Page 1

Computer-Based

Instruments

NI 4050 User Manual

Digital Multimeter Card for PCMCIA

NI 4050 User Manual

March 2000 Edition

Part Number 321427C-01

Page 2

Worldwide Technical Support and Product Information

www.ni.com

National Instruments Corporate Headquarters

11500 North Mopac Expressway Austin, Texas 78759-3504 USA Tel: 512 794 0100

Worldwide Offices

Australia 03 9879 5166, Austria 0662 45 79 90 0, Belgium 02 757 00 20, Brazil 011 284 5011,

Canada (Calgary) 403 274 9391, Canada (Ontario) 905 785 0085, Canada (Québec) 514 694 8521,

China 0755 3904939, Denmark 45 76 26 00, Finland 09 725 725 11, France 01 48 14 24 24,

Germany 089 741 31 30, Greece 30 1 42 96 427, Hong Kong 2645 3186, India 91805275406,

Israel 03 6120092, Italy 02 413091, Japan 03 5472 2970, Korea 02 596 7456, Mexico (D.F.) 5 280 7625,

Mexico (Monterrey) 8 357 7695, Netherlands 0348 433466, New Zealand 09 914 0488, Norway 32 27 73 00,

Poland 0 22 528 94 06, Portugal 351 1 726 9011, Singapore 2265886, Spain 91 640 0085,

Sweden 08 587 895 00, Switzerland 056 200 51 51, Taiwan 02 2528 7227, United Kingdom 01635 523545

For further support information, see the Technical Support Resources appendix. To comment on the

documentation, send e-mail to techpubs@ni.com

© Copyright 1999, 2000 National Instruments Corporation. All rights reserved.

Page 3

Important Information

Warranty

The NI 4050 is warranted against defects in materials and workmanship for a period of one year from the date of shipment, as

evidenced by receipts or other documentation. National Instruments will, at its option, repair or replace equipment that proves to

be defective during the warranty period. This warranty inclu des part s an d la bor.

The media on which you receive National Instruments software are warranted not to fail to execute programming instructions,

due to defects in materials and workmanship, for a period of 90 days from date of sh ipmen t, as evid enced b y receipt s o r other

documentation. National Instruments will, at its op ti on , repair or repl ace soft ware me dia th at do not ex ecu te pr ogram mi ng

instructions if National Instruments receives notice of such defects during the warranty period. National Instruments does not

warrant that the operation of the software shall be uni nterrup ted or error free.

A Return Material Authorization (RMA) number must be obtained from the factory and clearly marked on the outside of

the package before any equipment will be accepted for warranty work. National Instruments will pay the shipping costs of

returning to the owner parts which are covered by warrant y.

National Instruments believes that the information in this document is accurate. The document has been carefully reviewed

for technical accuracy. In the event that technical or typographical errors exist, National Instruments reserves the right to

make changes to subsequent editions of this document withou t p rio r no ti ce to hold ers o f thi s ed itio n. The read er sh ou ld consul t

National Instruments if errors are suspected. In no even t shall Nati on al Inst rum ents be l iable fo r any dama ges aris in g o ut of

or related to this document or the information contained in it.

XCEPT AS SPECIFIED HEREIN

E

WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE

NEGLIGENCE ON THE PART OF NATIONAL INSTRUMENTS SHALL BE LIMITED TO THE AMOUNT THERETOFORE PAID BY THE CUSTOMER

NSTRUMENTS WILL NOT BE LIABLE FOR DAMAGES RESULTING FROM LOSS OF DATA, PROFITS, USE OF PRODUCTS, OR INCIDENTAL OR

I

CONSEQUENTIAL DAMAGES, EVEN IF ADVISED OF THE POSSIBILITY THEREOF

apply regardless of the form of action, whether in contract or tort, including negligence. Any action against National Instruments

must be brought within one year after the cause of action accrues. National Instruments shall not be liable for any delay in

performance due to causes beyond its reasonable control. The warranty provided herein does not co ver d amag es, defects,

malfunctions, or service failures caused by ow ner’s fai lu re t o foll ow th e Nation al Inst rum ent s in stal l ation, op erat i on, or

maintenance instructions; owner’s modification of the pro du ct; ow ner’s abus e, m isus e, or negligent acts; and po wer failure or

surges, fire, flood, accident, actions of third parties, or other events outside reasonable control.

ATIONAL INSTRUMENTS MAKES NO WARRANTIES, EXPRESS OR IMPLIED, AND SPECIFICALLY DISCLAIMS ANY

, N

Copyright

Under the copyright laws, this publication may not be reproduced or transmitted in any form, electronic or mechanical, including

photocopying, recording, storing in an informatio n retriev al s ystem, o r t ran sl ating , in who le or i n p art, wit ho ut t he prior written

consent of National Instruments Corporation.

USTOMER’S RIGHT TO RECOVER DAMAGES CAUSED BY FAULT OR

. C

. This limitation of the liability of National Instruments will

. N

ATIONAL

Trademarks

CVI™, ComponentWorks™, LabVIEW™, National Instruments™, ni.com™, NI-DAQ™, SCXI™, and VirtualBench™ are trademarks

of National In strum ent s Co rporat ion.

Product and company names mentioned herein are trad emarks o r trad e name s of thei r respect ive compan ies .

WARNING REGARDING USE OF NATIONAL INSTRUMENTS PRODUCTS

(1) NATIONAL INSTRUMENTS PRODUCTS ARE NOT DESIGNED WITH COMPONENTS AND TESTING FOR A LEVEL

OF RELIABILITY SUITABLE FOR USE IN OR IN CONNECTION WITH SURGICAL IMPLANTS OR AS CRITICAL

COMPONENTS IN ANY LIFE SUPPORT SYSTEMS WHOSE FAILURE TO PERFORM CAN REASONABLY BE

EXPECTED TO CAUSE SIGNIFICANT INJURY TO A HUMAN.

(2) IN ANY APPLICATION, I NCLUDING THE ABOVE , RELIABILITY OF OP ERATION OF THE SOFT WARE PRODUCTS

CAN BE IMPAIRED BY ADVERSE FACTORS, INCLUDING BUT NOT LIMITED TO FLUCTUATIONS IN ELECTRICAL

POWER SUPPLY, COMPUTER HARDWARE MALFUNCTIONS, COMPUTER OPERATING SYSTEM SOFTWARE

FITNESS, FITNESS OF COMPILERS AND DEVELOPMENT SOFTWARE USED TO DE VEL OP AN APPLICAT ION,

INSTALLATION ERRORS, SOFTWARE AND HARDWARE COMPATIBILITY PROBLEMS, MALFUNCTIONS OR

FAILURES OF ELECTRONIC MONITORING OR CONTROL DEVICES, TRANSIENT FAILURES OF ELECTRONIC

SYSTEMS (HARDWARE AND/OR SOFTWARE), UNANTICIPATED USES OR MISUSES, OR ERRORS ON THE PART OF

THE USER OR APPLICATIONS DESIGNER (ADVERSE FACTORS SUCH AS THESE ARE HEREAFTER

COLLECTIVELY TERMED “SYSTEM FAILURES”). ANY APPLICATION WHERE A SYSTEM FAILURE WOULD

CREATE A RISK OF HARM TO PROPERTY OR PERSONS (INCLUDING THE RISK OF BODILY INJURY AND DEATH)

SHOULD NOT BE RELIANT SOLELY UPON ONE FORM OF ELECTRON IC SYSTE M DUE TO THE RISK OF SYSTEM

FAILURE. TO AVOID DAMAGE, INJURY, OR DEATH, THE USER OR APPLICATION DESIGNE R MU ST T AKE

REASONABLY PRUDENT STEPS TO PROTECT AGAINST SYSTEM FAILURES, INCLUDING BUT NOT LIMITED TO

BACK-UP OR SHUT DOWN MECHANISMS. BECAUSE EACH END-USER SYSTEM IS CUSTOMIZED AND DIFFERS

FROM NATIONAL INSTRUMENTS' TESTING PLATFORMS AND BECAUSE A USER OR APPLICATION DESIGNER

MAY USE NATIONAL INSTRUMENTS PRODUCTS IN COMBINATION WITH OTHER PRODUCTS IN A MANNER NOT

EVALUATED OR CONTEMPLATED BY NATIONAL INSTRUMENTS, THE USER OR A PPLICATION DE SIGNER IS

ULTIMATELY RESPONSIBLE FOR VERIFYING AND VALIDATING THE SUITAB ILITY OF NA TIONAL

INSTRUMENTS PRODUCTS WHENEVER NATIONAL INSTRUMENTS PRODUCTS ARE INCORPORATED IN A

SYSTEM OR APPLICATION, INCLUDING, WITHOUT LIMITATION, THE APPROPRIATE DESIGN, PROCESS AND

SAFETY LEVEL OF SUCH SYSTEM OR APPLICATION.

Page 4

Compliance

FCC/Canada Radio Frequency Interference Compliance*

Determining FCC Class

The Federal Communications Commission (FCC) has rules to protect wireless communications from interference.

The FCC places digital electronics into two classes. These classes are known as Class A (for use in industrialcommercial locations only) or Class B (for use in residential or commercial locations). Depending on where it is

operated, this product could be subject to restrictions in the FCC rules. (In Canada, the Department of

Communications (DOC), of Industry Canada, regulates wireless interference in much the same way.)

Digital electronics emit weak signals during normal operation that can affect radio, television, or other wireless

products. By examining the product you purchased, you can determine the FCC Class and therefore which of the two

FCC/DOC Warnings apply in the following sections. (Some products may not be labeled at all for FCC; if so, the

reader should then assume these are Class A devices.)

FCC Class A products only display a simple warning statement of one paragraph in length regarding interference and

undesired operation. Most of our products are FCC Class A. The FCC rules have restrictions regarding the locations

where FCC Class A products can be operated.

FCC Class B products display either a FCC ID code, starting with the letters EXN,

or the FCC Class B compliance mark that appears as shown here on the right.

Consult the FCC web site

http://www.fcc.gov for more information.

FCC/DOC Warnings

This equipment generates and uses radio frequency energy and, if not installed and used in strict accordance with the

instructions in this manual and the CE Mark Declaration of Conformity**, may cause interference to radio and

television reception. Classification requirements are the same for the Federal Communications Commission (FCC)

and the Canadian Department of Communications (DOC).

Changes or modifications not expressly approved by National Instruments could void the user’s authority to operate

the equipment under the FCC Rules.

Class A

Federal Communications Commission

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to part 15

of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference when the

equipment is operated in a commercial environment. This equipment generates, uses, and can radiate radio frequency

energy and, if not installed and used in accordance with the instruction manual, may cause harmful interference to

radio communications. Operation of this equipment in a residential area is likely to cause harmful interference in

which case the user will be required to correct the interference at his own expense.

Canadian Department of Communications

This Class A digital apparatus meets all requirements of the Canadian Interference-Causing Equipment Regulations.

Cet appareil numérique de la classe A respecte toutes les exigences du Règlement sur le matériel brouilleur du

Canada.

Class B

Federal Communications Commission

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to part 15

of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference in a

residential installation. This equipment generates, uses and can radiate radio frequency energy and, if not installed

and used in accordance with the instructions, may cause harmful interference to radio communications. However,

there is no guarantee that interference will not occur in a particular installation. If this equipment does cause harmful

interference to radio or television reception, which can be determined by turning the equipment off and on, the user

is encouraged to try to correct the interference by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

Page 5

• Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

• Consult the dealer or an experienced radio/TV technician for help.

Canadian Department of Communications

This Class B digital apparatus meets all requirements of the Canadian Interference-Causing Equipment Regulations.

Cet appareil numérique de la classe B respecte toutes les exigences du Règlement sur le matériel brouilleur du

Canada.

European Union - Compliance to EEC Directives

Readers in the EU/EEC/EEA must refer to the Manufacturer's Declaration of Conformity (DoC) for information**

pertaining to the CE Mark compliance scheme. The Manufacturer includes a DoC for most every hardware product

except for those bought for OEMs, if also available from an original manufacturer that also markets in the EU, or

where compliance is not required as for electrically benign apparatus or cables.

* Certain exemptions may apply in the USA, see FCC Rules §15.103 Exempted devices, and §15.105(c).

Also available in sections of CFR 47.

** The CE Mark Declaration of Conformity will contain important supplementary information and instructions

for the user or installer.

Page 6

Conventions

The following conventions are used in this manual:

» The » symbol leads you through nested menu items and dialog box options

to a final action. The sequence File»Page Setup»Options directs you to

pull down the File menu, select the Page Setup item, and select Options

from the last dialog box.

This icon denotes a note, which alerts you to important information.

This icon denotes a caution, which advises you of precautions to take to

avoid injury, data loss, or a system crash.

bold Bold text denotes items that you must select or click on in the software,

such as menu items and dialog box options. Bold text also denotes

parameter names.

italic Italic text denotes variables, emphasis, a cross reference, or an introduction

to a key concept. This font also denotes text that is a placeholder for a word

or value that you must supply.

monospace Text in this font denotes text or characters that you should enter from the

keyboard, sections of code, programming examples, and syntax examples.

This font is also used for the proper names of disk drives, paths, directories,

programs, subprograms, subroutines, device names, functions, operations,

variables, filenames and extensions, and code excerpts.

Page 7

Contents

Chapter 1

Taking Measurements with the NI 4050

Cable and Probes ...........................................................................................................1-1

Introduction to the VirtualBench-DMM Soft Front Panel.............................................1-3

Use the Soft Front Panel................................................................................................1-5

Measure DC and AC Voltage..........................................................................1-5

Measure 2-Wire Resistance.............................................................................1-6

Measure the Voltage Drop Across a Diode.....................................................1-7

Measure Current..............................................................................................1-8

Measure Temperature......................................................................................1-9

Chapter 2

NI 4050 Operation

Safety Instructions .........................................................................................................2-1

Measurement Fundamentals ...................................................................................... ....2-2

Warm Up.........................................................................................................2-2

Selecting the Resolution..................................................................................2-2

Grounding........................................................................................................2-2

Voltage Measurements ..................................................................................................2-2

DC Voltage......................................................................................................2-2

Input Ranges ................................... .................................. ................2-3

Measurement Considerations............................................................2-3

Input Impedance .................................................................2-3

Thermal EMF .....................................................................2-4

Noise Rejection...................................................................2-4

AC Voltage......................................................................................................2-6

Input Ranges ................................... .................................. ................2-7

Measurement Considerations............................................................2-7

AC Offset Voltage..............................................................2-7

Frequency Response...........................................................2-7

Resistance Measurements..............................................................................................2-8

2-Wire Resistance Measurements ...................................................................2-8

Input Ranges ................................... .................................. ................2-8

Continuity Measurements.............................................................................. ..2-9

Diode Measurements .....................................................................................................2-9

© National Instruments Corporation vii NI 4050 User Manual

Page 8

Contents

Appendix A

Specifications

Appendix B

Technical Support Resources

Glossary

Index

Figures

Figure 1-1. Installing the NI 4050 and Cables.........................................................1-2

Figure 1-2. NI-DMM Soft Front Panel ....................................................................1-3

Figure 1-3. Digits of Precision.................................................................................1-5

Figure 1-4. Connecting Probes for Voltage Measurement......................................1-6

Figure 1-5. Connections for Resistance Measurement............................................1-7

Figure 1-6. Connecting Signals for Diode Test.......................................................1-7

Figure 1-7. Connections for Current Measurement.................................................1-8

Figure 1-8. Connecting Signals for RTDs and Thermistors....................................1-9

Figure 2-1. Effect of Input Impedance on Signal Measurements............................2-3

Figure 2-2. Normal Mode Measurement Effects.....................................................2-5

Figure 2-3. Common Mode Measurement Effects ..................................................2-6

Figure 2-4. Circuit for 2-Wire Resistance Measurements.......................................2-8

Figure 2-5. Circuit for Diode Measurements...........................................................2-9

NI 4050 User Manual viii www.ni.com

Page 9

Taking Measurements with

the NI 4050

Thank you for buying a National Instruments 4050 digital multimeter card.

A system based on the NI 4050 offers the flexibility, performance, and

size that makes it ideal for service, repair, and manufacturing as well as

for use in industrial and laboratory environments. The NI 4050, used in

conjunction with your computer, is a versatile, cost-effective platform for

high-resolution measurements.

For the most current versions of manuals and example programs, visit

www.ni.com/instruments for free downloads.

Detailed specifications for the NI 4050 are in Appendix A, Specifications.

Note

Before using any measurement equipment, it is important that you thoroughly

understand the safety instructions for that product. The beginning of Chapter 2, NI 4050

Operation, covers the safety guidelines for your NI 4050.

1

Cable and Probes

The NI 4050 instrument kit contains the NI 4050 accessory cable that

connects the NI 4050 to a pair of test probes with shrouded banana plugs,

which are also included in the kit. Both the NI 4050 accessory cable and the

test probes meet international safety requirements including UL 3111 and

IEC 1010-1 for the full ranges of applications supported by the NI 4050 .

Before using any probes or accessories not supplied by National

Instruments, ensure that they meet applicable safety requirements for the

signal levels you may encounter.

To use the NI 4050 accessory cable and probes with the NI 4050, first

connect the cable to the card as shown in Figure 1-1. The accessory cable

connector is polarized so that it cannot be plugged in incorrectly.

© National Instruments Corporation 1-1 NI 4050 User Manual

Page 10

Chapter 1 Taking Measurements with the NI 4050

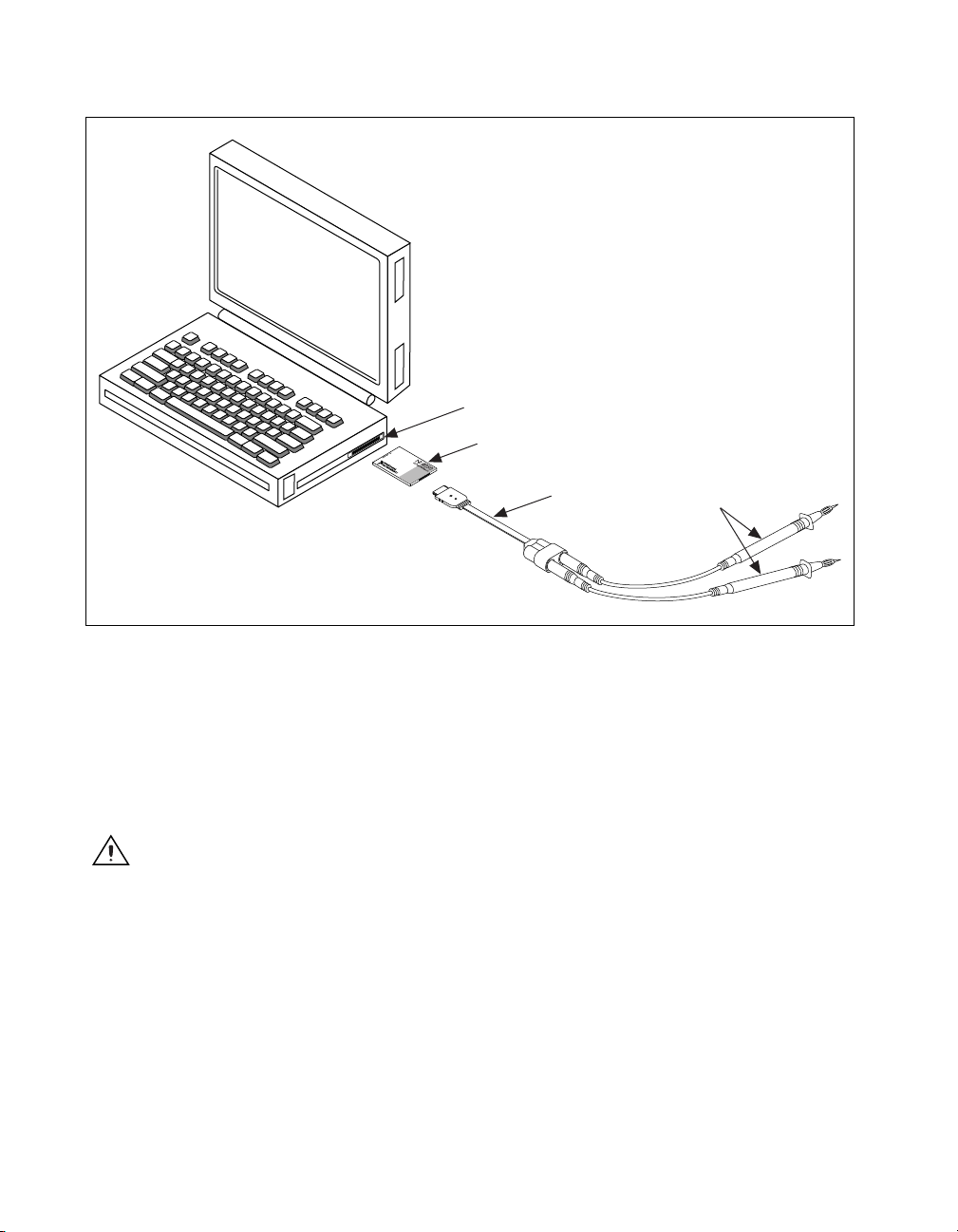

Portable

Computer

PCMCIA Slot

NI 4050

Accessory Cable

Probes

Figure 1-1. Installing the NI 4050 and Cables

The test probes connect to the NI 4050 accessory cable via shrouded

banana jacks. The shrouds around the banana jacks prevent you from

contacting potentially hazardous voltages connected to the test probes.

Y ou can also connect the cable to standard, unshrouded banana jack probes

or accessories; however, use unshrouded probes or accessories only when

the voltages are less than 30 V

Caution To prevent possible safety hazards, the maximum voltage between either of the

inputs and the ground of the computer should never exceed ±250 VDC or 250 V

or 42 V

rms

pk-to-pk

.

.

rms

NI 4050 User Manual 1-2 www.ni.com

Page 11

Chapter 1 Taking Measurements with the NI 4050

Introduction to the VirtualBench-DMM Soft Front Panel

The following sections explain how to make connections to your NI 4050

and take simple measurements using the VirtualBench-DMM, as shown in

Figure 1-2. To launch the soft front panel, select Start»Programs»

National Instruments DMM»Soft Front Panel.

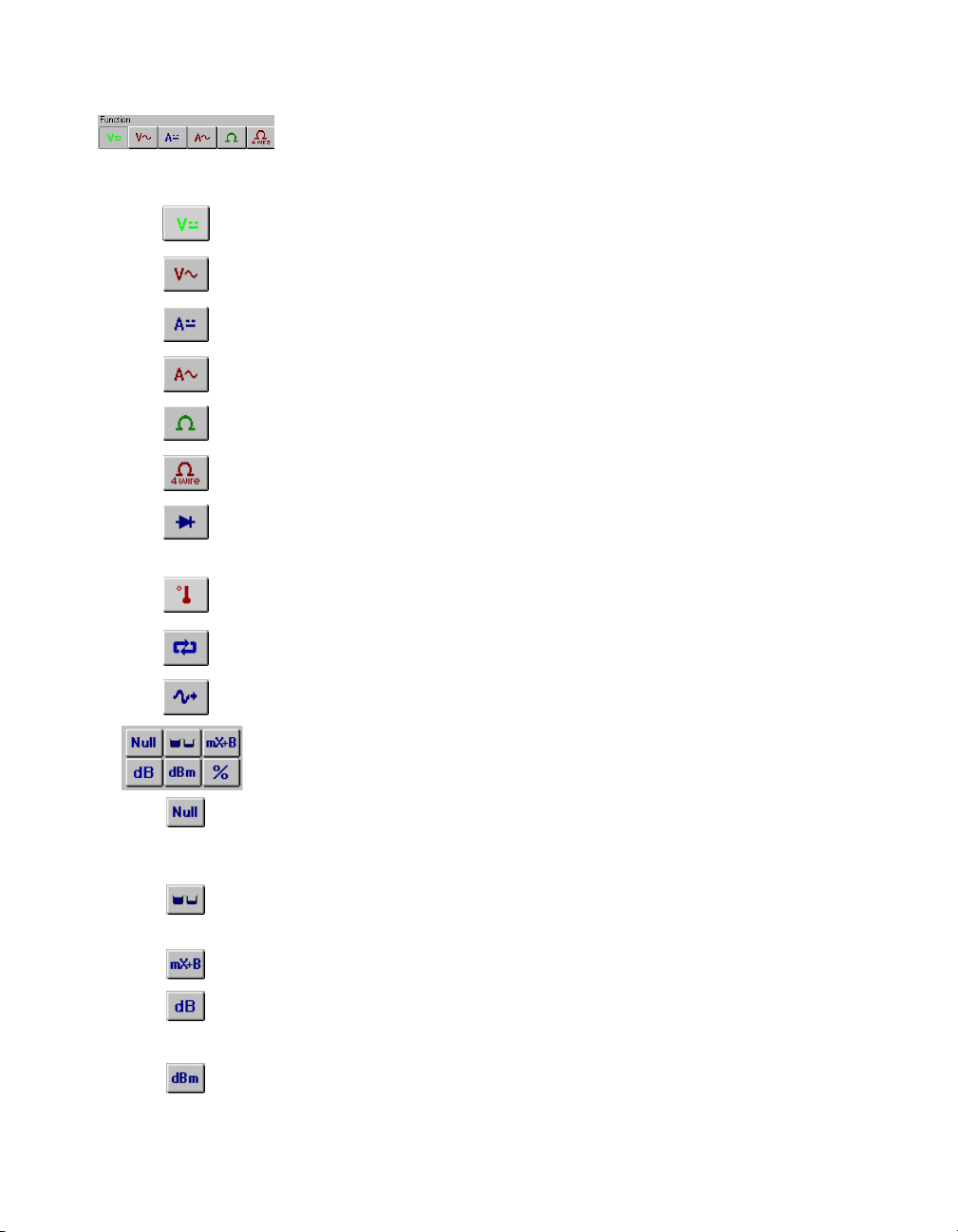

Figure 1-2.

The following text describes the options available on the soft front panel.

Refer to Help»Online Reference located on the soft front panel for

information on front panel menus.

The range selector determines the range of measurements

V irtualBench-DMM makes. The range differs for each measurement mode.

If the measurement exceeds the range, +OVER or –OVER appears in the

measurement display. Auto selects the range that best matches the input

signal.

The value indicator displays the value measured by your NI 4060

(The value shown is an example only.).

The unit indicator displays the measurement units of the value you are

measuring. The units are expressed as VAC, VDC, mVAC, mVDC, Ω,

kΩ,MΩ, mA, AC, or mA DC. The indicator also displays the digits of

resolution. By clicking on the indicator, you can change the DMM’s

resolution.

NI-DMM Soft Front Panel

© National Instruments Corporation 1-3 NI 4050 User Manual

Page 12

Chapter 1 Taking Measurements with the NI 4050

The Function selector allows you select a measurement mode. Select

Edit»Settings and click on the tabs for Current and Resistance or

Temperature to control the data type acquired by VirtualBench-DMM.

DC volts measures the DC component of a voltage signal.

AC volts measures the AC component of a voltage signal.

DC current measures the DC component of a current source.

AC current measures the AC component of a current source.

2-wire measures resistance using the 2-wire method.

4-wire measures resistance using the 4-wire method.

Diode measures the voltage drop across a diode. The maximum voltage

VirtualBench-DMM measures is 2 V.

Temperature measures temperature.

The run button starts and stops continuous DMM measurements.

The single button performs a single measurement.

The math buttons allow you to manipulate readings mathematically.

Null starts relative mode. VirtualBench-DMM makes all subsequent

measurements relative to the measurement it makes when you click

on Null.

Max/Min displays the maximum and minimum values that occur after you

start Relative mode.

mX+B enables the mX+B calculation on all readings.

dB compresses a large range of measurements into a much smaller range

by expressing DC or AC voltage in decibels.

dBm shows decibels above or below a 1 mW reference.

NI 4050 User Manual 1-4 www.ni.com

Page 13

Chapter 1 Taking Measurements with the NI 4050

% selects the percentage calculation. VirtualBench-DMM expresses the

displayed reading as a percent deviation from the reference value entered

in the Math Settings. Refer to Help»Online Reference, Math Settings topic

for more information about dB, dBm, mX+B, and percentage calculations.

The log button enables data logging. To configure the datalog file and log

interval, select Edit»Settings. Refer to Help»Online Reference, Logging

Measurements to Disk topic for more details.

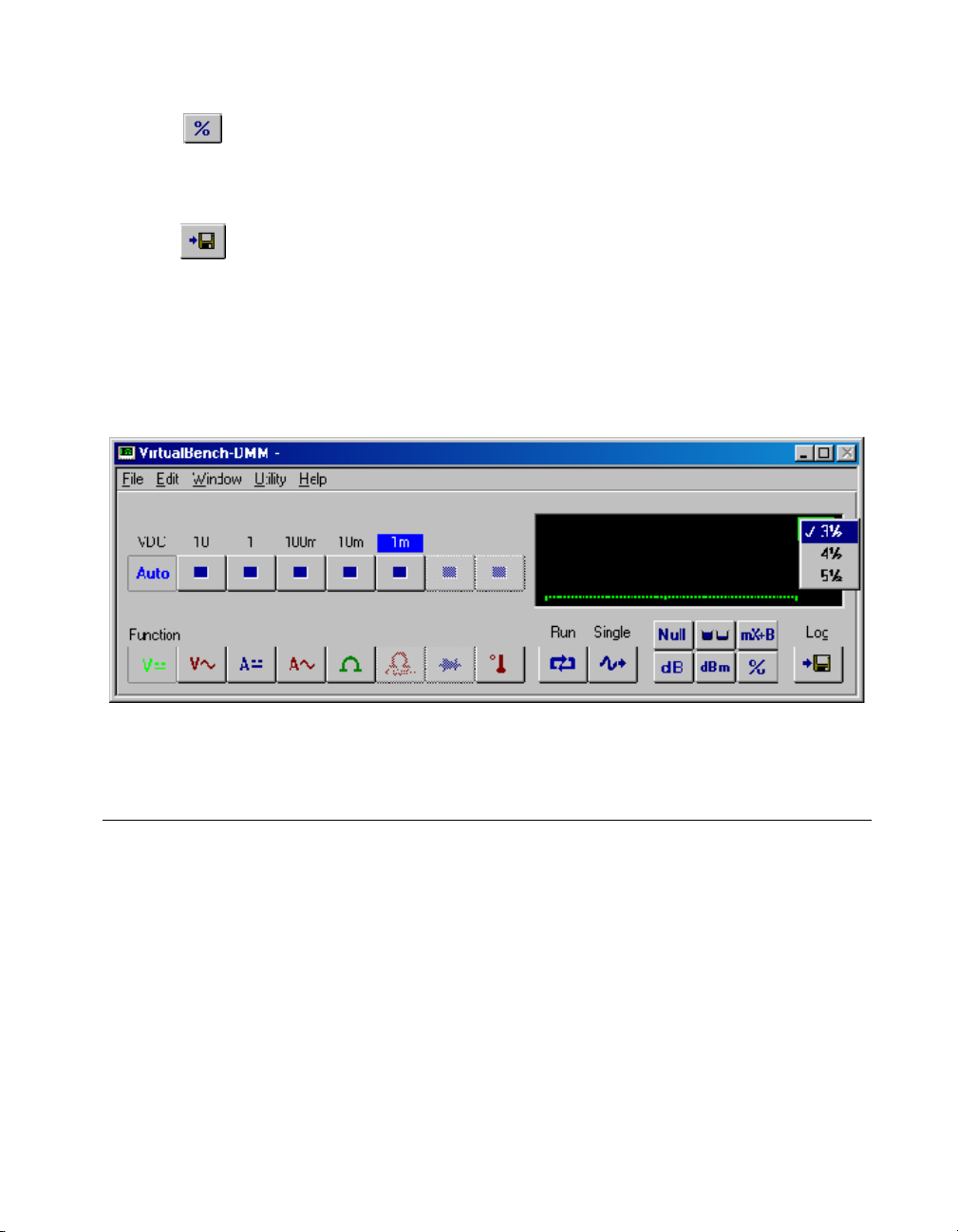

Digits of Precision—A pop-up ring control in the DMM front panel display

allows you to set measurement accuracy to 3 1/2, 4 1/2, or 5 1/2. A larger

value gives greater precision but slower measurement performance. Refer

to Figure 1-3.

Figure 1-3. Digits of Precision

Use the Soft Front Panel

The following sections describe procedures for measuring DC and AC

voltage, resistance, diode, and temperature, using the soft front panel.

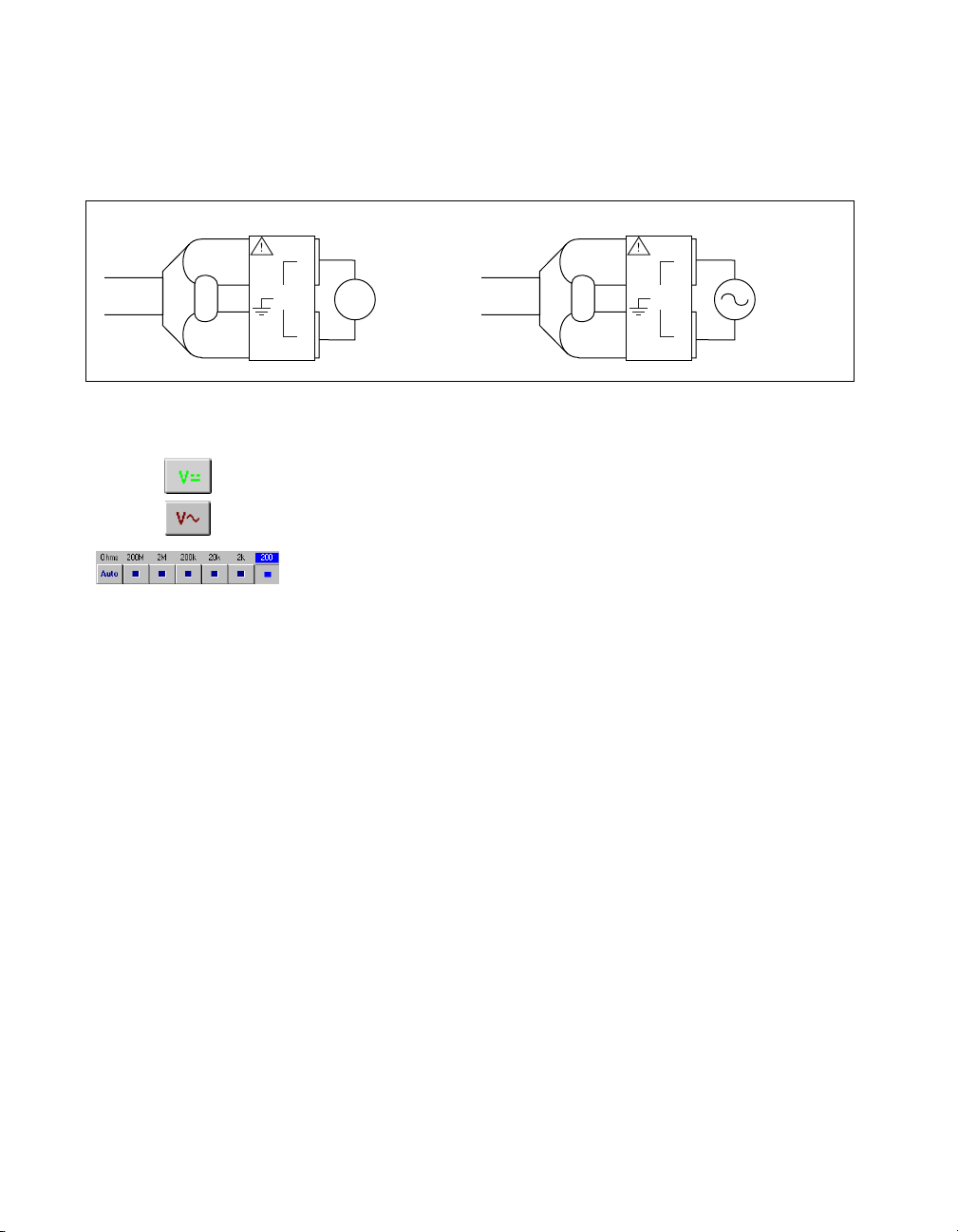

Measure DC and AC Voltage

Use the following procedure to measure DC and AC voltage using the soft

front panel:

1. Connect the test probes to voltage signals as shown in Figure 1-4. For

DC voltages, the HI (red) terminal is the positive terminal, and the

LO (black) terminal is negative. For A C voltages, positive and ne gative

terms are irrelevant.

© National Instruments Corporation 1-5 NI 4050 User Manual

Page 14

Chapter 1 Taking Measurements with the NI 4050

The NI 4050 is protected against damage from voltages within

±250 VDC or 250 V

above these levels to the inputs.

in all ranges. You should never apply voltages

rms

HI

250 V

MAX.

+

–

LO

2. Select the mode you will measure:

•DC Volts

•AC Volts

3. Select the range for your measurement or autoranging:

• DC Volts—± 20 mV, ± 200 mV, ± 2 V, ± 25 V, and ± 250 V

• AC Volts—20 mV

The value indicator displays the voltage measured.

Measure 2-Wire Resistance

Use the following procedure to measure 2-wire resistance using the soft

front panel:

1. Connect the test probes to a resistor as shown in Figure 1-5. To

accurately measure the value of a resistor, mak e sure the resistor is not

connected to any other circuits. Erroneous or misleading readings may

result if the resistor you are measuring is connected to external circuits

that supply voltages or currents or to external circuits that change the

effective resistance of that resistor.

HI

DC Voltage

Source

250 V

MAX.

LO

Figure 1-4. Connecting Probes for Voltage Measurement

, 200 mV

rms

rms

, 2 V

rms

, 25 V

, and 250 V

rms

AC Voltage

Source

rms

NI 4050 User Manual 1-6 www.ni.com

Page 15

Chapter 1 Taking Measurements with the NI 4050

Figure 1-5. Connections for Resistance Measurement

2. Select 2-wire resistance mode.

3. Select the range for your measurement—200 Ω, 2 kΩ, 20 kΩ, 200 kΩ,

2 MΩ, 200 MΩ, or autorange.

The value indicator indicates the resistance measured. See the 2-Wire

Resistance Measurements section of Chapter 2, NI 4050 Operation, for

more information on 2-wire resistance measurements.

Measuring the Voltage Drop Across a Diode

The NI 4050 can excite a device under test and read the resulting voltage

drop. Diode mode is useful for testing diodes. Use the following procedure

to measure the forward drop across a diode. Voltage up to 2 V can be

measured in this mode.

1. Connect the test probes to a diode as shown in Figure 1-6. To

accurately measure the forward voltage of a diode, make sure that the

diode is not connected to any other circuits. The NI 4050 biases the

diode with a current of 100 µA and measures the resulting voltage

drop. Diode measurements are made with a fixed range of 2.0 V.

250 V

MAX.

HI

Resistor

LO

100 µA

HI

250 V

MAX.

+

Diode

–

LO

Figure 1-6. Connecting Signals for Diode Test

© National Instruments Corporation 1-7 NI 4050 User Manual

Page 16

Chapter 1 Taking Measurements with the NI 4050

2. Select diode mode.

3. Select the range for your measurement. Only the 2 V range is av ailable

for diode measurement.

The value indicator will indicate the voltage drop measured. If the display

indicates 2.200 VDC, the diode is either reverse biased or defectiv e. See the

Diode Measurements section of Chapter 2, NI 4050 Operation, for more

information on diode measurements.

Measure Current

You can use the NI 4050 to measure current with an optional National

Instruments CSM series current shunt module. These accessories are

connected between the NI 4050 cable and the test probes as shown in

Figure 1-7.

250 V

MAX.

HI

Current

Source

LO

Current Shunt

Accessory

Figure 1-7.

Connections for Current Measurement

Current shunt accessories contain a precision resistor that converts the

current through the shunt into a voltage that the NI 4050 can measure in

voltage mode. While the soft front panel cannot measure current directly

with the NI 4050, you can calculate the value of the current flowing through

the shunt by dividing the voltage measured by the value of the precision

resistor.

NI 4050 User Manual 1-8 www.ni.com

Page 17

Measure Temperature

You can measure temperature using common temperature transducers such

as resistive temperature devices (RTD) and thermistors. You can measure

transducers in the 2-wire resistance mode, as shown in Figure 1-8.

Although the soft front panel does not support temperature measurements,

you can convert and scale the transducer value to temperature

programmatically through software.

Note

The NI 4050 for PCMCIA does not support 4-wire resistance measurements. To

avoid measurement errors due to resistance offset, before doing resistance measurements,

measure the resistance to your loads.

Chapter 1 Taking Measurements with the NI 4050

HI

250 V

MAX.

LO

Resistor

Figure 1-8.

Connecting Signals for RTDs and Thermistors

© National Instruments Corporation 1-9 NI 4050 User Manual

Page 18

NI 4050 Operation

This chapter contains safety instructions, measurement fundamentals and

concerns, and scanning information.

Safety Instructions

2

Cautions

following:

Do not operate this instrument in an explosive atmosphere or where there may be

flammable gases or fumes.

Equipment described in this document must be used in an Installation Category II

environment per IEC 664. This category requires local level supply mains-connected

installation.

The NI 4050 must be used in a UL-listed laptop or personal computer.

To prevent safety hazards, the maximum voltage between either of the inputs and the

ground of the computer should never exceed ±250 VDC or 250 V

Do not operate damaged equipment. The safety protection features built into this

instrument can become impaired if the instrument becomes damaged in any way. If the

instrument is damaged, do not use it until service-trained personnel can check its safety.

If necessary, return the instrument to National Instruments for service and repair to ensure

that its safety is not compromised.

Do not operate this instrument in a manner that contradicts the information specified in this

document. Misuse of this instrument could result in a shock hazard.

Do not substitute parts or modify equipment. Because of the danger of introducing

additional hazards, do not install unauthorized parts or modify the instrument. Return the

instrument to National Instruments for service and repair to ensure that its safety is not

compromised.

Connections that exceed any of the maximum signal ratings on the NI 4050 can create a

shock or fire hazard or can damage any or all of the devices connected to the NI 4050.

National Instruments is not liable for any damages or injuries resulting from incorrect

signal connections.

Clean the instrument and accessories by brushing off light dust with a soft, nonmetallic

brush. Remove other contaminants with a stiff nonmetallic brush. The unit must be

completely dry and free from contaminants before returning to service.

To avoid personal injury or damage to electronic equipment, observe the

.

rms

© National Instruments Corporation 2-1 NI 4050 User Manual

Page 19

Chapter 2 NI 4050 Operation

Measurement Fundamentals

Warm Up

The required warm-up time for the NI 4050 is 30 minutes. This warm-up

time is important because measurements made with the NI 4050

multimeter can change with temperature. This change is called a thermal

drift and affects your accuracy. To minimize the effects of thermal drift and

ensure the specified accuracies, take all measurements after the NI 4050

has had a chance to fully warm up. Depending on your environment, the

NI 4050 can operate significantly above ambient temperature. Therefore,

measurements made immediately after powering up the system can differ

significantly from measurements made after the system has fully warmed

up. The NI 4050 temperature specifications are listed in the Accuracy

sections in Appendix A, Specifications.

Selecting the Resolution

The resolution on the NI 4050 multimeter is programmable. You can select

from three different resolutions: 5 1/2 digits, 4 1/2 digits, or 3 1/2 digits.

These settings allow you to trade off speed for resolution. The 5 1/2 digit

setting has the highest resolution and slowest reading rate, while the

3 1/2 digit setting gives you the least resolution and fastest reading rate.

Measurement mode and range affect the reading rate by requiring different

conversion times to obtain a given resolution for the different modes and

ranges.

Grounding

When measuring ground-referenced signals, connect the

ground-referenced side of your signal to the IN HI + terminal for best

performance.

Voltage Measurements

DC Voltage

Your NI 4050 multimeter uses a high-resolution delta sigma, A/D

converter (ADC) to sample signals and convert them into a digital form.

The ADC is preceded by a series of gain and attenuation circuitry that allow

both small and large signals to be measured using the same converter. The

NI 4050 uses a digital filter, which heavily rejects powerline frequencies

(50–60 Hz) and their harmonics, as well as high-frequency noise.

NI 4050 User Manual 2-2 www.ni.com

Page 20

Chapter 2 NI 4050 Operation

Input Ranges

The NI 4050 has five input ranges available for measuring DC voltages.

These ranges are ±20 mV, ±200 mV, ±2.0 V, ±25V, and ±250 V. Each

range has a 10% overrange, except for the 250 V range. The 250 V and

25 V input ranges have a 1 MΩ input impedance; the 2 V, 200 mV, and

20 mV ranges have an input impedance greater than 1 GΩ. Take these

values into consideration when measuring high-impedance sources. When

the NI 4050 is powered off, the 250 V and 25 V input range have a 1 MΩ

input impedance and the 2 V, 200 mV, and 20 mV ranges have an input

impedance of 100 kΩ.

If you are taking measurements that require a high degree of accuracy, you

should consider problems associated with input impedance, noise effects,

and thermal electromotive forces (thermal EMFs). These effects are

discussed in the Measurement Considerations section.

Measurement Considerations

Input Impedance

Figure 2-1 illustrates the input impedance of an NI 4050 and its effect on

the measurement of a circuit under test. If you know the source impedance

of the circuit being tested, you can correct for the attenuation caused by the

NI 4050 in software. Since R

source impedance, R

, to cause a large change in the measured voltage, Vm.

s

is large, at least 1 MΩ, it will require a large

in

External Source

Measured

Voltage

V

+

m

–

© National Instruments Corporation 2-3 NI 4050 User Manual

Input

Impedance

R

in

Figure 2-1.

VsR

--------------- ------------=

Rs+ R

in

in

V

m

Effect of Input Impedance on Signal Measurements

HI

Input

VΩ

LO

Impedance R

s

+

–

Source

Voltage V

s

Page 21

Chapter 2 NI 4050 Operation

Thermal EMF

Thermal EMFs, or thermoelectric potentials, are voltages generated at the

junctions of dissimilar metals and are functions of temperature. Thermal

EMFs in a circuit under test can cause higher than expected offsets that

change with temperature.

Noise Rejection

The NI 4050 filters out AC voltages in the DC voltage measurement

ranges. However, if the amplitudes of the AC voltages are large compared

to the DC voltages, or if the peak value (AC + DC) of the measured voltage

is outside the overrange limits, the NI 4050 may exhibit additional errors.

To minimize these errors, keep the NI 4050 away from strong AC magnetic

sources and minimize the area of the loop formed by the test leads.

Choosing the 5 1/2 digit resolution will also help minimize noise from

AC sources. If the peak value of the measured voltage is likely to exceed

the selected input range, select the next highest input range.

Normal Mode Rejection

Normal mode rejection (NMR) is the ability of the NI 4050 to reject a

normally (differentially) applied signal. The ability is quantified in the

normal mode rejection ratio (NMRR) specification, which indicates the

capability of the NI 4050 to reject 50 or 60 Hz and is valid only at the

specified frequency and useful only when taking DC measurements. The

NMRR is specified at the powerline frequency because this is typically

where most measurement noise occurs.

Figure 2-2 shows a 60 Hz signal connected differentially to the NI 4050 in

DC Volts mode. V

is the voltage that will be measured after the signal is

m

rejected. NMR is very useful when trying to measure DC voltages in the

presence of large powerline interference.

NI 4050 User Manual 2-4 www.ni.com

Page 22

Chapter 2 NI 4050 Operation

HI

Measured

Voltage

V

+

m

–

VmV

VΩ

LO

×=

10

s

Input

–

NMRR

--------------------

20

Source

Voltage

V

s

at 60 Hz

Figure 2-2. Normal Mode Measurement Effects

If you are measuring signals in the presence of large normal mode voltages,

consult Appendix A, Specifications, to calculate the additional error to your

system. Use the equation in Figure 2-2 to calculate the voltage error due to

normal mode voltage.

Common Mode Rejection

Common mode rejection (CMR) is the ability of the NI 4050 to reject

signals that are common to both input terminals. The ability is quantified in

the common mode rejection ratio (CMRR) specification. Theoretically, the

floating measurement circuitry of the NI 4050 should have an infinite

CMRR. Parasitic resistances and capacitances to earth ground limit the

CMR of the NI 4050. This effect is most noticeable when measuring small

signals in the presence of a large common mode voltage, as shown in

Figure 2-3.

© National Instruments Corporation 2-5 NI 4050 User Manual

Page 23

Chapter 2 NI 4050 Operation

HI

Measured

Voltage

V

+

m

–

V

V

error

----- -

VmVsV

Input

VΩ

LO

–

CMRR

--------------------

s

+

V

c

2

20

10

×=

+=

error

+

–

+

–

Source

Voltage

V

s

Common

Voltage

V

c

Figure 2-3. Common Mode Measurement Effects

Using the equation in Figure 2-3, you can calculate the voltage error due to

the common mode voltage. If you are measuring signals in the presence of

large common mode voltages, consult Appendix A, Specifications, to

calculate the additional error to your system.

Effective Common Mode Rejection

Effective common mode rejection is the sum of the CMRR and the NMRR

at a given frequency. It is the effective rejection on a given noise signal that

is applied to both input leads as it gets rejected first by the CMR capability

of the instrument then again by its NMR capability. This specification is

most useful at the powerline frequency where most of the noise resides and

is only valid for DC measurements.

AC Voltage

In the AC voltage ranges, the NI 4050 measures the AC-coupled RMS

value of a signal. The RMS value of a signal is a fundamental measurement

of the magnitude of an AC signal. The RMS value of an AC signal can be

defined mathematically as the square root of the average of the square of

the signal.

In practical terms, the RMS value of an AC signal is the DC v alue required

to produce an equivalent amount of heat in the same resistive load. The

NI 4050 first AC-couples the measured signal to remove any DC

NI 4050 User Manual 2-6 www.ni.com

Page 24

Chapter 2 NI 4050 Operation

components and then measures the RMS value of the A C component. This

method lets you measure a small AC signal in the presence of a large DC

offset.

Input Ranges

The NI 4050 has five input ranges available for measuring AC voltages.

These ranges are 20 mV

The impedance in each of these ranges is a 0.068 µF capacitor followed by

1 MΩ. When the NI 4050 is powered off, the 250 V, 25 V, and 2 V input

ranges have a 0.068 µF capacitor, followed by a 1 MΩ input impedance.

The 200 mV and 20 mV ranges have a 0.068 µF capacit or, followed by

an approximate 100 kΩ input impedance.

The NI 4050 can measure AC voltages to its specif ied accuracy as long as

the voltage is at least 10% and no more than 100% of the selected input

range. The DC component in any of these ranges can be as high as

250 VDC. Each range, except for the 250 V range, has a 10% overrange.

The AC volta ge measurement accuracy depends on many factors, including

the signal amplitude, frequency, and waveform shape.

, 200 mV

rms

rms

, 2.0 V

rms

, 25 V

, and 250 V

rms

rms

.

Measurement Considerations

AC Offset Voltage

The AC measurements of the NI 4050 are specified over the range of 10%

to 100% of the full-scale input range. Below 10% of the input range, errors

due to the AC voltage offset become significant. This offset, unlike DC

voltage offsets, cannot simply be subtracted from the readings or zeroed out

because the offset gets converted in the RMS conversion. To minimize the

errors due to the AC offset voltage, choose an input range that keeps the

measured voltage between 10% and 100% of full scale.

Frequency Response

The accuracy of the NI 4050’s AC voltage measurements is a function of

the input signal frequency. Your NI 4050 is calibrated at the factory using

a 1 kHz sine wave. Your frequency-dependent error will be minimal around

this frequency. The error will then increase as you approach the upper and

lower bandwidth limits. This additional error is added to the accuracy

errors in computing the absolute error.

© National Instruments Corporation 2-7 NI 4050 User Manual

Page 25

Chapter 2 NI 4050 Operation

These additional errors are shown in Appendix A, Specifications. While the

NI 4050 is characterized and specified over the 20 Hz to 25 kHz frequency

range, measurements outside of this range can still be made with decreased

accuracy .

Resistance Measurements

2-Wire Resistance Measurements

The NI 4050 measures 2-wire resistance by passing a current through the

device under test and reading the resulting voltage drop through the same

connections, as illustrated in Figure 2-4. The resistance value is then

computed using Ohm’s Law (R=V/I). To accurately measure the value of

a resistor, make sure the resistor is not connected to any other circuits.

Erroneous or misleading readings can result if the resistor you are

measuring is connected to external circuits that supply voltages or currents,

or to external circuits that change the effective resistance of that resistor.

+

V

sense

–

I

ex

HI

I

ex

Input

VΩ

LO

R

unknown

I

ex

V

R

unknown =

I

= 100 µA (200 Ω, 2 kΩ, 20 kΩ ranges)

ex

Figure 2-4.

sense

I

ex

1 µA (200 kΩ, 2 MΩ, 200 MΩ ranges)

Circuit for 2-Wire Resistance Measurements

Input Ranges

The NI 4050 has five basic input ranges for 2-wire resistance as well as an

extended range. The basic ranges are 200 Ω, 2.0 kΩ, 20 kΩ, 200 kΩ, and

2 MΩ. With the extended range, measurements up to at least 200 MΩ are

possible.

NI 4050 User Manual 2-8 www.ni.com

Page 26

In the extended ohms range, the NI 4050 adds a 1 MΩ resistor in parallel

with the test resistor, and then calculates the value of the resistor being

tested. The test current for the 200 Ω, 2.0 kΩ, and 20 kΩ ranges is 100 µA.

The test current for the 200 kΩ, 2 MΩ, and 200 MΩ ranges is 1 µA.

Continuity Measurements

Many traditional multimeters can take continuity measurements, which test

for the presence or absence of continuity between the two test probes.

These measurements are simply resistance measurements, where the

resistance between the two probes is measured and compared to a set value.

You can perform continuity measurements on a circuit by setting the

NI 4050 to the 200 Ω range and comparing the measured value to some low

resistance value, typically 10 Ω. If the measured value is less than 10 Ω,

there is continuity between the test probes.

Diode Measurements

To properly measure the forward voltage of a diode, make sure that the

diode is not connected to any other circuits. The NI 4050 biases the diode

with a current of 100 µA and measures the resulting voltage drop, as

illustrated in Figure 2-5. Diode measurements are made with a fixed range

of 2.0 V.

Chapter 2 NI 4050 Operation

Note

Different multimeters use different currents to excite the diode. This may result in

different readings for the same diode.

I

HI

+

V

sense

–

Figure 2-5.

© National Instruments Corporation 2-9 NI 4050 User Manual

I

ex

Circuit for Diode Measurements

Input

VΩ

LO

ex

+

V

diode

–

I

ex

V

= V

sense

diode

Page 27

Specifications

This appendix lists the specifications of the NI 4050. These specifications

are guaranteed between 15 and 35 °C unless otherwise specified.

DC Voltage

Accuracy (% of reading ± µV)

A

24 Hour

Range

250.000 V 0.0032% ± 4.9 mV 0.021% ± 49 mV 0.024% ± 49 mV 0.0017% ± 4800 µV

25.0000 V 0.0032% ± 4.9 mV 0.021% ± 49 mV 0.024% ± 49 mV 0.0017% ± 4800 µV

2.00000 V 0.0029% ± 37 µV 0.014% ± 260 µV 0.017% ± 260 µV 0.0009% ± 25 µV

200.000 mV 0.0029% ± 27 µV 0.014% ± 250 µV 0.017% ± 250 µV 0.0009% ± 25 µV

20.0000 mV 0.0029% ± 27 µV 0.014% ± 250 µV 0.017% ± 250 µV 0.0009% ± 25 µV

Accuracy numbers are for 5 1/2 digits and include the effects of full-scale and zero-scale errors, temperature variation,

linearity, and noise.

(25 °C ± 1 °C)

90 Day

(25 °C ± 10 °C)

1 Year

(25° C ± 10 °C)

Temperature Coefficient

(% of Reading/ °C ± µV/ °C)

Noise Rejection

NMRR (10 Hz reading rate, 50/60 Hz

powerline frequency ±1%)..................... 80 dB

DC ECMRR...........................................140 dB (with a 1 kΩ imbalance

in LO lead)

AC ECMR (RDC to 60 Hz)...................150 dB (with a 1 kΩ imbalance

in LO lead)

Input Characteristics

Input bias current ...................................1 nA max

Input resistance ......................................> 1 GΩ (2 V, 200 mV,

20 mV ranges);

1MΩ (250 V, 25 V)

© National Instruments Corporation A-1 NI 4050 User Manual

Page 28

Appendix A Specifications

DC Current

Accuracy (% of reading ± µA

)

DC current measurements require the use of the CSM current shunt

modules.

24 Hour

Range

200.000 mA

20.0000 mA

10.0000 A

Accuracy numbers are for 5 1/2 digits and include the effects of full-scale and zero-scale errors, temperature variation,

linerarity, and noise.

*

Requires 200 mA shunt, CSM-200mA.

**

Requires 10 A shunt, CSM-10A.

(25 °C ± 1 °C)

*

0.1% ± 27 µA 0.14% ± 250 µA 0.15% ± 250 µA 0.0035% ± 25 µA

*

0.1% ± 27 µA 0.14% ± 250 µA 0.15% ± 250 µA 0.0035% ± 25 µA

**

0.02% ± 4 mA 0.035% ± 26 mA 0.035% ± 26 mA 0.007% ± 2.5 mA

90 Day

(25 °C ± 10 °C)

1 Year

(25 °C ± 10 °C)

Temperature Coefficient

(% of Reading/°C ± µA/°C

Input Characteristics

200 mA shunt

Input protection ...............................Fuse F1 500 mA/250 V fast

fusing

Shunt resistor...................................1 Ω

Burden voltage.................................< 400 mV at 200 mA

10 A shunt

Input protection ...............................Fuse F1 12.5 A/250 V fast fusing

Shunt resistor...................................10 mΩ

Burden voltage.................................< 300 mV at 10 A

)

NI 4050 User Manual A-2 www.ni.com

Page 29

AC Voltage

Appendix A Specifications

Accuracy (% of reading ± mV)

24 Hour

Range

250.000 V 0.6% ± 500 mV 0.62% ± 680 mV 0.62% ± 680 mV 0.007% ± 20 mV

25.0000 V 0.3% ± 30 mV 0.32% ± 210 mV 0.32% ± 210 mV 0.007% ± 20 mV

2.00000 V 0.4% ± 3 mV 0.42% ± 21 mV 0.42% ± 21 mV 0.019% ± 2 mV

200.000 mV 0.3% ± 0.22 mV 0.32% ± 1.20 mV 0.32% ± 1.20 mV 0.007% ± 0.110 mV

20.0000 mV 0.4% ± 100 µV 0.42% ± 170 µV 0.42% ± 170 µV 0.019% ± 12 µV

Accuracy numbers are for 5 1/2 digits and include the effects of full-scale and zero-scale errors, temperature variation,

linerarity, and noise, applies for sine waves ≥ 10% of input range. Accuracy may be affected by source impedance, cable

capacitances dielectric absorption, or slew rate.

(25 °C ± 1 °C)

90 Day

(25 °C ± 10 °C)

1 Year

(25 °C ± 10 °C)

Tempe rature Coefficient

(% of Reading/°C ± mV/°C

Noise Rejection

AC CMRR (DC to 60 Hz)......................> 80 dB (with a 1 kΩ imbalance

in LO lead)

Input Characteristics

Input resistance ......................................1 MΩ all ranges

Bandwidth..............................................20 Hz–25 kHz

Additional AC Errors

Frequency-dependent errors

)

Input Frequency Additional Error (% of Reading)

20–50 Hz 2.5%

50–100 Hz 1%

100 Hz–5 kHz 0%

5–10 kHz 1%

10–25 kHz 2.5%

© National Instruments Corporation A-3 NI 4050 User Manual

Page 30

Appendix A Specifications

AC Current

Accuracy (% of reading ± mA)

AC current measurements require the use of the CSM current shunt

module.

24 Hour

Range

200.000 mA

20.0000 mA

10.0000 A

Accuracy numbers are for 5 1/2 digits and include the effects of full-scale and zero-scale errors, temperature variation,

linerarity, and noise.

*

Requires 200 mA shunt, CSM-200mA.

**

Requires 10 A shunt, CSM-10A.

(25 °C ± 1 °C)

*

0.45% ± 0.22 mA 0.47% ± 1.2 mA 0.47% ± 1.2 mA 0.007% ± 0.110 mA

*

0.35% ± 110 µA 0.37% ± 170 µA 0.37% ± 170 µA 0.019% ± 0.120 mA

**

0.3% ± 22 mA 0.32% ± 120 mA 0.32% ± 120 mA 0.026% ± 11 mA

90 Day

(25 °C ± 10 °C)

1 Year

(25 °C ± 10 °C)

Temperature Coefficient

(% of Reading/°C ± mA/°C)

Input Characteristics

200 mA shunt

Input protection ...............................Fuse F1 500 mA/250 V fast

fusing

Shunt resistor...................................1 Ω

Burden voltage.................................< 400 mV at 200 mA

10 A shunt

Input protection ...............................Fuse F1 12.5 A/250 V fast fusing

Shunt resistor...................................10 mΩ

Burden voltage.................................< 300 mV at 10 A

NI 4050 User Manual A-4 www.ni.com

Page 31

Resistance

Appendix A Specifications

Accuracy (% of reading ± Ω)

24 Hour

Range

Extended Ohm

(> 2 M

Ω)

2.00000 M

200.000 k

20.0000 k

2.00000 k

200.000

Accuracy numbers are for 5 1/2 digits and include the effects of full-scale and zero-scale errors, temperature variation,

linearity, and noise.

Ω

Ω

Ω

Ω

Ω

(25 °C ± 1 °C)

0.1% ± 6 k

0.012% ± 55

0.012% ± 37

0.006% ± 0.5

0.006% ± 0.4

0.006% ± 0.4

Ω

Ω

Ω

Ω

Ω

Ω

90 Day

(25 °C ± 10 °C)

0.1% ± 60 k

0.077% ± 370

0.077% ± 350

0.024% ± 4

0.024% ± 4

0.024% ± 4

1 Year

(25 °C ± 10 °C)

Ω

Ω

Ω

Ω

Ω

Ω

0.1% ± 60 k

0.080% ± 20

0.080% ± 2

0.027% ± 4

0.027% ± 4

0.027% ± 4

Ω

Ω

Ω

Ω

Ω

Ω

Temperature Coefficient

(% of Reading/°C ±

0.0072% ± 6 k

0.0072% ± 35

0.0072% ± 35

0.0020% ± 0.40

0.0020% ± 0.40

0.0020% ± 0.40

Measurement mode................................2-wire Ohms

Test current ............................................ 100 µA for 200 Ω, 2 kΩ,

20 kΩ ranges

1 µA for 2 MΩ, 200 kΩ ranges

1 µA and 1 MΩ in parallel for

extended Ohms mode

Diode Testing

Accuracy (% of reading ± µV)

/°C)

ΩΩΩΩ

Ω

Ω

Ω

Ω

Ω

Ω

24 Hour

Range

2 V 0.006% ± 60 µV 0.024% ± 400 µV 0.027% ± 400 µV 0.002% ± 40 µV

Accuracy numbers are for 5 1/2 digits and include the effects of full-scale and zero-scale errors, temperature variation,

linearity, and noise.

(25 °C ± 1 °C)

90 Day

(25 °C ± 10 °C)

1 Year

(25 °C ± 10 °C)

Temperature Coefficient

(% of Reading/°C ± µV/°C)

Test current ................................... .........100 µA

© National Instruments Corporation A-5 NI 4050 User Manual

Page 32

Appendix A Specifications

General Specifications

Settling time............................................Affected by source impedance

Warm-up time.........................................30 minutes for measurements

Bus type..................................................PCMCIA, slave

Altitude.................................................. .Up to 2,000 m; at higher altitudes

Working voltage .....................................250 V maximum between either

Power requirement..................................+5 VDC, 45 mA in operational

Safety......................................................Designed in accordance with

and input signal changes

accurate within specifications

the installation category must be

derated

input terminal and earth ground

mode

IEC 1010-1 and UL 3 111 for

electrical measuring and testing

equipment,

Installation Category II,

Pollution Degree 2,

Double Insulated,

Indoor use,

UL 3111 listed

Physical

Dimensions.............................................Type II PC Card

Environment

Operating temperature............................0 to 55 °C

Storage temperature................................–20 to 70 °C

Relative humidity ...................................10% to 90% noncondensing

NI 4050 User Manual A-6 www.ni.com

Page 33

Technical Support Resources

This appendix describes the comprehensive resources available to you in

the Technical Support section of the National Instruments Web site and

provides technical support telephone numbers for you to use if you have

trouble connecting to our Web site or if you do not have internet access.

NI Web Support

To provide you with immediate answers and solutions 24 hours a day,

365 days a year, National Instruments maintains extensi ve online technical

support resources. They are available to you at no cost, are updated daily,

and can be found in the Technical Support section of our Web site at

www.ni.com/support.

Online Problem-Solving and Diagnostic Resources

• KnowledgeBase—A searchable database containing thousands of

frequently asked questions (F A Qs) and their corresponding answers or

solutions, including special sections devoted to our newest products.

The database is updated daily in response to new customer experiences

and feedback.

• Troubleshooting Wizards—Step-by-step guides lead you through

common problems and answer questions about our entire product line.

Wizards include screen shots that illustrate the steps being described

and provide detailed information ranging from simple getting started

instructions to advanced topics.

• Product Manuals—A comprehensive, searchable library of the latest

editions of National Instruments hardware and software product

manuals.

• Hardware Reference Database—A searchable database containing

brief hardware descriptions, mechanical drawings, and helpful images

of jumper settings and connector pinouts.

• Application Notes—A library with more than 100 short papers

addressing specific topics such as creating and calling DLLs,

developing your own instrument driver software, and porting

applications between platforms and operating systems.

B

© National Instruments Corporation B-1 NI 4050 User Manual

Page 34

Appendix B Technical Support Resources

Software-Related Resources

• Instrument Driver Network—A library with hundreds of instrument

drivers for control of standalone instruments via GPIB, VXI, or serial

interfaces. You also can submit a request for a particular instrument

driver if it does not already appear in the library.

• Example Programs Database—A database with numerous,

non-shipping example programs for National Instruments

programming environments. You can use them to complement the

example programs that are already included with National Instruments

products.

• Software Library—A library with updates and patches to application

software, links to the latest versions of driver software for National

Instruments hardware products, and utility routines.

Worldwide Support

National Instruments has offices located around the globe. Many branch

offices maintain a Web site to provide information on local services. You

can access these Web sites from

www.ni.com/worldwide

If you have trouble connecting to our Web site, please contact your local

National Instruments office or the source from which you purchased your

National Instruments product(s) to obtain support.

For telephone support in the United States, dial 512 795 8248. For

telephone support outside the United States, contact your local branch

office:

Australia 03 9879 5166, Austria 0662 45 79 90 0, Belgium 02 757 00 20,

Brazil 011 284 5011, Canada (Calgary) 4 03 274 9391,

Canada (Ontario) 905 785 0085, Canada (Québec) 514 694 8521,

China 0755 3904939, Denmark 45 76 26 00, Finland 09 725 725 11,

France 01 48 14 24 24, Germany 089 741 31 30, Greece 30 1 42 96 427,

Hong Kong 2645 3186, India 91805275406, Israel 03 6120092,

Italy 02 41309 1, Japan 03 5472 2970, Korea 02 596 7456,

Mexico (D.F.) 5 280 7625, Mexico (Monterrey) 8 357 7695,

Netherlands 0348 433466, New Zealand 09 914 0488,

Norway 32 27 73 00, Poland 0 22 528 94 06, Portugal 351 1 726 9011,

Singapore 2265886, Spain 91 640 0085, Sweden 08 587 895 00,

Switzerland 056 200 51 51, Taiwan 02 2528 7227,

United Kingdom 01635 523545

NI 4050 User Manual B-2 www.ni.com

Page 35

Glossary

Prefix Meanings Value

p- pico- 10

n- nano- 10

µ- micro- 10

m- milli- 10

k- kilo- 10

M- mega- 10

G- giga- 10

Numbers/Symbols

% percent

+ positive of, or plus

– negative of, or minus

–12

–9

–6

–3

3

6

9

/per

°degree

± plus or minus

Ω ohm

A

A amperes

AC alternating current

AC coupled the passing of a signal through a filter network that removes the

DC component of the signal

A/D analog-to-digital

© National Instruments Corporation G-1 NI 4050 User Manual

Page 36

Glossary

ADC analog-to-digital converter—an electronic device, often an integrated

circuit, that converts an analog voltage to a digital number

ADC resolution the resolution of the ADC, which is measured in bits. An ADC with16 bits

has a higher resolution, and thus a higher degree of accuracy, than a

12-bit ADC.

ADE Application Development Environment

amplification a type of signal conditioning that improves accuracy in the resulting

digitized signal and reduces noise

amplitude flatness a measure of how close to constant the gain of a circuit remains over a range

of frequencies

aperture time the period of time over which a measurement is averaged; also called the

number of powerline cycles

attenuate

autozero technique of internally shorting the internal circuit while disconnecting the

to reduce in magnitude

measurement to compensate for temperature effects

B

b bit—one binary digit, either 0 or 1

B byte—eight related bits of data, an eight-bit binary number. Also used to

denote the amount of memory required to store one byte of data.

bus the group of conductors that interconnect individual circuitry in a computer.

Typically, a bus is the expansion veh icle to wh ich I/O or other devices are

connected. Examples of PC buses are the PCI and ISA bus.

burden voltage the voltage drop across the input section of the current mode

C

C Celsius

CMRR common-mode rejection ratio—a measure of an instrument’s ability to

reject interference from a common-mode signal, usually expressed in

decibels (dB)

NI 4050 User Manual G-2 www.ni.com

Page 37

Glossary

CompactPCI refers to the core specification defined by the PCI Industrial Computer

Manufacturer’s Group (PICMG)

conversion device device that transforms a signal from one form to another. For example,

analog-to-digital converters (ADCs) for analog input, digital-to-analog

converters (DACs) for analog output, digital input or output ports, and

counter/timers are conversion devices.

conversion time the time required, in an analog input or output system, from the moment a

channel is interrogated (such as with a read instruction) to the moment that

accurate data is available

coupling the manner in which a signal is connected from one location to another

CPU central processing unit

crest factor the ratio of the peak value of the signal to the RMS value of the signal

CSM current shunt module

D

DAQ data acquisition—(1) collecting and measuring electrical signals from

sensors, transducers, and test probes or fixtures and inputting them to a

computer for processing; (2) collecting and measuring the same kinds of

electrical signals with A/D and/or DIO boards plugged into a computer , and

possibly generating control signals with D/A and/or DIO boards in the

same computer

dB decibel—the unit for expressing a logarithmic measure of the ratio of two

signal levels: dB=20log10 V1/V2, for signals in volts

DC direct current

default setting a default parameter value recorded in the driver. In many cases, the default

input of a control is a certain value (often 0) that means use the current

default setting.

device a plug-in data acquisition board, card, or pad that can contain multiple

channels and conversion devices. Plug-in boards, PCMCIA cards,

devices such as the DAQPad-1200, which connects to your computer

parallel port, are all examples of DAQ devices.

© National Instruments Corporation G-3 NI 4050 User Manual

Page 38

Glossary

dielectric absorption a parasitic phenomenon related to capacitors that can cause unexpectedly

long settling times in circuits using capacitors with poor dielectric

absorption specifications

differential input an analog input consisting of two terminals, both of which are isolated from

computer ground, whose difference is measured

DMM digital multimeter

DNL differential nonlinearity—a measure in LSB of the worst-case deviation of

code widths from their ideal value of 1 LSB

double insulated a device that contains the necessary insulating structures to pro vide electric

shock protection without the requirement of a safety ground connection

drivers software that controls a specific hardware instrument

E

ECMR Effective Common Mode Rejection—a measure of an instrument’s ability

to reject interference from a common-mode signal. This includes both the

effects of normal mode rejection and common mode rejection.

EEPROM electrically erasable programmable read-only memory—ROM that can be

erased with an electrical signal and reprogrammed

EXT TRIG IN external trigger input signal

F

F farads

filtering a type of signal conditioning that allows you to filter unwanted signals from

the signal you are trying to measure

G

gain the factor by which a signal is amplified, sometimes expressed in decibels

NI 4050 User Manual G-4 www.ni.com

Page 39

Glossary

H

harmonics multiples of the fundamental frequency of a signal

half-power bandwidth the frequency range ov er which a circuit maintains a level of at least –3 dB

with respect to the maximum level

hardware the physical components of a computer system, such as the circuit boards,

plug-in boards, chassis, enclosures, peripherals, cables, and so on

Hz hertz—per second, as in cycles per second or samples per second

I

I

ex

IEC International Electrotechnical Commission

IEEE Institute of Electrical and Electronics Engineers

in. inches

inductance the relationship of induced voltage to current

input bias current the current that flow s into the inputs of a circuit

input impedance the measured resistance and capacitance between the input terminals of a

Installation Category

(Overvoltage Category)

instrument driver a set of high-level software functions that controls a specific plug-in DAQ

interrupt a computer signal indicating that the CPU should suspend its current task

interrupt level the relative priority at which a device can interrupt

excitation current

circuit

classification system for expected transients on electrical supply

installations

board. Instrument drivers are available in several forms, ranging from a

function callable language to a virtual instrument (VI) in LabVIEW.

to service a designated activity

I/O input/output—the transfer of data to/from a computer system involving

communications channels, operator interface devices, and/or data

acquisition and control interfaces

© National Instruments Corporation G-5 NI 4050 User Manual

Page 40

Glossary

ISA industry standard architecture

isolation a type of signal conditioning in which you isolate the transducer signals

from the computer for safety purposes. This protects you and your

computer from large voltage spikes and mak es sure the measurements from

the DAQ device are not affected by differences in ground potentials.

isolation voltage the voltage that an isolated circuit can normally withstand, usually

specified from input to input and/or from any input to the amplifier output,

or to the computer bus

M

m meters

MB megabytes of memory

N

NI-DAQ National Instruments driver software for DAQ hardware.

NMRR normal mode rejection ratio—a measure of an instrument’ s ability to reject

a signal applied directly to the differential inputs of the instrument

noise an undesirable electrical signal—Noise comes from external sources such

as the AC po wer line, motors, generators, transformers, fluorescent lights,

soldering irons, CR T displays, computers, electrical storms , welders, radio

transmitters, and internal sources such as semiconductors, resistors, and

capacitors. Noise corrupts signals you are trying to send or receive.

O

Ohm’s Law (R=V/I)—the relationship of voltage to current in a resistance

overrange a segment of the input range of an instrument outside of the normal

measuring range. Measurements can still be made, usually with a

degradation in specifications.

NI 4050 User Manual G-6 www.ni.com

Page 41

Glossary

P

PCI Peripheral Component Interconnect—a high-performance expansion bus

architecture originally developed by Intel to replace ISA and EISA; it is

achieving widespread acceptance as a standard for PCs and workstations

and offers a theoretical maximum transfer rate of 132 Mbytes/s

peak value the absolute maximum or minimum amplitude of a signal (AC + DC)

PXI PCI eXtensions for Instrumentation. PXI is an open specification that

builds off the CompactPCI specification by adding

instrumentation-specific features.

R

Rresistor

RAM random-access memory

range error an error in accuracy that is determined by the input range that is selected.

The range error is independent of the value of the signal being measured.

reading error an error in accuracy that is determined by the input range, as well as the

value being measured

reading rate the rate at which a new measurement is taken. In addition to the

measurement speed, the selection of the reading rate affects the filtering,

and thus the noise level, of measurements.

resolution the smallest signal increment that can be detected by a measurement

system. Resolution can be expressed in bits or in digits. The number of bits

in a system is roughly equal to 3.3 times the number of digits.

rms root mean square—a measure of signal amplitude; the square root of the

average value of the square of the instantaneous signal amplitude

ROM read-only memory

R

sense

© National Instruments Corporation G-7 NI 4050 User Manual

the sense resistor. The vo ltage across this resistor is measured and

converted to a current.

Page 42

Glossary

S

s seconds

S samples

sense in four-wire resistance the sense measures the voltage across the resistor

being excited by the excitation current

settling time the amount of time required for a voltage to reach its final value within

specified limits

S/s samples per second—used to express the rate at which an instrument

samples an analog signal

system noise a measure of the amount of noise seen by an analog circuit or an ADC when

the analog inputs are grounded

T

temperature

coefficient

thermal drift measurements that change as the temperature varies

thermoelectric

potentials

thermal EMFs thermal electromotive forces—voltages generated at the junctions of

transfer rate the rate, m easured in bytes/s, at which data is moved from source to

the percentage that a measurement will vary according to temperature.

See also thermal drift

See thermal EMFs

dissimilar metals that are functions of temperature. Also called

thermoelectric potentials.

destination after software initialization and set up operations; the maximum

rate at which the hardware can operate

U

UL Underwriters Laboratory

NI 4050 User Manual G-8 www.ni.com

Page 43

V

V volts

VAC volts alternating current

VDC volts direct current

Glossary

V

error

voltage error

VI virtual instrument—(1) a combination of hardware and/or software

elements, typically used with a PC, that has the functionality of a classic

stand-alone instrument (2) a LabVIEW software module (VI), which

consists of a front panel user interface and a block diagram program

VMC voltmeter complete signal

V

V

rms

sense

volts, root mean square value

the voltage that is created across the device under test when excited by a

current

W

waveform shape the shape the magnitude of a signal creates over time

working voltage the highest voltage that should be applied to a product in normal use,

normally well under the breakdown voltage for safety margin

© National Instruments Corporation G-9 NI 4050 User Manual

Page 44

Index

A

AC current specifications, A-4

AC voltage measurement, 2-6 to 2-8

AC offset voltage, 2-7

frequency response, 2-7 to 2-8

input ranges, 2-7

using VirtualBench-DMM Soft Front

panel, 1-5 to 1-6

AC voltage specifications, A-3

C

cables and probes, 1-1 to 1-2

installing, 1-1 to 1-2

overview, 1-1

common mode rejection, 2-6 to 2-7

continuity measurements, 2-9

conventions used in manual, vi

current measurement, 1-8

D

DC current specifications, A-2

DC voltage measurement, 2-2 to 2-6

common mode rejection, 2-6 to 2-7

effective common mode rejection, 2-6

input impedance, 2-3

input ranges, 2-3

noise rejection, 2-4 to 2-6

normal mode rejection, 2-4 to 2-5

thermal EMF, 2-4

using VirtualBench-DMM Soft Front panel,

1-5to1-6

DC voltage specifications, A-1

diagnostic resources, online, B-1

diode measurement

circuit (figure), 2-9

description, 2-9

using VirtualBench-DMM Soft Front

panel, 1-7 to 1-8

diode testing specifications, A-5

E

effective common mode rejection, 2-6

environment specifications, A-6

F

frequency response, AC voltage

measurement, 2-7 to 2 -8

G

grounding the NI 4050, 2-2

I

input impedance, DC voltage measurement, 2-3

input ranges

AC voltage measurement, 2-7

DC voltage measurement, 2-3

two-wire resistance measurements,

2-8to2-9

M

measurement

AC voltage, 2-6 to 2-8

AC offset voltage, 2-7

frequency response, 2-7 to 2-8

input ranges, 2-7

© National Instruments Corporation I-1 NI 4050 User Manual

Page 45

Index

using VirtualBench-DMM Soft Front

panel, 1-5 to 1-6

current, 1-8

DC voltage, 2-2 to 2-6