Page 1

NI 6711/6713/6731/6733

C

ALIBRATIONPROCEDURE

Introduction

This document contains step-by-step instructions for calibrating

National Instruments 6711/6713/6731/6733 for PCI/PXI/CompactPCI

analog output (AO) devices. Use this calibration procedure in conjunction

with the

for calibrating NI 6711/6713/6731/6733 devices.

ni671xCal.dll

file, which contains specific functions required

Refer to

Note

ni671xCal.dll

ni.com/support/calibrat/mancal.htm

file.

What Is Calibration?

Calibration consists of verifying the measurement accuracy of a device

and adjusting for any measurement error. Verification is measuring the

performance of the device and comparing these measurements to the

factory specifications. During calibration, you supply and read voltage

levels using external standards, then you adjust the module calibration

constants. The new calibration constants are stored in the EEPROM.

The calibration constants are loaded from memory as needed to adjust

for the error in the measurements taken by the device.

Why Should You Calibrate?

The accuracy of electronic components drifts with time and temperature,

which can affect measurement accuracy as the device ages. Calibration

restores these components to their specified accuracy and ensures that the

device still meets NI standards.

for a copy of the

CVI™, LabVIEW™, National Instruments™, NI™, ni.com™, and NI-DAQ™ are trademarks of National Instruments

Corporation. Product and company names mentioned herein are trademarks or trade names of their respective

companies. For patents covering National Instruments products, refer to the appropriate location: Help»Patents in your

software, the patents.txt file on your CD, or ni.com/patents.

ni.com

© 2002 National Instruments Corp. All rights reserved.

May 2002

370555A-01

Page 2

How Often Should You Calibrate?

The measurement requirements of your application determine how often

the NI 6711/6713/6731/6733 must be calibrated to maintain accuracy.

NI recommends that you perform a complete calibration at least once every

year. You can shorten this interval to 90 days or six months based on the

demands of your application.

Calibration Options: External Versus Internal

The NI 6711/6713/6731/6733 has two calibration options: an internal,

or self-calibration, and an external calibration.

Internal Calibration

Internal calibration is a much simpler calibration method that does not rely

on external standards. In this method, the device calibration constants are

adjusted with respect to a high-precision voltage source on the

NI 6711/6713/6731/6733. This type of calibration is used after the device

has been calibrated with respect to an external standard. However, external

variables such as temperature can still affect measurements. The new

calibration constants are defined with respect to the calibration constants

created during an external calibration, ensuring that the measurements can

be traced back to the external standards. In essence, internal calibration is

similar to the auto-zero function found on a digital multimeter (DMM).

External Calibration

External calibration requires using a high-precision DMM. During external

calibration, the DMM supplies and reads voltages from the device.

Adjustments are made to the device calibration constants to ensure that the

reported voltages fall within the device specifications. The new calibration

constants are then stored in the device EEPROM. After the onboard

calibration constants have been adjusted, the high-precision voltage source

on the device is adjusted. An external calibration provides a set of

calibration constants that you can use to compensate for the error in the

measurements taken by the NI 6711/6713/6731/6733.

NI 6711/6713/6731/6733 Calibration Procedure 2 ni.com

Page 3

Equipment and Other Test Requirements

This section describes the equipment, test conditions, documentation,

and software you need to calibrate the NI 6711/6713/6731/6733.

Test Equipment

To calibrate the NI 6711/6713/6731/6733, you need a high-precision

DMM that is at least 10 ppm (0.001%) accurate. NI recommends that you

use the Agilent 3458A DMM for calibration.

If you do not have an Agilent 3458A DMM, use the accuracy specifications

to select a substitute calibration standard.

If you do not have custom connection hardware, you may need a connector

block such as the NI CB-68 and a cable such as the SH6868-D1. These

components give you easy access to the individual pins on the 68-pin

I/O connector.

Test Conditions

Follow these guidelines to optimize connections and test conditions during

calibration:

• Keep connections to the NI 6711/6713/6731/6733 short. Long cables

and wires act as antennae, picking up extra noise, which can affect

measurements.

• Use shielded copper wire for all cable connections to the device.

• Use twisted-pair wire to eliminate noise and thermal offsets.

• Maintain a temperature between 18 and 28 °C. To operate the module

at a specific temperature outside this range, calibrate the device at that

temperature.

• Keep relative humidity below 80%.

• Allow a warm-up time of at least 15 minutes to ensure that the

measurement circuitry is at a stable operating temperature.

Software

Because the NI 6711/6713/6731/6733 is a PC-based measurement device,

you must have the proper device driver installed in the calibration system

before attempting calibration. For this calibration procedure, you need

NI-DAQ version 6.9.2 or earlier installed on the calibration computer.

NI-DAQ, which configures and controls the NI 6711/6713/6731/6733,

is available at

© National Instruments Corporation 3 NI 6711/6713/6731/6733 Calibration Procedure

ni.com/downloads

.

Page 4

NI-DAQ supports a number of programming languages, including

LabVIEW, LabWindows/CVI, Microsoft Visual C++, Microsoft Visual

Basic and Borland C++. When you install the driver, you only need to

install support for the programming language that you intend to use.

You also need copies of the

ni671xCal.h

The DLL provides calibration functionality that does not reside in

NI-DAQ, including the ability to protect the calibration constants, update

the calibration date, and write to the factory calibration area. You can

access the functions in this DLL through any 32-bit compiler. The factory

calibration area and the calibration date should only be modified by a

metrology laboratory or another facility that maintains traceable standards.

files.

ni671xCal.dll,ni671xCal.lib

,and

Configuring the NI 6711/6713/6731/6733

The NI 6711/6713/6731/6733 must be configured in NI-DAQ, which

automatically detects the device. The following steps briefly explain how

to configure the device in NI-DAQ. Refer to the NI 671X/673X User

Manual for detailed installation instructions. You can install this manual

when you install NI-DAQ.

1. Power down the computer.

2. Install the NI 6711/6713/6731/6733 in an available slot.

3. Power on the computer.

4. Launch Measurement & Automation Explorer (MAX).

5. Configure the NI 6711/6713/6731/6733 device number.

6. Click Test Resources to ensure that the NI 6711/6713/6731/6733 is

properly working.

The NI 6711/6713/6731/6733 is now configured.

Note

After a device is configured in MAX, the device is assigned a device number, which

is used in each of the function calls to identify which DAQ device to calibrate.

Writing the Calibration Procedure

The calibration procedure in the Calibrating the NI 6711/6713/6731/6733

section provides step-by-step instructions on calling the appropriate

calibration functions. These calibration functions are C function calls from

NI-DAQ that are also valid for Microsoft Visual Basic and Microsoft

Visual C++ programs. Although LabVIEW VIs are not discussed in this

procedure, you can program in LabVIEW using the VIs that have similar

names to the NI-DAQ function calls in this procedure. Refer to the

NI 6711/6713/6731/6733 Calibration Procedure 4 ni.com

Page 5

Documentation

Flowcharts section for illustrations of the code used at each step of the

calibration procedure.

Often you must follow a number of compiler-specific steps to create an

application that uses NI-DAQ. Refer to the NI-DAQ User Manual for PC

Compatibles at

each of the supported compilers.

Many of the functions listed in the calibration procedure use variables that

are defined in the

include the

variable definitions, you can examine the function call listings in the

NI-DAQ documentation and the

values are required.

For information about NI-DAQ, refer to the following documentation:

• NI-DAQ Function Reference Help

(Start»Programs»National Instruments»NI-DAQ»NI-DAQ Help)

• NI-DAQ User Manual for PC Compatibles at

These two documents provide detailed information about using NI-DAQ.

The function reference help includes information on the functions in

NI-DAQ. The user manual provides instructions on installing and

configuring DAQ devices and detailed information on creating

applications that use NI-DAQ. These documents are the primary references

for writing the calibration utility. For further information on the device you

are calibrating, you may also want to install the device documentation.

ni.com/manuals

nidaqcns.h

nidaqcns.h

file in the code. If you do not want to use these

for details about the required steps for

file. To use these variables, you must

nidaqcns.h

file to determine what input

ni.com/manuals

Calibrating the NI 6711/6713/6731/6733

To calibrate the NI 6711/6713/6731/6733, complete the following steps:

1. Verify the performance of the NI 6711/6713/6731/6733. This step,

which is described in the Verifying the Performance of the

NI 6711/6713/6731/6733 section, confirms whether the device is in

specification prior to adjustment.

2. Adjust the NI 6711/6713/6731/6733 calibration constants with respect

to a known voltage source. This step is described in the Adjusting the

NI 6711/6713/6731/6733 section.

3. Re-verify the performance to ensure that the NI 6711/6713/6731/6733

is operating within its specifications after adjustment.

© National Instruments Corporation 5 NI 6711/6713/6731/6733 Calibration Procedure

Page 6

Verifying the Performance of the NI 6711/6713/6731/6733

Verification determines how well the device is meeting its specifications.

The verification procedure is divided into the major functions of the device.

Throughout the verification process, refer to the tables in the Specifications

section to see if the device needs adjustment.

Verifying Analog Output

This procedure verifies the AO performance of the

NI 6711/6713/6731/6733. NI recommends testing all channels of the

device. However, to save time, you can test only the channels used in your

application. Make sure that you have read the Equipment and Other Test

Requirements section before starting this procedure.

1. Disconnect all cables to the device. Make sure the device is not

connected to any circuits other than those specified by the calibration

procedure.

2. To internally calibrate the device, call the

function with the following parameters set as indicated:

• calOP set to

• setOfCalConst set to

• calRefVolts set to

ND_SELF_CALIBRATE

ND_USER_EEPROM_AREA

0

3. Connect the DMM to DAC0OUT as shown in Table 1.

Calibrate_E_Series

Table 1. Connecting the DMM to DAC0OUT

Output Channel DMMPositiveInput DMM Negative Input

DAC0OUT DAC0OUT (pin 22) AOGND (pin 56)

DAC1OUT DAC1OUT (pin 21) AOGND (pin 55)

DAC2OUT DAC2OUT (pin 57) AOGND (pin 23)

DAC3OUT DAC3OUT (pin 25) AOGND (pin 58)

DAC4OUT DAC4OUT (pin 60) AOGND (pin 26)

DAC5OUT DAC5OUT (pin 28) AOGND (pin 61)

DAC6OUT DAC6OUT (pin 30) AOGND (pin 63)

DAC7OUT DAC7OUT (pin 65) AOGND (pin 63)

Note: Pin numbers are given for 68-pin I/O connectors only. If you are using a 50-pin

I/O connector, refer to the device user manual for signal connection locations.

4. Refer to the table from the Specifications section that corresponds

to the device you are verifying. This specification table shows all

acceptable settings for the device.

NI 6711/6713/6731/6733 Calibration Procedure 6 ni.com

Page 7

5. Call

AO_Configure

to configure the device for the appropriate device

number, channel, and output polarity (the NI 6711/6713/6731/6733

devices support only bipolar output range). Use channel 0 as the

channel to verify. Read the remaining settings from the specification

table for the device.

6. Call

AO_VWrite

to update the AO channel with the appropriate

voltage. The voltage value is in the specification table.

7. Compare the resulting value shown by the DMM to the upper and

lower limits on the specification table. If the value falls between these

limits, the device has passed the test.

8. Repeat steps 3 through 5 until you have tested all values.

9. Disconnect the DMM from DAC0OUT, and reconnect it to the next

channel, making the connections from Table 1.

10. Repeat steps 3 through 9 until you have verified all channels.

11. Disconnect the DMM from the device.

You have now verified the AO channels of the device.

Verifying the Performance of the Counter

This procedure verifies the performance of the counter. The

NI 6711/6713/6731/6733 devices have only one timebase to verify, so you

only need to verify counter 0. Because you cannot adjust this timebase, you

can only verify the performance of counter 0. Make sure that you have read

the Equipment and Other Test Requirements section, and then follow this

procedure:

1. Connect the counter positive input to GPCTR0_OUT (pin 2) and the

counter negative input to DGND (pin 35).

Note

Pin numbers are given for 68-pin I/O connectors only. If you are using a 50-pin

I/O connector, refer to the device documentation for signal connection locations.

2. Call

GPCTR_Control

with action set to

ND_RESET

to place the

counter in a default state.

3. Call

GPCTR_Set_Application

ND_PULSE_TRAIN_GNR

to configure the counter for pulse-train

with application set to

generation.

4. Call

GPCTR_Change_Parameter

with paramID set to

ND_COUNT_1

and paramValue set to2to configure the counter to output a pulse

with an off time of 100 ns.

5. Call

GPCTR_Change_Parameter

with paramID set to

ND_COUNT_2

and paramValue set to2to configure the counter to output a pulse

with an on time of 100 ns.

© National Instruments Corporation 7 NI 6711/6713/6731/6733 Calibration Procedure

Page 8

6. Call

Select_Signal

ND_GPCTR0_OUTPUT

pin on the device I/O connector.

7. Call

GPCTR_Control

generation of the square wave. The device begins to generate a 5 MHz

square wave when

GPCTR_Control

8. Compare the value read by the counter to the test limits shown in the

appropriate table in the Specifications section. If the value falls

between these limits, the device has passed this test.

9. Disconnect the counter from the device.

You have now verified the device counter.

Adjusting the NI 6711/6713/6731/6733

This procedure adjusts the AO calibration constants. At the end of each

calibration procedure, these new constants are stored in the factory area

of the device EEPROM. An end-user cannot modify these values, which

provides a level of security that ensures users do not accidentally access or

modify any calibration constants adjusted by the metrology laboratory.

This step in the calibration process calls functions in NI-DAQ and in

the

ni671x.dll

ni671x.dll

1. Disconnect all cables to the device. Make sure the device is not

connected to any circuits other than those specified by the calibration

procedure.

2. To internally calibrate the device, call the

function with the following parameters set as indicated:

• calOP set to

• setOfCalConst set to

• calRefVolts set to

3. Connect the calibrator to the device according to Table 2.

. For further information on the functions in the

, refer to the comments in the

ND_SELF_CALIBRATE

with signal and source set to

to route the counter signal to the GPCTR0_OUT

with action set to

ND_PROGRAM

to start the

completes execution.

ni671x.h

Calibrate_E_Series

ND_USER_EEPROM_AREA

0

file.

Table 2. Connecting the Calibrator to the Device

6711/6713/6731/6733 Pins Calibrator

EXTREF (pin 20) Output High

AOGND (pin 54) Output Low

Pin numbers are given for 68-pin connectors only. If you are using a 50-pin connector,

refer to the device documentation for signal connection locations.

NI 6711/6713/6731/6733 Calibration Procedure 8 ni.com

Page 9

4. To find out the date of the last calibration, call

is included in the

device was last calibrated.

5. Set the calibrator to output a voltage of 5.0 V.

6. Call

Note

If the voltage supplied by the source does not maintain a steady 5.0 V, you receive

an error.

Calibrate_E_Series

indicated:

• calOP set to

• setOfCalConst set to

• calRefVolts set to

ni671x.dll

ND_EXTERNAL_CALIBRATE

5.0

. CalDate stores the date when the

with the following parameters set as

ND_USER_EEPROM_AREA

Get_Cal_Date

,which

Specifications

Using the Tables

7. Call

8. Disconnect the calibrator from the device.

The device is now adjusted with respect to the external source. After

the device is adjusted, you can verify the AO operation by repeating the

Verifying Analog Output section.

The following tables are accuracy specifications to use when verifying and

adjusting the NI 6711/6713/6731/6733. The tables show the specifications

for 1-year and 24-hour calibration intervals.

The following definitions describe how to use the specification tables in

this section.

Copy_Const

factory-protected portion of the EEPROM. This function also updates

the calibration date.

to copy the new calibration constants to the

Range

Range refers to the maximum allowable voltage range of an input or output

signal. For example, if a device is configured in bipolar mode with a range

of 20 V, the device can sense signals between +10 and –10 V.

Polarity

Polarity refers to the positive and negative voltages of the input signal that

can be read. Bipolar means the device can read both positive and negative

voltages. Unipolar means that the device can read only positive voltages.

© National Instruments Corporation 9 NI 6711/6713/6731/6733 Calibration Procedure

Page 10

Tes t Poi nt

The Test Point is the voltage value that is input or output for verification

purposes. This value is broken down into Location and Value. Location

refers to where the test value fits within the test range. Pos FS refers to

positive full-scale, and Neg FS refers to negative full-scale. Value refers to

the voltage to be verified, and Zero refers to the outputting of zero volts.

24-Hour Ranges

The 24-Hour Range column contains the upper limits and lower limits for

the test point value. If the device has been calibrated in the last 24 hours,

the test point value should fall between the upper and lower limit values.

These limit values are expressed in volts.

1-Year Ranges

The 1-Year Range column contains the upper limits and lower limits for the

test point value. If the device has been calibrated in the last year, the test

point value should fall between the upper and lower limit values. These

limits are expressed in volts.

Counters

Because you cannot adjust the resolution of the counter/timers, these values

do not have a 1-year or 24-hour calibration period. However, the test point

and upper and lower limits are provided for verification purposes.

Table 3. Analog Output for the NI 6711/6713

Te st P o i nt 24-Hour Ranges 1-Year Ranges

Lower

Range (V) Polarity

0 Bipolar Zero 0.0 –0.0059300 0.0059300 –0.0059300 0.0059300

20 Bipolar Pos FS 9.9900000 9.9822988 9.9977012 9.9818792 9.9981208

20 Bipolar Neg FS –9.9900000 –9.9977012 –9.9822988 –9.9981208 –9.9818792

Range (V) Polarity

0 Bipolar Zero 0.0 –0.0010270 0.0010270 –0.0010270 0.0010270

20 Bipolar Pos FS 9.9900000 9.9885335 9.9914665 9.9883636 9.9916364

20 Bipolar Neg FS –9.9900000 –9.9914665 –9.9885335 –9.9916364 –9.9883636

NI 6711/6713/6731/6733 Calibration Procedure 10 ni.com

Location Va lu e ( V)

Table 4. Analog Output for the NI 6731/6733

Te st P o i nt 24-Hour Ranges 1-Year Ranges

Location Va lu e ( V)

Limit (V)

Lower

Limit (V)

Upper

Limit (V)

Upper

Limit (V)

Lower

Limit (V)

Lower

Limit (V)

Upper

Limit (V)

Upper

Limit (V)

Page 11

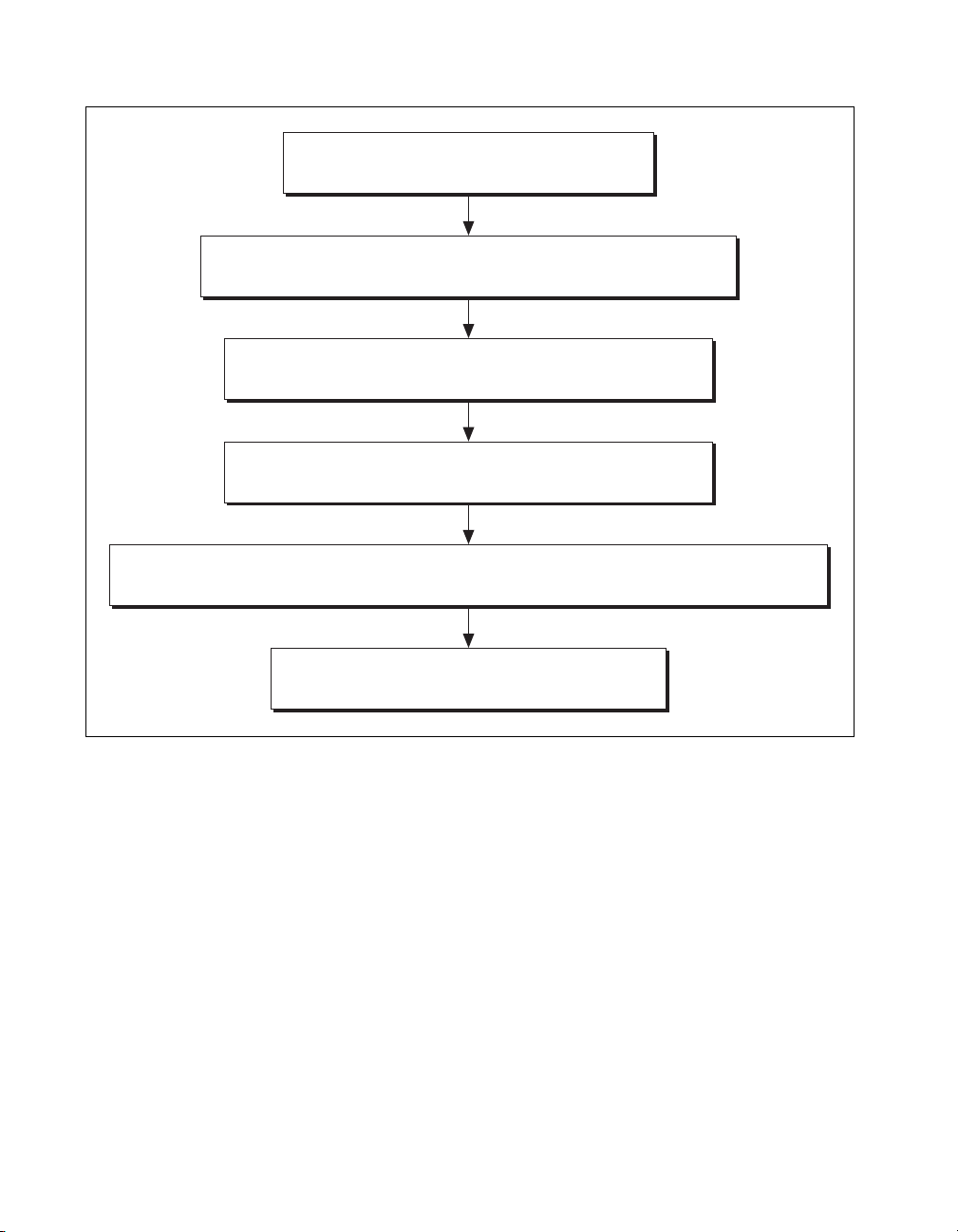

Flowcharts

These flowcharts show the appropriate NI-DAQ function calls for

verifying and adjusting the NI 6711/6713/6731/6733. Refer to the

Calibrating the NI 6711/6713/6731/6733 section, the NI-DAQ Function

Reference Help (Start»Programs»National Instruments»NI-DAQ»

NI-DAQ Help), and the NI-DAQ User Manual for PC Compatibles at

ni.com/manuals

Verifying Analog Output

AO_Configure (deviceNumber,channel,outputPolarity,0,10,0)

Table 5. Counter

Set Point (MHz) Upper Limit (MHz) Lower Limit (MHz)

5 4.9995 5.0005

for additional information on the software structure.

From the specification table for the product,

determine the channel and voltage to verify.

AO_VWrite (deviceNumber,channel,voltage)

Repeat with next channel.

Figure 1. Verifying Analog Output

© National Instruments Corporation 11 NI 6711/6713/6731/6733 Calibration Procedure

Page 12

Verifying the Counter

GPCTR_Control (deviceNumber,0,ND_RESET)

GPCTR_Set_Application (deviceNumber,0,ND_PULSE_TRAIN_GNR)

GPCTR_Change_Parameter (deviceNumber,0,ND_COUNT_1,2)

GPCTR_Change_Parameter (deviceNumber,0,ND_COUNT_2,2)

Select_Signal (deviceNumber,ND_GPCTR0_OUTPUT,ND_GPCTR0_OUTPUT,ND_LOW_TO_HIGH)

GPCTR_Control (deviceNumber,0,ND_PROGRAM)

Figure 2. Verifying the Counter

NI 6711/6713/6731/6733 Calibration Procedure 12 ni.com

Page 13

Adjusting the NI 6711/6713/6731/6733

Calibrate_E_Series (deviceNumber,ND_SELF_CALIBRATE,ND_USER_EEPROM_AREA,0)

Get_Cal_Date (deviceNumber,*CalDate)

Calibrate_E_Series (deviceNumber,ND_EXTERNAL_CALIBRATE,ND_USER_AREA,5.0)

Copy_Const (deviceNumber)

Figure 3. Adjusting the NI 6711/6713/6731/6733

© National Instruments Corporation 13 NI 6711/6713/6731/6733 Calibration Procedure

Loading...

Loading...