Page 1

USER GUIDE AND SPECIFICATIONS

NI 9683

General Purpose Inverter Controller RIO Mezzanine Card

This document provides pinouts, connectivity information, and specifications for the National

Instruments 9683 General Purpose Inverter Control (GPIC) RIO Mezzanine Card (RMC).

Caution National Instruments makes no product safety, electromagnetic

compatibility (EMC), or CE marking compliance claims for the NI 9683. The

end-product supplier is responsible for conformity to any and all compliance

requirements.

Caution The NI 9683 must be installed inside a suitable enclosure prior to use.

Hazardous voltages may be present.

Caution Exercise caution when placing the NI 9683 inside an enclosure. Auxiliary

cooling may be necessary to keep the device under the maximum ambient

temperature rating for the NI 9683. Refer to the Specifications section for more

information about the maximum ambient temperature rating.

Caution The NI 9683 is designed for low voltage signals. You must ensure that all

signals connected to the NI 9683 are isolated and no unsafe voltages are present at

the NI 9683 inputs. Voltages that exceed the specifications could result in damage to

the NI 9683.

Caution Use the NI 9683 with only NI sbRIO-9605/9606 devices. The NI 9683 is

not electrically or mechanically compatible with other NI sbRIO devices.

Caution Do not operate the NI 9683 in a manner not specified in this user guide.

Product misuse can result in a hazard. You can compromise the safety protection built

into the product if the product is damaged in any way. If the product is damaged,

return it to National Instruments for repair.

Page 2

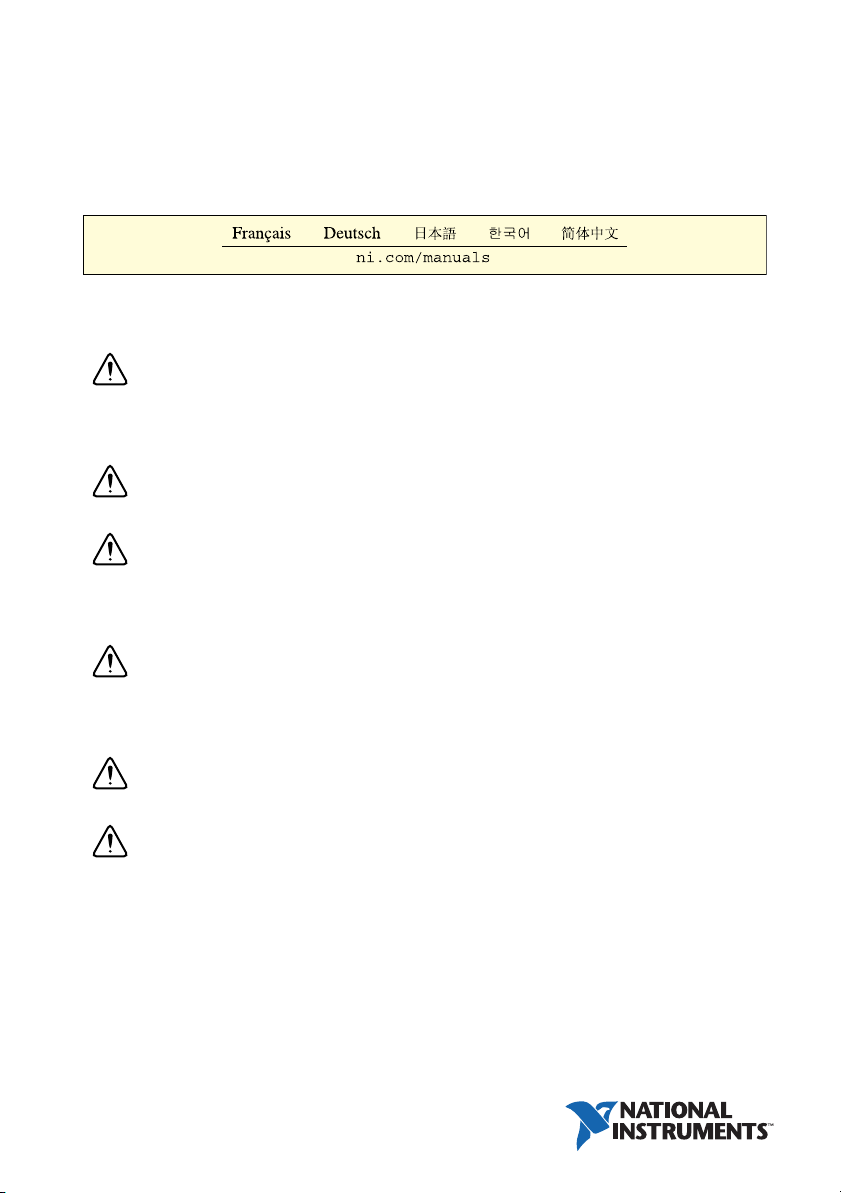

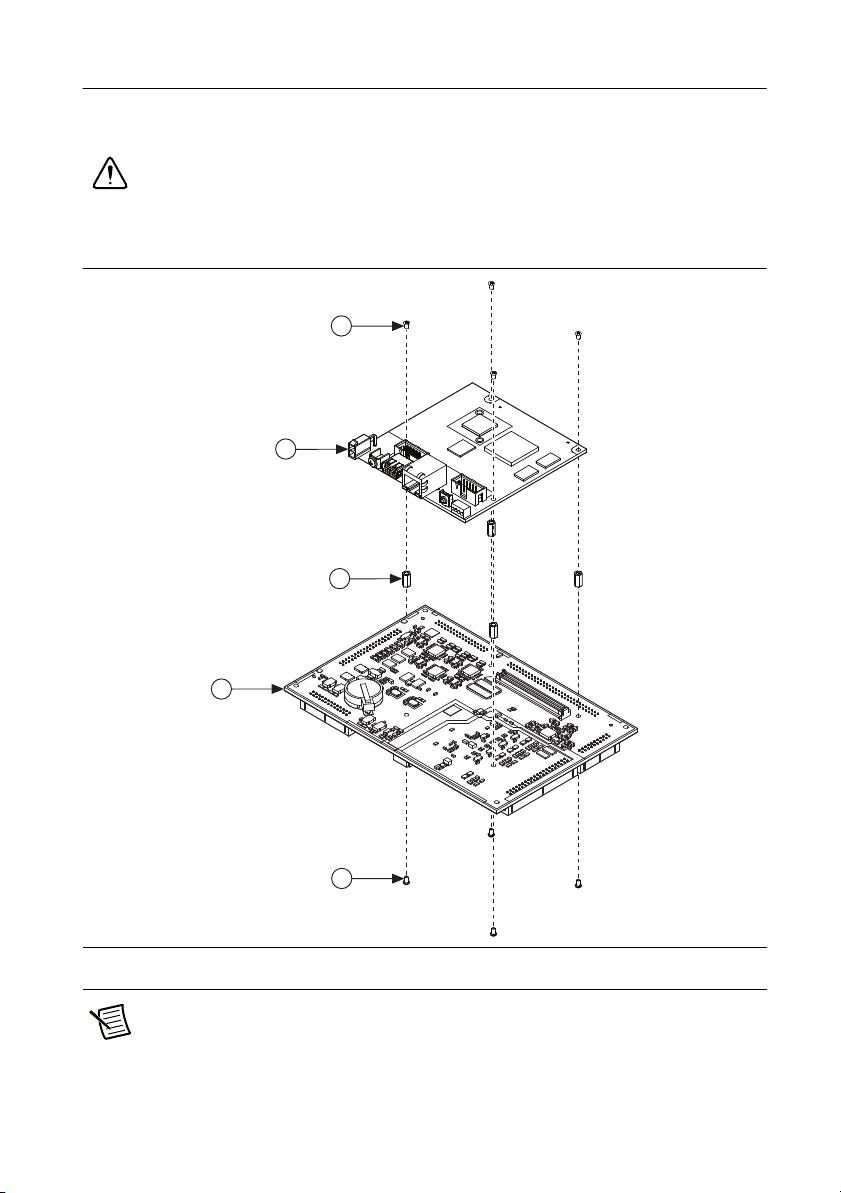

Figure 1. NI 9683 Parts Locator Diagram

1

2

7

5

9

3

4

6

8

1 Primary Side

2 Secondary Side

3 LVTTL DIO

4 Sourcing DI

5 Sinking DO and Relay Control DO

6 Half-bridge DO

Dimensions

Figures 2 through 4 show dimensional drawings of the NI 9683.

Figure 2. NI 9683 Primary Side Dimensions in Millimeters (Inches)

114.3 (4.500)

111.1 (4.374)

109.22 (4.300)

93.32 (3.674)

91.67 (3.609)

23.57 (0.928)

21.59 (0.850)

11.81 (0.465)

0.00 (0.000)

–5.08 (–0.200)

0.00 (0.000)

–5.08 (–0.200)

–1.88 (–0.074)

32.26 (1.270)

49.05 (1.931)

71.76 (2.825)

7 Simultaneous AI

8 Scanned AI and AO

9 sbRIO Mezzanine Connector

108.59 (4.275)

145.39 (5.724)

162.05 (6.380)

169.67 (6.680)

174.75 (6.880)

2 | ni.com | NI 9683 User Guide and Specifications

Page 3

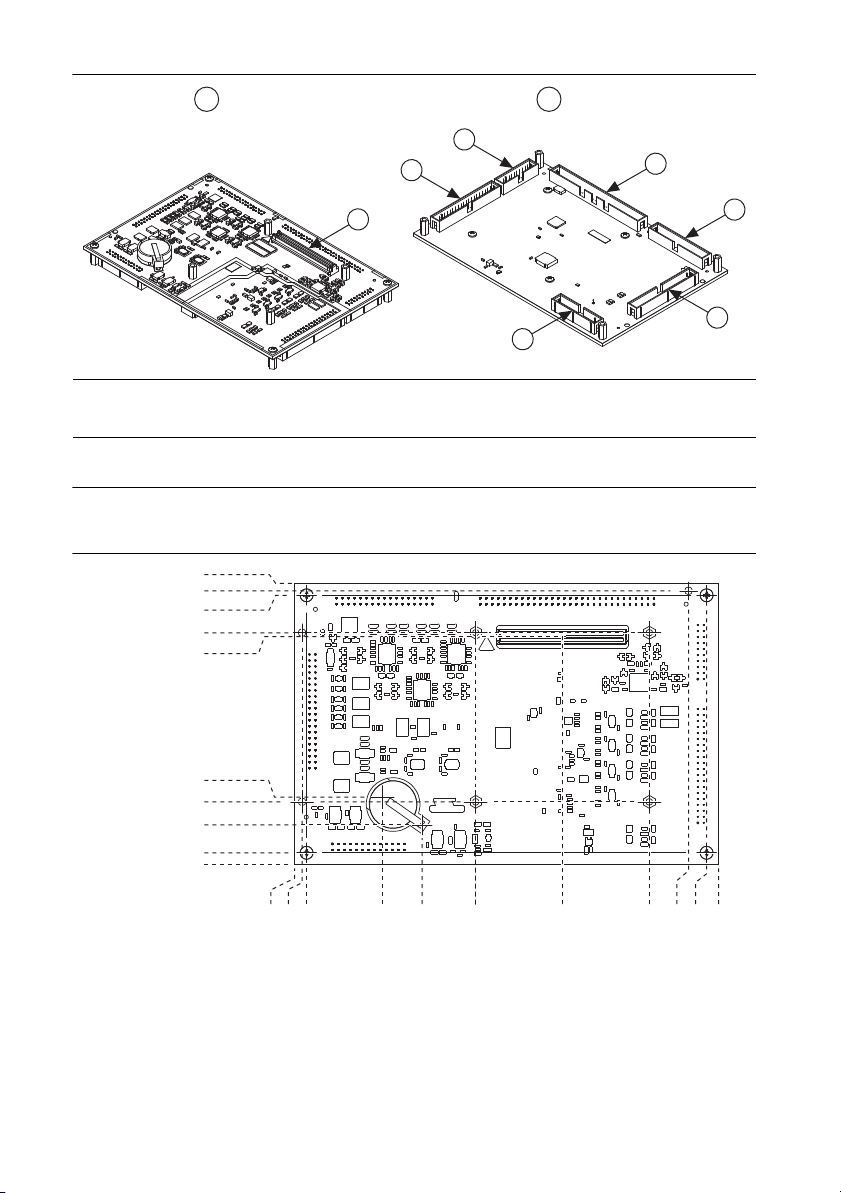

Figure 3. NI 9683 Secondary Side Dimensions in Millimeters (Inches)

105.46 (4.152)

84.12 (3.312)

73.66 (2.900)

12.70 (0.500)

165.91 (6.532)

53.34 (2.100)

10.92 (0.430)

147.32 (5.800)

3.76 (0.148)

0.00 (0.000)

–5.08 (–0.200)

3.76 (0.148)

0 (0.000)

–5.08 (–0.200)

11x Ø 3.30 (0.130)

9.98 (0.393)

Figure 4. NI 9683 Maximum Height of Components in Millimeters (Inches)

Note For more information about the dimensions of the NI 9683, including

two-dimensional drawings and three-dimensional models, go to

dimensions

.

NI 9683 User Guide and Specifications | © National Instruments | 3

ni.com/

Page 4

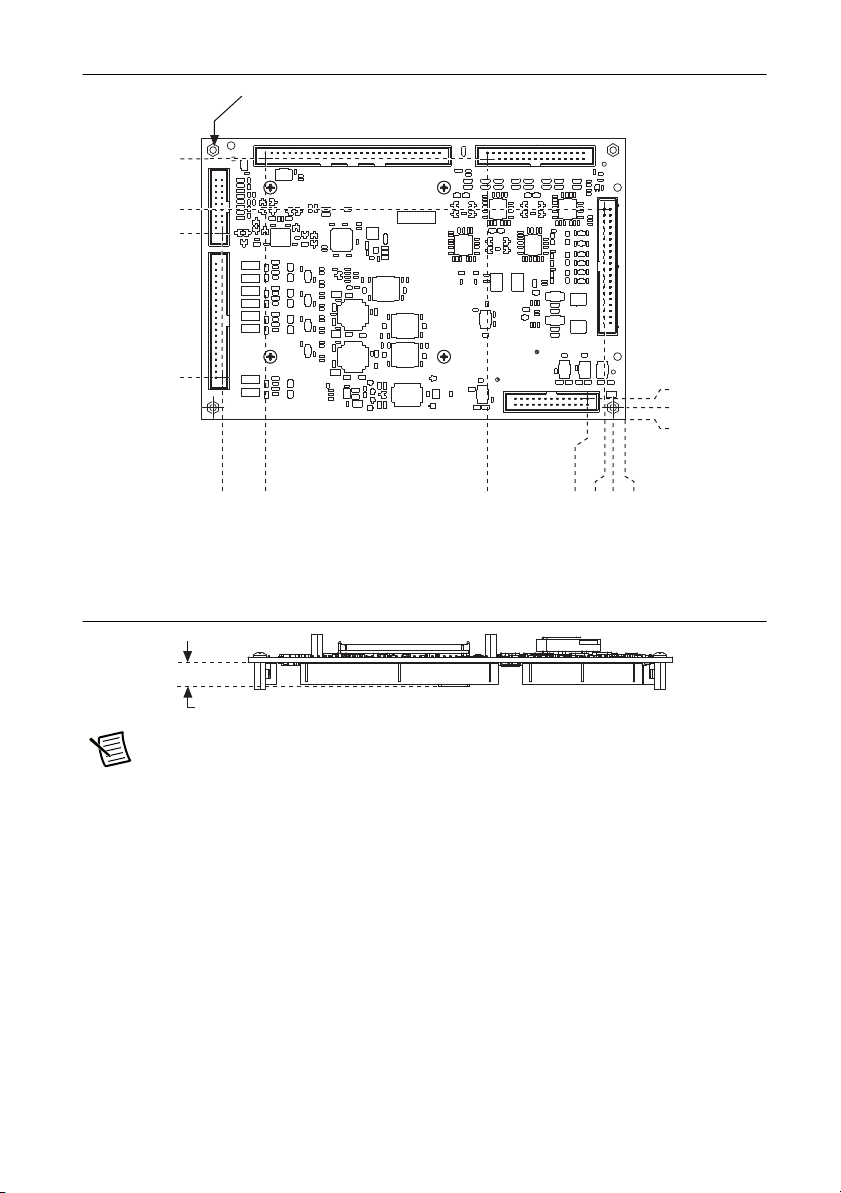

Typical NI 9683 System

Figure 5 shows a typical NI 9683 system.

Figure 5. Typical NI 9683 System

6

5

1

2

4

3

1 Enclosure. The NI 9683 must be installed inside a suitable enclosure.

2 NI sbRIO-9605/9606. Use the NI 9683 with only NI sbRIO-9605/9606 sbRIO devices.

3 NI 9683.

4 Interface board. The NI 9683 specifications assume direct board-to-board connections. Refer the Selecting

a Wire Gauge for Relay Control Digital Outputs section for information about designing ribbon cables to

meet the relay control DO specifications on the NI 9683.

5 Local ambient temperature location. The local ambient temperature is the operating temperature of the

NI 9683 inside the enclosure. Refer to the Environmental section for more information about the operating

temperature.

6 Ambient temperature location. The ambient temperature is the operating temperature outside of the

enclosure. Refer to the Environmental section for more information about the operating temperature.

4 | ni.com | NI 9683 User Guide and Specifications

Page 5

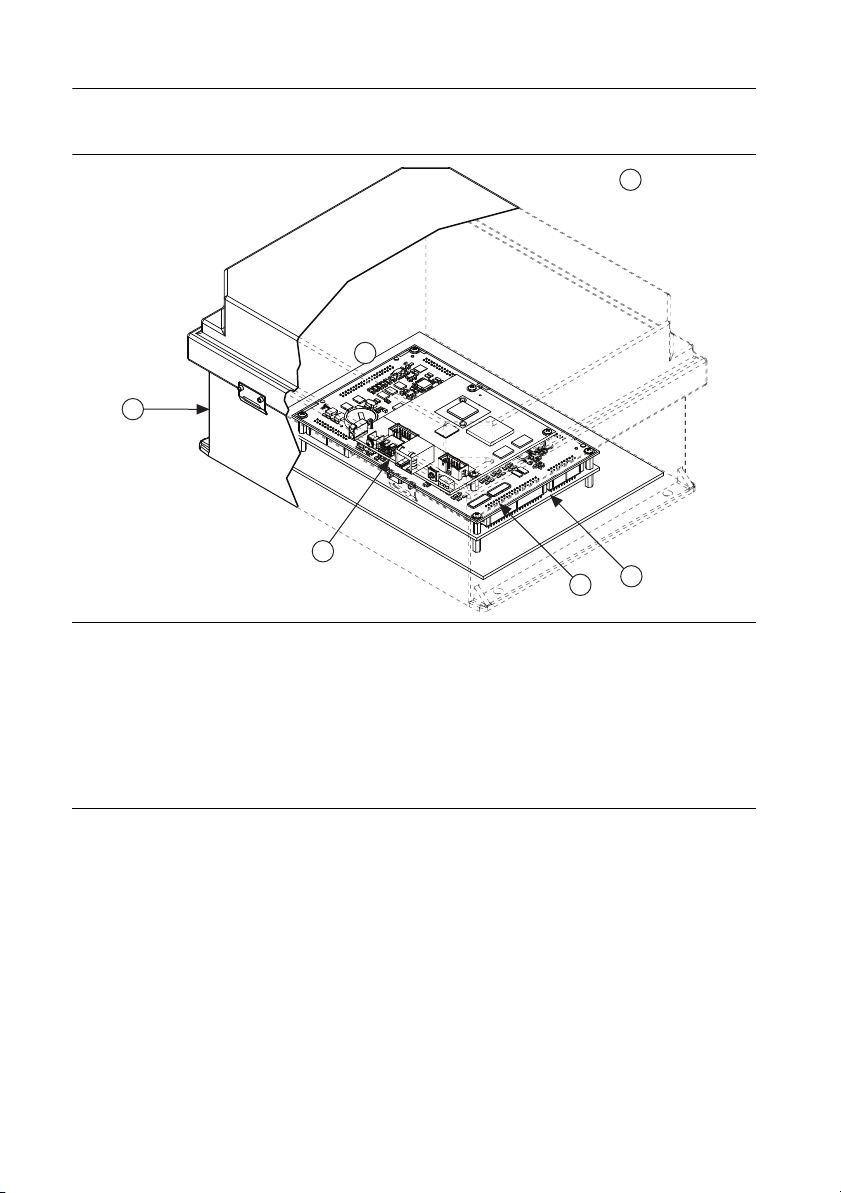

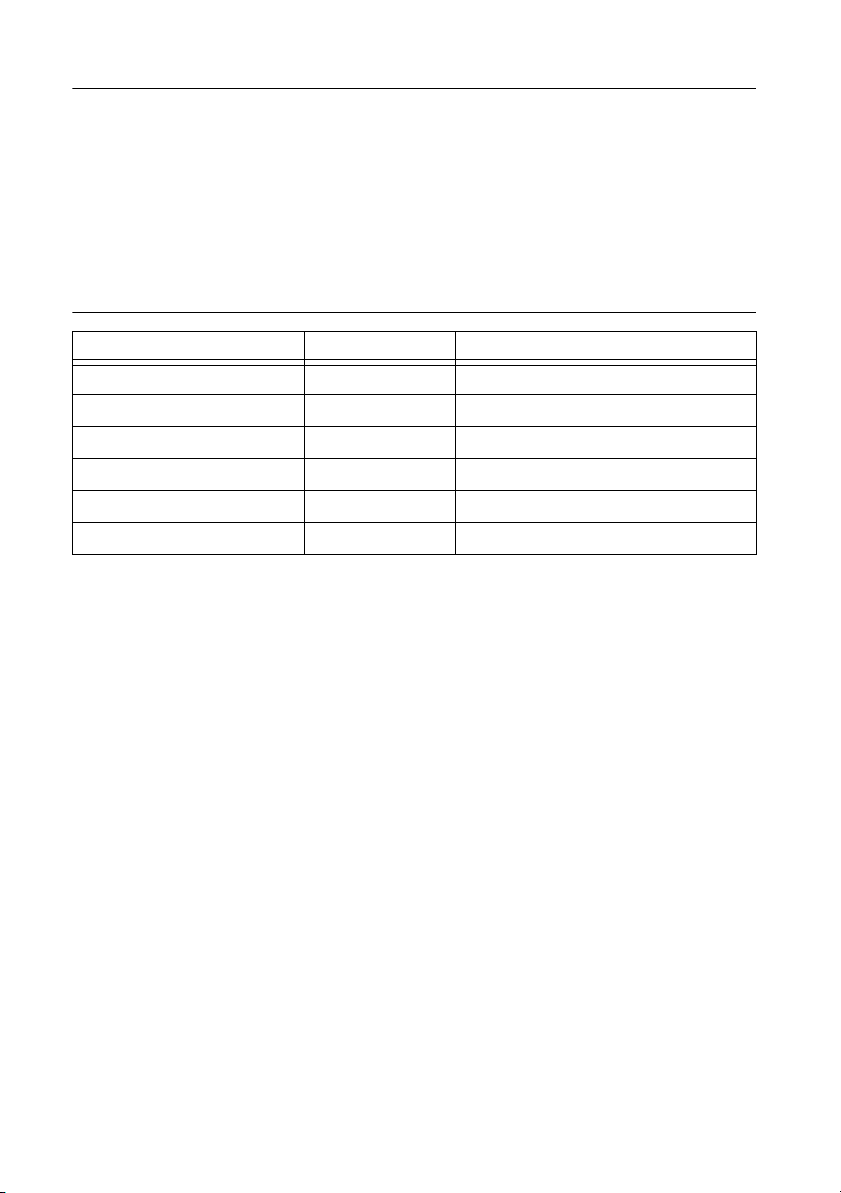

Mating the NI 9683 to the NI sbRIO-9605/9606

Figure 6 shows how to mate the NI 9683 to the NI sbRIO-9605/9606. Ensure that the

NI sbRIO-9605/9606 is powered off before connecting the NI 9683.

Caution You must use the standoffs specified below when mating the NI 9683 to

the NI sbRIO-9605/9606 to properly seat the sbRIO mezzanine connectors and

prevent damaging the device.

Figure 6. Mating the NI 9683 to the NI sbRIO-9605/9606

1

2

3

4

1 4-40 × 0.250 in. Screw (×8)

2 NI sbRIO-9605/9606

Note The screws include a nylon patch to prevent them from loosening when

subject to vibration. NI recommends using a 3/16 in. socket and Phillips screwdriver

when mating the NI 9683 to the NI sbRIO-9605/9606 to ensure the screw installs in

the standoff correctly.

1

3 4-40 × 0.380 in. Standoff (×4)

4 NI 9683

NI 9683 User Guide and Specifications | © National Instruments | 5

Page 6

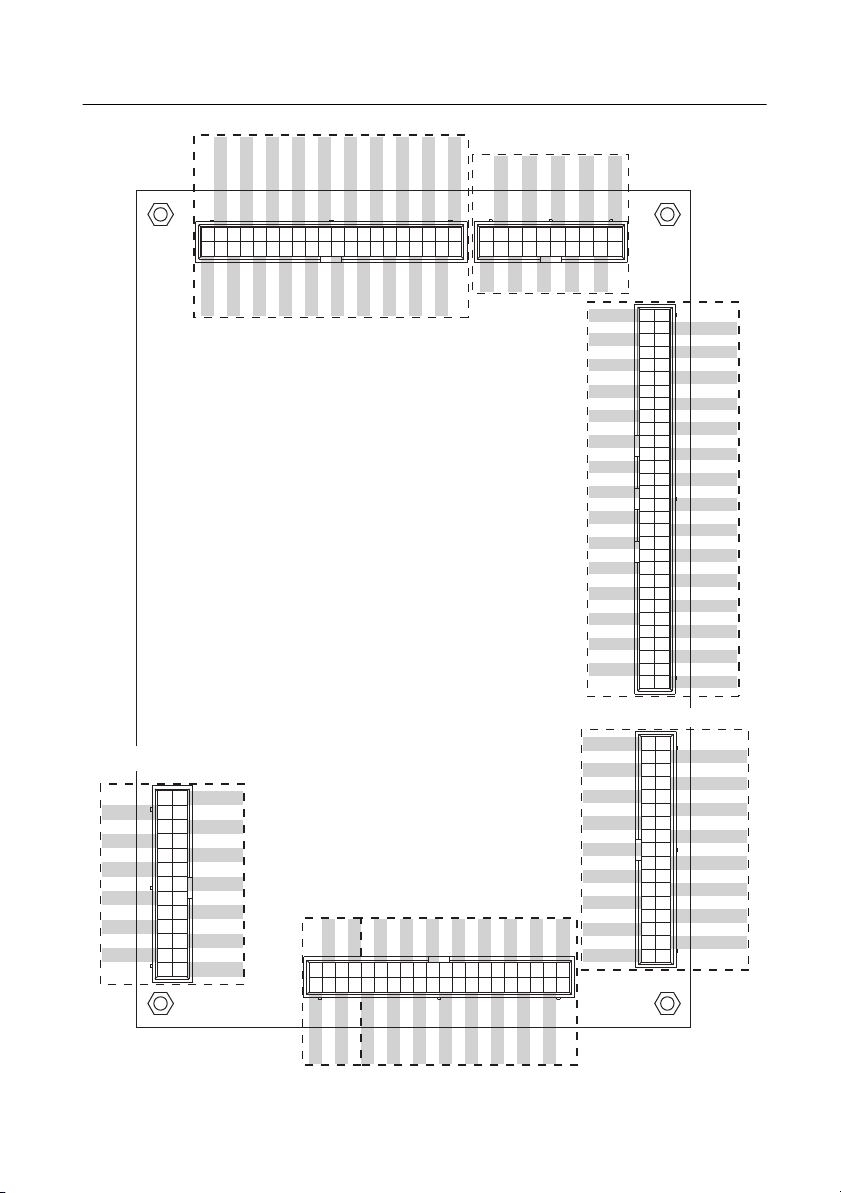

Connecting the NI 9683

The NI 9683 provides connections for 16 simultaneous analog input channels, 8 scanned analog

input channels, 8 analog output channels, 28 sourcing digital input channels, 14 half-bridge

digital output channels, 24 sinking digital output channels, 4 relay control digital output

channels, and 32 LVTTL digital input/output channels.

Table 7 lists and describes the connectors on the NI 9683 and the part number and manufacturer

of each connector. Refer to the manufacturer for information about using and matching these

connectors.

Figure 7. NI 9683 Connector Descriptions

Connector Description Recommended Mating Connector

Simultaneous AI 40-position header On-Shore Technology, Inc. (SH2-40G-PT)

Scanned AI, AO 20-position header On-Shore Technology, Inc. (SH2-20G-PT)

Sourcing DI 34-position header On-Shore Technology, Inc. (SH2-34G-PT)

Sinking DO, Relay Control DO 40-position header On-Shore Technology, Inc. (SH2-40G-PT)

Half-Bridge DO 26-position header On-Shore Technology, Inc. (SH2-26G-PT)

LVTTL DIO 60-position header On-Shore Technology, Inc. (SH2-60G-PT)

6 | ni.com | NI 9683 User Guide and Specifications

Page 7

Figure 8 shows the NI 9683 pin assignments.

Figure 8. NI 9683 Pin Assignments

AI14–

AI15–

4 3

21

AI14+

AI15+

AI12–

AI13–

8

65

7

AI12+

AI13+

AI11–

10

9

AI11+

Simultaneous AI

AI6–

AI7–

AI8–

AI9–

AI10–

18

161412

20

17

151311

19

AI6+

AI7+

AI8+

AI9+

AI10+

AI5–

AI5+

AI4–

AI4+

AI1–

AI2–

AI3–

28

262422

30

27

252321

29

AI1+

AI2+

AI3+

AI0–

31

AI0+

CS COM

CS COM

363432

33

35

CS COM

CS COM

CS COM

CS COM

38

40

37

39

CS COM

CS COM

Scanned AI & AO

AO6

AO7

AI6

AO0

AO2

GND

AO4

10

8

642

7

531

9

AI7

AO1

AO3

GND

AO5

AI4

AI5

GND

161412

151311

GND

+3.3 V

+3.3 V

DIO 31

DIO 30

GND

DIO 27

DIO 26

GND

DIO 23

DIO 22

GND

DIO 19

DIO 18

GND

DIO 15

DIO 14

DIO 13

DIO 12

DIO 11

DIO 10

DIO 9

DIO 8

DIO 7

DIO 6

DIO 5

DIO 4

DIO 3

DIO 2

DIO 1

DIO 0

AI2

18

17

AI3

AI0

20

19

AI1

LVTTL

1

3

5

7

10

9

12

11

14

13

16

15

18

17

20

19

22

21

24

23

26

25

28

27

30

29

32

31

34

33

36

35

38

37

40

39

42

41

44

43

46

45

48

47

50

49

52

51

54

53

56

55

58

57

60

59

2

GND

4

GND

6

GND

8

DIO 29

DIO 28

GND

DIO 25

DIO 24

GND

DIO 21

DIO 20

GND

DIO 17

DIO 16

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

Half-Bridge

DO0

DO1

DO2

DO3

DO4

DO5

DO6

GND

GND

GND

GND

GND

Vex t

DO

26

24

22

20

18

16

14

12

10

8

6

4

2

Sourcing DI

1

NC

VI P1

DI P1.13

DI P1.11

DO20

DO18

3

579

4

6

DO21

DO19

DO22

1

2

DO23

DI P1.9

DI P1.7

DI P1.5

DI P1.3

DI P1.1

DI P0.13

DI P0.11

DI P0.9

DI P0.7

DI P0.5

DI P0.3

DI P0.1

VI P0

25

GND

23

GND

21

GND

19

GND

17

GND

15

GND

13

DO7

11

DO8

9

DO9

7

DO10

5

DO11

3

DO12

1

DO13

Relay

Control

DO

DO2+

DO1+

DO0+

37 38

3940

DO2–

DO1–

DO0–

Sinking DO

DO8

GND

DO6

DO4

DO2

DO0

NC

NC

DO3+

NC

23

252729

NC

DO1

21

24

262830

22

DO9

GND

DO7

DO5

DO3

31

32

33

35 36

34

DO3–

DO12

DO10

151719

161820

DO13

DO11

13

14

GND

DO14

11

10

12

GND

DO15

DO16

8

DO17

2

NC

3

4

GND

5

6

DI P1.12

7

9

DI P1.10

9

10

DI P1.8

11

12

DI P1.6

13

14

DI P1.4

15

16

DI P1.2

17

18

DI P1.0

19

20

DI P0.12

21

22

DI P0.10

23

24

DI P0.8

25

26

DI P0.6

27

28

DI P0.4

29

30

DI P0.2

31

32

DI P0.0

33

34

GND

NI 9683 User Guide and Specifications | © National Instruments | 7

Page 8

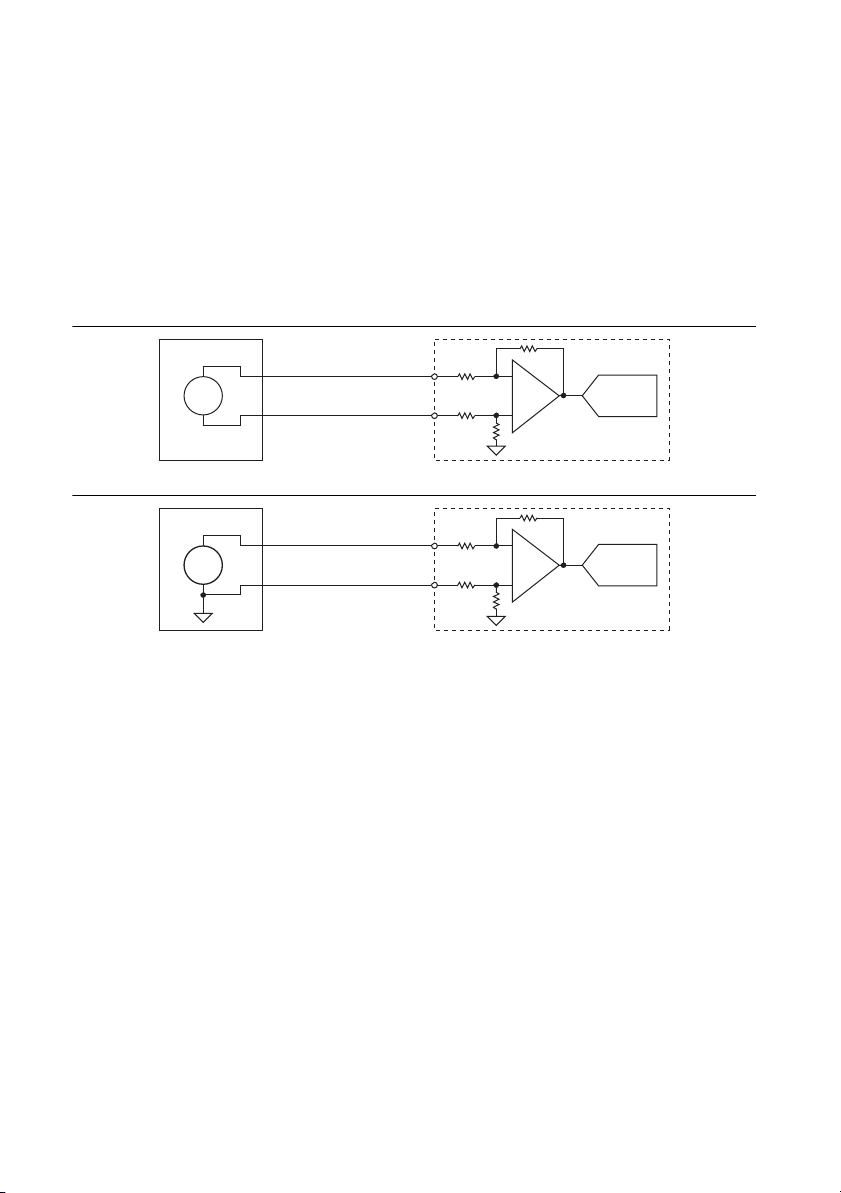

Simultaneous Analog Input

NI 9683

Simultaneous AI+

Simultaneous AI–

Isolated

ADC

Voltage Source

+

–

NI 9683

Simultaneous AI+

Simultaneous AI–

Isolated

ADC

Voltage Source

+

–

The NI 9683 provides connections for 16 pseudo-differential analog input channels.

Each channel has an AI+ and AI- pin to which you can connect a voltage signal. AI- is internally

connected to the isolated ground reference through a high value resistor.

Connecting Differential and Single-Ended Voltage Signals to the NI 9683

You can connect grounded or floating signal sources to the NI 9683. Connect the positive

voltage signal to AI+ and the negative voltage signal to the AI-.

Figure 9. Connecting a Differential Voltage Signal to a Simultaneous AI Channel

Figure 10. Connecting a Single-Ended Voltage Signal to a Simultaneous AI Channel

NI 9683 Circuitry

The NI 9683 analog channels share a common ground that is isolated from other parts of the

board. The NI 9683 protects each channel from overvoltages. Refer to the Specifications section

for more information about overvoltage protection. The incoming analog signal on each channel

is buffered and conditioned by the differential amplifier and then sampled by a 12-bit ADC.

Each channel has an independent track-and-hold amplifier and ADC that allow you to sample

and convert all 16 channel simultaneously.

Connecting Current Sensors to the NI 9683

You can connect current sensors to the NI 9683 using a termination resistor to convert the current

measurement to a single-ended voltage measurement.

Connect the current sensor output to AI+ and the external power supply COM to the current

sensor common pin (CS COM) on the NI 9683.

8 | ni.com | NI 9683 User Guide and Specifications

Page 9

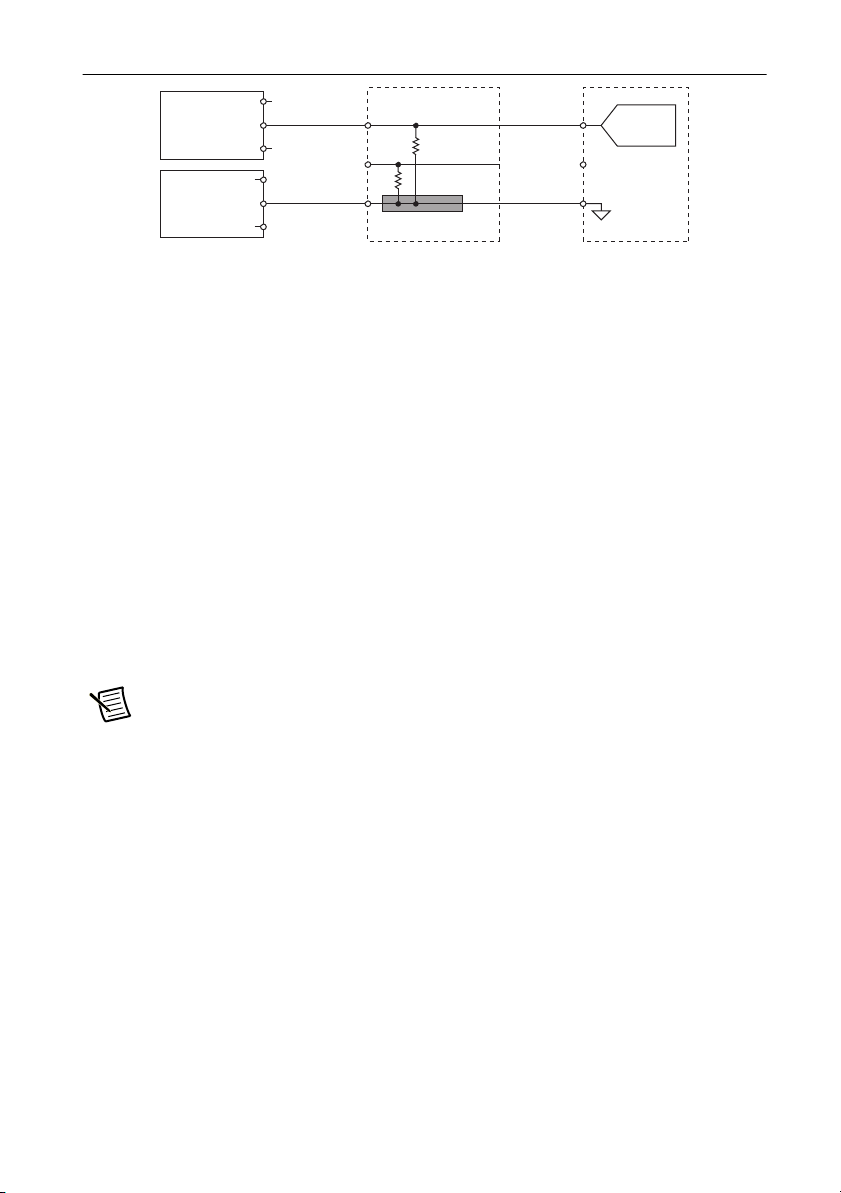

Figure 11. Connecting a Current Sensor to the NI 9683

NI 9683

Interface Board

Termination

Resistor

AI0+OUT

PS–

PS+

PS–

PS+

AI1+

CS COMCOM

Isolated

ADC

Current

Sensor

External

Powe r

Supply

R

max

5V

I_peak

max

--------------------------=

R

max

5V

0.07A

-------------- 71Ω==

To avoid the affect of common mode impedance on the measurement, connect one end of all the

termination resistors to a single, small plane. Then have a single connection from the plane to

the CS COM pin of the NI 9683.

The NI 9683 simultaneous analog inputs have ±10 V and ±5 V input ranges that can

accommodate termination resistor values in a certain range, based on the sensor peak current.

Select the highest possible termination resistor to maximize the dynamic range of the analog

input. Refer to the Specifications section for more information about the analog input range. Use

the following equation to determine the maximum value for the terminal resistor based on the

sensor peak current.

For a current sensor with a peak output current of 70 mA, the maximum termination resistor that

can be used with the NI 9683 is as follows:

Note Using the ±5 V input range can reduce the power dissipation on the

termination resistor by 50% when compared to the power dissipation of the ±10 V

input range.

Scanned Analog Input (Monitoring)

The NI 9683 provides connections for 8 single-ended scanned analog input channels.

Each channel has an AI pin to which you can connect a voltage signal. Scanned analog input and

scanned analog output channels share four GND pins on the dedicated 20-position connector.

NI 9683 User Guide and Specifications | © National Instruments | 9

Page 10

Figure 12. Connecting Single-Ended Voltage Signals to the Scanned Analog Inputs

NI 9683

ADCMUX

Scanned AI0

.

.

.

Scanned AI7

GND

Voltage Source

+

–

+

–

Scanned Analog Inputs Accuracy and Bandwidth

Use signal sources with an output impedance of less than 2 kΩ to ensure specified performance.

Large source impedances add to the input resistor inside the NI 9683, which results in increased

settling time and decreases the accuracy of the measurement. Increased input impedance also

results in a decrease of the -3 dB bandwidth.

Half-Bridge Digital Output

The NI 9683 provides connections for 14 half-bridge digital output channels.

Each channel has an half-bridge DO pin to which you can connect a digital input device. An

external power supply referenced to ground of the board must be connected to V

Figure 13. Connecting a Digital Device to a Half-Bridge DO Channel

.

ext

The NI 9683 has push-pull half-bridge digital outputs, meaning the NI 9683 can sink or source

current. When the channel is ON, the half-bridge DO pin is driven to the external power supply

minus a voltage drop due to the sourced current. When the channel is turned OFF, the half-bridge

DO pin is driven to ground plus a voltage drop due to the sinked current.

10 | ni.com | NI 9683 User Guide and Specifications

Vext

100 Ω

Half-Bridge DO

GND

NI 9683

Note Make sure the devices you connect to the NI 9683 are compatible with the

Device

half-bridge digital output specifications. Use connections that match the output

impedance of the NI 9683 half-bridge outputs. Refer to the Specifications section for

information about output voltages.

Page 11

Sinking Digital Output

NI 9683

Sinking DO

Device

Vcc

The NI 9683 provides connections for 24 sinking digital output channels.

Each channel has a sinking DO pin to which you can connect a digital input device. Sinking DO

pins have dedicated current return pins, GND, which are referenced to the ground of the board.

Figure 14. Connecting a Digital Device to a Sinking DO Channel

The NI 9683 has current sinking digital outputs, meaning that the output pin is driven to ground

(GND) when the channel is ON.

Make sure the devices you connect to the NI 9683 are compatible with the output specifications.

Refer to the Specifications section for information about output voltages.

Increasing Current Drive

Each channel has a continuous output current of 20 mA. If you want to increase the output

current to a device, you can connect any number of channels together in parallel. For example,

if you want to drive 80 mA of current, connect DO<0..3> in parallel as shown in Figure 15. You

must turn all parallel channels on and off simultaneously so that the current on any single

channel cannot exceed the 20 mA rating.

Figure 15. Increasing the Current to a Device Connected to the NI 9683

NI 9683

Sinking DO0

Sinking DO1

Sinking DO2

Sinking DO3

20 mA

20 mA

20 mA

20 mA

GND

NI 9683 User Guide and Specifications | © National Instruments | 11

80 mA

Device

+

_

External

Power

Supply

Page 12

Relay Control Digital Output

NI 9683

Relay Control DO+

Relay Control DO–

VDC1

VDC2

VDC3

VCM

+

–

Load

Relay Control DO+

Relay Control DO–

+

–

Load

Relay Control DO+

Relay Control DO–

+

–

Load

+

–

The NI 9683 provides connections for four relay control digital output channels. Each channel

has a relay control DO+ and a current return pin, relay control DO-.

The NI 9683 has current sinking outputs, meaning the relay control DO+ is driven to relay

control DO- when the channel is ON.

You can connect industrial devices such as solenoids, actuators, relays, and lamps to the NI 9683.

Refer to Figure 16 for an illustration of how to connect devices to the NI 9683.

Figure 16. Connecting an Industrial Device to a Relay Control DO Channel

Note Ensure that all the relay control DO+/- pins are held within the safety voltage

levels. A maximum common mode voltage of 30 VDC is allowed at a relay control

DO+/- pin with respect to the GND of the NI 9683. Refer to the Safety section for

maximum voltages allowed for the relay control DO channels.

Note NI recommends using the appropriate cabling for the current return pins

based on the amount of current returned per each relay control DO- output. Refer to

the Specifications section for information about peak and continuous current limits

based on the update rate.

Make sure the devices you connect to the NI 9683 are compatible with the output specifications.

Refer to the Specifications section for information about output voltages.

12 | ni.com | NI 9683 User Guide and Specifications

Page 13

Protecting the Relay Control Digital Outputs from Flyback Voltages

If the NI 9683 is switching an inductive or energy-storing device such as a solenoid, motor, or

relay and the device does not have flyback protection, install a flyback diode.

Figure 17. Connecting a Flyback Diode to a Relay Control DO Channel

Flyback

Diode

External

+

Powe r

–

Supply

NI 9683

Relay Control DO+

Relay Control DO–

Inductive

Device

Selecting a Wire Gauge for Relay Control Digital Outputs

The relay control digital output is capable of sinking 8 A of inrush current for a period of 300 ms

on a 60 second cycle and 500 mA of continuous current. Each channel is functionally isolated

from the other channels and the rest of the board, meaning that each relay control digital output

has a dedicated current return pin.

When using cables, make sure the current rating of the cable is able to handle the expected

current for your application. For example, a typical 28 AWG flat ribbon cable is rated at 225 mA

of continuous current per wire. In order to use the relay control digital outputs at their maximum

current capability, cables within category 24 AWG or lower should be used.

Sourcing Digital Input

The NI 9683 provides connections for 28 simultaneously sampled digital input channels

separated in ports P0 and P1. Ports P0 and P1 are independently powered using separate power

supply pins, VI P0 and VI P1. This allows you to connect the DI to multivoltage systems.

The NI 9683 has sourcing inputs, meaning the DI sources current from the VI P0 or VI P1 to the

sinking output device.The NI 9683 internally limits current signals connected to DI.

Each channel has a DI pin to which you can connect a digital input signal. The supply pins, VI P0

and VI P1, are referenced to the ground of the board. The DI operates in the low range or high

range based on the VI P0 or VI P1 voltage. Refer to the Specifications section for more

information about the low range and high range.

You can only connect 3-wire sinking-output devices to the NI 9683. Connect the sinking-output

device to the DI pin and the external power supply lead to the VI P0 or VI P1.

NI 9683 User Guide and Specifications | © National Instruments | 13

Page 14

Figure 18. Connecting a Digital Device to a Sourcing DI Channel

User

Board

NI sbRIO-9605/6

FPGA

DIO0

DIO31

.

.

.

NI 9683

Z0 = 55 Ω

Z

0 = 55 Ω

Z

0 = 55 Ω

Z

0 = 55 Ω

VI P0/VI P1

Sinking-Output

External

Powe r

Supply

+

–

Device

Sourcing DI

GND

4.32 kΩ

NI 9683

The NI 9683 channel registers ON when the sinking-output is in the ON range. The channel

registers as OFF when the sinking-output is in the OFF range. If no device is connected to the

sourcing DI, the channel registers as OFF. Refer to the Specifications section for more

information about the ON and OFF ranges of the sourcing DI.

Note NI recommends that you leave sourcing DI channels that are not used in your

application unconnected to lower power dissipation through the onboard pull-up

resistor.

LVTTL Digital Input/Output

The NI 9683 provides connections for 32 LVTTL digital input/output channels.

The NI 9683 LVTTL DIO channels connect directly to the FPGA DIO on the

NI sbRIO-9605/9606 and are unbuffered and unprotected. Refer to the Specifications section for

more information about the maximum current.

Caution Operating the LVTTL DIO outside the rated specifications may result in

permanent damage to the FPGA on NI sbRIO-9605/9606.

Figure 19. Connecting to the LVTTL DIO Channels

If overshoot and undershoot aberrations and signal integrity are concerns for your application,

use a single load per line that does not exceed 25 pF. For edge sensitive signals, use channels

DIO0 through DIO15 for better signal integrity and crosstalk performance since these channels

have an individual GND pin.

The LVTTL DIO channels on the NI 9863 are routed with a 55 Ω characteristic trace impedance.

Route all external circuitry with a similar impedance to ensure the best signal quality.

You should perform signal integrity measurements to test the effect of signal routing and cable

type on your application. To meet defined power-up states for outputs, use a pull-up or pull-down

resistor on the line.

14 | ni.com | NI 9683 User Guide and Specifications

Page 15

System Diagrams

Figures 20 and 21 show diagrams for interfacing digital and analog signals with the NI 9683.

Figure 20. Interfacing Digital Signals with the NI 9683

Relay +

+24V

+24V

+24V_COM

Supply

+24 VCC

+15V_HBDO

+15V_DI

Supply

+15 VCC

Relay –

Error Signal

Error

Monitor

+24 VDC IN

(13 V to 30 V)

GND (for power)

Top HB 1 IN

GND (for power)

IGBT Intelligent

Power Module

+24V_COM

+15V_DI

LED

+24V_COM

+15V_HBDO

+24V

Relay Control DO+

Relay Control DO–

VI P0 (5 V to 24 V)

Sourcing DI P0.0

Sinking DO

GND

GND

V

EXT (5 V to 24 V)

Half-Bride DO0

GND

GND

sbRIO Mezzanine Connector

9 V to 30 V

PS_COM

Digital GND (GND)

Isolation

Sourcing

DI0

NI 9683

NI sbRIO-9605/6

NI 9683 User Guide and Specifications | © National Instruments | 15

Page 16

+15 VCC

Bipolar Supply

+15V_CS

–15V_CS

CS_COM

+15V_CS

3

Figure 21. Interfacing Analog Signals with the NI 9683

Current

Sensor

RTermination

2

4 mA to 20 mA

Sensor

R

Termination

1

1

Simultaneous AI0+

Simultaneous AI0–

CS COM

Simultaneous AI1+

Simultaneous AI1–

ADC0

ADC1

Isolation

AO (Voltage)

GND aux

+24 VDC IN

+24V

+24V_COM

Supply

+24 VCC

1 Do not connect the AI- pin when using termination resistors.

2 Use a small plane shape for the current return point to reduce the common-mode impedance.

3 Do not connect CS COM to GND.

(13 V to 30 V)

GND (for power)

IGBT Intelligent

Power Module

Output

Sensor

Load

Simultaneous AI2+

Simultaneous AI2–

Scanned AI0

Scanned AI1

+

–

Scanned AI2

GND

AO0

GND

9 V to 30 V

PS_COM

.

.

.

sbRIO Mezzanine Connector

Digital GND (GND)

NI sbRIO-9605/6

ADC2

ADC

DAC

NI 9683

16 | ni.com | NI 9683 User Guide and Specifications

Page 17

Specifications

The following specifications are typical for the full operating temperature range unless otherwise

noted. Refer to the Environmental section for more information on operating temperatures.

Simultaneous Analog Input

Number of channels.......................................... 16

ADC resolution................................................. 12 bits

Input range

Typical ...................................................... ±5 V, ±10 V

Minimum .................................................. ±4.95 V, ±9.90 V

Common-mode range ....................................... ±10 V

Sample rate (per channel) ................................. 100 kS/s max

Accuracy

Nominal

Range (V)

Measurement Conditions

*

Percent of

Reading

(Gain Error)

Percent of

Range

(Offset Error)

±5 Maximum (-40 °C to 85 °C) 0.70% 0.28%

Typical (23 ° ±5 °C) 0.25% 0.12%

±10 Maximum (-40 °C to 85 °C) 0.70% 0.16%

Typical (23 ° ±5 °C) 0.25% 0.07%

AbsoluteAccuracy = Reading(GainError) + Range(OffsetError) + Noise

* Local ambient temperature. Refer to the Environmental section for more information about operating

temperatures.

†

Offset error includes the effect of INL.

Stability

Gain drift................................................... 15 ppm/°C

Offset drift ................................................ 15 µV/°C

Noise................................................................. 1.5 mV

rms

-3 dB bandwidth ............................................... 210 kHz

CMRR (f

= 60 Hz).......................................... 60 dB min

in

Input impedance

Differential................................................ 240 kΩ

Single-ended ............................................. 120 kΩ

Overvoltage protection ..................................... ±30 V max

†

NI 9683 User Guide and Specifications | © National Instruments | 17

Page 18

Scanned Analog Input (Monitoring)

Number of channels .......................................... 8

ADC resolution ................................................. 12 bits

Input range

Typical.......................................................0 V to 5 V

Minimum .................................................. 12 mV to 4.97 V

Sample rate (all channels) .................................1 kS/s max

Accuracy

Stability

Noise ................................................................. 0.5 mV

-3 dB bandwidth................................................ 130 kHz

Input impedance for channel ON ......................10 kΩ, 120 pF low pass filter

Input current for channel OFF .......................... 10 μA max

Overvoltage protection ..................................... ±30 V max

1

Measurement

Conditions

*

Percent of Reading

(Gain Error)

Percent of Range

(Offset Error)

‡

Maximum (-40 °C to 85 °C) 0.30% 0.23%

Typical (23 ° ±5 °C) 0.03% 0.03%

AbsoluteAccuracy = Reading(GainError) + Range(OffsetError) + Noise

*

Local ambient temperature. Refer to the Environmental section for more information about operating

temperatures.

†

Range equals 5 V.

‡

Offset error includes the effect of INL.

Gain drift...................................................3 ppm/°C

Offset drift.................................................3 µV/°C

rms

†

Analog Output (Set-Point)

Number of channels .......................................... 8

DAC resolution ................................................. 12 bits

Startup voltage .................................................. 0 V

1

With signal source impedance <2 kΩ. Refer to the Scanned Analog Input (Monitoring) section for more

information about the influence of source impedance over accuracy.

18 | ni.com | NI 9683 User Guide and Specifications

Page 19

Output range

Typical ...................................................... 0 V to 5 V

Minimum .................................................. 14 mV to 4.97 V

Current drive (per channel)............................... 4 mA max

Update rate........................................................ 1 kS/s min

Accuracy

Measurement Conditions

Percent of Reading

*

(Gain Error)

Percent of Range†

(Offset Error)

‡

Maximum (-40 °C to 85 °C) 0.33% 0.28%

Typical (23 ° ±5 °C) 0.06% 0.06%

AbsoluteAccuracy = OutputValue(GainError) + Range(OffsetError)

*

Local ambient temperature. Refer to the Environmental section for more information about operating

temperatures.

†

Range equals 5 V.

‡

Offset error includes the effect of INL.

Stability

Gain drift................................................... 3 ppm/°C

Offset drift ................................................ 3 µV/°C

Noise

1 MHz bandwidth ..................................... 2.5 mV

100 kHz bandwidth................................... 0.3 mV

rms

rms

Protection

Overvoltage .............................................. +15 V/-5 V max

Short-circuit .............................................. Indefinitely

Sourcing Digital Input

Number of channels.......................................... 28

Input type .......................................................... Sourcing

Input range........................................................ 0 V to 24 V

External power supply voltage range (VI P0, VI P1)

Low-range mode....................................... 3 V to 6 V

High-range mode ...................................... 10 V to 24 V

Not supported ........................................... 6 V to 10 V

Digital logic levels

Low-range mode

OFF state........................................... ≥1.8 V min

ON state ............................................ ≤1 V max

NI 9683 User Guide and Specifications | © National Instruments | 19

Page 20

High-range mode

OFF state........................................... ≥9.6 V min

ON state ............................................≤7.9 V max

1

Hold time

Setup time

.........................................................0 s

2

........................................................1 µs min

Update/transfer time ......................................... 3 µs max

Pull-up resistor .................................................. 4.32 kΩ

Overvoltage protection ..................................... ±30 V max

Sinking Digital Output

Number of channels .......................................... 24

Output type .......................................................Sinking

Startup voltage .................................................. Open

Output voltage (V

Continuous output current (IO)

on each channel................................................. 20 mA

Output impedance (RO)..................................... 6 Ω max

External power supply voltage range................ 0 V to 30 V

Maximum update time ...................................... 50 μs

Protection

Reversed-voltage ......................................None

Short-circuit .............................................. None

) ..........................................IO · R

O

O

Half-Bridge Digital Output

Number of channels .......................................... 14

Output type ....................................................... Sourcing/Sinking

Startup voltage .................................................. 0 V

Maximum continuous output current................ 10 mA

Output impedance ............................................. 100 Ω

External power supply voltage range (V

1

Hold time is the amount of time input signals must be stable after initiating a read from the NI 9683.

2

Setup time is the amount of time input signals must be stable before reading from the NI 9683.

20 | ni.com | NI 9683 User Guide and Specifications

)......5 V to 30 V

ext

Page 21

Digital logic levels

High (V

)

OH

Sourcing 0.1 mA............................... V

Sourcing 10 mA................................ V

- 0.01 V

ext

- 1.05 V

ext

Low (VOL)

Sinking 0.1 mA................................. 0.01 V

Sinking 10 mA.................................. 1.05 V

Minimum pulse-width ......................................500 ns

Maximum switching frequency

V

= 30 V, CL = 1 nF.............................. 100 kHz

ext

= 30 V, CL = 50 pF............................ 500 kHz

V

ext

1

1

The maximum switching frequency must be limited to 500 kHz, regardless of the supply voltage or the

capacitive load, in order to prevent output driver overstress.

NI 9683 User Guide and Specifications | © National Instruments | 21

Page 22

Figure 22. Maximum Switching Frequency Based on the Capacitive Load

Capacitive Load (nF)

8

18

16

14

12

10

6

4

2

5

10 25 50 100 200 300

Maximum Switching Frequency (kHz)

20

0

500

Vext = 5 V

Vext = 15 V

Vext = 30 V

Vext = 5 V

Vext = 15 V

Vext = 30 V

Supply Voltage (V)

30

25

20

15

10

5

10 25 50 100 200 300

Maximum Switching Frequency (ktHz)

35

5

500

CL = 0.47 nF

CL =

1 n

F

CL = 10 nF

Figure 23. Maximum Switching Frequency Based on the Supply Voltage

Propagation delay

V

= 5 V, CL = 50 pF..............................300 ns max

ext

> 15 V, CL = 50 pF............................100 ns max

V

ext

Protection

Overcurrent ............................................... None

Short-circuit .............................................. None

22 | ni.com | NI 9683 User Guide and Specifications

Page 23

Relay Control Digital Output

Relay control DO specifications assume the use of direct board-to-board connections to I/O

connectors on the NI 9683. Refer to the Selecting a Wire Gauge for Relay Control Digital

Outputs section for information about designing ribbon cables to meet the relay control DO

specifications on the NI 9683.

Number of channels.......................................... 4

Output type ....................................................... Sinking

Startup voltage .................................................. Open

External power supply voltage range ............... 0 V to 30 V

Continuous current ........................................... 500 mA

Maximum inrush current .................................. 8 A

Maximum inrush time ...................................... 300 ms

Turn ON rate

1

................................................... 1 operation per 60 s

Turn ON time.................................................... 6 ms max

Turn OFF time .................................................. 0.2 ms max

Protection

Reversed-voltage ...................................... None

Short-circuit .............................................. None

LVTTL Digital Input/Output

Number of DIO channels.................................. 32

Maximum tested current (per channel)............. 3 mA

Maximum total current (all lines) ..................... 96 mA

Note The performance of the LVTTL DIO lines is bound by the FPGA, signal

integrity, the applications timing requirements, and your design. For more

information on using DIO to connect to RMCs, go to

Info Code

1

Turn ON rate is the minimum time between inrush current events and is based on the maximum inrush

current over the maximum inrush time. You can turn OFF the relay control DO at any point during

operation.

RMCDIO.

NI 9683 User Guide and Specifications | © National Instruments | 23

ni.com/info and enter the

Page 24

Digital logic levels

Input low voltage, V

Input high voltage, V

Output high voltage, V

...............................0 V min, 0.8 V max

IL

............................. 2.0 V min, 3.465 V max

IH

OH

sourcing 3 mA...........................................2.7 V min, 3.3 V max

Output low voltage, V

OL

sinking 3 mA.............................................0.0 V min, 0.4 V max

Protection

Overvoltage............................................... None

Overcurrent ............................................... None

Short-circuit .............................................. None

Power Requirements

Power consumption from

NI Single-Board RIO device............................. 2 W max

Power-up time...................................................0.1 s

Safety

Maximum Voltage

Connect voltages that are within the following limits.

Relay control digital output

Relay control DO+ to

Relay control DO-.....................................0 VDC to 30 VDC

Relay control DO+/- to GND....................±30 VDC

Sinking digital output

DO-to-GND ..............................................±30 VDC

Simultaneous analog input, scanned analog input, analog output, sourcing digital input

Pin-to-pin or pin-to-GND ......................... ±30 VDC

Half-bridge digital output

-to-GND.............................................. 0 VDC to 30 VDC

V

ext

LVTTL digital input/output ..............................0 VDC to 3.465 VDC

Isolation Voltages

Simultaneous analog input

Channel-to-channel ................................... None

Channel-to-common

Continuous ........................................60 VDC, Measurement Category I

Withstand .......................................... 1,000 V

24 | ni.com | NI 9683 User Guide and Specifications

rms

Page 25

Measurement Category I is for measurements performed on circuits not directly connected to the

electrical distribution system referred to as MAINS voltage. MAINS is a hazardous live electrical

supply system that powers equipment. This category is for measurements of voltages from

specially protected secondary circuits. Such voltage measurements include signal levels, special

equipment, limited-energy parts of equipment, circuits powered by regulated low-voltage

sources, and electronics.

Caution Do not connect the NI 9683 to signals or use for measurements within

Measurement Categories II, III, or IV.

Environmental

Operating temperature (IEC 60068-2-1, IEC 60068-2-2)

Ambient temperature outside

a 12 in. × 10 in. × 6.34 in. enclosure

Ambient temperature with forced-air

cooling in an open environment

Note Visit ni.com/info and enter the Info Code sbRIOcooling for

information about NI sbRIO operating temperatures.

Storage temperature

(IEC 60068-2-1, IEC 60068-2-2) ..................... - 40 °C to 85 °C

Operating humidity (IEC 60068-2-56) ............. 10% to 90% RH, noncondensing

Storage humidity (IEC 60068-2-56)................. 5% to 95% RH, noncondensing

Pollution Degree (IEC 60664).......................... 2

Maximum altitude............................................. 2,000 m

Indoor use only.

1

....... - 40 °C to 50 °C

1

.............. -40 °C to 70 °C

Physical Characteristics

Weight............................................................... 153 g

Environmental Management

NI is committed to designing and manufacturing products in an environmentally responsible

manner. NI recognizes that eliminating certain hazardous substances from our products is

beneficial to the environment and to NI customers.

For additional environmental information, refer to the Minimize Our Environmental Impact web

ni.com/environment. This page contains the environmental regulations and

page at

directives with which NI complies, as well as other environmental information not included in

this document.

1

Ensure that the local ambient temperature of the NI 9863 is -40 °C to 85 °C. Measure the local ambient

temperature by placing thermocouples on both sides of the PCB, 5 mm (0.2 in.) from the board surface.

NI 9683 User Guide and Specifications | © National Instruments | 25

Page 26

Waste Electrical and Electronic Equipment (WEEE)

⬉ᄤֵᙃѻક∵ᶧࠊㅵ⧚ࡲ⊩ ˄Ё

RoHS

˅

Ёᅶ᠋

National Instruments

ヺড়Ё⬉ᄤֵᙃѻકЁ䰤ࠊՓ⫼ᶤѯ᳝ᆇ⠽䋼ᣛҸ

(RoHS)

DŽ݇Ѣ

National Instruments

Ё

RoHS

ড়㾘ᗻֵᙃˈ䇋ⱏᔩ

ni.com/

environment/rohs_china

DŽ

(For information about China RoHS compliance,

go to

ni.com/environment/rohs_china

.)

EU Customers At the end of the product life cycle, all products must be sent to

a WEEE recycling center. For more information about WEEE recycling centers,

National Instruments WEEE initiatives, and compliance with WEEE Directive

2002/96/EC on Waste and Electronic Equipment, visit

.

weee

ni.com/environment/

Battery Replacement and Disposal

Battery Directive This device contains a long-life coin cell battery. If you need

Cd/Hg/Pb

to replace it, use the Return Material Authorization (RMA) process or contact an

authorized National Instruments service representative. For more information

about compliance with the EU Battery Directives 2006/66/EC about Batteries

and Accumulators and Waste Batteries and Accumulators, visit

environment/batterydirective

.

ni.com/

Where to Go for Support

The National Instruments Web site is your complete resource for technical support. At

ni.com/support you have access to everything from troubleshooting and application

development self-help resources to email and phone assistance from NI Application Engineers.

National Instruments corporate headquarters is located at 11500 North Mopac Expressway,

Austin, Texas, 78759-3504. National Instruments also has offices located around the world to

help address your support needs. For telephone support in the United States, create your service

request at

ni.com/support and follow the calling instructions or dial 512 795 8248. For

telephone support outside the United States, visit the Worldwide Offices section of ni.com/

niglobal

to access the branch office Web sites, which provide up-to-date contact information,

support phone numbers, email addresses, and current events.

26 | ni.com | NI 9683 User Guide and Specifications

Page 27

Refer to the NI Trademarks and Logo Guidelines at ni.com/trademarks for more information on National Instruments trademarks. Other

product and company names mentioned herein are trademarks or trade names of their respective companies. For patents covering National

Instruments products/technology, refer to the appropriate location: Help»Patents in your software, the patents.txt file on your media, or the

National Instruments Patents Notice at ni.com/patents. You can find information about end-user license agreements (EULAs) and third-party

legal notices in the readme file for your NI product. Refer to the Export Compliance Information at ni.com/legal/export-compliance

for the National Instruments global trade compliance policy and how to obtain relevant HTS codes, ECCNs, and other import/export data.

© 2012–2013 National Instruments. All rights reserved.

375960B-01 Feb13

Loading...

Loading...