Page 1

DIO 6533

User Manual

High-Speed Digital I/O Boards for

PCI, PXI, CompactPCI, AT, EISA, or

PCMCIA Bus Systems

July 1997 Edition

Part Number 321464B-01

© Copyright 1997 National Instruments Corporation. All rights reserved.

Page 2

Internet Support

support@natinst.com

E-mail: info@natinst.com

FTP Site: ftp.natinst.com

Web Address: http://www.natinst.com

Bulletin Board Support

BBS United States: (512) 794 -5422

BBS United Kingdom: 01635 551422

BBS France: 01 48 65 15 5 9

Fax-on-Demand Support

(512) 418-1111

Telephone Support (U.S.)

Tel: (512) 795-8248

Fax: (512) 794-5678

International Offices

Australia 03 9879 5166, Austria 0662 45 79 90 0, Belgium 02 757 00 20,

Canada (Ontario) 905 785 0085, Canada (Québec ) 514 694 8521, Denmark 45 76 26 00,

Finland 09 725 725 11, France 01 48 14 24 24, Germany 089 741 31 30,

Hong Kong 2645 3186, Israel 03 5734815, Ital y 02 413091, Jap an 03 5472 2970,

Korea 02 596 7456, Mexico 5 520 2635, Nethe rlands 034 8 433466, Nor way 32 84 84 00,

Singapore 2265886, Spain 91 640 0085, Swede n 08 730 49 70, Switzerland 056 200 51 51,

Taiwan 02 377 1200, United Kingdom 01635 523545

National Instruments Corporate Headquarters

6504 Bridge Point Parkw ay Austin, TX 78730-503 9 Tel: (512) 794-0100

Page 3

Important Information

Warranty

The PCI-DIO-32HS, PXI-6533, AT-DIO-32HS, and DAQCard-6533 devices are warranted against defects in materials

and workmanship for a period of one year from the date of shipment, as evidenced by receipts or other documentation.

National Instruments will, at its option, repair or replace equipment that proves to be defective during the warranty

period. This warranty includes parts and l abor.

The media on which you receive National Instru ments software ar e warranted not to fail to execute pro grammi ng

instructions, due to defects in materials and workmanship, for a period of 90 days from date of shipment, as evidenced

by receipts or other documentation. National Instruments will, at its option, repair or replace soft ware media that do

not execute programming instructions if National Instruments receives notice of such defects during the warranty

period. National Instrument s does not war rant that the oper ation of the softwar e shall be un interr upted or error free.

A Return Material Authorization (RMA) number must be obtained from the factory and clearly marked on the outside

of the package before any equipment will be accepted for warranty work. National Instruments will pay the shipping

costs of returning to the owner par ts whi ch are cov ered by w arranty .

National Instruments believes that the information in this manual is accurate. The document has been carefully

reviewed for technical accuracy. In the event that technical or typographical errors exist, National Instruments reserves

the right to make ch anges to subsequent edition s of this document withou t prior notice to hol ders of this edition. The

reader should consult National Instruments if errors are suspected. In no event shall National Instruments be liable for

any damages arising out of or related to this docum ent or the in format ion contai ned in it.

E

XCEPT AS SPECIFIED HEREIN

SPECIFICALLY DISCLAIMS ANY WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE

C

USTOMER’S RIGHT TO RECOVER DAMAGES CAUSED BY FAULT OR NEGLIGENCE ON THE PART OF NATIONAL

I

NSTRUMENTS SHALL BE LIMITED TO THE AMOUNT THERETOFORE PAID BY THE CUSTOMER

WILL NOT BE LIABLE FOR DAMAGES RESULTING FROM LOSS OF DATA, PROFITS, USE OF PRODUCTS, OR INCIDENTAL OR

CONSEQUENTIAL DAMAGES, EVEN IF ADVISED OF THE POSSIBILITY THEREOF

Instruments will apply regardles s of the fo rm of acti on, whether i n contract or tort, incl uding neg lig ence. Any acti on

against National Instruments must be brought wit hin one year after the cause of action accrues. Nation al Instrument s

shall not be liable for any delay in performan ce due to causes beyo nd it s reasonable cont rol. The warranty pr ovided

herein does not cover damages, defects, malf unctio ns, or s ervice fai lures caused by owne r’s fail ure to fol low the

National Instruments in sta llat ion, o perat ion, or ma inte na nce instr uct ions; owner ’s modif icat ion of the p roduct;

owner’s abuse, misuse, or negligent acts; and power failure or surges, fire, flood, accident, actions of third parties, or

other events outside reasonable control.

, N

ATIONAL INSTRUMENTS MAKES NO WARRANTIES, EXPRESS OR IMPLIED, AND

.

. N

ATIONAL INSTRUMENTS

. This limitation of the liability of National

Copyright

Under the copyright laws, this publication may not be reproduced or transmitted in any form, electronic or mechanical,

including photocopying, reco rding, storin g in an in format ion retr iev al system , or tra nslati ng, in wh ole or in par t,

without the prior written consent of Nation al Inst rument s Corpo ration .

Trademarks

LabVIEW®, NI-DAQ®, RTSI®, ComponentWorks™, CVI™, DAQCard™, MITE™, SCXI™, and VirtualBench™

are trademarks of National Instruments Corpor ation.

Product and company names listed are trademarks or trade names of their respective companies.

WARNING REGARDING MEDICAL AND CLINICAL USE OF NATIONAL INSTRUMENTS PRODUCTS

National Instruments products are not design ed with comp onents and testing in tend ed to ensure a level o f reliabi lity

suitable for use in treatment and diag nosi s of humans . Appli cations of Nation al Instru men ts product s invol vin g

medical or clinical treatment can create a potential for accidental injury caused by product failure, or by err ors on the

part of the user or application designer . Any us e or applicat ion of Nat ional Ins trum ent s products for or involvi ng

medical or clinical treatment must be performed by properly trained and qualified medical personnel, and all traditional

medical safeguards, equipment, and procedures that are appropriate in the particular situation to prevent serious injury

or death should always continue to be used when National Instruments prod ucts ar e being used. National Instruments

products are NOT intended to be a substitute f or any for m of establ ished pr ocess, proce dure, or equi pmen t used to

monitor or safegua rd huma n he alth and sa fety in med ical or clin ical t reat ment .

Page 4

About This Manual

Organization of This Manual................................................ ...... ..... .............................xi

Conventions Used in This Manual................................................................................ xii

National Instruments Documentation.............................. ..... ........................................xii

Related Documentation.................................................................................................xiii

Customer Communication............................................................................................xiv

Chapter 1

Introduction

About the DIO 6533 Devices........................................................................................1-1

Using PXI with CompactPCI........................................................................................1-2

What You Need to Get Started.....................................................................................1-3

Software Programming Choices...................................................................................1-4

National Instruments Application Software...................................................1-4

NI-DAQ Driver Software...............................................................................1-5

Register-Level Programming.........................................................................1-6

Optional Equipment......................................................................................................1-7

Unpacking.....................................................................................................................1-8

Table of

Contents

Chapter 2

Installation and Configuration

Software Installation.....................................................................................................2-1

Hardware Installation....................................................................................................2-1

Installing the PCI-DIO-32HS.........................................................................2-1

Installing the PXI-6533..................................................................................2-2

Installing the AT-DIO-32HS..........................................................................2-3

Installing the DAQCard-6533........................................................................ 2-3

PCI, PXI, and DAQCard Device Configuration...........................................................2-4

©

National Instruments Corporation v DIO 6533 User Manual

Page 5

Table of Contents

AT Device Configuration.............................................................................................2-5

Bus Interface..................................................................................................2-5

Chapter 3

Hardware Overview

Unstrobed I/O...............................................................................................................3-4

Strobed I/O—Pattern Generation and Handshaking.................................................... 3-5

Pattern and Change Detection........................................................................ 3-6

Handshaking Protocols .................................................................................. 3-8

Comparing Protocols............................ ..... ..................................................... 3-10

Starting a Handshaking Transfer.................................................................... 3-12

Transfer Rates............................................................................................................... 3-13

Plug and Play Mode.........................................................................2-5

Switchless Data Acquisition............................................................ 2-5

Base I/O Address Selection...............................................2-6

DMA Channel Selection ...................................................2-6

Interrupt Channel Selection............................................... 2-6

Pattern-Detection Triggers ..............................................................3-6

Change Detection ............................................................................3-7

Message Generation ........................................................................ 3-8

8255 Emulation................................................................................ 3-9

Level ACK....................................................................................... 3-9

Leading-Edge Pulse........................................... ..............................3-9

Long Pulse....................................................................................... 3-9

Trailing-Edge Pulse......................................................................... 3-9

Burst Mode...................................................................................... 3-10

Controlling the Startup Sequence.................................................... 3-12

Controlling Line Polarities .............................................................. 3-13

Chapter 4

Signal Connections

I/O Connector............................................................................................................... 4-1

Signal Descriptions............................................... ......................................... 4-3

Signal Characteristics................................................... ...... ............. 4-6

Control Signal Summary.................................................................4-7

RTSI Bus Interface.........................................................................................4-7

Board and RTSI Clocks................................................................... 4-8

RTSI Triggers..................................................................................4-8

Data Signal Connections.............................................................................................. 4-9

Unstrobed I/O.................................................................................................4-10

Strobed I/O.....................................................................................................4-12

DIO 6533 User Manual vi

©

National Instruments Corporation

Page 6

Timing Connections......................................................................................................4-13

Pull-Up and Pull-Down Connections ...........................................................................4-13

Power Connections .............................................. ...... ...... .............................................4-14

Field Wiring and Termination ......................................................................................4-14

Chapter 5

Signal Timing

Pattern-Generation Timing...........................................................................................5-1

Handshake Timing........................................................................................................5-4

Table of Contents

Request Timing ..............................................................................................5-2

Internal Requests..............................................................................5-2

External Requests.............................................................................5-2

Trigger Timing...............................................................................................5-3

8255 Emulation ..............................................................................................5-4

Input.................................................................................................5-5

Output...............................................................................................5-6

8255 Emulation Mode Timing Specifications.................................5-8

Other Asynchronous Modes...........................................................................5-9

Level-ACK Mode ............................................................................5-9

Input...................................................................................5-9

Output................................................................................5-10

Level-ACK Mode Timing Specifications..........................5-11

Leading-Edge Mode....................................... ..... ...... .......................5-14

Input............................................................ ...... .................5-14

Output................................... ..... ........................................5-14

Leading-Edge Mode Timing Specifications......................5-16

Long-Pulse Mode.............................................................................5-19

Long-Pulse Mode Timing Specifications..........................5-20

Trailing-Edge Mode .........................................................................5-23

Input...................................................................................5-23

Output................................................................................5-23

Trailing-Edge Mode Timing Specifications......................5-25

Burst Mode.....................................................................................................5-27

Burst Mode Timing Specifications..................................................5-28

©

National Instruments Corporation vii DIO 6533 User Manual

Page 7

Table of Contents

Appendix A

Specifications

Appendix B

Optional Adapter Description

Appendix C

Customer Communication

Glossary

Index

Figures

Figure 1-1. The Relationship Between the Programming Environment, NI-DAQ,

and Your Hardware ............................................................................... 1-6

Figure 2-1. DAQCard-6533 Completed Installation................................................ 2-4

Figure 3-1. PCI-DIO-32HS/PXI-6533 Block Diagram ........................................... 3-2

Figure 3-2. AT-DIO-32HS Block Diagram.............................................................3-3

Figure 3-3. DAQCard-6533 Block Diagram............................................................3-4

Figure 3-4. Pattern Detection Example....................................................................3-7

Figure 4-1. 6533 Device I/O Connector Pin Assignments....................................... 4-2

Figure 4-2. RTSI Bus Signal Connection ................................................................ 4-9

Figure 4-3. Example of Data Signal Connections.................................................... 4-11

Figure 4-4. Transmission Line Terminations........................................................... 4-16

Figure 5-1. Pattern-Generation Timing.................................................................... 5-1

Figure 5-2. Internal Request Timing........................................................................ 5-2

Figure 5-3. External Request Timing....................................................................... 5-3

Figure 5-4. Trigger Input Signal Timing.................................................................. 5-4

Figure 5-5. 8255 Emulation Mode Input.................................................................. 5-6

Figure 5-6. 8255 Emulation Mode Output............................................................... 5-7

Figure 5-7. 8255 Emulation Timing......................................................................... 5-8

Figure 5-8. Level-ACK Mode Input ........................................................................5-10

Figure 5-9. Level-ACK Mode Output......................................................................5-11

Figure 5-10. Level-ACK Mode Input Timing............................................................ 5-12

DIO 6533 User Manual viii

©

National Instruments Corporation

Page 8

Table of Contents

Figure 5-11. Level-ACK Mode Output Timing.........................................................5-13

Figure 5-12. Leading-Edge Mode Input.....................................................................5-15

Figure 5-13. Leading-Edge Mode Output.................................................................. 5-16

Figure 5-14. Leading-Edge Mode Input Timing........................................................5-17

Figure 5-15. Leading-Edge Mode Output Timing......................................................5-18

Figure 5-16. Long-Pulse Mode Input.........................................................................5-19

Figure 5-17. Long-Pulse Mode Output.......................................................................5-20

Figure 5-18. Long-Pulse Mode Input Timing ............................................................5-21

Figure 5-19. Long-Pulse Mode Output Timing..........................................................5-22

Figure 5-20. Trailing-Edge Mode Input.....................................................................5-24

Figure 5-21. Trailing-Edge Mode Output...................................................................5-25

Figure 5-22. Trailing-Edge Mode Input Timing........................................................5-26

Figure 5-23. Trailing-Edge Mode Output Timing......................................................5-27

Figure 5-24. Input Burst Mode Transfer Example.....................................................5-28

Figure 5-25. Output Burst Mode Transfer Example...................................................5-29

Figure 5-26. Burst Mode Output Timing (Default)....................................................5-30

Figure 5-27. Burst Mode Input Timing (Default).......................................................5-31

Figure 5-28. Burst Mode Output Timing (PCLK Reversed)......................................5-32

Figure 5-29. Burst Mode Input Timing (PCLK Reversed)........................................5-33

Figure B-1. 68-to-50-Pin Adapter Pin Assignments.................................................B-2

Table

Table 1-1. Pins Used by the PXI-6533 Device.......................................................1-3

Table 2-1. PC AT I/O Address Map .......................................................................2-6

Table 2-2. PC AT Interrupt Assignment Map.........................................................2-8

Table 2-3. PC AT 16-Bit DMA Channel Assignment Map....................................2-9

Table 3-1. 6533 Handshaking Protocols.................................................................3-11

Table 4-1. Signal Descriptions................................................................................4-3

Table 4-2. Control Signal Summary .......................................................................4-7

©

National Instruments Corporation ix DIO 6533 User Manual

Page 9

This manual describes the elect rical and mechanical aspects of the

DIO6533 (formerly called DIO-32HS) family of devices, and contains

information concerning their ope ration and programming. U nless

otherwise noted, text applies to all devices in the DIO6533 family. The

devices named DIO-32HS and 6533 are the same in functionality; their

primary difference is the bus interface.

The DIO6533 family includes the following devices:

• PCI-DIO-32HS

• PXI-6533

• AT-DIO-32HS

• DAQCard-6533

Organization of This Manual

About

This

Manual

The DIO 6533 User Manual is orga nized as follows:

• Chapter1, Introduction, describes the DIO 6533 (DIO -32HS)

devices, lists what you need to get started, descr ibes optional

equipment, and explains how to unpack your de vice.

• Chapter2, Installation and Configuration, explains how to install

and configure your DIO 6533 device.

• Chapter3, Hardware Overview, provides an overview of the

hardware functions of your DIO 6533 devic e.

• Chapter4,

output signal connections to your DIO 6533 device via the device

I/O connector and RTSI connector.

• Chapter5, Signal Timing, provides detailed timing specifications

for DIO 6533 pattern generation and for the various full, two- way

handshaking modes.

• AppendixA, Specifications, lists the specifications for the DIO

6533 devices.

©

National Instruments Corporation xi DIO 6533 User Manual

Signal Connections, describes how to ma ke input a nd

Page 10

About This Manual

• AppendixB, Optional Adapter Description, describes the optional

68-to-50-pin DIO 6533 device adapter.

• AppendixC, Customer Communication, contains forms you can

use to request help from National Instruments or to comment on our

products.

•The Glossary contains an alphabetical list and descriptions of terms

used in this manual, including acronyms, abbreviations,

definitions, metric prefixes, mnemonics, and symbols.

•The Index alphabetically lists topics covered in this manual,

including the page where you can f ind the topic.

Conventions Used in This Manual

The following conventions are used in this manual:

<> Angle brackets containing numbers separated by an ellipsis represent a

range of values associate d with a bit or signal name (for example,

DIOB<3..0>).

♦ The ♦ symbol indicates that the text following it applies only to a

specific DIO6533 device.

bold italic Bold italic text denotes a note, caution, or warning.

6533 device 6533 device refers to the PCI-D IO- 32HS, PXI- 6533, A T-DI O-32HS,

and DAQCard-6533 devices, unless otherwise noted.

italic Italic text denotes emphasis, a cross reference, or an introduction to a

key concept.

SCXI SCXI stands for Signal Conditioning eXtensions for Instrumentation

and is a National Instruments product line designed to perform

front-end signal conditioning for National Instruments plug-in DAQ

boards.

The Glossary lists abbreviations, acronyms, def initions, metric prefixes,

mnemonics, symbols, and ter ms.

National Instruments Documentation

The DIO 6533 User Manual is one piece of the doc umentation set for

your DAQ system. You could have any of seve ral types of documents,

depending on the hardwa re a nd sof twa re in your syste m. U se the

documentation you have as follows:

©

DIO 6533 User Manual xii

National Instruments Corporation

Page 11

About This Manual

• Getting Started with SCXI—If you are using SCXI, this is the first

manual you should re ad. I t giv es an o ve rview of the SC XI sy stem

and contains the most commonly needed information for the

modules, chassis, and software.

• Your SCXI hardware user manuals—If you are using SCXI, read

these manuals next for detailed information about signal

connections and module configuration. They also explain in greater

detail how the module works and contain application hints.

• Your DAQ hardware documentation— This docum entation ha s

detailed information about the DAQ ha rdware that plu gs into or is

connected to your computer. Use this documentation for hardware

installation and configuration instructions, specification

information about your DAQ hardw are, an d applicatio n hints.

• Software documentation—You may have both application software

and NI-DAQ software docum entation. National Instrum ents

®

application software incl udes LabV IE W, L abW indow s

/CVI,

ComponentWorks, and Vir tualBe nch. Afte r you se t up y our

hardware system, use either your applic ation softw are

documentation or the N I-D AQ docu me ntation to he lp y ou write

your application. If y ou have a la rge, comp lica ted system, it is

worthwhile to look through the software documentation before you

configure your har dwar e.

• Accessory installation guides or manuals—If you are using

accessory products, read the terminal block and cable assembly

installation guides. They explain how to physically connect the

relevant pieces of the system. Consult these guides when you are

making your connec tions.

• SCXI Chassis Manual—If you are using SCXI, read this manual for

maintenance information on the chassis and installation

instructions.

Related Documentation

The following documents contain information that you may find helpful

as you read this manual:

• Your computer’s technical reference manual

• National Instruments PXI Specification, rev. 1.0

• PICMG CompactPCI 2 .0 R2 .1

©

National Instruments Corporation xiii DIO 6533 User Manual

Page 12

About This Manual

Customer Communication

National Instruments wants to receive your comments on our products

and manuals. We are interested in the applications you develop with our

products, and we want to help if you have problems with them. To make

it easy for you to contact us, this manual contains comment and

configuration forms for you to complete. These for ms are in

AppendixC, Customer Communication, at the end of this manual.

DIO 6533 User Manual xiv

©

National Instruments Corporation

Page 13

Chapter

Introduction

This chapter describes the DIO6533 (DIO-32HS) devices, lists what

you need to get started, describes optional equipment, and explains how

to unpack your device.

About the DIO 6533 Devices

Thank you for buying a National Instruments DIO6533 device . The

6533devices are 32-bit, parallel digital I/O interfaces for

PC-compatible computers, or PXI or CompactPCI chassis. The 6533

devices offer digital data acquisition, digital waveform generation, and

high-speed, flexible handshaking.

The PCI-DIO-32HS and PXI-6533 are com pletely switchless,

jumperless DAQ devices for PCI buses and PXI or CompactPCI

chassis, respectively. Both contain the National Instruments MITE PCI

interface. The MITE offers bus-master operation, PCI burst transfers,

and high-speed DMA controllers for continuous, scatter-gather DMA

without requiring DMA resources from your computer. See the Using

PXI with CompactPCI section in this chapter for more informatio n on

your PXI-6533 device.

1

The AT-DIO-32HS is a completely switchless, jumperless DAQ device

for AT (16-bit ISA) buses. The AT-DIO-32HS implements the Plug and

Play ISA Specification so that your operating system can configur e all

DMA channels, interrupts, and base I/O addresses. You ca n easily

change device configurations without removing the devic e from your

computer. The AT-DIO-32HS offers dual DMA with channel switching

for uninterrupted, high-speed data transfer.

The DAQCard-6533 is a general-purpose d igital I/O card for com puters

equipped with Type II PCMCIA slots. The small size and weight of the

DAQCard-6533, coupled with low power consumption, make this card

ideal for use in portable computers, making remote digital data

acquisition practical. The card requires very little operating power and

has a standby mode that uses even less power, thus extending the life of

your computer batteries.

© National Instruments Corporation 1-1 DIO 6533 User Manual

Page 14

Chapter 1 Introduction

Each 6533 device contains the National Instruments DAQ-DIO chip,

providing two independent channels of digital input and output, pattern

generation, and handshaking. Each channel offers the following

functions:

• Selectable data path width (8, 16, or 32 bits)

• 16-sample-deep FIFO buffer

• 16-bit and 32-bit counters for timeba se a nd inter val genera tion,

with a maximum timing resolution of 50 ns

• A handshaking controller implementing six flexible timing

protocols

• Start and stop trigger detection and digital pattern detection

• 24mA outputs

• Hysteresis and diode-based line termination on all inputs

With 6533 devices, you can use your c omputer or c hassis a s a digital

I/O tester, logic analyzer, or system controller for laboratory testing,

production testing, and industrial process monitoring and contr ol.

For detailed 6533 device speci fications, see AppendixA,

Specifications.

Using PXI with CompactPCI

Using PXI-compatible products with standard CompactPCI products is

an important feature provided by the PXI Specification, rev.1.0. If you

use a PXI compatible plug-in device in a standard Comp actPCI chassis,

you will be unable to use PXI-specific functions, but you can still use

the basic plug-in device functions. For example, the RTSI bus on your

PXI-6533 device is available in a PXI chassis, but n ot in a CompactPCI

chassis.

The CompactPCI specification permits vendors to develop sub-buses

that coexist with the basic PCI interface on the CompactPCI bus.

Compatible operation is not guaranteed between Compa ctPCI device s

with different sub-buses nor between CompactPCI devices with

sub-buses and PXI. The standard implementation for CompactPCI does

not include these sub-buses. Your PXI-6533 device wi ll work in any

standard CompactPCI chassis adhering to the PICMG

CompactPCI2.0R2.1 document.

DIO 6533 User Manual 1-2 © National Instruments Corporation

Page 15

Chapter 1 Introduction

PXI specific features are impleme nted on the J2 connec tor of the

CompactPCI bus. Table 1-1 lists the J2 pins used by yo ur PXI-6 533

device. Your PXI device is compatible with any CompactPCI chassis

with a sub-bus that does not drive these lines. Even if the sub-bus is

capable of driving these lines, the PXI device is still compatible as long

as those pins on the sub-bus are disabled by default and not ever

enabled. Damage m a y resu lt if these lines ar e dr iven b y the sub- bus.

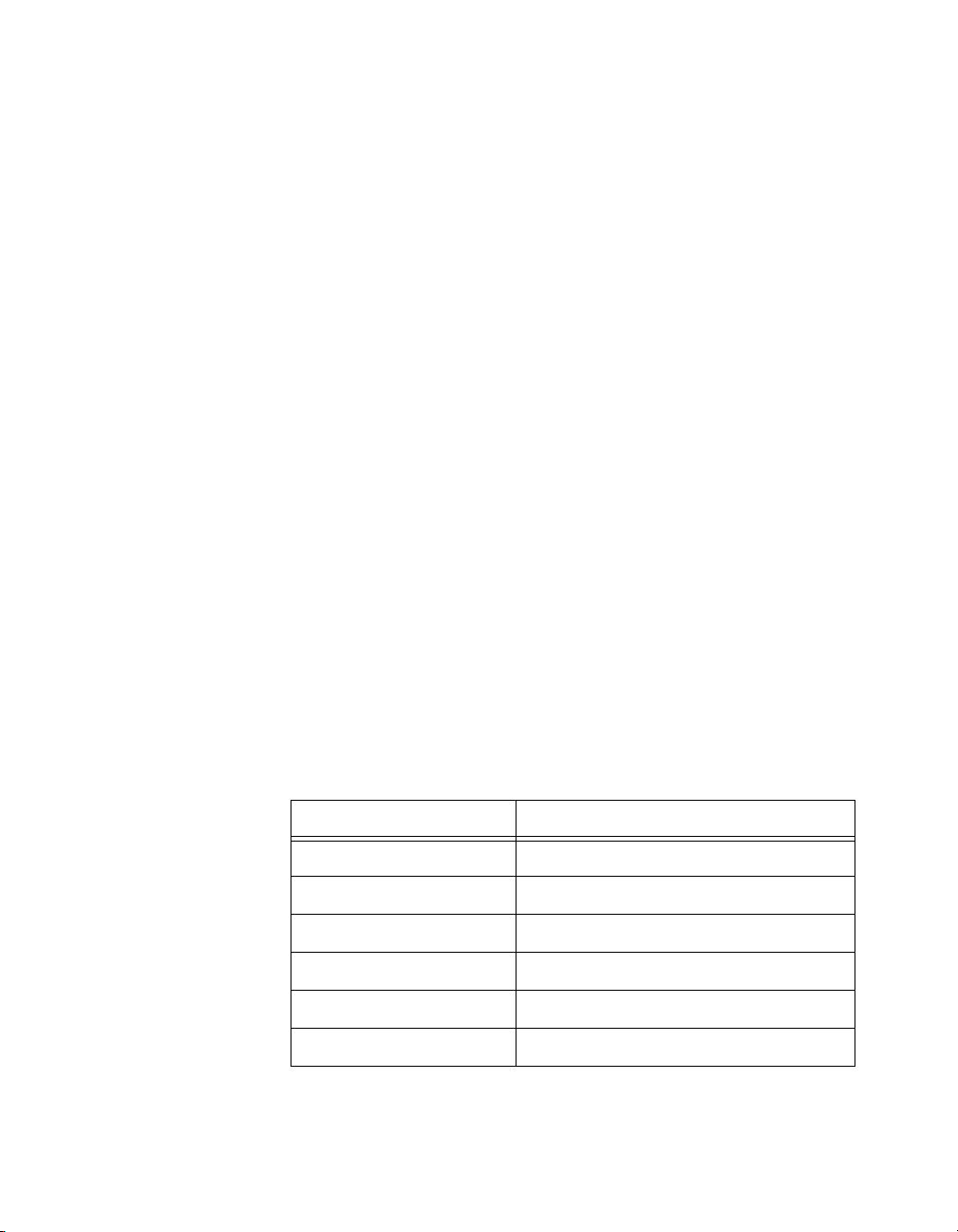

Table 1-1.

PXI-6533

Signal

RTSI

Trigger

(0..6)

Reserved PXI Star D17

RTSI Clock PXI Trigger (7) E16

Reserved LBR (7, 8, 10, 11,

PXI Pin Name PXI J2 Pin Number

PXI Trigger (0..6) B16, A16, A17, A18, B18,

12)

What You Need to Get Started

To set up and use your DIO 6533 device, you will need the following:

❑ One of the following devices:

PCI-DIO-32HS

PXI-6533

AT-DIO-32HS

DAQCard-6533

Pins Used by the PXI-6533 Device

C18, E18

A3, C3, E3, A2, B2

❑ D IO 6 533 Us er Man ual

© National Instruments Corporation 1-3 DIO 6533 User Manual

Page 16

Chapter 1 Introduction

❑ One of the following software packages and documentation:

NI-DAQ for PC compatibles

LabVIEW for Windows

LabWindows/CVI

ComponentWorks

VirtualBen ch

❑ Appropriate cable:

PSHR68-68M (DAQCard-6 533 only)

Shielded or ribbon c able (f or all de vices)

❑ Your computer, PXI, or CompactPCI chassis and controller

Software Programming Choices

There are several op tions to choo se from whe n programm ing your

National Instruments DAQ hardware. You can use LabVIEW,

LabWindows/CVI, Comp one ntWorks, V irtu alBench, or NI -DA Q.

National Instruments Application Software

LabVIEW features interactive graphics, a state-of-the art user interface,

and a powerful gr aphic al progra mm ing lan gua ge. Th e LabV IEW D ata

Acquisition VI Library, a series of VIs for using LabVIE W with

National Instruments DAQ hardware, is included with LabVIEW. The

LabVIEW Data Acquisition VI Library is f unctionally equivalent to the

NI-DAQ software.

LabWindows/CVI features interactive graphics and a state-of-the-art

user interface, and uses the ANSI sta ndard C pro gram ming langua ge.

The LabWindows/CVI Data A cquisition Lib rary, a serie s of fun ction s

for using National Instruments DAQ hardware, is included with

LabWindows/CVI. The LabWindows/CVI Data Acquisition Library is

functionally equivalent to the NI-DAQ software.

ComponentWorks con tains tools for data acq uisition and instr ument

control built on NI-DAQ driver softw are. Component Works provide s a

higher-level programming interface for building virtual instruments

through standard OLE controls and DLLs. With ComponentWorks, you

can use all of the configuration tools, resource management utilities,

and interactive control utilities included with NI-DAQ.

DIO 6533 User Manual 1-4 © National Instruments Corporation

Page 17

VirtualBench features virtual instruments that combine DAQ products,

software, and your co mputer to create a stand- alone instrumen t with the

added benefit of the processing, display, and storage capabilities of

your computer. VirtualBench instruments load and save waveform data

to disk in the same forms that can be used i n popular s preads heet

programs and word proce ssors.

Using LabVIEW, LabWindows/CVI, ComponentWorks, or

VirtualBench software will greatly reduce the development time for

your data acquisition and control application.

NI-DAQ Driver Software

The NI-DAQ driver software is included at no ch ar ge with all Natio n al

Instruments DAQ hardware. NI-DAQ is not packaged with SCXI or

accessory products, except for the SCXI-1200. NI-DAQ has an

extensive library of functions that you can c all from your application

programming enviro nment. These fu nctions includ e routines for analo g

input (A/D conversion), buffered data acquisition (high-speed A/D

conversion), analog output (D/A conversion), wavefor m generation

(timed D/A conversion), digital I/O, counter/timer operations, SCXI,

RTSI, calibration, messaging, and acquiring da ta to extended memory.

Chapter 1 Introduction

NI-DAQ has both high-level DAQ I/O functions for maximum ease of

use and low-level DAQ I/O functions for maximum flexibility and

performance. Examples for high-l evel funct ions a re strea ming dat a t o

disk or acquiring a certain number of da ta points. An example of a

low-level function is writing directly to registers on the DAQ device.

NI-DAQ does not sacrifice performance of National Instruments DAQ

devices because it lets multiple devices operate at their peak

performance, even simul taneous ly.

NI-DAQ also internally addresses many of the com plex issues between

the computer and the DAQ hardware such as programming interrupts

and DMA controllers. NI-DAQ maintains a consistent software

interface so that you can change platforms with minimal modifications

to your code. Whether you are using c onventional program ming

languages or NI-DAQ software, your application uses the NI-DAQ

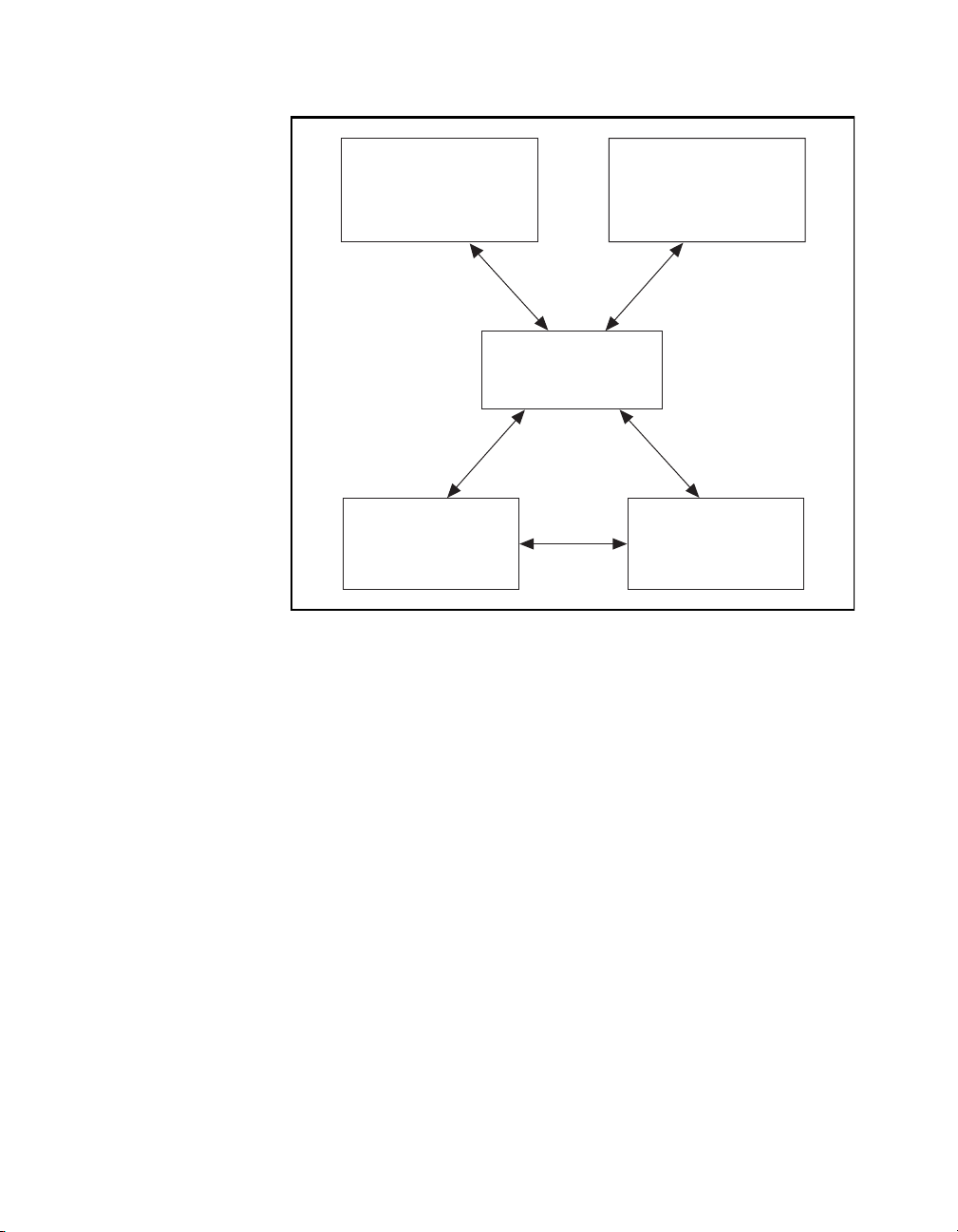

driver software, as illustrated in Figure1-1.

© National Instruments Corporation 1-5 DIO 6533 User Manual

Page 18

Chapter 1 Introduction

Conventional

Programming

Environment

NI-DAQ

Driver Software

DAQ or

SCXI Hardware

Figure 1-1. The Relationship Between the Programming Environment, NI-DAQ,

and Your Hardware

ComponentWorks,

LabVIEW,

LabWindows/CVI,

or VirtualBench

Personal

Computer or

Workstation

You can use your 6533 device, together wi th other AT (16-b it ISA),

PCI, PC, EISA, DAQCard, and DAQPad Series DAQ hardware, with

NI-DAQ software for PC compatibles. The PCI-DIO-32HS or

AT-DIO-32HS requires version 5 .0 or late r. T he PXI -65 33 or

DAQCard-6533 requires ve rsion 5.1 or later.

Register-Level Programming

The final option for programming any National Instruments DAQ

hardware is t o wr it e r eg iste r- lev el softw are . Writ ing re gist er-l ev el

programming software can be very time-consuming and inefficient and

is not recommended for most u ser s.

Even if you are an experienced register-level programmer, consider

using NI-DAQ or National I nstruments applicatio n software to prog ram

your National Instruments DAQ hardware. Using National Instruments

application softw are is as easy and as flex ible as regis ter-lev el

programming and can save weeks of develop ment time.

DIO 6533 User Manual 1-6 © National Instruments Corporation

Page 19

Optional Equipment

National Instruments offers a variety of pr oducts to use with your

6533device, including cables, connector blocks, and other accessories,

as follows:

• Cables and cable assemblies, shielded and ribbon

• Connector blocks, shielded and unshielded 50 a nd 68- pin scr ew

terminals

• Real Time System Integration (RTSI) bus cables

• SCXI modules and accessories for isolating digital signals,

controlling relays, and creating isolated analog outputs

• Low channel-count signal conditioning modules, devices, and

accessories, including relays and optical isolation

Some cables and accessories require use of the 68 to 50-pin DIO 6533

device adaptor, detailed in Appe ndixB, Optional Adapter D escription.

For more specific information about these products, refer to your

National Instruments catalogue or web site, or c all the office near est

you.

Chapter 1 Introduction

© National Instruments Corporation 1-7 DIO 6533 User Manual

Page 20

Chapter 1 Introduction

Unpacking

Your 6533 device is ship ped in an a ntistatic p ackage to pr ev ent

electrostatic damage to the device. El ectrostatic disc harge can da mage

several components on the device. To avoid such damage in handling

the device, take the following precautions:

• Ground yourself via a grounding strap or by hold ing a ground ed

object.

• Touch the antistatic package to a metal part of your computer

chassis before rem oving the d evic e f rom the pack age .

• Remove the device from the package and inspect the device for

loose components or a ny sign of d amag e. N otify N atio na l

Instruments if the device appear s damaged in any way. Do not

install a damaged dev ice into yo ur comp uter .

• Never touch the exposed pins of connectors.

• Store your 6533 device in the antistatic envelope when not in use.

DIO 6533 User Manual 1-8 © National Instruments Corporation

Page 21

Installation and

Chapter

Configuration

This chapter expla ins how to insta ll and co nfig ure y our DIO 653 3

device.

Software Installation

Install your software before you install your 6533 devi ce. Refe r to the

appropriate release notes indicated be low for specific instruc tions on

the software ins tall ation sequ ence .

If you are using NI-DAQ, refer to your NI-D AQ release notes. Find

the insta llation section fo r your o perating sy stem and fo llow the

instructions given there.

If you are using LabV IEW, L a bWindow s/CVI, or o ther N ationa l

Instruments applica tion sof tware packag es, refe r to th e appro priat e

release notes. After you have installed yo ur application software, refer

to your NI-DAQ relea se no tes an d follow th e instruc tions give n there

for your operating sy stem a nd ap plica tion softwa re p acka ge.

2

Hardware Installation

Following are general installation instructions for each device. Consult

your computer or chassis user manual or technical reference manual for

specific instructions about installing new devices in your com puter or

chassis.

Installing the PCI-DIO-32HS

You can install a PCI-DIO-32HS in any ava ilable 5 V PCI expansion

slot in your computer.

1. Turn off and unplug your comp uter .

2. Remove the top cover or access port to the e xpan sion slots.

3. Remove the expansion slot cover on the back panel of the

computer.

© National Instruments Corporation 2-1 DIO 6533 User Manual

Page 22

Chapter 2 Installation and Configuration

4. Touch the metal part inside your computer to discharge any static

electricity that might be on your clothes or body.

5. Insert the PCI-DIO-32HS into a 5 V PCI slot. It may be a tight fit, but

do not force the device into place.

6. Screw the mounting bracket of the PCI-DIO-32HS to the back panel

rail of the computer.

7. Visually verify the installation.

8. Replace the top cover of your com puter.

9. Plug in and turn on your compute r.

Installing the PXI-6533

You can install a PXI-6533 in any available 5V periphera l slot in your

PXI or CompactPCI chassis.

Note: The PXI-6533 has connections to several reserved lines on the

CompactPCI J2 connector. Before installing a PXI-6533 in a CompactPCI

system that uses J2 connector lines for purposes other than PXI, see Using

PXI with CompactPCI in Chapter1, Introduction, of this manual.

1. Turn off and unplug your PXI or CompactPCI c hassis.

2. Choose an unused PXI or CompactPCI 5V peri phera l slot. For

maximum performance, install the PXI-6533 in a slot that supports

bus arbitration, or bus-master cards. T he PX I-6533 c ontains

onboard bus-master DMA logic that can operate only in such a slot.

If you choose a slot that does not support bus masters, you will have

to disable the onboard DMA controller using your software. PXIcompliant chassis must have bus arbitration for all slots.

3. Remove the filler panel for the peripheral slot you have chosen.

4. Touch a metal part on your cha ssis to discha rge a ny sta tic

electricity that might be on your clothes or body.

5. Insert the PXI-6533 in the selected 5V slo t. Use the injector/ejector

handle to fully inject the device into place.

6. Screw the front panel of the PXI-6533 to the front panel mounting

rails of the PXI or CompactPCI chassis.

DIO 6533 User Manual 2-2 © National Instruments Corporation

Page 23

7. Visually verify the installation.

8. Plug in and turn on the PXI or CompactPCI chassis.

Installing the AT-DIO-32HS

You can install an AT-DIO-32HS in any available AT (16-bit ISA) or

EISA expansion slot in your com puter.

1. Turn off and unplug your computer.

2. Remove the top cover or access port to the expansion slots.

3. Remove the expansion slot cover on the back panel of the

computer.

4. Touch the metal part inside your computer to discharge any static

electricity that might be on your clothes or body.

5. Insert the AT-DIO-32HS into an AT (16-bit ISA) or EISA slot. It

may be a tight fit, but do not force the device into place.

6. Screw the mounting bracket of the AT-DIO-32HS to the back panel

rail of the computer.

7. Visually verify the installation.

8. Replace the top cover of the computer.

9. Plug in and turn on your compute r.

Chapter 2 Installation and Configuration

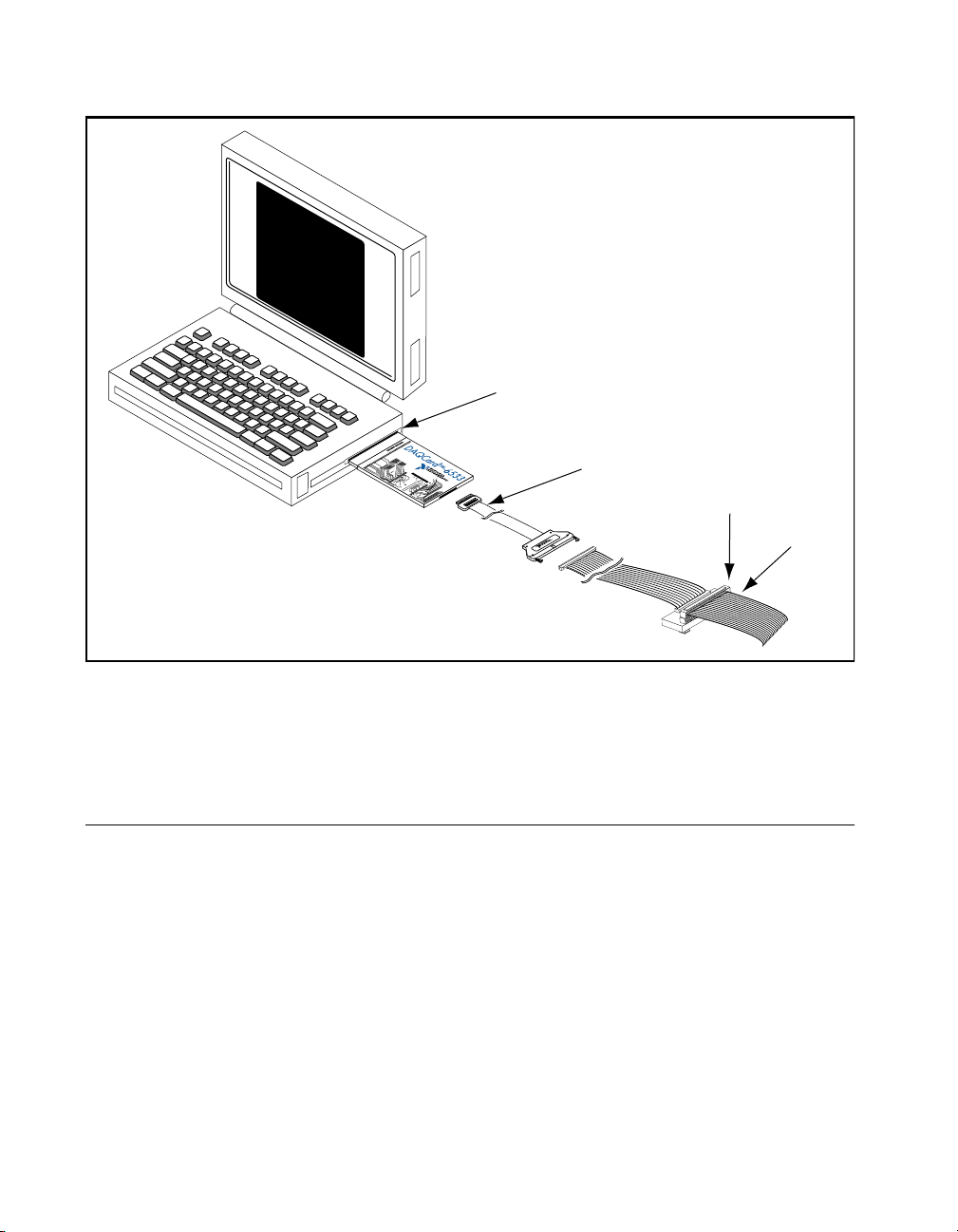

Installing the DAQCard-6533

You can install your DAQCard-6533 in any available Type II PCMCIA

slot in your computer. See Figure2-1 for the completed installation.

1. Turn off your computer. If your compute r supports hot insertion,

you may insert or remove the DAQCard-6533 at any time, whether

the computer is powered on or off.

2. Remove the PCMCIA slot cover on your computer, if any.

3. Insert the PCMCIA bus connector of the DAQCard-6533 into the

PCMCIA slot. The card is keye d so tha t you ca n insert it only one

way.

4. Attach the I/O cable. Be very careful not to put strain on the I/O

cable when inserting it into and removing it from the

DAQCard-6533. When plugging and unplugging the cable, always

grasp the cable by the connector. Never pull directly on the I/O

cable to unplug it from the DAQCard-6533.

© National Instruments Corporation 2-3 DIO 6533 User Manual

Page 24

Chapter 2 Installation and Configuration

Portable

Computer

PCMCIA Socket

I/O Cable

CB-68

I/O Signals

Figure 2-1. DAQCard-6533 Completed Installation

Your 6533 device is insta lled. T he d evice is now r eady f or softwa re

configuration.

PCI, PXI, and DAQCard Device Configuration

The PCI-DIO-32HS , PXI -65 33, a nd DAQC ard-6 533 a re c omple tely

software configurable. The system software automatically allocates all

device resources, incl uding b ase m emor y add ress a nd inte rrupt level.

These devices do not require DMA controller resources from your

computer.

DIO 6533 User Manual 2-4 © National Instruments Corporation

Page 25

AT Device Configuration

The plug and play feature of the AT-DIO -32HS mak es it completely

software configurable. You can use software to configure the base I/O

address, DMA cha nnels, an d in terr upt lev els.

Bus Interface

The AT-DIO-32HS works in either a Plug and Play mo de or a

switchless mode. These modes dictate how system resources are

determined and assigned to the devic e.

Plug and Play Mode

The AT-DIO-32HS is fully compatible with the industry-standard

Intel/Microsoft Plug and Play Specification version 1.0a. A Plug and

Play system arbitrates and assigns system resources through software,

freeing you from man ually se tting switc hes and jump ers. Th ese

resources include the device base I/O address, DMA channels, and

interrupt channels. Th e A T-DI O-32 HS is c onf igured a t the f act ory to

request these resources from the Plug and Play Configuration Manager.

Chapter 2 Installation and Configuration

The Configuration Manager receives all of the resource requests at

startup, compares the available resources to those requested, and

assigns the available resou rces as efficie ntly as possible to the Plug and

Play devices. Applicatio n softwa re c an qu er y th e Configu ratio n

Manager to determine the resources assigned to each device without

your involvement. The Plug and Play so ftware is instal led a s a d ev ice

driver or as an integra l com pon en t of the c om puter BIOS .

Switchless Data Acquisition

You can use your AT-DIO-32HS device in a non-Plug and Play system

as a switchless DAQ device. A non-Plug and Play system is a system in

which the Configuration Manager has not been installed and which does

not contain any non-National Instruments Plug and Play products. Use

a configuration utility, such as the NI-PnP or Intel configuration

utilities, to enter the base address, DMA, and interrupt selections, and

the application software assigns them to the device.

Note: Avoid resource conflicts with non-National Instruments d evices. For

example, do not configure two devices to have the same base address.

© National Instruments Corporation 2-5 DIO 6533 User Manual

Page 26

Chapter 2 Installation and Configuration

Base I/O Address Selection

The AT-DIO-32HS device can be configured to use a base address in

the range of 100 to 3E 0 hex. T he A T-D IO-32 H S occ upies 1 6 b ytes of

address space and must be located on a 16-byte boun dary. Therefore ,

valid addresses include 100, 110, 120, ..., 3D0, 3E0 hex. This selection

is software configured and does not require you to manually change any

settings on the device.

DMA Channel Selection

The AT-DIO-32HS can a chieve h igh tra nsfe r ra tes by usin g u p to two

16-bit DMA channels. The AT-DI O-32HS can use only 16-bit DMA

channels, w h ich co rr esp ond t o ch an ne ls 5, 6 , a nd 7 i n an AT (1 6-b i t

ISA) computer and channels 0, 1, 2, 3, 5, 6, and 7 in an EISA computer.

These selections are all software configured and do not require you to

manually change any settings on the device.

Interrupt Channel Selection

The AT-DIO-32HS increases bus efficiency by using an interrupt

channel for event notification. Th e AT-DI O-32HS can use interrupt

channel 3, 4, 5, 6, 7, 9, 10, 11, 12, 14, or 15. This selection is softwareconfigured and does not require you to manually change any settings on

the device.

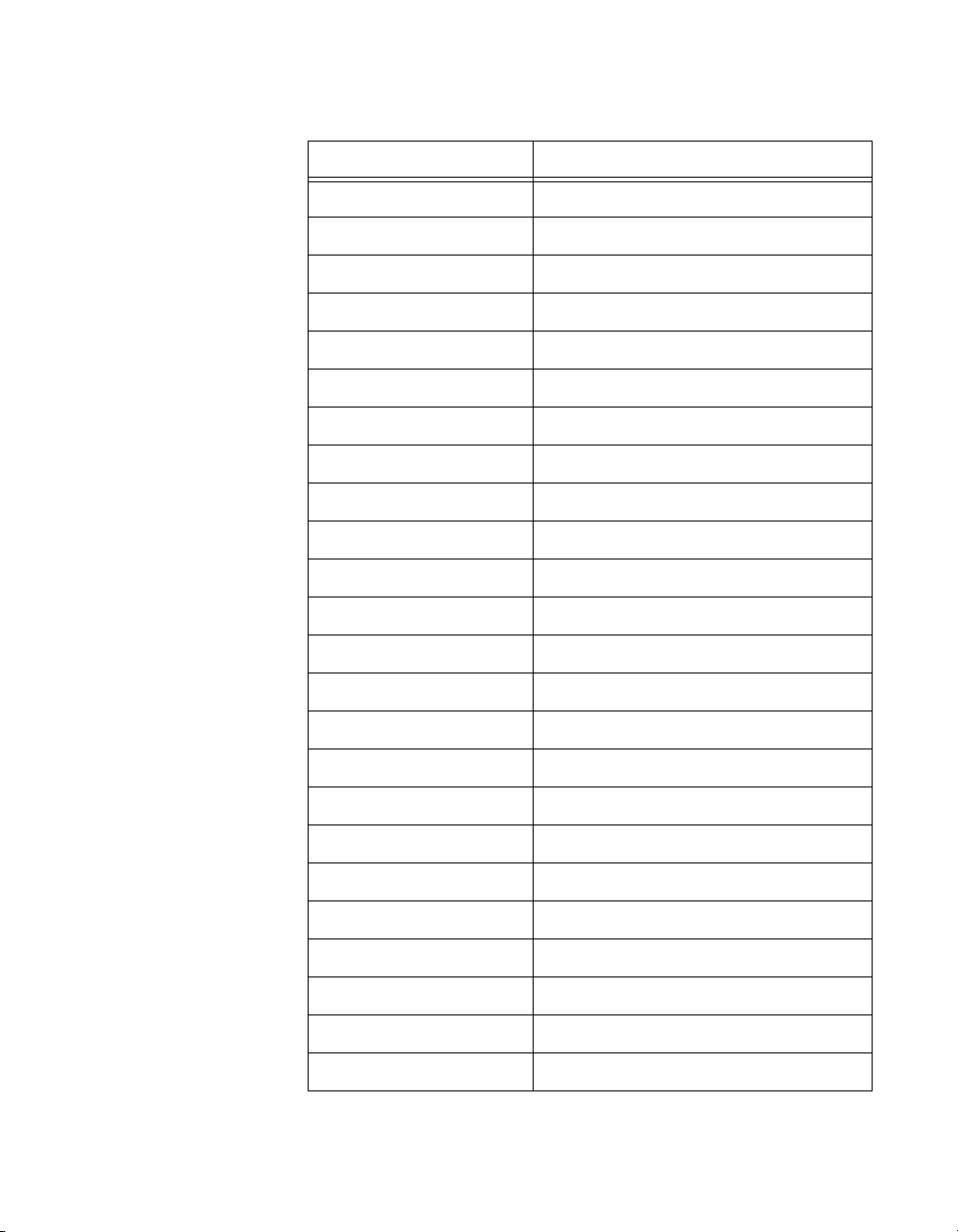

Tables 2-1, 2-2, and 2-3 provide information concerning possible

conflicts in base address, DMA cha nnel, and interr upt chan nel

assignment when configuring you r AT-DIO -32HS de vice.

Table 2-1.

I/O Address Range (Hex) Device

100 to 1EF —

1F0 to 1F8 IBM PC AT Fixed Disk

200 to 20F PC and PC AT Game Controller, reserve d

210 to 213 PC-DIO-24 – default

218 to 21F —

220 to 23F Previous generation of AT-MIO boards – default

DIO 6533 User Manual 2-6 © National Instruments Corporation

PC AT I/O Address Map

Page 27

Chapter 2 Installation and Configuration

Table 2-1. PC AT I/O Address Map (Continued)

I/O Address Range (Hex) Device

240 to 25F AT-DIO-32F – default

260 to 27F Lab-PC/PC+ – default

278 to 28F AT Parallel Printer Port 2 (LPT 2)

279 Reserved for Plug and Play operation

280 to 29F WD EtherCard+ – default

2A0 to 2BF —

2E2 to 2F7 —

2F8 to 2FF PC, AT Serial Port 2 (COM2)

300 to 30F 3Com EtherLink – defa ul t

310 to 31F —

320 to 32F IBM PC/XT Fixed Disk Controll er

330 to 35F —

360 to 363 PC Network (low address)

364 to 367 Reserved

368 to 36B PC Network (high address)

36C to 36F Reserved

370 to 366 PC, AT Parallel Printer Port 1 (LPT1)

380 to 38C SDLC Communications

380 to 389 Bisynchronous (BSC) Communications (alternate )

390 to 393 Cluster Ada pter 0

394 to 39F —

3A0 to 3A9 BSC Communications (primary)

3AA to 3AF —

3B0 to 3BF Monochrome Display/Parallel Printer Adapter 0

© National Instruments Corporation 2-7 DIO 6533 User Manual

Page 28

Chapter 2 Installation and Configuration

I/O Address Range (Hex) Device

Table 2-2 shows the PC AT interrupt assignments.

Table 2-1. PC AT I/O Address Map (Continued)

3C0 to 3CF Enhanced Graphics Adapter, VGA

3D0 to 3DF Color/Graphics Monitor Adapter, VGA

3E0 to 3EF —

3F0 to 3F7 Diskette Controller

3F8 to 3FF Serial Port 1 (COM1)

A79 Reserved for Plug and Play operation

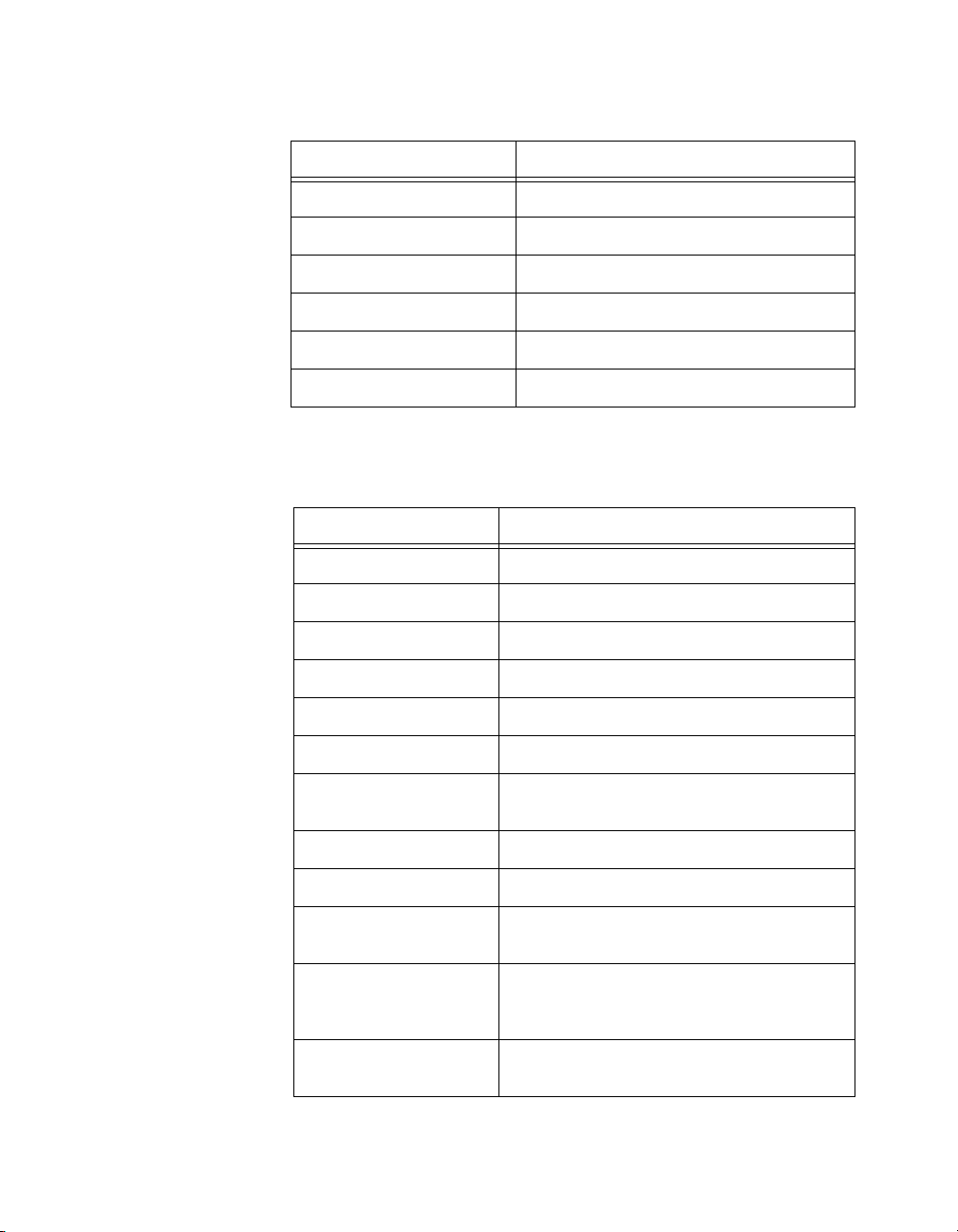

Table 2-2. PC AT Interrupt Assignment Map

IRQ Device

15 Available

14 Fixed Disk Controller

13 Coprocessor

12 AT-DIO-32F – default

11 AT-DIO-32F – default

10 AT-MIO-16 – default

9 PC Network – default

8 Real-Time Clock

7 Parallel Port 1 (LPT1)

6 Diskette Drive Control ler

5 Parallel Port 2 (LPT2)

4 Serial Port 1 (COM1)

PC Network Alternate – defa ult

Fixed Disk and Diskette Drive Controller

PC-DIO-24 – default

Lab-PC/PC+ – default

BSC, BSC Alternate

DIO 6533 User Manual 2-8 © National Instruments Corporation

Page 29

Chapter 2 Installation and Configuration

Table 2-2. PC AT Interrupt Assignment Map (Continued)

IRQ Device

3 Serial Port 2 (COM2)

2 IRQ 8-15 Chain (from in terrupt controller 2)

1 Keyboard Controller Output Buffer Full

0 Timer Channel 0 Output

BSC, BSC Alternate

Cluster (primary)

PC Network, PC Network Alte rna te

WD EtherCard+ – default

3Com EtherLink – default

Table 2 -3 shows the PC AT 16- bit DMA chan nel assignmen ts.

Table 2-3. PC AT 16-Bit DMA Channel Assignment Map

Channel Device

7 AT-MIO-16 Series – default

6 AT-MIO-16 Series – default

5 AT-DIO-32F – default

4 Cascade for DMA Controll er #1 (ch ann els<0..3>)

AT-DIO-32F – default

Note: EISA computers also have channels<0..3> available as 16-bit DMA

channels.

© National Instruments Corporation 2-9 DIO 6533 User Manual

Page 30

Chapter

Hardware Overview

This chapter provides an overview of the ha rdwa re f unc tions of your

DIO6533 device.

Each 6533 device contains the National Instruments DAQ-DIO chip, a

32-bit general-purpose digital I/O interface. The DAQ-DIO chip

enables the 6533 device to perform single-line and single-point input

and output, digital data acquisition, digital waveform generation, a nd

high-speed data transfer using a wide range of ha ndshaking protoc ols.

Figures3-1,3-2, and3-3 show the block diagrams for the 6533devices.

3

© National Instruments Corporation 3-1 DIO 6533 User Manual

Page 31

Chapter 3 Hardware Overview

PCI I/O Channel

Data Lines

(32)

MITE PCI

Interface

EEPROM

Data Lines

Bus

Interface

DMA/

Interrupt

Requests

Counters

and

Timers

20 MHz RTSI

Oscillator Interface

Internal

FIFOs

DAQ-DIO

Clock

Selection

RTSI/PXI Trigger Bus

Data Latches

and

Drivers

Handshaking

and

Control

Request

Processing

Control

Lines (8)

Figure 3-1. PCI-DIO-32HS/PXI-6533 Block Diagram

(32)

Connector

I/O

DIO 6533 User Manual 3-2 © National Instruments Corporation

Page 32

Chapter 3 Hardware Overview

AT I/O Channel

Data Lines

(16)

AT Plug and Play

Interface

EEPROM

Bus

Interface

DMA/

Interrupt

Requests

Counters

and

Timers

20 MHz RTSI

Oscillator Interface

Internal

FIFOs

DAQ-DIO

Clock

Selection

Data Latches

and

Drivers

Handshaking

and

Control

Request

Processing

RTSI Bus

Figure 3-2. AT-DIO-32HS Block Diagram

Data Lines

(32)

Control

Lines (8)

Connector

I/O

© National Instruments Corporation 3-3 DIO 6533 User Manual

Page 33

Chapter 3 Hardware Overview

Data Lines

(16)

PCMCIA

Interface

PCMCIA I/O Channel

Bus

Interface

DMA/

Interrupt

Requests

Counters

and

Timers

20 MHz

Oscillator

Internal

FIFOs

DAQ-DIO

Clock

Selection

Data Latches

and

Drivers

Handshaking

and

Control

Request

Processing

Figure 3-3. DAQCard-6533 Block Diagram

Data Lines

(32)

Control

Lines (8)

Connector

I/O

Unstrobed I/O

The 6533 devices can perform unstrobed I/O, which is basic digital I/O

that employs no handshaking or har dwa re-contro lled timing. You ca n

write or read data directly to or from the four digital I/O ports of the

6533 devices. The I/O ports contain eight lines each and are labeled A,

B, C, and D. You can conf igure ea ch line individua lly for e ither input

or output.

When you perform only unstrobed I/O, the 6533 device does not require

its handshaking control and status signals to carry timing information .

Therefore, you can use the REQ and STOPTRIG lines as extra data

inputs, and the ACK an d PCLK lines as ex tra da ta ou tputs.

DIO 6533 User Manual 3-4 © National Instruments Corporation

Page 34

Chapter 3 Hardware Overview

Strobed I/O—Pattern Generation and Handshaking

The 6533 devices can also perf orm strobed I/O. Strobe d I/O is data

transfer in which the 6533 hardware regulates tim ing or perform s

handshaking functions. The 6533 devices have two handsha king

controllers and can perfo rm up to two strobed ope rations

simultaneously. The operations can be input transfers, output transfers,

or one of each.

You select the width of each transfer by allocating the digital I/O ports

into two groups for the two c ontr ollers. For example , by a llocating

ports A a nd B to g roup 1, you c an p erfo rm a 16 -bit str obed transfe r

using the group 1 controller. Any por t that you do not allocate to a

group, you can use for unstrobed I/O.

LabVIEW users should note that the LabVIEW documentation uses the

term group in another context. LabVIE W grou ps do not corresp ond

directly to hardware g rou ps.

Each hardware group ha s its ow n, ind epen dent set o f tim ing con trol

lines—ACK (STARTTRIG), REQ, PCLK, and STOPTRIG—to carry

control, status, clock ing, and trigg er inf orm ation.

Any external device that the 6533 de vices control, monitor, test, or

communicate with is referred to as a peripheral device.

Strobed operations fall into two categories—pattern generation and

full, or two-way, handshaking transfer.

In pattern generation, data acquisition applications typically requ ire

sampling input data at a predetermined frequenc y. Similarly,

waveform-generation applications re quire driving outpu t data to

specific output patterns at a predetermined frequency. You can regulate

the frequency by supplying a timing signal to the REQ line; this signal

is an external request. The 6533 de vices can also gene rate their own

REQ pulses, or internal r eque sts. Eac h grou p h as a 32-bit co unter to

regulate the period between transfers.

In pattern generation, you can also supply start and stop triggers to

begin and end an opera tion. You can selec t e ither a rising ed ge or a

falling edge as a trigger signal. You can also trigger when the

6533 device detects a specified digital pattern on its data lines.

© National Instruments Corporation 3-5 DIO 6533 User Manual

Page 35

Chapter 3 Hardware Overview

A variant of pattern generation is change detection. In change detection,

the 6533 device generates an interna l re quest only w hen the input data

changes. This feature allows you to monitor activity on the input lines

efficiently, without capturing multiple copies of the same input pattern.

See the Pattern and Change Detection section for more information.

In full, or two-way, handshaking transfer, control information passes

both to and from the peripheral device . The 6533 device a nd the

peripheral device each provides the other wi th strobe signals a s data

becomes available or is acquired. By withholding strobe signals, either

the 6533 device or the peripheral device can slow down the transfer, if

necessary. Because of this capability, and because fixed rates are not

critical, you can run full-hand shaking operations at th e highest p ossible

speeds.

Pattern and Change Detection

You can configure the 6533 device to do several types of pattern and

change detection. These modes add additional monitoring capabilities

to strobed input operation.

Pattern-Detection Triggers

You can configure the 6533 device to search f or a partic ular pa ttern in

the input data. When the pattern occurs, the 6533 device ca n:

• Generate a start trigger to begin a digital data acquisition operation

• Generate a stop trigger to end a digital data acquisition operation

To use a start or stop trigger, you must configure the 6533 devic e for

pattern-generation mode. See Chapter5, Signal Timing, for more

information on start and stop triggers.

You can specify the following three parameters to the pattern-detection

circuit:

• A mask, declaring which data bits you wish to examine

• The pattern value you wish to search for

• Polarity (whether to search for data that matches or that mismatches

the specified pattern)

DIO 6533 User Manual 3-6 © National Instruments Corporation

Page 36

Figure3-4 shows a patt ern-de t ect ion example.

Chapter 3 Hardware Overview

Value to Detect

Pattern

Mask

Polarity

Figure 3-4. Pattern Detection Example

XXXXXX10

00000010

00000011

Postive: Search for Match

The 6533 device provides the following two types of pattern detection

timing:

• Compare all data to the input pattern immediately, without waiting

for a request pulse (typica lly us ed for start trig gers).

• Compare acquired data to the pa ttern, after a re quest pulse str obes

the data in (typically used for stop triggers).

In immediate, unstrobed pattern-detection, the 6533 device detects any

occurrence of the pattern, with or w ithout a request strobe. Howeve r,

the 6533 device filters out very short patte rn ma tches, to ensure that a

transient data value that occurs during line switching does not falsely

cause a match. A glitch must be present for no more than 20ns to

guarantee rejection. A valid pattern must be present for at least 60ns to

guarantee detection.

In strobed, request-based pattern detection, data is checked as it is

strobed in by request pulses. Strobed pattern detection is typically used

to generate triggers. You can use strobed pa ttern detection to ge nera te

start triggers too, but only when using an external request source. See

the Request Timing section in Chapter5, Signal Timing, for the timing

of the request pulses that strobe in data.

Change Detection

You can configure the 6533 device to search for transitions on one or

more input lines. Whenever a change occurs, the 6533 device generates

an internal request, capturing the new input pattern.

© National Instruments Corporation 3-7 DIO 6533 User Manual

Page 37

Chapter 3 Hardware Overview

The pattern mask, which selects the bits that are significant for pattern

detection, also applies to change detec tion. The 6533 device monitors

only the significant bits for changes. After detecting a change, however,

the 6533 device captures the values of all bits.

Change detection can increase CPU and bus efficiency for control

applications. You can monitor activity on input lines without

continuously polling, and without transferring unnecessary data during

periods of inactivity.

After a change occurs, the 6533 device takes from 50to 150ns to clock

in the new data. Therefore, the resolution of change detection is 150ns.

Repeatedly changing data is also subject to the usual pattern generation

rate limits; see the Transfer Rates section in this chapter for more

information.

You can use change detection in conjunction with pattern detection.

Within a single group, the change and pattern detect ion masks are the

same; input lines that are significant for pattern detection are also

significant for change detection.

Message Generation

Some software environments, such a s La bVIE W and

LabWindows/CVI, support message generation. Messages allow you to

run a user-specified routine when a particular data acquisition event

occurs. For example:

• Generate a message upon acquisition of a specified input pattern

• Generate a message every time the 6533devi ce transfers a data

point. You can apply this option to change-de tection mode to

generate a message every time the input data changes.

These message-generation options can extend your pattern and

change-detection capabilities. Some message-generation options

require that you select interrupt-driven rather than DMA transfers. See

your software documentation for further information about messa ges.

Handshaking Protocols

When you perform full, two-way handshaking operations, you can

select among several timing protocols offered by the 6533 devices. The

protocol you select determines the timing of the ACK signals that the

6533 device sends to the peripheral device and of the REQ signals

DIO 6533 User Manual 3-8 © National Instruments Corporation

Page 38

Chapter 3 Hardware Overview

expected from the peripheral device. One protocol, burst mode, a lso

uses PCLK signals.

The following sections describe the handshaking prot ocols offe red by

the 6533 devices. Refer to Table3-1 for further information on thes e

protocols. For timing details, see Chapter5, Signal Timing.

8255 Emulation

The 8255 emulation protocol emulates the strobed protocols obeyed by

the 8255 and 82C55 PPI chips—chips that are used, for example, on the

National Instruments PC-DIO-24 and PC-DIO -96/PnP. Be cause of

faster response times, a wide r da ta path, and FIFO buff er ing, 8255

emulation mode offers much higher data transfer ra tes than an actual

8255 chip. The 8255 emulation protocol offers the highest peak transfer

rate of any protocol except burst mode.

Level ACK

After each transfer, the 6533 device asserts the ACK signal to the

peripheral device. Holding the ACK line at the asserted level, the

6533device does not begin a new transfer until a false-to-true tra nsition

on the REQ line from the peripheral device occurs.

Leading-Edge Pulse

After each transfer, the 6533 device sends a pulse on the ACK line to

the peripheral device. The 6533 devic e then waits for a false-to-true

transition on the REQ line, the start of a REQ pulse, before starting a

new transfer. You can specify an AC K pulse delay.

Long Pulse

Long-pulse mode is the same as le ading-edge pulse mode , exce pt that

you can specify a minimum pulse width, instead of an ACK pulse delay.

Trailing-Edge Pulse

After each transfer, the 6533 device sends a pulse on the ACK line to

the peripheral device. The 6533 device waits for a true-to-false

transition on the REQ line, the end of a REQ pulse, before starting a

new transfer.

© National Instruments Corporation 3-9 DIO 6533 User Manual

Page 39

Chapter 3 Hardware Overview

Burst Mode

The 6533 device sends or receives a c loc k signal to or fr om the

peripheral device over the PCLK line. Every cycle, the 6533 device

asserts an ACK signal if ready for a transfer, and th e perip h er al device,

likewise, asserts a REQ signal if ready for a transfer. Each cycle during

which both the 6533 device and the peripheral device indicate that they

are ready for a transfer, one data point is latched. Burst mode c an

transfer data at high rates, particularly over short ca bles.

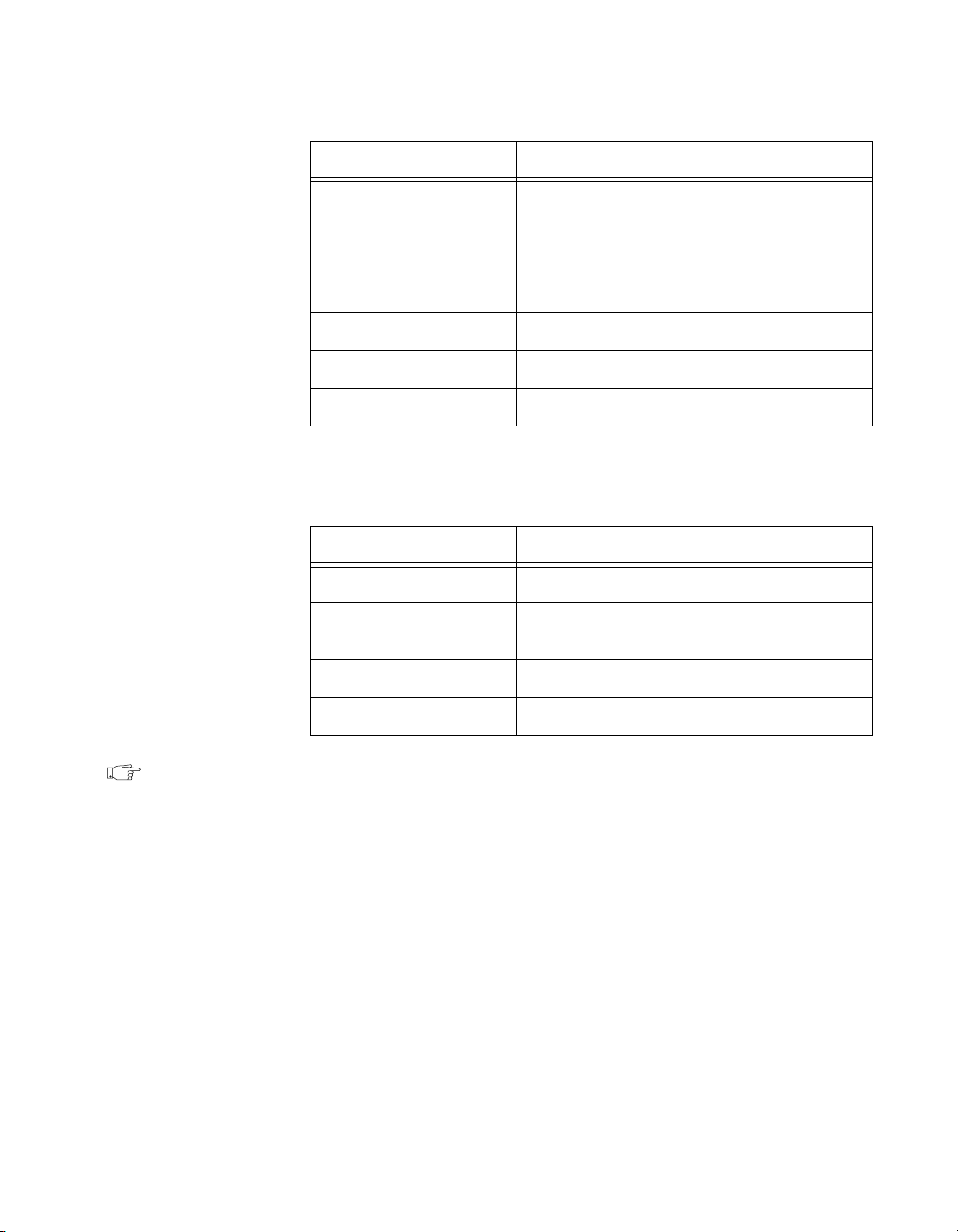

Comparing Protocols

Table3-1 shows similarities and diffe renc es a mong the 6533 devi ce

handshaking modes. Asynchronous protocols use only the ACK and

REQ signals. Burst mode, a synchronous protocol, uses the ACK, REQ,

and PCLK signals. The PCLK line shares a clock signal between the

6533 device and the peripheral de vice .

Table3-1 shows peak handshaking rates f or typical ca ble len gths. The

peak rates give an upper limit, deriving from the pulse widths and other

timing specifications of the handshaking protocol. Your actual

maximum rate depends on many factors; see the Transfer Rates section

in this chapter.

Table3-1 also shows whether the ACK a nd RE Q signa ls are active

high, active low, or programma ble polar ity. The table shows w het her

the leading or trailing edge of a REQ pulse initiates a data transfer. The

table also describes the ef fect on eac h protocol of se tting a

programmable delay. See Chapter5, Signal Timing, for timing details.

The table also shows complementary protocols with which the protocol

can communicate, assuming that you choose complementary settings

for any options the two protocols offer . For example, a 6533 device in

8255 emulation mode can communicate wi th a 6533 de vice in long

pulse mode, if you select A CK and REQ to be active low.

DIO 6533 User Manual 3-10 © National Instruments Corporation

Page 40

Chapter 3 Hardware Overview

Table 3-1.

Protocol Peak Rates (MS/s)

at Various Cable

Lengths

1 m 2 or 5 m

Asynchronous Protocols

8255

Emulation

Level

ACK

LeadingEdge Pulse

Long Pulse 3.33 2.5 Programmable Leading For pulse width

TrailingEdge Pulse

5 2.67 Active-low Trailing Between

3.33 2.5 Programmable Leading Before ACK

3.33 2.5 Programmable Leading Before ACK

1.8 1.5 Prog rammable Trailing For pulse width

653 3 Handshaking Protocols

REQ and ACK

Polarity

That Requests

REQ Edge

Transfer

Programmable

Delay Location

transfers

and between

transfers

and between

transfers

and between

transfers

and between

transfers

Complementary

Protocols

Leading-Edge

Pulse

Level ACK

Leading-Edge

Pulse

Long Pulse,

8255

Emula-tion,

PC-DIO-24,

PC-DIO-96/PnP,

8255, 82C55

Trailing-Edge

Pulse

Synchronous Protocol

Burst 20 10* Programmable Neither

(level REQ)

* Although asynchronous modes can adjust automatically to cable length, for synchronous modes, you must

select an appropriate speed for your cable at configuration time. Select a delay of at least the following: 0 for

a typical cable up to 1 m, 1 (100 ns) for a typical cable up to 5 m, and 2 (200 ns) for a typical cable up to 15 m

long.

For clock speed Burst

© National Instruments Corporation 3-11 DIO 6533 User Manual

Page 41

Chapter 3 Hardware Overview

Starting a Handshaking Transfer

Starting a handshaking transfer correctly protects against incorrect or

missed data when the ACK and REQ lines are ch anging po larity to

active-high or active-low. This is particularly important in burst mode

because of the potential to miss a lot of data. You ca n us e ei ther of the

following two startup methods:

• Control the configuration an d startup se quen ce .

• Select compatible line polarities and default line levels.

Controlling the Startup Sequence

One startup method is to follow a prescribed initialization order in

which you can ma ke su re the 6 533 devic e is c on figure d and is d riving

a valid ACK value before you enable the transfer on the perip heral

device. Similarly, you can make sure the peripheral device is configured

and is driving a valid REQ value before you enable the transfer on the

6533 device.

To use a prescribed initialization order, perform the following steps:

1. Configure the 6533 devic e for a protoco l compatible with your

peripheral device.

2. Configure and reset the perip heral device, if appropriate.

3. Enable the inpu t device (6533 de vice or peripher al device) and

begin a transfer.

4. Enable th e outp ut de vice (6 533 de vic e or p eriphe ral devic e) a nd

begin a transfer.

To control the startup order, you must be able to enable and disable the

peripheral device , a nd you m ust c ontrol the ord er in which the 6533

device and the pe riphera l dev ice are ena bled. T he 65 33 devic e ex tra

input and output lines can be helpful for these purposes.

Controlling the startup sequence does not ap ply to buffer ed (bloc k)

operations. In a buffered operation, the NI-DAQ sof tware con figures

and enables the 6533 device at the same time, whe n you star t the actu al

data transfer. For buffered operations, therefore, use the second startup

method, controlling the line polarities.

DIO 6533 User Manual 3-12 © National Instruments Corporation

Page 42

Transfer Rates

Chapter 3 Hardware Overview

Controlling Line Polarities

If you cannot control the initialization order of the 6533 device and

peripheral device, you can still start a transfer reliably if you select the

polarities of the ACK and REQ lines so that the power-up, undriven

states of the control lines are the inactive states.

By default, the power-up, undrive n stat e of the REQ and ACK lines is

low, due to the onboard 2.2kΩ pull-down re sistors. There fore, you

should either select a protocol w ith ac tive-high REQ and A CK signals

or use the CPULL bias-selection line or your own pull-up re sistors to

change the power-up, undriven control-line state to high. See Chapter4,

Signal Connections, for information on using the CPULL line to control

the 6533device pull-up and pull-down resistor s.

The maximum average transfer rate that the 6533 d evice can achieve for

two-way handshaking applications is the lower of the following two

rates:

• The peak handshaking rate from Table3-1, which c an be lowe red

by the handshaking speed of your peripheral device

•The average available bus bandwidth, ba sed on your computer

system, the number of other devices generating bus cycles, and

your application software

The maximum sustainable transfer rate the 6533device can achieve for

pattern generation application is the minimum available bus bandwidth,

based on your computer system, the number of other devices generating

bus cycles, and your application software (this rate is always lower than

the peak pattern gene ration ra te).

To achieve the highest possible rates, consider the follow ing

information:

• Full, two-way handshaking is faster than pattern generation,

because two-way handsha king uses the average rathe r than the

minimum bus bandwidth.

• Burst mode is the fastest handshaking protocol, especially for short

cables.

• Your system bus should be as free a s possible fr om unrelate d

activity. Minimize the number of other I/O cards active in the

system.

© National Instruments Corporation 3-13 DIO 6533 User Manual

Page 43

Chapter 3 Hardware Overview

• Direct-memory access (DMA) transfers are faster than

interrupt-driven transfers, especially for pattern generation. By

default, the software uses DMA if available.

♦ The PCI-DIO-32HS always supports DMA transfers.

♦ The PXI-6533 supports DMA if inserted into a p eripheral slot t hat

allows bus arbitration (bus mastering). When using a slot that does

not allow bus arbitration, use software to select interrupt-driven

transfers.