Page 1

OPERATING INSTRUCTIONS

FP-PWM-520

8-Channel, 5 or 24 V PWM

Output Module

These operating instructions describe the installation, features, and

characteristics of the FP-PWM-520. For details on configuring

and accessing the FP-PWM-520 over a network, refer to the user

manual for the particular FieldPoint network module you are using

with the FP-PWM-520.

Features

The FP-PWM-520 is a FieldPoint pulse-width modulated (PWM)

output module with the following features:

• Eight PWM output channels

• 0 to 100% duty-cycle capability with 12-bit resolution

• One millisecond period resolution

• Overcurrent protected outputs

• Sourcing outputs compatible with sinking inputs or 24 VDC

devices

• On/off LED indicators

• Hot plug and play operation

• 3,000 Vrms input-to-output isolation

• Double insulated for 250 V safe working voltage

• Independent configuration of the output period for each

channel from 1 to 65,535 ms in 1 ms increments

FieldPoint ™ is a trademark of National Instruments Corporation. Product and company names

mentioned herein are trademarks or trade names of their respective companies.

322139B-01 © Copyright 1998, 1999 National Instruments Corp. All rights reserved. June 1999

Page 2

Installation

The FP-PWM-520 mounts on a FieldPoint terminal base

(FP-TB-xx) unit. Because of its hot plug and play operation, you

can install the FP-PWM-520 onto a powered terminal base without

disturbing the operation of other modules or terminal bases. The

FP-PWM-520 receives operating power from the terminal base.

To install your module, refer to Figure 1 and complete the

following steps:

1. Slide the terminal base key to either position X (used for any

module) or position 4 (used for the FP-PWM-520 module).

2. Align the FP-PWM-520 alignment slots with the guide rails on

the terminal base.

3. Press firmly to seat the FP-PWM-520 on the terminal base.

When the module is firmly seated, the terminal base latch locks

it into place.

Key

Latch

Alignment

Slot

Guide Rails

Terminal BaseI/O Module

Figure 1.

Install Your Module

Field Wiring

The terminal base provides connections for each of the eight output

channels and for an external supply to power f i eld devices.

Although the module does not need the external supply for its

internal operation, the output channels source current from this

external supply and require it to operate.

Each channel has one output terminal, V

terminals, COM (internally connected to the C terminal); and a

supply terminal, V

(internally connected to the V terminal).

sup

If you want to connect an external supply to power field devices,

connect to the V and C terminals of the terminal base, or to the V

FP-PWM-520 2 www.natinst.com

; two common

out

sup

Page 3

and COM terminals for the individual channels. If the total current

supplied by the FP-PWM-520 channels is more than 4 A, route the

external supply to the V

and COM terminals. Otherwise, you can

sup

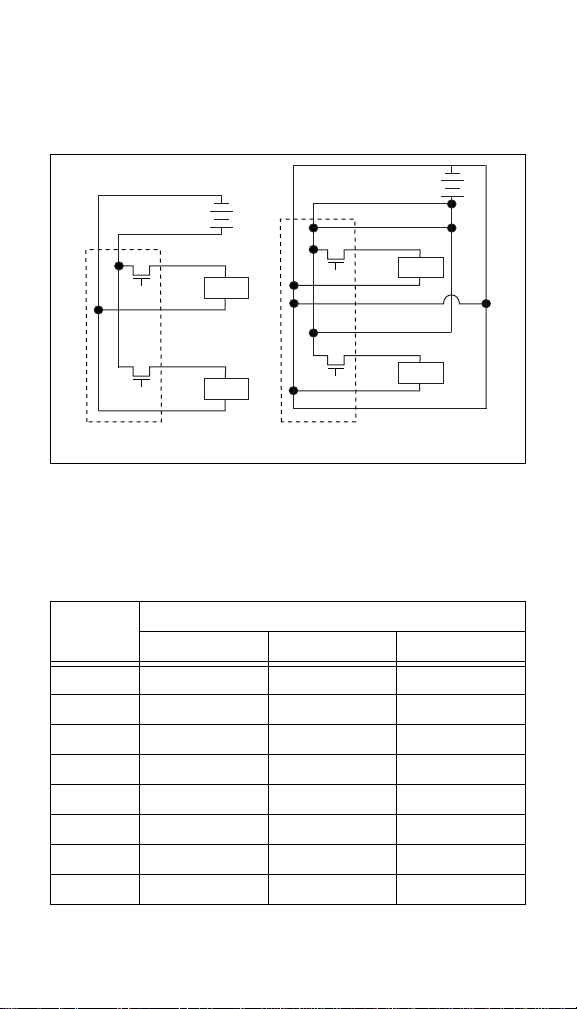

connect the external supply only to the V and C terminals. Figure 2

shows two examples of basic wiring connections.

–

CV

a. Total Current Less

Than 4 Amps

Figure 2.

–

V

out

COM

V

out

COM

CV

+

Load

Load

V

sup

V

out

COM

COM

V

sup

V

out

COM

COM

b. Total Current Greater

Than 4 Amps

Basic Field Connections (Two Channels Shown)

+

Load

Load

Table 1 lists the terminal assignments for the signals of each

channel. T erminal assignments and wiring diagrams are also listed

under the slide-in card on the front of the FP-PWM-520 module.

Table 1.

Terminal Assignments

Terminal Numbers

Channel

V

out

V

sup

COM

0 1 17 2, 18

1 3 19 4, 20

2 5 21 6, 22

3 7 23 8, 24

4 9 25 10, 26

5 11 27 12, 28

6 13 29 14, 30

7 15 31 16, 32

© National Instruments Corp. 3 FP-PWM-520

Page 4

Pulse-Width Modulated Output Circuit

The FP-PWM-520 PWM output channels have optically isolated

sourcing outputs with overcurrent protection circuitry. In the ON

state of the output period, a transistor is turned on between the

positive external supply v oltage (the V and V

output (V

) terminal. In the OFF state, this transistor is turned off,

out

allowing only a small leakage current to flow . Select the impedance

of the loads driven by the output channels so that the current

supplied by any one channel in the ON state is no more than 1 A.

The output channels need an external power supply of 5 VDC

or between 10 and 30 VDC connected to the C and V terminals

of the module.

In the ON state, the effective resistance between the output and the

external supply voltage is 0.3 Ω, which causes a voltage drop.

For example, if the external supply voltage is 5 V and the output

current is 1 A, the output voltage is 4.7 V:

[5 V – (1 A x 0.3 Ω)=4.7V].

Figure 3 shows a diagram of the discrete output circuit of one

channel.

terminals) and the

sup

Optical

Isolation

Figure 3.

V

C

Discrete Output Circuit

V

sup

V

out

COM

Overcurrent Protection

Overcurrent protection circuitry on each output deactiva tes the

output if the current it sources to the V

level. This level is always at least 1 A. A slightly higher inrush

current that exists for a short time will not trigger the protection

circuitry. If the protectio n circuitry disables an output that would

otherwise be in the ON state, the status indicator for that channel is

still lit, but the output transistor is turned off.

FP-PWM-520 4 www.natinst.com

terminal exceeds a safe

out

Page 5

Detecting an Overcurrent Condition

To determine whether an overcurrent condition exists, complete

the following steps:

1. Use the FieldPoint Explorer to set the duty cycle to 100% for

the channel in question.

2. Measure the voltage between the V

and COM terminals for

out

that channel.

Under normal load conditions, the V

-to-COM voltage is

out

within 1 V of the supply voltage when the output is on

continuously. Any voltage more than 1 V less than the supply

voltage indicates an overcurrent condition. Typically, the

V

-to-COM voltage is nearly zero if the protection circuitry

out

is activated.

The overcurrent protection circuitry resets when the output

switches to the OFF state, when you disconnect field power from

the module, when you remove the FP-PWM-520 from its terminal

base, or when you turn off the network module. Unless you set the

output duty cycle to 0% or 100%, the output channel switches to

the OFF state once per output period during normal operation.

Remedying an Overcurrent Condition

To remedy an overcurrent condition, determine the cause of the

overcurrent condition and disconnect the load that is causing the

problem from the FP-PWM-520. The channel resets automatically

when the load is removed.

Alternatively, if completely removing the channel load is not

convenient, reset the channel in any of the following ways:

• Use the FieldPoint Explorer to set the duty cycle to any value

other than 100% and wait at least one output period for the

channel to reset.

• Use the FieldPoint Explorer to set the duty cycle to 0%.

The channel resets immediately.

• Disconnect the external power supply from the module.

• Remove the FP-PWM-520 from the terminal base.

• Turn off the network module that the FP-PWM-520 is

connected to.

Normal operation can resume after you correct the overcurrent

condition.

© National Instruments Corp. 5 FP-PWM-520

Page 6

Output Channel Operation

Each of the PWM output channels uses a period and a duty cycle

setting to determine when to switch its output to the ON or OFF

state.

The output period is the only configuration attribute for each

channel. You can set the period to any value between 1 ms (1 kHz)

and 65,535 ms (0.01525 Hz), in increments of 1 ms.

The output duty cycle is written as the data v alue for each channel.

Y ou can set the duty cycle to any percentage v alue between 0% and

100%, with 12-bit resolution (4,096 discrete duty-cycle settings).

Status Indicators

Figure 4 shows the module label and status indicators. To see

wiring diagrams for the input channels, remove the slide-in card.

Figure 4.

After you insert the module into a terminal base (and app ly power),

the green POWER indicator lights and the FP-PWM-520 informs

the network module of its presence. When the network module

recognizes the FP-PWM-520, it sends initial configuration

information to the FP-PWM-520. After receiving this initial

information, the green READY indicator lights and the

FP-PWM-520 is in its normal operating mode. In addition to the

green POWER and READY indicators, each channel has a

numbered, green, output state indicator that lights when the

channel is in the ON state.

FP-PWM-520 6 www.natinst.com

Status Indicators and Module Label

Page 7

Isolation and Safety Guidelines

Caution

Before you connect any circuits that may

contain hazardous voltages to the FP-PWM-520, read

the following information.

This section describes the isolation of the FP-PWM-520 and its

compliance with international safety standards. The outputs are

isolated from the backplane provided by the terminal base with an

optical isolation barrier designed and tested to provide protection

against fault voltages of up to 3,000 Vrms. In addition, the

FP-PWM-520 provides double insulation (compliant with UL and

IEC safety standards) for working common-mode voltages of

250 Vrms. Safety standards (such as those published by UL and

IEC) require the use of double insulation between hazardous

voltages and any human-accessible parts or circuits.

Never try to use any isolation product between human-accessible

parts (such as DIN rails or monitoring stations) and circuits that

may be at hazardous potentials under normal conditions, unless the

product is specifically designed for such an application, as is the

FP-PWM-520.

When you use a product like the FP-PWM-520 in applications with

hazardous potentials, follow these guidelines to make sure your

total system is safe:

• The safety isolation of the FP-PWM-520 is from input to

output, not between channels on the same module. If an y of the

channels on a module are wired at a hazardous potential, make

sure that all other devices or circuits connected to that mo dule

are properly insulated from human contact.

•Do not share the e xternal supply voltages (V, C, V

, and COM

sup

terminals on the terminal base) with other devices (including

other FieldPoint devices), unless those devices are isolated

from human contact.

• As with any hazardous voltage wiring, make sure that all

wiring and connections meet with applicable electrical codes

and common sense practices. Mount terminal bases in an area,

position, or cabinet that prevents accidental or unauthorized

access to wiring that carries hazardous voltages.

• The isolation of the FP-PWM-520 is certified as

double-insulated for normal operating voltages of 250 Vrms.

Do not use the FP-PWM-520 as the only isolating barrier

between human contact and working voltages of more than

250 Vrms.

© National Instruments Corp. 7 FP-PWM-520

Page 8

Specifications

The following specifications are typical for a range –40 to +70 °C,

unless otherwise noted.

Output

Number of channels..........................8

Output type .......................................24 VDC, sourcing

Supply voltage..................................5 VDC or 10 to 30 VDC,

user-provided

Output current...................................1 A, with built-in overcurrent

Output impedance.............................0.3 Ω

Pulse-width accuracy........................–1, +3 µs, any period and

Physical

Indicators ..........................................Green POWER and

Weight...............................................140 g (4.8 oz.)

Power Requirements

Power from network module............300 mW

protection circuitry,

8 A maximum for all

channels

duty cycle

READY indicators, 8 green

output state indicators

Environment

Operating temperature......................–40 to +70 °C

Storage temperature..........................–55 to +85 °C

Relative humidity..............................5% to 90%, non-condensing

CE Mark Compliance

This product meets applicable EU directive(s), as follows:

Safety isolation .................................EN 61010 (double insulation

FP-PWM-520 8 www.natinst.com

for 250 Vrms working

isolation, installation

category II)

Page 9

EMC directive

Immunity.................................... EN 50082-1:1994

Emissions ................................... EN 55011:1991 Group I

Class A at 10 m

Mechanical Dimensions

Figure 5 shows the mechanical dimensions of the FP-PWM-520

installed on a terminal base. Dimensions are given in inches

[millimeters].

4.22 [107.19]

4.31

[109.5]

3.60 [91.44]

Figure 5.

© National Instruments Corp. 9 FP-PWM-520

Mechanical Dimensions

Page 10

Loading...

Loading...