Page 1

DAQ

6023E/6024E/6025E User Manual

Multifunction I/O Devices for PCI, PXI ,

CompactPCI, and PCMCIA Bus Computers

6023E/6024E/6025E User Manual

December 2000 Edition

Part Number 322072C-01

Page 2

Support

Worldwide Technical Support and Product Information

ni.com

National Instruments Corporate Headquarters

11500 North Mopac Expressway Austin, Texas 78759-3504 USA Tel: 512 794 0100

Worldwide Offices

Australia 03 9879 5166, Austria 0662 45 79 90 0, Belgium 02 757 00 20, Brazil 011 284 5011,

Canada (Calgary) 403 274 9391, Canada (Ottawa) 613 233 5949, Canada (Québec) 514 694 8521,

China (Shanghai) 021 6555 7838, China (ShenZhen) 0755 3904939, Denmark 45 76 26 00,

Finland 09 725 725 11, France 01 48 14 24 24, Germany 089 741 31 30, Greece 30 1 42 96 427,

Hong Kong 2645 3186, India 91805275406, Israel 03 6120092, Italy 02 413091, Japan 03 5472 2970,

Korea 02 596 7456, Mexico 5 280 7625, Netherlands 0348 433466, New Zealand 09 914 0488,

Norway 32 27 73 00, Poland 0 22 528 94 06, Portugal 351 1 726 9011, Singapore 2265886, Spain 91 640 0085,

Sweden 08 587 895 00, Switzerland 056 200 51 51, Taiwan 02 2528 7227, United Kingdom 01635 523545

For further support information, see the Technical Support Resources appendix. To comment on the

documentation, send e-mail to techpubs@ni.com

© Copyright 1998, 2000 National Instruments Corporation. All rights reserved.

Page 3

Important Information

Warranty

The DAQCard-6024E, PCI-6023E, PCI-6024E, PCI-6025E, and PXI-6025E devices are warranted against defectsin materials and

workmanship for a period of one year from the date of shipment, as evidenced by receipts or other documentation. National

Instruments will, at its option, repair or replace equipment that proves to be defective during the warranty period. This warranty

includes parts and labor.

The media on which you receive National Instruments software are warranted not to fail to execute programming instructions,

due to defects in materials and workmanship, for a period of 90 days from date of shipment, as evidenced by receipts or other

documentation. National Instruments will, at its option, repair or replace software media that do not execute programming

instructions if National Instruments receives notice of such defects during the warranty period. National Instruments does not

warrant that the operation of the software shall be uninterrupted or error free.

A Return Material Authorization (RMA) number must be obtained from the factory and clearly marked on the outside of

the package before any equipment will be accepted for warranty work. National Instruments will pay the shipping costs of

returning to the owner parts which are covered by warranty.

National Instruments believes that the information in this document is accurate. The document has been carefully reviewed

for technical accuracy. In the event that technical or typographical errors exist, National Instruments reserves the right to

make changes to subsequent editions of this document without prior notice to holders of this edition. The reader should consult

National Instruments if errors are suspected. In no event shall National Instruments be liable for any damages arising out of

or related to this document or the information contained in it.

E

XCEPT AS SPECIFIED HEREIN,NATIONAL INSTRUMENTS MAKES NO WARRANTIES, EXPRESS OR IMPLIED, AND SPECIFICALLY DISCLAIMS ANY

Copyright

WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE

NEGLIGENCE ON THE PART OF

INSTRUMENTS WILL NOT BE LIABLE FOR DAMAGES RESULTING F ROM LOSS OF DATA, PROFITS, USE OF PRODUCTS, OR INCIDENTAL OR

CONSEQUENTIAL DAMAGES

apply regardless of the form of action, whether in contract or tort, including negligence. Any action against National Instruments

must be brought within one year after the cause of action accrues. National Instruments shall not be liable for any delay in

performance due to causes beyond its reasonable control. The warranty provided herein does not cover damages, defects,

malfunctions, or service failures caused by owner’s failure to follow the National Instruments installation, operation, or

maintenance instructions; owner’s modification of the product; owner’s abuse, misuse, or negligent acts; and power failure or

surges, fire, flood, accident, actions of third parties, or other events outside reasonable control.

Under the copyright laws, this publication may not be reproduced or transmitted in any form, electronic or mechanical, including

photocopying, recording, storing in an information retrieval system, or translating, in whole or in part, without the prior written

consent of National Instruments Corporation.

NATIONAL INSTRUMENTS SHALL BE LIMITED TO THE AMOUNT THERETOFORE PAID BY THE CUSTOMER.NATIONAL

, EVEN IF ADVISED OF THE POSSIBILITY THEREOF. This limitation of the liability of National Instruments will

.CUSTOMER’S RIGHT TO RECOVER DAMAGES CAUSED BY FAULT OR

Trademarks

CVI™, DAQ-STC™,LabVIEW™, Measurement Studio™,MITE™, National Instruments™,ni.com™, NI-DAQ™, NI-PGIA™,

™

,RTSI™,SCXI™,andVirtualBench™are trademarks of National Instruments Corporation.

PXI

Product and company names mentioned herein are trademarks or trade names of their respective companies.

WARNING REGARDING USE OF NATIONAL INSTRUMENTS PRODUCTS

(1) NATIONAL INSTRUMENTS PRODUCTS ARENOT DESIGNED WITH COMPONENTS AND TESTING FOR A LEVEL

OF RELIABILITY SUITABLE FOR USE IN OR IN CONNECTION WITH SURGICAL IMPLANTS OR AS CRITICAL

COMPONENTS IN ANY LIFE SUPPORT SYSTEMS WHOSE FAILURE TO PERFORM CAN REASONABLY BE

EXPECTED TO CAUSE SIGNIFICANT INJURY TO A HUMAN.

(2) IN ANY APPLICATION, INCLUDING THEABOVE, RELIABILITYOF OPERATION OF THE SOFTWARE PRODUCTS

CAN BE IMPAIRED BY ADVERSE FACTORS, INCLUDING BUT NOT LIMITED TO FLUCTUATIONS IN ELECTRICAL

POWER SUPPLY, COMPUTER HARDWARE MALFUNCTIONS, COMPUTER OPERATING SYSTEM SOFTWARE

FITNESS, FITNESS OF COMPILERS AND DEVELOPMENT SOFTWARE USED TO DEVELOP AN APPLICATION,

INSTALLATION ERRORS, SOFTWARE AND HARDWARE COMPATIBILITY PROBLEMS, MALFUNCTIONS OR

FAILURES OF ELECTRONIC MONITORING OR CONTROL DEVICES, TRANSIENT FAILURES OF ELECTRONIC

SYSTEMS (HARDWARE AND/OR SOFTWARE), UNANTICIPATED USES OR MISUSES, OR ERRORS ON THE PART OF

THE USER OR APPLICATIONS DESIGNER (ADVERSE FACTORS SUCH AS THESE ARE HEREAFTER

COLLECTIVELY TERMED “SYSTEM FAILURES”). ANY APPLICATION WHERE A SYSTEM FAILURE WOULD

CREATE A RISK OF HARM TO PROPERTY OR PERSONS (INCLUDING THE RISK OF BODILY INJURY AND DEATH)

SHOULD NOT BE RELIANT SOLELY UPON ONE FORM OF ELECTRONIC SYSTEM DUE TO THE RISK OF SYSTEM

FAILURE. TO AVOID DAMAGE, INJURY, OR DEATH, THE USER OR APPLICATION DESIGNER MUST TAKE

REASONABLY PRUDENT STEPS TO PROTECT AGAINST SYSTEM FAILURES, INCLUDING BUT NOT LIMITED TO

BACK-UP OR SHUT DOWN MECHANISMS. BECAUSE EACH END-USER SYSTEM IS CUSTOMIZED AND DIFFERS

FROM NATIONAL INSTRUMENTS' TESTING PLATFORMS AND BECAUSE A USER OR APPLICATION DESIGNER

MAY USE NATIONAL INSTRUMENTS PRODUCTS IN COMBINATION WITH OTHER PRODUCTS IN A MANNER NOT

EVALUATED OR CONTEMPLATED BY NATIONAL INSTRUMENTS, THE USER OR APPLICATION DESIGNER IS

ULTIMATELY RESPONSIBLE FOR VERIFYING AND VALIDATING THE SUITABILITY OF NATIONAL

INSTRUMENTS PRODUCTS WHENEVER NATIONAL INSTRUMENTS PRODUCTS ARE INCORPORATED IN A

SYSTEM OR APPLICATION, INCLUDING, WITHOUT LIMITATION, THE APPROPRIATE DESIGN, PROCESS AND

SAFETY LEVEL OF SUCH SYSTEM OR APPLICATION.

Page 4

Contents

About This Manual

Conventions Used in This Manual.................................................................................xi

Related Documentation..................................................................................................xii

Chapter 1

Introduction

Features of the 6023E, 6024E, and 6025E.....................................................................1-1

Using PXI with CompactPCI.........................................................................................1-2

What You Need to Get Started ......................................................................................1-2

Software Programming Choices ....................................................................................1-3

National Instruments Application Software ....................................................1-3

NI-DAQ Driver Software ................................................................................1-4

Optional Equipment.......................................................................................................1-5

Chapter 2

Installation and Configuration

Software Installation ......................................................................................................2-1

Unpacking......................................................................................................................2-1

Hardware Installation.....................................................................................................2-2

Hardware Configuration ................................................................................................ 2-3

Chapter 3

Hardware Overview

Analog Input ..................................................................................................................3-2

Input Mode ......................................................................................................3-2

Input Range .....................................................................................................3-3

Dithering..........................................................................................................3-4

Multichannel Scanning Considerations...........................................................3-5

Analog Output................................................................................................................3-6

Analog Output Glitch ......................................................................................3-6

Digital I/O ......................................................................................................................3-7

Timing Signal Routing................................................................................................... 3-7

Programmable Function Inputs .......................................................................3-8

Device and RTSI Clocks .................................................................................3-9

RTSI Triggers..................................................................................................3-9

© National Instruments Corporation v 6023E/6024E/6025E User Manual

Page 5

Contents

Chapter 4

Signal Connections

I/O Connector ................................................................................................................ 4-1

Analog Input Signal Overview...................................................................................... 4-8

Types of Signal Sources.................................................................................. 4-8

Analog Input Modes........................................................................................ 4-9

Analog Input Signal Connections.................................................................................. 4-11

Differential Connection Considerations (DIFF Input Configuration) ............ 4-13

Single-Ended Connection Considerations ...................................................... 4-17

Common-Mode Signal Rejection Considerations........................................... 4-19

Analog Output Signal Connections............................................................................... 4-19

Digital I/O Signal Connections ..................................................................................... 4-20

All Devices...................................................................................................... 4-20

Programmable Peripheral Interface (PPI) ..................................................................... 4-22

Port C Pin Assignments .................................................................................. 4-23

Power-up State ................................................................................................ 4-24

Timing Specifications ..................................................................................... 4-25

Mode 1 Input Timing ...................................................................................... 4-27

Mode 1 Output Timing ................................................................................... 4-28

Mode 2 Bidirectional Timing.......................................................................... 4-29

Power Connections........................................................................................................ 4-30

Timing Connections ...................................................................................................... 4-30

Programmable Function Input Connections ................................................... 4-31

DAQ Timing Connections .............................................................................. 4-32

Floating Signal Sources .................................................................... 4-9

Ground-Referenced Signal Sources.................................................. 4-9

Differential Connections for Ground-Referenced Signal Sources ... 4-14

Differential Connections for Nonreferenced or Floating Signal

Sources........................................................................................... 4-15

Single-Ended Connections for Floating Signal Sources

(RSE Configuration)...................................................................... 4-18

Single-Ended Connections for Grounded Signal Sources

(NRSE Configuration) ................................................................... 4-18

Changing DIO Power-up State to Pulled Low ................................. 4-24

SCANCLK Signal ............................................................................ 4-33

EXTSTROBE* Signal...................................................................... 4-33

TRIG1 Signal.................................................................................... 4-34

TRIG2 Signal.................................................................................... 4-35

STARTSCAN Signal........................................................................ 4-36

CONVERT* Signal .......................................................................... 4-38

AIGATE Signal ................................................................................ 4-39

SISOURCE Signal............................................................................ 4-40

6023E/6024E/6025E User Manual vi ni.com

Page 6

Field Wiring Considerations..........................................................................................4-49

Chapter 5

Calibration

Loading Calibration Constants ......................................................................................5-1

Self-Calibration..............................................................................................................5-2

External Calibration....................................................................................................... 5-2

Other Considerations .....................................................................................................5-3

Contents

Waveform Generation Timing Connections ...................................................4-40

WFTRIG Signal ................................................................................4-40

UPDATE* Signal..............................................................................4-41

UISOURCE Signal ...........................................................................4-42

General-Purpose Timing Signal Connections .................................................4-43

GPCTR0_SOURCE Signal............................................................... 4-43

GPCTR0_GATE Signal....................................................................4-44

GPCTR0_OUT Signal ...................................................................... 4-45

GPCTR0_UP_DOWN Signal ...........................................................4-45

GPCTR1_SOURCE Signal............................................................... 4-46

GPCTR1_GATE Signal....................................................................4-46

GPCTR1_OUT Signal ...................................................................... 4-47

GPCTR1_UP_DOWN Signal ...........................................................4-47

FREQ_OUT Signal ...........................................................................4-49

Appendix A

Specifications

Appendix B

Custom Cabling and Optional Connectors

Appendix C

Common Questions

Appendix D

Technical Support Resources

Glossary

Index

© National Instruments Corporation vii 6023E/6024E/6025E User Manual

Page 7

Contents

Figures

Figure 1-1. The Relationship Between the Programming Environment,

NI-DAQ, and Your Hardware............................................................... 1-5

Figure 3-1. PCI-6023E, PCI-6024E, PCI-6025E, and PXI-6025E

Block Diagram ...................................................................................... 3-1

Figure 3-2. DAQCard-6024E Block Diagram......................................................... 3-2

Figure 3-3. Dithering ............................................................................................... 3-5

Figure 3-4. CONVERT* Signal Routing................................................................. 3-8

Figure 3-5. PCI RTSI Bus Signal Connection.........................................................3-10

Figure 3-6. PXI RTSI Bus Signal Connection......................................................... 3-11

Figure 4-1. I/O Connector Pin Assignment for the 6023E/6024E........................... 4-2

Figure 4-2. I/O Connector Pin Assignment for the 6025E ...................................... 4-3

Figure 4-3. Programmable Gain Instrumentation Amplifier (PGIA) ...................... 4-10

Figure 4-4. Summary of Analog Input Connections ............................................... 4-12

Figure 4-5. Differential Input Connections for Ground-Referenced Signals .......... 4-14

Figure 4-6. Differential Input Connections for Nonreferenced Signals .................. 4-15

Figure 4-7. Single-Ended Input Connections for Nonreferenced or

Floating Signals .................................................................................... 4-18

Figure 4-8. Single-Ended Input Connections for Ground-Referenced Signals ....... 4-19

Figure 4-9. Analog Output Connections.................................................................. 4-20

Figure 4-10. Digital I/O Connections ........................................................................ 4-21

Figure 4-11. Digital I/O Connections Block Diagram............................................... 4-22

Figure 4-12. DIO Channel Configured for High DIO Power-up State with

External Load........................................................................................ 4-24

Figure 4-13. Timing Specifications for Mode 1 Input Transfer ................................ 4-27

Figure 4-14. Timing Specifications for Mode 1 Output Transfer ............................. 4-28

Figure 4-15. Timing Specifications for Mode 2 Bidirectional Transfer.................... 4-29

Figure 4-16. Timing I/O Connections ....................................................................... 4-31

Figure 4-17. Typical Posttriggered Acquisition ........................................................ 4-32

Figure 4-18. Typical Pretriggered Acquisition.......................................................... 4-33

Figure 4-19. SCANCLK Signal Timing.................................................................... 4-33

Figure 4-20. EXTSTROBE* Signal Timing ............................................................. 4-34

Figure 4-21. TRIG1 Input Signal Timing.................................................................. 4-34

Figure 4-22. TRIG1 Output Signal Timing ...............................................................4-35

Figure 4-23. TRIG2 Input Signal Timing.................................................................. 4-36

Figure 4-24. TRIG2 Output Signal Timing ...............................................................4-36

Figure 4-25. STARTSCAN Input Signal Timing...................................................... 4-37

Figure 4-26. STARTSCAN Output Signal Timing ................................................... 4-37

Figure 4-27. CONVERT* Input Signal Timing ........................................................ 4-38

Figure 4-28. CONVERT* Output Signal Timing...................................................... 4-39

Figure 4-29. SISOURCE Signal Timing ................................................................... 4-40

6023E/6024E/6025E User Manual viii ni.com

Page 8

Tables

Contents

Figure 4-30. WFTRIG Input Signal Timing ..............................................................4-41

Figure 4-31. WFTRIG Output Signal Timing............................................................4-41

Figure 4-32. UPDATE* Input Signal Timing............................................................4-42

Figure 4-33. UPDATE* Output Signal Timing .........................................................4-42

Figure 4-34. UISOURCE Signal Timing ...................................................................4-43

Figure 4-35. GPCTR0_SOURCE Signal Timing ......................................................4-44

Figure 4-36. GPCTR0_GATE Signal Timing in Edge-Detection Mode...................4-45

Figure 4-37. GPCTR0_OUT Signal Timing..............................................................4-45

Figure 4-38. GPCTR1_SOURCE Signal Timing ......................................................4-46

Figure 4-39. GPCTR1_GATE Signal Timing in Edge-Detection Mode...................4-47

Figure 4-40. GPCTR1_OUT Signal Timing..............................................................4-47

Figure 4-41. GPCTR Timing Summary.....................................................................4-48

Figure B-1. 68-Pin E Series Connector Pin Assignments ........................................B-3

Figure B-2. 68-Pin Extended Digital Input Connector Pin Assignments .................B-4

Figure B-3. 50-Pin E Series Connector Pin Assignments ........................................B-5

Figure B-4. 50-Pin Extended Digital Input Connector Pin Assignments .................B-6

Table 3-1. Available Input Configurations.............................................................3-3

Table 3-2. Measurement Precision ......................................................................... 3-3

Table 3-3. Pins Used by PXI E Series Device........................................................3-11

Table 4-1. I/O Connector Details............................................................................4-1

Table 4-2. I/O Connector Signal Descriptions........................................................4-4

Table 4-3. I/O Signal Summary..............................................................................4-7

Table 4-4. Port C Signal Assignments.................................................................... 4-23

Table 4-5. Signal Names Used in Timing Diagrams.............................................. 4-25

© National Instruments Corporation ix 6023E/6024E/6025E User Manual

Page 9

About This Manual

The 6023, 6024, and 6025 E Series boards are high-performance

multifunction analog, digital, and timing I/O boards for PCI, PXI,

PCMCIA, and CompactPCI bus computers. Supported functions include

analog input, analog output, digital I/O, and timing I/O.

This manual describes the electrical and mechanical aspects of the

PCI-6023E, PCI-6024E, DAQCard-6024E, PCI-6025E, and PXI-6025E

boards from the E Series product line and contains information concerning

their operation and programming.

Conventions Used in This Manual

The following conventions are used in this manual:

<> Angle brackets containing numbers separated by an ellipsis represent a

range of values associated with a bit or signal name—for example,

DBIO<3..0>.

♦ The ♦ symbol indicates that the text following it applies only to a specific

product, a specific operating system, or a specific software version.

This icon denotes a note, which alerts you to important information.

This icon denotes a caution, which advises you of precautions to take to

avoid injury, data loss, or a system crash.

bold Bold text denotes items that you must select or click on in the software,

such as menu items and dialog box options. Bold text also denotes

parameter names.

CompactPCI CompactPCI refers to the core specification defined by the PCI Industrial

Computer Manufacturer’s Group (PICMG).

italic Italic text denotes variables, emphasis, a cross reference, or an introduction

to a key concept. This font also denotes text that is a placeholder for a word

or value that you must supply.

monospace

© National Instruments Corporation xi 6023E/6024E/6025E User Manual

Monospace font denotes text or characters that you should enter from the

keyboard, sections of code, programming examples, and syntax examples.

This font is also used for the proper names of disk drives, paths, directories,

Page 10

About This Manual

programs, subprograms, subroutines, device names, functions, operations,

variables, filenames and extensions, and code excerpts.

NI-DAQ NI-DAQ refers to the NI-DAQ driver software for PC compatible

computers unless otherwise noted.

PXI PXI stands for PCI eXtensions for Instrumentation. PXI is an open

specification that builds off the CompactPCI specification by adding

instrumentation-specific features.

Related Documentation

The following documents contain information you may find helpful:

• DAQ-STC Technical Reference Manual

• National Instruments Application Note 025, FieldWiringandNoise

Considerations for Analog Signals

• PCI Local Bus Specification Revision 2.2

• PICMG CompactPCI 2.0 R2.1

• PXI Specification Revision 2.0

• PC Card (PCMCIA) 7.1 Standard

6023E/6024E/6025E User Manual xii ni.com

Page 11

Introduction

This chapter describes the 6023E, 6024E, and 6025E devices, lists what

you need to get started, gives unpacking instructions, and describes the

optional software and equipment.

Features of the 6023E, 6024E, and 6025E

The 6025E features 16 channels (eight differential) of analog input,

two channels of analog output, a 100-pin connector, and 32 lines of digital

I/O. The 6024E features 16 channels of analog input, two channels of

analog output, a 68-pin connector and eight lines of digital I/O. The 6023E

is identical to the 6024E, except that it does not have analog output

channels.

These devices use the National Instruments DAQ-STC system timing

controller for time-related functions. The DAQ-STC consists of three

timing groups that control analog input, analog output, and general-purpose

counter/timer functions. These groups include a total of seven 24-bit and

three 16-bit counters and a maximum timing resolution of 50 ns. The

DAQ-STC makes possible such applications as buffered pulse generation,

equivalent time sampling, and seamless changing of the sampling rate.

1

♦ PCI-6023E, PCI-6024E, PCI-6025E, and PXI-6025E only

With many DAQ devices, you cannot easily synchronize several

measurement functions to a common trigger or timing event. These devices

have the Real-Time System Integration (RTSI) bus to solve this problem. In

a PCI system, the RTSI bus consists of the National Instruments RTSI bus

interface and a ribbon cable to route timing and trigger signals between

several functions on as many as five DAQ devices in your computer. In a

PXI system, the RTSI bus consists of the National Instruments RTSI bus

interface and the PXI trigger signals on the PXI backplane to route timing

and trigger signals between several functions on as many as seven DAQ

devices in your system.

© National Instruments Corporation 1-1 6023E/6024E/6025E User Manual

Page 12

Chapter 1 Introduction

These devices can interface to an SCXI system—the instrumentation front

end for plug-in DAQ devices—so that you can acquire analog signals from

thermocouples, RTDs, strain gauges, voltage sources, and current sources.

You can also acquire or generate digital signals for communication and

control.

Using PXI with CompactPCI

Using PXI compatible products with standard CompactPCI products is an

important feature provided by PXI Specification, Revision 1.0. If you use a

PXI compatible plug-in card in a standard CompactPCI chassis, you cannot

use PXI-specific functions, but you can still use the basic plug-in card

functions. For example, the RTSI bus on your PXI E Series device is

available in a PXI chassis, but not in a CompactPCI chassis.

The CompactPCI specification permits vendors to develop sub-buses that

coexist with the basic PCI interface on the CompactPCI bus. Compatible

operation is not guaranteed between CompactPCI devices with different

sub-buses nor between CompactPCI devices with sub-buses and PXI.

The standard implementation for CompactPCI does not include these

sub-buses. Your PXI E Series device works in any standard CompactPCI

chassis adhering to PICMG CompactPCI 2.0 R2.1 core specification.

PXI specific features are implemented on the J2 connector of the

CompactPCI bus. Table 3-3, Pins Used by PXI E Series Device, lists the J2

pins used by your PXI E Series device. Your PXI device is compatible with

any Compact PCI chassis with a sub-bus that does not drive these lines.

Even if the sub-bus is capable of driving these lines, the PXI device is still

compatible as long as those pins on the sub-bus are disabled by default and

not ever enabled. Damage can result if these lines are driven by the sub-bus.

What You Need to Get Started

To set up and use your device, you need the following:

❑

One of the following devices:

– PCI-6023E

– PCI-6024E

– PCI-6025E

– PXI-6025E

– DAQCard-6024E

6023E/6024E/6025E User Manual 1-2 ni.com

Page 13

6023E/6024E/6025E User Manual

❑

❑

One of the following software packages and documentation:

– LabVIEW for Windows

– Measurement Studio

– VirtualBench

❑

NI-DAQ for PC Compatibles

❑

Your computer equipped with one of the following:

– PCIbusforaPCIdevice

– PXI or CompactPCI chassis and controller for a PXI device

– Type II PCMCIA slot for a DAQCard device

Note

Read Chapter 2, Installation and Configuration, before installing your device.

Always install your software before installing your device.

Software Programming Choices

When programming your National Instruments DAQ and SCXI hardware,

you can use National Instruments application software or another

application development environment (ADE). In either case, you use

NI-DAQ.

Chapter 1 Introduction

National Instruments Application Software

LabVIEW features interactive graphics, a state-of-the-art user interface,

and a powerful graphical programming language. The LabVIEW Data

Acquisition VI Library, a series of virtual instruments for using LabVIEW

with National Instruments DAQ hardware, is included with LabVIEW. The

LabVIEW Data Acquisition VI Library is functionally equivalent to

NI-DAQ software.

Measurement Studio, which includes LabWindows/CVI, tools for Visual

C++, and tools for Visual Basic, is a development suite that allows you to

use ANSI C, Visual C++, and Visual Basic to design your test and

measurement software. For C developers, Measurement Studio includes

LabWindows/CVI, a fully integrated ANSI C application development

environment that features interactive graphics and the LabWindows/CVI

Data Acquisition and Easy I/O libraries. For Visual Basic developers,

Measurement Studio features a set of ActiveX controls for using National

Instruments DAQ hardware. These ActiveX controls provide a high-level

© National Instruments Corporation 1-3 6023E/6024E/6025E User Manual

Page 14

Chapter 1 Introduction

programming interface for building virtual instruments. For Visual C++

developers, Measurement Studio offers a set of Visual C++ classes and

tools to integrate those classes into Visual C++ applications. The libraries,

ActiveX controls, and classes are available with Measurement Studio and

the NI-DAQ software.

VirtualBench features virtual instruments that combine DAQ products,

software, and your computer to create a stand-alone instrument with the

added benefit of the processing, display, and storage capabilities of your

computer. VirtualBench instruments load and save waveform data to disk

in the same forms that can be used in popular spreadsheet programs and

word processors.

Using LabVIEW, Measurement Studio, or VirtualBench software greatly

reduces the development time for your data acquisition and control

application.

NI-DAQ Driver Software

The NI-DAQ driver software shipped with your 6023E/6024E/6025E is

compatible with you device. It has an extensive library of functions that

you can call from your application programming environment. These

functions allow you to use all features of your 6023E/6024E/6025E.

NI-DAQ addresses many of the complex issues between the computer and

the DAQ hardware such as programming interrupts. NI-DAQ maintains a

consistent software interface among its different versions so that you can

change platforms with minimal modifications to your code. Whether you

are using LabVIEW, Measurement Studio, or other programming

languages, your application uses the NI-DAQ driver software, as illustrated

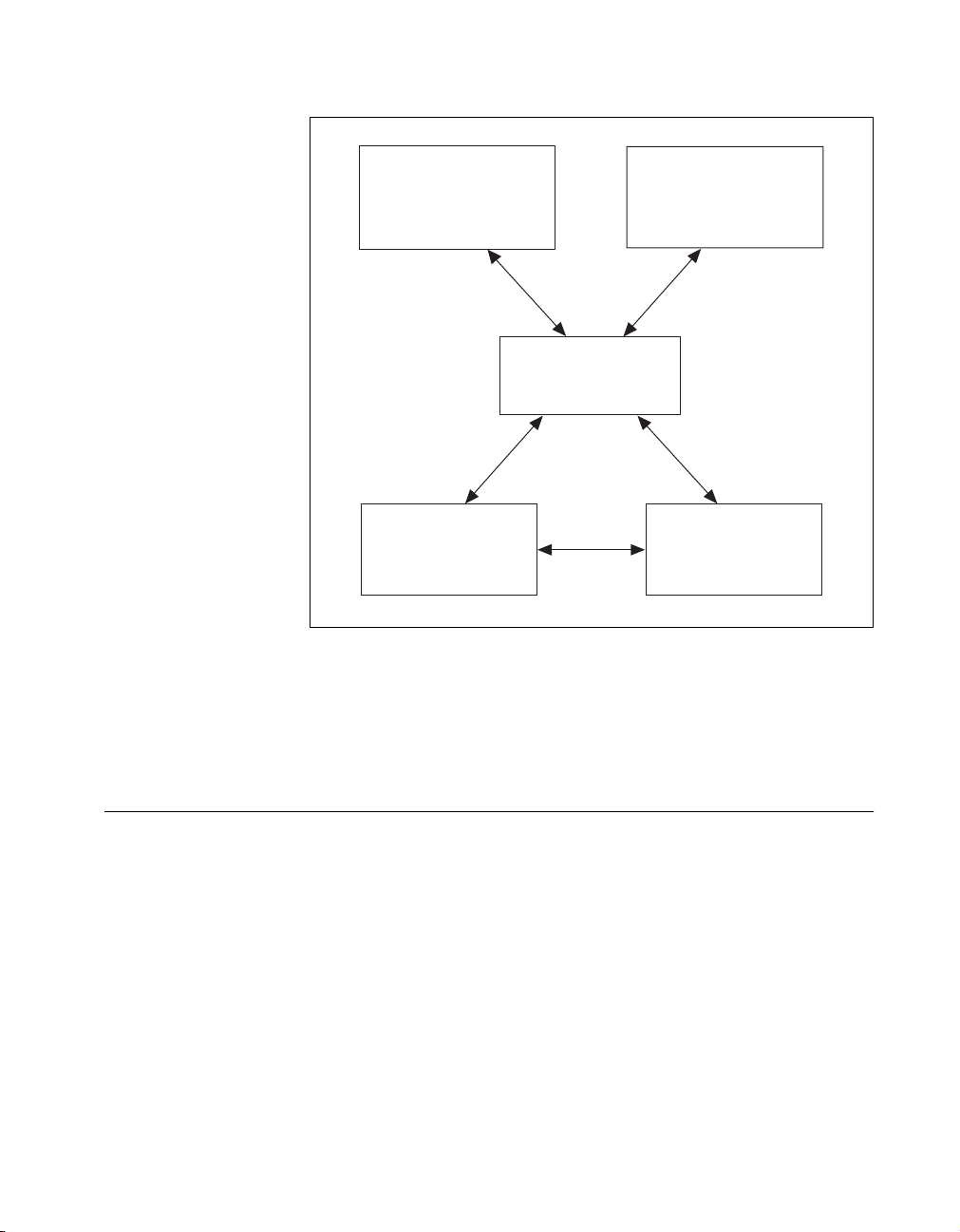

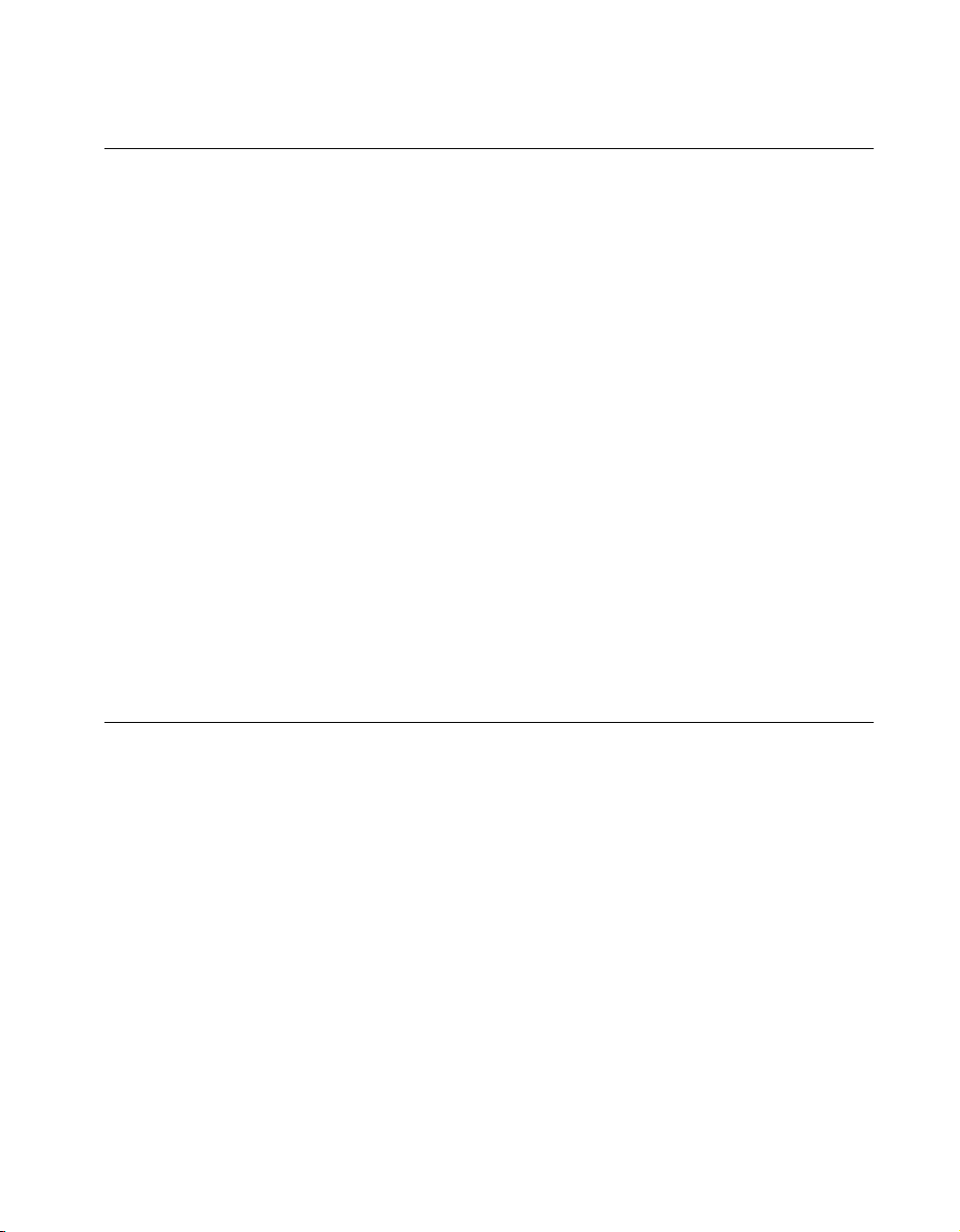

in Figure 1-1.

6023E/6024E/6025E User Manual 1-4 ni.com

Page 15

Chapter 1 Introduction

Conventional

Programming Environment

DAQ or

SCXI Hardware

Figure 1-1.

The Relationship Between the Programming Environment,

NI-DAQ, and Your Hardware

NI-DAQ

Driver Software

LabVIEW,

Measurement Studio,

or VirtualBench

Personal

Computer or

Workstation

To download a free copy of the most recent version of NI-DAQ, click

Download Software at

ni.com

.

Optional Equipment

National Instruments offers a variety of products to use with your device,

including cables, connector blocks, and other accessories, as follows:

• Cables and cable assemblies, shielded and ribbon

• Connector blocks, shielded and unshielded screw terminals

• RTSI bus cables

• SCXI modules and accessories for isolating, amplifying, exciting, and

multiplexing signals for relays and analog output. With SCXI you can

condition and acquire up to 3,072 channels.

• Low channel count signal conditioning modules, devices, and

accessories, including conditioning for strain gauges and RTDs,

simultaneous sample and hold, and relays

© National Instruments Corporation 1-5 6023E/6024E/6025E User Manual

Page 16

Chapter 1 Introduction

For more information about these products, refer to the National

Instruments catalogue or web site or call the office nearest you.

6023E/6024E/6025E User Manual 1-6 ni.com

Page 17

Installation and Configuration

This chapter explains how to install and configure your 6023E, 6024E,

or 6025E device.

Software Installation

Install your software before installing your device.

If you are using LabVIEW, LabWindows/CVI, ComponentWorks, or

VirtualBench, install this software before installing the NI-DAQ driver

software. Refer to the software release notes of your software for

installation instructions.

If you are using NI-DAQ, refer to your NI-DAQ release notes. Find

the installation section for your operating system and follow the

instructions given there.

Unpacking

2

Your device is shipped in an antistatic package to prevent electrostatic

damage to the device. Electrostatic discharge can damage several

components on the device. To avoid such damage in handling the device,

take the following precautions:

• Ground yourself by using a grounding strap or by holding a grounded

object.

• Touch the antistatic package to a metal part of your computer chassis

before removing the device from the package.

• Remove the device from the package and inspect the device for

loose components or any other sign of damage. Notify National

Instruments if the device appears damaged in any way. Do not install

a damaged device into your computer.

Never touch the exposed pins of connectors.

© National Instruments Corporation 2-1 6023E/6024E/6025E User Manual

Page 18

Chapter 2 Installation and Configuration

Hardware Installation

After installing your software, you are ready to install your hardware. Your

device will fit in any available slot in your computer. However, to achieve

best noise performance, leave as much room as possible between your

device and other devices. The following are general installation

instructions. Consult your computer user manual or technical reference

manual for specific instructions and warnings.

♦ PCI device installation

1. Turn off and unplug your computer.

2. Remove the top cover of your computer.

3. Remove the expansion slot cover on the back panel of the computer.

4. Touch any metal part of your computer chassis to discharge any static

electricity that might be on your clothes or body.

5. Insert the device into a 5 V PCI slot. Gently rock the device to ease it

into place. It may be a tight fit, but do not force the device into place.

6. Screw the mounting bracket of the device to the back panel rail of the

computer.

7. Visually verify the installation.

8. Replace the top cover of your computer.

9. Plug in and turn on your computer.

♦ PCMCIA card installation

Insert the DAQCard into any available Type II PCMCIA slot until the

connector is seated firmly. Insert the card face-up. It is keyed so that you

can only insert it one way.

♦ PXI device installation

1. Turn off and unplug your computer.

2. Choose an unused PXI slot in your system. For maximum

performance, the device has an onboard DMA controller that you can

only use if the device is installed in a slot that supports bus arbitration,

or bus master cards. National Instruments recommends installing the

device in such a slot. The PXI specification requires all slots to support

bus master cards, but the CompactPCI specification does not. If you

install in a CompactPCI non-master slot, you must disable the onboard

DMA controller of the device using software.

3. Remove the filler panel for the slot you have chosen.

6023E/6024E/6025E User Manual 2-2 ni.com

Page 19

4. Touch any metal part of your computer chassis to discharge any static

electricity that might be on your clothes or body.

5. Insert the device into a 5 V PXI slot. Use the injector/ejector handle to

fully insert the device into the chassis.

6. Screw the front panel of the device to the front panel mounting rail of

the system.

7. Visually verify the installation.

8. Plug in and turn on your computer.

The device is installed. You are now ready to configure your hardware and

software.

Hardware Configuration

National Instruments standard architecture for data acquisition and

standard bus specifications, makes these devices completely

software-configurable. Youmust perform two types of configuration on the

devices—bus-related and data acquisition-related configuration.

The PCI devices are fully compatible with the industry-standard PCI Local

Bus Specification Revision 2.2. The PXI device is fully compatible with the

PXI Specification Revision 2.0. These specifications let your computer

automatically set the device base memory address and interrupt channel

without your interaction.

Chapter 2 Installation and Configuration

You can modify data acquisition-related configuration settings, such as

analog input range and mode, through application-level software. Refer to

Chapter 3, Hardware Overview, for more information about the various

settings available for your device. These settings are changed and

configured through software after you install your device. Refer to your

software documentation for configuration instructions.

© National Instruments Corporation 2-3 6023E/6024E/6025E User Manual

Page 20

Hardware Overview

This chapter presents an overview of the hardware functions on your

device.

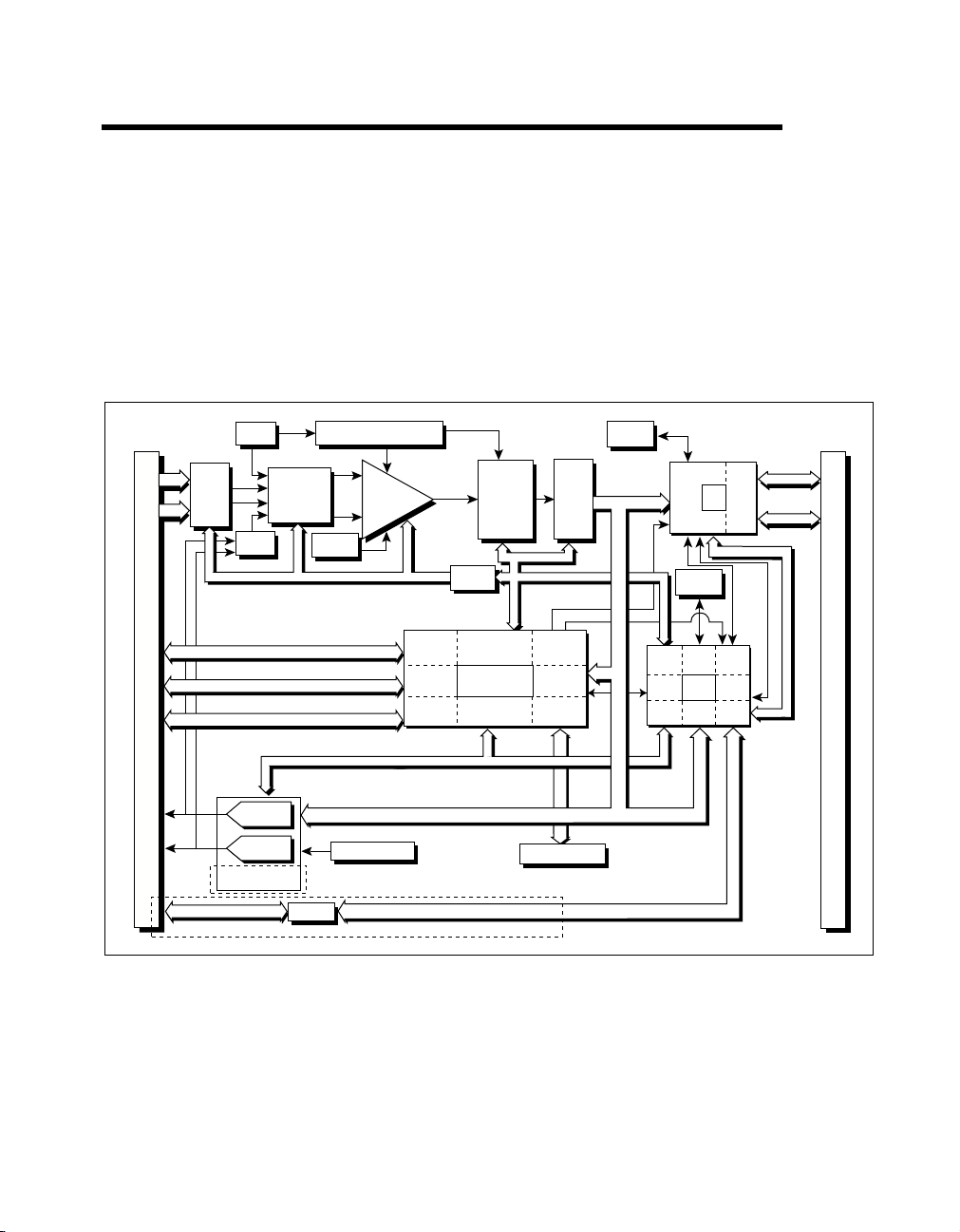

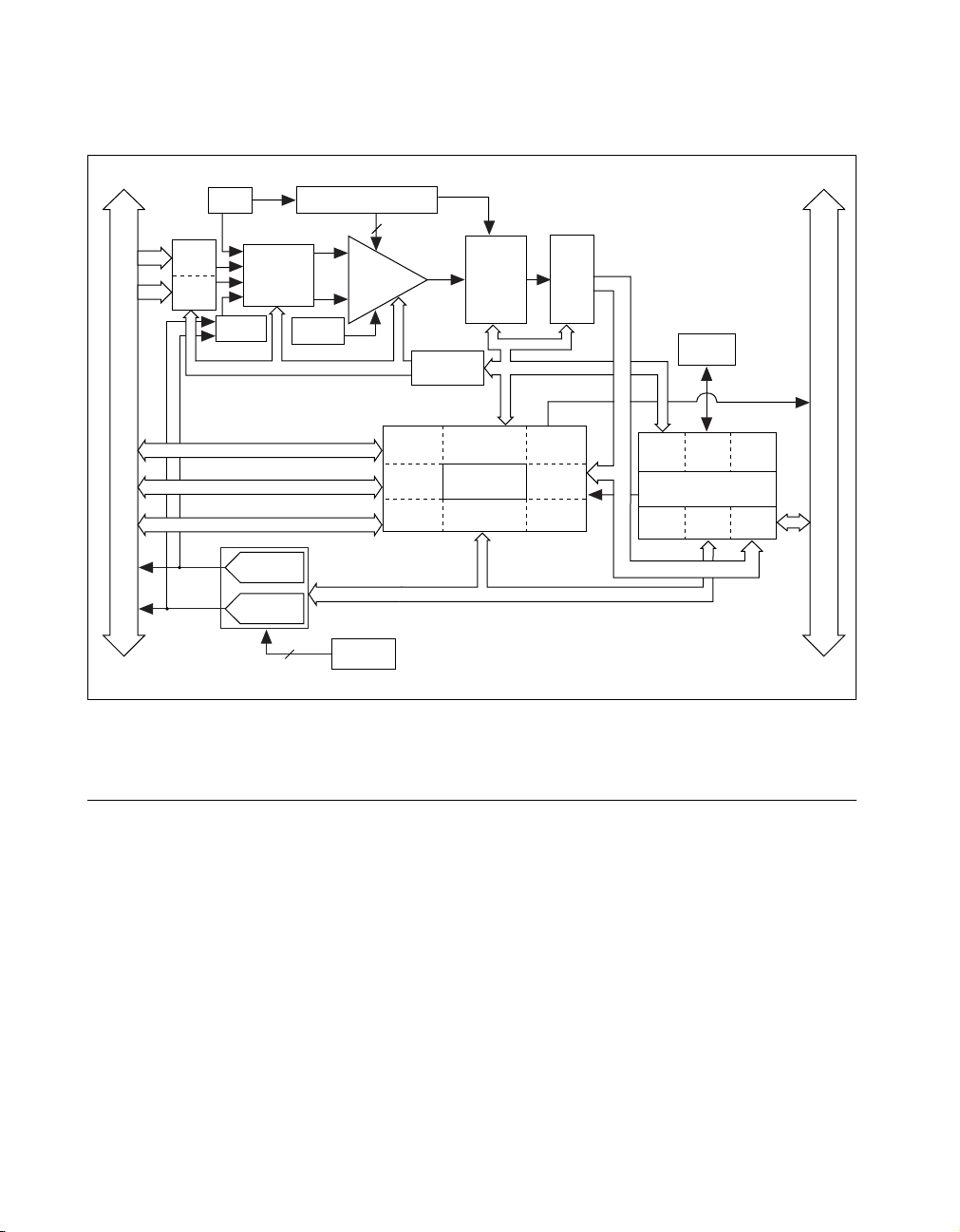

Figure 3-1 shows a block diagram for the PCI-6023E, PCI-6024E,

PCI-6025E, and PXI-6025E.

3

(8)

Analog

Input

Muxes

(8)

I/O Connector

DIO (24)

Voltage

REF

Calibration

Mux

PFI / Trigger

Timing

Digital I/O

DAC0

DAC1

Analog Output

(Not on 6023E)

Analog Mode

Multiplexer

AO Control

82C55A

Dither

Generator

Calibration DACs

Calibration

DACs

PGIA

(6025E Only)

Trigger

Interface

Counter/

Timing I/O

Digital I/O

DIO Control

Converter

Configuration

Memory

Analog Input

Timing/Control

DAQ - STC

Analog Output

Timing/Control

A/D

ADC

FIFO

AI Control

DMA/

Interrupt

Request

Bus

Interface

RTSI Bus

Interface

RTSI Connector

IRQ

DMA

EEPROM

Data

Analog

Input

Control

DAQ-STC

Bus

Interface

Analog

Output

Control

Generic

Bus

Interface

EEPROM

EEPROM

Control

DAQ - APE

Interface

Control

PCI

MINI-

Bus

MITE

Interface

Address/Data

DMA

Interface

Plug

and

Play

82C55

Bus

DIO

Control

Address

PCI Connector for PCI-602X, PXI Connector for PXI-6025E

Figure 3-1. PCI-6023E, PCI-6024E, PCI-6025E, and PXI-6025E Block Diagram

© National Instruments Corporation 3-1 6023E/6024E/6025E User Manual

Page 21

Chapter 3 Hardware Overview

Figure 3-2 shows the block diagram for the DAQCard-6024E.

(8)

Analog

(8)

Muxes

I/O Connector

Voltage

REF

Calibration

Mux

PFI / Trigger

Digital I/O (8)

Mux Mode

Selection

Switches

Timing

DAC0

DAC1

Circuitry

6

Dither

Calibration

DACs

3

+

NI-PGIA

Gain

Amplifier

–

Calibration

DACs

12-Bit

Configuration

Trigger

Counter/

Timing I/O

Digital I/O

Memory

Analog Input

Timing/Control

DAQ - STC

Analog Output

Timing/Control

AO Control

Sampling

A/D

Converter

ADC

FIFO

AI Control

Interrupt

Request

Bus

Interface

RTSI Bus

Interface

Data (16)

IRQ

Figure 3-2. DAQCard-6024E Block Diagram

EEPROM

Analog

EEPROM

Input

Control

Control

DAQ-PCMCIA

DAQ-STC

Analog

Bus

Output

Interface

Control

Bus

Interface

PCMCIA Connector

Analog Input

The analog input section of each device is software configurable. The

following sections describe in detail each of the analog input settings.

Input Mode

The devices have three differentinput modes—nonreferenced single-ended

(NRSE), referenced single-ended (RSE), and differential (DIFF) input. The

single-ended input configurations provide up to 16 channels. The DIFF

input configuration provides up to eight channels. Input modes are

programmed on a per channel basis for multimode scanning. For example,

you can configure the circuitry to scan 12 channels—four DIFF channels

and eight RSE channels. Table 3-1 describes the three input configurations.

6023E/6024E/6025E User Manual 3-2 ni.com

Page 22

Chapter 3 Hardware Overview

Input Range

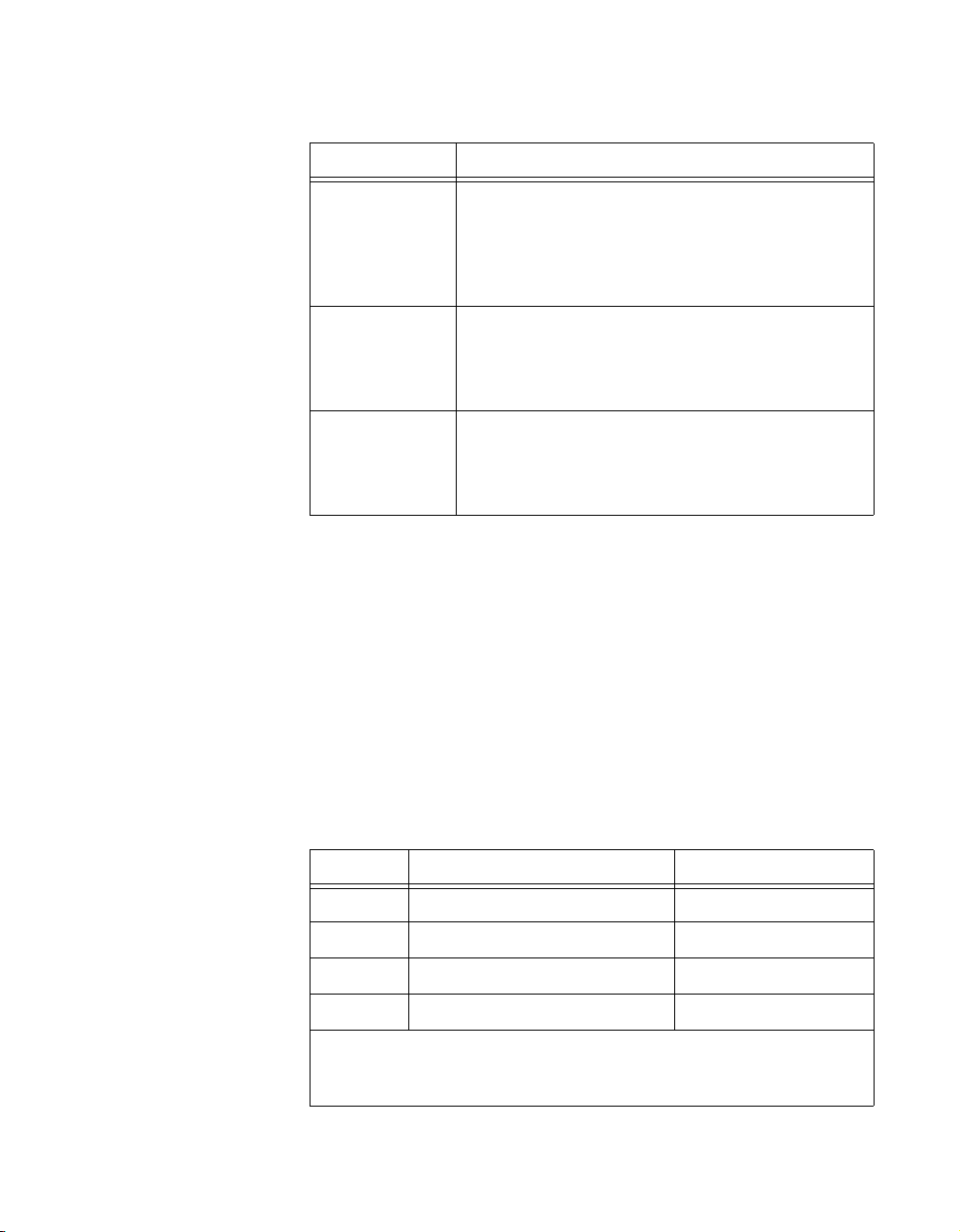

Table 3-1.

Available Input Configurations

Configuration Description

DIFF A channel configured in DIFF mode uses two analog

input lines. One line connects to the positive input of

the programmable gain instrumentation amplifier

(PGIA) of the device, and the other connects to the

negative input of the PGIA.

RSE A channel configured in RSE mode uses one analog

input line, which connects to the positive input of the

PGIA. The negative input of the PGIA is internally

tied to analog input ground (AIGND).

NRSE A channel configured in NRSE mode uses one

analog input line, which connects to the positive

input of the PGIA. The negative input of the PGIA

connects to analog input sense (AISENSE).

For diagrams showing the signal paths of the three configurations, refer to

the Analog Input Signal Overview section in Chapter 4, Signal

Connections.

The devices have a bipolar input range that changes with the programmed

gain. You can program each channel with a unique gain of 0.5, 1.0, 10, or

100 to maximize the 12-bit analog-to-digital converter (ADC) resolution.

With the proper gain setting, you can use the full resolution of the ADC to

measure the input signal. Table 3-2 shows the input range and precision

according to the gain used.

Table 3-2.

Gain Input Range Precision

Measurement Precision

1

0.5 –10 to +10 V 4.88 mV

1.0 –5to+5V 2.44 mV

10.0 –500 to +500 mV 244.14 µV

100.0 –50 to +50 mV 24.41 µV

1

The value of 1 LSB of the 12-bit ADC; that is, the voltage increment corresponding to a

change of one count in the ADC 12-bit count.

Note: See Appendix A, Specifications, for absolute maximum ratings.

© National Instruments Corporation 3-3 6023E/6024E/6025E User Manual

Page 23

Chapter 3 Hardware Overview

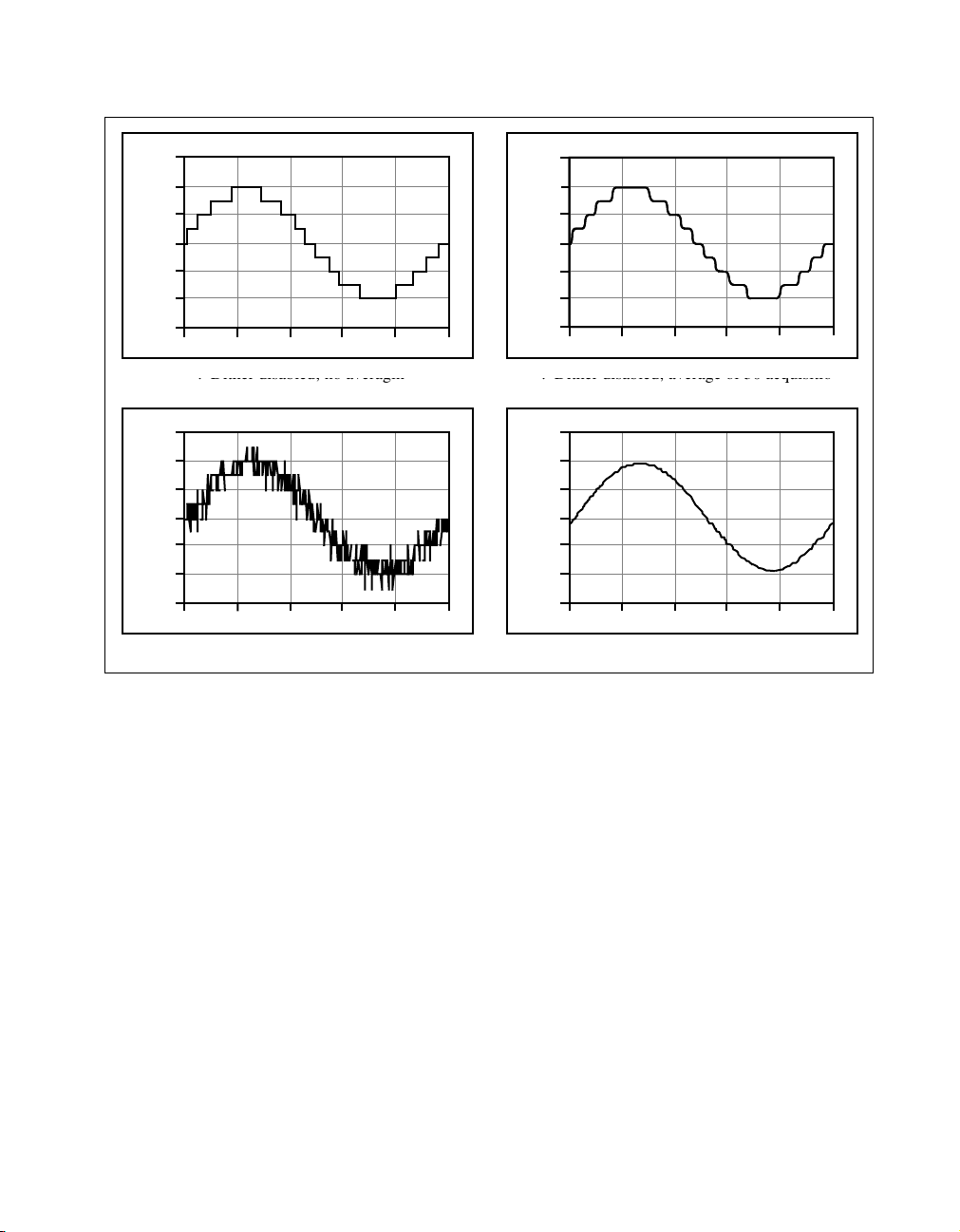

Dithering

When you enable dithering, you add approximately 0.5 LSB

rms

of white

Gaussian noise to the signal to be converted by the ADC. This addition is

useful for applications involving averaging to increase the resolution of

your device, as in calibration or spectral analysis. In such applications,

noise modulation is decreased and differential linearity is improved by the

addition of dithering. When taking DC measurements, such as when

checking the device calibration, enable dithering and average about

1,000 points to take a single reading. This process removes the effects of

quantization and reduces measurement noise, resulting in improved

resolution. For high-speed applications not involving averaging or spectral

analysis, you may want to disable dithering to reduce noise. Your software

enables and disables the dithering circuitry.

Figure 3-3 illustrates the effect of dithering on signal acquisition.

Figure 3-3a shows a small (±4 LSB) sine wave acquired with dithering off.

The ADC quantization is clearly visible. Figure 3-3b shows what happens

when 50 such acquisitions are averaged together; quantization is still

plainly visible. In Figure 3-3c, the sine wave is acquired with dithering on.

There is a considerable amount of visible noise, but averaging about 50

such acquisitions, as shown in Figure 3-3d, eliminates both the added noise

and the effects of quantization. Dithering has the effect of forcing

quantization noise to become a zero-mean random variable rather than a

deterministic function of the input signal.

6023E/6024E/6025E User Manual 3-4 ni.com

Page 24

Chapter 3 Hardware Overview

LSBs

LSBs

6.0

6.0

4.0

4.0

2.0

2.0

0.0

0.0

-2.0

-2.0

-4.0

-4.0

-6.0

-6.0

100 200 300 4000 500

100 200 300 4000 500

a. Dither disabled; no averaging b. Dither disabled; average of 50 acquisitions

a. Dither disabled; no averaging b. Dither disabled; average of 50 acquisitions

LSBs

LSBs

6.0

6.0

4.0

4.0

2.0

2.0

0.0

0.0

-2.0

-2.0

-4.0

-4.0

-6.0

-6.0

100 200 300 4000 500

100 200 300 4000 500

c. Dither enabled; no averaging

c. Dither enabled; no averaging

LSBs

LSBs

6.0

6.0

4.0

4.0

2.0

2.0

0.0

0.0

-2.0

-2.0

-4.0

-4.0

-6.0

-6.0

LSBs

LSBs

6.0

6.0

4.0

4.0

2.0

2.0

0.0

0.0

-2.0

-2.0

-4.0

-4.0

-6.0

-6.0

d. Dither enabled; average of 50 acquisitions

d. Dither enabled; average of 50 acquisitions

100 200 300 4000 500

100 200 300 4000 500

100 200 300 4000 500

100 200 300 4000 500

Figure 3-3.

Dithering

Multichannel Scanning Considerations

The devices can scan multiple channels at the same maximum rate as their

single-channel rate; however, pay careful attention to the settling times for

each of the devices. No extra settling time is necessary between channels

as long as the gain is constant and source impedances are low. Refer to

Appendix A, Specifications, for a complete listing of settling times for each

of the devices.

When scanning among channels at various gains, the settling times can

increase. When the PGIA switches to a higher gain, the signal on the

previous channel can be well outside the new, smaller range. For instance,

suppose a 4 V signal connects to channel 0 and a 1 mV signal connects to

channel 1, and suppose the PGIA is programmed to apply a gain of one to

channel 0 and a gain of 100 to channel 1. When the multiplexer switches to

channel 1 and the PGIA switches to a gain of 100, the new full-scale range

is ±50 mV.

© National Instruments Corporation 3-5 6023E/6024E/6025E User Manual

Page 25

Chapter 3 Hardware Overview

Analog Output

The approximately 4 V step from 4 V to 1 mV is 4,000% of the new

full-scale range. It can take as long as 100 µs for the circuitry to settle to

1 LSB after such a large transition. In general, this extra settling time is not

needed when the PGIA is switching to a lower gain.

Settling times can also increase when scanning high-impedance signals

due to a phenomenon called charge injection, where the analog input

multiplexer injects a small amount of charge into each signal source when

that source is selected. If the impedance of the source is not low enough,

the effect of the charge—a voltage error—has not decayed by the time the

ADC samples the signal. For this reason, keep source impedances under

1kΩ to perform high-speed scanning.

Due to the previously described limitations of settling times resulting from

these conditions, multiple-channel scanning is not recommended unless

sampling rates are low enough or it is necessary to sample several signals

as nearly simultaneously as possible. The data is much more accurate and

channel-to-channel independent if you acquire data from each channel

independently (for example, 100 points from channel 0, then 100 points

from channel 1, then 100 points from channel 2, and so on).

♦ 6025E and 6024E only

These devices supply two channels of analog output voltage at the I/O

connector. The bipolar range is fixed at ±10 V. Data written to the

digital-to-analog converter (DAC) is interpreted in two’s complement

format.

Analog Output Glitch

In normal operation, a DAC output glitches whenever it is updated with a

new value. The glitch energy differs from code to code and appears as

distortion in the frequency spectrum.

6023E/6024E/6025E User Manual 3-6 ni.com

Page 26

Digital I/O

Chapter 3 Hardware Overview

The devices contain eight lines of digital I/O (DIO<0..7>) for

general-purpose use. You can individually software-configure each line for

either input or output. At system startup and reset, the digital I/O ports are

all high impedance.

The hardware up/down control for general-purpose counters 0 and 1 are

connected onboard to DIO6 and DIO7, respectively. Thus, you can use

DIO6 and DIO7 to control the general-purpose counters. The up/down

control signals are input only and do not affect the operation of the DIO

lines.

♦ 6025E only

The 6025E device uses an 82C55A programmable peripheral interface to

provide an additional 24 lines of digital I/O that represent three 8-bit

ports—PA, PB, PC. You can program each port as an input or output port.

The 82C55A has three modes of operation—simple I/O (mode 0), strobed

I/O (mode 1), and bidirectional I/O (mode 2). In modes 1 and 2, the three

ports are divided into two groups—group A and group B. Each group has

eight data bits, plus control and status bits from Port C (PC). Modes 1 and

2 use handshaking signals from the computer to synchronize data transfers.

Refer to Chapter 4, Signal Connections, for more detailed information.

Timing Signal Routing

The DAQ-STC chip provides a flexible interface for connecting timing

signals to other devices or external circuitry. Your device uses the RTSI

bus to interconnect timing signals between devices (PCI and PXI buses

only), and the programmable function input (PFI) pins on the I/O connector

to connect the device to external circuitry. These connections are designed

to enable the device to both control and be controlled by other devices and

circuits.

There are a total of 13 timing signals internal to the DAQ-STC that you can

control by an external source. You can also control these timing signals by

signals generated internally to the DAQ-STC, and these selections are fully

software-configurable. Figure 3-4 shows an example of the signal routing

multiplexer controlling the CONVERT* signal.

© National Instruments Corporation 3-7 6023E/6024E/6025E User Manual

Page 27

Chapter 3 Hardware Overview

†

RTSI Trigger <0..6>

PFI<0..9>

Sample Interval Counter TC

GPCTR0_OUT

CONVERT*

†

PCI and PXI Buses Only

Figure 3-4. CONVERT* Signal Routing

Figure 3-4 shows that CONVERT* can be generated from a number of

sources, including the external signals RTSI<0..6> (PCI and PXI buses

only) and PFI<0..9> and the internal signals Sample Interval Counter TC

and GPCTR0_OUT.

On PCI and PXI devices, many of these timing signals are also available as

outputs on the RTSI pins, as indicated in the RTSI Triggers sectioninthis

chapter, and on the PFI pins, as indicated in Chapter 4, Signal Connections.

Programmable Function Inputs

Ten PFI pins are available on the device connector as PFI<0..9> and

connect to the internal signal routing multiplexer of the device for each

timing signal. Software can select any one of the PFI pins as the external

source for a given timing signal. It is important to note that you can use any

of the PFI pins as an input by any of the timing signals and that multiple

timing signals can use the same PFI simultaneously. This flexible routing

6023E/6024E/6025E User Manual 3-8 ni.com

Page 28

scheme reduces the need to change physical connections to the I/O

connector for different applications.

You can also individually enable each of the PFI pins to output a specific

internal timing signal. For example, if you need the UPDATE* signal as an

output on the I/O connector, software can turn on the output driver for the

PFI5/UPDATE* pin.

Device and RTSI Clocks

♦ PCIandPXIbuses

Many device functions require a frequency timebase to generate the

necessary timing signals for controlling A/D conversions, DAC updates,

or general-purpose signals at the I/O connector.

These devices can use either its internal 20 MHz timebase or a timebase

received over the RTSI bus. In addition, if you configure the device to use

the internal timebase, you can also program the device to drive its internal

timebase over the RTSI bus to another device that is programmed to receive

this timebase signal. This clock source, whether local or from the RTSI bus,

is used directly by the device as the primary frequency source. The default

configuration at startup is to use the internal timebase without driving the

RTSI bus timebase signal. This timebase is software selectable.

Chapter 3 Hardware Overview

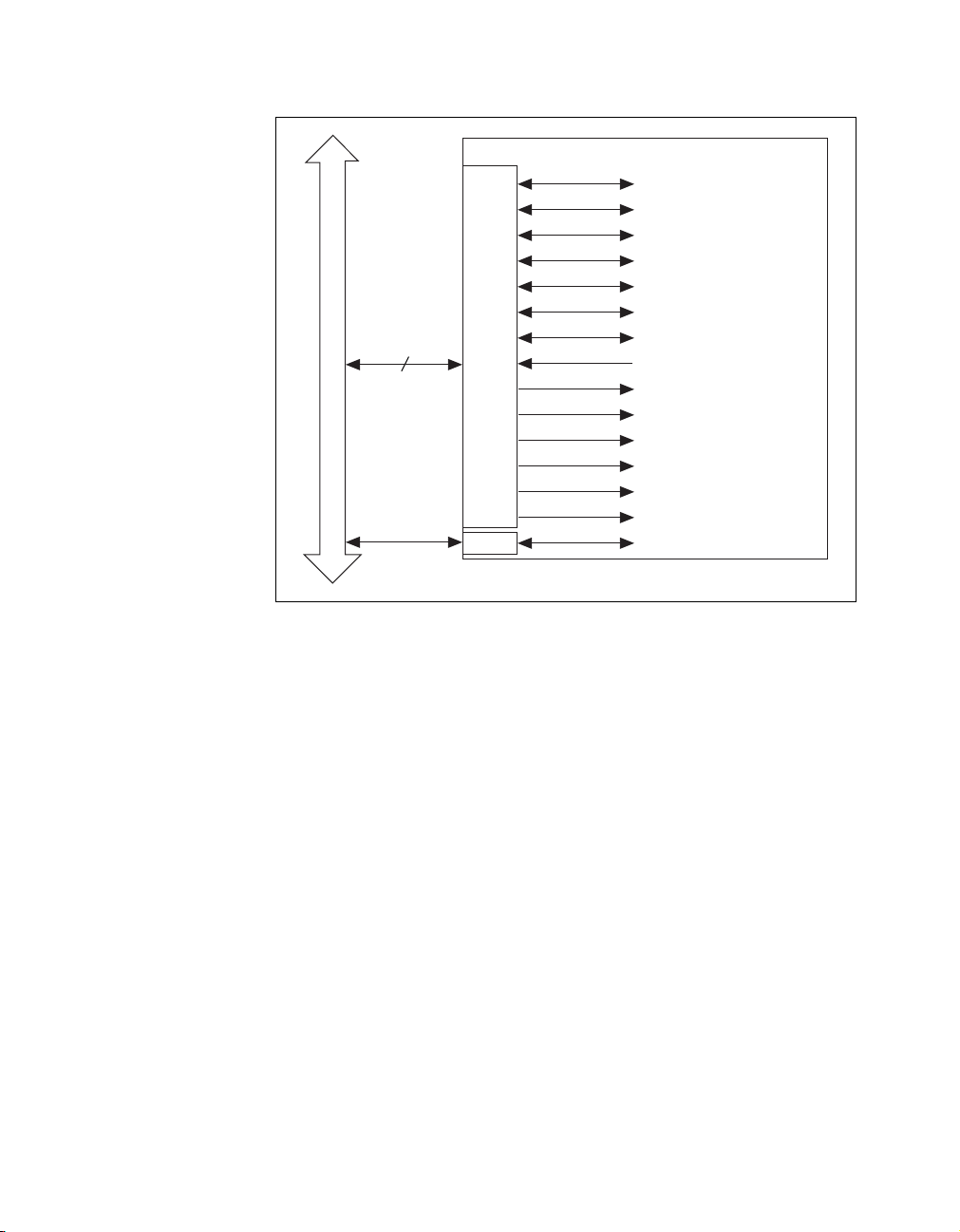

♦ PXI-6025E

The RTSI clock connects to other devices through the PXI trigger bus on

the PXI backplane. The RTSI clock signal uses the PXI trigger <7> line for

this connection.

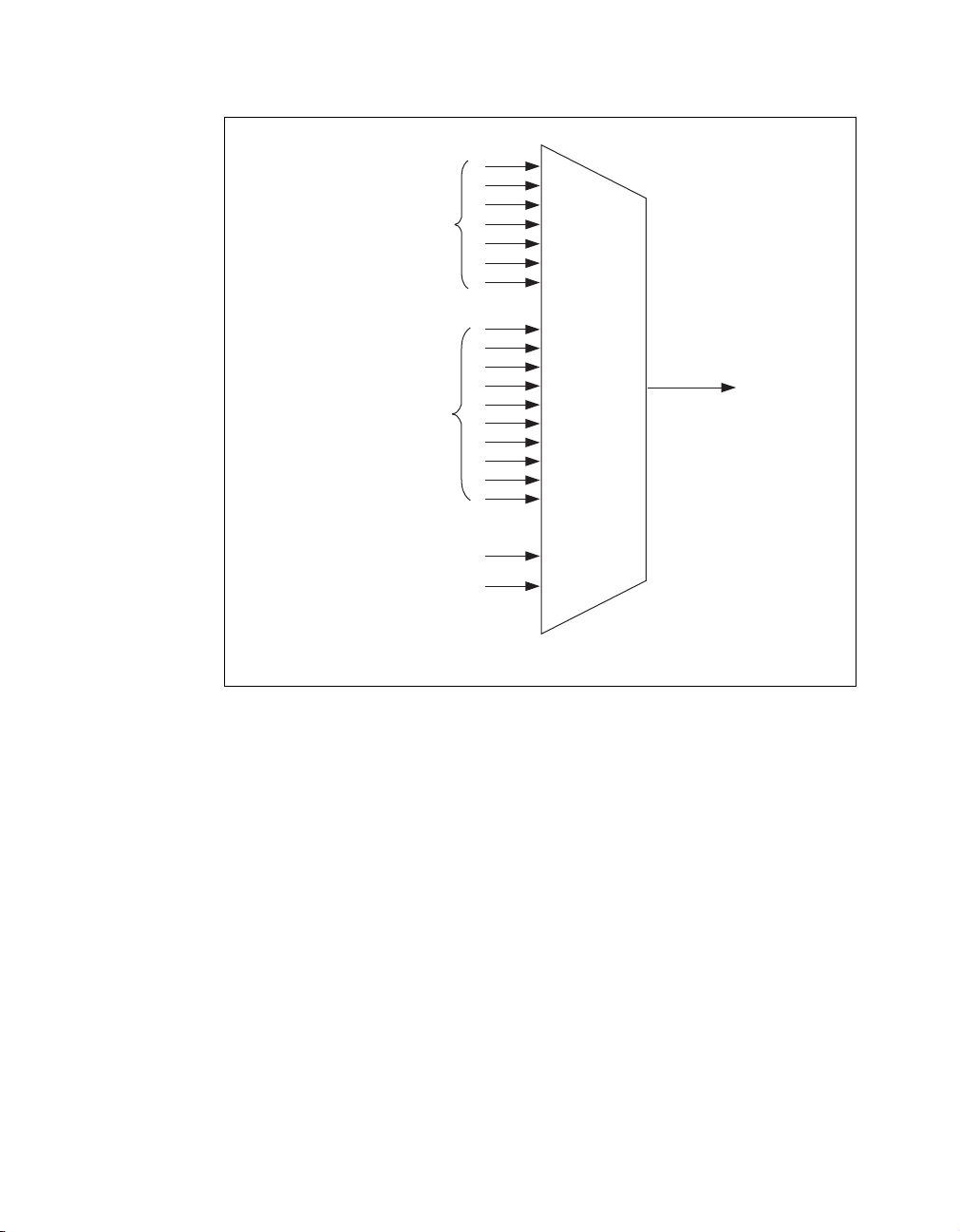

RTSI Triggers

♦ PCIandPXIbuses

The seven RTSI trigger lines on the RTSI bus provide a very flexible

interconnection scheme for any device sharing the RTSI bus. These

bidirectional lines can drive any of eight timing signals onto the RTSI bus

and can receive any of these timing signals. This signal connection scheme

is shown in Figure 3-5 for PCI devices and Figure 3-6 for PXI devices.

© National Instruments Corporation 3-9 6023E/6024E/6025E User Manual

Page 29

Chapter 3 Hardware Overview

Trigger

RTSI Bus Connector

Clock

DAQ-STC

TRIG1

TRIG2

CONVERT*

UPDATE*

WFTRIG

GPCTR0_SOURCE

GPCTR0_GATE

GPCTR0_OUT

7

RTSI Switch

switch

STARTSCAN

AIGATE

SISOURCE

UISOURCE

GPCTR1_SOURCE

GPCTR1_GATE

RTSI_OSC (20 MHz)

Figure 3-5. PCI RTSI Bus Signal Connection

6023E/6024E/6025E User Manual 3-10 ni.com

Page 30

PXI Star (6)

PXI Trigger (0..5)

PXI Bus Connector

PXI Trigger (7)

RTSI Switch

switch

Chapter 3 Hardware Overview

DAQ-STC

TRIG1

TRIG2

CONVERT*

UPDATE*

WFTRIG

GPCTR0_SOURCE

GPCTR0_GATE

GPCTR0_OUT

STARTSCAN

AIGATE

SISOURCE

UISOURCE

GPCTR1_SOURCE

GPCTR1_GATE

RTSI_OSC (20 MHz)

Figure 3-6. PXI RTSI Bus Signal Connection

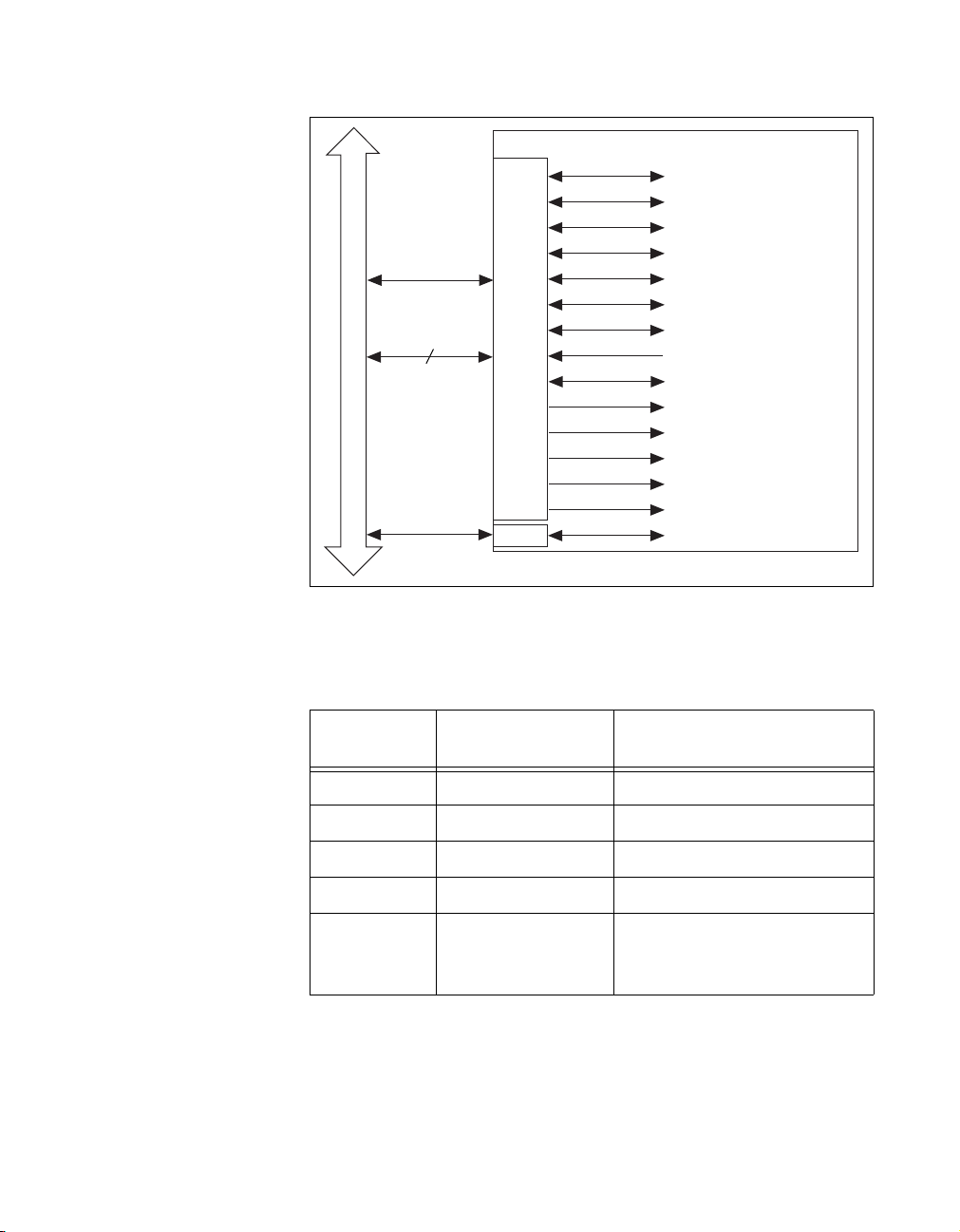

Table 3-3 lists the name and number of pins used by the PXI-6025E.

Table 3-3.

Pins Used by PXI E Series Device

PXI E Series

Signal

PXI Pin Name PXI J2 Pin Number

RTSI<0..5> PXI Trigger<0..5> B16, A16, A17, A18, B18, C18

RTSI 6 PXI Star D17

RTSI Clock PXI Trigger 7 E16

Reserved LBL<0..3> C20, E20, A19, C19

Reserved LBR<0..12> A21, C21, D21, E21, A20,

B20, E15, A3, C3, D3, E3,

A2, B2

Refer to the Timing Connections section of Chapter 4, Signal Connections,

for a description of the signals shown in Figures 3-5 and 3-6.

© National Instruments Corporation 3-11 6023E/6024E/6025E User Manual

Page 31

Signal Connections

This chapter describes how to make input and output signal connections to

your device through the I/O connector. Table 4-1 shows the cables that can

be used with the I/O connectors to connect to different accessories.

Table 4-1. I/O Connector Details

4

Cable for

Connecting

Device with I/O

Connector

PCI-6023E,

PCI-6024E

DAQCard-6024E 68 N/A SHC68-68EP

6025E 100 SH100100

Caution

on the devices can damage the device and the computer. Maximum input ratings for each

signal are given in the Protection column of Table 4-3. National Instruments is not liable

for any damages resulting from such signal connections.

Number of

Pins

68 N/A SH6868 Shielded

Connections that exceed any of the maximum ratings of input or output signals

to 100-pin

Accessories

Shielded Cable

Cable for

Connecting

to 68-pin

Accessories

Cable,

R6868 Ribbon

Cable

Shielded Cable,

RC68-68 Ribbon

Cable

SH1006868

Shielded Cable

I/O Connector

Cable for

Connecting to

50-pin Signal

Accessories

SH6850 Shielded

Cable,

R6850 Ribbon

Cable

68M-50F

Adapter when

used with the

SHC68-68EP or

RC68-68

R1005050

Ribbon Cable

Figure 4-1 shows the pin assignments for the 68-pin I/O connector on the

PCI-6023E, PCI-6024E, and DAQCard-6024E. Figure 4-2 shows the pin

assignments for the 100-pin I/O connector on the PCI-6025E. Refer to

Appendix B, Custom Cabling and Optional Connectors, for pin

© National Instruments Corporation 4-1 6023E/6024E/6025E User Manual

Page 32

Chapter 4 Signal Connections

assignments ofthe optional 50- and 68-pin connectors. A signal description

follows the figures.

ACH8

ACH1

AIGND

ACH10

ACH3

AIGND

ACH4

AIGND

ACH13

ACH6

AIGND

ACH15

DAC0OUT

DAC1OUT

RESERVED

DIO4

DGND

DIO1

DIO6

DGND

+5 V

DGND

DGND

PFI0/TRIG1

PFI1/TRIG2

DGND

+5 V

DGND

PFI5/UPDATE*

PFI6/WFTRIG

DGND

PFI9/GPCTR0_GATE

GPCTR0_OUT

FREQ_OUT

1

1

34 68

33 67

32 66

31 65

30 64

29 63

28 62

27 61

26 60

25 59

24 58

23 57

22 56

21 55

20 54

19 53

18 52

17 51

16 50

15 49

14 48

13 47

12 46

11 45

10 44

943

842

741

640

539

438

337

236

135

ACH0

AIGND

ACH9

ACH2

AIGND

ACH11

AISENSE

ACH12

ACH5

AIGND

ACH14

ACH7

AIGND

AOGND

AOGND

DGND

DIO0

DIO5

DGND

DIO2

DIO7

DIO3

SCANCLK

EXTSTROBE*

DGND

PFI2/CONVERT*

PFI3/GPCTR1_SOURCE

PFI4/GPCTR1_GATE

GPCTR1_OUT

DGND

PFI7/STARTSCAN

PFI8/GPCTR0_SOURCE

DGND

DGND

1

Not available on the 6023E

Figure 4-1. I/O Connector Pin Assignment for the 6023E/6024E

6023E/6024E/6025E User Manual 4-2 ni.com

Page 33

Chapter 4 Signal Connections

AIGND PC7

AIGND GND

ACH0 PC6

ACH8 GND

ACH1 PC5

ACH9 GND

ACH2 PC4

ACH10 GND

ACH3 PC3

ACH11 GND

ACH4 PC2

ACH12 GND

ACH5 PC1

ACH13 GND

ACH6 PC0

ACH14 GND

ACH7 PB7

ACH15 GND

AISENSE PB6

DAC0OUT GND

DAC1OUT PB5

RESERVED GND

AOGND PB4

DGND GND

DIO0 PB3

DIO4 GND

DIO1 PB2

DIO5 GND

DIO2 PB1

DIO6 GND

DIO3 PB0

DIO7 GND

DGND PA7

SCANCLK GND

EXTSTROBE* PA5

PFI0/TRIG1 GND

PFI1/TRIG2 PA4

PFI2/CONVERT* GND

PFI3/GPCTR1_SOURCE PA3

PFI4/GPCTR1_GATE GND

GPCTR1_OUT PA2

PFI5/UPDATE* GND

PFI6/WFTRIG PA1

PFI7/STARTSCAN GND

PFI8/GPCTR0_SOURCE PA0

PFI9/GPCTR0_GATE GND

GPCTR0_OUT +5 V

FREQ_OUT GND

151

252

353

454

555

656

757

858

959

10 60

11 61

12 62

13 63

14 64

15 65

16 66

17 67

18 68

19 69

20 70

21 71

22 72

23 73

24 74

25 75

26 76

27 77

28 78

29 79

30 80

31 81

32 82

33 83

34 84

+5 V GND

35 85

+5 V PA6

36 86

37 87

38 88

39 89

40 90

41 91

42 92

43 93

44 94

45 95

46 96

47 97

48 98

49 99

50 100

Figure 4-2. I/O Connector Pin Assignment for the 6025E

© National Instruments Corporation 4-3 6023E/6024E/6025E User Manual

Page 34

Chapter 4 Signal Connections

Table 4-2 shows the I/O connector signal descriptions for the 6023E,

6024E, and 6025E.

Table 4-2. I/O Connector Signal Descriptions

Signal Name Reference Direction Description

AIGND — — Analog input ground—these pins are the reference point for

single-ended measurements in RSE configuration and the

bias current return point for DIFF measurements. All three

ground references—AIGND, AOGND, and DGND—are

connected on your device.

ACH<0..15> AIGND Input Analog input channels 0 through 15—you can configure

each channel pair, ACH<i, i+8> (i = 0..7), as either one

DIFF input or two single-ended inputs.

AISENSE AIGND Input Analog input sense—this pin serves as the reference node

for any of channels ACH <0..15> in NRSE configuration.

DAC0OUT

1

AOGND Output Analog channel 0 output—this pin supplies the voltage

output of analog output channel 0.

DAC1OUT

1

AOGND Output Analog channel 1 output—this pin supplies the voltage

output of analog output channel 1.

AOGND — — Analog output ground—the analog output voltages are

referenced to this node. All three ground

references—AIGND, AOGND, andDGND—are connected

together on your device.

DGND — — Digital ground—this pin supplies the reference for the

digital signals at the I/O connector as well as the +5 VDC

supply. All three ground references—AIGND, AOGND,

and DGND—are connected on your device.

DIO<0..7> DGND Input or

Output

2

PA <0 . . 7>

DGND Input or

Output

Digital I/O signals—DIO6 and 7 can control the up/down

signal of general-purpose counters 0 and 1, respectively.

Port A bidirectional digital data lines for the 82C55A

programmable peripheral interface on the 6025E. PA7

is the MSB. PA0 is the LSB.

PB<0..7>

2

DGND Input or

Output

Port B bidirectional digital data lines for the 82C55A

programmable peripheral interface on the 6025E. PB7

is the MSB. PB0 is the LSB.

PC<0..7>

2

DGND Input or

Output

Port C bidirectional digital data lines for the 82C55A

programmable peripheral interface on the 6025E. PC7

is the MSB. PC0 is the LSB.

+5 V DGND Output +5 VDC Source—these pins are fused for up to 1 A of

+5 V supply on the PCI and PXI devices, or up to 0.75 A

from a DAQCard device. The fuse is self-resetting.

6023E/6024E/6025E User Manual 4-4 ni.com

Page 35

Chapter 4 Signal Connections

Table 4-2. I/O Connector Signal Descriptions (Continued)

Signal Name Reference Direction Description

SCANCLK DGND Output scan clock—this pin pulses once for each A/D conversion

in scanning mode when enabled. The low-to-high edge

indicates when the input signal can be removed from the

input or switched to another signal.

EXTSTROBE* DGND Output External strobe—you can toggle this output under software

PFI0/TRIG1 DGND Input

Output

PFI1/TRIG2 DGND Input

Output

PFI2/CONVERT* DGND Input

Output

PFI3/GPCTR1_SOURCE DGND Input

Output

PFI4/GPCTR1_GATE DGND Input

control to latch signals or trigger events on external devices.

PFI0/Trigger 1—as an input, this is one of the

programmable function inputs (PFIs). PFI signals are

explained in the Timing Connections sectioninthischapter.

As an output, this is the TRIG1 (AI start trigger) signal.

In posttrigger data acquisition sequences, a low-to-high

transition indicates the initiation of the acquisition

sequence. In pretrigger applications, a low-to-high

transition indicates the initiation of the pretrigger

conversions.

PFI1/Trigger 2—as an input, this is one of the PFIs.

As an output, this is the TRIG2 (AI stop trigger) signal. In

pretrigger applications, a low-to-high transition indicates

the initiation of the posttrigger conversions. TRIG2 is not

used in posttrigger applications.

PFI2/Convert—as an input, this is one of the PFIs.

As an output, this is the CONVERT* (AI convert) signal.

A high-to-low edge on CONVERT* indicates that an A/D

conversion is occurring.

PFI3/Counter 1 Source—as an input, this is one of the PFIs.

As an output, this is the GPCTR1_SOURCE signal. This

signal reflects the actual source connected to the

general-purpose counter 1.

PFI4/Counter 1 Gate—as an input, this is one of the PFIs.

Output

GPCTR1_OUT DGND Output Counter 1 Output—this output is from the general-purpose

© National Instruments Corporation 4-5 6023E/6024E/6025E User Manual

As an output, this is the GPCTR1_GATE signal. This signal

reflects the actual gate signal connected to the

general-purpose counter 1.

counter 1 output.

Page 36

Chapter 4 Signal Connections

Table 4-2. I/O Connector Signal Descriptions (Continued)

Signal Name Reference Direction Description

PFI5/UPDATE* DGND Input

PFI5/Update—as an input, this is one of the PFIs.

Output

As an output, this is the UPDATE* (AO Update) signal. A

high-to-low edge on UPDATE* indicates that the analog

output primary group is being updated for the 6024E or

6025E.

PFI6/WFTRIG DGND Input

PFI6/Waveform Trigger—as an input, this is one of the

PFIs.

Output

As an output, this is the WFTRIG (AO Start Trigger) signal.

In timed analog output sequences, a low-to-high transition

indicates the initiation of the waveform generation.

PFI7/STARTSCAN DGND Input

Output

PFI7/Start of Scan—as an input, this is one of the PFIs.

As an output, this is the STARTSCAN (AI Scan Start)

signal. This pin pulses once at the start of each analog input

scan in the interval scan. A low-to-high transition indicates

the start of the scan.

PFI8/GPCTR0_SOURCE DGND Input

PFI8/Counter 0 Source—as an input, this is one of the

PFIs.

Output

As an output, this is the GPCTR0_SOURCE signal.

This signal reflects the actual source connected to the

general-purpose counter 0.

PFI9/GPCTR0_GATE DGND Input

Output

PFI9/Counter 0 Gate—as an input, this is one of the PFIs.

As an output, this is the GPCTR0_GATE signal. This signal

reflects the actual gate signal connected to the

general-purpose counter 0.

GPCTR0_OUT DGND Output Counter 0 Output—this output is from the general-purpose

counter 0 output.

FREQ_OUT DGND Output Frequency Output—this output is from the frequency

generator output.

*

Indicates that the signal is active low

1

Not available on the 6023E

2

Not available on the 6023E or 6024E

6023E/6024E/6025E User Manual 4-6 ni.com

Page 37

Chapter 4 Signal Connections

Table 4-3 shows the I/O signal summary for the 6023E, 6024E, and 6025E.

Table 4-3. I/O Signal Summary

Signal

Signal Name

Typ e a nd

Direction

ACH<0..15> AI 100 GΩ

Impedance

Input/

Output

Protection

(Volts)

On/Off

Source

(mA at V)

Sink

(mA

at V)

Rise

Time

(ns)

Bias

42/35 — — — ±200 pA

in

parallel

with

100 pF

AISENSE AI 100 GΩ

40/25 — — — ±200 pA

in

parallel

with

100 pF

AIGND AO — — — — — —

DAC0OUT

(6024E and 6025E only)

DAC1OUT

(6024E and 6025E only)

AO 0.1 Ω Short-circuit

to ground

AO 0.1 Ω Short-circuit

to ground

5at10 5at-10 10

V/µs

5at10 5at-10 10

V/µs

—

—

AOGND AO — — — — — —

DGND DO — — — — — —

VCC DO 0.1 Ω Short-circuit

1A fused — — —

to ground

DIO<0..7> DIO — Vcc+0.5 13 at (Vcc-0.4) 24 at

1.1 50 kΩ pu

0.4

PA <0 . . 7>

(6025E only)

PB<0..7>

(6025E only)

PC<0..7>

(6025E only)

DIO — Vcc+0.5 2.5 at 3.7min 2.5 at

0.4

DIO — Vcc+0.5 2.5 at 3.7min 2.5 at

0.4

DIO — Vcc+0.5 2.5 at 3.7min 2.5 at

0.4

5 100 kΩ

pu

5 100 kΩ

pu

5 100 kΩ

pu

SCANCLK DO — — 3.5 at (Vcc-0.4) 5at0.4 1.5 50 kΩ pu

EXTSTROBE* DO — — 3.5 at (Vcc-0.4) 5at0.4 1.5 50 kΩ pu

PFI0/TRIG1 DIO — Vcc+0.5 3.5 at (Vcc-0.4) 5at0.4 1.5 50 kΩ pu

PFI1/TRIG2 DIO — Vcc+0.5 3.5 at (Vcc-0.4) 5at0.4 1.5 50 kΩ pu

PFI2/CONVERT* DIO — Vcc+0.5 3.5 at (Vcc-0.4) 5at0.4 1.5 50 kΩ pu

PFI3/GPCTR1_SOURCE DIO — Vcc+0.5 3.5 at (Vcc-0.4) 5at0.4 1.5 50 kΩ pu

© National Instruments Corporation 4-7 6023E/6024E/6025E User Manual

Page 38

Chapter 4 Signal Connections

Table 4-3. I/O Signal Summary (Continued)

Signal

Signal Name

PFI4/GPCTR1_GATE DIO — Vcc+0.5 3.5 at (Vcc-0.4) 5at0.4 1.5 50 kΩ pu

GPCTR1_OUT DO — — 3.5 at (Vcc-0.4) 5at0.4 1.5 50 kΩ pu

PFI5/UPDATE* DIO — Vcc+0.5 3.5 at (Vcc-0.4) 5at0.4 1.5 50 kΩ pu

PFI6/WFTRIG DIO — Vcc+0.5 3.5 at (Vcc-0.4) 5at0.4 1.5 50 kΩ pu

PFI7/STARTSCAN DIO — Vcc+0.5 3.5 at (Vcc-0.4) 5at0.4 1.5 50 kΩ pu

PFI8/GPCTR0_SOURCE DIO — Vcc+0.5 3.5 at (Vcc-0.4) 5at0.4 1.5 50 kΩ pu

PFI9/GPCTR0_GATE DIO — Vcc+0.5 3.5 at (Vcc-0.4) 5at0.4 1.5 50 kΩ pu

GPCTR0_OUT DO — — 3.5 at (Vcc-0.4) 5at0.4 1.5 50 kΩ pu

FREQ_OUT DO — — 3.5 at (Vcc-0.4) 5at0.4 1.5 50 kΩ pu

AI = Analog Input DIO = Digital Input/Output pu = pullup

AO = Analog Output DO = Digital Output

Note: The tolerance on the 50 kΩ pullup and pulldown resistors is very large. Actual value can range between 17 kΩ and

100 kΩ.

Typ e a nd

Direction

Impedance

Input/

Output

Protection

(Volts)

On/Off

Source

(mA at V)

Sink

(mA

at V)

Rise

Time

(ns)

Bias

Analog Input Signal Overview

The analog input signals for these devices are ACH<0..15>, ASENSE, and

AIGND. Connection of these analog input signals to your device depends

on the type of input signal source and the configuration of the analog input

channels you are using. This section provides an overview of the different

types of signal sources and analog input configuration modes. More

specific signal connection information is provided in the Analog Input

Signal Connections section.

Types of Signal Sources

When configuring the input channels and making signal connections,

you must first determine whether the signal sources are floating or

ground-referenced.

6023E/6024E/6025E User Manual 4-8 ni.com

Page 39

Chapter 4 Signal Connections

Floating Signal Sources

A floating signal source is not connected in any way to the building ground

system, but has an isolated ground-reference point. Some examples of

floating signal sources are outputs of transformers, thermocouples,

battery-powered devices, optical isolators, and isolation amplifiers. An

instrument or device that has an isolated output is a floating signal source.

You must tie the ground reference of a floating signal to the analog input