National Instruments myDAQ User Manual

USER GUIDE

1

A

MA

X

60

V

2

0

V

r

ms

MA

X

VΩ

A

NI myDAQ

DeutschFrançais

ni.com/manuals

NI myDAQ is a low-cost portable data acquisition (DAQ) device that uses NI LabVIEW-based

software instruments, allowing students to measure and analyze real-world signals. NI myDAQ

is ideal for exploring electronics and taking sensor measurements. Combined with NI LabVIEW

on the PC, students can analyze and process acquired signals and control simple processes

anytime, anywhere.

Figure 1. NI myDAQ

NI myDAQ

P

ower Supply

US

B

Cu

rr

e

nt

D

C-to

DC

L

imit

e

r

Co

n

ve

r

ter

±

15 V

5

S

ystem

T

imin

g

Digital I

Con

t

roller

Analog

Analog-

to-Digital

Co

nverte

r

A

n

alog

Output

D

ig

it

a

l-

to

A

n

a

lo

g

Co

n

v

e

r

te

r

D

ig

ita

l

M

u

ltimet

e

r

V

Ω

A

NI

myDA

Q

A

n

s

u

p

p

VΩ

20 V

M

AX

H

I

S

a

l

o

g

I

C

s

li

e

d

b

y

r

ms

1

A

C

MA

O

X

M

H

V

n

put/Output

DI

O

In

put

r

e

x

e

G

a

in

AI

pl

i

t

ul

AUD

M

I

O

IN

h

c

AO

it

Sw

AU

D

I

O

O

U

T

y

st

em

D

iagr

am

I

Contents

Safety Information .................................................................................................................... 2

Electromagnetic Compatibility Guidelines .............................................................................. 3

NI myDAQ Hardware Overview.............................................................................................. 3

Analog Input (AI) .............................................................................................................4

Analog Output (AO) ......................................................................................................... 4

Digital Input/Output (DIO)............................................................................................... 5

Power Supplies ................................................................................................................. 5

Digital Multimeter (DMM) .............................................................................................. 5

NI myDAQ Software Overview ............................................................................................... 6

NI ELVISmx Driver Software.......................................................................................... 6

NI LabVIEW and NI ELVISmx Express VIs ..................................................................6

NI myDAQ and NI Multisim............................................................................................ 6

Getting Started .......................................................................................................................... 6

Making Signal Connections with NI myDAQ..........................................................................7

Setting up Your NI myDAQ Device.................................................................................7

Connecting Signals ...........................................................................................................9

Connecting Analog Input Signals ..................................................................................... 10

NI myDAQ DMM Fuse Replacement .............................................................................. 13

Digital I/O (DIO) and Counters/Timers.................................................................................... 15

Using NI myDAQ with NI ELVISmx Software Instruments ...................................................16

NI ELVISmx Instrument Launcher .................................................................................. 17

Digital Multimeter (DMM)...............................................................................................18

Oscilloscope (Scope) ........................................................................................................ 19

Function Generator (FGEN) ............................................................................................. 20

Bode Analyzer .................................................................................................................. 21

Dynamic Signal Analyzer (DSA) .....................................................................................22

Arbitrary Waveform Generator (ARB).............................................................................23

Digital Reader ................................................................................................................... 24

Digital Writer .................................................................................................................... 25

Example: Measuring a Signal Using the NI ELVISmx Oscilloscope

with NI myDAQ ............................................................................................................ 26

Using NI myDAQ with LabVIEW ...........................................................................................27

NI ELVISmx Express VIs in LabVIEW...........................................................................27

Example: Measuring Signals Using the NI ELVISmx Oscilloscope Express VI

with NI myDAQ ............................................................................................................ 28

Using NI-DAQmx with NI myDAQ ................................................................................30

Example: Measuring Audio Pass-Through in LabVIEW with NI myDAQ .....................30

Texas Instruments Components in NI myDAQ........................................................................ 34

Resource Conflicts .................................................................................................................... 35

Additional Resources ................................................................................................................ 37

Related Documentation..................................................................................................... 37

Other Resources ................................................................................................................ 38

Common Terms and Acronyms........................................................................................38

Warranty ........................................................................................................................... 39

Worldwide Support and Services ..................................................................................... 39

Safety Information

Caution Do not operate the hardware in a manner not specified in this document

and in the user documentation. Misuse of the hardware can result in a hazard. You

can compromise the safety protection if the hardware is damaged in any way. If the

hardware is damaged, return it to National Instruments for repair.

Clean the hardware with a soft, nonmetallic brush. Make sure that the hardware is completely

dry and free from contaminants before returning it to service.

2 | ni.com | NI myDAQ User Guide

Electromagnetic Compatibility Guidelines

Cautions To ensure the specified EMC performance:

• The USB cable must be less than 2.0 m (6.6 ft) in length.

• The length of any wire or cable connected to the 20-pin screw terminal

connector must be no longer than 0.3 m (1 ft).

• The length of any wire or cable connected to the Audio or DMM ports must be

no longer than 3 m (10 ft).

This product was tested and complies with the regulatory requirements and limits for

electromagnetic compatibility (EMC) as stated in the product specifications. These requirements

and limits are designed to provide reasonable protection against harmful interference when the

product is operated in its intended operational electromagnetic environment.

This product is intended for use in residential, commercial, and industrial locations. There is no

guarantee that harmful interference will not occur in a particular installation or when the product

is connected to a test object. To minimize the potential for the product to cause interference to

radio and television reception or to experience unacceptable performance degradation, install

and use this product in strict accordance with the instructions in the product documentation.

Furthermore, any changes or modifications to the product not expressly approved by National

Instruments could void your authority to operate it under your local regulatory rules.

NI myDAQ Hardware Overview

NI myDAQ provides analog input (AI), analog output (AO), digital input and output (DIO),

audio, power supplies, and digital multimeter (DMM) functions in a compact USB device.

Tip The Common Terms and Acronyms section has a list of acronyms and terms

that you will see in this manual, and in many engineering and measurement

documents and websites.

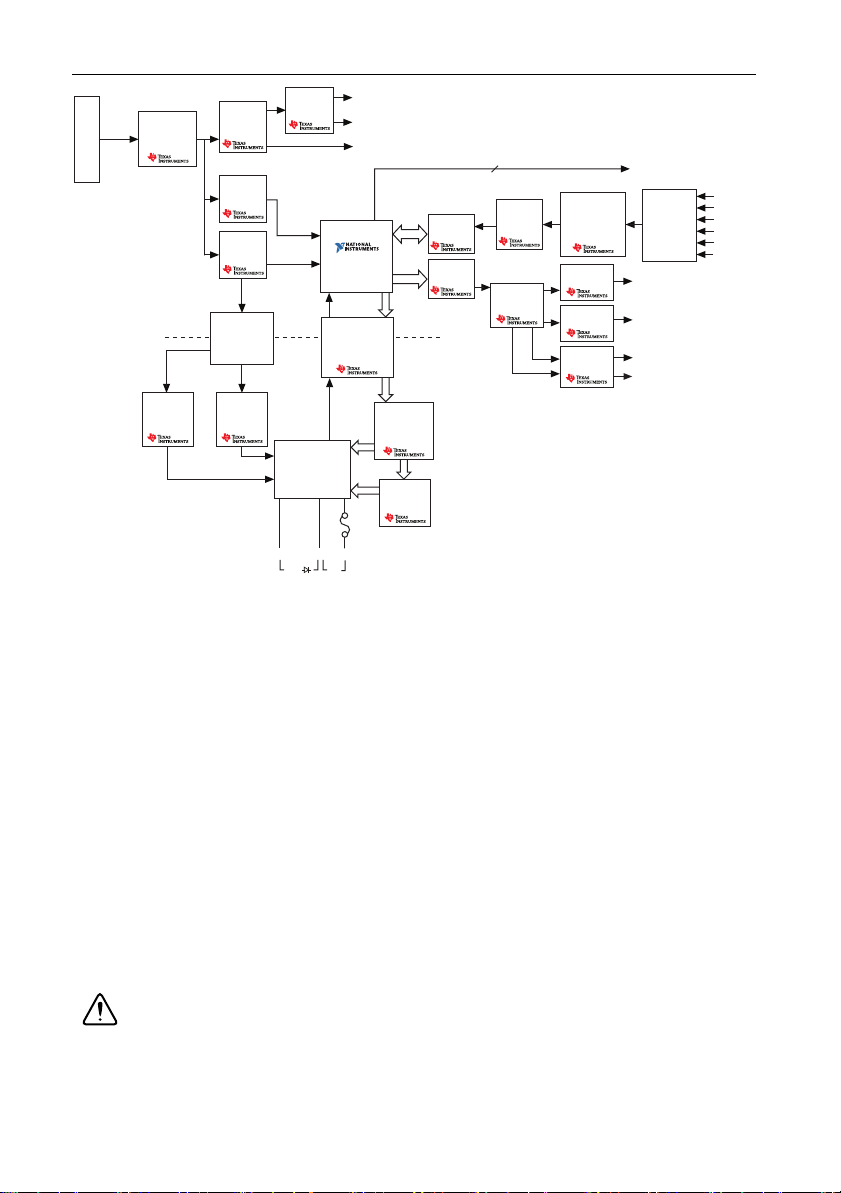

Integrated circuits supplied by Texas Instruments form the power and analog I/O subsystems of

NI myDAQ. Figure 2 depicts the arrangement and function of the NI myDAQ subsystems. Refer

to Table 5 for more information on all of the Texas Instruments components used in NI myDAQ.

NI myDAQ User Guide | © National Instruments | 3

Figure 2. NI myDAQ Hardware Block Diagram

Protection

Circuit

(CSD25302Q2)

DC/DC

Isolation

Transformer

LDO

Regulator

(TPS76433)

LDO

Regulator

(TPS76433)

VBUS

Isolated +3.3 V

+15 V

+3.3 V

+1.2 V

+5 V

–15 V

USB-STC3

Digital

Isolator

(ISO7241)

DMM

Shift

Register

(SN74AHC595)

Switch

(TS5A3159)

Regulator

(TPS61170)

Isolation

Barrier

HI

HI

COM

DAC

(DAC8551)

Switch

(TS12A44514)

Gain

(TLE2082)

OP AMP

(OPA1642)

Audio AMP

(TPA6110A2)

AO 0

AO 1

Line Out R

Line Out L

Instrumentation

Amplifier

(OPA1642)

Channel

Multiplexer

AI 0–

AI 0+

AI 1–

AI 1+

Line In L

Line In R

8

DIO x

USB Connector

Regulator

(TPS62007)

Regulator

(TPS62003)

ADC

(ADS8319)

OP AMP

(OPA1642)

Current

Limiter

(TPS2553)

(V Ω ) (A)

+3.3 V

LDO

Regulator

(TPS71501)

Isolated +5 V

Note: NI myDAQ components may be changed or substituted without notice.

Analog Input (AI)

There are two analog input channels on NI myDAQ. These channels can be configured either as

general-purpose high-impedance differential voltage input or audio input. The analog inputs are

multiplexed, meaning a single analog-to-digital converter (ADC) is used to sample both

channels. In general-purpose mode, you can measure up to ±10 V signals. In audio mode, the

two channels represent left and right stereo line level inputs. Analog inputs can be measured at

up to 200 kS/s per channel, so they are useful for waveform acquisition. Analog inputs are used

in the NI ELVISmx Oscilloscope, Dynamic Signal Analyzer, and Bode Analyzer instruments.

Analog Output (AO)

There are two analog output channels on NI myDAQ. These channels can be configured as either

general-purpose voltage output or audio output. Both channels have a dedicated

digital-to-analog converter (DAC), so they can update simultaneously. In general-purpose

mode, you can generate up to ±10 V signals. In audio mode, the two channels represent left and

right stereo outputs.

Caution f using earphones to listen to the audio output of the NI myDAQ, ensure

that the volume is set to a safe level. Listening to audio signals at a high volume may

result in permanent hearing loss.

4 | ni.com | NI myDAQ User Guide

Analog outputs can be updated at up to 200 kS/s per channel, making them useful for waveform

generation. Analog outputs are used in the NI ELVISmx Function Generator, Arbitrary

Waveform Generator, and Bode Analyzer instruments.

Digital Input/Output (DIO)

There are eight DIO lines on NI myDAQ. Each line is a Programmable Function Interface (PFI),

meaning that it can be configured as a general-purpose software-timed digital input or output, or

it can act as a special function input or output for a digital counter. Refer to Digital I/O (DIO)

and Counters/Timers section for more information about the counter on NI myDAQ.

Note The digital I/O lines are 3.3 V LVTTL and are tolerant to 5 V inputs. The

digital output is not compatible with 5 V CMOS logic levels.

Power Supplies

There are three power supplies available for use on NI myDAQ. +15 V and -15 V can be used

to power analog components such as operational amplifiers and linear regulators. +5 V can be

used to power digital components such as logic devices.

The total power available for the power supplies, analog outputs, and digital outputs is limited

to 500 mW (typical)/100 mW (minimum). To calculate the total power consumption of the

power supplies, multiply the output voltage by the load current for each voltage rail and sum

them together. For digital output power consumption, multiply 3.3 V by the load current. For

analog output power consumption, multiply 15 V by the load current. Using audio output

subtracts 100 mW from the total power budget.

For example, if you use 50 mA on +5 V, 2 mA on +15 V, 1 mA on -15 V, use four DIO lines to

drive LEDs at 3 mA each, and have a 1 mA load on each AO channel, the total output power

consumption is:

5 V × 50 mA = 250 mW

|+15 V| × 2 mA = 30 mW

|-15 V| × 1 mA = 15 mW

3.3 V × 3 mA × 4 = 39.6 mW

15 V × 1 mA × 2 = 30 mW

Total output power consumption = 250 mW + 30 mW + 15 mW + 39.6 mW +

30 mW = 364.6 mW

Digital Multimeter (DMM)

The NI myDAQ DMM provides the functions for measuring voltage (DC and AC), current (DC

and AC), resistance, and diode voltage drop.

DMM measurements are software-timed, so update rates are affected by the load on the

computer and USB activity.

NI myDAQ User Guide | © National Instruments | 5

NI myDAQ Software Overview

NI ELVISmx Driver Software

NI ELVISmx is the driver software that supports NI myDAQ. NI ELVISmx uses

LabVIEW-based software instruments to control the NI myDAQ device, providing the

functionality of a suite of common laboratory instruments. Refer to the Using NI myDAQ with

NI ELVISmx Software Instruments section for information on the NI ELVISmx suite of

measurement instruments.

NI ELVISmx is located on your driver software installation media included in the NI myDAQ

kit, or can be found by searching for

drivers

of LabVIEW, go to

. To determine the version of NI ELVISmx software support required for your version

ni.com/info and enter the Info Code exsbw6.

NI LabVIEW and NI ELVISmx Express VIs

Also installed with NI ELVISmx are the LabVIEW Express VIs, which use NI ELVISmx

software instruments to program NI myDAQ with more enhanced functionality. For more

information on the NI ELVISmx Express VIs, refer to the Using NI myDAQ with LabVIEW

section.

Note NI ELVISmx supports LabVIEW (32 bit). To use NI ELVISmx with

LabVIEW on a 64-bit operating system, you must have LabVIEW (32 bit) installed.

NI myDAQ and NI Multisim

You can use NI ELVISmx instruments in NI Multisim to simulate a circuit, measure the real

signals with NI myDAQ, and compare simulated and acquired data. To see step-by-step

instructions for using NI ELVISmx instruments in NI Multisim, refer to Using NI ELVISmx in

NI Multisim help file, installed with NI ELVISmx. To access this help file, go to Start»

All Programs»National Instruments»NI ELVISmx for NI ELVIS & NI myDAQ»Using

NI ELVISmx in NI Multisim.

ELVISmx on the Drivers and Updates page at ni.com/

Getting Started

Getting started with NI myDAQ is a simple process, but it is important to ensure that you install

the right components in the correct order. To get started with your NI myDAQ, complete the

following steps:

1. Install the NI myDAQ Software Suite from the DVD shipped with your device.

The NI myDAQ Software Suite installs application software (NI LabVIEW, NI Multisim)

first, and then installs the NI ELVISmx driver software.

Note If you are not installing software from the NI myDAQ Software Suite media,

make sure to install all application software before installing the driver software.

6 | ni.com | NI myDAQ User Guide

2. Connect the cable from the computer Hi-Speed USB port to the USB port on the device.

The computer will recognize the NI myDAQ and the NI ELVISmx Instrument Launcher

appears. You can also manually open NI ELVISmx Instrument Launcher by selecting

Start»All Programs»National Instruments»NI ELVISmx for NI ELVIS &

NI myDAQ»NI ELVISmx Instrument Launcher.

Caution To ensure the specified EMC performance, the USB cable must be less

than 2.0 m (6.6 ft) in length.

Making Signal Connections with NI myDAQ

Setting up Your NI myDAQ Device

Caution Insert and remove the 20-position screw terminal connector aligned

evenly to the NI myDAQ. Inserting the screw terminal connector at an angle to the

NI myDAQ may cause damage to the connector.

The screw terminal connector must snap securely into place to ensure proper signal

connection.

NI myDAQ User Guide | © National Instruments | 7

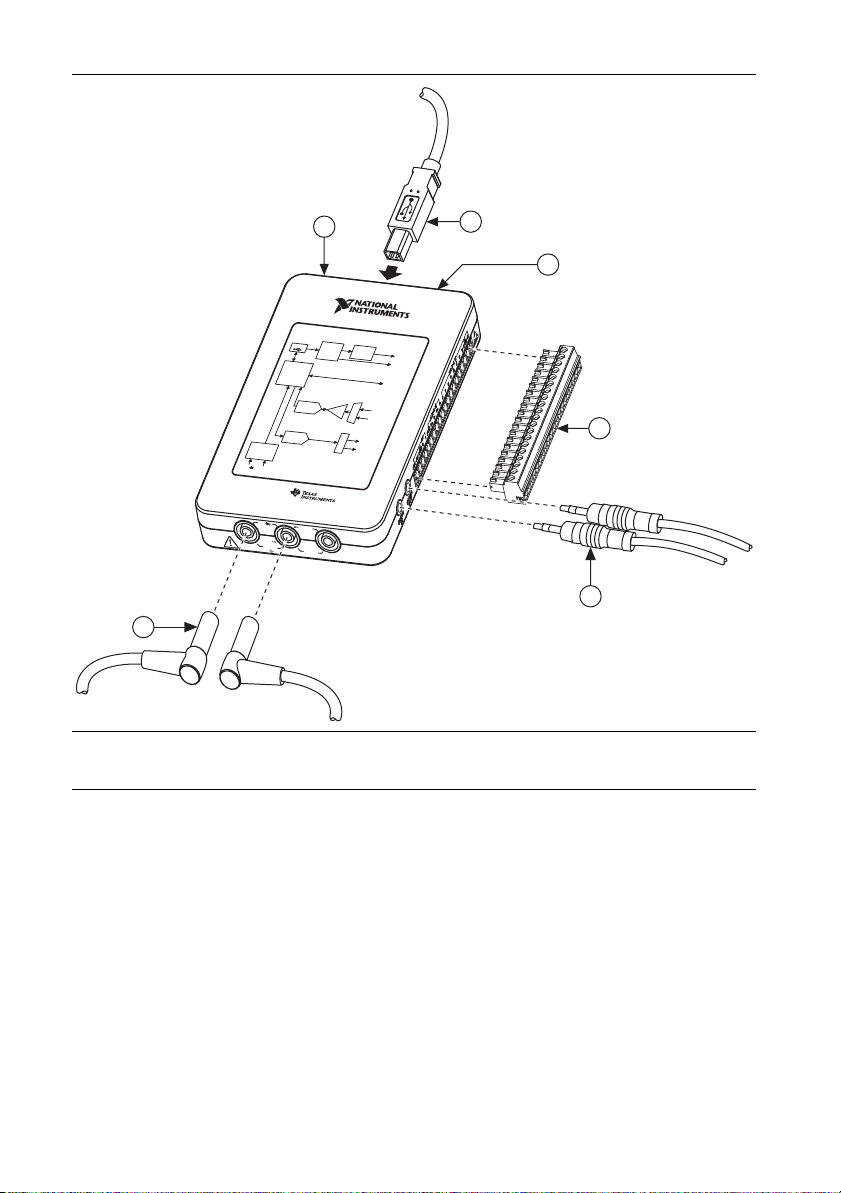

Figure 3. NI myDAQ Connection Diagram

1 A

M

A

X

6

0

V

2

0

V

rms

M

A

X

VΩ

A

6

1NI myDAQ

2USB Cable

3LED

1

2

3

NI myDAQ

Power Supply

U

SB

Current

DC-toDC

Limiter

Conver

t

e

r

±15 V

5

S

y

stem

Tim

in

g

Dig

ital

Controlle

r

An

a

log

I

An

a

log

-

to-Digit

a

l

Con

Gain

v

ert

e

r

A

n

a

log Output

D

ig

ital-

to-Analo

g

C

o

n

ve

r

ter

Dig

i

ta

l

Multimet

e

r

VΩ

A

N

I m

y

D

A

supp

V

Ω

2

0

MAX

H

I

AQ Sys

nalog

IC

s

lied b

y

Vr

m

s

1

A

CO

MAX

M

H

I

V

Input

/

O

u

tput

D

IO

n

p

ut

exer

AI

pl

ti

AUDIO

Mul

IN

ch

AO

t

i

Sw

AUDIO OUT

te

m

Dia

g

ram

4

5

4 20-Position Screw Terminal Connector

5 Audio Cable

6 DMM Banana Cable

8 | ni.com | NI myDAQ User Guide

Connecting Signals

AUDI OINAUDI O

OUT

Figure 4 shows the available audio, AI, AO, DIO, GND, and power signals accessed through the

3.5 mm audio jacks and screw terminal connections. Refer to Table 1 for descriptions of these

signals.

Cautions Signal wires must be securely affixed and screwed down in the screw

terminal connector to ensure proper connection.

To ensure the specified EMC performance:

• The length of any wire or cable connected to the 20-pin screw terminal

connector must be no longer than 0.3 m (1 ft).

• The length of any wire or cable connected to the Audio or DMM ports must be

no longer than 3 m (10 ft).

Figure 4. NI myDAQ 20-Position Screw Terminal I/O Connector

Table 1. Screw Terminal Signal Descriptions

Signal

Name

AUDIO IN — Input Audio Input—Left and right audio inputs

Reference Direction Description

on a stereo connector

AUDIO OUT — Output Audio Output—Left and right audio

outputs on a stereo connector

+15V/-15V AGND Output +15 V/-15 V power supplies

AGND — — Analog Ground—Reference terminal for

AI, AO, +15 V, and -15 V

AO 0/AO 1 AGND Output Analog Output Channels 0 and 1

AI 0+/AI 0-;

AGND Input Analog Input Channels 0 and 1

AI 1+/AI 1-

DIO <0..7> DGND Input or

Output

Digital I/O Signals—General-purpose

digital lines or counter signals

DGND — — Digital Ground—Reference for the DIO

lines and the +5 V supply

5V DGND Output 5 V power supply

NI myDAQ User Guide | © National Instruments | 9

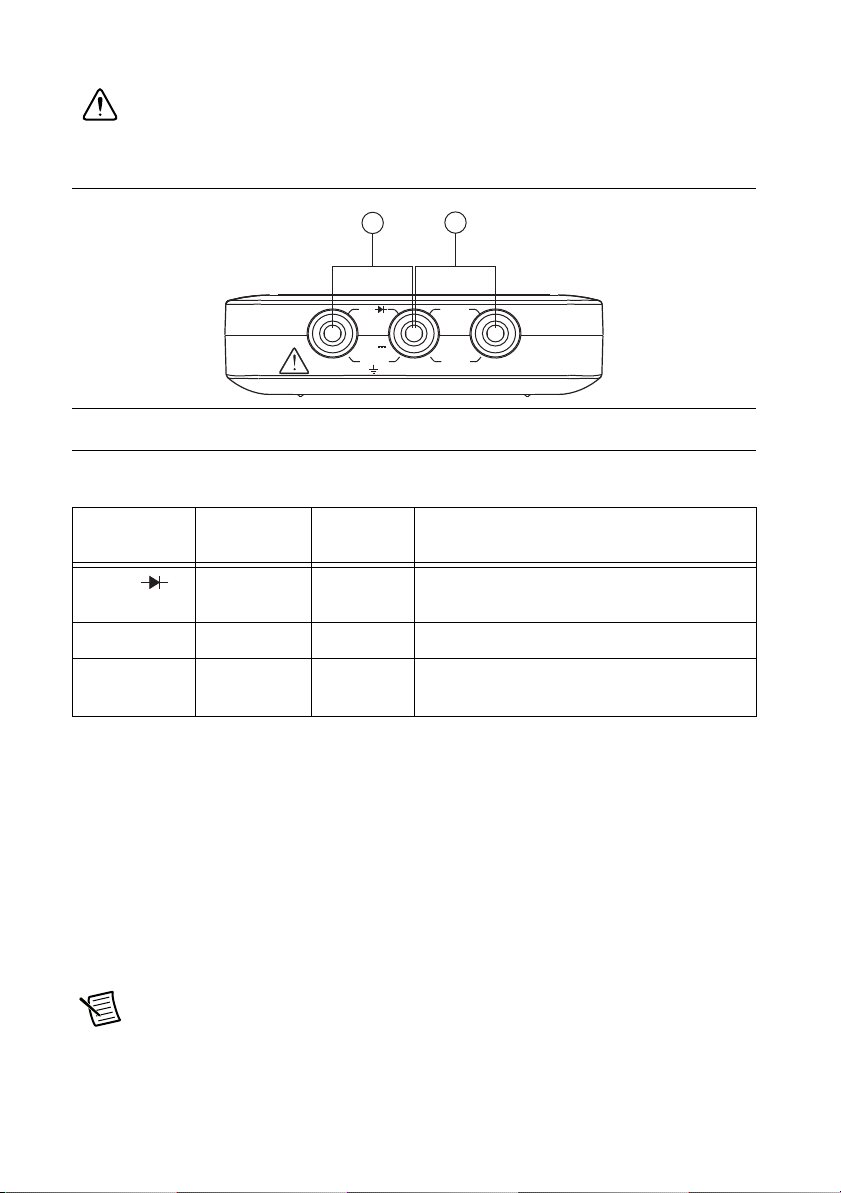

Figure 5 shows the DMM connections on the NI myDAQ. Table 2 describes these signals.

1 A A

MAX

6

0 V

20 Vrms

MAX

A

V

Ω

Caution 60 VDC/20 Vrms maximum. Do not plug digital multimeter probes into

circuits with Hazardous Voltages, such as wall outlets.

Figure 5. Connections for DMM Measurements

MAX

2

HIHI COM

1

0 V

20 Vrms

MAX

1 Connectors for Voltage/Resistance/Diode/Continuity

2 Connectors for Current

Table 2. DMM Signal Descriptions

Signal

Name

Reference Direction Description

HI (VΩ ) COM Input Positive terminal for voltage, resistance,

and diode measurements

COM — — Reference for all DMM measurements

HI (A) COM Input Positive terminal for current measurements

(Fused: F 1.25 A 250 V Fast-Acting)

Connecting Analog Input Signals

When configuring the input channels and making signal connections, you must first determine

whether the signal sources are floating or ground referenced. The following sections describe

these two signal types.

Ground-Referenced Signal Sources

A ground-referenced signal source is connected to the building system ground, so it is already

connected to a common ground point with respect to the NI myDAQ device, assuming that the

computer is plugged into the same power system. Instruments or devices with nonisolated

outputs that plug into the building power system are ground-referenced signal sources.

Note Most laptop computers have isolated power supplies, and are consequently

not connected to the building ground system. In these cases, treat the analog input

signal as floating with respect to NI myDAQ.

10 | ni.com | NI myDAQ User Guide

The difference in ground potential between two instruments connected to the same building power

+

–

+

–

AI+

AGND

Signal Source

AI–

+

–

AI+

AGND

Signal Source

R

source

>100

Ω

AI–

+

–

system is typically between 1 and 100 mV. This difference can be much higher if power

distribution circuits are improperly connected. If a grounded signal source is improperly measured,

this difference might appear as a measurement error. Connect the differential analog inputs across

the signal source and do not connect the NI myDAQ AGND pin to the grounded source.

Figure 6. Ground-Referenced Differential Connection

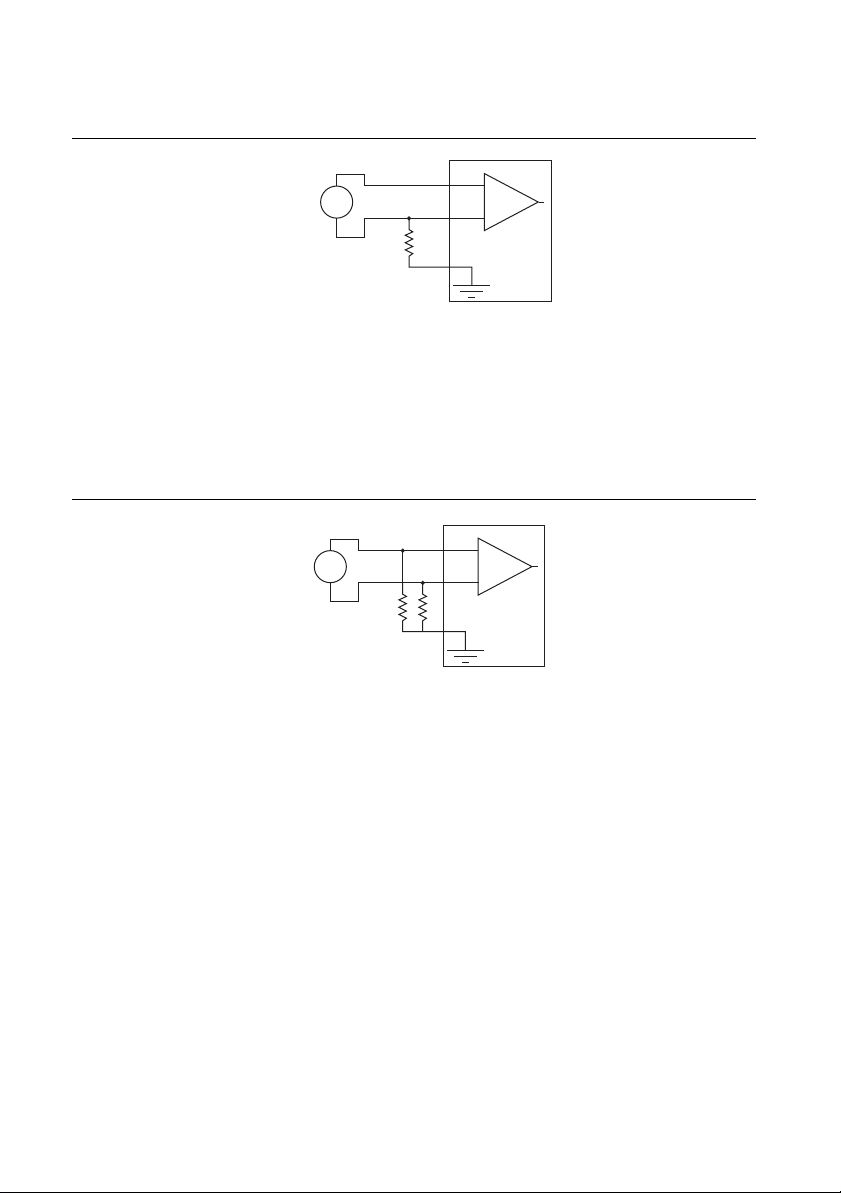

Floating Signal Sources

A floating signal source is not connected to the same ground reference as NI myDAQ, but

instead has an isolated reference point. Some examples of floating signal sources are

battery-powered devices, outputs of transformers, thermocouples, optical isolator outputs, and

isolation amplifiers. An instrument or device that has an isolated output is a floating signal

source. You must connect the ground reference of a floating signal to an NI myDAQ AGND pin

through a bias resistor or jumper wire to establish a local or onboard reference for the signal.

Otherwise, the measured input signal varies as the source floats out of the common-mode input

range.

The easiest way to reference the source to AGND is to connect the positive side of the signal to

AI+ and connect the negative side of the signal to AGND as well as to AI- without using

resistors. This connection works well for DC-coupled sources with low source impedance (less

than 100 Ω).

Figure 7. Differential Connections for Floating Signal Sources without Resistors

For larger source impedances, however, this connection leaves the differential signal path

significantly off balance. Noise that couples electrostatically onto the positive line does not

couple onto the negative line because it is connected to ground. This noise appears as a

differential-mode signal instead of a common-mode signal, and thus appears in your data. In this

case, instead of directly connecting the negative line to AGND, connect the negative line to

AGND through a resistor that is about 100 times the equivalent source impedance. The resistor

puts the signal path nearly in balance, so that about the same amount of noise couples onto both

NI myDAQ User Guide | © National Instruments | 11

connections, yielding better rejection of electrostatically coupled noise. This configuration does

+

–

+

–

AI+

AGND

Signal Source

R

source

>100

Ω

AI–

+

–

+

–

AI+

AGND

Signal Source

R

source

>100

Ω

AI–

not load down the source.

Figure 8. Differential Connections for Floating Signal Sources with a Single Resistor

You can fully balance the signal path by connecting another resistor of the same value between

the positive input and AGND, as shown in Figure 9. This fully balanced configuration offers

slightly better noise rejection, but has the disadvantage of loading the source down with the

series combination (sum) of the two resistors. If, for example, the source impedance is 2 kΩ and

each of the two resistors is 100 kΩ, the resistors load down the source with 200 kΩ and produce

a -1% gain error.

Figure 9. Differential Connections for Floating Signal Sources with Two Resistors

Both positive and negative analog input lines require a DC path to ground in order for the

instrumentation amplifier to work. If the source is AC coupled (capacitively coupled), a resistor

is needed between the positive input and AGND. If the source has low impedance, choose a

resistor that is large enough not to significantly load the source but small enough not to produce

significant input offset voltage as a result of input bias current (typically 100 kΩ to 1 MΩ). In

this case, connect the negative input directly to AGND. If the source has high output impedance,

balance the signal path as previously described using the same value resistor on both the positive

and negative inputs.

12 | ni.com | NI myDAQ User Guide

Loading...

Loading...