Page 1

FieldPoint™ Operating Instructions

FP-AI-112 and cFP-AI-112

16-Channel, 16-Bit Analog Input Modules

These operating instructions describe how to install and use the

FP-AI-112 and cFP-AI-112 analog input modules (referred

to inclusively as the [c]FP-AI-112). For information about

configuring and accessing the [c]FP-AI-112 over a network, refer

to the user manual for the FieldPoint network module you are

using.

Features

The [c]FP-AI-112 is a FieldPoint analog input module with the

following features:

• 16 analog voltage input channels

• Eight voltage input ranges: 0–1 V, 0–5 V, 0–10 V, ±60 mV,

±300 mV, ±1V, ±5V, and ±10 V

• 16-bit resolution

• 50 and 60 Hz filter settings

• 250 V

verified by 2,300 V

• –40 to 70 °C operation

• Hot swappable

CAT II continuous channel-to-ground isolation,

rms

,1 minute dielectric withstand test

rms

Installing the FP-AI-112

The FP-AI-112 mounts on a FieldPoint terminal base (FP-TB-x),

which provides operating power to the module. Installing the

FP-AI-112 onto a powered terminal base does not disrupt the

operation of the FieldPoint bank.

Page 2

To install the FP-AI-112, refer to Figure 1 and complete the

following steps:

1. Slide the terminal base key to either position X (used for any

module) or position 1 (used for the FP-AI-112).

2. Align the FP-AI-112 alignment slots with the guide rails on the

terminal base.

3. Press firmly to seat the FP-AI-112 on the terminal base. When

the FP-AI-112 is firmly seated, the latch on the terminal base

locks it into place.

4

5

3

6

1 I/O Module

2 Terminal Base

3 Alignment Slot

1

4Key

5 Latch

6 Guide Rails

Figure 1. Installing the FP-AI-112

2

Installing the cFP-AI-112

The cFP-AI-112 mounts on a Compact FieldPoint backplane

(cFP-BP-x), which provides operating power to the module.

Installing the cFP-AI-112 onto a powered backplane does not

disrupt the operation of the FieldPoint bank.

To install the cFP-AI-112, refer to Figure 2 and complete the

following steps:

1. Align the captive screws on the cFP-AI-112 with the holes on

the backplane. The alignment keys on the cFP-AI-112 prevent

backward insertion.

2. Press firmly to seat the cFP-AI-112 on the backplane.

FP-AI-112 and cFP-AI-112 2 ni.com

Page 3

3. Using a number 2 Phillips screwdriver with a shank of at least

64 mm (2.5 in.) length, tighten the captive screws to 1.1 N ⋅ m

(10 lb ⋅ in.) of torque. The nylon coating on the screws prevents

them from loosening.

3 5

2

2

1

1cFP-AI-112

2 Captive Screws

3 cFP Controller Module

Figure 2. Installing the cFP-AI-112

4 Screw Holes

5 cFP Backplane

Wiring the [c]FP-AI-112

4

4

The FP-TB-x terminal base has connections for each of the

16 input channels and for an optional external power supply to

power field devices. The cFP-CB-x connector block provides the

same connections. Each channel has one input terminal (V

IN

) for

voltage input. All 16 inputs are referenced to the COM terminals,

which are internally connected to each other and to the C terminals.

The channels share eight V

terminals, all of which are internally

SUP

connected to each other and to the V terminals.

© National Instruments Corp. 3 FP-AI-112 and cFP-AI-112

Page 4

You can use an external power supply to power field devices.

Connect the positive lead of the external power supply to both

V terminals and the negative lead to both C terminals. Ensure that

the current through both V terminals can never exceed 2 A.

Install 2 A maximum, fast-acting fuses between the external power

supply and the V terminals. The wiring diagrams in this document

show fuses where appropriate.

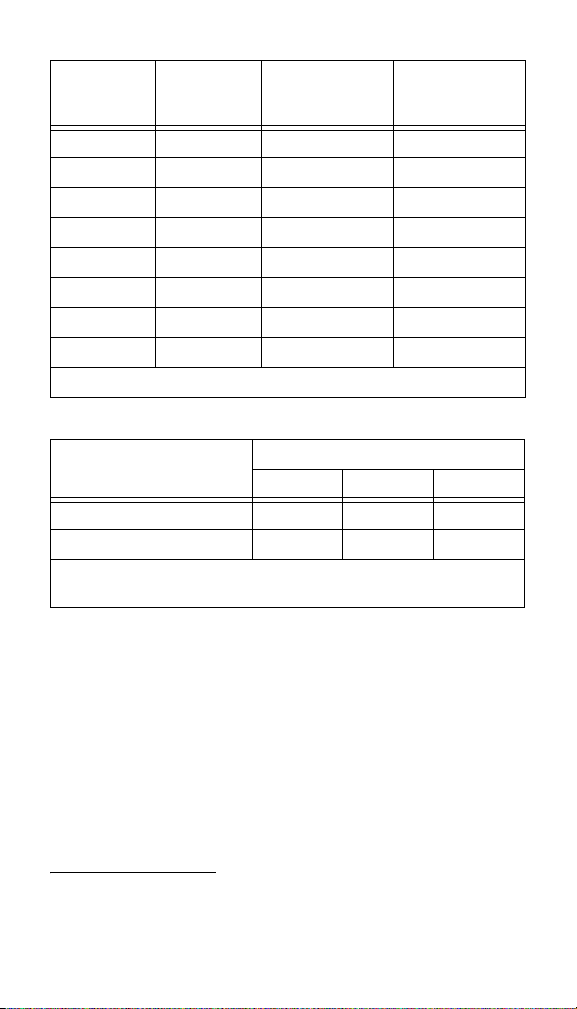

Table 1 lists the terminal assignments for the signals associated

with each channel. The terminal assignments are the same for the

FP-TB-x terminal bases and the cFP-CB-x connector blocks.

Table 1. Terminal Assignments

Terminal Numbers

Channel

0 1 17 18

1 2 17 18

2 3 19 20

3 4 19 20

4 5 21 22

5 6 21 22

6 7 23 24

7 8 23 24

8 9 25 26

9 10 25 26

10 11 27 28

11 12 27 28

12 13 29 30

13 14 29 30

14 15 31 32

15 16 31 32

V

IN

V

SUP

COM

FP-AI-112 and cFP-AI-112 4 ni.com

Page 5

Caution Cascading power between two modules defeats

isolation between those modules. Cascading power from

the network module defeats all isolation between

modules in the FieldPoint bank.

Measuring Voltage with the [c]FP-AI-112

Figure 3 shows how to connect a voltage source without an

external power supply to one channel of the [c]FP-AI-112.

VC

Voltage

Source

V

SUP

V

IN

+

–

COM

Input

Circuitry

>100 MΩ

Input

Impedance

[c]FP-AI-112

Figure 3. Voltage Source without External Power Supply

Figure 4 shows how to connect a voltage source with an external

power supply to one channel of the [c]FP-AI-112.

Powered

Voltage

Transducer

+

OUT

–

V

SUP

V

COM

External

Power Supply

(Optional)

IN

>100 MΩ

Input

Impedance

Input

Circuitry

+

–

2 A

Max

VC

[c]FP-AI-112

Figure 4. Voltage Source with External Power Supply

© National Instruments Corp. 5 FP-AI-112 and cFP-AI-112

Page 6

Input Ranges

The input ranges for voltage signals are 0–1 V, 0–5 V, 0–10 V,

±60 mV, ±300 mV, ±1V, ±5 V, and ±10 V. To prevent inaccurate

readings, choose an input range such that the signal you are

measuring does not exceed either end of the range. Signals that

greatly exceed the configured range can adversely affect

measurements on other channels.

Measurements on a channel may be invalid for up to one update

period after you change the input range.

Overranging

The [c]FP-AI-112 has an overranging feature that measures a little

beyond the nominal values of each range. For example, the actual

measurement limit of the ±10 V range is ±10.4 V. The overranging

feature enables the [c]FP-AI-112 to compensate for field devices

with span errors of up to +4% of full scale. Also, the overranging

feature helps prevent errors caused by clipping.

Filter Settings

Three filter settings are available for each channel. The filters

on the [c]FP-AI-112 input channels are comb filters that provide

notches of rejection at multiples, or harmonics, of a fundamental

frequency. You can select a fundamental frequency of 50, 60,

or 500 Hz. At the 50 and 60 Hz settings, the [c]FP-AI-112 applies

95 dB of rejection at the fundamental frequency and at least 60 dB

of rejection at each of the harmonics. In many cases, most of the

noise components of input signals are related to the local AC power

line frequency, so a filter setting of either 50 or 60 Hz is best.

The 500 Hz filter setting provides faster update rates but much less

accurate measurements.

Update Rate

The update rate of the [c]FP-AI-112 is determined by the filter

settings and the number of input ranges in use. Higher filter

settings and fewer input ranges yield faster update rates. Use the

following formula to determine the approximate update period:

(number of channels with 50 Hz filter) × 0.061 s +

(number of input ranges with 50 Hz filter) × 0.12 s +

(number of channels with 60 Hz filter) × 0.051 s +

1

The update rate is the reciprocal of the update period.

FP-AI-112 and cFP-AI-112 6 ni.com

1

Page 7

(number of input ranges with 60 Hz filter) × 0.10 s +

(number of channels with 500 Hz filter) × 0.007 s +

(number of input ranges with 500 Hz filter) × 0.012 s + 0.16 s

= Update Period

For the fastest performance, configure all unused channels for the

500 Hz filter setting and for an input range in use on one or more

other channels with the 500 Hz filter setting. For example, if

10 channels are configured for 0–10 V input and 500 Hz, four

channels are configured for 0–5 V and 60 Hz, and two channels

are unconnected, use the FieldPoint software to configure the

unconnected channels for 0–10 V input and 500 Hz filter setting.

Some combinations of two input ranges count as only one range for

calculating update rates. Those combinations are ±60 mV and

±300 mV; 0–1 V and 0 –5 V; and ±1 V and ±5V.

The update rate does not affect the rate at which the network

module reads the data. Set up your application so that the update

rate is faster than the rate at which the network module polls the

[c]FP-AI-112 for data.

Status Indicators

The [c]FP-AI-112 has two green status LEDs, POWER and

READY. After you insert the [c]FP-AI-112 into a terminal base or

backplane and apply power to the connected network module, the

green POWER indicator lights and the [c]FP-AI-112 informs the

network module of its presence. When the network module

recognizes the [c]FP-AI-112, it sends initial configuration

information to the [c]FP-AI-112. After the [c]FP-AI-112 receives

this initial information, the green READY indicator lights and the

module is in normal operating mode.

Upgrading the FieldPoint Firmware

You may need to upgrade the FieldPoint firmware when you add

new I/O modules to the FieldPoint system. For information on

determining which firmware you need and how to upgrade your

firmware, go to

© National Instruments Corp. 7 FP-AI-112 and cFP-AI-112

ni.com/info and enter fpmatrix.

Page 8

Isolation and Safety Guidelines

Caution Read the following information before

attempting to connect the [c]FP-AI-112 to any circuits

that may contain hazardous voltages.

This section describes the isolation of the [c]FP-AI-112 and its

compliance with international safety standards. The field wiring

connections are isolated from the backplane and the inter-module

communication bus. The isolation barriers in the module provide

250 V

2,300 V

provides double insulation (compliant with IEC 61010-1) for

working voltages of 250 V

published by UL and IEC) require the use of double insulation

between hazardous voltages and any human-accessible parts or

circuits.

Never try to use any isolation product between human-accessible

parts (such as DIN rails or monitoring stations) and circuits that

can be at hazardous potentials under normal conditions, unless the

product is specifically designed for such an application, as is the

[c]FP-AI-112.

Even though the [c]FP-AI-112 is designed to handle applications

with hazardous potentials, follow these guidelines to ensure a safe

total system:

• There is no isolation between channels on the [c]FP-AI-112.

•Do not share the external supply voltages (the V and C

• For Compact FieldPoint, you must connect the protective earth

Installation Category II continuous isolation, verified by

rms

, 1 minute dielectric withstand test. The [c]FP-AI-112

rms

1

. Safety standards (such as those

rms

If a hazardous voltage is present on any channel, all channels

are considered hazardous. Make sure that all other devices and

circuits connected to the module are properly insulated from

human contact.

terminals) with other devices (including other FieldPoint

devices), unless those devices are isolated from human contact.

(PE) ground terminal on the cFP-BP-x backplane to the system

safety ground. The backplane PE ground terminal has the

following symbol stamped beside it: . Connect the

backplane PE ground terminal to the system safety ground

1

Working voltage is defined as the signal voltage plus the common-mode voltage.

Common-mode voltage is the voltage of the module with respect to ground.

FP-AI-112 and cFP-AI-112 8 ni.com

Page 9

using 14 AWG (1.6 mm) wire with a ring lug. Use the 5/16 in.

panhead screw shipped with the backplane to secure the ring

lug to the backplane PE ground terminal.

• As with any hazardous voltage wiring, make sure that all

wiring and connections meet applicable electrical codes and

commonsense practices. Mount terminal bases and backplanes

in an area, position, or cabinet that prevents accidental or

unauthorized access to wiring that carries hazardous voltages.

•Do not use the [c]FP-AI-112 as the only isolating barrier

between human contact and working voltages higher than

250 V

• Operate the [c]FP-AI-112 only at or below Pollution Degree 2.

Pollution Degree 2 means that only nonconductive pollution

occurs in most cases. Occasionally, however, a temporary

conductivity caused by condensation must be expected.

•Do not operate FieldPoint products in an explosive atmosphere

or where there may be flammable gases or fumes. If you need

to operate FieldPoint products in such an environment, the

FieldPoint products must be in a suitably rated enclosure.

• Operate the [c]FP-AI-112 at or below Installation Category II.

Installation Category II is for measurements performed on

circuits directly connected to the low-voltage installation.

This category refers to local-level distribution, such as that

provided by a standard wall outlet.

rms

.

Specifications

The following specifications are typical for the –40 to 70 °C

temperature range and for 50 and 60 Hz filter settings unless

otherwise noted. Specifications are subject to change without

notice.

Input Characteristics

Number of channels .......................... 16

ADC resolution................................. 16 bits at 50 or 60 Hz;

10 bits at 500 Hz

(refer to table)

Type of ADC..................................... Delta-sigma

© National Instruments Corp. 9 FP-AI-112 and cFP-AI-112

Page 10

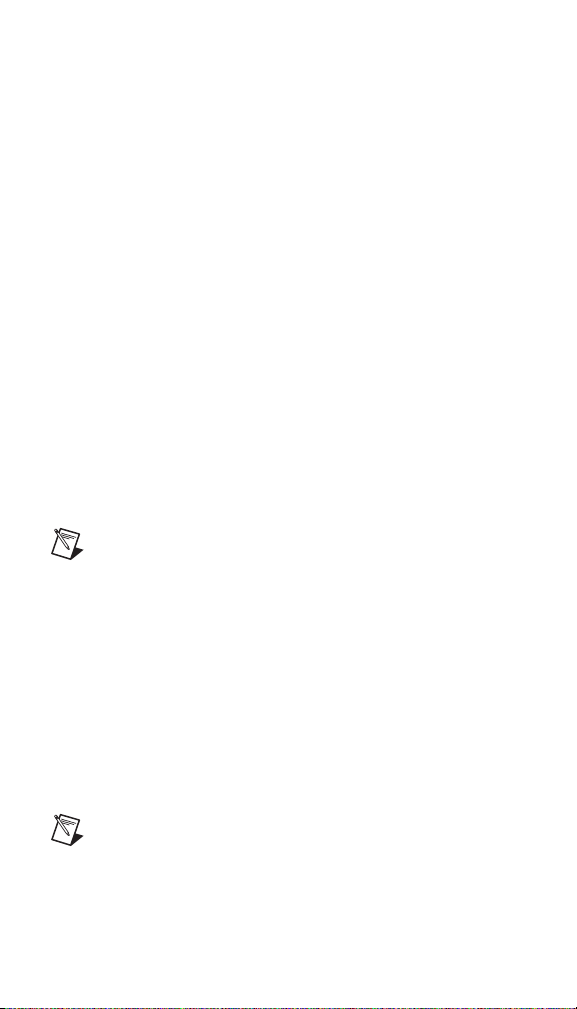

Effective resolution by input range and filter setting

Nominal

Input Range

With

Overranging

Effective

Resolution

at 50 or 60 Hz

*

±60 mV ±65 mV 3 µV 25 µV

±300 mV ±325 mV 16 µV 100 µV

±1 V ±1.04 V 40 µV 300 µV

±5 V ±5.2 V 190 µV 1500 µV

±10 V ±10.4 V 380 µV 3000 µV

0–1 V 0 –1.04 V 20 µV 300 µV

0–5 V 0–5.2 V 95 µV 1500 µV

0–10 V 0–10.4 V 190 µV 3000 µV

*

Includes quantization errors and typical rms noise.

Effective

Resolution

at 500 Hz

Update period and input bandwidth by filter setting

Filter Settings

Characteristic

Update period

*

Input bandwidth (–3 dB) 13 Hz 16 Hz 130 Hz

*

Applies when all 16 channels are set to the same filter setting. Refer to

the

Update Rate

section for information about calculating the update rate.

50 Hz 60 Hz 500 Hz

1.25–1.75 s 1.05–1.45 s 0.27– 0.32 s

*

Normal-mode rejection ..................... 95 dB

Nonlinearity ...................................... 0.0015% (monotonicity

1

warranted over the operating

temperature range)

Input impedance (with power on)..... >100 MΩ

Overvoltage protection ..................... ±40 V

Input current

25 °C........................................... 400 pA typ, 1 nA max

70 °C........................................... 3 nA typ, 15 nA max

1

A characteristic of an ADC in which the digital code output always increases as the

value of the analog input to it increases.

FP-AI-112 and cFP-AI-112 10 ni.com

Page 11

Typical and warranted accuracy by input range and temperature

range

Typical Accuracy

at 15 to 35

Nominal

Input Range

±60 mV ±0.03%; ±0.05% ±0.05%; ±0.3%

±300 mV ±0.03%; ±0.015% ±0.05%; ±0.1%

±1 V ±0.03%; ±0.008% ±0.05%; ±0.04%

±5 V ±0.03%; ±0.005% ±0.05%; ±0.02%

±10 V ±0.03%; ±0.005% ±0.05%; ±0.02%

0–1 V ±0.03%; ±0.005% ±0.05%; ±0.03%

0–5 V ±0.03%; ±0.003% ±0.05%; ±0.01%

0–10 V ±0.03%; ±0.003% ±0.05%; ±0.01%

(% of Reading;

% of Full Scale)

°C

Warranted Accuracy

at 15 to 35

(% of Reading;

% of Full Scale)

°C

Typical Accuracy

at –40 to 70

Nominal

Input Range

±60 mV ±0.06%; ±0.35% ±0.10%; ±1.50%

±300 mV ±0.06%; ±0.08% ±0.10%; ±0.40%

±1 V ±0.06%; ±0.03% ±0.10%; ±0.13%

±5 V ±0.06%; ±0.01% ±0.10%; ±0.04%

±10 V ±0.06%; ±0.01% ±0.10%; ±0.03%

0–1 V ±0.06%; ±0.025% ±0.10%; ±0.12%

0–5 V ±0.06%; ±0.007% ±0.10%; ±0.03%

0–10 V ±0.06%; ±0.005% ±0.10%; ±0.02%

Note Full scale is the maximum value of the nominal

(% of Reading;

% of Full Scale)

°C

Warranted Accuracy

at –40 to 70

(% of Reading;

% of Full Scale)

°C

input range. For example, for the ±10 V input range,

full scale is 10 V and ±0.01% of full scale is 1 mV.

Gain error drift.................................. ±20 ppm/°C

Offset error drift................................ 6 µV/°C

© National Instruments Corp. 11 FP-AI-112 and cFP-AI-112

Page 12

Physical Characteristics

Indicators .......................................... Green POWER and

READY indicators

Weight

FP-AI-112................................... 142 g (5.0 oz)

cFP-AI-112................................. 113 g (4.0 oz)

Power Requirements

Power from network module ............350 mW

Isolation Voltage

Channel-to-ground isolation

Continuous ................................. 250 V

rms

,

Installation Category II

Dielectric withstand.................... 2,300 V

, 1 minute

rms

Channel-to-channel isolation ............ None

Environmental

FieldPoint modules are intended for indoor use only. For outdoor

use, they must be mounted inside a sealed enclosure.

Operating temperature ...................... – 40 to 70 °C

Storage temperature .......................... –50 to 85 °C

Humidity ........................................... 10 to 90% RH,

noncondensing

Maximum altitude............................. 2,000 m; at higher altitudes

Pollution Degree ............................... 2

the isolation voltage ratings

must be lowered.

FP-AI-112 and cFP-AI-112 12 ni.com

Page 13

Shock and Vibration

These specifications apply only to the cFP-AI-112.

NI recommends Compact FieldPoint if your application

is subject to shock and vibration.

Operating vibration, random

(IEC 60068-2-64).............................. 10 –500 Hz, 5 g

rms

Operating vibration, sinusoidal

(IEC 60068-2-6)................................ 10 –500 Hz, 5 g

Operating shock

(IEC 60068-2-27).............................. 50 g, 3 ms half sine,

18 shocks at 6 orientations;

30 g, 11 ms half sine,

18 shocks at 6 orientations

Safety

This product is designed to meet the requirements of the following

standards of safety for electrical equipment for measurement,

control, and laboratory use:

• IEC 61010-1, EN 61010-1

• UL 61010-1

• CAN/CSA-C22.2 No. 61010-1

Note For UL, hazardous locations, and other safety

certifications, refer to the product label, or visit

ni.com/certification, search by model number or

product line, and click the appropriate link in the

Certification column.

Electromagnetic Compatibility

Emissions.......................................... EN 55011 Class A at 10 m;

FCC Part 15A above 1 GHz

Immunity........................................... EN 61326:1997 + A2:2001,

CE, C-Tick, and FCC Part 15 (Class A) Compliant

Note For EMC compliance, operate this device with

shielded cabling.

© National Instruments Corp. 13 FP-AI-112 and cFP-AI-112

Table 1

Page 14

CE Compliance

This product meets the essential requirements of applicable

European Directives, as amended for CE marking, as follows:

Low-Voltage Directive (safety).........73/23/EEC

Electromagnetic Compatibility

Directive (EMC) ............................... 89/336/EEC

Note Refer to the Declaration of Conformity (DoC) for

this product for any additional regulatory compliance

information. To obtain the DoC for this product, visit

ni.com/certification, search by model number or

product line, and click the appropriate link in the

Certification column.

Mechanical Dimensions

Figure 5 shows the mechanical dimensions of the FP-AI-112

installed on a terminal base. If you are using the cFP-AI-112,

refer to the Compact FieldPoint controller user manual for the

dimensions and cabling clearance requirements of the Compact

FieldPoint system.

109.5 mm

(4.31 in.)

107.19 mm

(4.22 in.)

91.44 mm

(3.60 in.)

Figure 5. FP-AI-112 Mechanical Dimensions

FP-AI-112 and cFP-AI-112 14 ni.com

Page 15

Where to Go for Support

For more information about setting up the FieldPoint system, refer

to these National Instruments documents:

• FieldPoint network module user manual

• Other FieldPoint I/O module operating instructions

• FieldPoint terminal base and connector block operating

instructions

Go to

ni.com/support for the most current manuals, examples,

and troubleshooting information.

National Instruments corporate headquarters is located at 11500

North Mopac Expressway, Austin, Texas, 78759-3504. National

Instruments also has offices located around the world to help

address your support needs. For telephone support in the United

States, create your service request at

the calling instructions or dial 512 795 8248. For telephone

support outside the United States, contact your local branch office:

Australia 1800 300 800, Austria 43 0 662 45 79 90 0,

Belgium 32 0 2 757 00 20, Brazil 55 11 3262 3599,

Canada (Calgary) 403 274 9391, Canada (Ottawa) 613 233 5949,

Canada (Québec) 450 510 3055, Canada (Toronto) 905 785 0085,

Canada (Vancouver) 604 685 7530, China 86 21 6555 7838,

Czech Republic 420 224 235 774, Denmark 45 45 76 26 00,

Finland 385 0 9 725 725 11, France 33 0 1 48 14 24 24,

Germany 49 0 89 741 31 30, India 91 80 51190000,

Israel 972 0 3 6393737, Italy 39 02 413091,

Japan 81 3 5472 2970, Korea 82 02 3451 3400,

Malaysia 603 9131 0918, Mexico 01 800 010 0793,

Netherlands 31 0 348 433 466, New Zealand 0800 553 322,

Norway 47 0 66 90 76 60, Poland 48 22 3390150,

Portugal 351 210 311 210, Russia 7 095 783 68 51,

Singapore 65 6226 5886, Slovenia 386 3 425 4200,

South Africa 27 0 11 805 8197, Spain 34 91 640 0085,

Sweden 46 0 8 587 895 00, Switzerland 41 56 200 51 51,

Taiwan 886 2 2528 7227, Thailand 662 992 7519,

United Kingdom 44 0 1635 523545

ni.com/support and follow

© National Instruments Corp. 15 FP-AI-112 and cFP-AI-112

Page 16

FieldPoint™, National Instruments™, NI™, and ni.com™ are trademarks of National Instruments Corporation.

Product and company names mentioned herein are trademarks or trade names of their respective companies.

For patents covering National Instruments products, refer to the appropriate location: Help»Patents in your software,

the

patents.txt file on your CD, or ni.com/patents.

© 2004 National Instruments Corp. All rights reserved.

*371330A-01*

371330A-01 Jul04

Loading...

Loading...