Page 1

FieldPoint™ FP-1000 and

FP-1001 RS-232/RS-485

Network Module

User Manual

FieldPoint FP-1000/FP-1001 User Manual

July 1997 Edition

Part Number 321631A-01

© Copyright 1997 National Instruments Corporation. All rights reserved.

Page 2

Internet Support

support@natinst.com

E-mail: info@natinst.com

FTP Site: ftp.natinst.com

Web Address: http://www.natinst.com

Bulletin Board Support

BBS United States: (512) 794 -5422

BBS United Kingdom: 01635 551422

BBS France: 01 48 65 15 5 9

Fax-on-Demand Support

(512) 418-1111

Telephone Support (U.S.)

Tel: (512) 795-8248

Fax: (512) 794-5678

International Offices

Australia 03 9879 5166, Austria 0662 45 79 90 0, Belgium 02 757 00 20,

Canada (Ontario) 905 785 0085, Canada (Québec ) 514 694 8521, Denmark 45 76 26 00,

Finland 09 725 725 11, France 01 48 14 24 24, Germany 089 741 31 30,

Hong Kong 2645 3186, Israel 03 5734815, Ital y 02 413091, Jap an 03 5472 2970,

Korea 02 596 7456, Mexico 5 520 2635, Nethe rlands 034 8 433466, Nor way 32 84 84 00,

Singapore 2265886, Spain 91 640 0085, Swede n 08 730 49 70, Switzerland 056 200 51 51,

Taiwan 02 377 1200, United Kingdom 01635 523545

National Instruments Corporate Headquarters

6504 Bridge Point Parkw ay Austin, TX 78730-503 9 Tel: (512) 794-0100

Page 3

Important Information

Warranty

The FieldPoint modules are warranted against defects in materials and workmanship for a period of one year from the

date of shipment, as evidenced by receipts or other documentation. National Instruments will, at its option, repair or

replace equipment that proves to be defective during the warranty period. This warranty includes parts and labor.

The media on which you receive National Instru ments software ar e warranted not to fail to execute pro grammi ng

instructions, due to defects in materials and workmanship, for a period of 90 days from date of shipment, as evidenced

by receipts or other documentation. National Instruments will, at its option, repair or replace soft ware media that do

not execute programming instructions if National Instruments receives notice of such defects during the warranty

period. National Instrument s does not war rant that the oper ation of the softwar e shall be un interr upted or error free.

A Return Material Authorization (RMA) number must be obtained from the factory and clearly marked on the outside

of the package before any equipment will be accepted for warranty work. National Instruments will pay the shipping

costs of returning to the owner par ts whi ch are cov ered by w arranty .

National Instruments believes that the information in this manual is accurate. The document has been carefully

reviewed for technical accuracy. In the event that technical or typographical errors exist, National Instruments reserves

the right to make ch anges to subsequent editions of this document without prior not ice to holders of th is edition. The

reader should consult National Instruments if errors are suspected. In no event shall National Instruments be liable for

any damages arising out of or related to this docum ent or the in format ion contai ned in it.

E

XCEPT AS SPECIFIED HEREIN

SPECIFICALLY DISCLAIMS ANY WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE

C

USTOMER’S RIGHT TO RECOVER DAMAGES CAUSED BY FAULT OR NEGLIGENCE ON THE PART OF NATIONAL

I

NSTRUMENTS SHALL BE LIMITED TO THE AMOUNT THERETOFORE PAID BY THE CUSTOMER

WILL NOT BE LIABLE FOR DAMAGES RESULTING FROM LOSS OF DATA, PROFITS, USE OF PRODUCTS, OR INCIDENTAL OR

CONSEQUENTIAL DAMAGES, EVEN IF ADVISED OF THE POSSIBILITY THEREOF

Instruments will apply regardles s of the fo rm of acti on, whether i n contract or tort, incl uding neg lig ence. Any acti on

against National Instruments must be brought wit hin one year after the cause of action accrues. Nat ion al Instrument s

shall not be liable for any delay in performan ce due to causes beyo nd it s reasonable cont rol. The warranty pr ovided

herein does not cover damages, defects, malf unctio ns, or s ervice fai lures caused by owne r’s fail ure to fol low the

National Instruments in sta llat ion, o perat ion, or ma inte na nce instr uct ions; owner ’s modif icat ion of the p roduct;

owner’s abuse, misuse, or negligent acts; and power failure or surges, fire, flood, accident, actions of third parties, or

other events outside reasonable control.

, N

ATIONAL INSTRUMENTS MAKES NO WARRANTIES, EXPRESS OR IMPLIED, AND

.

. N

ATIONAL INSTRUMENTS

. This limitation of the liability of National

Copyright

Under the copyright laws, this publication may not be reproduced or transmitted in any form, electronic or mechanical,

including photocopying, reco rding, storin g in an in format ion retr iev al system , or tra nslati ng, in wh ole or in par t,

without the prior written consent of Nation al Inst rument s Corpo ration .

Trademarks

BridgeVIEW™, FieldPoint™, Lab VIEW™ , and Lookou t™ are trad emarks of Nat ional Inst ru ments Corpo ration.

Product and company names listed are trademarks or trade names of their respective companies.

WARNING REGARDING MEDICAL AND CLINICAL USE OF NATIONAL INSTRUMENTS PRODUCTS

National Instruments products are not design ed with comp onents and testing in tend ed to ensure a level o f reliabi lity

suitable for use in treatment and diag nosi s of humans . Appli cations of Nation al Instru men ts product s invol vin g

medical or clinical treatment can create a potential for accidental injury caused by product failure, or by errors on the

part of the user or application designer . Any us e or applicat ion of Nat ional Ins trum ent s products for or involvi ng

medical or clinical treatment must be performed by properly trained and qualified medical personnel, and all traditional

medical safeguards, equipment, and procedures that are appropriate in the particular situation to prevent serious injury

or death should always continue to be used when National Instruments prod ucts ar e being used. National Instruments

products are NOT intended to be a substitute f or any for m of establ ished pr ocess, proce dure, or equi pmen t used to

monitor or safegua rd huma n he alth and sa fety in med ical or clin ical t reat ment .

Page 4

About This Manual

How to Use This Manual Set........................................................................................ix

Organization of This Manual........................................................................................x

Conventions Used in This Manual................................................................................ x

Related Documentation.................................................................................................xi

Customer Communication.............................. ..... .........................................................xi

Chapter 1

FP-1000 and FP-1001 Network Module Overview

FP-1000 Connects to RS-232 .......................................................................................1-1

FP-1001 Connects to RS-485 .......................................................................................1-2

Chapter 2

Installation and Configuration

Installing the Network Module.....................................................................................2-1

Removing the Network Module ...................................................................................2-2

Connecting Terminal Bases..........................................................................................2-2

Connecting the FP-1000 to the Network......................................................................2-3

Connecting the FP-1001 to the Network......................................................................2-4

Connecting to the Serial Ports ......................................................................................2-5

RS-232 Interface Specifications.....................................................................2-6

RS-485 Interface Specifications.....................................................................2-7

RS-485 Network Termination and Biasing....................................................2-7

Configuring the Network Module.................................................................................2-9

Setting the Network Address.......................................................................... 2-10

Setting the Baud Rate.....................................................................................2-12

Connecting Power to the FP-1000 or FP-1001.............................................................2-12

Calculating Power for a FieldPoint Bank.....................................................................2-13

Table of

Contents

Chapter 3

Feature Set Description

High-Speed Local Bus.............................. ....................................................................3-1

Network Watchdog Timer............................................................................................3-1

©

National Instruments Corporation v FieldPoint FP-1000/FP-1001 User Manual

Page 5

Table of Contents

SnapShot Feature.......................................................................................................... 3-2

Programmable Power-Up State....................................................................................3-3

HotPnP (Hot Plug and Play)......................................................................................... 3-4

HotPnP During Power-Up ............................................................................. 3-4

HotPnP During Operation.............................................................................. 3-5

Inserting New I/O Modules.............................................................3-5

Replacing I/O Modules....................................................................3-5

Power-On Self Test (POST).........................................................................................3-6

LED Indicators ........................................................ ...... ............................................... 3-7

Chapter 4

Using the FieldPoint Software

FieldPoint Software Overview..................................................................................... 4-1

Using the FieldPoint Explorer...................................................................................... 4-2

Using the FieldPoint Server with BridgeVIEW........................................................... 4-2

Using the FieldPoint Server with LabVIEW................................................................4-3

Using the FieldPoint Server with LabWindows/CVI................................................... 4-3

Using the FieldPoint Lookout Driver ........................................................................... 4-4

Using FieldPoint with Optomux Servers......................................................................4-4

Appendix A

Specifications

Appendix B

Customer Communication

Glossary

Index

Figures

Figure 2-1. DIN Rail Clip in the Unlocked Position................................................ 2-1

Figure 2-2. Installing the Network Module onto a DIN Rail...................................2-1

Figure 2-3. Locking the FieldPoint Network Module onto a DIN Rail................... 2-2

Figure 2-4. Connecting Terminal Bases................................................................... 2-3

Figure 2-5. Host Computer Connected to One FP-1000 and Two FP-1001

Network Modules.................................................................................. 2-4

Figure 2-6. Host Computer Connected to Three FP-1001 Network Modules......... 2-5

Figure 2-7. RS-232 Connector Pinout for the FP-1000........................................... 2-6

FieldPoint FP-1000/FP-1001 User Manual vi

©

National Instruments Corporation

Page 6

Tables

Table of Contents

Figure 2-8. RS-485 Connector Pinout for the FP-1000 and FP-1001......................2-7

Figure 2-9. Terminating RS-485 Using the Combicon Adapter ..............................2-8

Figure 2-10. Typical Signal Connections for Host Computer Connected to

One FP-1000 and Multiple FP-1001 Network Modules........................2-8

Figure 2-11. Typical Signal Connections for Host Computer Connected to

Multiple FP-1001 Network Modules.....................................................2-9

Figure 2-12. Address and Baud Rate Switch..............................................................2-9

Figure 2-13. FP-1000 and FP-1001 Power Connector Pinout....................................2-13

Figure 3-1. LEDs on the FP-1000 and FP-1001.......................................................3-7

Table 2-1. Network Address Switch Settings for the FP-1000 and FP-1001

Network Modules ..................................................................................2-11

Table 2-2. Baud Rate Switch Settings for the FP-1000 and FP-1001

Network Modules ..................................................................................2-12

Table 3-1. Module Configuration Results After HotPnP Replacement..................3-6

Table 3-2. STATUS LED Flashes and Corresponding Error Conditions...............3-8

©

National Instruments Corporation vii FieldPoint FP-1000/FP-1001 User Manual

Page 7

This manual describes how to install and use the FieldPo int FP-1000

and FP-1001 network modules.

How to Use This Manual Set

Operating

Instructions

for Modules

and Bases

Installation

Specifications

About

This

Manual

FieldPoint Server

Online Help

FieldPoint

FieldPoint

User Manual

©

National Instruments Corporation ix FieldPoint FP-1000/FP-1001 User Manual

Network Connection,

Hardware

Configuration, and

Feature Set

Description

Programmer

Reference

Manual

Command Syntax

Page 8

About This Manual

Organization of This Manual

This manual is or ganize d as f ollow s:

• Chapter 1, FP-1000 and FP -10 01 Ne twork Mo dule O verv iew ,

provides an overview of the Field Point n etwork m od ules.

• Chapter 2, Installation and Configuration, describes how to install

and configure your Field Point n etwor k modu le, conn ect it to a n

RS-232 or RS-485 netw ork, an d con nect p ower to the networ k

module.

• Chapter 3, Feature Set Description, describes the feature set for the

FP-1000 and FP-1001 network module s.

• Chapter 4, Using the FieldPoint Software, describes ho w to use th e

FieldPoint hardware with various serv ers and softwa re pack ages.

• Appendix A, Specifications, describes the specifications of the

FP-1000 and FP-1001 network module s.

• Appendix B, Customer Communication, co ntain s f orm s y ou ca n

use to request help from National Instruments or to comment on our

products and manuals.

•The Glossary contains an alphabetical list and description of terms

used in this manual, including abbreviations, acronym s, metric

prefixes, mnemonics, and symbols.

•The Index cont ains a n al phabe tical list o f key te rms a nd topic s in

this manual, including the page n umb er w here you c an fin d e ach

one.

Conventions Used in This Manual

The following conventions are used in this manual:

This icon to the left of bold italicized text denotes a note, which alerts

you to important information.

!

bold Bold text denotes the names of menus, menu items, parameters, dialog

bold italic Bold italic text denotes a note, caution, or warning.

FieldPoint FP-1000/FP-1001 User Manual x

This icon to the left of bold italicized text denotes a caution, which

advises you of precau tions to take to av oid injury , d ata lo ss, or a

system crash.

box, dialog box buttons or o ptions, ico ns, window s, Windo ws 95 tabs,

or LEDs.

©

National Instruments Corporation

Page 9

About This Manual

italic Italic text denotes emphasis, a cross reference, or an introduction to a

key concept. This font also deno tes text from which y ou supply the

appropriate word or v alue, as in Wind ow s 3 .x .

italic monospace

monospace Text in this font denotes text or characters that should literally enter

Italic text in this font denotes th at you mu st su pply the appr opriate

words or values in the place of these items.

from the keyboard, sections of co de, pro gramming ex ample s, and

syntax examples. This font is also used for the pro per names of disk

drives, paths, directories, programs, subprogram s, subroutines, device

names, functions, operations, variables, file names and exten sions, and

for statements and c omm en ts take n from p rogra ms.

Related Documentation

The following documents contain information that you may find helpful

as you read this manual:

• Operating Instruction s (f or ne twork m odu le, ter minal base s, a nd

I/O modules)

• FieldPoint Server Online Help

Customer Communication

National Instruments wants to rece ive you r com ments o n ou r prod ucts

and manuals. We are interested in the applications you develop with our

products, and we want to help if you have problems with them. To make

it easy for you to contact us, this manual contains comment and

configuration forms for you to complete. These for ms are in

Appendix B, Customer Communication, at the end of this manual.

©

National Instruments Corporation xi FieldPoint FP-1000/FP-1001 User Manual

Page 10

FP-1000 and FP-1001

Chapter

Network Module Overview

This chapter prov ides an o ve rview of the Fie ldPoin t ne twork mo dules .

The FP-1000 FieldPoint network module connects an industrial RS-232

network to FieldPoint I/O modu les. The FP-1001 Fiel dPoint ne twork

module connects an industrial RS-485 netwo rk to FieldPoint I/O

modules.

The FP-1000 and FP-1001 support stan dard co mmands (subs et of

Optomux command set), and a set of extended commands to completely

support the FieldPoint I/O modules. Both network modules can co-exist

with other Optomux devices on the same network.

The FP-1000 and FP-10 01 use the Op tomux p rotocol. The refor e, a f ter

you have configure d the FieldPoin t ba nk ( ne twork mod ule a nd I/O

modules), you can use any application software that supports Optomux

to communicate wi th Field Point m od ules in the ba nk.

In a distributed application, many FieldPo int ba nks a re n etwor ked

together. You can netw ork up to 25 FieldPoi nt bank s to each

RS-232/RS-485 port of y our ho st c ompute r. Eac h ban k ca n c ont ain up

to nine I/O modules, thus connecting up to 225 I/O modules per RS-232

(or RS-485) port in your host co mpu ter. You c an furth er in cr ease you r

field I/O count by using more RS-232/RS-485 por ts in your host

computer.

1

FP-1000 Connects to RS-232

The FP-1000 connec ts dir ectly to the RS- 232 p ort that is a vailable on

most host computers. Since RS-232 is a point-to-poin t network that

allows connection to only one device, the FP-1000 provides an RS-485

repeater so that you can build a network with multiple FieldPoint banks.

©

National Instruments Corporation 1-1 FieldPoint FP-1000/FP-1001 User Manual

Page 11

Chapter 1 FP-1000 and FP-1001 Network Module Overview

FP-1001 Connects to RS-485

The FP-1001 FieldPoint netw ork modu le co nnects dire ctly to an

RS-485 adapter card that is installed in your host computer. Since

RS-485 is inherently a multidrop n etwork , the FP-1001 do es not

provide a separate RS-485 repeater. You can network multiple FP-1001

modules in multidrop fashion.

The FP-1001 communicates over RS-485, utilizing full-duplex mode. It

is optically isolated, which prevents fault coupling between the RS-485

network and the FP-1001.

FieldPoint FP-1000/FP-1001 User Manual 1-2

©

National Instruments Corporation

Page 12

Installation and

Chapter

Configuration

This chapter describes how to insta ll a nd co nfig ure y our FieldP oint

network module, connect it to an RS-232 or RS-485 network, a nd

connect power to the netwo rk module.

Installing the Network Module

The FieldPoint network m odule s ha ve rugge d, simple clips fo r

mounting reliably onto a standard 35 mm DIN rail. Follow these step s

to mount the network module onto a DIN rail. Terminal ba ses must be

connected to the network module before power is applied.

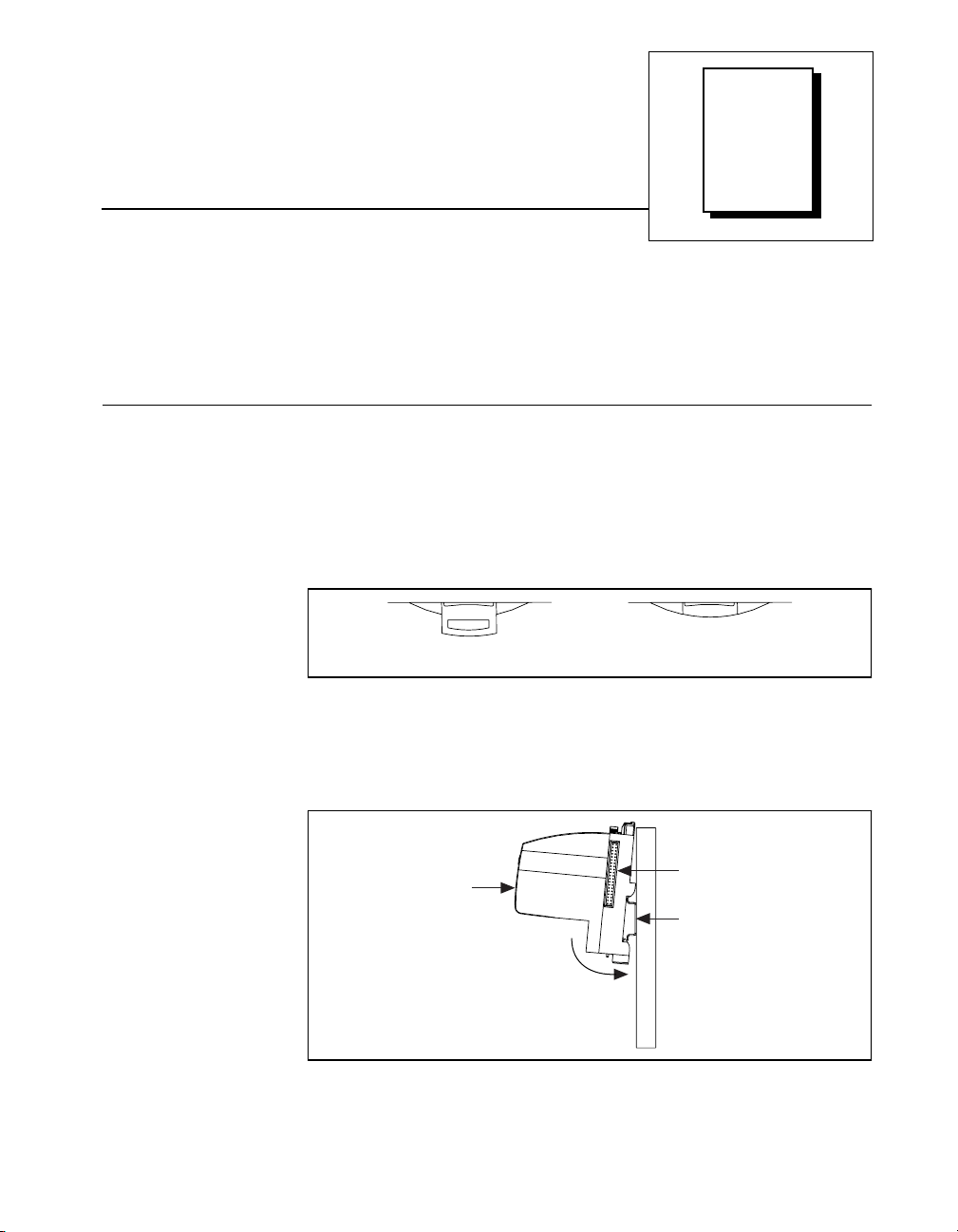

1. Use a flat-bladed screwdriver to open the DIN rail clip to the

unlocked position, as shown in Figure 2-1.

Figure 2-1.

2. Hook the lip on the rear of the network module onto the top of a

35 mm DIN rail and press the ne twork module down onto the DIN

rail as shown in Figure 2-2.

2

Rail Clip LockedRail Clip Unlocked

DIN Rail Clip in the Unlocked Position

Local Bus

Cover

Press

Figure 2-2.

©

National Instruments Corporation 2-1 FieldPoint FP-1000/FP-1001 User Manual

Installing the Network Module onto a DIN Rail

Connector

DIN Rail

Page 13

Chapter 2 Installation and Configuration

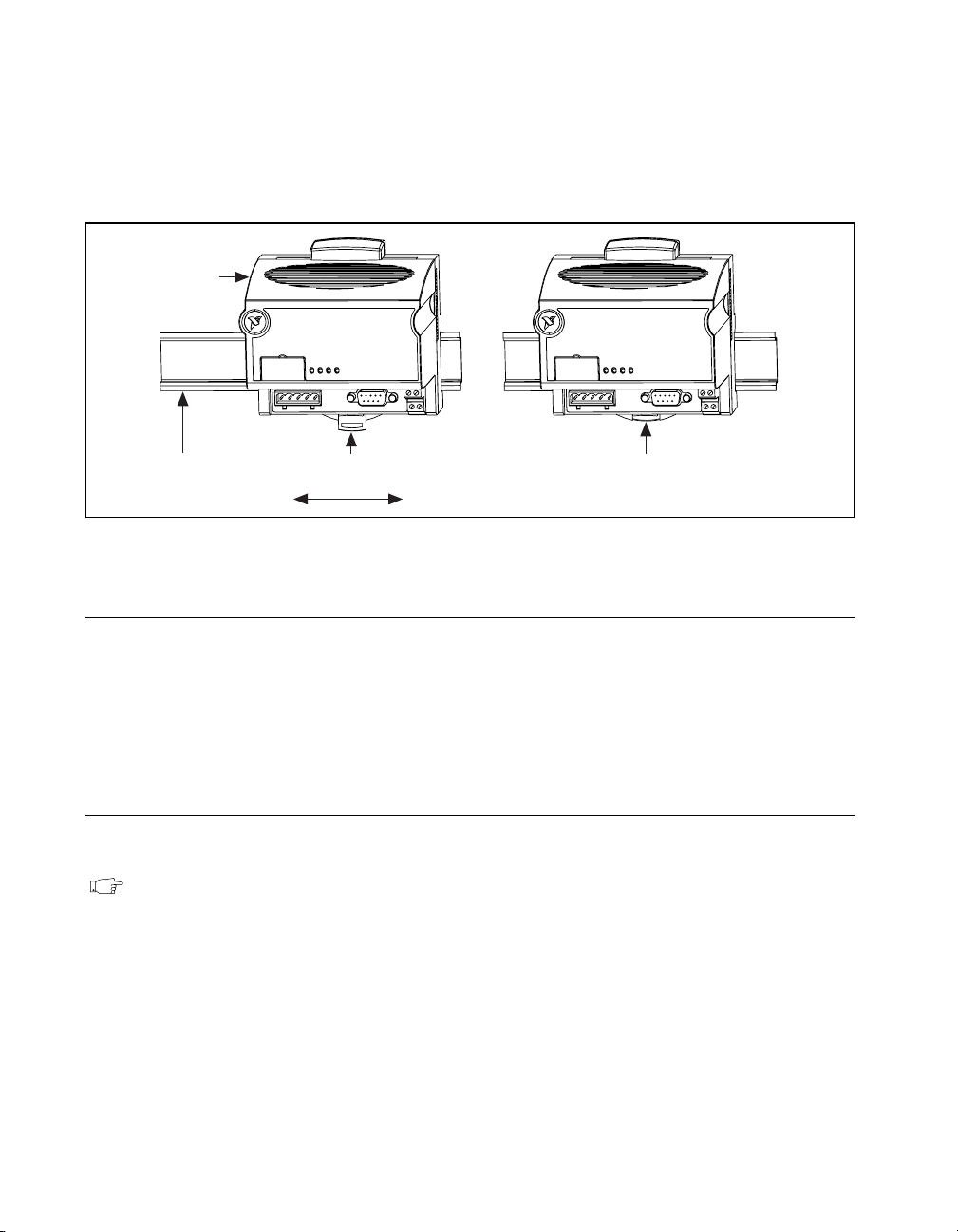

3. Slide the network modu le to the desir ed po sition o n th e D IN r ail.

After the module is in position, push the rail snap into the locked

position to lock the module in place on the DIN rail, as shown in

Figure 2-3.

Network

Module

DIN

Rail

Rail Snap Unlocked

(Position Module Along DIN Rail)

Figure 2-3. Locking the FieldPoint Network Module onto a DIN Rail

Removing the Network Module

To remove a network module, unlock it from the DIN rail by placing a

screwdriver in the slot on the rail snap a nd o pen ing it to th e unloc ked

position as shown in Figure 2-1. T hen d isco nnect the termina l b ase

from the network module’s local bus connector, and lift the module off

of the rail.

Connecting Terminal Bases

Follow these steps to connect a terminal base and a network module.

Note: Ensure that power is not applied to the network module, before you install

or remove terminal bases.

1. Remove the protective cover from the network module’s local bus

connector (see Figure 2-2).

2. Install the terminal base onto the DIN rail in the same way you

installed the network module. Refer to the operating instructions

for the FP-TB-1/2 more information on how to install your terminal

base onto the DIN rail.

Rail Snap

Locked

FieldPoint FP-1000/FP-1001 User Manual 2-2

©

National Instruments Corporation

Page 14

Chapter 2 Installation and Configuration

3. Attach the terminal base to the network module by firm ly m ating

the local bus connectors.

4. To add more terminal bases, install them on the rail and mate their

local bus connectors together.

5. Place the protective cover that you remo ved f rom the ne two rk

module on the last term inal base on the b an k, as sho w n in

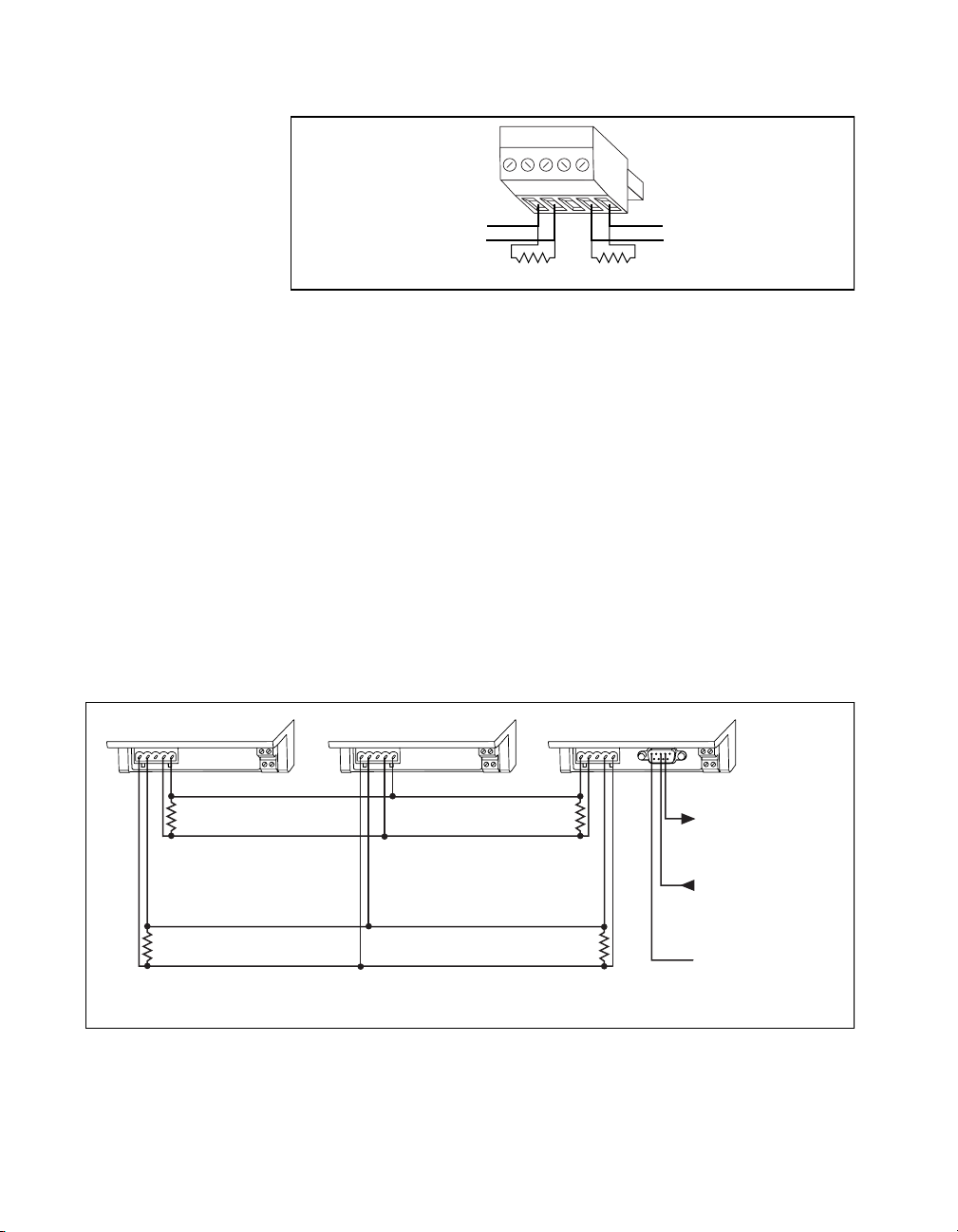

Figure 2-4.

Local Bus Connectors

Firmly Mated

Protective

Cover

Rail Snap

Figure 2-4. Connecting Terminal Bases

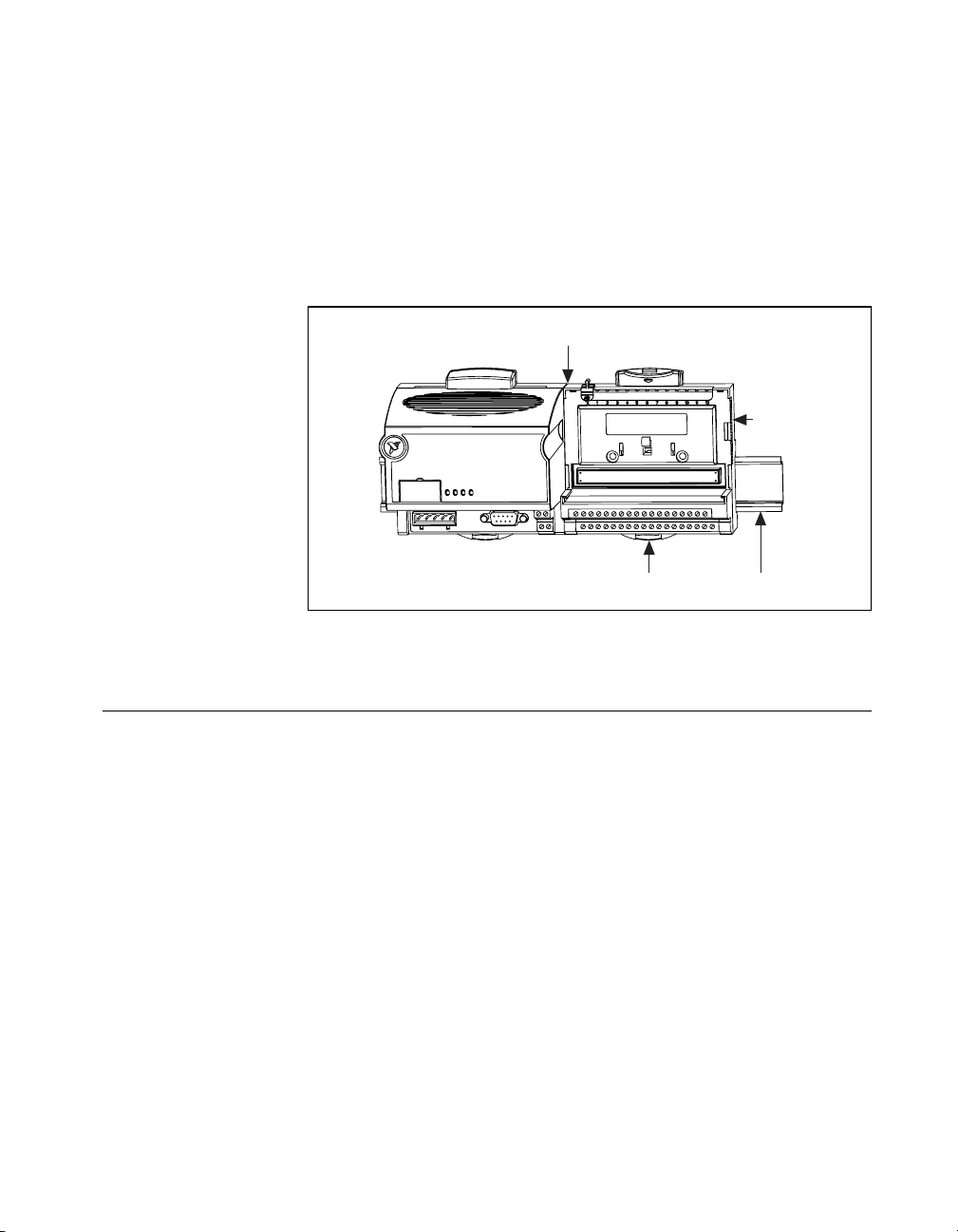

Connecting the FP-1000 to the Network

This section describes the network config urations possibl e with the

FP-1000 FieldPoint network module. The connec tor pinouts are

described in the RS-232 In terface Specification s and RS-485 Inte rface

Specifications sections later in this chapter.

Connect the RS-232 por t of the FP-10 00 to y our ho st c ompute r’s

RS-232 port. Use a 9-pin Dsub male-to- female “ straight-thr ough”

cable. Do not use a null modem cable (usually female-to-female).

You can connec t on ly on e FP-1000 ne twork m odule f or each RS-2 32

port in your host computer. You can add more FieldPoint banks without

using more RS-232 p orts of your host co mp uter, by co nnec ting o ne or

more (up to 24) FP-1001 network mo dules to the RS-485 r epeater port

of the FP-1000. This network c onfigur ation is show n in Figure 2-5.

Locked

DIN

Rail

©

National Instruments Corporation 2-3 FieldPoint FP-1000/FP-1001 User Manual

Page 15

Chapter 2 Installation and Configuration

FP-1000FP-1001FP-1001

RS-232RS-485

Figure 2-5. Host Computer Connected to One FP-1000 and Two FP-1001

Network Modules

Connecting the FP-1001 to the Network

This section describes the network config urations possibl e with the

FP-1001 FieldPoint network m odu le. T he c onnec tor pinouts a re

described in the RS-485 In terface Specification s section later in this

chapter.

Host Computer

One option for connecting the FP-1001 is to connec t it to the RS-485

repeater port of an FP-10 00 as shown in Figure 2-5. A n alter nat ive

method is to connect the FP-1001 directly to your host computer, if your

host computer provid es an RS- 485 interf ace (c ontac t N atio nal

Instruments for in for ma tio n ab out a va ilab le RS -4 85 ha rdw are ). You

can connect up to 25 FP-1001 network modules to each RS-485 port on

the host computer. Th is ne twork conf iguration is shown in Fig ure 2-6.

FieldPoint FP-1000/FP-1001 User Manual 2-4

©

National Instruments Corporation

Page 16

Chapter 2 Installation and Configuration

Host Computer with

RS-485 Board Installed

FP-1001FP-1001FP-1001

RS-485

Figure 2-6. Host Computer Connected to Three FP-1001 Network Modules

The multidrop topology used in the networking configurations provides

protection against powe r fa ilures a t ind ividua l FieldPoint ban ks. I t

eliminates the possibility that a power failure at one FP-1001 bank

might affect the communication be twee n other ban ks in y our ne two rk.

Because the FP-1000 provides an RS-485 repeater, a power failure at

that bank will affe ct comm unic ation s.

Connecting to the Serial Ports

The following sections give information about the RS-232 and RS-485

ports on the network modules, and how to connect to them.

The RS-232 port on the FP- 1000 ne twork mod ule is a full-d uplex

interface. The RS-485 port o n the FP-10 00 and FP-10 01 netwo rk

modules are optically isolated , full-duple x inter faces.

Caution: The RS-485 interfac e o n bo th the FP -10 00 and the FP -1001 mod ules is

!

©

National Instruments Corporation 2-5 FieldPoint FP-1000/FP-1001 User Manual

isolated from the rest of the FieldPoint system, including the power supply,

backplane, and the RS-232 interface on the FP-1000. It is isolated with a

galvanic and optical isolation barrier, which has been designed and tested

to withstand fault voltages of up to 2500 Vrms. However, the safety rating

of this barrier is only for working voltage s of up to 2 50 Vrms . Do not use

the isolation barrier of the RS-485 interface as a way to protect human

contact from common mode voltages of more than 250 Vrms. Also note that

while the RS-232 interface on the FP-1000 is isolated from the RS-485

interface, it is NOT isolated from the power supply inputs (the V and C

terminals).

Page 17

Chapter 2 Installation and Configuration

Both serial interfaces are self-configured to use the following

parameters:

1 Start Bit, 8 Data Bits, 1 Stop Bit, No Parity

The supported ba ud ra tes ar e 30 0, 12 00, 24 00, 9 600 , 192 00, 38 400 ,

57600, and 115200. Re fer to the Configu ring the Network Module

section for informatio n about s etting the ba ud rate fo r you r m od ules.

Host computer RS-232 ports and RS-485 interface boards provide FIFO

buffers for transmit and receive that he lp to decrease the ove rhead on

host computers. Na tional I nstru ments r e comme nd s that you en ab le

these FIFO buffers in your host computer or RS-485 interface board for

best performance.

RS-232 Interface Specifications

RS-232 specifies a maximum cabling distance of 50 ft, but

improvements in line drivers and cabling technology often allow you to

design your network beyond the re co mmen dation s of the specific ation.

The RS-232 connector is 9-pin female Dsub connector whose pinout is

shown in Figure 2-7.

Legend:

NC = Not Connected

GND = Ground

RX = Recieve

Figure 2-7.

FieldPoint FP-1000/FP-1001 User Manual 2-6

GNDNCRX

54321

9876

NC

RS-232 Connector Pinout for the FP-1000

TX

NC

NC

RTS

DSR

TX = Transmit

RTS = Request to Send

DSR = Data Set Ready

©

National Instruments Corporation

Page 18

The FP-1000 does not use RS-232 hardware handshaking, but it still

asserts the RTS and DSR signals for host comp uters or s oftware that

may require thes e signals. A ho st c omp uter tha t d oe s n ot u se thes e

signals does not need to connect to them.

RS-485 Interface Specifications

RS-485 specifies a maximum cabling distance of 4000 ft, but

improvements in line drivers and cabling technology often allow you to

design your network beyond the recommendations of the specification.

If even longer distan ces ar e desira ble, y ou can use R S-48 5 rep eate rs.

An RS-485 stub is created whe n you ta p the RS-48 5 bac kbon e to form

a T-junction. RS-48 5 stubs m ust be less tha n 3 in. lo ng. H owe ver, you

can create longer stubs by using an RS-485 repeater to start the stub,

ensuring that the repeater is close to the junction.

The RS-485 connec tor is a 5-p in Co mbicon co nne ctor w ho se pinout is

shown in Figure 2-8.

RX+

RX–

Chapter 2 Installation and Configuration

TX–

GND

TX+

12345

Figure 2-8.

RS-485 Connector Pinout for the FP-1000 and FP-1001

RS-485 Network Termination and Biasing

An RS-485 network must be terminated at each end of the network, but

not anywhere else. At e a ch e nd ba nk , termina tion r es istors should be

installed between the RX pair and between the TX pair. These network

terminating resistors are nominally 120 Ω and are provided in your kit.

To install them, twist the resistor leads w ith the RS-485 signal wires and

then insert them into the RS-485 Combicon adapter as shown in

Figure 2-9. The 120 Ω resistor in the figure is a terminating resistor.

©

National Instruments Corporation 2-7 FieldPoint FP-1000/FP-1001 User Manual

Page 19

Chapter 2 Installation and Configuration

RX+

RX-

GND

TX-

TX+

RS-485

Signal Pair

+

–

120 Ω 120 Ω

Figure 2-9. Terminating RS-485 Using the Combicon Adapter

An RS-485 network also needs biasing resistors to protect the devices

on the network against noise du ring intervals when no RS- 485 drivers

are transmitting on the network. The host computer’s RS-485 interface

normally has provision for such biasing resistors. When you are using

FP-1001 network module s d ire ctly conne cted to a h ost com pu ter’s

RS-485 interface, you s hould use the biasing fe ature of the h ost

computer’s RS-485 interface for better reliability and noise immunity.

The RS-485 repeater interface on the FP-1 000 alre ady has biasing

resistors, so you do not ne ed to do an ything whe n conne cting o ne or

more FP-1001 modules to the FP- 100 0.

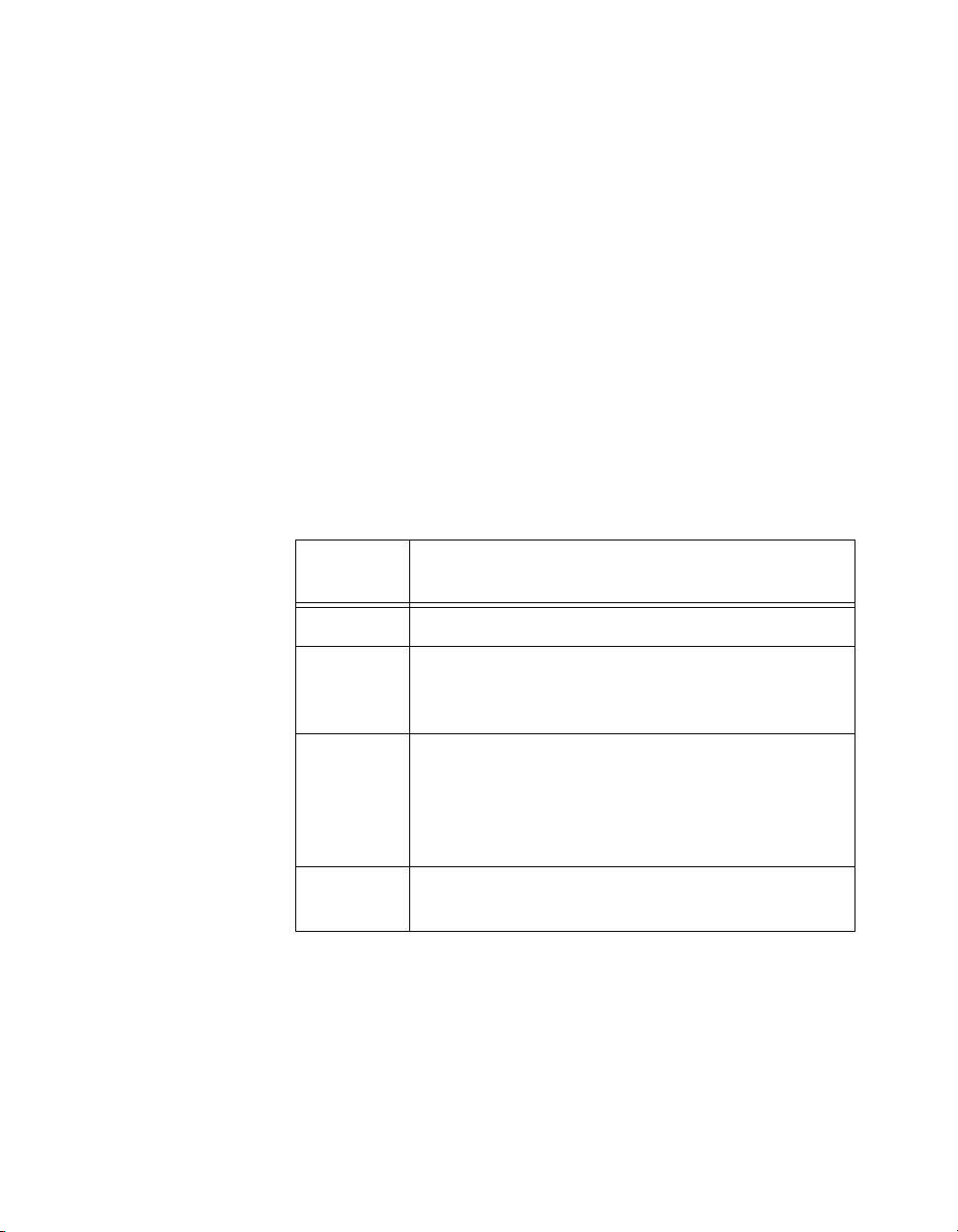

Figures 2-10 and 2-11 show typ ica l RS- 232 and RS-4 85 signal

connections and terminatio n for a FieldPoint network. Figure 2-10 is a

more detailed depiction of Figure 2-5, and Figur e 2-11 is a more

detailed depiction of Figure 2-6.

FP-1001 FP-1001 FP-1000

+

RS-485

–

Signal Pair

TX

120Ω

RX

120Ω

Connect the TX outputs of the FP-1001 to the RX inputs of the FP-1000,

and the RX inputs of the FP-1001 to the TX outputs of the FP-1000.

TX RX

RX TX

Figure 2-10. Typical Signal Connections for Host Computer Connected to One

FP-1000 and Multiple FP-1001 Network Modules

FieldPoint FP-1000/FP-1001 User Manual 2-8

120Ω

120Ω

To Host

Computer's RS-232

Receive Input

From Host

Computer's RS-232

Transmit Output

Ground

©

National Instruments Corporation

Page 20

Chapter 2 Installation and Configuration

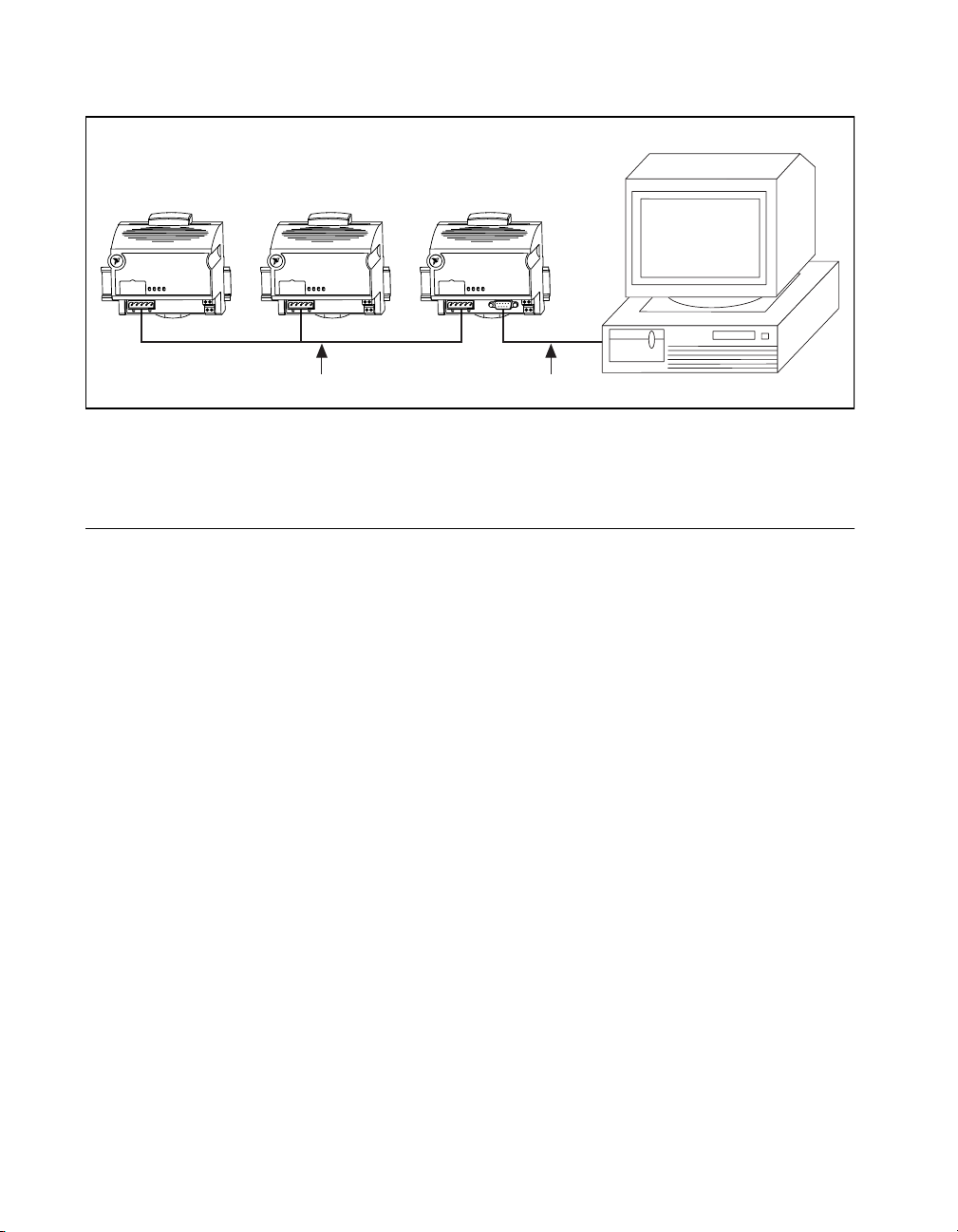

FP-1001 FP-1001

RX TX RX TX RX TX

120Ω

120Ω

Connect the TX outputs of the host computer to the RX inputs of the FP-1001,

and the RX inputs of the host computer to the TX outputs of the FP-1001.

Figure 2-11. Typical Signal Connections for Host Computer Connected to Multiple

FP-1001 Network Modules

Configuring the Network Module

Figure 2-12 shows the 8-position switch on the FP-1000 and FP-1001

FieldPoi nt netw ork module s. Sw itche s 1-5 set the net work ad dress , and

switches 6-8 set the baud rate.

FP-1001

120Ω

120Ω

+

To Host

Computer's RS-485

–

Receive Input Pair (RX)

–

From Host

Computer's RS-485

+

Transmit Output Pair (TX)

Baud

Address

12345678

Rate

12345678

Switch Cover

(Removed)

Figure 2-12. Address and Baud Rate Switch

©

National Instruments Corporation 2-9 FieldPoint FP-1000/FP-1001 User Manual

Page 21

Chapter 2 Installation and Configuration

Follow these steps to set the address and baud rate for your network

module.

1. Choose and set a network address. Refer to the following section,

Setting the Network Address, for mor e info rmati on.

2. Choose and set the baud rate. F or mo re inf orm a tion , re fer t o th e

section, Setting the Baud Rate, later in this chapter.

3. Write your address and baud rate settings in the space provided on

the network module label.

4. Apply (or cycle) power to the bank, to enable the n etwor k module

for the new network address and baud ra te.

5. Make the same address and baud rate changes in your FieldPoint

software. Refer to the Fi el dPoint softwa re on line he lp for more

information.

Setting the Network Address

Switches 1-5 set the network module address. The a ddresses of the

terminal bases in a FieldPoint bank are automatically configured by the

network module to be sequ en tial ly h ighe r th an the n etwor k mod ule’ s

address. For example, if the network module is set to address 20, the I/O

module in the terminal base adjacent to the network module is at

address 21, the next I/O mo dule is at address 22, and so on. A terminal

base is assigned an add ress whe ther an I /O mod ule is in ser ted on it or

not.

Note: If you are connecting more than one network module to the same host

computer port, ensure that e ach ne twork module has a uniq ue addre ss.

Table 2- 1 shows the possible switch pos itions and the correspon ding

address of the FieldPoint network module.

FieldPoint FP-1000/FP-1001 User Manual 2-10

©

National Instruments Corporation

Page 22

Chapter 2 Installation and Configuration

12345678

12345678

12345678

12345678

12345678

12345678

12345678

12345678

12345678

12345678

12345678

12345678

Table 2-1. Network Address Switch Settings for the FP-1000 and FP-1001 Network Modules

Switch

Positions 1 - 5

12345678

12345678

12345678

12345678

12345678

12345678

12345678

12345678

Network Module

Address (Decimal)

0 130

10 140

20 150

30 160

40 170

50 180

60 190

70 200

Switch

Positions 1 - 5

Network Module

Address (Decimal)

12345678

90 220

80 210

12345678

100 230

12345678

110 240

12345678

120 Other Settings Not Allowed

12345678

©

National Instruments Corporation 2-11 FieldPoint FP-1000/FP-1001 User Manual

Page 23

Chapter 2 Installation and Configuration

12345678

12345678

12345678

12345678

Setting the Baud Rate

Switches 6-8 set the network module baud rate. Table 2-2 show s the

switch positions and the corresponding ne twork baud ra tes of the

network module.

Note: If you are connecting more than one network module to the same host

computer port, ensure that every network module’s baud rate setting is

identical.

Table 2-2.

Switch

Positions 6-8

Baud Rate Switch Settings for the FP-1000 and FP-1001 Network Modules

Network Module

Baud Rate

Switch

Positions 6-8

300 19200

12345678

1200 38400

12345678

2400 57600

12345678

9600 115200

12345678

Connecting Power to the FP-1000 or FP-1001

An 11-30 VDC power supp ly is re quir ed by each FieldPo int n etwork

module. The network module filters and regulates this supplied power

and provides power fo r all the I /O m odules in th e b an k. The refo re you

need not provide power separately to each FieldPoint I/O module in the

bank.

Network Module

Baud Rate

FieldPoint FP-1000/FP-1001 User Manual 2-12

The power connector is a 4-pin screw terminal connector whose pinout

is shown in Figure 2-13.

©

National Instruments Corporation

Page 24

Chapter 2 Installation and Configuration

VV

V

11-30 VDC

Figure 2-13. FP-1000 and FP-1001 Power Connector Pinout

+

-

CC

To Adjacent Terminal Base

(Optional Connection)

C

The two terminals labeled V are internally connected on the network

module, as are the two terminals labeled C. Power must be applied to

one V and C pair for operation of the FieldPoint bank. If you want to

power your field I/O devices from th e same pow er supply, the second

V and C pair provid es a conv enie nt mean s o f con necting po wer to the

V and C terminals of a term inal base. Figu re 2-13 sh ows this option al

connection.

If your field I/O devices need to be powered separately, you can use the

terminals provided on each terminal base for such power supply

connections. Refer to the documen tation that came w ith your terminal

base and I/O module for more informa tion on powe ring your field I/O

devices.

Calculating Power for a FieldPoint Bank

The power requirements fo r a Fie ldPoint ba nk that uses an FP-1000 or

FP-1001 network module a re ca lcu lated a s follow s:

Power = 1 watt + 1.15 * ∑(I/O Module Co nsump tion)

The operating instructions fo r eac h Fie ldPoint I/O m odu le cont ain

power consumption information.

©

National Instruments Corporation 2-13 FieldPoint FP-1000/FP-1001 User Manual

Page 25

Chapter

Feature Set Description

This chapter describes the fea ture se t for the FP- 1000 and FP-1 001

network modules.

Both the FP-1000 and FP-1 001 have a n identica l fea ture set, so this

chapter uses the term network module to refer to either one. Any specific

differences ar e note d.

High-Speed Local Bus

The network modules provid e a high-spee d local bus for

communication to the I/O modules in the bank. The high-speed local

bus has low overhead that enables fast response to commands from the

host computer.

Network Watchdog Timer

The network module c an d etect unexp ec ted perio ds o f ne two rk

inactivity and respond to it in a user-defined way. The network

watchdog timer feature enables you to guard your system against

failures in the network connection, cables, or host computer, and to put

the channel outputs in a user-defined state (the watchdog state) if such

failures do occur.

3

You can set the watchdog output values to be different from the

power-up output values. Some system applications do not differentiate

between power-up o utput values a nd w atchdo g o utpu t value s, wh ile

other applications treat the two conditions differently. The network

module supports both types of applications.

By default, the watchdog timer for the bank is disabled on power up. To

use the watchdog timer, set up the following parameters. You can use

either the FieldPoint Explorer software or the FieldPoint com mand se t.

• Watchdog data value for each channel.

• Watchdog data enable/disable status for each channel.

©

National Instruments Corporation 3-1 FieldPoint FP-1000/FP-1001 User Manual

Page 26

Chapter 3 Feature Set Description

• Watchdog enabled/disabled status for each I/O module.

• Watchdog timeout value for the bank.

Note: Each bank has only one watchdog timeout value that is common for all the

modules in that bank. In addition, the current watchdog timeout value is

not stored when you store the SnapShot.

SnapShot Feature

Many applications require that, upon startup, the system’s I/O power up

with user-specified configuration and outpu t levels rather than factory

default settings. The SnapShot feature pro vides y ou with a sing le-step

method to store the current state of your Fie l dPoint bank for use as the

power-up state of the ba nk.

If you subsequently e nab le the SnapSh ot f eature , you c an ens ure th at

your system will power up with the configuration and output levels that

you specified when storin g the Sna pShot.

Prior to storing the SnapShot, you should bring all the channels to the

desired power-up settings. You can use either the FieldPoint Server

software or the FieldPoint command set to change the configuration of

the FieldPoint bank, and then store the SnapShot. The SnapShot stores

all the following information in a single step:

• Attribute and range settings of each chan nel.

• Output values of each channel.

• Watchdog data values of each channel. See the Network Watchdog

• Watchdog data enabled (o r disabled ) status for each cha nnel. See

• Watchdog enabled (or disabled) status of each module. See the

Timer section in this chapter for more information.

the Network Watchdog Timer section in this chapter for more

information.

Network Watchdog Timer section in this chapter for more

information.

After you store the SnapShot information, you can still choose whether

the network module u ses that stored inf orm ation during f uture

power-ups. Enable the SnapShot feature if you want the FieldPoint bank

to power-up with the stored SnapShot information.

FieldPoint FP-1000/FP-1001 User Manual 3-2

©

National Instruments Corporation

Page 27

If you have enabled the SnapShot feature, the network module restores

the stored settings to all I/O modules and channels in the bank every

time you power up, un til you disable the Sn ap Shot fe atur e. If the

SnapShot feature is disabled, the FieldPo int bank will powe r up with

factory-default settings.

At some time you might want to change the stored SnapShot

information. To make incremental changes in the stored SnapShot

information, you can use the featur es de scribe d in the next se ction ,

Programmable Power-Up State.

Note: The current watchdog timeout value for the FieldPoint bank is not saved

when you store the SnapShot.

Note: The SnapShot feature inherently requires that the entire FieldPoint bank

be at your desired power-up state, since when you store the SnapShot

information, the current settings of the entire bank are stored for use at

future power-ups.

Programmable Power-Up State

The SnapShot feature described in the SnapShot section provides you

with a single-s tep me thod to s tore th e curr ent s tate of the F ieldP oint

bank for use a s the p ow er-u p state. Th e FieldPo i nt netw ork m odu le

provides an alternative method to define power-up states that allows

you to store the SnapShot information with more flexibility, as

described in this section.

Chapter 3 Feature Set Description

The Programmable Power -Up State feature enables you to def ine the

power-up configuration on a module-by-module basis. In addition, you

do not need to actually set any of the channels to the desired pow er- up

state. You can therefore define the power-up states regardless of the

current settings of any channel of a module.

Optionally, you can utilize the Programmable Power-Up State feature

to incrementally modify previously stored SnapShot information.

If you subsequently e nab le the Sna pShot f eat ure, yo u ca n ens ure th at

your system will power up with the configuration and output levels that

you specified when storing the Programmab le Power-Up States .

You can utilize the Programmable Power-Up State feature to

individually store the following information. Y ou can use either the

FieldPoint Explorer software or the Fiel dPoint comm and set.

©

National Instruments Corporation 3-3 FieldPoint FP-1000/FP-1001 User Manual

Page 28

Chapter 3 Feature Set Description

• Attribute and range settings of each chan nel.

• Output values of each channel.

• Watchdog data value of each channel. See the Network Watchdog

• Watchdog data enabled (o r disabled ) status for each cha nnel. See

• Watchdog timer enabled (or disabled) status of each module. See

• Power-up watchdog timeout va lue fo r th e FieldPoin t ba nk.

• The turn-around delay fo r eac h module.

• The hot-swap reporting mode for th e FieldPoint stack . See the

If you have enabled the SnapShot feature, the network module restores

your desired settings to all I/O modules and channels in the bank every

time you power up, un til you disable the Sn ap Shot fe atur e.

Timer section in this chapter for more information.

the Network Watchdog Timer section in this chapter for more

information.

the Network Watchdog Timer section in this chapter for more

information.

HotPnP section for more in forma tio n on th e ho t-sw ap repo rting

mode.

HotPnP (Hot Plug and Play)

The HotPnP feature simplifies system installation, configuration, and

maintenance. With the HotPnP feature, you c an remove or inser t I/O

modules into the FieldPoint terminal bases while power is on, even if

the system is already engaged in network activity. You do not need to

power down the entire system or even a bank to inser t, remove, or

replace I/O modules. In addition, you do not ne ed to chan ge the

operation of the host com pute r or sof tware to use the H otPnP fe atur e.

When you insert an I/O module with the power on, it is automatically

recognized, configured, and made ava ilable on the netw ork. The

following sections describe how the HotPnP fe ature work s under

different conditions.

Note: An I/O module can be hot-inserted only if an empty terminal base is already

available in the bank. You should not add or remove terminal bases w hile

power is applied to the bank.

FieldPoint FP-1000/FP-1001 User Manual 3-4

©

National Instruments Corporation

Page 29

HotPnP During Power-Up

Upon power-up, the network module automatically uploads an

electronic data sheet (EDS) from each I/O module in its bank. The

network module then configures each I/O module in the bank to factory

default settings in the module’s EDS, or stored SnapShot settings if the

SnapShot feature is enabled.

HotPnP During Operation

You may need to insert or replac e one or mo re I/O mo dules in a bank

while your system is ope rationa l (pow er is on and the network m ay or

may not be active).

Inserting New I/O Modules

When a new I/O module is inserted, the network module automatically

uploads the EDS and configures the I/O module to factor y default

settings in the module’s EDS, or to stored SnapShot settings if the

SnapShot feature is enabled. This configuration is accomplished

without any intervention from the host computer or software.

While one or more new I/O modules in a bank are being serviced by the

HotPnP feature, the other I/O mo dule s in the b ank r emain fully

operational and accessible on the network without any interruptions. As

soon as the netwo rk mo dule conf igures the new I/ O module v ia th e

HotPnP service, that I/O module becomes automatically accessible on

the network.

Chapter 3 Feature Set Description

Replacing I/O Modules

When an I/O module is r emov ed , the ne two rk mo dule doe s no t

undertake any special course of action for the bank. The host computer

(or the software executing on it) may be unaware that the I/O module is

missing, and may continue to send commands to the missing I/O

module. Each com mand re turns a n erro r r es pons e, bu t the netw ork

module remembers the c omman ds sent to the mi ssing I/O mod ule.

When a new I/O module is connected in place of the one that was

removed, the network modu le first verifie s that the r eplac eme nt I/O

module is compatible with the one that was removed. If the I/O module

is the same as, or is compatible with, the one removed, the network

module configures the replacement I/O module with its predecessor’s

configuration and output value settings. It also applies the effects of any

commands sent by the host computer while the I/O module was missing.

©

National Instruments Corporation 3-5 FieldPoint FP-1000/FP-1001 User Manual

Page 30

Chapter 3 Feature Set Description

If the replacement module is incompatible with the one that was

removed, the network module looks at the inform ation stored in the

SnapShot. If the SnapShot is enabled and the replacement module is

compatible with the information in the SnapShot, the network module

configures the replacement mod ule with the Snap Shot configu ration.

Otherwise, the network module configures the replacement module to

factory default settings.

Table 3- 1 shows how mod ules a re con figured a fter HotPnP

replacement.

Table 3-1. Module Configuration Results After HotPnP Replacement

Replacement Module

SnapShot

Feature

Replacement Module

Configuration After

HotPnP

Enabled/

Disabled

Disabled Incompatible with the

Compatible with the

removed module

removed module

Same as the configuration

of the removed module

Factory default

configuration of

replacement module

Enabled Incompatible with the

removed module but

Same as the configuration

stored in the SnapShot

compatible with the

SnapShot information

Enabled/

Disabled

Incompatible with the

removed module and

incompatible with the

Factory default

configuration of

replacement module

stored SnapShot

information

While one or more r epl acem ent I /O mo dules in the bank a re b eing

serviced by the HotPnP feature, the other I/O modules in the bank

remain fully operational and accessible on the network without any

interruptions. As soon as the network module configures a replacement

I/O module via the HotPnP servic e, tha t I /O mo dule b ecom es

automatically accessible on the network.

FieldPoint FP-1000/FP-1001 User Manual 3-6

©

National Instruments Corporation

Page 31

Power-On Self Test (POST)

The power-on self test (POST) is a test suite that the network module

performs at power up to verify its o wn o peratio nal statu s. The test is

non-invasive and therefore does not affect the operation of the network,

nor does it affect any of your field wiring connected to the terminal

bases in the bank.

If the self-test suite fails, the network module does not participate in the

network communication traffic, thereby eliminating potential conflicts

with the other banks in your network.

The network module indicates POST failure via the STATUS LED.

Refer to the next section, LED Indicators, for more information.

LED Indicators

The network module has four LE D indica tors: POWER, NETWORK,

ACCESS, and STATUS. Figures 3-1 shows th e LED s o n th e ne two rk

modules.

Chapter 3 Feature Set Description

ADDRESS BAUD

POWER

NETWORK

Figure 3-1.

ADDRESS BAUD

STATUS

ACCESS

LEDs on the FP-1000 and FP-1001

STATUS

POWER

NETWORK

ACCESS

The green POWER LED is lit while the network module is powered up.

This LED indicates that the power supply connected to the network

module is acceptable, and that the network module is supplying power

to the I/O modules.

©

National Instruments Corporation 3-7 FieldPoint FP-1000/FP-1001 User Manual

Page 32

Chapter 3 Feature Set Description

The yellow NETWORK LED is lit during transmissions from the host

computer on the network. This LED indicates that the network module

is receiving from the network, and that the communication wires to it

are not broken. The NETW OR K LED gets brighter as activity on the

network increases.

The yellow ACCESS LED flashes when th e netwo rk mo dule or any of

the I/O modules in its bank respond to the host computer. This LED

indicates that a module in the bank was addressed by a c orrectly

formatted command, and that the module is responding to that

command (either with a success or error response).

The red STATUS LED is lit when the network module detects a failure.

If STATUS is not lit, the network module has not detected a fail ure. The

network module indicates specific error conditions by flashing

STATUS a specific number of times. Table 3-2 describes the STATUS

LED flashing sequen ce s and the c or respo nding err or condition.

Table 3-2. STATUS LED Flashes and Corresponding Error Conditions

Number of

Flashes

Error Condition

0 (stays lit) The network module initialization failed.

1 The network module address switch is incorrectly

configured. Refer to the Setting the Network Address

section in Chapter 2, Installation and Configuration.

2 The network module has detected an error in the

terminal bases in the bank. Check whether there are

more than nine terminal bases (maximum allowed) in

the bank or whether removing one or more terminal

bases eliminates the error condition.

3 The network module has detected an irrecoverable

internal error.

FieldPoint FP-1000/FP-1001 User Manual 3-8

©

National Instruments Corporation

Page 33

Using the FieldPoint

Chapter

Software

This chapter describes how to use the FieldPoint hardware with various

servers and software packages.

FieldPoint Software Overview

Your FieldPoint software consists of three parts: the FieldPoint

Explorer, the FieldPoint Se rver, and a Fie ldPoint driver fo r Loo kou t.

The FieldPoint Explorer and the Fie ldPoint Serve r ar e both 32 -bit

applications that run on Windows 95 or Window s NT.

• The FieldPoint Explorer is a configuration utility for FieldPoin t

modules. The FieldPo in t E xplorer conf igur es the Fie ldPoint

hardware; the FieldPoint server, which is used with BridgeVIE W,

LabVIEW, LabWindows

Control) client software; and the FieldPoint driver for the Lookout

software package.

• The FieldPoint Server manages the communication s between the

host computer and the FieldPoint hardware. The Fiel dPoint Server

is an interface to the BridgeVIEW, LabVIEW, and

LabWindows/CVI softwa re p acka ges fro m Na tional I nstru ments.

In addition, it provides an OPC interface for other software

packages that have OPC client capability.

• The FieldPoint driver for L ookout m a nages the c ommun ica tions

between a host computer running Look out and the FieldPo int

hardware.

4

®

/CVI, and OPC (OLE fo r Proc ess

You can also choose to communicate with the FieldPoint system using

an Optomux compatible serv er , or by usin g the Fiel dPoint comm an d

set. If you use either of these methods, refer the FieldPoint FP-1000 and

FP-1001 Programmer Reference Manual. You may, however, still use

the FieldPoint Explorer to c onfigur e the Fie ldPoint d evices bef ore

running your software.

©

National Instruments Corporation 4-1 FieldPoint FP-1000/FP-1001 User Manual

Page 34

Chapter 4 Using the FieldPoint Software

Using the FieldPoint Explorer

You can use the FieldPoint Explorer to accomplish the following tasks:

• Configure the characteristics and hard ware of a FieldPo int device

network

• Configure the tag name spac e an d I/O item s o f the FieldPo int

Server

• Write and read I/O value s to a nd fro m the Field Point h ardwar e

After configuring the FieldPoint system with FieldPoint Explor er, yo u

can save the configuration in an Industri al Automation K ernel (IAK )

file (

.iak file). This file contains the configuration information

necessary for the Fi eldPo int Serve r.

The FieldPoint Explorer include s online h elp. T o ge t starte d, ru n the

FieldPoint Explorer program and select FieldPoint from the Help menu.

Using the FieldPoint Server with BridgeVIEW

To use the FieldPoint Se rve r w ith Br idge VIEW , yo u m ust expor t the

configuration information saved by the FieldPoint Explorer in an

file to the BridgeVI EW serve r c onf igur ation da ta store, the C omm on

Configuration Database (CCDB). After you have configured and tested

your FieldPoint network from FieldPoint Explorer, select Export to

Active CCDB from the File menu option to expor t the c urre nt IA K

configuration to BridgeVIEW.

.iak

Once the IAK configuration information is exported to BridgeVIEW,

you can automatically generate BridgeVIEW tags from your FieldPoint

items by launching the B ridgeVIE W Ta g Configur ation Editor an d

clicking on the Tag Wizard button.

Refer to the BridgeVIEW user manual for more information about

BridgeVIEW server configuration, the tag configuration editor, the tag

wizard, and the active CCDB files.

Note: If you edit, rename, or move your

it to the BridgeVIEW active CCDB, you must export the

configuration file again. Also, if you select another CCDB file as the active

CCDB, you must export the

selected active CCDB file.

FieldPoint FP-1000/FP-1001 User Manual 4-2

.iak configuration file af ter you export

.iak

.iak configuration file again, to the newly

©

National Instruments Corporation

Page 35

Chapter 4 Using the FieldPoint Software

Using the FieldPoint Server with LabVIEW

To use the FieldPoint se rv er f rom Lab VIEW , first config ure and te st

your FieldPoint device network from FieldPoint Explorer. After you are

satisfied with the configuration, save your

can then access name d FieldPoint item value s us ing th e La bVI EW

FieldPoint S e rver In te rf ace .

The LabVIEW FieldPo int Serve r In ter face c on sists of se ven VI s th at

are used as an interface to the FieldPoint Server, as well as example VIs

that demonstrate the use of this interface.

•The FP Open.vi and the FP Close.vi are used to open and close a

communications session to the FieldPoi nt serv er, using the

configuration information stored in an IAK file.

•The FP Create Tag.vi is used to establish a communications session

with an I/O point defined in the IAK file.

• After establishing this session, use the FP Read.vi, FP Write.vi, or

FP Advise.vi to communicate with the device.

•The FP Get Configuration Info.vi is used to read the names of

communication resources, de vices, and I/O ite ms define d in the

IAK file.

.iak configuration file. You

During the FieldPoint Server installation, these VIs are installed and

made available in the LabVIEW function palette. For more information

on how to use thes e fu nc tions o r the ex am ple V Is, r efe r to the f ile

Fplvreadme.wri that is installed with the FieldPoint Server, or refer

to the FieldPoint Server online help.

Using the FieldPoint Server with LabWindows/CVI

The LabWindows/CVI interface to the FieldPoint Server is an

instrument driver that has C functions similar to the VIs in the

LabVIEW FieldPoint Server interface. This instrument driver is

installed with the FieldPoint Serv er if La bWin dows/CVI was al read y

installed on th e comp uter .

After opening a session to the FieldPoint network using the

configuration information in a n IAK file, you m ay e ither r ead or write

data using blocking calls or using callbacks. The function pane ls for

each of these C routines includes information on how to use the

functions.

©

National Instruments Corporation 4-3 FieldPoint FP-1000/FP-1001 User Manual

Page 36

Chapter 4 Using the FieldPoint Software

Using the FieldPoint Lookout Driver

The FieldPoint Lookout driver uses the configuration information in the

IAK file created by the Fiel dPoint Ex plore r fo r its own co nfigura tio n.

The tag names used wi th the FieldPoint Look o ut dr iv er ar e th e sam e as

the names assigned using FieldPoint Explorer. There is a separate disk

in your kit that contain s the Fie ldPoint Lo okout dr iver. T his disk a lso

contains documentation for this driver in the

Using FieldPoint with Optomux Servers

The protocol used by Field Point is co mpatible wi th the Op tomu x

protocol, and you may use Optom ux serve r s to co mm unicate with the

FieldPoint system. However, O ptomux se rver s do not inc lude

provisions for setting all the configurable parameters of a FieldPoint

system (such as input ranges and power up settings ). Thus, you sho uld

use FieldPoint Explorer to set up (and optionally store using SnapShot)

the configuration of the FieldPoint hardware before using an Optomux

server.

Refer to the FieldPoint FP-1000 and FP-1001 Programmer Reference

Manual for a description of which O ptomux co mman ds a re supp orted,

and how to scale the data retu rned whe n using this p rotocol.

lkreadme.wri file.

FieldPoint FP-1000/FP-1001 User Manual 4-4

©

National Instruments Corporation

Page 37

Appendix

Specifications

This appendix describes the specifications of the FP-1000 and FP-1001

network modules.

All FieldPoint network modules undergo extensive testing for operating

under rugged environmental conditions that exist in industrial

applications. FieldPoint network modules are design ed and tested for

immunity and susceptibility, as well as for emissions.

Network

FP-1000 ............ .. .... .. .. .... ... .. .... .. .... .. .. . 1 RS -23 2 por t, 1 RS- 485

FP-1001 ............ .... ...... .... ....... .... ...... ... 1 RS-48 5 port

Baud Rates.......... ........ ....... ...... .... ...... . 300, 120 0, 2400, 9600, 19200,

Communication Parameters ................1 Start Bit, 8 Data Bits, 1 Stop

A

repeater port

38400, 57600, 115 200

(switch settable)

Bit, No Parity

Integrity..............................................Checksum

Cabling Distance from Host*

FP-1000 ........... ...... ..... ...... .... ..... 50 ft (nomina l)*

FP-1001 ....... .. .... .. ..... .. .. .... .. .... .. .4000 ft (nom inal ) *

* Refer to the RS-232 Interface Specifications and RS-485 Interface

Specifications sections in Chapter 2, Installation and

Configuration.

Maximum Termin al Base s p er Bank ...9

Maximum Number of Banks...............25

RS-232/RS-485 Interface Chips . .... .... . 15 kV ESD, Low noise and Slew

rate interface ICs

©

National Instruments Corporation A-1 FieldPoint FP-1000/FP-1001 User Manual

Page 38

Appendix A Specifications

RS-485 Isolation ................................2500 Vrms breakdown,

250 Vrms opera tiona l

Environment

Operating Tem pe rat ure....... ..... .. .. .... .. . –40° C t o +70 ° C

Storage Tempera tur e ........ .. ..... .. .... .. ... –55° C t o + 100° C

Relative Hum idi ty ............ .. ... .... .. .. .... . 5% to 9 0% n onc on dens ing

Compliance

Electrical S afe ty ... .... .. .... .. ..... .. .. .... .. ... de signe d to mee t I EC 10 10

EMI Emissions/ I mm unity........ .... .. .. ... CISP R 11

FieldPoint FP-1000/FP-1001 User Manual A-2

©

National Instruments Corporation

Page 39

Appendix

Customer Communication

For your convenience, this appendix contains forms to help you gather the information necessary to

help us solve your technical problems and a form you can use to comment on the product

documentation. When you contact us, we need th e information on the Technical Suppor t Form and the

configuration form, if your manual contains one, about your system configuration to answer your

questions as quickly as possible.

National Instruments has techn ica l assistan ce thr ou gh electronic , fa x, a nd telepho ne sys tems to

quickly provid e the informat ion you need. Our electron ic services incl ude a bullet in board ser vice,

an FTP site, a fax-on-demand system , and e-ma il support. If you have a hardware or software

problem, first try the electronic support systems. If the information available on these systems

does not answer your questions, we offer fax and telephone support through our technical support

centers, which are staffed by applica tions engine ers.

B

Electronic Services

Bulletin Board Support

National Instruments has BBS and FTP sites dedicated for 24-hour support with a collection of files

and documents to answer most common customer questions. From these sites, you can also download

the latest instrument drivers, updates, and example programs. For recorded instructions on how to use

the bulletin board and FTP services and for BBS automated information, call (512) 795-6990. You can

access these services at:

United States: (512) 794-5422

Up to 14,400 baud, 8 data bits, 1 stop bit, no parity

United Kingdom: 01635 551422

Up to 9,600 baud, 8 data bits, 1 stop bit, no parity

France: 01 48 65 15 59

Up to 9,600 baud, 8 data bits, 1 stop bit, no parity

FTP Support

To access our FTP site, log on to our Internet host, ftp.natinst.com, as anonymous and use

your Internet address, such as joesmith@anywhere.com, as your passwor d. The support files and

documents are located in the /support directories.

©

National Instruments Corporation B-1 FieldPoint FP-1000/FP-1001 User Manual

Page 40

Fax-on-Demand Support

Fax-on-Demand is a 24-hour inf ormation re trieval sys tem containing a library o f documents on a wide

range of technical information. You can access Fax-on-Demand from a touch-tone telephone at

(512) 418-1111.

E-Mail Support (currently U.S. only

You can submit technical support questions to the applications enginee ring team through e-m ail at the

Internet address listed below. Remember to include your name, address, and phone number so we can

contact you with solutions and sugg estions.

support@natinst.com

)

Telephone and Fax Support

National Instruments has branch offices all over the world. Use the list below to find the technical

support number for your country. If there is no Nat ional Instruments office in your countr y, contact the

source from which you purchased your software to obtain support.

Telephone Fax

Australia 03 9879 5166 03 9879 6277

Austria 0662 45 79 90 0 0662 45 79 90 19

Belgium 02 757 00 20 02 757 03 11

Canada (Ontario) 905 785 0085 905 785 0086

Canada (Quebec) 514 694 8521 514 694 4399

Denmark 45 76 26 00 45 76 26 02

Finland 09 725 725 11 09 725 725 55

France 01 48 14 24 24 01 48 14 24 14

Germany 089 741 31 30 089 714 60 35

Hong Kong 2645 3186 2686 8505

Israel 03 5734815 03 5734816

Italy 02 413091 02 41309215

Japan 03 5472 2970 03 5472 2977

Korea 02 596 7456 02 596 7455

Mexico 5 520 2635 5 520 3282

Netherlands 0348 433466 0348 430673

Norway 32 84 84 00 32 84 86 00

Singapore 2265886 2265887

Spain 91 640 0085 91 640 0533

Sweden 08 730 49 70 08 730 43 70

Switzerland 056 200 51 51 056 200 51 55

Taiwan 02 377 1200 02 737 4644

United Kingdom 01635 523545 01635 523154

United States 512 795 8248 512 794 5678

Page 41

FieldPoint System Configuration Form

Record the settings and revisions of your hardware and software on the line to the right of each item.

Complete a new copy of this form each time you revise your software or hardware configuration, and

use this form as a reference for your current configuration . Completing this form accurately also helps

us to answer your questions more efficiently.

Host Computer

Computer brand ________________ Model ________________ Processor __________________

Operating system (include version number ) ___________________________________________

Clock speed ______MHz RAM _____MB Display adapter __________________________

Mouse ___yes ___no Mouse type _________________________________________________

National Instruments application software product ______________________ Version _________

Other application software product ___________________________________ Version ________

National Instruments server _________________________________________ Version ________

Other installed software that may use serial ports _______________________________________

_______________________________________________________________________________

Serial adaptor (COM port or adaptor card) used ________________________________________

Configuration _________________________________________________________________

Serial driver ______________________________________________________ Version ______

Configuration _________________________________________________________________

Serial port timeout value _____________ ms

Number of FieldPoint banks _______

COM Port

Number

Baud Rate

Data Bits/Stop Bits/

Parity

Serial Hardware That

Uses This Port

TX/RX FIFOs

FieldPoint Software

List the applications and/or servers that you are using with the FieldPoint hardware ____________

_______________________________________________________________________________

Page 42

FieldPoint Banks

Please use one page per FieldPoint bank.

Network module _____________________________________ Firmware revision ____________

Address __________________________________________ Baud rate __________________

Circle the state of the following items when your problem occurs:

LEDs POWER: ON/OFF

SnapShot feature Enabled/Disabled

Watchdog timer Enabled/Disabled Timeout value ______ ms

Number of FieldPoint terminal bases ________________________________________________

Number of FieldPoint I/O modules __________________________________________________

NETWORK: ON/OFF ACCESS: ON/OFF STATUS: ON/OFF

Base

#

0 FP-1000/FP-1001 ON/OFF ON/OFF

1 ON/OFF ON/OFF

2 ON/OFF ON/OFF

3 ON/OFF ON/OFF

4 ON/OFF ON/OFF

5 ON/OFF ON/OFF

6 ON/OFF ON/OFF

7 ON/OFF ON/OFF

8 ON/OFF ON/OFF

9 ON/OFF ON/OFF

* If a terminal base is present but no module is inserted, write “none.”

Module Name*

POWER

LED

READY

LED

Module Configuration Information

Page 43

Technical Support Form

Photocopy this form and update it each time y ou make ch anges to you r software or h ardware, and use

the completed copy of this form as a reference for your current configuration. Completing this form

accurately before contacting National Instruments for technical support helps our applications

engineers answer your questions more efficiently.

If you are using any National Instruments hardware or software products related to this problem,

include the configuration forms from their user manuals. Include additional pages if necessary.

Name __________________________________________________________________________

Company _______________________________________________________________________

Address ________________________________________________________________________

_______________________________________________________________________________

Fax (___ )___________________ Phone (___ ) ________________________________________

Computer brand ________________ Model ________________ Processor___________________

Operating system (include version number)____________________________________________

Clock speed ______MHz RAM _____MB Display adapter __________________________

Mouse ___yes ___no Other adapters installed _______________________________________

Hard disk capacity _____MB Brand _____________________________________________

Instruments used _________________________________________________________________

_______________________________________________________________________________

National Instrument s hard war e produ c t mode l__________ Revision _______________ ___ ____

Configuration ___________________________________________________________________

National Instrument s sof t war e produ ct____________________________ Version ____________

Configuration ___________________________________________________________________

The problem is: __________________________________________________________________

_______________________________________________________________________________

_______________________________________________________________________________

_______________________________________________________________________________

_______________________________________________________________________________

List any error messages: ___________________________________________________________

_______________________________________________________________________________

_______________________________________________________________________________

The following steps reproduce the problem:____________________________________________

_______________________________________________________________________________

_______________________________________________________________________________

_______________________________________________________________________________

_______________________________________________________________________________

_______________________________________________________________________________

Page 44

Documentation Comment Form

National Instruments encourages you to comment on the documentation supplied with our products.

This information helps us provide quality products to meet your needs.

Title:

Edition Date:

Part Number:

Please comment on the completeness, clarity, and organization of the manual.

_______________________________________________________________________________

_______________________________________________________________________________

_______________________________________________________________________________

_______________________________________________________________________________

_______________________________________________________________________________