Page 1

TM

IMAQ

IMAQ Vision

TM

for LabWindows

User Manual

IMAQ Vision for LabWindows/CVI User Manual

/CVITM

August 2004 Edition

Part Number 371266A-01

Page 2

Support

Worldwide Technical Support and Product Information

ni.com

National Instruments Corporate Headquarters

11500 North Mopac Expressway Austin, Texas 78759-3504 USA Tel: 512 683 0100

Worldwide Offices

Australia 1800 300 800, Austria 43 0 662 45 79 90 0, Belgium 32 0 2 757 00 20, Brazil 55 11 3262 3599,

Canada (Calgary) 403 274 9391, Canada (Ottawa) 613 233 5949, Canada (Québec) 450 510 3055,

Canada (Toronto) 905 785 0085, Canada (Vancouver) 604 685 7530, China 86 21 6555 7838,

Czech Republic 420 224 235 774, Denmark 45 45 76 26 00, Finland 385 0 9 725 725 11,

France 33 0 1 48 14 24 24, Germany 49 0 89 741 31 30, India 91 80 51190000, Israel 972 0 3 6393737,

Italy 39 02 413091, Japan 81 3 5472 2970, Korea 82 02 3451 3400, Malaysia 603 9131 0918,

Mexico 01 800 010 0793, Netherlands 31 0 348 433 466, New Zealand 0800 553 322, Norway 47 0 66 90 76 60,

Poland 48 22 3390150, Portugal 351 210 311 210, Russia 7 095 783 68 51, Singapore 65 6226 5886,

Slovenia 386 3 425 4200, South Africa 27 0 11 805 8197, Spain 34 91 640 0085, Sweden 46 0 8 587 895 00,

Switzerland 41 56 200 51 51, Taiwan 886 2 2528 7227, Thailand 662 992 7519,

United Kingdom 44 0 1635 523545

For further support information, refer to the Technical Support and Professional Services appendix. To comment

on National Instruments documentation, refer to the National Instruments Web site at ni.com/info and enter

the info code feedback.

© 2001–2004 National Instruments Corporation. All rights reserved.

Page 3

Important Information

Warranty

The media on which you receive National Instruments software are warranted not to fail to execute programming instructions, due to defects

in materials and workmanship, for a period of 90 days from date of shipment, as evidenced by receipts or other documentation. National

Instruments will, at its option, repair or replace software media that do not execute programming instructions if National Instruments receives

notice of such defects during the warranty period. National Instruments does not warrant that the operation of the software shall be

uninterrupted or error free.

A Return Material Authorization (RMA) number must be obtained from the factory and clearly marked on the outside of the package before

any equipment will be accepted for warranty work. National Instruments will pay the shipping costs of returning to the owner parts which are

covered by warranty.

National Instruments believes that the information in this document is accurate. The document has been carefully reviewed for technical

accuracy. In the event that technical or typographical errors exist, National Instruments reserves the right to make changes to subsequent

editions of this document without prior notice to holders of this edition. The reader should consult National Instruments if errors are suspected.

In no event shall National Instruments be liable for any damages arising out of or related to this document or the information contained in it.

E

XCEPT AS SPECIFIED HEREIN, NATIONAL INSTRUMENTS MAKES NO WARRANTIES, EXPRESS OR IMPLIED, AND SPECIFICALLY DISCLAIMS ANY WAR RANTY OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE . CUSTOMER’S RIGHT TO RECOVER DAMAGES CAUSED BY FAULT OR NEGLIGENCE ON THE PART OF

N

ATIONAL INSTRUMENTS SHALL BE LIMITED TO THE AMOUNT THERETOFORE PAID BY THE CUSTOMER. NATIONAL INSTRUMENTS WILL NOT BE LIABLE FOR

DAMAGES RESULTING FROM LOSS OF DATA, PROFITS, USE OF PRODUCTS, OR INCIDENTAL OR CONSEQUENTIAL DAMAGES, EVEN IF ADVISED OF THE POSS IBILITY

THEREOF. This limitation of the liability of National Instruments will apply regardless of the form of action, whether in contract or tort, including

negligence. Any action against National Instruments must be brought within one year after the cause of action accrues. National Instruments

shall not be liable for any delay in performance due to causes beyond its reasonable control. The warranty provided herein does not cover

damages, defects, malfunctions, or service failures caused by owner’s failure to follow the National Instruments installation, operation, or

maintenance instructions; owner’s modification of the product; owner’s abuse, misuse, or negligent acts; and power failure or surges, fire,

flood, accident, actions of third parties, or other events outside reasonable control.

Copyright

Under the copyright laws, this publication may not be reproduced or transmitted in any form, electronic or mechanical, including photocopying,

recording, storing in an information retrieval system, or translating, in whole or in part, without the prior written consent of National

Instruments Corporation.

Trademarks

CVI™, IMAQ™, LabVIEW™, National Instruments™, National Instruments Alliance Partner™, NI™, ni.com™, NI Developer Zone™,

and NI-IMAQ

Product and company names mentioned herein are trademarks or trade names of their respective companies.

Members of the National Instruments Alliance Partner Program are business entities independent from National Instruments and have no

agency, partnership, or joint-venture relationship with National Instruments.

™

are trademarks of National Instruments Corporation.

Patents

For patents covering National Instruments products, refer to the appropriate location: Help»Patents in your software, the patents.txt file

on your CD, or

ni.com/patents.

WARNING REGARDING USE OF NATIONAL INSTRUMENTS PRODUCTS

(1) NATIONAL INSTRUMENTS PRODUCTS ARE NOT DESIGNED WITH COMPONENTS AND TESTING FOR A LEVEL OF

RELIABILITY SUITABLE FOR USE IN OR IN CONNECTION WITH SURGICAL IMPLANTS OR AS CRITICAL COMPONENTS IN

ANY LIFE SUPPORT SYSTEMS WHOSE FAILURE TO PERFORM CAN REASONABLY BE EXPECTED TO CAUSE SIGNIFICANT

INJURY TO A HUMAN.

(2) IN ANY APPLICATION, INCLUDING THE ABOVE, RELIABILITY OF OPERATION OF THE SOFTWARE PRODUCTS CAN BE

IMPAIRED BY ADVERSE FACTORS, INCLUDING BUT NOT LIMITED TO FLUCTUATIONS IN ELECTRICAL POWER SUPPLY,

COMPUTER HARDWARE MALFUNCTIONS, COMPUTER OPERATING SYSTEM SOFTWARE FITNESS, FITNESS OF COMPILERS

AND DEVELOPMENT SOFTWARE USED TO DEVELOP AN APPLICATION, INSTALLATION ERRORS, SOFTWARE AND

HARDWARE COMPATIBILITY PROBLEMS, MALFUNCTIONS OR FAILURES OF ELECTRONIC MONITORING OR CONTROL

DEVICES, TRANSIENT FAILURES OF ELECTRONIC SYSTEMS (HARDWARE AND/OR SOFTWARE), UNANTICIPATED USES OR

MISUSES, OR ERRORS ON THE PART OF THE USER OR APPLICATIONS DESIGNER (ADVERSE FACTORS SUCH AS THESE ARE

HEREAFTER COLLECTIVELY TERMED “SYSTEM FAILURES”). ANY APPLICATION WHERE A SYSTEM FAILURE WOULD

CREATE A RISK OF HARM TO PROPERTY OR PERSONS (INCLUDING THE RISK OF BODILY INJURY AND DEATH) SHOULD

NOT BE RELIANT SOLELY UPON ONE FORM OF ELECTRONIC SYSTEM DUE TO THE RISK OF SYSTEM FAILURE. TO AVOID

DAMAGE, INJURY, OR DEATH, THE USER OR APPLICATION DESIGNER MUST TAKE REASONABLY PRUDENT STEPS TO

PROTECT AGAINST SYSTEM FAILURES, INCLUDING BUT NOT LIMITED TO BACK-UP OR SHUT DOWN MECHANISMS.

BECAUSE EACH END-USER SYSTEM IS CUSTOMIZED AND DIFFERS FROM NATIONAL INSTRUMENTS' TESTING

PLATFORMS AND BECAUSE A USER OR APPLICATION DESIGNER MAY USE NATIONAL INSTRUMENTS PRODUCTS IN

COMBINATION WITH OTHER PRODUCTS IN A MANNER NOT EVALUATED OR CONTEMPLATED BY NATIONAL

INSTRUMENTS, THE USER OR APPLICATION DESIGNER IS ULTIMATELY RESPONSIBLE FOR VERIFYING AND VALIDATING

THE SUITABILITY OF NATIONAL INSTRUMENTS PRODUCTS WHENEVER NATIONAL INSTRUMENTS PRODUCTS ARE

INCORPORATED IN A SYSTEM OR APPLICATION, INCLUDING, WITHOUT LIMITATION, THE APPROPRIATE DESIGN,

PROCESS AND SAFETY LEVEL OF SUCH SYSTEM OR APPLICATION.

Page 4

Contents

About This Manual

Conventions ...................................................................................................................ix

Related Documentation..................................................................................................x

IMAQ Vision...................................................................................................x

NI Vision Assistant..........................................................................................x

NI Vision Builder for Automated Inspection ..................................................x

Other Documentation ......................................................................................xi

Chapter 1

Introduction to IMAQ Vision

About IMAQ Vision ......................................................................................................1-1

Application Development Environments.......................................................................1-1

IMAQ Vision Function Tree..........................................................................................1-2

IMAQ Machine Vision Function Tree...........................................................................1-3

Creating IMAQ Vision Applications.............................................................................1-4

Chapter 2

Getting Measurement-Ready Images

Set Up Your Imaging System ........................................................................................2-1

Calibrate Your Imaging System ....................................................................................2-2

Create an Image .............................................................................................................2-2

Source and Destination Images .......................................................................2-4

Acquire or Read an Image .............................................................................................2-5

Acquiring an Image .........................................................................................2-6

Reading a File..................................................................................................2-6

Converting an Array to an Image ....................................................................2-7

Display an Image ...........................................................................................................2-7

Attach Calibration Information......................................................................................2-8

Analyze an Image ..........................................................................................................2-8

Improve an Image ..........................................................................................................2-9

Lookup Tables .................................................................................................2-10

Filters...............................................................................................................2-10

Convolution Filter .............................................................................2-11

Nth Order Filter.................................................................................2-11

Grayscale Morphology ....................................................................................2-11

FFT ..................................................................................................................2-12

Complex Image Operations ..............................................................2-13

© National Instruments Corporation v IMAQ Vision for LabWindows/CVI User Manual

Page 5

Contents

Chapter 3

Making Grayscale and Color Measurements

Define Regions of Interest............................................................................................. 3-1

Defining Regions Interactively ....................................................................... 3-1

Tools Palette Transformation ........................................................... 3-5

Defining Regions Programmatically............................................................... 3-6

Defining Regions with Masks......................................................................... 3-6

Measure Grayscale Statistics......................................................................................... 3-7

Measure Color Statistics................................................................................................ 3-7

Comparing Colors ........................................................................................... 3-9

Learning Color Information ............................................................................ 3-9

Specifying the Color Information to Learn ...................................... 3-9

Choosing a Color Representation Sensitivity ................................... 3-12

Ignoring Learned Colors................................................................... 3-13

Chapter 4

Performing Particle Analysis

Create a Binary Image ................................................................................................... 4-1

Improve the Binary Image............................................................................................. 4-2

Removing Unwanted Particles........................................................................ 4-3

Separating Touching Particles ........................................................................ 4-3

Improving Particle Shapes .............................................................................. 4-3

Make Particle Measurements ........................................................................................ 4-4

Chapter 5

Performing Machine Vision Tasks

Locate Objects to Inspect .............................................................................................. 5-2

Using Edge Detection to Build a Coordinate Transform ................................ 5-4

Using Pattern Matching to Build a Coordinate Transform .............................5-6

Choosing a Method to Build the Coordinate Transform................................. 5-7

Set Search Areas............................................................................................................ 5-8

Defining Regions Interactively ....................................................................... 5-8

Defining Regions Programmatically............................................................... 5-9

Find Measurement Points .............................................................................................. 5-9

Finding Features Using Edge Detection ......................................................... 5-9

Finding Lines or Circles ................................................................... 5-10

Finding Edge Points Along One Search Contour ............................. 5-11

Finding Edge Points Along Multiple Search Contours ....................5-12

Finding Points Using Pattern Matching.......................................................... 5-13

Defining and Creating Good Template Images ................................ 5-13

Training the Pattern Matching Algorithm ........................................ 5-15

IMAQ Vision for LabWindows/CVI User Manual vi ni.com

Page 6

Contents

Defining a Search Area .....................................................................5-16

Setting Matching Parameters and Tolerances...................................5-17

Testing the Search Algorithm on Test Images..................................5-18

Using a Ranking Method to Verify Results ......................................5-19

Finding Points Using Color Pattern Matching ................................................5-19

Defining and Creating Good Color Template Images ......................5-20

Training the Color Pattern Matching Algorithm...............................5-21

Defining a Search Area .....................................................................5-22

Setting Matching Parameters and Tolerances...................................5-23

Testing the Search Algorithm on Test Images..................................5-25

Finding Points Using Color Location..............................................................5-25

Convert Pixel Coordinates to Real-World Coordinates.................................................5-26

Make Measurements ......................................................................................................5-26

Distance Measurements...................................................................................5-26

Analytic Geometry Measurements ..................................................................5-27

Instrument Reader Measurements ...................................................................5-27

Identify Parts Under Inspection .....................................................................................5-28

Classifying Samples ........................................................................................5-28

Reading Characters..........................................................................................5-29

Reading Barcodes............................................................................................5-30

Reading 1D Barcodes........................................................................5-30

Reading Data Matrix Barcodes .........................................................5-30

Reading PDF417 Barcodes ...............................................................5-31

Display Results ..............................................................................................................5-31

Chapter 6

Calibrating Images

Perspective and Nonlinear Distortion Calibration .........................................................6-1

Defining a Calibration Template.....................................................................6-2

Defining a Reference Coordinate System .......................................................6-3

Learning Calibration Information....................................................................6-5

Specifying Scaling Factors................................................................6-6

Choosing a Region of Interest...........................................................6-6

Choosing a Learning Algorithm .......................................................6-6

Using the Learning Score..................................................................6-7

Learning the Error Map.....................................................................6-8

Learning the Correction Table ..........................................................6-8

Setting the Scaling Method ...............................................................6-8

Calibration Invalidation ....................................................................6-8

Simple Calibration .........................................................................................................6-9

Save Calibration Information.........................................................................................6-10

Attach Calibration Information......................................................................................6-10

© National Instruments Corporation vii IMAQ Vision for LabWindows/CVI User Manual

Page 7

Contents

Appendix A

Technical Support and Professional Services

Glossary

Index

IMAQ Vision for LabWindows/CVI User Manual viii ni.com

Page 8

About This Manual

The IMAQ Vision for LabWindows/CVI User Manual is intended for

engineers and scientists who have knowledge of the LabWindows

programming environment and need to create machine vision and image

processing applications using C functions. The manual guides you through

tasks beginning with setting up your imaging system to taking

measurements.

™

/CVI™

Conventions

The following conventions are used in this manual:

» The » symbol leads you through nested menu items and dialog box options

to a final action. The sequence File»Page Setup»Options directs you to

pull down the File menu, select the Page Setup item, and select Options

from the last dialog box.

This icon denotes a tip, which alerts you to advisory information.

This icon denotes a note, which alerts you to important information.

bold Bold text denotes items that you must select or click in the software, such

as menu items and dialog box options. Bold text also denotes parameter

names.

italic Italic text denotes variables, emphasis, a cross reference, or an introduction

to a key concept. This font also denotes text that is a placeholder for a word

or value that you must supply.

monospace Text in this font denotes text or characters that you should enter from the

keyboard, sections of code, programming examples, and syntax examples.

This font is also used for the proper names of disk drives, paths, directories,

programs, subprograms, subroutines, device names, functions, operations,

variables, filenames, and extensions.

© National Instruments Corporation ix IMAQ Vision for LabWindows/CVI User Manual

Page 9

About This Manual

Related Documentation

In addition to this manual, the following documentation resources are

available to help you create your vision application.

IMAQ Vision

• IMAQ Vision Concepts Manual—If you are new to machine vision

and imaging, read this manual to understand the concepts behind

IMAQ Vision.

• IMAQ Vision for LabWindows/CVI Function Reference—If you need

information about IMAQ Vision functions while creating your

application, refer to this help file.

NI Vision Assistant

• NI Vision Assistant Tutorial—If you need to install NI Vision

Assistant and learn the fundamental features of the software, follow

the instructions in this tutorial.

• NI Vision Assistant Help—If you need descriptions or step-by-step

guidance about how to use any of the functions or features of NI Vision

Assistant, refer to this help file.

NI Vision Builder for Automated Inspection

• NI Vision Builder for Automated Inspection Tutorial—If you have

little experience with machine vision, and you need information about

how to solve common inspection tasks with NI Vision Builder AI,

follow the instructions in this tutorial.

• NI Vision Builder for Automated Inspection: Configuration

Help—If you need descriptions or step-by-step guidance about how to

use any of the NI Vision Builder AI functions to create an automated

vision inspection system, refer to this help file.

• NI Vision Builder for Automated Inspection: Inspection Help—If you

need information about how to run an automated vision inspection

system using NI Vision Builder AI, refer to this help file.

IMAQ Vision for LabWindows/CVI User Manual x ni.com

Page 10

Other Documentation

• Your National Instruments image acquisition (IMAQ) device user

• Getting Started With Your IMAQ System—If you need instructions

• NI-IMAQ User Manual—If you need information about how to use

• NI-IMAQ VI or function reference guides—If you need information

• IMAQ Vision Deployment Engine Note to Users—If you need

• Example programs—If you want examples of how to create specific

• Application Notes—If you want to know more about advanced

• NI Developer Zone (NIDZ)—If you want even more information

About This Manual

manual—If you need installation instructions and device-specific

information, refer to your device user manual.

for installing the NI-IMAQ software and your IMAQ hardware,

connecting your camera, running Measurement & Automation

Explorer (MAX) and the NI-IMAQ Diagnostics, selecting a camera

file, and acquiring an image, refer to this getting started document.

NI-IMAQ and IMAQ image acquisition devices to capture images for

processing, refer to this manual.

about the features, functions, and operation of the NI-IMAQ image

acquisition VIs or functions, refer to these help files.

information about how to deploy your custom IMAQ Vision

applications on target computers, read this CD insert.

applications, go to

<CVI>\samples\vision.

IMAQ Vision concepts and applications, refer to the Application

Notes located on the National Instruments Web site at

appnotes.nsf

.

ni.com/

about developing your vision application, visit the NI Developer Zone

at

ni.com/zone. The NI Developer Zone contains example

programs, tutorials, technical presentations, the Instrument Driver

Network, a measurement glossary, an online magazine, a product

advisor, and a community area where you can share ideas, questions,

and source code with vision developers around the world.

© National Instruments Corporation xi IMAQ Vision for LabWindows/CVI User Manual

Page 11

Introduction to IMAQ Vision

This chapter describes the IMAQ Vision for LabWindows/CVI software,

outlines the IMAQ Vision function organization, and lists the steps for

making a machine vision application.

Note Refer to the Vision Development Module Release Notes that came with your

software for information about the system requirements and installation procedure for

IMAQ Vision for LabWindows/CVI.

About IMAQ Vision

IMAQ Vision for LabWindows/CVI—a part of the Vision Development

Module—is a library of C functions that you can use to develop machine

vision and scientific imaging applications. The Vision Development

Module also includes the same imaging functions for LabVIEW,

and ActiveX controls for Microsoft Visual Basic. Vision Assistant, another

Vision Development Module software product, enables you to prototype

your application strategy quickly without having to do any programming.

Additionally, NI offers Vision Builder for Automated Inspection:

configurable machine vision software that you can use to prototype,

benchmark, and deploy applications.

1

Application Development Environments

This release of IMAQ Vision for LabWindows/CVI supports the

following Application Development Environments (ADEs) for

Windows 2000/NT/XP.

• LabWindows/CVI version 6.0 and later

• Microsoft Visual C/C++ version 6.0 and later

Note IMAQ Vision has been tested and found to work with these ADEs, although other

ADEs may also work.

© National Instruments Corporation 1-1 IMAQ Vision for LabWindows/CVI User Manual

Page 12

Chapter 1 Introduction to IMAQ Vision

IMAQ Vision Function Tree

The IMAQ Vision function tree (NIVision.lfp) contains separate

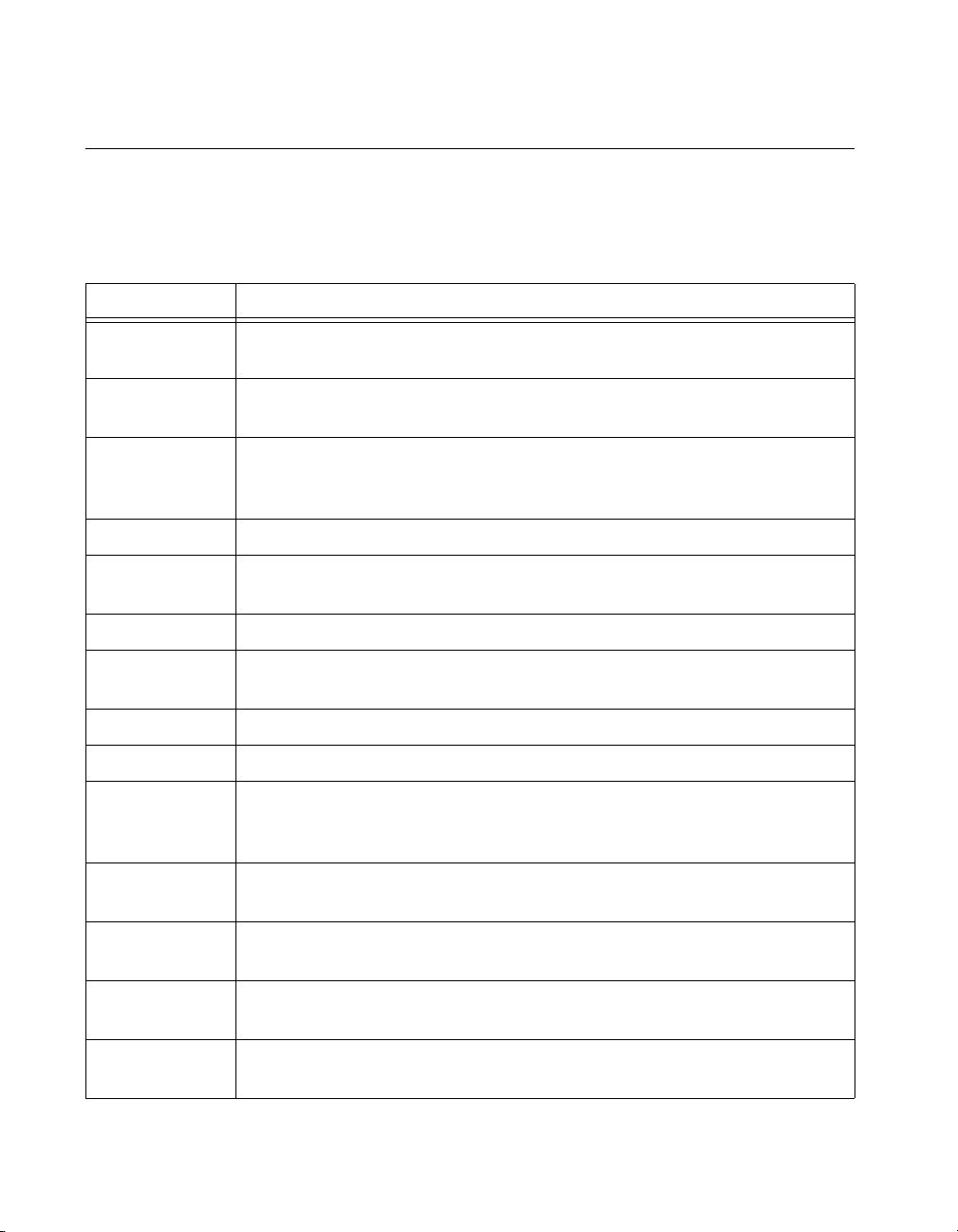

classes corresponding to groups or types of functions. Table 1-1 lists the

IMAQ Vision function types and gives a description of each type.

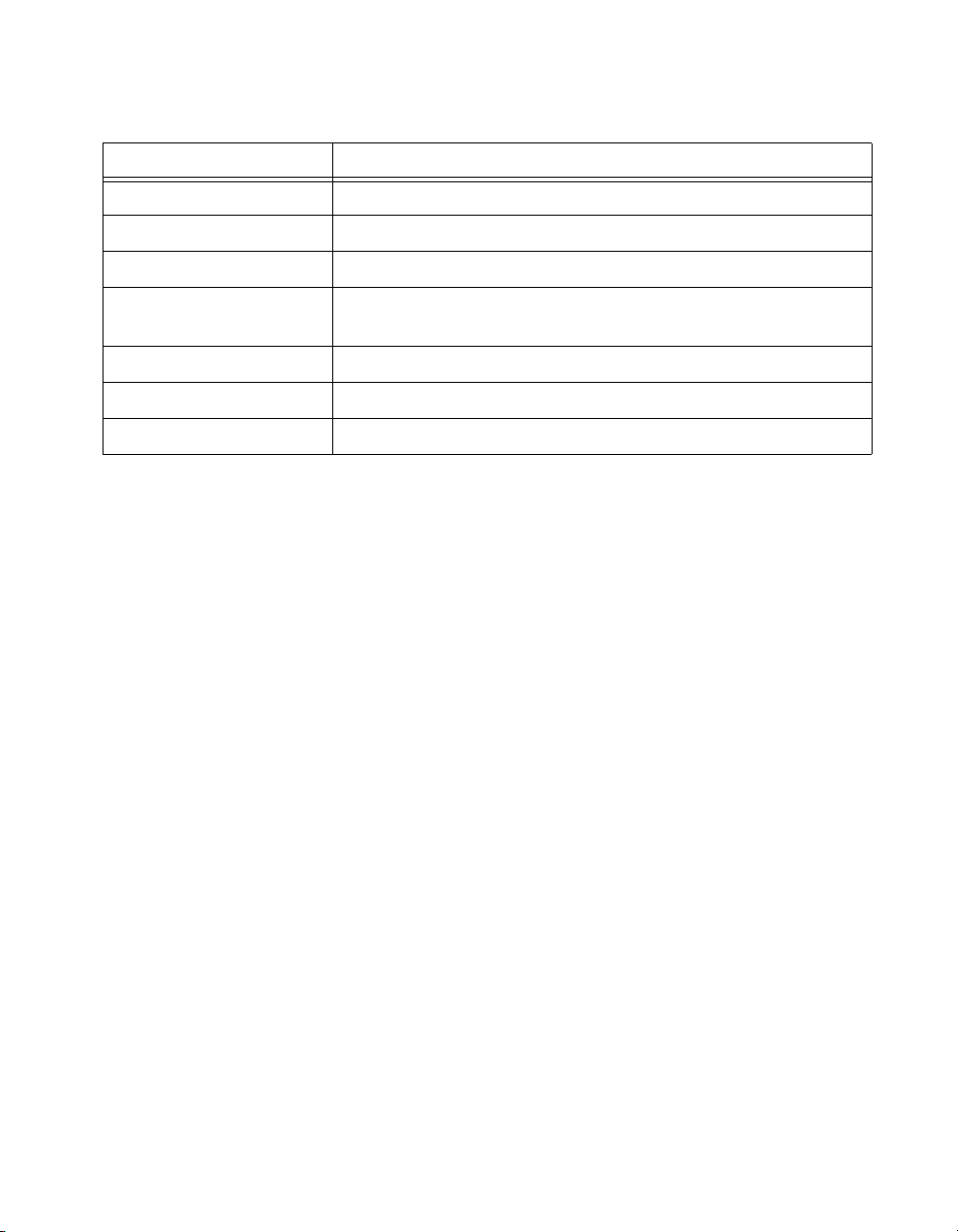

Table 1-1. IMAQ Vision Function Types

Function Type Description

Image

Management

Memory

Management

Error

Management

Acquisition Functions that acquire images through an IMAQ hardware device.

Display Functions that cover all aspects of image visualization and image window

Overlay Functions that create and manipulate overlays.

Regions of

Interest

File I/O Functions that read and write images from and to files.

Calibration Functions that learn calibration information and correct distorted images.

Image

Analysis

Grayscale

Processing

Functions that create space in memory for images and perform basic image

manipulation.

Function that returns, to the operating system, previously used memory that is

no longer needed.

Functions that set the current error, return the name of the function in which the

last error occurred, return the error code of the last error, and clear any pending

errors.

management.

Functions that create and manipulate regions of interest.

Functions that compute the centroid of an image, profile of a line of pixels,

and the mean line profile. This type also includes functions that calculate the

pixel distribution and statistical parameters of an image.

Functions for grayscale image processing and analysis.

Binary

Processing

Color

Processing

Pattern

Matching

IMAQ Vision for LabWindows/CVI User Manual 1-2 ni.com

Functions for binary image processing and analysis.

Functions for color image processing and analysis.

Functions that learn patterns and search for patterns in images.

Page 13

Chapter 1 Introduction to IMAQ Vision

Table 1-1. IMAQ Vision Function Types (Continued)

Function Type Description

Caliper Functions designed for gauging, measurement, and inspection applications.

Operators Functions that perform arithmetic, logic, and comparison operations with

two images or with an image and a constant value.

Analytic

Geometry

Frequency

Domain

Analysis

Barcode I/O Functions that find and read barcodes.

LCD Functions that find and read seven-segment LCD characters.

Meter Functions that return the arc information of a meter and read the meter.

Utilities Functions that return structures, and a function that returns a pointer to

OCR Functions that perform optical character recognition on an image.

Classification Functions that classify an image or feature vector.

Obsolete Functions that are no longer necessary but may exist in older applications.

Functions that perform basic geometric calculations on an image.

Functions for the extraction and manipulation of complex planes. Functions

of this type perform Fast Fourier Transform (FFT), inverse FFT, truncation,

attenuation, addition, subtraction, multiplication, and division of complex

images.

predefined convolution matrices.

IMAQ Machine Vision Function Tree

The IMAQ Machine Vision function tree (NIMachineVision.fp)

contains separate classes corresponding to groups or types of functions.

Table 1-2 lists the IMAQ Machine Vision function types and gives a

description of each type.

Table 1-2. IMAQ Machine Vision Function Types

Function Type Description

Coordinate Transform Functions that find coordinate transforms based on image contents.

Count and Measure Objects Function that counts and measures objects in an image.

Find Patterns Function that finds patterns in an image.

Locate Edges Functions that locate different types of edges in an image.

© National Instruments Corporation 1-3 IMAQ Vision for LabWindows/CVI User Manual

Page 14

Chapter 1 Introduction to IMAQ Vision

Table 1-2. IMAQ Machine Vision Function Types (Continued)

Function Type Description

Measure Distances Functions that measure distances between objects in an image.

Measure Intensities Functions that measure light intensities in various shaped regions

within an image.

Select Region of Interest Functions that allow a user to select a specific region of interest in

an image.

Creating IMAQ Vision Applications

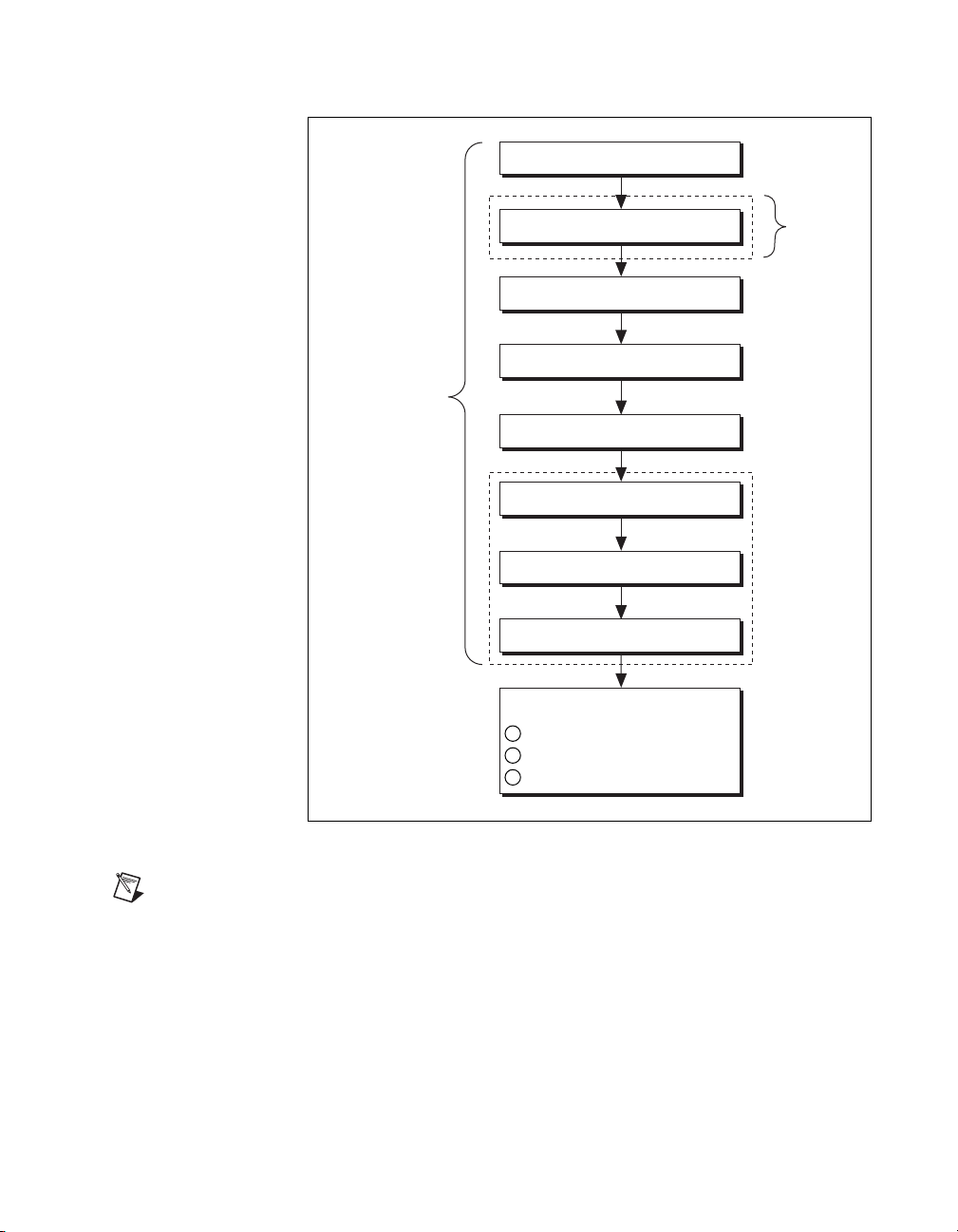

Figures 1-1 and 1-2 illustrate the steps for creating an application with

IMAQ Vision. Figure 1-1 describes the general steps to designing a Vision

application. The last step in Figure 1-1 is expanded upon in Figure 1-2.

You can use a combination of the items in the last step to create your IMAQ

Vision application. Refer to the corresponding chapter listed to the side of

the item for more information about items in either diagram.

IMAQ Vision for LabWindows/CVI User Manual 1-4 ni.com

Page 15

Chapter 1 Introduction to IMAQ Vision

Set Up Your Imaging System

Chapter 2:

Measurement-Ready

Getting

Images

Calibrate Your Imaging System

Create an Image

Acquire or Read an Image

Display an Image

Attach Calibration Information

Analyze an Image

Improve an Image

Improve an Image

Make Measurements or Identify Objects

1

2

3

in an Image Using

Grayscale or Color Measurements, and/or

Particle Analysis, and/or

Machine Vision

Chapter 6:

Calibration

Figure 1-1. General Steps for Designing a Vision Application

Note

Diagram items enclosed with dashed lines are optional steps.

© National Instruments Corporation 1-5 IMAQ Vision for LabWindows/CVI User Manual

Page 16

Chapter 1 Introduction to IMAQ Vision

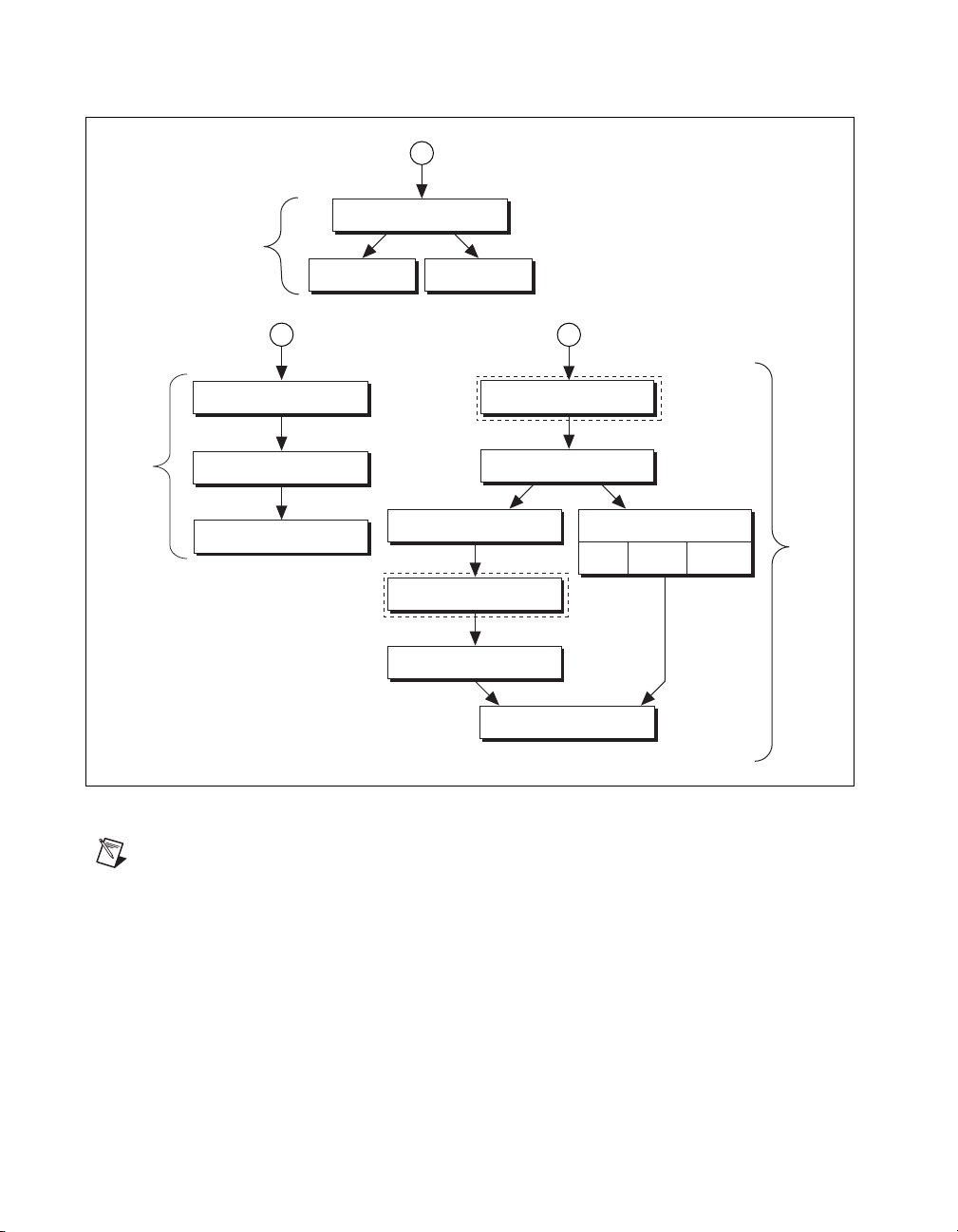

2

Chapter 5:

Particle

Analysis

Chapter 4:

Grayscale and Color

Measurements

Create a Binary Image

Improve a Binary Image

Make Particle Measurements

Grayscale Statistics

3

Define Regions of Interest

Measure

Find Measurement Points

Convert Pixel Coordinates to

Real-World Coordinates

Make Measurements

Measure

Color Statistics

4

Locate Objects to Inspect

Set Search Areas

Identify Parts Under Inspection

Classify

Objects

Display Results

Read

Characters

Read

Symbologies

Chapter 6:

Machine

Vision

Figure 1-2. Inspection Steps for Building a Vision Application

Note

Diagram items enclosed with dashed lines are optional steps.

IMAQ Vision for LabWindows/CVI User Manual 1-6 ni.com

Page 17

Getting Measurement-Ready

Images

This chapter describes how to set up your imaging system, acquire and

display an image, analyze the image, and prepare the image for additional

processing.

Set Up Your Imaging System

Before you acquire, analyze, and process images, you must set up your

imaging system. How you set up your system depends on your imaging

environment and the type of analysis and processing you need to do. Your

imaging system should produce images with high enough quality so that

you can extract the information you need from the images.

Complete the following steps to set up your imaging system.

1. Determine the type of equipment you need given your space

constraints and the size of the object you need to inspect. Refer to

Chapter 3, System Setup and Calibration, of the IMAQ Vision

Concepts Manual for more information.

a. Make sure your camera sensor is large enough to satisfy your

minimum resolution requirement.

b. Make sure your lens has a depth of field high enough to keep all

of your objects in focus regardless of their distance from the lens.

Also, make sure your lens has a focal length that meets your

needs.

c. Make sure your lighting provides enough contrast between the

object under inspection and the background for you to extract the

information you need from the image.

2. Position your camera so that it is perpendicular to the object under

inspection. If your camera acquires images of the object from an angle,

perspective errors occur. Even though you can compensate for these

errors with software, NI recommends that you use a perpendicular

inspection angle to obtain the most accurate results.

2

© National Instruments Corporation 2-1 IMAQ Vision for LabWindows/CVI User Manual

Page 18

Chapter 2 Getting Measurement-Ready Images

3. Select an IMAQ device that meets your needs. National Instruments

offers several IMAQ devices, including analog color and monochrome

devices as well as digital devices. Visit

information about IMAQ devices.

4. Configure the driver software for your image acquisition device. If

you have a National Instruments image acquisition device, configure

the NI-IMAQ driver software through MAX. Open MAX by

double-clicking the Measurement & Automation Explorer icon on

your desktop. Refer to the NI-IMAQ User Manual and the

Measurement and Automation Explorer Help for IMAQ for more

information.

Calibrate Your Imaging System

After you set up your imaging system, you may want to calibrate your

system to assign real-world coordinates to pixel coordinates. This allows

you to compensate for perspective and nonlinear errors inherent in your

imaging system.

Perspective errors occur when your camera axis is not perpendicular to the

object under inspection. Nonlinear distortion may occur from aberrations

in the camera lens. Perspective errors and lens aberrations cause images to

appear distorted. This distortion misplaces information in an image, but it

does not necessarily destroy the information in the image.

ni.com/imaq for more

Use simple calibration if you only want to assign real-world coordinates to

pixel coordinates. Use perspective and nonlinear distortion calibration if

you need to compensate for perspective errors and nonlinear lens distortion.

For detailed information about calibration, refer to Chapter 5, Performing

Machine Vision Tasks.

Create an Image

To create an image in IMAQ Vision for LabWindows/CVI, call

imaqCreateImage(). This function returns an image reference you can

use when calling other IMAQ Vision functions. The only limitation to the

size and number of images you can acquire and process is the amount of

memory on your computer. When you create an image, specify the type of

the image. Table 2-1 lists the valid image types.

IMAQ Vision for LabWindows/CVI User Manual 2-2 ni.com

Page 19

Chapter 2 Getting Measurement-Ready Images

Table 2-1. IMAQ Vision for LabWindows/CVI Image Types

Val ue Description

IMAQ_IMAGE_U8

IMAQ_IMAGE_I16

IMAQ_IMAGE_SGL

IMAQ_IMAGE_COMPLEX 2 × 32 bits per pixel—floating point, native format after a Fast

8 bits per pixel—unsigned, standard monochrome

16 bits per pixel—signed, monochrome

32 bits per pixel—floating point, monochrome

Fourier Transform (FFT)

IMAQ_IMAGE_RGB

IMAQ_IMAGE_HSL

IMAQ_IMAGE_RGB_U64

32 bits per pixel—standard color

32 bits per pixel—color

64 bits per pixel—standard color

You can create multiple images by executing imaqCreateImage() as

many times as you want. Determine the number of required images through

an analysis of your intended application. The decision is based on different

processing phases and your need to keep the original image after each

processing step. The decision to keep an image occurs before each

processing step.

When you create an image, IMAQ Vision creates an internal image

structure to hold properties of the image, such as its name and border size.

However, no memory is allocated to store the image pixels at this time.

IMAQ Vision functions automatically allocate the appropriate amount of

memory when the image size is modified. For example, functions that

acquire or resample an image alter the image size, so they allocate the

appropriate memory space for the image pixels. The return value of

imaqCreateImage() is a pointer to the image structure. Supply this

pointer as an input to all subsequent IMAQ Vision functions.

Most functions in the IMAQ Vision library require one or more image

pointers. The number of image pointers a function takes depends on the

image processing function and the type of image you want to use. Some

IMAQ Vision functions act directly on the image and require only one

image pointer. Other functions that process the contents of images require

pointers to the source image(s) and to a destination image.

At the end of your application, dispose of each image that you created using

imaqDispose().

© National Instruments Corporation 2-3 IMAQ Vision for LabWindows/CVI User Manual

Page 20

Chapter 2 Getting Measurement-Ready Images

Source and Destination Images

Some IMAQ Vision functions that modify the contents of an image have

source image and destination image input parameters. The source image

receives the image to process. The destination image receives the

processing results. The destination image can receive either another image

or the original, depending on your goals. If you do not want the contents of

the original image to change, use separate source and destination images.

If you want to replace the original image with the processed image, pass the

same image as both the source and destination.

Depending on the function, the image type of the destination image can be

the same or different than the image type of the source image. The function

descriptions in the IMAQ Vision for LabWindows/CVI Function Reference

include the type of images you can use as image inputs and outputs. IMAQ

Vision resizes the destination image to hold the result if the destination is

not the appropriate size.

The following examples illustrate source and destination images with

imaqTranspose():

•

imaqTranspose(myImage, myImage);

This function creates a transposed image using the same image for the

source and destination. The contents of

•

imaqTranspose(myTransposedImage, myImage);

This function creates a transposed image and stores it in a destination

different from the source. The

and

myTransposedImage contains the result.

myImage change.

myImage image remains unchanged,

Functions that perform arithmetic or logical operations between two

images have two source images and a destination image. You can perform

an operation between two images and then either store the result in a

separate destination image or in one of the two source images. In the

latter case, make sure you no longer need the original data in the source

image before storing the result over the data.

The following examples show the possible combinations using

imaqAdd():

•

imaqAdd(myResultImage, myImageA, myImageB);

This function adds two source images (myImageA and myImageB) and

stores the result in a third image (

myResultImage). Both source

images remain intact after processing.

IMAQ Vision for LabWindows/CVI User Manual 2-4 ni.com

Page 21

• imaqAdd(myImageA, myImageA, myImageB);

This function adds two source images and stores the result in the first

source image.

•

imaqAdd(myImageB, myImageA, myImageB);

This function adds two source images and stores the result in the

second source image.

Most operations between two images require that the images have the

same type and size. However, some arithmetic operations can work

between two different types of images, such as 8-bit and 16-bit images.

Some functions perform operations that populate an image. Examples of

this type of operation include reading a file, acquiring an image from an

IMAQ device, or transforming a 2D array into an image. This type of

function can modify the size of an image.

Some functions take an additional mask parameter. The presence of this

parameter indicates that the processing or analysis is dependent on the

contents of another image, the image mask.

Note The image mask must be an 8-bit image.

Chapter 2 Getting Measurement-Ready Images

If you want to apply a processing or analysis function to the entire image,

pass NULL for the image mask. Passing the same image to both the source

image and image mask also gives the same effect as passing NULL for the

image mask, except in this case the source image must be an 8-bit image.

Acquire or Read an Image

After you create an image reference, you can acquire an image into your

imaging system in three ways. You can acquire an image with a camera

through your IMAQ device, load an image from a file stored on your

computer, or convert data stored in a 2D array to an image. Functions that

acquire images, load images from file, or convert data from a 2D array to

an image automatically allocate the memory space required to

accommodate the image data.

© National Instruments Corporation 2-5 IMAQ Vision for LabWindows/CVI User Manual

Page 22

Chapter 2 Getting Measurement-Ready Images

Acquiring an Image

Use one of the following methods to acquire images with a National

Instruments IMAQ device.

• Acquire a single image using

this function, it initializes the IMAQ device and acquires the next

incoming video frame. Use this function for low-speed single capture

applications where ease of programming is essential.

• Acquire a single image using

function, it acquires the next incoming video frame on an IMAQ

device you have already initialized using

i

mgSessionOpen(). Use this function for high-speed single capture

applications.

• Acquire images continually through a grab acquisition. Grab functions

perform high-speed acquisitions that loop continually on one buffer.

Use

imaqSetupGrab() to start the acquisition. Use imaqGrab()

to return a copy of the current image. Use

to stop the acquisition.

• Acquire a fixed number of images using a sequence acquisition.

Set up the acquisition using

imaqStartAcquisition() to acquire the number of images you

requested during setup. If you want to acquire only certain images,

supply

of frames to skip after each acquired frame.

• Acquire images continually through a ringed buffer acquisition.

Set up the acquisition using

imaqStartAcquisition() to start acquiring images into the

acquired ring buffer. To get an image from the ring, call

imaqExtractFromRing() or imaqCopyRing(). Use

imaqStopAcquisition() to stop the acquisition.

imaqEasyAcquire(). When you call

imaqSnap(). When you call this

imgInterfaceOpen() and

imaqStopAcquisition()

imaqSetupSequence(). Use

imaqSetupSequence() with a table describing the number

imaqSetupRing(). Use

Note You must use imgClose() to release resources associated with the image

acquisition device.

Reading a File

Use imaqReadFile() to open and read data from a file stored on your

computer into the image reference. You can read from image files stored

in several standard formats: BMP, TIFF, JPEG, PNG, and AIPD. The

software automatically converts the pixels it reads into the type of image

you pass in.

IMAQ Vision for LabWindows/CVI User Manual 2-6 ni.com

Page 23

Chapter 2 Getting Measurement-Ready Images

Use imaqReadVisionFile() to open an image file containing additional

information, such as calibration information, template information for

pattern matching, or overlay information. For more information about

pattern matching templates and overlays, refer to Chapter 5, Performing

Machine Vision Tasks.

You can also use

properties—such as image size, recommended image type, and

calibration units—without actually reading all the image data.

Converting an Array to an Image

Use imaqArrayToImage() to convert a 2D array to an image. You can

also use

imaqImageToArray() to convert an image to a 2D array.

Display an Image

Display an image in an external window using imaqDisplayImage().

You can display images in 16 different external windows. Use the other

display functions to configure the appearance of each external window.

Properties you can set include whether the window has scroll bars, a title

bar, and whether it is resizable. You can also use

position the external image window at a particular location on you monitor.

Refer to the IMAQ Vision for LabWindows/CVI Function Reference for a

complete list of Display functions.

Note Image windows are not LabWindows/CVI panels. They are managed directly by

IMAQ Vision .

You can use a color palette to display grayscale images by applying a color

palette to the window. Use

color palettes. For example, if you need to display a binary image—an

image containing particle regions with pixel values of 1 and a background

region with pixel values of 0—apply the predefined binary palette. For

more information about color palettes, refer to Chapter 2, Display, of the

IMAQ Vision Concepts Manual.

imaqGetFileInfo() to retrieve image

imaqMoveWindow() to

imaqSetWindowPalette() to set predefined

Note At the end of your application, close all open external windows using

imaqCloseWindow().

© National Instruments Corporation 2-7 IMAQ Vision for LabWindows/CVI User Manual

Page 24

Chapter 2 Getting Measurement-Ready Images

Attach Calibration Information

If you want to attach the calibration information of the current setup to

each image you acquire, use

function takes in a source image containing the calibration information and

a destination image that you want to calibrate. The output image is your

inspection image with the calibration information attached to it. For

detailed information about calibration, refer to Chapter 6, Calibrating

Images.

Note Because calibration information is part of the image, it is propagated throughout

the processing and analysis of the image. Functions that modify the image size, such as

geometrical transforms, void the calibration information. Use

to save the image and all of the attached calibration information to a file.

Analyze an Image

After you acquire and display an image, you may want to analyze the

contents of the image for the following reasons:

• To determine whether the image quality is high enough for your

inspection task.

• To obtain the values of parameters that you want to use in processing

functions during the inspection process.

imaqCopyCalibrationInfo(). This

imaqWriteVisionFile()

The histogram and line profile tools can help you analyze the quality of

your images.

Use

imaqHistogram() to analyze the overall grayscale distribution in the

image. Use the histogram of the image to analyze two important criteria

that define the quality of an image—saturation and contrast. If your image

is underexposed, or does not have enough light, the majority of your pixels

will have low intensity values, which appear as a concentration of peaks on

the left side of your histogram. If your image is overexposed, or has too

much light, the majority of your pixels will have high intensity values,

which appear as a concentration of peaks on the right side of your

histogram. If your image has an appropriate amount of contrast, your

histogram will have distinct regions of pixel concentrations. Use the

histogram information to decide if the image quality is high enough to

separate objects of interest from the background.

IMAQ Vision for LabWindows/CVI User Manual 2-8 ni.com

Page 25

Chapter 2 Getting Measurement-Ready Images

If the image quality meets your needs, use the histogram to determine the

range of pixel values that correspond to objects in the image. You can use

this range in processing functions, such as determining a threshold range

during particle analysis.

If the image quality does not meet your needs, try to improve the imaging

conditions to get the necessary image quality. You may need to re-evaluate

and modify each component of your imaging setup, including lighting

equipment and setup, lens tuning, camera operation mode, and acquisition

device parameters. If you reach the best possible conditions with your setup

but the image quality still does not meet your needs, try to improve the

image quality using the image processing techniques described in the

Improve an Image section of this chapter.

Use

imaqLineProfile() to get the pixel distribution along a line in the

image, or use

one-dimensional path in the image. By looking at the pixel distribution, you

can determine if the image quality is high enough to provide you with sharp

edges at object boundaries. Also, you can determine if the image is noisy

and identify the characteristics of the noise.

If the image quality meets your needs, use the pixel distribution

information to determine some parameters of the inspection functions you

want to use. For example, use the information from the line profile to

determine the strength of the edge at the boundary of an object. You can

input this information into

along the line.

imaqROIProfile() to get the pixel distribution along a

imaqEdgeTool2() to find the edges of objects

Improve an Image

Using the information you gathered from analyzing your image, you may

want to improve the quality of your image for inspection. You can improve

your image with lookup tables, filters, grayscale morphology, and FFTs.

© National Instruments Corporation 2-9 IMAQ Vision for LabWindows/CVI User Manual

Page 26

Chapter 2 Getting Measurement-Ready Images

Lookup Tables

Apply lookup table (LUT) transformations to highlight image details in

areas containing significant information at the expense of other areas.

A LUT transformation converts input grayscale values in the source image

into other grayscale values in the transformed image. IMAQ Vision

provides four functions that directly or indirectly apply lookup tables to

images.

•

imaqMathTransform()—Converts the pixel values of an image

by eplacing them with values from a predefined lookup table.

IMAQ Vision has seven predefined lookup tables based on

mathematical transformations. For more information about these

lookup tables, refer to Chapter 5, Image Processing, of the IMAQ

Vision Concepts Manual.

•

imaqLookup()—Converts the pixel values of an image by replacing

them with values from a user-defined lookup table.

•

imaqEqualize()—Distributes the grayscale values evenly within a

given grayscale range. Use

in images containing few grayscale values.

•

imaqInverse()—Inverts the pixel intensities of an image to

compute the negative of the image. For example, use

before applying an automatic threshold to your image if the

background pixels are brighter than the object pixels.

imaqEqualize() to increase the contrast

imaqInverse()

Filters

Filter your image when you need to improve the sharpness of transitions in

the image or increase the overall signal-to-noise ratio of the image. You can

choose either a lowpass or highpass filter depending on your needs.

Lowpass filters remove insignificant details by smoothing the image,

removing sharp details, and smoothing the edges between the objects

and the background. You can use

lowpass filter with

imaqConvolve() or imaqNthOrderFilter().

Highpass filters emphasize details, such as edges, object boundaries,

or cracks. These details represent sharp transitions in intensity value.

You can define your own highpass filter with

imaqNthOrderFilter(), or you can use a predefined highpass filter

with

imaqEdgeFilter() or imaqCannyEdgeFilter(). The

imaqEdgeFilter() function allows you to find edges in an image using

predefined edge detection kernels, such as the Sobel, Prewitt, and Roberts

kernels.

IMAQ Vision for LabWindows/CVI User Manual 2-10 ni.com

imaqLowPass() or define your own

imaqConvolve() or

Page 27

Convolution Filter

The imaqConvolve() function allows you to use a predefined set of

lowpass and highpass filters. Each filter is defined by a kernel of

coefficients. Use

predefined kernels do not meet your needs, define your own custom filter

using a 2D array of floating point numbers.

Nth Order Filter

The imaqNthOrderFilter() function allows you to define a lowpass or

highpass filter depending on the value of N that you choose. One specific

Nth order filter, the median filter, removes speckle noise, which appears as

small black and white dots. Use

filter. For more information about Nth order filters, refer to Chapter 5,

Image Processing, of the IMAQ Vision Concepts Manual.

Grayscale Morphology

Perform grayscale morphology when you want to filter grayscale

features of an image. Grayscale morphology helps you remove or

enhance isolated features, such as bright pixels on a dark background.

Use these transformations on a grayscale image to enhance non-distinct

features before thresholding the image in preparation for particle analysis.

Chapter 2 Getting Measurement-Ready Images

imaqGetKernel() to retrieve predefined kernels. If the

imaqMedianFilter() to apply a median

Grayscale morphological transformations compare a pixel to those pixels

surrounding it. The transformation keeps the smallest pixel values when

performing an erosion or keeps the largest pixel values when performing

a dilation.

Refer to Chapter 5, Image Processing, of the IMAQ Vision Concepts

Manual for more information about grayscale morphology

transformations.

Use

imaqGrayMorphology() to perform one of the following seven

transformations:

• Erosion—Reduces the brightness of pixels that are surrounded by

neighbors with a lower intensity.

• Dilation—Increases the brightness of pixels surrounded by neighbors

with a higher intensity. A dilation produces the opposite effect of an

erosion.

• Opening—Removes bright pixels isolated in dark regions and smooths

boundaries.

© National Instruments Corporation 2-11 IMAQ Vision for LabWindows/CVI User Manual

Page 28

Chapter 2 Getting Measurement-Ready Images

• Closing—Removes dark pixels isolated in bright regions and smooths

boundaries.

• Proper-opening—Removes bright pixels isolated in dark regions and

smooths the inner contours of particles.

• Proper-closing—Removes dark pixels isolated in bright regions and

smooths the inner contours of particles.

• Auto-median—Generates simpler particles that have fewer details.

FFT

Use the Fast Fourier Transform (FFT) to convert an image into its

frequency domain. In an image, details and sharp edges are associated

with mid to high spatial frequencies because they introduce significant

gray-level variations over short distances. Gradually varying patterns are

associated with low spatial frequencies.

An image can have extraneous noise, such as periodic stripes, introduced

during the digitization process. In the frequency domain, the periodic

pattern is reduced to a limited set of high spatial frequencies. Also, the

imaging setup may produce non-uniform lighting of the field of view,

which produces an image with a light drift superimposed on the

information you want to analyze. In the frequency domain, the light drift

appears as a limited set of low frequencies around the average intensity of

the image, the DC component.

You can use algorithms working in the frequency domain to isolate and

remove these unwanted frequencies from your image. Complete the

following steps to obtain an image in which the unwanted pattern has

disappeared but the overall features remain.

1. Use

imaqFFT() to convert an image from the spatial domain to the

frequency domain. This function computes the FFT of the image and

results in a complex image representing the frequency information of

your image.

2. Improve your image in the frequency domain with a lowpass or

highpass frequency filter. Specify which type of filter to use with

imaqAttenuate() or imaqTruncate(). Lowpass filters smooth

noise, details, textures, and sharp edges in an image. Highpass filters

emphasize details, textures, and sharp edges in images, but they also

emphasize noise.

• Lowpass attenuation—The amount of attenuation is directly

proportional to the frequency information. At low frequencies,

there is little attenuation. As the frequencies increase, the

IMAQ Vision for LabWindows/CVI User Manual 2-12 ni.com

Page 29

Chapter 2 Getting Measurement-Ready Images

attenuation increases. This operation preserves all of the zero

frequency information. Zero frequency information corresponds

to the DC component of the image or the average intensity of

the image in the spatial domain.

• Highpass attenuation—The amount of attenuation is inversely

proportional to the frequency information. At high frequencies,

there is little attenuation. As the frequencies decrease, the

attenuation increases. The zero frequency component is removed

entirely.

• Lowpass truncation—Frequency components above the ideal

cutoff frequency are removed, and the frequencies below it remain

unaltered.

• Highpass truncation—Frequency components above the ideal

cutoff frequency remain unaltered, and the frequencies below it

are removed.

3. To transform your image back to the spatial domain, use

imaqInverseFFT().

Complex Image Operations

The imaqExtractComplexPlane() and

imaqReplaceComplexPlane() functions allow you to access, process,

and update independently the real and imaginary planes of a complex

image. You can also convert planes of a complex image to an array

and back with

imaqArrayToComplexPlane().

imaqComplexPlaneToArray() and

© National Instruments Corporation 2-13 IMAQ Vision for LabWindows/CVI User Manual

Page 30

Making Grayscale and Color

Measurements

This chapter describes how to take measurements from grayscale and color

images. You can make inspection decisions based on image statistics, such

as the mean intensity level in a region. Based on the image statistics, you

can perform many machine vision inspection tasks on grayscale or color

images, such as detecting the presence or absence of components, detecting

flaws in parts, and comparing a color component with a reference.

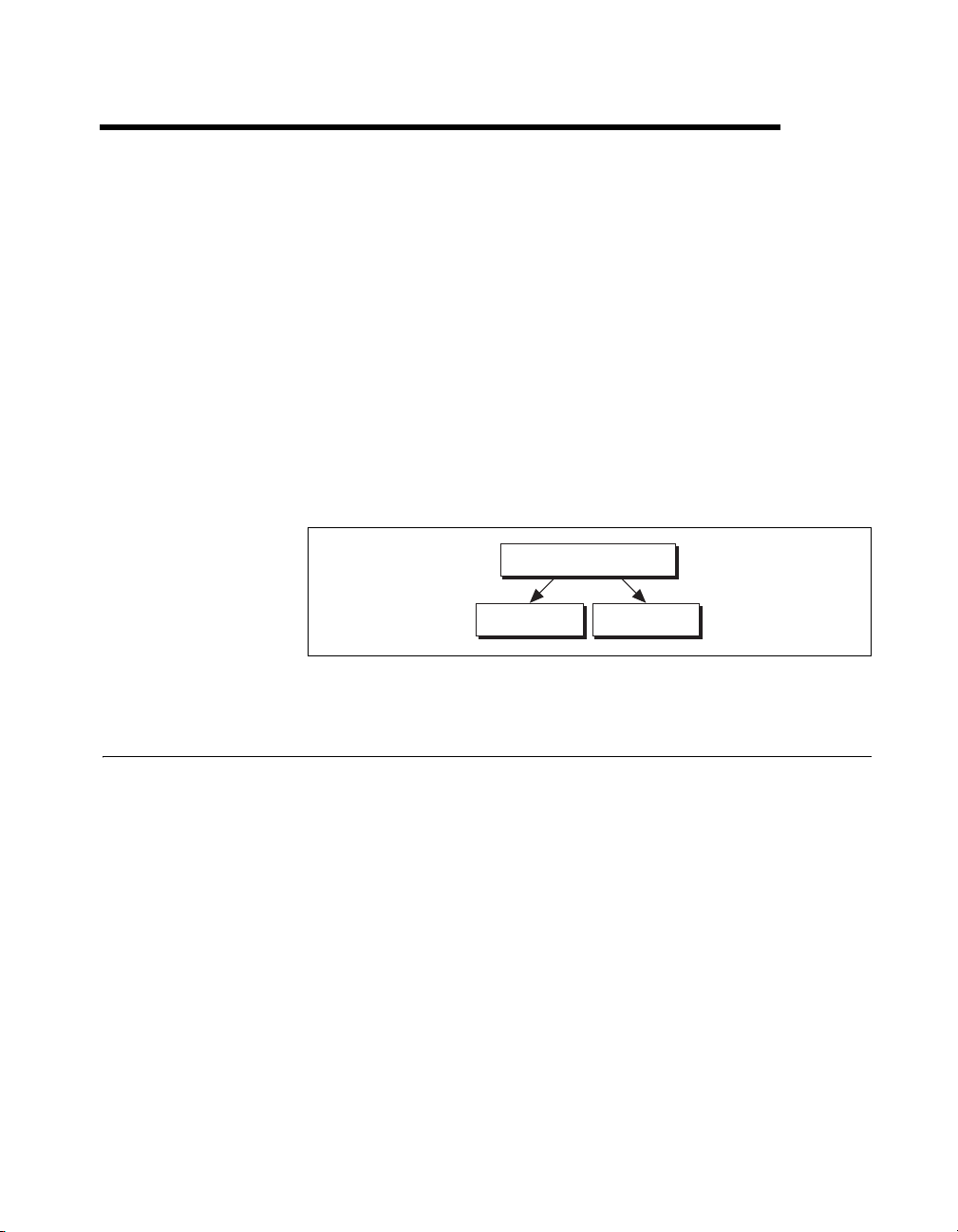

Figure 3-1 illustrates the basic steps involved in making grayscale and

color measurements.

Define Regions of Interest

3

Figure 3-1. Steps to Taking Grayscale and Color Measurements

Define Regions of Interest

A region of interest (ROI) is an area of an image in which you want

to focus your image analysis. You can define an ROI interactively,

programmatically, or with an image mask.

Defining Regions Interactively

You can interactively define an ROI in a window that displays an image.

Use the tools from the IMAQ Vision tools palette to interactively define and

manipulate an ROI.

Measure

Grayscale Statistics

Measure

Color Statistics

© National Instruments Corporation 3-1 IMAQ Vision for LabWindows/CVI User Manual

Page 31

Chapter 3 Making Grayscale and Color Measurements

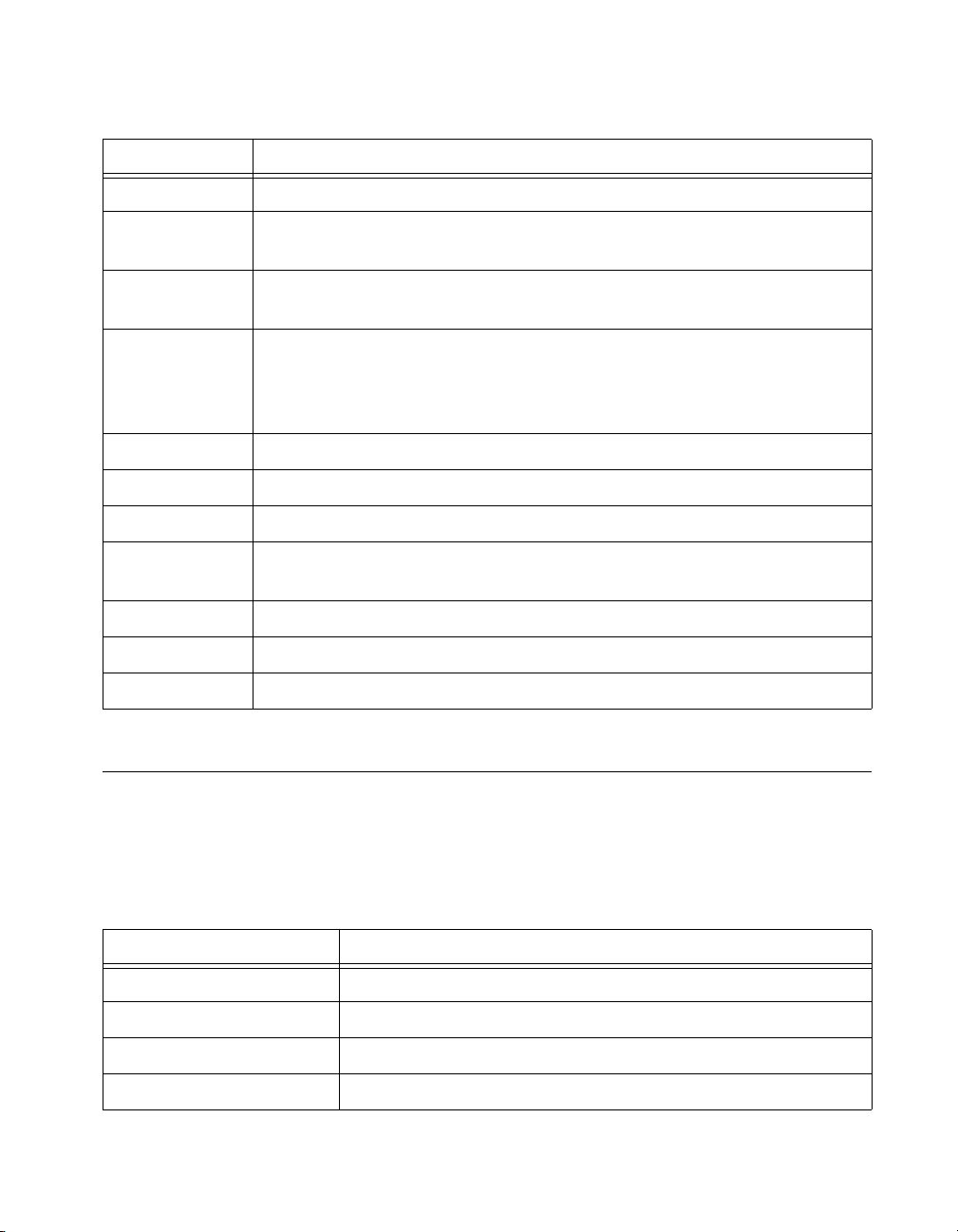

Table 3-1 describes each of the tools and the manner in which you use

them.

Table 3-1. Tools Palette Functions

Icon Tool Name Function

Selection Tool Select an ROI in the image and adjust the position of its control

points and contours.

Action: Click the desired ROI or control points.

Point Select a pixel in the image.

Action: Click the desired position.

Line Draw a line in the image.

Action: Click the initial position, move the cursor to the final

position, and click again.

Rectangle Draw a rectangle or square in the image.

Action: Click one corner and drag to the opposite corner.

Rotated Rectangle Draw a rotated rectangle in the image.

Action: Click one corner and drag to the opposite corner to create

the rectangle. Then, click the lines inside the rectangle and drag

to adjust the rotation angle.

Oval Draw an oval or circle in the image.

Action: Click the center position and drag to the desired size.

Annulus Draw an annulus in the image.

Action: Click the center position and drag to the desired size.

Adjust the inner and outer radii, and adjust the start and end

angles.

Broken Line Draw a broken line in the image.

Action: Click to place a new vertex and double-click to complete

the ROI element.

Polygon Draw a polygon in the image.

Action: Click to place a new vertex and double-click to complete

the ROI element.

IMAQ Vision for LabWindows/CVI User Manual 3-2 ni.com

Page 32

Chapter 3 Making Grayscale and Color Measurements

Table 3-1. Tools Palette Functions (Continued)

Icon Tool Name Function

Freehand Line Draw a freehand line in the image.

Action: Click the initial position, drag to the desired shape,

and release the mouse button to complete the shape.

Freehand Region Draw a freehand region in the image.

Action: Click the initial position, drag to the desired shape,

and release the mouse button to complete the shape.

Zoom Zoom-in or zoom-out in an image.

Action: Click the image to zoom in. Hold down the <Shift> key

and click to zoom out.

Pan Pan around an image.

Action: Click an initial position, drag to the desired position,

and release the mouse button to complete the pan.

Hold down the <Shift> key while drawing an ROI to constrain the ROI to

the horizontal, vertical, or diagonal axes. Use the Selection Tool to position

an ROI by its control points or vertices. ROIs are context sensitive, meaning

that the cursor actions differ depending on the ROI with which you interact.

For example, if you move your cursor over the side of a rectangle, the

cursor changes to indicate that you can click and drag the side to resize the

rectangle. If you want to draw more than one ROI in a window, hold down

the <Ctrl> key while drawing additional ROIs.

© National Instruments Corporation 3-3 IMAQ Vision for LabWindows/CVI User Manual

Page 33

Chapter 3 Making Grayscale and Color Measurements

You can display the IMAQ Vision tools palette as part of an ROI

constructor window or in a separate, floating window. Follow these steps

to invoke an ROI constructor and define an ROI from within the ROI

constructor window:

1. Use

imaqConstructROI2() to display an image and the tools palette

in an ROI constructor window, as shown in Figure 3-2.

Figure 3-2. ROI Constructor

2. Select an ROI tool from the tools palette.

3. Draw an ROI on your image. Resize and reposition the ROI until it

designates the area you want to inspect.

4. Click OK to output a descriptor of the region you selected. You can

input this ROI descriptor into many analysis and processing functions.

You can also convert the ROI descriptor into an image mask, which

you can use to process selected regions in the image. Use

imaqROIToMask() to convert the ROI descriptor into an image mask.

You can also use

imaqSelectRect(), and imaqSelectAnnulus() to define regions

imaqSelectPoint(), imaqSelectLine(),

of interest. Complete the following steps to use these functions.

1. Call the function to display an image in an ROI Constructor window.

Only the tools specific to that function are available for you to use.

2. Draw an ROI on your image. Resize or reposition the ROI until it

covers the area you want to process.

IMAQ Vision for LabWindows/CVI User Manual 3-4 ni.com

Page 34

Chapter 3 Making Grayscale and Color Measurements

3. Click OK to populate a structure representing the ROI. You can use

this structure as an input to a variety of functions, such as the following

functions that measure grayscale intensity.

•

imaqLightMeterPoint()—Uses the output of

imaqSelectPoint()

• imaqLightMeterLine()—Uses the output of

imaqSelectLine()

• imaqLightMeterRect()—Uses the output of

imaqSelectRect()

Tools Palette Transformation

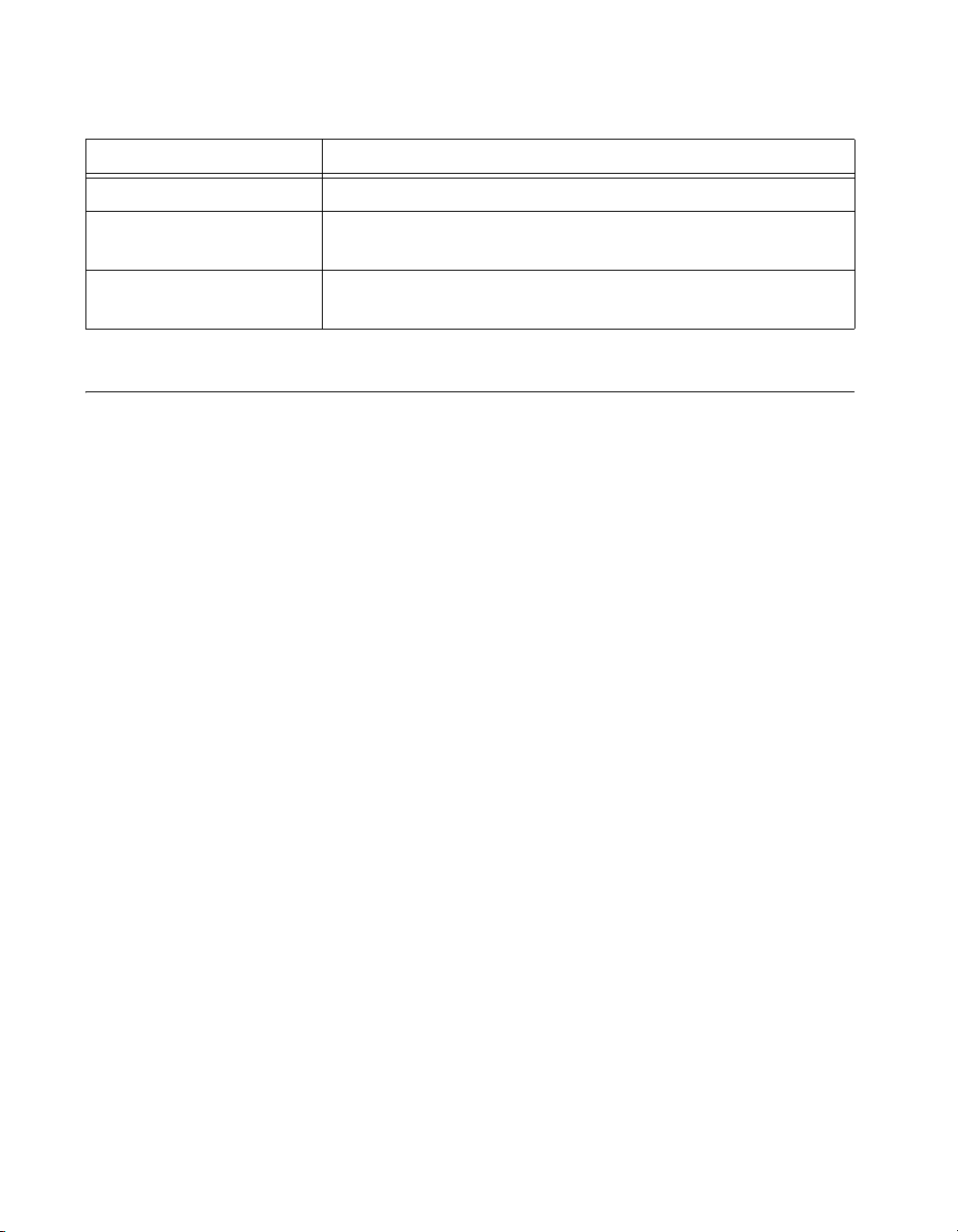

The tools palette, shown in Figure 3-3, automatically transforms from the

palette on the left to the palette on the right when you manipulate an ROI

tool in an image window. The palette on the right displays the

characteristics of the ROI you are drawing.

Pixel Intensity

Image-type indicator (8-bit, 16-bit, Float, RGB, HSL, Complex)

Coordinates of the mouse

on the active image window

Anchoring coordinates of a Region of Interest

Size of an active Region of Interest

Length and horizontal angle

of a line region

Figure 3-3. Tools Palette Tools and Information

© National Instruments Corporation 3-5 IMAQ Vision for LabWindows/CVI User Manual

Page 35

Chapter 3 Making Grayscale and Color Measurements

The following list describes how you can display the tools palette in a

separate window and manipulate the palette.

•Use

imaqShowToolWindow() to display the tools palette in a floating

window.

•Use

imaqSetupToolWindow() to configure the appearance of the

tools palette.

•Use

•Use

imaqMoveToolWindow() to move the tools palette.

imaqCloseToolWindow() to close the tools palette.

If you want to draw an ROI without using an ROI constructor or displaying

the tools palette in a separate window, use

This function allows you to select a contour from the tools palette without

opening the palette.

Defining Regions Programmatically

When you have an automated application, you may need to define regions

of interest programmatically. To programmatically define an ROI, create

the ROI using

A contour is a shape that defines an ROI. You can create contours from

points, lines, rectangles, ovals, polygons, and annuli. For example, to add a

rectangular contour to an ROI, use

imaqCreateROI(), and then add the individual contours.

imaqSetCurrentTool().

imaqAddRectContour().

Specify regions by providing basic parameters that describe the region you

want to define. For example, define a point by providing the x-coordinate

and y-coordinate. Define a line by specifying the start and end coordinates.

Define a rectangle by specifying the coordinates of the top, left point; the

width and height; and in the case of a rotated rectangle, the rotation angle.

Defining Regions with Masks

You can define regions to process with image masks. An image mask is

an 8-bit image of the same size as or smaller than the image you want to

process. Pixels in the mask image determine whether the corresponding

pixel in the source image needs to be processed. If a pixel in the image

mask has a value different than 0, the corresponding pixel in the source

image is processed. If a pixel in the image mask has a value of 0, the

corresponding pixel in the source image is left unchanged.

When you need to make intensity measurements on particles in an image,

you can use a mask to define the particles. First, threshold your image to

make a new binary image. For more information about binary images, refer

to Chapter 4, Performing Particle Analysis. You can input the binary image

IMAQ Vision for LabWindows/CVI User Manual 3-6 ni.com

Page 36

or a labeled version of the binary image as a mask image to the intensity

measurement function. If you want to make color comparisons, convert the

binary image into an ROI descriptor using

Measure Grayscale Statistics

You can measure grayscale statistics in images using light meters or

quantitative analysis functions. You can obtain the center of energy for

an image with the centroid function.

Use

imaqLightMeterPoint() to measure the light intensity at a

point in the image. Use

statistics along a line in the image, such as mean intensity,

standard deviation, minimum intensity, and maximum intensity.

Use

imaqLightMeterRect() to get the pixel value statistics within

a rectangular region in an image.

Use

imaqQuantify() to obtain the following statistics about the entire

image or individual regions in the image: mean intensity, standard

deviation, minimum intensity, maximum intensity, area, and the percentage

of the image that you analyzed. You can specify regions in the image with

a labeled image mask. A labeled image mask is a binary image that has

been processed so that each region in the image mask has a unique intensity

value. Use

imaqLabel2() to label your image mask.

imaqLightMeterLine() to get pixel value

Chapter 3 Making Grayscale and Color Measurements

imaqMaskToROI().

Use

imaqCentroid() to compute the energy center of the image, or of a

region within an image.

Measure Color Statistics

Most image processing and analysis functions apply to 8-bit images.

However, you can analyze and process individual components of a color

image.

Using

imaqExtractColorPlanes(), you can break down a color image

into various sets of primary components, such as RGB (Red, Green, and

Blue), HSI (Hue, Saturation, and Intensity), HSL (Hue, Saturation, and

Luminance), or HSV (Hue, Saturation, and Value). Each component

becomes an 8-bit or 16-bit image that you can process like any other

grayscale image. Using

reassemble a color image from a set of three 8-bit or 16-bit images, where

each image becomes one of the three primary components. Figures 3-4

and 3-5 illustrate how a color image breaks down into its three primary

components.

© National Instruments Corporation 3-7 IMAQ Vision for LabWindows/CVI User Manual

imaqReplaceColorPlanes(), you can

Page 37

Chapter 3 Making Grayscale and Color Measurements

Color

Image

32

Red

Green

Blue

Hue

or

Saturation

Intensity

Hue

Saturation

or

Luminance

Hue

or

Saturation

Value

8

8

8

8

8

8

8

8

8

8

8

8

8-bit Image Processing

8

8

8

8

8

8

8

8

8

8

8

8

Red

Green

Blue

Hue

Saturation

Intensity

Hue

Saturation

Luminance

Hue

Saturation

Value

or

Color

Image

32

or

or

Figure 3-4. Primary Components of a 32-Bit Color Image

16

Color

Image

1664

Red

Green

Blue

161616

16

16

16-bit

Image

Processing

16161616

16

16

Red

Green

Blue

1664

Color

Image

Figure 3-5. Primary Components of a 64-Bit Color Image

Use imaqExtractColorPlanes() to extract the red, green, blue, hue

saturation, intensity, luminance, or value plane of a color image into an

8-bit image.

Note You can also use imaqExtractColorPlanes() to process the red, green, and blue

components of a 64-bit image.

IMAQ Vision for LabWindows/CVI User Manual 3-8 ni.com

Page 38

Comparing Colors

Chapter 3 Making Grayscale and Color Measurements

You can use the color matching capability of IMAQ Vision to compare or

evaluate the color content of an image or regions in an image.

Complete the following steps to compare colors using color matching:

1. Select an image containing the color information that you want to use

as a reference. The color information can consist of a single color or

multiple dissimilar colors, such as red and blue.

2. Use the entire image or regions in the image to learn the color

information using

spectrum that contains a compact description of the color information

in an image or ROI. Use the color spectrum to represent the learned

color information for all subsequent matching operations.

Refer to Chapter 14, Color Inspection, of the IMAQ Vision Concepts

Manual for more information about color learning.

3. Define an entire image, a region, or multiple regions in an image as the

inspection or comparison area.

4. Use

5. Use the color matching score as a measure of similarity between the

imaqMatchColor() to compare the learned color information to

the color information in the inspection regions. This function returns

an array of scores that indicates how close the matches are to the

learned color information.