Page 1

NI MATRIXx

Xmath™ Control Design Module

Xmath Control Design Module

TM

April 2007

370753C-01

Page 2

Support

Worldwide Technical Support and Product Information

ni.com

National Instruments Corporate Headquarters

11500 North Mopac Expressway Austin, Texas 78759-3504 USA Tel: 512 683 0100

Worldwide Offices

Australia 1800 300 800, Austria 43 662 457990-0, Belgium 32 (0) 2 757 0020, Brazil 55 11 3262 3599,

Canada 800 433 3488, China 86 21 5050 9800, Czech Republic 420 224 235 774, Denmark 45 45 76 26 00,

Finland 385 (0) 9 725 72511, France 33 (0) 1 48 14 24 24, Germany 49 89 7413130, India 91 80 41190000,

Israel 972 3 6393737, Italy 39 02 413091, Japan 81 3 5472 2970, Korea 82 02 3451 3400,

Lebanon 961 (0) 1 33 28 28, Malaysia 1800 887710, Mexico 01 800 010 0793, Netherlands 31 (0) 348 433 466,

New Zealand 0800 553 322, Norway 47 (0) 66 90 76 60, Poland 48 22 3390150, Portugal 351 210 311 210,

Russia 7 495 783 6851, Singapore 1800 226 5886, Slovenia 386 3 425 42 00, South Africa 27 0 11 805 8197,

Spain 34 91 640 0085, Sweden 46 (0) 8 587 895 00, Switzerland 41 56 2005151, Taiwan 886 02 2377 2222,

Thailand 662 278 6777, Turkey 90 212 279 3031, United Kingdom 44 (0) 1635 523545

For further support information, refer to the Technical Support and Professional Services appendix. To comment

on National Instruments documentation, refer to the National Instruments Web site at ni.com/info and enter

the info code feedback.

© 2007 National Instruments Corporation. All rights reserved.

Page 3

Important Information

Warranty

TThe media on which you receive National Instruments software are warranted not to fail to execute programming instructions, due to defects

in materials and workmanship, for a period of 90 days from date of shipment, as evidenced by receipts or other documentation. National

Instruments will, at its option, repair or replace software media that do not execute programming instructions if National Instruments receives

notice of such defects during the warranty period. National Instruments does not warrant that the operation of the software shall be

uninterrupted or error free.

A Return Material Authorization (RMA) number must be obtained from the factory and clearly marked on the outside of the package before any

equipment will be accepted for warranty work. National Instruments will pay the shipping costs of returning to the owner parts which are covered by

warranty.

National Instruments believes that the information in this document is accurate. The document has been carefully reviewed for technical accuracy. In

the event that technical or typographical errors exist, National Instruments reserves the right to make changes to subsequent editions of this document

without prior notice to holders of this edition. The reader should consult National Instruments if errors are suspected. In no event shall National

Instruments be liable for any damages arising out of or related to this document or the information contained in it.

E

XCEPT AS SPECIFIED HEREIN, NATIONAL INSTRUMENTS MAKES NO WARRANTIES, EXPRESS OR IMPLIED, AND SPECIFICALLY DISCLAIMS ANY WARRANTY OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. CUSTOMER’S RIGHT TO RECOVER DAMAGES CAUSED BY FAULT OR NEGLIGENCE ON THE PART OF NATIONAL

I

NSTRUMENTS SHALL BE LIMITED TO THE AMOUNT THERETOFORE PAID BY THE CUSTOMER. NATIONAL INSTRUMENTS WILL NOT BE LIABLE FOR DAMAGES RESULTING

FROM LOSS OF DATA, PROFITS, USE OF PRODUCTS, OR INCIDENTAL OR CONSEQUENTIAL DAMAGES, EVEN IF ADVISED OF THE POSSIBILITY THEREOF. This limitation of

the liability of National Instruments will apply regardless of the form of action, whether in contract or tort, including negligence. Any action against

National Instruments must be brought within one year after the cause of action accrues. National Instruments shall not be liable for any delay in

performance due to causes beyond its reasonable control. The warranty provided herein does not cover damages, defects, malfunctions, or service

failures caused by owner’s failure to follow the National Instruments installation, operation, or maintenance instructions; owner’s modification of the

product; owner’s abuse, misuse, or negligent acts; and power failure or surges, fire, flood, accident, actions of third parties, or other events outside

reasonable control.

Copyright

Under the copyright laws, this publication may not be reproduced or transmitted in any form, electronic or mechanical, including photocopying,

recording, storing in an information retrieval system, or translating, in whole or in part, without the prior written consent of National

Instruments Corporation.

National Instruments respects the intellectual property of others, and we ask our users to do the same. NI software is protected by copyright and other

intellectual property laws. Where NI software may be used to reproduce software or other materials belonging to others, you may use NI software only

to reproduce materials that you may reproduce in accordance with the terms of any applicable license or other legal restriction.

Trademarks

MATRIXx™, National Instruments™, NI™, ni.com™, and Xmath™ are trademarks of National Instruments Corporation.

Other product and company names mentioned herein are trademarks or trade names of their respective companies.

Members of the National Instruments Alliance Partner Program are business entities independent from National Instruments and have no agency,

partnership, or joint-venture relationship with National Instruments.

Patents

For patents covering National Instruments products, refer to the appropriate location: Help»Patents in your software, the patents.txt file

on your CD, or

ni.com/patents.

WARNING REGARDING USE OF NATIONAL INSTRUMENTS PRODUCTS

(1) NATIONAL INSTRUMENTS PRODUCTS ARE NOT DESIGNED WITH COMPONENTS AND TESTING FOR A LEVEL OF

RELIABILITY SUITABLE FOR USE IN OR IN CONNECTION WITH SURGICAL IMPLANTS OR AS CRITICAL COMPONENTS IN

ANY LIFE SUPPORT SYSTEMS WHOSE FAILURE TO PERFORM CAN REASONABLY BE EXPECTED TO CAUSE SIGNIFICANT

INJURY TO A HUMAN.

(2) IN ANY APPLICATION, INCLUDING THE ABOVE, RELIABILITY OF OPERATION OF THE SOFTWARE PRODUCTS CAN BE

IMPAIRED BY ADVERSE FACTORS, INCLUDING BUT NOT LIMITED TO FLUCTUATIONS IN ELECTRICAL POWER SUPPLY,

COMPUTER HARDWARE MALFUNCTIONS, COMPUTER OPERATING SYSTEM SOFTWARE FITNESS, FITNESS OF COMPILERS

AND DEVELOPMENT SOFTWARE USED TO DEVELOP AN APPLICATION, INSTALLATION ERRORS, SOFTWARE AND HARDWARE

COMPATIBILITY PROBLEMS, MALFUNCTIONS OR FAILURES OF ELECTRONIC MONITORING OR CONTROL DEVICES,

TRANSIENT FAILURES OF ELECTRONIC SYSTEMS (HARDWARE AND/OR SOFTWARE), UNANTICIPATED USES OR MISUSES, OR

ERRORS ON THE PART OF THE USER OR APPLICATIONS DESIGNER (ADVERSE FACTORS SUCH AS THESE ARE HEREAFTER

COLLECTIVELY TERMED “SYSTEM FAILURES”). ANY APPLICATION WHERE A SYSTEM FAILURE WOULD CREATE A RISK OF

HARM TO PROPERTY OR PERSONS (INCLUDING THE RISK OF BODILY INJURY AND DEATH) SHOULD NOT BE RELIANT SOLELY

UPON ONE FORM OF ELECTRONIC SYSTEM DUE TO THE RISK OF SYSTEM FAILURE. TO AVOID DAMAGE, INJURY, OR DEATH,

THE USER OR APPLICATION DESIGNER MUST TAKE REASONABLY PRUDENT STEPS TO PROTECT AGAINST SYSTEM FAILURES,

INCLUDING BUT NOT LIMITED TO BACK-UP OR SHUT DOWN MECHANISMS. BECAUSE EACH END-USER SYSTEM IS

CUSTOMIZED AND DIFFERS FROM NATIONAL INSTRUMENTS' TESTING PLATFORMS AND BECAUSE A USER OR APPLICATION

DESIGNER MAY USE NATIONAL INSTRUMENTS PRODUCTS IN COMBINATION WITH OTHER PRODUCTS IN A MANNER NOT

EVALUATED OR CONTEMPLATED BY NATIONAL INSTRUMENTS, THE USER OR APPLICATION DESIGNER IS ULTIMATELY

RESPONSIBLE FOR VERIFYING AND VALIDATING THE SUITABILITY OF NATIONAL INSTRUMENTS PRODUCTS WHENEVER

NATIONAL INSTRUMENTS PRODUCTS ARE INCORPORATED IN A SYSTEM OR APPLICATION, INCLUDING, WITHOUT

LIMITATION, THE APPROPRIATE DESIGN, PROCESS AND SAFETY LEVEL OF SUCH SYSTEM OR APPLICATION.

Page 4

Conventions

The following conventions are used in this manual:

<> Angle brackets that contain numbers separated by an ellipsis represent a

range of values associated with a bit or signal name—for example,

DIO<3..0>.

[ ] Square brackets enclose optional items—for example, [

» The » symbol leads you through nested menu items and dialog box options

to a final action. The sequence File»Page Setup»Options directs you to

pull down the File menu, select the Page Setup item, and select Options

from the last dialog box.

This icon denotes a note, which alerts you to important information.

bold Bold text denotes items that you must select or click in the software, such

as menu items and dialog box options. Bold text also denotes parameter

names.

italic Italic text denotes variables, emphasis, a cross-reference, or an introduction

to a key concept. Italic text also denotes text that is a placeholder for a word

or value that you must supply.

monospace Text in this font denotes text or characters that you should enter from the

keyboard, sections of code, programming examples, and syntax examples.

This font is also used for the proper names of disk drives, paths, directories,

programs, subprograms, subroutines, device names, functions, operations,

variables, filenames, and extensions.

monospace italic

Italic text in this font denotes text that is a placeholder for a word or value

that you must supply.

response].

Page 5

Contents

Chapter 1

Introduction

Using This Manual.........................................................................................................1-1

Document Organization...................................................................................1-1

Bibliographic References ................................................................................1-2

Commonly Used Nomenclature ......................................................................1-2

Related Publications ........................................................................................1-3

MATRIXx Help...............................................................................................1-3

Control Design Tutorial .................................................................................................1-4

Helicopter Hover Problem: An Ad Hoc Approach .........................................1-4

Helicopter Hover Problem: State Feedback and Observer Design .................1-13

Helicopter Hover Problem: Discrete Formulation ..........................................1-18

Inverted Wedge-Balancing Problem: LQG Control........................................1-20

Chapter 2

Linear System Representation

Linear Systems Represented in Xmath..........................................................................2-1

Transfer Function System Models.................................................................................2-2

State-Space System Models...........................................................................................2-5

Basic System Building Functions....................................................................2-6

system( ) ..........................................................................................................2-6

abcd( )..............................................................................................................2-8

numden( ).........................................................................................................2-10

period( ) ...........................................................................................................2-10

names( ) ...........................................................................................................2-11

Size and Indexing of Dynamic Systems ........................................................................2-12

Using check( ) with System Objects..............................................................................2-12

Discretizing a System ....................................................................................................2-13

discretize( ) ......................................................................................................2-13

Numerical Integration Methods: forward, backward, tustins ........... 2-14

Pole-Zero Matching: polezero ..........................................................2-15

Z-Transform: ztransform...................................................................2-15

Hold Equivalence Methods: exponential and firstorder ...................2-15

makecontinuous( ) ...........................................................................................2-17

© National Instruments Corporation v Xmath Control Design Module

Page 6

Contents

Chapter 3

Building System Connections

Linear System Interconnection Operators ..................................................................... 3-1

Linear System Interconnection Functions ..................................................................... 3-4

afeedback( )..................................................................................................... 3-4

Algorithm.......................................................................................... 3-5

append( ) ......................................................................................................... 3-6

connect( ).........................................................................................................3-8

Algorithm.......................................................................................... 3-10

feedback( )....................................................................................................... 3-11

Algorithm.......................................................................................... 3-12

Chapter 4

System Analysis

Time-Domain Solution of System Equations................................................................ 4-1

System Stability: Poles and Zeros ................................................................................. 4-2

poles( )............................................................................................................. 4-3

zeros( )............................................................................................................. 4-3

Algorithm.......................................................................................... 4-5

Partial Fraction Expansion ............................................................................................4-5

residue( ) ......................................................................................................... 4-8

combinepf( ).................................................................................................... 4-9

General Time-Domain Simulation ................................................................................ 4-10

Impulse Response of a System ...................................................................................... 4-13

impulse( ) ........................................................................................................ 4-13

deftimerange( )................................................................................................ 4-15

System Response to Initial Conditions.......................................................................... 4-16

initial( )............................................................................................................ 4-16

Step Response................................................................................................................ 4-18

step( )............................................................................................................... 4-18

Chapter 5

Classical Feedback Analysis

Feedback Control of a Plant Model............................................................................... 5-1

Root Locus..................................................................................................................... 5-2

rlocus( ) ...........................................................................................................5-3

Frequency Response and Dynamic Response ............................................................... 5-5

freq( )............................................................................................................... 5-5

Algorithm.......................................................................................... 5-6

Xmath Control Design Module vi ni.com

Page 7

Bode Frequency Analysis ..............................................................................................5-7

bode( )..............................................................................................................5-10

margin( ) ..........................................................................................................5-12

nichols( )..........................................................................................................5-14

Nyquist Stability Analysis .............................................................................................5-15

nyquist( )..........................................................................................................5-16

Linear Systems and Power Spectral Density .................................................................5-20

psd( )................................................................................................................5-20

Chapter 6

State-Space Design

Controllability................................................................................................................6-1

controllable( ) ..................................................................................................6-3

Observability and Estimation.........................................................................................6-4

observable( ) ....................................................................................................6-6

Minimal Realizations.....................................................................................................6-7

minimal( ) ........................................................................................................6-8

stair( )...............................................................................................................6-9

Duality and Pole Placement...........................................................................................6-10

poleplace( ) ......................................................................................................6-10

Linear Quadratic Regulator ...........................................................................................6-12

regulator( ).......................................................................................................6-14

Linear Quadratic Estimator............................................................................................6-16

estimator( ).......................................................................................................6-20

Linear Quadratic Gaussian Compensation ....................................................................6-21

lqgcomp( ) .......................................................................................................6-23

Riccati Equation.............................................................................................................6-25

riccati( ) ...........................................................................................................6-26

Steady-State System Response Using Lyapunov Equations .........................................6-28

lyapunov( ).......................................................................................................6-30

rms( ) ...............................................................................................................6-32

Balancing a Linear System ............................................................................................6-33

balance( ) .........................................................................................................6-35

Modal Form of a System ...............................................................................................6-37

modal( ) ...........................................................................................................6-37

mreduce( )........................................................................................................6-38

Contents

Algorithm ..........................................................................................6-30

© National Instruments Corporation vii Xmath Control Design Module

Page 8

Contents

Appendix A

Technical References

Appendix B

Technical Support and Professional Services

Index

Xmath Control Design Module viii ni.com

Page 9

Introduction

The Control Design Module (CDM) is a complete library of classical and

modern control design functions that provides a flexible, intuitive control

design framework.

This chapter starts with an outline of the manual and some user notes. It

also contains a tutorial that presents several problems and uses a variety of

approaches to obtain solutions. The tutorial is designed to familiarize you

with many of the functions in this module.

Using This Manual

This manual provides an overview of different aspects of linear systems

analysis, describes the Xmath Control Design function library, and gives

examples of how you can use Xmath to solve problems rapidly. It also

explains how you can represent and analyze linear systems in Xmath and

provides a brief syntax listing and supplementary algorithm information for

each CDM function. Detailed descriptions of function inputs, outputs, and

behavior are provided in the Xmath Help.

1

Document Organization

This manual includes the following chapters:

• Chapter 1, Introduction, starts with an outline of the manual and some

user notes. It also contains a tutorial that presents several problems and

uses a variety of approaches to obtain solutions. The tutorial is

designed to familiarize you with many of the functions in this module.

• Chapter 2, Linear System Representation, describes the types of linear

systems that can be represented within Xmath. In addition, it discusses

the implementation of systems as objects–data structures

encompassing different information fields. The Xmath functions for

creating a system or extracting its components are part of the general

Xmath package and not exclusive to the Control Design Module, but

they are used so extensively that they warrant a detailed treatment here.

This chapter also discusses the functions you can use to check for

© National Instruments Corporation 1-1 Xmath Control Design Module

Page 10

Chapter 1 Introduction

particular system properties or to change the format of a system. These

topics include continuous/discrete system conversion, as well as

finding equivalent transfer function state-space representations.

• Chapter 3, Building System Connections, details Xmath functions that

perform different types of linear system interconnections. It also

discusses a number of simpler connections that have been

implemented as overloaded operators on system objects.

• Chapter 4, System Analysis, describes the Xmath functions relating to

system stability and time-domain analysis. These include poles, zeros,

and residue. The chapter moves from the discussion of time-domain

stability to time-domain system simulation. Xmath provides built-in

functions for obtaining impulse and step responses, as well as

examining system response to arbitrary initial conditions. In addition,

the General Time-Domain Simulation section discusses a

mathematically natural syntax for time-domain system simulation

with any input.

• Chapter 5, Classical Feedback Analysis, discusses topics pertaining

to classical feedback-based control design. These include root locus

techniques and functions for frequency-domain analysis of

closed-loop systems, given open-loop system descriptions.

• Chapter 6, State-Space Design, focuses on modern control. Beginning

with the topics of system controllability and observability, it covers

general pole placement, linear quadratic control, and system

balancing.

Bibliographic References

Throughout this document, bibliographic references are cited with

bracketed entries. For example, a reference to [DeS74] corresponds to

a document published by Desoer and Schulman in 1974. For a table of

bibliographic references, refer to Appendix A, Technical References.

Commonly Used Nomenclature

This manual uses the following general nomenclature:

• Matrix variables are generally denoted with capital letters; vectors are

represented in lowercase.

• G(s) is used to denote a transfer function of a system where s is the

Laplace variable. G(q) is used when both continuous and discrete

systems are allowed.

Xmath Control Design Module 1-2 ni.com

Page 11

• H(s) is used to denote the frequency response, over some range of

• A single apostrophe following a matrix variable, for example, x',

Related Publications

For a complete list of MATRIXx publications, refer to Chapter 2,

MATRIXx Publications, Online Help, and Customer Support, of the

MATRIXx Getting Started Guide. The following documents are particularly

useful for topics covered in this manual:

• MATRIXx Getting Started Guide

• Xmath User Guide

• Control Design Module

• Interactive Control Desing Module

• Interactive System Identification Module, Part 1

• Interactive System Identification Module, Part 2

• Model Reduction Module

• Optimization Module

• Robust Control Module

• Xμ Module

Chapter 1 Introduction

frequencies of a system where s is the Laplace variable. H(q) is used to

indicate that the system can be continuous or discrete.

denotes the transpose of that variable. An asterisk following a matrix

variable (for example, A*) indicates the complex conjugate, or

Hermitian, transpose of that variable.

MATRIXx Help

Control Design Module function reference information is available in the

MATRIXx Help. The MATRIXx Help includes all Control Design functions.

Each topic explains a function’s inputs, outputs, and keywords in detail.

Refer to Chapter 2, MATRIXx Publications, Online Help, and Customer

Support, of the MATRIXx Getting Started Guide for complete instructions

on using the Help feature.

© National Instruments Corporation 1-3 Xmath Control Design Module

Page 12

Chapter 1 Introduction

Control Design Tutorial

This tutorial illustrates the use of functions and commands provided in

Xmath and the Xmath Control Design Module to solve control problems.

The emphasis of the tutorial is on using a number of different approaches,

not on any one “correct” way to solve a problem. It demonstrates the

flexibility of Xmath’s tools and scripting language to customize your

analysis in a way that is as straightforward and mathematically intuitive as

possible.

The models in this tutorial are adapted from the studies in [ShH92], of the

equations presented in [FPE87], for the longitudinal motion of a helicopter

near hover, and in [HW91], for the inverted-wedge-balancing problem.

Helicopter Hover Problem: An Ad Hoc Approach

[FPE87] gives this state-space model for the longitudinal motion of the

helicopter:

·

q

·

θ

·

v

0.4– 00.01–

10 0

1.4– 9.8 0.02–

q

6.3

0

9.8

δ+=

θ

v

y

=

001qθ

v

letting the state variables q, θ, and v represent the helicopter’s pitch rate,

pitch angle, and horizontal velocity, respectively. The input control to the

system is the rotor tilt angle, δ.

You can store the information that this model provides in an Xmath

state-space system object:

A = [-0.4,0,-0.01;1,0,0;-1.4,9.8,-0.02];

B = [6.3;0;9.8];

C = [0,0,1];

D = 0;

ssys = system(A,B,C,D,

{inputNames ="Rotor Angle",

outputNames="Horizontal v",

stateNames =["Pitch Rate", "Pitch Angle",

"Horizontal v"]})

Xmath Control Design Module 1-4 ni.com

Page 13

Chapter 1 Introduction

ssys (a state space system) =

A

-0.4 0 -0.01

1 0 0

-1.4 9.8 -0.02

B

6.3

0

9.8

C

0 0 1

D

0

X0

0

0

0

State Names

-----------

Pitch Rate Pitch Angle Horizontal v

Input Names

-----------

Rotor Angle

Output Names

------------

Horizontal v

System is continuous

Use check( ) to convert the model to transfer-function form:

[,Gs] = check(ssys,{tf,convert})

Gs (a transfer function) =

2

9.8(s - 0.5s + 6.3)

-----------------------------------------

2

(s + 0.656513)(s - 0.236513s + 0.149274)

initial integrator outputs

0

0

0

© National Instruments Corporation 1-5 Xmath Control Design Module

Page 14

Chapter 1 Introduction

Input Names

----------Rotor Angle

Output Names

-----------Horizontal v

System is continuous

The system has poles and zeros in the right half of the complex plane and

therefore is open-loop unstable. Checking the pole and zero locations

confirms this:

ol_poles=poles(ssys)

ol_poles (a column vector) =

0.118256 - 0.367817 j

0.118256 + 0.367817 j

-0.656513

ol_zeros=zeros(ssys)

ol_zeros (a column vector) =

0.25 + 2.4975 j

0.25 - 2.4975 j

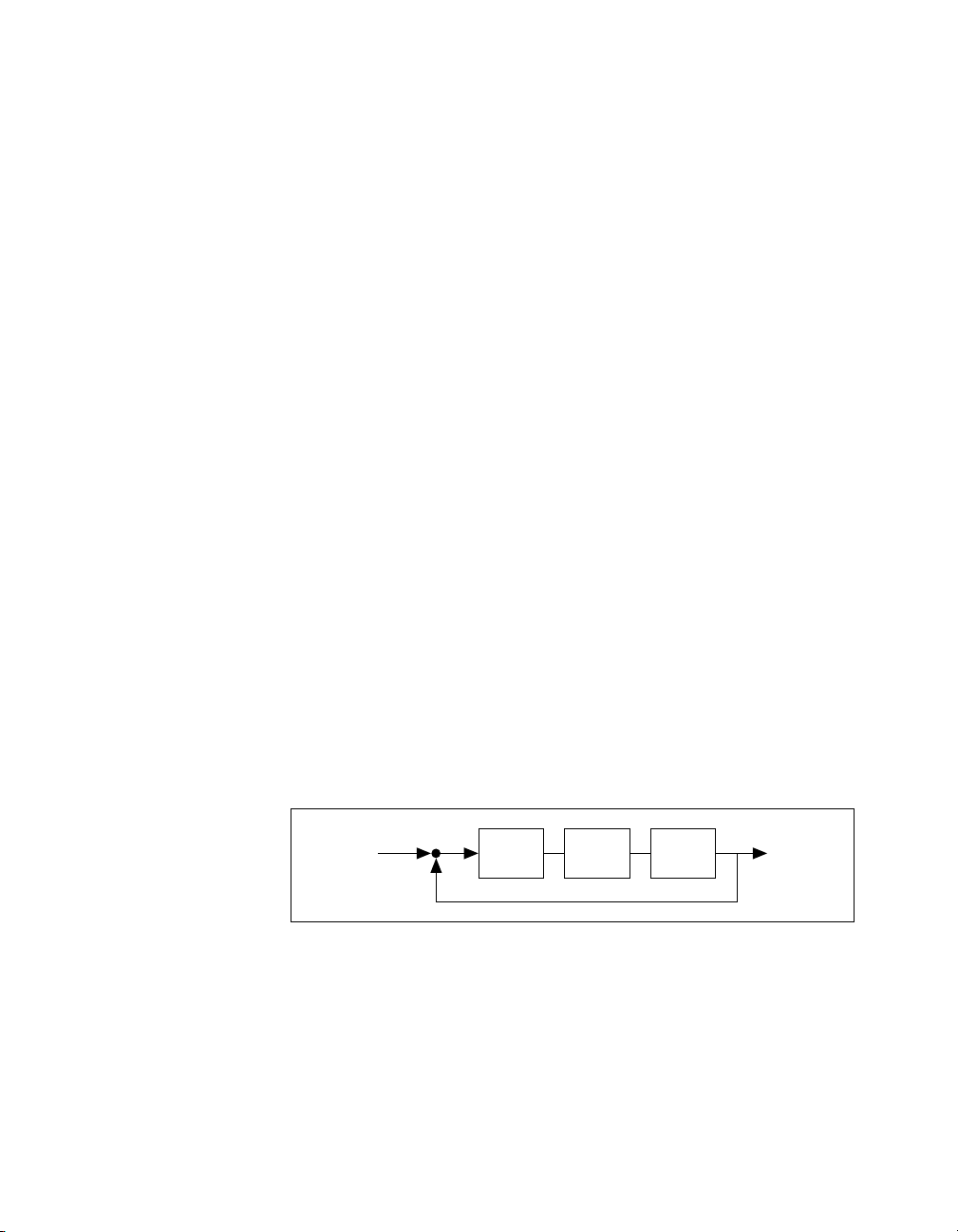

Try to stabilize the system using feedback compensation. You have two

major performance goals to achieve through your controller design: first,

the system must be closed-loop stable, and second, you want the system

output to track a unit step input. To begin, put two compensators in the

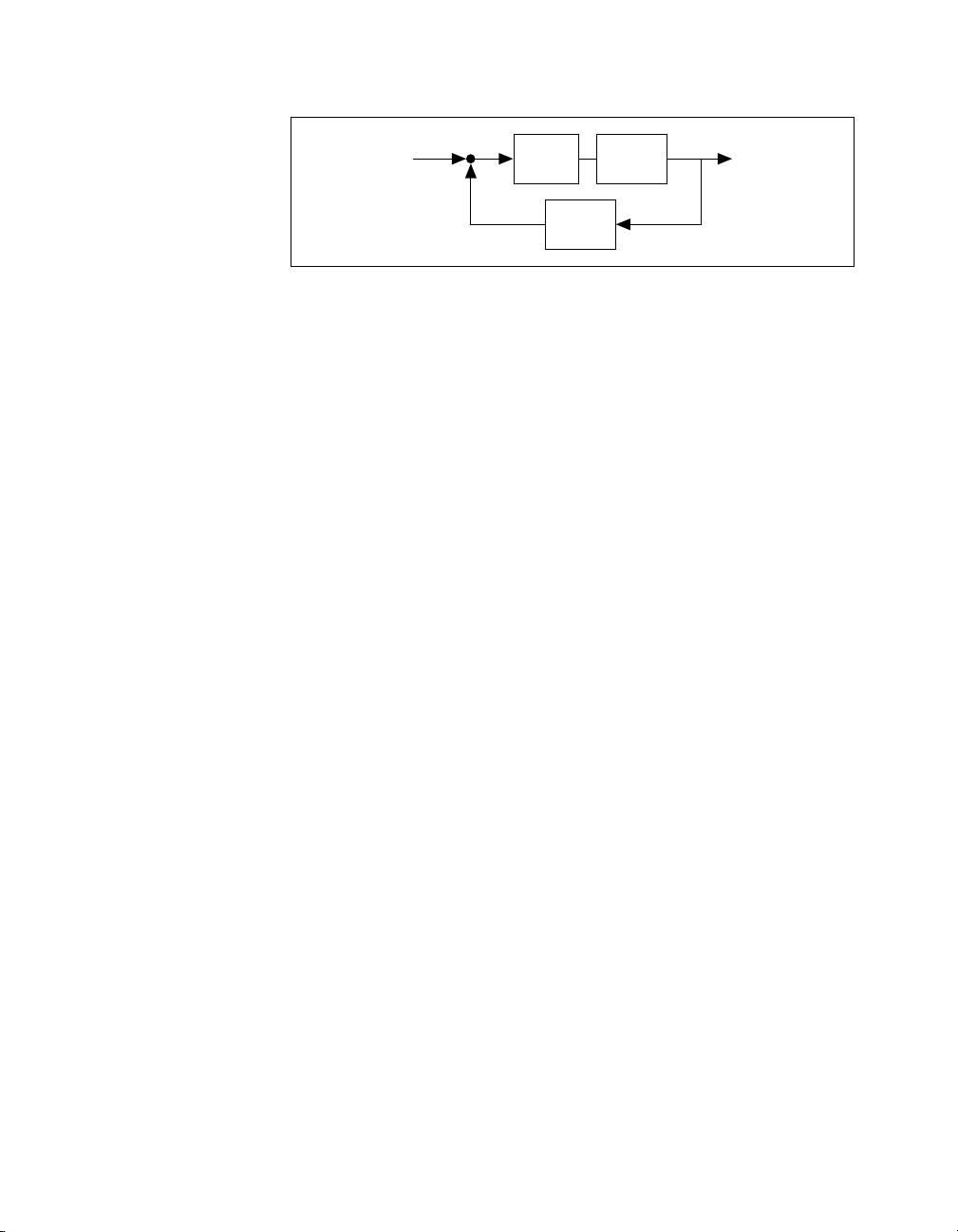

feedforward path of the closed-loop system. Figure 1-1 is a closed-loop

block diagram of helicopter system H(s) with compensators K

(s) and K2(s)

1

in the feedforward path.

U(s) Y(s)

+

–

Figure 1-1. Block Diagram of Helicopter System H(s) with Compensators K1(s) and

Xmath Control Design Module 1-6 ni.com

G(s) K1(s) K2(s)

K

(s) in the Feedforward Path

2

Page 15

Chapter 1 Introduction

One approach to stabilizing this system is to try to cancel the pole at

–0.656513 by adding a compensator, K

Note It is important to understand that this is primarily an academic exercise. Accurate

(s), with a zero at –0.656513.

1

pole-zero cancellations are impracticable in the real world, and the mode corresponding to

that pole still exists internally.

This compensator must have a pole for realizability, so you add one at –10,

which is far enough away that its effect on dynamic response will be small

compared to that of the system’s other modes. In addition, you need to add

a zero to the left of the positive (and unstable) poles to pull the closed-loop

system roots into the left half plane. Choose s = 0 for the zero location and,

again, select a corresponding pole at –10. Call this second compensator

K

(s). To create these two compensators:

2

K1s=polynomial(ol_poles(3),"s")/...

polynomial(-10,"s");

K2s=polynomial(0,"s")/polynomial(-10,"s");

You then can cascade them in series with the original system Gs (or ssys)

and examine the locus of closed-loop roots for varying total compensator

gain K

. The poles out at –10 have a smaller effect on the system dynamics

c

than do the poles closer to the origin, so you can use the optional

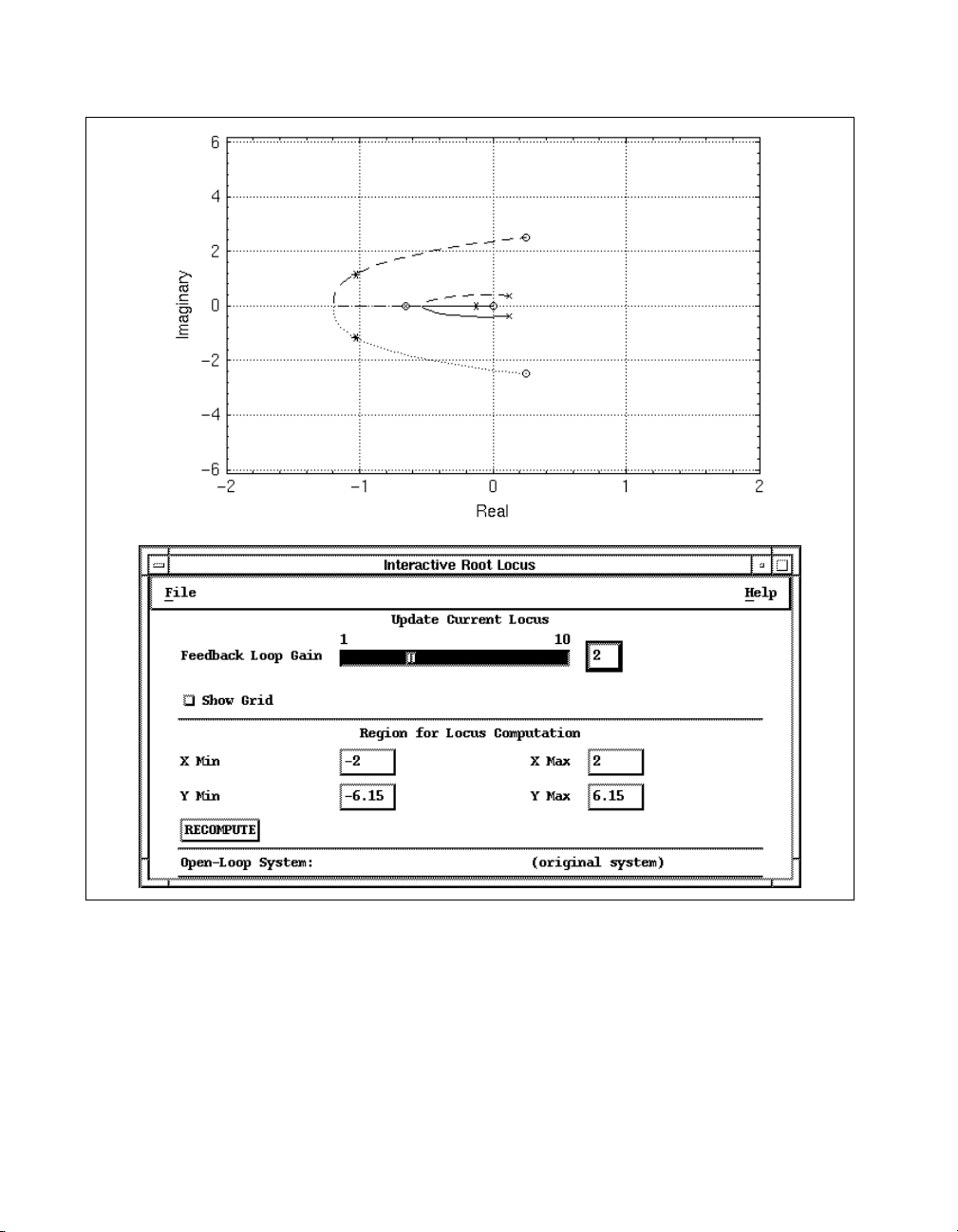

rlocus( ) keywords to zoom in on the part of the locus nearer the origin.

rlocus(K2s*K1s*Gs, {xmin = -2, xmax = 2})

The single input syntax activates interactive mode. A user interface lets

you change the gain through the Feedback Loop Gain slider and button.

The graphics window shows the closed-loop locus as a solid line, with the

open-loop poles shown as large

Increase the gain by moving the slider; notice the asterisks (

xs and the open-loop zeros shown as Os.

*) denoting

closed-loop pole location moving along the locus. The system is maximally

stable with total compensator gain K

figure, small

xs denote the pole location for K

= 2 as shown in Figure 1-2. In this

c

= 2, and the root locus gain

c

window shows settings.

© National Instruments Corporation 1-7 Xmath Control Design Module

Page 16

Chapter 1 Introduction

Figure 1-2. Locus of all Open-Loop and Closed-Loop Roots of Gs

If you cannot move the slider so that the gain is exactly 2, click the box to

the right of the slider and enter

2. To close the interactive root locus dialog

box, select File»Exit.

Xmath Control Design Module 1-8 ni.com

Page 17

Chapter 1 Introduction

Close the loop using the single-input syntax of feedback( ), which

implements direct unity-gain negative feedback, and obtain the system’s

step response using

Kc = 2; cl_syscomp1 = feedback(Kc*K1s*K2s*Gs);

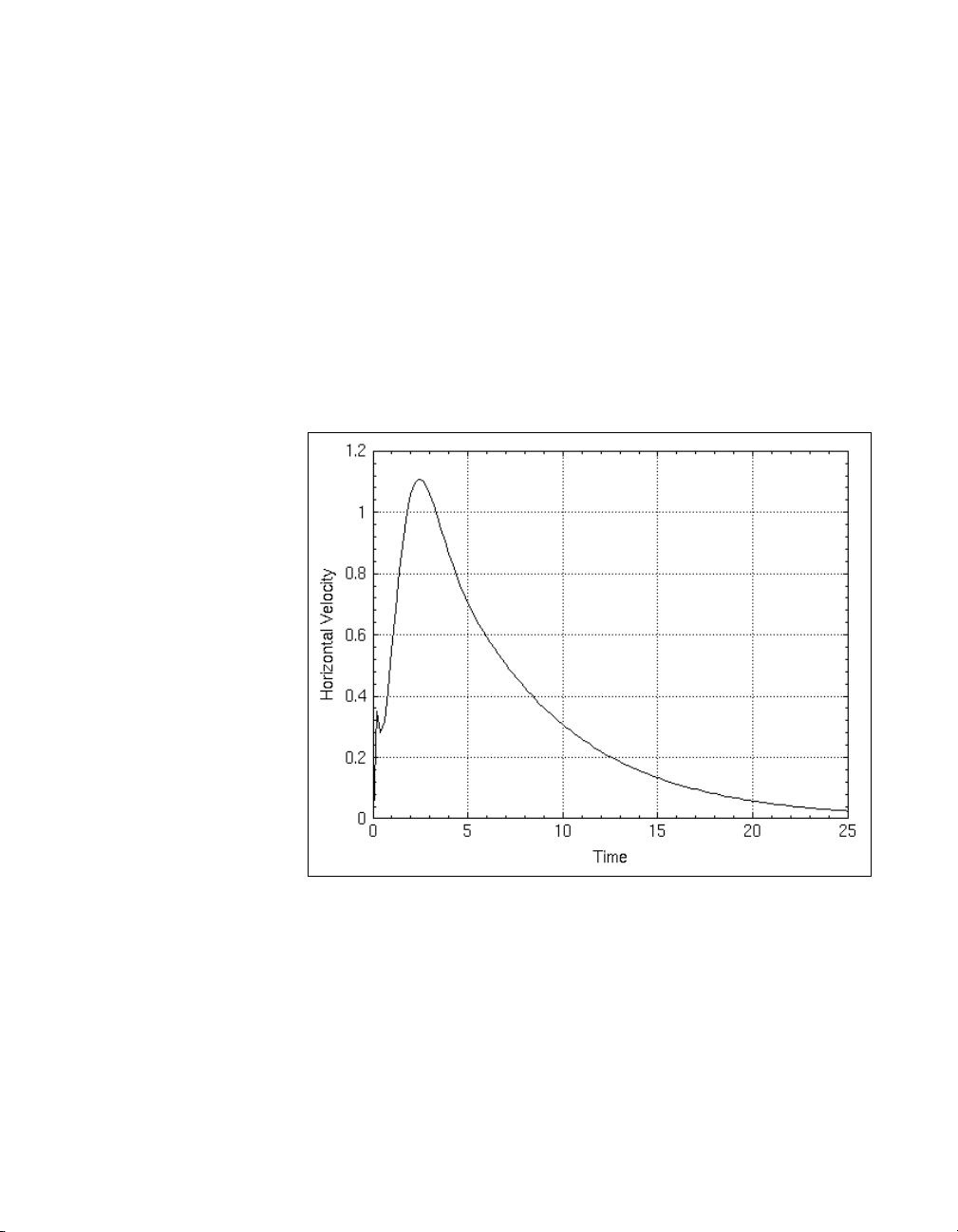

v = step(cl_syscomp1, 0:.2:25);

plot(v,{xlab="Time", ylab="Horizontal Velocity"})

step( ):

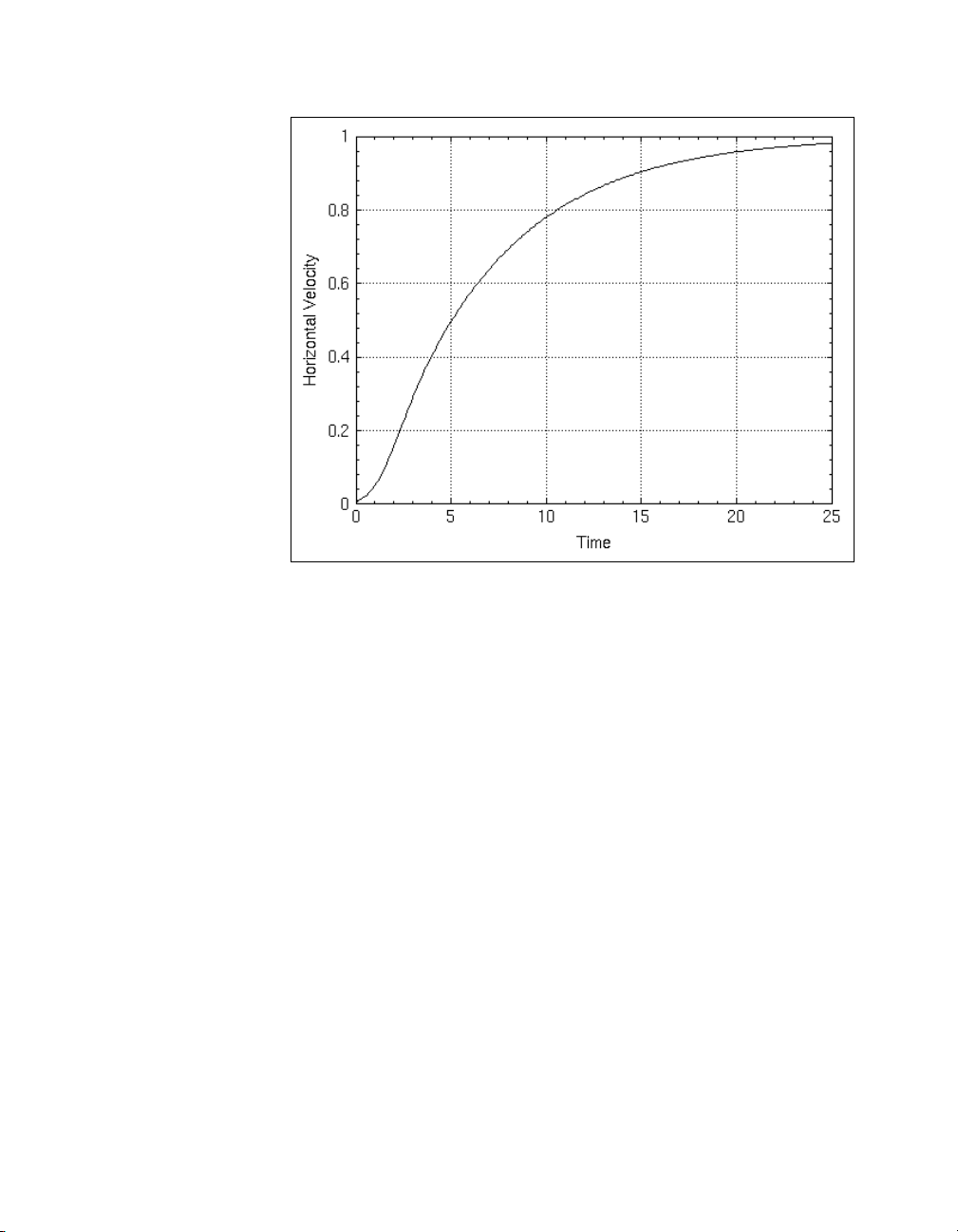

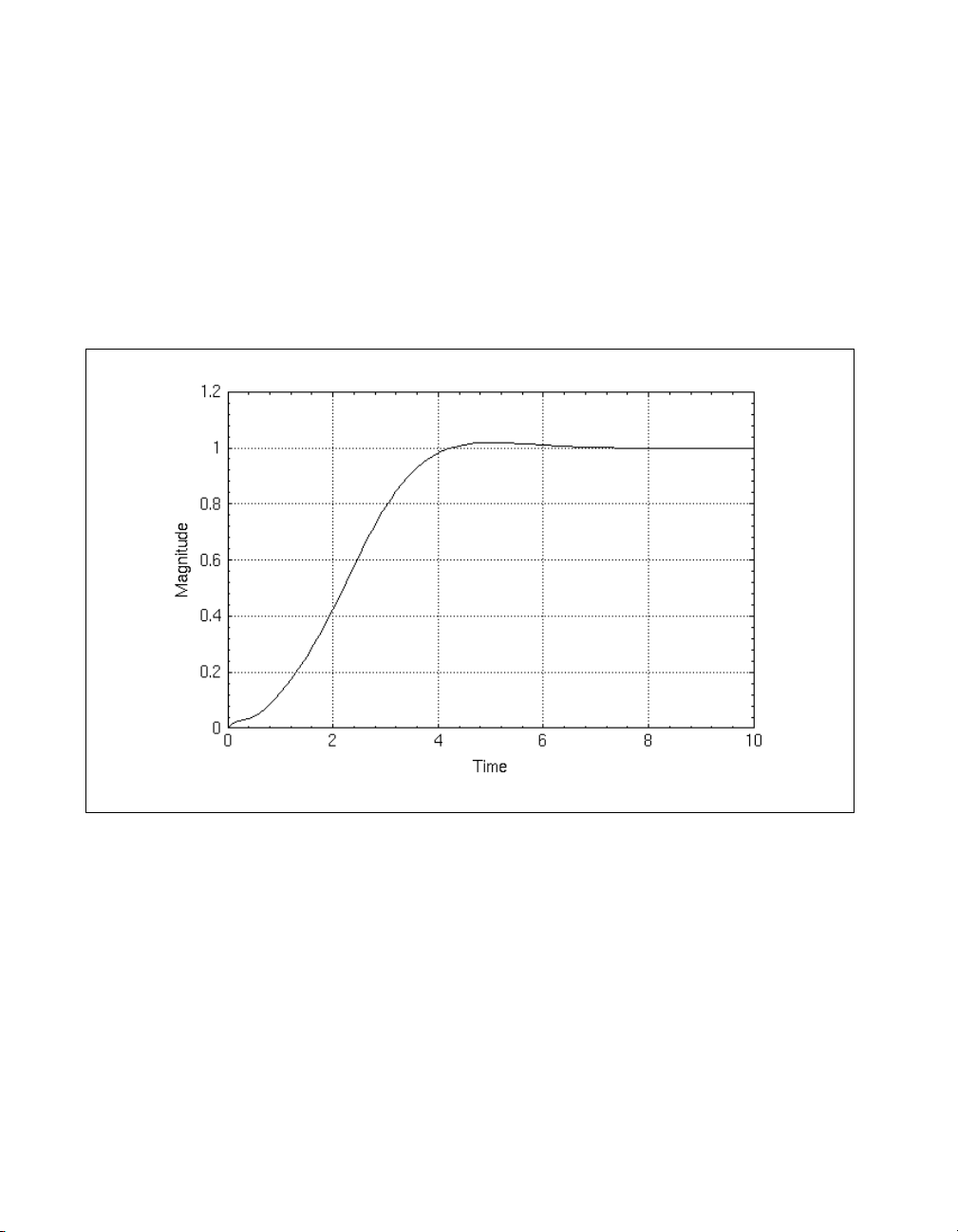

The resulting plot is shown in Figure 1-3. This result is not desirable. You

want the output (the helicopter velocity) to track the step input provided as

the rotor tilt angle, not zero out its effects over time (which would be an

appropriate response if the input corresponded to a disturbance). This

results from the compensator zero at s = 0 in the forward path of the

feedback loop.

Figure 1-3. Helicopter Velocity Response to a Step Input at the Rotor

Instead, you now place K1(s) in the forward path and K2(s) in the feedback

path, so that the closed-loop system now has the configuration shown in

Figure 1-4.

© National Instruments Corporation 1-9 Xmath Control Design Module

Page 18

Chapter 1 Introduction

U(s) Y(s)

+

–

Figure 1-4. Block Diagram of the Closed-Loop Controller

G(s)

Kc1K1(s)

Kc2K2(s)

This is a block diagram of the closed-loop controller with compensator

K

(s) in the feedforward path and Kc2K2(s) in the feedback path.

c1K1

This time, instead of having all your gain K

in the forward path of the

c

closed-loop system, the system gain is split between the two compensators.

The gains K

closed-loop transfer function T

and Kc2 are defined such that Kc=2=Kc1Kc2 and the

c1

(s) is unity at s =0(DC).

c1

The closed-loop transfer function is represented by:

s()Gs()

K

Tcls()

-------------------------------------------------------------------=

1 K

c1K1

c1Kc2K1

s()K2s()Gs()+

You can find the values of the individual transfer functions at s =0 using

freq( ), and then substitute to solve the previous equation:

a = makematrix(freq(K1s*Gs,0));

b = makematrix(freq(K1s*K2s*Gs,0));

Solving:

Kc1 = (1+2*b)/a

Kc1 (a scalar) = 0.0241778

Kc2 = 2/Kc1

Kc2 (a scalar) = 82.7206

You now call feedback( ) again, this time using its second input

argument to indicate that the outputs of the first input system (forward path)

are fed back as the inputs to the second system (feedback path) in a

negative-feedback loop.

cl_syscomp2 = feedback(Kc1*K1s*Gs, Kc2*K2s);

Xmath Control Design Module 1-10 ni.com

Page 19

Chapter 1 Introduction

Because cl_syscomp2 contains an internal pole-zero cancellation, you

can rewrite it in minimal form and then check the closed-loop pole and zero

locations:

cl_syscomp2m = minimal(cl_syscomp2);

The system has 1 uncontrollable state

cl_poles = poles(cl_syscomp2m)

cl_poles (a column vector) =

-0.166518

-1.0325 + 1.16109 j

-1.0325 - 1.16109 j

-37.132

cl_zeros = zeros(cl_syscomp2m)

cl_zeros (a column vector) =

0.25 - 2.4975 j

0.25 + 2.4975 j

-10

Now, examine the step response as shown in Figure 1-5.

vcomp = step(cl_syscomp2m, 0:.1:25);

plot (vcomp, {xlab = "Time",

ylab = "Horizontal Velocity"})

© National Instruments Corporation 1-11 Xmath Control Design Module

Page 20

Chapter 1 Introduction

Figure 1-5. Helicopter Velocity Tracking Step Input at the Rotor

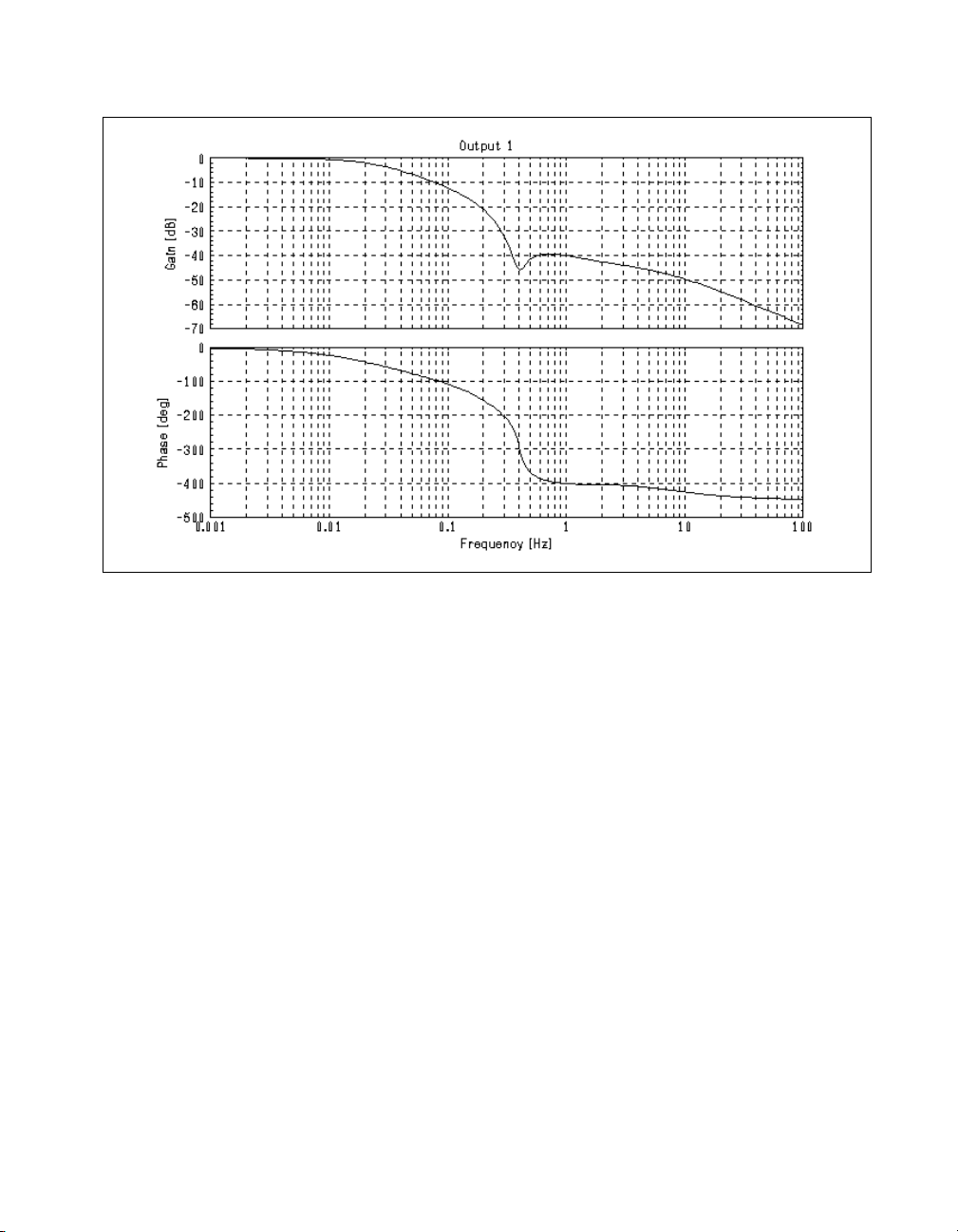

You also can look at the gain and phase margins of the system.

H = bode(cl_syscomp2m, {npts = 200, !wrap});

[gm,pm] = margin(H)

There are no 0 dB gain crossings.

gm (a pdm) =

domain |

---------+----------

0.250101 | 26.1694

---------+----------

pm is null

The bode plot of the closed-loop system is shown in Figure 1-6.

Xmath Control Design Module 1-12 ni.com

Page 21

Chapter 1 Introduction

Figure 1-6. Closed-Loop System Bode Plot

The domain of the gain and phase margin PDMs indicates the frequency

(in hertz) at which the margin occurs. So the gain can be increased by about

26.1 dB before the system becomes unstable.

Helicopter Hover Problem: State Feedback and Observer Design

The approach taken in the Helicopter Hover Problem: An Ad Hoc

Approach section, although producing a desirable response, often cannot

be used in practice because uncertainty in modeling generally precludes

exact knowledge of the location of the pole one plans to cancel.

Another approach is to feed the information obtained from the states back

to the inputs through gains calculated to relocate the closed-loop poles.

Refer to the Controllability section of Chapter 6, State-Space Design,

for more information. For this approach, you first need to verify that your

system is controllable and observable. When you have confirmed that it

is—that there are no hidden modes—you can design a full-state feedback

control law that will place the system eigenvalues at values that will yield

a stable system. Because the system is observable, you then can design an

estimator to yield estimates for the missing states. Again, you will require

that your system track a step input.

© National Instruments Corporation 1-13 Xmath Control Design Module

Page 22

Chapter 1 Introduction

You can verify that your system is controllable, then define the closed-loop

poles you want and use

poleplace( ) to find the feedback gains required

given the system A and B matrices.

[,,nuc] = controllable(Gs)

nuc (a scalar) = 0

Because the number of uncontrollable states is zero, Gs is controllable. This

means that you can use feedback through appropriately-sized gains to

position the system’s closed-loop poles anywhere you want. If you choose

the three poles to be moved to –1 ±j and –2, you get the following set of

gains:

clp = [-1+jay, -2];

Kfsb = poleplace(A,B,clp)

Kfsb (a row vector) = 0.470648 1.00004 0.062747

Note poleplace( )

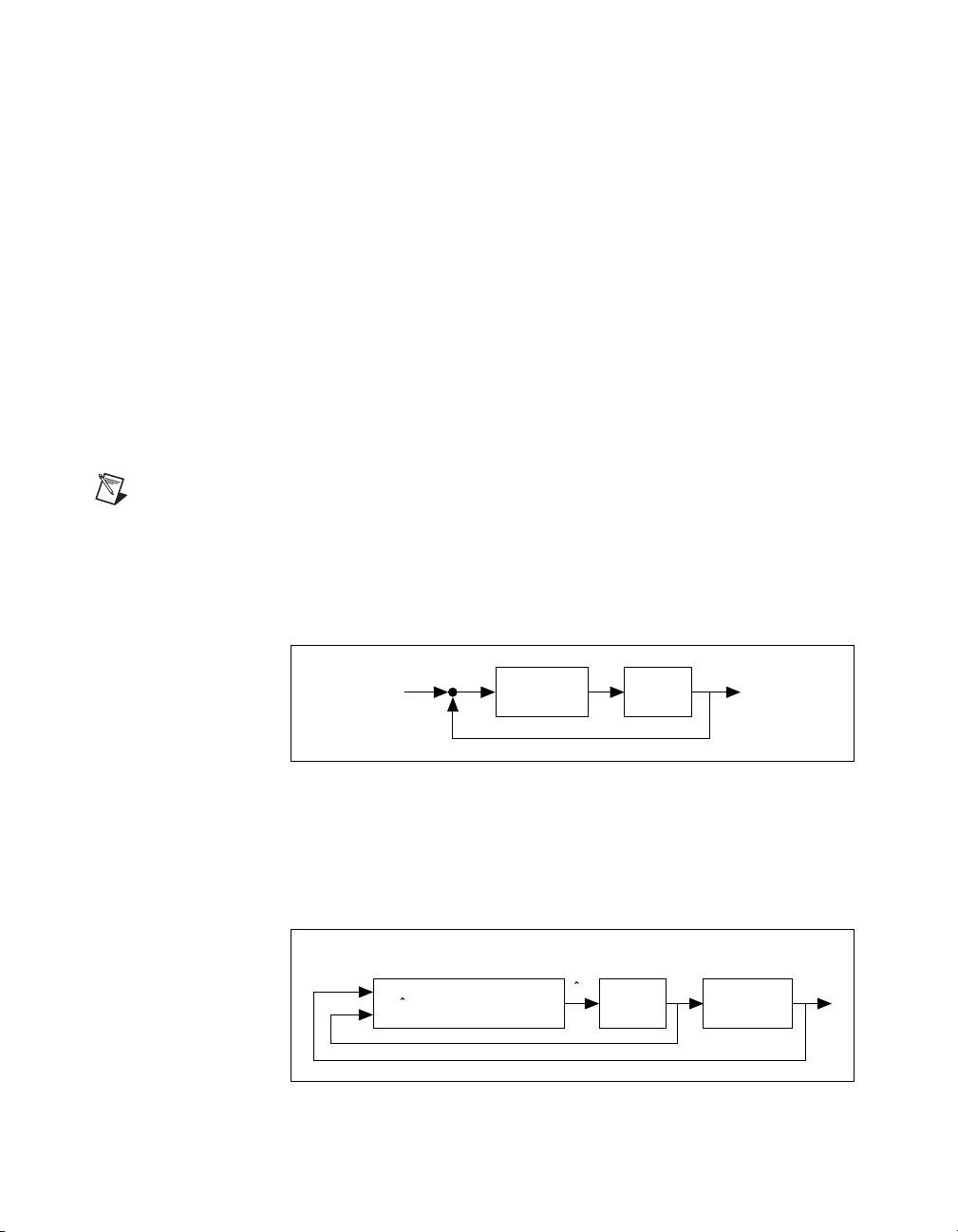

If you assume that the outputs of the system are just the values of all the

states, you can draw the open-loop system block diagram as shown in

Figure 1-7. In this figure, the feedback path is shown in dotted lines and the

open-loop system in solid lines.

Because you do not have access to all three states—only one, the horizontal

velocity, is returned as an output—you need to estimate the other states,

thus implementing an observer-based controller. The block diagram for the

observer and controller together is shown in Figure 1-8.

does not require you to list both poles in a conjugate pair.

ru x

+

–

Figure 1-7. Full-State Feedback Regulator

Estimator Control Plant

x = (A

– LC)

⋅

x = Ax + Bu

x + Bu

+

K

fsb

x

Ly

uy

⋅

K

fsb

x = Ax + Bu

y = Cx + Du

Figure 1-8. Complete Controller and Estimator

Xmath Control Design Module 1-14 ni.com

Page 23

Chapter 1 Introduction

Specify the observer poles at [–3 + 3j, –4] and call poleplace( ) again:

op = [-3+3*jay, -4];

L = poleplace(A',C',op)

L (a row vector) = 5.46645 4.67623 9.58

You connect the controller to the observer using lqgcomp( ). L needs to

be a column vector, so you transpose it.

sys_obc = lqgcomp(ssys, Kfsb, L');

You can use names( ) to modify the names of the state estimates to be

more descriptive. To distinguish the estimated states from the “true” states,

you can use the

+ operator to append the string est to the estimated state

names, as shown in this example.

[,,osNames] = names(sys_obc);

estNames = osNames + [" (est)"," (est)"," (est)"];

estNames'?

ans (a column vector of strings) =

Pitch Rate (est)

Pitch Angle (est)

Horizontal v (est)

You can append these modified names to sys_obc:

sys_obc = system(sys_obc,{stateNames=estNames});

Then you close the loop and verify that the closed-loop poles are all in the

left-half plane.

sys_cl = feedback(ssys, sys_obc);

poles(sys_cl)

ans (a column vector) =

-1 + 1 j

-1 - 1 j

-2

-4

-3 + 3 j

-3 - 3 j

© National Instruments Corporation 1-15 Xmath Control Design Module

Page 24

Chapter 1 Introduction

You can choose to scale the system output here for zero steady-state error

in the step response. This is accomplished in an intuitive manner, dividing

the system

sys_cl = sys_cl/51.76;

v_obc = step(sys_cl, 0:.1:10);

plot (v_obc, {xlab = "Time", ylab = "Magnitude"})

sys_cl by the desired scaling factor.

In Figure 1-9 the step response shows zero-steady-state error, little

overshoot, and a response time of less than seven seconds.

Figure 1-9. Step Response for Observer-Based Design

The system response is quite good, implying that your state estimates were

satisfactory. You can do some further simulation, this time returning all the

states directly from the original plant, and get a graphical picture of how the

estimates track the actual states. First, you need to create the closed-loop

system with all states available.

The

abcd( ) function extracts the A, B, C, and D matrices from a system

object. When you call it here, all you are interested in is the closed-loop

A matrix, so you do not need to extract the other state-space matrices.

A_cl = abcd(sys_cl);

Xmath Control Design Module 1-16 ni.com

Page 25

Chapter 1 Introduction

When you create the estimator system sys_est, you use the original

A matrix for the state-update equation, but you provide a zero external

input (a B matrix of zero). The output matrix is an identity matrix passing

back the three real state values and the three estimated state values as

output, again with no external input values affecting the output. Here you

use the optional

system( ) keyword X0 to set the real state values to

[1,2,3] and the estimated state values to [–1,–2,–3].

By simulating with a general input over two seconds, you can see how long

it takes for the state values provided by the estimator to correct the incorrect

initial conditions and track the real state values.

[,,allStates]=names(sys_cl);

sys_est = system(A_cl, zeros(6,1), eye(6,6), ...

zeros(6,1),{x0 = [1,2,3,-1,-2,-3], ...

stateNames = allStates});

state_resp = sys_est*pdm(ones(100,1), 0:(2/99):2);

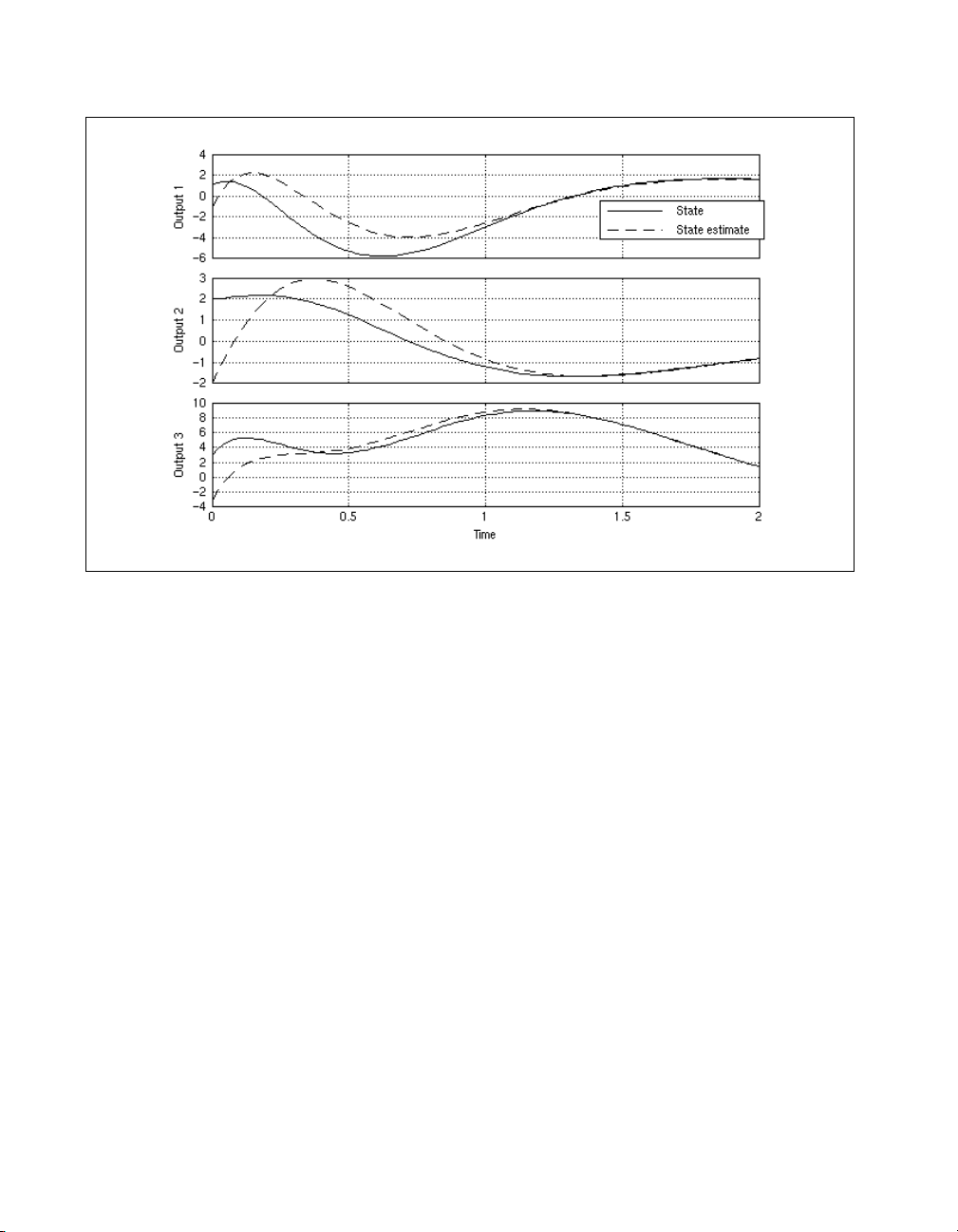

Plot the results, referring to Figure 1-10:

plot(state_resp,{strip=2,xlab="Time",

legend=["State","State estimate"]})

Even in the relatively short time span of this simulation, the estimates and

the real states quickly converge.

© National Instruments Corporation 1-17 Xmath Control Design Module

Page 26

Chapter 1 Introduction

Figure 1-10. Multiple Plots Showing Time Needed for States to be Correctly Tracked

by Estimator, Given Incorrect Initial Values

Helicopter Hover Problem: Discrete Formulation

Discrete-time control systems are most frequently designed in one of

two ways: either directly implemented in the discrete domain, or first

solved as continuous problems—often deriving directly from differential

equations of motion—and then discretized. Here you take the second

approach with the problem solved in the Helicopter Hover Problem: State

Feedback and Observer Design section.

A guideline for choosing a sample rate for a system to be discretized is that

it be significantly less than the smallest time constant of the continuous

system divided by π.

Look at the open-loop pole magnitudes of your original open-loop

continuous-time system

max(abs(ol_poles))

ans (a scalar) = 0.656513

Xmath Control Design Module 1-18 ni.com

ssys:

Page 27

Chapter 1 Introduction

You can use the default exponential discretization method with dt =0.01

and compare frequency responses between the original system and the

discretized system:

ssysd = discretize(ssys, 0.01);

f = freq(ssys,logspace(.001,10,200));

fd = freq(ssysd,logspace(.001,10,200));

In the following statements you compute the gain and phase of both

systems and then plot them.

db = 20*log10(abs(f)); ph = (180/pi)*atan2(f);

dbd = 20*log10(abs(fd)); phd = (180/pi)*atan2(fd);

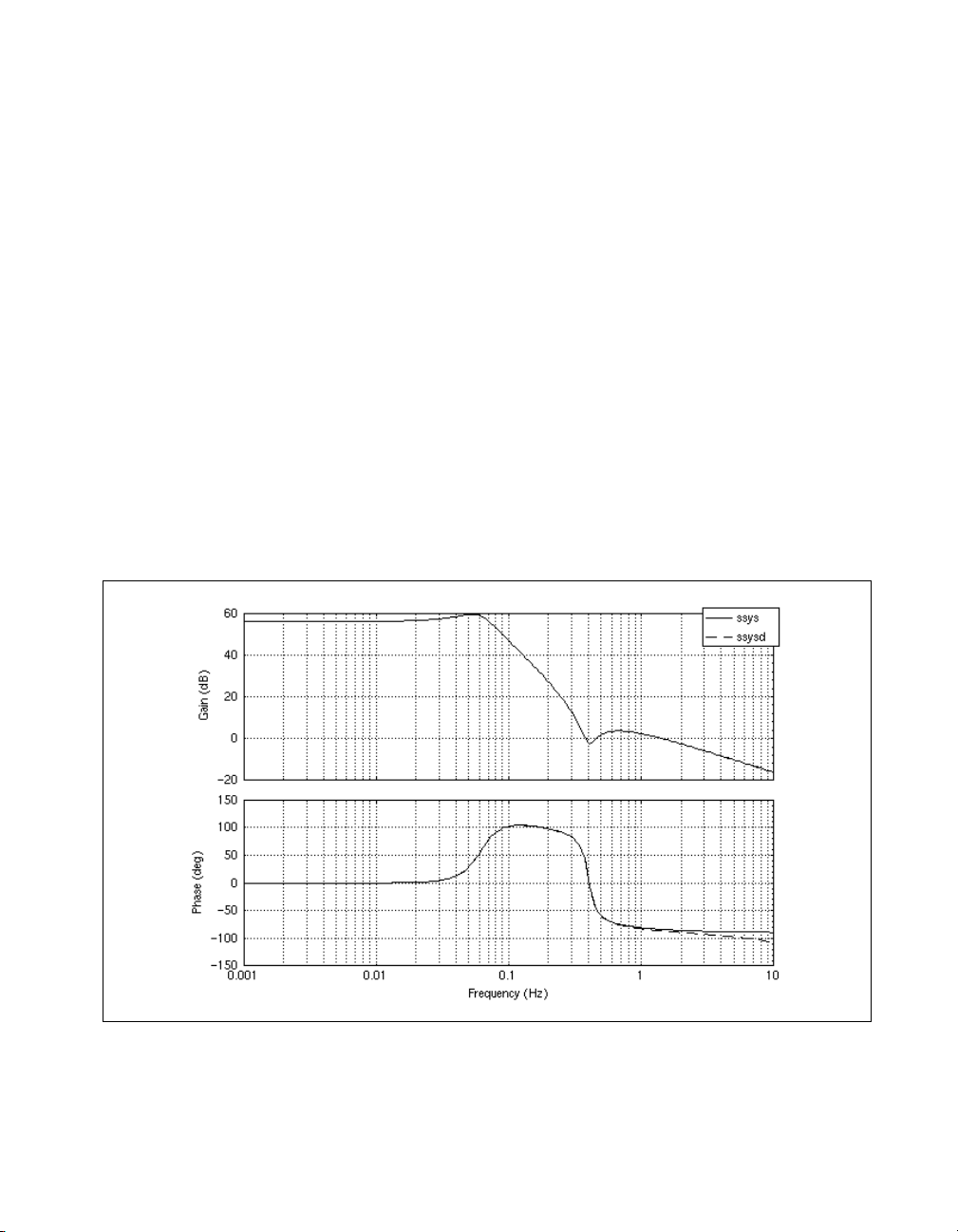

plot([db;ph;dbd;phd],{strip=2,xlog,

ylab = ["Gain (dB)";"Phase (deg)"],

x_lab = "Frequency (Hz)",

legend = ["ssys";"ssysd"]})

In Figure 1-11 you can see the frequency responses match closely,

indicating that this discretization method captures the continuous system’s

dynamics accurately.

Figure 1-11. Frequency Response of ssys and Its Discrete Equivalent ssysd

© National Instruments Corporation 1-19 Xmath Control Design Module

Page 28

Chapter 1 Introduction

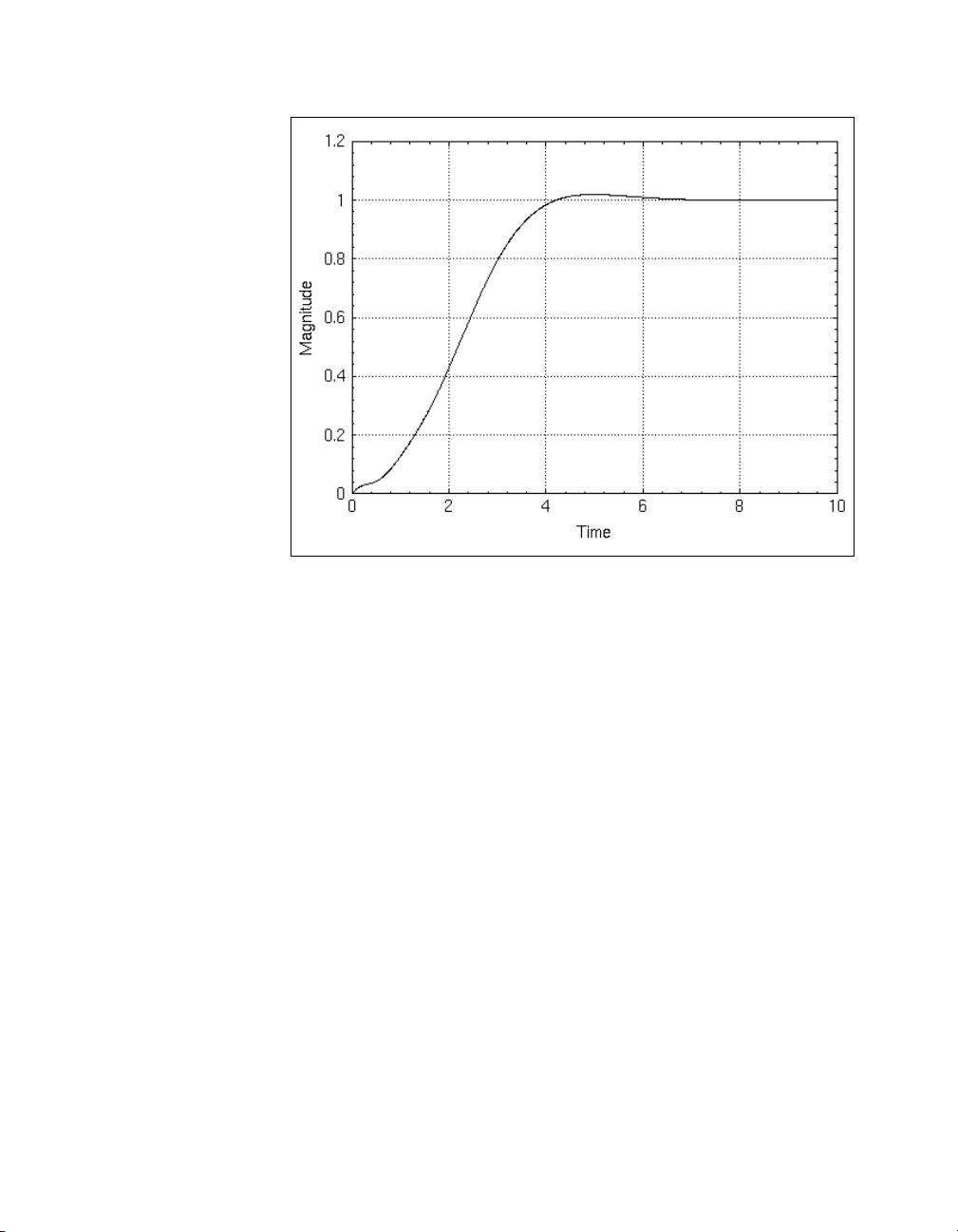

Figure 1-12. Step Response of a Discrete System Using Discretized

Observer-Based Controller

As you discretize the compensator, form the closed-loop, scaled system,

and simulate its response to a step input, you must ensure that the sampling

interval is the same (

sys_obcd = discretize(sys_obc, 0.01);

sys_cld = feedback(ssysd,sys_obcd)/51.76;

v_cld = step(sys_cld, 0:0.01:10);

plot (v_cld, {xlab = "Time", ylab = "Magnitude"})

dt = 0.01).

The resulting response is shown in Figure 1-12.

Inverted Wedge-Balancing Problem: LQG Control

[HW91] discusses an approach to balancing an inverted wedge by

controlling the location of a sliding mass along the inside of the wedge.

This example illustrates use of optimal control with a multi-input,

multi-output (MIMO) system. This approach is based on minimizing a

quadratic performance index with weight values based on the natural

constraints of the system.

Xmath Control Design Module 1-20 ni.com

Page 29

Chapter 1 Introduction

The linearized state-space equations, including the actuator and sensor

dynamics, are as follows:

·

θ

·

x

··

θ

··

x

0010

0001

15.54 10.93– 00

5.31– 0 0 16.24–

θ

x

θ

x

0

0

·

·

u+=

0

1.96

θ

57.29000

=

y

0 29.9 0 0

x

·

θ

·

x

θ is the angle (in radians) the wedge makes with the vertical axis, x is the

position of the sliding mass, and u is the control input voltage. The outputs

are scaled to give the measured angle in degrees and the measured position

in meters.

A = [0,0,1,0;0,0,0,1;

15.54,-10.93,0,0;

-5.31,0,0,-16.24];

B = [0,0,0,1.96]';

C = [57.29,0,0,0;0,29.9,0,0];

D = [0;0];

states = ["Angle", "Mass Position",

"Angular Velocity","Mass Velocity"];

wsys = system(A,B,C,D,

{inputNames= "Voltage",

stateNames = states,

outputNames=["Measured Angle","Measured

Position"]});

You need to ensure that you have no uncontrollable or unobservable modes

of the system:

[,,nuco] = minimal(wsys)

nuco (a scalar) = 0

Because there are no uncontrollable or unobservable states, you can

proceed with the design of a regulator and estimator. The weighting matrix

used here in designing the regulator reflects the desire to bring the value of

the first state, the angle with the vertical, to zero as quickly as possible.

© National Instruments Corporation 1-21 Xmath Control Design Module

Page 30

Chapter 1 Introduction

Because this system is open-loop unstable and has fairly fast poles in both

halves of the s-plane, you want to make sure it can bring the effect of an

external disturbance (such as a sharp push to the cart) to zero as quickly as

possible.

[Kr,EVr,Pr] = regulator(wsys,diag([1e8,1,1,1]),1);

You then can verify that the regulator gain Kr can be used with full-state

feedback to control this system by using an identity matrix for C to feed

back the states:

[no, ni, ns] = size(wsys);

augwsys = system(A,B,eye(ns, ns),[]);

creating the compensator (which is a system object, though it has no states

and thus has

comp = system([],[],[],Kr);

NULL A, B, and C matrices) with the gains Kr:

and feeding back the states:

wsysreg = feedback(augwsys, comp);

You then can observe the system response to a sustained disturbance by

simulating a five-second step response:

stepreg = step(wsysreg, 0:0.01:5);

plot (stepreg, {legend=states,

xlab="Time",ylab="Magnitude",

title="System Step Response with "+...

"Full State Availability",!grid})

The resulting plot is shown in Figure 1-13.

Xmath Control Design Module 1-22 ni.com

Page 31

Chapter 1 Introduction

Figure 1-13. Response of Full-State Feedback Controller to a Unit Step Disturbance

Having established your regulator design, you build the estimator and

simulate performance of the closed-loop system feeding back state

estimates. You select the weights for the estimator based on the assumption

that the state noise intensities corresponding to the wedge angle are smaller

than those corresponding to the wedge position. The output weight matrix

reflects your higher priority on the wedge angle than position.

The following steps generate the plot shown in Figure 1-14:

[Ke,EVe,Pe] = estimator(wsys,

diag([1e-3,1,1e-3,10]), diag([14,0.01]));

wcomp = lqgcomp(wsys,Kr,Ke);

wlqg = feedback(wsys,wcomp);

resp = step(wlqg,0:0.01:3);

plot (resp, {legend = names(wlqg),

xlab = "Time",ylab = "Magnitude",

title = "Observer-Controller System "+...

"Step Response",!grid})

© National Instruments Corporation 1-23 Xmath Control Design Module

Page 32

Chapter 1 Introduction

Figure 1-14. Response of Observer-Based Controller to a Unit Step Disturbance

Xmath Control Design Module 1-24 ni.com

Page 33

Linear System Representation

Xmath provides a structure for system representation called a system

object. This object includes system parameters in a data structure designed

to reflect the way these systems are analyzed mathematically. Operations

on these systems are likewise defined using operators that mirror as closely

as possible the notation control engineers use. This chapter outlines the

types of linear systems the system object represents and then discusses the

implementation of a system within Xmath. The functions used to create a

system object and to extract data from this object are an intrinsic part of the

object and are also described. Finally, this chapter discusses the functions

check( ), discretize( ), and makecontinuous( ), which use

information stored in the system object to convert systems from one

representation to another.

Linear Systems Represented in Xmath

Xmath handles finite-dimensional, linear, and time-invariant linear

systems in both discrete and continuous time. These systems take one

of the forms shown in Table 2-1.

2

Table 2-1. Summary of Linear Systems

System Type Continuous Time Discrete Time

State-spec

Transfer function

The transfer function representation can be used to describe single-input,

single output (SISO) systems only; there are no restrictions on the number

of input and outputs that can be specified for a state-space system. All of

these systems can be created using the Xmath

© National Instruments Corporation 2-1 Xmath Control Design Module

x·Ax Bu+=

yCxDu+=

Hs() CsI A–()

1–

BD+= Hz() CzI A–()1–BD+=

x

k 1+

y

k

AxkBu

+=

CxkDu

+=

k

system( ) function.

k

Page 34

Chapter 2 Linear System Representation

Transfer Function System Models

One way of representing continuous-time finite-dimensional linear

time-invariant systems is with the transfer function:

Hs()

num s()

------------------=

den s()

with num(s) and den(s) being polynomials in s. They can be specified either

by their roots or their coefficients. Transfer functions are defined using the

Laplace transform operators for continuous time and the forward shift

operator z for discrete time. Both forms of transfer functions are written

with positive coefficients, each higher order terms having successively

larger coefficients.

Discrete systems are defined analogously, using the z variable instead of s.

Xmath does not automatically perform cancellations of polynomial roots

appearing in both the numerator and the denominator of a transfer function.

If you want to cancel common roots in a transfer function, use the function

cancel( ). For state-space systems, refer to the minimal( ) function.

For more information, refer to the Minimal Realizations section of

Chapter 6, State-Space Design.

To illustrate how you arrive at a particular transfer function, if you have a

system differential equation that takes the form:

y··6y·8y++ 2u·u–=

(2-1)

Laplace-transforming equation (assuming zero initial conditions) yields:

2

s

Ys() 6sY s() 8 Ys()++ 2sU s() Us()–=

(2-2)

Collecting terms, you can find the transfer function from U(s) to Y(s), H(s):

Ys()

----------- Hs()

Us()

2s 1–

--------------------------==

2

s

(2-3)

6s 8++

The roots of the numerator polynomial are the zeros of the transfer

function, and the roots of the denominator are its poles. In some

circumstances, you might want to construct a transfer function based on

where you know the pole and zero locations to be. For example, you can

Xmath Control Design Module 2-2 ni.com

Page 35

Chapter 2 Linear System Representation

form the same transfer function as that derived in the preceding transfer

function equation using known pole, zero, and gain values:

The systems represented in Equations 2-3 and 2-4 can be represented using

Xmath’s system objects, as shown in Example 2-1.

The Xmath transfer function system object currently can be used to

represent single-input, single-output systems only. State-space form can

be used to describe systems with multiple inputs or outputs. For more

information, refer to the State-Space System Models section.

Example 2-1 Creating Transfer Functions

The polynomials in the numerator and denominator of the transfer function

in Equation 2-3 are both in coefficients form, (described using just

coefficients, not roots).

them to the

num3 = makepoly([2,-1],"s");

den3 = makepoly([1,6,8],"s");

H3 = system(num3,den3)

system( ) function:

This displays as:

H3 (a transfer function) =

2s - 1

----------

2

s

+ 6s + 8

initial integrator outputs

0

0

Input Names

----------Input 1

Output Names

-----------Output 1

System is continuous

Hs()

makepoly( ) creates two polynomials and passes

2 s 0.5–()

---------------------------------=

s 2+()s 4+()

(2-4)

The three statements used to create the transfer function could be more

compactly combined as one. The use of s as the variable in which to express

the transfer function is optional. Any variable, including the default x, can

© National Instruments Corporation 2-3 Xmath Control Design Module

Page 36

Chapter 2 Linear System Representation

be used so long as a consistent choice of variable is used for both numerator

and denominator polynomials.

The transfer function in pole-zero-gain form from the preceding equation

can be similarly implemented using the

specify the numerator and denominator by their roots.

Note The / operator also can be used to create systems in transfer function form, as an

alternative to using

system( ).

H4 = 2*polynomial(0.5,"s")/polynomial([-2,-4],"s")

which displays as:

H4 (a transfer function) =

2(s - 0.5)

--------------

(s + 2)(s + 4)

initial integrator outputs

0

0

Input Names

-----------

Input 1

Output Names

------------

Output 1

System is continuous

polynomial( ) function to

In both of these cases you have created a continuous system. Systems

created in Xmath contain sample rate information as well as the numbers

representing system dynamics. However, unless a sample rate is explicitly

given as a keyword to

system( ), it defaults to zero and the system is

continuous. For an illustration of how to create a discrete system, refer to

Example 2-2. The full discussion of the

system( ) function in the

system( ) section contains a listing of all the keywords associated with

system( ).

Xmath Control Design Module 2-4 ni.com

Page 37

State-Space System Models

State-space models comprise the second category of linear system

representations in Xmath. In state-space form, first-order differential

(continuous-time) and difference (discrete-time) equations are represented

as a set of state and output updates. The states are represented by a vector

x; u and y are vectors with as many elements as there are inputs and outputs,

respectively. This system model is useful for representing multi-input,

multi-output (MIMO) systems.

continuous time:

discrete time:

Chapter 2 Linear System Representation

x·Ax Bu+=

yCxDu+=

A straightforward mathematical transformation from the state-space form

to the transfer function form is as follows:

Hq() CqI A–()

All of the forms represented in these equations can be represented using

Xmath’s system objects, as shown in Example 2-2.

Example 2-2 Creating a Discrete State-Space System

Suppose you have a system which you describe in state-space form as:

x

and you know that the sample period of the system is 0.5 seconds between

samples—that is, the states and outputs are updated at every discrete

interval k, consisting in this case of 0.5 seconds.

k 1+

x

y

=

k

k 1+

y

k

AxkBu

CxkDu

01

0.75– 0

x

01

+=

k

+=

k

1–

BD+=

1

x

k

u

+=

k

k

0

© National Instruments Corporation 2-5 Xmath Control Design Module

Page 38

Chapter 2 Linear System Representation

Again, you create the system using the system( ) function. This time you

use the optional

A = [0,1;-0.75,0];

B = [1,0]';

C = [0,1];

D = 0;

sys4 = system(A,B,C,D, {dt = 0.5})

sys4 (a state space system) =

A

B

C

D

X0

System is discrete, sampling at 0.5 seconds.

dt keyword to indicate that this system is discrete.

0 1

-0.75 0

1

0

0 1

0

0

0

Although five lines of MathScript were used to be as explicit as possible in

creating this system, the call to

Note When you create a system object, its inputs (A, B, C, D) are no longer needed.

system( ) can encompass all of them.

Basic System Building Functions

The functions discussed in the following sections are available with the

general Xmath package. However, Control Design Module users will find

these functions an intrinsic part of their work, warranting this discussion.

The Xmath Help provides additional details about these functions and

examples of their use.

system( )

Sysd=system(A,B,C,D,{dt,inputNames,

outputNames,stateNames,X0})

Sys = system(num,den,{dt,inputNames,outputNames})

Sys = system(Sys,{keywords})

Xmath Control Design Module 2-6 ni.com

Page 39

Chapter 2 Linear System Representation

The system( ) function can create both the transfer-function and

state-space forms of the system object. It requires four compatibly-sized

matrices to create a state-space system, or a pair of polynomials to create

a transfer function.

You can use optional keywords to store additional information about your

system. Assigning

discrete, with a sampling period equal to that value. If

dt to a positive scalar value indicates that the system is

dt is not specified,

the system is continuous, with a sampling period defaulting to zero.

Because information indicating whether the system is continuous or

discrete is encapsulated within the system object itself, Xmath does not

have separate functions for discrete- and continuous-time system analysis.

Systems can be recognized by Xmath’s functions as discrete or continuous

using the

check( ) function and handled accordingly. For more

information, refer to the Using check( ) with System Objects section.

The capability to assign a discrete sample rate does not actually discretize

a continuous-time system, however. For information on discretizing a

system, refer to the Discretizing a System section.

A shortcut for creating state-space systems with an all-zero D matrix is

to use a null-matrix specifier

([]) for the D matrix instead of entering an

appropriately sized zero matrix. This will automatically set the D matrix to

be a zero matrix with row size equal to the row size of C, and column size

equal to the column size of B.

In addition, descriptive names for the inputs and outputs of a system can

be specified as vectors of string names and assigned to the

outputNames, and stateNames keywords. stateNames is valid only

when used in conjunction with a state-space system, as is the keyword

inputNames,

X0,

which can be used to set a vector of initial values for the states.

When you have created a system, you can modify it by changing the values

of any of the keywords discussed in this section by calling

system( ) with

the appropriate keyword setting.

Examples 2-1 and 2-2 illustrate how

transfer function and state-space system, respectively.

system( ) can be called to create a

system( ) also can

be used to change the attributes of an existing system.

Note In Example 2-3, the [] notation indicates that the D matrix should be an

appropriately sized (in this case, scalar) zero matrix.

© National Instruments Corporation 2-7 Xmath Control Design Module

Page 40

Chapter 2 Linear System Representation

Example 2-3 Using system( ) to Change the Attributes of an Existing System

sys4=system([0,1;-0.75,0],[1,0]',[0,1],[],

{dt=0.5});

sys4 = system(sys4, {inputNames = "Current",

outputNames = "Velocity",

stateNames = ["Torque","Angle"]})

sys4 (a state space system) =

A

0 1

-0.75 0

B

1

0

C

0 1

D

0

X0

0

0

State Names

----------Torque Angle

Input Names

----------Current

Output Names

-----------Velocity

System is discrete, sampling at 0.5 seconds.

abcd( )

[A,B,C,D,X0] = abcd(Sys)

The abcd( ) function extracts the component A, B, C, and D matrices

described in equations from a state-space system object as shown in the

State-Space System Models section. In addition, it returns the initial

conditions on the states if a fifth output argument is requested.

abcd( ) can be called on systems in either state-space or transfer function

form. If the system is a transfer function, the conversion to state-space is

Xmath Control Design Module 2-8 ni.com

Page 41

done internally to return A, B, C, and D, though the format of the variable

Sys itself remains unchanged. The transfer function must be proper.

Using the systems defined in Examples 2-1 and 2-2, Example 2-4

illustrates the use of

Example 2-4 Using abcd( ) to Extract the State-Space Matrices

H3=makepoly([2,-1],"s")/makepoly([1,6,8],"s");

sys4=system([0,1;-0.75,0],[1,0]',[0,1],0,

{dt=0.5});

abcd( ).

You can extract the state-space matrices from each.

Note For the transfer function H3, an internal conversion is performed.

[A3,B3,C3,D3] = abcd(H3)?

A3 (a square matrix) =

-2 1.58114

0 -4

B3 (a column vector) =

0

2

C3 (a row vector) = -1.58114 1

D3 (a scalar) = 0

[A4,B4,C4,D4,X0] = abcd(sys4)

A4 (a square matrix) =

0 1

-0.75 0

B4 (a column vector) =

1

0

C4 (a row vector) = 0 1

D4 (a scalar) = 0

X0 (a column vector) =

0

0

Chapter 2 Linear System Representation

© National Instruments Corporation 2-9 Xmath Control Design Module

Page 42

Chapter 2 Linear System Representation

numden( )

[num,den] = numden(Sys)

The numden( ) function returns the numerator and denominator

polynomials comprising a single-input, single-output system in transfer

function form. If the system is in state-space form, an internal conversion

is performed to find the transfer function equivalent, but the format of the

system variable itself remains unchanged. State-space systems used in

conjunction with

As noted in the Transfer Function System Models section, common roots in

the numerator and denominator polynomials are not canceled.

Example 2-5 uses the state-space system from Example 2-2 to illustrate the

use of

numden( ).

Example 2-5 Using numden( ) to Extract the Transfer Function Polynomials

sys4=system([0,1;-0.75,0],[1,0]',[0,1],0,

{dt=0.5});

[num,den] = numden(sys4)?

num (a polynomial) =

-0.75

den (a polynomial) =

2

(z

+ 0.75)

numden( ) must be single-input, single-output.

Because num and den are polynomial objects and not a complete system,

the discrete sampling time is not explicitly saved. You can use

with the

convert keyword to map the two internal representations to each

check( )

other, as described in the Using check( ) with System Objects section.

However, notice that z was used as the polynomial variable, indicating that

these numerator and denominator polynomials were obtained from a

discrete-time system. Had the system been continuous, s would have been

used instead of z.

period( )

dt = period(Sys)

The period( ) function extracts the sample period (in seconds) of a

system. If the system is continuous,

In Example 2-5, you found the numerator and denominator polynomials

corresponding to the discrete state-space system. Example 2-6 combines

Xmath Control Design Module 2-10 ni.com

period( ) will return zero.

Page 43

these polynomials into a transfer-function and uses period( ) to set the

sampling interval to match that of

Example 2-6 Using period( ) to Extract the Sampling Period

[num,den]=numden(sys4);

H4 = system(num,den,{dt = period(sys4)})

H4 (a transfer function) =

-0.75

-----------

2

(z

+ 0.75)

System is discrete, sampling at 0.5 seconds.

Chapter 2 Linear System Representation

sys4.

check( )

provides a more concise means of converting between

state-space and transfer function form, as described in the Using check( )

with System Objects section, but this example illustrates how the output of

one function can be specified directly as keyword input to another.

names( )

[outputNames,inputNames,stateNames] = names(Sys)

The names( ) function extracts matrices of strings representing the input,

output, and (if the system is in state space form) state names of a system.

names( ) also can be used to extract information from the PDM and

polynomial objects. More information on these functions can be found in

the MATRIXx Help.

When you create a system without specifying any names, a default set of

names are assigned to it. Unlike user-specified names, these default names

are not displayed in the Xmath Commands

subset of the names you select to store with the system still can be extracted

using

names( ) as shown in Example 2-7.

Example 2-7 Using names( ) to Extract the Variable Names Associated with a System

H3 = system(makepoly([2,-1],"s"),

makepoly([1,6,8],"s"));

[outputNames, inputNames] = names(H3)

outputNames (a string) = Output 1

inputNames (a string) = Input 1

sys5=system([0,1;-0.75,0],[1,0]',[0,1],0,{dt=0.5,

inputNames = "Current",

window. However, all, or any

© National Instruments Corporation 2-11 Xmath Control Design Module

Page 44

Chapter 2 Linear System Representation

outputNames = "Velocity",

stateNames = ["Torque","Angle"]});

[,,stateNames] = names(sys5)?

statenames (a row vector of strings)=Torque Angle

Size and Indexing of Dynamic Systems

The size of a system object is defined by how many outputs, inputs, and

(in the case of a state-space system) states it has. You can use the

function to find these dimensions.

You can index into a dynamic system to create a new dynamic system

which has a subset of the original inputs and outputs:

Sys = Sys1(i,j) is defined to be a system such that y = y1(i) and u = u1(j).

i and j can both be vectors as well, in which case multiple inputs and

outputs will be extracted.

The previous definition of indexing was designed with the traditional

definition of a transfer function in mind.

size( )

yq() Sys q() uq()×=

Using check( ) with System Objects

Several common attributes of systems can be easily determined using

Xmath’s ability to distinguish between object types and characteristics.

You can use the

Example 2-8, to determine whether a system is in transfer function or

state-space form, discrete, continuous, or stable. In addition, you can use

check( ) with the convert keyword to change a system’s representation

between SISO state-space and transfer-function forms.

Example 2-8 Using check( ) with a System

a = [1.875,0;0,-0.26];

b = [1;0];

c = [0.5,1];

d = 0;

sys = system(a,b,c,d, {dt = 0.001});

Because this system is discrete and has a pole where magnitude exceeds 1,

it is not stable.

check( ) function with systems, as shown in

Xmath Control Design Module 2-12 ni.com

Page 45

check(sys, {stable})

ans (a scalar) = 0

check(sys, {discrete, ss})

ans (a scalar) = 1

[, tfsys] = check(sys, {tf, convert})

tfsys (a transfer function) =

(z + 0.26)

--------------------(z + 0.26)(z - 1.875)

initial delay outputs

0

0

System is discrete, sampling at 0.001 seconds.

Discretizing a System

Many systems where behavior derives from physical equations of motion

can be modeled most naturally as continuous processes, using differential

equations. Therefore, you often choose to discretize these models for use

with a digital controller. A number of mathematical methods have been

developed to approximate the behavior of a continuous system in a

discrete-time representation with an appropriately fast sampling rate.

Xmath provides two functions,

makecontinuous( ), which encompass a range of these techniques.

discretize( ) converts a system from its representation as a continuous

function in the s-domain to a discrete-time z-domain function.

makecontinuous( ) does the reverse, transforming a discrete system to

its continuous form.

Chapter 2 Linear System Representation

discretize( ) and

discretize( )

SysD = discretize(Sys,{dt,exponential,forward,backward,

tustins,ztransform,polezero,firstorder})

The discretize( ) function has a number of keywords that correspond

to the different methods of continuous-to-discrete conversion that are

implemented within Xmath. The sampling interval (in seconds) for the

discrete system should be set equal to the keyword

is specified, a default of 0.5 seconds is used. The default discretization

method used is the exponential (step-invariant) transform. The different

© National Instruments Corporation 2-13 Xmath Control Design Module

dt. If no value for dt

Page 46

Chapter 2 Linear System Representation

discretization methods used based on the specification of each keyword are

discussed in the following sections.

Numerical Integration Methods: forward, backward, tustins

Xmath provides three methods of numerical integration of a differential

transfer function: the forward and backward rectangular rules, and Tustin’s

rule (also called the bilinear or trapezoidal transform).

To convert the system description from a continuous differential equation

to a discrete difference equation, you approximate the value of the

derivative in the continuous equation over each

find the area of the geometric region having width

the derivative. You can do this in a number of ways, as discussed in

[FPW90].

For the forward rectangular method, you assume the incremental area term

between sampling times k * dt and (k +1)*dt to be a rectangle having

width dt and height equal to the integral form of the differential equation at

time (k +1)*dt. In essence, you get your amplitude estimate for each

rectangle by looking forward, hence the name. The backward rectangular

method arises similarly, except that you get the rectangle’s height by

looking backward and taking the value of the integral at k * dt. The forward

rectangular approach tends to overestimate the incremental area somewhat

and the backward approach tends to underestimate it (though with a

sufficiently small sampling interval, this may not pose a large problem).

The trapezoid rule strikes a balance between these two methods by taking

the average of the rectangles defined by the forward and backward methods

and using that value as the incremental area in approximating the difference

equation.

dt seconds of time, then

dt and height equal to

These approaches can be summarized as substitutions between the

continuous-time Laplace-transform operators and the discrete z-transform

operator z as shown in Table 2-1.

Table 2-2. Mapping Methods for discretize( )

Method of Approximation Continuous to Discrete

Forward rectangular rule:

Keyword:

Xmath Control Design Module 2-14 ni.com

forward