Page 1

ER-8/16

User Manual

An 8-Channel or 16-Channel SPDT Relay Accessory

for Data Acquisition Boards

December 1996 Edition

Part Number 371197A-01

© Copyright 1995, 1996 National Instruments Corporation.

All Rights Reserved.

Page 2

National Instruments Corporate Headquarters

6504 Bridge Point Parkway

Austin, TX 78730-5039

(512) 794-0100

Technical support fax: (800) 328-2203

(512) 794-5678

Branch Offices:

Australia 03 9879 5166, Austria 0662 45 79 90 0, Belgium 02 757 00 20, Canada (Ontario) 905 785 0085,

Canada (Québec) 514 694 8521, Denmark 45 76 26 00, Finland 09 527 2321, France 01 48 14 24 24,

Germany 089 741 31 30, Hong Kong 2645 3186, Israel 03 5734815, Italy 02 413091, Japan 03 5472 2970,

Korea 02 596 7456, Mexico 5 520 2635, Netherlands 0348 433466, Norway 32 84 84 00, Singapore 2265886,

Spain 91 640 0085, Sweden 08 730 49 70, Switzerland 056 200 51 51, Taiwan 02 377 1200, U.K. 01635 523545

Page 3

Limited Warranty

The ER-8 or ER-16 is warranted against defects in materials and workmanship for a period of one year from the date

of shipment, as evidenced by receipts or other documentation. National Instruments will, at its option, repair or

replace equipment that proves to be defective during the warranty period. This warranty includes parts and labor.

The media on which you receive National Instruments software are warranted not to fail to execute programming

instructions, due to defects in materials and workmanship, for a period of 90 days from date of shipment, as

evidenced by receipts or other documentation. National Instruments will, at its option, repair or replace software

media that do not execute programming instructions if National Instruments receives notice of such defects during

the warranty period. National Instruments does not warrant that the operation of the software shall be uninterrupted

or error free.

A Return Material Authorization (RMA) number must be obtained from the factory and clearly marked on the

outside of the package before any equipment will be accepted for warranty work. National Instruments will pay the

shipping costs of returning to the owner parts which are covered by warranty.

National Instruments believes that the information in this manual is accurate. The document has been carefully

reviewed for technical accuracy. In the event that technical or typographical errors exist, National Instruments

reserves the right to make changes to subsequent editions of this document without prior notice to holders of this

edition. The reader should consult National Instruments if errors are suspected. In no event shall National

Instruments be liable for any damages arising out of or related to this document or the information contained in it.

EXCEPT AS SPECIFIED HEREIN, NATIONAL INSTRUMENTS MAKES NO WARRANTIES, EXPRESS OR IMPLIED,

AND SPECIFICALLY DISCLAIMS ANY WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE

OF

NATIONAL INSTRUMENTS WILL NOT BE LIABLE FOR DAMAGES RESULTING FROM LOSS OF DATA, PROFITS,

USE OF PRODUCTS, OR INCIDENTAL OR CONSEQUENTIAL DAMAGES, EVEN IF ADVISED OF THE POSSIBILITY

THEREOF

whether in contract or tort, including negligence. Any action against National Instruments must be brought within

one year after the cause of action accrues. National Instruments shall not be liable for any delay in performance due

to causes beyond its reasonable control. The warranty provided herein does not cover damages, defects,

malfunctions, or service failures caused by owner’s failure to follow the National Instruments installation, operation,

or maintenance instructions; owner’s modification of the product; owner’s abuse, misuse, or negligent acts; and

power failure or surges, fire, flood, accident, actions of third parties, or other events outside reasonable control.

. CUSTOMER’S RIGHT TO RECOVER DAMAGES CAUSED BY FAULT OR NEGLIGENCE ON THE PART

NATIONAL INSTRUMENTS SHALL BE LIMITED TO THE AMOUNT THERETOFORE PAID BY THE CUSTOMER.

. This limitation of the liability of National Instruments will apply regardless of the form of action,

Copyright

Under the copyright laws, this publication may not be reproduced or transmitted in any form, electronic or

mechanical, including photocopying, recording, storing in an information retrieval system, or translating, in whole or

in part, without the prior written consent of National Instruments Corporation.

Trademarks

LabVIEW

®

, NI-DAQ

Corporation.

Product and company names listed are trademarks or trade names of their respective companies.

®

, DAQCard

TM

DAQPad

,

TM

, and SCXI

TM

are trademarks of National Instruments

Page 4

WARNING REGARDING MEDICAL AND CLINICAL USE

OF NATIONAL INSTRUMENTS PRODUCTS

National Instruments products are not designed with components and testing intended to ensure a level of reliability

suitable for use in treatment and diagnosis of humans. Applications of National Instruments products involving

medical or clinical treatment can create a potential for accidental injury caused by product failure, or by errors on the

part of the user or application designer. Any use or application of National Instruments products for or involving

medical or clinical treatment must be performed by properly trained and qualified medical personnel, and all

traditional medical safeguards, equipment, and procedures that are appropriate in the particular situation to prevent

serious injury or death should always continue to be used when National Instruments products are being used.

National Instruments products are NOT intended to be a substitute for any form of established process, procedure, or

equipment used to monitor or safeguard human health and safety in medical or clinical treatment.

Page 5

Contents

About This Manual

Organization of This Manual.........................................................................................ix

Conventions Used in This Manual.................................................................................x

National Instruments Documentation ............................................................................xi

Customer Communication .............................................................................................xii

Chapter 1

Introduction

About the ER-8/16.........................................................................................................1-1

What You Need to Get Started ......................................................................................1-1

Optional Equipment.......................................................................................................1-2

Software .........................................................................................................................1-2

Unpacking......................................................................................................................1-2

..........................................................................................................................1-1

Chapter 2

Setup

........................................................................................................................................2-1

Safety Information .........................................................................................................2-4

Connecting the ER-8/16 to Your DAQ Device .............................................................2-5

Chapter 3

Signal Connections

Front Connectors............................................................................................................3-1

Using DIO-24 Devices.......................................................................................3-1

Using DIO-32 Boards ........................................................................................3-2

Power Supply.................................................................................................................3-2

Channel Connections .....................................................................................................3-3

Power-up Conditions..........................................................................................3-4

Wire Gauge ........................................................................................................3-4

Channel Isolation ...............................................................................................3-4

Contact Protection for Inductive Loads .............................................................3-4

Connecting Your Signal Lines.......................................................................................3-6

Internal Connectors........................................................................................................3-7

Daisy Chaining the ER-8/16..............................................................................3-8

Using the SC-205X Series with the ER-8......................................................................3-8

DAQ System Configurations with the ER-8/16.............................................................3-9

............................................................................................................ix

.............................................................................................................3-1

Chapter 4

Theory of Operation

Functional Overview......................................................................................................4-1

Digital Interface .............................................................................................................4-3

Relay Channels ..............................................................................................................4-3

© National Instruments Corporation v ER-8/16 User Manual

..........................................................................................................4-1

Page 6

Contents

Appendix A

Specifications

........................................................................................................................A-1

Appendix B

I/O Connectors

.....................................................................................................................B-1

Appendix C

Contact Protection

..............................................................................................................C-1

Appendix D

Takamisawa VE Series Relay Technical Data

.........................................................D-1

Appendix E

Customer Communication

...............................................................................................E-1

Glossary...................................................................................................................... Glossary-1

Index..................................................................................................................................Index-1

ER-8/16 User Manual vi © National Instruments Corporation

Page 7

Contents

Figures

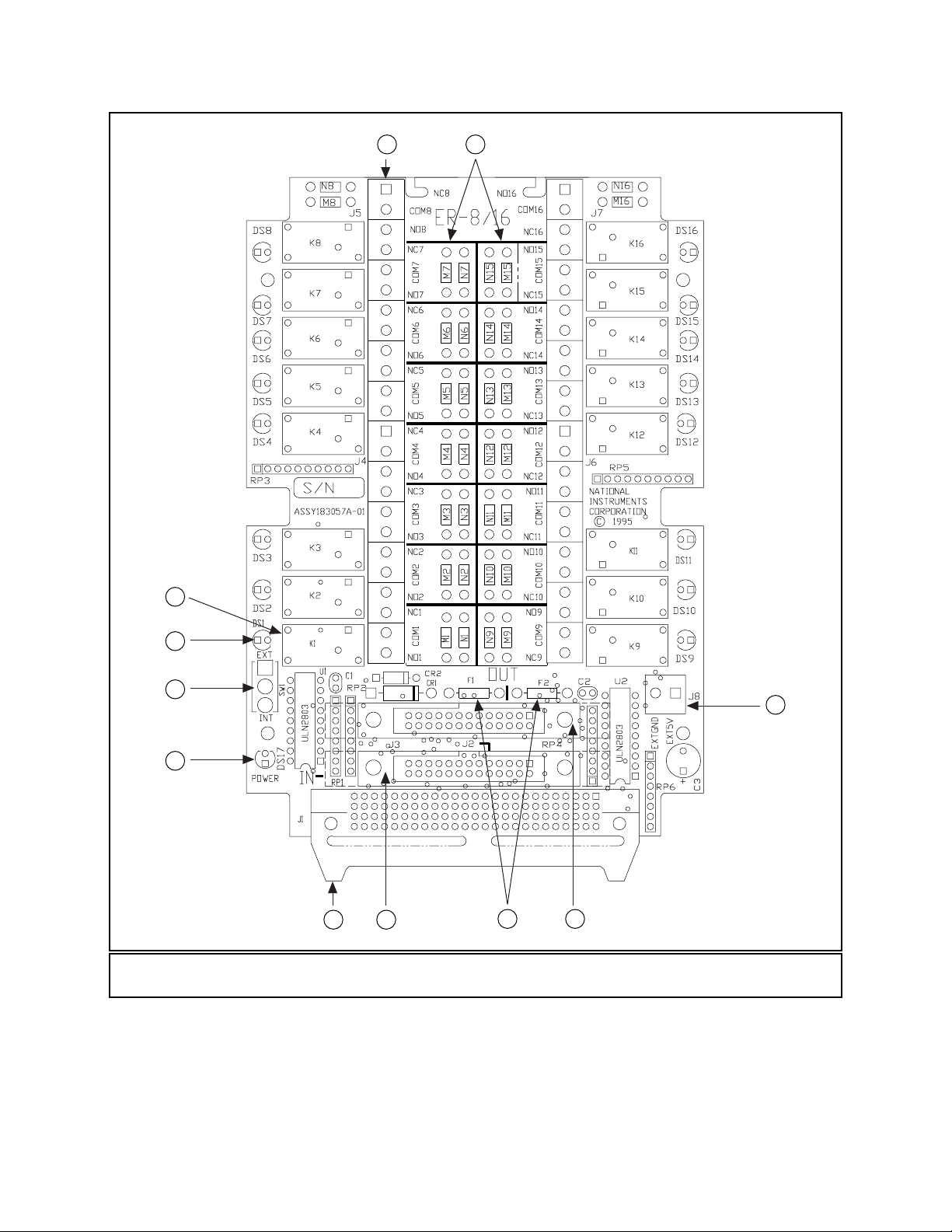

Figure 2-1. ER-8/16 Parts Locator Diagram.........................................................................2-2

Figure 2-2. The ER-8/16 Front Connector............................................................................2-7

Figure 3-1. Contact Protection Using a Flyback Diode for DC Loads.................................3-5

Figure 3-2. Arc Suppressor Pad Locations for Channel 1....................................................3-6

Figure 3-3. ER-8/16 Configurations with DIO Devices.......................................................3-9

Figure 3-4. ER-8/16 Configurations with Multifunction DAQ Devices ..............................3-10

Figure 4-1. ER-8/16 Block Diagram.....................................................................................4-2

Figure 4-2. ER-8/16 Onboard Equivalent Circuit.................................................................4-3

Figure B-1. The DIO-24 Connector ......................................................................................B-1

Figure B-2. The DIO-32 Connector ......................................................................................B-3

Figure B-3. 26-Pin Internal Connectors ................................................................................B-5

Tables

Table 2-1. Parts Locator Diagram Descriptions..................................................................2-3

Table 3-1. Arc Suppressor Placement, COM to NO...........................................................3-5

Table 3-2. Arc Suppressor Placement, COM to NC ...........................................................3-6

Table B-1. DIO-24 Connector Pin Descriptions..................................................................B-2

Table B-2. DIO-32 Connector Pin Descriptions..................................................................B-4

Table B-3. 26-Pin IN Connector Pin Descriptions...............................................................B-5

Table B-4. 26-Pin OUT Connector Pin Descriptions...........................................................B-6

© National Instruments Corporation vii ER-8/16 User Manual

Page 8

About This Manual

This manual describes the electrical and mechanical aspects of the ER-8 and ER-16 and contains

information concerning their setup, operation, and safety. Both the ER-8 and ER-16 are singlepole double-throw (SPDT) relay accessories for use with other data acquisition (DAQ) products.

The ER-8 has eight channels; the ER-16 has 16 channels.

Throughout this manual, ER-8/16 refers to either the ER-8 or ER-16, unless otherwise noted.

The ER-8/16 interfaces to any National Instruments DAQ device with digital I/O capabilities for

the Macintosh and PC/XT/AT (AT Series, Lab) computers. More specifically, the National

Instruments product families that interface with the ER-8/16 are the DIO-24, DIO-32, Lab,

E Series, MIO, DAQCards, and 1200 Series devices.

This accessory is designed for low-cost control applications in laboratory testing, production

testing, and industrial process monitoring and control.

Organization of This Manual

The ER-8/16 User Manual is organized as follows:

• Chapter 1, Introduction, describes the ER-8/16; lists what you need to get started and

optional equipment; describes software support; and explains how to unpack the ER-8/16.

• Chapter 2, Setup, describes how to set up the ER-8/16.

• Chapter 3, Signal Connections, describes the signal connections, channel connections, and

digital interface to the ER-8/16.

• Chapter 4, Theory of Operation, contains a functional overview of the ER-8/16 and explains

the operation of each functional unit making up the ER-8/16.

• Appendix A, Specifications, lists the specifications of the ER-8/16.

• Appendix B, I/O Connectors, contains the connector pinouts and pin descriptions for the

ER-8/16.

• Appendix C, Contact Protection, contains technical data on contact protection when you are

switching inductive loads.

• Appendix D, Takamisawa VE Series Relay Technical Data, contains a manufacturer data

sheet for the relay used on the ER-8/16.

• Appendix E, Customer Communication, contains forms you can use to request help from

National Instruments or to comment on our products.

• The Glossary contains an alphabetical list and description of terms used in this manual,

including abbreviations, acronyms, metric prefixes, mnemonics, symbols, and terms.

© National Instruments Corporation ix ER-8/16 User Manual

Page 9

About This Manual

• The Index contains an alphabetical list of key terms and topics used in this manual, including

the page where each one can be found.

Conventions Used in This Manual

The following conventions are used in this manual:

bold Bold text denotes menu items, function panel items, and dialog box

buttons or options.

italic Italic text denotes emphasis, a cross reference, or an introduction to a

key concept.

bold italic Bold italic text denotes a note, caution, or warning.

< > Angle brackets containing numbers separated by an ellipsis represent a

range of values associated with a bit, signal name, or port (for example,

ACH<0..7> stands for ACH0 through ACH7).

device Device refers generically to National Instruments boards, cards, or

modules.

ER-8/16 ER-8/16 refers to the ER-8 or ER-16 unless otherwise noted.

DIO device DIO device refers to National Instruments digital I/O devices such as the

AT-DIO-32F, NB-DIO-24, NB-DIO-96, NB-DIO-32F, PC-DIO-24,

DAQCard-DIO-24, and PC-DIO-96, unless otherwise noted.

DIO-24 device DIO-24 device refers to the National Instruments NB-DIO-24,

DAQCard-DIO-24, and PC-DIO-24 digital I/O devices unless otherwise

noted.

DIO-32 board DIO-32 board refers to the National Instruments AT-DIO-32F and

NB-DIO-32F digital I/O boards unless otherwise noted.

DIO-type board DIO-type board refers to the National Instruments DIO boards with only

digital I/O capabilities. These boards include the DIO-24, DIO-32F, and

DIO-96 boards unless otherwise noted.

Lab board Lab board refers to the National Instruments Lab-LC, Lab-NB, Lab-PC,

and Lab-PC+ boards unless otherwise noted.

E Series device E Series device refers to National Instruments digital I/O devices such as

the AT-MIO-16E-2, AT-MIO-64E-3, AT-MIO-16E-10,

AT-MIO-16DE-10, AT-MIO-16XE-50, NEC-MIO-16E-4, and

NEC-AI-16XE-50, unless otherwise noted.

MIO board MIO board refers to National Instruments boards such as the

AT-MIO-16F-5, AT-MIO-16D, AT-MIO-64F-5, AT-MIO-16, and

AT-MIO-16X unless otherwise noted.

ER-8/16 User Manual x © National Instruments Corporation

Page 10

About this Manual

DAQCard DAQCard refers to National Instruments cards such as the

DAQCard-500 and DAQCard-700 unless otherwise noted.

1200 Series 1200 Series refers to the National Instruments DAQPad-1200 and

DAQCard-1200 unless otherwise noted.

NB NB refers to the NuBus Series computers.

NI-DAQ NI-DAQ is used in this manual to refer to the NI-DAQ software for

Macintosh and PC compatibles unless otherwise noted.

Macintosh Macintosh refers to all Macintosh II, Macintosh Quadra, and Macintosh

Centris computers except the Centris 610 unless otherwise noted.

PC PC refers to PC/XT/AT and IBM PS/2, models 25 and 30, computers.

Port A Port A is used in this manual to refer to port A or port 0 (as in your

NI-DAQ manuals).

Port B Port B is used in this manual to refer to port B or port 1 (as in your

NI-DAQ manuals).

Port C Port C is used in this manual to refer to port C or port 2 (as in your

NI-DAQ manuals).

Port D Port D is used in this manual to refer to port D or port 3 (as in your

NI-DAQ manuals).

Abbreviations, acronyms, metric prefixes, mnemonics, symbols, and terms are listed in the

Glossary.

National Instruments Documentation

The ER-8/16 User Manual is one piece of the documentation set for your DAQ system. You

could have any of several types of manuals, depending on the hardware and software in your

system. Use the different types of manuals you have as follows:

• Your DAQ hardware user manuals—These manuals have detailed information about the

DAQ hardware that plugs into or is connected to your computer. Use these manuals for

hardware installation and configuration instructions, specification information about your

DAQ hardware, and application hints.

• Software manuals—Examples of software manuals you may have are the LabVIEW and

LabWindows/CVI manual sets and the NI-DAQ manuals. After you set up your hardware

system, use either the application software (LabVIEW or LabWindows/CVI) manuals or the

NI-DAQ manuals to help you write your application. If you have a large and complicated

system, it is worthwhile to look through the software manuals before you configure your

hardware.

© National Instruments Corporation xi ER-8/16 User Manual

Page 11

About This Manual

• Accessory installation guides or manuals—If you are using accessory products, read the

terminal block and cable assembly installation guides or accessory device user manuals.

They explain how to physically connect the relevant pieces of the system. Consult these

guides when you are making your connections.

Customer Communication

National Instruments wants to receive your comments on our products and manuals. We are

interested in the applications you develop with our products, and we want to help if you have

problems with them. To make it easy for you to contact us, this manual contains comment and

configuration forms for you to complete. These forms are in Appendix E, Customer

Communication, at the end of this manual.

ER-8/16 User Manual xii © National Instruments Corporation

Page 12

Chapter 1 Introduction

This chapter describes the ER-8/16; lists what you need to get started and optional equipment;

describes software support; and explains how to unpack the ER-8/16.

About the ER-8/16

Thank you for buying the National Instruments ER-8/16. The ER-8 consists of eight isolated

single-pole double-throw (SPDT) or form C relay channels. The ER-16 consists of 16 isolated

SPDT or form C relay channels. The ER-8/16 can serve as a controller or switcher in laboratory

testing, production testing, and industrial-process monitoring and control applications. The

ER-8/16 operates with full functionality with most National Instruments digital I/O products. It

also interfaces with the Lab and MIO boards using the SC-205X Series cable adapters. The

ER-8/16 has onboard screw terminals for easy wire attachment. You can also build a 32-channel

ER system by daisy-chaining two ER-16s.

Detailed ER-8/16 specifications are in Appendix A, Specifications.

What You Need to Get Started

To set up and use your ER-8/16, you will need the following:

ER-8 or ER-16

ER-8/16 User Manual

Your DIO-24, DIO-32, Lab, E Series, MIO, DAQCard, or 1200 Series device and

documentation

SC-205X Series cable adapter if you are using a Lab or MIO board

Interface cable (different for DIO-24 and DIO-32 devices, DAQCards, and SC-205X Series

adapters)

Your computer

© National Instruments Corporation 1-1 ER-8/16 User Manual

Page 13

Introduction Chapter 1

Optional Equipment

You can use the following National Instruments products with your ER-8/16.

• Any National Instruments DAQ device with digital I/O capability

• SC-2050 cable adapter with NB1 cable

• SC-2051 cable adapter with NB1 cable

• SC-2052 cable adapter with NB1 cable

• SC-2053 cable adapter with NB1 cable

• SC-2054 48-channel kit with NB5 cable

• SC-2054 96-channel kit with NB5 cable

• SC-2055 cable adapter with NB1 cable

• NB7 cable assembly

• SH6850 shielded cable

• R6850 ribbon cable

• R1005050 ribbon cable

• Type NB5 cable

For more information about optional equipment available from National Instruments, refer to

your National Instruments catalog or call the office nearest you.

Refer to Chapter 3, Signal Connections, for additional information on cabling, connectors, and

adapters.

Software

The ER-8/16 requires no additional software beyond what you are using for your DAQ device.

Unpacking

Your ER-8/16 is shipped in an antistatic package to prevent electrostatic damage to the unit.

Electrostatic discharge can damage several components on the ER-8/16. To avoid such damage

in handling the unit, take the following precautions:

• Ground yourself via a grounding strap or by holding a grounded object.

• Touch the antistatic package to a metal part of your computer chassis before removing the

ER-8/16 from the package.

• Remove the unit from the package and inspect it for loose components or any other sign of

damage. Notify National Instruments if the ER-8/16 appears damaged in any way. Do not

install a damaged unit.

• Never touch the exposed pins of connectors.

ER-8/16 User Manual 1-2 © National Instruments Corporation

Page 14

Chapter 2 Setup

This chapter describes how to set up the ER-8/16.

The ER-8 has eight SPDT relays controlled by eight digital lines. Each of these relays has a

normally closed (NC) contact that connects to the common (COM) contact when the

corresponding digital output line is low, and a normally open (NO) contact that connects to the

COM contact when the digital line is high. The contacts are break-before-make so that all three

contacts are never shorted.

The ER-8/16 is an accessory to National Instruments DAQ devices with digital I/O. No

hardware or software configuration is necessary. To configure the DAQ device driving the

ER-8/16, refer to your DAQ hardware user manual.

Figure 2-1 shows the parts locator diagram for the ER-8/16. See Table 2-1 for detailed

descriptions of the parts called out on the parts locator diagram.

© National Instruments Corporation 2-1 ER-8/16 User Manual

Page 15

Setup Chapter 2

5 6

4

3

2

7

1

11 10

1 Power LED 4 Channel 1 Relay 7 J8—EXT power supply conn. 10 J2—26-pin IN conn.

2 SW1—power supply switch 5 Screw Terminals 8 J3—26-pin OUT conn. 11 J1—DIO-24 and

3 Channel 1 LED 6 Surge Protector Pads 9 Fuses DIO-32 conn.

89

Figure 2-1. ER-8/16 Parts Locator Diagram

ER-8/16 User Manual 2-2 © National Instruments Corporation

Page 16

Chapter 2 Setup

Table 2-1. Parts Locator Diagram Descriptions

Callout Name Description

1 Power LED When illuminated red, this LED indicates that the ER-8/16

is receiving power.

2 SW1 This is the main +5 V power supply switch for selecting

external or internal supply. Move the switch to EXT if

using external supply and to INT if using internal (driving

device or ER-16) supply. By default, your ER-8/16 is

shipped with SW1 in the EXT position.

3 Channel 1 LED These DS<1..16> LEDs are illuminated green when the NO

contact is shorted to the COM contact for the respective

channel. Otherwise the LED is shut off.

4 Channel 1 Relay These K<1..16> relays are controlled digitally on the

ER-8/16.

5 Screw Terminals The NC<1..16> screw terminals are for the NC contact for

channels 1 through 16.

The NO<1..16> screw terminals are for the NO contact for

channels 1 through 16.

The COM<1..16> screw terminals are for the COM contact

for the channels 1 through 16.

6 Surge Protector Pads The M<1..16> pads across NC and COM contacts are for

protecting the relay contacts from inductive loads. A

resistor and capacitor combination can be placed across

these pads to suppress sparking on the relay contacts due to

inductive loads.

The N<1..16> pads across NO and COM contacts are for

protecting the relay contacts from inductive loads. A

resistor and capacitor combination can be placed across

these pads to suppress sparking on the relay contacts due to

inductive loads.

7 J8 This external power-supply connector, EXT +5 V, is for

external +5 V supply. EXT GND is the reference for the

external +5 V supply, and is connected to the ER-8/16

ground.

8 J3 This 26-pin OUT connector sends the 26-pin daisy-chain

cable to the ER-8 or the ER-16.

9 Fuses F1 and F2 are socketed power supply fuses. You may

replace these fuses if they are blown. The fuse is

LIT-PICOII, 2 A, 125 V, fast.

10 J2 This 26-pin IN connector receives the 26-pin daisy-chain

cable from the ER-16 or SC-205X cable adapter.

11 J1 This 50-pin dual connector has the top connector for DIO-32

boards, and the bottom connector for DIO-24 devices.

© National Instruments Corporation 2-3 ER-8/16 User Manual

Page 17

Setup Chapter 2

Safety Information

The following warnings contain important safety information concerning hazardous voltages.

!

Warning: Connections that exceed any of the maximum input signal ratings on the

ER-8/16 can create a shock or a fire hazard, or damage the ER-8/16, your

computer, and the DAQ device. Maximum input ratings for each signal are

given in Appendix A, Specifications. National Instruments is

any damages resulting from signal connections that exceed any of these

ratings.

Do not operate your ER-8/16 in an explosive atmosphere or where there may

be flammable gases or fumes.

K

EEP AWAY FROM LIVE CIRCUITS. DO NOT REMOVE THE TOP COVER of the

ER-8/16 when it is operating or is powered on. If signal wires are connected

to the unit, dangerous voltages may exist even when the equipment is turned

off. To avoid dangerous electrical shock, do not perform procedures

involving cover removal unless you are qualified to do so. Before removing

the cover make sure that the computer and the power supply are turned off

and that the signal wires connected to the screw terminals do not contain live

voltages.

NOT liable for

D

O NOT OPERATE DAMAGED EQUIPMENT. The safety protection features built

into your ER-8/16 can become impaired if it is damaged in any way. If

necessary, return the unit to National Instruments for service and repair to

ensure that safety is not compromised.

D

O NOT SUBSTITUTE PARTS OR MODIFY EQUIPMENT. To avoid introducing

additional hazards, do not install unauthorized parts or modify your ER-8/16.

If necessary, return the unit to National Instruments for service and repair to

ensure that safety is not compromised.

When using the unit with high common mode voltages, you must insulate

your signal wires appropriately. National Instruments is

NOT liable for any

damages or injuries resulting from inadequate signal wire insulation.

When connecting or disconnecting signal lines to the ER-8/16 screw terminal,

verify that the lines are powered off. Potential differences between the lines

and the ER-8/16 ground create a shock hazard while you connect the lines.

Connections, including power signals to ground and vice versa, that exceed

any of the maximum signal ratings on the ER-8/16 can create a shock or a

fire hazard, or can damage any or all of the devices connected to the ER-8/16,

the host computer, and the ER-8/16. National Instruments is

NOT liable for

any damages or injuries resulting from incorrect signal connections.

ER-8/16 User Manual 2-4 © National Instruments Corporation

Page 18

Chapter 2 Setup

Use and connect to only one of the following connectors when operating the

ER-8/16: the DIO-24, DIO-32, or IN connector. National Instruments is

NOT

liable for any damages resulting from incorrect connections.

Equipment described in this document must be used in an Installation

Category II environment per IEC 664. This category requires local level

supply mains-connected installation.

Do not operate this equipment in a manner that contradicts the information

specified in this document. Misuse of this equipment could result in a shock

hazard.

Terminals are for use only with equipment that has no accessible live parts.

Use only 26-16 AWG wire with a voltage rating of 300 V and 60° C for

controlling 250 V. Prepare your signal wire by stripping the insulation no

more than 7 mm.

Connect the signal wires to the screw terminals by inserting the stripped end

of the wire fully into the terminals. Tighten the terminals to a torque of 57 in.-lb.

Clean devices and terminal blocks by brushing off light dust with a soft,

nonmetallic brush. Remove other contaminants with deionized water and a

stiff nonmetallic brush. The unit must be completely dry and free from

contaminants before returning to service.

Connecting the ER-8/16 to Your DAQ Device

The following are general instructions for setting up your ER-8/16. Consult your computer user

manual or technical reference manual for specific instructions and warnings.

Warning: Connections that exceed any of the maximum rating of the input signals on the

ER-8/16 can damage the ER-8/16, your computer, and the DAQ device.

Maximum input ratings for each signal are given in Appendix A, Specifications.

National Instruments is

connections that exceed any of these ratings.

1. Turn off the host computer power before making any connections.

Warning: Keep away from live circuits.

ER-8/16 when it is operating or is powered on. If signal wires are

connected to the unit, dangerous voltages may exist even when the

equipment is turned off. To avoid dangerous electrical shock, do not

perform procedures involving cover removal unless you are qualified to do

so. Before removing the cover make sure that the computer and the power

supply are turned off and that the signal wires connected to the screw

terminals do not contain live voltages.

NOT liable for any damages resulting from signal

DO NOT REMOVE THE TOP COVER of the

© National Instruments Corporation 2-5 ER-8/16 User Manual

Page 19

Setup Chapter 2

2. Remove the top cover of your ER-8/16 by removing the four screws located on the bottom

of your unit.

3. Connect the 50-pin interfacing cable to the appropriate 50-pin connector located on the

front end of the ER-8/16 as shown in Figure 2-2.

• If you are connecting a DIO-24 device to the ER-8/16, use the DIO-24 50-pin

connector. This is the bottom connector.

• If you are connecting a DIO-32 board to the ER-8/16, use the DIO-32 50-pin connector.

This is the top connector.

Warning: Connecting the cable to the wrong connector can damage the ER-8/16 or

your DAQ device. National Instruments is

NOT liable for any damages

resulting from such connections.

Only one of the following connectors should be used and connected when

operating the ER-8/16: the DIO-24, DIO-32, or IN connector. National

Instruments is

NOT liable for any damages resulting from any other

connections.

• If you are daisy chaining the ER-8/16 or using the SC-205X Series cable adapter,

connect the 26-pin cable to the correct 26-pin connector, either IN or OUT. For

additional information on signal connections and cabling refer to Chapter 3, Signal

Connections.

4. Switch the +5 V power supply switch (SW1) to the correct position, either INT or EXT.

The switch position depends on the number of channels and the type of DAQ device you

are using with the ER-8/16. Set the switch to INT if you are using your DAQ device’s

internal +5 V supply. Set the switch to EXT if you are using an external +5 supply. For

additional information on power supply connections, refer to the Power Supply section in

Chapter 3, Signal Connections.

Note: By default, your ER-8/16 is shipped with SW1 set to the EXT position.

5. Verify the connections and setup.

6. Turn on the external power supply, if necessary, then turn on your computer. The red

Power LED should light up indicating that the ER-8/16 is receiving power. If the red

Power LED does not light up, verify that the power supply connections and electrical

power supply are switched ON. If the connections and external power supply are working,

check the electrical continuity on fuses F1 and F2. If the continuity test fails on these

fuses, a fuse is blown. You can either replace the fuse yourself or send it to National

Instruments for replacement.

Note: The fuses are socketed. If you choose to replace them yourself, the fuse

specification is LIT-PICOII, 2 A, 125 V, fast. The manufacturer is Littelfuse,

and the manufacturer part number is R251002T1.

ER-8/16 User Manual 2-6 © National Instruments Corporation

Page 20

Chapter 2 Setup

7. You can now test your ER-8/16 without making any connections to the screw terminals by

writing to port A (0). When you write a digital 1 to port A (0), the DS1 LED should turn

green, indicating it is ON. You may also hear a clicking sound. Port A (0) corresponds to

channel 1 on the ER-8/16. Use this procedure to test all the channels on your ER-8/16.

Note: LEDs are present only for verifying your digital cable connections.

Warning:

DO NOT connect any wires to the channel screw terminals when you are

conducting this test. National Instruments is

NOT liable for any damages

resulting from such connections.

If the ER-8/16 does not respond to the control signals, check your cable connections and

try again. If the test fails again, contact National Instruments.

8. Switch off your computer and the external power supply. Make wire connections to the

ER-8/16 channels by wiring to the proper screw terminals, marked NC, COM, and NO.

For additional information, refer to the Channel Connections section in Chapter 3, Signal

Connections.

9. When you have connected the wires, check the connections again.

10. Replace the top cover and screw it on tightly.

11. Turn on your computer and the external power supply.

Your ER-8/16 is now ready for operation.

TOP: DIO-32

BOTTOM: DIO-24

Figure 2-2. The ER-8/16 Front Connector

© National Instruments Corporation 2-7 ER-8/16 User Manual

Page 21

Chapter 3 Signal Connections

This chapter describes the signal connections, channel connections, and digital interface to the

ER-8/16.

Front Connectors

This section describes the signal connections to the ER-8/16 via the I/O connectors for the digital

interface.

Warning: Connections that exceed any of the maximum ratings of the input signals on the

ER-8/16 can damage the ER-8/16, your computer, and the DAQ device.

Maximum input ratings for each signal are given in Appendix A, Specifications.

National Instruments is

connections that exceed any of these ratings.

Turn off signal sources before connecting or disconnecting any additional signal.

NOT liable for any damages resulting from signal

DO NOT attempt to connect your ER-8/16 to any connector for which it is not

designed. Incorrect connection can damage your ER-8/16 or the host computer.

National Instruments is

connections.

The front end of the ER-8/16 has two 50-pin connectors. The top connector, DIO-32, is for

interfacing to DIO-32 boards, and the bottom connector, DIO-24, is for interfacing to DIO-24

devices.

Warning: Use only one connector, either the DIO-24 or the DIO-32 connector.

connect cables to both connectors.

Connecting the cable to the wrong connector can damage the ER-8/16 or your

DAQ device. National Instruments is NOT liable for any damages resulting from

such connections.

NOT liable for any damages resulting from incorrect

DO NOT

Using DIO-24 Devices

If you are using a National Instruments DIO-24 device to control the ER-8/16, connect the cable

to the DIO-24 connector.

© National Instruments Corporation 3-1 ER-8/16 User Manual

Page 22

Signal Connections Chapter 3

You can control a maximum of 24 channels using this connector, one ER-16, and one ER-8.

Daisy chain the ER-8 to the ER-16 using the NB7 cable.

The ER-8 uses port A<0..7> to control channels 1 through 8. Port C<0..7> wraps back to the

26-pin OUT connector.

The ER-16 uses port A<0..7> to control channels 1 through 8 and port B<0..7> to control

channels 9 through 16. Port C<0..7> wraps back to the 26-pin OUT connector. For additional

information on daisy chaining, refer to the Daisy Chaining the ER-8/16 section later in this

chapter.

Using DIO-32 Boards

If you are using a National Instruments DIO-32 board to control the ER-8/16, connect the cable

to the DIO-32 connector.

Note: You will need an external +5 V power supply if you use this connector.

Warning: Connecting the cable to the wrong connector can damage the ER-8/16 or your

DAQ device. National Instruments is NOT liable for any damages resulting from

such connections.

You can control a maximum of 32 channels using the DIO-32 connector and two ER-16s. Daisy

chain one ER-16 to the other ER-16 using the NB7 cable.

The ER-16 uses port A<0..7> to control channels 1 through 8 and port B<0..7> to control

channels 9 through 16. Port C<0..7> and port D<0..7> wrap back to the 26-pin OUT connector.

For additional information on daisy chaining refer to the Daisy Chaining the ER-8/16 section

later in this chapter.

Power Supply

You can use either your DAQ device’s internal +5 V supply or an external +5 V supply to power

up your ER-8/16. If you use an external +5 V supply, use the two screw terminals to connect

external +5 V and GND. Refer to Figure 2-1 in Chapter 2, Setup, for the location of this screw

terminal on the ER-8/16.

Warning: Connections that exceed any of the input signal maximum ratings on the ER-8/16

can damage the ER-8/16, your computer, and the DAQ device. Maximum input

ratings for each signal are given in Appendix A, Specifications. National

Instruments is

exceed any of these ratings.

NOT liable for any damages resulting from signal connections that

ER-8/16 User Manual 3-2 © National Instruments Corporation

Page 23

Chapter 3 Signal Connections

Current requirements for the ER-8/16 are as follows:

Channels Current (Amps)

8 0.5 A

16 1.0 A

24 1.5 A

32 2.0 A

If you use its internal +5 V supply setting, make sure your device can supply the required amount

of +5 V power to the ER-8/16.

Note: DIO-32F boards do not provide internal +5 V supply. You will need an external +5 V

supply for DIO-32F boards.

DAQCard-DIO-24 and other DAQCards can provide a maximum of 500 mA of

current. You can drive only one ER-8 with the internal supply. You will need an

external +5 V supply for driving more than eight channels.

In addition to the above note, refer to Figures 3-3 and 3-4 for information on configurations that

require an external +5 V supply.

When you connect more than one ER-8 with any of the SC-205X Series cable adapters, you will

need an external +5 V power supply.

Warning: Connecting the cable to the wrong connector can damage the ER-8/16 or your

DAQ device. National Instruments is

NOT liable for any damages resulting from

such connections.

Use and connect only one of the following connectors when operating the

ER-8/16: the DIO-24, DIO-32, or IN connector. National Instruments is

NOT

liable for any damages resulting from incorrect connections.

If you use your DAQ device’s internal +5 V supply, make sure that the power supply switch

(SW1) is set to the INT position. If you are using an external +5 V supply, make sure that SW1

is set to the EXT position. Refer to Figure 2-1 for the location of the SW1 switch.

Note: By default, your ER-8/16 is shipped with SW1 set to the EXT position.

Channel Connections

The ER-8/16 has 26 screw terminals. Twenty-four of these screw terminals are for connecting

the loads to the relay channels and two screw terminals are for providing the external +5 V

supply to the unit. Each channel consists of a COM position, an NC position, and an NO

position.

© National Instruments Corporation 3-3 ER-8/16 User Manual

Page 24

Signal Connections Chapter 3

Power-up Conditions

When the digital interface cable is not connected to either connector, the COM contact is

connected to the relay NC contact at power up.

When the digital interface cable is connected to any of the connectors, the power-up state

depends on the power-up state of the digital signals on the DAQ device. If the power-up state of

the digital lines driving the ER-8/16 is low, the COM contact is connected to the relay NC

contact. If the power-up state of the digital lines driving the ER-8/16 is high, the COM contact is

connected to the relay NO contact.

Wire Gauge

When using the ER-8, you can use up to 16 AWG gauge wire for all channels. If you are using

the ER-16 and all channels are in use, use 18 AWG gauge wire, maximum.

Warning: When using the ER-8/16 with high voltages, you must insulate your signal wires

appropriately. National Instruments is

resulting from inadequate signal wire insulation.

NOT liable for any damages or injuries

Make sure that your wires are properly insulated to avoid any short circuit to the

other channels, ground, or any other point on the printed wire board (PWB).

Channel Isolation

All contacts have a working voltage of 250 VAC or 30 VDC. This product complies with

IEC-1010 for Voltage Installation Category II Pollution Degree 2. Refer to the specifications

listed in Appendix A, Specifications, for further details before connecting the signals to the relay

contacts.

Contact Protection for Inductive Loads

When inductive loads are connected to the relays, a large counter-electromotive force can occur

at relay-switching time because of the energy stored in the inductive load. These flyback

voltages can severely damage the relay contacts and greatly reduce the relay life.

It is best to limit these flyback voltages at your inductive load by installing, across your

inductive load, a flyback diode for DC loads, as shown in Figure 3-1, or a metal oxide varistor

(MOV) for AC loads. Refer to the Diode Circuit and Varistor Circuit information in the table in

the Contact Protection Circuit section of Appendix C, Contact Protection, for more information.

If placing a diode or an MOV across the load is not possible, use arc suppressor pads on the

ER-8/16 to limit the voltage spike generated during the switching of the inductive loads. These

pads are between the COM position and the NO position, and between the COM position and the

ER-8/16 User Manual 3-4 © National Instruments Corporation

Page 25

Chapter 3 Signal Connections

NC position of the relays. Refer to the CR Circuit information in the table in the Contact

Protection Circuit section of Appendix C, Contact Protection, for more information.

To determine the placement of each arc suppressor, refer to Tables 3-1 and 3-2, which list the

channel and suppressor pad assignments.

+

Inductive

Load

Flyback Diode

NO

Relay

VDC

COM

V

-

NC

Figure 3-1. Contact Protection Using a Flyback Diode for DC Loads

Table 3-1. Arc Suppressor Placement, COM to NO

COM to NO

Channel Number

1N1

2N2

3N3

4N4

5N5

6N6

7N7

8N8

9N9

10 N10

11 N11

12 N12

13 N13

14 N14

15 N15

16 N16

Transient Voltage Suppressor

Reference Designator

© National Instruments Corporation 3-5 ER-8/16 User Manual

Page 26

Signal Connections Chapter 3

Table 3-2. Arc Suppressor Placement, COM to NC

COM to NC

Channel Number

Transient Voltage Suppressor

Reference Designator

1M1

2M2

3M3

4M4

5M5

6M6

7M7

8M8

9M9

10 M10

11 M11

12 M12

13 M13

14 M14

15 M15

16 M16

Figure 3-2 shows how to connect a transient voltage suppressor for AC and DC inductive loads.

NC1

Relay

r

c

r

c

M1

Arc Suppressor Pads

N1

Inductive

Load

COM1

NO1

Figure 3-2. Arc Suppressor Pad Locations for Channel 1

Connecting Your Signal Lines

To connect the signal wires to the screw terminals, perform the following steps:

1. Turn off your ER-8/16. Make sure the signal wires you are connecting to the screw terminals

are also turned off and do not contain any live voltages. Also make sure the host computer is

turned off.

ER-8/16 User Manual 3-6 © National Instruments Corporation

Page 27

Chapter 3 Signal Connections

Warning: KEEP AWAY FROM LIVE CIRCUITS. DO NOT REMOVE THE TOP COVER of the

ER-8/16 when it is operating or is powered on. If signal wires are connected to

the ER-8/16, dangerous voltages may exist even when the equipment is turned

off. To avoid dangerous electrical shock, do not perform procedures involving

cover removal unless you are qualified to do so. Before removing the cover make

sure that the computer and the power supply are turned off and that the signal

wires connected to the screw terminals do not contain live voltages.

2. Remove the ER-8/16 top cover by placing a screwdriver in the groove at the bottom of the

ER-8/16 and rotating the screwdriver.

3. Install the contact protection, preferably across the load, if your load is inductive. Refer to

the Contact Protection for Inductive Loads section earlier in this chapter. For additional

information refer to Appendix C, Contact Protection.

4. Connect the wires to the screw terminals.

5. Bundle the wires at the rear end of the ER-8/16 and use a tie-wrap to tie them together.

6. Replace the top cover so that the bundled wires fall within the smaller rectangular hole in the

top cover.

7. Tighten the top cover by fastening the screws to the bottom cover.

Internal Connectors

There are two 26-pin connectors marked IN and OUT on the ER-8/16 PWB. These connectors

are visible when you remove the top cover.

Warning: KEEP AWAY FROM LIVE CIRCUITS. DO NOT REMOVE THE TOP COVER of the

ER-8/16 when it is operating or is powered on. If signal wires are connected to

the ER-8/16, dangerous voltages may exist even when the equipment is turned

off. To avoid dangerous electrical shock, do not perform procedures involving

cover removal unless you are qualified to do so. Before removing the cover make

sure that the computer and the power supply are turned off and that the signal

wires connected to the screw terminals do not contain live voltages.

The internal connectors expand the switching system to 24 or 32 channels with the minimum

number of cables or accessories. Use the IN connector to interface the ER-8 with the SC-205X

Series cable adapters so you can interface your ER-8 to the Lab or MIO boards.

Warning: If you are using the IN internal connector,

front connectors.

DO NOT connect a cable to any of the

Connecting the cable to the wrong connector can damage the ER-8/16 or your

DAQ device. National Instruments is

NOT liable for any damages resulting from

such connections.

© National Instruments Corporation 3-7 ER-8/16 User Manual

Page 28

Signal Connections Chapter 3

Daisy Chaining the ER-8/16

To expand your system from 16 channels to 24 channels, connect a 26-pin NB7 ribbon cable

from the ER-16 OUT connector to the ER-8 IN connector.

Note: DO NOT connect an external supply to the ER-8 (the receiving unit). Verify that SW1 is

in the INT position on the receiving unit. Connect the external supply to the sending

unit.

The power supply will also be daisy-chained through the NB7 cable to the expanded system.

To expand your system from 16 channels to 32 channels, connect a 26-pin NB7 ribbon cable

from one ER-16 OUT connector to the other ER-16 IN connector.

Note: DO NOT connect an external supply to the ER-16 (the receiving unit). Verify that SW1

(see Figure 2-1) is in the INT position on the receiving unit. Connect the external

supply to the sending unit.

The power supply will also be daisy-chained through the NB7 cable to the expanded system.

Warning: Connecting the cable to the wrong connector can damage the ER-8/16 or your

DAQ device. National Instruments is

NOT liable for any damages resulting from

such connections.

Using the SC-205X Series with the ER-8

You can use your SC-205X Series cable adapter with the Lab or MIO boards to control the ER-8.

Connect the 26-pin cable to the ER-8 IN connector only. In this configuration, you can control

only channels 1 through 8. Digital lines—port A<0..7> as shown in

Figure 3-3a—control the relays. Port B<0..7> is not used.

Warning: When connecting more than one ER-8 with any of the SC-205X Series cable

adapters, verify that SW1 (see Figure 2-1) is at the EXT position and that you are

using an external power supply.

Connecting the cable to the wrong connector can damage the ER-8/16 or your

DAQ device. National Instruments is

incorrect connections.

DO NOT attempt to connect an ER-16 to any of the SC-205X Series cable adapters.

NOT liable for any damages resulting from

For additional information on the SC-205X Series cable adapters refer to the SC-205X Series

User Manual.

ER-8/16 User Manual 3-8 © National Instruments Corporation

Page 29

Chapter 3 Signal Connections

DAQ System Configurations with the ER-8/16

The following figures show the possible DAQ system configurations using the ER-8/16 for

multichannel control.

DIO-24 Boards

(or AT -MIO-16D,

AT -MIO-16DE-10)

Cable*1

Port A

ER-8

a. 8-Channel Relay Control

DIO-24 Boards

(or AT -MIO-16D,

AT -MIO-16DE-10)

Cable*1

NB7 Cable

Port A, Port B

ER-16

OUT

Port C

ER-8

IN

*2

c. 24-Channel Relay Control

Port AA, Port AB

ER-16

OUT

Port AC

ER-8

IN

Port BA, Port BB

ER-16

OUT

Port BC

ER-8

IN

*2

*2

DIO-96

Boards

SC-2054

(48-Channel)

NB1 Cable

NB7 Cable

NB1 Cable

NB7 Cable

e. 48-Channel Relay Control

*1 Cable Options: DAQCard-DIO-24: PSH27-50F-D1 cable

*2 External supply should be connected to the ER-16

*3 External supply needed for PCMCIA DAQCards

PC-DIO-24, NB-DIO-24: NB-1 cable

AT-MIO-16D: Type NB5 cable (pin # 51-100)

AT-MIO-16DE-10: R1005050 ribbon cable (pin # 51-100)

DIO-24 Boards

(or AT -MIO-16D,

AT -MIO-16DE-10)

DIO-96

Boards

(48-Channel)

(48-Channel)

Cable*1

Port A, Port B

ER-16

*3

b. 16-Channel Relay Control

DIO-32

Boards

NB1 Cable

NB7 Cable

Port A, Port B

ER-16

OUT

Port C, Port D

ER-16

IN

*2

d. 32-Channel Relay Control

NB1 Cable

NB7 Cable

SC-2054

NB1 Cable

SC-2054

NB7 Cable

NB1 Cable

NB7 Cable

NB1 Cable

NB7 Cable

Port AA, Port AB

ER-16

OUT

Port AC

ER-8

IN

Port BA, Port BB

ER-16

OUT

Port BC

ER-8

IN

Port CA, Port CB

ER-16

OUT

Port CC

ER-8

IN

Port DA, Port DB

ER-16

OUT

Port DC

ER-8

IN

*2

*2

*2

*2

f. 96-Channel Relay Control

Figure 3-3. ER-8/16 Configurations with DIO Devices

© National Instruments Corporation 3-9 ER-8/16 User Manual

Page 30

Signal Connections Chapter 3

Figure 3-4 shows the possible DAQ system configurations using National Instruments

multifunction DAQ devices and the ER-8/16.

E-Series/MIO

Boards *1

DAQCard-700/

PC-LPM-16

DAQCard-AO-2DC

DIO-24

Boards

*1 E-Series boards except AT-MIO-16DE-10

MIO boards except AT-MIO-16D

*2 Cable Options: AT-MIO-16E-2, AT-MIO-16E-10, AT-MIO-16XE-50:

*3 External supply should be connected to the ER-8/16

Cable *2

SC-2050

SC-2055

PSH27-50F-D1 Cable PSH27-50F-D1 Cable

SC-2051

AT-MIO-16F-5, AT-MIO-16, AT-MIO-16X: NB1 cable

AT-MIO-64E-3: R1005050 ribbon cable (pin # 1-50)

AT-MIO-64F-5: Type NB5 cable (pin # 1-50)

Digital I/O

NB7 Cable

NB7 Cable

NB7 Cable

NB7 Cable

NB7 Cable

SH6850 shielded cable or R6850 ribbon cable

Port A

ER-8

Port A

ER-8

Port A

ER-8

Port A

ER-8 or other 8-channel accessories

Port B

ER-8 or other 8-channel accessories

Port C

ER-8 or other 8-channel accessories

1200 Series/

Lab Boards

PC-AO-2DC

DAQCard-AO-2DC

SC-2053

SC-2053

*3

*3

NB7 Cable

NB7 Cable

NB7 Cable

NB7 Cable

NB7 Cable

Port A

ER-8

Port B

ER-8

*3

Port C

ER-8

*3

Port A

ER-8

Port B

ER-8

*3

Port A, Port B

ER-16

*3

Figure 3-4. ER-8/16 Configurations with Multifunction DAQ Devices

ER-8/16 User Manual 3-10 © National Instruments Corporation

Page 31

Chapter 4 Theory of Operation

This chapter contains a functional overview of the ER-8/16 and explains the operation of each

functional unit making up the ER-8/16.

Functional Overview

The ER-8 has eight SPDT relays controlled by eight digital lines connected to the ER-8. Each of

these relays has an NC contact that is connected to the COM contact when the corresponding

digital output line is low, and an NO contact that is connected to the COM contact when the

digital line is high. The contacts are break-before-make, so all three contacts are never shortcircuited. The block diagram in Figure 4-1 illustrates the key functional components of the

ER-8/16.

© National Instruments Corporation 4-1 ER-8/16 User Manual

Page 32

Theory of Operation Chapter 4

EXT +5 V

Port A

Port B

DIO-32

Port C

Port D

Port A

Port B

DIO-24

Port C

+5 V

Port C

OUT

Port D

Port A

IN

Port B

FUSE (F2)

EXT

INT

Switch

+5 V

+5 V

Port A

Relay

Driver

Included on the ER-16

Port B

Relay

Digital Input

Driver

8 Lines

Digital Input

8 Lines

CH1 RELAY

CH2 RELAY

CH3 RELAY

CH4 RELAY

CH5 RELAY

CH6 RELAY

CH7 RELAY

CH8 RELAY

CH9 RELAY

CH10 RELAY

CH11 RELAY

CH12 RELAY

CH13 RELAY

CH14 RELAY

CH15 RELAY

CH16 RELAY

24 Power

Lines

24 Power

Lines

NO 1

CH1 COM 1

NC 1

NO 2

CH2 COM 2

NC 2

NO 3

CH3 COM 3

NC 3

NO 4

CH4 COM 4

NC 4

NO 5

CH5 COM 5

NC 5

NO 6

CH6 COM 6

NC 6

NO 7

CH7 COM 7

NC 7

NO 8

CH8 COM 8

NC 8

Terminal Block

NO 9

CH9 COM 9

NC 9

NO 10

CH10 COM 10

NC 10

NO 11

CH11 COM 11

NC 11

NO 12

CH12 COM 12

NC 12

NO 13

CH13 COM 13

NC 13

NO 14

CH14 COM 14

NC 14

NO 15

CH15 COM 15

NC 15

NO 16

CH16 COM 16

NC 16

Terminal Block

Figure 4-1. ER-8/16 Block Diagram

ER-8/16 User Manual 4-2 © National Instruments Corporation

Page 33

Chapter 4 Theory of Operation

Digital Interface

There are four connectors with which to interface an ER-8/16 to digital devices or to daisy-chain

it to another ER-8/16. The two front connectors are marked DIO-24 and DIO-32; the two

internal connectors are marked IN and OUT. Use the internal connectors when daisy-chaining

the

ER-8/16 or when using SC-205X Series cable adapters.

Warning: Use only one of the connectors—DIO-24, DIO-32, or IN—at a time. Using more

than one of these connectors can damage your host computer, DAQ device, and

the ER-8/16. National Instruments is

NOT liable for any damages resulting from

incorrect connections.

For additional information on signal connections, refer to Chapter 3, Signal Connections.

Relay Channels

Figure 4-2 shows the onboard equivalent circuit for the ER-8/16. When the channel receives a

digital low signal, the relay for that channel remains unenergized, the NC contact shorts to the

COM contact, and the NO contact remains open. When a digital high signal is present on a

channel, the relay for that channel is energized, the NO contact shorts to the COM contact, and

the NC contact is open.

A green LED just above each relay illuminates when the relay is energized. To reduce the power

consumption and to help extend relay life, control the signals so that relays are energized for

only short periods of time and only a minimal number of relays are energized.

+5 V

NO

COM

Digital Line

ULN 2803

High-Current Driver

NC

Figure 4-2. ER-8/16 Onboard Equivalent Circuit

© National Instruments Corporation 4-3 ER-8/16 User Manual

Page 34

Appendix A Specifications

This appendix lists the specifications for the ER-8/16. These specifications are typical at 25° C and 50% humidity

unless otherwise noted.

Channel Rating

Number of channels ................................................................8 channels for ER-8

16 channels for ER-16

Relay type................................................................................SPDT (1 Form C), nonlatching

Max switching capacity (resistive load)

AC........................................................................................3 A at 250 VAC

DC........................................................................................3 A at 30 VDC

Max working voltage ..............................................................250 Vrms (channel to ground)

Switching current ....................................................................3 A max per channel

Channel on resistance..............................................................100 mΩ

Contact material ......................................................................Silver-nickel alloy

2

Life

Mechanical ..........................................................................10,000,000 operations min

Electrical .............................................................................100,000 at rated load

Isolation

Complies with IEC 1010 for Voltage Installation Category II Pollution Degree 2

Operate time............................................................................10 ms

Release time ............................................................................5 ms

1

250 Vrms (channel to channel, same phase)

40 A max for ER-16, all channels

24 A max for ER-8, all channels

Power Requirement

External Supply

Voltage....................................................................................+5 V (±5%)

Current ....................................................................................0.5 A for 8 channels

1.0 A for 16 channels

1.5 A for 24 channels

2.0 A for 32 channels

1

If you operate at high currents, later operation at low currents may not be possible.

2

Relays are subject to normal wear based on the number of operations.

© National Instruments Corporation A-1 ER-8/16 User Manual

Page 35

Specifications Appendix A

Physical

Dimensions..............................................................................17.5 by 5.2 by 12.25 cm (6.9 by 2.05 by 4.82 in.)

Connectors

External................................................................................DIO-24 and DIO-32 50-pin male, latching type, ribbon-

cable front connectors

Internal.................................................................................IN and OUT 26-pin male, latching type, ribbon-cable

internal connectors

Channel screw terminals .........................................................24 for ER-8, 16 AWG wire max,

48 for ER-16, 18 AWG wire max

Power supply screw terminals.................................................2

Environment

Operating temperature.............................................................0° to 50° C

Storage temperature ................................................................-55° to 150° C

Relative humidity....................................................................5% to 90% noncondensing

ER-8/16 User Manual A-2 © National Instruments Corporation

Page 36

Appendix B I/O Connectors

This appendix contains the connector pinouts and pin descriptions for the ER-8/16.

DIO-24 Connector

PC7 1 2 NC

PC6 3 4 NC

PC5 5 6 NC

PC4 7 8 NC

PC3 9 10 NC

PC2 11 12 NC

PC1 13 14 NC

PC0 15 16 NC

PB7 17 18 NC

PB6 19 20 NC

PB5 21 22 NC

PB4 23 24 NC

PB3 25 26 GND

PB2 27 28 GND

PB1 29 30 GND

PB0 31 32 GND

PA7 33 34 GND

PA6 35 36 NC

PA5 37 38 NC

PA4 39 40 NC

PA3 41 42 NC

PA2 43 44 NC

PA1 45 46 NC

PA0 47 48 NC

+5 V 49 50 NC

Figure B-1. The DIO-24 Connector

© National Instruments Corporation B-1 ER-8/16 User Manual

Page 37

I/O Connectors Appendix B

Table B-1. DIO-24 Connector Pin Descriptions

Pin Signal Name Description

1, 3, 5, 7, 9,

11, 13 15

17, 19, 21,

23, 25, 27,

29, 31

33, 35, 37,

39, 41, 43,

45, 47

2, 4, 6, 8, 10,

12, 14, 16, 18,

20, 22, 24, 36,

38, 40, 42, 44,

46, 48, 50

49 +5 V +5 V supply—This pin is connected to the internal +5 V

26, 28, 30, 32,

34

PC<7..0> Port C Channels 7 through 0—These signals are routed back

to the 26-pin OUT connector for daisy chaining to another

ER-8. Each of these pins controls the relay channel of the

daisy-chained ER-8. A digital high on these pins connects

the COM contact of a channel to the NO contact of that

channel. A digital low on these pins connects the COM

contact of a channel to the NC contact of that channel.

PB<7..0> Port B Channels 7 through 0—Each of these pins controls

the relay channel. A digital high on these pins connects the

COM contact of a channel to the NO contact of that channel.

A digital low on these pins connects the COM contact of a

channel to the NC contact of that channel.

PA<7..0> Port A Channels 7 through 0—Each of these pins controls

the relay channel. A digital high on these pins connects the

COM contact of a channel to the NO contact of that channel.

A digital low on these pins connects the COM contact of a

channel to the NC contact of that channel.

NC Not connected.

signal on the ER-8/16.

GND Ground—These pins are connected to the internal ground on

the ER-8/16.

ER-8/16 User Manual B-2 © National Instruments Corporation

Page 38

Appendix B I/O Connectors

DIO-32 Connector

PD1 1 2 PD4

PD3 3 4 PD0

PD6 5 6 PD7

PD2 7 8 PD5

PC5 9 10 PC7

PC3 11 12 PC1

PC2 13 14 PC0

PC6 15 16 PC4

NC 17 18 NC

NC 19 20 NC

NC 21 22 NC

NC 23 24 NC

NC 25 26 GND

NC 27 28 GND

NC 29 30 GND

NC 31 32 GND

NC 33 34 GND

PA4 35 36 PA6

PA0 37 38 PA2

PA1 39 40 PA3

PA7 41 42 PA5

PB5 43 44 PB2

PB7 45 46 PB6

PB0 47 48 PB3

PB4 49 50 PB1

Figure B-2. The DIO-32 Connector

© National Instruments Corporation B-3 ER-8/16 User Manual

Page 39

I/O Connectors Appendix B

Table B-2. DIO-32 Connector Pin Descriptions

Pin Signal Name Description

6, 5, 8, 2, 3, 7,

1, 4

10, 15, 9, 16,

11, 13, 12, 14

45, 46, 43, 49,

48, 44, 50, 47

41, 36, 42, 35,

40, 38, 39, 37

26, 28, 30, 32,

34

17–25, 27, 29,

31, 33

PD<7..0> Port D Channels 7 through 0—These signals are routed back

to the 26-pin OUT connector for daisy chaining to another

ER-8 or ER-16. Each of these pins controls the relay

channel of the daisy chained ER-8 or ER-16. A digital high

on these pins connects the COM contact of a channel to the

NO contact of that channel. A digital low on these pins

connects the COM contact of a channel to the NC contact of

that channel.

PC<7..0> Port C Channels 7 through 0—These signals are routed back

to the 26-pin OUT connector for daisy chaining to another

ER-8 or ER-16. Each of these pins controls the relay

channel of the daisy chained ER-8 or ER-16. A digital high

on these pins connects the COM contact of a channel to the

NO contact of that channel. A digital low on these pins

connects the COM contact of a channel to the NC contact of

that channel.

PB<7..0> Port B Channels 7 through 0—Each of these pins controls

the relay channel. A digital high on these pins connects the

COM contact of a channel to the NO contact of that channel.

A digital low on these pins connects the COM contact of a

channel to the NC contact of that channel.

PA<7..0> Port A Channels 7 through 0—Each of these pins controls

the relay channel. A digital high on these pins connects the

COM contact of a channel to the NO contact of that channel.

A digital low on these pins connects the COM contact of a

channel to the NC contact of that channel.

GND Ground—These pins are connected to the internal ground on

the ER-8/16.

NC Not connected.

ER-8/16 User Manual B-4 © National Instruments Corporation

Page 40

Appendix B I/O Connectors

26-Pin Internal Connectors

+5 V 1 2 GND

+5 V 3 4 GND

+5 V 5 6 GND

+5 V 7 8 GND

PA7 9 10 PB7

PA6 11 12 PB6

PA5 13 14 PB5

PA4 15 16 PB4

PA3 17 18 PB3

PA2 19 20 PB2

PA1 21 22 PB1

PA0 23 24 PB0

+5 V 25 26 GND

+5 V 1 2 GND

+5 V 3 4 GND

+5 V 5 6 GND

+5 V 7 8 GND

PC7 9 10 PD7

PC6 11 12 PD6

PC5 13 14 PD5

PC4 15 16 PD4

PC3 17 18 PD3

PC2 19 20 PD2

PC1 21 22 PD1

PC0 23 24 PD0

+5 V 25 26 GND

a. 26-Pin IN Connector b. 26-Pin OUT Connector

Figure B-3. 26-Pin Internal Connectors

Table B-3. 26-Pin IN Connector Pin Descriptions

Pin Signal Name Description

10, 12, 14,

16, 18, 20,

22, 24

PB<7..0> Port B Channels 7 through 0—Each of these pins controls

the relay channel. A digital high on these pins connects the

COM contact of a channel to the NO contact of that channel.

A digital low on these pins connects the COM contact of a

channel to the NC contact of that channel.

9, 11, 13,

15, 17, 19,

21, 23

PA<7..0> Port A Channels 7 through 0—Each of these pins controls

the relay channel. A digital high on these pins connects the

COM contact of a channel to the NO contact of that channel.

A digital low on these pins connects the COM contact of a

channel to the NC contact of that channel.

2, 4, 6, 8,

26

1, 3, 5, 7,

25

GND Ground—These pins are connected to the internal ground on

the ER-8/16.

+5 V +5 VDC supply—These pins are connected to the internal

(INT) +5 VDC supply on the ER-8/16.

© National Instruments Corporation B-5 ER-8/16 User Manual

Page 41

I/O Connectors Appendix B

Table B-4. 26-Pin OUT Connector Pin Descriptions

Pin Signal Name Description

10, 12, 14,

16, 18, 20,

22, 24

9, 11, 13,

15, 17, 19,

21, 23

2, 4, 6,

8, 26

1, 3, 5, 7,

25

PD<7..0> Port D Channels 7 through 0—These signals are for daisy

chaining to another ER-8 or ER-16. Each of these pins

controls the relay channel of the daisy chained ER-8 or

ER-16. A digital high on these pins connects the COM

contact of a channel to the NO contact of that channel. A

digital low on these pins connects the COM contact of a

channel to the NC contact of that channel.

PC<7..0> Port C Channels 7 through 0—These signals are for daisy

chaining to another ER-8 or ER-16. Each of these pins

controls the relay channel of the daisy chained ER-8 or

ER-16. A digital high on these pins connects the COM

contact of a channel to the NO contact of that channel. A

digital low on these pins connects the COM contact of a

channel to the NC contact of that channel.

GND Ground—These pins are connected to the ground on the

ER-8/16.

+5 V +5 VDC supply—These pins are connected to the +5 V

supply on the ER-8/16.

ER-8/16 User Manual B-6 © National Instruments Corporation

Page 42

Page 43

Page 44

Page 45

Page 46

Page 47

Page 48

Appendix D

Takamisawa VE Series Relay

Technical Data*

This appendix contains a manufacturer data sheet for the relays used on the ER-8/16.

* Copyright © Farnell Electronics, Inc. 1995. Reprinted with permission of copyright owner.

All rights reserved.

Farnell Electronics, Inc. Farnell Relay Products, Takamisawa Relay & SSR General Catalog ‘95–’96.

© National Instruments Corporation D-1 ER-8/16 User Manual

Page 49

Page 50

Page 51

Page 52

Page 53

Page 54

Appendix E Customer Communication

___________________________________________________

For your convenience, this appendix contains forms you can use to request help from National

Instruments or to comment on our products. Filling out a copy of the Technical Support Form

before contacting National Instruments helps us help you better and faster.

National Instruments provides comprehensive technical assistance around the world. In the U.S.

and Canada, applications engineers are available Monday through Friday from 8:00 a.m. to

6:00 p.m. (central time). In other countries, contact the nearest branch office. You may fax

questions to us at any time.

Corporate Headquarters

(512) 795-8248

Technical support fax: (800) 328-2203

(512) 794-5678

Branch Offices Phone Number Fax Number

Australia 03 9879 5166 03 9879 6277

Austria 0662 45 79 90 0 0662 45 79 90 19

Belgium 02 757 00 20 02 757 03 11

Canada (Ontario) 905 785 0085 905 785 0086

Canada (Quebec) 514 694 8521 514 694 4399

Denmark 45 76 26 00 45 76 26 02

Finland 09 527 2321 09 502 2930

France 01 48 14 24 24 01 48 14 24 14

Germany 089 741 31 30 089 714 60 35

Hong Kong 2645 3186 2686 8505

Israel 03 5734815 03 5734816

Italy 02 413091 02 41309215

Japan 03 5472 2970 03 5472 2977

Korea 02 596 7456 02 596 7455

Mexico 5 520 2635 5 520 3282

Netherlands 0348 433466 0348 430673

Norway 32 84 84 00 32 84 86 00

Singapore 2265886 2265887

Spain 91 640 0085 91 640 0533

Sweden 08 730 49 70 08 730 43 70

Switzerland 056 200 51 51 056 200 51 55

Taiwan 02 377 1200 02 737 4644

U.K. 01635 523545 01635 523154

© National Instruments Corporation E-1 ER-8/16 User Manual

Page 55

Technical Support Form

___________________________________________________

Photocopy this form and update it each time you make changes to your software or hardware, and use the completed

copy of this form as a reference for your current configuration. Completing this form accurately before contacting

National Instruments for technical support helps our applications engineers answer your questions more efficiently.

If you are using any National Instruments hardware or software products related to this problem, include the

configuration forms from their user manuals. Include additional pages if necessary.

Name

Company

Address

Fax ( ) Phone ( )

Computer brand Model Processor

Operating system

Speed MHz RAM MB Display adapter

Mouse yes no Other adapters installed

Hard disk capacity MB Brand

Instruments used

National Instruments hardware product model Revision

Configuration

National Instruments software product Version

Configuration