National Instruments FieldPoint FP-TB-1, FieldPoint FP-TB-3, FieldPoint FP-TB-2 Operating Instructions Manual

Page 1

Artisan Technology Group is your source for quality

new and certied-used/pre-owned equipment

• FAST SHIPPING AND

DELIVERY

• TENS OF THOUSANDS OF

IN-STOCK ITEMS

• EQUIPMENT DEMOS

• HUNDREDS OF

MANUFACTURERS

SUPPORTED

• LEASING/MONTHLY

RENTALS

• ITAR CERTIFIED

SECURE ASSET SOLUTIONS

SERVICE CENTER REPAIRS

Experienced engineers and technicians on staff

at our full-service, in-house repair center

Instra

Remotely inspect equipment before purchasing with

our interactive website at www.instraview.com

Contact us: (888) 88-SOURCE | sales@artisantg.com | www.artisantg.com

SM

REMOTE INSPECTION

View

WE BUY USED EQUIPMENT

Sell your excess, underutilized, and idle used equipment

We also offer credit for buy-backs and trade-ins

www.artisantg.com/WeBuyEquipment

LOOKING FOR MORE INFORMATION?

Visit us on the web at www.artisantg.com for more

information on price quotations, drivers, technical

specications, manuals, and documentation

Page 2

FieldPoint Operating Instructions

FP-TB-1/2/3

FieldPoint Terminal Bases

These operating instructions describe the installation, features,

and characteristics of the FP-TB-1, FP-TB-2, and FP-TB-3.

Features

The FP-TB-1, FP-TB-2, and FP-TB-3 are FieldPoint terminal

bases with the following features:

• Works with all FieldPoint I/O modules (the FP-TB-3 is

designed specifically to work with thermocouple I/O modules)

• V andC terminals provideexternal supply voltages common to

all channels

• DIN-rail mounting or panel mounting

• 32 terminals available for field connections (FP-TB-3 has 16)

• Available with screw terminals (FP-TB-1 and FP-TB-3) or

spring terminals (FP-TB-2)

• Isothermal construction (FP-TB-3) minimizes temperature

gradients when using thermocouples

• –40 to 70 °C operation

The FP-TB-1, FP-TB-2, and FP-TB-3 terminal bases provide the

intra-system communication link between FieldPoint I/O modules

and network modules, provide a means for wiring field

connections, and provide the mounting mechanism. You can

choose your terminal base depending on the type of field wiring

terminal you prefer: screw terminal or spring terminal.

FieldPoint™, National Instruments™, NI™, and ni.com™ aretrademarks of National Instruments Corporation.

Product and company names mentioned herein are trademarks or trade names of their respective companies.

For patents coveringNational Instrumentsproducts, refer tothe appropriate location:

patents.txt

the

321699E-01 May 2002

©

1999–2002 National Instruments Corp. All rights reserved.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

file on your CD, or

ni.com/patents

.

Help»Patents

in yoursoftware,

Page 3

MountingtheFP-TB-1/2/3onaDINRail

Caution

To avoid damaging the network module and

terminal base, make sure that power is not applied to the

network module while you are installing or removing a

terminal base.

FieldPoint terminal bases have simple rail clips for reliable

mounting on a standard 35 mm DIN rail. Follow these steps to

mount the terminal base on a DIN rail.

1. Write down the serial number, located on the back of the

terminal base, before you mount it on the DIN rail.

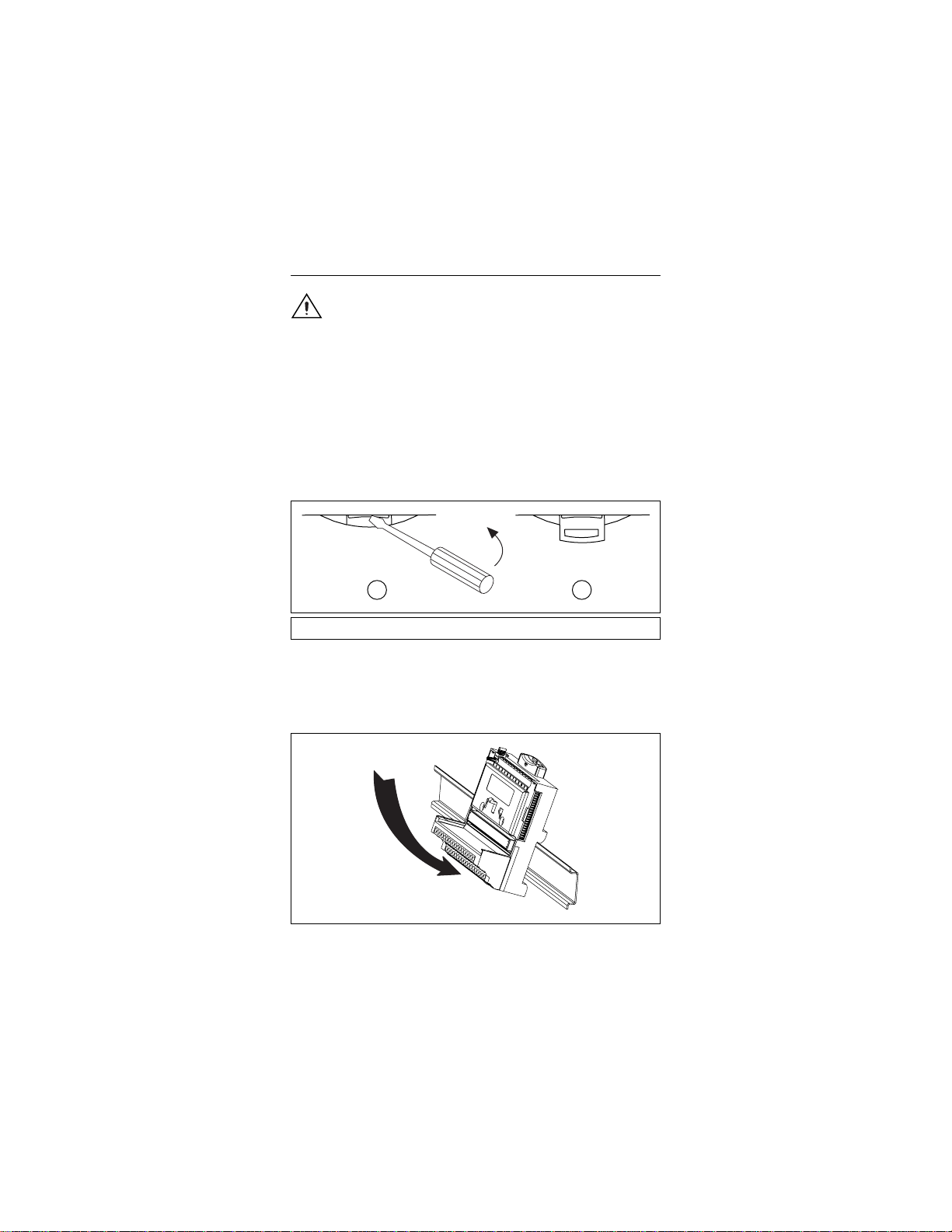

2. Use a flathead screwdriver to open the DIN rail clip to the

unlocked position, as shown in Figure 1.

1 2

1 Rail clip locked 2 Rail clip unlocked

Figure 1. Unlocking the Rail Clip

3. Attach the lip on the rear of the terminal base onto the top of a

35 mm DIN rail and press it down onto the DIN rail, as shown

in Figure 2.

Figure 2. Attaching the Terminal Base to a DIN Rail

FP-TB-1/2/3 Operating Instructions 2 ni.com

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 4

4. Slide the terminal base along the DIN rail until its local bus

connector mates with the connector of the terminal base or

network module adjacent to it.

5. After the terminal base is in position, lock it to the DIN rail by

pushing the rail clip to the locked position.

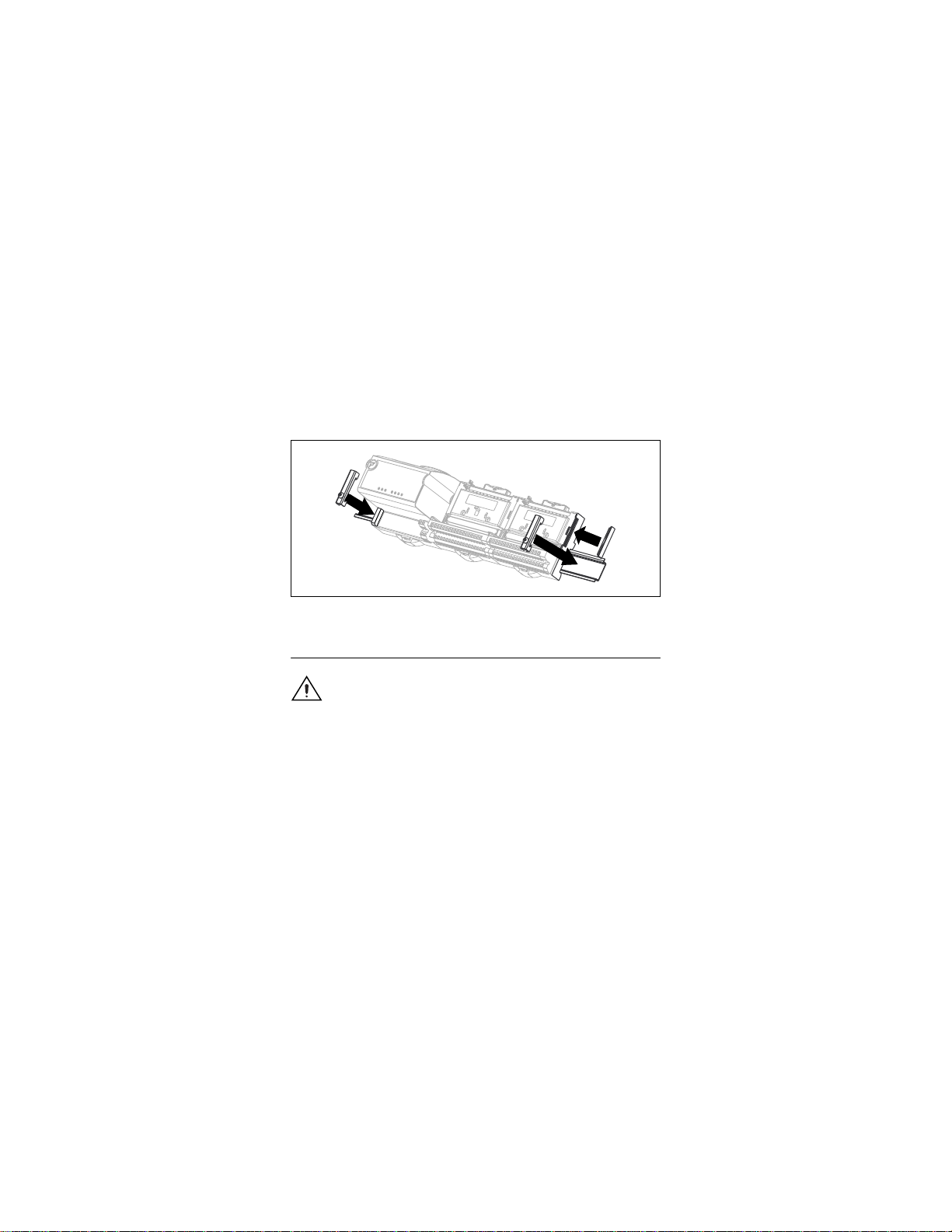

6. To add more terminal bases, install them on the rail and

connect their local bus connectors together.

7. Place the protective cover onto the local bus connector of the

last terminal base on the bank, as shown in Figure 3. Add rail

locks by sliding them on and tightening the screws.

Figure 3. Adding Rail Locks and Protective Cover

Mounting the FP-TB-1/2/3 to a Panel

Caution

To avoid damaging the network module and

terminal base, make sure that power is not applied to the

network module while you are installing or removing a

terminal base.

Follow these steps to mount the terminal base on a wall or panel.

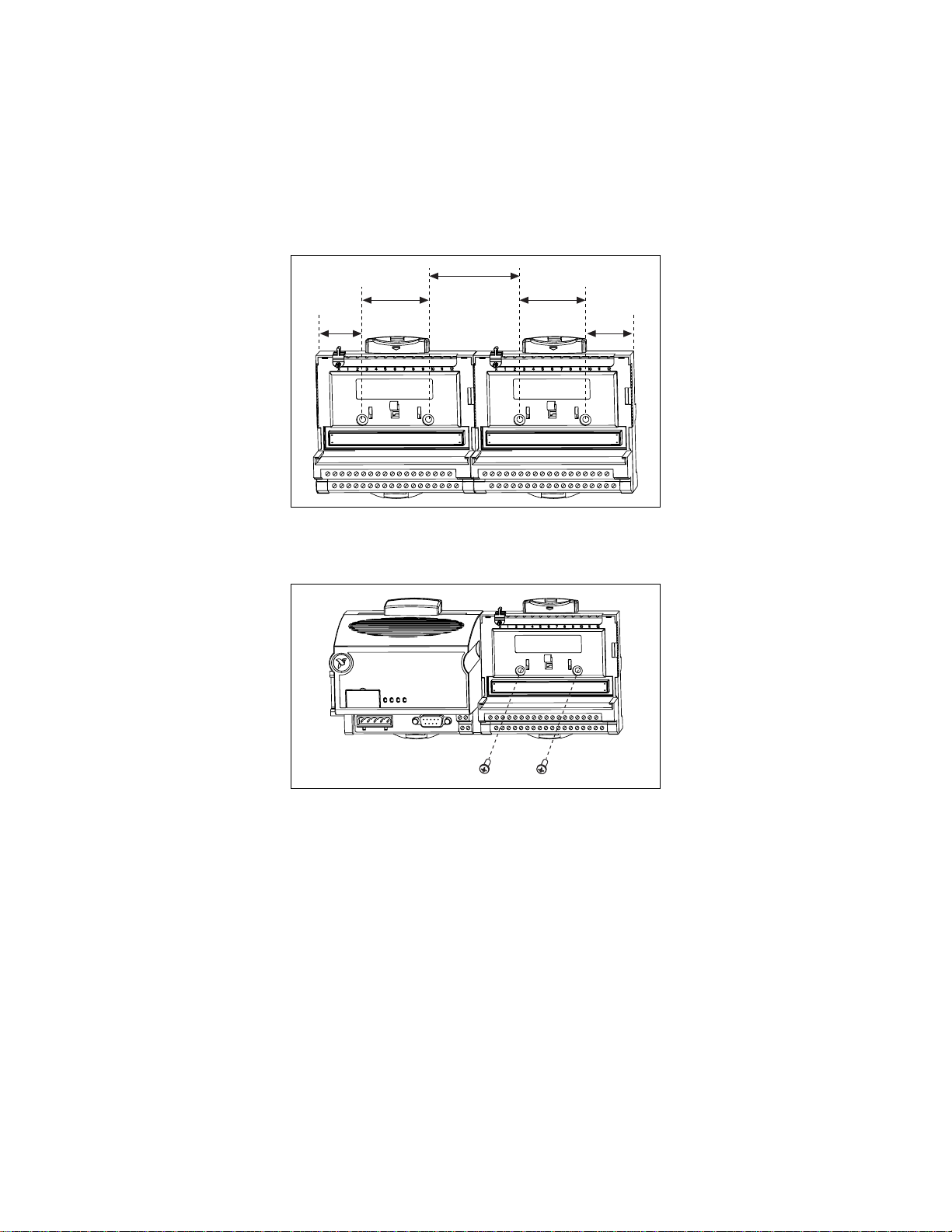

1. Use Figure 4 to locate where to drill the mounting holes on the

panel. Dimensions are given in millimeters [inches].

© National Instruments Corp. 3 FP-TB-1/2/3 Operating Instructions

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 5

62.48 [2.46]

31.24

[1.23]

44.64 [1.76]

44.64 [1.76]

31.24

[1.23]

Figure 4. Locating the Mounting Holes

2. When you have located and drilled the mounting holes, mount

the terminal base as shown in Figure 5.

Figure 5. Mounting the Terminal Base

3. Place the protective cover over the local bus connector of the

last terminal base in the bank.

FP-TB-1/2/3 Operating Instructions 4 ni.com

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 6

Mounting I/O Modules

on the Terminal Base

Refer to Figure 6 and follow these steps to install an I/O module on

the terminal base.

1. Slide the terminal base key to the appropriate position for the

I/O module. The position marked X is a universal position that

works for all modules.

2. Align the alignment slots on the I/O module with the guide

rails on the terminal base.

Key

Latch

Alignment

Slot

Guide Rails

Terminal BaseI/O Module

Figure 6. Mounting the I/O Module on the Terminal Base

3. Press firmly to seat the I/O module on the terminal base. When

the module is firmly seated, the terminalbase latch locks it into

place and the ejector button on the top of the terminal base

pops up.

4. To remove an I/O module, press the ejector button on top of the

terminal base and pull off the module.

© National Instruments Corp. 5 FP-TB-1/2/3 Operating Instructions

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 7

Field Wiring

The FP-TB-1 and FP-TB-2 provide four dedicated terminals and

32 numbered terminals defined by the I/O module. The terminals

are designed for 16–26 AWG copper conductor wire with 7 mm

(0.28 in.) of insulation stripped from the end as shown in Figure 7.

Use only copper wire unless you are working with a sensing

device, such as a thermocouple, that requires a different kind

of wire.

7mm

Figure 7. Conductor Wire with the Correct Strip Length

The four dedicated terminals are two V and two C terminals, one

of each at both ends of the terminal base. The two V terminals

are internally connected by the terminal base, as are the two

C terminals. Generally, these terminals are intended to connect

external power supplies to field devices. FieldPoint I/O modules

get their power from the network module through the backplane,

and in most cases require no external power for proper operation.

Refer to the appropriate I/O module operating instructions

for details on the use of these terminals and the other 32 terminals.

The FP-TB-3 provides two dedicatedC terminals and 16 numbered

terminals defined by the I/O module. Although the FP-TB-3 is

designed specifically to work with thermocouple modules, I/O

modules that do not require external power and that only use

terminals 1 to 16 can be used with the FP-TB-3.

Caution

make sure that power is not applied to it.

Before you connect wires to the terminal base,

Connecting Wires to the FP-TB-1 or FP-TB-3

Follow these steps to connect wires to the FP-TB-1 or FP-TB-3.

1. Loosen the terminal screw you want to wire.

2. Insert the wire in the terminal.

3. Tighten the screw terminal to 0.5–0.6 N ⋅ m (4.4–5.3 lb ⋅ in.) of

torque.

FP-TB-1/2/3 Operating Instructions 6 ni.com

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 8

Connecting Wires to the FP-TB-2

Follow these steps to connect wires to the FP-TB-2.

1. Insert a screwdriver into the slot directly below the terminal

number and push the screwdriver downward into the slot. You

may need to push hard. This forces the spring-loaded terminal

to open.

2. Insert the wire in the terminal.

3. Withdraw the screwdriver, allowing the spring terminal to

clamp securely onto the wire.

V12345678910111213141516V

C17181920212223242526272829303132C

Figure 8. Connecting Wires to the Spring Terminals of the FP-TB-2

© National Instruments Corp. 7 FP-TB-1/2/3 Operating Instructions

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 9

Powering the FieldPoint System

Consider the following points when connecting power to the

FieldPoint system.

• The total current flowing through the V and C terminals must

be limited to 10 A. If you have a single external supply for the

field devices of more than one module, wire the supply to the

V and C terminals as shown in Figure 9.

1

2

1 When total current draw is

less than 10 A

Figure 9. Connecting Power for Current Draws Below and Above 10 A

Caution

Cascading power from neighboring bases or

2 When total current draw is

greater than 10 A

network modules defeats isolation between cascaded

modules.

• When total current draw is less than 3 A, you can use a single

terminal for the return path. If the total current draw is greater

than 3 A, you should use separate C terminals, as shown in

Figure 10.

FP-TB-1/2/3 Operating Instructions 8 ni.com

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 10

1

2

1 When total current draw is

lessthan3A

2 When total current draw is

greater than 3 A

Figure 10. Connecting Power for Current Draws Below and Above 3 A

• You need to wire power to the terminal bases only if you want

to use the terminal bases to route power to field devices or if

the I/O module requires it. FieldPoint I/O modules get their

power from the network module through the backplane and,

in most cases, require no external power for proper operation.

Refer to your I/O module operating instructions for details. In

Figure 11, shades of gray indicate differing voltage potentials.

FP-TC-120 FP-AO-200FP-AI-110

Figure 11. Different Voltage Potentials

Caution

Cascading power from neighboring bases or

Live (V)

Ground

Neutral (C)

FP-RLY-420

network modules defeats isolation between cascaded

modules.

• You may want to use separate power supplies for I/O modules

both to prevent power dips caused by field devices from

disrupting the operation of the networkmodule and tomaintain

© National Instruments Corp. 9 FP-TB-1/2/3 Operating Instructions

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 11

the isolation barrier between the I/O modules and the network

module. Figure 12 shows an example configuration with both

separate power supplies and cascading power.

FP-TC-120 FP-RLY-420FP-AO-200FP-AI-110

1

2

Thermocouple

(self powered)

17

V

sup

4-20 mA

Figure 12. Example Power Supply Configuration for a FieldPoint Bank

V

COM

IN

2

I

IN

–+

±5V

1 18 Common

Channel 0

2

18

Caution

Cascading power from neighboring bases or

network modules defeats isolation between cascaded

modules.

Thermocouple Wiring

The FP-TC-120 thermocouple input module has the ability to

measure the temperature of the terminals on any of the FieldPoint

terminal bases. This measurement is called the cold junction

temperature and indicates the temperature of the junctions

between your thermocouple wire and the screw terminals. This

measurement is used internally by the FP-TC-120 to correct for

the thermoelectric voltages that are generated at these junctions.

Heat dissipated by adjacent modules (or other nearby heat sources)

can cause errors in thermocouple measurements by heating up the

terminals so that they are at a different temperature than the sensor

used to measure the cold junction. The thermal gradient generated

across the terminals can cause the terminals of different channels

FP-TB-1/2/3 Operating Instructions 10 ni.com

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 12

to be at different temperatures, and so the resulting measurement

creates not only errors in absolute accuracy but also in the relative

accuracy between channels. The accuracy specifications for the

FP-TC-120 include the errors caused by a 0.2 °C (0.36 °F)

gradient. The actual gradient you can expect to encounter depends

on the terminal base you use and the details of your installation.

The following sections provide guidelines for estimating and

minimizing thermal gradients.

Estimating Thermal Gradients with the FP-TB-3

Isothermal Terminal Base

The FP-TB-3 is designed with isothermal construction to keep

the terminals at the same temperature. It is the terminal

base recommended for the best accuracy of thermocouple

measurements. Adjacent FieldPoint modules (either network

modules or I/O modules) create a thermal gradient across the

terminals of the FP-TB-3, which you can estimate by dividing

the larger of the amounts of heat dissipated by each of the adjacent

modules by 20 W/°C(11W/°F). For example, if the FP-TB-3 is

between an analog input module dissipating 0.35 W and a discrete

output module dissipating 3 W, the thermal gradient would be

3W÷ 20 W/ °C = 0.15 °C.

Estimating Thermal Gradients with the FP-TB-1

or FP-TB-2 Terminal Bases

The lack of isothermal construction in the FP-TB-1 and FP-TB-2

terminal bases makes them more susceptible to errors caused by

thermal gradients. These terminal bases are recommended for use

with thermocouple measurements only if such errors are

acceptable or if they can be minimized, as described in the

Minimizing Thermal Gradients section. Adjacent FieldPoint

modules (either network modules or I/O modules) create a thermal

gradient across the terminals of the FP-TB-1, which you can

estimate by dividing the larger of the amounts of heat dissipated by

each of the adjacent modules by 1 W/°C (0.6 W/°F). For example,

if the FP-TB-1/2 is between an analog input module dissipating

0.35 W and a discrete output module dissipating 3 W, the thermal

gradient would be 3 W ÷ 1W/°C=3°C. The typical thermal

gradient created by the FP-TC-120 mounted on an FP-TB-1

(neglecting any adjacent modules) is about 0.2 °C.

© National Instruments Corp. 11 FP-TB-1/2/3 Operating Instructions

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 13

Minimizing Thermal Gradients

The most common source of thermal gradients, particularly for the

FP-TB-1 and FP-TB-2, is the heat generated by adjacent modules.

For example, placing an FP-TB-1 next to an FP-1000 network

module can create more than a 1 °C thermal gradient. Mounted

thermocouple modules can be separated from the higher-power

modules by the lowest-power modules in your system or by the

FieldPoint Bus Extender Cable (part number 185576-15). This

precaution is generally not necessary with the FP-TB-3.

Hot or cold air draft can be another source of thermal gradients.

It is usually best to avoid having air blowing directly on the

terminals, although circulating air around other nearby

components may help them dissipate their heat and cause them

to be less of a source of thermal gradients on the terminal base.

Thermocouple wire also has the potential to be a significant source

of thermal gradients. Even the FP-TB-3 can be susceptible to these

errors. Heat or cold may be directly conducted to the terminal

junction by the thermocouple wire. If the thermocouple wires,

or objects they are in contact with, such as wiring ducts, near the

terminal base are at a different temperature than the terminals,

the wires transfer heat to or from the terminals and cause thermal

errors. To minimize these errors, follow these guidelines:

• Use small-gauge thermocouple wire. Smaller wires transfer

less heat.

• Run thermocouple wires together near the terminal base to

keep them at the same temperature.

• Avoid running thermocouple wires near hot or cold objects.

Specifications

The following specifications are typical for a range of

–40 to 70 °C, unless otherwise noted.

Installation

Terminal wiring ................................ 16–26 AWG copper

conductor wire with 7 mm

(0.28 in.) of insulation

stripped from the end

1

Use only copper conductor wire unless you are working with a sensing

device, such as a thermocouple, that requires a different kind of wire.

FP-TB-1/2/3 Operating Instructions 12 ni.com

1

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 14

Torque for screw terminals ............... 0.5–0.6 N ⋅ m

(4.4–5.3 lb ⋅ in.)

Physical

Weight

FP-TB-1...................................... 210 g (7.4 oz)

FP-TB-2...................................... 160 g (5.7 oz)

FP-TB-3...................................... 240 g (8.5 oz)

Maximum Working Voltage

Maximum working voltage refers to the signal voltage plus the

common-mode voltage.

Channel-to-earth ............................... 250 V, Installation

Category II

Channel-to-channel........................... See I/O module operating

instructions

1

Caution

Improper wiring may defeat isolation barrier.

Environmental

FieldPoint modules are intended for indoor use only.

Operating temperature ...................... –40 to 70 °C

Storage temperature ..........................–55 to 85 °C

Humidity ...........................................10 to 90% RH,

noncondensing

Maximum altitude............................. 2,000 m

Pollution degree ................................2

Safety

The FP-TB-1/2/3 meets the requirements of the following

standards for safety and electrical equipment for measurement,

control, and laboratory use:

• EN 61010-1:1993/A2:1995, IEC 61010-1:1990/A2:1995

• UL 3121:1998

• CAN/CSA c22.2 no. 1010.1:1992/A2:1997

1

May vary by I/O module. See I/O module operating instructions.

© National Instruments Corp. 13 FP-TB-1/2/3 Operating Instructions

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 15

Electromagnetic Compatibility

CE, C-Tick and FCC Part 15 (Class A) Compliant

Electrical emissions .......................... EN 55011 Class A at 10 m

FCC Part 15A above 1 GHz

Electrical immunity ..........................Evaluated to EN 61326:

1997/A1: 1998, Table 1

For full EMC compliance, you must operate this

Note

device with shielded cabling. See the Declaration of

Conformity (DoC) for this product for any additional

regulatory compliance information. To obtain the DoC

for this product, click Declaration of Conformity at

ni.com/hardref.nsf/

.

Mechanical Dimensions

Figure 13 show the mechanical dimensions of the FP-TB-1/2/3

with an I/O module installed. Dimensions are given in millimeters

[inches].

107.19 [4.22]

109.5

[4.31]

91.44 [3.60]

Figure 13. Mechanical Dimensions

Where to Go for Support

For more information about setting up your FieldPoint system,

refer to these National Instruments documents:

• Your FieldPoint network module user manual

• Your other FieldPoint I/O module operating instructions

• Your FieldPoint terminal base operating instructions

Go to

ni.com/support

and troubleshooting information.

FP-TB-1/2/3 Operating Instructions 14 ni.com

for the most current manuals, examples,

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 16

For telephone support in the United States, create your service

request at

ni.com/ask

and follow the calling instructions or dial

512 795 8248. For telephone support outside the United States,

contact your local branch office:

Australia 03 9879 5166, Austria 0662 45 79 90 0, Belgium 02 757 00 20,

Brazil 011 3262 3599, Canada (Calgary) 403 274 9391,

Canada (Montreal) 514 288 5722, Canada (Ottawa) 613 233 5949,

Canada (Québec) 514 694 8521, Canada (Toronto) 905 785 0085,

China (Shanghai) 021 6555 7838, China (ShenZhen) 0755 3904939,

Czech Republic 02 2423 5774, Denmark 45 76 26 00,

Finland 09 725 725 11, France 01 48 14 24 24, Germany 089 741 31 30,

Greece 30 1 42 96 427, Hong Kong 2645 3186, India 91 80 4190000,

Israel 03 6393737, Italy 02 413091, Japan 03 5472 2970,

Korea 02 3451 3400, Malaysia 603 9596711, Mexico 001 800 010 0793,

Netherlands 0348 433466, New Zealand 09 914 0488,

Norway 32 27 73 00, Poland 0 22 3390 150, Portugal 351 210 311 210,

Russia 095 238 7139, Singapore 6 2265886, Slovenia 386 3 425 4200,

South Africa 11 805 8197, Spain 91 640 0085, Sweden 08 587 895 00,

Switzerland 056 200 51 51, Taiwan 02 2528 7227,

United Kingdom 01635 523545

© National Instruments Corp. 15 FP-TB-1/2/3 Operating Instructions

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 17

Artisan Technology Group is your source for quality

new and certied-used/pre-owned equipment

• FAST SHIPPING AND

DELIVERY

• TENS OF THOUSANDS OF

IN-STOCK ITEMS

• EQUIPMENT DEMOS

• HUNDREDS OF

MANUFACTURERS

SUPPORTED

• LEASING/MONTHLY

RENTALS

• ITAR CERTIFIED

SECURE ASSET SOLUTIONS

SERVICE CENTER REPAIRS

Experienced engineers and technicians on staff

at our full-service, in-house repair center

Instra

Remotely inspect equipment before purchasing with

our interactive website at www.instraview.com

Contact us: (888) 88-SOURCE | sales@artisantg.com | www.artisantg.com

SM

REMOTE INSPECTION

View

WE BUY USED EQUIPMENT

Sell your excess, underutilized, and idle used equipment

We also offer credit for buy-backs and trade-ins

www.artisantg.com/WeBuyEquipment

LOOKING FOR MORE INFORMATION?

Visit us on the web at www.artisantg.com for more

information on price quotations, drivers, technical

specications, manuals, and documentation

Loading...

Loading...