Page 1

FP-1600 FieldPoint Quick Start Guide

What You Need to Get Set Up

·

Network Module

·

Mounting Hardware (DIN rail

or panel mount accessory)

·

Terminal Base(s)

· I/O Module(s)

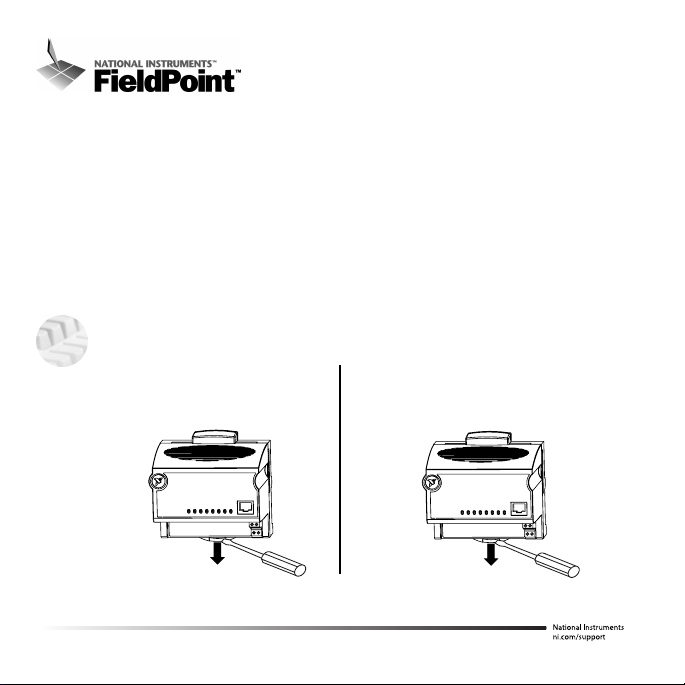

Install the Network Module

1

A. Unlock rail clip.

· Power Supply

· FieldPoint Software CD

· Accessories: Ethernet cable,

screwdriver

A. Unlock rail clip.

Panel MountDIN Rail Mount

1

Page 2

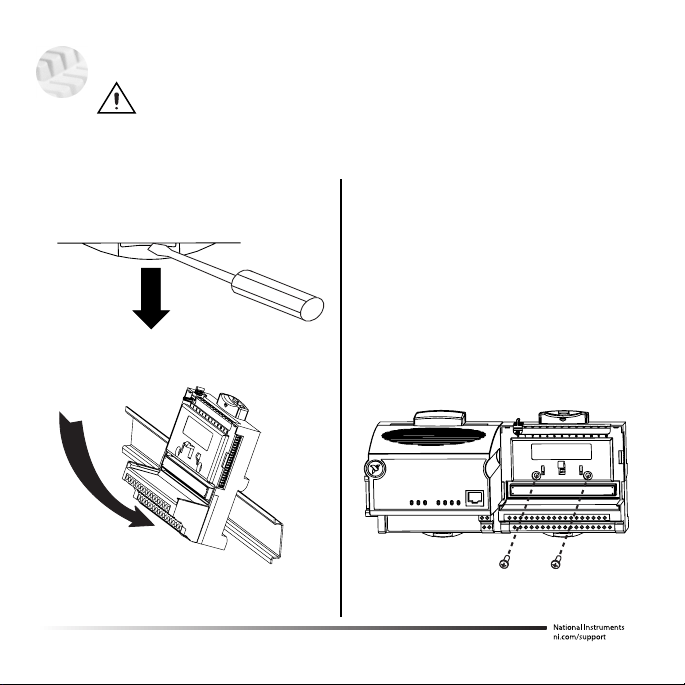

NOTE: Do not use spliced DIN

rails. Use only a single DIN rail.

B. Hook lip on back of module onto top

of DIN rail, press down, and snap

into place.

Panel MountDIN Rail Mount

B. Snap panel mount accessory

(which you can order separately)

onto module.

C. Lock rail clip.

C. Slide module into position and lock

rail clip.

2

D. Use template that came with your

accessory to drill pilot holes and

mount module onto

panel using

accessory.

Page 3

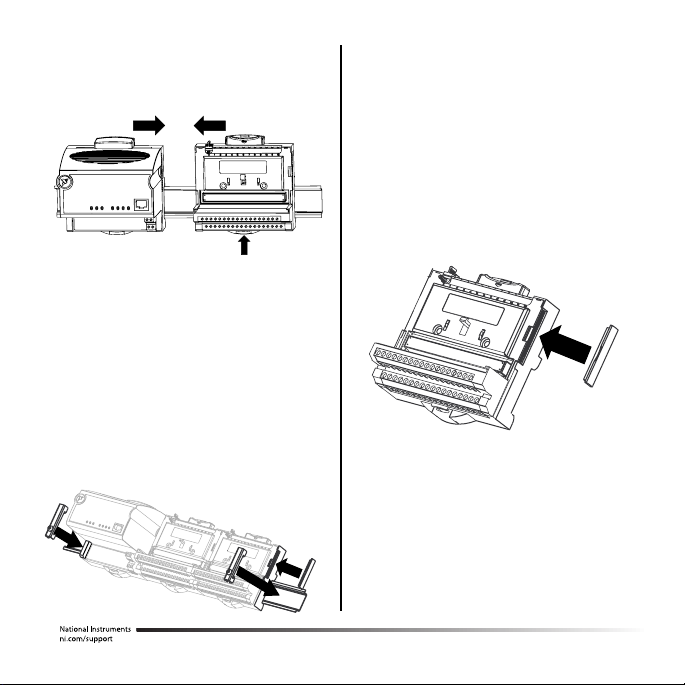

Install the Terminal Base(s)

2

CAUTION: Terminal bases must be connected to the network module

before applying power to the module. Do

terminal bases while power is applied to the network module.

not

connect or disconnect

DIN Rail Mount

A. Unlock rail clip.

B. Press base onto rail.

Panel Mount

A. Use template that came with your

accessory to drill pilot holes.

B. Connect terminal base to network

module connector, being careful not

to bend any connector pins.

C. Fasten terminal base to panel.

3

Page 4

DIN Rail Mount

C. Slide into position and lock the rail

clip. Be careful not to bend any pins.

D. Repeat for each terminal base, up

to nine for each network module in

most cases. You can use one or

two extender cables (which you can

order separately) if your FieldPoint

bank is too long for your available

space.

E. Place protective cover on last base,

and install rail locks at each end.

Panel Mount

D. Repeat for each terminal base, up to

nine for each network module in

most cases. You can use one or two

extender cables (which you can order

separately) if your FieldPoint bank is

too long for your available space.

E. Place protective cover on last base.

4

Page 5

Install the I/O Module(s)

3

It does not matter where you install each I/O module, except for

these types of situations:

····If you plan to cascade power between any I/O modules using the

V and C terminals, those modules should be grouped together.

····For more accurate measurements, you might want to locate any

thermocouple modules away from heat sources, including network

modules or relay modules, unless you are mounting them on an FP-TB-3.

A. Align slots on module with guide rails on

base, and press onto base until terminal

base’s latch locks the module in place.

B. Repeat for each I/O module.

Connect the Network Cables

4

Connect the FP-1600 to an Ethernet network by connecting the RJ-45

Ethernet port of the FP-1600 to an Ethernet hub using a standard Category 5

Ethernet cable.

Straight-Through

UTP Cable

Straight-Through

UTP Cable

5

Page 6

Optionally, you can connect an FP-1600 directly to a computer using an

Ethernet crossover cable.

Cross-Over Cable

Do not use a cable longer than 100 m. If you are using a 100 Mbps Ethernet,

National Instruments recommends using a Category 5 shielded twisted-pair

Ethernet. If you need to build your own cable, refer to the FP-1600 User

Manual for cabling details.

Wire Power to Your FieldPoint System

5

A. Connect 11-30 VDC power supply leads to V and C terminals of the

network module. If you want to verify that your power supply is sufficient

for your modules and devices, refer to your FieldPoint hardware

documents for instructions on calculating power requirements.

B. Connect power to the FieldPoint modules that require external power for

outputs (output modules, counter modules, PWM, PG, QUAD). Refer to

the I/O module’s operating instructions for power requirement details.

You can power a module by connecting the V and C inputs on its terminal

base to a separate power supply, connecting the V and C outputs of a

neighboring terminal base or network module, or using a combination of

both methods. If you want to power field I/O devices from a terminal

base, supply power to the terminal base, and then connect the terminal

base V and C output terminals to the field device.

6

Page 7

CAUTION: Cascading power from neighboring bases or network modules

defeats isolation between cascaded modules.

Separate Power Supply

(Recommended)

Cascaded Power

(Reduces Isolation)

FP-1600 FP-AI-100 FP-AO-200 FP-RLY-420 FP-TC-120

No External

Power Required

Power Supply

Power Supply

Shades of gray indicate

different voltage potentials.

15

31 32 C

16 V

V

1

32

C

17

CAUTION: Cascading

18

power defeats isolation.

7

Page 8

6

FP-AI-110

8 Channel, 16-Bit Analog Input Module

Highlights

Overview

FP-AI-110

Self-Powered

Floating Sensor

15

32

Loop-Powered

Sensor

17

2

I

Sensor

Channel 0

V

Sensor

Channel 7

To Po we r

Supply

24

8

23

7

CH3

CH7

15

CH4

CH5

CH6

9

11

13

311632

25

27

29

10

12

14

26

28

30

C

COM

I

IN

VOLTAGE

SOURCE

-

+

SOURCE

POWERED

V

COM

IN

V

CH1

CH2

CH0

3

5

1

VINI

SUP

19

21

17

4

6

2

20

22

18

SOURCE

CURRENT

V

IN

SUP

V

V

OUT

mV,V,20mA

FP-AI-110FP-AI-110

8-Ch.16-Bit Analog Input

0

1

2

3

4

5

6

7

1

POWER

8-Ch.16-Bit Analog Input

READY

FP-AI-110

T

EMP

_1

T

EMP

_2

T

EMP

_3

Connect to Field Devices

Use each I/O module’s operating instructions, or the diagram under its

removable label, to help you connect your field devices.

8

NOTE: Either the self-powered

sensor or power supply should be

floating (not tied to earth ground).

Page 9

Power Up Your FieldPoint System

7

CAUTION: Terminal bases must be connected to the FP-1600 before

power is applied to the FP-1600.

Plug in each power supply to

your FieldPoint bank. You should

see all except the STATUS and

PROCESS LEDs flash once, and

the POWER LED come on and

stay on. After a few seconds, the

POWER and READY LEDs should

be lit on each I/O module. If this

is not the case, refer to your

FP-1600 user manual for

troubleshooting instructions.

The READY LEDs will not light until an IP address is assigned. Likewise, the

STATUS LED will stay lit until an IP address is assigned.

After the hardware is installed, you should verify communication, configure

the modules, configure your power-up states and watchdog settings. If you

are using National Instruments FieldPoint software for these tasks, continue

to the following section.

POWER and READY LEDs Stay Lit

9

Page 10

Install the FieldPoint Software

8

A. Close all other applications. If you

plan to install National Instruments

development software such as

Lookout, LabVIEW, or Measurement

Studio, install them before you

install the FieldPoint software.

B. Insert the FieldPoint software CD and follow the onscreen instructions.

Verify the Installation

9

A. Select Start»Programs»National Instruments FieldPoint»FieldPoint

Explorer.

B. Right-click on the FieldPoint icon and select Add a comm resource to this

server.

10

Page 11

C. In the Comm Resource

Configuration dialog box, select

Ethernet as the Type.

D. Click Browse, select the

FP-1600, and click the Device

Properties button.

11

Page 12

E. In the FP-1600 Properties box, enter

values for the IP address, Subnet

mask, and Time server IP. You might

also want to enter a comment to help

you identify the FP-1600 module.

• IP address is the address of the

FP-1600 on the network.

• Subnet mask is the mask that is

applied to the IP address that the

device uses to find other devices on

the Ethernet network (255.255.255.0

is the most common).

• Time server IP is the address of the

host computer that the FP-1600 will synchronize its clock to. The

computer must have the Lookout Time Synch service (installed with

Lookout 4.x or FieldPoint 2.x).

F Click on Apply, then OK twice to return to the Comm Resource

Configuration dialog box.

G. Click on Find Devices.

H. Expand the +FP Res item on the left side of the Explorer window to see

the devices found on the network.

12

Page 13

If your modules are not

listed, check the cable and

connections and make sure the

modules are all powered on. If

you still have problems, refer

to your FP-1600 user manual

for troubleshooting

information.

I. Select an input module and

click on the start monitoring button to view live data.

J. Select an output channel and click on the write button to change

outputs.

K. Select File»Save.

13

Page 14

Configure I/O Modules

10

A. Right-click on the device name in FieldPoint Explorer and select Edit this

Device from the pop-up menu.

B. Click on the Channel Configuration button to bring up the Channel

Configuration dialog box.

C. Select the type of

channel to show,

then select the

channel(s) that

you want to

change. To select

more than one

channel, uncheck

the One channel

at a time box.

NOTE: Configuration options are module-dependent. The options

listed here might not be available for your particular module. Refer to

your I/O module operating instructions for details on configuration

options.

14

Page 15

D. Set the range and output values of the selected channel(s).

E. Set the attributes for the selected channel(s) by selecting the attribute and

entering the desired value.

F. Send commands to the selected channel(s) by choosing a command and

value and clicking on Send.

G. Repeat this procedure for each channel you want to configure.

H. Click on the OK button when you are finished, or click on the Apply

button to save the changes and continue to configure channels. When

you click on OK or Apply, the changes are immediately sent to the device.

I. Select File»Save when you are done.

15

Page 16

Where to Go from Here

11

After you get your hardware up and running, you might want to implement

features such as power-up defaults or network watchdog settings. Refer to

your FP-1600 user manual or online help for information about features,

configuration, application development, and troubleshooting.

16

Page 17

FP-1600 Specifications

Network interface ....................10BaseT and 100BaseTX Ethernet

Compatibility........................IEEE 802.3

Communications rate .................10Mbps, 100 Mbps, autonegotiated

Cabling distance .....................100m

Power supply range ..................11to30VDC

Power consumption ..................7W+1.15

Maximum terminal bases per bank .......9

Maximum number of banks .............determined by network topology

Operating temperature.................–20to+55°C

Storage temperature ..................–55to+85°C

Relative humidity ....................5%to90%non-condensing

Weight ............................280g(9.9 oz.)

Compliance

Electrical safety ......................designed to meet IEC 1010

EMI emissions/immunity ...............CISPR 11

CE Mark Compliance

This product meets applicable EU directive(s) as follows:

EMC directive

Immunity ......................EN50082–1:1994

Emissions .....................EN55011:1991 Group I Class A at 10 meters

(I/O module power requirements)

*

17

Page 18

Mechanical Dimensions

Dimensions are given in inches [millimeters].

4.31

[109.5]

3.60 [91.44]

4.22 [107.19]

18

Page 19

United States 512 795-8248

Australia 03 9879 5166, Austria 0662 45 79 90 0, Belgium 02 757 00 20,

Brazil 011 284 5011, Canada (Calgary) 403 274 9391,

Canada (Ontario) 905 785 0085, Canada (Québec) 514 694 8521,

China 0755 3904939, Denmark 45 76 26 00, Finland 09 725 725 11,

France 01 48 14 24 24, Germany 089 741 31 30, Greece 30 1 42 96 427,

Hong Kong 2645 3186, India 91805275406, Israel 03 6120092, Italy 02 413091,

Japan 03 5472 2970, Korea 02 596 7456, Mexico (D.F.) 5 280 7625,

Mexico (Monterrey) 8 357 7695, Netherlands 0348 433466, Norway 32 27 73 00,

Singapore 2265886, Spain (Barcelona) 93 582 0251, Spain (Madrid) 91 640

0085, Sweden 08 587 895 00, Switzerland 056 200 51 51, Taiwan 02 2377 1200,

United Kingdom 01635 523545

© Copyright 1999, 2000 National Instruments Corporation.

All rights reserved. CVI™, FieldPoint™, LabVIEW™, Lookout™, Measurement Studio™, and

ni.com™ are trademarks of National Instruments Corporation. Product and company names

mentioned herein are trademarks or trade names of their respective companies.

Loading...

Loading...