Page 1

™

IMAQ

IMAQ PCI/PXI™-1409 User Manual

High-Quality Monochrome Image Acquisition Boards

for PCI, PXI, and CompactPCI Bus

IMAQ PCI/PXI-1409 User Manual

November 2000 Edition

Part Number 322811A-01

Page 2

Worldwide Technical Support and Product Information

ni.com

National Instruments Corporate Headquarters

11500 North Mopac Expressway Austin, Texas 78759-3504 USA Tel: 512 794 0100

Worldwide Offices

Australia 03 9879 5166, Austria 0662 45 79 90 0, Belgium 02 757 00 20, Brazil 011 284 5011,

Canada (Calgary) 403 274 9391, Canada (Ontario) 905 785 0085, Canada (Québec) 514 694 8521,

China 0755 3904939, Denmark 45 76 26 00, Finland 09 725 725 11, France 01 48 14 24 24,

Germany 089 741 31 30, Greece 30 1 42 96 427, Hong Kong 2645 3186, India 91805275406,

Israel 03 6120092, Italy 02 413091, Japan 03 5472 2970, Korea 02 596 7456, Mexico (D.F.) 5 280 7625,

Mexico (Monterrey) 8 357 7695, Netherlands 0348 433466, Norway 32 27 73 00, Poland 48 22 528 94 06,

Portugal 351 1 726 9011, Singapore 2265886, Spain 91 640 0085, Sweden 08 587 895 00,

Switzerland 056 200 51 51, Taiwan 02 2377 1200, United Kingdom 01635 523545

For further support information, see the Technical Support Resources appendix. To comment on the

documentation, send e-mail to techpubs@ni.com

© Copyright 2000 National Instruments Corporation. All rights reserved.

Page 3

Important Information

Warranty

The IMAQ PCI-1409 and PXI-1409 are warranted against defects in materials and workmanship for a period of one year from the

date of shipment, as evidenced by receipts or other documentation. National Instruments will, at its option, repair or replace

equipment that proves to be defective during the warranty period. This warranty includes parts and labor.

The media on which you receive National Instruments software are warranted not to fail to execute programming instructions,

due to defects in materials and workmanship, for a period of 90 days from date of shipment, as evidenced by receipts or other

documentation. National Instruments will, at its option, repair or replace software media that do not execute programming

instructions if National Instruments receives notice of such defects during the warranty period. National Instruments does not

warrant that the operation of the software shall be uninterrupted or error free.

A Return Material Authorization (RMA) number must be obtained from the factory and clearly marked on the outside of

the package before any equipment will be accepted for warranty work. National Instruments will pay the shipping costs of

returning to the owner parts which are covered by warranty.

National Instruments believes that the information in this document is accurate. The document has been carefully reviewed

for technical accuracy. In the event that technical or typographical errors exist, National Instruments reserves the right to

make changes to subsequent editions of this document without prior notice to holders of this edition. The reader should consult

National Instruments if errors are suspected. In no event shall National Instruments be liable for any damages arising out of

or related to this document or the information contained in it.

E

XCEPT AS SPECIFIED HEREIN,NATIONAL INSTRUMENTS MAKES NO WARRANTIES, EXPRESS OR IMPLIED, AND SPECIFICALLY DISCLAIMS ANY

WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE

NEGLIGENCE ON THE PART OF

INSTRUMENTS WILL NOT BE LIABLE FOR DAMAGES RESULTING F ROM LOSS OF DATA, PROFITS, USE OF PRODUCTS, OR INCIDENTAL OR

CONSEQUENTIAL DAMAGES

apply regardless of the form of action, whether in contract or tort, including negligence. Any action against National Instruments

must be brought within one year after the cause of action accrues. National Instruments shall not be liable for any delay in

performance due to causes beyond its reasonable control. The warranty provided herein does not cover damages, defects,

malfunctions, or service failures caused by owner’s failure to follow the National Instruments installation, operation, or

maintenance instructions; owner’s modification of the product; owner’s abuse, misuse, or negligent acts; and power failure or

surges, fire, flood, accident, actions of third parties, or other events outside reasonable control.

NATIONAL INSTRUMENTS SHALL BE LIMITED TO THE AMOUNT THERETOFORE PAID BY THE CUSTOMER.NATIONAL

, EVEN IF ADVISED OF THE POSSIBILITY THEREOF. This limitation of the liability of National Instruments will

.CUSTOMER’S RIGHT TO RECOVER DAMAGES CAUSED BY FAULT OR

Copyright

Under the copyright laws, this publication may not be reproduced or transmitted in any form, electronic or mechanical, including

photocopying, recording, storing in an information retrieval system, or translating, in whole or in part, without the prior written

consent of National Instruments Corporation.

Trademarks

CVI™,IMAQ™,LabVIEW™,MITE™, National Instruments™,ni.com™, NI-IMAQ™,PXI™,andRTSI™are trademarks of

National Instruments Corporation.

Product and company names mentioned herein are trademarks or trade names of their respective companies.

WARNING REGARDING USE OF NATIONAL INSTRUMENTS PRODUCTS

(1) NATIONAL INSTRUMENTS PRODUCTS ARENOT DESIGNED WITH COMPONENTS AND TESTING FOR A LEVEL

OF RELIABILITY SUITABLE FOR USE IN OR IN CONNECTION WITH SURGICAL IMPLANTS OR AS CRITICAL

COMPONENTS IN ANY LIFE SUPPORT SYSTEMS WHOSE FAILURE TO PERFORM CAN REASONABLY BE

EXPECTED TO CAUSE SIGNIFICANT INJURY TO A HUMAN.

(2) IN ANY APPLICATION, INCLUDING THE ABOVE, RELIABILITY OF OPERATION OFTHE SOFTWARE PRODUCTS

CAN BE IMPAIRED BY ADVERSE FACTORS, INCLUDING BUT NOT LIMITED TO FLUCTUATIONS IN ELECTRICAL

POWER SUPPLY, COMPUTER HARDWARE MALFUNCTIONS, COMPUTER OPERATING SYSTEM SOFTWARE

FITNESS, FITNESS OF COMPILERS AND DEVELOPMENT SOFTWARE USED TO DEVELOP AN APPLICATION,

INSTALLATION ERRORS, SOFTWARE AND HARDWARE COMPATIBILITY PROBLEMS, MALFUNCTIONS OR

FAILURES OF ELECTRONIC MONITORING OR CONTROL DEVICES, TRANSIENT FAILURES OF ELECTRONIC

SYSTEMS (HARDWARE AND/OR SOFTWARE), UNANTICIPATED USES ORMISUSES, ORERRORS ON THE PART OF

THE USER OR APPLICATIONS DESIGNER (ADVERSE FACTORS SUCH AS THESE ARE HEREAFTER

COLLECTIVELY TERMED “SYSTEM FAILURES”). ANY APPLICATION WHERE A SYSTEM FAILURE WOULD

CREATE A RISK OF HARM TO PROPERTY OR PERSONS (INCLUDING THE RISK OF BODILY INJURY AND DEATH)

SHOULD NOT BE RELIANT SOLELY UPON ONE FORM OF ELECTRONIC SYSTEM DUE TO THE RISK OF SYSTEM

FAILURE. TO AVOID DAMAGE, INJURY, OR DEATH, THE USER OR APPLICATION DESIGNER MUST TAKE

REASONABLY PRUDENT STEPS TO PROTECT AGAINST SYSTEM FAILURES, INCLUDING BUT NOT LIMITED TO

BACK-UP OR SHUT DOWN MECHANISMS. BECAUSE EACH END-USER SYSTEM IS CUSTOMIZED AND DIFFERS

FROM NATIONAL INSTRUMENTS' TESTING PLATFORMS AND BECAUSE A USER OR APPLICATION DESIGNER

MAY USE NATIONAL INSTRUMENTS PRODUCTS IN COMBINATION WITH OTHER PRODUCTS IN A MANNER NOT

EVALUATED OR CONTEMPLATED BY NATIONAL INSTRUMENTS, THE USER OR APPLICATION DESIGNER IS

ULTIMATELY RESPONSIBLE FOR VERIFYING AND VALIDATING THE SUITABILITY OF NATIONAL

INSTRUMENTS PRODUCTS WHENEVER NATIONAL INSTRUMENTS PRODUCTS ARE INCORPORATED IN A

SYSTEM OR APPLICATION, INCLUDING, WITHOUT LIMITATION, THE APPROPRIATE DESIGN, PROCESS AND

SAFETY LEVEL OF SUCH SYSTEM OR APPLICATION.

Page 4

Compliance

FCC/Canada Radio Frequency Interference Compliance*

Determining FCC Class

The Federal Communications Commission (FCC) has rules to protect wireless communications from interference.

The FCC places digital electronics into two classes. These classes are known as Class A (for use in industrialcommercial locations only) or Class B (for use in residential or commercial locations). Depending on where it is

operated, this product could be subject to restrictions in the FCC rules. (In Canada, the Department of

Communications (DOC), of Industry Canada, regulates wireless interference in much the same way.)

Digital electronics emit weak signals during normal operation that can affect radio, television, or other wireless

products. By examining the product you purchased, you can determine the FCC Class and therefore which of the two

FCC/DOC Warnings apply in the following sections. (Some products may not be labeled at all for FCC; if so, the

reader should then assume these are Class A devices.)

FCC Class A products only display a simple warning statement of one paragraph in lengthregarding interference and

undesired operation. Most of our products are FCC Class A. The FCC rules have restrictions regarding the locations

where FCC Class A products can be operated.

FCC Class B products display either a FCC ID code, starting with the letters EXN,

or the FCC Class B compliance mark that appears as shown here on the right.

Consult the FCC web site

http://www.fcc.gov

FCC/DOC Warnings

This equipment generates and uses radio frequency energy and, if not installed and used in strict accordance with the

instructions in this manual and the CE Mark Declaration of Conformity**, may cause interference to radio and

television reception. Classification requirements are the same for the Federal Communications Commission (FCC)

and the Canadian Department of Communications (DOC).

Changes or modifications not expressly approved by National Instruments could void the user’s authority to operate

the equipment under the FCC Rules.

Class A

Federal Communications Commission

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to part 15

of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference when the

equipment is operated in a commercial environment. This equipment generates, uses, and can radiate radio frequency

energy and, if not installed and used in accordance with the instruction manual, may cause harmful interference to

radio communications. Operation of this equipment in a residential area is likely to cause harmful interference in

which case the user will be required to correct the interference at his own expense.

for more information.

Canadian Department of Communications

This Class A digital apparatus meets all requirements of the Canadian Interference-Causing Equipment Regulations.

Cet appareil numérique de la classe A respecte toutes les exigences du Règlement sur le matériel brouilleur du

Canada.

Class B

Federal Communications Commission

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to part 15

of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference in a

residential installation. This equipment generates, uses and can radiate radio frequency energy and, if not installed

and used in accordance with the instructions, may cause harmful interference to radio communications. However,

there is no guarantee that interference will not occur in a particular installation. If this equipment does cause harmful

interference to radio or television reception, which can be determined by turning the equipment off and on, the user

is encouraged to try to correct the interference by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

Page 5

• Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

• Consult the dealer or an experienced radio/TV technician for help.

Canadian Department of Communications

This Class B digital apparatus meets all requirements of the Canadian Interference-Causing Equipment Regulations.

Cet appareil numérique de la classe B respecte toutes les exigences du Règlement sur le matériel brouilleur du

Canada.

European Union - Compliance to EEC Directives

Readers in the EU/EEC/EEA must refer to the Manufacturer's Declaration of Conformity (DoC) for information**

pertaining to the CE Mark compliance scheme. The Manufacturer includes a DoC for most every hardware product

except for those bought for OEMs, if also available from an original manufacturer that also markets in the EU, or

where compliance is not required as for electrically benign apparatus or cables.

* Certain exemptions may apply in the USA, see FCC Rules §15.103 Exempted devices,and§15.105(c).

Also available in sections of CFR 47.

** The CE Mark Declaration of Conformity will contain important supplementary information and instructions

for the user or installer.

Page 6

Conventions

The following conventions are used in this manual:

♦ The ♦ symbol indicates that the following text applies only to a specific

product, a specific operating system, or a specific software version.

This icon denotes a note, which alerts you to important information.

This icon denotes a warning, which advises you of precautions to take to

avoid being electrically shocked.

italic Italic text denotes variables, emphasis, a cross reference, or an introduction

to a key concept. This font also denotes text that is a placeholder for a word

or value that you must supply.

Page 7

Contents

Chapter 1

Introduction

About Your 1409 Device...............................................................................................1-1

Using PXI with CompactPCI.........................................................................................1-2

Software Programming Choices ....................................................................................1-3

NI-IMAQ Driver Software..............................................................................1-4

National Instruments IMAQ Vision ................................................................1-5

IMAQ Vision Builder......................................................................................1-5

Integration with DAQ......................................................................................1-6

Vision and Motion...........................................................................................1-6

Chapter 2

Configuration and Installation

What You Need to Get Started ......................................................................................2-1

Optional Equipment.......................................................................................................2-2

How to Set up Your IMAQ System...............................................................................2-2

Unpacking......................................................................................................................2-4

Board Configuration ......................................................................................................2-4

VIDEO0 Input Mode....................................................................................... 2-6

Installation .....................................................................................................................2-7

Chapter 3

Hardware Overview

Functional Overview...................................................................................................... 3-1

Video Mux.......................................................................................................3-2

Programmable Gain and Offset.......................................................................3-2

Analog Bandwidth Control Circuitry .............................................................. 3-2

10-Bit ADC .....................................................................................................3-2

Digital Filter and LUT.....................................................................................3-3

Onboard Memory ............................................................................................3-3

Scatter-Gather DMA Controllers ....................................................................3-3

PCI Interface.................................................................................................... 3-3

Genlock Circuit and SYNC Mux .................................................................... 3-3

Acquisition and Region-of-Interest (ROI) Control .........................................3-4

RTSI Bus .........................................................................................................3-4

Digital Input/Output Circuitry.........................................................................3-4

Acquisition Modes.........................................................................................................3-4

© National Instruments Corporation vii IMAQ PCI/PXI-1409 User Manual

Page 8

Contents

Analog Front End Considerations ................................................................................. 3-5

10-bit/8-bit Mode ............................................................................................ 3-5

Chapter 4

Signal Connections

BNC Connector ............................................................................................................. 4-1

I/O Connector ................................................................................................................4-1

I/O Connector Signal Connection Descriptions.............................................. 4-3

Appendix A

Specifications

Appendix B

Custom Cables

Appendix C

Technical Support Resources

Glossary

Index

Figures

Figure 1-1. The Relationship between the Programming Environment,

Figure 1-2. NI-IMAQ Functions.............................................................................. 1-4

Figure 1-3. IMAQ Vision Builder and Application Development Tools................ 1-5

Figure 2-1. How to Set up Your IMAQ System...................................................... 2-3

Figure 2-2. PCI-1409 Parts Locator Diagram.......................................................... 2-5

Figure 2-3. Configuring VIDEO0 with Jumper W1................................................ 2-6

Figure 3-1. 1409 Device Block Diagram................................................................. 3-2

Figure 3-2. IMAQ PCI/PXI-1409 Analog Front End.............................................. 3-5

Figure 4-1. BNC Connector Pin Assignment .......................................................... 4-1

Figure 4-2. I/O Connector Pin Assignments............................................................ 4-2

NI-IMAQ, and Your Hardware............................................................. 1-3

IMAQ PCI/PXI-1409 User Manual viii ni.com

Page 9

Tables

Contents

Table 1-1. Pins Used by the PXI-1409 Device.......................................................1-2

Table 4-1. I/O Connector Signals ...........................................................................4-3

© National Instruments Corporation ix IMAQ PCI/PXI-1409 User Manual

Page 10

Introduction

This chapter describes the PCI-1409 and PXI-1409 devices and describes

your software programming choices.

About Your 1409 Device

The PCI-1409 and PXI-1409 devices are high-accuracy, monochrome,

IMAQ boards for PCI, PXI, or CompactPCI chassis that support RS-170,

CCIR, NTSC, and PAL video standards as well as some nonstandard

cameras from any of four input sources. The boards feature a 10-bit

analog-to-digital converter (ADC) that converts video signals to digital

formats. The PCI-1409 acquires images in real time and can store these

images in onboard frame memory or transfer these images directly to

system memory.

The 1409 device is simple to configure so that you can easily install the

board and begin your image acquisition. The 1409 device ships with

NI-IMAQ, the National Instruments complete image acquisition driver

software you can use to directly control your 1409 device. Using NI-IMAQ,

you can quickly and easily start your application without having to program

the board at the register level.

1

Featuring low cost and high accuracy, the 1409 device is ideal for

both industrial and scientific environments. As a standalone board, the

1409 device supports four general purpose control lines that you can

configure to generate precise timing signals for controlling camera

acquisition. The 1409 device also supports four video sources and four

external I/O lines that you can use as triggers or digital I/O lines. If you

require more advanced triggering or additional I/O lines (either digital or

analog), you can use the 1409 device and NI-IMAQ with the National

Instruments data acquisition (DAQ) product line.

A common problem with many image acquisition boards is that you cannot

easily synchronize several functions to a common trigger or timing event.

The 1409 device uses its Real-Time System Integration (RTSI) bus to solve

this problem. The RTSI bus consists of the National Instruments RTSI bus

© National Instruments Corporation 1-1 IMAQ PCI/PXI-1409 User Manual

Page 11

Chapter 1 Introduction

interface and ribbon cable to route additional timing and trigger signals

between the 1409 device and up to four National Instruments DAQ, Motion

Control, or other IMAQ boards in your computer.

Detailed specifications of the PCI-1409 and PXI-1409 are in Appendix A,

Specifications.

Using PXI with CompactPCI

Using PXI-compatible products with standard CompactPCI products is an

important feature provided by the PXI Specification, Revision 1.0. If you

use a PXI-compatible plug-in device in a standard CompactPCI chassis,

you will be unable to use PXI-specific functions, but you can still use the

basic plug-in device functions. For example, the RTSI bus on your

PXI-1409 device is available in a PXI chassis, but not in a CompactPCI

chassis.

The CompactPCI specification permits vendors to develop sub-buses that

coexist with the basic PCI interface on the CompactPCI bus. Compatible

operation is not guaranteed between CompactPCI devices with different

sub-buses nor between CompactPCI devices with sub-buses and PXI.

The standard implementation for CompactPCI does not include these

sub-buses. Your PXI-1409 device will work in any standard CompactPCI

chassis adhering to the PICMG 2.0 R2.1 CompactPCI core specification

using the 64-bit definition for J2.

PXI specific features are implemented on the J2 connector of the

CompactPCI bus. Table 1-1 lists the J2 pins your PXI-1409 device uses.

Your PXI device is compatible with any CompactPCI chassis with a

sub-bus that does not drive these lines. Even if the sub-bus is capable of

driving these lines, the PXI device is still compatible as long as those pins

on the sub-bus are disabled by default and not ever enabled. Damage may

result if these lines are driven by the sub-bus.

Table 1-1. Pins Used by the PXI-1409 Device

PXI-1409 Signal PXI Pin Name PXI J2 Pin Number

RTSI Trigger <0..6> PXI Trigger <0..6> B16, A16, A17, A18,

B18, C18, E18

IMAQ PCI/PXI-1409 User Manual 1-2 ni.com

Page 12

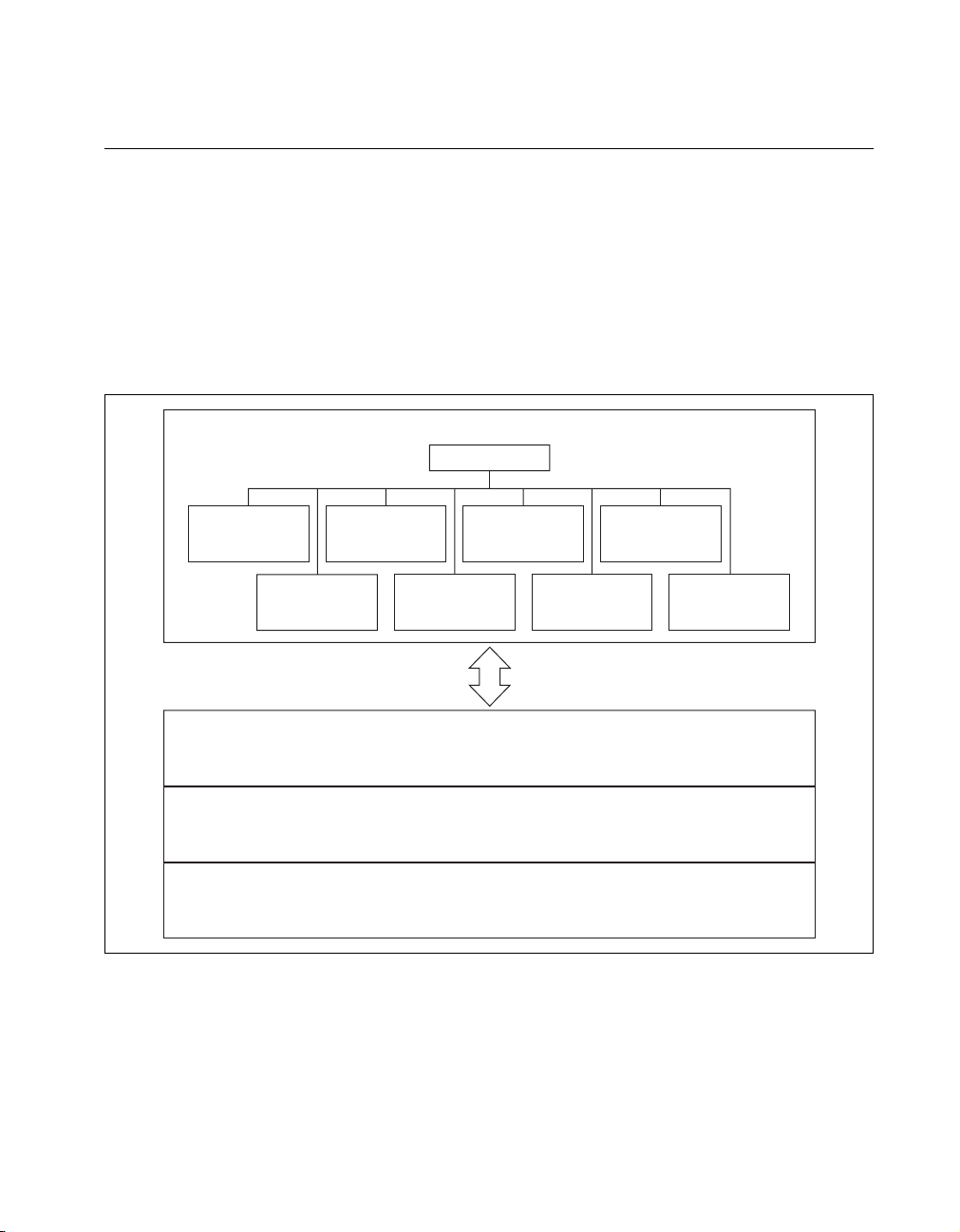

Software Programming Choices

Using NI-IMAQ, the National Instruments image acquisition driver

software, you can program your IMAQ board to acquire and save images.

You can use NI-IMAQ with other National Instruments software for a

complete image acquisition and analysis solution, as shown in Figure 1-1.

NI-IMAQ works with LabVIEW and LabWindows/CVI, as well

as conventional programming languages. National Instruments

IMAQ Vision adds powerful image processing and analysis to these

programming environments. You can also use IMAQ Vision Builder to

quickly and easily prototype your IMAQ image analysis applications.

Vision Software

IMAQ Vision

Chapter 1 Introduction

Image

Analysis

LabVIEW

Filters

Blob

Analysis

Color Matching

and Analysis

Application Software

Figure 1-1.

Pattern

Matching

(LabWindows/CVI, Visual C++, Visual Basic)

Driver Software

Hardware

DAQIMAQ

Gauging and

Measurement

Display

and ROI

Measurement Studio

NI-MotionNI-DAQNI-IMAQ

ValueMotion/

FlexMotion

Morphology

The Relationship between the Programming Environment,

NI-IMAQ, and Your Hardware

© National Instruments Corporation 1-3 IMAQ PCI/PXI-1409 User Manual

Page 13

Chapter 1 Introduction

NI-IMAQ Driver Software

The NI-IMAQ driver software is included with your IMAQ device.

NI-IMAQ has an extensive library of functions that you can call from your

application programming environment. These functions include routines

for video configuration, image acquisition (continuous and single-shot),

memory buffer allocation, trigger control, and board configuration, as

shown in Figure 1-2.

NI-IMAQ

Acquisition

Triggering

and Timing

DAQ

Synchronization

Buffer ControlImage

Figure 1-2. NI-IMAQ Functions

Camera Control Lookup Table

The NI-IMAQ driver software performs all of the functions required for

acquiring and saving images. The NI-IMAQ software does not perform any

image analysis. For image analysis functionality, refer to the National

Instruments IMAQ Vision section in this chapter.

NI-IMAQ has both high-level and low-level functions for maximum

flexibility and performance. Examples of high-level functions include the

functions to acquire images in single-shot or continuous mode. An example

of a low-level function is configuring an image sequence, since it requires

advanced understanding of your IMAQ device and image acquisition.

NI-IMAQ internally resolves many of the complex issues between the

computer and your IMAQ device, such as programming interrupts and

DMA controllers.

NI-IMAQ is also the interface path between LabVIEW, LabWindows/CVI,

or a conventional programming environment and your IMAQ device. The

NI-IMAQ software kit includes a series of libraries for image acquisition

for LabVIEW and Measurement Studio, which contains libraries for

LabWindows/CVI, Visual C++, and Visual Basic. These libraries are

functionally equivalent to the NI-IMAQ software.

Control

IMAQ PCI/PXI-1409 User Manual 1-4 ni.com

Page 14

National Instruments IMAQ Vision

IMAQ Vision is an image acquisition, processing, and analysis library of

more than 200 functions for grayscale, color, and binary image display,

image processing, pattern matching, shape matching, blob analysis,

gauging, and measurement.

You can use IMAQ Vision functions directly or in combination for unique

image processing. With IMAQ Vision you can acquire, display, manipulate,

and store images as well as perform image analysis, processing, and

interpretation. Using IMAQ Vision, an imaging novice or expert can

perform graphical programming of the most basic or complicated image

applications without knowledge of any algorithm implementations.

IMAQ Vision is available for LabVIEW and Measurement Studio, which

includes support for LabWindows/CVI, Visual C++, and Visual Basic.

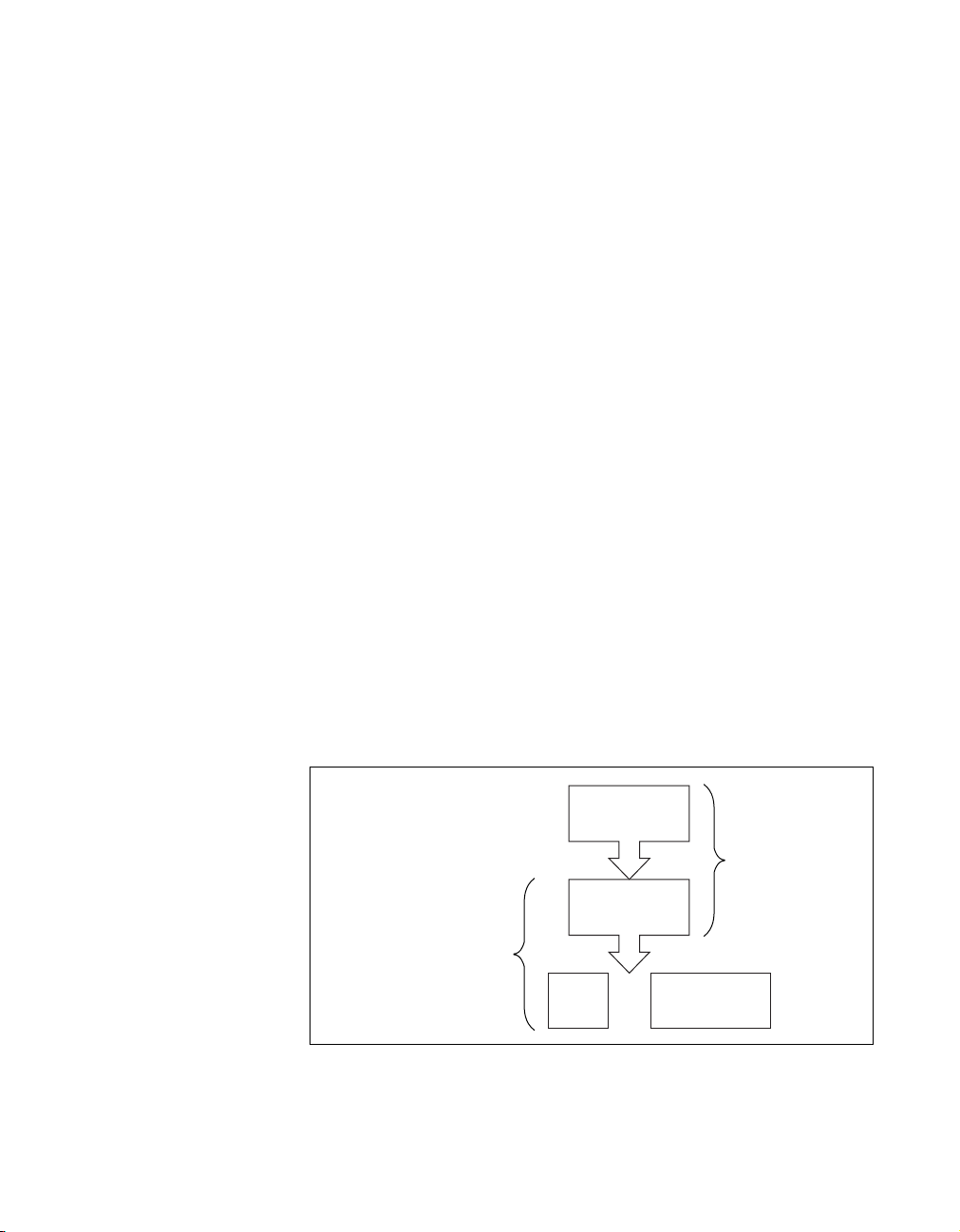

IMAQ Vision Builder

IMAQ Vision Builder is an interactive prototyping tool for machine vision

and scientific imaging developers. With IMAQ Vision Builder, you can

prototype vision software quickly or test how various vision image

processing functions work.

Chapter 1 Introduction

As shown in Figure 1-3, IMAQ Vision Builder generates a Builder file,

which is a text description that contains a recipe of the machine vision and

image processing functions. This Builder file provides a guide you can use

for developing applications with IMAQ Vision in LabVIEW or

Measurement Studio.

IMAQ

Vision Builder

Prototype

Builder File

Vision Application

Development

IMAQ

Vision

Figure 1-3. IMAQ Vision Builder and Application Development Tools

© National Instruments Corporation 1-5 IMAQ PCI/PXI-1409 User Manual

and

Application

Software

Page 15

Chapter 1 Introduction

Integration with DAQ

Any platform that supports NI-IMAQ also supports NI-DAQ and a variety

of National Instruments DAQ boards, allowing your IMAQ device and

NI-IMAQ development to integrate with National Instruments DAQ

products.

Vision and Motion

With National Instruments IMAQ hardware and IMAQ Vision pattern

matching software you can quickly and accurately locate objects in

instances where objects vary in size, orientation, focus, and even when the

part is poorly illuminated. Use National Instruments high-performance

stepper and servo motion control products with pattern matching software

in inspection and guidance applications such as locating alignment markers

on semiconductor wafers, guiding robotic arms, inspecting the quality of

manufactured parts, and locating cells.

IMAQ PCI/PXI-1409 User Manual 1-6 ni.com

Page 16

Configuration and Installation

This chapter lists what you need to get started acquiring images with your

IMAQ device; describes optional equipment and custom cables; and

explains how to unpack, configure, and install your IMAQ device.

What You Need to Get Started

To set up and use your 1409 device, you will need the following:

❑

One of the following 1409 devices:

– PCI-1409

– PXI-1409

Getting Started with Your IMAQ System

❑

❑

NI-IMAQ release notes

IMAQ PCI/PXI-1409 User Manual

❑

2

❑

NI-IMAQ for Windows 2000/NT/Me/9x and online documentation

❑

Optional software packages and documentation:

– IMAQ Vision for LabVIEW or Measurement Studio

(LabWindows/CVI, Visual C++, Visual Basic)

– IMAQ Vision Builder

– LabVIEW

– Measurement Studio (LabWindows/CVI, Tools for Visual Basic)

❑

IMAQ BNC-1 shielded, 75 Ω BNC cable for VIDEO0 (included with

the 1409 device)

❑

BNC-to-RCA adapter (included with your 1409 device)

© National Instruments Corporation 2-1 IMAQ PCI/PXI-1409 User Manual

Page 17

Chapter 2 Configuration and Installation

❑

Your Pentium-based PCI, PXI, or CompactPCI computer running

Windows 2000, Windows NT, Windows Me, Windows 98, or

Windows 95

❑

A video camera or other video source

Note

The IMAQ PCI-1409 and PXI-1409 devices rely on your computer’s PCI interface

chipset for the highest throughput to system memory. For the best results, your computer

should have a Pentium or better processor and an Intel 430 or 440 series or compatible PCI

interface chipset.

Optional Equipment

National Instruments offers a variety of products for use with your

PCI/PXI-1409 board, including the following cables and other National

Instruments products:

• IMAQ 6822 BNC breakout box and cable for trigger and additional

camera support

• RTSI bus cables for connecting the 1409 device to other IMAQ or DAQ

hardware

• Other National Instruments DAQ devices for enhanced triggering,

timing, or input/output

For more specific information about these products, refer to your National

Instruments catalog or Web site, or call the office nearest you.

How to Set up Your IMAQ System

Use Figure 2-1 as a guide while you install your software and hardware,

configure your hardware, and begin using NI-IMAQ in your application

programs.

Follow the instructions in the Getting Started with Your IMAQ System

document to install your NI-IMAQ software and IMAQ hardware.

If you will be accessing the NI-IMAQ device drivers through LabVIEW,

you should read the NI-IMAQ release notes and the NI-IMAQ User Manual

to help you get started.

IMAQ PCI/PXI-1409 User Manual 2-2 ni.com

Page 18

Chapter 2 Configuration and Installation

Read the

document and the NI-IMAQ release notes to install

LabVIEW

Read:

• The section in chapter 4 in the

NI-IMAQ User Manual

information on using LabVIEW

with your IMAQ hardware.

• NI-IMAQ VI online help

• Your IMAQ Vision for

LabVIEW documentation

if you are using IMAQ

Vision for LabVIEW

for

Getting Started with Your IMAQ System

your NI-IMAQ software, IMAQ hardware,

Measurement & Automation Explorer and

and documentation.

Configure your hardware using

online help.

What

application software

are you using?

Measurement

Studio

(Visual Basic)

Read

Getting Results with

(LabWindows/CVI, Visual C++,

ComponentWorks IMAQ Vision

for information on using

ComponentWorks in your

application environment.

Use the ComponentWorks

IMAQ Vision documentation

when you need specific

information about individual

NI-IMAQ functions.

Measurement Studio

Borland C++))

Read Chapter 1,

to NI-IMAQ

Introduction

, in the

NI-IMAQ User Manual

Read the sections in

chapters 2 and 3 in the

User Manual

will use in your application.

Look at the self-documented

example source code on your

distribution CD for your

application language

that apply to the

function groups you

and environment.

NI-IMAQ

.

Use the

Reference Manual

need specific information about

individual NI-IMAQ functions.

If you are using IMAQ Vision for

LabWindows/CVI, read the

documentation for IMAQ Vision

NI-IMAQ Function

when you

for LabWindows/CVI.

Figure 2-1. How to Set up Your IMAQ System

© National Instruments Corporation 2-3 IMAQ PCI/PXI-1409 User Manual

Page 19

Chapter 2 Configuration and Installation

Unpacking

Your 1409 device is shipped in an antistatic package to prevent

electrostatic damage to the board. Electrostatic discharge can damage

several components on the board. To avoid such damage in handling the

board, take the following precautions:

• Ground yourself via a grounding strap or by holding a grounded object.

• Touch the antistatic package to a metal part of your computer chassis

before removing the board from the package.

• Remove the board from the package and inspect the board for loose

components or any other signs ofdamage. Notify National Instruments

if the board appears damaged in any way. Do not install a damaged

board in your computer.

• Never touch the exposed pins of connectors.

Board Configuration

This section describes how to configure the VIDEO0 input mode on the

1409 device.

All other configuration options are software configurable.

IMAQ PCI/PXI-1409 User Manual 2-4 ni.com

Page 20

Chapter 2 Configuration and Installation

Figure 2-2 shows the locations of user-configurable jumpers and switches

as well as factory-default settings on the PCI-1409.

.

43

2

1

1 68-pin VHDCI

Connector

2 BNC Connector 3W1 4 RTSI Bus Connector

Figure 2-2. PCI-1409 Parts Locator Diagram

© National Instruments Corporation 2-5 IMAQ PCI/PXI-1409 User Manual

Page 21

Chapter 2 Configuration and Installation

VIDEO0 Input Mode

VIDEO0 has two different input sources via a BNC connector or a 68-pin

VHDCI port and two different input modes—referenced single-ended

(RSE) and differential (DIFF) input. When you use the BNC input for

VIDEO0, set the input mode to RSE (W1 populated). When you use

the 68-pin VHDCI port for VIDEO0, set the input mode for either RSE

or DIFF.

When in RSE mode, the video input uses one analog input line, which

connects to the video multiplexer circuitry. The negative input to the video

multiplexer is tied internally to analog ground. When in DIFF mode, the

video input uses two analog input signals. One signal connects to the

positive input of the video multiplexer circuitry while the other input

signal connects to the negative input of the video multiplexer circuitry.

Jumper W1 controls the input mode selection, as shown in Figure 2-3.

Unpopulating W1 configures VIDEO0 for DIFF mode. Populating W1

configures VIDEO0 for RSE mode.

a. RSE Mode (Default) b. DIFF Mode

Figure 2-3. Configuring VIDEO0 with Jumper W1

Video channels 1, 2, and 3 are always in differential mode. To take an RSE

measurement on these channels, tie the negative terminal of the connector

to ground (Pins 26 or 60 on the 68-pin VHDCI connector). See Chapter 4,

Signal Connections, for more information on pin assignments.

IMAQ PCI/PXI-1409 User Manual 2-6 ni.com

Page 22

Installation

Note

You must install the NI-IMAQ driver software before installing your 1409 device.

For information on how to install NI-IMAQ, please see the Getting Started with Your

IMAQ System document and your NI-IMAQ release notes.

Chapter 2 Configuration and Installation

♦ PCI-1409

You can install the PCI-1409 in any available PCI expansion slot in your

computer. However, to achieve the best noise performance, you should

leave as much room as possible between the PCI-1409 and other boards

and hardware. The following are general instructions, but consult your

computer user manual or technical reference manual for specific

instructions and warnings.

1. Turn off and unplug your computer.

Warning

should remain off and unplugged until you finish installing the 1409 device.

To protect both yourself and the computer from electrical hazards, the computer

2. Follow the electrostatic discharge guidelines in the Unpacking section

of this chapter.

3. Remove the cover of your computer.

4. Make sure there are no lighted LEDs on your motherboard. If any are

lit, wait until they go out before continuing your installation.

5. Touch the metal part of the power supply case inside the computer to

discharge any static electricity that might be on your clothes or body.

6. Select any available PCI expansion slot.

7. Locate the metal bracket that covers the cut-out in the back panel

of the chassis for the slot you have selected. Remove and save the

bracket-retaining screw and the bracket cover.

8. Line up the PCI-1409 with the 68-pin VHDCI and BNC connectors

near the cut-out on the back panel. Slowly push down on the top of the

PCI-1409 until its card-edge connector is resting on the expansion slot

receptacle. Using slow, evenly distributed pressure, press the PCI-1409

straight down until it seats in the expansion slot.

9. Reinstall the bracket-retaining screw to secure the PCI-1409 to the

back panel rail.

10. Check the installation.

11. Replace the computer cover.

© National Instruments Corporation 2-7 IMAQ PCI/PXI-1409 User Manual

Page 23

Chapter 2 Configuration and Installation

Your PCI-1409 is now installed.

♦ PXI-1409

You can install a PXI-1409 in any available 5 V peripheral slot in your PXI

or CompactPCI chassis.

Note

The PXI-1409 has connections to several reserved lines on the CompactPCI J2

connector. Before installing a PXI-1409 in a CompactPCI system that uses J2 connector

lines for purposes other than PXI, see Using PXI with CompactPCI, in Chapter 1,

Introduction, of this manual.

1. Turn off and unplug your PXI or CompactPCI chassis.

2. Choose an unused PXI or CompactPCI 5 V peripheral slot. Install the

PXI-1409 in a slot that supports bus arbitration or bus-master cards.

PXI-compliant chassis must have bus arbitration for all slots.

3. Remove the filler panel for the peripheral slot you have chosen.

4. Touch a metal part on your chassis to discharge any static electricity

that might be on your clothes or body.

5. Insert the PXI-1409 in the selected 5 V slot. Use the injector/ejector

handle to fully inject the device into place.

6. Screw the front panel of the PXI-1409 to the front panel mounting rails

of the PXI or CompactPCI chassis.

7. Visually verify the installation.

8. Plug in and turn on the PXI or CompactPCI chassis.

Your PXI-1409 is now installed.

IMAQ PCI/PXI-1409 User Manual 2-8 ni.com

Page 24

Hardware Overview

This chapter presents an overview of the hardware functions on your

PCI/PXI-1409 board and explains the operation of each functional unit

making up the PCI/PXI-1409.

Functional Overview

The PCI/PXI-1409 features a flexible, high-speed data path optimized for

the acquisition and formatting of video data from analog cameras. The

1409 device can acquire from RS-170/NTSC, CCIR/PAL, VGA, and

progressive scan cameras, as well as from non-standard cameras such as

line scan cameras. The 1409 device digitizes analog video signals to

8 or 10 bits of resolution at sampling frequencies up to 40 MHz.

The 1409 device has a factory calibrated gain circuit to improve

measurement accuracy and board-to-board consistency. It uses a PCI

interface for high-speed data transfer, 16 MB of SDRAM for data

buffering, and region-of-interest control circuitry for optimizing the data

transfer. The 16 MB of SDRAM also allows you to acquire entire images

into on-board memory when necessary. The 1409 device includes four

external triggers, four camera control signals, seven RTSI bus triggers, and

six video synchronization signals.

3

© National Instruments Corporation 3-1 IMAQ PCI/PXI-1409 User Manual

Page 25

Chapter 3 Hardware Overview

The block diagram in Figure 3-1 illustrates the key functional units of the

PCI/PXI-1409.

RTSI Bus

4 Camera Control Lines

4 External Triggers

External Clock Generation

External PCLK,

HSYNC, VSYNC

External CSYNC

68-pin VHDIC Connector

Video

0,1,2,3

Video 0

BNC

Video

Mux

Genlock Circuit

and SYNC Mux

Programmable

Gain and Offset

Aspect Ratio Correction

HSYNC, VSYNC

Analog

Bandwidth

Control

Circuitry

PCLK

Video Mux

The video multiplexer routes one of the four AC-coupled video inputs to

the 10-bit ADC circuitry. The input impedance at the input to the board is

75 Ω.

Programmable Gain and Offset

The PCI/PXI-1409 uses programmable gainand offsetcircuitry to optimize

the input signal range.

Digital

Input/Output

Circuitry

Acquisition and

Region-of-Interest

Control

10-Bit

ADC

Digital

Filter

and

LUT

Onboard

Memory and

Control Circuitry

Figure 3-1. 1409 Device Block Diagram

PCI Interface and

Scatter-Gather

DMA Controller

PCI Bus

Analog Bandwidth Control Circuitry

You can select either the full bandwidth of 30 MHz or a reduced bandwidth

of 9 MHz. The 9 MHz bandwidth setting is available using a 5th order

Butterworth lowpass filter.

10-Bit ADC

The 10-bit ADC digitizes the conditioned video signal.

IMAQ PCI/PXI-1409 User Manual 3-2 ni.com

Page 26

Digital Filter and LUT

The digital filter removes chrominance from a composite color video signal

that conforms to either PAL or NTSC. The output of the digital filter passes

through the 1024

to implement simple imaging operations such as contrast enhancement,

data inversion, gamma correction, or other user-defined transfer functions.

Onboard Memory

The PCI/PXI-1409 comes with 16 MB of SDRAM for temporary storage

of the image data being transferred to the system memory through the PCI

bus. The memory can store multiple image buffers.

Scatter-Gather DMA Controllers

The PCI/PXI-1409 uses three independent onboard direct memory access

(DMA) controllers. The DMA controllers transfer data between the

onboard SDRAM memory buffer and the PCI bus. Each of these controllers

supports scatter-gather DMA, which allows the controllers to reconfigure

on the fly. Therefore, the PCI/PXI-1409 can perform continuous image

transfers directly to either contiguous or fragmented memory buffers.

Chapter 3 Hardware Overview

10-bit lookup table (LUT). You can configure the LUT

x

PCI Interface

The PCI/PXI-1409 implements the PCI interface with a National

Instruments custom application-specific integrated circuit (ASIC), the

PCI MITE. The PCI interface can transfer data at a maximum rate of

132 MB/s in bus master mode.

Genlock Circuit and SYNC Mux

The genlock circuit receives the incoming video signal and generates

PCLK, HSYNC, and VSYNC signals for use by the acquisition and control

circuitry. The 1409 device can lock to the standard RS-170/NTSC and

CCIR/PAL video signals as well as progressive scan and VGA

(640 × 480 resolution) signals. The genlock circuit on the 1409 device can

also lock to external HSYNC and VSYNC or CSYNC signals.

© National Instruments Corporation 3-3 IMAQ PCI/PXI-1409 User Manual

Page 27

Chapter 3 Hardware Overview

Acquisition and Region-of-Interest (ROI) Control

The acquisition and region-of-interest control circuitry routes the active

pixels from the 10-bitADC to the onboard memory. The PCI/PXI-1409 can

perform ROI and scaling on all video lines. Pixel and line scaling transfers

certain multiples (two, four, or eight) of pixels and lines to onboard

memory.

RTSI Bus

The seven trigger lines on the RTSI bus provide a flexible interconnection

scheme between multiple PCI/PXI-1409 boards as well as between any

National Instruments DAQ or Motion device and the PCI/PXI-1409.

Digital Input/Output Circuitry

The digital input/output circuitry routes, monitors, and drives the external

trigger lines, RTSI bus lines, and camera control lines. You can use the

trigger lines to start or stop an acquisition on a rising or falling edge.

In addition, you can map onboard signals such as HSYNC, VSYNC,

ACQUISTION_IN_PROGRESS, and ACQUISITION_DONE to these

lines. The camera control lines provide a means to generate deterministic

signals for triggering cameras, strobe lights, or other timing-critical

applications. This module also contains an external clock generation

circuit. You can use this external clock as the source clock for a line scan

camera.

Acquisition Modes

The 1409 device supports five video acquisition modes.

• Standard Mode—In standard mode, the 1409 device receives an

incoming composite video signal from the external BNC or 68-pin

VHDCI connector and generates CSYNC, HSYNC, VSYNC, and

PCLK signals. The generated CSYNC signal is output on the VHDCI

connector to synchronize other image acquisition boards or cameras.

• CSYNC External Mode—In CYSNC external mode, the 1409 device

receives an incoming video signal (composite or luminance) and an

external CSYNC signal from the external connector and generates

HSYNC, VSYNC, and PCLK signals.

IMAQ PCI/PXI-1409 User Manual 3-4 ni.com

Page 28

Chapter 3 Hardware Overview

• External Lock Mode—In external lock mode, the 1409 device receives

HSYNC, VSYNC, and PCLK signals from the camera and uses these

signals to acquire the video signals directly. You can also use this mode

to acquire from a line scan camera.

• External HSYNC/VSYNC Mode—In external HSYNC/VSYNC

mode, the 1409 device receives the external HSYNC and VSYNC

from the connector and internally generates the PCLK signal. The

device’s genlock circuitry locks to the external HSYNC and VSYNC

signals. You can use this mode to acquire from VGA monitors

(640

480 resolution).

x

• External HSYNC/VSYNC (HLOCK only) mode—In external

HSYNC/VSYNC (HLOCK only) mode, the 1409 device receives the

external HSYNC and VSYNC signals and internally generates the

PCLK signal. In this mode, the device’s genlock circuitry uses only the

HSYNC signal for locking. You can use this mode to acquire from

asynchronously-reset cameras which output a continuous HSYNC.

Note

Connect a FIELD signal to TRIG3 when the 1409 device is in external lock mode

with an interlaced camera.

Analog Front End Considerations

The analog front end of the IMAQ PCI/PXI-1409 device features a

calibrated gain circuit, programmable DC-restore circuit, and 10-bit ADC

asshowninFigure3-2.

10-bit/8-bit Mode

Analog

Video

The 1409 device digitizes the incoming video signal to 10 bits of resolution

at all times. In 10-bit mode, the 1409 device has four fixed, full-scale

ranges where the gain for each range is calibrated. The nominal full-scale

ranges are 0.20, 0.35, 0.70, and 1.40 V. As a result, the gain is not

continuously variable in this mode. To maintain compatibility with other

IMAQ analog devices, the 1409 device has an 8-bit mode, in which the

10-bit data from the ADC is converted to 8-bit data in the lookup table

(LUT) after gain correction and any digital filtering has occurred.

1of4

Gain

Figure 3-2. IMAQ PCI/PXI-1409 Analog Front End

DC-restore

10-bit

ADC

Digital Gain

Correction,

Filtering, and LUT

10- or 8-bit

© National Instruments Corporation 3-5 IMAQ PCI/PXI-1409 User Manual

Page 29

Signal Connections

This chapter describes cable connections for the PCI-1409 and PXI-1409

devices.

BNC Connector

The BNC external connector supplies an immediate connection to the

1409 device VIDEO0 input. Use the 2 m BNC cable shipped with the

PCI/PXI-1409 to connect a camera to VIDEO0. You cannot use this

connection with VIDEO0 on the 68-pin VHDCI I/O connector. You

can configure the BNC connector only for RSE mode.

Note

Verify that Jumper W1 is installed when using the BNC input.

4

GND

VIDEO0+

Figure 4-1. BNC Connector Pin Assignment

I/O Connector

The 68-pin VHDCI connector connects to all video signals (VIDEO0,

VIDEO1, VIDEO2, and VIDEO3), the external digital I/O lines, triggers,

and external signals. To access these connections, you can build your own

custom cable or use one of the optional cables from National Instruments.

Figure 4-2 shows the pinout of the 68-pin VHDCI connector.

Note

Do not use the VIDEO0 connection on the 68-pin VHDCI connector when using the

BNC connection.

© National Instruments Corporation 4-1 IMAQ PCI/PXI-1409 User Manual

Page 30

Chapter 4 Signal Connections

VIDEO(0) +

VIDEO(0) –

VIDEO(1) +

VIDEO(1) –

RESERVED

RESERVED

RESERVED

RESERVED

DGND

RESERVED

RESERVED

RESERVED

RESERVED

RESERVED

RESERVED

RESERVED

RESERVED

RESERVED

HSYNC_IN –

VSYNC_IN –

CSYNC_IN –

CSYNC_OUT –

CTRL(0) –

CTRL(1) –

CTRL(2) –

CTRL(3) –

DGND

DGND

DGND

DGND

CHASSIS_GND

PCLK_IN –

DGND

PCLK_OUT –

68

67

66

65

64

63

62

61

60

59

58

57

56

55

54

53

52

51

50

49

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

VIDEO(2) +

33

VIDEO(2) –

32

VIDEO(3) +

31

VIDEO(3) –

30

RESERVED

29

RESERVED

28

RESERVED

27

RESERVED

26

DGND

25

RESERVED

24

RESERVED

23

RESERVED

22

RESERVED

21

RESERVED

20

RESERVED

19

RESERVED

18

RESERVED

17

RESERVED

16

HSYNC_IN +

15

VSYNC_IN +

14

CSYNC_IN +

13

CSYNC_OUT +

12

CTRL(0) +

11

CTRL(1) +

10

CTRL(2) +

9

CTRL(3) +

8

TRIG(0)

7

TRIG(1)

6

TRIG(2)

5

TRIG(3)

4

CHASSIS_GND

3

PCLK_IN +

2

DGND

1

PCLK_OUT +

Figure 4-2. I/O Connector Pin Assignments

IMAQ PCI/PXI-1409 User Manual 4-2 ni.com

Page 31

Chapter 4 Signal Connections

I/O Connector Signal Connection Descriptions

Table 4-1 describes each signal connection on the 68-pin VHDCI

connector.

Table 4-1. I/O Connector Signals

Signal Name Description

VIDEO0± VIDEO0± allows for a DIFF or RSE connection to video channel 0. To operate

in RSE mode, connect VIDEO0– to GND. When you use VIDEO0+ or

VIDEO0–, you must disconnect the BNC connector.

VIDEO<3..1>± VIDEO<3..1>± allows for a DIFF or RSE connection to video channels

1, 2, and 3. To operate in RSE mode, connect VIDEO– to GND.

PCLKIN± Use PCLKIN± when the 1409 device is in external lock mode. In this mode,

PCLKIN represents the A/D sampling clock. You can select PCLKIN to be

either TTL or RS-422 mode and program its polarity through software. In

RS-422 mode, both PCLKIN+ and PCLKIN– receive the PCLK signal.

PCLKOUT± Use PCLKOUT± when your camera requires an external pixel clock source.

The 1409 device can generate variable pixel clock frequencies between

500 kHz and 40 MHz. You can set PCLKOUT± through your software in TTL

and RS-422 modes.

HSYNCIN± Use HSYNCIN± when the 1409 device is in external lock mode. HSYNC is a

synchronization pulse produced at the beginning of each video scan line that

keeps a video monitor's horizontal scan rate in step with the transmission of

each new line. You can set HSYNCIN to be either TTL or RS-422 mode and

program its polarity through software. In RS-422 mode, both HSYNCIN+ and

HSYNCIN– receive the HSYNC signal.

VSYNCIN± Use VSYNCIN± when the 1409 device is in external lock mode. VSYNC is a

synchronization pulse generated at the beginning of each video frame that tells

the video monitor when to start a new field. You can set VSYNCIN to be either

TTL or RS-422 mode and program its polarity through software. In RS-422

mode, both VSYNCIN+ and VSYNCIN– receive the VSYNC signal.

CSYNCIN± Use CSYNCIN± when the 1409 device is in CSYNC external mode. CSYNC

is a signal consisting of horizontal sync pulses, vertical sync pulses, and

equalizing pulses only. You can set CSYNCIN to be either TTL or RS-422

mode and program its polarity through software. In RS-422 mode, both

CSYNCIN+ and CSYNCIN– receive the CSYNC signal.

CSYNCOUT CSYNCOUT is a TTL output of the internal CSYNC signal. In CSYNC

external mode, CSYNCOUT maps directly to CSYNCIN. In standard mode,

the synchronization circuitry of the 1409 device generates CSYNCOUT.

© National Instruments Corporation 4-3 IMAQ PCI/PXI-1409 User Manual

Page 32

Chapter 4 Signal Connections

Table 4-1. I/O Connector Signals (Continued)

Signal Name Description

TRIG<3..0> Triggers <3..0> are TTL I/O lines used to start or stop an acquisition or output

an acquisition status. You can program the triggers to be rising- or falling-edge

sensitive. You can also program the triggers to be programmatically asserted or

unasserted similar in function to a digital I/O line or to contain internal status

signals (by using the onboard events) or specific pulse widths.

CTRL<3..0>± Use the control lines on the PCI-1409 to control camera features and timing

information. Either static or dynamic, TTL or differential, signals can be

generated on these lines to perform such functions as generating integration or

shutter pulses to the cameras.

GND GND is a direct connection to digital GND on the 1409 device.

CHASSIS_GND CHASSIS_GND is a direct connection to the computer’s chassis, which is

grounded through the power cord.

IMAQ PCI/PXI-1409 User Manual 4-4 ni.com

Page 33

Specifications

This appendix lists the specifications of the PCI-1409 and PXI-1409

devices. These specifications are typical at 25 °C, unless otherwise stated.

Formats Supported

RS-170/NTSC ........................................ 60 Hz

CCIR/PAL..............................................50 Hz

VGA ....................................................... 60 Hz, 640 × 480 resolution

Variable scan.......................................... Programmable

Video Input

Quantity..................................................Four monochrome

Input impedance..................................... 75 Ω ±1%

A

(Interlaced mode: 60 fields/s)

(Interlaced mode: 50 fields/s)

VIDEO0 ................................................. RSE (BNC), RSE or DIFF

(VHDCI)

VIDEO<3..0>......................................... RSE or DIFF (VHDCI)

Frequency response................................ 30 MHz (–3dB)typ

Digital Antichrominance filter ............... Programmable (disabled,

3.58 MHz notch filter, or

4.43 MHz notch filter)

Filter characteristics ............................... Attenuation at notch

frequency > 30 dB

© National Instruments Corporation A-1 IMAQ PCI/PXI-1409 User Manual

Page 34

Appendix A Specifications

A/D Conversion

Internal Pixel Clock

Input range (black to white)....................700 mV (calibrated)

200mVto1.40Vfullscale

Accuracy.................................................±1.5% of reading

Temperature drift ....................................< 250 ppm/°C

Gray levels..............................................1024 (10-bit)

Differential nonlinearity .........................±1 LSB max

RMS noise ..............................................< 0.5 LSB rms

Signal-to-noise ratio ...............................56 dB typ

Sampling rate..........................................2 MHz to 40 MHz, externally

clocked

Pixel aspect ratio.....................................Programmable ±5% of nominal

Frequencies range ...................................11.6 to 25.8 MHz

Pixel ratio for

standard video sources............................±5%

Pixel jitter ...............................................< 2 ns peak

PCI Interface

PCI initiator (master) capability .............Supported

PCI target (slave) capability ...................Supported

Data path.................................................32 bits

Card voltage............................................5 V only

Card type.................................................32-bit half-size card

Parity generation/checking,

error reporting.........................................Supported

Target decode speed ...............................Medium (1 clock)

IMAQ PCI/PXI-1409 User Manual A-2 ni.com

Page 35

Target fast back-to-back capability........ Supported

Resource locking.................................... Supported as a master and slave

PCI interrupts ......................................... Interrupts passed on

Base address registers ............................ BAR0 (16 KB)

Expansion ROM..................................... 4 KB

PCI master performance

Power Requirements

Voltage ................................................... +5 V (1.5 A)

Appendix A Specifications

INTA# signal

BAR1 (64 KB)

Ideal ................................................ 133 Mbytes/s

Sustained......................................... 100 Mbytes/s

+12 V (100 mA)

–12 V (50 mA)

Physical

Dimensions

PCI-1409 ......................................... 10.7 by 17.5 cm

(4.2 by 6.9 in.)

PXI-1409......................................... 10 by 16 cm

(3.9 by 6.3 in.)

Weight

PCI-1409 ......................................... 0.127 kg

(0.28 lb)

PXI-1409......................................... 0.172 kg

(0.38 lb)

Environment

Operating temperature............................ 0 to 55 °C

Storage temperature ............................... –20 to 70 °C

Relative humidity...................................10 to 90%, noncondensing

© National Instruments Corporation A-3 IMAQ PCI/PXI-1409 User Manual

Page 36

Appendix A Specifications

Note

This device should only be operated with shielded cable for full EMC and EMI

compliance. See the Compliance section of this manual and the Declaration of Conformity

included in your kit for any additional regulatory compliance information.

Electromagnetic Compatibility

EMC/EMI........................................CE, C-Tick, and FCC Part 15

(Class A) Compliant

Electrical Emissions ........................EN 55011 Class A at 10 meters.

FCC Part 15A above 1 GHz

Electrical Immunity.........................Evaluated to EN 61326:1998,

Table 1

Functional shock (PXI only)...................MIL-T-28800 E Class 3 (per

Section 4.5.5.4.1) Half-sine shock

pulse, 11 ms duration, 30 g peak,

30 shocks per face

Operational random

vibration (PXI only)................................5 to 500 Hz, 0.31 grms, 3 axes

Nonoperational random

vibration (PXI only)................................5 to 500 Hz, 2.5 grms, 3 axes

Note

Random vibration profiles were developed in accordance with MIL-T-28800E and

MIL-STD-810E Method 514. Test levels exceed those recommended in MIL-STD-810E

for Category 1 (Basic Transportation, Figures 514.4-1 through 514.4-3).

IMAQ PCI/PXI-1409 User Manual A-4 ni.com

Page 37

Custom Cables

This appendix lists specifications for building custom cables for your 1409

device.

Cable Specification

National Instruments offers cables and accessories for you to connect to

video sources, trigger sources, or synchronization sources. However, if you

want to develop your own cables, the following guidelines must be met:

• For the video inputs, use a 75 Ω shielded coaxial cable.

• For the digital triggers and synchronization signals, twisted pairs

for each signal yield the best result.

For information on connector pin assignments, see the I/O Connector

section in Chapter 4, Signal Connections.

Connector specifications include:

• Video and sync signals 75 Ω impedance

• Trigger signals TTL

• Type 75 Ω BNC or

B

68-pin VHDCI receptacle

© National Instruments Corporation B-1 IMAQ PCI/PXI-1409 User Manual

Page 38

Technical Support Resources

Web Support

National Instruments Web support is your first stop for help in solving

installation, configuration, and application problems and questions. Online

problem-solving and diagnostic resources include frequently asked

questions, knowledge bases, product-specific troubleshooting wizards,

manuals, drivers, software updates, and more. Web support is available

through the Technical Support section of

NI Developer Zone

ni.com

C

The NI Developer Zone at

building measurement and automation systems. At the NI Developer Zone,

you can easily access the latest example programs, system configurators,

tutorials, technical news, as well as a community of developers ready to

share their own techniques.

Customer Education

National Instruments provides a number of alternatives to satisfy your

training needs, from self-paced tutorials, videos, and interactive CDs to

instructor-led hands-on courses at locations around the world. Visit the

Customer Education section of

syllabi, training centers, and class registration.

System Integration

If you have time constraints, limited in-house technical resources, or other

dilemmas, you may prefer to employ consulting or system integration

services. You can rely on the expertise available through our worldwide

network of Alliance Program members. To find out more about our

Alliance system integration solutions, visit the System Integration section

of

ni.com

ni.com/zone

ni.com

is the essential resource for

for online course schedules,

© National Instruments Corporation C-1 IMAQ PCI/PXI-1409 User Manual

Page 39

Appendix C Technical Support Resources

Worldwide Support

National Instruments has offices located around the world to help address

your support needs. You can access our branch office Web sites from the

Worldwide Offices section of

up-to-date contact information, support phone numbers, e-mail addresses,

and current events.

If you have searched the technical support resources on our Web site and

still cannot find the answers you need, contact your local office or National

Instruments corporate. Phone numbers for our worldwide offices are listed

at the front of this manual.

ni.com

. Branch office Web sites provide

IMAQ PCI/PXI-1409 User Manual C-2 ni.com

Page 40

Glossary

Prefix Meanings Value

p- pico- 10

n- nano- 10

µ- micro- 10

m- milli- 10

k- kilo- 10

M- mega- 10

G- giga- 10

Numbers/Symbols

% percent

+ positive of, or plus

–12

–9

– 6

–3

3

6

9

– negative of, or minus

/per

+5V 5 V signal

± plus or minus

Ω ohm

A

A Amperes.

A/D Analog-to-digital.

AC Alternating current.

acquisition window The image size specific to a video standard or camera resolution.

© National Instruments Corporation G-1 IMAQ PCI/PXI-1409 User Manual

Page 41

Glossary

active line region The region of lines actively being stored. Defined by a line start (relative to

the vertical synchronization signal (VSYNC)) and a line count.

active pixel region The region of pixels actively being stored. Defined by a pixel start [relative

to the horizontal synchronization signal(HSYNC)] and a pixel count.

ADC Analog-to-digital converter. An electronic device, often an integrated

circuit, that converts an analog voltage to a digital value.

address Value that identifies a specific location (or series of locations) in memory.

ANSI American National Standards Institute.

antichrominance filter Removes the color information from the video signal.

API Application programming interface.

area A rectangular portion of an acquisition window or frame that is controlled

and defined by software.

array Ordered, indexed set of data elements of the same type.

ASIC Application-Specific Integrated Circuit. A proprietary semiconductor

component designed and manufactured to perform a set of specific

functions for specific customer needs.

aspect ratio The ratio of a picture or image’s width to its height.

B

b Bit. One binary digit, either 0 or 1.

B Byte. Eight related bits of data, an eight-bit binary number. Also denotes

the amount of memory required to store one byte of data.

back porch The area of the video signal between the rising edge of the horizontal

synchronization signal (HSYNC) and the active video information.

black reference level The level that represents the darkest an image can get.Seealsowhite

reference level.

IMAQ PCI/PXI-1409 User Manual G-2 ni.com

Page 42

Glossary

buffer Temporary storage for acquired data.

bus A group of conductors that interconnect individual circuitry in a computer,

such as the PCI bus; typically the expansion vehicle to which I/O or other

devices are connected.

C

CCelsius.

cache High-speed processor memory that buffers commonly used instructions or

data to increase processing throughput.

CCIR Comite Consultatif International des Radiocommunications. A committee

that developed standards for video signals. Also used to describe signals,

boards, and cameras that adhere to the CCIR standards.

chroma The color information in a video signal.

chrominance See chroma.

CMOS Complementary metal-oxide semiconductor.

CompactPCI Refers to the core specification defined by the PCI Industrial Computer

Manufacturer’s Group (PICMG).

conversion device Device that transforms a signal from one form to another. For example,

analog-to-digital converters (ADCs) for analog input and digital-to-analog

converters (DACs) for analog output.

CPU Central processing unit.

CSYNC Composite synchronization signal. Signals in a color video system that

multiplex all picture information into a single signal, such as NTSC, PAL,

or SECAM.

D

D/A Digital-to-analog.

DAC Digital-to-analog converter. An electronic device, often an integrated

circuit, that converts a digital number into a corresponding analog voltage

or current.

© National Instruments Corporation G-3 IMAQ PCI/PXI-1409 User Manual

Page 43

Glossary

DAQ Data acquisition. (1) Collecting and measuring electrical signals from

sensors, transducers, and test probes or fixtures and inputting them to a

computer for processing. (2) Collecting and measuring the same kinds of

electrical signals with A/D or DIO boards plugged into a computer, and

possibly generating control signals with D/A and/or DIO boards in the

same computer.

dB Decibel. The unit for expressing a logarithmic measure of the ratio of two

signal levels: dB = 20log

V1/V2, for signals in volts.

10

DC Direct current.

default setting A default parameter value recorded in the driver. In many cases, the default

input of a control is a certain value (often 0).

DMA Direct memory access. A method by which data can be transferred between

computer memory and a device or memory on the bus while the processor

does something else. DMA is the fastest method of transferring data

to/from computer memory.

DRAM Dynamic RAM.

driver Software that controls a specific hardware device, such as an IMAQ or

DAQ device.

dynamic range The ratio of the largest signal level a circuit can handle to the smallest

signal level it can handle (usually taken to be the noise level), normally

expressed in decibels.

E

EEPROM Electrically erasable programmable read-only memory. ROM that can be

erased with an electrical signal and reprogrammed.

external trigger A voltage pulse from an external source that triggers an event such as A/D

conversion.

IMAQ PCI/PXI-1409 User Manual G-4 ni.com

Page 44

Glossary

F

field For an interlaced video signal, a field is half the number of horizontal lines

needed to represent a frame of video. The first field of a frame contains all

the odd-numbered lines, the second field contains all of the even-numbered

lines.

FIFO First-in first-out memory buffer. The first data stored is the first data sent

to the acceptor. FIFOs are used on IMAQ devices to temporarily store

incoming data until that data can be retrieved.

flash ADC An ADC whose output code is determined in a single step by a bank of

comparators and encoding logic.

frame A complete image. In interlaced formats, a frame is composed of two fields.

front porch The area of a video signal between the start of the horizontal blank and the

start of the horizontal synchronization signal (HSYNC).

ft Feet.

function A set of software instructions executed by a single line of code that may

have input and/or output parameters and returns a value when executed.

G

gamma The nonlinear change in the difference between the video signal’s

brightness level and the voltage level needed to produce that brightness.

genlock The process of synchronizing a video source to the signal from a separate

video source. The circuitry aligns the video timing signals by locking

together the horizontal, vertical, and color subcarrier frequencies and

phases and generates a pixel clock that clocks pixel data into memory for

display or into another circuit for processing.

GUI Graphical user interface. An intuitive, easy-to-use means of

communicating information to and from a computer program by means

of graphical screen displays. GUIs can resemble the front panels of

instruments or other objects associated with a computer program.

© National Instruments Corporation G-5 IMAQ PCI/PXI-1409 User Manual

Page 45

Glossary

H

hHour.

hardware The physical components of a computer system, such as the circuit boards,

plug-in boards, chassis, enclosures, peripherals, and cables.

HSYNC Horizontal synchronization signal. The synchronization pulse signal

produced at the beginning of each video scan line that keeps a video

monitor’s horizontal scan rate in step with the transmission of each new

line.

hue Represents the dominant color of a pixel. The hue function is a continuous

function that covers all the possible colors generated using the R, G, and B

primaries. See also RGB.

Hz Hertz. Frequency in units of 1/second.

I

I/O Input/output. The transfer of data to/from a computer system involving

communications channels, operator interface devices, and/or data

acquisition and control interfaces.

IC Integrated circuit.

IEEE Institute of Electrical and Electronics Engineers.

in. Inches.

INL Integral nonlinearity. A measure of LSB of the worst-case deviation from

the ideal A/D or D/A transfer characteristic of the analog I/O circuitry.

instrument driver A set of high-level software functions, such as NI-IMAQ, that control

specific plug-in computer boards. Instrument drivers are available in

several forms, ranging from a function callable from a programming

language to a virtual instrument (VI) in LabVIEW.

interlaced A video frame composed of two interleaved fields. The number of lines in

a field are half the number of lines in an interlaced frame.

interpreter A software utility that executes source code from a high-level language

such as Basic, C or Pascal, by reading one line at a time and executing the

specified operation.

IMAQ PCI/PXI-1409 User Manual G-6 ni.com

Page 46

Glossary

interrupt A computer signal indicating that the CPU should suspend its current task

to service a designated activity.

interrupt level The relative priority at which a device can interrupt.

IRQ Interrupt request. See interrupt.

K

k Kilo. The standard metric prefix for 1,000, or 103, used with units of

measure such as volts, hertz, and meters.

K Kilo. The prefix for 1,024, or 2

10

, used with B in quantifying data or

computer memory.

kbytes/s A unit for data transfer that means 1,000 or 10

3

bytes/s.

Kword 1,024 words of memory.

L

line count The total number of horizontal lines in the picture.

LSB Least significant bit.

luma The brightness information in the video picture. The luma signal amplitude

varies in proportion to the brightness of the video signal and corresponds

exactly to the monochrome picture.

luminance See luma.

LUT Lookup table. Table containing values used to transform the gray-level

values of an image. For each gray-level value in the image, the

corresponding new value is obtained from the lookup table.

M

m Meters.

M (1) Mega, the standard metric prefix for 1 million or 10

6

,whenusedwith

units of measure such as volts and hertz (2) Mega, the prefix for 1,048,576,

20

or 2

, when used with B to quantify data or computer memory.

© National Instruments Corporation G-7 IMAQ PCI/PXI-1409 User Manual

Page 47

Glossary

MB Megabyte of memory.