Page 1

USER MANUAL AND SPECIFICATIONS

ni.com/manuals

DeutschFrançais

NI 9503

Stepper Drive

Page 2

This document describes how to use the National Instruments 9503

module and includes specifications and pin assignments for the

NI 9503. Visit ni.com/info and enter rdsoftwareversion to

determine which software you need for the modules you are using.

For information about installing, configuring, and programming the

system, refer to the system documentation. Visit

enter

cseriesdoc for information about C Series documentation.

Note The safety guidelines and specifications in this

ni.com/info and

document are specific to the NI 9503. The other

components in the system may not meet the same safety

ratings and specifications. Refer to the documentation for

each component in the system to determine the safety

ratings and specifications for the entire system.

Safety Guidelines

Operate the NI 9503 only as described in these operating

instructions.

Hot Surface This icon denotes that the component may

be hot. Touching this component may result in bodily

injury.

2 | ni.com | NI 9503 User Manual and Specifications

Page 3

Caution Do not operate the NI 9503 in a manner not

specified in these operating instructions. Product misuse

can result in a hazard. You can compromise the safety

protection built into the product if the product is damaged

in any way. If the product is damaged, return it to

National Instruments for repair.

Safety Guidelines for Hazardous Locations

The NI 9503 is suitable for use in Class I, Division 2, Groups A, B,

C, D, T4 hazardous locations; Class I, Zone 2, AEx nA IIC T4, and

Ex nA IIC T4 hazardous locations; and nonhazardous locations

only. Follow these guidelines if you are installing the NI 9503 in a

potentially explosive environment. Not following these guidelines

may result in serious injury or death.

Caution Do not disconnect I/O-side wires or connectors

unless power has been switched off or the area is known

to be nonhazardous.

Caution Do not remove modules unless power has been

switched off or the area is known to be nonhazardous.

NI 9503 User Manual and Specifications | © National Instruments | 3

Page 4

Caution Substitution of components may impair

suitability for Class I, Division 2.

Caution For Division 2 and Zone 2 applications, install

the system in an enclosure rated to at least IP 54 as

defined by IEC 60529 and EN 60529.

Caution For Division 2 and Zone 2 applications, install

a protection device between the input signal and the V

pin. The device must prevent the V

-to-channel voltage

sup

sup

from exceeding 42 V if there is a transient overvoltage

condition.

Caution For Zone 2 applications, connected signals

must be within the following limit:

Capacitance .......................... 0.2 μF max

Special Conditions for Hazardous Locations Use in

Europe

This equipment has been evaluated as Ex nA IIC T4 Gc equipment

under DEMKO Certificate No. 12 ATEX

1202658X. Each module

is marked II 3G and is suitable for use in Zone 2 hazardous

locations, in ambient temperatures of -40 °C ≤ Ta ≤ 70 °C. If you are

4 | ni.com | NI 9503 User Manual and Specifications

Page 5

using the NI 9503 in Gas Group IIC hazardous locations, you

must use the device in an NI chassis that has been evaluated as

Ex nC IIC T4, EEx nC IIC T4, Ex nA IIC T4, or Ex nL IIC T4

equipment.

Caution You must make sure that transient disturbances

do not exceed 140% of the rated voltage.

Caution The system shall be mounted in an ATEX

certified enclosure with a minimum ingress protection

rating of at least IP54 as defined in IEC/EN 60529 and

used in an environment of not more than Pollution

Degree 2.

Caution The enclosure must have a door or cover

accessible only by the use of a tool.

Electromagnetic Compatibility Guidelines

This product was tested and complies with the regulatory

requirements and limits for electromagnetic compatibility (EMC)

as stated in the product specifications. These requirements and

limits are designed to provide reasonable protection against

NI 9503 User Manual and Specifications | © National Instruments | 5

Page 6

harmful interference when the product is operated in its intended

operational electromagnetic environment.

This product is intended for use in industrial locations. As such,

there is no guarantee that harmful interference will not occur in

a particular installation, when the product is connected to a test

object, or if the product is used in residential areas. To minimize

the potential for the product to cause interference to radio and

television reception or to experience unacceptable performance

degradation, install and use this product in strict accordance with

the instructions in the product documentation.

Furthermore, any changes or modifications to the product not

expressly approved by National Instruments could void your

authority to operate it under your local regulatory rules.

Caution To ensure compliance with the applicable

regulatory requirements, product installation requires

either special considerations or user-installed, add-on

devices. See the product installation instructions for

further information.

6 | ni.com | NI 9503 User Manual and Specifications

Page 7

Caution The inputs/outputs of this product can be

damaged if subjected to Electrostatic Discharge (ESD).

To prevent damage, industry-standard ESD prevention

measures must be employed during installation,

maintenance, and operation.

Special Guidelines for Marine Applications

Some products are Lloyd’s Register (LR) Type Approved for

marine (shipboard) applications. To verify Lloyd’s Register

certification for a product, visit ni.com/certification and

search for the LR certificate, or look for the Lloyd’s Register mark

on the product label.

Caution In order to meet the EMC requirements for

marine applications, install the product in a shielded

enclosure with shielded and/or filtered power and

input/output ports. In addition, take precautions when

designing, selecting, and installing measurement probes

and cables to ensure that the desired EMC performance is

attained.

NI 9503 User Manual and Specifications | © National Instruments | 7

Page 8

NI 9503 Hardware Overview

The NI 9503 is a stepper motor drive for use with 2-phase hybrid

stepper motors in either bipolar or unipolar winding configuration.

It uses software-programmable control algorithms that reduce

torque ripple, dampen high-speed resonance, and implements

smoother motion during microstepping.

The NI 9503 returns the motor current and bus voltage to the

LabVIEW FPGA module for use in a current PI loop and

antiresonance algorithms. NI 9503 status information such as drive

status and drive faults are also returned to the LabVIEW FPGA

module. Refer to the NI 9503 topic in the LabVIEW Help, available

by selecting Help»LabVIEW Help, for information about the

available status information.

Note National Instruments offers NEMA 8, NEMA 11,

NEMA 14, NEMA 17 and NEMA 23 stepper motors

compatible with the NI 9503. Go to ni.com/motion/

stepper

for more information about NI stepper motors.

The NI 9503 reduces torque ripple at speeds near 1 RPS that are

caused by fourth harmonic disturbances. The torque ripple

smoothing algorithm is software programmable and can be tuned

8 | ni.com | NI 9503 User Manual and Specifications

Page 9

for any motor. Motors supported by National Instruments have

already been tuned for optimal torque smoothing.

The NI 9503 uses a software-programmable antiresonance

algorithm to reduce stepper motor resonance above 2 RPS. The

antiresonance algorithm allows a stepper motor to use more

available torque and run at higher speeds without stalling.

The NI 9503 supports software-programmable microstepping.

Microstepping divides full steps into smaller steps to create

smoother motion. The NI 9503 supports microstepping rates up to

256. When full-stepping, a resonance can occur, causing vibration

and reducing the motor torque. The NI 9503 offers the best

performance when combining microstepping with the torque

smoothing and antiresonance properties. Refer to the Step Resolver

topic in the LabVIEW Help, available by selecting Help»

LabVIEW Help, for information about microstepping options.

The NI 9503 allows for phase current reduction after the motor

stops moving. Unlike servo motors, stepper motor coils remain

fully energized when the motor is not moving. This allows for

strong holding torque, but generates substantial heat in the motor.

Many applications do not require maximum holding torque when

the motor is at rest, which means that the motor is wasting power.

The amount of current reduction and delay before current

NI 9503 User Manual and Specifications | © National Instruments | 9

Page 10

reduction becomes active is software-programmable. Refer to the

Current Scheduler topic in the LabVIEW Help, available by

selecting Help»LabVIEW Help, for information about current

reduction.

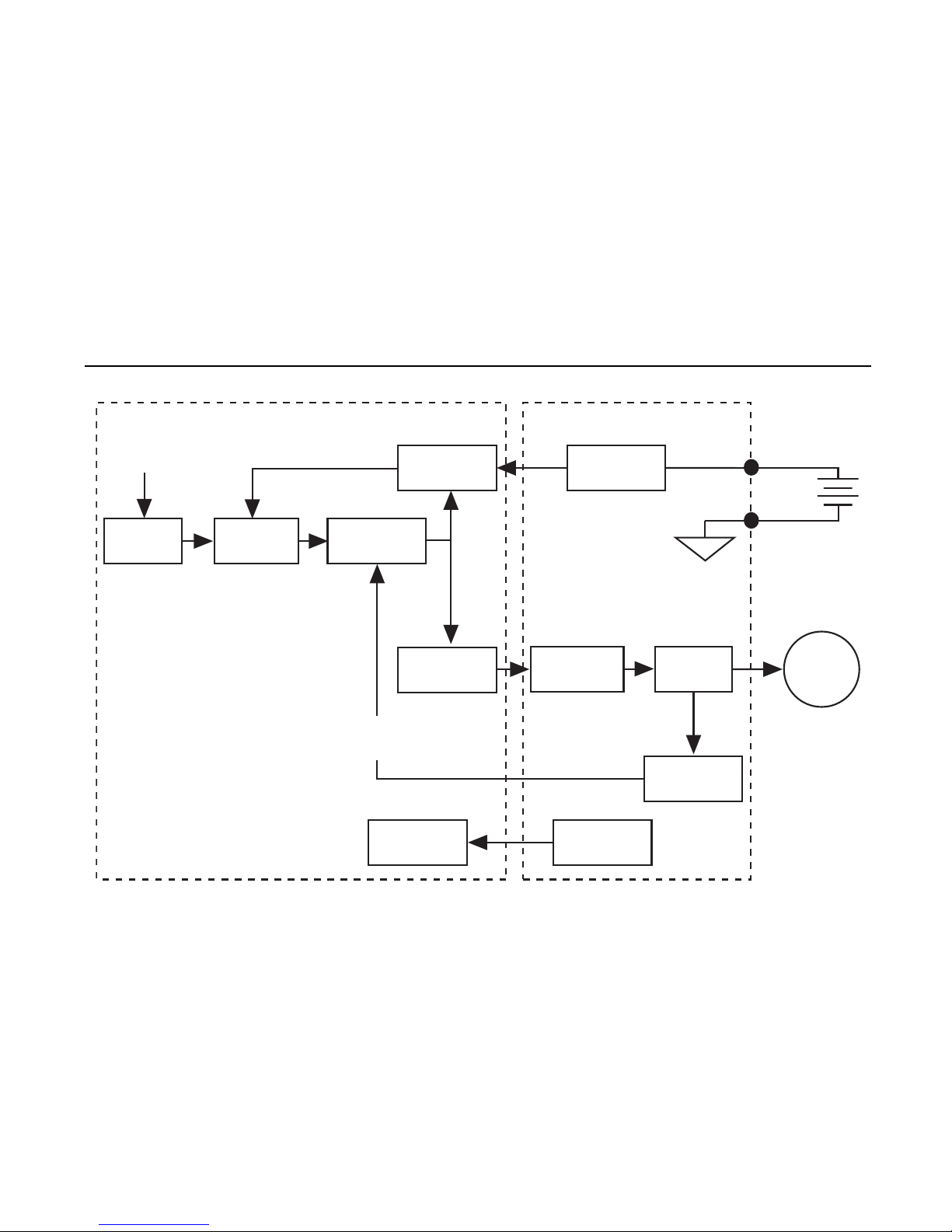

Figure 1. NI 9503 Block Diagram

LabVIEW FPGA Module with SoftMotion

Position

Setpoint

Step

Resolver

Current

Scheduler

Correction

Angle

Current

Loop

Phase A & B

Current

Fault

Monitor

Anti-

resonance

PWM

Generator

NI 9503

Bridge

Controller

Detection

Bus

voltage

Fault

Power

Stage

Current

Sense

V

sup

COM

+

–

Motor

10 | ni.com | NI 9503 User Manual and Specifications

Page 11

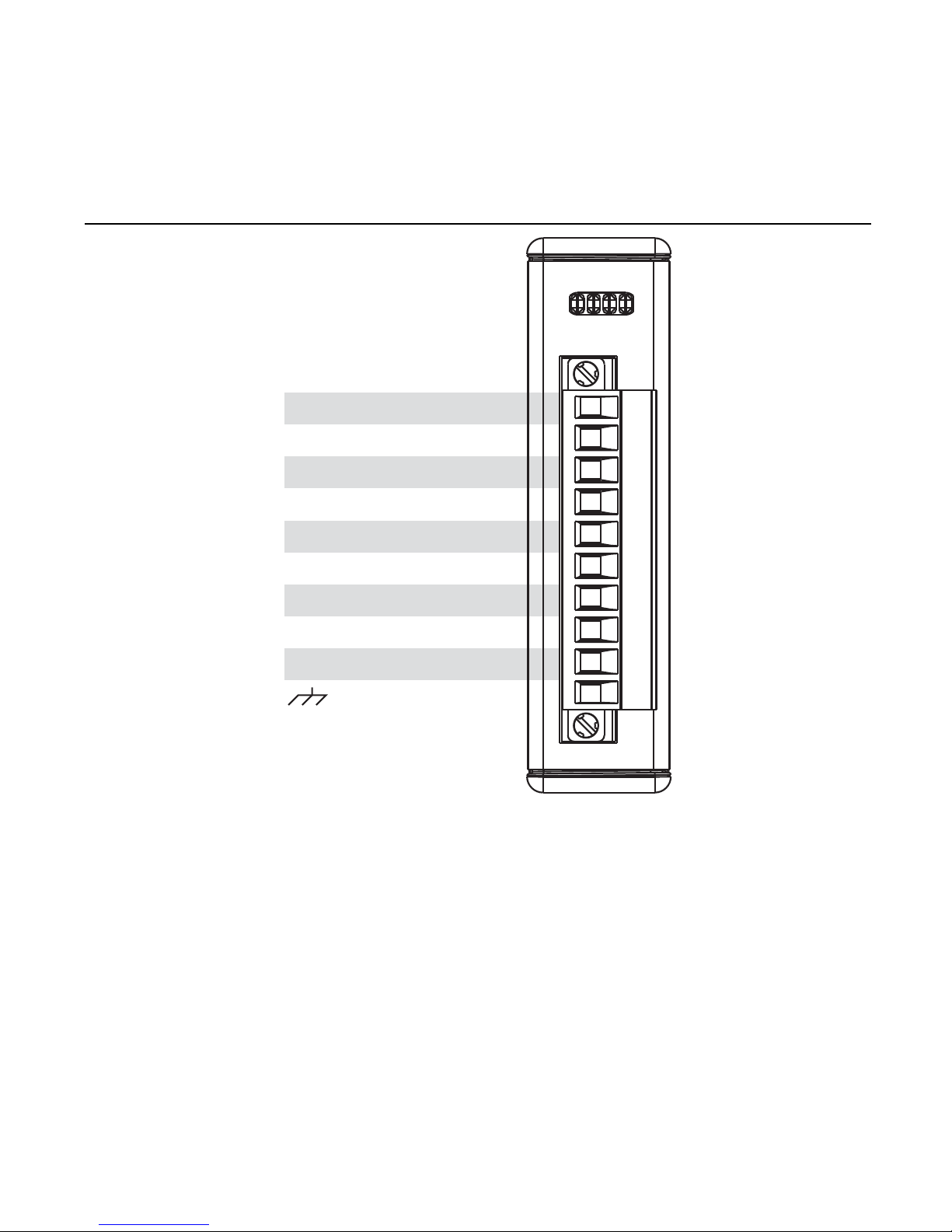

Connecting the NI 9503

The NI 9503 has a 10-terminal detachable screw-terminal

connector that provides connections for the stepper motor signals,

a motor DC power supply, COM, and chassis ground. Refer to

Figure 2 for the pin assignments.

Caution To ensure EMC compliance, special

considerations are required for all cable connections.

Refer to the Cable Requirements for EMC Compliance

section.

Note You must use 2-wire ferrules to create a secure

connection when connecting more than one wire to a

single terminal on the NI 9503 screw terminal.

Caution Do not turn on or plug in the motor DC power

supply until the screw-terminal connector is fully

inserted.

NI 9503 User Manual and Specifications | © National Instruments | 11

Page 12

Figure 2. NI 9503 Connections

Phase A+

Phase A–

Phase B+

Phase B–

Reserved

Reserved

Reserved

COM

Vsup

(Chassis Ground)

0

1

2

3

4

5

6

7

8

9

12 | ni.com | NI 9503 User Manual and Specifications

Page 13

Motor Power Signals

The Phase A± and Phase B± signals power the stepper motor.

Figure 3 shows a typical bipolar stepper motor connection.

Figure 3. Typical Bipolar Stepper Motor (2-Phase Type) Connection

Red

Blue

Yellow

White

Phase A+

Phase A–

Phase B+

Phase B–

Phase A+

Phase A–

Phase B+

Phase B–

Reserved

Reserved

Reserved

COM

Vsup

0

1

2

3

4

5

6

7

8

9

Caution The stepper motor terminals on this drive are

energized when the module is enabled. Do not connect

wires to or disconnect wires from the NI 9503 when it

is enabled.

Use a multiconductor cable with an overall shield and conductors

of 20 AWG or larger for the motor power cable.

NI 9503 User Manual and Specifications | © National Instruments | 13

Page 14

The NI 9503 contains a highly efficient power stage. Two-phase

stepper motors come in 4-, 6-, and 8-wire variations. You must wire

the stepper motors in a 4-wire configuration as shown in Figure 3.

Caution Never connect unused stepper motor terminals

to pin 9 (Chassis Ground) or to each other.

When using a 6- or 8-wire stepper motor you must leave unused

lead wires disconnected. Figure 4 shows a 6-wire and an 8-wire

stepper motor.

Figure 4. 6-Wire and 8-Wire Stepper Motors

6-wire 8-wire

14 | ni.com | NI 9503 User Manual and Specifications

Page 15

A 4-wire motor is the same as a 6-wire motor except that the center

taps (CT) are not brought out. To use a 6-wire motor in a 4-wire

configuration you can isolate the center taps for a series (full coil)

configuration. Series configurations produce the most torque per

amp but have the disadvantage of poorer high-speed performance.

Figure 5. 6-Wire Series Stepper Motor Connection

(Higher Torque, Lower Speed)

Phase A+

NC*

Phase A–

Phase B+

NC*

Phase B–

*NC = Not Connected

Phase A+

Phase A–

Phase B+

Phase B–

Reserved

Reserved

Reserved

COM

Vsup

0

1

2

3

4

5

6

7

8

9

NI 9503 User Manual and Specifications | © National Instruments | 15

Page 16

You can obtain improved high-speed performance with a 6-wire

motor by using a half-coil configuration shown in Figure 6. This

configuration sacrifices low-speed torque for better high-speed

performance. With this configuration, it is typically not possible to

produce the rated torque of the motor without the risk of the motor

overheating because only half of the windings are used.

Figure 6. 6-Wire Half-Coil Stepper Motor Connection

(Higher Speed, Lower Torque)

Phase A+

Phase A–

NC*

Phase B+

Phase B–

NC*

*NC = Not Connected

16 | ni.com | NI 9503 User Manual and Specifications

Phase A+

Phase A–

Phase B+

Phase B–

Reserved

Reserved

Reserved

COM

Vsup

0

1

2

3

4

5

6

7

8

9

Page 17

For maximum flexibility, you can connect 8-wire stepper motors

Phase B–

0

1

2

3

4

5

6

7

8

9

Phase A+

Phase A–

Phase B+

Phase B–

Reserved

Reserved

Reserved

COM

Vsup

Phase A+

Phase A–

Phase B+

Orange

Org/Wht

Blk/Wht

Black

Red

Red/Wht

Yel/Wht

Yellow

in series, parallel, or half-coil configurations. Connecting the

windings in a series configuration, as shown in Figure 7, produces

the most torque per amp but has the disadvantage of higher

inductance and poorer high-speed performance.

Figure 7. 8-Wire Series Stepper Motor Connection

(Higher Torque, Lower Speed)

NI 9503 User Manual and Specifications | © National Instruments | 17

Page 18

Notice that an 8-wire motor wired in a series configuration is

virtually identical to a 6-wire motor and typically has the same

high torque but low-speed characteristics.

Alternatively, you can connect 8-wire stepper motors in a parallel

configuration as shown in Figure 8. This configuration produces

better high-speed performance but requires more current to

produce rated torque.

Figure 8. 8-Wire Parallel Stepper Motor Connection

(Higher Speed, Lower Torque)

Phase A+

Phase A–

Black

Blk/Wht

Org/Wht

Orange

Red

Red/Wht

Yel/Wht

Yellow

Phase B+

Phase B–

Phase A+

Phase A–

Phase B+

Phase B–

Reserved

Reserved

Reserved

COM

Vsup

0

1

2

3

4

5

6

7

8

9

18 | ni.com | NI 9503 User Manual and Specifications

Page 19

Finally, you can connect 8-wire stepper motors in a half-coil

0

1

2

3

4

5

6

7

8

9

Phase A+

Phase A–

Phase B+

Phase B–

Reserved

Reserved

Reserved

COM

Vsup

Phase B–

Phase A+

Phase A–

Phase B+

NCNC

NC

NC

*NC = Not Connected

configuration as shown in Figure 9. The half-coil configuration

sacrifices low-speed torque for better high-speed performance.

With this configuration, it is typically not possible to produce the

rated torque of the motor without the risk of the motor overheating

because only half of the windings are used.

Figure 9. 8-Wire Half-Coil Stepper Motor Connection

NI 9503 User Manual and Specifications | © National Instruments | 19

Page 20

Wiring for High Vibration Applications

Ferrule

If an application is subject to high vibration, National Instruments

recommends that you use ferrules to terminate wires to the

detachable screw-terminal connector.

Refer to Figure 10 for an illustration of using ferrules.

Figure 10. 10-Terminal Detachable Screw-Terminal Connector with

Ferrule Terminated Wire

20 | ni.com | NI 9503 User Manual and Specifications

Page 21

LED Indicators

1 2 3 4

The NI 9503 has four LEDs to display status information.

1 Enabled (green)

2 Vsup (Motor Power) (green)

3 User (yellow)

4 Fault (red)

Enabled

The Enabled LED (green) illuminates when the drive is enabled

and the output power stage is active, and is flashing when the drive

is disabled and the output power stage is inactive. Refer to the

NI 9503 topic in the LabVIEW Help, available by selecting Help»

LabVIEW Help, for information about enabling the drive.

Vsup

The Vsup LED (green) illuminates when the motor DC power

supply is properly connected.

NI 9503 User Manual and Specifications | © National Instruments | 21

Page 22

User

You can define the User LED (yellow) to meet the needs of your

application. Use the User LED I/O node to turn this LED on and

off. Refer to the NI 9503 topic in the LabVIEW Help, available

by selecting Help»LabVIEW Help, for information about the

NI 9503 User LED I/O node.

Fault

Caution If the Fault LED is lit, determine the cause of

the fault and correct it before enabling the drive.

The Fault LED (red) illuminates when a fault occurs. A fault

disables the drive. Causes for fault are the following:

• Vsup undervoltage

Caution Vsup greater than 40 V will result in damage to

the NI 9503.

• Vsup overvoltage

• Overcurrent

22 | ni.com | NI 9503 User Manual and Specifications

Page 23

Hot-Swap Behavior

The NI 9503 is always disabled when it is first inserted in the

chassis, regardless of whether Vsup is present or not. You can

enable the drive using the Enable Drive method in software. Refer

to the NI 9503 topic in the LabVIEW Help, available by selecting

Help»LabVIEW Help, for more information about enabling the

drive.

When the NI 9503 is removed from the chassis while it is enabled,

the power to the motor is removed and the motor decelerates to a

stop based on its own friction.

Sleep Mode

This module supports a low-power sleep mode. Support for sleep

mode at the system level depends on the chassis that the module is

plugged into. Refer to the chassis manual for information about

support for sleep mode. If the chassis supports sleep mode, refer

to the software help for information about enabling sleep mode.

Visit

ni.com/info and enter cseriesdoc for information about

C Series documentation.

NI 9503 User Manual and Specifications | © National Instruments | 23

Page 24

Typically, when a system is in sleep mode, you cannot

communicate with the modules. In sleep mode, the system

consumes minimal power and may dissipate less heat than it does

in normal mode. Refer to the Specifications section for more

information about power consumption and thermal dissipation.

Cable Requirements for EMC Compliance

Select and install cables for the NI 9503 in accordance with the

following requirements:

• Do not tie the motor case to the NI 9503 chassis ground.

• Use only shielded cables to connect the NI 9503 to a motor and

a power supply.

• Terminate the motor and power supply cable shields to the

COM terminal of the NI 9503. In addition, terminate the cable

shields at the other end to either earth ground or the chassis of

the connected motor and/or power supply.

24 | ni.com | NI 9503 User Manual and Specifications

Page 25

• Install a clamp-on ferrite bead onto both the motor cable and

Motor DC

Power

Supply

Phase A+

Phase A–

Phase B+

Phase B–

COM

Vsup

NI 9503

Shield

Ferrites

Motor

Vsup cable, as shown in Figure 11. Power to the module must

be off when adding ferrites.

Note The wire connecting the motor cable shield to

COM bypasses the ferrite as shown in Figure 11.

Figure 11. NI 9503 Cable Connection

NI 9503 User Manual and Specifications | © National Instruments | 25

Page 26

Clamp-on ferrites must be connected to the motor cable and Vsup

cable as close to the module as possible with a full turn as shown

in Figure 12. Placing the ferrite elsewhere on the cable noticeably

impairs its effectiveness.

Figure 12. Installing a Ferrite

• Determine the clamp-on ferrite beads to install based on

twice the motor cable and Vsup cable diameter. Order the

appropriate ferrite beads from NI.

26 | ni.com | NI 9503 User Manual and Specifications

Page 27

NI Part Number Aperture Size mm (inches)

781233-01 7.0 (0.275)

781233-02 10.2 (0.402)

777297-01 13.4 (0.528)

Specifications

The following specifications are typical for the temperature range

-40 to 70 °C unless otherwise noted. All voltages are relative to

COM unless otherwise noted.

Input/Output Characteristics

Motor DC power supply (Vsup) .......+9 to +30 VDC

Minimum phase inductance.............. 1 mH

Maximum phase inductance ............. 20 mH

Type .................................................. PWM

PWM frequency................................ 20 kHz

Current per phase.............................. 3 A RMS

(4.24 A peak)

NI 9503 User Manual and Specifications | © National Instruments | 27

Page 28

Current reduction .............................. 0% to 99%

(software-selectable)

Microstepping selections .................. x2, 4, 8, 16, 32, 64, 128, 256

(software-selectable)

Vsup capacitance .............................. 750 μF

MTBF ............................................... Contact NI for Bellcore

MTBF specifications.

Drive Protection

Undervoltage..................................... <6 V

Caution Vsup greater than 40 V will result in damage

to the module.

Overvoltage....................................... >32 V

Power Requirements

Power consumption from chassis

Active mode ............................... 500 mW max

Sleep mode ................................. 2.5 mW max

28 | ni.com | NI 9503 User Manual and Specifications

Page 29

Thermal dissipation (at 70 °C)

Active mode ............................... 1.5 W max

Sleep mode ................................. 2.5 mW max

Physical Characteristics

If you need to clean the module, wipe it with a dry towel.

Note For two-dimensional drawings and

three-dimensional models of the C Series module

and connectors, visit ni.com/dimensions and

search by module number.

Screw terminal wiring

Gauge ......................................... 12 to 24 AWG copper

conductor wire with 10 mm

(0.39 in.) of insulation

stripped from the end

Temperature rating ..................... 85 °C min.

Wires per screw terminal .................. One wire per screw terminal,

two when using 2-wire

ferrule

NI 9503 User Manual and Specifications | © National Instruments | 29

Page 30

Ferrules ............................................. 0.25 mm2 to 2.5 mm

Torque for screw terminals ............... 0.5 to 0.6 N · m

(4.4 to 5.3 lb · in.)

Connector securement

Securement type ......................... Screw flanges provided

Torque for screw flanges ............ 0.2 N · m (1.8 lb · in.)

Weight............................................... 144 g (5.1 oz)

Safety

Safety Voltages

Connect only voltages that are within the following limits.

2

Channel-to-COM .............................. 0 to +30 VDC max,

Measurement Category I

Isolation

Channel-to-channel .................... None

Channel-to-earth ground

Continuous ........................... 60 VDC,

Measurement Category I

Withstand ............................. 1000 V

, verified by a 5 s

rms

dielectric withstand test

30 | ni.com | NI 9503 User Manual and Specifications

Page 31

Measurement Category I is for measurements performed on

circuits not directly connected to the electrical distribution system

referred to as MAINS voltage. MAINS is a hazardous live electrical

supply system that powers equipment. This category is for

measurements of voltages from specially protected secondary

circuits. Such voltage measurements include signal levels, special

equipment, limited-energy parts of equipment, circuits powered by

regulated low-voltage sources, and electronics.

Caution Do not connect the NI 9503 to signals or use

for measurements within Measurement Categories II, III,

or IV.

Note Measurement Categories CAT I and CAT O

(Other) are equivalent. These test and measurement

circuits are not intended for direct connection to the

MAINs building installations of Measurement

Categories CAT II, CAT III, and CAT IV.

NI 9503 User Manual and Specifications | © National Instruments | 31

Page 32

Hazardous Locations

U.S. (UL) .......................................... Class I, Division 2,

Groups A, B, C, D, T4;

Class I, Zone 2,

AEx nA IIC T4

Canada (C-UL) ................................. Class I, Division 2,

Groups A, B, C, D, T4;

Class I, Zone 2,

Ex nA IIC T4

Europe (DEMKO) ............................ Ex nA IIC T4 Gc

Power Supply Requirements

Safety and Hazardous Locations Standards

The NI 9503 is designed to meet the requirements of the following

standards of safety for electrical equipment for measurement,

control, and laboratory use:

• IEC 61010-1, EN 61010-1

• UL 61010-1, CSA 61010-1

• EN 60079-0:2012, EN 60079-15:2010

• IEC 60079-0: Ed 6, IEC 60079-15: Ed 4

32 | ni.com | NI 9503 User Manual and Specifications

Page 33

• UL 60079-0: Ed 5, UL 60079-15: Ed 3

• CSA 60079-0:2011, CSA 60079-15:2012

Note For UL and other safety certifications, refer to the

product label or the Online Product Certification section.

Electromagnetic Compatibility

This product meets the requirements of the following EMC

standards for electrical equipment for measurement, control,

and laboratory use:

• EN 61326-1 (IEC 61326-1): Class A emissions; Industrial

immunity

• EN 55011 (CISPR 11): Group 1, Class A emissions

• AS/NZS CISPR 11: Group 1, Class A emissions

• FCC 47 CFR Part 15B: Class A emissions

• ICES-001: Class A emissions

Note For the standards applied to assess the EMC of

this product, refer to the Online Product Certification

section.

NI 9503 User Manual and Specifications | © National Instruments | 33

Page 34

Note For EMC compliance, operate this device with

shielded cabling.

CE Compliance

This product meets the essential requirements of applicable

European directives as follows:

• 2006/95/EC; Low-Voltage Directive (safety)

• 2004/108/EC; Electromagnetic Compatibility Directive

(EMC)

• 94/9/EC; Potentially Explosive Atmosphere (ATEX)

Online Product Certification

Refer to the product Declaration of Conformity (DoC) for

additional regulatory compliance information. To obtain product

certifications and the DoC for this product, visit ni.com/

certification

, search by module number or product line,

and click the appropriate link in the Certification column.

34 | ni.com | NI 9503 User Manual and Specifications

Page 35

Shock and Vibration

To meet these specifications, you must panel mount the system and

affix ferrules to the end of the screw terminal wires.

Operating vibration

Random (IEC 60068-2-64)......... 5 g

, 10 to 500 Hz

rms

Sinusoidal (IEC 60068-2-6) ....... 5 g, 10 to 500 Hz

Operating shock

(IEC 60068-2-27).............................. 30 g, 11 ms half sine,

50 g, 3 ms half sine,

18 shocks at 6 orientations

Environmental

National Instruments C Series modules are intended for indoor use

only. Refer to the manual for the chassis you are using for more

information about meeting these specifications.

Operating temperature

(IEC 60068-2-1, IEC 60068-2-2) .....-40 to 70 °C

Storage temperature

(IEC 60068-2-1, IEC 60068-2-2) .....-40 to 85 °C

Ingress protection.............................. IP 40

NI 9503 User Manual and Specifications | © National Instruments | 35

Page 36

Operating humidity

(IEC 60068-2-56).............................. 10 to 90% RH,

noncondensing

Storage humidity

(IEC 60068-2-56).............................. 5 to 95% RH,

noncondensing

Maximum altitude............................. 2,000 m

Pollution Degree (IEC 60664).......... 2

Indoor use only.

Environmental Management

NI is committed to designing and manufacturing products in an

environmentally responsible manner. NI recognizes that

eliminating certain hazardous substances from our products is

beneficial to the environment and to NI customers.

For additional environmental information, refer to the Minimize

Our Environmental Impact web page at

ni.com/environment.

This page contains the environmental regulations and directives

with which NI complies, as well as other environmental

information not included in this document.

36 | ni.com | NI 9503 User Manual and Specifications

Page 37

Waste Electrical and Electronic Equipment (WEEE)

⬉ᄤֵᙃѻક∵ᶧࠊㅵ⧚ࡲ⊩ ˄Ё

RoHS

˅

Ёᅶ᠋

National Instruments

ヺড়Ё⬉ᄤֵᙃ

ѻકЁ䰤ࠊՓ⫼ᶤѯ᳝ᆇ⠽䋼ᣛҸ

(RoHS)

DŽ݇Ѣ

National Instruments

Ё

RoHS

ড়㾘ᗻֵᙃˈ䇋ⱏᔩ

ni.com/environment/rohs_china

DŽ

(For information

about China RoHS compliance, go to

ni.com/

environment/rohs_china

.)

EU Customers At the end of the product life cycle,

all products must be sent to a WEEE recycling center.

For more information about WEEE recycling centers,

National Instruments WEEE initiatives, and compliance

with WEEE Directive 2002/96/EC on Waste and

Electronic Equipment, visit

weee

.

ni.com/environment/

NI 9503 User Manual and Specifications | © National Instruments | 37

Page 38

Worldwide Support and Services

The National Instruments website is your complete resource for

technical support. At

ni.com/support you have access to

everything from troubleshooting and application development

self-help resources to email and phone assistance from

NI Application Engineers.

Visit

ni.com/services for NI Factory Installation Services,

repairs, extended warranty, and other services.

Visit

ni.com/register to register your National Instruments

product. Product registration facilitates technical support and

ensures that you receive important information updates from NI.

A Declaration of Conformity (DoC) is our claim of compliance

with the Council of the European Communities using the

manufacturer’s declaration of conformity. This system affords the

user protection for electromagnetic compatibility (EMC) and

product safety. You can obtain the DoC for your product by visiting

ni.com/certification. If your product supports calibration,

you can obtain the calibration certificate for your product

at ni.com/calibration.

38 | ni.com | NI 9503 User Manual and Specifications

Page 39

National Instruments corporate headquarters is located at

11500 North Mopac Expressway, Austin, Texas, 78759-3504.

National Instruments also has offices located around the world. For

telephone support in the United States, create your service request

at

ni.com/support or dial 1 866 ASK MYNI (275 6964). For

telephone support outside the United States, visit the Worldwide

Offices section of ni.com/niglobal to access the branch office

websites, which provide up-to-date contact information, support

phone numbers, email addresses, and current events.

NI 9503 User Manual and Specifications | © National Instruments | 39

Page 40

Refer to the NI Trademarks and Logo Guidelines at ni.com/trademarks for more information on National

Instruments trademarks. Other product and company names mentioned herein are trademarks or trade names of

their respective companies. For patents covering National Instruments products/technology, refer to the appropriate

location: Help»Patents in your software, the

Notice at

third-party legal notices in the readme file for your NI product. Refer to the Export Compliance Information at

ni.com/patents. You can find information about end-user license agreements (EULAs) and

patents.txt file on your media, or the National Instruments Patent

ni.com/legal/export-compliance for the National Instruments global trade compliance policy and

how to obtain relevant HTS codes, ECCNs, and other import/export data. NI MAKES NO EXPRESS OR IMPLIED

WARRANTIES AS TO THE ACCURACY OF THE INFORMATION CONTAINED HEREIN AND SHALL NOT BE LIABLE FOR

ANY ERRORS. U.S. Government Customers: The data contained in this manual was developed at private expense

and is subject to the applicable limited rights and restricted data rights as set forth in FAR 52.227-14,

DFAR 252.227-7014, and DFAR 252.227-7015.

© 2014 National Instruments. All rights reserved.

375481B-01 Aug14

Loading...

Loading...