Page 1

OPERATING INSTRUCTIONS

NI 9219

4-Channel, 24-Bit, Universal Analog Input Module

Page 2

These operating instructions describe how to use the National

Instruments 9219. For information about installing, configuring,

and programming the system, refer to the system documentation.

Vis it

ni.com/info and enter the info code rdsoftwareversion

to determine which software you need for the modules you are

using.

Note The safety guidelines and specifications in this

document are specific to the NI 9219. The other

components in the system might not meet the same safety

ratings and specifications. Refer to the documentation for

each component in the system to determine the safety

ratings and specifications for the entire system.

Safety Guidelines

Operate the NI 9219 only as described in these operating

instructions.

Hot Surface This icon denotes that the component may be

hot. Touching this component may result in bodily injury.

NI 9219 Operating Instructions 2 ni.com

Page 3

Safety Guidelines for Hazardous Voltages

If hazardous voltages are connected to the module, take the

following precautions. A hazardous voltage is a voltage greater

than 42.4 V

© National Instruments Corp. 3 NI 9219 Operating Instructions

or 60 VDC to earth ground.

pk

Caution Ensure that hazardous voltage wiring is

performed only by qualified personnel adhering to

local electrical standards.

Caution Do not mix hazardous voltage circuits and

human-accessible circuits on the same module.

Caution Make sure that devices and circuits connected to

the module are properly insulated from human contact.

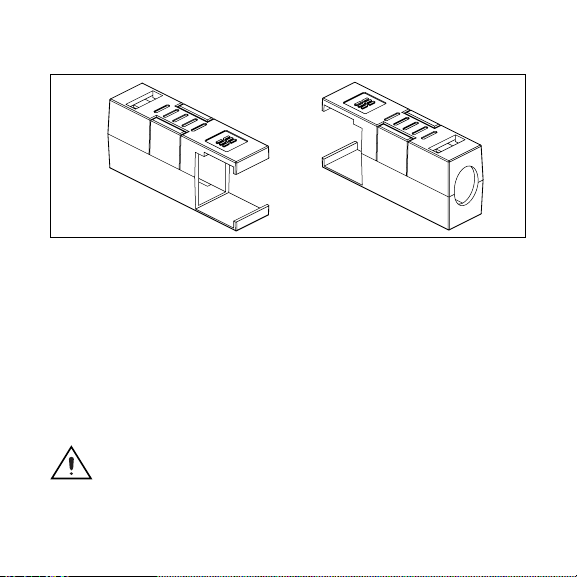

Caution When module terminals are hazardous voltage

LIVE (>42.4 V

/60 VDC), you must ensure that devices

pk

and circuits connected to the module are properly insulated

from human contact. You must use the NI 9972 connector

backshell kit to ensure that the terminals are not accessible.

Page 4

Figure 1 shows the NI 9972 connector backshell.

Figure 1. NI 9972 Connector Backshell

Safety Guidelines for Hazardous Locations

The NI 9219 is suitable for use in Class I, Division 2, Groups A, B,

C, D, T4 hazardous locations; Class I, Zone 2, AEx nC IIC T4

hazardous locations; and nonhazardous locations only. Follow

these guidelines if you are installing the NI 9219 in a potentially

explosive environment. Not following these guidelines may result

in serious injury or death.

Caution Do not disconnect I/O-side wires or connectors

unless power has been switched off or the area is known

to be nonhazardous.

NI 9219 Operating Instructions 4 ni.com

Page 5

Caution Do not remove modules unless power has been

switched off or the area is known to be nonhazardous.

Caution Substitution of components may impair

suitability for Class I, Division 2.

Caution For Zone 2 applications, install the system

in an enclosure rated to at least IP 54 as defined by

IEC 60529 and EN 60529.

Special Conditions for Marine Applications

Some modules are Lloyd’s Register (LR) Type Approved for

marine applications. To verify Lloyd’s Register certification, visit

ni.com/certification and search for the LR certificate, or

look for the Lloyd’s Register mark on the module.

Caution To meet radio frequency emission requirements

for marine applications, use shielded cables and install

the system in a metal enclosure. Suppression ferrites

must be installed on power supply inputs near power

entries to modules and controllers. Power supply and

module cables must be separated on opposite sides of

the enclosure and must enter/exit through opposing

enclosure walls.

© National Instruments Corp. 5 NI 9219 Operating Instructions

Page 6

Wiring the NI 9219

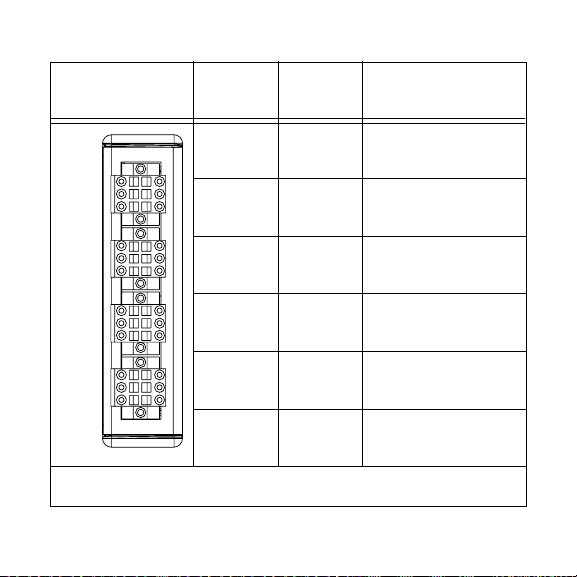

The NI 9219 has four 6-terminal connectors that provide

connections for four analog input channels. Connect the positive

signal of the signal source to the positive input signal terminal (HI)

and the negative signal of the signal source to the negative input

signal terminal (LO). Use the excitation terminals if your sensor

requires a separate excitation connection. Refer to Table 1 for the

signal names and Table 2 for the terminal assignments for each

mode. Refer to the NI 9219 Circuitry section for information about

connections in each mode.

NI 9219 Operating Instructions 6 ni.com

Page 7

Table 1. Signal Names

Module Terminal

1 T+ TEDS Data

Signal

Name

Signal Description

Ch 0

Ch 1

Ch 2

Ch 3

1

2

3

1

2

3

1

2

3

1

2

3

4

5

6

4

5

6

4

5

6

4

5

6

2 T– TEDS COM

3 EX+/HI*Positive excitation or

input signal

4 HI Positive input signal

5 EX–/LO*Negative excitation or

input signal

6 LO Negative input signal

*

Depending on the mode, terminals 3 and 5 are either the excitation signals or the

input signals.

© National Instruments Corp. 7 NI 9219 Operating Instructions

Page 8

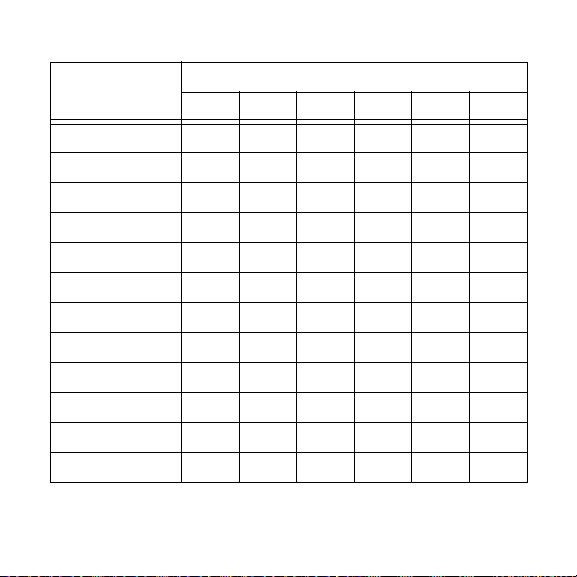

Table 2. Terminal Assignments

Terminal

Mode

1 2 3 4 5 6

Voltage T+ T– — HI LO —

Current T+ T– HI — LO —

4-Wire Resistance T+ T– EX+ HI EX– LO

2-Wire Resistance T+ T– HI — LO —

Thermocouple T+ T– — HI LO —

4-Wire RTD T+ T– EX+ HI EX– LO

3-Wire RTD T+ T– EX+ — EX– LO

Quarter-Bridge T+ T– HI — LO —

Half-Bridge T+ T– EX+ HI EX– —

Full-Bridge T+ T– EX+ HI EX– LO

Digital In T+ T– — HI LO —

Open Contact T+ T– HI — LO —

NI 9219 Operating Instructions 8 ni.com

Page 9

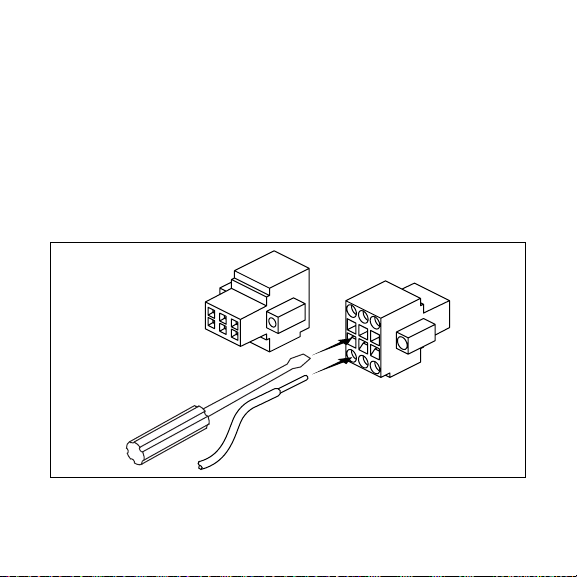

Connecting Wires to the NI 9219 Connectors

Use a flathead screwdriver with a blade smaller than 2.3 × 1.0 mm

(0.09 × 0.04 in.) to connect wires to the detachable spring-terminal

connectors. Insert the screwdriver into a spring clamp activation

slot and press a wire into the corresponding connector terminal,

then remove the screwdriver to clamp the wire into the terminal.

Refer to the Specifications section for more information about

spring-terminal wiring. Refer to Figure 2 for an illustration of

connecting wires to the NI 9219.

Figure 2. Connecting Wires to the NI 9219 Connectors

© National Instruments Corp. 9 NI 9219 Operating Instructions

Page 10

Wiring TEDS Channels

The NI 9219 supports only Class II

TEDS lines to

TEDS Data (T+) and TEDS COM (T–) and ensure

that neither T+ nor T– is tied in common to any of the signal inputs

(terminals 3 through 6) on the NI 9219. Visit ni.com/info and

enter the info code

rdteds for information about TEDS sensors.

TEDS sensors. Connect the two

Grounding and Shielding Considerations

You can connect ground-referenced or floating signal sources to

the NI 9219. If you make a floating connection between the signal

source and the NI 9219, make sure the voltages on the positive and

negative connections are within the channel-to-earth working

voltage range to ensure proper operation of the NI 9219. Refer to

the Specifications section for more information about operating

voltages and overvoltage protection.

Note For best signal quality, National Instruments

recommends using shielded cables and twisted pair

wiring whenever possible.

Figures 3 and 4 illustrate connecting grounded and floating signal

sources to the NI 9219 in Voltage mode.

NI 9219 Operating Instructions 10 ni.com

Page 11

Signal Source

+

V

SIG

–

V

Ground

SIG

Reference

Shielding

Twisted-Pair

Wiring

Figure 3. Connecting a Grounded Signal Source to the NI 9219

LO

HI

NI 9219

Signal Source

+

V

SIG

–

Shielding

Twisted-Pair

Wiring

LO

HI

NI 9219

Figure 4. Connecting a Floating Signal Source to the NI 9219

© National Instruments Corp. 11 NI 9219 Operating Instructions

Page 12

NI 9219 Timing Options

The NI 9219 supports four different timing options that are

optimized for different types of applications by using different

ADC conversion times. High Speed is optimized for high speed at

the expense of noise rejection, Best 60 Hz Rejection is optimized

for rejection of 60 Hz noise, Best 50 Hz Rejection is optimized for

rejection of 50 Hz noise, and High Resolution is optimized for

maximum overall noise rejection and provides good rejection of

50 Hz and 60 Hz noise. Refer to the Specifications section for more

information.

NI 9219 Circuitry

The NI 9219 is channel-to-channel isolated. Four 24-bit

analog-to-digital converters (ADCs) simultaneously sample all

four analog input channels. An excitation circuit is enabled for

all input modes that require excitation. The ADC and excitation

circuits are reconfigured in each mode to accommodate each type

of sensor. Refer to Figure 5 for an illustration of the input circuitry

for one channel of the NI 9219.

NI 9219 Operating Instructions 12 ni.com

Page 13

CHx

+

1

TEDS

–

2

3

6

FilterMUX

NI 9219

Isolated

ADC

Figure 5. Input Circuitry for One Channel

Voltage and Current Modes

In Voltage and Current modes, connect the signal source to the

NI 9219 across the HI and LO terminals. The current is computed

from the voltage that the ADC measures across an internal shunt

resistor. Refer to Figure 6 for an illustration of the connections.

HI

+

V

–

LO

Voltage/Digital In modes

ADC

NI 9219

HI

LO

R

SH

Current mode

I

ADC

NI 9219

Figure 6. Connections in Voltage, Current, and Digital In Modes

© National Instruments Corp. 13 NI 9219 Operating Instructions

Page 14

4-Wire Resistance and 4-Wire RTD Modes

4-Wire Resistance and 4-Wire RTD modes source a current, which

varies based on the resistance of the load, between the EX+ and

EX– terminals. The measured resistance is computed from the

resulting voltage reading. These modes are not affected by lead

wire resistance because a negligible amount of current flows across

the HI and LO terminals due to the high input impedance of the

ADC. Refer to Figure 7 for an illustration of the connections.

Wire

EX+

HI

RTD/

Resistor

Wire

Wire

Wire

LO

EX–

I

Figure 7. Connections in 4-Wire Resistance and 4-Wire RTD Modes

I

ADC

NI 9219

3-Wire RTD Mode

3-Wire RTD mode sources a current, which varies based on the

resistance of the load, between the EX+ and EX– terminals. This

mode compensates for lead wire resistance in hardware if all the

NI 9219 Operating Instructions 14 ni.com

Page 15

lead wires have the same resistance. A gain of 2x is applied to the

voltage across the negative lead wire and the ADC uses this voltage

as the negative reference to cancel the resistance error across the

positive lead wire. Refer to Figure 8 for an illustration of the

connections.

I

ADC

NI 9219

RTD

Wire

Wire

Wire

EX+

LO

EX–

I

x2

I

Figure 8. Connections in 3-Wire RTD Mode

2-Wire Resistance and Quarter-Bridge Modes

In 2-Wire Resistance and Quarter-Bridge modes, connect the

two ends of the resistor or gauge to the NI 9219 across the HI and

LO terminals. These modes source a current, which varies based on

the resistance of the load, between the HI and LO terminals. The

resulting resistance is computed from the voltage measurement.

2-Wire Resistance and Quarter-Bridge modes do not compensate

© National Instruments Corp. 15 NI 9219 Operating Instructions

Page 16

for lead wire resistance. Refer to Figure 9 for an illustration of the

connections.

Wire

HI

R

Wire

LO

ADC

I

I

NI 9219

Figure 9. Connections in 2-Wire Resistance and Quarter-Bridge Modes

Half-Bridge and Full-Bridge Modes

Half-Bridge and Full-Bridge modes use the internal voltage

excitation to set the input range of the ADC and return voltage

readings that are proportional to the excitation level. The internal

excitation voltage is nominally 2.5 V but it varies based on the

resistance of the sensor. Refer to the Specifications section for

more information about excitation levels.

In Half-Bridge mode, the HI input is referenced to EX–.

In Full-Bridge mode, the ADC reads the HI and LO inputs

differentially. Refer to Figure 10 for an illustration of the

connections.

NI 9219 Operating Instructions 16 ni.com

Page 17

Wire

EX+

R

1

R

2

R

4

R

3

Wire

HI

ADC

LO

1

EX–

NI 9219

1 The dotted line represents the portion of the circuit that is connected

only in Full-Bridge mode.

Figure 10. Connections in Half-Bridge and Full-Bridge Modes

Thermocouple Mode

In Thermocouple mode, connect the positive end of the

thermocouple to HI and the negative end of the thermocouple to

LO. This mode uses the ±125 mV range of the ADC to return a

voltage reading. Use shielded cables and twisted pair wiring and

ground the shielded cables. Each channel has a built-in thermistor

for cold-junction compensation (CJC) calculations. For improved

CJC sensor accuracy, operate the NI 9219 in a stable temperature

© National Instruments Corp. 17 NI 9219 Operating Instructions

Page 18

environment and avoid placing heat sources near the module

or its connectors. Refer to the Specifications section for more

information about accuracy. The NI 9219 does not support open

thermocouple detection. Refer to Figure 11 for an illustration of

the connections.

HI

+

TC

–

LO

Figure 11. Connections in Thermocouple Mode

ADC

NI 9219

Digital In Mode

Digital In mode has a 60 V unipolar threshold that you can set in

software. Refer to the software documentation for information

about setting this threshold. Digital In mode is supported only in

CompactRIO systems. Refer to Figure 6 for an illustration of the

connections.

Open Contact Mode

Open Contact mode sources a current between the HI and LO

terminals and determines if the two terminals are open or closed

based on the measured current through the terminals. When the

NI 9219 Operating Instructions 18 ni.com

Page 19

circuit is open, make sure no more than ±60 V is sourced across the

switch. Open Contact mode is supported only in CompactRIO

systems. Refer to Figure 12 for an illustration of the connections.

HI

LO

ADC

Figure 12. Connections in Open Contact Mode

I

NI 9219

Sleep Mode

This module supports a low-power sleep mode. Support for sleep

mode at the system level depends on the chassis that the module is

plugged into. Refer to the chassis documentation for information

about support for sleep mode. You can enable sleep mode in

software. Refer to the driver software documentation for more

information.

Typically, when a system is in sleep mode, you cannot

communicate with the modules. In sleep mode, the system

consumes minimal power and may dissipate less heat than it does

in normal mode. Refer to the Specifications section for more

information about power consumption and thermal dissipation.

© National Instruments Corp. 19 NI 9219 Operating Instructions

Page 20

Binary Data

NI 9219 modules in the system return calibrated binary data when

used in a CompactRIO chassis. For these modules, you can convert

the data to engineering units in software. Refer to the software

documentation for information about converting data. When used

in a CompactDAQ chassis, NI 9219 modules automatically return

the data in terms of engineering units. Refer to the software

documentation for more information.

Excitation Protection

The NI 9219 excitation circuit is protected from overcurrent and

overvoltage fault conditions. The circuit is automatically disabled

in the event of a fault condition. Whenever possible, channels

automatically recover after the fault is removed. Refer to the

software documentation for information on how an excitation fault

is displayed and handled.

Specifications

The following specifications are typical for the range –40 to 70 °C

unless otherwise noted.

NI 9219 Operating Instructions 20 ni.com

Page 21

Input Characteristics

Number of channels .......................... 4 analog input channels

ADC resolution................................. 24 bits

Type of ADC..................................... Delta-sigma (with analog

prefiltering)

Sampling mode ................................. Simultaneous

Type of TEDS supported ..................IEEE 1451.4 TEDS Class II

(Interface)

Mode input ranges

Mode Nominal Range(s) Actual Range(s)

Voltage ±60 V, ±15 V, ±4 V,

±1 V, ±125 mV

Current ±25 mA ±25 mA

4-Wire and 2-Wire Resistance 10 kΩ, 1 kΩ 10.5 kΩ, 1.05 kΩ

Thermocouple ±125 mV ±125 mV

4-Wire and 3-Wire RTD Pt 1000, Pt 100 5.05 kΩ, 505 Ω

Quarter-Bridge 350 Ω, 120 Ω 390 Ω, 150 Ω

Half-Bridge ±500 mV/V ±500 mV/V

© National Instruments Corp. 21 NI 9219 Operating Instructions

±60 V, ±15 V, ±4 V,

±1 V, ±125 mV

Page 22

Mode Nominal Range(s) Actual Range(s)

Full-Bridge ±62.5 mV/V,

±7.8 mV/V

Digital In — 0– 60 V

Open Contact — 1.05 kΩ

±62.5 mV/V,

±7.8125 mV/V

Conversion time, no channels in TC mode

High speed.................................. 10 ms for all channels

Best 60 Hz rejection ................... 110 ms for all channels

Best 50 Hz rejection ................... 130 ms for all channels

High resolution........................... 500 ms for all channels

Conversion time, one or more channels in TC mode

High speed.................................. 20 ms for all channels

Best 60 Hz rejection ................... 120 ms for all channels

Best 50 Hz rejection ................... 140 ms for all channels

High resolution........................... 510 ms for all channels

Overvoltage protection

Terminals 1 and 2 ....................... ±30 V

Terminals 3 through 6,

across any combination .............. ±60 V

NI 9219 Operating Instructions 22 ni.com

Page 23

Input impedance

Voltage and Digital In modes

(

±60 V, ±15 V, ±4 V) ..................... 1 MΩ

Current mode.............................. < 40 Ω

All other modes .......................... >1 GΩ

Accuracy

Gain Error

(% of

Reading)

Typ (25 °C, ±5 °C),

Mode, Range

Voltage, ±60 V ±0.3, ±0.4 ±20, ±50

Voltage, ±15 V ±0.3, ±0.4 ±60, ±180

Voltage, ±4 V ±0.3, ±0.4 ±240, ±720

Voltage, ±1 V ±0.1, ±0.18 ±15, ±45

Voltage/Thermocouple, ±125 mV ±0.1, ±0.18 ±120, ±360

Current, ±25 mA ±0.1, ±0.6 ±30, ±100

4-Wire and 2-Wire* Resistance, 10 kΩ ±0.1, ±0.5 ±120, ±320

4-Wire and 2-Wire* Resistance, 1 kΩ ±0.1, ±0.5 ±1200, ±3200

© National Instruments Corp. 23 NI 9219 Operating Instructions

Max (–40 to 70 °C)

Offset Error

(ppm of

Range)

Page 24

Gain Error

(% of

Reading)

Offset Error

(ppm of

Range)

Typ (25 °C, ±5 °C),

Mode, Range

Max (–40 to 70 °C)

4-Wire and 3-Wire RTD, Pt 1000 ±0.1, ±0.5 ±240, ±640

4-Wire and 3-Wire RTD, Pt 100 ±0.1, ±0.5 ±2400, ±6400

Quarter-Bridge, 350 Ω ±0.1, ±0.5 ±2400, ±6400

Quarter-Bridge, 120 Ω ±0.1, ±0.5 ±2400, ±6400

Half-Bridge, ±500 mV/V ±0.03, ±0.07 ±300, ±450

Full-Bridge, ±62.5 mV/V ±0.03, ±0.08 ±300, ±1000

Full-Bridge, ±7.8 mV/V ±0.03, ±0.08 ±2200, ±8000

*

2-Wire Resistance mode accuracy depends on the lead wire resistance. This table

assumes 0 Ω of lead wire resistance.

Cold-junction compensation

sensor accuracy ................................. ±1°C typ

NI 9219 Operating Instructions 24 ni.com

Page 25

Stability

Gain Drift

(ppm of

Mode, Range

Reading/°C)

Voltage, ±60 V ±20 ±0.2

Voltage, ±15 V ±20 ±0.8

Voltage, ±4 V ±20 ±3.2

Voltage, ±1 V ±10 ±0.2

Voltage/Thermocouple, ±125 mV ±10 ±1.6

Current, ±25 mA ±15 ±0.4

4-Wire and 2-Wire Resistance, 10 kΩ ±15 ±3

4-Wire and 2-Wire Resistance, 1 kΩ ±15 ±30

4-Wire and 3-Wire RTD, Pt 1000 ±15 ±6

4-Wire and 3-Wire RTD, Pt 100 ±15 ±60

Quarter-Bridge, 350 Ω ±15 ±120

Quarter-Bridge, 120 Ω ±15 ±240

Half-Bridge, ±500 mV/V ±3 ±20

© National Instruments Corp. 25 NI 9219 Operating Instructions

Offset Drift

(ppm of

Range/°C)

Page 26

Mode, Range

Gain Drift

(ppm of

Reading/°C)

Offset Drift

(ppm of

Range/°C)

Full-Bridge, ±62.5 mV/V ±3 ±20

Full-Bridge, ±7.8 mV/V ±3 ±20

Input noise in ppm of Range

rms

Conversion Time

Mode, Range

High

speed

Best

60 Hz

rejection

Best

50 Hz

rejection

High

reso-

lution

Voltage, ±60 V 7.6 1.3 1.3 0.5

Voltage, ±15 V 10.8 1.9 1.9 0.7

Voltage, ±4 V 10.8 2.7 2.7 1.3

Voltage, ±1 V 7.6 1.3 1.3 0.5

Voltage/Thermocouple,

10.8 1.9 1.9 1.0

±125 mV

Current, ±25 mA 10.8 1.9 1.9 1.0

NI 9219 Operating Instructions 26 ni.com

Page 27

Conversion Time

Mode, Range

4-Wire and 2-Wire Resistance,

Best

High

speed

60 Hz

rejection

4.1 1.3 0.8 0.3

Best

50 Hz

rejection

High

reso-

lution

10 kΩ

4-Wire and 2-Wire Resistance,

7.1 1.8 1.2 0.7

1 kΩ

4-Wire and 3-Wire RTD,

7.6 1.7 1.1 0.4

Pt 1000

4-Wire and 3-Wire RTD, Pt 100 10.8 1.9 1.9 0.9

Quarter-Bridge, 350 Ω 5.4 1.0 1.0 0.7

Quarter-Bridge, 120 Ω 5.4 1.0 1.0 0.7

Half-Bridge, ±500 mV/V 3.8 0.5 0.5 0.2

Full-Bridge, ±62.5 mV/V 5.4 1.0 1.0 0.8

Full-Bridge, ±7.8 mV/V 30 4.7 4.7 2.3

© National Instruments Corp. 27 NI 9219 Operating Instructions

Page 28

Input bias current .............................. <1 nA

INL.................................................... ±15 ppm

CMRR (f

= 60 Hz) .......................... >100 dB

in

NMRR

Best 60 Hz rejection ................... 90 dB at 60 Hz

Best 50 Hz rejection ................... 80 dB at 50 Hz

High resolution ........................... 65 dB at 50 Hz and 60 Hz

Excitation level for Half-Bridge and Full-Bridge modes

Mode Load Resistance (Ω) Excitation (V)

Half-Bridge 700 2.5

Half-Bridge 240 2.0

Full-Bridge 350 2.7

Full-Bridge 120 2.2

NI 9219 Operating Instructions 28 ni.com

Page 29

Excitation level for Resistance, RTD, and Quarter-Bridge modes

Load Resistance (Ω) Excitation (mV)

120 50

350 150

1 k 430

10 k 2200

MTBF ............................................... 384,716 hours at 25 °C;

Bellcore Issue 6, Method 1,

Case 3, Limited Part Stress

Method

Note Contact NI for Bellcore MTBF specifications

at other temperatures or for MIL-HDBK-217F

specifications.

Power Requirements

Power consumption from chassis

Active mode ...............................750 mW max

Sleep mode ................................. 25 μW max

© National Instruments Corp. 29 NI 9219 Operating Instructions

Page 30

Thermal dissipation (at 70 °C)

Active mode ...............................625 mW max

Sleep mode ................................. 25 μW max

Physical Characteristics

If you need to clean the module, wipe it with a dry towel.

Spring-terminal wiring...................... 18 to 28 AWG copper

conductor wire with 7 mm

(0.28 in.) of insulation

stripped from the end

Weight ............................................... 156 g (5.5 oz)

Safety

Safety Voltages

Connect only voltages that are within these limits.

Isolation

Channel-to-channel

Continuous ........................... 250 VAC,

Withstand ............................. 1390 VAC, verified by a 5 s

NI 9219 Operating Instructions 30 ni.com

Measurement Category II

dielectric withstand test

Page 31

Channel-to-earth ground

Continuous ........................... 250 VAC,

Measurement Category II

Withstand ............................. 2300 VAC, verified by a 5 s

dielectric withstand test

Measurement Category II is for measurements performed on

circuits directly connected to the electrical distribution system.

This category refers to local-level electrical distribution, such as

that provided by a standard wall outlet, for example, 115 V for U.S.

or 230 V for Europe. Do not connect the NI 9219 to signals or

use for measurements within Measurement Categories III or IV.

Safety Standards

This product is designed to meet the requirements of the following

standards of safety for electrical equipment for measurement,

control, and laboratory use:

• IEC 61010-1, EN 61010-1

• UL 61010-1, CSA 61010-1

Note For UL and other safety certifications, refer to the

product label or visit

© National Instruments Corp. 31 NI 9219 Operating Instructions

ni.com/certification, search

Page 32

by module number or product line, and click the

appropriate link in the Certification column.

Hazardous Locations

U.S. (UL) .......................................... Class I, Division 2,

Groups A, B, C, D, T4;

Class I, Zone 2,

AEx nC IIC T4

Environmental

National Instruments C Series modules are intended for indoor use

only but may be used outdoors if installed in a suitable enclosure.

Refer to the installation instructions for the chassis you are using

for more information about meeting these specifications.

Operating temperature

(IEC60068-2-1, IEC 60068-2-2) ......–40 to 70 °C

Storage temperature

(IEC60068-2-1, IEC 60068-2-2) ......–40 to 85 °C

Ingress protection.............................. IP 40

Operating humidity

(IEC 60068-2-56) ................................. 10 to 90% RH, noncondensing

Storage humidity

(IEC 60068-2-56).............................. 5 to 95% RH, noncondensing

NI 9219 Operating Instructions 32 ni.com

Page 33

Maximum altitude............................. 2,000 m

Pollution Degree (IEC 60664).......... 2

Shock and Vibration

To meet these specifications, you must panel mount the system.

Operating vibration

Random (IEC 60068-2-34)......... 5 g

, 10 to 500 Hz

rms

Sinusoidal (IEC 60068-2-6) ....... 5 g, 10 to 500 Hz

Operating shock

(IEC 60068-2-27).............................. 30 g, 11 ms half sine,

50 g, 3 ms half sine,

18 shocks at 6 orientations

Electromagnetic Compatibility

This product is designed to meet the requirements of the following

standards of EMC for electrical equipment for measurement,

control, and laboratory use:

• EN 61326 EMC requirements; Industrial Immunity

• EN 55011 Emissions; Group 1, Class A

• CE, C-Tick, ICES, and FCC Part 15 Emissions; Class A

© National Instruments Corp. 33 NI 9219 Operating Instructions

Page 34

Note For EMC compliance, operate this device with

shielded cabling.

CE Compliance

This product meets the essential requirements of applicable

European directives, as amended for CE markings, as follows:

• 73/23/EEC; Low-Voltage Directive (safety)

• 89/336/EEC; Electromagnetic Compatibility Directive (EMC)

Note Refer to the Declaration of Conformity (DoC) for

this product for any additional regulatory compliance

information. To obtain the DoC for this product, visit

ni.com/certification, search by module number or

product line, and click the appropriate link in the

Certification column.

Waste Electrical and Electronic Equipment (WEEE)

EU Customers At the end of their life cycle, all products

must be sent to a WEEE recycling center. For more

information about WEEE recycling centers and National

Instruments WEEE initiatives, visit

environment/weee.htm

NI 9219 Operating Instructions 34 ni.com

.

ni.com/

Page 35

Calibration

You can obtain the calibration certificate and information about

calibration services for the NI 9219 at

ni.com/calibration.

Calibration interval ........................... 1 year

Where to Go for Support

The National Instruments Web site is your complete resource for

technical support. At

ni.com/support you have access to

everything from troubleshooting and application development

self-help resources to email and phone assistance from

NI Application Engineers.

National Instruments corporate headquarters is located at

11500 North Mopac Expressway, Austin, Texas, 78759-3504.

National Instruments also has offices located around the world to

help address your support needs. For telephone support in the

United States, create your service request at

ni.com/support

and follow the calling instructions or dial 512 795 8248. For

telephone support outside the United States, contact your local

branch office:

Australia 1800 300 800, Austria 43 662 457990-0,

Belgium 32 (0) 2 757 0020, Brazil 55 11 3262 3599,

© National Instruments Corp. 35 NI 9219 Operating Instructions

Page 36

Canada 800 433 3488, China 86 21 5050 9800,

Czech Republic 420 224 235 774, Denmark 45 45 76 26 00,

Finland 385 (0) 9 725 72511, France 01 57 66 24 24,

Germany 49 89 7413130, India 91 80 41190000,

Israel 972 3 6393737, Italy 39 02 413091, Japan 81 3 5472 2970,

Korea 82 02 3451 3400, Lebanon 961 (0) 1 33 28 28,

Malaysia 1800 887710, Mexico 01 800 010 0793,

Netherlands 31 (0) 348 433 466, New Zealand 0800 553 322,

Norway 47 (0) 66 90 76 60, Poland 48 22 3390150,

Portugal 351 210 311 210, Russia 7 495 783 6851,

Singapore 1800 226 5886, Slovenia 386 3 425 42 00,

South Africa 27 0 11 805 8197, Spain 34 91 640 0085,

Sweden 46 (0) 8 587 895 00, Switzerland 41 56 2005151,

Taiwan 886 02 2377 2222, Thailand 662 278 6777,

Turkey 90 212 279 3031, United Kingdom 44 (0) 1635 523545

National Instruments, NI, ni.com, and LabVIEW are trademarks of National Instruments Corporation. Refer to the

Terms of Use section on

product and company names mentioned herein are trademarks or trade names of their respective companies.

For patents covering National Instruments products, refer to the appropriate location: Help»Patents in your software,

patents.txt file on your CD, or ni.com/patents.

the

© 2007 National Instruments Corp. All rights reserved.

374473D-01 Jun07

ni.com/legal for more information about National Instruments trademarks. Other

Loading...

Loading...