Page 1

OPERATING INSTRUCTIONS AND SPECIFICATIONS

NI 9475

8-Channel, 60 V, High-Speed, Sourcing Digital Output

Module

DeutschFrançais

ni.com/manuals

Page 2

This document describes how to use the National Instruments 9475

and includes specifications and pin assignments for the NI 9475.

Vis it ni.com/info and enter rdsoftwareversion to determine

which software you need for the modules you are using. For

information about installing, configuring, and programming the

system, refer to the system documentation. Visit

and enter

cseriesdoc for information about C Series

ni.com/info

documentation.

Note The safety guidelines and specifications in this

document are specific to the NI 9475. The other

components in the system might not meet the same safety

ratings and specifications. Refer to the documentation for

each component in the system to determine the safety

ratings and specifications for the entire system. Visit

ni.com/info and enter cseriesdoc for information

about C Series documentation.

NI 9475 Operating Instructions and Specifications 2 ni.com

Page 3

Safety Guidelines

Operate the NI 9475 only as described in these operating

instructions.

Hot Surface This icon denotes that the component may be

hot. Touching this component may result in bodily injury.

Safety Guidelines for Hazardous Locations

The NI 9475 is suitable for use in Class I, Division 2, Groups A, B,

C, D, T4 haza rdous locations; Class I, Zone 2, AEx nA IIC T4, and

Ex nA IIC T4 hazardous locations; and nonhazardous locations

only. Follow these guidelines if you are installing the NI 9475 in a

potentially explosive environment. Not following these guidelines

may result in serious injury or death.

Caution Do not disconnect I/O-side wires or connectors

unless power has been switched off or the area is known

to be nonhazardous.

Caution Do not remove modules unless power has been

switched off or the area is known to be nonhazardous.

© National Instruments Corp. 3 NI 9475 Operating Instructions and Specifications

Page 4

Caution Substitution of components may impair

suitability for Class I, Division 2.

Caution For Zone 2 applications, install the system

in an enclosure rated to at least IP 54 as defined by

IEC 60529 and EN 60529.

Caution For Zone 2 applications, install a protection

device between the input signal and the NI 9475 input

pin. The device must prevent the input V

-to-COM

sup

voltage from exceeding 84 V if there is a transient

overvoltage condition.

Special Conditions for Hazardous Locations Use in Europe

This equipment has been evaluated as Ex nA IIC T4 equipment

under DEMKO Certificate No. 07 ATEX 0626664X. Each module

is marked II 3G and is suitable for use in Zone 2 hazardous

locations. If you are using the NI 9475 in Gas Group IIC hazardous

locations or in ambient temperatures of –40 °C ≤ Ta ≤ 70 °C, you

must use the device in an NI chassis that has been evaluated as

EEx nC IIC T4, Ex nA IIC T4, or Ex nL IIC T4 equipment.

NI 9475 Operating Instructions and Specifications 4 ni.com

Page 5

Special Conditions for Marine Applications

Some modules are Lloyd’s Register (LR) Type Approved for

marine applications. To verify Lloyd’s Register certification, visit

ni.com/certification and search for the LR certificate, or

look for the Lloyd’s Register mark on the module.

Caution To meet radio frequency emission requirements

for marine applications, use shielded cables and install

the system in a metal enclosure. Suppression ferrites

must be installed on power supply inputs near power

entries to modules and controllers. Power supply and

module cables must be separated on opposite sides of the

enclosure and must enter and exit through opposing

enclosure walls.

© National Instruments Corp. 5 NI 9475 Operating Instructions and Specifications

Page 6

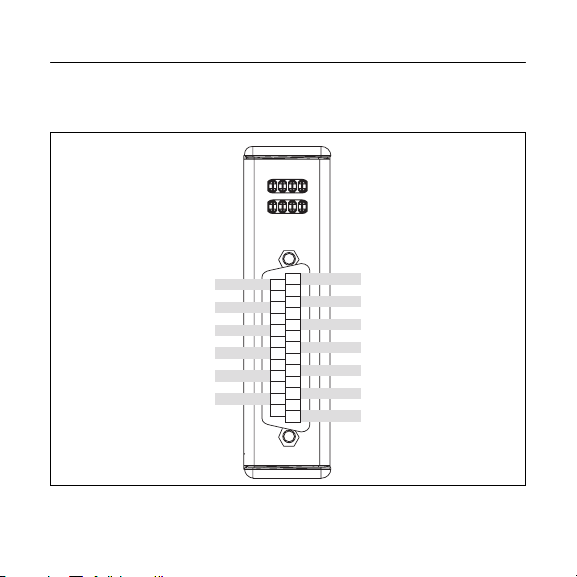

Connecting the NI 9475

The NI 9475 has a 25-pin DSUB connector that provides

connections for eight digital output channels.

03

47

1

DO0

14

15

Vsup

DO1

16

17

DO2

Vsup

18

19

DO3

20

DO4

21

Vsup

22

DO5

23

DO6

24

Vsup

25

DO7

Figure 1. NI 9475 Pin Assignments

NI 9475 Operating Instructions and Specifications 6 ni.com

COM

2

Vsup

3

COM

4

COM

5

Vsup

6

COM

7

COM

8

Vsup

9

COM

10

COM

11

Vsup

12

COM

13

COM

Page 7

Each channel of the NI 9475 has a DO pin to which you can

connect a device. Each channel also has a COM pin and a V

sup

pin.

National Instruments recommends you provide independent COM

and V

COM and V

wiring for each channel to minimize current flow in the

sup

wiring. The COM pins are all connected together

sup

internally.

Each channel has an LED that indicates the state of the channel.

When a channel LED is lit, the channel is on. When the LED is

dark, the channel is off.

Yo u must connect an external power supply to the NI 9475. This

power supply provides the current for the devices you connect to

the module. Connect the positive lead of the power supply to V

sup

and the negative lead of the power supply to COM. Refer to the

Specifications section for information about the power supply

voltage range.

Caution Do not remove or insert modules if the external

power supply connected to the V

and COM pins is

sup

powered on.

The NI 9475 has current sourcing outputs, meaning the DO pin is

driven to V

© National Instruments Corp. 7 NI 9475 Operating Instructions and Specifications

when the channel is turned on.

sup

Page 8

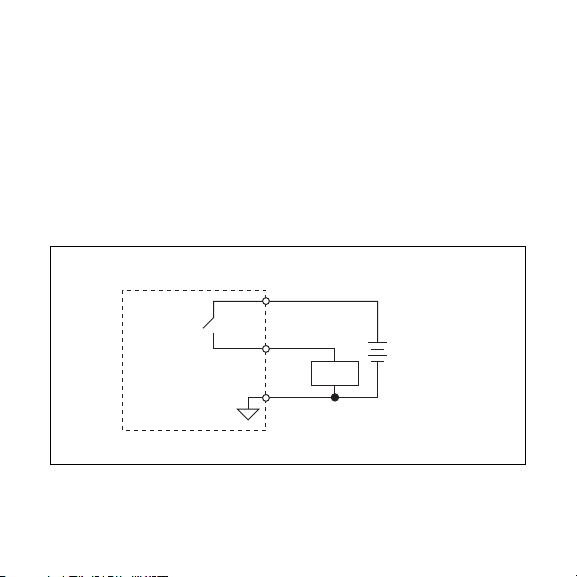

Yo u can directly connect the NI 9475 to a variety of industrial

devices such as solenoids, motors, actuators, relays, and lamps.

Make sure the devices you connect to the NI 9475 are compatible

with the output specifications of the module. Refer to the

Specifications section for more information about the output

specifications.

Connect the device to DO and connect the common of the device

to COM. Refer to Figure 2 for an illustration of how to connect a

device to the NI 9475.

V

sup

External

DO

Device

COM

NI 9475

Figure 2. Connecting a Device to the NI 9475

NI 9475 Operating Instructions and Specifications 8 ni.com

+

Power

–

Supply

Page 9

Increasing Current Drive

Each channel has a continuous output current of 1 A. If you want

to increase the output current to a device, you can connect any

number of channels together in parallel. For example, if you want

to drive 4 A of current, connect DO<0..3> in parallel as shown

in Figure 3. You must turn all parallel channels on and off

simultaneously so that the current on any single channel cannot

exceed the 1 A rating.

V

sup

1 A

DO0

DO1

DO2

DO3

1 A

1 A

1 A

Device

4 A

External

+

Powe r

_

Supply

NI 9475

COM

Figure 3. Increasing the Current to a Device Connected to the NI 9475

© National Instruments Corp. 9 NI 9475 Operating Instructions and Specifications

Page 10

I/O Protection

The NI 9475 is short-circuit proof in accordance with IEC 1131-2

and provides overcurrent protection.

Understanding Short-Circuit-Proof Devices

Each channel on the NI 9475 has circuitry that protects it from

current surges resulting from short circuits. Whether the module

suffers damage from these overcurrent conditions depends on the

following factors:

• The amount of current through the channel

• The amount of time the current is above the current limit

• The frequency of the current surges

When the amount of current through the DO pin is greater than

13 A, the channel trips and goes into an overcurrent state. In an

overcurrent state, the channel turns off and the module is not

damaged. If the current through DO is between 6 A and 13 A, the

state of the channel is indeterminate and depends on factors such

as the current level, the temperature, and the power supply.

NI 9475 Operating Instructions and Specifications 10 ni.com

Page 11

Higher inrush currents that exist for less than the trip time do not

trip the protection circuitry. Refer to the Specifications section for

more information about the maximum continuous output current,

short-circuit behavior, and short-circuit trip time. You also can

refer to the IEC 1131-2 standard for more information about

short-circuit-proof devices.

Tip Because the NI 9475 includes internal flyback

diodes, you do not need to add external diodes when

connecting to switching energy storing devices.

Power Supplies and Overcurrent Conditions

If a short-circuit occurs, the current through DO can exceed the

current rating for the power supply and the maximum continuous

output current for the NI 9475.

If the power supply you are using with the NI 9475 cannot supply

more than 13 A, the module may be damaged if a short-circuit

condition occurs.

Detecting an Overcurrent Condition

If a device connected to the module is not working while the

channel is on, the module channel may be in an overcurrent state.

Neither the software nor the module LEDs indicate if an

© National Instruments Corp. 11 NI 9475 Operating Instructions and Specifications

Page 12

overcurrent condition occurs. A channel LED may be on even if the

channel is off because of an overcurrent condition. To determine if

the channel is in an overcurrent state, measure the voltage between

DO and V

. If the voltage is equal to the voltage of the external

sup

power supply connected to the module, the channel is in an

overcurrent state.

Resetting Channels After an Overcurrent Condition

After you have determined and fixed the cause of the overcurrent

condition, reset the channel by turning it off. For more information

about writing to output channels, refer to the software help. Visit

ni.com/info and enter cseriesdoc for information about

C Series documentation. Alternatively, you can disconnect the

external power supply from the module. However, doing so

disconnects power from all of the module channels. Normal

operation can resume after you correct the overcurrent condition

and reset the channel.

Sleep Mode

This module supports a low-power sleep mode. Support for sleep

mode at the system level depends on the chassis that the module is

plugged into. Refer to the chassis manual for information about

NI 9475 Operating Instructions and Specifications 12 ni.com

Page 13

support for sleep mode. Refer to the software help for information

about enabling sleep mode. Visit

cseriesdoc for information about C Series documentation.

ni.com/info and enter

Typically, when a system is in sleep mode, you cannot

communicate with the modules. In sleep mode, the system

consumes minimal power and may dissipate less heat than it does

in normal mode. Refer to the Specifications section for more

information about power consumption and thermal dissipation.

Specifications

The following specifications are typical for the range –40 to 70 °C

unless otherwise noted. All voltages are relative to COM unless

otherwise noted.

Output Characteristics

Number of channels..........................8 digital output channels

Output type ....................................... Sourcing

Power-on output state ....................... Channels off

External power supply

voltage range (V

© National Instruments Corp. 13 NI 9475 Operating Instructions and Specifications

)........................... 0–60 VDC

sup

Page 14

Output impedance (R0) ..................... 0.14 Ω max

Continuous output current (I

),

0

per channel........................................1 A max

Output voltage .................................. V

– (I0 · R0)

sup

I/O protection

Voltage........................................ 60 VDC max

Reversed voltage ........................ None

Short-circuit behavior

Current Channel Behavior Module Protection

0 to 1 A Channel does not trip Module is not damaged

1 to 6 A Channel does not trip Module may be damaged

6 to 13 A Channel may trip Module may be damaged

>13 A Channel trips Module is not damaged

Short-circuit trip time ................. 10

μs at 13 A

Output delay time (full load) ............ 1 μs max

NI 9475 Operating Instructions and Specifications 14 ni.com

Page 15

MTBF ............................................... 1,096,296 hours at 25 °C;

Bellcore Issue 6, Method 1,

Case 3, Limited Part Stress

Method

Note Contact NI for Bellcore MTBF specifications

at other temperatures or for MIL-HDBK-217F

specifications.

Power Requirements

Power consumption from chassis

Active mode ............................... 355 mW max

Sleep mode ................................. 25 μW max

Thermal dissipation (at 70 °C)

Active mode ............................... 1.5 W max

Sleep mode ................................. 25

μW max

Physical Characteristics

If you need to clean the module, wipe it with a dry towel.

Weight............................................... 142 g (4.9 oz)

© National Instruments Corp. 15 NI 9475 Operating Instructions and Specifications

Page 16

Safety

Maximum Voltage

Connect only voltages that are within the following limits.

-to-COM..................................... 60 VDC,

V

sup

Measurement Category I is for measurements performed on

circuits not directly connected to the electrical distribution system

referred to as MAINS voltage. MAINS is a hazardous live electrical

supply system that powers equipment. This category is for

measurements of voltages from specially protected secondary

circuits. Such voltage measurements include signal levels, special

equipment, limited-energy parts of equipment, circuits powered by

regulated low-voltage sources, and electronics.

Caution Do not connect the NI 9475 to signals or use for

measurements within Measurement Categories II, III,

or IV.

1

The maximum voltage that can be applied or output between V

creating a safety hazard.

NI 9475 Operating Instructions and Specifications 16 ni.com

1

Measurement Category I

and COM without

sup

Page 17

Isolation Voltages

Channel-to-channel........................... No isolation between

channels

Channel-to-earth ground

Continuous ................................. 60 VDC,

Measurement Category I

Withstand.................................... 1,000 V

, verified by a 5 s

rms

dielectric withstand test

Safety Standards

This product is designed to meet the requirements of the following

standards of safety for electrical equipment for measurement,

control, and laboratory use:

• IEC 61010-1, EN 61010-1

• UL 61010-1, CSA 61010-1

Note For UL and other safety certifications, refer to the

product label or visit

by modu le number or product line, and click the

appropriate link in the Certification column.

© National Instruments Corp. 17 NI 9475 Operating Instructions and Specifications

ni.com/certification, search

Page 18

Hazardous Locations

U.S. (UL) .......................................... Class I, Division 2,

Canada (C-UL) ................................. Class I, Division 2,

Europe (DEMKO)............................. Ex nA IIC T4

Groups A, B, C, D, T4;

Class I, Zone 2,

AEx nA IIC T4

Groups A, B, C, D, T4;

Class I, Zone 2,

Ex nA IIC T4

Environmental

National Instruments C Series modules are intended for indoor use

only but may be used outdoors if installed in a suitable enclosure.

Refer to the manual for the chassis you are using for more

information about meeting these specifications.

Operating temperature

(IEC 60068-2-1, IEC 60068-2-2) .....–40 to 70 °C

Storage temperature

(IEC 60068-2-1, IEC 60068-2-2) .....–40 to 85 °C

Ingress protection.............................. IP 40

NI 9475 Operating Instructions and Specifications 18 ni.com

Page 19

Operating humidity

(IEC 60068-2-56).............................. 10 to 90% RH,

noncondensing

Storage humidity

(IEC 60068-2-56).............................. 5 to 95% RH,

noncondensing

Maximum altitude............................. 2,000 m

Pollution Degree (IEC 60664).......... 2

Shock and Vibration

To meet these specifications, you must panel mount the system.

Operating vibration

Random (IEC 60068-2-64)......... 5 g

Sinusoidal (IEC 60068-2-6) .......5 g, 10 to 500 Hz

Operating shock

(IEC 60068-2-27).............................. 30 g, 11 ms half sine,

© National Instruments Corp. 19 NI 9475 Operating Instructions and Specifications

, 10 to 500 Hz

rms

50 g, 3 ms half sine,

18 shocks at 6 orientations

Page 20

Electromagnetic Compatibility

This product is designed to meet the requirements of the following

standards of EMC for electrical equipment for measurement,

control, and laboratory use:

• EN 61326 EMC requirements; Industrial Immunity

• EN 55011 Emissions; Group 1, Class A

• CE, C-Tick, ICES, and FCC Part 15 Emissions; Class A

Note For EMC compliance, operate this device with

shielded cabling.

CE Compliance

This product meets the essential requirements of applicable

European directives, as amended for CE markings, as follows:

• 2006/95/EC; Low-Voltage Directive (safety)

• 2004/108/EC; Electromagnetic Compatibility Directive

(EMC)

NI 9475 Operating Instructions and Specifications 20 ni.com

Page 21

Note Refer to the Declaration of Conformity (DoC) for

this product for any additional regulatory compliance

information. To obtain the DoC for this product, visit

ni.com/certification, search by module number

or product line, and click the appropriate link in the

Certification column.

Environmental Management

National Instruments is committed to designing and manufacturing

products in an environmentally responsible manner. NI recognizes

that eliminating certain hazardous substances from our products is

beneficial not only to the environment but also to NI customers.

For additional environmental information, refer to the NI and the

Environment Web page at

contains the environmental regulations and directives with which

NI complies, as well as other environmental information not

included in this document.

© National Instruments Corp. 21 NI 9475 Operating Instructions and Specifications

ni.com/environment. This page

Page 22

Waste Electrical and Electronic Equipment (WEEE)

⬉ᄤֵᙃѻક∵ᶧࠊㅵ⧚ࡲ⊩ ˄Ё

˅

Ёᅶ᠋

EU Customers At the end of their life cycle, all products

must be sent to a WEEE recycling center. For more

information about WEEE recycling centers and National

Instruments WEEE initiatives, visit

environment/weee.htm

.

ni.com/

RoHS

ѻકЁ䰤ࠊՓ⫼ᶤѯ᳝ᆇ⠽䋼ᣛҸ

National Instruments

National InstrumentsЁRoHS

ni.com/environment/rohs_china

about China RoHS compliance, go to

environment/rohs_china

ヺড়Ё⬉ᄤֵᙃ

DŽ݇Ѣ

(RoHS)

ড়㾘ᗻֵᙃˈ䇋ⱏᔩ

DŽ

(For information

ni.com/

.)

NI 9475 Operating Instructions and Specifications 22 ni.com

Page 23

Where to Go for Support

The National Instruments Web site is your complete resource for

technical support. At

everything from troubleshooting and application development

self-help resources to email and phone assistance from

NI Application Engineers.

National Instruments corporate headquarters is located at

11500 North Mopac Expressway, Austin, Texas, 78759-3504.

National Instruments also has offices located around the world to

help address your support needs. For telephone support in the

United States, create your service request at

and follow the calling instructions or dial 512 795 8248. For

telephone support outside the United States, contact your local

branch office:

Australia 1800 300 800, Austria 43 662 457990-0,

Belgium 32 (0) 2 757 0020, Brazil 55 11 3262 3599,

Canada 800 433 3488, China 86 21 5050 9800,

Czech Republic 420 224 235 774, Denmark 45 45 76 26 00,

Finland 358 (0) 9 725 72511, France 01 57 66 24 24,

Germany 49 89 7413130, India 91 80 41190000,

Israel 972 3 6393737, Italy 39 02 41309277, Japan 0120-527196,

© National Instruments Corp. 23 NI 9475 Operating Instructions and Specifications

ni.com/support you have access to

ni.com/support

Page 24

Korea 82 02 3451 3400, Lebanon 961 (0) 1 33 28 28,

Malaysia 1800 887710, Mexico 01 800 010 0793,

Netherlands 31 (0) 348 433 466, New Zealand 0800 553 322,

Norway 47 (0) 66 90 76 60, Poland 48 22 3390150,

Portugal 351 210 311 210, Russia 7 495 783 6851,

Singapore 1800 226 5886, Slovenia 386 3 425 42 00,

South Africa 27 0 11 805 8197, Spain 34 91 640 0085,

Sweden 46 (0) 8 587 895 00, Switzerland 41 56 2005151,

Taiwan 886 02 2377 2222, Thailand 662 278 6777,

Turkey 90 212 279 3031, United Kingdom 44 (0) 1635 523545

National Instruments, NI, ni.com, and LabVIEW are trademarks of National Instruments Corporation. Refer to the

Terms of Use section on

product and company names mentioned herein are trademarks or trade names of their respective companies.

For patents covering National Instruments products, refer to the appropriate location: Help»Patents in your software,

patents.txt file on your CD, or ni.com/patents.

the

© 2007–2008 National Instruments Corp. All rights reserved.

374711C-01 Feb08

ni.com/legal for more information about National Instruments trademarks. Other

Loading...

Loading...