Page 1

National Instruments IC-3173 Manual

Get Pricing & Availability at

ApexWaves.com

Call Today: 1-800-915-6216

Email: sales@apexwaves.com

https://www.apexwaves.com/modular-systems/national-instruments/industrial-controllers/IC-3173

Page 2

USER MANUAL

IC-317x

Industrial Controller with Reconfigurable I/O

This document describes the features of the National Instruments IC-317x and contains

information about mounting and operating the device.

Contents

IC-3171, IC-3172, and IC-3173................................................................................................1

About the IC-317x............................................................................................................ 1

Hardware Overview.......................................................................................................... 2

Mounting the IC-317x.....................................................................................................21

IC-3173 (IP67)........................................................................................................................ 27

About the IC-3173 (IP67)............................................................................................... 27

Hardware Overview........................................................................................................ 28

Mounting the IC-3173 (IP67)......................................................................................... 45

Software Options.....................................................................................................................48

IEEE 1588 Precision Time Protocol References.....................................................................49

BIOS Configuration and System Recovery............................................................................ 49

Entering BIOS Setup.......................................................................................................49

BIOS Setup Utility Keyboard Navigation...................................................................... 49

Main Setup Menu............................................................................................................50

Advanced Menu.............................................................................................................. 51

Boot Menu.......................................................................................................................53

Save & Exit Menu...........................................................................................................54

Restoring the NI Linux Real-Time Operating System....................................................55

Restoring the Windows Operating System..................................................................... 55

Where to Go Next................................................................................................................... 57

Resources for LabVIEW Users.......................................................................................57

Resources for Vision Builder AI Users...........................................................................57

Worldwide Support and Services............................................................................................57

IC-3171, IC-3172, and IC-3173

The following information applies to the IC-3171, IC-3172, and IC-3173.

About the IC-317x

The IC-317x is a high-performance, small, fanless embedded computer designed for rugged

industrial applications. The IC-317x also provides multiple digital input/output (I/O) options

for communicating with external devices.

Page 3

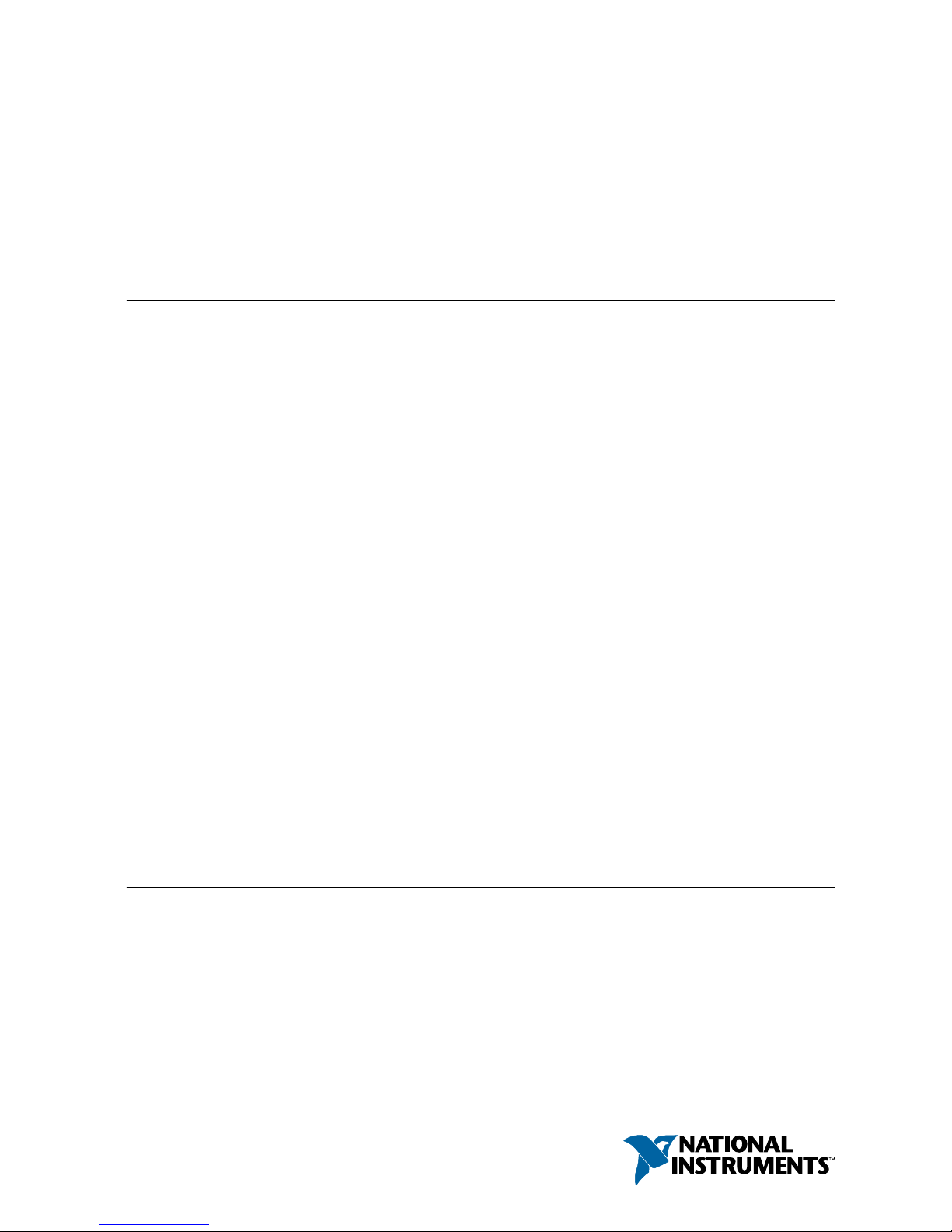

Figure 1. IC-317x Block Diagram

Intel Dual-Core Processor

i7-5650U, i5-5350U,

or Celeron 3765U

Xilinx

Kintex-7 FPGA

7K160T

IC-317x

Hardware

Data

x2 DisplayPort

8/4 GB DDR3L

Memory

64/32/4 GB

Solid-state Drive

RJ50 Serial Port

RS-232/422/485

x8 TTL I/O

x2 RS-422 I/O

x8 Isolated

Outputs

x8 Isolated

Inputs

RJ45 Primary Gigabit

Ethernet Port

x2 USB 3.0

Host Ports

x4 USB 2.0

Host Ports

x4 RJ45 Gigabit

Ethernet Ports with PoE

2 GB DDR3L

Memory

4.5 MB

QDR-II+ SRAM

PCI Express

Switch

44-pin D-sub

IC-3173 Only

PCIe

Gen 2

x4

PCIe

Gen 2

x4

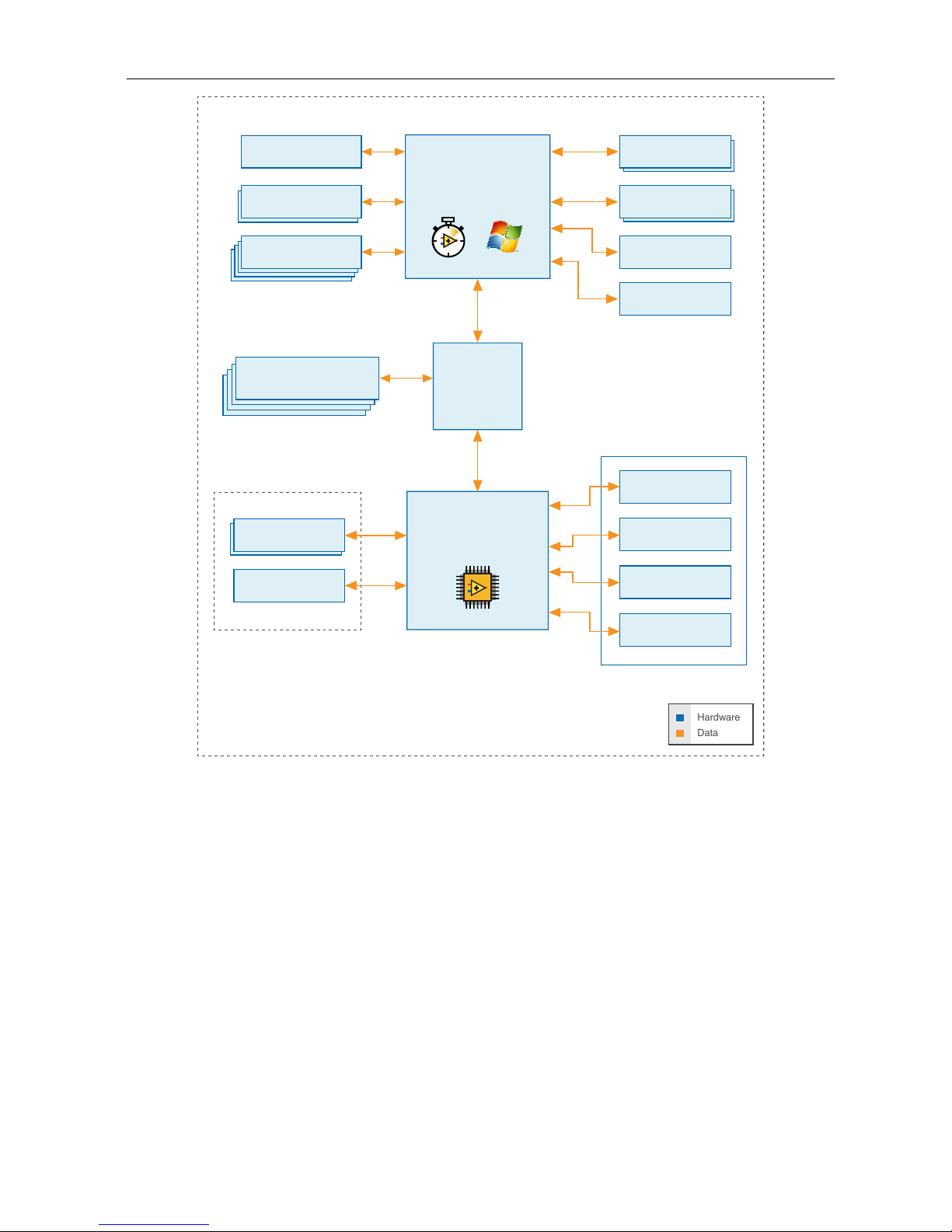

Hardware Overview

The IC-317x front panel consists of four Gigabit Ethernet ports with Power over Ethernet

(PoE), one RS-232/RS-485 serial port, one standard Gigabit Ethernet Port, two USB 3.0 ports,

four USB 2.0 ports, and two DisplayPort connectors.

The IC-317x front panel also includes LEDs for communicating system status and a 44-pin

Digital I/O port. The Digital I/O port offers 8 isolated inputs, 8 isolated outputs, 2 bidirectional

differential I/O (RS-422) or single-ended input lines that can be used with a quadrature

encoder, and 8 bidirectional TTL lines.

2 | ni.com | IC-317x User Manual

Page 4

Figure 2. IC-317x Front Panel

POWER

PoE1

PoE2

PoE3

PoE4

DIO

STATUS

USER1

DP

DP

USER FPGA1

ACT/

LINK

10/100/

1000

17

4

14

5

6

7

1

12

13

9

10

11

16

15

8

2

3

1. DisplayPort Connectors

2. LED Indicators

3. Power over Ethernet (PoE) LED Indicators

4. Gigabit Ethernet Ports with PoE

5. 44-pin Digital I/O Connector

6. Isolated Power Input Connector

7. Chassis Grounding Screw

8. Reset Button (not pictured)

9. Power Button

10. System Power Connector

11. User-Accessible Battery Compartment (not

pictured)

12. RS-232/RS-485 Serial Port

13. USB 3.0 Ports

14. Primary Gigabit Ethernet Port

15. Retention Mounts for USB 3.0 Ports

16. Retention Mounts for USB 2.0 Ports

17. USB 2.0 Ports

Connector Pinouts

The IC-317x provides the following connectors.

DisplayPort

Use the DisplayPort connectors to connect one or more monitors to implement a local HMI for

your controller. You can develop a single real-time VI to use for both your user interface and

system logic. For more information, refer to the Using the Embedded UI to Access RT Target

IC-317x User Manual | © National Instruments | 3

Page 5

VIs topic in the LabVIEW Help. For up-to-date information about supported NI cables and

accessories, refer to the pricing section of the product page at ni.com.

Use an appropriate adapter cable to connect a DisplayPort connector to a VGA or DVI

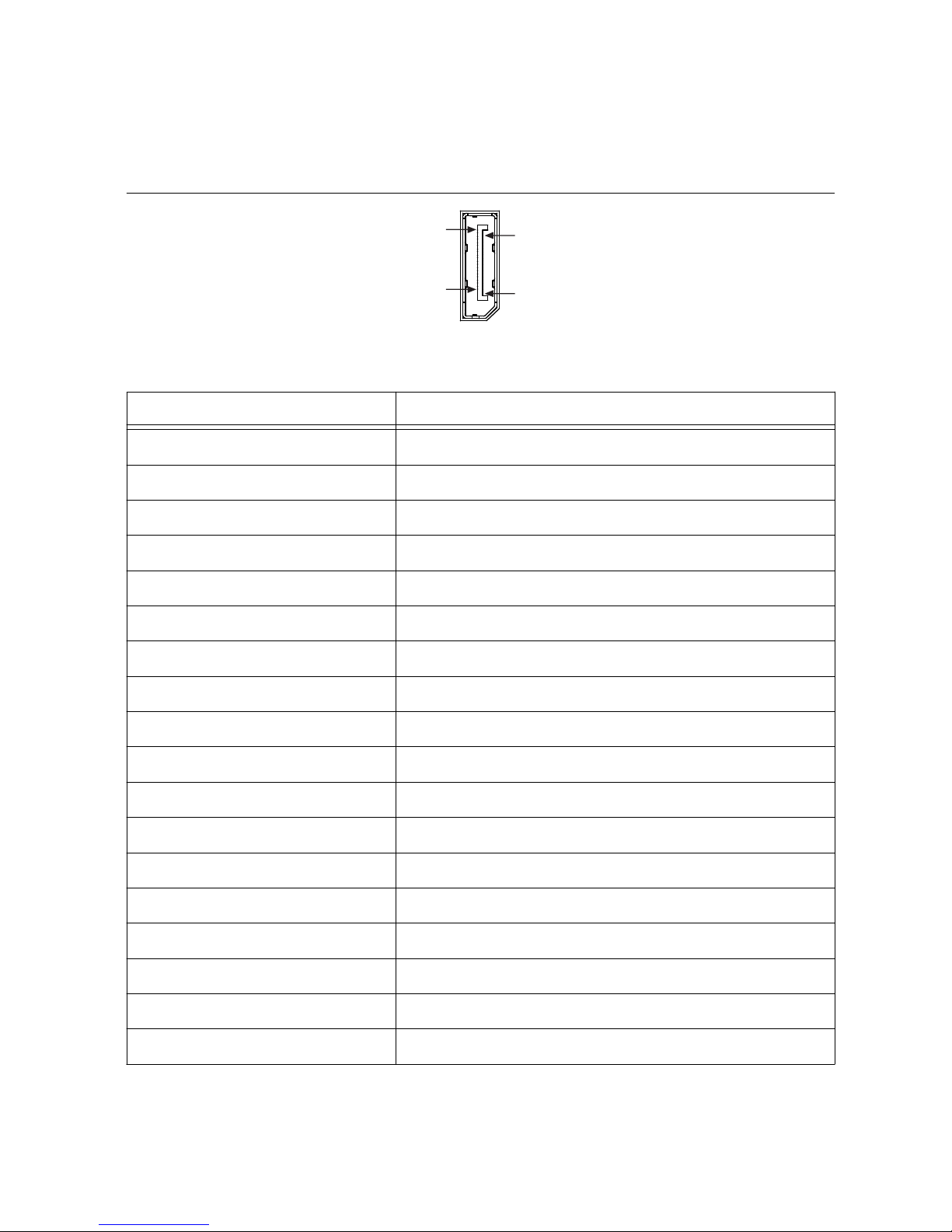

connector. The following figure lists the DisplayPort pins and signals.

Figure 3. DisplayPort Connector Pin Locations (IP20)

1

19

20

2

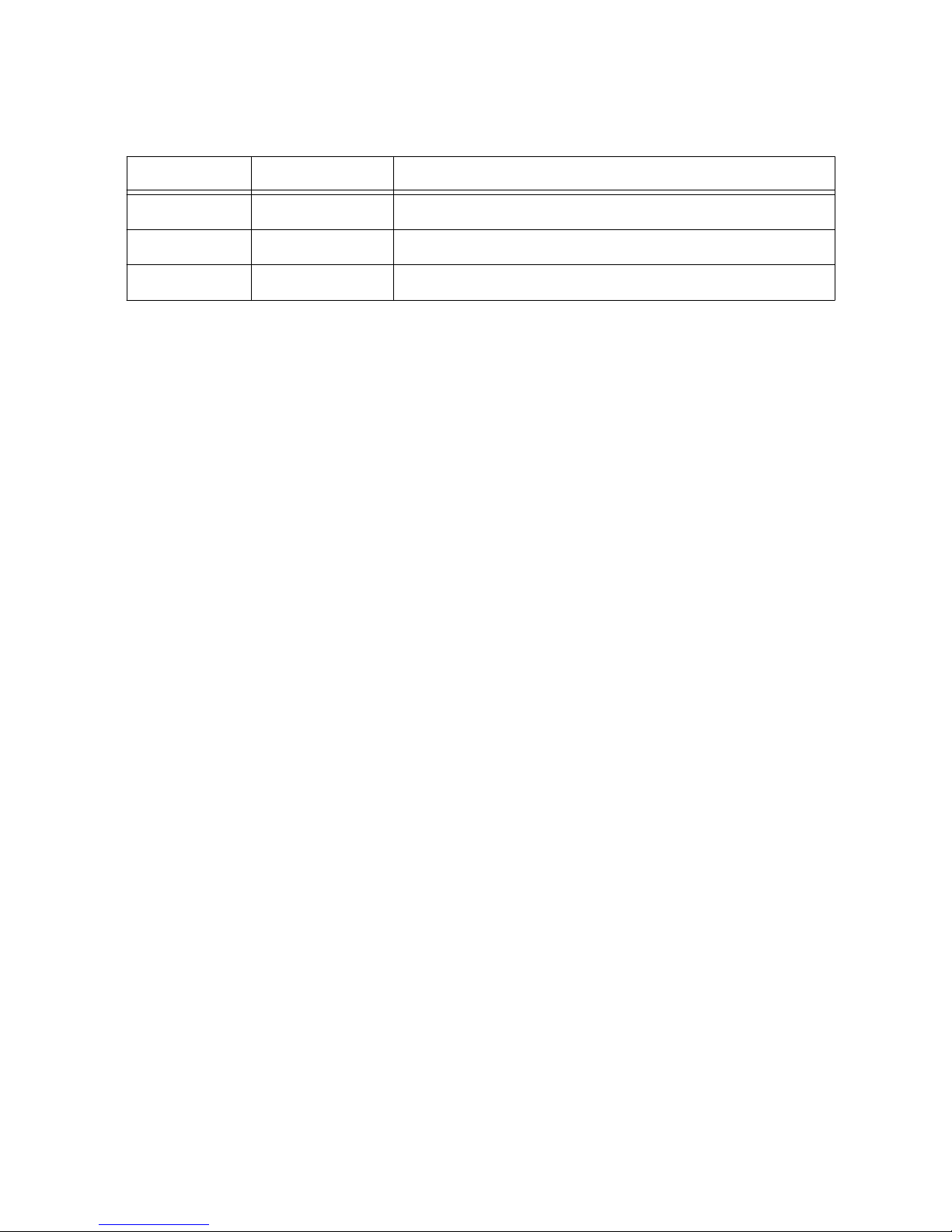

Table 1. DisplayPort Connector Pin Descriptions

Pin Signal Name

1 ML_Lane0(p)

2 GND

3 ML_Lane0(n)

4 ML_Lane1(p)

5 GND

6 ML_Lane1(n)

7 ML_Lane2(p)

8 GND

9 ML_Lane2(n)

10 ML_Lane3(p)

11 GND

12 ML_Lane3(n)

13 CONFIG1

14 CONFIG2

15 AUX CH (p)

16 GND

17 AUX CH (n)

18 Hot Plug Detect

4 | ni.com | IC-317x User Manual

Page 6

Table 1. DisplayPort Connector Pin Descriptions (Continued)

Pin Signal Name

19 Return

20 DP_PWR

Ethernet Ports

The IC-317x provides one standard Gigabit Ethernet network port and four Gigabit Ethernet

ports with Power over Ethernet (PoE). The Ethernet ports provide a connection between the

IC-317x, a network, and other Ethernet devices. The IC-317x automatically detects the speed

of the connection and configures itself accordingly.

If a PoE-capable device is plugged into an Ethernet port with PoE, the IC-317x automatically

supplies power to the device. When the IC-317x supplies PoE, the LED that corresponds to the

port illuminates. When you unplug a PoE device, PoE is automatically disabled. You can use

non-PoE Ethernet devices with PoE-enabled Gigabit Ethernet ports.

A CAT 5e or CAT 6 1000Base-T Ethernet cable is required to achieve 1,000 Mbps (Gigabit)

Ethernet performance. CAT 5 Ethernet cables are not guaranteed to meet the necessary

requirements. While CAT 5 cables may appear to work at 1,000 Mbps, CAT 5 cables can cause

bit errors, resulting in degraded or unreliable network performance.

(Windows only) The network Ethernet port provides Wake-on-LAN functionality from the

power off state when associated with the Intel® driver. Wake-on-LAN must be enabled in the

Power Management tab of the Intel I210 Gigabit Network Connection Properties dialog for the

primary Ethernet port in Device Manager. The NI GigE Vision driver (NI-GEV) does not

support Wake-on-LAN. The Ethernet ports with PoE do not support Wake-on-LAN.

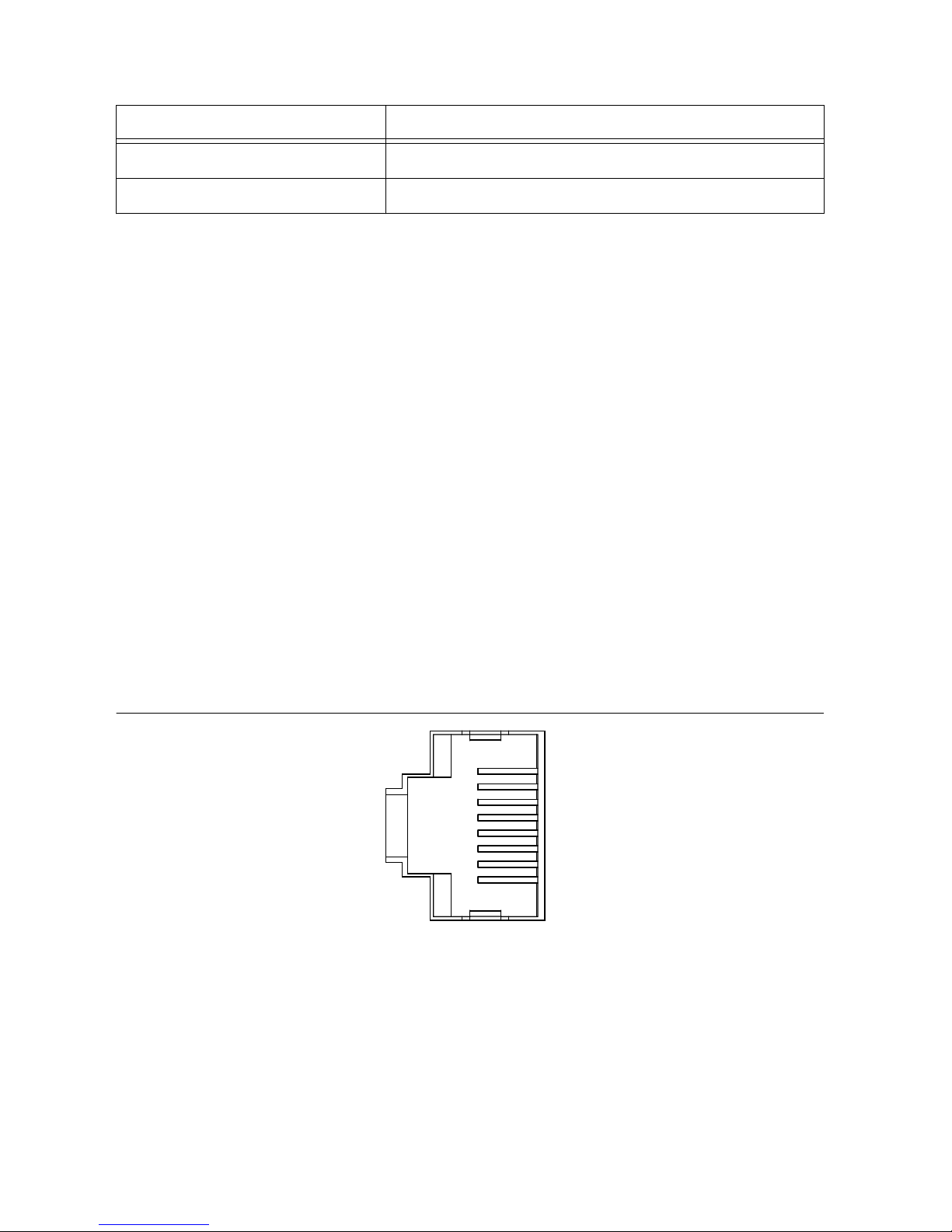

Figure 4. Ethernet Port Pin Locations (IP20)

1

2

3

4

5

6

7

8

IC-317x User Manual | © National Instruments | 5

Page 7

Table 2. Ethernet Port Pin Descriptions

Pin Fast Ethernet (100 Mbps) Gigabit Ethernet

MDI MDI-X

1 TX+ BI_DA+ BI_DB+

2 TX- BI_DA- BI_DB-

3 RX+ BI_DB+ BI_DA+

4 No Connect BI_DC+ BI_DD-

5 No Connect BI_DC- BI_DD-

6 RX- BI_DB- BI_DA-

7 No Connect BI_DD+ BI_DC+

8 No Connect BI_DD- BI_DC-

Digital I/O

The 44-pin Digital I/O port on the IC-317x offers 8 isolated inputs, 8 isolated outputs, 2

bidirectional differential inputs (RS-422) or single-ended input lines that can be used with a

quadrature encoder, and 8 bidirectional TTL lines. The Digital I/O port can be connected to

any appropriate shielded device or connector block using a shielded cable.

NI recommends the following digital I/O cables for the IC-317x.

Cable

Part Number

44-pin D-sub male to pigtail cable 156083-03 for 3 meter cable

44-pin D-sub male to 44-position D-sub female cable 156084-03 for 3 meter cable

156084-0R5 for 0.5 meter cable

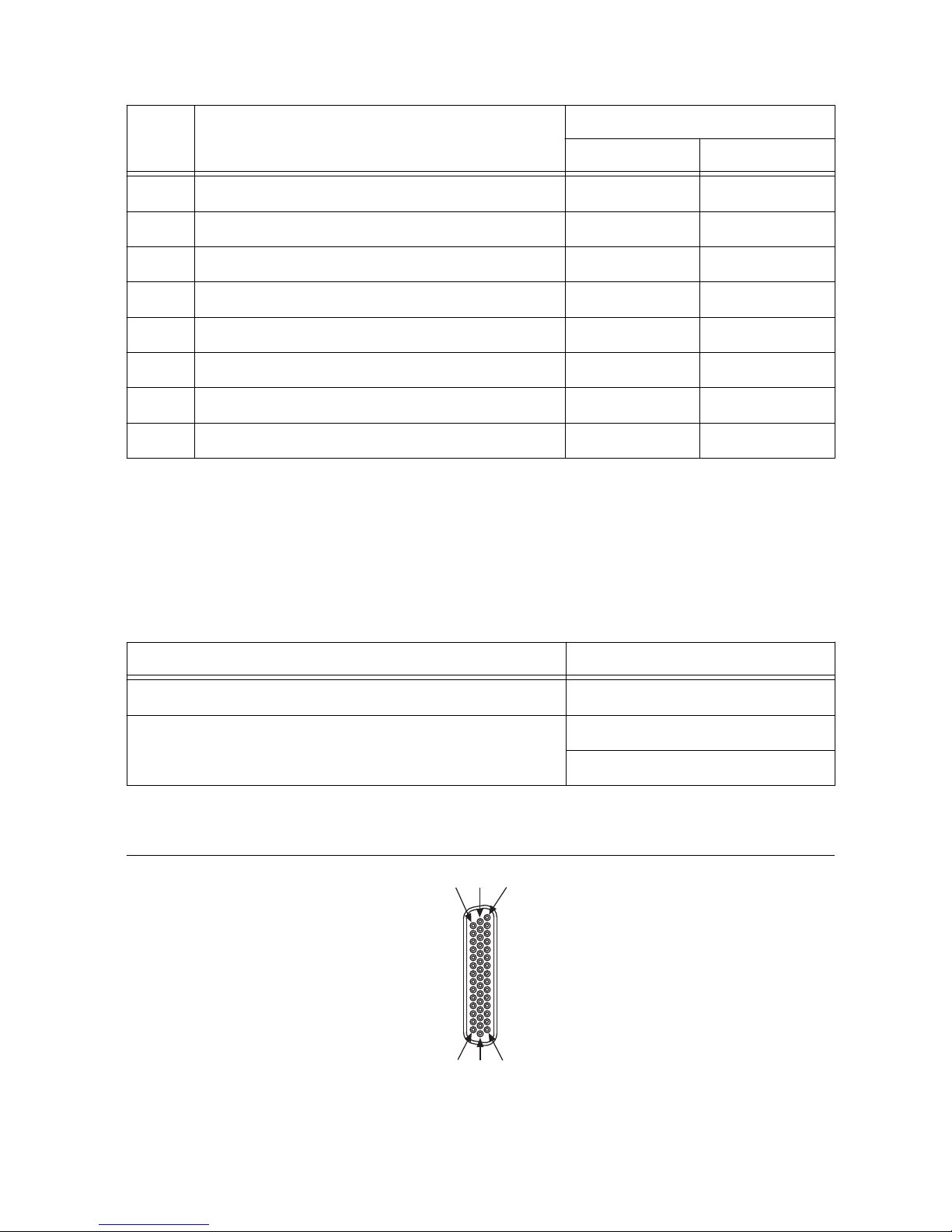

Refer to the following image and table for pin locations and descriptions.

Figure 5. 44-pin Digital I/O Connector Pin Locations (IP20)

15

30

44

1

16

31

6 | ni.com | IC-317x User Manual

Page 8

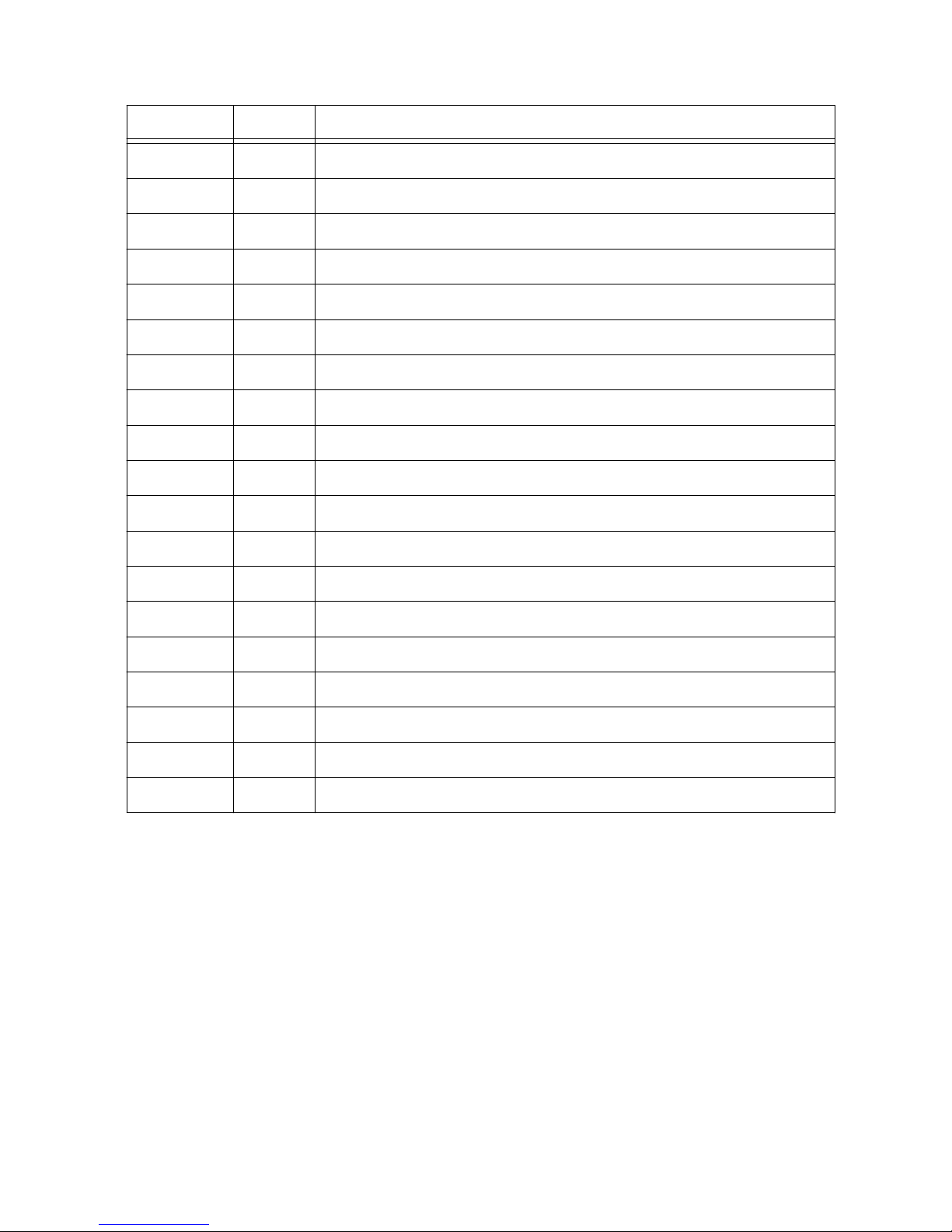

Table 3. Digital I/O Pin Descriptions

Pin Number Signal Description

1 Diff 0+ Bidirectional RS-422 I/O (positive side), or quadrature encoder

phase A+

2 GND Digital ground reference for TTL and differential I/O

3 TTL 0 Bidirectional TTL I/O

4 TTL 1 Bidirectional TTL I/O

5 GND Digital ground reference for TTL and differential I/O

6 TTL 2 Bidirectional TTL I/O

7 TTL 3 Bidirectional TTL I/O

8 GND Digital ground reference for TTL and differential I/O

9 Diff 1+ Bidirectional RS-422 I/O (positive side), or quadrature encoder

phase B+

10 V

ISO

Isolated power voltage reference output

11 C

ISO

Common ground reference for isolated inputs and outputs

12 Iso Out 0 General purpose isolated input

13 Iso Out 1 General purpose isolated input

14 C

ISO

Common ground reference for isolated inputs and outputs

15 Iso Out 4 General purpose isolated output

16 Diff 0- Bidirectional RS-422 I/O (negative side), or quadrature encoder

phase A-

17 GND Digital ground reference for TTL and differential I/O

18 TTL 4 Bidirectional TTL I/O

19 TTL 5 Bidirectional TTL I/O

20 GND Digital ground reference for TTL and differential I/O

21 TTL 6 Bidirectional TTL I/O

22 TTL 7 Bidirectional TTL I/O

23 GND Digital ground reference for TTL and differential I/O

24 Diff 1- Bidirectional RS-422 I/O (negative side), or quadrature encoder

phase B-

25 V

ISO

Isolated power voltage reference output

IC-317x User Manual | © National Instruments | 7

Page 9

Table 3. Digital I/O Pin Descriptions (Continued)

Pin Number Signal Description

26 C

ISO

Common ground reference for isolated inputs and outputs

27 Iso Out 2 General purpose isolated output

28 Iso Out 3 General purpose isolated output

29 C

ISO

Common ground reference for isolated inputs and outputs

30 Iso Out 5 General purpose isolated output

31 Iso In 0 General purpose isolated input

32 iso In 1 General purpose isolated input

33 C

ISO

Common ground reference for isolated inputs and outputs

34 Iso In 2 General purpose isolated input

35 Iso In 3 General purpose isolated input

36 C

ISO

Common ground reference for isolated inputs and outputs

37 Iso In 4 General purpose isolated input

38 Iso In 5 General purpose isolated input

39 C

ISO

Common ground reference for isolated inputs and outputs

40 Iso In 6 General purpose isolated input

41 Iso In 7 General purpose isolated input

42 C

ISO

Common ground reference for isolated inputs and outputs

43 Iso Out 6 General purpose isolated output

44 Iso Out 7 General purpose isolated output

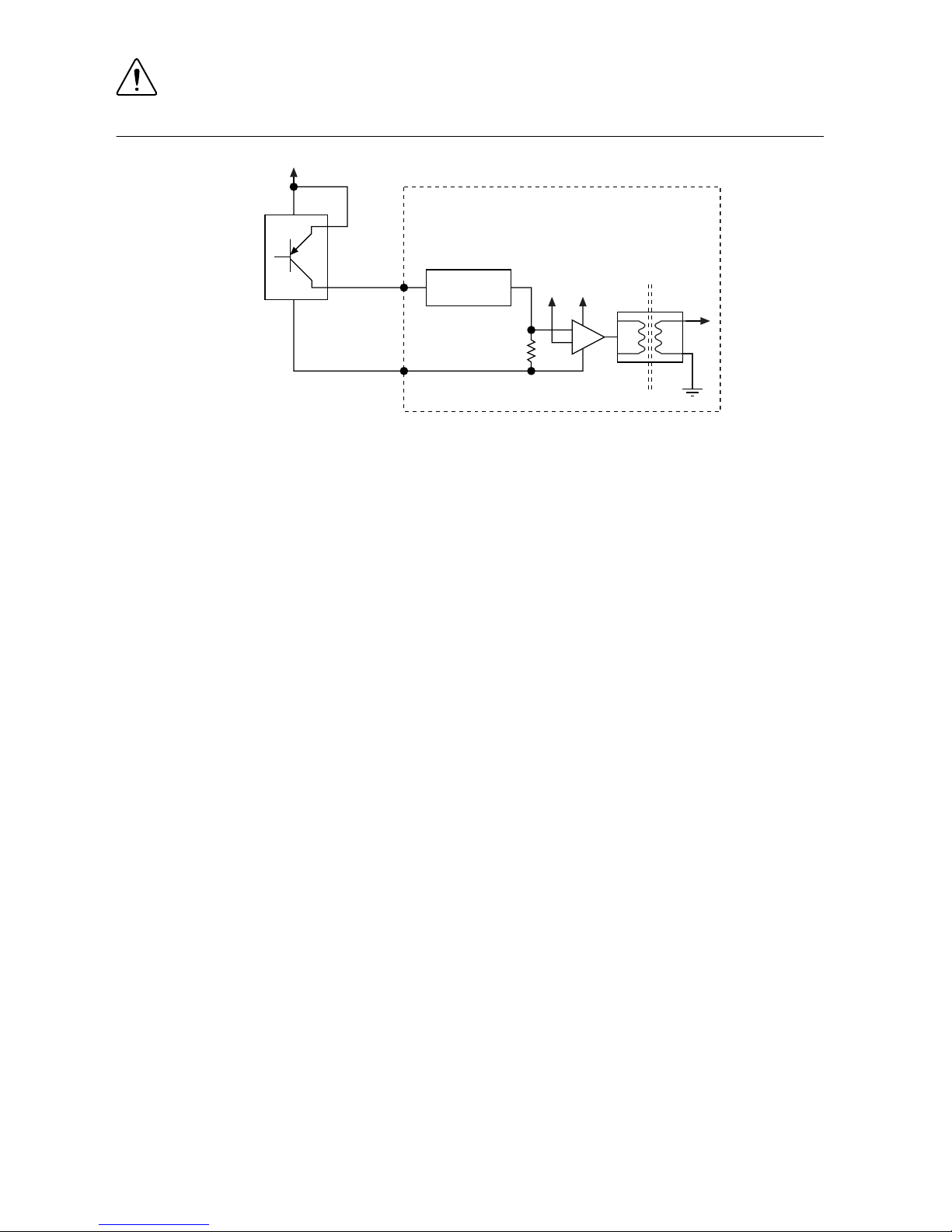

Wiring an Isolated Input

You can wire an isolated input to a sourcing output device.

8 | ni.com | IC-317x User Manual

Page 10

Caution Do not allow the voltage on the isolated inputs to exceed 30 VDC. Doing

so will damage the IC-317x.

Figure 6. Connecting an Isolated Input to a Sourcing Output Device

V

REF

C

ISO

Industrial Controller

Input

Sourcing

Output

Device

Current

Limiter

Power Supply

+

–

Wiring an Isolated Output

The digital isolated output circuits source current to external loads.

When an inductive load, such as a relay or solenoid, is connected to an output, a large counterelectromotive force may occur at switching time due to energy stored in the inductive load.

This flyback voltage can damage the outputs and the power supply.

To limit flyback voltages at the inductive load, install a flyback diode across the load. Mount

the flyback diode as close to the load as possible. Use this protection method if you connect

any of the isolated outputs on the IC-317x to an inductive load.

The following image shows an example of an isolated output wired to an external load with a

flyback diode installed across the load.

IC-317x User Manual | © National Instruments | 9

Page 11

Caution Do not draw more than 35 mA from each isolated output when V

ISO

is

5 V. Do not draw more than 80 mA from each isolated output when V

ISO

is 24 V.

Figure 7. Connecting an Isolated Output to an External Load

Digital Output

External Flyback

Diode for

Inductive Loads

V

ISO

C

ISO

V

CC

Industrial Controller

Load

Overcurrent

Protection Circuit

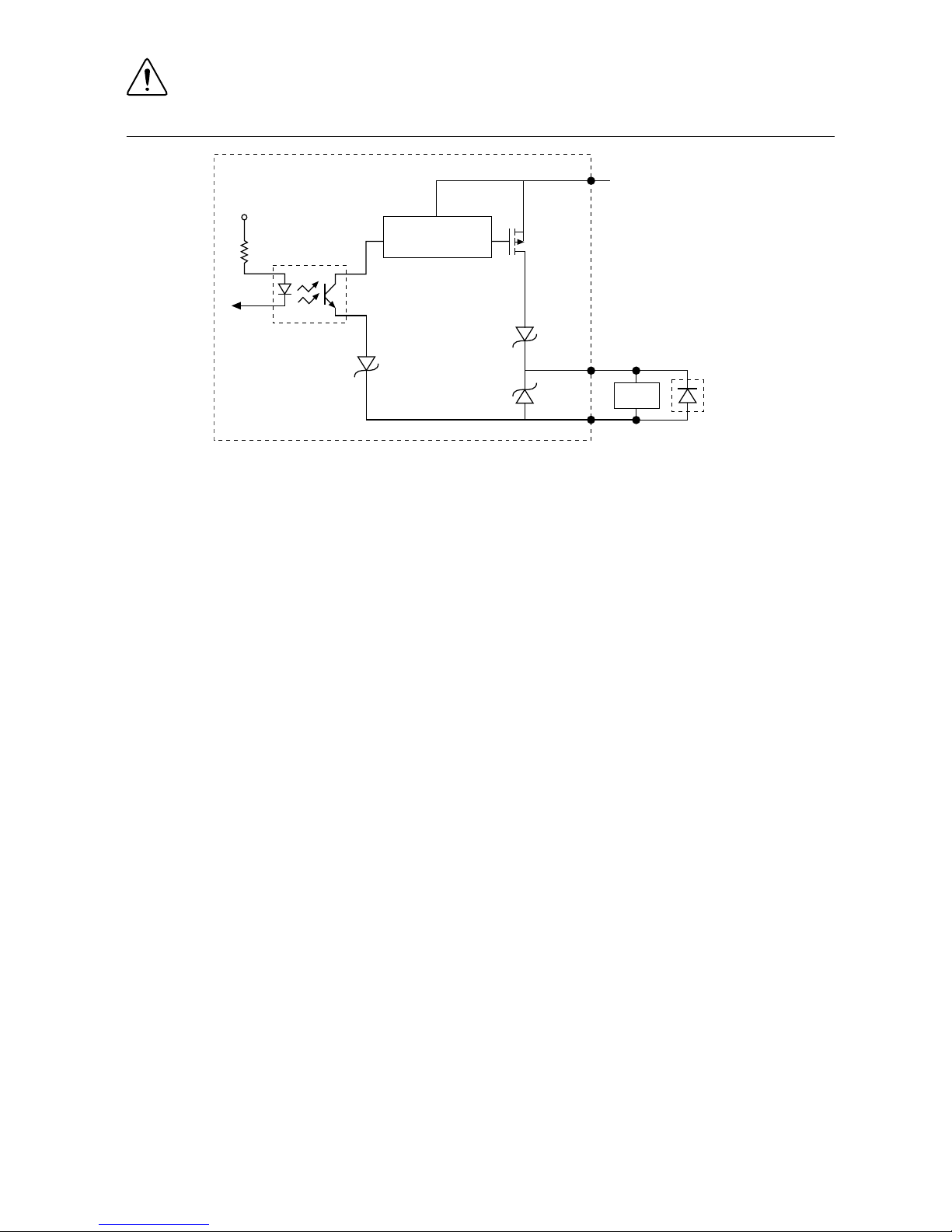

Connecting to Differential I/O

The IC-317x accepts differential (RS-422) line driver inputs. Each of the two differential I/O

can be configured as an output. Use shielded cables for all applications. Unshielded cables are

more susceptible to noise and can corrupt signals.

10 | ni.com | IC-317x User Manual

Page 12

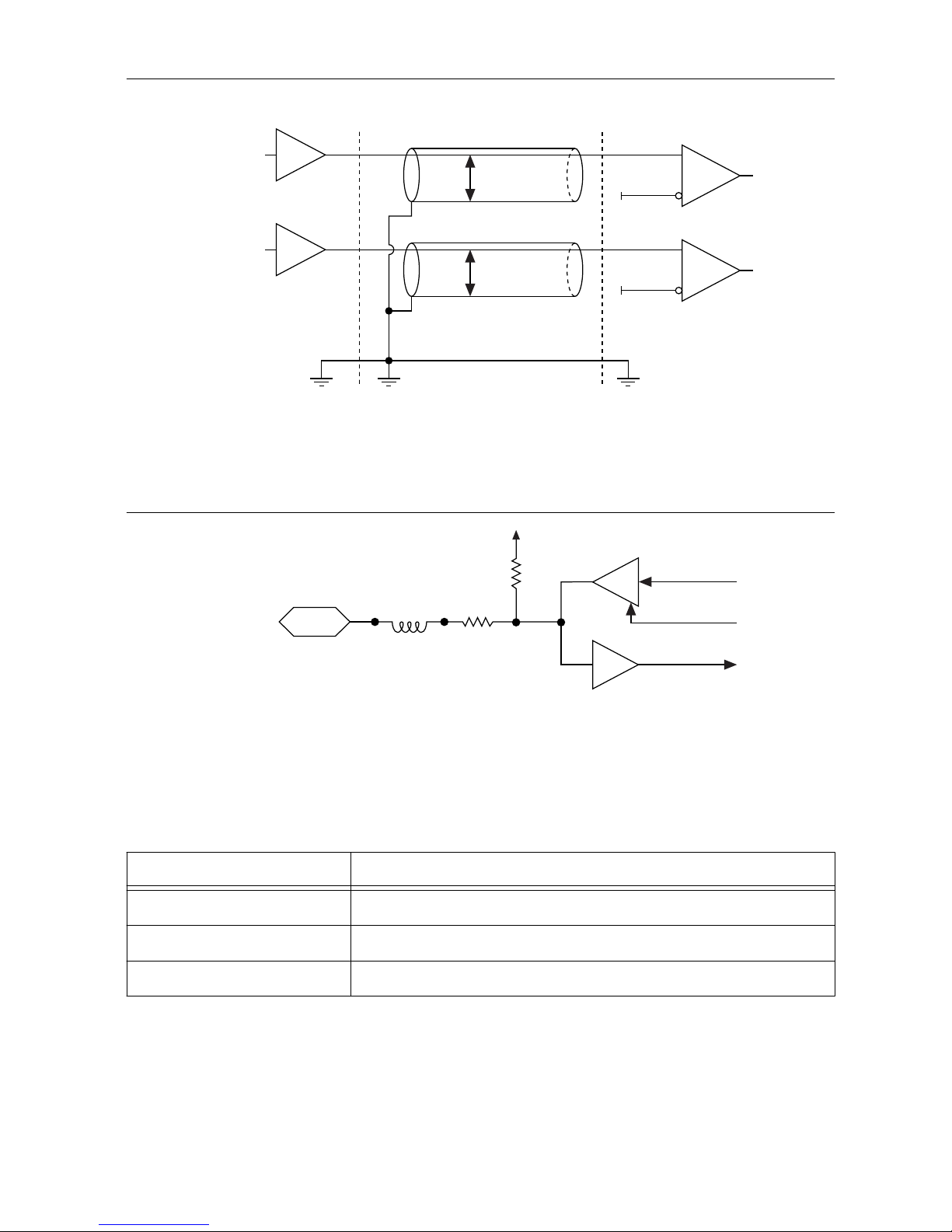

Figure 8. Quadrature Encoder/RS-422 Input/Output Circuit

+

–

Diff I/O 0–

Diff I/O 0+

Diff I/O 1–

Diff I/O 1+

+3.3 V

+

–

10 kΩ 10 kΩ 10 kΩ 10 kΩ

EN

EN

7.5 kΩ 7.5 kΩ 7.5 kΩ

7.5 kΩ

Figure 9. Connecting Differential Line Drivers

Diff In 0+

Diff In 0–

Phase A

Phase A

Diff In 1+

Diff In 1–

Phase B

Phase B

External Device Industrial Controller

Twisted Pair

Twisted Pair

+

–

+

–

IC-317x User Manual | © National Instruments | 11

Page 13

Figure 10. Connecting Single-Ended Line Drivers

Diff In 0+

Diff In 0–

Phase A

Twisted Pair

Twisted Pair

Diff In 1+

Diff In 1–

Phase B

External Device Industrial Controller

+

–

+

–

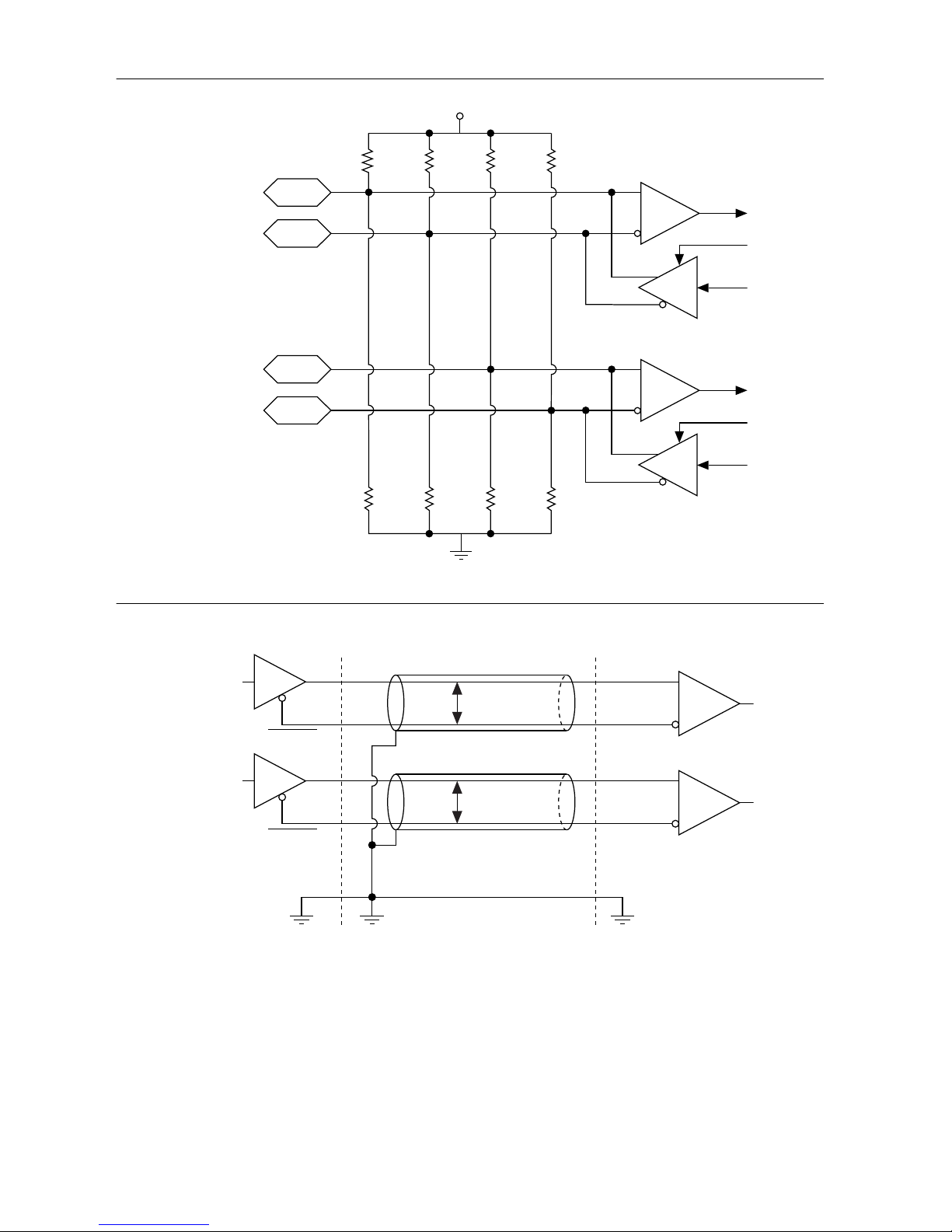

TTL I/O

The following image shows the circuit for a bidirectional TTL I/O.

Figure 11. TTL Input/Output Circuit

100 Ω

TTL_OUT

TTL_OE

TTL_IN

10 kΩ

FB

TTL I/O

Power Input Connectors

The IC-317x requires a power supply to power the system and, if you want to use the isolated

outputs, a power supply to power the isolated outputs.

Table 4. System Power Connector Terminals

Terminal Description

V

1

System power (9-30 VDC)

C Common signal

V

2

System power (9-30 VDC)

12 | ni.com | IC-317x User Manual

Page 14

Table 5. Isolated Power Connector Terminals

Terminal Description

C

ISO

Isolated common signal

V

ISO

Power for isolated outputs (4.5 to 30 VDC)

Chassis Grounding Screw

Use the grounding screw to connect the chassis to earth ground. An earth ground connection is

optional.

RS-485/422/232 Serial Port

The IC-317x has a single serial port that can operate in either RS-485/422 mode or RS-232

mode. Set the serial port mode in the BIOS setup utility.

The serial port is a 10-position RJ50 modular jack, which can connect to serial devices, such

as PLCs, scanners, and lighting devices.

NI recommends the following serial cables for the IC-317x.

Cable Part Number

RJ50 10-position modular plug to DB-9 serial cable 182845-01 for 1 meter cable

182845-02 for 2 meter cable

182845-03 for 3 meter cable

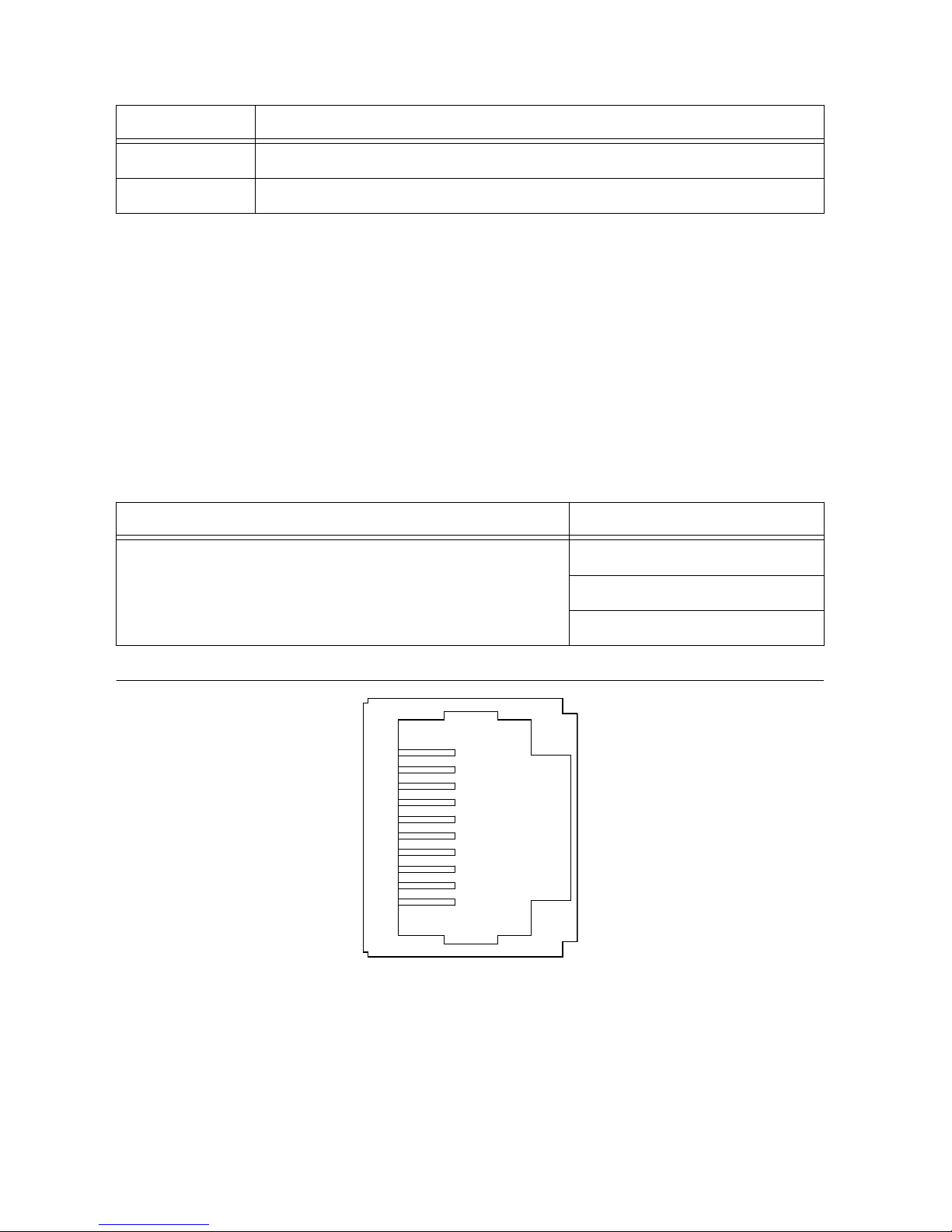

Figure 12. RS-485/422/232 Serial Port Pin Locations (IP20)

3

4

5

6

7

8

9

10

1

2

IC-317x User Manual | © National Instruments | 13

Page 15

Table 6. RS-485/422/232 Serial Port Pin Descriptions

Pin RS-485/422 Mode RS-232 Mode

1 No Connect No Connect

2 TXD- Unused

3 TXD+ Unused

4 No Connect No Connect

5 No Connect No Connect

6 RXD- GND

7 RXD+ Unused

8 Unused TXD

9 Unused RXD

10 GND Unused

Related Information

Serial Port Configuration Submenu on page 53

Serial Port Configuration Submenu on page 53

USB 3.0 Ports

The USB ports support common USB peripheral devices such as USB flash drives, USB hard

drives, USB-to-IDE adapters, keyboards, mice, and USB cameras.

LabVIEW Real-Time usually maps USB mass-storage devices to the /U, /V, /W, or /X drive,

starting with the /U drive if it is available. Refer to the LabVIEW Help for more information.

LabVIEW Real-Time usually maps USB mass-storage devices to the /U, /V, /W, or /X drive,

starting with the /U drive if it is available. Refer to the LabVIEW Help for more information.

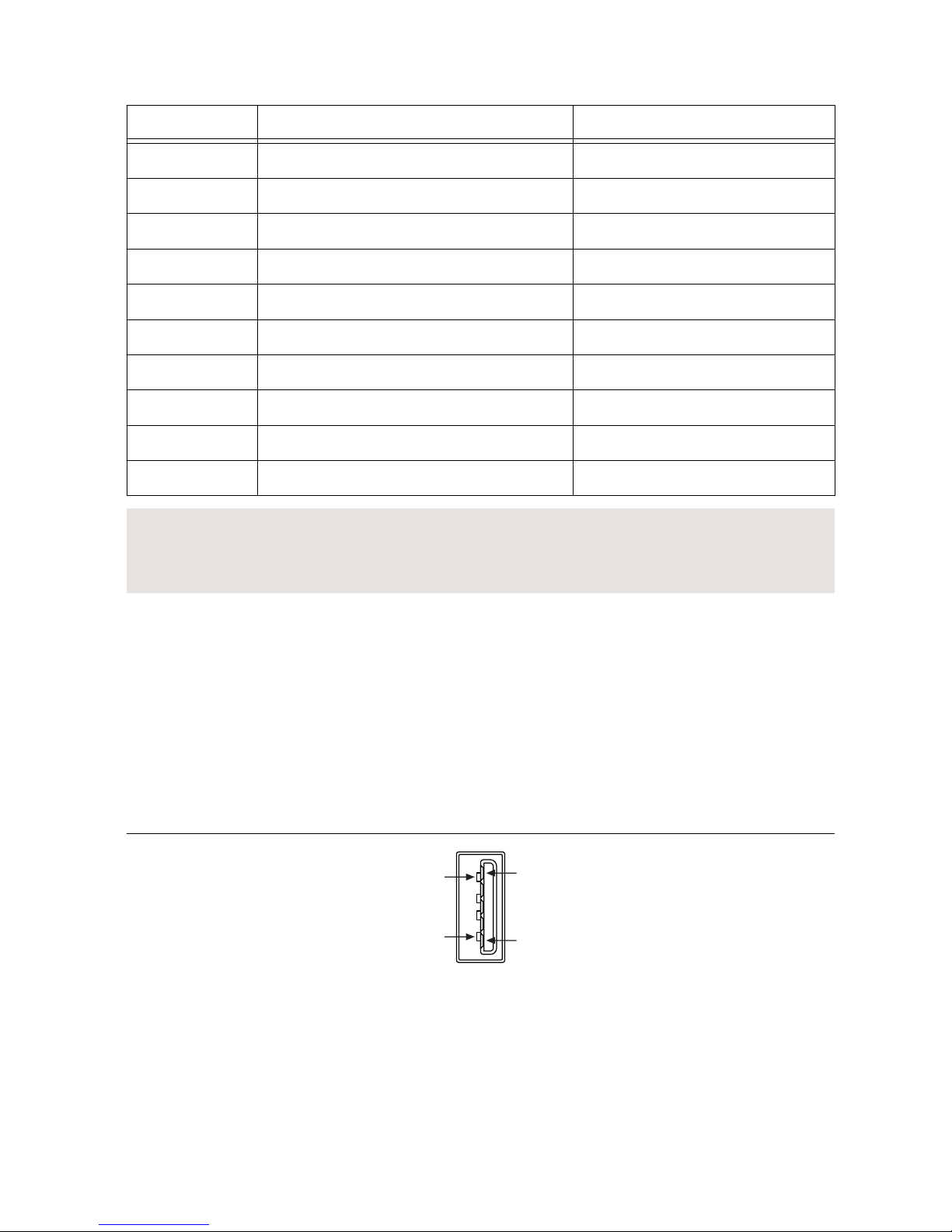

Figure 13. USB 3.0 Port Pin Locations (IP20)

1

4

9

5

14 | ni.com | IC-317x User Manual

Page 16

Table 7. USB 3.0 Port Pin Descriptions

Pin Signal Name Signal Description

1 VBUS Cable Power (+5 VDC)

2 D- USB Data -

3 D+ USB Data +

4 GND Ground for power return

5 StdA_SSRX- SuperSpeed receiver differential pair

6 StdA_SSRX+

7 GND_DRAIN Ground for signal return

8 StdA_SSTX- SuperSpeed transmitter differential pair

9 StdA_SSTX+

USB 2.0 Ports

The USB ports support common USB peripheral devices such as USB flash drives, USB hard

drives, USB-to-IDE adapters, keyboards, mice, and USB cameras.

LabVIEW Real-Time usually maps USB mass-storage devices to the /U, /V, /W, or /X drive,

starting with the /U drive if it is available. Refer to the LabVIEW Help for more information.

LabVIEW Real-Time usually maps USB mass-storage devices to the /U, /V, /W, or /X drive,

starting with the /U drive if it is available. Refer to the LabVIEW Help for more information.

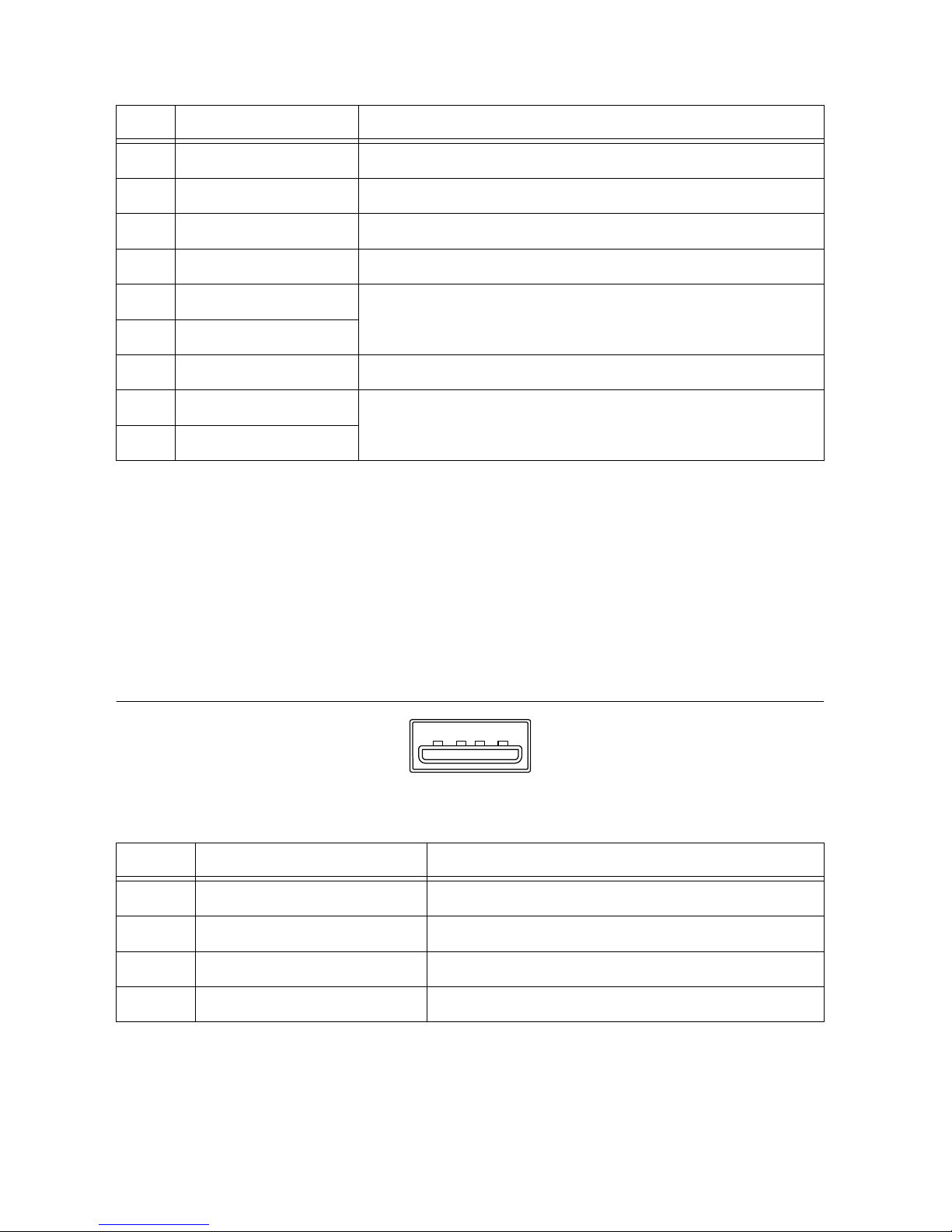

Figure 14. USB 2.0 Pin Locations (IP20)

4

3

2

1

Table 8. USB 2.0 Port Pin Descriptions

Pin Signal Name Signal Description

1 VBUS Cable Power (+5 VDC)

2 D- USB Data -

3 D+ USB Data +

4 GND Ground for power return

LED Indicators

The LED indicators are located on the front panel of the device. The IC-317x provides the

following LED indicators.

IC-317x User Manual | © National Instruments | 15

Page 17

POWER LED

The following table lists the POWER LED indications.

Table 9. POWER LED Indications

LED Color LED Pattern Indication

Green Solid The IC-317x is powered from the V1 input.

Yellow Solid The IC-317x is powered from the V2 input.

— Off The IC-317x is powered off.

STATUS LED

The following table describes the STATUS LED indications.

16 | ni.com | IC-317x User Manual

Page 18

Table 10. STATUS LED Indications

LED Color LED State Indication

Yellow OFF The IC-317x initialized successfully and is ready for use.

2 blinks (RT only) The device has automatically booted into safe

mode. This occurs when there is no software installed, which

is the out-of-box state, or the device has detected an error in

its software. Reinstall software on the IC-317x.

3 blinks (RT only) The IC-317x has booted into safe mode.

4 blinks (RT only) The IC-317x has experienced two consecutive

software exceptions. The IC-317x automatically restarts after

an exception. After the second exception, the IC-317x

remains in the exception state, alerting you to resolve the

problem. Reinstall software on the IC-317x or contact

National Instruments.

Continuous

blink

(RT only) The IC-317x has not booted into NI Linux RealTime. The controller either booted into an unsupported

operating system, was interrupted during the boot process, or

detected an unrecoverable software error.

ON (RT only) The IC-317x is booting up.

(Windows only) An internal drive is being accessed.

Red Continuous

blink

This indicates a hardware error. An internal power supply has

failed. Check front-panel I/O connections for shorts. Remove

any shorts and cycle power to the IC-317x. If the problem

persists, contact National Instruments.

Related Information

Safe Mode on page 19

Safe Mode on page 19

User LEDs

You can define the USER1 and USER FPGA1 LEDs to meet the needs of your application.

The following table describes the USER1 and USER FPGA1 LED indicators.

IC-317x User Manual | © National Instruments | 17

Page 19

Table 11. User LEDs

LED LED Color Indication

USER1 Green/Yellow Use LabVIEW Real-Time to define the USER1 LED with the

RT LEDs VI. For more information about the RT LEDs VI,

refer to the LabVIEW Help.

USER

FPGA1

Green/Yellow Use the LabVIEW FPGA Module and NI Industrial Controller

Device Drivers software to define the USER FPGA1 LED.

Use the USER FPGA1 LED to help debug your application or

display application status. Refer to the LabVIEW Help for

information about programming this LED.

PoE LEDs

The PoE (Power over Ethernet) LEDs are located to the left of the PoE ports. The following

table describes the PoE LED indications:

Table 12. PoE LED Indications

PoE LED State Indication

OFF The corresponding PoE port is not supplying power.

ON The corresponding PoE port is powering the connected device.

Ethernet LEDs

The Gigabit Ethernet ports have the following LEDs.

Figure 15. LEDs for the Gigabit Ethernet Ports

1

2

1. Speed LED

2. Activity/Link LED

Table 13. Ethernet LED Indications

LED Status Indication

Speed

OFF No link, or 10 Mbps link

Green 100 Mbps link

Amber 1,000 Mbps link

18 | ni.com | IC-317x User Manual

Page 20

Table 13. Ethernet LED Indications (Continued)

LED Status Indication

Activity/Link

OFF No link has been established

Solid A link has been negotiated

Blinking Activity on the link

Using the RESET Button

Pressing the RESET button resets the processor in the same manner as cycling power. You can

also use the RESET button to troubleshoot network connectivity.

The RESET button is located on the bottom of the controller.

1. Hold the RESET button for 5 seconds, and then release it to boot the IC-317x into safe

mode and enable Console Out.

2. After booting the controller into safe mode, hold the RESET button again for 5 seconds to

enable IP reset, which resets the network adapter to its default configuration.

Safe Mode

When you boot the IC-317x into safe mode, it launches only the services necessary for

updating its configuration and installing software. To resume normal operations, press the

RESET button for less than 5 seconds.

IP Reset

Use IP reset to reset the TCP/IP settings when moving the system from one subnet to another

or when the current TCP/IP settings are invalid.

When the IC-317x is in the IP reset state, the IP address of the network port resets to DHCP or

a link-local address. You can then set up a new network configuration for the IC-317x from a

development machine on the same subnet, or you can connect the IC-317x directly to the

development computer.

Note By default, the target automatically attempts to connect to the network using

DHCP. If the target is unable to initiate a DHCP connection, the target connects to

the network with a link-local IP address (169.254.x.x).

Replacing the Battery

The IC-317x contains a user-replaceable battery. The battery compartment is located on the

left side of the device as you look at the device from the front. Take the following steps to

replace the battery:

Caution Before removing the battery cover, disconnect all power connectors and

I/O cables from the device. To prevent damage from electrostatic discharge (ESD),

ground the unit and yourself by using a grounding strap or touching a grounded

object, such as a computer chassis.

IC-317x User Manual | © National Instruments | 19

Page 21

1. Use a Phillips head screwdriver to remove the two screws holding the battery cover plate.

Remove the plate, then remove battery from the device.

2. Insert a new battery in the device. Ensure the positive terminal of the battery faces

outward. Refer to the device specifications for the required battery type.

3. Replace the battery cover plate.

Replacing the battery resets the BIOS settings to their default values.

Increasing the Battery Life

When storing the controller, you can disconnect the battery to deactivate the real-time clock

and reset the BIOS settings to their default values. Take the following steps to disconnect the

battery:

Caution Before removing the battery cover, disconnect all power connectors and

I/O cables from the device. To prevent damage from electrostatic discharge (ESD),

ground the unit and yourself by using a grounding strap or touching a grounded

object, such as a computer chassis.

1. Use a Phillips head screwdriver to remove the two screws holding the battery cover plate.

Remove the plate.

2. Locate the BATTERY CONNECT switch above the battery and move the switch toward

the front panel of the device. The battery is now disconnected from the device.

3. Replace the battery cover plate.

20 | ni.com | IC-317x User Manual

Page 22

Figure 16. Side of Device with Removed Battery Cover Plate and BATTERY

CONNECT Switch in Disconnected Position

Mounting the IC-317x

This section provides information for creating a custom mount for the IC-317x. If you do not

want to create a custom mount, a panel mount kit for the IC-317x is available from National

Instruments (part number 784791-01).

Caution Do not position the IC-317x with the heat sinks resting on any surface.

Doing so may cause the IC-317x device to overheat. Refer to the IC-317x

Specifications for temperature specifications.

To obtain the maximum allowable ambient temperature, you must mount the IC-317x

vertically. The following figures provide dimensional drawings and clearance information for

the IC-317x.

IC-317x User Manual | © National Instruments | 21

Page 23

Figure 17. Front View Dimensions

POWER

PoE1

PoE2

PoE3

PoE4

DIO

STATUS

USER1

DP

DP

USER FPGA1

ACT/

LINK

10/100/

1000

SYS PWR IN

150

W MAX

ISO PWR IN

5-24 V

RESET

9-30 V

21.35 mm

(0.84 in.)

46.94 mm

(1.85 in.)

46.17 mm

(1.58 in.)

42.60 mm

(1.68 in.)

28.19 mm

(1.11 in.)

22.72 mm

(0.89 in.)

27.94 mm

(1.10 in.)

30.75 mm

(1.21 in.)

26.95 mm

(1.06 in.)

35.18 mm

(1.39 in.)

30.48 mm

(1.20 in.)

11.45 mm

(0.45 in.)

22.7 mm

(0.89 in.)

8.5 mm

(0.34 in.)

31.58 mm

(1.24 in.)

16.97 mm

(0.67 in.)

13.45 mm

(0.53 in.)

22.21 mm

(0.87 in.)

22.21 mm

(0.87 in.)

2.58 mm

(0.10 in.)

28.02 mm

(1.10 in.)

3.27 mm

(0.129 in.)

36.12mm

(1.42 in.)

22 | ni.com | IC-317x User Manual

Page 24

Figure 18. Side View Dimensions

15.08 mm

(0.20 in.)

173.99 mm

(6.85 in.)

4.23 mm

(0.17 in.)

167.63 mm

(6.60 in.)

176.94 mm

(6.97 in.)

IC-317x User Manual | © National Instruments | 23

Page 25

Figure 19. Rear View Dimensions

132.08 mm

(5.20 in.)

18.03 mm

(0.71 in.)

23.88 mm

(0.94 in.)

33.15 mm

(1.31 in.)

22.29 mm

(0.88 in.)

37.27 mm

(1.47 in.)

92.71 mm

(3.65 in.)

4x 6-32

7.00 mm (0.28 in.)

Securing the IC-317x to a Mount

1. Align the screw holes of the mounting bracket with the four holes on the back of the

IC-317x.

2. Insert four 6-32 screws and tighten them 0.28 N · m (3.5 lb · in) until they are secure.

Ensure the heads of the screws are flush with the mounting bracket.

24 | ni.com | IC-317x User Manual

Page 26

Figure 20. Securing a Mounting Bracket to the Device

IC-317x User Manual | © National Instruments | 25

Page 27

Figure 21. Mounting Bracket Dimensions

157.48 mm

(6.20 in.)

16.26 mm

(0.64 in.)

170.18 mm

(6.70 in.)

27.11 mm

(1.07 in.)

72.39 mm

(2.85 in.)

91.44 mm

(3.6 in.)

3.18 mm

(0.13 in.)

Clearance Requirements

The IC-317x installation must meet the following space and cabling clearance requirements

for optimum cooling:

• Allow 101.6 mm (4.0 in.) on the top and bottom of the IC-317x for air circulation.

• Allow 50.8 mm (2.0 in.) on the sides of the IC-317x for air circulation.

• Allow enough space in front of the IC-317x to connect cables.

26 | ni.com | IC-317x User Manual

Page 28

Figure 22. Clearance Requirements for the IC-317x

101.6 mm

(4.00 in.)

101.6 mm

(4.00 in.)

50.8 mm

(2.00 in.)

50.8 mm

(2.00 in.)

IC-3173 (IP67)

The following information applies to the IC-3173 (IP67).

About the IC-3173 (IP67)

The IC-3173 (IP67) is a high-performance, small, fanless embedded computer designed for

rugged industrial applications. The IC-3173 (IP67) also provides multiple digital input/output

(I/O) options for communicating with external devices.

IC-317x User Manual | © National Instruments | 27

Page 29

Figure 23. IC-3173 (IP67) Block Diagram

Intel Dual-Core Processor

i7-5650U, i5-5350U,

or Celeron 3765U

Xilinx

Kintex-7 FPGA

7K160T

IC-317x

Hardware

Data

x2 DisplayPort

8/4 GB DDR3L

Memo ry

64/32/ 4 GB

Solid-stat e Drive

Serial Port

RS-232/422/485

x8 TTL I/O

x2 RS-422 I/O

x8 Isolated

Outputs

x8 Isolated

Inputs

RJ45 Primary Gigabit

Ethernet Port

x2 USB 3.0

Host Ports

x1 USB 2.0

Host Ports

x4 Gigabit

Ethernet Ports with PoE

2 GB DDR3L

Memory

4.5 MB

QDR-II+ SRAM

PCI Express

Swit ch

x3 DIO Connectors

IC-3173 Only

PCIe

Gen 2

x4

PCIe

Gen 2

x4

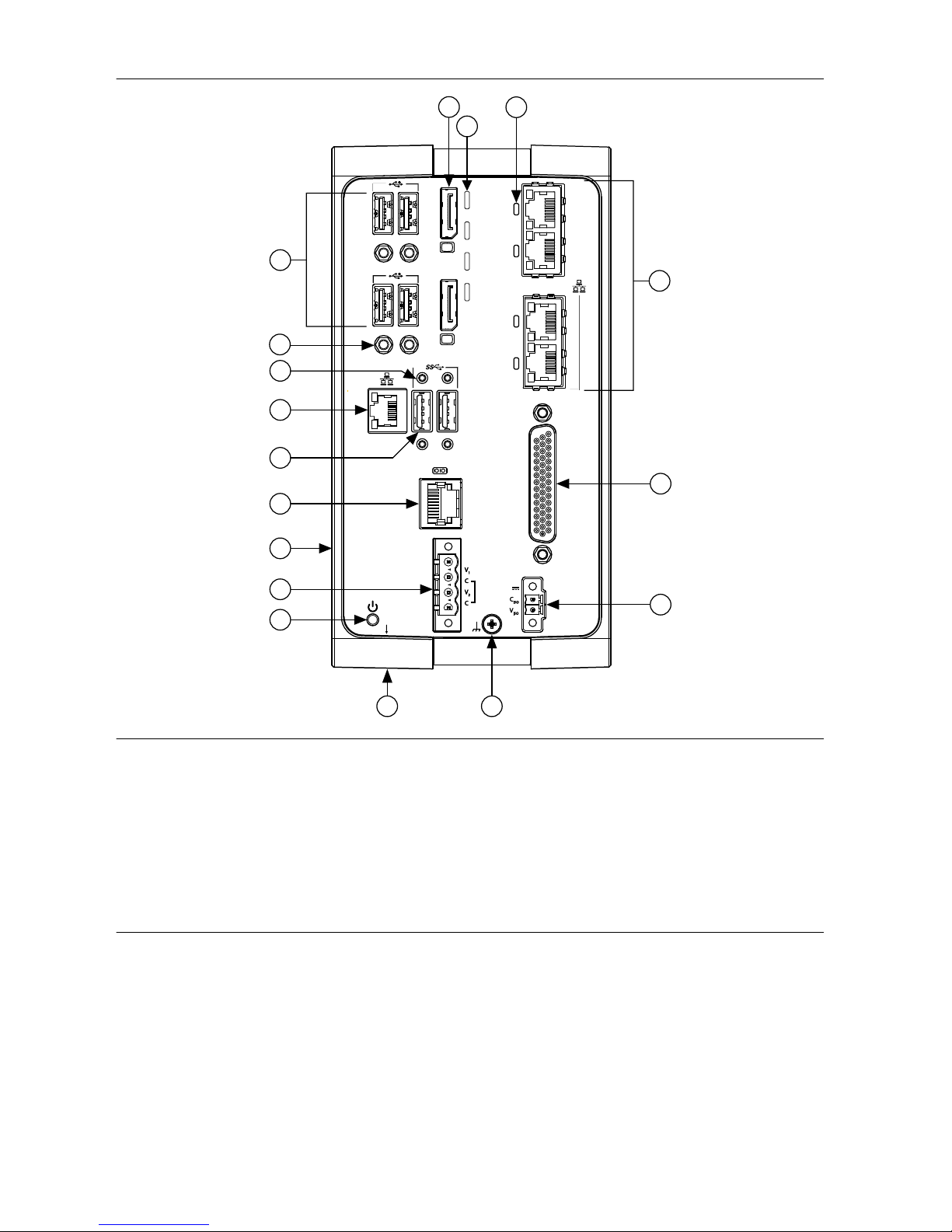

Hardware Overview

The IC-3173 (IP67) front panel consists of four Gigabit Ethernet ports with Power over

Ethernet (PoE), one RS-232/RS-485 serial port, one system Gigabit Ethernet Port, two USB

3.0 ports, one USB 2.0 port, and two DisplayPort connectors.

The IC-3173 (IP67) front panel also includes LEDs for communicating system status and three

17-pin Digital I/O ports. The Digital I/O ports offer 8 isolated inputs, 8 isolated outputs, 2

bidirectional differential I/O (RS-422) or single-ended input lines that can be used with a

quadrature encoder, and 8 bidirectional TTL lines.

28 | ni.com | IC-317x User Manual

Page 30

Figure 24. IC-3173 (IP67) Front Panel

IC-3173

IP67 Industrial Controller

ISO PWR IN

5-24V

CONNECTOR 2

CONNECTOR 1

SYS PWR IN

9-30V

150W MAX

RESET

CONNECTOR 0

POWER STATUS

SS

DP

DIGITAL I/O

SS

PoE 4

PoE 2PoE 1

PoE 3

SYNC

8

8

8

7

7

7

7

1

2

3

5

1

4

10

6

3

9

1. USB 3.0 Ports

2. USB 2.0 Port

3. DisplayPort Connectors

4. System Gigabit Ethernet Port

5. RS-232/RS-485 Serial Port

6. System Power Connector

7. Gigabit Ethernet Ports with PoE

8. 17-pin Digital I/O Ports

9. Chassis Grounding Screw

10. Isolated Power Input Connector

Connector Pinouts

The IC-3173 (IP67) provides the following connectors.

DisplayPort

Use the DisplayPort connectors to connect one or more monitors to implement a local HMI for

your controller. You can develop a single real-time VI to use for both your user interface and

system logic. For more information, refer to the Using the Embedded UI to Access RT Target

VIs topic in the LabVIEW Help. For up-to-date information about supported NI cables and

accessories, refer to the pricing section of the product page at ni.com.

For each DisplayPort connector you use, you must install one ferrite clip, NI part number

711856-01, approximately 25 to 50 mm (1 to 2 in.) from the end of the connector.

IC-317x User Manual | © National Instruments | 29

Page 31

Figure 25. Installing a Ferrite on the Cable

NI recommends the following DisplayPort cable for the IC-3173 (IP67).

Cable Part Number

20-position M12 to DisplayPort male cable for IC-3173 (IP67), 3 meters 146858-03

The following figure and table lists the DisplayPort pins and signals.

Figure 26. DisplayPort Connector Pin Locations (IC-3173 (IP67))

8

13

5

10

15

19

20

4

9

14

18

2

6

11

16

3

7

12

17

Pin 1

Table 14. DisplayPort Connector Pin Descriptions

Pin Signal Name

1 DP_PWR

2 ML_Lane 0 (p)

3 ML_Lane 0 (n)

30 | ni.com | IC-317x User Manual

Page 32

Table 14. DisplayPort Connector Pin Descriptions (Continued)

Pin Signal Name

4 Hot Plug Detect

5 ML_Lane 1 (p)

6 Return

7 GND

8 CONFIG1

9 GND

10 ML_Lane 1 (n)

11 ML_Lane 2 (p)

12 GND

13 CONFIG2

14 AUX CH (n)

15 GND

16 ML_Lane 2 (n)

17 GND

18 ML_Lane 3 (n)

19 AUX CH (p)

20 ML_Lane 3 (p)

Ethernet Ports

The IC-3173 (IP67) provides one system Gigabit Ethernet network port and four Gigabit

Ethernet ports with Power over Ethernet (PoE). The Ethernet ports provide a connection

between the IC-3173 (IP67), a network, and other Ethernet devices. The IC-3173 (IP67)

automatically detects the speed of the connection and configures itself accordingly.

If a PoE-capable device is plugged into an Ethernet port with PoE, the IC-3173 (IP67)

automatically supplies power to the device. When you unplug a PoE device, PoE is

automatically disabled. You can use non-PoE Ethernet devices with PoE-enabled Gigabit

Ethernet ports.

(Windows only) The network Ethernet port provides Wake-on-LAN functionality from the

power off state when associated with the Intel® driver. Wake-on-LAN must be enabled in the

Power Management tab of the Intel I210 Gigabit Network Connection Properties dialog for the

primary Ethernet port in Device Manager. The NI GigE Vision driver (NI-GEV) does not

support Wake-on-LAN. The Ethernet ports with PoE do not support Wake-on-LAN.

IC-317x User Manual | © National Instruments | 31

Page 33

NI recommends the following ethernet cables for the IC-3173 (IP67).

Cable Part Number

X-Code M12 to X-Code M12 CAT 6A network cable, 5 meters 145231-05

X-Code M12 to RJ45 CAT 6A network cable, 5 meters 145230-05

Figure 27. Ethernet Port Pin Locations (IC-3173 (IP67))

Pin 1

Pin 8

Table 15. Ethernet Port Pin Descriptions

Pin Fast Ethernet (100 Mbps) Gigabit Ethernet

MDI MDI-X

1 TX+ BI_DA+ BI_DB+

2 TX- BI_DA- BI_DB-

3 RX+ BI_DB+ BI_DA+

4 RX- BI_DB- BI_DA-

5 No Connect BI_DD+ BI_DC+

6 No Connect BI_DD- BI_DC-

7 No Connect BI_DC- BI_DD-

8 No Connect BI_DC+ BI_DD+

Digital I/O

The three 17-pin Digital I/O ports on the IC-3173 (IP67) offer 8 isolated inputs, 8 isolated

outputs, 2 bidirectional differential inputs (RS-422) or single-ended input lines that can be

used with a quadrature encoder, and 8 bidirectional TTL lines. The Digital I/O port can be

connected to any appropriate shielded device or connector block using a shielded cable.

NI recommends the following digital I/O cable for the IC-3173 (IP67).

32 | ni.com | IC-317x User Manual

Page 34

Cable Part Number

17-position M12 A-coded pigtail FPGA I/O cable for IC-3173 (IP67), 3

meters

785932-01

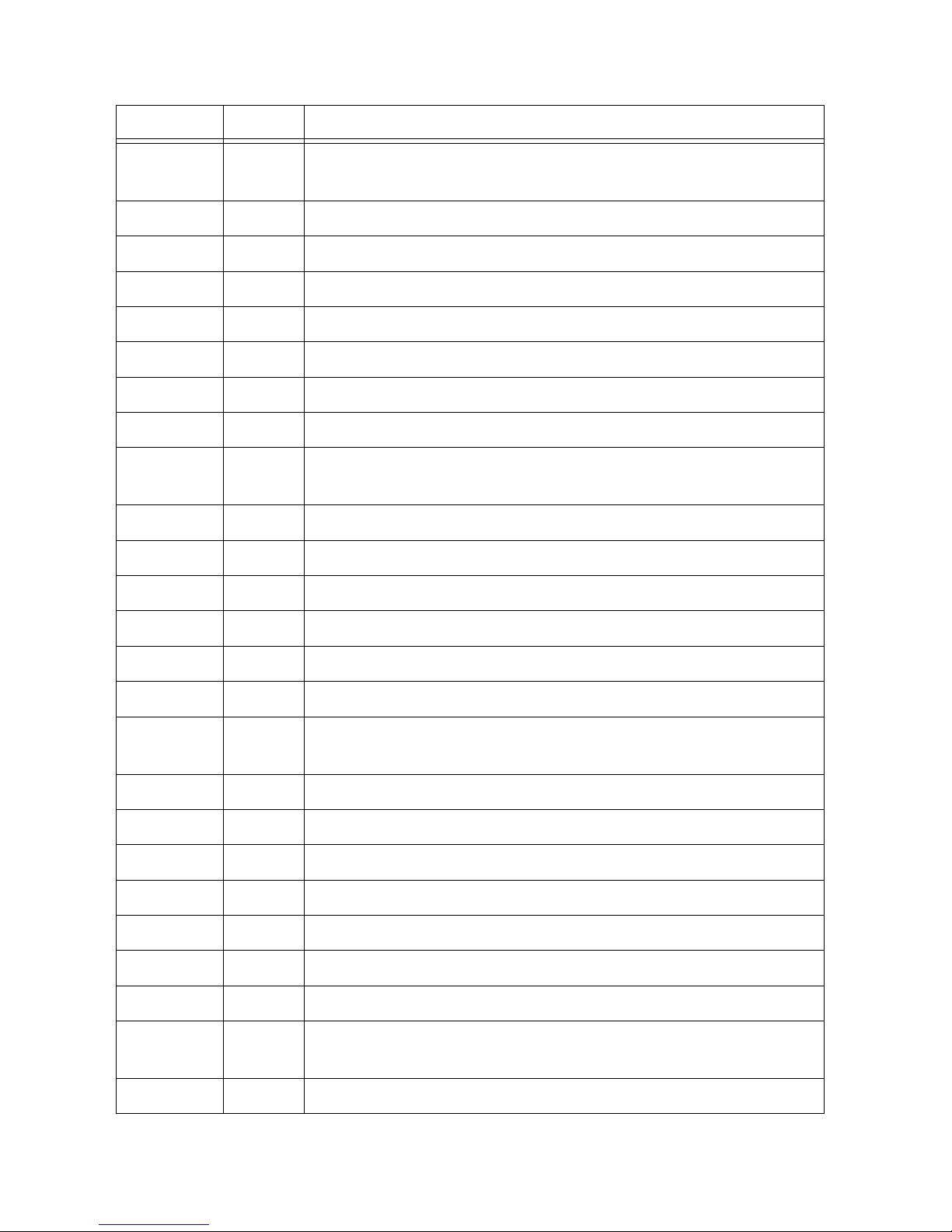

Refer to the following image and table for pin locations and descriptions.

Figure 28. 17-pin Digital I/O Connector Pin Locations (IC-3173 (IP67))

Pin 1

Conn 1

Pin 1

Conn 2

Pin 1

Conn 0

IC-317x User Manual | © National Instruments | 33

Page 35

Table 16. Digital I/O Connector 0 Pin Descriptions

Pin Number Signal Description

1 Iso In 0 Isolated Input

2 NC No connection

3 GND Ground for TTL and differential I/O

4 TTL 0 Bidirectional TTL I/O

5 TTL 2 Bidirectional TTL I/O

6 GND Ground for TTL and differential I/O

7 Iso Out 0 Isolated output

8 Iso Out 1 Isolated output

9 V

ISO

Isolated power voltage reference output

10 Iso In 1 Isolated input

11 Iso In 2 Isolated input

12 NC No connection

13 TTL 1 Bidirectional TTL I/O

14 TTL 3 Bidirectional TTL I/O

15 Iso Out 2 Isolated output

16 C

ISO

Common for isolated inputs and outputs

17 C

ISO

Common for isolated inputs and outputs

Table 17. Digital I/O Connector 1 Pin Descriptions

Pin Number Signal Description

1 Iso In 3 Isolated Input

2 NC No connection

3 GND Ground for TTL and differential I/O

4 TTL 4 Bidirectional TTL I/O

5 TTL 6 Bidirectional TTL I/O

6 GND Ground for TTL and differential I/O

7 Iso Out 3 Isolated output

8 Iso Out 4 Isolated output

34 | ni.com | IC-317x User Manual

Page 36

Table 17. Digital I/O Connector 1 Pin Descriptions (Continued)

Pin Number Signal Description

9 V

ISO

Isolated power voltage reference output

10 Iso In 4 Isolated input

11 Iso In 5 Isolated input

12 NC No connection

13 TTL 5 Bidirectional TTL I/O

14 TTL 7 Bidirectional TTL I/O

15 Iso Out 5 Isolated output

16 C

ISO

Common for isolated inputs and outputs

17 C

ISO

Common for isolated inputs and outputs

Table 18. Digital I/O Connector 2 Pin Descriptions

Pin Number Signal Description

1 Iso In 6 Isolated Input

2 NC No connection

3 GND Ground for TTL and differential I/O

4 Diff 0+ Bidirectional RS-422+/Quadrature Encoder A+

5 Diff 1+ Bidirectional RS-422+/Quadrature Encoder B+

6 GND Ground for TTL and differential I/O

7 Iso Out 6 Isolated output

8 Iso Out 7 Isolated output

9 V

ISO

Isolated power voltage reference output

10 Iso In 7 Isolated input

11 NC No connection

12 NC No connection

13 Diff 0- Bidirectional RS-422+/Quadrature Encoder A-

14 Diff 1- Bidirectional RS-422+/Quadrature Encoder B-

15 NC No connection

IC-317x User Manual | © National Instruments | 35

Page 37

Table 18. Digital I/O Connector 2 Pin Descriptions (Continued)

Pin Number Signal Description

16 C

ISO

Common for isolated inputs and outputs

17 C

ISO

Common for isolated inputs and outputs

Wiring an Isolated Input

You can wire an isolated input to a sourcing output device.

Caution Do not apply a voltage greater than 30 VDC to the isolated inputs.

Voltage greater than 30 VDC may damage the IC-3173 (IP67).

Figure 29. Connecting an Isolated Input to a Sourcing Output Device

V

REF

C

ISO

Industrial Controller

Input

Sourcing

Output

Device

Current

Limiter

Power Supply

+

–

Wiring an Isolated Output

The digital isolated output circuits source current to external loads.

When an inductive load, such as a relay or solenoid, is connected to an output, a large counterelectromotive force may occur at switching time due to energy stored in the inductive load.

This flyback voltage can damage the outputs and the power supply.

To limit flyback voltages at the inductive load, install a flyback diode across the load. Mount

the flyback diode as close to the load as possible. Use this protection method if you connect

any of the isolated outputs on the IC-3173 (IP67) to an inductive load.

The following image shows an example of an isolated output wired to an external load with a

flyback diode installed across the load.

36 | ni.com | IC-317x User Manual

Page 38

Caution Do not draw more than 35 mA from each isolated output when V

ISO

is

5 V. Do not draw more than 80 mA from each isolated output when V

ISO

is 24 V.

Figure 30. Connecting an Isolated Output to an External Load

Digital Output

External Flyback

Diode for

Inductive Loads

V

ISO

C

ISO

V

CC

Industrial Controller

Load

Overcurrent

Protection Circuit

Connecting to Differential I/O

The IC-3173 (IP67) accepts differential (RS-422) line driver inputs. Each of the two

differential I/O can be configured as an output. Use shielded cables for all applications.

Unshielded cables are more susceptible to noise and can corrupt signals.

IC-317x User Manual | © National Instruments | 37

Page 39

Figure 31. Quadrature Encoder/RS-422 Input/Output Circuit

+

–

Diff I/O 0–

Diff I/O 0+

Diff I/O 1–

Diff I/O 1+

+3.3 V

+

–

10 kΩ 10 kΩ 10 kΩ 10 kΩ

EN

EN

7.5 kΩ 7.5 kΩ 7.5 kΩ

7.5 kΩ

Figure 32. Connecting Differential Line Drivers

Diff In 0+

Diff In 0–

Phase A

Phase A

Diff In 1+

Diff In 1–

Phase B

Phase B

External Device Industrial Controller

Twisted Pair

Twisted Pair

+

–

+

–

38 | ni.com | IC-317x User Manual

Page 40

Figure 33. Connecting Single-Ended Line Drivers

Diff In 0+

Diff In 0–

Phase A

Twisted Pair

Twisted Pair

Diff In 1+

Diff In 1–

Phase B

External Device Industrial Controller

+

–

+

–

TTL I/O

The following image shows the circuit for a bidirectional TTL I/O.

Figure 34. TTL Input/Output Circuit

100 Ω

TTL_OUT

TTL_OE

TTL_IN

10 kΩ

FB

TTL I/O

Power Input Connectors

The IC-3173 (IP67) requires a power supply to power the system and, if you want to use the

isolated outputs, a power supply to power the isolated outputs.

NI recommends the following accessories for the IC-3173 (IP67).

Cable

Part Number

4-position M12 T-coded pigtail power cable for IC-3173 (IP67), 3 meters 785930-01

4-position M12 T-coded power connector for IC-3173 (IP67) 785928-01

The following figure shows the system power connector.

IC-317x User Manual | © National Instruments | 39

Page 41

Figure 35. System Power Connector (IC-3173 (IP67))

1

2

4

3

1. C

2. V2

3. C

4. V1

Table 19. System Power Connector Terminals

Terminal Description

V

1

System power (9-30 VDC)

C Common signal

V

2

System power (9-30 VDC)

NI recommends the following accessories for the isolated power input of the IC-3173 (IP67).

Cable Part Number

4-position M12 A-coded pigtail ISO power cable for IC-3173 (IP67), 3

meters

785931-01

4-position M12 A-coded ISO power connector for IC-3173 (IP67) 785929-01

The following figure shows the terminal of the isolated power input connector.

Figure 36. Isolated Power Input Connector (IC-3173 (IP67))

4

3

1

2

1. C (Negative) Terminal

2. V (Positive) Terminal

3. No connect

4. No connect

Table 20. Isolated Power Connector Terminals

Terminal Description

C

ISO

Isolated common signal

V

ISO

Power for isolated outputs (4.5 to 30 VDC)

40 | ni.com | IC-317x User Manual

Page 42

Chassis Grounding Screw

Use the grounding screw to connect the chassis to earth ground. An earth ground connection is

optional.

RS-485/422/232 Serial Port

The IC-3173 (IP67) has a single serial port that can operate in either RS-485/422 mode or

RS-232 mode. Set the serial port mode in the BIOS setup utility.

The serial port is an 8-position A-code M12 connector, which can connect to serial devices,

such as PLCs, scanners, and lighting devices.

NI recommends the following serial cables for the IC-3173 (IP67).

Cable Part Number

8-position M12 A-coded pigtail serial cable for IC-3173 (IP67), 5 meters 785933-01

Figure 37. RS-485/422/232 Serial Port Pin Locations (IC-3173 (IP67))

Pin 1

2

3

4

5

6

7

8

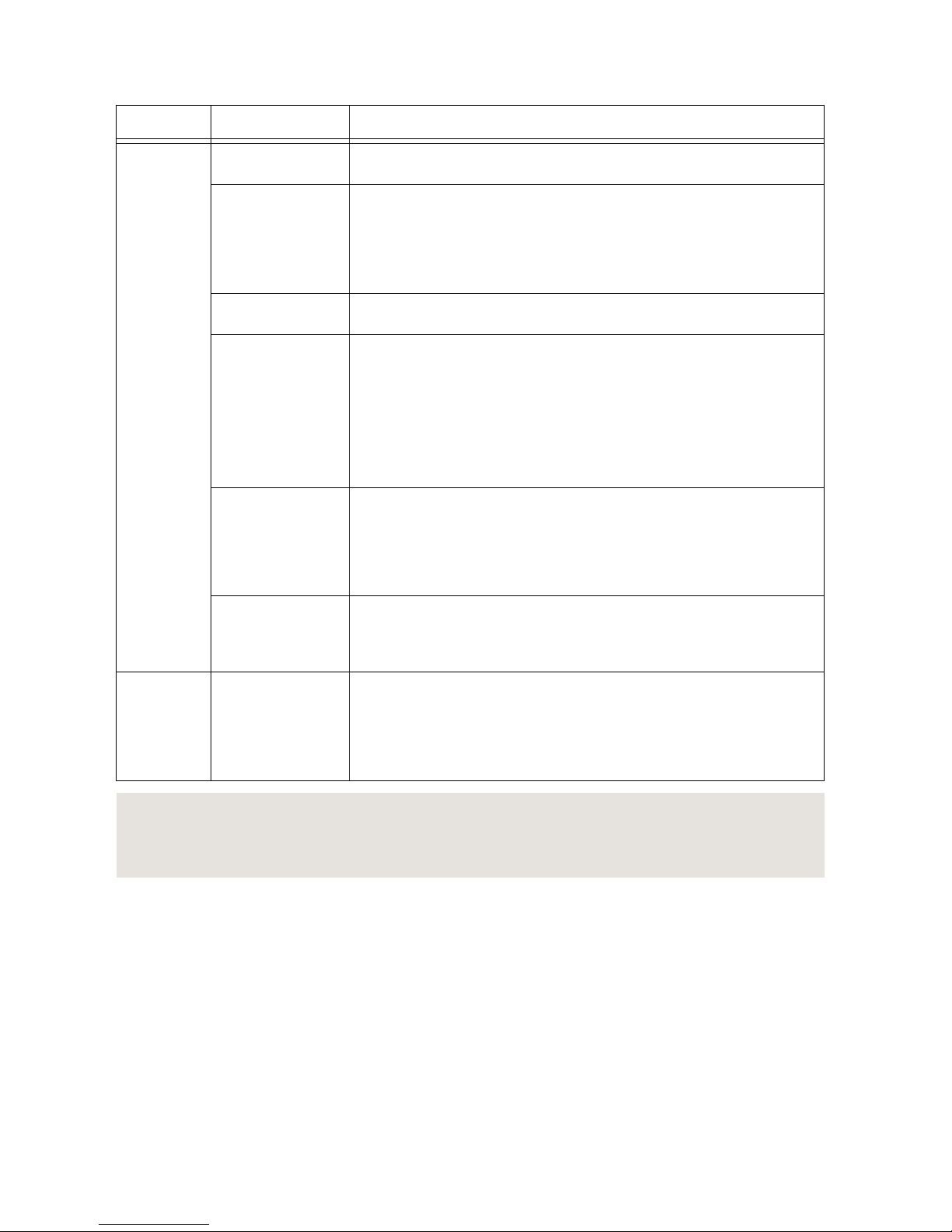

Table 21. RS-485/422/232 Serial Port Pin Descriptions

Pin RS-485/422 Mode RS-232 Mode

1 No Connect No Connect

2 TXN Unused

3 TXP Unused

4 RXN GND

5 RXP Unused

6 Unused TX

7 Unused RX

8 GND Unused

IC-317x User Manual | © National Instruments | 41

Page 43

USB 3.0 Ports

The USB ports support USB peripheral devices such as USB flash drives, USB hard drives,

USB-to-IDE adapters, keyboards, mice, and USB cameras.

Figure 38. USB 3.0 Port Pin Locations (IC-3173 (IP67))

4

3

2

1

5

6

7

8

9

Table 22. USB 3.0 Port Pin Descriptions

Pin Signal Name Signal Description

1 VBUS Cable Power (+5 VDC)

2 D- USB Data -

3 D+ USB Data +

4 GND Ground for power return

5 StdA_SSRX- SuperSpeed receiver differential pair

6 StdA_SSRX+

7 GND_DRAIN Ground for signal return

8 StdA_SSTX- SuperSpeed transmitter differential pair

9 StdA_SSTX+

USB 2.0 Port

The USB port supports common USB peripheral devices such as USB flash drives, USB hard

drives, USB-to-IDE adapters, keyboards, mice, and USB cameras.

Figure 39. USB 2.0 Pin Locations (IC-3173 (IP67))

1

4

42 | ni.com | IC-317x User Manual

Page 44

Table 23. USB 2.0 Port Pin Descriptions

Pin Signal Name Signal Description

1 VBUS Cable Power (+5 VDC)

2 D- USB Data -

3 D+ USB Data +

4 GND Ground for power return

LED Indicators

The LED indicators are located on the front panel of the device. The IC-3173 (IP67) provides

the following LED indicators.

POWER LED

The following table lists the POWER LED indications.

Table 24. POWER LED Indications

LED Color LED Pattern Indication

Green Solid The IC-3173 (IP67) is powered from the V1 or V2 input.

— Off The IC-3173 (IP67) is powered off.

STATUS LED

The following table describes the STATUS LED indications.

IC-317x User Manual | © National Instruments | 43

Page 45

Table 25. STATUS LED Indications

LED

Color

LED State Indication

Yellow OFF The IC-3173 (IP67) initialized successfully and is ready for

use.

2 blinks (RT only) The device has automatically booted into safe mode.

This occurs when there is no software installed, which is the

out-of-box state, or the device has detected an error in its

software. Reinstall software on the IC-3173 (IP67).

3 blinks (RT only) The IC-3173 (IP67) has booted into safe mode.

4 blinks (RT only) The IC-3173 (IP67) has experienced two

consecutive software exceptions. The IC-3173 (IP67)

automatically restarts after an exception. After the second

exception, the IC-3173 (IP67) remains in the exception state,

alerting you to resolve the problem. Reinstall software on the

IC-3173 (IP67) or contact National Instruments.

Continuous

blink

This indicates one of the following errors.

(RT only) The IC-3173 (IP67) has not booted into NI Linux

Real-Time. The controller either booted into an unsupported

operating system, was interrupted during the boot process, or

detected an unrecoverable software error.

An internal power supply has failed. Check front-panel I/O

connections for shorts. Remove any shorts and cycle power to

the IC-3173 (IP67). If the problem persists, contact National

Instruments.

ON (RT only) The IC-3173 (IP67) is booting up.

(Windows only) An internal drive is being accessed.

Using the RESET Button

Pressing the RESET button resets the processor in the same manner as cycling power. If the

controller is powered but shut down, pressing the RESET button turns on the controller. You

can also use the RESET button to troubleshoot network connectivity.

The RESET button is located on the bottom of the controller.

1. Remove the IC-3173 (IP67) from any wet or dusty environment, as the product is not

rated IP67 while the reset screw is removed.

2. Remove the reset screw using a screwdriver. Retain the gasket.

3. Hold the RESET button for 5 seconds, and then release it to boot the IC-3173 (IP67) into

safe mode and enable Console Out.

44 | ni.com | IC-317x User Manual

Page 46

4. After booting the controller into safe mode, hold the RESET button again for 5 seconds to

enable IP reset, which resets the network adapter to its default configuration.

5. Reattach the reset screw using a recommended torque range of 2 Nm - 3 Nm with the

gasket in place. These values are recommended average values only. Variations in local

conditions may require deviations from these recommended values.

Safe Mode

When you boot the IC-3173 (IP67) into safe mode, it launches only the services necessary for

updating its configuration and installing software. To resume normal operations, press the

RESET button for less than 5 seconds.

IP Reset

Use IP reset to reset the TCP/IP settings when moving the system from one subnet to another

or when the current TCP/IP settings are invalid.

When the IC-3173 (IP67) is in the IP reset state, the IP address of the network port resets to

DHCP or a link-local address. You can then set up a new network configuration for the

IC-3173 (IP67) from a development machine on the same subnet, or you can connect the

IC-3173 (IP67) directly to the development computer.

Note By default, the target automatically attempts to connect to the network using

DHCP. If the target is unable to initiate a DHCP connection, the target connects to

the network with a link-local IP address (169.254.x.x).

Mounting the IC-3173 (IP67)

The IC-3173 (IP67) has 11 screw holes with M4x0.7 thread and 8mm depth on both sides of

the device that can be used for mounting.

Caution Mounting the IC-3173 (IP67) to a hot surface may result in undesirable

performance. Refer to the IC-3173 (IP67) Specifications for temperature

specifications.

To obtain the maximum allowable ambient temperature, you must mount the IC-3173 (IP67)

vertically. The following figures provide dimensional drawings and clearance information for

the IC-3173 (IP67).

IC-317x User Manual | © National Instruments | 45

Page 47

Figure 40. Front View Dimensions

IC-3173

IP67 Industrial Controller

ISO PWR IN

5-24V

CONNECTOR 2

CONNECTOR 1

SYS PWR IN

9-30V

150W MAX

RESET

CONNECTOR 0

POWER STATUS

SS

DP

DIGITAL I/O

SS

PoE 4

PoE 2PoE 1

PoE 3

SYNC

3.65 in (92.71 mm)

2X 1.3 in (33.01 mm)

1.36 in (34.44 mm)

2X 2.28 in (57.79 mm)

4.12 in (104.55 mm)

2X 6.48 in (164.68 mm)

2X 5.58 in (141.82 mm)

2.42 in (61.37 mm)

3.27 in (82.96 mm)

1.05 in (26.71 mm)

3.82 in (97.11 mm)

7.59 in (192.77 mm)

2X 6.02 in (152.97 mm)

2.89 in (73.46 mm)

3.65 in (92.65 mm)

2.43 in (61.79 mm)

1.05 in (26.74 mm)

0 in (0 mm)

0 in (0 mm)

4X .53 in (13.34 mm)

1.38 in (34.92 mm)

2.26 in (57.31 mm)

3.65 in (92.71 mm)

46 | ni.com | IC-317x User Manual

Page 48

Figure 41. Side View Dimensions

7.60 in

(193.11 mm)

.02 in

(.38 mm)

0 in (0 mm)

12.64 in (320.92 mm)

12.09 in (307.03 mm)

7.29 in (185.14 mm)

5.86 in (148.77 mm)

8.72 in (221.51 mm)

10.15 in (257.89 mm)

4.43 in (112.39 mm)

1.56 in (39.65 mm)

2.99 in (76.02 mm)

11X M4 HOLE

.32 in (8 mm)

0 in (0 mm)

1.29 in (32.87 mm)

3.79 in (96.37 mm)

6.29 in (159.87 mm)

7.59 in (192.73 mm)

2X 12.42 in (315.52 mm)

3X 12.49 in (317.11 mm)

12.64 in (320.92 mm)

Clearance Requirements

The IC-3173 (IP67) installation must meet the following space and cabling clearance

requirements for optimum cooling:

• Allow 50.8 mm (2.0 in.) on the top and bottom of the IC-3173 (IP67) for air circulation.

• Allow 50.8 mm (2.0 in.) on the sides of the IC-3173 (IP67) for air circulation.

• Allow enough space in front of the IC-3173 (IP67) to connect cables.

IC-317x User Manual | © National Instruments | 47

Page 49

Figure 42. Clearance Requirements for the IC-3173 (IP67)

IC-3173

IP67 Industrial Controller

ISO PWR IN

5-24V

CONNECTOR 2

CONNECTOR 1

SYS PWR IN

9-30V

150W MAX

RESET

CONNECTOR 0

POWER STATUS

SS

DP

DIGITAL I/O

SS

PoE 4

PoE 2PoE 1

PoE 3

SYNC

2 in (50.8 mm)

2 in

(50.8 mm)

Software Options

Use the following software to develop applications with the IC-317x. Refer to the IC-317x

Getting Started Guide for information about installing software.

• NI Industrial Controller Device Drivers 15.5 or later driver software.

• One of the following options for developing machine vision applications:

– LabVIEW 2014 SP1 or later, LabVIEW Real-Time 2014 SP1 or later, the NI Vision

Development Module 2015 SP1 or later.

– NI Vision Builder for Automated Inspection (Vision Builder AI) 2015 or later.

• Software for using and reconfiguring the IC-317x FPGA. Different configurations are

referred to as hardware personalities, and are defined by bitfiles. NI Industrial Controller

Device Drivers include a reconfigurable I/O personality that you can use out of the box.

Install the following software if you need to compile a custom personality for your

application:

– LabVIEW 2014 SP1 or later and LabVIEW FPGA Module 2014 SP1 or later—You

must install the LabVIEW FPGA Module to reconfigure the default personality of

the IC-317x FPGA.

48 | ni.com | IC-317x User Manual

Page 50

IEEE 1588 Precision Time Protocol References

IC-317x controllers are compatible with the IEEE 1588 Precision Time Protocol (PTP). Visit

ni.com/info and enter the following info codes for more information on the IEEE 1588 PTP

and IC-317x industrial controllers.

• ICConnect1588 - Provides information on which IC-317x port to connect to an IEEE

1588 PTP Grand Master.

• ICLinkSpeed1588 - Provides information on which link speed optimizes IEEE 1588

PTP synchronization performance on the IC-317x.

• ICModSysTime1588 - Provides information on modifying system time on the IC-317x

when NI-TimeSync is installed.

• swsync - Provides an introduction to distributed clock synchronization and the IEEE

Precision Time Protocol.

BIOS Configuration and System Recovery

You can change the configuration settings for the IC-317x in the BIOS setup utility. The BIOS

is the low-level interface between the hardware and PC software that configures and tests your

hardware when you boot the system. The BIOS setup utility includes menus for configuring

settings and enabling features.

Most users do not need to use the BIOS setup utility. The system ships with default settings

that work well for most configurations.

Entering BIOS Setup

Complete the following steps to start the BIOS setup utility.

1. Connect a monitor to one of the DisplayPort connectors on the IC-317x.

2. Connect a USB keyboard to one of the USB ports on the IC-317x.

3. Power on or reboot the IC-317x.

4. Immediately hold down the <Delete> key until the BIOS setup utility appears.

The Main setup menu is displayed when you first enter the BIOS setup utility.

BIOS Setup Utility Keyboard Navigation

Use the following keys to navigate through the BIOS setup utility:

IC-317x User Manual | © National Instruments | 49

Page 51

Table 26. Navigation Keys

Key(s) Function(s)

Left Arrow, Right

Arrow

Move between the different setup menus. If you are in a submenu,

these keys have no effect, and you must press <Esc> to leave the

submenu first.

Up Arrow, Down

Arrow

Move between the options within a setup menu.

<Enter> Enter a submenu or display all available settings for a highlighted

configuration option.

<Esc> Return to the parent menu of a submenu. At the top-level menus, this

key serves as a shortcut to the Exit menu.

<+>, <-> Cycle between all available settings for a selected configuration option.

<Tab> Select time and date fields.

<F9> Load the optimal default values for all BIOS configuration settings.

The optimal default values are the same as the shipping configuration

default values.

<F10> Save settings and exits the BIOS setup utility.

Main Setup Menu

The Main setup menu reports the following configuration information:

• BIOS Version and Build Date—These values indicate the version of the controller BIOS

and the date on which the BIOS was built.

• Embedded Firmware Version—This value identifies the built-in hardware capabilities.

• Processor Type, Base Processor Frequency, and Active Processor Cores—These values

indicate the type of processor used in the controller, the speed of the processor, and the

number of active processor cores.

• Total Memory—This value indicates the size of system RAM detected by the BIOS.

The Main setup menu includes System Date and System Time settings, which are the most

commonly accessed and modified BIOS settings. These settings are stored in a battery-backed

real-time clock. In the BIOS menu, use <+> and <-> in conjunction with <Enter> and <Tab>

to change these values. You can also change these settings using NI-MAX or Vision Builder

AI.

• System Date—This value controls the date.

• System Time—This value controls the time of day.

50 | ni.com | IC-317x User Manual

Page 52

Advanced Menu

This menu contains BIOS settings that normally do not require modification. If you have

specific problems such as unbootable disks or resource conflicts, you may need to examine

these settings.

The Advanced setup menu includes the following submenus:

• SATA Configuration

• CPU Configuration

• Video Configuration

• Power/Wake Configuration

• AMT Configuration

• USB Configuration

• Serial Port Configuration

SATA Configuration Submenu

Use this submenu to apply custom configurations to the internal disk drive of the IC-317x.

Normally, you do not need to modify these settings, as the factory default settings provide the

most compatible and optimal configuration.

• SATA Controller(s)—Enables or disables the SATA controller. The default is Enabled.

– SATA Port 0—Enables or disables SATA port 0.

– SATA Port 1—Enables or disables SATA port 1.

– SATA Port 3—Enables or disables SATA port 3.

• Onboard Storage—Lists the SATA disk drive and displays the size of the disk.

CPU Configuration Submenu

Use this submenu to apply custom configurations to the internal processor of the device.

Normally, you do not need to modify these settings, as the factory default settings provide the

most compatible and optimal configuration.

• Hyper-Threading—This setting specifies whether or not to enable Intel Hyper-Threading

technology in the processor. When enabled, performance may increase because virtual

processing cores are enabled, but software jitter may increase. The default setting is

Disabled.

• Enabled CPU Cores—This setting specifies the number of processing cores that are

enabled. The default setting is All.

• Turbo Boost—This setting specifies whether or not to enable Intel Turbo Boost

technology. When enabled, if current conditions within the processor allow, the processor

operates at frequencies higher than the base frequency. This may increase processing

performance, but software jitter may increase. The default setting is Enabled.

• C-States—This setting specifies whether or not to enable CPU power management. When

enabled, the processor may achieve maximum operating frequency when Turbo Boost is

enabled, but software jitter may increase. The default setting is Enabled.

• Hardware Prefetcher—This setting specifies whether or not to enable the hardware

prefetcher. Enabling this setting may increase performance by prefetching portions of

IC-317x User Manual | © National Instruments | 51

Page 53

memory for the processor, but software jitter may increase. The default setting is

Enabled.

• Adjacent Cache Prefetcher—This setting specifies whether or not to enable the adjacent

cache line prefetcher. Enabling the adjacent cache prefetcher may increase performance

by prefetching portions of memory for the processor, but software jitter may increase.

The default setting is Enabled.

Video Configuration Submenu

Use this submenu to enable or disable the display interface.

• Primary Display—This setting can disable the onboard video for the product. Setting the

value to Onboard Video enables the internal display capabilities and the DisplayPort

connectors. Setting the value to Disabled disables the internal display capabilities and the

DisplayPort connectors. The default setting is Onboard Video.

Power/Wake Configuration Submenu

The Power/Wake configuration submenu contains the power and wake settings for the

IC-317x. The factory default settings provide the most compatible and optimal configuration.

• Restore After Power Loss—This setting specifies the power state that the IC-317x should

return to after power is lost. Valid values are Stay Off and Turn On. The default value is

Turn On. When set to Stay Off, the IC-317x returns to the soft off power state after

power is restored. When set to Turn On, the IC-317x powers on when power is restored.

• Power Button Off Behavior—This setting specifies how the system responds to the power

button. Valid options are Normal and Disabled. The default value is Normal. If the value

is Normal, the system responds to the power button as defined by the OS. If the value is

Disabled, pressing the power button has no effect when the system is on. When the

system is in the soft off state, pushing the power button always powers on the system.

This setting has no effect on the IC-3173 (IP67)

AMT Configuration Submenu

The AMT configuration submenu contains settings to configure Intel Active Management

Technology.

• Management Engine Setup Prompt—This setting specifies whether or not to show the

Intel Management Engine prompt during boot. Enabling this option enables the other

options on this submenu. The default setting is Disabled.

• Unconfigure Management Engine—This setting specifies whether or not to unconfigure

the Management Engine during the next boot. The default setting is Disabled.

• USB-Based Configuration—This setting specifies whether or not to search connected

USB drives for AMT configuration files. The system prompts the user if it finds any

configuration files. The default setting is Disabled.

52 | ni.com | IC-317x User Manual

Page 54

USB Configuration Submenu

The USB configuration submenu contains the USB host ports settings. The factory default

settings provide the most compatible and optimal configuration.

• USB Devices—This item lists the total number of devices detected in the system,

categorized by device type.

• Legacy USB Support—This setting specifies whether legacy USB support is enabled.

Legacy USB support refers to the ability to use a USB keyboard and mouse in a legacy

operating system such as DOS.

• Overcurrent Reporting—This setting allows the BIOS to notify the operating system

about any USB ports that source too much current. The default value is Disabled.

Hardware overcurrent protection is always active and cannot be disabled.

• Transfer Timeout—This setting specifies the timeout value for Control, Bulk, and

Interrupt USB transfers. The default value is 20 seconds.

• Device Reset Timeout—This setting specifies the number of seconds the POST waits for

a USB mass-storage device to start. The default value is 20 seconds.

• Device Power-Up Delay—This setting specifies the maximum time a device takes before

enumerating. Valid options are Auto and Manual. The default value is Auto. When set to

Auto, a root port is granted 100 ms, and the delay value of a hub port is assigned from the

hub descriptor.

• Device Power-Up Delay in Seconds—This setting specifies the number of seconds the

POST waits for a USB device or hub to power on. This setting is only visible when the

Device Power-Up Delay is set to Manual. The default value is 5 seconds.

• Mass Storage Devices—This list allows you to configure how the BIOS presents the USB

mass-storage device to the system for each detected USB mass-storage device. This

option presents a USB mass-storage device as a floppy, Zip, hard disk, or CD-ROM

drive. The default value is Auto, which allows the BIOS to treat small USB flash disk

drives as floppy drives and larger USB flash disk drives as hard disk drives.

Serial Port Configuration Submenu

Use this submenu to view the serial port configuration.

• RS485/RS232 Select—This setting selects the transceiver mode between RS-232 and

RS-485. The default value is RS485.

• RS-485 Configuration—Use this menu to configure the RS-485/422 wire-mode. The

default value is Auto.

Boot Menu

This screen displays the boot order of devices associated with the IC-317x and allows you to

configure the boot settings.

The Boot setup menu includes the following submenus:

• Boot Settings Configuration—Use this setting to access the Boot Settings Configuration

submenu.

• PXE Network Boot—This setting specifies whether or not the PXE network boot agent is

enabled. The default value is Disabled. To enable this setting, you must select Enable

and then select Save & Exit to restart the device. When this setting is enabled, the Intel

IC-317x User Manual | © National Instruments | 53

Page 55

Boot Agent is visible in the Boot Option Priorities menu. This allows you to boot from a

PXE server on the local subnet. Note that the Intel Boot Agent device names are preceded

by IBA GE Slot in the Boot Option Priorities menu.

• Boot Option Priorities—These settings specify the order in which the BIOS attempts to

boot from bootable devices, including the local hard disk drive, removable devices such

as USB flash disk drives or USB CD-ROM drives, or the PXE network boot agent. The

BIOS will first attempt to boot from the device associated with Boot Option #1, followed

by Boot Option #2 and Boot Option #3. If multiple boot devices are not present, the

BIOS setup utility will not display all of these configuration options. To select a boot

device, press <Enter> on the desired configuration option and select a boot device from

the resulting menu. You can also disable individual boot options by selecting Disabled.

Note For each detected drive, the boot option may list a UEFI option and an option

without UEFI. This depends on whether the drive supports booting with UEFI,

legacy BIOS, or both. If a drive is not displayed as a boot option, use the Drive or

Device BBS Priorities setting to change the relative priority of the drive.

Boot Settings Configuration Submenu

• Setup Prompt Timeout—This setting specifies the amount of time the system waits for a

BIOS Setup menu keypress (the <Delete> key) in units of a second. The default value is 1

for a delay of one second.

• Bootup NumLock State—This setting specifies the power-on state of the keyboard

NumLock setting. The default value is On.

Save & Exit Menu

The Save & Exit setup menu includes all available options for exiting, saving, and loading the

BIOS default configuration. You can also press <F9> to load BIOS default settings and <F10>

to save changes and exit setup.

The Save & Exit setup menu includes the following settings:

• Save Changes and Reset—Any changes made to BIOS settings are stored in NVRAM.

The setup utility then exits and reboots the controller.

• Discard Changes and Reset—Any changes made to BIOS settings during this session

since the last save are discarded. The setup utility then exits and reboots the controller.

• Save Changes—Any changes made to BIOS settings during this session are committed to

NVRAM. The setup utility remains active, allowing further changes.

• Discard Changes—Any changes made to BIOS settings during this session since the last

save are discarded. The BIOS setup continues to be active.

• Restore Defaults—This option restores all BIOS settings to the factory default. This

option is useful if the controller exhibits unpredictable behavior due to an incorrect or

inappropriate BIOS setting. The <F9> key can also be used to select this option.

• Save as User Defaults—This option saves a copy of the current BIOS settings as the User

Defaults. This option is useful for preserving custom BIOS setup configurations.

• Restore User Defaults—This option restores all BIOS settings to the values last saved as

user defaults.

• Boot Override—This option lists all possible bootable devices and allows the user to

override the Boot Option Priorities list for the current boot. If no changes have been

54 | ni.com | IC-317x User Manual

Page 56

made to the BIOS setup options, the system will continue booting to the selected device

without first rebooting. If BIOS setup options have been changed and saved, a reboot is

required and the boot override selection will not be valid.

Restoring the NI Linux Real-Time Operating System

Complete the following steps to restore the NI Linux Real-Time operating system to its factory

default condition. These steps do not restore the BIOS settings to factory default. Use the

Restore Defaults option in the Save & Exit Menu of the BIOS setup utility to restore the BIOS

settings.

Caution Restoring the operating system erases the contents of the hard drive. Back

up any files you want to keep before restoring the hard drive.

1. Start the IC-317x in safe mode. To start in safe mode, apply power, turn on the device,

press the RESET button for more than 5 seconds, then release the button.

2. Launch NI MAX on the development computer.

3. In the MAX configuration tree, expand Remote Systems.

4. Right-click the name of the IC-317x you want to restore and select Format Disk.

5. Enter the username and password for the device. By default, the username is admin and

the password field is blank.

6. Click Format.

7. After formatting is complete, a confirmation dialog window appears. Click Close.

8. Refer to the IC-317x Getting Started Guide for information about installing software and

configuring the device.

Restoring the Windows Operating System

You can restore the Windows operating system on the hard drive of the IC-317x from the

reinstallation DVD shipped with device.

Note Restoring the operating system erases the contents of the hard drive. Back up

any files you want to keep before restoring the hard drive.

Creating a Bootable USB Flash Drive

You can create a bootable USB flash drive from the reinstallation DVD if you do not have a

USB DVD drive to connect to the IC-317x. The USB flash drive must be at least 8 GB. Ensure

the USB flash drive appears as a Removable Drive in Windows. Avoid using drives that

appear as Fixed Disk drives. Complete the following steps to prepare the USB flash drive for

recovery.

Note If you have an external USB DVD drive, you can use the external DVD drive

to restore Windows without creating a bootable USB flash drive. Proceed to the next

section if you are using an external DVD drive.

1. Insert the USB flash drive into a computer with a DVD drive running Windows, and wait

for the flash drive to be recognized.

2. Open a command prompt as an administrator.

3. Type diskpart.exe and press <Enter>.

IC-317x User Manual | © National Instruments | 55

Page 57

4. Type list disk and press <Enter>.

5. Identify the drive number that corresponds to the USB flash drive.

6. Type select disk x, where x is the drive number of the USB flash drive, and press

<Enter>. For example, in the following image, the USB flash drive is disk number 5. The

command is select disk 5.

Caution Following this process will delete all data on the USB flash drive.

7. Type clean and press <Enter>. This command deletes all data from the USB flash drive.

8. Type create partition primary and press <Enter>.

9. Type active and press <Enter>

10. Type format fs=ntfs quick and press <Enter> to format the USB flash drive.

11. Type assign letter free volume letter, where free volume letter is a

letter not currently associated with any disk drives. For example, assign letter K.

12. Copy the contents of the reinstallation DVD to the root of the USB flash drive.