAQ-9172 chassis.

88.1 mm

(3.50 in.)

46.0 mm

(1.81 in.)

24.8 mm

(0.98 in.)

59.6 mm

(2.35 in.)

NI cDAQ-9172

Ready

Active

11-30 VDC

15 W

53.8 mm

(2.12 in.)

165.1 mm

(6.50 in.)

ON

OFF

254.0 mm

(10.00 in.)

23.7 mm

(0.94 in.)

20.3 mm

(0.80 in.)

25.0 mm

(0.98 in.)

44.1 mm

(1.74 in.)

63.1 mm

(2.49 in.)

8 7 6 5 4 3 2 1

19.0 mm

(0.75 in.)

36.4 mm

(1.43 in.)

51.7 mm

(2.04 in.)

4.10 mm

(0.16 in.)

44.1 mm

(1.74 in.)

58.9 mm

(2.32 in.)

31.7 mm

(1.25 in.)

19.1 mm

(0.75 in.)

23.2 mm

(0.91 in.)

Figure 2. NI cDAQ-9172 with Dimensions in Millimeters (Inches)

© National Instruments Corporation 11 NI cDAQ-9172 User Guide and Specifications

Page 12

Mounting the NI cDAQ-9172

You can mount the NI cDAQ-9172 chassis using a desktop, a 35 mm

DIN-Rail, or a panel mount accessory kit. For accessory ordering

information, refer to

Caution Your installation must meet the following requirements:

• Allows 25.4 mm (1 in.) of clearance above and below the NI cDAQ-9172 chassis for

air circulation.

• Allows at least 50.8 mm (2 in.) of clearance in front of the modules for common

connector cabling such as the 10-terminal detachable screw terminal connector and, as

needed, up to 88.9 mm (3.5 in.) of clearance in front of the modules for other types of

cabling. For more information about mechanical dimensions, refer to

info

and enter the info code cDAQMechanical. For more information about cable

dimensions, refer to

ni.com/info and enter the info code cDAQCable.

NI 9901 Desktop Mounting Kit

The NI 9901 Desktop Mounting Kit includes two metal feet you can install

on the sides of the NI cDAQ-9172 chassis for desktop use. With this kit,

you can tilt the NI cDAQ-9172 chassis for convenient access to the I/O

module connectors. When you install the two metal feet, the two existing

screws on the power switch side of the chassis must be removed. After

removing the screws, replace them with the two longer screws included in

the NI 9901 Desktop Mounting Kit.

ni.com.

ni.com/

Figure 3. NI 9901 Desktop Mounting Kit

NI cDAQ-9172 User Guide and Specifications 12 ni.com

Page 13

NI 9910 DIN-Rail Kit

The NI 9910 DIN-Rail Kit contains one clip for mounting the chassis on a

standard 35 mm DIN-Rail. To mount the chassis on a DIN-Rail, fasten the

DIN-Rail clip to the chassis using a number 2 Phillips screwdriver and

two M4 × 17 screws. The screws are included in the DIN-Rail kit. Make

sure the DIN-Rail kit is installed as illustrated in Figure 4, with the larger

lip of the DIN-RAIL positioned up. When the DIN-Rail kit is properly

installed, the NI cDAQ-9172 chassis is centered on the DIN-Rail.

Caution Remove the I/O modules before removing the chassis from the DIN-Rail.

Figure 4. DIN-Rail Installation on the NI cDAQ-9172

NI 9905 Panel Mount Kit

To mount the chassis on a panel, align the chassis on the panel mount

accessory. Attach the chassis to the panel mount kit using two M4 × 17

screws (as shown in Figure 5). National Instruments provides these screws

with the panel mount kit. You must use these screws because they are the

correct depth and thread for the panel. These slots in the panel mount kit

© National Instruments Corporation 13 NI cDAQ-9172 User Guide and Specifications

Page 14

can be used with M4, M5, No. 8, or No.10 panhead screws. Figure 5

illustrates the panel dimensions and installation on the NI cDAQ-9172

chassis. Refer to the documentation included with the NI 9905 Panel

Mount Kit for more detailed dimensions.

330.2 mm

(13.00 in.)

NATIONAL

INSTRUMENTS

NI cDAQ-9172

11-30 VDC

Ready

Active

15 W

ON

OFF

48.1 mm

(1.90 in.)

28.1 mm

(1.11 in.)

87654321

88.1 mm

(3.47 in.)

Figure 5. Panel Mount Dimensions and Installation on the NI cDAQ-9172

NI cDAQ-9172 User Guide and Specifications 14 ni.com

Page 15

Setting Up the NI cDAQ-9172

Complete the following steps to prepare the NI cDAQ-9172 chassis for use:

1. Before connecting the hardware, install the NI-DAQmx software.

Refer to the DAQ Getting Started Guide for more information about

software installation.

Note The NI-DAQmx software is included on the CD shipped with your kit and is

available for download at

after installation from Start»All Programs»National Instruments»NI-DAQ»DAQ

Getting Started Guide. Other NI documentation is available from

2. If you are not using any mounting accessories, attach the provided

3. Make sure the NI cDAQ-9172 chassis power switch is turned off.

4. Attach a ring lug to a 14 AWG (1.6 mm) wire. Connect the ring lug to

ni.com/support. The DAQ Getting Started Guide is available

rubber standoffs to the back of the NI cDAQ-9172 chassis.

the ground terminal on the side of the chassis using the ground screw.

Attach the other end of the wire to the system safety ground.

ni.com/manuals.

1

1 Attached to System Ground

Figure 6. Ring Lug Attached to Ground Terminal

Note

Additionally, attach a wire with a ring lug to all other C Series I/O module cable

shields. You must connect this wire to the ground terminal of the chassis using the ground

screw.

5. Remove the plastic cover from the connector in any empty module slot.

© National Instruments Corporation 15 NI cDAQ-9172 User Guide and Specifications

Page 16

6. Squeeze both C Series I/O module latches, insert the I/O module into

the module slot, and press until both latches lock the module in place.

7. Connect the NI cDAQ-9172 chassis with the supplied USB cable to

any available USB port on your computer.

8. Connect the power source to the NI cDAQ-9172 chassis. The

NI cDAQ-9172 chassis requires an external power supply that meets

the specifications in the Power Requirements section.

Note The NI cDAQ-9172 chassis uses a DC input jack with a locking ring. Use only this

connector with the NI cDAQ-9172 chassis. Refer to the Specifications section for more

information about the connector.

9. Secure the power supply and USB cables, as depicted in Figure 7,

using the two tie wraps and adhesive tie wrap mounts included in the

shipping kit. The tie wraps and adhesive mounts help secure the

non-latching USB connection. They can also be used to route the

cables to a desirable position.

NI cDAQ-9172

Figure 7. cDAQ Chassis With Secured Cables

10. Power on the NI cDAQ-9172 chassis.

11. Double-click the Measurement & Automation icon, shown at left,

on the desktop to open MAX.

12. Expand Devices and Interfaces, and then expand NI-DAQmx

Devices.

NI cDAQ-9172 User Guide and Specifications 16 ni.com

Page 17

13. Check that your device appears under Devices and Interfaces. If your

device does not appear, press <F5> to refresh the view in MAX. If your

device is still not recognized, refer to

troubleshooting information.

14. Right-click your device and select Self-Test.

If you need help during the self-test, select Help»Help Topics»

NI-DAQmx and click MAX Help for NI-DAQmx.

When the self-test finishes, a message indicates successful verification

or an error. If an error occurs, refer to

for troubleshooting information.

Note When in use, the NI cDAQ-9172 chassis may become warm to the touch. This is

normal.

Understanding LED Indications

Active LED

The Active LED indicates whether the NI cDAQ-9172 chassis is

communicating over the USB bus.

ni.com/support/install for

ni.com/support/install

Table 2. Active LED

Ready LED

LED Definition

Amber Power is applied, but USB connection is not

established

Green USB traffic present

Off No USB traffic present

The Ready LED is lit when the NI cDAQ-9172 chassis is ready for use. The

color indicates whether the USB connection is Full-Speed or Hi-Speed.

Table 3. Ready LED

LED Definition

Amber Hi-Speed (480 Mbit/sec)

Green Full-Speed (12 Mbit/sec)

Off USB connection is not established

© National Instruments Corporation 17 NI cDAQ-9172 User Guide and Specifications

Page 18

Using the NI cDAQ-9172

The cDAQ system consists of three parts: C Series I/O modules, the cDAQ

module interface, and the USB-STC2. These components digitize signals,

perform D/A conversions to generate analog output signals, measure and

control digital I/O signals, and provide signal conditioning.

C Series

I/O Module

cDAQ Module

Interface

C Series

I/O Module

C Series

I/O Module

USB-

STC2

Figure 8. NI cDAQ-9172 Block Diagram

USB

2.0

C Series I/O Modules

National Instruments C Series I/O modules provide built-in signal

conditioning and screw terminal, spring terminal, BNC, D-SUB, or

RJ-50 connectors. A wide variety of I/O types are available, allowing

you to customize the cDAQ system to meet your application needs.

C Series I/O modules are hot-swappable and automatically detected by the

NI cDAQ-9172 chassis. I/O channels are accessible using the NI-DAQmx

driver software.

Because the modules contain built-in signal conditioning for extended

voltage ranges or industrial signal types, you can usually make your

wiring connections directly from the C Series I/O modules to your

sensors/actuators. In most cases, the C Series I/O modules provide isolation

from channel-to-earth ground.

For more information about which C Series I/O modules are compatible

with the NI cDAQ-9172 chassis, refer to the KnowledgeBase document,

C Series Modules Supported in the NI cDAQ-9172 CompactDAQ.

NI cDAQ-9172 User Guide and Specifications 18 ni.com

Page 19

To access this KnowledgeBase, go to ni.com/info and enter the info

code

Correlated vs. Static DIO Modules

Digital I/O module capabilities are determined by the type of digital signals

that the module is capable of measuring or generating. Static digital I/O

modules are designed for signals that change slowly and are accessed by

software-timed reads and writes. Correlated digital I/O modules are for

signals that change rapidly and are updated by either software-timed or

hardware-timed reads and writes. For more information about Digital I/O

modules, refer to the Digital I/O section.

cDAQ Module Interface

The cDAQ Module Interface manages data transfers between the

USB-STC2 and the C Series I/O modules. The interface also handles

autodetection, signal routing, and synchronization.

USB-STC2

The USB-STC2 features independent high-speed data streams; flexible

AI and AO sample timing; triggering; PFI signals for multi-device

synchronization; flexible counter/timers with hardware gating; digital

waveform acquisition and generation; and static DIO.

rdcdaq.

AI and AO Sample Timing

The USB-STC2 contains advanced analog input and analog output timing

engines. A wide range of timing and synchronization signals are available

through the PFI lines. Refer to the Analog Input Timing Signals and

Analog Output Timing Signals sections for more information about the

configuration of these signals.

Triggering Modes

The NI cDAQ-9172 supports different trigger modes, such as start trigger,

reference trigger, and pause trigger with analog, digital, or software

sources. Refer to the Analog Input Triggering and Analog Output

Triggering sections for more information.

Independent Data Streams

The NI cDAQ-9172 supports four independent high-speed data streams;

allowing for up to four simultaneous hardware timed tasks, such as analog

input, analog output, buffered counter/timers, and correlated digital

input/output.

© National Instruments Corporation 19 NI cDAQ-9172 User Guide and Specifications

Page 20

Analog Input

PFI Signals

The PFI signals, available through correlated digital input and output

modules installed in slots 5 and/or 6, provide access to advanced features

such as triggering, synchronization, and counter/timers. Refer to the PFI

section for more information.

The PFI pins have a digital filter circuit at the inputs that is configurable on

a per-line basis. The filters allow the rejection of noise caused by noisy

environments, bounces on switches, and so on.

Flexible Counter/Timers

The NI cDAQ-9172 includes two general-purpose 32-bit counter/timers

that can be used to count edges, measure pulse-widths, measure periods and

frequencies, and perform position measurements (encoding). In addition,

the counter/timers can generate pulses, pulse trains, and square waves with

adjustable frequencies. You can access the counter inputs and outputs using

correlated digital I/O modules in slots 5 and/or 6. Refer to the Counters

section for more information.

To perform analog input measurements, insert a supported analog input

C Series I/O module into any slot on the cDAQ chassis. The measurement

specifications, such as number of channels, channel configuration, sample

rate, and gain, are determined by the type of C Series I/O module used. For

more information and wiring diagrams, refer to the documentation included

with your C Series I/O modules.

The NI cDAQ-9172 has one AI timing engine, which means that only

one analog input task can be running at a time on a chassis. However, the

analog input task can include channels from multiple analog input modules.

Analog Input Triggering

A trigger is a signal that causes an action, such as starting or stopping the

acquisition of data. When you configure a trigger, you must decide how

you want to produce the trigger and the action you want the trigger to cause.

The NI cDAQ-9172 chassis supports internal software, external digital

triggering, and analog triggering.

Three triggers are available: start trigger, reference trigger, and pause

trigger. An analog or digital trigger can initiate these three trigger actions.

Any C Series correlated digital input module can supply a digital trigger

when installed in slots 5 or 6, and some C Series analog modules can supply

an analog or digital trigger in any slot. The start, reference, and pause

NI cDAQ-9172 User Guide and Specifications 20 ni.com

Page 21

triggers can come from three separate modules if desired. To find your

module triggering options, refer to the documentation included with your

C Series I/O modules. For more information about using digital modules

for triggering, refer to the Digital I/O section.

AI Start Trigger Signal

Use the AI Start Trigger (ai/StartTrigger) signal to begin a measurement

acquisition. A measurement acquisition consists of one or more samples. If

you do not use triggers, begin a measurement with a software command.

Once the acquisition begins, configure the acquisition to stop in one of the

following ways:

• When a certain number of points is sampled (in finite mode)

• After a hardware reference trigger (in finite mode)

• With a software command (in continuous mode)

An acquisition that uses a start trigger (but not a reference trigger) is

sometimes referred to as a posttriggered acquisition. That is, samples are

measured only after the trigger.

When you are using an internal sample clock, you can specify a delay from

the start trigger to the first sample.

Using a Digital Source

To use ai/StartTrigger with a digital source, specify a source and an edge.

Use the following signals as the source:

•Any PFI terminal.

• Counter n Internal Output

The source also can be one of several other internal signals on your

NI cDAQ-9172 chassis. Refer to the Device Routing in MAX topic in the

NI-DAQmx Help or the LabVIEW Help in version 8.0 or later for more

information.

The NI-DAQmx Help is available after installation from Start»

All Programs»National Instruments»NI-DAQ»NI-DAQmx Help.

To view the LabVIEW Help, in version 8.0 or later, select Help»

Search the LabVIEW Help in LabVIEW. Alternately, to download

the LabVIEW Help, go to

You also can specify whether the measurement acquisition begins on the

rising edge or falling edge of ai/StartTrigger.

© National Instruments Corporation 21 NI cDAQ-9172 User Guide and Specifications

ni.com/manuals.

Page 22

Using an Analog Source

Some C Series I/O modules can generate a trigger based on an analog

signal. In NI-DAQmx, this is called the Analog Comparison Event.

When you use an analog trigger source for ai/StartTrigger, the acquisition

begins on the first rising edge of the Analog Comparison Event signal.

Routing AI Start Trigger to an Output Terminal

You can route ai/StartTrigger to any output PFI terminal. The output is an

active high pulse.

AI Reference Trigger Signal

Use a reference trigger (ai/ReferenceTrigger) signal to stop a measurement

acquisition. To use a reference trigger, specify a buffer of finite size and

a number of pretrigger samples (samples that occur before the reference

trigger). The number of posttrigger samples (samples that occur after the

reference trigger) desired is the buffer size minus the number of pretrigger

samples.

Once the acquisition begins, the NI cDAQ-9172 chassis writes samples to

the buffer. After the NI cDAQ-9172 chassis captures the specified number

of pretrigger samples, the NI cDAQ-9172 chassis begins to look for the

reference trigger condition. If the reference trigger condition occurs before

the NI cDAQ-9172 captures the specified number of pretrigger samples, the

NI cDAQ-9172 ignores the condition.

If the buffer becomes full, the NI cDAQ-9172 continuously discards the

oldest samples in the buffer to make space for the next sample. This data

can be accessed (with some limitations) before the NI cDAQ-9172 chassis

discards it. Refer to the KnowledgeBase document, Can a Pretriggered

Acquisition be Continuous?, for more information. To access this

KnowledgeBase, go to

NI cDAQ-9172 User Guide and Specifications 22 ni.com

ni.com/info and enter the info code rdcanq.

Page 23

When the reference trigger occurs, the NI cDAQ-9172 continues to write

samples to the buffer until the buffer contains the number of posttrigger

samples desired. Figure 9 shows the final buffer.

Reference Trigger

Pretrigger Samples

Complete Buffer

Figure 9. Reference Trigger Final Buffer

Posttrigger Samples

Using a Digital Source

To use ai/ReferenceTrigger with a digital source, specify a source and an

edge. Either PFI or one of several internal signals on the NI cDAQ-9172

chassis can provide the source. Refer to the Device Routing in MAX topic

in the NI-DAQmx Help or the LabVIEW Help in version 8.0 or later for

more information.

The NI-DAQmx Help is available after installation from Start»

All Programs»National Instruments»NI-DAQ»NI-DAQmx Help.

To view the LabVIEW Help, in version 8.0 or later, select Help»

Search the LabVIEW Help in LabVIEW. Alternately, to download

the LabVIEW Help, go to

You also can specify whether the measurement acquisition stops on the

rising edge or falling edge of ai/ReferenceTrigger.

ni.com/manuals.

Using an Analog Source

Some C Series I/O modules can generate a trigger based on an analog

signal. In NI-DAQmx, this is called the Analog Comparison Event.

When you use an analog trigger source, the acquisition stops on the first

rising or falling edge of the Analog Comparison Event signal, depending

on the trigger properties.

Routing AI Reference Trigger Signal to an Output Terminal

You can route ai/ReferenceTrigger to any output PFI terminal.

© National Instruments Corporation 23 NI cDAQ-9172 User Guide and Specifications

Page 24

AI Pause Trigger Signal

You can use the AI Pause Trigger (ai/PauseTrigger) signal to pause and

resume a measurement acquisition. The internal sample clock pauses while

the external trigger signal is active and resumes when the signal is inactive.

You can program the active level of the pause trigger to be high or low.

Using a Digital Source

To use ai/PauseTrigger, specify a source and a polarity. The source

can be either from PFI or one of several other internal signals on

your NI cDAQ-9172 chassis. Refer to the Device Routing in MAX topic in

the NI-DAQmx Help or the LabVIEW Help in version 8.0 or later for more

information.

The NI-DAQmx Help is available after installation from Start»

All Programs»National Instruments»NI-DAQ»NI-DAQmx Help.

To view the LabVIEW Help, in version 8.0 or later, select Help»

Search the LabVIEW Help in LabVIEW. Alternately, to download

the LabVIEW Help, go to

Using an Analog Source

Some C Series I/O modules can generate a trigger based on an analog

signal. In NI-DAQmx, this is called the Analog Comparison Event.

ni.com/manuals.

When you use an analog trigger source, the internal sample clock pauses

when the Analog Comparison Event signal is low and resumes when the

signal goes high (or vice versa).

Note Pause triggers are only sensitive to the level of the source, not the edge.

Analog Input Timing Signals

AI Sample Clock

A sample consists of one reading from each channel in the AI task.

ai/SampleClock signals the start of a sample of all analog input channels

in the task. ai/SampleClock can be generated from external or internal

sources.

NI cDAQ-9172 User Guide and Specifications 24 ni.com

Page 25

k

PFI

Analog Comparison

Event

20 MHz Timebase

100 kHz Timebase

PFI

Analog Comparison Event

Ctr

n

Sigma-Delta Module Internal Output

ai/SampleClock

Timebase

Programmable

Divider

Figure 10. Sample Clock Timing Options

Internal Output

Clock

ai/SampleCloc

Routing AI Sample Clock to an Output Terminal

You can route ai/SampleClock to any output PFI terminal.

AI Sample Clock Timebase

The AI Sample Clock Timebase (ai/SampleClockTimebase) signal is

divided down to provide a source for ai/SampleClock. ai/SampleClock

Timebase can be generated from external or internal sources.

ai/SampleClockTimebase is not available as an output from the chassis.

Convert Behavior For Analog Input Modules

Scanned

Scanned C Series analog input modules contain a single A/D converter and

a multiplexer to select between multiple input channels. When the cDAQ

Module Interface receives a Sample Clock pulse, it begins generating a

Convert Clock for each scanned module in the current task. Each Convert

Clock signals the acquisition of a single channel from that module. The

Convert Clock rate depends on the module being used, the number of

channels used on that module, and the system Sample Clock rate.

The driver chooses the fastest conversion rate possible based on the speed

of the A/D converter for each module and adds 10 µs of padding between

each channel to allow for adequate settling time. This scheme enables the

channels to approximate simultaneous sampling. If the AI Sample Clock

rate is too fast to allow for 10 µs of padding, NI-DAQmx selects a

conversion rate that spaces the AI Convert Clock pulses evenly throughout

the sample. NI-DAQmx uses the same amount of padding for all the

modules in the task. To explicitly specify the conversion rate, use the

© National Instruments Corporation 25 NI cDAQ-9172 User Guide and Specifications

Page 26

ActiveDevs and AI Convert Clock Rate properties using the DAQmx

Timing property node or functions.

Simultaneous Sample-and-Hold

Simultaneous sample-and-hold (SSH) C Series analog input modules

contain multiple A/D converters or circuitry that allows all the input

channels to be sampled at the same time. These modules sample their

inputs on every Sample Clock pulse.

Sigma-Delta

Sigma-delta C Series analog input modules function much like SSH

modules, but use A/D converters that require a high-frequency oversample

clock to produce accurate, synchronized data. Sigma-delta modules in

the cDAQ chassis automatically share a single oversample clock to

synchronize data from all sigma-delta modules.

This clock is used as the AI Sample Clock Timebase. While most modules

supply a common oversample clock frequency (12.8 MHz), some modules,

such as the NI 9234, supply a different frequency. When sigma-delta

modules with different oversample clock frequencies are used in an analog

input task, the AI Sample Clock Timebase can use any of the available

frequencies; by default, the fastest available is used. The sampling

rate of all modules in the system is an integer divisor of the frequency

of the AI Sample Clock Timebase.

When one or more sigma-delta modules are in an analog input task, the

sigma-delta modules also provide the signal used as the AI Sample Clock.

This signal is used to cause A/D conversion for other modules in the

system, just as the AI Sample Clock does when a sigma-delta module is not

being used.

When sigma-delta modules are in an AI task, the chassis automatically

issues a synchronization pulse to each sigma-delta modules that resets their

ADCs at the same time. Both the synchronization pulse and the oversample

clock can be routed from or to any PFI line to allow synchronization

between multiple chassis. Because of the filtering used in sigma-delta A/D

converters, these modules usually exhibit a fixed input delay relative to

non-sigma-delta modules in the system. This input delay is specified in the

C Series I/O module documentation.

NI cDAQ-9172 User Guide and Specifications 26 ni.com

Page 27

ai/StartTrigger

Data from

A/D Conversion

(Slow Module)

ai/SampleClock

Slow Sample Rate Modules

Some C Series analog input modules are specifically designed for

measuring signals that vary slowly, such as temperature. Because of their

slow rate, it is not appropriate for these modules to constrain the AI Sample

Clock to operate at or slower than their maximum rate. When using such a

module in the cDAQ chassis, the maximum Sample Clock rate can run

faster than the maximum rate for the module. When operating at a rate

faster than these slow rate modules can support, the slow rate module

returns the same point repeatedly, until a new conversion completes. The

first point is acquired when the task is committed. The second point is

acquired after the start trigger.

1st A/D Conversion 2nd A/D Conversion 3rd A/D Conversion

A

B C

Data Returned

to AI Task

A A A B B B C

Figure 11. Sample Clock Timing Example

For example, if running an AI task at 1 kHz using a module with a

maximum rate of 10 Hz, the slow module returns 100 samples of the first

point, followed by 100 samples of the second point, etc. Other modules in

the task will return 1,000 new data points per second, which is normal.

When performing a single-point acquisition, no points are repeated.

Refer to the KnowledgeBase document, C Series Modules Supported in the

NI cDAQ-9172 CompactDAQ, for more information. To access this

KnowledgeBase, go to

© National Instruments Corporation 27 NI cDAQ-9172 User Guide and Specifications

ni.com/info and enter the info code rdcdaq.

Page 28

Getting Started with AI Applications in Software

You can use the NI cDAQ-9172 chassis in the following analog input

applications:

• Single-Point

•Finite

• Continuous

For more information about programming analog input applications and

triggers in software, Refer to the NI-DAQmx Help or the LabVIEW Help in

version 8.0 or later for more information.

The NI-DAQmx Help is available after installation from Start»

All Programs»National Instruments»NI-DAQ»NI-DAQmx Help.

To view the LabVIEW Help, in version 8.0 or later, select Help»

Search the LabVIEW Help in LabVIEW. Alternately, to download

the LabVIEW Help, go to

ni.com/manuals.

Analog Output

To generate analog output, insert an analog output C Series I/O module in

any slot on the NI cDAQ-9172 chassis. The generation specifications, such

as the number of channels, channel configuration, update rate, and output

range, are determined by the type of C Series I/O module used. For more

information, refer to the documentation included with your C Series I/O

modules.

You can run one hardware-timed (waveform) analog output task at a time

on the NI cDAQ-9172 chassis, with up to 16 waveform channels. At the

same time, you can also run one or more software-timed (single-point or

immediate) tasks.

For each analog output module, you can either:

• Assign all of the channels on the module to the hardware-timed task.

• Assign all of the channels on the module to one or more

software-timed tasks.

On a single AO module, you cannot assign some channels to a

hardware-timed task and other channels (on the same module) to

a software-timed task.

Analog Output Data Generation Methods

When performing an analog output operation, you either can perform

software-timed or hardware-timed generations. Hardware-timed

generations must be buffered.

NI cDAQ-9172 User Guide and Specifications 28 ni.com

Page 29

Software-Timed Generations

With a software-timed generation, software controls the rate at which data

is generated. Software sends a separate command to the hardware to initiate

each DAC conversion. In NI-DAQmx, software-timed generations are

referred to as on-demand timing. Software-timed generations are also

referred to as immediate or static operations. They are typically used for

writing out a single value, such as a constant DC voltage.

The following considerations apply to software-timed generations:

• If any AO channel on a module is used in a hardware-timed

(waveform) task, no channels on that module can be used in a

software-timed task.

• You can configure software-timed generation to simultaneously

update.

• Only one simultaneous update task can run at a time.

• Simultaneous update is not restricted to 16 channels.

• A hardware-timed AO task and a simultaneous update AO task cannot

run at the same time.

Hardware-Timed Generations

With a hardware-timed generation, a digital hardware signal controls the

rate of the generation. This signal can be generated internally on the chassis

or provided externally.

Hardware-timed generations have several advantages over software-timed

acquisitions:

• The time between samples can be much shorter.

• The timing between samples is deterministic.

• Hardware-timed acquisitions can use hardware triggering.

Hardware-timed AO operations on the NI cDAQ-9172 chassis must be

buffered.

Buffered Analog Output

A buffer is a temporary storage in computer memory for generated

samples. In a buffered generation, data is moved from a host buffer to the

NI cDAQ-9172 onboard FIFO before it is written to the C Series I/O

modules.

© National Instruments Corporation 29 NI cDAQ-9172 User Guide and Specifications

Page 30

One property of buffered I/O operations is sample mode. The sample mode

can be either finite or continuous:

• Finite—Finite sample mode generation refers to the generation of a

specific, predetermined number of data samples. After the specified

number of samples is written out, the generation stops.

• Continuous—Continuous generation refers to the generation of an

unspecified number of samples. Instead of generating a set number of

data samples and stopping, a continuous generation continues until

you stop the operation. There are three different continuous generation

modes that control how the data is written. These modes are

regeneration, onboard regeneration, and non-regeneration:

– In regeneration mode, you define a buffer in host memory. The

data from the buffer is continually downloaded to the FIFO to be

written out. New data can be written to the host buffer at any time

without disrupting the output.

– With onboard regeneration, the entire buffer is downloaded to the

FIFO and regenerated from there. After the data is downloaded,

new data cannot be written to the FIFO. To use onboard

regeneration, the entire buffer must fit within the FIFO size. The

advantage of using onboard regeneration is that it does not require

communication with the main host memory once the operation is

started, which prevents problems that may occur due to excessive

bus traffic or operating system latency.

– With non-regeneration, old data is not repeated. New data must

continually be written to the buffer. If the program does not write

new data to the buffer at a fast enough rate to keep up with the

generation, the buffer underflows and causes an error.

Analog Output Triggering

Analog output supports two different triggering actions:

• Start trigger

• Pause trigger

An analog or digital trigger can initiate these actions. Any C Series

correlated digital module in slots 5 and/or 6 can supply a digital trigger, and

some C Series analog modules can supply an analog trigger. For more

information refer to the AO Start Trigger Signal section of this document

or to the documentation included with your C Series I/O module(s).

NI cDAQ-9172 User Guide and Specifications 30 ni.com

Page 31

Analog Output Timing Signals

The NI cDAQ-9172 chassis features the following AO (waveform

generation) timing signals:

• AO Sample Clock

•AO Start Trigger

• AO Pause Trigger

AO Sample Clock

The AO sample clock (ao/SampleClock) signals when all the analog output

channels in the task update. ao/SampleClock can be generated from

external or internal sources.

PFI

Analog Comparison

Event

20 MHz Timebase

ao/SampleClock

Timebase

PFI

Analog Comparison Event

Ctr

n

Internal Output

Programmable

Clock

Divider

ao/SampleClock

100 kHz Timebase

Figure 12. Analog Output Timing Options

Routing AO Sample Clock to an Output Terminal

You can route ao/SampleClock to any output PFI terminal.

AO Sample Clock Timebase Signal

The AO Sample Clock Timebase (ao/SampleClockTimebase)

signal is divided down to provide a source for ao/SampleClock.

ao/SampleClockTimebase can be generated from external or internal

sources, and is not available as an output from the chassis.

AO Start Trigger Signal

Use the AO Start Trigger (ao/StartTrigger) signal to initiate a waveform

generation. If you do not use triggers, you can begin a generation

with a software command. If you are using an internal sample clock,

you can specify a delay from the start trigger to the first sample. For

© National Instruments Corporation 31 NI cDAQ-9172 User Guide and Specifications

Page 32

more information, refer to the NI-DAQmx Help. The NI-DAQmx Help

is available after installation from Start»All Programs»National

Instruments»NI-DAQ»NI-DAQmx Help.

Using a Digital Source

To use ao/StartTrigger, specify a source and a rising or falling edge.

The source can be one of the following signals:

• A pulse initiated by host software

• Any PFI terminal

• ai/ReferenceTrigger

• ai/StartTrigger

The source also can be one of several internal signals on the NI cDAQ-9172

chassis. Refer to the Device Routing in MAX topic in the NI-DAQmx Help

or the LabVIEW Help in version 8.0 or later for more information.

The NI-DAQmx Help is available after installation from Start»

All Programs»National Instruments»NI-DAQ»NI-DAQmx Help.

To view the LabVIEW Help, in version 8.0 or later, select Help»

Search the LabVIEW Help in LabVIEW. Alternately, to download

the LabVIEW Help, go to

You also can specify whether the waveform generation begins on the rising

edge or falling edge of ao/StartTrigger.

ni.com/manuals.

Using an Analog Source

Some C Series I/O modules can generate a trigger based on an analog

signal. In NI-DAQmx, this is called the Analog Comparison Event,

depending on the trigger properties.

When you use an analog trigger source, the waveform generation begins on

the first rising or falling edge of the Analog Comparison Event signal,

depending on the trigger properties. The analog trigger circuit must be

configured by a simultaneously running analog input task.

Routing AO Start Trigger Signal to an Output Terminal

You can route ao/StartTrigger to any output PFI terminal. The output is an

active high pulse.

NI cDAQ-9172 User Guide and Specifications 32 ni.com

Page 33

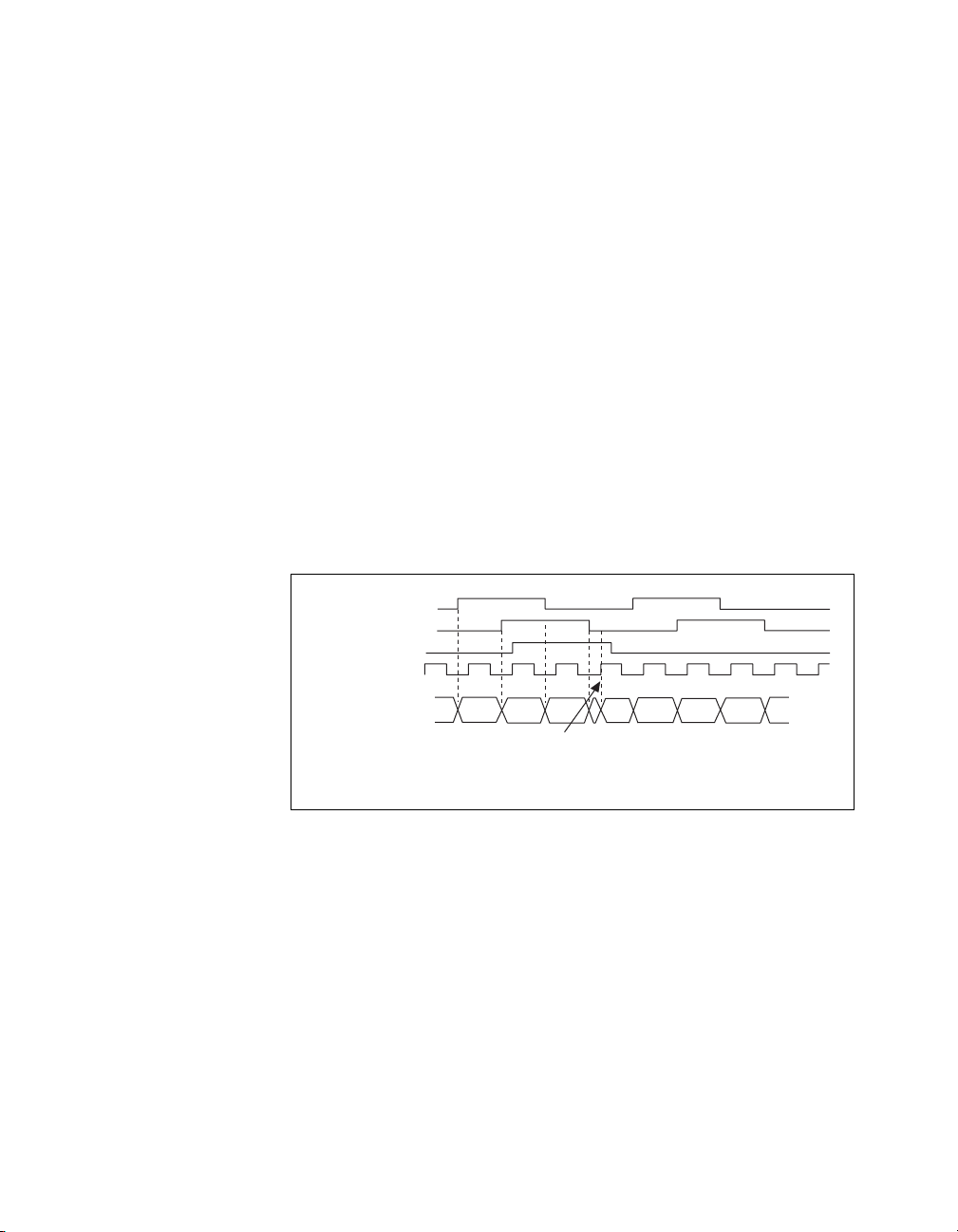

AO Pause Trigger Signal

Use the AO Pause trigger signal (ao/PauseTrigger) to mask off samples in

a DAQ sequence. When ao/PauseTrigger is active, no samples occur, but

ao/PauseTrigger does not stop a sample that is in progress. The pause does

not take effect until the beginning of the next sample.

When you generate analog output signals, the generation pauses as soon as

the pause trigger is asserted. If the source of the sample clock is the onboard

clock, the generation resumes as soon as the pause trigger is deasserted,

as shown in Figure 13.

Pause Trigger

Sample Clock

Figure 13. ao/PauseTrigger with the Onboard Clock Source

If you are using any signal other than the onboard clock as the source of

the sample clock, the generation resumes as soon as the pause trigger is

deasserted and another edge of the sample clock is received, as shown in

Figure 14.

Pause Trigger

Sample Clock

Figure 14. ao/PauseTrigger with Other Signal Source

Using a Digital Source

To use ao/PauseTrigger, specify a source and a polarity. The source can be

a PFI signal or one of several other internal signals on the NI cDAQ-9172

chassis.

You also can specify whether the samples are paused when ao/PauseTrigger

is at a logic high or low level. Refer to the Device Routing in MAX topic in

the NI-DAQmx Help or the LabVIEW Help in version 8.0 or later for more

information.

© National Instruments Corporation 33 NI cDAQ-9172 User Guide and Specifications

Page 34

The NI-DAQmx Help is available after installation from Start»

All Programs»National Instruments»NI-DAQ»NI-DAQmx Help.

To v iew th e LabVIEW Help, in version 8.0 or later, select Help»Search the

LabVIEW Help in LabVIEW. Alternately, to download the LabVIEW

Help, go to

ni.com/manuals.

Using an Analog Source

Some C Series I/O modules can generate a trigger based on an analog

signal. In NI-DAQmx, this is called the Analog Comparison Event,

depending on the trigger properties.

When you use an analog trigger source, the samples are paused when the

Analog Comparison Event signal is at a high or low level, depending on

the trigger properties. The analog trigger circuit must be configured by

a simultaneously running analog input task.

Minimizing Glitches on the Output Signal

When you use a DAC to generate a waveform, you may observe glitches

on the output signal. These glitches are normal; when a DAC switches from

one voltage to another, it produces glitches due to released charges. The

largest glitches occur when the most significant bit of the DAC code

changes. You can build a lowpass deglitching filter to remove some of

these glitches, depending on the frequency and nature of the output signal.

Go to

ni.com/support for more information about minimizing glitches.

Getting Started with AO Applications in Software

You can use the NI cDAQ-9172 chassis in the following analog output

applications:

• Single-Point (On-Demand) Generation

• Finite Generation

• Continuous Generation

• Waveform Generation

For more information about programming analog output applications and

triggers in software, refer the LabVIEW Help, in version 8.0 or later, or to

the NI-DAQmx Help.

The NI-DAQmx Help is available after installation from Start»

All Programs»National Instruments»NI-DAQ»NI-DAQmx Help.

To view the LabVIEW Help, in version 8.0 or later, select Help»

Search the LabVIEW Help in LabVIEW. Alternately, to download

the LabVIEW Help, go to

NI cDAQ-9172 User Guide and Specifications 34 ni.com

ni.com/manuals.

Page 35

Digital I/O

To use digital I/O, insert a digital I/O C Series module into any slot on

the NI cDAQ-9172 chassis. The I/O specifications, such as number of lines,

logic levels, update rate, and line direction, are determined by the type

of C Series I/O module used. For more information, refer to the

documentation included with your C Series I/O modules.

Correlated vs. Static DIO Modules

Digital I/O module capabilities are determined by the type of digital signals

that the module is capable of measuring or generating. Static digital I/O

modules are designed for signals that change slowly and are accessed by

software-timed reads and writes. Correlated digital I/O modules are

for signals that change rapidly and are updated by either software-timed or

hardware-timed reads and writes. Correlated digital I/O modules can

perform the following tasks:

• Used in any slot—Software-timed reads and writes

• Used in slots 1 though 4—Digital waveform generation and

acquisition (correlated input/output)

• Used in slots 5 and 6—Counter/timer

• Used in slots 5 and 6—Access PFI signals

To determine the capability of digital I/O modules supported by the

NI cDAQ-9172 chassis, refer to the KnowledgeBase document,

C Series Modules Supported in the NI cDAQ-9172 CompactDAQ.

To access this KnowledgeBase document, go to

the info code

rdcdaq.

ni.com/info and enter

Available features, such as trigger and counter/timer, are determined by the

slot containing the digital I/O C Series module and the capabilities of the

module.

Table 4. Digital Module Slot Features

Digital

Waveform/Change

Slots Static DIO PFI

1

Counter/Timer

1

Detection

1

1 Ye s — — Ye s

2 Ye s — — Ye s

3 Ye s — — Ye s

4 Ye s — — Ye s

© National Instruments Corporation 35 NI cDAQ-9172 User Guide and Specifications

Page 36

Table 4. Digital Module Slot Features (Continued)

Slots Static DIO PFI

5 Ye s Ye s Ye s —

6 Ye s Ye s Ye s —

7 Ye s — — —

8 Ye s — — —

1

Requires the use of a correlated digital I/O module.

Static DIO

Each of the DIO lines can be used as a static DI or DO line. You can use

static DIO lines to monitor or control digital signals on some C Series I/O

modules. Each DIO line can be individually configured as a digital input

(DI) or digital output (DO), depending on the C Series I/O module being

used.

All samples of static DI lines and updates of static DO lines are

software-timed.

Digital

Waveform/Change

1

Counter/Timer

1

Detection

1

Digital Waveform Acquisition (Correlated Input)

You can acquire digital waveforms using correlated digital modules in

slots 1 through 4. The DI waveform acquisition FIFO stores the digital

samples. The NI cDAQ-9172 chassis samples the DIO lines on each rising

or falling edge of the di/SampleClock signal.

DI Sample Clock Signal

Use the DI Sample Clock (di/SampleClock) signal to sample digital I/O on

slots 1 through 4, using correlated digital modules, and store the result in

the DI waveform acquisition FIFO. The NI cDAQ-9172 chassis does not

have an independent DI Sample Clock circuit. Therefore, you must route

an external signal or one of many internal signals from another subsystem

to function as the DI Sample Clock. For example, you can correlate digital

and analog samples in time by setting the AI Sample Clock or AO Sample

Clock as the source of the DI Sample Clock. To sample a digital signal

independent of an AI, AO, or DO operation, you can configure a counter

to generate the desired DI Sample Clock or use an external signal as the

source of the DI Sample Clock.

If the NI cDAQ-9172 chassis receives a di/SampleClock signal when the

FIFO is full, it reports an overflow error to the host software.

NI cDAQ-9172 User Guide and Specifications 36 ni.com

Page 37

Using an Internal Source

To use di/SampleClock with an internal source, specify the signal source

and the polarity of the signal. Use the following signals as the source:

• AI Sample Clock

• AI Convert Clock

• AO Sample Clock

• Counter n Internal Output

•Frequency Output

• DI Change Detection Output

Several other internal signals can be routed to di/SampleClock. Refer to the

Device Routing in MAX topic in the NI-DAQmx Help or the LabVIEW Help

in version 8.0 or later for more information.

The NI-DAQmx Help is available after installation from Start»

All Programs»National Instruments»NI-DAQ»NI-DAQmx Help.

To view the LabVIEW Help, in version 8.0 or later, select Help»

Search the LabVIEW Help in LabVIEW. Alternately, to download

the LabVIEW Help, go to

ni.com/manuals.

Using an External Source

You can route the following signals as di/SampleClock:

•Any PFI terminal

• Analog Comparison Event (an analog trigger)

You can sample data on the rising or falling edge of di/SampleClock.

Routing DI Sample Clock to an Output Terminal

You can route di/SampleClock to any output PFI terminal. The PFI

circuitry inverts the polarity of di/SampleClock before driving the PFI

terminal.

Digital Waveform Generation (Correlated Output)

With a hardware-timed generation, a digital hardware signal controls the

rate of the generation. This signal can be generated internally on the chassis

or provided externally.

Hardware-timed generations have several advantages over software-timed

acquisitions:

• The time between samples can be much shorter.

• The timing between samples can be deterministic.

Hardware-timed operations must be buffered.

© National Instruments Corporation 37 NI cDAQ-9172 User Guide and Specifications

Page 38

Buffered Digital Waveform Generation

A buffer is a temporary storage in computer memory for generated

samples. In a buffered generation, data is moved from a host buffer to the

NI cDAQ-9172 onboard FIFO before it is written to the C Series I/O

modules. Buffered generations typically allow for much faster transfer

rates than nonbuffered generations because data is moved in large blocks,

rather than one point at a time. The DO sample clock causes all lines in the

task to update at the same time.

One property of buffered I/O operations is the sample mode. The sample

mode can be either finite or continuous:

• Finite—Finite sample mode generation refers to the generation of a

specific, predetermined number of data samples. After the specified

number of samples has been written out, the generation stops.

• Continuous—Continuous generation refers to the generation of an

unspecified number of samples. Instead of generating a set number of

data samples and stopping, a continuous generation continues until

you stop the operation. There are several different methods of

continuous generation that control what data is written. These methods

are regeneration, onboard regeneration, and non-regeneration modes:

– In regeneration mode, you define a buffer in host memory. The

data from the buffer is continually downloaded to the FIFO to be

written out. New data can be written to the host buffer at any time

without disrupting the output.

– With onboard regeneration, the entire buffer is downloaded to the

FIFO and regenerated from there. After the data is downloaded,

new data cannot be written to the FIFO. To use onboard

regeneration, the entire buffer must fit within the FIFO size. The

advantage of using on board regeneration is that it does not require

communication with the main host memory once the operation is

started, thereby preventing any problems that may occur due to

excessive bus traffic or operating system latency.

– With non-regeneration, old data is not repeated. New data must be

continually written to the buffer. If the program does not write new

data to the buffer at a fast enough rate to keep up with the

generation, the buffer underflows and causes an error.

NI cDAQ-9172 User Guide and Specifications 38 ni.com

Page 39

Change Detection Event

The Change Detection Event is the signal generated when a change on the

rising or falling edge lines is detected by the change detection task.

Routing Change Detection Event to an Output Terminal

You can route ChangeDetectionEvent to any output PFI terminal.

Change Detection Acquisition

You can configure lines on correlated digital modules in slots 1 through 4

to detect rising or falling edges. When one or more of these lines sees the

edge specified for that line, the NI cDAQ-9172 chassis samples all the lines

in the task. The rising and falling edge lines do not necessarily have to be

in the task.

Change detection acquisitions can be buffered or nonbuffered:

• Nonbuffered Change Detection Acquisition—In nonbuffered

acquisitions, correlated digital input modules in any slot may be in the

task, but the rising/falling edge detection lines must be in slots 1

through 4.

• Buffered Change Detection Acquisition—A buffer is a temporary

storage in computer memory for acquired samples. In a buffered

acquisition, data is stored in the NI cDAQ-9172 onboard FIFO then

transferred to a PC buffer. Buffered acquisitions typically allow for

much faster transfer rates than nonbuffered acquisitions because data

accumulates and is transferred in blocks, rather than one sample at a

time. With buffered acquisitions, all modules in the task must be in

slots 1 through 4.

Digital Input/Output Configuration for NI 9401

When you change the configuration of lines on a NI 9401 digital I/O

module between input and output, NI-DAQmx temporarily reserves all

of the lines on the module for communication to send the module a line

configuration command. If another task or route is actively using the

module, to avoid interfering with the other task, NI-DAQmx generates an

error instead of sending the line configuration command. During the line

configuration command, the output lines are maintained without glitching.

© National Instruments Corporation 39 NI cDAQ-9172 User Guide and Specifications

Page 40

PFI

Counters

You can configure channels of a correlated digital module in slots 5 and 6

as Programmable Function Interface (PFI) terminals.

You can configure each PFI individually as the following:

• Static digital input

• Static digital output

• Timing input signal for AI, AO, DI, DO, or counter/timer functions

• Timing output signal from AI, AO, DI, DO, or counter/timer functions

Each PFI input also has a programmable digital filter circuit that is

configurable on a per-line basis. The filters allow the rejection of noise

caused by noisy environments, bounces on switches, and so on. Refer to the

NI-DAQmx Help for more information. The NI-DAQmx Help is available

after installation from Start»All Programs»National Instruments»

NI-DAQ»NI-DAQmx Help.

The NI cDAQ-9172 chassis has two general-purpose 32-bit counter/timers

and one frequency generator, as shown in Figure 15. The general-purpose

counter/timers can be used for many measurement and pulse generation

applications.

Some counter/timer signals may be routed to PFI signals. To access

PFI signals, you must use a correlated digital I/O C Series module in

slot 5 and/or 6.

Note For more information about C Series signal connections for counters, refer to

the NI-DAQmx Help. The NI-DAQmx Help is available after installation from Start»

All Programs»National Instruments»NI-DAQ»NI-DAQmx Help.

NI cDAQ-9172 User Guide and Specifications 40 ni.com

Page 41

Input Selection Muxes

Counter 0

Counter 0 Source (Counter 0 Timebase)

Input Selection Muxes

Input Selection Muxes

Counter 0 Gate

Counter 0 Aux

Counter 0 HW Arm

Counter 0 A

Counter 0 B (Counter 0 Up_Down)

Counter 0 Z

Counter 1 Source (Counter 1 Timebase)

Counter 1 Gate

Counter 1 Aux

Counter 1 HW Arm

Counter 1 A

Counter 1 B (Counter 1 Up_Down)

Counter 1 Z

Frequency Generator

Counter 0 Internal Output

Counter 1

Counter 1 Internal Output

Counter 0 TC

Counter 1 TC

Frequency Output Timebase Freq Out

Figure 15. NI cDAQ-9172 Counters

Counters have seven input signals, although in most applications only a few

inputs are used.

For information about connecting the counter signals, refer to the Default

Counter/Timer Routing section. The following sections describe various

counter applications.

© National Instruments Corporation 41 NI cDAQ-9172 User Guide and Specifications

Page 42

Counter Input Applications

Counting Edges

In edge counting applications, the counter counts edges on its Source after

the counter is armed. You can configure the counter to count rising or

falling edges on its Source input. You also can control the direction of

counting (up or down).

The counter values can be read on demand or with a sample clock.

Single-Point (On-Demand) Edge Counting

With single-point (on-demand) edge counting, the counter counts the

number of edges on the Source input after the counter is armed. On-demand

refers to the fact that software can read the counter contents at any time

without disturbing the counting process. Figure 16 shows an example of

single-point edge counting.

Counter Value 1 0 5 4 3 2

Counter Armed