Page 1

NI 5782R User Manual and

Specifications

The NI 5782 is an analog dual-input, dual-ouput, intermediate-frequency (IF) transceiver

adapter module designed to work with your NI FlexRIO™ FPGA module. The NI 5782 features

two analog input (AI) channels with 14-bit sample rates of up to 250 MS/s. The NI 5782 also

has two analog output (AO) channels with 16-bit sample rates of up to 500 MS/s when using

both AO channels, or up to 1 GS/s when using only one AO channel.

This document contains signal information and specifications for the NI 5782R, which is

composed of an NI FlexRIO FPGA module and the NI 5782 adapter module. This document

also contains tutorial sections that demonstrate how to acquire data using a LabVIEW FPGA

example VI and how to create and run your own LabVIEW project with the NI 5782R.

Note NI 5782R refers to the combination of your NI 5782 adapter module and your

NI FlexRIO FPGA module. NI 5782 refers to your NI 5782 adapter module only.

Caution The protection provided by the NI 5782R can be impaired if it is used in

a manner not described in this document.

Contents

Electromagnetic Compatibility Guidelines .............................................................................. 2

How to Use Your NI FlexRIO Documentation Set.................................................................. 3

Front Panel and Connector Pinouts .......................................................................................... 4

Block Diagram.......................................................................................................................... 7

NI 5782 Component-Level Intellectual Property (CLIP)......................................................... 8

Connecting Cables .................................................................................................................... 10

Clocking.................................................................................................................................... 10

Using Your NI 5782R with a LabVIEW FPGA Example VI .................................................. 11

Creating a LabVIEW Project and Running a VI on an FPGA Target...................................... 13

Appendix A: Specifications......................................................................................................16

Appendix B: Installing EMI Controls ...................................................................................... 34

Where to Go for Support .......................................................................................................... 36

Page 2

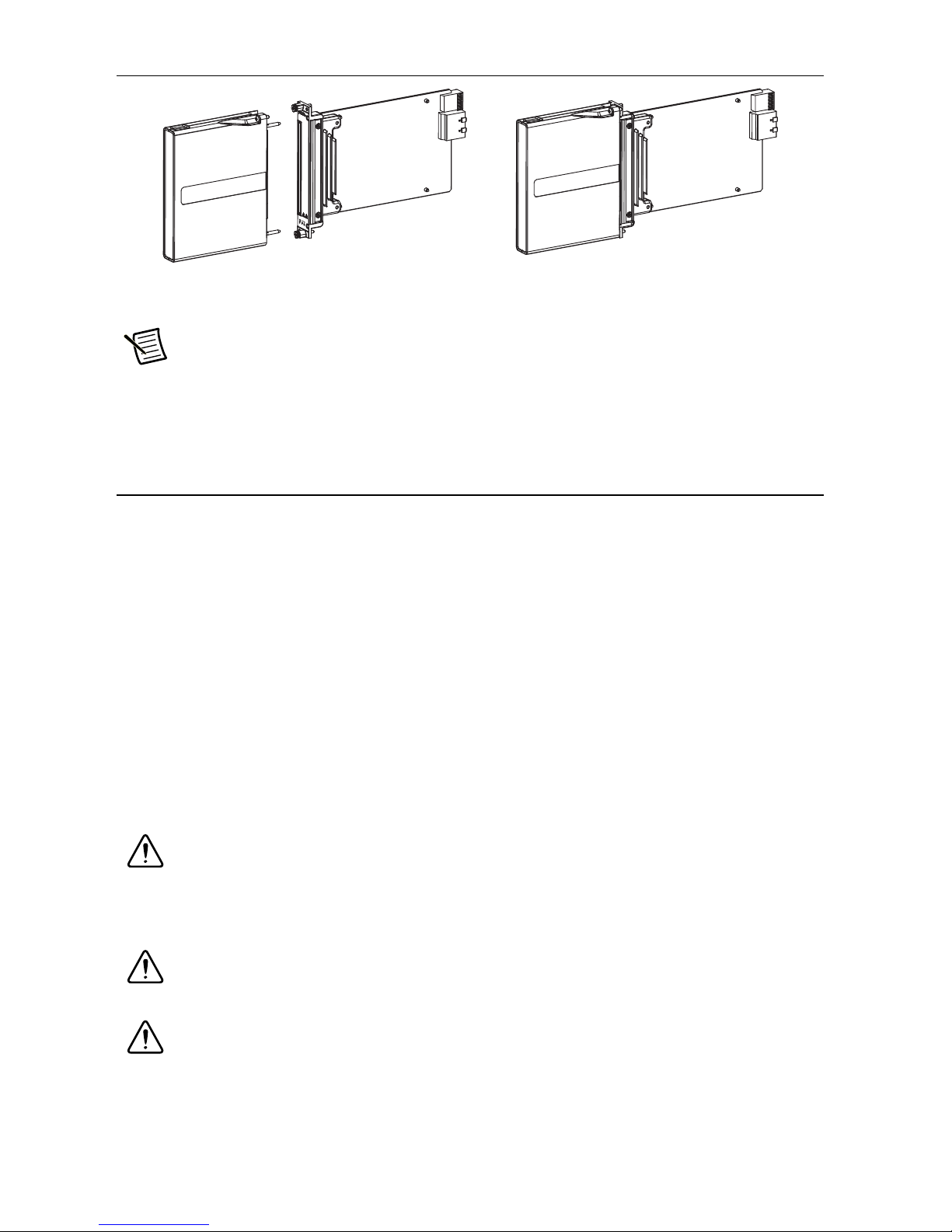

Figure 1. NI FlexRIO Device

NI FlexRIO

Adapter Module

Note Before configuring your NI 5782R, you must install the appropriate software

NI FlexRIO

+ = NI FlexRIO Device

FPGA Module

and hardware. Refer to the NI FlexRIO FPGA Module Installation Guide and

Specifications for installation instructions. Figure 1 shows an example of a properly

connected NI FlexRIO device.

Electromagnetic Compatibility Guidelines

This product was tested and complies with the regulatory requirements and limits for

electromagnetic compatibility (EMC) as stated in the product specifications. These requirements

and limits are designed to provide reasonable protection against harmful interference when the

product is operated in its intended operational electromagnetic environment.

This product is intended for use in industrial locations. There is no guarantee that harmful

interference will not occur in a particular installation, when the product is connected to a test

object, or if the product is used in residential areas. To minimize the potential for the product to

cause interference to radio and television reception or to experience unacceptable performance

degradation, install and use this product in strict accordance with instructions in the product

documentation.

Furthermore, any changes or modifications to the product not expressly approved by National

Instruments could void your authority to operate it under your local regulatory rules.

Caution To ensure the specified EMC performance, you must install PXI EMC

Filler Panels (National Instruments part number 778700-01) in adjacent chassis slots.

For more information about installing PXI EMC filler panels in your system, refer to

the Appendix B: Installing EMI Controls section of this document.

Caution To ensure the specified EMC performance, operate this product only with

shielded cables and accessories.

Caution This product is sensitive to electrostatic discharge (ESD). To ensure the

specified EMC performance, follow the programming instructions listed at the end of

the Using Your NI 5782R with a LabVIEW FPGA Example VI and Creating a

LabVIEW Project and Running a VI on an FPGA Target sections of this document.

2 | ni.com | NI 5782R User Manual and Specifications

Page 3

Caution To ensure the specified EMC performance, the length of all I/O cables

LabVIEW FPGA

Module Help

NI FlexRIO

Help

LabVIEW

Examples

INSTALL Hardware

and Software

CONNECT Signals

and Learn About

Your Adapter

Module

LEARN About

LabVIEW FPGA

Module

PROGRAM Your

NI FlexRIO System

in LabVIEW FPGA

Module

NI FlexRIO FPGA Module

Installation Guide and Specifications

NI FlexRIO Adapter Module

User Guide and Specifications

Are

You New to

LabVIEW FPGA

Module?

Yes No

No

must be no longer than 30 m (100 ft).

How to Use Your NI FlexRIO Documentation Set

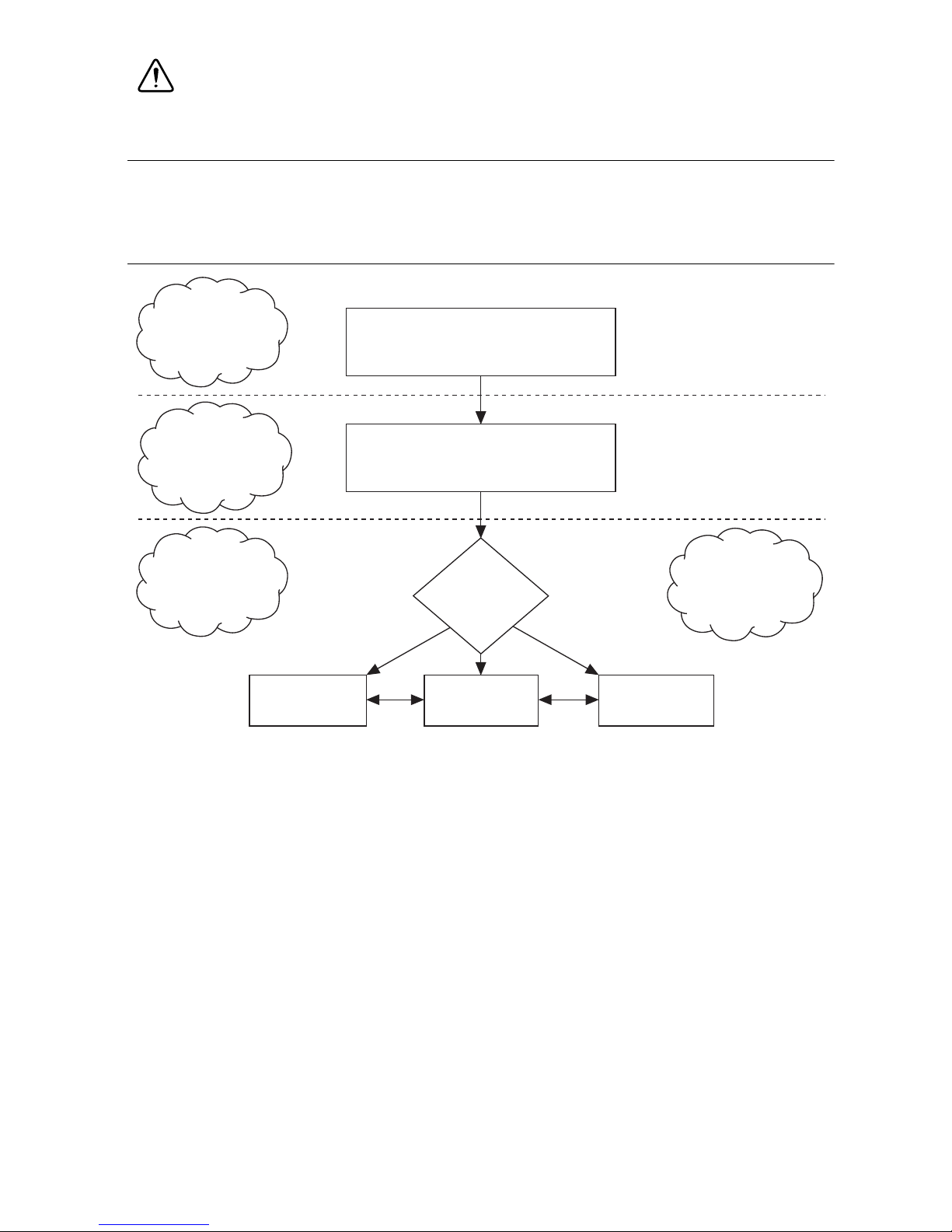

Refer to Figure 2 and Table 1 for information about how to use your NI FlexRIO documentation

set.

Figure 2. How to Use Your NI FlexRIO Documentation Set

NI 5782R User Manual and Specifications | © National Instruments | 3

Page 4

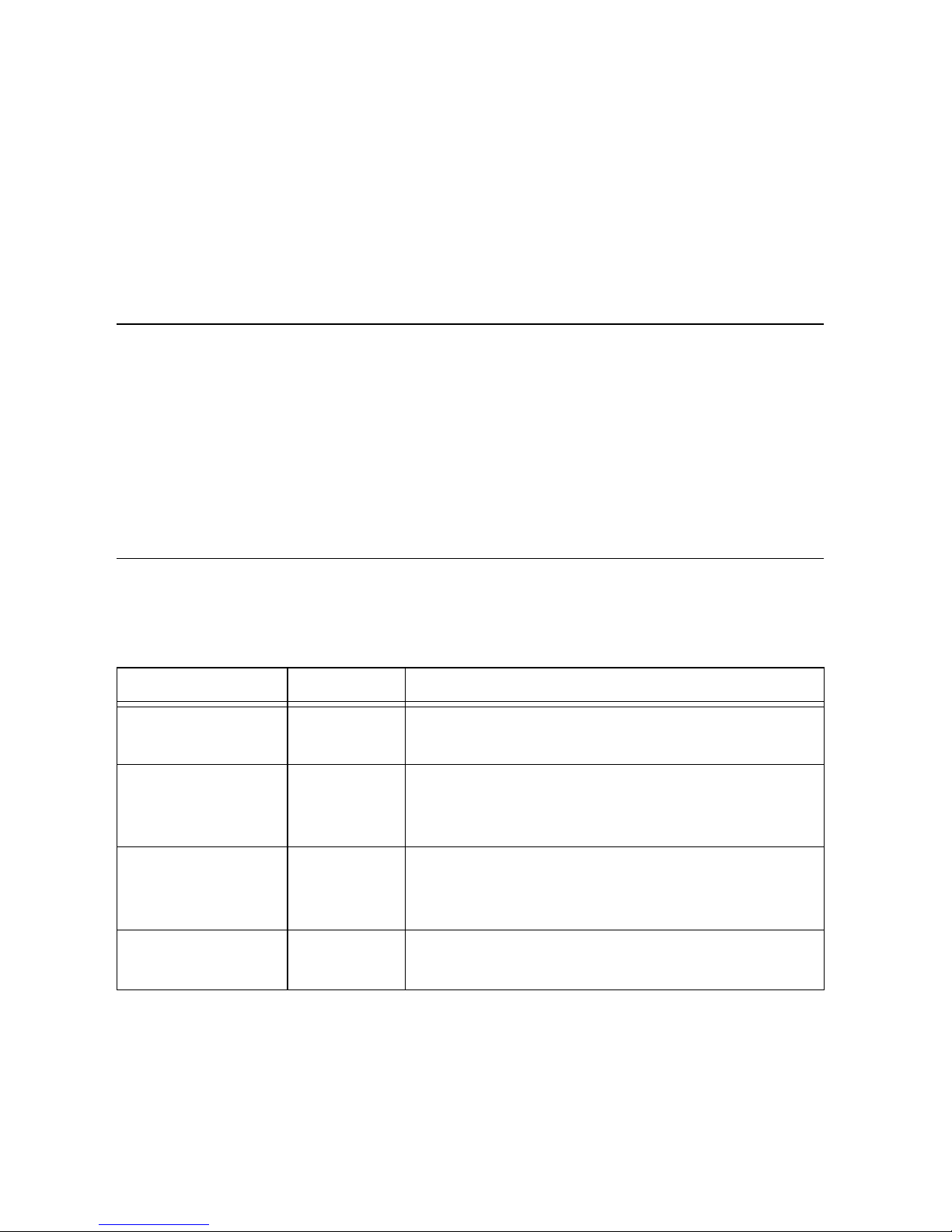

Table 1. NI FlexRIO Documentation Locations and Descriptions

Document Location Description

NI FlexRIO FPGA

Module Installation

Guide and

Specifications

NI 5782R User

Manual and

Specifications

(this document)

LabVIEW FPGA

Module Help

NI FlexRIO Help Available from the Start menu

LabVIEW Examples Available in NI Example

IPNet ni.com/ipnet

NI FlexRIO

product page

Available in your FPGA

module hardware kit, from the

Start Menu, and at

manuals.

Available from the Start Menu

ni.com/manuals.

and at

Embedded in LabVIEW Help

ni.com/manuals.

and at

ni.com/manuals.

and at

Finder.

ni.com/flexrio

ni.com/

Contains installation instructions for your

NI FlexRIO system and specifications for

your FPGA module.

Contains signal information, examples,

CLIP details, and specifications for your

adapter module.

Contains information about the basic

functionality of the LabVIEW FPGA

module.

Contains FPGA module, adapter module,

and CLIP configuration information.

Contains examples of how to run FPGA VIs

and Host VIs on your device.

Contains LabVIEW FPGA functions and

intellectual property to share.

Contains product information and data

sheets for NI FlexRIO devices.

Front Panel and Connector Pinouts

Table 2 shows the front panel connector and signal descriptions for the NI 5782. Refer to

Appendix A: Specifications for additional signal information.

Caution To avoid permanent damage to the NI 5782, disconnect all signals

connected to the NI 5782 before powering down the module, and connect signals

only after the adapter module has been powered on by the NI FlexRIO FPGA module.

Caution Connections that exceed any of the maximum ratings of any connector on

the NI 5782R can damage the device and the chassis. NI is not liable for any damage

resulting from such signal connections. For the maximum input and output ratings for

each signal, refer to Appendix A: Specifications.

4 | ni.com | NI 5782R User Manual and Specifications

Page 5

Device Front

Panel

NI 5782

AUX

I/O

Table 2. NI 5782 Front Panel Connectors

Connector Signal Description

AUX I/O Refer to Table 3 for the signal list and

descriptions.

CLK IN 50 Ω single-ended (SE) external Reference or

Sample Clock input.

TRIG Trigger input channel.

CLK IN

TRIG

AI 0

AI 1

AO 0

AO 1

14-Bit AI

16-Bit AO

Analog I/O

AI 0 50 Ω SE analog input (AI) channel 0.

AI 1 50 Ω SE AI channel 1.

AO 0 50 Ω SE analog output (AO) channel 0.

AO 1 50 Ω SE AO channel 1.

NI 5782R User Manual and Specifications | © National Instruments | 5

Page 6

AUX I/O Connector

Table 3. NI 5782 AUX I/O Connector Pin Assignments

AUX I/O Connector Pin Signal Signal Description

1 DIO Port 0 (Bit 0) Bidirectional single-ended (SE)

digital I/O (DIO) data channel.

2 GND Ground reference for signals.

3 DIO Port 0 (Bit 1) Bidirectional SE DIO data channel.

4 DIO Port 0 (Bit 2) Bidirectional SE DIO data channel.

5 GND Ground reference for signals.

18

16

14

12

10

8

6

4

2

19

17

15

13

11

6 DIO Port 0 (Bit 3) Bidirectional SE DIO data channel.

7 DIO Port 1 (Bit 0) Bidirectional SE DIO data channel.

8 GND Ground reference for signals.

9 DIO Port 1 (Bit 1) Bidirectional SE DIO data channel.

9

10 DIO Port 1 (Bit 2) Bidirectional SE DIO data channel.

7

5

3

1

11 GND Ground reference for signals.

12 DIO Port 1 (Bit 3) Bidirectional SE DIO data channel.

13 PFI 0 Bidirectional SE DIO data channel.

14 NC No connect.

15 PFI 1 Bidirectional SE DIO data channel.

16 PFI 2 Bidirectional SE DIO data channel.

17 GND Ground reference for signals.

18 +5V +5 V power (10 mA maximum).

19 PFI 3 Bidirectional SE DIO data channel.

Caution The AUX I/O connector accepts a standard, third-party HDMI cable, but

the AUX I/O port is not an HDMI interface. Do not connect the AUX I/O port on the

NI 5782 into the HDMI port of another device. NI is not liable for any damage

resulting from such signal connections.

6 | ni.com | NI 5782R User Manual and Specifications

Page 7

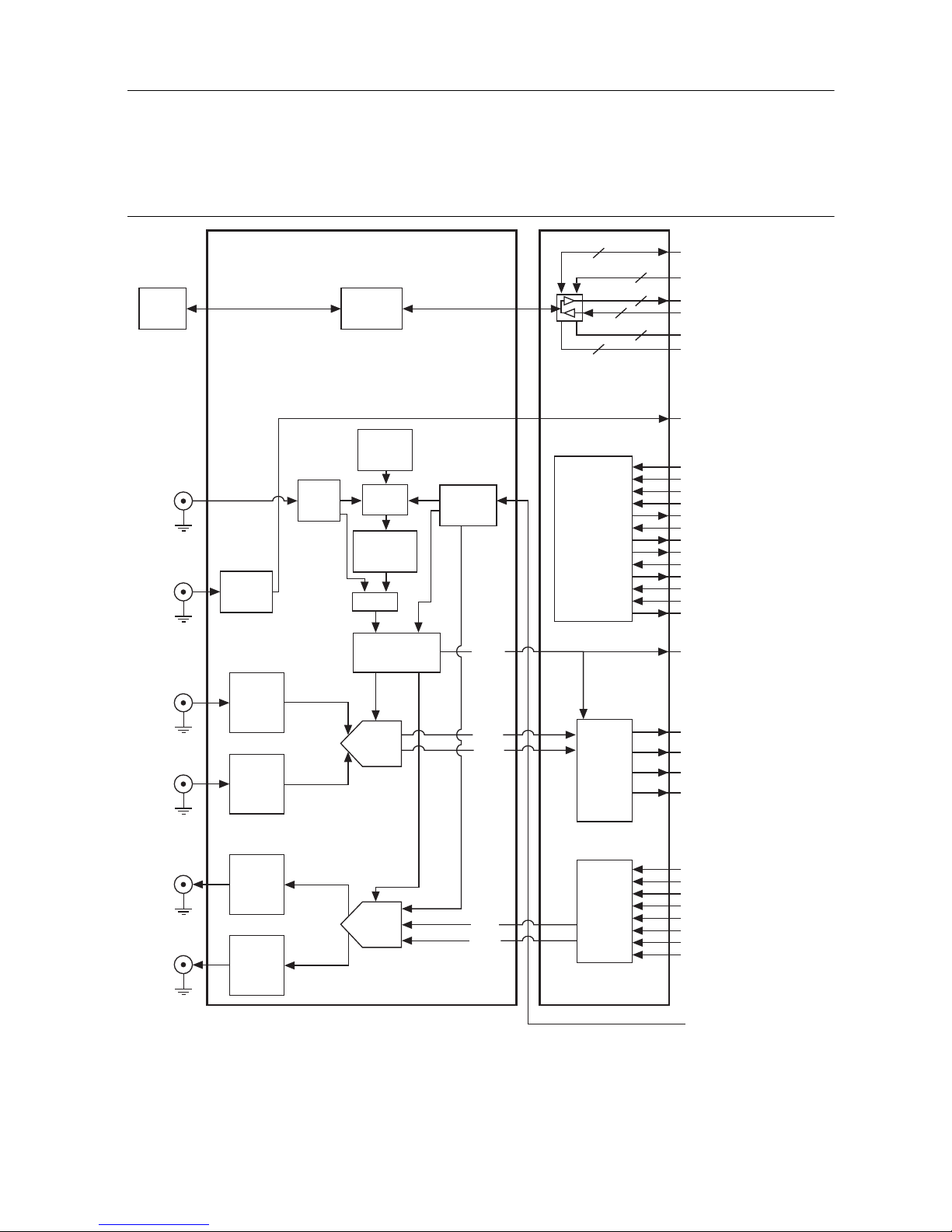

Block Diagram

Figure 3 shows the NI 5782 block diagram and signal flow to and from the NI 5782

component-level intellectual property (CLIP) by way of the adapter module and the

corresponding NI 5782 Multiple Sample CLIP in LabVIEW FPGA.

Figure 3. NI 5782 Connector Signals and NI 5782 CLIP Signal Block Diagram

AUX I/O

CLK IN

TRIG

Bus

Tr anslator

Bus

Tr ansceiv

Internal

Reference

Clock

SwitchSwitch

Clock

Synthesizer

Switch

AD9512

LabVIEW FPGA CLIPNI 5782 Adapter Module

8

er

Clock

Buffer

Sample

Clock

SPI Engine

Interfacing

Switches

Analog front

end (FE)

4

4

with:

AD9512

ADCs

DACs

DIO Port 0 Rd Data <0..3>,

DIO Port 1 Rd Data <0..3>

DIO Port 0 Wr Data <0..3>,

8

DIO Port 1 Wr Data <0..3>

PFI <0..3> Rd Data

4

PFI <0..3> Wr Data

DIO Port <0..1> Write Enable

2

PFI <0..3> Write Enable

Trigger Input

SPI Read

SPI Write

SPI Address

SPI Write Data

SPI Read Data

SPI Device Select

SPI Idle

Initialization Done

Reinitialize

Configuration Error

Sample Clock Select

Sample Clock Commit

Synthesizer Locked

Data Clock

AI 0

AI 1

AO 0

AO 1

Analog

Front End

Analog

Front End

Analog

Front End

Analog

Front End

ADC

DAC

Data

Clock

Data

Clock

ADC

Interface

DAC

Interface

AI 0 Data N

AI 0 Data N–1

AI 1 Data N

AI 1 Data N–1

AO 0 Data N

AO 0 Data N–1

AO 0 Data N–

AO 0 Data N–3

AO 1 Data N

AO 1 Data N–1

AO 1 Data N–2

AO 1 Data N–3

IOModSyncClock

2

NI 5782R User Manual and Specifications | © National Instruments | 7

Page 8

NI 5782 Component-Level Intellectual Property

(CLIP)

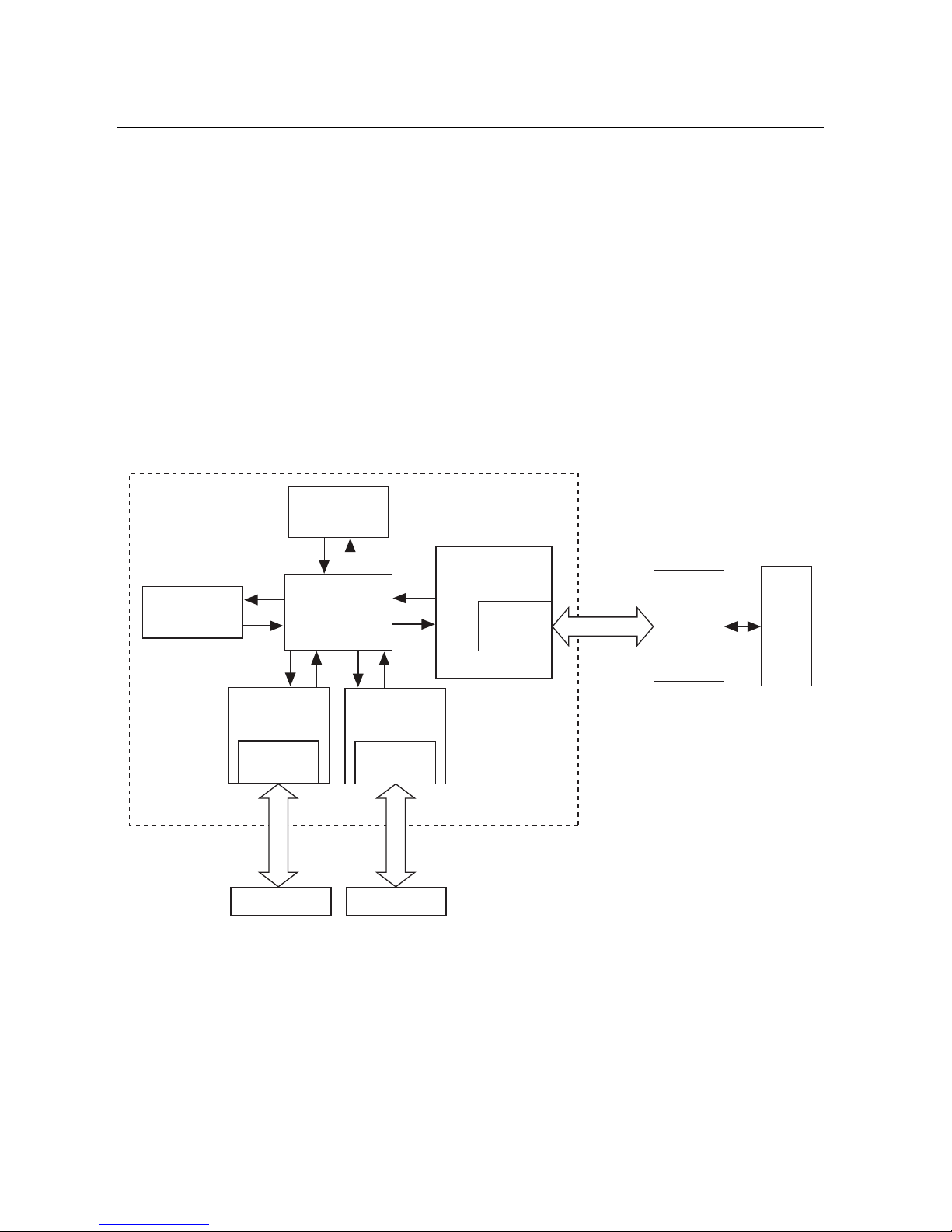

The LabVIEW FPGA Module includes component-level intellectual property (CLIP) for HDL

IP integration. NI FlexRIO devices support two types of CLIP: user-defined and socketed.

• User-defined CLIP allows you to insert HDL IP into an FPGA target, enabling VHDL code

to communicate directly with an FPGA VI.

• Socketed CLIP provides the same IP integration functionality of the user-defined CLIP, but

also allows the CLIP to communicate directly with circuitry external to the FPGA. Adapter

module socketed CLIP allows your IP to communicate directly with both the FPGA VI and

the external adapter module connector interface.

The following figure shows the relationship between an FPGA VI and CLIP.

Figure 4. CLIP and FPGA VI Relationship

NI FlexRIO FPGA Module

FPGA

User-Defined

CLIP

User-Defined

CLIP

LabVIEW

FPGA VI

DRAM 0

CLIP Socket

Socketed

CLIP

Fixed I/O

DRAM0 DRAM1

DRAM 1

CLIP Socket

Socketed

CLIP

Adapter Module

Fixed I/O

CLIP Socket

Socketed

CLIP

Fixed I/O

Adapter

Module

External

I/O Connector

8 | ni.com | NI 5782R User Manual and Specifications

Page 9

The NI 5782 ships with socketed CLIP items that add module I/O to the LabVIEW project. The

NI 5782 ships with the following CLIP items:

1. NI 5782 Multiple Sample CLIP—The analog input channels generate two samples per

clock cycle at a clock rate that is half the sample rate. The analog output channels generate

four samples per clock cycle at a clock rate that is one quarter of the sample rate. The AI

default sample rate is 250 MHz, and the AO default sample rate is 500 MHz. The default

clock rate for this CLIP is 125 MHz. You can set a lower sample rate by using an external

Sample Clock.

This CLIP presents the data to the diagram in a decelerated format. The ADC data lands at

half the rate as the ADC clock. The DAC data must be presented in four time samples per

clock on each channel.

This CLIP provides access to two AI channels, two AO channels, eight bidirectional DIO

channels, four bidirectional PFI channels, and an input clock selector that can be configured

to use one of the following settings:

– Internal Sample Clock

– Internal Sample Clock locked to an external Reference Clock through the CLK IN

connector

– External Sample Clock through the CLK IN connector

– Internal Sample Clock locked to an external Reference Clock through

IoModSyncClock

– External Sample Clock through IoModSyncClock

This CLIP also contains an engine to program the CLK chip, ADCs, and DACs, either

through predetermined settings for an easier instrument setup, or through a raw SPI address

and data signals for a more advanced setup. The NI 5782 Multiple Sample CLIP is the

default CLIP.

2. NI 5782 Single Sample CLIP—The analog input channels generate one sample per clock

cycle and the analog output channels generate two samples per clock cycle. The default

clock rate for the Multiple Sample CLIP is 250 MHz. The Sample Clock rates of

AI (250 MHz) and AO (500 MHz) are the same as Multiple Sample CLIP. You can set

lower sample rates with the external Sample Clock.

This CLIP presents the data to the diagram at a clock rate such that the ADC data lands at

the same rate as the ADC clock. However, the DAC data must be presented in two time

samples per clock on each channel.

This CLIP provides access to two AI channels, two AO channels, eight bidirectional DIO

channels, four bidirectional PFI channels, and an input clock selector that can be configured

to use one of the following settings:

– Internal Sample Clock

– Internal Sample Clock locked to an external Reference Clock through the CLK IN

connector

– External Sample Clock through the CLK IN connector

NI 5782R User Manual and Specifications | © National Instruments | 9

Page 10

– Internal Sample Clock locked to an external Reference Clock through

IoModSyncClock

– External Sample Clock through IoModSyncClock

This CLIP also contains an engine to program the CLK chip, ADCs, and DACs, either

through predetermined settings for an easier instrument setup, or through a raw SPI address

and data signals for a more advanced setup.

Refer to the NI FlexRIO Help for more information about NI FlexRIO CLIP items, how to

configure the NI 5782 with a socketed CLIP, and for a list of available socketed CLIP signals.

Connecting Cables

•Use any 50Ω SMA cable to connect signals to the connectors on the front panel of your

NI 5782.

• Use the SHH19-H19-AUX cable (NI part number: 152629-01 or 152629-02) to connect to

the DIO and PFI signals on the AUX I/O connector.

For more information about connecting I/O signals on your device, refer to the Appendix A:

Specifications section of this document.

Clocking

The NI 5782 clocks control the sample rate and other timing functions on the device. Table 4

contains information about the possible NI 5782 clock resources.

Table 4. NI 5782 Clock Sources

Clock Frequency Source Options

Internal Clock

PLL Off

Internal Clock

PLL On

(IoModSyncClock)

Internal Clock

PLL On

(CLK IN)

External Clock

(CLK IN)

500 MHz The internal voltage-controlled oscillator (VCO) acts

as a free-running clock.

500 MHz The internal VCO locks to PXI_CLK10 through

IoModSyncClock, which is available only through

the backplane of NI PXIe-796xR devices.

500 MHz The internal VCO locks to an external Reference

Clock (10 MHz). Connect the external Reference

Clock through the CLK IN front panel connector.

250 MHz to

1 GHz

Connect an external Sample Clock through the

CLK IN front panel connector.

10 | ni.com | NI 5782R User Manual and Specifications

Page 11

Using Your NI 5782R with a LabVIEW FPGA

Example VI

Note You must install the software before running this example. Refer to the

NI FlexRIO FPGA Module Installation Guide and Specifications for more

information about installing your software.

The NI FlexRIO Adapter Module Support software includes example projects to help you get

started creating your LabVIEW FPGA application. This section explains how to use an existing

LabVIEW FPGA example project to generate and acquire samples with the NI 5782R. This

example requires at least one SMA cable to connect signals to your NI 5782R.

Note The examples available for your device depend on the version of the software

and driver you are using. For more information about which software versions are

compatible with your device, visit

the text field.

Each NI 5782R example project includes the following components:

• A LabVIEW FPGA VI that can be compiled and run on the FPGA embedded in the

hardware

ni.com/info and enter rdsoftwareversion in

• A VI that runs on Windows and interacts with the LabVIEW FPGA VI

Note In the LabVIEW FPGA Module software, NI FlexRIO adapter modules are

referred to as IO Modules.

Complete the following steps to run an example that acquires a waveform on CH 0 of the

NI 5782.

1. Connect one end of an SMA cable to AI 0 on the front panel of the NI 5782 and the other

end of the cable to your device under test (DUT).

2. Launch LabVIEW.

3. Click Help»Find Examples to display the NI Example Finder.

4. In the NI Example Finder window, select Hardware Input and Output»FlexRIO»

IO Modules»NI 5782.

5. Select NI 5782 - Getting Started.lvproj.

6. In the Project Explorer window, open NI 5782 - Getting Started (Host).vi under My

Computer to open the host VI. The Open FPGA VI Reference function in this VI uses the

NI 7952R as the FPGA target by default. If you are using an NI FlexRIO FPGA module

other than the NI 7952R, complete the following steps to change to the FPGA VI to support

your target.

a. Select Window»Show Block Diagram to open the VI block diagram.

b. On the block diagram, right-click the Open FPGA VI Reference (PXI-7952R)

function and select Configure Open FPGA VI Reference.

NI 5782R User Manual and Specifications | © National Instruments | 11

Page 12

c. In the Configure Open FPGA VI Reference dialog box, click the Browse button

next to the Bitfile button.

d. In the Select Bitfile dialog box that opens, select the bitfile for your desired target. The

bitfile name is based on the adapter module, example type, and FPGA module.

e. Click the Select button.

f. Click OK in the Configure Open FPGA VI Reference dialog box.

g. Save the VI.

7. On the front panel, in the RIO Resource pull-down menu, select an NI 5782R resource that

corresponds with the target that you configured in step 6.

8. Select AI 0 in the AI Channel control.

9. Set the Trigger Level (V) and the Record Size controls to the desired values.

10. In the Trigger Type box, select either Software or Data Edge. If you select Software, the

VI acquires data every time you click the Software Trigger button on the front panel of the

VI. If you select Data Edge, the VI acquires data every time an edge occurs.

11. Click the Run button to run the VI.

12. Click the Software Trigger button if you selected Software in the Trigger Type control.

The VI acquires data and displays the captured waveform on the Acquired Waveform

graph as shown in Figure 5.

13. Click the STOP button to stop the VI.

14. Close the VI.

12 | ni.com | NI 5782R User Manual and Specifications

Page 13

Figure 5. NI 5782 - Getting Started (Host) VI Front Panel

Creating a LabVIEW Project and Running a VI on

an FPGA Target

This section explains how to set up your target and create an FPGA VI and a host VI for data

communication. This section focuses on proper project configuration, proper CLIP

configuration, and how to access 5782 AI IO nodes. For more detailed information about

acquiring data on your NI 5782R, refer to the device-specific examples available in NI Example

Finder.

Creating a Project

1. Launch LabVIEW. If LabVIEW is already running, select File»Create Project.

2. In the Create Project dialog box, select LabVIEW FPGA Project and click Finish.

3. In the Create New LabVIEW FPGA Project dialog box, select FlexRIO on My

Computer and click Next.

4. If your FlexRIO device is connected to your system, select Discover Existing System. If

your device is not connected to your system, select Create New System and click Next.

5. Select your device and click Next.

NI 5782R User Manual and Specifications | © National Instruments | 13

Page 14

6. LabVIEW generates a preview of your project. Verify that the project is correct and select

Finish. The new project opens in the Project Explorer window.

Creating an FPGA Target VI

1. Right-click FPGA Target (RIOx, PXI-79xxR) and select New»FPGA Base Clock.

2. In the Resource pull-down menu, select 200 MHz Clock and click OK.

3. Right-click IO Module (5782) in the Project Explorer window and select Properties.

4. In the Clock Selections category, select 200 MHz Clock from the pull-down menu for

Clk200. Leave Clk40 configured as the Top-Level Clock.

5. Select NI 5782 CLIP in the Name list of the Component Level IP pane.

6. In the Clock Selections category, select 200 MHz Clock from the pull-down menu for

Clk200. Leave Clk40 configured as the Top-Level Clock.

7. Click OK.

Note Configuring these clocks is required for proper CLIP operation. Refer to the

NI 5782 CLIP topics in the NI FlexRIO Help for more information about configuring

your clocks.

8. In the Project Explorer window, right-click the FPGA target and select New»VI to open

a blank VI.

9. Select Window»Show Block Diagram to open the VI block diagram.

10. In the Project Explorer window, expand the IO Module (NI 5782 : NI 5782) tree view.

11. Drag AI 0 Data N-1 to the block diagram.

12. Click and drag the bottom edge of the control node to expose the other signals, AI 0

N-1...AI 1 N.

13. Add a Timed Loop structure around the node.

14. Wire indicators to each output terminal of the IO Module\AI 0 N-1...AI 1 N.

15. Right-click the input node of the Timed Loop to wire an FPGA Clock Constant to the node.

Set this constant to IO Module\Data Clock.

Your block diagram should resemble the block diagram in Figure 6.

Figure 6. 5782SampleAcq (FPGA).vi Block Diagram

14 | ni.com | NI 5782R User Manual and Specifications

Page 15

Tip Click the Clean Up Diagram button on the toolbar to cleanly organize the VI

block diagrams.

16. Save the VI as 5782SampleAcq (FPGA).vi.

17. Click the Run button. LabVIEW creates a default build specification and begins compiling

the VI. The Generating Intermediate Files window opens and displays the code

generation progress. Next, the Compilation Status window opens and displays the

progress of the compilation. The compilation takes several minutes.

18. Click Close in the Compilation Status window.

19. Save and close the VI.

20. Save the project.

Creating a Host VI

1. In the Project Explorer window, right-click My Computer and select New»VI to open a

blank VI.

2. Select Window»Show Block Diagram to open the VI block diagram.

3. Add the Open FPGA VI Reference function, located on the FPGA Interface palette, to the

block diagram.

4. Drag and drop your 5782SampleAcq(FPGA).vi into the Open FPGA VI Reference. The

target name appears under the Open FPGA VI Reference function in the block diagram.

5. In the block diagram, add a While Loop to the right of the Open FPGA VI Reference

function.

6. Right-click the conditional terminal inside the While Loop and select Create Control to

create a STOP button on the VI front panel window.

7. Add the Read/Write Control function, located on the FPGA Interface palette, inside the

While Loop.

8. Wire the FPGA VI Reference Out output terminal of the Open FPGA VI Reference

function to the FPGA VI Reference In input terminal of the Read/Write Control function.

9. Wire the error out terminal of the Open FPGA VI Reference function to the error in

control of the Read/Write Control function.

10. Configure the Read/Write Control function by clicking the terminal section labeled

Unselected, and selecting IO Module/AI 0 N-1.

11. Click and drag the bottom edge of the control edge to expose the other signals, AI 0

N-1...AI 1 N, to the Read/Write Control function.

12. Wire indicators to each output terminal of the IO Module\AI 0 N-1...AI 1 N.

13. Add the Close FPGA VI Reference function, located on the FPGA Interface palette, to the

right of the While Loop on the block diagram.

14. Wire the FPGA VI Reference Out terminal of the Read/Write Control function to the

FPGA VI Reference In terminal of the Close FPGA VI Reference function.

15. Wire the error out terminal of the Read/Write Control function to the error in terminal of

the Close FPGA VI Reference function.

NI 5782R User Manual and Specifications | © National Instruments | 15

Page 16

Your block diagram should resemble the block diagram in Figure 7.

Figure 7. 5782SampleAcq(Host).vi Block Diagram

16. Save the VI as 5782SampleAcq(Host).vi.

Running the Host VI

1. Connect one end of an SMA cable to AI 0 on the front panel of the NI 5782 and the other

end of the cable to your DUT.

2. Open the front panel of

3. Click the Run button to run the VI.

4. The VI acquires data from the DUT on AI 0, AI 0 N-1, AI 1 N, and AI 1 N-1.

5. Click the STOP button on the front panel and close the VI.

5782SampleAcq(Host).vi.

Appendix A: Specifications

This section lists the specifications of the NI FlexRIO adapter module (NI 5782). Pair these

specifications with the specifications listed in the NI FlexRIO FPGA Module Installation Guide

and Specifications. For more information about safety and electromagnetic compatibility refer

to the Read Me First: Safety and Electromagnetic Compatibility document included in your

hardware kit or available at

Caution To avoid permanent damage to the NI 5782, disconnect all signals

connected to the NI 5782 before powering down the module, and only connect

signals after the module has been powered on by the NI FlexRIO FPGA module.

Note All numeric specifications are typical unless otherwise noted. All graphs

illustrate the performance of a representative module.

ni.com/manuals.

Specifications are subject to change without notice. For the most recent device specifications,

visit

ni.com/manuals.

16 | ni.com | NI 5782R User Manual and Specifications

Page 17

Analog Input (AI 0 and AI 1)

General Characteristics

Number of channels.......................................... Two, single-ended, simultaneously sampled

Connector.......................................................... SMA

Input impedance ............................................... 50 Ω , per connector

Sample rate

Internal Sample Clock .............................. 250 MHz

External Sample Clock ............................. 175 MHz to 250 MHz

ADC part number ............................................. ADS62P49

1

; 14-bit resolution, dual ADC

AC-Coupled Specifications

Input range (normal operating conditions) ....... +10.2 dBm (2.05 V

Absolute maximum input ................................. 50 Ω , ±10 V DC, +18 dBm (5 V

Bandwidth (-1 dB) ............................................ 1 MHz to 250 MHz

Bandwidth (-3 dB) ............................................ 0.1 MHz to 500 MHz

Table 5 lists the AC-coupled spectral performance measurements. All values are measured with

a 500 MHz internal Sample Clock.

Table 5. Analog Input AC-Coupled Spectral Performance

Measurement 20.1 MHz 70.1 MHz 124.1 MHz

Signal-to-noise

70.5 dB 70.0 dB 68.8 dB

ratio (SNR)

Signal-to-noise and

70.5 dB 69.8 dB 68.6 dB

distortion ratio

(SINAD)

pk-pk

)

) AC

pk-pk

Spurious-free

dynamic range

(SFDR)

Channel-to-channel isolation

1 MHz ....................................................... >90 dB

100.1 MHz ................................................ 90 dB

501 MHz ................................................... 70 dB

1

For additional information on the ADS62P49, refer to the Texas Instruments device data sheet at

www.ti.com.

90.0 dB 83.0 dB 80.0 dB

NI 5782R User Manual and Specifications | © National Instruments | 17

Page 18

Figure 8. Bandwidth (Passband)

Amplitude (dBFS)

–5

–1

–2

–3

–4

–6

–7

–8

–9

0

200 240 280 320 360 400 440 480 520 56080 120 16040

Frequency (MHz)

0

–10

600

Figure 9. Terminated Input

0

–10

–20

–30

–40

–50

–60

dBFS (dB)

–70

–80

–90

–100

–110

0

4020 60 80 100 120

Frequency (MHz)

18 | ni.com | NI 5782R User Manual and Specifications

Page 19

Figure 10. Analog Input One-Tone Spectral Measurement (70 MHz, -1 dBFS)

0

–10

–20

–30

–40

–50

–60

dBFS (dB)

–70

–80

–90

–100

–110

0

4020 60 80 100 120

Frequency (MHz)

Figure 11. Two-Tone Spectral Measurement (19.5 and 20.5 MHz, -10 dBFS)

0

–10

–20

–30

–40

–50

–60

dBFS (dB)

–70

–80

–90

–100

–110

0

4020 60 80 100 120

Frequency (MHz)

NI 5782R User Manual and Specifications | © National Instruments | 19

Page 20

DC-Coupled Specifications

Input range (normal operating conditions) .......+4.0 dBm, 1.0 V

Absolute maximum input..................................50 Ω , ±4.5 V DC, +15 dBm (3.6 V

pk-pk

pk-pk

) AC

Bandwidth (-1 dB) ............................................DC to 170 MHz

Bandwidth (-3 dB) ............................................DC to 330 MHz

Table 6 lists the DC-coupled spectral performance measurements. All values are measured with

a 1 GHz internal Sample Clock.

Table 6. Analog Input DC-Coupled Spectral Performance

Measurement 20.1 MHz 70.1 MHz 124.1 MHz

SNR 67.3 dB 66.2 dB 65.5 dB

SINAD 67.0 dB 65.4 dB 64.0 dB

SFDR 80.0 dB 78.0 dB 66.0 dB

Channel-to-channel isolation

1 MHz ....................................................... 85 dB

100.1 MHz ................................................85 dB

501 MHz ...................................................60 dB

Figure 12. Analog Input Bandwidth (Passband)

0

–1

–2

–3

–4

–5

–6

Amplitude (dBFS)

–7

–8

–9

–10

0

200 240 280 320 360 400 440 480 520 56080 120 16040

Frequency (MHz)

600

20 | ni.com | NI 5782R User Manual and Specifications

Page 21

dBFS (dB)

–100

–110

–10

–20

–30

–40

–50

–60

–70

–80

–90

Figure 13. Analog Input Terminated Input

0

0

4020 60 80 100 120

Frequency (MHz)

Figure 14. Analog Input One-Tone Spectral Measurement (70 MHz, -1 dBFS)

0

–10

–20

–30

–40

–50

–60

dBFS (dB)

–70

–80

–90

–100

–110

0

4020 60 80 100 120

Frequency (MHz)

NI 5782R User Manual and Specifications | © National Instruments | 21

Page 22

Figure 15. Two-Tone Spectral Measurement (19.5 and 20.5 MHz, -10 dBFS)

0

–10

–20

–30

–40

–50

–60

dBFS (dB)

–70

–80

–90

–100

–110

0

4020 60 80 100 120

Frequency (MHz)

Analog Output (AO 0 and AO 1)

General Characteristics

Number of channels ..........................................Two, single-ended, simultaneously sampled

Connector..........................................................SMA

Output impedance .............................................50 Ω, per connector

Sample rate

DLL Off .................................................... <250 MHz

DLL On..................................................... 250 MHz to 1 GHz

DAC part number.............................................. DAC5682Z

1

; 16-bit resolution, dual DAC

1

For additional information on the DAC5682Z, refer to the Texas Instruments device data sheet at

www.ti.com.

22 | ni.com | NI 5782R User Manual and Specifications

Page 23

AC-Coupled Specifications

Amplitude (dBFS)

–5

–1

–2

–3

–4

–6

–7

–8

–9

0

200 240 280 320 360 400 440 48080 120 16040

Frequency (MHz)

0

–10

Output range (normal operating conditions) .... -0.5 dBm (0.6 V

pk-pk

Bandwidth (-3 dB) ............................................ 1 MHz to 225 MHz

SNR .................................................................. 70 dBc

Table 7. SFDR (70 MHz Out, 1 GS/s, no PLL)

Non-Harmonic Second Harmonic Third Harmonic

77 dBc 61 dBc 72 dBc

Channel-to-channel isolation

1 MHz ....................................................... 100 dB

100.1 MHz ................................................ 90 dB

251 MHz ................................................... 90 dB

Figure 16. Bandwidth (Passband)

)

1

1

Includes DAC sinc response.

NI 5782R User Manual and Specifications | © National Instruments | 23

Page 24

Figure 17. Analog Output One-Tone Spectral Measurement (70 MHz, 0.25 dBm,

Amplitude (dBm)

–50

–10

0.0

–20

–30

–40

–60

–70

–80

–90

–100

69.95

69.96 69.97 69.98 69.99 70 70.01 70.02 70.03 70.04 70.05

Frequency (MHz)

5.0

–110

100 Hz Resolution Bandwidth, 100 kHz Bandwidth)

Figure 18. Analog Output One-Tone Spectral Measurement (70 MHz, 0.25 dBm,

1 kHz Resolution Bandwidth, 1 MHz Bandwidth)

5.0

0.0

–10

–20

–30

–40

–50

–60

–70

Amplitude (dBm)

–80

–90

–100

–110

24 | ni.com | NI 5782R User Manual and Specifications

69.5

69.6 69.7 69.8 69.9 70.0 70.1 70.2 70.3 70.4 70.5

Frequency (MHz)

Page 25

Figure 19. Analog Output One-Tone Spectral Measurement (70 MHz, 0.25 dBm,

1 kHz Resolution Bandwidth, 100 MHz Bandwidth)

5.0

0.0

–10

–20

–30

–40

–50

–60

–70

Amplitude (dBm)

–80

–90

–100

–110

20

30 40 50 60 70 80 90 100 110 120

Frequency (MHz)

Figure 20. Analog Output One-Tone Spectral Measurement (70 MHz, 0.25 dBm,

1 kHz Resolution Bandwidth, 500 MHz Bandwidth)

5.0

0.0

–10

–20

–30

–40

–50

–60

–70

Amplitude (dBm)

–80

–90

–100

–110

0

50 10 150 200 250 300 350 400 450 500

Frequency (MHz)

NI 5782R User Manual and Specifications | © National Instruments | 25

Page 26

DC-Coupled Specifications

Output range (normal operating conditions)..... +4 dBm (1.0 V

Bandwidth (-3 dB) ............................................DC to 180 MHz

SNR................................................................... 66 dBc

Table 8. SFDR (70 MHz Out, 1 GS/s, no PLL)

Non-Harmonic Second Harmonic Third Harmonic

77 dBc 47 dBc 47 dBc

Channel-to-channel isolation

1.0 MHz ....................................................100 dB

100.1 MHz ................................................100 dB

251.0 MHz ................................................87 dB

Figure 21. Analog Output Bandwidth (Passband)

0

–1

pk-pk

1

)

–2

–3

–4

–5

–6

Amplitude (dBFS)

–7

–8

–9

–10

0

200 240 280 320 360 400 440 48080 120 16040

Frequency (MHz)

1

Includes DAC sinc response.

26 | ni.com | NI 5782R User Manual and Specifications

Page 27

Figure 22. Analog Output One-Tone Spectral Measurement (70 MHz, 0.25 dBm,

Amplitude (dBm)

–50

–10

0.0

–20

–30

–40

–60

–70

–80

–90

–100

69.95

69.96 69.97 69.98 69.99 70.00 70.01 70.02 70.03 70.04 70.05

Frequency (MHz)

5.0

–110

100 Hz Resolution Bandwidth, 100 kHz Bandwidth)

Figure 23. Analog Output One-Tone Spectral Measurement (70 MHz, 0.25 dBm,

1 kHz Resolution Bandwidth, 1 MHz Bandwidth)

5.0

0.0

–10

–20

–30

–40

–50

–60

–70

Amplitude (dBm)

–80

–90

–100

–110

69.5

69.6 69.7 69.8 69.9 70.0 70.1 70.2 70.3 70.4 70.5

Frequency (MHz)

NI 5782R User Manual and Specifications | © National Instruments | 27

Page 28

Figure 24. Analog Output One-Tone Spectral Measurement (70 MHz, 0.25 dBm,

1 kHz Resolution Bandwidth, 100 MHz Bandwidth)

5.0

0.0

–10

–20

–30

–40

–50

–60

–70

Amplitude (dBm)

–80

–90

–100

–110

20

30 40 50 60 70 80 90 100 110 120

Frequency (MHz)

Figure 25. Analog Output One-Tone Spectral Measurement (70 MHz, 0.25 dBm,

1 kHz Resolution Bandwidth, 500 MHz Bandwidth)

5.0

0.0

–10

–20

–30

–40

–50

–60

–70

Amplitude (dBm)

–80

–90

–100

–110

0

50 10 150 200 250 300 350 400 450 500

Internal Sample Clock

General Characteristics

Frequency (MHz)

Oscillator type...................................................Fixed frequency synthesizer

Frequency (default)........................................... 1 GHz

Reference spurs .................................................<60 dBc

28 | ni.com | NI 5782R User Manual and Specifications

Page 29

Phase noise

10 kHz offset............................................. -95 dBc/Hz

100 kHz offset........................................... -115 dBc/Hz

Clock distribution part number......................... AD9512

1

Reference Clock sources .................................. Internal, External through the CLK IN

connector, or IoModSyncClock

2

Internal reference type ...................................... TCXO

Internal reference stability ................................ ±1 ppm

Internal reference frequency (default) .............. 10 MHz

Internal reference phase noise

1 kHz offset............................................... -137 dBc/Hz

10 kHz offset............................................. -150 dBc/Hz

100 kHz offset........................................... -155 dBc/Hz

CLK IN

General Characteristics

Number of channels.......................................... 1, single-ended

Connector.......................................................... SMA

Input impedance ............................................... 50 Ω

Input coupling................................................... AC

External Sample Clock

Input voltage range ........................................... 0.63 V

Input frequency range ....................................... 250 MHz to 1 GHz

Absolute maximum input ................................. ±10 V DC, 3.1 V

Input power (50 Ω ).......................................... 0 dBm to 12 dBm

pk-pk

to 2.5 V

pk-pk

pk-pk

External Reference Clock

Input voltage range ........................................... 1.4 V

Input frequency range ....................................... 10 MHz

Absolute maximum input ................................. ±10 V DC, 5 V

Input power (50 Ω ).......................................... 7.0 dBm to 16.8 dBm

pk-pk

to 4.4 V

pk-pk

pk-pk

AC

AC

1

For additional information about the AD9512, refer to the Analog Devices device data sheet at

www.analog.com.

2

IoModSyncClock is available only on NI PXIe-796xR FPGA modules.

NI 5782R User Manual and Specifications | © National Instruments | 29

Page 30

TRIG

General Characteristics

Number of channels ..........................................1, single-ended

Connector..........................................................SMA

Input impedance................................................10k kW

Input coupling ...................................................DC

Table 9. Input Levels

Voltage Level Minimum Maximum

V

V

IL

IH

0.0 V 0.8 V

2.0 V 3.6 V

Absolute maximum input.................................. ±10 V

AUX I/O (Port 0 DIO <0..3>, Port 1 DIO <0..3>, and

PFI <0..3>)

General Characteristics

Number of channels ..........................................12 bidirectional (8 DIO and 4 PFI)

Connector type .................................................. HDMI

Interface standard..............................................3.3 V LVCMOS

Interface logic

Maximum V

Minimum V

Minimum V

Maximum VIH........................................... 3.6 V

........................................... 0.8 V

IL

............................................ -0.3 V

IL

............................................ 2.0 V

IH

Maximum V

Minimum V

Minimum V

Maximum V

............................................................ 50 Ω ± 20%

Z

out

I

(DC)..................................................... ±2 mA

out

.......................................... 0.4 V

OL

...........................................0 V

OL

........................................... 2.7 V

OH

.......................................... 3.6 V

OH

Pull-down resistor ............................................. 150 k Ω

Recommended operating voltage......................-0.3 V to 3.6 V

Overvoltage protection ..................................... ±10 V

Maximum toggle frequency..............................6.6 MHz

30 | ni.com | NI 5782R User Manual and Specifications

Page 31

+5 V maximum power ...................................... 10 mA

+5 V voltage tolerance...................................... 4 V to 5.0 V

EEPROM

Table 10. EEPROM Map

Byte Address Size (Bytes) Field Name

0x0 2 Vendor ID

0x2 2 Product ID

0x4 4 Serial Number

0x8 116 Reserved

0x7C 132 User Space

Caution Only write to User Space. Writing to any other offset may cause the

NI 5782 to stop functioning.

Power

Power draw (W)

AC-coupled build ..................................... 4.59

DC-coupled build ..................................... 5.26

DC Power Requirements

VCCOA, VCCOB ............................................ 2.37 V to 2.60 V

VEEPROM ....................................................... 2.50 V to 5.50 V

P33V ................................................................. 3.09 V to 3.47 V

P12V ................................................................. 11.12 V to 12.60 V

Physical

Dimensions ....................................................... 11.4 × 10.2 × 2.00 cm

(4.5 × 4.0 × 0.8 in.)

Weight ............................................................... 317.5 g (11.2 oz)

NI 5782R User Manual and Specifications | © National Instruments | 31

Page 32

Environmental

Operating environment1.................................... 0 °C to 55 °C,

tested in accordance with IEC-60068-2-1 and

IEC-60068-2-2.

Relative humidity range....................................10% to 90%, noncondensing,

tested in accordance with IEC-60068-2-56.

Maximum altitude.............................................2,000 m at 25 °C ambient temperature.

Pollution Degree ...............................................2

Indoor use only.

Storage environment

Ambient temperature range ...................... -20 °C to 70 °C,

tested in accordance with IEC-60068-2-1 and

IEC-60068-2-2.

Relative humidity range............................5% to 95%, noncondensing,

tested in accordance with IEC-60068-2-56.

Note Clean the device with a soft, non-metallic brush. Make sure that the device is

completely dry and free from contaminants before returning it to service.

Shock and Vibration

Operational shock ............................................. 30 g peak, half-sine, 11 ms pulse,

tested in accordance with IEC-60068-2-27.

Test profile developed in accordance with

MIL-PRF-28800F.

Random vibration

Operating ..................................................5 Hz to 500 Hz, 0.3 g

Nonoperating ............................................5 Hz to 500 Hz, 2.4 g

rms

rms

,

tested in accordance with IEC-60068-2-64.

Nonoperating test profile exceeds the

requirements of MIL-PRF-28800F, Class 3.

Safety

This product meets the requirements of the following standards of safety for electrical equipment

for measurement, control, and laboratory use:

• IEC 61010-1, EN 61010-1

• UL 61010-1, CSA 61010-1

1

For PXI/PXI Express chassis configurations that group NI FlexRIO adapter modules in three or more

contiguous slots, National Instruments recommends limiting the ambient operating temperature to less

than 50

32 | ni.com | NI 5782R User Manual and Specifications

°C.

Page 33

Note For UL and other safety certifications, refer to the product label or the Online

Product Certification section.

Electromagnetic Compatibility

This product meets the requirements of the following EMC standards for electrical equipment

for measurement, control, and laboratory use:

• EN 61326-1 (IEC 61326-1): Class A emissions; Basic immunity

• EN 55011 (CISPR 11): Group 1, Class A emissions

• AS/NZS CISPR 11: Group 1, Class A emissions

• FCC 47 CFR Part 15B: Class A emissions

• ICES-001: Class A emissions

Note In the United States (per FCC 47 CFR), Class A equipment is intended for use

in commercial, light-industrial, and heavy-industrial locations. In Europe, Canada,

Australia, and New Zealand (per CISPR 11), Class A equipment is intended for use

only in heavy-industrial locations.

Note Group 1 equipment (per CISPR 11) is any industrial, scientific, or medical

equipment that does not intentionally generate radio frequency energy for the

treatment of material or inspection/analysis purposes.

Note For EMC declarations and certifications, refer to the Online Product

Certification section of this document.

CE Compliance

This product meets the essential requirements of applicable European Directives as follows:

• 2006/95/EC; Low-Voltage Directive (safety)

• 2004/108/EC; Electromagnetic Compatibility Directive (EMC)

Online Product Certification

To obtain product certifications and the Declaration of Conformity for this product, visit

ni.com/certification, search by model number or product line, and click the appropriate link

in the Certification column.

Environmental Management

NI is committed to designing and manufacturing products in an environmentally responsible

manner. NI recognizes that eliminating certain hazardous substances from our products is

beneficial to the environment and to NI customers.

For additional environmental information, refer to the Minimize Our Environmental Impact web

page at

ni.com/environment. This page contains the environmental regulations and directives

NI 5782R User Manual and Specifications | © National Instruments | 33

Page 34

with which NI complies, as well as other environmental information not included in this

⬉ᄤֵᙃѻક∵ᶧࠊㅵ⧚ࡲ⊩ ˄Ё

RoHS

˅

Ёᅶ᠋

National Instruments

ヺড়Ё⬉ᄤֵᙃѻકЁ䰤ࠊՓ⫼ᶤѯ᳝ᆇ⠽䋼ᣛҸ

(RoHS)

DŽ݇Ѣ

National Instruments

Ё

RoHS

ড়㾘ᗻֵᙃˈ䇋ⱏᔩ

ni.com/

environment/rohs_china

DŽ

(For information about China RoHS compliance,

go to

ni.com/environment/rohs_china

.)

document.

Waste Electrical and Electronic Equipment (WEEE)

EU Customers At the end of the product life cycle, all products must be sent to a

WEEE recycling center. For more information about WEEE recycling centers,

National Instruments WEEE initiatives, and compliance with WEEE Directive

2002/96/EC on Waste and Electronic Equipment, visit

weee.

ni.com/environment/

Appendix B: Installing EMI Controls

To ensure specified EMC performance, an HDMI cable ferrite and PXI EMC filler panels must

be properly installed in your NI FlexRIO system. Your kit includes the HDMI cable ferrite, but

the PXI EMC filler panels (National Instruments part number 778700-01) must be purchased

separately. For more installation information, refer to the NI FlexRIO FPGA Module Installation

Guide and Specifications.

Installing PXI EMC Filler Panels

Complete the following instructions to install PXI EMC filler panels (National Instruments part

number 778700-01) in your PXI chassis:

1. Remove the captive screw covers.

2. Install the PXI EMC filler panels by securing the captive mounting screws to the chassis,

as shown in the figure below. Make sure that the EMC gasket is on the right side of the

PXI EMC filler panel.

34 | ni.com | NI 5782R User Manual and Specifications

Page 35

Figure 26. PXI EMC Filler Panels and Chassis

1

2

3

1

1 Captive Screw Covers 2 Captive Mounting Screws 3 EMC Gasket

Note You must populate all slots with a module or a PXI EMC filler panel to ensure

proper module cooling. Do not over tighten screws (2.5 lb-inch maximum). For

additional information about the use of PXI EMC filler panels in your PXI system,

ni.com/info and enter emcpanels.

visit

NI 5782R User Manual and Specifications | © National Instruments | 35

Page 36

Where to Go for Support

The National Instruments website is your complete resource for technical support. At ni.com/

support you have access to everything from troubleshooting and application development

self-help resources to email and phone assistance from NI Application Engineers.

A Declaration of Conformity (DoC) is our claim of compliance with the Council of the European

Communities using the manufacturer’s declaration of conformity. This system affords the user

protection for electromagnetic compatibility (EMC) and product safety. You can obtain the DoC

for your product by visiting

can obtain the calibration certificate for your product at

National Instruments corporate headquarters is located at 11500 North Mopac Expressway,

Austin, Texas, 78759-3504. National Instruments also has offices located around the world to

help address your support needs. For telephone support in the United States, create your service

request at

ni.com/support and follow the calling instructions or dial 512 795 8248. For

telephone support outside the United States, visit the Worldwide Offices section of ni.com/

niglobal to access the branch office websites, which provide up-to-date contact information,

support phone numbers, email addresses, and current events.

ni.com/certification. If you product supports calibration, you

ni.com/calibration.

LabVIEW, National Instruments, NI, ni.com, the National Instruments corporate logo, and the Eagle logo are trademarks of National Instruments

Corporation. Refer to the Trademark Information at ni.com/trademarks for other National Instruments trademarks. Other product and

company names mentioned herein are trademarks or trade names of their respective companies. For patents covering National Instruments

products/technology, refer to the appropriate location: Help»Patents in your software, the patents.txt file on your media, or the National

Instruments Patents Notice at ni.com/patents. You can find information about end-user license agreements (EULAs) and third-party legal

notices in the NI 5782 Readme. Refer to the Export Compliance Information at ni.com/legal/export-compliance for the National

Instruments global trade compliance policy and how to obtain relevant HTS codes, ECCNs, and other import/export data.

© 2013 National Instruments. All rights reserved.

373580A-01 Jan13

Loading...

Loading...