Page 1

Getting Started with the

NI 17xx Smart Camera

The National Instruments 17xx Smart Camera combines an image

sensor and a high-performance processor to return either

inspection results or images. While a typical industrial camera

acquires and transmits images through a standard camera bus for

processing on another device, the smart camera performs both

acquisition and processing operations directly on the smart camera.

This document describes how to set up and configure the smart

camera hardware, configure the IP address, install software, and

acquire an initial image.

Refer to the NI 17xx Smart Camera User Manual for information

about specific features and specifications of the smart camera.

Select Start»All Programs»National Instruments»Vision»

Documentation»NI-IMAQ to access the NI 17xx Smart Camera

User Manual after configuring the smart camera using the

procedures described in this document.

Unpack and Verify Components

Remove the NI Smart Camera from the package and inspect the

device for any sign of damage. Notify National Instruments if the

device appears damaged in any way. Do not use a damaged device.

For safety and compliance information, refer to the specifications

in the NI 17xx Smart Camera User Manual.

Required Components

This section describes the hardware and software components

necessary to set up and use the NI Smart Camera.

Hardware

The following hardware components are included in the NI Smart

Camera kit:

❑ NI 17xx Smart Camera

Page 2

❑ 5-position lighting connector (additional/replacement plugs

for use with the lighting connector are available from NI,

part number 780260-01)

In addition to the items included in the smart camera kit, the

following components are necessary to set up and configure the

smart camera:

❑ One or two CAT 5 10/100Base-TX or CAT 5e or CAT 6

1000Base-T Ethernet cables. One Ethernet cable is required to

connect the smart camera directly to the development

computer. Two Ethernet cables are required to connect the

smart camera to the development computer through a network.

Note A CAT 5e or CAT 6 1000Base-T Ethernet cable is

required to achieve maximum 1,000 Mbps (Gigabit)

Ethernet performance. CAT 5e and CAT 6 Ethernet

cables adhere to higher electrical standards required for

Gigabit Ethernet communication. CAT 5 cables are not

guaranteed to meet the necessary electrical requirements.

While CAT 5 cables may appear to work at 1,000 Mbps

in some installations, CAT 5 cables are likely to cause

increased bit errors resulting in degraded or unreliable

network performance.

❑ One of the following power supply options:

Caution Use the smart camera only with a 24 VDC, UL

listed, limited power source (LPS) supply. The power

supply will bear the UL listed mark, LPS. The power

supply must also meet any safety and compliance

requirements for the country of use.

– NI desktop power supply (part number 780237-01) and

power supply cord. Refer to

cord part number specific to your region and ordering

information.

– Any 24 VDC, +20%/–15% (IEC 1311) power supply and

one of the following cable options for connecting to the

power supply and I/O:

• 15-pin D-SUB pigtail cable, 5 m (part number

197818-05)

• 15-pin D-SUB to 15-pin D-SUB cable, 2 m

(part number 197817-02) or 5 m (part number

197817-05), and a 15-pin D-SUB terminal block

ni.com for the power supply

Getting Started with the NI 17xx 2 ni.com

Page 3

❑ Standard C-mount lens. Other lenses available from NI are

listed in the Optional Components section.

❑ Development computer running Windows Vista/XP/2000

Software

Use one of the following application development environments to

develop NI Smart Camera applications. Refer to Table 1 for the

Vision Builder for Automated Inspection (Vision Builder AI)

information or to Table 2 for LabVIEW and LabVIEW module

information.

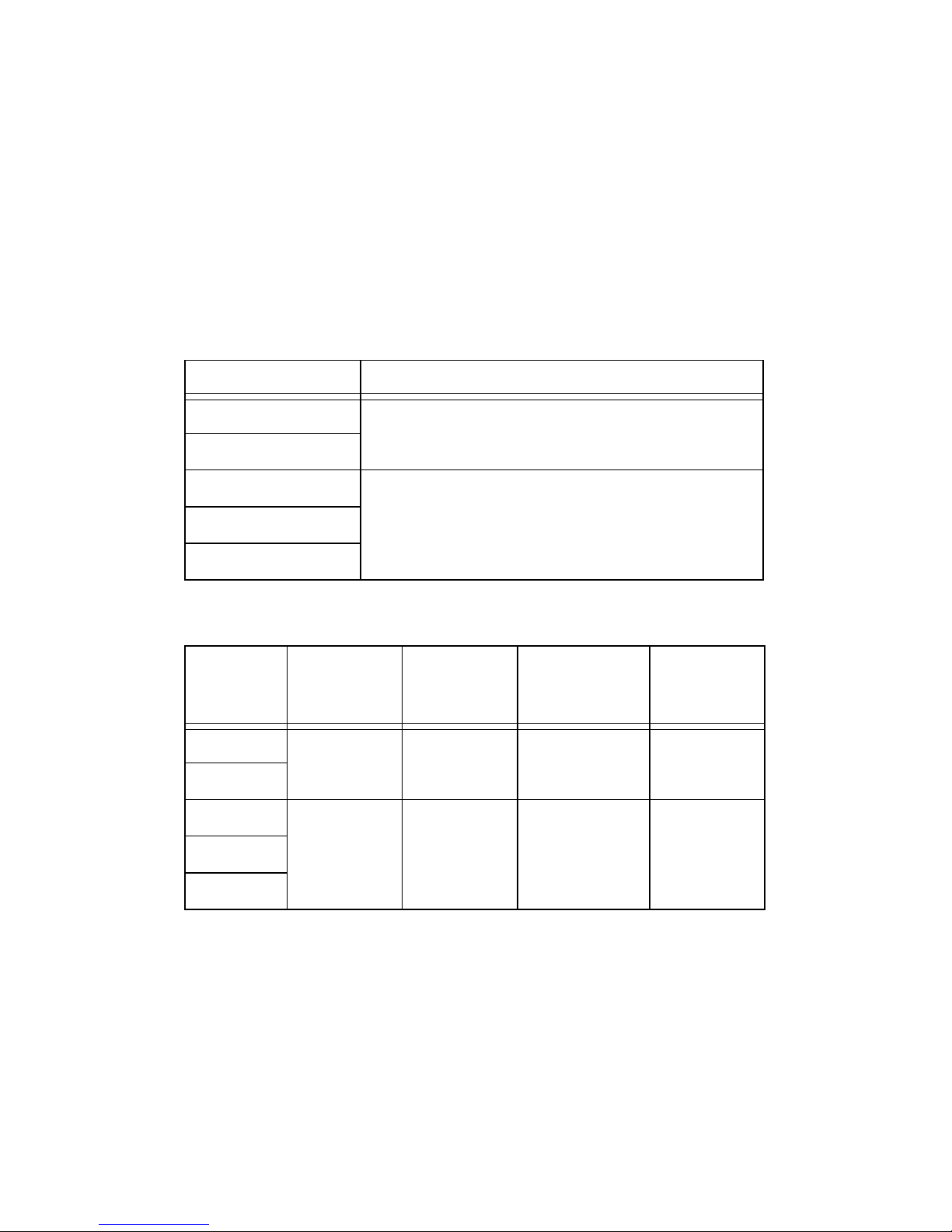

Table 1. NI Vision Builder AI Minimum Versions

NI Smart Camera NI Vision Builder AI Version (Included)

NI 1722 3.5 or later

NI 1742

NI 1744 3.6 or later

NI 1762

NI 1764

Table 2. LabVIEW and Necessary Modules Minimum Versions

Smart

Camera

NI 1722 8.5

NI 1742

NI 1744 8.5.1

NI 1762

NI 1764

LabVIEW

or later

or later

LabVIEW

Real-Time

Optional Components

8.5

or later

8.5.1

or later

Vision

Development

Module

8.5

or later

8.6

or later

Vision

Acquisition

Software

8.6

or later

8.6

or later

National Instruments offers a variety of accessories for use with the

NI Smart Camera, including the following items:

•Lenses

– 8 mm (part number 780024-01)

– 12 mm (part number 780025-01)

© National Instruments Corp. 3 Getting Started with the NI 17xx

Page 4

– 16 mm (part number 780026-01)

– 25 mm (part number 780027-01)

• Current controlled lights

– Back light (part number 780221-01)

– Ring light (part number 780222-01)

– Broad area linear light array (part number 780223-01)

– Spot light (part number 780224-01)

• Mounting brackets

– Tripod adapter plate (part number 780239-01)

– Panel mount (part number 780240-01)

• Accessories

– NI 17xx unshielded screw terminal breakout with 2 m

cable (part number 780261-01)

– NI Smart Camera I/O accessory (part number 780443-01)

Visit

ni.com or contact the branch office nearest you for more

information about these and other products.

Connect the Lens and Lighting

Complete the following steps to connect a standard C-mount lens

and external lighting accessories to the NI Smart Camera.

1. Remove the lens cover from the smart camera.

2. Gently align the threads on the base of the lens with the threads

on the sensor opening, and twist clockwise until the lens is

securely attached.

Lighting

The NI Smart Camera offers two options for controlling a light—a

Direct Drive internal lighting controller, or 5 V TTL or 24 V

external strobe generation for use with a third-party lighting

controller. Refer to the NI 17xx Smart Camera User Manual for

information about using the smart camera with a light.

Note The Direct Drive lighting controller is not available

on NI 1722 smart cameras. NI 1722 smart cameras

support only 5 V TTL or 24 V external strobe generation.

Getting Started with the NI 17xx 4 ni.com

Page 5

Connect the Power Supply and I/O

To connect a power supply to the NI Smart Camera, complete the

steps listed in one of the following sections. Refer to the Power

Only section to connect the NI desktop power supply directly to the

smart camera with no additional I/O. Refer to the Power with

Additional I/O section to connect a third-party power supply or

if your application requires I/O, such as a trigger signal.

Caution Use the smart camera only with a 24 VDC, UL

listed, limited power source (LPS) supply. The power

supply will bear the UL listed mark, LPS. The power

supply must also meet any safety and compliance

requirements for the country of use.

Power Only

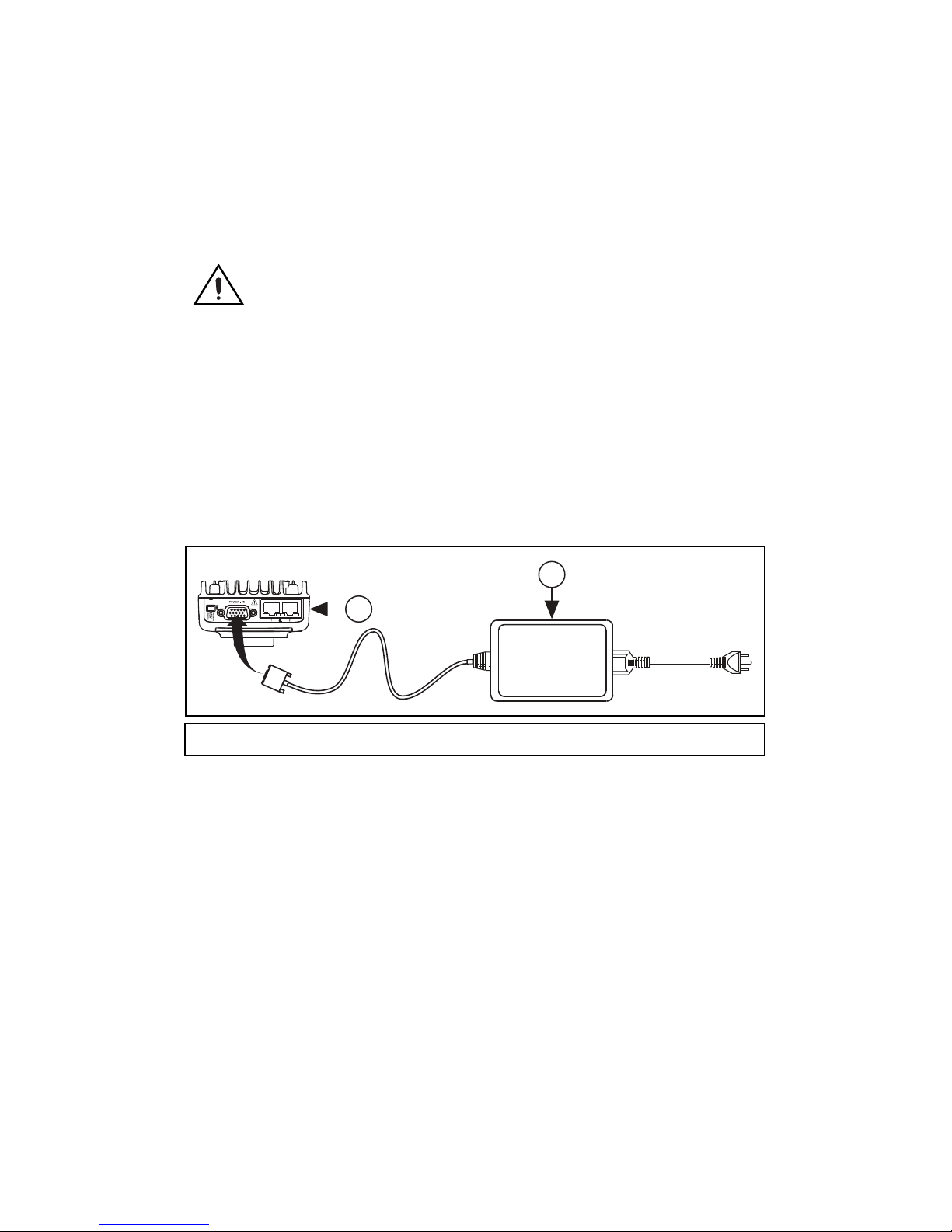

Refer to Figure 1 while completing the following steps to connect

the NI desktop power supply to the NI Smart Camera with no

additional I/O.

2

1

1 NI Smart Camera 2 Power Supply

Figure 1. Connecting the NI Smart Camera to the NI Desktop Power Supply

1. Connect and secure the 15-pin D-SUB connector on the NI

desktop power supply to the POWER-I/O connector on the

smart camera.

2. Plug the power supply power cord into the power supply.

3. Plug the power supply into an outlet.

When power is first applied to the smart camera, the POWER LED

flashes red for one second while internal systems power up. The

POWER LED then lights green when power is correctly wired to

the smart camera.

© National Instruments Corp. 5 Getting Started with the NI 17xx

Page 6

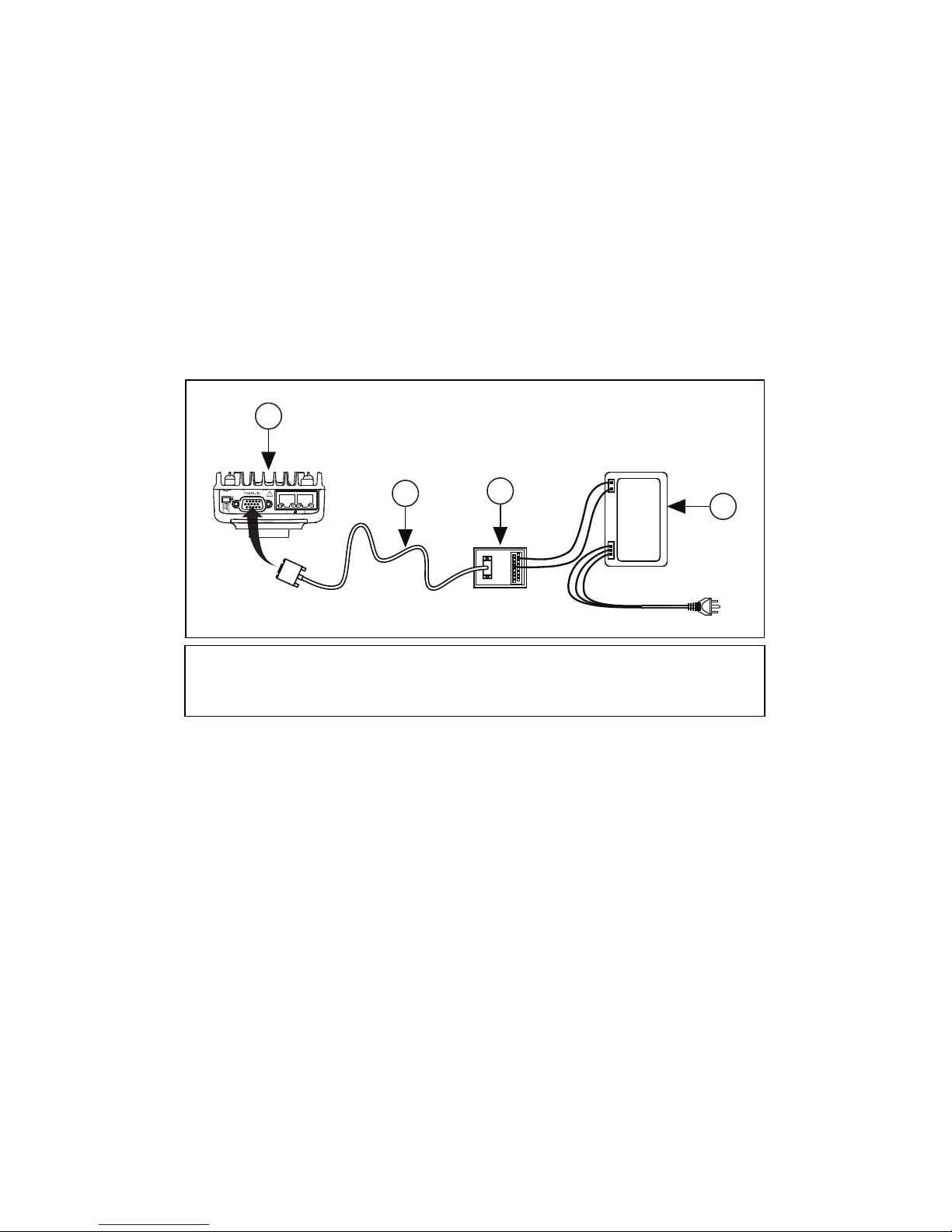

Power with Additional I/O

3

2

4

1

National Instruments provides the following two cable options for

connecting a third-party power supply and I/O to the NI Smart

Camera.

• Terminal block with a 15-pin D-SUB connector, such as the

NI Smart Camera I/O Accessory, and a 15-pin D-SUB to

15-pin D-SUB cable

• 15-pin D-SUB pigtail cable

Refer to Figure 2 while completing the following steps to connect

a third-party power supply and I/O to the smart camera using either

a terminal block or the pigtail cable.

1 NI Smart Camera

2 15-Pin D-SUB to 15-Pin

D-SUB Cable

Figure 2. Connecting the NI Smart Camera to a Third-Party Power Supply

3 Optional Terminal Block

4 Power Supply

1. Connect and secure the 15-pin D-SUB connector on your cable

to the POWER-I/O connector on the smart camera.

2. If you are using a terminal block, connect the cable to the

terminal block.

3. Connect the +24 V signal from the cable or terminal block to

the corresponding signal on the power supply.

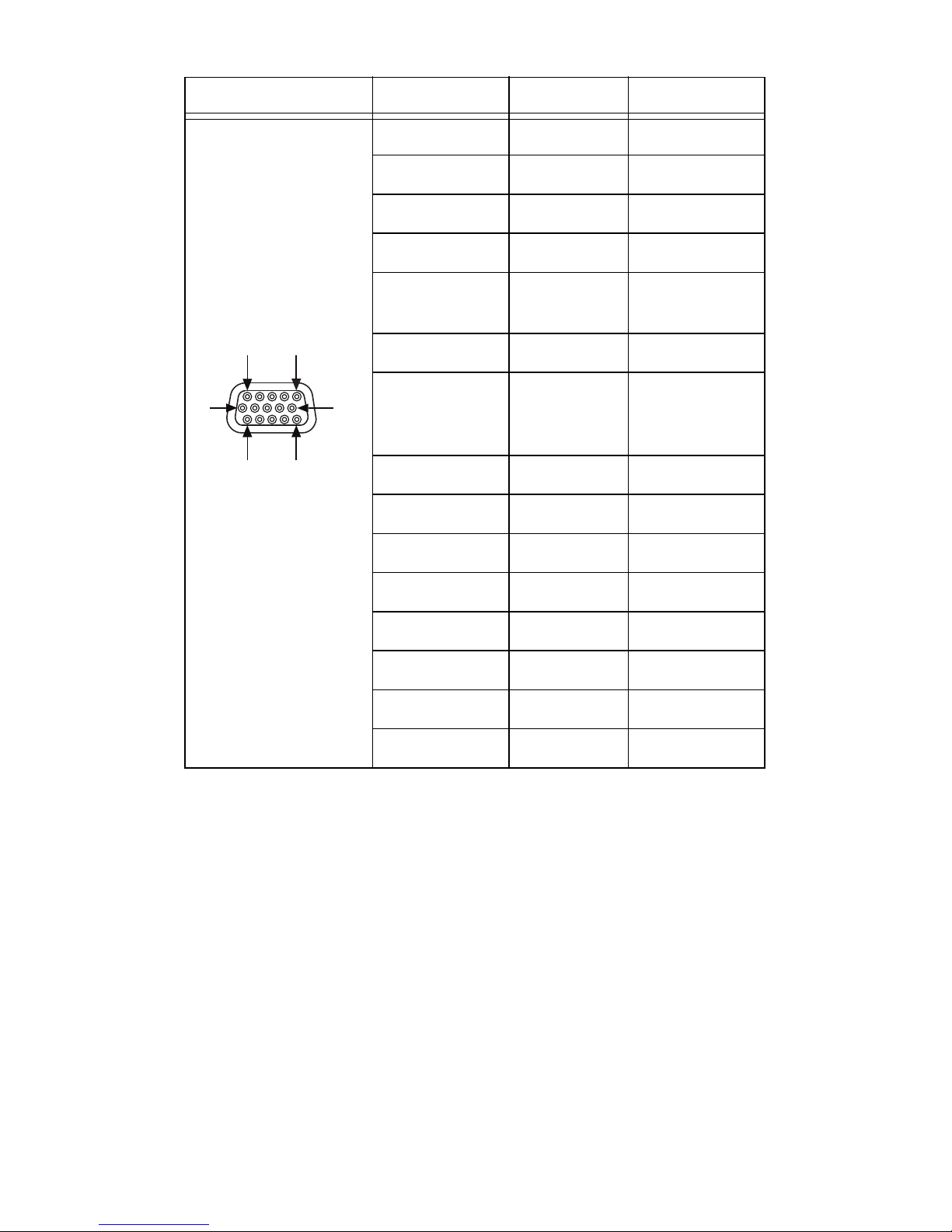

Table 3 shows the pin locations for the POWER-I/O connector

and lists the signal names and pin numbers. The table also lists

wire colors for the National Instruments 15-pin D-SUB pigtail

cable. Cables from another vendor may have different wire

colors.

Getting Started with the NI 17xx 6 ni.com

Page 7

Table 3. NI Smart Camera POWER-I/O Connector Signal Descriptions

1

6

11

5 (+24 V)

10

15 (COM)

Connector Diagram Signal Name Pin Number Wire Color

+24 V 5 Red

COM 15 Black

RS_232TXD 10 Pink

RS_232RXD 14 Black/White

TrigIn+

IsoIn(0)+

IsoIn(1)+ 8 Orange

TrigIn–

IsoIn(0)–

IsoIn(1)–

IsoOut(0)+ 6 Yellow

IsoOut(0)– 1 Green

IsoOut(1)+ 11 Light Blue

IsoOut(1)– 7 Gray

PhaseA+ 3 Blue

PhaseA– 13 Brown/White

PhaseB+ 9 Purple

2 Brown

12 Light Green

PhaseB– 4 White

4. Connect the COM signal from the cable or terminal block to

the corresponding signal on the power supply.

5. Connect any additional I/O signals necessary for your

application to the appropriate signal on the cable or terminal

block. Refer to Table 3 for pin information.

6. If necessary, connect the power cord to the power supply.

7. Plug the power supply into an outlet.

When power is first applied to the smart camera, the POWER LED

flashes red for one second while internal systems power up. The

POWER LED then lights green when power is correctly wired to

the smart camera.

© National Instruments Corp. 7 Getting Started with the NI 17xx

Page 8

Connect to the Development Computer

The NI Smart Camera can connect to the development computer

directly or through a network using an Ethernet cable. The smart

camera provides automatic MDI/MDI-X correction, so you can use

either a standard Ethernet cable or a crossover Ethernet cable

to connect to the development computer. If the development

computer is configured on a network, you must configure the smart

camera on the same network subnet as the development computer

to connect through the network.

Caution To prevent data loss and to maintain the integrity

of your Ethernet installation, do not use a cable longer

than 100 m. National Instruments recommends using a

shielded twisted pair Ethernet cable for maximum signal

integrity.

Firewall Configuration

If your firewall is controlled remotely or you are unsure about

configuring the firewall, contact your network administrator. Refer

to Appendix B, Troubleshooting, of the NI 17xx Smart Camera

User Manual to troubleshoot network configuration issues.

Direct Connection

To connect the NI Smart Camera directly to the development

computer, refer to Figure 3 and complete the following steps.

Getting Started with the NI 17xx 8 ni.com

Page 9

2

1

1 Connecting an Ethernet Cable to Port 1 on the NI Smart Camera

2 Connecting an Ethernet Cable to an Ethernet Port on the

Development Computer

Figure 3. Connecting the NI Smart Camera Directly to the

Development Computer

1. Use an Ethernet cable to connect from the Ethernet port on the

development computer to Ethernet port 1 on the smart camera.

2. Configure the network card on the development computer to

use a static IP address. Refer to your Windows networking

documentation for information about configuring a static

IP address.

The smart camera is now connected directly to the development

computer.

Network Connection

To connect the NI Smart Camera to the development computer

through a network, refer to Figure 4 and complete the following

steps.

© National Instruments Corp. 9 Getting Started with the NI 17xx

Page 10

3

1

1 Connecting an Ethernet Cable to Port 1 on the NI Smart Camera

2 Ethernet Hub or Other Network Port

3 Connecting an Ethernet Cable to an Ethernet Port on the

Development Computer

Figure 4. Connecting the NI Smart Camera to the Development Computer

Through a Network

2

1. Verify that the development computer is connected to the

network and powered on.

2. Using an Ethernet cable, connect from an Ethernet hub or other

network port to Ethernet port 1 on the smart camera.

The smart camera is now connected to the development computer

through a network.

Subnet Considerations

To configure the NI Smart Camera, it must reside on the same

subnet as the development computer. Once the smart camera is

configured, as described in the Configuring the NI Smart Camera

with Vision Builder AI section and the Configuring the NI Smart

Camera with LabVIEW section, other subnets can be used to

access it.

To use the smart camera on a subnet other than the one on which

the development computer resides, first connect and configure the

smart camera on the same subnet as the development computer.

Next, physically move the smart camera to the other subnet.

Contact your network administrator for assistance in determining

which network ports reside on the same subnet.

Getting Started with the NI 17xx 10 ni.com

Page 11

Software Options

Vision Builder

for

Automated Inspection

LabVIEW

LabVIEW Real-Time Module

NI Vision Development Module

NI Vision Acquisition Software

or

National Instruments provides two options for developing

applications for the NI Smart Camera.

• NI Vision Builder for Automated Inspection (Vision

Builder AI)—Interactive, menu-driven configuration software

for developing, benchmarking, and deploying machine vision

applications. The latest version of Vision Builder AI is

included with the smart camera.

To use Vision Builder AI to configure the smart camera and

develop your application, complete the instructions in the

Configuring the NI Smart Camera with Vision Builder AI

section of this document.

• NI LabVIEW—Graphical programming environment for

developing flexible and scalable applications. The following

add-on modules are required for developing machine vision

applications:

– LabVIEW Real-Time Module—Programming library

for developing distributed, deterministic applications.

– NI Vision Development Module—Programming library

for developing machine vision and scientific imaging

applications.

– NI Vision Acquisition Software—Includes NI-IMAQ

driver software for acquiring images and controlling I/O

using the smart camera. The latest version of NI Vision

Acquisition software is included with the smart camera.

To use LabVIEW to configure the smart camera and develop

your application, complete the instructions in the Configuring

the NI Smart Camera with LabVIEW section of this document.

© National Instruments Corp. 11 Getting Started with the NI 17xx

Page 12

Note The installation and configuration process for each

development environment is different. Complete only the

instructions for your chosen development environment.

Configuring the NI Smart Camera

with Vision Builder AI

Complete the following steps to install Vision Builder AI and

configure the NI Smart Camera.

1. Install and activate Vision Builder AI on the development

computer. Refer to the NI Vision Builder for Automated

Inspection Readme for installation instructions.

2. Launch Vision Builder AI.

3. On the Vision Builder AI welcome screen, select the NI Smart

Camera in the list of targets.

If the NI Smart Camera does not appear in the list of targets,

refer to the Subnet Considerations section of this document

and Appendix B, Troubleshooting, of the NI 17xx Smart

Camera User Manual for information about subnets and

troubleshooting smart camera configuration issues.

4. Click Install Software. The Remote Target Configuration

Wizard launches in a new window.

5. In the Name field, enter a name for the device. Use the

Description field to enter any additional information or a brief

description of the device.

Device names are limited to 31 characters with no spaces or

special characters, except hyphens. The first and last characters

must be alphanumeric.

6. Click Next.

Configure the IP Address

1. If the network is configured to issue IP addresses using DHCP,

select Obtain IP address from DHCP server. Otherwise,

configure the IP address manually by selecting Edit the IP

settings and clicking Suggest Values.

2. If you want to prevent other users from configuring the smart

camera, select Enable Password and click Set Password to

set up password protection.

3. Click Next.

Getting Started with the NI 17xx 12 ni.com

Page 13

Install Software on the NI Smart Camera

Complete the following steps to install software from the

development computer to the NI Smart Camera.

1. In the Remote Target Configuration Wizard, enable the

Update Target Software checkbox.

2. Click the Browse button next to the Software Image to Install

on the Target control.

3. Navigate to the Vision Builder AI software image you want to

use, and click OK. Software images provided by National

Instruments are installed to the

RT Images

directory, where <Vision Builder AI> is the

location where Vision Builder AI is installed.

4. Click OK to apply the IP configuration settings and download

software to the smart camera.

5. Click OK to close the Remote Target Configuration Successful

dialog box.

<Vision Builder AI>\

Acquire an Image

Complete the following steps to acquire an image using Vision

Builder AI.

1. On the Vision Builder AI welcome screen, select the NI Smart

Camera in the list of targets.

2. Click Acquire Image (Smart Camera) Example to open the

image acquisition example in the Vision Builder AI

Configuration Interface.

3. Click the Run State Once button to acquire a single image.

4. In the State Configuration Window, select the Acquire Image

(Smart Camera) step.

5. Click the Edit Step button. The property page for the step

opens.

6. Use the controls on the Main, Trigger, Lighting, and

Advanced tabs to configure any additional settings necessary

for your application.

7. Click OK to save the step configuration.

The smart camera is now configured and acquiring images. Use

Vision Builder AI to add and configure additional inspection steps

to create your application. Refer to the Where to Go from Here

section for a list of documentation and other resources to help you

set up and use the smart camera in an application.

© National Instruments Corp. 13 Getting Started with the NI 17xx

Page 14

Configuring the NI Smart Camera

with LabVIEW

Complete the following steps to install LabVIEW, the LabVIEW

Real-Time Module, the NI Vision Development Module, and

NI Vision Acquisition Software and configure the NI Smart

Camera. Install the software in the following order:

1. LabVIEW—Refer to the LabVIEW Release Notes for

installation instructions for LabVIEW and system

requirements for the LabVIEW software. Refer to the

LabVIEW Upgrade Notes for additional information about

upgrading to the most recent version of LabVIEW.

Documentation for LabVIEW is available by selecting

Start»All Programs»National Instruments»LabVIEW»

LabVIEW Manuals.

2. LabVIEW Real-Time Module—Refer to the LabVIEW

Real-Time Module Release and Upgrade Notes for installation

instructions and information about getting started with the

LabVIEW Real-Time Module.

Documentation for the LabVIEW Real-Time Module is

available by selecting Start»All Programs»National

Instruments»LabVIEW»LabVIEW Manuals.

3. NI-IMAQ—Refer to the NI Vision Acquisition Software

Release Notes on the NI Vision Acquisition Software

installation media for system requirements and installation

instructions for the NI-IMAQ driver.

Documentation for the NI-IMAQ driver software is available

by selecting Start»All Programs»National Instruments»

Vision»Documentation»NI-IMAQ.

4. NI Vision Development Module—Refer to the NI Vision

Development Module Readme on the NI Vision Development

Module installation media for system requirements and

installation instructions.

Documentation for the NI Vision Development Module is

available by selecting Start»All Programs»National

Instruments»Vision»Documentation»NI Vision.

Getting Started with the NI 17xx 14 ni.com

Page 15

Configure the IP Address

You can assign the NI Smart Camera a static IP address or

configure it to automatically acquire an IP address from a DHCP

server. Complete the following steps to configure an IP address for

the NI Smart Camera.

1. Launch Measurement & Automation Explorer (MAX), the

National Instruments configuration utility, by double-clicking

the Measurement & Automation icon on the desktop, or

selecting Start»All Programs»National Instruments»

Measurement & Automation.

2. Expand the Remote Systems branch of the configuration tree,

and select the device you want to configure. To uniquely

identify multiple unconfigured devices, connect and configure

one device at a time.

Refer to the Subnet Considerations section of this document

and Appendix B, Troubleshooting, of the NI 17xx Smart

Camera User Manual for information about subnets and

troubleshooting smart camera configuration issues.

3. In the Name field, enter a name for the device. Use the

Comment field to enter any additional information or a brief

description of the device.

4. Device names are limited to 31 characters with no spaces or

special characters, except hyphens. The first and last characters

must be alphanumeric.

5. Verify the IP address configuration. The IP address is either

a network address, an automatic private IP address

(

169.254.x.x), or 0.0.0.0, depending on how the network

is configured to issue network addresses.

• If the network is configured to issue IP addresses using

DHCP, select Obtain IP address from DHCP server.

• Otherwise, configure the IP address manually. Select Edit

the IP settings, click Suggest Values, and click OK.

Note If the smart camera IP address is 169.254.x.x or

0.0.0.0, the smart camera is only accessible from the

local subnet. To access the smart camera from a remote

subnet, configure the smart camera to obtain an IP

address from a DHCP server or manually assign a static

IP address.

© National Instruments Corp. 15 Getting Started with the NI 17xx

Page 16

6. If you want to prevent other users from resetting the smart

camera, click the Lock button on the MAX toolbar to set up

password protection for the smart camera. To require users to

enter the password before restarting the smart camera, enable

the Password-protect Resets checkbox.

7. Click Apply on the MAX toolbar.

8. When prompted, click Yes to restart the smart camera.

The initialization process may take several minutes.

Install Software on the NI Smart Camera

Complete the following steps to install software from the

development computer to the NI Smart Camera.

1. In the Remote Systems branch of the MAX configuration tree,

expand the folder for your device and select Software.

2. Click Add/Remove Software on the MAX toolbar to launch

the LabVIEW Real-Time Software Wizard.

3. Select LabVIEW Real-Time, NI Vision RT, NI-IMAQ RT,

NI-IMAQ Server, and any additional software necessary for

your application, as shown in Figure 6.

Figure 5. Selecting Software to Install in MAX

4. Click Next.

5. Verify your software installation choices, and click Next.

6. When the installation is complete, click Finish.

Getting Started with the NI 17xx 16 ni.com

Page 17

Acquire an Image

Complete the following steps to acquire an image using MAX.

1. In the Remote Systems branch of the MAX configuration tree,

expand the folder for your device.

2. Click img0:NI 17xx, where 17xx is replaced by the actual

model number of your smart camera.

3. Click Snap to acquire a single image, or click Grab to acquire

continuous images. Click Grab again to stop a continuous

acquisition.

4. Use the controls on the Sensor, Triggering, Lighting, and

LUT tabs to adjust the acquisition settings.

The NI Smart Camera is now configured and acquiring images.

Use LabVIEW to create your application. Refer to the Where to Go

from Here section for a list of documentation and other resources

to help you set up and use the smart camera in an application.

Where to Go from Here

The following documents and resources contain information you

may find helpful as you set up and use the NI Smart Camera in an

application.

Refer to the NI 17xx Smart Camera User Manual for detailed

information about:

• Power and I/O requirements

• The image sensor and scan modes

• Exposure time and field of view

• The Direct Drive Lighting Controller and external lighting

controllers

• Acquiring images with the smart camera and calculating the

maximum frame rate

• Understanding the LED indicators and configuring the DIP

switches

• Ethernet connections

• Smart camera specifications

• Troubleshooting network, firewall, software, and power issues

© National Instruments Corp. 17 Getting Started with the NI 17xx

Page 18

Additional Resources for Vision Builder for

Automated Inspection Users

Refer to the NI Vision Builder for Automated Inspection Tutorial

to learn how to perform basic machine vision techniques using

Vision Builder AI. You can access the NI Vision Builder for

Automated Inspection Tutorial and other documentation by

selecting Start»All Programs»National Instruments»Vision

Builder AI»Documentation. You can also access context help

within Vision Builder AI by clicking the Show Context Help

button on the Vision Builder AI toolbar.

Examples of common Vision Builder AI inspections are installed

to the

<Vision Builder AI>\Examples directory.

Visit the NI Developer Zone at

ni.com/zone for the latest

example programs, tutorials, technical presentations, and a

community area where you can share ideas, questions, and source

code with developers around the world.

Additional Resources for LabVIEW Users

Documentation for LabVIEW and the LabVIEW Real-Time

Module is available from the Help menu on the LabVIEW toolbar.

You can access documentation for the NI Vision Development

Module by selecting Start»All Programs»National

Instruments»Vision»Documentation»NI Vision.

Documentation for the NI-IMAQ driver software is available by

selecting Start»All Programs»National Instruments»Vision»

Documentation»NI-IMAQ.

Documentation for the MAX configuration software is available

from the Help menu on the MAX toolbar. Specific information

about using MAX with NI Vision hardware is available by

selecting Help»Help Topics»NI Vision»NI-IMAQ.

Examples of image acquisitions and common machine vision

inspections are installed to the

<LabVIEW>\Examples\Vision directories, where <LabVIEW>

is the location where LabVIEW is installed.

Visit the NI Developer Zone at

example programs, tutorials, technical presentations, and a

community area where you can share ideas, questions, and source

code with developers around the world.

Getting Started with the NI 17xx 18 ni.com

<LabVIEW>\Examples\IMAQ and

ni.com/zone for the latest

Page 19

Safety Information

Caution The following paragraphs contain important

safety information you must follow when installing and

operating the NI smart camera.

Do not operate the device in a manner not specified in the

documentation. Misuse of the device may result in a hazard and

may compromise the safety protection built into the device. If the

device is damaged, turn it off and do not use it until service-trained

personnel can check its safety. If necessary, return the device to

National Instruments for repair.

Keep away from live circuits. Do not remove equipment covers or

shields unless you are trained to do so. If signal wires are

connected to the device, hazardous voltages can exist even when

the equipment is turned off. To avoid a shock hazard, do not

perform procedures involving cover or shield removal unless you

are qualified to do so. Disconnect all field power prior to removing

covers or shields.

If the device is rated for use with hazardous voltages (>30 V

42.4 V

, or 60 Vdc), it may require a safety earth-ground

pk

rms

,

connection wire. Refer to the device specifications for maximum

voltage ratings.

Because of the danger of introducing additional hazards, do not

install unauthorized parts or modify the device. Use the device

only with the chassis, modules, accessories, and cables specified in

the installation instructions. All covers and filler panels must be

installed while operating the device.

Do not operate the device in an explosive atmosphere or where

flammable gases or fumes may be present. Operate the device only

at or below the pollution degree stated in the specifications.

Pollution consists of any foreign matter—solid, liquid, or

gas—that may reduce dielectric strength or surface resistivity.

The following is a description of pollution degrees.

• Pollution Degree 1—No pollution or only dry, nonconductive

pollution occurs. The pollution has no effect.

• Pollution Degree 2—Normally only nonconductive pollution

occurs. Occasionally, nonconductive pollution becomes

conductive because of condensation.

© National Instruments Corp. 19 Getting Started with the NI 17xx

Page 20

• Pollution Degree 3—Conductive pollution or dry,

nonconductive pollution occurs. Nonconductive pollution

becomes conductive because of condensation.

Clean the device and accessories by brushing off light dust with a

soft, nonmetallic brush. Remove other contaminants with a stiff,

nonmetallic brush. The unit must be completely dry and free from

contaminants before returning it to service.

You must insulate signal connections for the maximum voltage for

which the device is rated. Do not exceed the maximum ratings for

the device. Remove power from signal lines before connection to

or disconnection from the device.

Caution National Instruments measurement products

may be classified as either Measurement Category I or II.

Operate products at or below the Measurement Category

level specified in the hardware specifications.

Measurement Category

working voltages

2

and transient stresses (overvoltage) from the

1

: Measurement circuits are subjected to

circuit to which they are connected during measurement or test.

Measurement (Installation3) Category establishes standardized

impulse withstand voltage levels that commonly occur in electrical

distribution systems. The following is a description of

Measurement Categories:

• Measurement Category I is for measurements performed on

circuits not directly connected to the electrical distribution

system referred to as MAINS

4

voltage. This category is for

measurements of voltages from specially protected secondary

circuits. Such voltage measurements include signal levels,

special equipment, limited-energy parts of equipment, circuits

powered by regulated low-voltage sources, and electronics.

• Measurement Category II is for measurements performed on

circuits directly connected to the electrical distribution system.

This category refers to local-level electrical distribution, such

1

Measurement Categories as defined in electrical safety standard IEC 61010-1.

2

Working voltage is the highest rms value of an AC or DC voltage that can occur

across any particular insulation.

3

Measurement Category is also referred to as Installation Category.

4

MAINS is defined as the (hazardous live) electrical supply system to which

equipment is designed to be connected for the purpose of powering the equipment.

Suitably rated measuring circuits may be connected to the MAINS for measuring

purposes.

Getting Started with the NI 17xx 20 ni.com

Page 21

as that provided by a standard wall outlet (e.g., 115 V for U.S.

or 230 V for Europe). Examples of Measurement Category II

are measurements performed on household appliances,

portable tools, and similar products.

• Measurement Category III is for measurements performed in

the building installation at the distribution level. This category

refers to measurements on hard-wired equipment such as

equipment in fixed installations, distribution boards, and

circuit breakers. Other examples are wiring, including cables,

bus-bars, junction boxes, switches, socket-outlets in the fixed

installation, and stationary motors with permanent connections

to fixed installations.

• Measurement Category IV is for measurements performed

at the primary electrical supply installation (<1,000 V).

Examples include electricity meters and measurements on

primary overcurrent protection devices and on ripple control

units.

Where to Go for Support

The National Instruments Web site is your complete resource for

technical support. At

everything from troubleshooting and application development

self-help resources to email and phone assistance from

NI Application Engineers.

National Instruments corporate headquarters is located at

11500 North Mopac Expressway, Austin, Texas, 78759-3504.

National Instruments also has offices located around the world to

help address your support needs. For telephone support in the

United States, create your service request at

and follow the calling instructions or dial 512 795 8248. For

telephone support outside the United States, contact your local

branch office:

Australia 1800 300 800, Austria 43 662 457990-0,

Belgium 32 (0) 2 757 0020, Brazil 55 11 3262 3599,

Canada 800 433 3488, China 86 21 5050 9800,

Czech Republic 420 224 235 774, Denmark 45 45 76 26 00,

Finland 358 (0) 9 725 72511, France 01 57 66 24 24,

Germany 49 89 7413130, India 91 80 41190000,

Israel 972 3 6393737, Italy 39 02 41309277, Japan 0120-527196,

Korea 82 02 3451 3400, Lebanon 961 (0) 1 33 28 28,

Malaysia 1800 887710, Mexico 01 800 010 0793,

ni.com/support you have access to

ni.com/support

© National Instruments Corp. 21 Getting Started with the NI 17xx

Page 22

Netherlands 31 (0) 348 433 466, New Zealand 0800 553 322,

Norway 47 (0) 66 90 76 60, Poland 48 22 328 90 10,

Portugal 351 210 311 210, Russia 7 495 783 6851,

Singapore 1800 226 5886, Slovenia 386 3 425 42 00,

South Africa 27 0 11 805 8197, Spain 34 91 640 0085,

Sweden 46 (0) 8 587 895 00, Switzerland 41 56 2005151,

Taiwan 886 02 2377 2222, Thailand 662 278 6777,

Turkey 90 212 279 3031, United Kingdom 44 (0) 1635 523545

Getting Started with the NI 17xx 22 ni.com

Page 23

LabVIEW, National Instruments, NI, ni.com, the National Instruments corporate logo, and the Eagle logo are

trademarks of National Instruments Corporation. Refer to the Trademark Information at ni.com/trademarks

for other National Instruments trademarks. Other product and company names mentioned herein are trademarks or

trade names of their respective companies. For patents covering National Instruments products/technology, refer to

the appropriate location: Help»Patents in your software, the patents.txt file on your media, or the National

Instruments Patent Notice at ni.com/patents.

© 2007–2010 National Instruments Corp. All rights reserved.

372351D-01 Oct10

Loading...

Loading...