Page 1

FieldPoint™ FP-3000 Network Module User Manual

FieldPoint FP-3000 User Manual

January 1999 Edition

Part Number 322169A-01

Page 2

Worldwide Technical Support and Product Information

http://www.natinst.com

National Instruments Corporate Headquarters

11500 North Mopac Expressway Austin, Texas 78759-3504 USA Tel: 512 794 0100

Worldwide Offices

Australia 03 9879 5166, Austria 0662 45 79 90 0, Belgium 02 757 00 20, Brazil 011 284 5011,

Canada (Ontario) 905 785 0085, Canada (Québec) 514 694 8521, Denmark 45 76 26 00, Finland 09 725 725 11,

France 0 1 48 14 24 24, Germany 089 741 31 30, Hong Kong 2645 3186, India 91805275406,

Israel 03 6120092, Italy 02 413091, Japan 03 5472 2970, Korea 02 596 7456, Mexico (D.F.) 5 280 7625,

Mexico (Monterrey) 8 357 7695, Netherlands 0348 433466, Norway 32 84 84 00, Singapore 2265886,

Spain (Madrid) 91 640 0085, Spain (Barcelona) 93 582 0251, Sweden 08 587 895 00,

Switzerland 056 200 51 51, Taiwan 02 2377 1200, United Kingdom 01635 523545

For further support information, see the Technical Support Resources appendix of this manual.

© Copyright 1999 National Instruments Corporation. All rights reserved.

Page 3

Important Information

Warranty

The FieldPoint FP-3000 network module is warran ted agai nst d efects in mat erial s and wo rkm ans hip fo r a peri od of one

year from the date of shipment, as evidenced by receipts or other documentation. National Instruments will, at its option,

repair or replace equipment that proves to be defective during the warranty period. This warranty includes parts and labor.

The media on which you receive National Instruments software are warranted not to fail to execute programming

instructions, due to defects in materials and work man ship, for a peri od of 90 d ays from da te o f sh ipm ent, as evi denced

by receipts or other documentation. National Instruments will, at its option, repair or replace software media that do not

execute programming instructions if National Instruments receives noti ce of su ch defect s d uring th e warranty perio d.

National Instruments does not warrant that the op eration of t he soft ware shall b e uni nterrup ted or erro r free.

A Return Material Authorization (RMA) number must be obtained from the factory and clearly marked on the outside of

the package before any equipment will be accepted for warranty work. National Instruments will pay the shipping costs

of returning to the owner parts which are covered by warran ty.

National Instruments believes that the information in this document is accurate. The document has been carefully

reviewed for technical accuracy. In the event that technical or typographical errors exist, National Instruments reserves

the right to make changes to subsequent editions of this document without prior notice to holders of this edition. The

reader should consult National Instruments if errors are suspected. In no event shall National Instruments be liable for

any damages arising out of or related to th is d ocum ent o r th e in form ation con tained in i t.

XCEPT AS SPECIFIED HEREIN

E

ANY WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE

BY FAULT OR NEGLIGENCE ON THE PART OF NATIONAL INSTRUMENTS SHALL BE LIMITED TO THE AMOUNT THERETOFORE PAID BY THE

CUSTOMER

OR INCIDENTAL OR CONSEQUENTIAL DAMAGES, EVEN IF ADVISED OF THE POSSIBILITY THEREOF

National Instruments will apply regardless of the form of action, wh ether in con tract or tort , incl udin g n egli gen ce. Any

action against National Instruments must be brought within one year after the cause of action accrues. National

Instruments shall not be liable for any delay in performance due to causes beyond its reasonable control. The warranty

provided herein does not cover damages, defects, malfuncti ons, or s ervice failur es caused by own er’s fai lure to fol low

the National Instruments installation, operation, or maintenance instructions; owner’s modification of the product;

owner’s abuse, misuse, or negligent acts; and power failure or surges, fire, flood, accident, actions of third parties, or other

events outside reasonable control.

ATIONAL INSTRUMENTS WILL NOT BE LIABLE FOR DAMAGES RESULTING FROM LOSS OF DATA, PROFITS, USE OF PRODUCTS

. N

ATIONAL INSTRUMENTS MAKES NO WARRANTIES, EXPRESS OR IMPLIED, AND SPECIFICALLY DISCLAIMS

, N

Copyright

Under the copyright laws, this publication may not be reproduced or transmitted in any form, electronic or mechanical,

including photocopying, recording, storing in an information retrieval system, or translating, in whole or in part, without

the prior written consent of National Instruments Corporation.

USTOMER’S RIGHT TO RECOVER DAMAGES CAUSED

. C

. This limitation of the liability of

,

Trademarks

FieldPoint™, Lookout™, natinst.com™, and NI-FBUS™ are trademarks of National Instruments Corporation.

Product and company names mentioned herein are trademarks or trade names of their respective companies.

WARNING REGARDING MEDICAL AND CLINICAL USE OF NATIONAL INSTRUMENTS PRODUCTS

National Instruments products are not designed with com ponent s and tes ting inten ded to ensure a l evel of reliab ilit y

suitable for use in treatment and diagnosis of humans. Applications of National Instruments products invol ving m edical

or clinical treatment can create a potential for accidental injury caused by product failure, or by errors on the part of the

user or application designer. Any use or application of National Instruments products for or involving medical or clinical

treatment must be performed by properly trained and qualified medical personnel, and all traditional medical safeguards,

equipment, and procedures that are appropriate in the particular situation to prevent serious injury or death should always

continue to be used when National Instruments products are being used . National Instrum ents product s are NOT intended

to be a substitute for any form of established process, procedure, or equipment used to monitor or safeguard human health

and safety in medical or clinical treatment.

Page 4

Contents

About This Manual

Conventions ...................................................................................................................xv

Related Documentation........................................... .......................................................xv

Chapter 1

FP-3000 Network Module Overview

Overview of the FP-3000 Network Module ..................................................................1-1

Features of the FP-3000 Network Module ....................................................................1-3

Function Blocks...............................................................................................1-3

PID Control .....................................................................................................1-3

Block Instantiation...........................................................................................1-3

Interoperability................................................................................................1-4

Link Active Scheduler (LAS) Functionality ...................................................1-4

HotPnP (Hot Plug and Play)............................................................................1-4

Field Upgradability..........................................................................................1-4

Chapter 2

Installation and Configuration

Install the Device Description File ................................................................................2-1

Updating the Device Description ....................................................................2-3

Mount the FP-3000 and Terminal Bases .......................................................................2-4

Mounting the FP-3000 on a DIN Rail.............................................................2-4

Connecting Terminal Bases with DIN Rail Mounting......................2-5

Removing the FP-3000 from the DIN Rail.......................................2-6

Mounting the FP-3000 to a Panel....................................................................2-6

Connecting Terminal Bases with Panel Mounting ...........................2-7

Removing the FP-3000 and Terminal Bases from the Panel............2-8

Mount I/O Modules onto Terminal Bases .....................................................................2-8

Connect Power to the FP-3000......................................................................................2-9

Calculating Power for a FieldPoint Bank........................................................2-9

Power-On Self Test (POST) .......................................................................................... 2-10

Connect the FP-3000 to the Fieldbus Network..............................................................2-10

LED Indicators...............................................................................................................2-12

HotPnP (Hot Plug and Play)..........................................................................................2-14

HotPnP During Operation ...............................................................................2-14

Inserting New I/O Modules...............................................................2-15

Replacing I/O Modules.....................................................................2-15

Updating the FP-3000 Firmware ...................................................................................2-15

©

National Instruments Corporation v FieldPoint FP-3000 User Manual

Page 5

Contents

Chapter 3

Example Applications

Initial Power On: Assigning Address and Device Tag.................................................. 3-1

Example 1: Converting a 4–20 mA Pressure Sensor to Fieldbus Using FP-3000 ........ 3-2

Getting Started ........................................................... .....................................3-2

Convert the Pressure Sensor Reading............................................................. 3-2

Create Function Block........................ ..................................... .........3-2

Assign a Tag to the New Block........................................................3-3

Select the Module and Channel........................................................3-3

Set the Input Range...........................................................................3-4

Scale the Reading .............................................................................3-4

Set Up Scheduling ............................................................................3-5

Bring the Block Online.....................................................................3-6

Example 2: Temperature Control with the FP-3000.....................................................3-6

Getting Started ........................................................... .....................................3-6

Taking Temperature Readings........................................................................ 3-7

Create an FP-TC-120 Block .............................................................3-7

Assign a Tag to the New Block........................................................3-7

Select the Module and Channel........................................................3-7

Set the Input Range and Thermocouple Type..................................3-8

Scale the Reading .............................................................................3-8

Set Up Scheduling ............................................................................3-9

Bring the Block Online.....................................................................3-10

Controlling a Heating Element .......................................................................3-10

Instantiate an FP-AO-200 Block ......................................................3-10

Assign a Tag to the New Block........................................................3-10

Select the Module and Channel........................................................3-11

Set the Output Range........................................................................3-11

Scale the Output................................................................................3-11

Set Up Scheduling ............................................................................3-12

Bring the Block Online.....................................................................3-12

PID Control.....................................................................................................3-13

Instantiate a PID Block.....................................................................3-13

Assign a Tag to the New Block........................................................3-13

Scale the PID ....................................................................................3-13

Connect the PID to the AI and AO Blocks.......................................3-14

Download and Bring the Loop into Auto.........................................3-14

Tune the PID.....................................................................................3-15

Alarming .........................................................................................................3-15

FieldPoint FP-3000 User Manual vi

©

National Instruments Corporation

Page 6

Chapter 4

Block Reference

Block Overview.................................. ..................................... ......................................4-1

Function Blocks...............................................................................................4-1

Resource Block.............................................. ..................................................4-2

Types of Function Blocks..............................................................................................4-2

AI (Analog Input)............................................................................................4-2

AO (Analog Output)........................................................................................4-2

PID (Proportional–Integral–Derivative)..........................................................4-3

DI (Discrete Input) ..........................................................................................4-3

DO (Discrete Output)......................................................................................4-3

CDO (Complex Discrete Output)....................................................................4-3

LOG (FieldPoint Log Block) (FP-3000 Specific)...........................................4-4

STAT (FieldPoint Statistics Block) (FP-3000 Specific).................................4-4

Function Blocks and FieldPoint Modules......................................................................4-4

PID Control....................................................................................................................4-5

Alarming........................................................................................................................4-6

Alarm Parameters............................................................................................4-6

Status and Mode Handling Overview............................................................................4-8

Status Handling ...............................................................................................4-8

MODE_BLK Parameter and Mode Handling.................................................4-10

FP-3000 Specific Parameters.........................................................................................4-13

CFG_OPTS......................................................................................................4-13

DEV_OPTS.....................................................................................................4-13

EXECUTION_STATISTICS..........................................................................4-13

FIELDPOINT_CHANNEL.............................................................................4-14

FIELDPOINT_MODULE...............................................................................4-14

FP_AI_100_RANGE.......................................................................................4-14

FP_AI_110_RANGE.......................................................................................4-14

FP_AI_111_RANGE.......................................................................................4-14

FP_AO_200_RANGE.....................................................................................4-15

Contents

UNACKNOWLEDGED...................................................................4-7

ALARM_STATE/UPDATE_STATE ..............................................4-7

TIME_STAMP..................................................................................4-8

SUBCODE........................................................................................4-8

VALUE.............................................................................................4-8

Quality...............................................................................................4-9

Substatus ...........................................................................................4-9

Limit ..................................................................................................4-10

Target Mode............................................. .........................................4-10

Actual Mode......................................................................................4-11

Permitted Mode.................................................................................4-12

Normal Mode....................................................................................4-12

©

National Instruments Corporation vii FieldPoint FP-3000 User Manual

Page 7

Contents

FP_CJC_SOURCE..........................................................................................4-15

FP_MOD_STATUS........................................................................................4-15

FP_NOISE_REJECTION...............................................................................4-15

FP_PWM_520_PERIOD ................................................................................ 4-16

FP_RTD_122_RANGE .................................................................................. 4-16

FP_RTD_TYPE ..............................................................................................4-16

FP_TC_120_RANGE .....................................................................................4-16

FP_TC_120_CJ_RANGE............................................................................... 4-16

FP_THERMOCOUPLE_TYPE......................................................................4-16

LAST_BLOCK_EVENT................................................................................4-16

VERSION_INFORMATION .........................................................................4-17

Appendix A

Configuring the FP-3000

Simulate Enable.............................................................................................................A-1

Write Lock.....................................................................................................................A-2

Reset..............................................................................................................................A-2

Appendix B

Troubleshooting

Fieldbus Communication Problems ..............................................................................B-1

Setting Device Tag and Network Address......................................................B-1

I/O Module Problems ...................................................................................... B-3

Software Configuration Problems...................................................................B-3

Appendix C

Fieldbus Parameters

ACK_OPTION................................................................................................C-1

ALARM_HYS................................................................................................C-1

ALARM_SUM................................................................................................C-1

ALERT_KEY..................................................................................................C-1

ALG_RUN_TIME..........................................................................................C-1

BAL_TIME.....................................................................................................C-1

BINARY_CL..................................................................................................C-1

BINARY_OP..................................................................................................C-2

BKCAL_HYS.................................................................................................C-2

BKCAL_IN.....................................................................................................C-2

BKCAL_OUT.................................................................................................C-2

BLOCK_ALM................................................................................................C-2

BLOCK_ERR .................................................................................................C-2

BLOCK_RESET.............................................................................................C-4

FieldPoint FP-3000 User Manual viii

©

National Instruments Corporation

Page 8

Contents

BYPASS..........................................................................................................C-4

CHANNEL......................................................................................................C-4

CHECKBACK ................................................................................................C-4

CLR_FSTATE.................................................................................................C-5

CONFIRM_TIME...........................................................................................C-5

CONTROL_OPTS ..........................................................................................C-6

CYCLE_SEL/CYCLE_TYPE.........................................................................C-6

DD_RESOURCE ............................................................................................C-6

DD_REV .........................................................................................................C-7

DEV_REV.......................................................................................................C-7

DEV_TYPE.....................................................................................................C-7

DV_HI_ALM..................................................................................................C-7

DV_HI_LIM....................................................................................................C-7

DV_HI_PRI.....................................................................................................C-7

DV_LO_ALM.................................................................................................C-7

DV_LO_LIM...................................................................................................C-7

DV_LO_PRI....................................................................................................C-7

FAULT_STATE..............................................................................................C-7

FEATURE_SEL/FEATURES.........................................................................C-8

FF_GAIN.........................................................................................................C-8

FF_SCALE......................................................................................................C-8

FF_VAL ..........................................................................................................C-9

FIELD_VAL....................................................................................................C-9

FP_AUTOCONFIGURE.................................................................................C-9

FP_MOD_LIST...............................................................................................C-9

FREE_SPACE.................................................................................................C-9

FREE_TIME....................................................................................................C-9

GAIN...............................................................................................................C-9

GRANT_DENY..............................................................................................C-9

HARD_TYPES................................................................................................C-10

HI_ALM..........................................................................................................C-10

HI_HI_ALM....................................................................................................C-10

HI_HI_LIM .....................................................................................................C-10

HI_HI_PRI ......................................................................................................C-10

HI_LIM............................................................................................................C-10

HI_PRI.............................................................................................................C-10

IO_OPTS.........................................................................................................C-10

L_TYPE...........................................................................................................C-11

LIM_NOTIFY.................................................................................................C-12

LO_ALM.........................................................................................................C-12

LO_LIM ..........................................................................................................C-12

LO_LO_ALM..................................................................................................C-12

LO_LO_LIM...................................................................................................C-12

LO_LO_PRI....................................................................................................C-12

©

National Instruments Corporation ix FieldPoint FP-3000 User Manual

Page 9

Contents

LO_PRI...........................................................................................................C-13

LOW_CUT......................................................................................................C-13

MANUFAC_ID ..............................................................................................C-13

MAX_NOTIFY...............................................................................................C-13

MEMORY_SIZE............................................................................................C-13

MIN_CYCLE_T .............................................................................................C-13

MODE_BLK...................................................................................................C-13

NV_CYCLE_T ...............................................................................................C-14

OP_CMD_CXO..............................................................................................C-15

OUT ................................................................................................................C-15

OUT_HI_LIM.................................................................................................C-15

OUT_LO_LIM................................................................................................C-15

OUT_SCALE..................................................................................................C-15

PV....................................................................................................................C-16

PV_FTIME......................................................................................................C-16

PV_SCALE.....................................................................................................C-16

RATE..............................................................................................................C-16

RCAS_IN........................................................................................................C-16

RCAS_OUT....................................................................................................C-17

RESET ............................................................................................................C-17

RESTART.......................................................................................................C-17

ROUT_IN........................................................................................................C-17

ROUT_OUT....................................................................................................C-17

RS_STATE .....................................................................................................C-18

SAFEGUARD_CL..........................................................................................C-18

SAFEGUARD_OP..........................................................................................C-18

SET_FSTATE.................................................................................................C-18

SHED_OPT.....................................................................................................C-18

SHED_RCAS..................................................................................................C-19

SHED_ROUT .................................................................................................C-19

SIMULATE ....................................................................................................C-19

SP_HI_LIM.....................................................................................................C-19

SP_LO_LIM....................................................................................................C-19

SP_RATE_DN................................................................................................C-20

SP_RATE_UP.................................................................................................C-20

ST_REV..........................................................................................................C-20

STATUS_OPTS..............................................................................................C-20

STRATEGY....................................................................................................C-21

TAG_DESC....................................................................................................C-21

TEST_RW.......................................................................................................C-21

TRK_IN_D......................................................................................................C-21

TRK_SCALE..................................................................................................C-21

TRK_VAL ......................................................................................................C-21

UPDATE_EVT...............................................................................................C-22

FieldPoint FP-3000 User Manual x

©

National Instruments Corporation

Page 10

WRITE_ALM..................................................................................................C-22

WRITE_LOCK................................................................................................C-22

WRITE_PRI....................................................................................................C-22

XD_SCALE.....................................................................................................C-22

Appendix D

Advanced Function Block Behavior

Cascade Initialization.....................................................................................................D-1

Parameter Connections for Cascade Initialization ..........................................D-1

Mode and Status Behavior during Cascade Initialization...............................D-2

Remote Cascades.............................................................................................D-3

Bypassing Cascade Initialization.....................................................................D-4

Fault State and Mode Shedding.....................................................................................D-4

Fault State........................................................................................................D-4

Mode Shedding................................................................................................D-4

Appendix E

Specifications

Appendix F

Technical Support Resources

Contents

Glossary

Index

Figures

Figure 1-1. Fieldbus Network Setup........................................................................1-2

Figure 2-1. NI-FBUS Configuration Utility Dialog Box.........................................2-2

Figure 2-2. DD Info Dialog Box..............................................................................2-2

Figure 2-3. Import DD Dialog Box..........................................................................2-3

Figure 2-4. fbconf Dialog Box.................................................................................2-3

Figure 2-5. DIN Rail Clip ........................................................................................2-4

Figure 2-6. Mounting the FP-3000 onto a DIN Rail................................................2-5

Figure 2-7. Connecting Terminal Bases...................................................................2-6

Figure 2-8. Installing the Network Panel Mount Accessory....................................2-7

Figure 2-9. Mounting I/O Module to Terminal Base...............................................2-8

Figure 2-10. FP-3000 Power Connector Pinout.........................................................2-9

Figure 2-11. Fieldbus Connectors on the FP-3000....................................................2-11

©

National Instruments Corporation xi FieldPoint FP-3000 User Manual

Page 11

Contents

Tables

Figure 2-12. FP-3000 Connector Pinout.................................................................... 2-12

Figure 2-13. LEDs on the FP-3000............................................................................2-12

Figure 2-14. FP-3000 Firmware Update Dialog Box ................................................ 2-16

Figure 2-15. FP-3000 Search Dialog Box ................................................................. 2-17

Figure 2-16. Select FP-3000 Module Dialog Box.....................................................2-18

Figure 3-1. Setting the Channel Dialog Box ...........................................................3-3

Figure 3-2. Downloading Configuration Dialog Box..............................................3-5

Figure 3-3. Set the Input Range and Thermocouple Type Dialog Box................... 3-8

Figure 3-4. PID Block Connections Dialog Box.....................................................3-14

Figure 3-5. High Limit Alarm Parameters Dialog Box...........................................3-16

Figure 3-6. PID Alarm Connection Dialog Box......................................................3-17

Figure 4-1. PID Function Block Application Dialog Box.......................................4-6

Figure A-1. Configuration Toggle Switches ............................................................A-1

Figure D-1. Parameter Connections for Cascade Initialization................................D-2

Figure D-2. Remote Cascade Model ........................................................................D-3

Table 2-1. Description of Fieldbus NETWORK LED States ...............................2-13

Table 2-2. STATUS LED Flashes and Corresponding Error Conditions .............2-14

Table 4-1. CDO Block Interlock Priorities ...........................................................4-3

Table 4-2. Function Blocks and FieldPoint Modules............................................. 4-5

Table 4-3. Quality Values .....................................................................................4-9

Table 4-4. Limit Values .........................................................................................4-10

Table 4-5. Target Modes .......................................................................................4-10

Table 4-6. Actual Modes .......................................................................................4-11

Table 4-7. Configuration Options ..........................................................................4-13

Table 4-8. Device Options .....................................................................................4-13

Table 4-9. Execution Statistics ..............................................................................4-14

Table 4-10. Module Status ......................................................................................4-15

Table 4-11. Block Events ........................................................................................4-17

Table B-1. Fieldbus Communication Problems .....................................................B-2

Table B-2. I/O Module Problems ...........................................................................B-3

Table B-3. Generic Software Configuration Problems ..........................................B-4

Table B-4. Resource Block Configuration Problems .............................................B-6

Table C-1. Error Codes ..........................................................................................C-3

Table C-2. Block Reset Options ............................................................................C-4

FieldPoint FP-3000 User Manual xii

©

National Instruments Corporation

Page 12

Contents

Table C-3. Checkback States ..................................................................................C-5

Table C-4. Control Options ....................................................................................C-6

Table C-5. Feature Parameter Options ...................................................................C-8

Table C-6. Hard Types ...........................................................................................C-10

Table C-7. Operation Bitmasks ..............................................................................C-11

Table C-8. Linearization Types...............................................................................C-12

Table C-9. Operational Modes ...............................................................................C-14

Table C-10. Command Parameters ...........................................................................C-15

Table C-11. OUT_SCALE Parameter ......................................................................C-16

Table C-12. Restart Values .......................................................................................C-17

Table C-13. Device States.........................................................................................C-18

Table C-14. Shed Conditions ...................................................................................C-19

Table C-15. Status Options .......................................................................................C-20

Table C-16. Scaling Parameter Values .....................................................................C-22

Table D-1. Mode Shedding Options........................................................................D-5

©

National Instruments Corporation xiii FieldPoint FP-3000 User Manual

Page 13

About This Manual

This manual describes how to use your FieldPoint FP-3000 Network

Module.

Conventions

The following conventions appear in this manual:

» The » symbol leads you through nested menu items and dialog box options

to a final action. The sequence File»Page Setup»Options directs you to

pull down the File menu, select the Page Setup item, and select Options

from the last dialog box.

This icon denotes a note, which alerts you to important information.

This icon denotes a caution, which advises you of precautions to take to

avoid injury, data loss, or a system crash.

bold Bold text denotes items that you must select or click on in the software,

such as menu items and dialog box options. Bold text also denotes

parameter names.

italic Italic text denotes variables, emphasis, a cross reference, or an introduction

to a key concept.

monospace Text in this font denotes text or characters that you should enter from the

keyboard, sections of code, programming examples, and syntax examples.

This font is also used for the proper names of disk drives, paths, directories,

programs, subprograms, subroutines, device names, functions, operations,

variables, filenames and extensions, and code excerpts.

Related Documentation

The following documents contain information that you might find helpful

as you read this manual:

• Operating Instructions (for network module, terminal bases, and

I/O modules)

• Fieldbus Foundation’s Wiring and Installation 31.25 kbit/s,

Voltage Mode, Wire Medium Application Guide

• Fieldbus Standard for Use in Industrial Control Systems, Part 2,

ISA-550.01.1992

©

National Instruments Corporation xv FieldPoint FP-3000 User Manual

Page 14

FP-3000 Network Module

Overview

This chapter provides an overview of the FP-3000 network module.

Overview of the FP-3000 Network Module

The FP-3000 is an intelligent network interface and controller module that

manages a bank of up to nine FieldPoint I/O modules and terminal bases.

The FP-3000 network module and the terminal bases snap together to form

a high-speed data bus for communications between the FP-3000 network

module and any I/O modules in the bank. The FP-3000 includes an H1

Fieldbus interface for direct connection to an H1 FOUNDATION Fieldbus

segment. A Fieldbus segment is a multidrop network and can consist of up

to 32 H1-compliant devices. You can connect a Fieldbus segment to up to

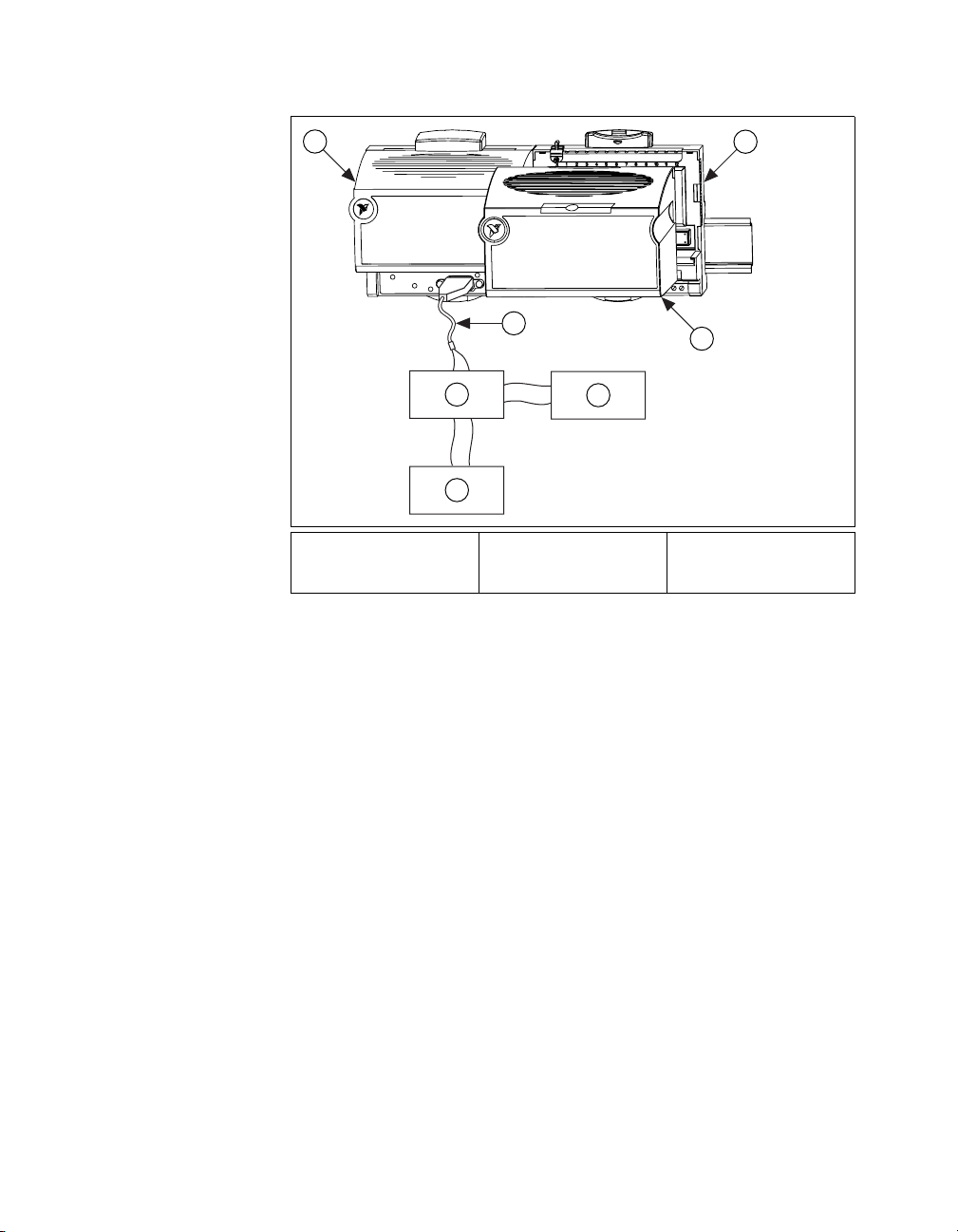

32 FP-3000 network modules. Figure 1-1 shows an FP-3000 connected to

a Fieldbus network.

1

©

National Instruments Corporation 1-1 FieldPoint FP-3000 User Manual

Page 15

Chapter 1 FP-3000 Network Module Overview

1

1 FP-3000 Network

Module

2 Terminal Base

+

–

5

+

–

6

3 I/O Module

4 Fieldbus Trunk

4

+

–

6

5 Fieldbus

6 Fieldbus Devices

2

3

Figure 1-1. Fieldbus Network Setup

The FP-3000 network module provides a Fieldbus interf ace to conventional

analog and discrete I/O devices. For example, the FP-3000 makes a

4–20 mA pressure transmitter connected to a FieldPoint 8-channel analog

input module behave like a Fieldbus pressure transmitter. By using an

FP-3000 network module, you can significantly reduce wiring and

installation costs. Instead of running a pair of wires from each 4–20 mA

device to your controller, you can mount an FP-3000 network module in the

field and run a single pair of wires (called the trunk) from your PC to the

FP-3000. You connect the 4–20 mA devices to the FieldPoint I/O modules

by short stretches of wire.

FieldPoint FP-3000 User Manual 1-2

©

National Instruments Corporation

Page 16

Chapter 1 FP-3000 Network Module Overview

Features of the FP-3000 Network Module

Function Blocks

Conventional devices connected to I/O modules are made visible as

Fieldbus function blocks. Function blocks are software modules which

describe the fundamental elements of an I/O or control system. The

FP-3000, like any FOUNDATION Fieldbus–compliant device, has one or

more function blocks. The function blocks in different devices can be

connected to form a distributed control system.

The FP-3000 implements FOUNDATION Fieldbus–compliant

I/O function blocks, such as Analog Input (AI), Analog Output (AO),

Discrete Input (DI), and Discrete Output (DO). These blocks provide

functionality such as scaling, trending, and alarming. For example, when

you connect a 4–20 mA pressure transmitter to a FieldPoint I/O, you can

configure an FP-3000 Analog Input function block to convert from

4–20 mA to engineering units. You can set up alarm limits so that the

FP-3000 sends an alarm when the pressure exceeds the limits. The FP-3000

network module can also collect trend samples and broadcast them to

applications on a PC.

PID Control

The FP-3000 implements the FOUNDATION Fieldbus–compliant PID

control function block. This PID can be used to control either an analog

output element connected to FieldPoint I/O or a native Fieldbus device,

such as a valve, connected to the Fieldbus network. The FP-3000 executes

the PID and other function blocks deterministically in accordance to a

configured schedule.

Block Instantiation

You can instantiate (create multiple copies of) the PID function block on

an as-needed basis. For example, if you are adding a new loop to an existing

Fieldbus network, you can instantiate a PID function block in the FP-3000

to control the loop. You can also instantiate the I/O function blocks on an

as-needed basis. If you have an 8-channel Analog Input module and you are

using only two channels, you would instantiate two AI function blocks.

You can instantiate additional AI function blocks when you use additional

channels.

©

National Instruments Corporation 1-3 FieldPoint FP-3000 User Manual

Page 17

Chapter 1 FP-3000 Network Module Overview

Interoperability

The FP-3000 network module can send or receive data from any

Fieldbus-compliant device. The PID block in the FP-3000 can get its input

from any Fieldbus-compliant device; it can also control any

Fieldbus-compliant output device.

The control and I/O functionality of the FP-3000 can be configured by any

Fieldbus configurator, such as the National Instruments NI-FBUS

Configurator . This is possible because all of the features added by National

Instruments are described using Device Descriptions. Any

Fieldbus-compliant HMI package or OPC server can also access the

FP-3000 function blocks.

Link Active Scheduler (LAS) Functionality

Fieldbus networks require a Link Active Scheduler (LAS) to control

communications on the Fieldbus. The FP-3000 can act as a primary or

back-up Link Active Scheduler. This enables the FP-3000 to execute PID

and other function blocks without a PC connected to the network. If a PC

is connected and the PC goes down, the FP-3000 takes over the bus and

executes the control without causing a bump.

HotPnP (Hot Plug and Play)

FP-3000 network modules can be added or removed from H1 Fieldbus

networks without affecting other Fieldbus devices.

You can insert or remove I/O modules into FieldPoint terminal bases while

the power is on, even if the FP-3000 is already operational. The other

I/O modules connected to the FP-3000 are fully operational during this

process. Y ou do not need to po wer down the FP-3000, Fieldbus network, or

even a bank to insert or remove I/O modules. You do not need to restart the

host computer software to use the HotPnP feature. You can replace an

I/O module only with another I/O module of the same type.

Field Upgradability

You can download new versions of the firmware to the FP-3000 over the

Fieldbus network without powering down the Fieldbus network or

affecting the operation of other devices. You should use the National

Instruments FP-3000 Firmware Update utility to download the firmware.

This feature lets you take advantage of new function blocks as they are

made available from National Instruments.

FieldPoint FP-3000 User Manual 1-4

©

National Instruments Corporation

Page 18

Installation and Configuration

This chapter describes how to install device description files, mount your

FieldPoint FP-3000 network module, connect the terminal bases, connect

power to the network module, and connect the FP-3000 to a Fieldbus

network.

Install the Device Description File

The Device Description file (DD) contains a list of the types of function

blocks and parameters supported by the FP-3000, along with online help

describing the uses of given parameters. Before you can use the FP-3000

with NI-FBUS (or other host software), you must install the device

description file (shipped with the device) on the host computer or

computers. After the DD file for the FP-3000 network module is initially

installed, the DD works for all FP-3000s on the Fieldbus connected to the

computer on which the DD has been installed. To install the DD for use

with NI-FBUS, complete the following steps:

Note

This process is correct for use with National Instruments NI-FBUS. The process can

vary with other host software packages.

2

1. Install your Fieldbus interface and NI-FBUS software, if you have not

done so already.

2. Insert the Device Description diskette (shipped with the FP-3000) into

the disk drive of the host computer.

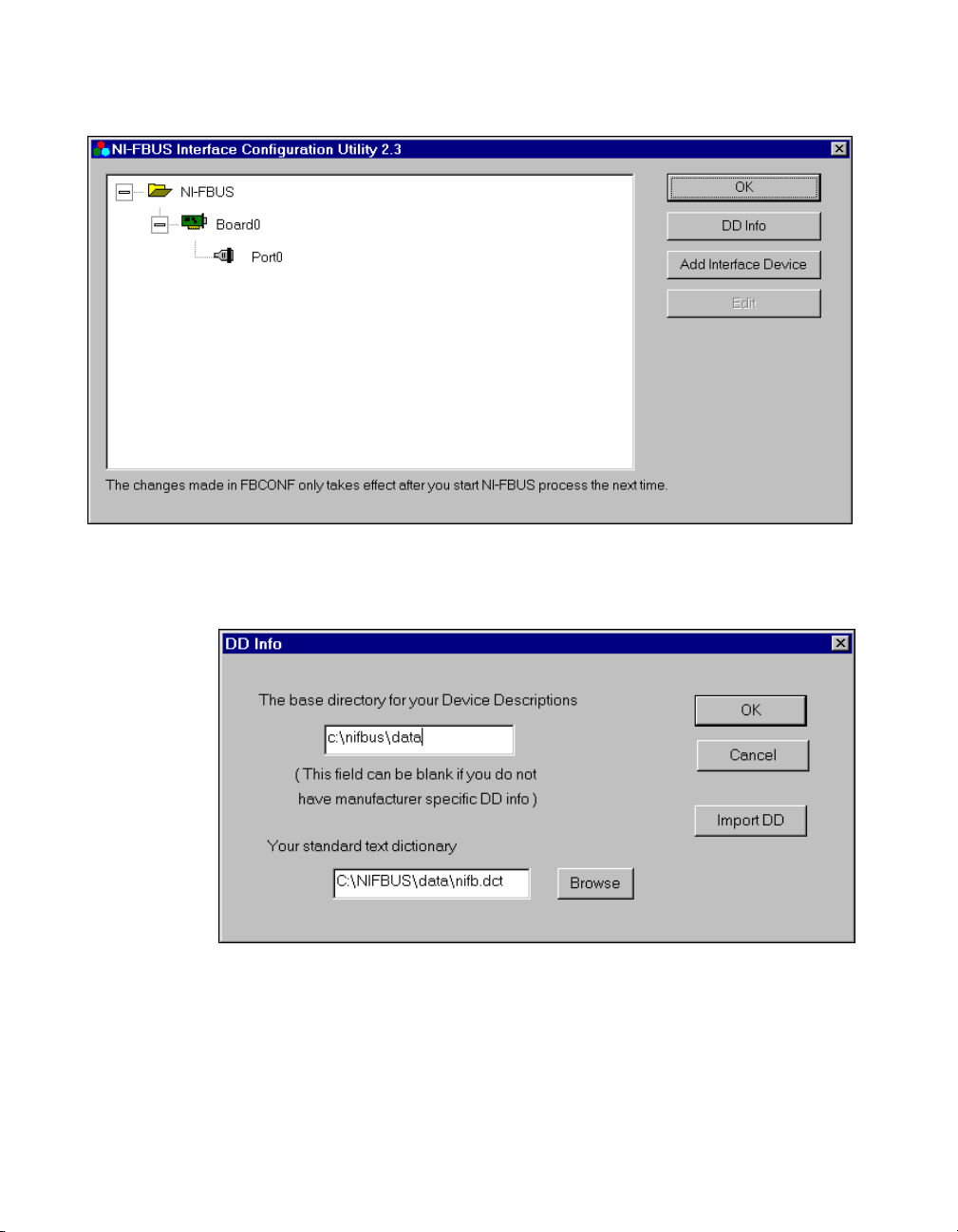

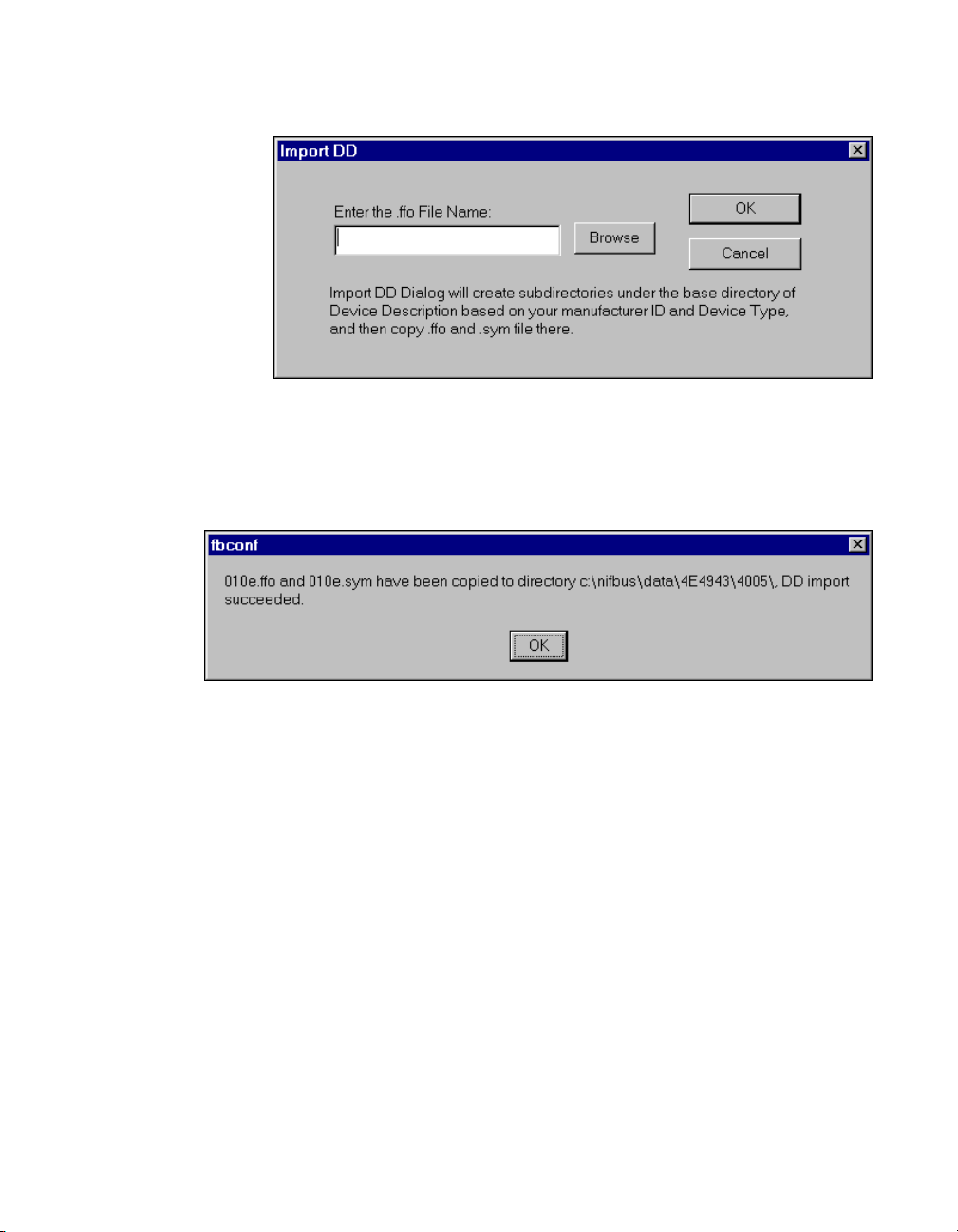

3. Select Start»Programs»NI-FBUS»Interface Config. The following

dialog box appears.

©

National Instruments Corporation 2-1 FieldPoint FP-3000 User Manual

Page 19

Chapter 2 Installation and Configuration

4. Click on the DD Info button. The following dialog box appears.

Figure 2-1. NI-FBUS Configuration Utility Dialog Box

Figure 2-2. DD Info Dialog Box

5. Click on the Import DD button. The following dialog box appears.

FieldPoint FP-3000 User Manual 2-2

©

National Instruments Corporation

Page 20

Chapter 2 Installation and Configuration

Figure 2-3. Import DD Dialog Box

6. Enter the file name for the device description into the entry field, then

click on OK. If the import process is successful, the following dialog

box appears, indicating that the software installation is complete.

Figure 2-4. fbconf Dialog Box

You only need to install the DD file one time for a version of the firmware.

You do not have to repeat the DD installation for each FP-3000 connected

to your computer.

Updating the Device Description

Any enhancement to the FP-3000 functionality, such as the addition of new

function blocks or support of new types of I/O modules, results in a new

Device Description file describing the features of the FP-3000. You must

install the new Device Description files. If you are using NI-FBUS

Communications manager or the NI-FBUS Configuration, refer to the

section Updating the FP-3000 Firmware for instructions on installing the

new Device Description file.

©

National Instruments Corporation 2-3 FieldPoint FP-3000 User Manual

Page 21

Chapter 2 Installation and Configuration

Mount the FP-3000 and Terminal Bases

You can mount your FieldPoint system either to a DIN rail or directly on a

panel. Panel mounting is generally the more secure option, but DIN rail

mounting might be more convenient for your application. The following

sections give instructions for both mounting methods.

Mounting the FP-3000 on a DIN Rail

The FP-3000 has a simple rail clip for reliable mounting onto a standard

35 mm DIN rail. Follow these steps to mount the FP-3000 on a DIN rail.

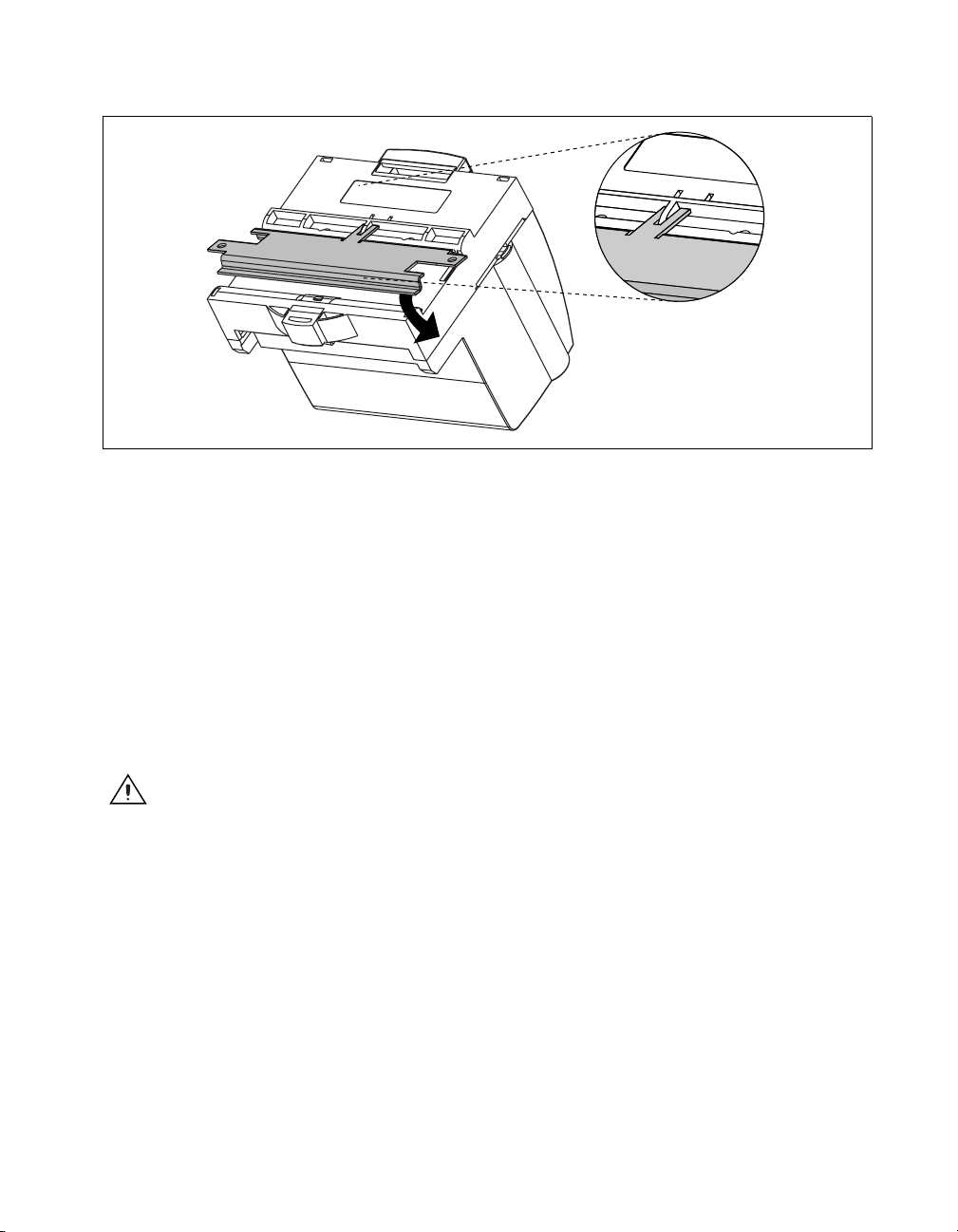

1. Use a flat-bladed screwdriver to open the DIN rail clip to the unlocked

position, as shown in Figure 2-5.

Rail Clip Locked Rail Clip Unlocked

Figure 2-5.

2. Hook the lip on the rear of the FP-3000 onto the top of a 35 mm DIN

rail and press the FP-3000 down onto the DIN rail, as shown in

Figure 2-6.

DIN Rail Clip

FieldPoint FP-3000 User Manual 2-4

©

National Instruments Corporation

Page 22

Chapter 2 Installation and Configuration

Local Bus

Connector

Lip

Cover

Press

Figure 2-6. Mounting the FP-3000 onto a DIN Rail

35 mm DIN Rail

3. Slide the FP-3000 to the desired position along the DIN rail. After the

FP-3000 is in position, lock it to the DIN rail by pushing the rail clip

to the locked position, as shown in Figure2-5.

After the FP-3000 is mounted to the DIN rail, connect the terminal base to

the FP-3000 as explained in the next section, Connecting Terminal Bases

with DIN Rail Mounting.

Connecting Terminal Bases with DIN Rail Mounting

Follow these steps to connect a terminal base to an FP-3000 network

module using DIN rail mounting.

Caution To avoid damaging the FP-3000 and the terminal bases, make sure that power is

not applied to the FP-3000 while you install or remove terminal bases.

1. Mount the terminal base onto the DIN rail in the same way you

installed the FP-3000.

2. Attach the terminal base to the FP-3000 by firmly mating the local bus

connectors.

©

National Instruments Corporation 2-5 FieldPoint FP-3000 User Manual

Page 23

Chapter 2 Installation and Configuration

3. To add more terminal bases, install them on the rail and connect their

local bus connectors together . A single FP-3000 can support up to nine

terminal bases.

4. Place the protective cover (from the bag of accessories that came with

your FP-3000) onto the local bus connector of the last terminal base on

the bank, as shown in Figure 2-7.

Local Bus Connectors

Firmly Mated

Protective

Cover

Removing the FP-3000 from the DIN Rail

To remove an FP-3000 network module, unlock it from the DIN rail by

placing a screwdriver in the slot on the rail clip and opening it to the

unlocked position, as shown in Figure 2-5. Then, disconnect the FP-3000

from the local bus connector of the terminal base, and lift the FP-3000 off

the rail.

Mounting the FP-3000 to a Panel

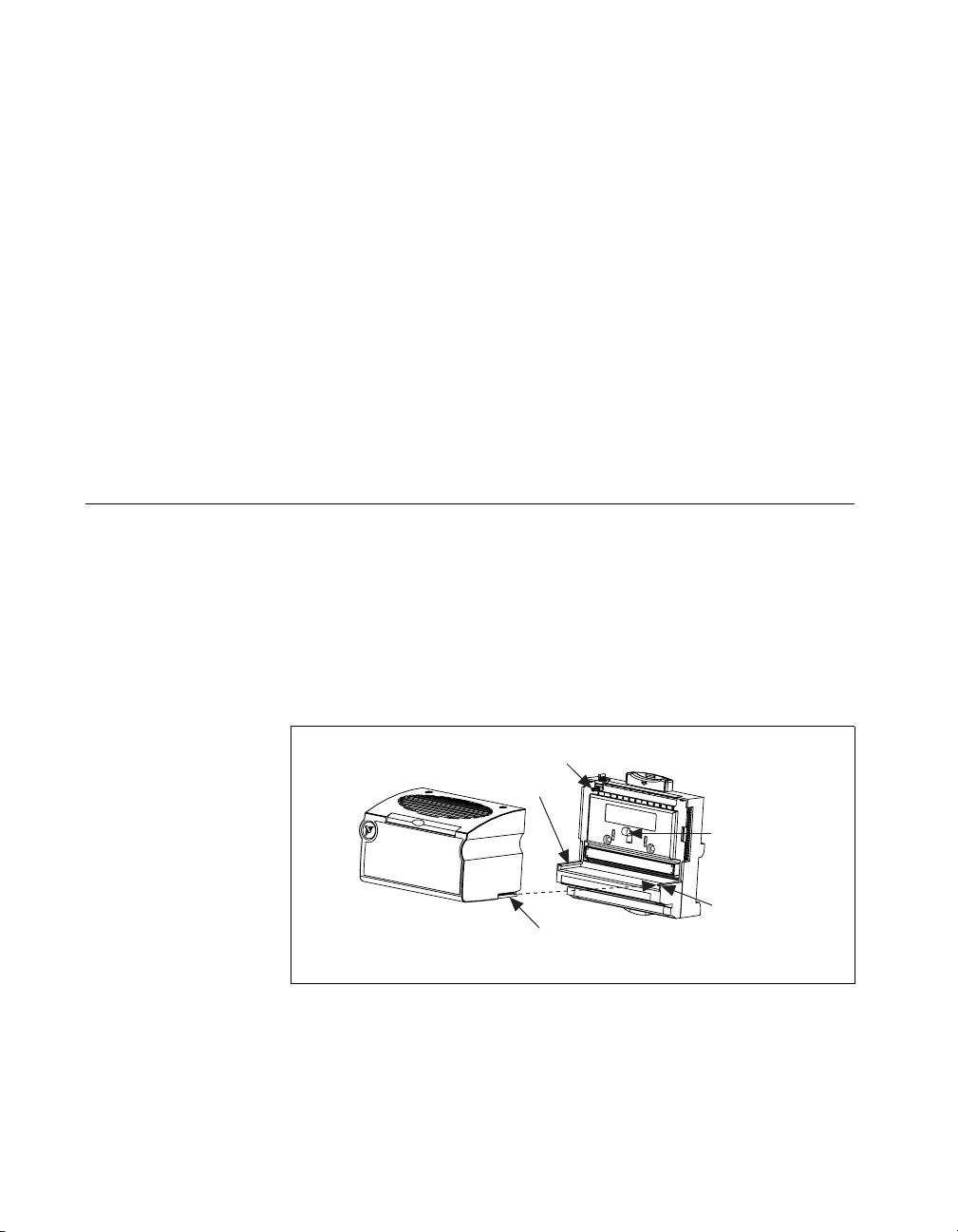

Follow these steps to install the optional FieldPoint network panel mount

accessory and mount the FP-3000 network module to a panel. You can

order the panel mount accessory, part number 777609-01, from National

Instruments.

1. Use a flat-bladed screwdriver to open the rail clip to the unlocked

position, as shown in Figure 2-5.

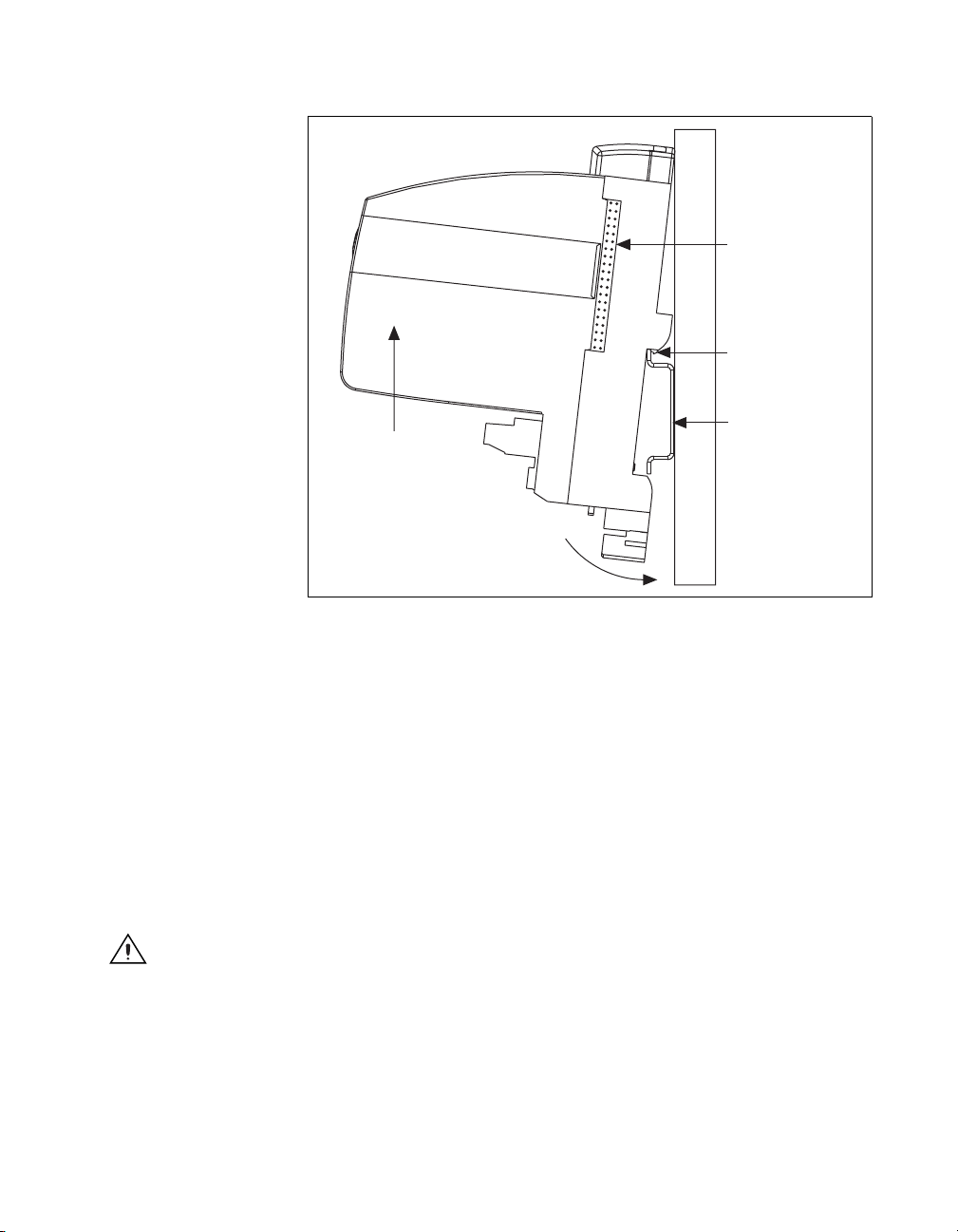

2. Snap the panel mount accessory onto the module, as shown in

Figure 2-8.

Rail Clip

Locked

Figure 2-7. Connecting Terminal Bases

DIN

Rail

FieldPoint FP-3000 User Manual 2-6

©

National Instruments Corporation

Page 24

Chapter 2 Installation and Configuration

Press

Figure 2-8. Installing the Network Panel Mount Accessory

3. Lock the panel mount accessory into place by pushing the rail clip to

the locked position, as shown in Figure 2-5.

4. Mount the FP-3000 to your panel with the panel mount accessory. The

installation guide that came with the panel mount accessory includes a

guide that you can use to drill pilot holes for mounting the FP-3000.

Connecting Terminal Bases with Panel Mounting

You can install terminal bases directly, without using the panel mount

accessory needed to mount the FP-3000 network module. Follow these

steps to connect terminal bases to a network module using panel mounting.

Caution To avoid damaging the FP-3000 and the terminal bases, make sure that power is

not applied to the FP-3000 while you install or remove terminal bases.

1. Drill pilot holes in the panel to mount the terminal bases. A drilling

guide is provided with the network module panel mount accessory.

2. Attach the terminal base to the FP-3000 by firmly mating the local bus

connectors.

3. Bolt, screw, or otherwise fasten the terminal base to the panel. Make

sure that the local bus connectors remain firmly mated after the

terminal base is mounted.

4. To add more terminal bases, repeat Steps 1 through 3, mating the local

bus connectors of each new terminal base to the connector of the last

installed base. If all the pilot holes were correctly drilled, the local bus

©

National Instruments Corporation 2-7 FieldPoint FP-3000 User Manual

Page 25

Chapter 2 Installation and Configuration

connectors should remain firmly mated after all the bases are mounted

to the panel.

5. Place the protective cover (from the bag of accessories that came with

your FP-3000) onto the local bus connector of the last terminal base on

the bank.

Removing the FP-3000 and Terminal Bases from

the Panel

To remove an FP-3000 network module and terminal bases from the panel,

reverse the process described in the previous sections, Mounting the

FP-3000 to a Panel and Connecting Terminal Bases with Panel Mounting.

First remove the terminal bases, starting with the last one, then remove the

network module.

Mount I/O Modules onto Terminal Bases

Follow these steps to connect an I/O module to a terminal base:

1. Position the first module with its alignment slots aligned with the guide

rails on the terminal base, as shown in Figure 2-9.

2. Firmly press the module onto the terminal base. The terminal base

latch locks the I/O module into place.

3. Repeat this procedure to install additional I/O modules onto terminal

bases.

Figure 2-9.

FieldPoint FP-3000 User Manual 2-8

Key

Guide Rail

Latch

Guide Rail

Alignment Slot

Terminal BaseI/O Module

Mounting I/O Module to Terminal Base

©

National Instruments Corporation

Page 26

Connect Power to the FP-3000

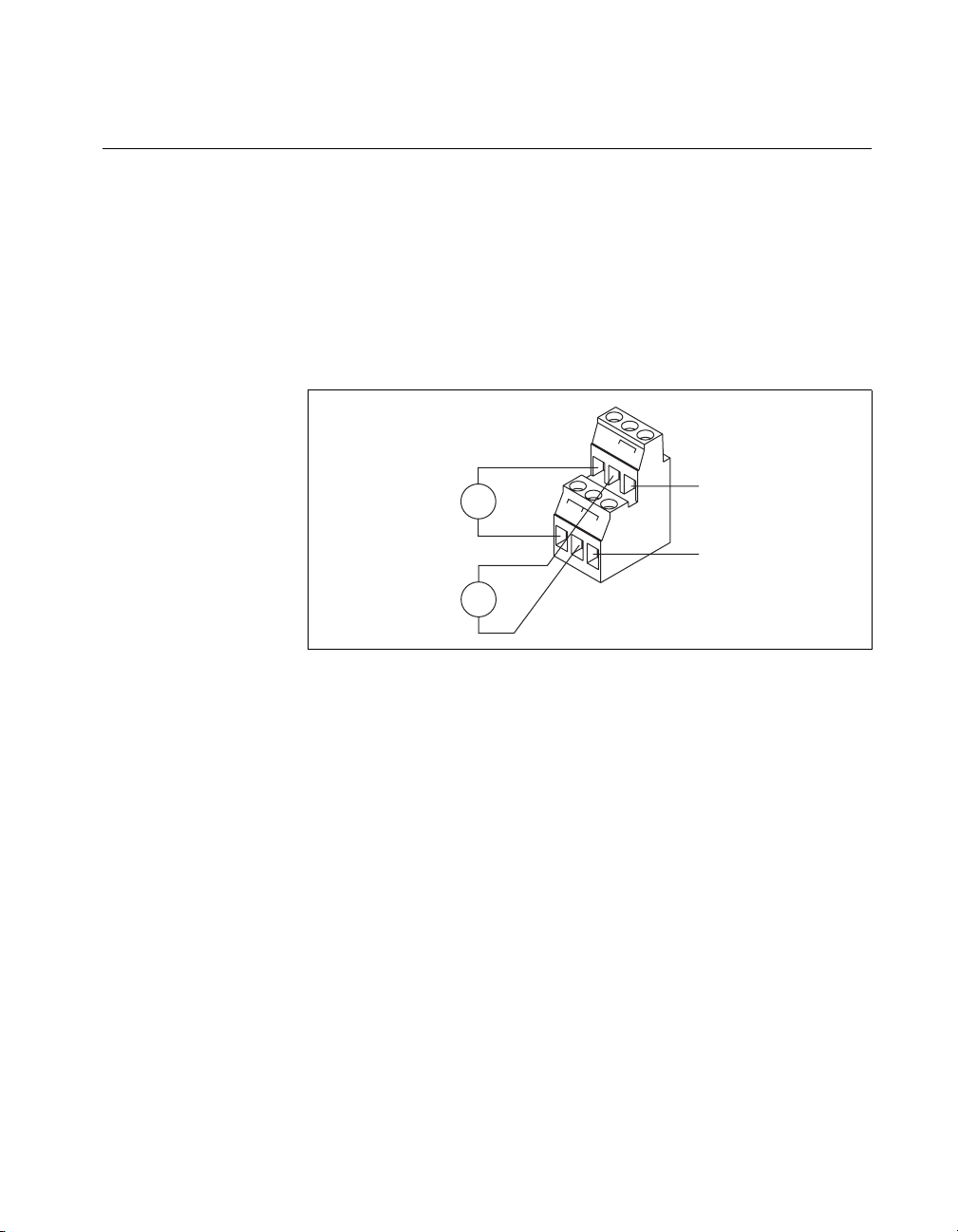

An 11–30 VDC power supply is required by each FP-3000 on your

network. The FP-3000 filters and regulates this supplied power and

provides power for all the I/O modules in the bank. Therefore, you do not

need to provide power separately to each FieldPoint I/O module in

the bank.

The power connector is a 6-pin screw terminal power connector whose

pinout is shown in Figure 2-10. See Figure 2-11 for the location of the

power connector.

11-30 VDC

Backup Power

Supply

(optional)

11-30 VDC

Primary Power

Supply

+

–

+

–

Chapter 2 Installation and Configuration

v

v

v

V

c

c

c

To adjacent device

(optional connection)

C

Figure 2-10.

FP-3000 Power Connector Pinout

Connect the primary power supply to the center V and C pair with the

positive and negative wires on your power cable in the V and C terminals,

respectively. You can connect an optional backup power supply to the left

V and C pair. The right V and C pair provides a convenient means of

connecting power to the V and C terminals of a terminal base. Figure 2-10

shows this optional connection.

If your field I/O devices need to be powered separately, you can use the

terminals provided on each terminal base for such power supply

connections. Refer to the documentation that came with your terminal base

and I/O module for more information on powering your field I/O devices.

Calculating Power for a FieldPoint Bank

The power requirements for a FieldPoint bank that uses an FP-3000

network module are calculated as follows:

Power = 6 watts + 1.15 * ∑(I/O Module Consumption)

©

National Instruments Corporation 2-9 FieldPoint FP-3000 User Manual

Page 27

Chapter 2 Installation and Configuration

This is the amount of power the network module consumes from the power

supply to power itself and the I/O modules. It does not include any power

consumed by devices that you wire to the terminal bases.

The operating instructions for each FieldPoint I/O module contain power

consumption information.

Power-On Self Test (POST)

The power-on self test (POST) is a test suite that the FP-3000 performs at

power up to verify its own operational status. The test takes several

seconds. The test is non-invasive and therefore does not affect the operation

of the network, nor does it affect any of your field wiring connected to the

terminal bases in the bank.

If the self-test suite fails, the FP-3000 does not participate in the network

communication traffic, eliminating potential conflicts with the other banks

in your network.

The FP-3000 indicates POST failure through the POWER and STATUS

LEDs. Refer to the section LED Indicators for more information.

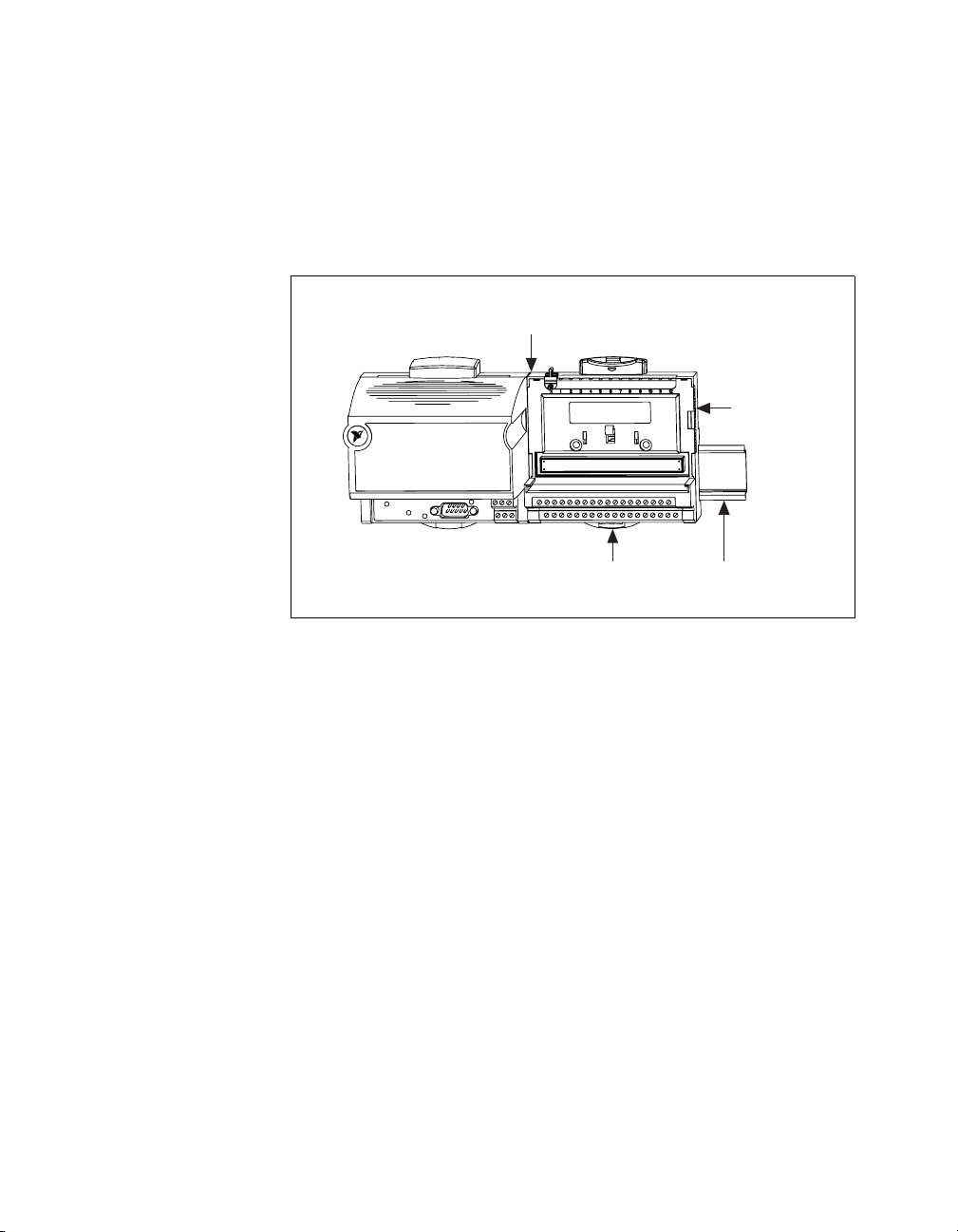

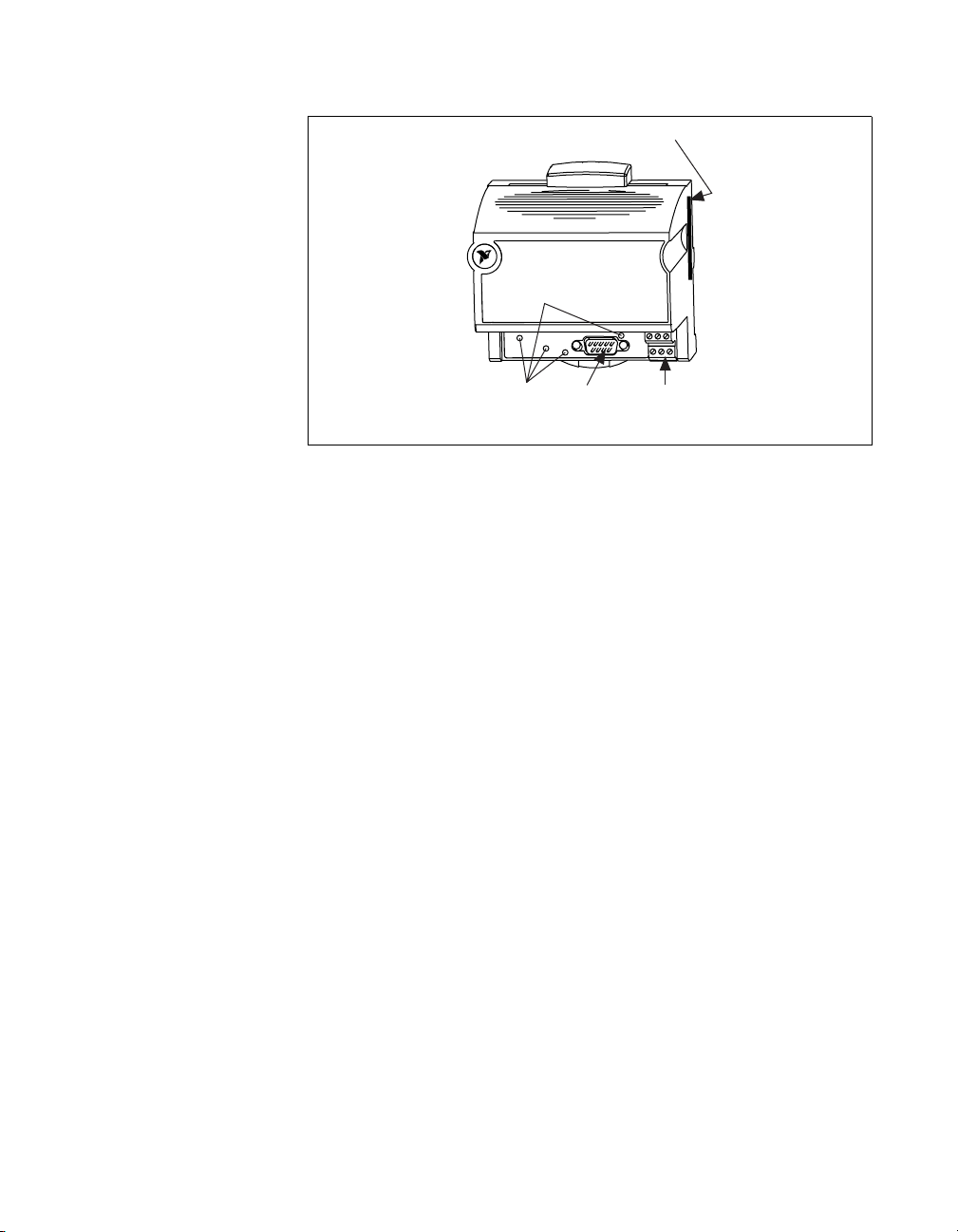

Connect the FP-3000 to the Fieldbus Network

The FP-3000 can be one of 32 devices connected to a Fieldbus network.

The connection is made through the 9-pin male Dsub Fieldbus connector

on the FP-3000, shown in Figure 2-11.

©

FieldPoint FP-3000 User Manual 2-10

National Instruments Corporation

Page 28

Chapter 2 Installation and Configuration

Local Bus Connector

Status

LEDs

Dsub

Fieldbus

Connector

Power

Connector

Figure 2-11. Fieldbus Connectors on the FP-3000

Use a Fieldbus cable with a 9-pin female Dsub connector to connect the

FP-3000 to a properly terminated Fieldbus network. Refer to the Fieldbus

Foundation Wiring and Installation 31.25 kbit/s, Voltage Mode, Wire

Medium Application Guide for specific information about wiring and

installing a Fieldbus network. If you want to make your own Fieldbus cable,

refer to the Fieldbus Standard for Use in Industrial Control Systems, Part

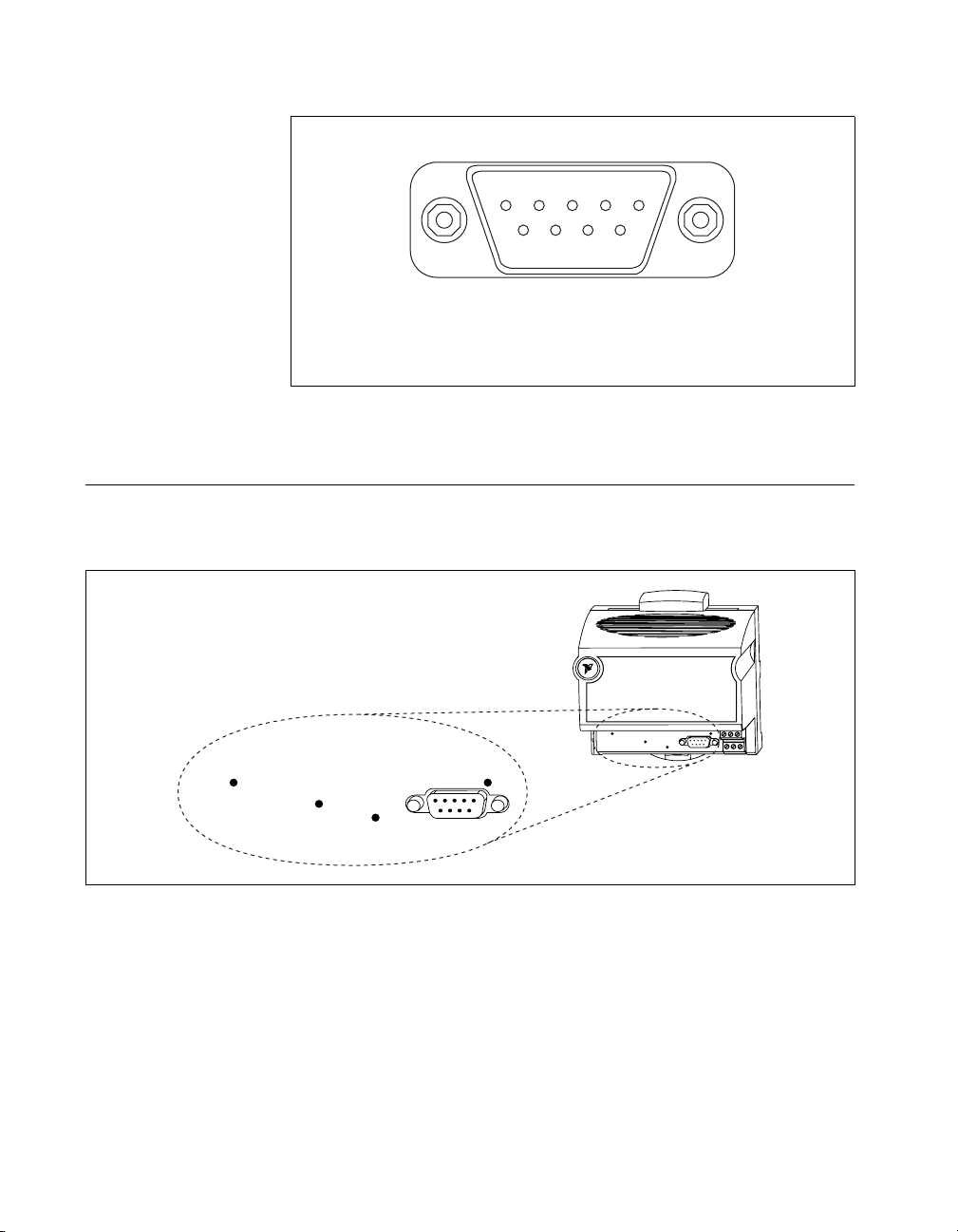

2, ISA-S50.02.1992. The FP-3000 Fieldbus connector pinout is shown in

Figure 2-12.

©

National Instruments Corporation 2-11 FieldPoint FP-3000 User Manual

Page 29

Chapter 2 Installation and Configuration

LED Indicators

The FP-3000 has four LED indicators: POWER, NETWORK,

PROCESS, and STATUS. Figure 2-13 shows the LEDs on the FP-3000.

NC

NC

NC

NC

NC

1 2345

6

789

NC

Data –

NC

Data +

NC = No Connection

Figure 2-12. FP-3000 Connector Pinout

STATUS NETWORK

PROCESS

POWER

FF-H1 PORT

Figure 2-13. LEDs on the FP-3000

When power is applied, the POWER LED blinks green for approximately

seven seconds during the power on self test. If the self test passes, the

POWER LED turns solid green and the READY LEDs on each

I/O module are lit green. If the self test fails, the POWER LED is lit red

and the module enters an inactive state.

FieldPoint FP-3000 User Manual 2-12

STATUS NETWORK

PROCESS

POWER

FF-H1 PORT

©

National Instruments Corporation

Page 30

Chapter 2 Installation and Configuration

The multicolored PROCESS LED is used to indicate the current state of

the processes being controlled by the FP-3000. When a PID function block

on the FP-3000 module is in initialization, the light flashes green. When all

the executing PID blocks on the FP-3000 are in Target mode, the light

remains lit solid green. Any active alarm of priority greater than eight

results in the light being lit red. For more information on PID blocks, refer

to the section PID (Proportional–Integral–Derivative) in Chapter 4, Block

Reference.

Table 2-1 describes the NETWORK LED states.

Table 2-1. Description of Fieldbus NETWORK LED States

NETWORK LED State Meaning

Off Fieldbus port not receiving data.

Flashing green Fieldbus port is currently the Link Active

Scheduler on the Fieldbus segment. The

FP-3000 module can control

communications on the Fieldbus.

Steady green Fieldbus port is a basic device. The

FP-3000 cannot control communication

on the Fieldbus.

Flashing red and green Fieldbus port is seeing traffic but is at a

default Fieldbus network address. You

need to assign a permanent network

address through a Fieldbus configurator.

Steady red Fieldbus port encountered fatal network

error. Check the Fieldbus network

connections.

The red STATUS LED is lit when the FP-3000 detects a failure. If

STATUS is not lit, the FP-3000 has not detected a failure. The FP-3000

indicates specific error conditions by flashing STATUS a specific number

of times. T able 2-2 describes the STATUS LED flashing sequences and the

corresponding error conditions.

©

National Instruments Corporation 2-13 FieldPoint FP-3000 User Manual

Page 31

Chapter 2 Installation and Configuration

Table 2-2.

Number of

Flashes

0 (stays lit) Configuration has changed and has not been stored in

1 Parameter storage of nonvolatile and static parameters

2 The FP-3000 detected an error in the terminal bases in

STATUS LED Flashes and Corresponding Error Conditions

static memory.

has been lost. Re-enter all stored parameters into the

module. You can do this by re-downloading a saved

configuration over the Fieldbus.

the bank or identified a module in an illegal state. V e rify

that the protective cover is on the local bus connector of

the last terminal base and that none of the pins of that

connector are touching or bent. Verify that there are no

more than nine terminal bases in the bank and that no

terminal bases were added to the bank while power was

applied.

HotPnP (Hot Plug and Play)

The HotPnP feature simplifies system installation, configuration, and

maintenance. With the HotPnP feature, you can remove or insert

I/O modules into the FieldPoint terminal bases while power is on, even if

the system is already engaged in network activity. You do not need to

power down the entire system or even a bank to insert, remove, or replace

I/O modules. In addition, you do not need to change the operation of the

host computer or software to use the HotPnP feature.

Error Condition

Caution

you do not add or remove terminal bases while power is applied to the bank. An I/O module

can be hot-inserted only if an empty terminal base is already available in the bank.

To avoid damaging the network module and the terminal bases, make sure that

HotPnP During Operation

You might need to insert or replace one or more I/O modules in a bank

while your system is operational (power is on and the network might or

might not be active).

While one or more new or replacement I/O modules in a bank are being

serviced by the HotPnP feature, the other I/O modules in the bank remain

fully operational and accessible on the network without any interruptions.

FieldPoint FP-3000 User Manual 2-14

©

National Instruments Corporation

Page 32

Chapter 2 Installation and Configuration

As soon as the FP-3000 configures the new I/O module through the HotPnP

service, that I/O module becomes automatically accessible on the network.

Inserting New I/O Modules

When a new I/O module is inserted, the FP-3000 automatically configures

the I/O module to factory default settings. This configuration is

accomplished without any intervention from the host computer or software.

Replacing I/O Modules

The host computer can detect missing I/O modules through the block alarm

on the associated function blocks.

When a new I/O module is connected in place of one that was removed, the

FP-3000 first verifies that the replacement I/O module is compatible with

the one that was removed. If the I/O module is either the same as or

compatible with the one removed, the FP-3000 configures the replacement

I/O module with its predecessor’s configuration and output value settings.

Hot-swap a module only with a compatible module. If you hot-swap a

module with an incompatible module, the associated function blocks must

be entirely reconfigured.

Updating the FP-3000 Firmware

As the FP-3000 evolves, National Instruments will release updates to the

module that contain new features. These new features will include support

for new types of FieldPoint I/O modules as they are released, as well as new

function blocks and other enhancements. To update the firmware on an

FP-3000, the FP-3000 Update utility (provided with the FP-3000) must be

on a machine running the NI-FBUS Communications manager. You need

to use the National Instruments AT-FBUS or PCMCIA-FBUS card on your

PC or laptop computer. The new firmware features will be described by a

new version of the Device Description.

Caution

settings to be lost, depending on the degree of change in the firmware. You should make

sure that all settings for the FP-3000 have been saved in your PC configurator before you

update the firmware so that you can restore the settings after you update the firmware.

©

National Instruments Corporation 2-15 FieldPoint FP-3000 User Manual

Updating the firmware on the FP-3000 may cause all FP-3000 configuration

It is possible for two FP-3000 modules with different versions of the

firmware and different DDs to co-e xist on the same Fieldbus segment or a

Page 33

Chapter 2 Installation and Configuration

Fieldbus system. You do not need to update all the FP-3000 modules with

the new firmware. Follow these steps to update the firmware:

1. Select FP-3000 Update Utility from the start menu of the host PC.

Figure 2-14. FP-3000 Firmware Update Dialog Box

2. Click on the Search for FP-3000s button. This causes the update

utility to search every Fieldbus segment on the host PC for FP-3000

modules. Located modules are displayed as shown in Figure 2-15.

FieldPoint FP-3000 User Manual 2-16

©

National Instruments Corporation

Page 34

Chapter 2 Installation and Configuration

Figure 2-15. FP-3000 Search Dialog Box

3. Select the FP-3000 module that needs to be updated, and enter the path

to the firmware image file.

©

National Instruments Corporation 2-17 FieldPoint FP-3000 User Manual

Page 35

Chapter 2 Installation and Configuration

Figure 2-16. Select FP-3000 Module Dialog Box

4. Click on the Download button of the update utility. This process takes

about 15 minutes. At the end of the process, the FP-3000 is updated to

include the new features. At the end of the update process, the

configuration information in the FP-3000 is cleared.

FieldPoint FP-3000 User Manual 2-18

©

National Instruments Corporation

Page 36

Example Applications

This chapter provides examples that show you how to configure the

FP-3000 to perform common tasks, including reading from a 4–20 mA

current loop device, taking temperature readings from a thermocouple

module, and controlling the output current through an analog output

module. This chapter also provides information about hardware and

software configuration.

These examples assume you have the NI-FBUS Configurator; however,

you can use any Fieldbus configuration utility capable of writing function

block parameters, configuring linkages between parameters, and

configuring function block schedules. If you are not using the NI-FBUS

Configurator , refer to the documentation that came with your configurator

for more details on how to perform software configuration-related tasks.

Before you run these examples, install the FP-3000 and the I/O modules.

Connect the FP-3000 to the Fieldbus network and power it on. Start the

NI-FBUS Configurator on your PC. Your configurator should show the

FP-3000. For more information on installing the FP-3000, refer to

Chapter 2, Installation and Configuration.

3

Initial Power On: Assigning Address and Device Tag

If you are powering on the FP-3000 for the first time, you need to perform

some extra steps before you try these examples. You must assign each

FP-3000 a unique device tag and network address before it can become

operational. If you are using the NI-FBUS Configurator, the configurator

automatically assigns a network address to the FP-3000 when it powers up.

It also assigns a tag, which you can change if necessary by right-clicking

on the device and choosing Set Tag. The process of automatic address

assignment and tagging can take a few minutes. After the FP-3000 has a

network address and tag, you can perform any of these examples. If you are

not using the NI-FBUS Configurator, refer to the documentation that came

with your configurator for information about setting the network address

and device tag.

©

National Instruments Corporation 3-1 FieldPoint FP-3000 User Manual

Page 37

Chapter 3 Example Applications

Example 1: Converting a 4–20 mA Pressure Sensor to

Fieldbus Using FP-3000

One common application of the FP-3000 is interfacing to a conventional

device, such as a 4-20 mA pressure sensor or a 4-20 mA temperature

transmitter. This example helps you configure the FP-3000 to interface to

a 4-20 mA pressure sensor. This example shows you how to instantiate an

AI function block, assign a tag to the block, set up scaling parameters and

range for the I/O channel, schedule the function block, and download the

configuration to the FP-3000.

Getting Started

Example 1 requires the following materials:

• 4–20 mA sensor, such as a pressure sensor

• FP-AI-100, FP-AI-110, or FP-AI-111 module (this example assumes

you are using the FP-AI-110 module)

• FP-3000 network module

• Host configuration system capable of instantiating function blocks on

devices (such as National Instruments NI-FBUS Configurator)

Wire the 4–20 mA current loop into the current source input FP-AI-110

terminals. For channel zero, use terminals 1 and 17, as indicated on the

wiring diagram on the front of the FP-AI-110 module. Make sure your

current loop is powered and the sensor is operating normally.

Convert the Pressure Sensor Reading

Configure the software to perform the translation from the 4–20 mA sensor

signal to the engineering units used on the Fieldbus.

Create Function Block

You must create a block for the FP-AI-110 since the pressure sensor is

connected to a channel on the FP-AI-110 input module. To create a block

for the FP-AI-110, follow these steps:

1. Right-click on the FP-3000 entry in your configurator.

2. Select Instantiate New Block. This causes a dialog box listing all the

blocks supported by the FP-3000 to appear and allows them to be

instantiated.

FieldPoint FP-3000 User Manual 3-2

©

National Instruments Corporation

Page 38

Chapter 3 Example Applications

3. Select FP AI 110 Block from the list, then click on th e OK button.

This creates the correct analog input block on the FP-3000.

Assign a Tag to the New Block

By default, new blocks are created without a tag. To assign a tag, follow

these steps:

1. Right-click on the new block, then select Set Tag.

2. Enter the tag you choose in the dialog box. The tag can be up to

32 characters in length and should not contain the dot (“.”) character.

3. Click on OK.

Select the Module and Channel

Determine the FieldPoint module number by counting each module in the