Page 1

USER GUIDE

MID-7654/7652 S

This user guide describes the electrical and mechanical aspects of the

MID-7654/7652 servo power motor drive and describes how to use

the MID-7654/7652 with your motion controller.

Contents

Conventions ............................................................................................2

Introduction.............................................................................................2

What You Need to Get Started ............................................................... 3

Safety Information .................................................................................. 3

Front Panel Switches...............................................................................5

Host Bus Interlock Circuit ......................................................................6

Front Panel LEDs.................................................................................... 6

Amplifier Fault Output LEDs .......................................................... 7

Amplifier Inhibit LEDs.................................................................... 7

Limit Status LEDs ........................................................................... 7

Front Panel DIP Switch Settings............................................................. 8

Inhibit Input Polarity Setting ........................................................... 9

Inhibit Output Polarity Setting......................................................... 9

Limit Status LED Polarity Setting................................................... 10

Setting Continuous and Peak Current Limits .................................. 10

Setting Motor Inductance Levels..................................................... 13

Back Panel Connector Wiring.................................................................15

Terminal Block Wiring.................................................................... 17

Servo Motor Power Terminal Blocks....................................... 17

Rear Guard................................................................................ 19

Encoder Terminal Blocks ......................................................... 22

Limit Switch Terminal Blocks ................................................. 24

Breakpoint and Trigger Terminal Blocks................................. 25

Analog I/O Terminal Blocks .................................................... 25

Step and Direction Terminal Block ..........................................26

Cable Installation for CE Compliance .............................................27

Accessories Included for Optional Use...................................................28

Strain-Relief Bar Installation ........................................................... 28

Panel Mount Kit Installation............................................................ 29

ERVOPOWER

M

OTOR

D

RIVE

National Instruments™, NI™, and ni.com™ are trademarks of National Instruments Corporation. Product and company names mentioned herein are

trademarks or trade names of their respective companies.

322691B-01 Copyright © 2000, 2001 National Instruments Corp. All rights reserved. June 2001

Page 2

Modifying the Power Entry Module........................................................30

Replacing a Fuse...............................................................................30

Changing the Line Voltage...............................................................31

Amplifier/Driver Command Signals .......................................................31

Specifications...........................................................................................31

Technical Support Resources ..................................................................36

NI Web Support................................................................................36

Worldwide Support ..........................................................................36

Conventions

The following conventions are used in this guide:

This icon denotes a note, which alerts you to important information.

This icon denotes a caution, which advises you of precautions to take to

avoid injury, data loss, or a system crash.

This icon denotes a warning, which advises you of precautions to take to

avoid being electrically shocked.

italic Italic text denotes emphasis, a cross reference, or an introduction to a key

concept.

monospace

overline

Introduction

Text in this font denotes text or characters that you should enter from the

keyboard, sections of code, programming examples, and syntax examples.

This font is also used for the proper names of disk drives, paths, directories,

programs, subprograms, subroutines, device names, functions, operations,

variables, filenames and extensions, and code excerpts.

Indicates the signal is active-low.

Your MID-7654 or 7652 servo power motor drive is a complete power

amplifier and system interface for use with four or two axes of

simultaneous servo motion control, respectively. The MID-7654/7652

is ideal for industrial and laboratory applications and has everything you

need to connect motors, encoders, limit switches, I/O, and other motion

hardware to National Instruments motion controllers.

The MID-7654/7652 can drive a broad range of servo motors with its

pulse-width modulation (PWM) amplifiers with user-specified peak and

continuous output current settings. In all configurations, power supplies are

built in and use standard 240/120 VAC for operation. Electronics are

fan-cooled to ensure reliable operation.

MID-7654/7652 Servo Power Motor Drive User Guide 2 ni.com

Page 3

The MID-7654/7652 simplifies your field wiring through separate encoder,

limit switch, and motor power removable screw terminal connector blocks

for each axis. The terminal blocks do not require any special wiring tools

for installation. The MID-7654/7652 connects to National Instruments

motion controllers via a 68-pin, high-density interconnect cable.

The MID-7654/7652 has four levels of amplifier inhibit/disable protection

for motion system shut down. The front panel contains both enable and

power switches for direct motor inhibiting and system power-down

operations. The MID-7654/7652 also has a host bus power interlock that

activates an internal driver inhibit signal if the host computer is shut down

or if the motion controller interface cable is disconnected. The inhibit input

from the back panel connectors also inhibits the servo drives when

activated.

You can use the MID-7654/7652 enclosure as a benchtop unit, panel

mounted using a panel mount kit, or rack-mounted using a 19-inch standard

rack kit.

What You Need to Get Started

To set up and use your MID-7654/7652 accessory, you must have the

following items:

❑

The MID-7654/7652 servo power motor drive with attached rear guard

MID-7654/7652 Servo Power Motor Drive User Guide

❑

❑

Power cord (IEC type)

❑

Strain-relief bar, part number 187407-01 (included)

❑

Panel-mount kit, part number 187243-01 (included)

❑

SHC68-C68-S shielded cable assembly, part number 186380-02

(not included)

Refer to the Specifications section later in this guide for detailed

specifications for the MID-7654/7652.

Safety Information

Follow these guidelines to ensure your safety and protect your equipment:

• Keep away from live circuits. Do not remove equipment covers or

shields unless you are trained to do so. Hazardous voltages may exist

even when the equipment is turned off. To avoid a shock hazard, do not

perform procedures involving cover or shield removal unless you are

© National Instruments Corporation 3 MID-7654/7652 Servo Power Motor Drive User Guide

Page 4

qualified to do so and disconnect all field power prior to removing

covers or shields.

• Do not operate damaged equipment. The safety protection features

built into this device can become impaired if the device becomes

damaged in any way. If the device is damaged, turn the device off and

do not use it until service-trained personnel can check its safety.

If necessary, return the device to National Instruments for service and

repair to ensure its safety is not compromised.

• Do not operate this equipment in a manner that contradicts the

information specified in this guide. Misuse of this equipment could

result in a shock hazard.

• Do not substitute parts or modify equipment. Because of the danger

of introducing additional hazards, do not install unauthorized parts

or modify the device. Return the device to National Instruments for

service and repair to ensure its safety features are not compromised.

• When connecting or disconnecting signal lines to the MID-7654/7652

terminal block screw terminals, make sure the lines are powered off.

Potential differences between the lines and the MID-7654/7652

ground create a shock hazard while you connect the lines.

• Connections that exceed any of the maximum signal ratings on the

MID-7654/7652 device can create a shock or fire hazard or can

damage any or all of the motion controllers connected to the

MID-7654/7652 chassis, the host computer, and the MID-7654/7652

device. This includes power signals to ground and vice versa. National

Instruments is not liable for any damages or injuries resulting from

incorrect signal connections.

• The servo motor connectors on this drive are energized when the unit

is powered on. The rear guard must be in place at all times while the

unit is connected to a power outlet. Disconnect the MID-7654/7652

unit from power outlet before connecting wires to or disconnecting

wires from the servo motor connectors. Strip back the insulation of

the servo motor wires to the servo motor connectors no more than

7 mm. Reattach the rear guard before you reconnect the unit to a power

outlet. Failure to do so could result in electric shock leading to serious

bodily injury or death.

• The bottom surface of the MID-7654/7652 can get very hot to the

touch under certain conditions. To avoid a burn hazard, refer to the

Setting Continuous and Peak Current Limits section within the Front

Panel DIP Switch Settings section of this guide for the appropriate

current setting and safety hazards.

MID-7654/7652 Servo Power Motor Drive User Guide 4 ni.com

Page 5

Front Panel Switches

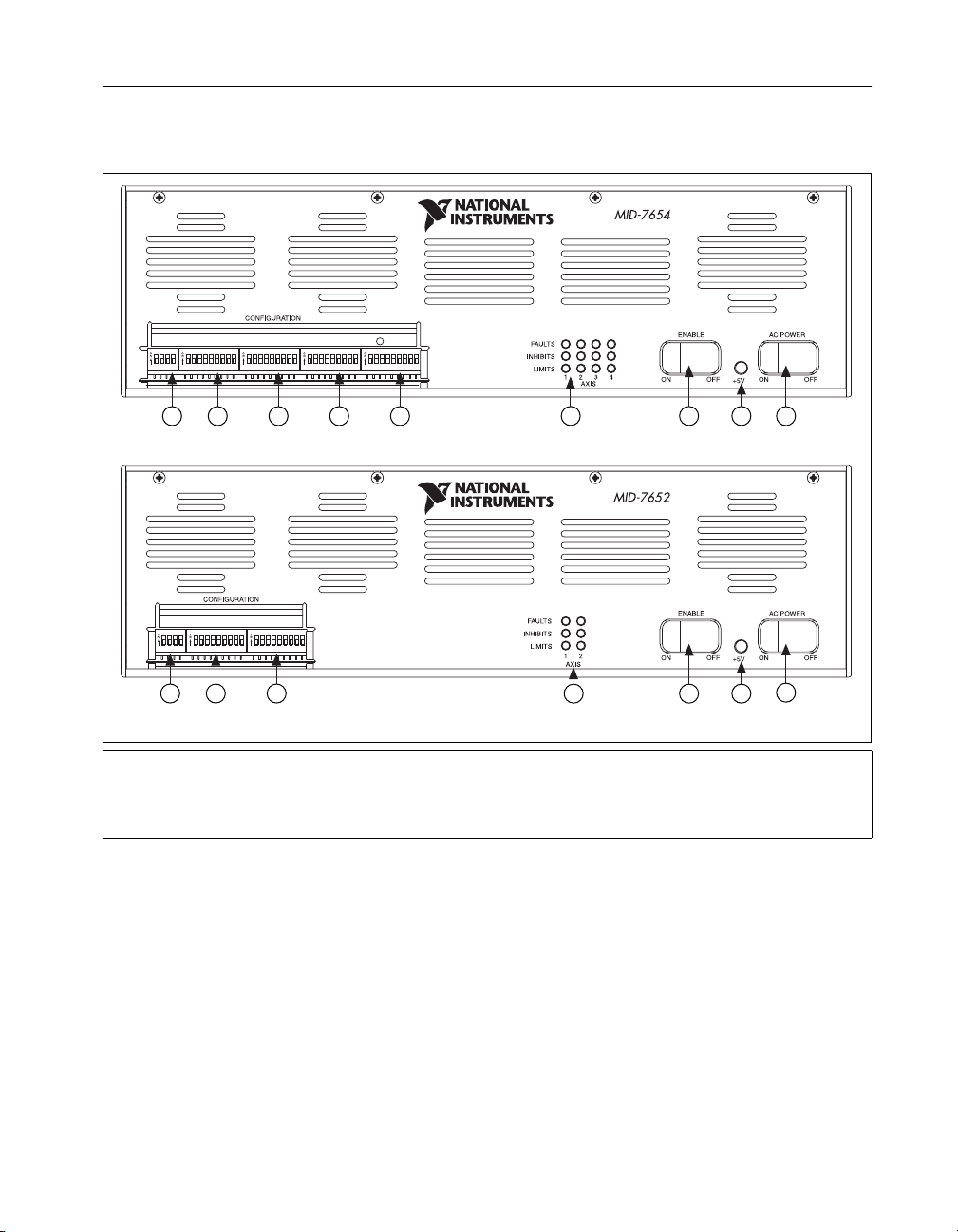

Figure 1 shows the front panel for your MID-7654/7652. The DIP switches

are shown with the detachable metal cover plate removed.

POL AXIS 1 AXIS 2 AXIS 3 AXIS 4

21 3 4 5

MID-7654

4 Axis Servo Motor Drive

4 Axis Servo Motor Drive

6

2 Axis Servo Motor Drive

7

8

9

POL AXIS 1 AXIS 2

21 3

6

7

9

8

MID-7652

1 Polarity DIP Switch Bank

2 Axis 1 DIP Switch Bank

3 Axis 2 DIP Switch Bank

4Axis3DIPSwitchBank*

5Axis4DIPSwitchBank*

6 LED Status Array

7 Enable Switch

8 Green Power LED

9 Power Switch

* This DIP switch bank is only available on the MID-7654.

Figure 1. MID-7654/7652 Front Panel

There are two rocker switches on the MID-7654/7652 front panel:

AC POWER and ENABLE. Figure 1 illustrates the location of these

switches.

The AC POWER switch energizes the motor bus (+48 V) and the logic

(+5 V) power supplies. When switched on, the green power LED labeled

+5 V illuminates. If this LED fails to illuminate, check the power cord and

main input fuse on the back panel.

© National Instruments Corporation 5 MID-7654/7652 Servo Power Motor Drive User Guide

Page 6

The ENABLE switch enables or inhibits the servo amplifiers. If the

ENABLE switch is in the inhibit position (OFF), the amplifier output stages

are inhibited and the yellow LEDs for all axes illuminate. See the Front

Panel LEDs section of this guide for more information.

Both the AC POWER and ENABLE switches can inhibit the servo

amplifiers. However, as long as the AC POWER switch is on, only the servo

amplifier output stages are disabled. The remaining circuitry remains

active, including the quadrature encoder circuit.

Warning

change the line voltage from the factory setting. Refer to the Specifications section of this

guide for fuse specifications. Refer to the Modifying the Power Entry Module section for

moreinformationonhandlingthepowerentrymodule.

Yo u must change the MID-7654/7652 main input fuse on the rear panel if you

Host Bus Interlock Circuit

The MID-7654/7652 has a host bus interlock circuit that monitors the

presence of +5 V from the host computer and disables the MID-7654/7652

when the voltage is not present or falls out of tolerance. This circuit shuts

down the servo amplifiers for all axes by activating the inhibit when the

host computer is disconnected from the MID-7654/7652 or inadvertently

shut down. Activation of the host bus interlock circuitry illuminates the

yellow LEDs (middle row) of the LED status array for all axes. See the

FrontPanelLEDssection of this guide for more information.

Front Panel LEDs

The front panel LEDs consist of a single green LED to indicate if the main

5 V power is active. If the DC power supplies are active, the green power

LED illuminates. If this LED fails to illuminate, check the power cord and

the main input fuse on the front panel.

An LED status array of 3 rows by 4 columns on the MID-7654 or 3 rows

by 2 columns on the MID-7652 provides a variety of status information.

Refer to Figure 1 for the location of the front panel LEDs. The LED status

array is arranged by motor axes. Each of the four columns represents an

axis, and each of the three rows represents a particular status. Table 1

summarizes the axes and statuses to which the different LEDs in the 3 × 4

or 3 × 2 array correspond.

MID-7654/7652 Servo Power Motor Drive User Guide 6 ni.com

Page 7

Amplifier Fault Output (red) 1 2 3

Amplifier Inhibit (yellow) 1 2 3

Limit Status (green) 1 2 3

*

These LEDs only appear on the MID-7654.

Amplifier Fault Output LEDs

The top row of the LED status array indicates the status of the amplifiers.

A red LED indicates an overcurrent condition, a short circuit condition, an

over temperature condition, or a problem with the motor bus voltage on that

axis.

Amplifier Inhibit LEDs

The middle row of the LED status array indicates if a motor axis is

inhibited. An axis is inhibited and the LED illuminates yellow if the host

bus interlock circuitry is activated from the back panel, if the ENABLE

switch on the front panel is in the inhibit position, if the motion controller’s

inhibit signal is low, or if the per-axis inhibit input is actively driven. You

can select the polarity of the per-axis inhibit input from the front panel DIP

switches. See the Front Panel DIP Switch Settings section of this guide for

more information.

Table 1. Front Panel LED Indicators

Status Motor Axis

*

*

*

*

4

*

4

*

4

Limit Status LEDs

The bottom row of the LED status array indicates if a limit switch is

currently active. The LED illuminates green when either the forward or

reverse limit switch is active for each axis. You can select the polarity for

the limit status LEDs from the front panel DIP switches. See the Front

Panel DIP Switch Settings of this guide for more information.

© National Instruments Corporation 7 MID-7654/7652 Servo Power Motor Drive User Guide

Page 8

Front Panel DIP Switch Settings

The MID-7654/7652 front panel has a detachable metal plate that, when

removed, provides access to one 4-position DIP switch bank and either four

(MID-7654) or two (MID-7652) 9-position DIP switch banks. Refer to

Figure 1 for the location of these switches.

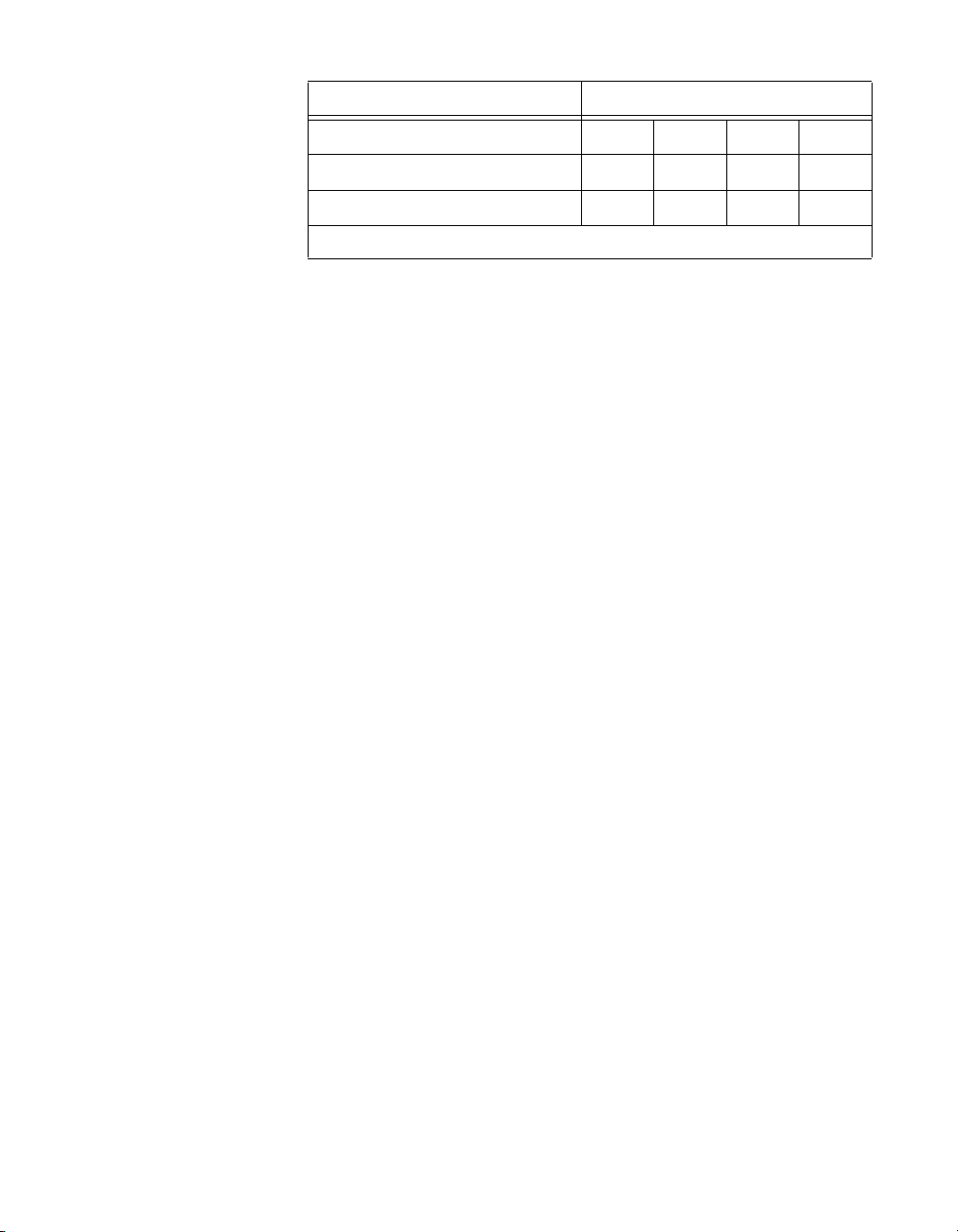

Use the DIP switches on the 4-position DIP switch bank to configure the

inhibit in, inhibit out, and limit status LED polarity as shown in Figure 2.

The different settings for these switches are described in the following

sections.

O

N

1234

1 2 3 4

1 Inhibit In Polarity Switch

2 Inhibit Out Polarity Switch

3 Limit Status LED Polarity Switch

4 Reserved

Figure 2. 4-Position DIP Switch Bank Layout

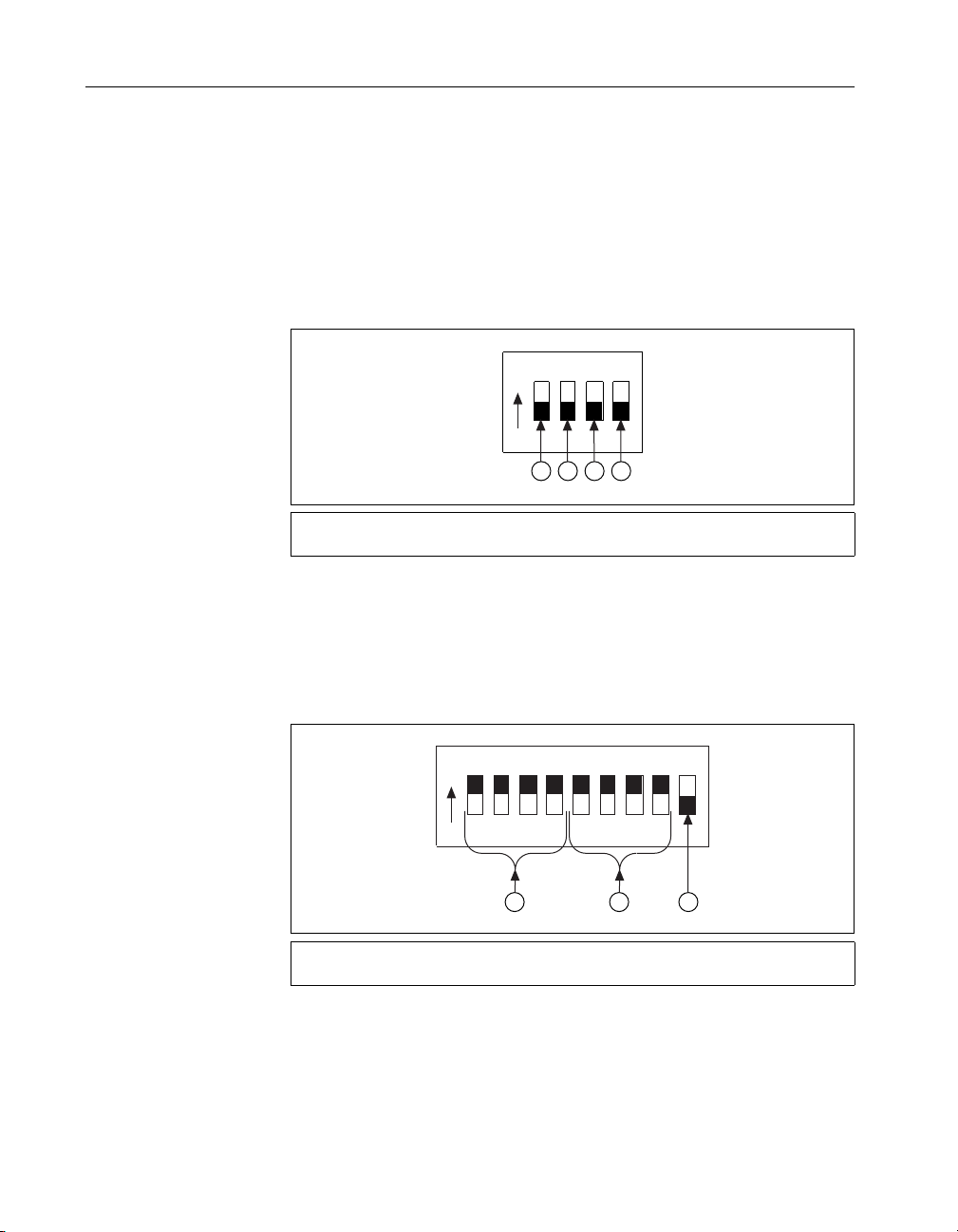

Use the DIP switches on each 9-position DIP switch bank to configure the

continuous current limit, the peak current limit, and the motor inductance

(low or standard) for each axis, as shown in Figure 3. The different settings

for these switches are described in the following sections.

O

123456789

N

1 2

1 Continuous Current Limit Switches

2 Peak Current Limit Switches

Figure 3. 9-Position DIP Switch Bank Layout

3 Motor Inductance Switch

3

MID-7654/7652 Servo Power Motor Drive User Guide 8 ni.com

Page 9

Inhibit Input Polarity Setting

UseDIPswitch1onthe4-positionDIPswitchbanktogloballysetthe

polarity for the inhibit input for all axes. Refer to Figures 1 and 3 for the

location of this switch.

The factory-default setting of DIP switch 1 is active-low. If the inhibit input

is active, the axis is inhibited and the yellow status LED (middle row)

corresponding tothat axis illuminates. Table 2 shows the DIP switch setting

for the inhibit input polarity selection.

Switch Setting Operation

Inhibit Output Polarity Setting

UseDIPswitch2onthe4-positionDIPswitchbanktogloballysetthe

polarity for the inhibit output for all axes. Refer to Figures 1 and 3 for the

location of this switch.

The factory-default setting of DIP switch 2 is active-high. Table 3 shows

the DIP switch setting for the inhibit output polarity selection.

Switch Setting Operation

Table 2.

O

N

1

O

N

1

Table 3.

O

N

3

Inhibit Input Polarity DIP Switch Settings

Active-high

Active-low

(factory default)

Inhibit Output Polarity DIP Switch Settings

Active-high

(factory default)

O

N

3

© National Instruments Corporation 9 MID-7654/7652 Servo Power Motor Drive User Guide

Active-low

Page 10

Limit Status LED Polarity Setting

UseDIPswitch3onthe4-positionDIPswitchbanktogloballysetthe

polarity for the Limit Status LED. Refer to Figures 1 and 3 for the location

of this switch.

The factory-default setting is active-high. Typically, you set the switch to

match your controller’s polarity setting, so if either the reverse or forward

limits for an axis are active, the green status LED (on the bottom row)

corresponding to that axis illuminates. This DIP switch alters only the

polarity for the LEDs, not the actual limit to the motion controller. Table 4

shows the DIP switch setting for the Limit Status LED polarity selection.

Table 4. Limit Status LED DIP Switch Settings

Switch Setting Operation

O

N

2

O

N

2

Setting Continuous and Peak Current Limits

The MID-7654/7652 uses high-efficiency PWM amplifiers configured as

torque blocks (current amplifiers or transconductance amplifiers). The

peak current limit is the maximum current your motor can withstand for

short periods of time. The continuous current limit is the maximum current

your motor can withstand indefinitely. The MID-7654/7652 varies the gain

applied to the input voltage so the maximum input voltage corresponds to

a current output equal to the peak current limit, I

Caution

error trip point is set above zero in the motion controller configuration software. The

default following error is 32,767.

To avoid overheating the drive under a motor fault condition, ensure the following

Active-high

(factory default)

Active-low

.

peak

MID-7654/7652 Servo Power Motor Drive User Guide 10 ni.com

Page 11

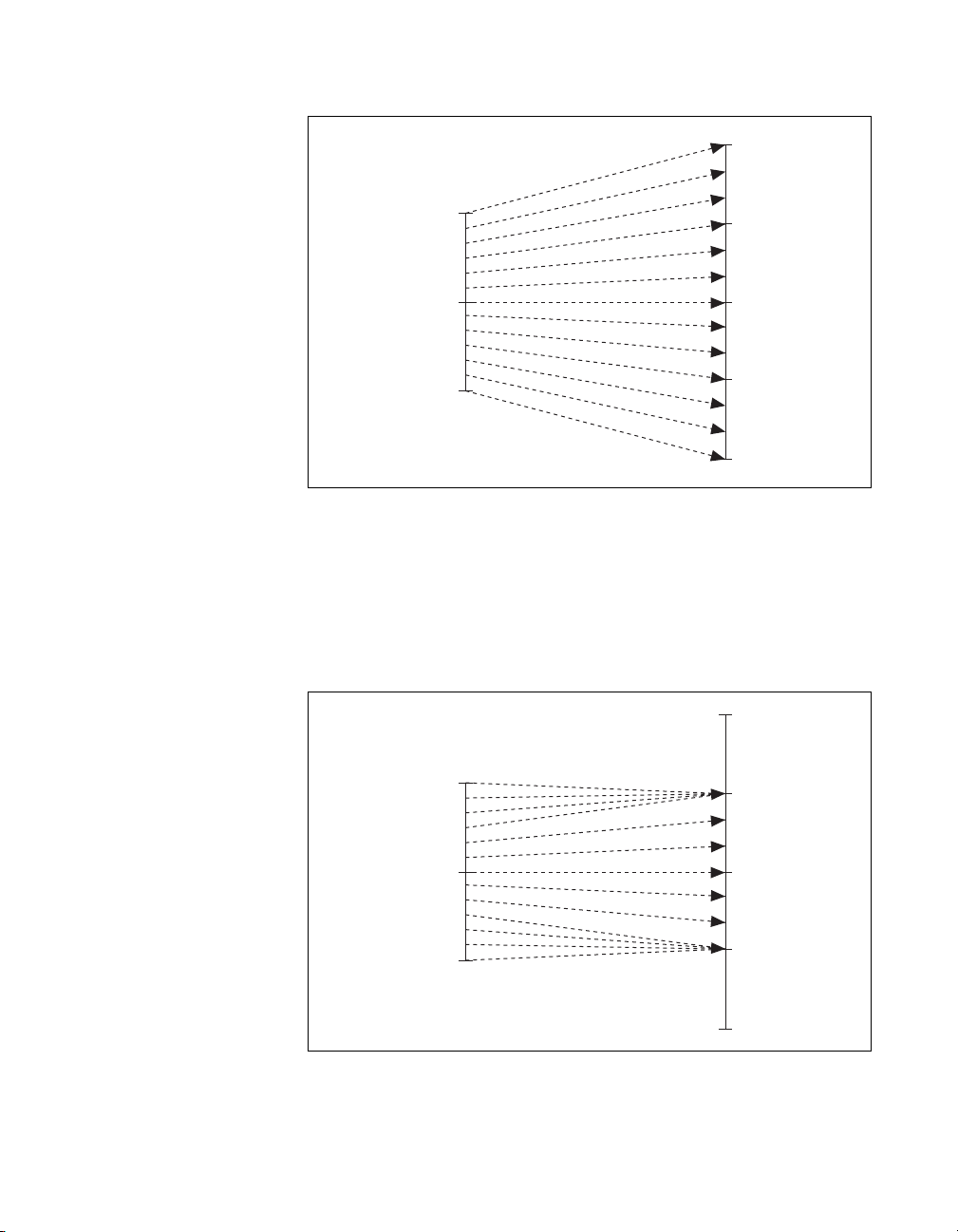

Figure 4 illustrates the command voltage input to current output

relationship for periods of time less than 2.7 seconds.

+I

peak

+V

max

+I

cont

0V

0A

Output Current

–I

Input Command Voltage

–V

max

Gain Applied

cont

–I

peak

Figure 4. Input Voltage to Output Current Relationship for Periods

of Time Less Than 2.7 Seconds

Figure 5 shows the command voltage input to current output relationship

for periods of time greater than 2.7 seconds. The maximum current output

corresponds to the continuous current limit, I

voltages that would result in a higher current output than I

is applied instead result in a current output of I

+V

max

. Therefore, command

cont

cont

.

when the gain

cont

+I

peak

+I

cont

0V

0A

Output Current

–I

Input Command Voltage

–V

max

Gain Applied

cont

–I

peak

Figure 5. Input Voltage to Output Current Relationship for Periods

of Time Greater Than 2.7 Seconds

© National Instruments Corporation 11 MID-7654/7652 Servo Power Motor Drive User Guide

Page 12

The amplifier peak and continuous current limits have been factory set for

5 A continuous current output and 10 A peak current output. Verify that

these settings are appropriate for your application before powering your

motors.

Use DIP switches 1 through 4 on each of the 9-position DIP switch banks

to set the continuous current limit for each axis. Use DIP switches

5 through 8 on each of the 9-position DIP switch banks to set the peak

current limit for each axis. Refer to Figures 1 and 3 for the location of the

continuous current limit and peak current limit switches. Table 5 shows the

DIP switch settings for all possible current limit settings.

Note

The switches shown in Table 5 show the settings for switches 1 through 4, which are

the continuous current DIP switches. Configure the settings for switches 5 through 8 in the

same manner to set the peak current values.

Table 5. Continuous and Peak Output Current DIP Switch Settings

Continuous

Switch

O

N

1

234

O

N

1

234

O

N

1

234 1

O

N

1

234 1

O

N

1

234

O

N

1

234 1

O

N

1

234

O

N

1

234

Current (A)

5.00 10.00 1.25 2.50

4.50 9.00 1.15 2.30

3.80 7.55 1.10 2.20

3.00 6.00 1.05 2.10

2.45 4.90 1.00 1.95

2.10 4.20 0.95 1.85

1.95 3.85 0.90 1.80

1.70 3.45 0.85

Peak Current

(A)

Switch

O

N

1

234

O

N

1

234

O

N

234

O

N

234

O

N

1

234

O

N

234

O

N

1

234

O

N

1

234

Continuous

Current (A)

(default)

Peak Current

(A)

1.70

(default)

MID-7654/7652 Servo Power Motor Drive User Guide 12 ni.com

Page 13

If you are connecting multiple motors to your MID-7654/7652, verify that

the total power dissipated by the motors at any given time is less than the

total power the drive can provide. If the total power requirement exceeds

the capability of the drive at any point, the drive will provide less power to

the motors than desired until the total power requirement drops back down.

Your MID-7654/7652 may overheat under continuous operation with loads

that exceed specified limits.

Caution

400 W at 25% duty cycle for a sustained period of time.

A fire safety hazard exists when the total power dissipated by the motors exceeds

To determine the maximum total power dissipation of all of the motors

combined, add up the maximum power each motor can dissipate. If this

value is less than or equal to 400 W at 25% duty cycle, you will not exceed

the capabilities of the MID-7654/7652.

If the value is greater than 400 W at 25% duty cycle, you may still be within

the operating capabilities of the MID-7654/7652, since it is unlikely you

will run all of your motors simultaneously at their maximum levels. Make

a reasonable estimation of the maximum power your motors will require at

any given time and verify that this value is less than 400 W at 25% duty

cycle.

Setting Motor Inductance Levels

Depending on the construction of your motor, you may need to configure

one or more axes to the low inductance setting rather than the default

standard inductance setting. Table 6 shows the motor inductance level

ranges for the two different settings.

Motor Inductance MID-7654/7652 Setting

Table 6. Motor Inductance Levels

Greater than 440 µH Standard

Between 110 and 440 µH Low

© National Instruments Corporation 13 MID-7654/7652 Servo Power Motor Drive User Guide

Page 14

Use the last DIP switch on each of the 9-position DIP switch banks to set

the motor inductance level for each axis. Refer to Figures 1 and 3 for the

location of the of the motor inductance level switch. Table 7 shows the DIP

switch settings for low and standard motor inductance.

Table 7. Motor Inductance Level DIP Switch Settings

Switch Setting Operation

O

N

9

O

N

9

Low motor inductance

Standard motor inductance

(factory default)

MID-7654/7652 Servo Power Motor Drive User Guide 14 ni.com

Page 15

Back Panel Connector Wiring

Figure 6 shows the MID-7654/7652 back panel connectors without their

rear guards.

MID-7654

MID-7652

1 Motion Controller Connector

2 Analog Input Connector

3 Analog Output Connector

4 Trigger Connector

5 Breakpoint Connector

6 Step/Direction Connector

7ACPower

* This connector is available only on the MID-7654.

Encoder

Connectors

8Axis1

9Axis2

10 Axis 3*

11 Axis 4*

Limit

Connectors

12 Axis 1

13 Axis 2

14 Axis 3*

15 Axis 4*

Motor

Connectors

16 Axis 1

17 Axis 2

18 Axis 3*

19 Axis 4*

Figure 6. MID-7654/7652 Back Panel Connectors

© National Instruments Corporation 15 MID-7654/7652 Servo Power Motor Drive User Guide

Page 16

Caution

Be sure to turn off the ENABLE and AC POWER switches for your

MID-7654/7652 and host computer and disconnect the unit from the power outlet before

making connections to your motion controller.

Warning

The servo motor connectors on this drive are energized when the unit is powered

on. The rear guard must be in place at all times while the unit is connected to a power

outlet. Disconnect the MID-7654/7652 unit from power outlet before connecting wires

to or disconnecting wires from the servo motor connectors. Strip back the insulation of

the servo motor wires to the servo motor connectors no more than 7 mm. Reattach the rear

guard before you reconnect the unit to a power outlet. Failure to do so could result in

electric shock leading to serious bodily injury or death. Refer to the Rear Guard section of

this guide for information on using the rear guard.

Take the following steps to wire your motion system to your

MID-7654/7652:

1. Connect the motion controller to the MID-7654/7652 using the

interface cable. Wire the motor power, limit switch, encoder, and I/O

terminal blocks to your motion control system.

2. For proper operation, configure the power entry module to match the

voltage of your power source. Refer to the Modifying the Power Entry

Module section for more information.

Caution

Yo u must change the MID-7654/7652 main input fuse on the rear panel if you

change the line voltage from the factory setting. Refer to the Replacing a Fuse section in

the Modifying the Power Entry Module section of this guide for information on changing

afuse.

3. Install the power cord into the back panel AC connector and plug it into

a correctly rated power source.

MID-7654/7652 Servo Power Motor Drive User Guide 16 ni.com

Page 17

Terminal Block Wiring

This section describes how to wire the terminal blocks on your

MID-7654/7652.

Servo Motor Power Terminal Blocks

For motor power wiring, each MID-7654/7652 axis has a separate

5-position removable screw terminal block. Figure 7 shows a typical servo

motor configuration pin assignment. The dotted loop indicates a shielded

cable.

Warning

Motor +

Motor –

Shield

Figure 7.

+ –

Servo Motor

Typical Servo Motor (DC Brush Type) Terminal Block Pin Assignment

Motor Case Ground

The servo motor connectors on this drive are energized when the unit is powered

1

2

3

4

5

on. The rear guard must be in place at all times while the unit is connected to a power

outlet. Disconnect the MID-7654/7652 unit from power outlet before connecting wires

to or disconnecting wires from the servo motor connectors. Strip back the insulation of

the servo motor wires to the servo motor connectors no more than 7 mm. Reattach the rear

guard before you reconnect the unit to a power outlet. Failure to do so could result in

electric shock leading to serious bodily injury or death. Refer to the Rear Guard section of

this guide for information on using the rear guard.

You should use shielded 20 AWG wire or larger for the motor power

cable. If available, connect a motor case ground wire to pin 3

(Ground/Shield) on the MID-7654/7652 as shown in Figure 7; this wire

helps avoid ground loops and signal noise problems. (Case ground connects

to the motor housing, not to any of the motor power terminals.)

Caution

© National Instruments Corporation 17 MID-7654/7652 Servo Power Motor Drive User Guide

Never connect unused center taps or winding terminals to pin 3.

Page 18

Depending on your motor, you may need to reverse the connections shown

in Figure 7, as there is no industry standard for direction of movement

relative to the positive and negative motor inputs. Table 8 shows the

National Instruments motion control standard directional polarity.

Table 8. National Instruments Standard Directional Polarity

Commanded

Direction

Description

Forward Clockwise (CW) facing

motor shaft

Reverse Counter-clockwise (CCW)

facing motor shaft

Figure 8 shows clockwise and counter-clockwise motor rotation.

Figure 8. Clockwise and Counter-Clockwise Motor Rotation

Motor Signal

Relationship

Motor – is greater than

Motor +

Motor + is greater than

Motor –

CCW

Command

Signal

Positive voltage

Negative voltage

CW

MID-7654/7652 Servo Power Motor Drive User Guide 18 ni.com

Page 19

Rear Guard

The rear guard consists of the protection cover, protection plates, and

bottom mounting plate as shown in Figure 9.

1 Bottom Mounting Plate

2ProtectionCover

Figure 9. Rear Guard Consisting of the Protection Cover,

Protection Plates, and Bottom Mounting Plate

3ProtectionPlate

© National Instruments Corporation 19 MID-7654/7652 Servo Power Motor Drive User Guide

Page 20

The rear guard installed on the MID-7654/7652 is shown in Figure 10.

INSTRUMENTS

NATIONAL

Figure 10. Rear Guard Installed on the MID-7654/7652

Warning

The servo motor connectors on this drive are energized when the unit is powered

on. The rear guard must be in place at all times while the unit is connected to a power

outlet. Disconnect the MID-7654/7652 unit from power outlet before connecting wires

to or disconnecting wires from the servo motor connectors. Strip back the insulation of

the servo motor wires to the servo motor connectors no more than 7 mm. Reattach the rear

guard before you reconnect the unit to a power outlet. Failure to do so could result in

electric shock leading to serious bodily injury or death.

Follow these steps carefully to ensure safe operation of your

MID-7654/7652:

1. Ensure that the MID-7654/7652 is powered off and disconnected from

the power outlet before wiring any cables to the unit. The +5V green

LED should not be illuminated after the MID-7654/7652 is powered

off and disconnected from the power outlet.

2. Ensure that the bottom mounting plate of the rear guard is securely

fastened to both sides of the MID-7654/7652, as shown in Figure 10.

3. Remove the protection plates for the axes to be used, rotate, and

re-install the protection plates in the open position, as shown in

Figure 11.

MID-7654/7652 Servo Power Motor Drive User Guide 20 ni.com

Page 21

1ProtectionCover 2ProtectionPlate

Figure 11. Protection Cover and Protection Plates:

Used Axes 1 & 2, Unused Axes 3 & 4.

Note

The protection plates for any unused axes should remain installed in the closed

position at all times, as shown on axes 3 and 4 in Figure 11. For axes you are using, the

protection plates must be removed, rotated, and re-installed in the open position, as shown

onaxes1and2inFigure11.

Contact your National Instruments sales representative to replace lost protection plates

(part number 188063A-01).

4. Remove the protection cover using the following procedure:

a. Remove the two screws that attach the protection cover to the side

of the bottom mounting plate, as shown in Figure 10.

b. Lift the protection cover from the slot on the bottom mounting

plate, as shown in Figure 9.

5. Plug the servo motor cables into the servo motor terminals of the

MID-7654/7652. The cables must be placed over the bottom mounting

plate of the rear guard.

6. Re-attach the protection cover

a. Insert the tab of the protection cover, shown in Figure 9, into the

slot on the bottom mounting plate.

b. Lower the protection cover over the servo motor cables and secure

it to the side of the bottom mounting plate using the two screws

youremovedinstep4.

© National Instruments Corporation 21 MID-7654/7652 Servo Power Motor Drive User Guide

Page 22

7. Ensure that the rear guard is held securely in place before reconnecting

your MID-7654/7652 to a power outlet.

Encoder Terminal Blocks

For quadrature incremental encoder signals, each MID-7654/7652 axis has

a separate 8-position removable screw terminal block. Where applicable,

the MID-7654/7652 accepts two types of encoder signal inputs:

single-ended (TTL) or differential line driver. You can accommodate

open-collector output encoders by using 2.2 kΩ pullup resistors to

+5 VDC.

Figure 12 shows the typical encoder wiring pin assignment for

single-ended signal input.

Encoder A

Encoder B

Encoder Index

+5 V

Digital Ground

1

2

3

4

5

6

7

8

Figure 12. Typical Single-Ended Encoder Wiring Pin Assignment

Figure 13 shows the typical encoder wiring pin assignment for differential

line driver signal inputs.

Encoder A

Encoder A

Encoder B

Encoder B

Encoder Index

Encoder Index

+5 V

Digital Ground

Figure 13. Typical Differential Line Driver Encoder Wiring Pin Assignment

1

2

3

4

5

6

7

8

If the encoder cable length is greater than 10 ft, use encoders with line

driver outputs for your applications. Power for a +5 V encoder—generated

by a power supply inside the MID-7654/7652—is available on pin 7.

MID-7654/7652 Servo Power Motor Drive User Guide 22 ni.com

Page 23

Note

If you require other encoder power voltages, reference an external power supply to

the Digital Ground signal on the 8-pin encoder terminal block.

The MID-7654/7652 supports differential inputs for Phase A, Phase B, and

Index signals. You can easily accommodate encoders with various phase

relationships by swapping the signals and/or connecting them to the

inverting inputs as required by your application. The Index signal must

occur when both Phase A and Phase B signals are low, as shown in

Figure 14. If the Index polarity is inverted, try reversing the Index and

Index

signals on differential encoders or using the Index input on

single-ended encoders.

Figure 14 shows the proper encoder phasing for CW (forward) motor

rotation.

Phase A

Phase B

Index

Figure 14. Encoder Signal Phasing, CW Rotation

Closed-loop servo applications require consistent directional polarity

between the motor and encoder for correct operation. The National

Instruments motion control standard directional polarity is as follows:

• Positive = forward = clockwise (CW) facing motor shaft

• Negative = reverse = counter-clockwise (CCW) facing motor shaft

Refer to Figure 8 for a depiction of clockwise and counter-clockwise

rotation.

When connecting the encoder wiring to your MID-7654/7652, use shielded

wire of at least 24 AWG. You must use cables with twisted pairs and an

overall shield for improved noise immunity and enhanced encoder signal

integrity. Figure 15 shows twisted pairs in a shielded cable.

© National Instruments Corporation 23 MID-7654/7652 Servo Power Motor Drive User Guide

Page 24

Shield

Drain

Encoder A

Encoder A

Encoder B

Encoder B

Encoder Index

Encoder Index

+5 V

Digital

Ground

Figure 15. Shielded Twisted Pairs

Note

Using an unshielded cable may produce noise, which can corrupt the encoder signals

and cause lost counts, reduced accuracy, or other erroneous encoder and controller

operation.

Limit Switch Terminal Blocks

For end-of-travel limit, home, inhibit input, and inhibit output connections,

MID-7654/7652 axes have a separate, 6-position removable screw terminal

connector block. Figure 16 shows the limit switch terminal block pin

assignments.

Forward Limit

Home Input

Reverse Limit

Inhibit Input

Inhibit Output

Digital Ground

1

2

3

4

5

6

Figure 16. Limit Switch Terminal Block Pin Assignment

(Passive Limit Switch Connection Example)

You can configure the inhibit output signal to be asserted low or asserted

high from the MID-7654/7652 when an axis is inhibited. This signal can be

useful for actuating mechanical brakes or for monitoring an axis status.

Refer to the Amplifier Inhibit LEDs section of this guide for a description

of the conditions that will cause an axis to be inhibited.

MID-7654/7652 Servo Power Motor Drive User Guide 24 ni.com

Page 25

Breakpoint and Trigger Terminal Blocks

Both the breakpoint and trigger connectors use a 6-pin removable terminal

block.

The trigger terminal block provides access to the trigger input lines,

shutdown input line, and digital ground. The breakpoint terminal block

provides access to the breakpoint output lines, the +5 V supplied by the

MID-7654/7652, and the digital ground. Figures 17 and 18 show the

breakpoint and trigger 6-position terminal block assignments.

Trigger Input 1

Trigger Input 2

Trigger Input 3

Trigger Input 4

Shutdown Input

Digital Ground

Figure 17. Trigger Terminal Block Pin Assignment

Breakpoint Output 1

Breakpoint Output 2

Breakpoint Output 3

Breakpoint Output 4

+5 V

Digital Ground

Figure 18. Breakpoint Terminal Block Pin Assignment

1

2

3

4

5

6

1

2

3

4

5

6

Analog I/O Terminal Blocks

The MID-7654/7652 features two analog I/O connectors.

The analog input connector uses a 6-pin removable terminal block, which

provides access to four analog-to-digital converter channels, an analog

reference voltage from the converter circuit, and an analog input ground

signal.

The analog output connector uses a 5-pin removable terminal block, which

provides access to four digital-to-analog converter channels and analog

output ground. Refer to Figures 19 and 20 for terminal block pin

assignments.

© National Instruments Corporation 25 MID-7654/7652 Servo Power Motor Drive User Guide

Page 26

Analog Input 1

Analog Input 2

Analog Input 3

Analog Input 4

Analog Reference (Output)

Analog Input Ground

1

2

3

4

5

6

Figure 19. Analog Input Terminal Block Pin Assignment

Analog Output 1

Analog Output 2

Analog Output 3

Analog Output 4

Analog Output Ground

1

2

3

4

5

Figure 20. Analog Output Terminal Block Pin Assignment

Step and Direction Terminal Block

The MID-7654/7652 passes step and direction signals from the controller

directly through the drive, allowing you to access them through the 8-pin

removable terminal block. This feature is useful if your system includes

both stepper and servo motors, as it reduces the amount of custom cabling

required to connect your motors and drives to the controller.

To use the step and direction connector, select an unused axis on the

MID-7654/7652 and connect the step and direction outputs for that axis

to your stepper drive. Refer to Figure 21 for the terminal block pin

assignments. Connect additional signals for the axis, such as inhibit

outputs, limit switches, breakpoints and triggers, and encoder feedback,

as described earlier in this guide.

Step 1

Direction 1

Step 2

Direction 2

Step 3

Direction 3

Step 4

Direction 4

1

2

3

4

5

6

7

8

Figure 21. Step and Direction Terminal Block Pin Assignment

MID-7654/7652 Servo Power Motor Drive User Guide 26 ni.com

Page 27

Cable Installation for CE Compliance

Take the following additional steps to ensure CE Compliance:

1. Enclose the terminal block wires in a 360-degree shielded cable. This

requires a braided shield.

2. Install the strain-relief bar on the MID-7654/7652 as described in the

Accessories Included for Optional Use section of this guide.

3. Place all cables connecting to the back panel through the strain-relief

bar, as follows:

a. All servo motor cables must pass through the far right clamp on

the strain-relief bar, which is directly aligned with the servo motor

terminals and protection cover.

b. All remaining cables should pass through the three clamps to the

left of the servo motor terminals.

c. Cables passing through the same clamp must be of the same cable

diameter.

d. Cables passing through the same clamp must be parallel and must

not overlap each other, as shown in Figure 22.

4. All cables must be properly grounded to the strain-relief bar, which

grounds them to the MID-7654/7652 chassis ground. Follow these

steps to ground the cables to the strain-relief bar:

a. Remove the outer jacket from the section of the cable to be

inserted between the strain-relief bar clamp and foam, as shown in

Figure 22. This will expose the braided shield of the cable.

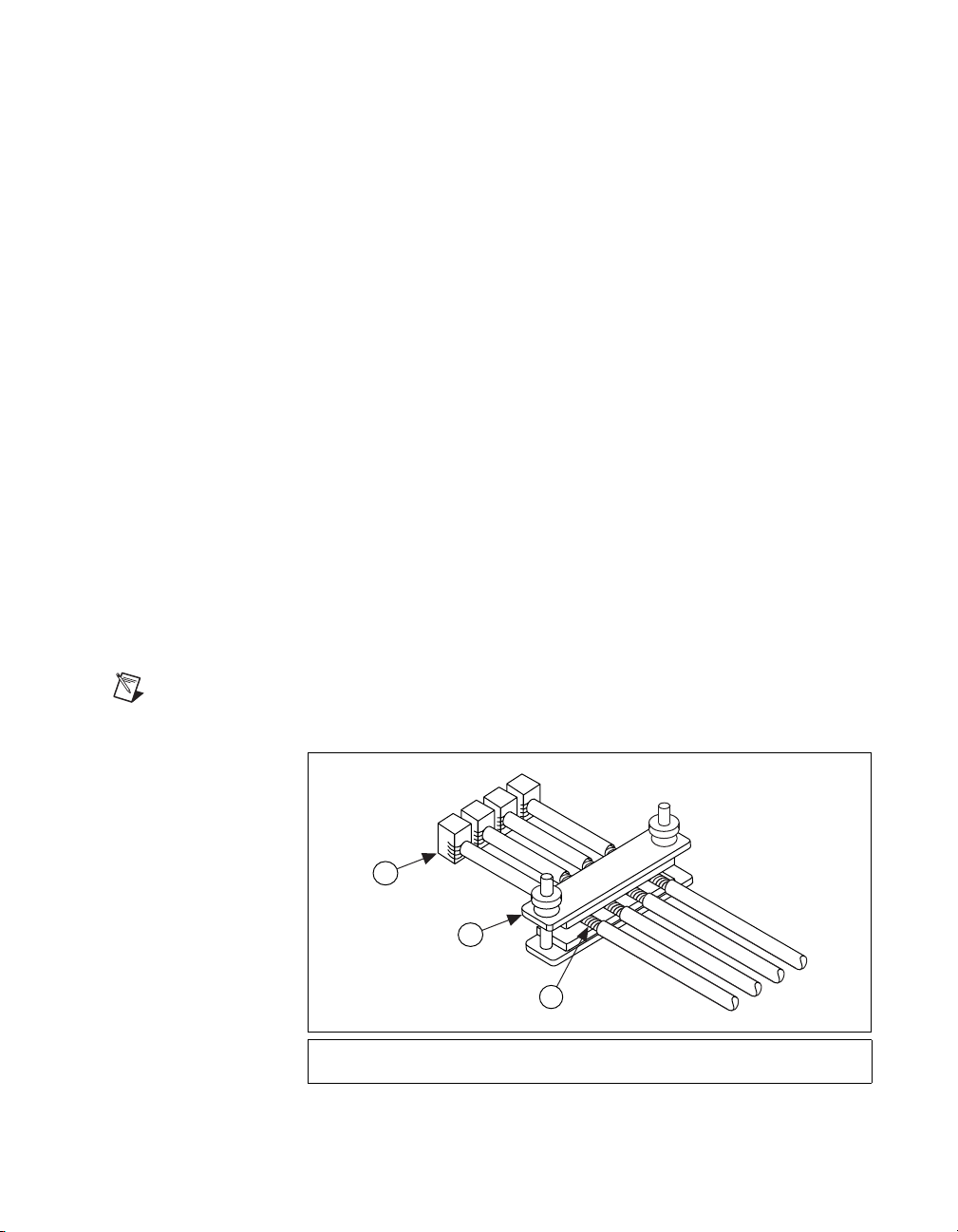

Note

Do not cut the braided shield of the cable.

3

2

1

1 Braided Shield of the Cable

2 Strain Relief Bar

Figure 22. Required Cabling for CE Compliance

© National Instruments Corporation 27 MID-7654/7652 Servo Power Motor Drive User Guide

3 Terminal Block Connector

Page 28

b. Lay the cables so that the braided shield makes full contact with

the foam of the strain-relief bar. The braided shield must only

make contact with the strain-relief bar, and no other part of the

device.

c. Lower the clamp and tighten the thumb nuts to remove all gaps

between the foam and the cable shields. The foam should press

around the shield of the cable to provide 360-degree grounding to

the cable shield.

5. Ground the braided shield at the opposite end of the cables to your

destination enclosure ground.

Accessories Included for Optional Use

Strain-Relief Bar Installation

The strain-relief bar provides strain relief for wiring to the back panel

terminals of the MID-7654/7652. It must be used to provide necessary

grounding for CE compliance. Refer to the Cable Installation for CE

Compliance section of this guide for more information.

The arms of the strain-relief bar attach between the sides of the

MID-7654/7652 and the bottom mounting plate of the rear guard with the

thumb nuts facing upwards, as shown in Figure 23. Refer to the Rear Guard

section of this guide for more information on removing and replacing the

protection cover from the rear guard. Refer to Figure 23 while following

these strain-relief bar installation steps:

1. Remove the protection cover of the rear guard.

2. Place the strain-relief bar so it fits within the sides of the bottom

mounting plate.

3. Attach the strain-relief bar to the side panels of the MID-7654/7652

using the provided screws.

4. Replace the protection cover.

MID-7654/7652 Servo Power Motor Drive User Guide 28 ni.com

Page 29

1

1 Rear Guard Assembly 2 Strain Relief Bar

Figure 23. MID-7654/7652 with the Strain-Relief Bar Installed

Panel Mount Kit Installation

The panel mount kit allows you to mount the MID-7654/7652 inside a

cabinet or enclosure. Attach the panel mount kit to the rear and front set

of screw holes on the side panels of the MID-7654/7652, as shown in

Figure 24, using the provided screws.

2

© National Instruments Corporation 29 MID-7654/7652 Servo Power Motor Drive User Guide

Page 30

INSTRUMENTS

NATIONAL

1

1 Rear Guard Assembly 2 Panel Mount

Figure 24. MID-7654/7652 with the Panel Mount Kit Installed

Note

The strain-relief bar and panel mount kit cannot be installed at the same time,

because they will not simultaneously fit under the sides of the bottom mounting plate.

Modifying the Power Entry Module

This section covers replacing fuses and switching the line voltage for

your drive.

Replacing a Fuse

Follow these steps to replace a fuse on your MID-7654/7652:

1. Pry open the hinged cover on the power entry module (number 7 in

Figure 6).

2. Remove the fuse holder. Notice how the fuse holder is oriented so you

can replace it properly.

3. Replace the blown fuse in the fuse holder. Be sure the new fuse is

oriented in the same way as the original fuse, and that it is rated at the

proper voltage.

2

MID-7654/7652 Servo Power Motor Drive User Guide 30 ni.com

Page 31

4. Push the fuse holder back into the power entry module with the same

orientation you observed in step 2.

5. Close the hinged cover.

Changing the Line Voltage

Follow these steps to change the line voltage on your MID-7654/7652:

1. Pry open the hinged cover on the power entry module (number 7 in

Figure 6).

2. Remove the fuse holder.

3. Replace the two fuses with the appropriate fuses for the desired line

voltage as listed in the Specifications section.

4. Rotate the fuse holder 180 degrees so the desired line voltage number

shows through the window when the power module cover is closed.

5. Push the fuse holder back into the power entry module with the new

orientation.

6. Close the hinged cover.

Amplifier/Driver Command Signals

The PWM amplifiers used in the MID-7654/7652 accept an

industry-standard ±10 V analog torque (current) command signal. Servo

motion controllers used with the MID-7654/7652 provide this standard

output and are programmed to close both the velocity loop and position

loop using an enhanced PID algorithm.

Specifications

The following specifications apply only to the MID-7654/7652. You must

account for your motion controller to obtain a system specification. Refer

to your controller specifications to determine overall system specifications.

Some signals define compatibility as signal pass-through, which means the

MID-7654/7652 may use passive filtering on these signals. This will not

affect the voltage range or current handling capability. Consult your motion

controller specifications to determine the allowable voltage range and logic

level compatibility of the signal.

Servo Amplifiers

Type ....................................................... Elmo Motion Control VIO 10/100

Peak current limit (2.7 s)........................ 1.7–10 A (default 1.7 A)

© National Instruments Corporation 31 MID-7654/7652 Servo Power Motor Drive User Guide

Page 32

Continuous current limit.........................0.85–5 A (default 0.85 A)

DC-bus motor voltage ............................48 VDC

PWM frequency......................................32 kHz

Continuous power output rating

(all axes combined).................................400 W at 25% duty cycle

Encoders

Inputs ......................................................Quadrature, incremental

Differential input threshold ....................± 0.3 V (typical)

Single ended input threshold ..................TTL/CMOS

Voltage range..........................................0–5VDC

Maximum quadrature frequency.............20 MHz

Limit and Home Switch Inputs

Compatibility ..........................................Signal pass-through

Inhibit Inputs

Voltage range..........................................0–12 VDC

Input low voltage ....................................0.8 V

Input high voltage...................................2 V

Inhibit Outputs

Voltage range..........................................0–5VDC

Output low voltage .................................0.5 V at 64 mA

Output high voltage ................................2.4 V at 32 mA

Trigger Input

Noise filter (RC time constant)...............100 ns

Compatibility ..........................................Signal pass-through

Breakpoint Outputs

Compatibility ..........................................Signal pass-through

MID-7654/7652 Servo Power Motor Drive User Guide 32 ni.com

Page 33

Analog Inputs

Noise filter (RC time constant) .............. 10 µs

Compatibility ......................................... Signal pass-through

Analog Outputs

Compatibility ......................................... Signal pass-through

Step/Direction Outputs

Compatibility ......................................... Signal pass-through

Shutdown Input

Compatibility ......................................... Signal pass-through

User 5 V Supply

Voltage range @ 0.5 A...........................4.7–5.2 V

Included Connectors

Encoders................................................. 8-position mini-combicon

3.81 mm plug (1 per axis)

Limits ..................................................... 6-position mini-combicon

3.81 mm plug (1 per axis)

Servo Motors.......................................... 5-position combicon

5.08 mm plug (1 per axis)

Breakpoints ............................................ 6-position mini-combicon

3.81 mm plug (1 total)

Triggers .................................................. 6-position mini-combicon

3.81 mm plug (1 total)

Step/Direction ........................................ 8-position mini-combicon

3.81 mm plug (1 total)

Analog input........................................... 6-position mini-combicon

3.81 mm plug (1 total)

Analog output......................................... 5-position mini-combicon

3.81 mm plug (1 total)

© National Instruments Corporation 33 MID-7654/7652 Servo Power Motor Drive User Guide

Page 34

Environment

Power Supply

AC power................................................Detachable AC power cord

(IEC standard type)

Motion I/O ..............................................68-pin female high density

VHDCI type

Operating temperature ............................0 to 50 °C (32 to 122 °F)

Storage temperature................................–20 to 70 °C(–4to158°F)

Humidity.................................................10% – 90% (noncondensing)

Maximum Altitude .................................2,000 meters

Pollution Degree .....................................2

Indoor Use Only

Input voltage ...........................................90–132 VAC / 198–264 VAC,

47–63 Hz

Input fuse

115 VAC (factory default)...............8 A (Littelfuse #312008)

230 VAC..........................................6 A (Littelfuse #312006)

Input fuse dimensions.............................0.25 in. by 1.25 in.

Input Power Peak Current (at max load)

115 VAC..........................................10 A

230 VAC..........................................5 A

Installation category ...............................II

Host Bus Voltage Interlock

Undervoltage threshold...........................4 VDC

Physical

Length.....................................................30.6 by 25.4 by 8.8 cm

(12.0by10by3.5in.)

Weight ....................................................10.2 kg (22.5 lb.)

MID-7654/7652 Servo Power Motor Drive User Guide 34 ni.com

Page 35

Safety

Meets the requirements of the following standards for safety for electrical

equipment for measurement, control, and laboratory use:

• EN 61010-1:1993/A2:1995, IEC 61010-1:1990/A2:1995

• UL 3101-1:1993, UL 3111-1:1994, UL 3121-1:1998

• CAN/CSA C22.2 No. 1010.1:1992/A2:1997

UL Recognized to UL 508C, power conversion equipment, File # E208822

Electromagnetic Compatibility

EMC/EMI............................................... CE, C-Tick and FCC Part 15

Electrical emissions................................ EN 55011 Class A @ 10 meters

Electrical immunity................................ Evaluated to EN 61326:1998,

Note

This device should only be operated with shielded cabling for full EMC & EMI

compliance. Refer to the Declaration of Conformity (DoC) for this product for any

additional regulatory compliance information. The DoC for this product is available via the

following web site:

by product family. Select the appropriate product family, followed by your product and a

link to the DoC will appear in Adobe Acrobat format. Click on the Acrobat icon to

download or read the DoC.

http://digital.ni.com/hardref.nsf

(Class A) Compliant.

FCC Part 15A above 1 GHz.

Table 1

. This site lists the DoCs

© National Instruments Corporation 35 MID-7654/7652 Servo Power Motor Drive User Guide

Page 36

Technical Support Resources

NI Web Support

National Instruments Web support is your first stop for help in solving

installation, configuration, and application problems and questions.

Online problem-solving and diagnostic resources include frequently

asked questions, knowledge bases, product-specific troubleshooting

wizards, manuals, drivers, software updates, and more. Web support is

available through the Technical Support section of

Worldwide Support

National Instruments has offices located around the world to help address

your support needs. You can access our branch office Web sites from the

Worldwide Offices section of

up-to-date contact information, support phone numbers, e-mail addresses,

and current events.

If you have searched the technical support resources on our Web site

and still cannot find the answers you need, contact your local office or

National Instruments corporate. For telephone support in the United States,

dial 512 795 8248. For telephone support outside the United States, contact

your local branch office:

Australia 03 9879 5166, Austria 0662 45 79 90 0, Belgium 02 757 00 20,

Brazil 011 284 5011, Canada (Calgary) 403 274 9391,

Canada (Montreal) 514 288 5722, Canada (Ottawa) 613 233 5949,

Canada (Québec) 514 694 8521, Canada (Toronto) 905 785 0085,

China (Shanghai) 021 6555 7838, China (ShenZhen) 0755 3904939,

Denmark 45 76 26 00, Finland 09 725 725 11, France 01 48 14 24 24,

Germany 089 741 31 30, Greece 30 1 42 96 427, Hong Kong 2645 3186,

India 91805275406, Israel 03 6120092, Italy 02 413091,

Japan 03 5472 2970, Korea 02 596 7456, Malaysia 603 9596711,

Mexico 5 280 7625, Netherlands 0348 433466,

New Zealand 09 914 0488, Norway 32 27 73 00, Poland 0 22 528 94 06,

Portugal 351 1 726 9011, Singapore 2265886, Spain 91 640 0085,

Sweden 08 587 895 00, Switzerland 056 200 51 51,

Taiwan 02 2528 7227, United Kingdom 01635 523545

ni.com

ni.com

. Branch office Web sites provide

.

Loading...

Loading...