Page 1

LM1085

3A Low Dropout Positive Regulators

LM1085 3A Low Dropout Positive Regulators

June 2005

General Description

The LM1085 is a series of low dropout positive voltage

regulators with a maximum dropout of 1.5V at 3A of load

current. It has the same pin-out as National Semiconductor’s

industry standard LM317.

The LM1085 is available in an adjustable version, which can

set the output voltage with only two external resistors. It is

also available in three fixed voltages: 3.3V, 5.0V and 12.0V.

The fixed versions integrate the adjust resistors.

The LM1085 circuit includes a zener trimmed bandgap reference, current limiting and thermal shutdown.

The LM1085 series is available in TO-220 and TO-263 packages. Refer to the LM1084 for the 5A version, and the

LM1086 for the 1.5A version.

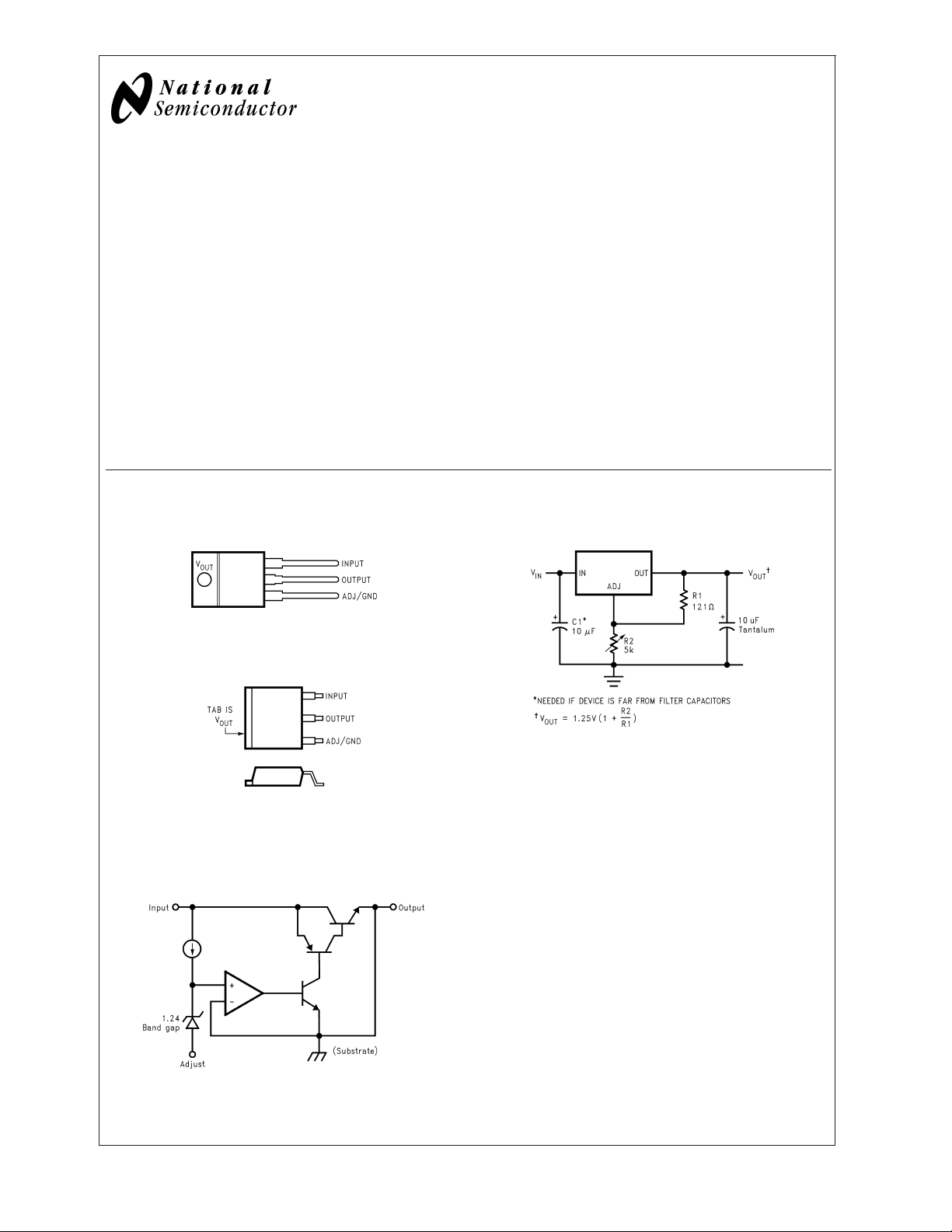

Connection Diagrams

TO-220

10094702

Top View

TO-263

Features

n Available in 3.3V, 5.0V, 12V and Adjustable Versions

n Current Limiting and Thermal Protection

n Output Current 3A

n Line Regulation 0.015% (typical)

n Load Regulation 0.1% (typical)

Applications

n High Efficiency Linear Regulators

n Battery Charger

n Post Regulation for Switching Supplies

n Constant Current Regulator

n Microprocessor Supply

Application Circuit

1.2V to 15V Adjustable Regulator

10094704

Top View

10094752

Basic Functional Diagram, Adjustable Version

10094765

© 2005 National Semiconductor Corporation DS100947 www.national.com

Page 2

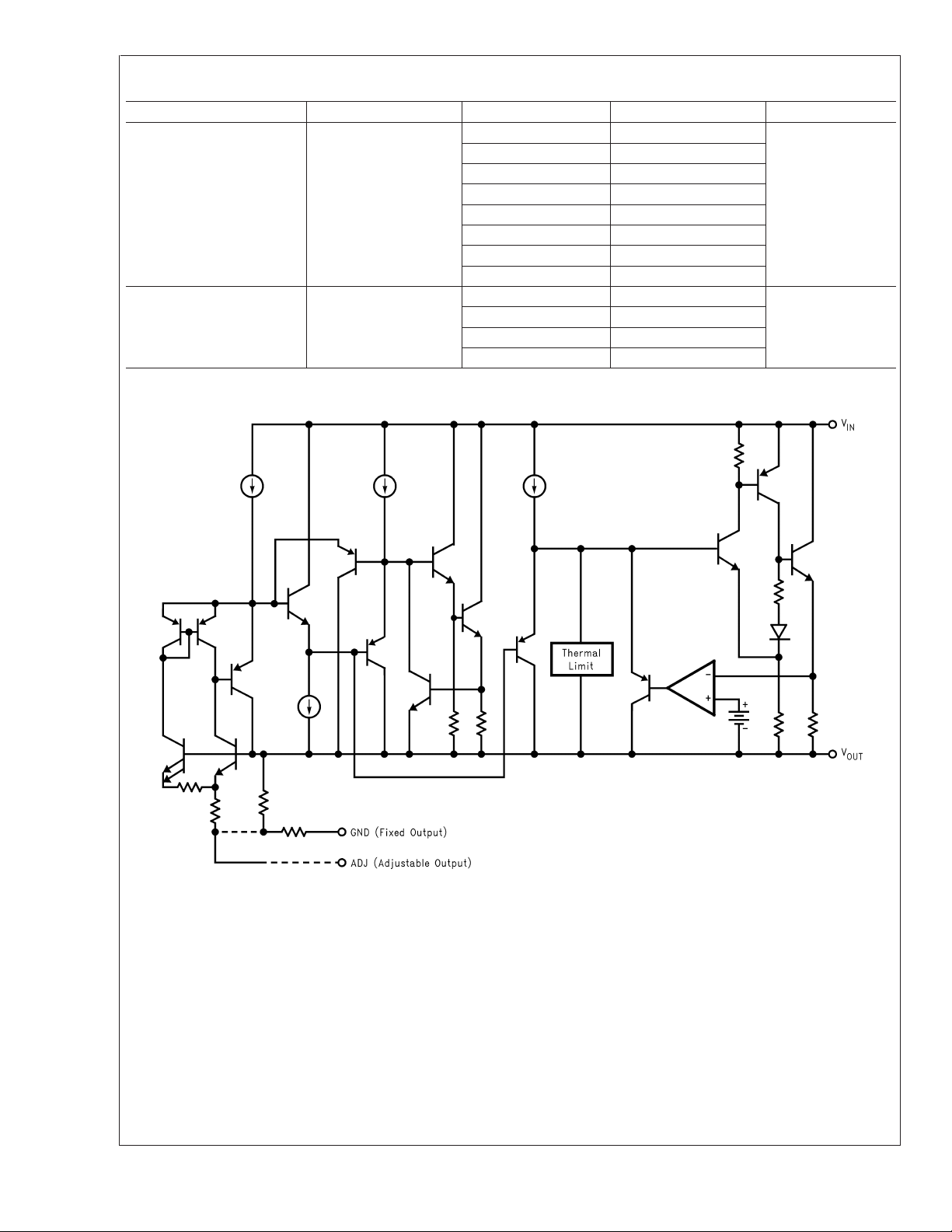

Ordering Information

LM1085

3-lead TO-263 −40˚C to +125˚C LM1085IS-ADJ Rails

3-lead TO-220 −40˚C to + 125˚C LM1085IT-ADJ Rails

Package Temperature Range Part Number Transport Media NSC Drawing

LM1085ISX-ADJ Tape and Reel

LM1085IS-12 Rails

LM1085ISX-12 Tape and Reel

LM1085IS-3.3 Rails

LM1085ISX-3.3 Tape and Reel

LM1085IS-5.0 Rails

LM1085ISX-5.0 Tape and Reel

LM1085IT-12 Rails

LM1085IT-3.3 Rails

LM1085IT-5.0 Rails

Simplified Schematic

TS3B

T03B

www.national.com 2

10094734

Page 3

LM1085

Absolute Maximum Ratings (Note 1)

If Military/Aerospace specified devices are required,

please contact the National Semiconductor Sales Office/

Distributors for availability and specifications.

Junction Temperature (TJ)(Note 3) 150˚C

Storage Temperature Range -65˚C to 150˚C

Lead Temperature 260˚C, to 10 sec

ESD Tolerance (Note 4) 2000V

Maximum Input to Output Voltage Differential

LM1085-ADJ 29V

Operating Ratings (Note 1)

LM1085-12 18V

LM1085-3.3 27V

LM1085-5.0 25V

Power Dissipation (Note 2) Internally Limited

Junction Temperature Range (T

Control Section −40˚C to 125˚C

Output Section −40˚C to 150˚C

) (Note 3)

J

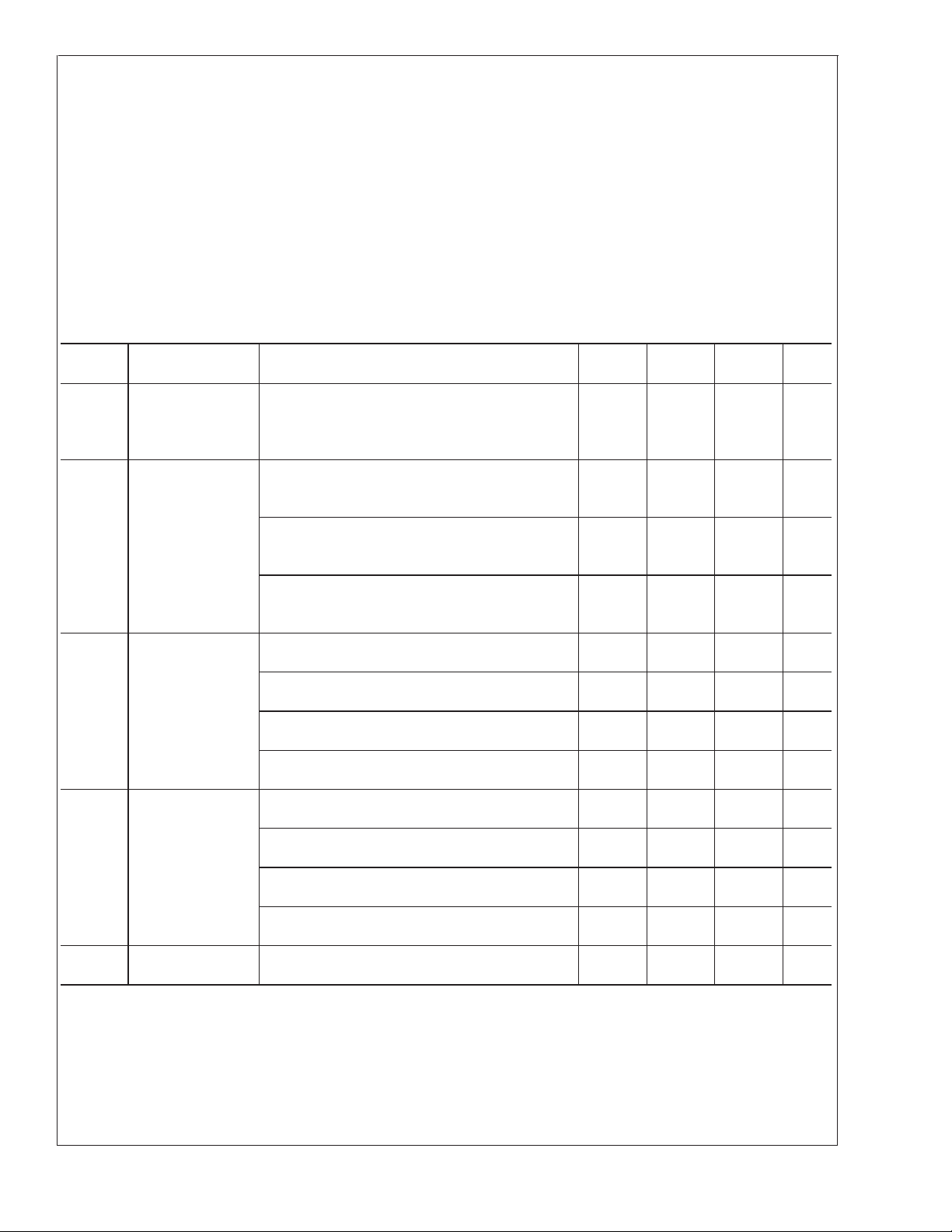

Electrical Characteristics

Typicals and limits appearing in normal type apply for TJ= 25˚C. Limits appearing in Boldface type apply over the entire junction temperature range for operation.

Symbol Parameter Conditions

V

REF

Reference Voltage LM1085-ADJ

= 10mA, VIN−V

I

OUT

10mA ≤I

OUT

≤ I

FULL LOAD

=3V

OUT

,1.5V ≤ (VIN−V

(Note 7)

V

OUT

Output Voltage

(Note 7)

LM1085-3.3

= 0mA, VIN=5V

I

OUT

0 ≤ I

OUT≤IFULL LOAD

, 4.8V≤ VIN≤15V

LM1085-5.0

= 0mA, VIN=8V

I

OUT

0 ≤ I

OUT

≤ I

FULL LOAD

, 6.5V ≤ VIN≤ 20V

LM1085-12

= 0mA, VIN= 15V

I

OUT

∆V

OUT

Line Regulation

(Note 8)

OUT

≤ I

FULL LOAD

0 ≤ I

LM1085-ADJ

=10mA, 1.5V≤ (VIN-V

I

OUT

, 13.5V ≤ VIN≤ 25V

OUT

LM1085-3.3

= 0mA, 4.8V ≤ VIN≤ 15V

I

OUT

LM1085-5.0

I

= 0mA, 6.5V ≤ VIN≤ 20V

OUT

LM1085-12

=0mA, 13.5V ≤ VIN≤ 25V

I

OUT

∆V

OUT

Load Regulation

(Note 8)

LM1085-ADJ

(V

IN-VOUT

) = 3V, 10mA ≤ I

OUT

LM1085-3.3

= 5V, 0 ≤ I

V

IN

OUT

≤ I

FULL LOAD

LM1085-5.0

= 8V, 0 ≤ I

V

IN

OUT

≤ I

FULL LOAD

LM1085-12

Dropout Voltage

(Note 9)

= 15V, 0 ≤ I

V

IN

LM1085-ADJ, 3.3, 5, 12

, ∆V

∆V

REF

OUT

OUT

= 1%, I

≤ I

FULL LOAD

=3A 1.3 1.5 V

OUT

) ≤ 15V

≤ I

FULL LOAD

OUT

) ≤ 15V

Min

(Note 6)

1.238

1.225

3.270

3.235

4.950

4.900

11.880

11.760

Typ

(Note 5)

1.250

1.250

3.300

3.300

5.000

5.000

12.000

12.000

0.015

0.035

0.5

1.0

0.5

1.0

1.0

2.0

0.1

0.2

3

7

5

10

12

24

Max

(Note 6)

1.262

1.270

3.330

3.365

5.050

5.100

12.120

12.240

0.2

0.2

6

6

10

10

25

25

0.3

0.4

15

20

20

35

36

72

Units

V

V

V

V

V

V

V

V

%

%

mV

mV

mV

mV

mV

mV

%

%

mV

mV

mV

mV

mV

mV

www.national.com3

Page 4

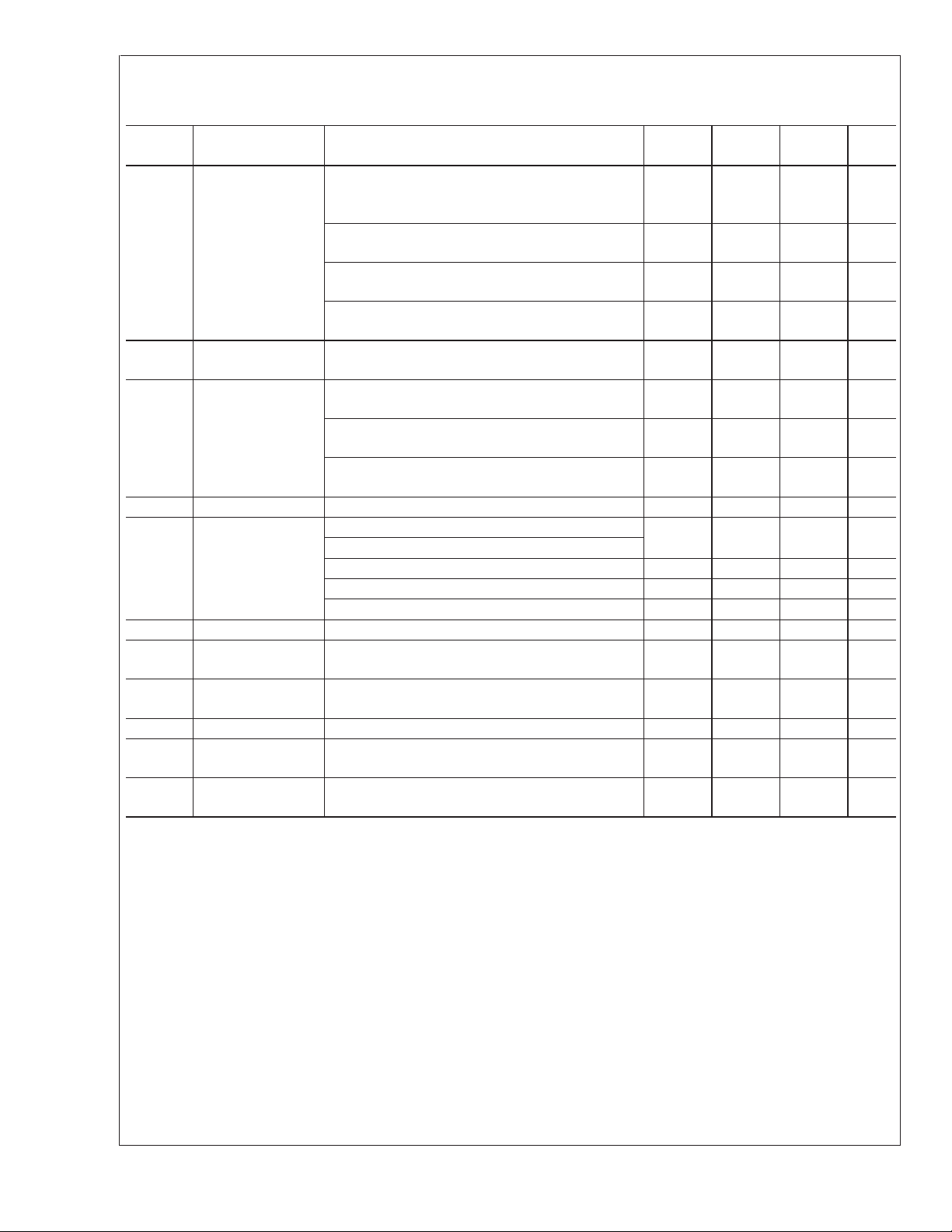

Electrical Characteristics (Continued)

Typicals and limits appearing in normal type apply for TJ= 25˚C. Limits appearing in Boldface type apply over the entire junc-

LM1085

tion temperature range for operation.

Symbol Parameter Conditions

I

LIMIT

Current Limit LM1085-ADJ

V

IN−VOUT

V

IN−VOUT

=5V

= 25V

LM1085-3.3

VIN=8V 3.2 5.5 A

LM1085-5.0

= 10V 3.2 5.5 A

V

IN

LM1085-12

VIN= 17V 3.2 5.5 A

Minimum Load

Current (Note 10)

LM1085-ADJ

V

IN−VOUT

= 25V 5.0 10.0 mA

Quiescent Current LM1085-3.3

VIN≤ 18V 5.0 10.0 mA

LM1085-5.0

≤ 20V 5.0 10.0 mA

V

IN

LM1085-12

≤ 25V 5.0 10.0 mA

V

IN

Thermal Regulation T

Ripple Rejection f

= 25˚C, 30ms Pulse .004 0.02 %/W

A

= 120Hz, C

RIPPLE

LM1085-3.3, V

LM1085-5.0, V

LM1085-12 V

IN

IN

IN

= 25µF Tantalum, I

OUT

= 25µF, (VIN−VO)=3V

ADJ

= 6.3V 60 72 dB

=8V 60 68 dB

= 15V 54 60 dB

Adjust Pin Current LM1085 55 120 µA

Adjust Pin Current

10mA ≤ I

OUT

≤ I

FULL LOAD

, 1.5V ≤ VIN−V

Change

Temperature

Stability

Long Term Stability T

RMS Output Noise

OUT

)

(% of V

Thermal Resistance

Junction-to-Case

=125˚C, 1000Hrs 0.3 1.0 %

A

10Hz ≤ f≤ 10kHz 0.003 %

3-Lead TO-263: Control Section/Output Section

3-Lead TO-220: Control Section/Output Section

OUT

OUT

Min

(Note 6)

3.2

0.2

=3A

60 75 dBLM1085-ADJ, C

≤ 25V

Typ

(Note 5)

(Note 6)

5.5

0.5

0.2 5 µA

0.5 %

0.7/3.0

0.7/3.0

Max

Units

A

A

˚C/W

˚C/W

Note 1: Absolute Maximum Ratings indicate limits beyond which damage to the device may occur. Operating Ratings indicate conditions for which the device is

intended to be functional, but specific performance is not guaranteed. For guaranteed specifications and the test conditions, see the Electrical Characteristics.

Note 2: Power dissipation is kept in a safe range by current limiting circuitry. Refer to Overload Recovery in Application Notes.

Note 3: The maximum power dissipation is a function of T

P

=(T

D

J(max)–TA

Note 4: For testing purposes, ESD was applied using human body model, 1.5kΩ in series with 100pF.

Note 5: Typical Values represent the most likely parametric norm.

Note 6: All limits are guaranteed by testing or statistical analysis.

Note 7: I

dissipation for the LM1085 is only achievable over a limited range of input-to-output voltage.

Note 8: Load and line regulation are measured at constant junction temperature, and are guaranteed up to the maximum power dissipation of 30W. Power

dissipation is determined by the input/output differential and the output current. Guaranteed maximum power dissipation will not be available over the full input/output

range.

Note 9: Dropout voltage is specified over the full output current range of the device.

Note 10: The minimum output current required to maintain regulation.

www.national.com 4

)/θJA. All numbers apply for packages soldered directly into a PC board. Refer to Thermal Considerations in the Application Notes.

FULL LOAD

is defined in the current limit curves. The I

, θJA, and TA. The maximum allowable power dissipation at any ambient temperature is

J(max)

FULL LOAD

Curve defines the current limit as a function of input-to-output voltage. Note that 30W power

Page 5

Typical Performance Characteristics

Dropout Voltage vs. Output Current Short-Circuit Current vs. Input/Output Difference

LM1085

10094763

10094768

Percent Change in Output Voltage vs. Temperature Adjust Pin Current vs. Temperature

10094799

10094798

Maximum Power Dissipation vs. Temperature Ripple Rejection vs. Frequency (LM1085-Adj.)

10094770

10094743

www.national.com5

Page 6

Typical Performance Characteristics (Continued)

LM1085

Ripple Rejection vs. Output Current (LM1085-Adj.) Line Transient Response

10094744

Load Transient Response

10094772

10094771

www.national.com 6

Page 7

Application Note

GENERAL

Figure 1 shows a basic functional diagram for the LM1085Adj (excluding protection circuitry) . The topology is basically

that of the LM317 except for the pass transistor. Instead of a

Darlingtion NPN with its two diode voltage drop, the LM1085

uses a single NPN. This results in a lower dropout voltage.

The structure of the pass transistor is also known as a quasi

LDO. The advantage a quasi LDO over a PNP LDO is its

inherently lower quiescent current. The LM1085 is guaranteed to provide a minimum dropout voltage 1.5V over temperature, at full load.

10094765

FIGURE 1. Basic Functional Diagram for the LM1085,

excluding Protection circuitry

OUTPUT VOLTAGE

The LM1085 adjustable version develops at 1.25V reference

voltage, (V

As shown in figure 2, this voltage is applied across resistor

R1 to generate a constant current I1. This constant current

then flows through R2. The resulting voltage drop across R2

adds to the reference voltage to sets the desired output

voltage.

The current I

output error . But since it is small (120uA max), it becomes

negligible when R1 is in the 100Ω range.

For fixed voltage devices, R1 and R2 are integrated inside

the devices.

), between the output and the adjust terminal.

REF

from the adjustment terminal introduces an

ADJ

STABILITY CONSIDERATION

Stability consideration primarily concern the phase response

of the feedback loop. In order for stable operation, the loop

must maintain negative feedback. The LM1085 requires a

certain amount series resistance with capacitive loads. This

series resistance introduces a zero within the loop to increase phase margin and thus increase stability. The equivalent series resistance (ESR) of solid tantalum or aluminum

electrolytic capacitors is used to provide the appropriate zero

(approximately 500 kHz).

The Aluminum electrolytic are less expensive than tantalums, but their ESR varies exponentially at cold temperatures; therefore requiring close examination when choosing

the desired transient response over temperature. Tantalums

are a convenient choice because their ESR varies less than

2:1 over temperature.

The recommended load/decoupling capacitance is a 10uF

tantalum or a 50uF aluminum. These values will assure

stability for the majority of applications.

The adjustable versions allows an additional capacitor to be

used at the ADJ pin to increase ripple rejection. If this is done

the output capacitor should be increased to 22uF for tantalums or to 150uF for aluminum.

Capacitors other than tantalum or aluminum can be used at

the adjust pin and the input pin. A 10uF capacitor is a

reasonable value at the input. See Ripple Rejection section

regarding the value for the adjust pin capacitor.

It is desirable to have large output capacitance for applications that entail large changes in load current (microprocessors for example). The higher the capacitance, the larger the

available charge per demand. It is also desirable to provide

low ESR to reduce the change in output voltage:

∆V=∆I x ESR

It is common practice to use several tantalum and ceramic

capacitors in parallel to reduce this change in the output

voltage by reducing the overall ESR.

Output capacitance can be increased indefinitely to improve

transient response and stability.

RIPPLE REJECTION

Ripple rejection is a function of the open loop gain within the

feed-back loop (refer to Figure 1 and Figure 2). The LM1085

exhibits 75dB of ripple rejection (typ.). When adjusted for

voltages higher than V

function of adjustment gain: (1+R1/R2) or V

, the ripple rejection decreases as

REF

O/VREF

. Therefore a 5V adjustment decreases ripple rejection by a factor of

four (−12dB); Output ripple increases as adjustment voltage

increases.

However, the adjustable version allows this degradation of

ripple rejection to be compensated. The adjust terminal can

be bypassed to ground with a capacitor (C

ance of the C

should be equal to or less than R1 at the

ADJ

). The imped-

ADJ

desired ripple frequency. This bypass capacitor prevents

ripple from being amplified as the output voltage is increased.

1/(2π*f

RIPPLE*CADJ

) ≤ R

1

LM1085

FIGURE 2. Basic Adjustable Regulator

10094717

LOAD REGULATION

The LM1085 regulates the voltage that appears between its

output and ground pins, or between its output and adjust

pins. In some cases, line resistances can introduce errors to

the voltage across the load. To obtain the best load regulation, a few precautions are needed.

www.national.com7

Page 8

Application Note (Continued)

Figure 3 shows a typical application using a fixed output

LM1085

regulator. Rt1 and Rt2 are the line resistances. V

than the V

resistances. In this case, the load regulation seen at the

R

LOAD

To improve this, the load should be tied directly to the output

terminal on the positive side and directly tied to the ground

terminal on the negative side.

FIGURE 3. Typical Application using Fixed Output

When the adjustable regulator is used (Figure 4), the best

performance is obtained with the positive side of the resistor

R1 tied directly to the output terminal of the regulator rather

than near the load. This eliminates line drops from appearing

effectively in series with the reference and degrading regulation. For example, a 5V regulator with 0.05Ω resistance

between the regulator and load will have a load regulation

due to line resistance of 0.05Ω xI

connected near the load the effective line resistance will be

0.05Ω (1 + R2/R1) or in this case, it is 4 times worse. In

addition, the ground side of the resistor R2 can be returned

near the ground of the load to provide remote ground sensing and improve load regulation.

FIGURE 4. Best Load Regulation using Adjustable

PROTECTION DIODES

Under normal operation, the LM1085 regulator does not

need any protection diode. With the adjustable device, the

internal resistance between the adjustment and output terminals limits the current. No diode is needed to divert the

current around the regulator even with a capacitor on the

by the sum of the voltage drops along the line

OUT

would be degraded from the data sheet specification.

Regulator

.IfR1(=125Ω)is

L

Output Regulator

LOAD

10094718

10094719

is less

adjustment terminal. The adjust pin can take a transient

±

signal of

25V with respect to the output voltage without

damaging the device.

When an output capacitor is connected to a regulator and

the input is shorted, the output capacitor will discharge into

the output of the regulator. The discharge current depends

on the value of the capacitor, the output voltage of the

regulator, and rate of decrease of V

. In the LM1085 regu-

IN

lator, the internal diode between the output and input pins

can withstand microsecond surge currents of 10A to 20A.

With an extremely large output capacitor (≥1000 µf), and

with input instantaneously shorted to ground, the regulator

could be damaged. In this case, an external diode is recommended between the output and input pins to protect the

regulator, shown in Figure 5.

10094715

FIGURE 5. Regulator with Protection Diode

OVERLOAD RECOVERY

Overload recovery refers to regulator’s ability to recover from

a short circuited output. A key factor in the recovery process

is the current limiting used to protect the output from drawing

too much power. The current limiting circuit reduces the

output current as the input to output differential increases.

Refer to short circuit curve in the curve section.

During normal start-up, the input to output differential is

small since the output follows the input. But, if the output is

shorted, then the recovery involves a large input to output

differential. Sometimes during this condition the current limiting circuit is slow in recovering. If the limited current is too

low to develop a voltage at the output, the voltage will

stabilize at a lower level. Under these conditions it may be

necessary to recycle the power of the regulator in order to

get the smaller differential voltage and thus adequate start

up conditions. Refer to curve section for the short circuit

current vs. input differential voltage.

THERMAL CONSIDERATIONS

ICs heats up when in operation, and power consumption is

one factor in how hot it gets. The other factor is how well the

heat is dissipated. Heat dissipation is predictable by knowing

the thermal resistance between the IC and ambient (θ

JA

Thermal resistance has units of temperature per power (C/

W). The higher the thermal resistance, the hotter the IC.

The LM1085 specifies the thermal resistance for each package as junction to case (θ

resistance to ambient (θ

). In order to get the total

JC

), two other thermal resistance

JA

).

www.national.com 8

Page 9

Application Note (Continued)

must be added, one for case to heat-sink (θ

heatsink to ambient (θ

). The junction temperature can be

HA

predicted as follows:

T

J=TA+PD(θJC

+ θCH+ θHA)=TA+PDθ

TJis junction temperature, TAis ambient temperature, and

is the power consumption of the device. Device power

P

D

consumption is calculated as follows:

) and one for

CH

JA

FIGURE 6. Power Dissipation Diagram

I

IN=IL+IG

PD=(VIN−V

OUT)IL+VINIG

Figure 6 shows the voltages and currents which are present

in the circuit.

10094716

LM1085

Once the devices power is determined, the maximum allowable (θ

θ

JA(max)=TR(max)/PD=TJ(max−TA(max)

) is calculated as:

JA(max)

)/P

D

The LM1085 has different temperature specifications for two

different sections of the IC: the control section and the output

section. The Electrical Characteristics table shows the junction to case thermal resistances for each of these sections,

while the maximum junction temperatures (T

J(max)

) for each

section is listed in the Absolute Maximum section of the

datasheet. T

is 150˚C for the output section.

T

J(max)

θ

should be calculated separately for each section as

JA(max)

is 125˚C for the control section, while

J(max)

follows:

(max, CONTROL SECTION) = (125˚C - T

θ

JA

θJA(max, OUTPUT SECTION) = (150˚C - T

A(max)

A(max)

)/P

)/P

D

D

The required heat sink is determined by calculating its required thermal resistance (θ

HA(max)

).

θ

θ

θ

TROL SECTION) + θ

θ

SECTION) + θ

If thermal compound is used, θ

C/W. If the case is soldered to the heat sink, then a θ

= θ

HA(max)

should also be calculated twice as follows:

HA(max)

= θJA(max, CONTROL SECTION) - (θJC(CON-

HA(max)

HA(max)=θJA

−(θJC+ θCH)

JA(max)

)

CH

(max, OUTPUT SECTION) - (θJC(OUTPUT

)

CH

can be estimated at 0.2

CH

can

CH

be estimated as 0 C/W.

After, θ

lower of the two θ

is calculated for each section, choose the

HA(max)

values to determine the appropriate

HA(max)

heat sink.

If PC board copper is going to be used as a heat sink, then

Figure 7 can be used to determine the appropriate area

(size) of copper foil required.

10094764

FIGURE 7. Heat sink thermal Resistance vs Area

www.national.com9

Page 10

Typical Applications

LM1085

5V to 3.3V, 1.5A Regulator

Adjustable@5V

10094767

10094754

Battery Charger

10094750

10094755

Adjustable Fixed Regulator

10094756

Regulator with Reference

1.2V to 15V Adjustable Regulator

10094752

10094753

5V Regulator with Shutdown

www.national.com 10

High Current Lamp Driver Protection

10094757

Page 11

Typical Applications (Continued)

LM1085

Battery Backup Regulated Supply

Ripple Rejection Enhancement

Automatic Light control

10094761

10094759

10094762

Generating Negative Supply voltage

10094760

Remote Sensing

10094758

www.national.com11

Page 12

Physical Dimensions inches (millimeters) unless otherwise noted

LM1085

3-Lead TO-263

NS Package Number TS3B

3-Lead TO-220

NS Package Number T03B

www.national.com 12

Page 13

Notes

LM1085 3A Low Dropout Positive Regulators

National does not assume any responsibility for use of any circuitry described, no circuit patent licenses are implied and National reserves

the right at any time without notice to change said circuitry and specifications.

For the most current product information visit us at www.national.com.

LIFE SUPPORT POLICY

NATIONAL’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT DEVICES OR SYSTEMS

WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE PRESIDENT AND GENERAL COUNSEL OF NATIONAL SEMICONDUCTOR

CORPORATION. As used herein:

1. Life support devices or systems are devices or systems

which, (a) are intended for surgical implant into the body, or

(b) support or sustain life, and whose failure to perform when

properly used in accordance with instructions for use

2. A critical component is any component of a life support

device or system whose failure to perform can be reasonably

expected to cause the failure of the life support device or

system, or to affect its safety or effectiveness.

provided in the labeling, can be reasonably expected to result

in a significant injury to the user.

BANNED SUBSTANCE COMPLIANCE

National Semiconductor manufactures products and uses packing materials that meet the provisions of the Customer Products

Stewardship Specification (CSP-9-111C2) and the Banned Substances and Materials of Interest Specification (CSP-9-111S2) and contain

no ‘‘Banned Substances’’ as defined in CSP-9-111S2.

Leadfree products are RoHS compliant.

National Semiconductor

Americas Customer

Support Center

Email: new.feedback@nsc.com

Tel: 1-800-272-9959

www.national.com

National Semiconductor

Europe Customer Support Center

Fax: +49 (0) 180-530 85 86

Email: europe.support@nsc.com

Deutsch Tel: +49 (0) 69 9508 6208

English Tel: +44 (0) 870 24 0 2171

Français Tel: +33 (0) 1 41 91 8790

National Semiconductor

Asia Pacific Customer

Support Center

Email: ap.support@nsc.com

National Semiconductor

Japan Customer Support Center

Fax: 81-3-5639-7507

Email: jpn.feedback@nsc.com

Tel: 81-3-5639-7560

Loading...

Loading...