Page 1

Computer-Based

Instruments

NI 2501/2503 User Manual

24-Channel Two-Wire Multiplexer

NI 2501/2503 User Manual

July 1998 Edition

Part Number 321906B-01

Page 2

Internet Support

E-mail: support@natinst.com

FTP Site: ftp.natinst.com

Web Address: http://www.natinst.com

Bulletin Board Support

BBS United States: 512 794 5422

BBS United Kingdom: 01635 551422

BBS France: 01 48 65 15 59

Fax-on-Demand Support

512 418 1111

Telephone Support (USA)

Tel: 512 795 8248

Fax: 512 794 5678

International Offices

Australia 03 9879 5166, Austria 0662 45 79 90 0, Belgium 02 757 00 20, Brazil 011 288 3336,

Canada (Ontario) 905 785 0085, Canada (Québec) 514 694 8521, Denmark 45 76 26 00, Finland 09 725 725 11,

France 01 48 14 24 24, Germany 089 741 31 30, Hong Kong 2645 3186, Israel 03 6120092, Italy 02 413091,

Japan 03 5472 2970, Korea 02 596 7456, Mexico 5 520 2635, Netherlands 0348 433466, Norway 32 84 84 00,

Singapore 2265886, Spain 91 640 0085, Sweden 08 730 49 70, Switzerland 056 200 51 51, Taiwan 02 377 1200,

United Kingdom 01635 523545

National Instruments Corporate Headquarters

6504 Bridge Point Parkway Austin, Texas 78730-5039 USA Tel: 512 794 0100

© Copyright 1998 National Instruments Corporation. All rights reserved.

Page 3

Important Information

Warranty

The NI 2501 and NI 2503 are warranted against defects in materials and workmanship for a period of one year from the

date of shipment, as evidenced by receipts or other documentation. National Instruments will, at its option, repair or

replace equipment that proves to be defective durin g the warranty p eriod . T his w arran ty i nclu des part s an d labo r.

The media on which you receive National Instruments software are warranted not to fail to execute programming

instructions, due to defects in materials and work man ship, for a peri od of 90 d ays from da te o f sh ipm ent, as evi denced

by receipts or other documentation. National Instruments will, at its option, repair or replace software media that do not

execute programming instructions if National Instruments receives noti ce of su ch defect s d uring th e warranty perio d.

National Instruments does not warrant that the op eration of t he soft ware shall b e uni nterrup ted or erro r free.

A Return Material Authorization (RMA) number must b e ob tain ed fro m th e facto ry an d clearl y mark ed on t he outsi de

of the package before any equipment wil l be accepted for warranty work. National Instruments will pay the shippi ng costs

of returning to the owner parts which are covered by warran ty.

National Instruments believes that the information in this manual is accurate. The document has been c arefully reviewed

for technical accuracy. In the event that technical or typographical errors exist, National Instruments reserves the right to

make changes to subsequent editions of th is do cume nt with ou t p rio r no ti ce to hold ers o f thi s ed itio n. The read er sh ou ld

consult National Instruments if errors are suspected. In no event shall National Instruments be liable for any damages

arising out of or related to this docume nt o r th e in form ati on con tai ned in i t.

XCEPT AS SPECIFIED HEREIN

E

ANY WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE

BY FAULT OR NEGLIGENCE ON THE PART OF NATIONAL INSTRUMENTS SHALL BE LIMITED TO THE AMOUNT THERETOFORE PAID BY THE

CUSTOMER

OR INCIDENTAL OR CONSEQUENTIAL DAMAGES, EVEN IF ADVISED OF THE POSSIBILITY THEREOF

National Instruments will apply regardless of the form of action, wh ether in con tract or tort , incl udin g n egli gen ce.

Any action against National Instruments must be brought within one year after the cause of action accrues. National

Instruments shall not be liable for any delay in performance due to causes beyond its reasonable control. The warranty

provided herein does not cover damages, defects, malfuncti ons, or s ervice failur es caused by own er’s fai lure to fol low

the National Instruments installation, operation, or maintenance instructions; owner’s modification of the product;

owner’s abuse, misuse, or negligent acts; and power failure or surges, fire, flood, accident, actions of third parties,

or other events outside reasonable control.

ATIONAL INSTRUMENTS WILL NOT BE LIABLE FOR DAMAGES RESULTING FROM LOSS OF DATA, PROFITS, USE OF PRODUCTS

. N

ATIONAL INSTRUMENTS MAKES NO WARRANTIES, EXPRESS OR IMPLIED, AND SPECIFICALLY DISCLAIMS

, N

Copyright

Under the copyright laws, this publication may not be reproduced or transmitted in any form, electronic or mechanical,

including photocopying, recording, storing in an information retrieval system, or translating, in whole or in part, without

the prior written consent of National Instruments Corporation.

USTOMER’S RIGHT TO RECOVER DAMAGES CAUSED

. C

. This limitation of the liability of

,

Trademarks

CVI™, LabVIEW™, NI-SWITCH™, and PXI™ are tra d e marks of National In st rume nts Co rporat io n.

Product and company names listed are trademarks or trade names of their respective companies.

WARNING REGARDING MEDICAL AND CLINICAL USE OF NATIONAL INSTRUMENTS PRODUCTS

National Instruments products are not designed with com ponent s and tes ting inten ded to ensure a l evel of reliab ilit y

suitable for use in treatment and diagnosis of humans. Applications of National Instruments products invol ving m edical

or clinical treatment can create a potential for accidental injury caused by product failure, or by errors on the part of the

user or application designer. Any use or application of National Instruments products for or involving medical or clinical

treatment must be performed by properly trained and qualified medical personnel, and all traditional medical safeguards,

equipment, and procedures that are appropriate in the particular situation to prevent serious injury or death should always

continue to be used when National Instruments products are being used . National Instrum ents product s are NOT intended

to be a substitute for any form of established process, procedure, or equipment used to monitor or safeguard human health

and safety in medical or clinical treatment.

Page 4

Compliance

FCC/DOC Radio Frequency Interference

Class A Compliance

This equipment generates and uses radio frequency energy and, if not installed and used in strict accordance

with the instructions in this manual, may cause interference to radio and television reception. Classification

requirements are the same for the Federal Communications Commission (FCC) and the Canadian

Department of Communications (DOC). This equipment has been tested and found to comply with the

following two regulatory agencies:

Federal Communications Commission

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant

to part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial environment. This equipment generates,

uses, and can radiate radio frequency energy and, if not installed and used in accordance with the instruction

manual, may cause harmful interference to radio communications. Operation of this equipment in a

residential area is likely to cause harmful interference in which case the user will be required to correct the

interference at his own expense.

Notices to User: Changes or modifications not expressly approved by National Instruments could void

If necessary, consult National Instruments or an experienced radio/television technician for additional

suggestions. The following booklet prepared by the FCC may also be helpful: Interference to Home

Electronic Entertainment Equipment Handbook. This booklet is available from the U.S. Government

Printing Office, Washington, DC 20402.

the user’s authority to operate the equipment under the FCC Rules.

This device complies with the FCC rules only if used with shielded interface cables

of suitable quality and construction. National Instruments used such cables to test

this device and provides them for sale to the user. The use of inferior or nonshielded

interface cables could void the user’s authority to operate the equipment under the

FCC rules.

Canadian Department of Communications

This Class A digital apparatus meets all requirements of the Canadian Interference-Causing Equipment

Regulations.

Cet appareil numérique de la classe A respecte toutes les exigences du Règlement sur le matériel brouilleur

du Canada.

Page 5

Conventions

The following conventions are used in this manual.

<> Angle brackets containing numbers separated by an elli psis r epresen t a

range of values associated with a port, bit, or signal name (for example,

CH<0..7> stands for the signals CH0 through CH7).

This icon to the left of bold italic ized text denotes a n ote, which alerts

you to important information.

!

bold italic Bold italic text denotes a note, caution, or warning.

italic Italic text denotes variables, emphasis, a cross reference, or an introduction

This icon to the left of bold italic ized text denotes a ca ution, wh ich

advises you of precautions to take to avoid injury, data loss, or a

system crash.

This icon to the left of bold italicized text denotes a warning, which advises

you of precautions to take to avoid being electrically shocked.

to a key concept. This font also denotes text from which you supply the

appropriate word or value, as in CHx.

Page 6

Contents

Chapter 1

Routing Signals with Your NI 2501/2503

About the NI 2501/2503 ................................................................................................1-1

Analog Bus......................................................................................................1-2

Triggers............................................................................................................1-2

Cold-Junction Sensor Channel........................................................................1-3

NI 2501 Amplifier...........................................................................................1-3

Connecting Signals ........................................................................................................1-4

Front Connector...............................................................................................1-4

Contact Protection..........................................................................................................1-10

Terminal Blocks.............................................................................................................1-10

Software Choices...........................................................................................................1-10

NI-SWITCH Driver Software .........................................................................1-10

National Instruments Application Software....................................................1-11

Third Party Software .......................................................................................1-11

Chapter 2

NI 2501/2503 Operation

Functional Overview......................................................................................................2-1

Multiplexer.....................................................................................................................2-4

Two-Wire Mode..............................................................................................2-4

One-Wire Mode...............................................................................................2-4

Four-Wire Mode..............................................................................................2-5

Matrix Mode....................................................................................................2-5

Switch Control Circuitry................................................................................................2-5

Random Scanning..........................................................................................................2-5

PXI Interface..................................................................................................................2-6

Triggers............................................................................................................2-6

External Trigger Input.......................................................................2-6

Scanner Advanced.............................................................................2-7

Modes................................................................................................2-7

Initiating Scanning...........................................................................................2-8

Multicard Triggering.......................................................................................2-8

Appendix A

Specifications

©

National Instruments Corporation vii NI 2501/2503 User Manual

Page 7

Contents

Appendix B

Accessories

Appendix C

Customizing Your Card

Appendix D

Architecture Drawings

Appendix E

Common Questions

Appendix F

Customer Communication

Glossary

Index

Figures

Figure 1-1. Front Connector Pinout Assignments for Two-Wire Mode .................1-5

Figure 1-2. Front Connector Pinout Assignments for One-Wire Mode..................1-6

Figure 1-3. Front Connector Pinout Assignments for Four-Wire Mode.................1-7

Figure 1-4. Front Connector Pinout Assignments to Create a 6 x 4 Matrix............ 1-8

Figure 2-1. NI 2501 Module Block Diagram .......................................................... 2-2

Figure 2-2. NI 2503 Module Block Diagram ..........................................................2-3

Figure C-1. Bent and Trimmed Resistor..................................................................C-2

Figure D-1. NI 2501 Switch Architecture................................................................ D-2

Figure D-2. NI 2503 Switch Architecture................................................................ D-3

Tables

Table 1-1. Front Connector Signal Description ....................................................1-9

NI 2501/2503 User Manual viii

©

National Instruments Corporation

Page 8

Routing Signals with Your

NI2501/2503

This manual describes the electrical and mechanical aspects of the

NI2501 FET multiplexer and the NI2503 mechanical relay multiplexer

and contains information concerning their installation andoperation.

This manual uses the term NI2501/2503 whenever information applies

to both instruments.

About the NI2501/2503

This section summarizes the features and operation of the NI2501/2503

switch card. Refer to Chapter2, NI2501/2503 Operation, for more

complete details. In addition, refer to AppendixA, Specifications,

fordetailed specifications of the two switch cards.

The NI2501 is a FET switch card, and the NI2503 is an armature

relayswitch card. Each consists of a 24 x 1 two-wire multiplexer in

PXI/Compact PCI format. You can take advantage of the switch card’s

flexibility to handle a wide variety of test systems through the use of

various accessories and software configurations. You can use the National

Instruments NI-SWITCH software included with your kit to configure and

operate the NI2501/2503 switch card.

1

The NI2501/2503 can also operate as two 12 x 1 or four 6 x 1 two-wire

multiplexers. You can use software-configurable switches to configure

theswitch card as a 48 x 1 one-wire multiplexer for making large numbers

of common referenced measurements. In addition, the NI2501/2503 can

operate as a 12 x 1 four-wire multiplexer to handle resistive measurements,

such as thermistors or RTDs. Finally, you can use a National Instruments

TB-2606 terminal block to further configure the NI2501/2503 as a 6 x 4

two-wire matrix.

The Connecting Signals section of this chapter contains more information

on one-wire, two-wire, four-wire, and matrix configurations, and includes

diagrams of the pinout connections to make.

©

National Instruments Corporation 1-1 NI 2501/2503 User Manual

Page 9

Chapter 1 Routing Signals with Your NI 2501/2503

Refer to AppendixB, Accessories, for more information on terminal blocks

you can order from National Instruments.

You can also use multiple NI2501/2503 cards together to expand the size

of the multiplexer or matrix. For example, you can connect two cards to

create a 48 x 1 two-wire multiplexer or a 12 x 4 two-wire matrix.

Caution The maximum voltage is different for the NI2501 and NI2503 switch cards.

!

Ifyou intend to use more than one type of card, be sure you do not exceed the

maximum voltage of any card in your system. Refer to AppendixA, Specifications,

for information.

Analog Bus

The NI2501/2503 works with a four-wire analog bus. You connect the

analog bus to the switch card through its main front-panel connector.

Youcan use the analog bus to simplify connecting multiple cards to an

instrument such as a digital multimeter (DMM). This bus makes it possible

to create large systems using multiple switch cards.

For example, if you have two NI2501/2503 cards—or one of each—in two

adjacent slots, you can connect them through the analog bus and create a

48x1 two-wire multiplexer. With this flexibility, you keep the wiring of

the modules to a minimum while you create large switching solutions. In

such cases, the scanning architecture uses some of the PXI trigger lines for

synchronization and delivers full access to all of the scanning features for

the cards. The National Instruments software you receive with the

NI2501/2503 handles the complexity of programming the cards.

Triggers

Two triggers are used to handshake the NI2501/2503 switch with PXI

instruments or other external instruments. The Scanner Advanced trigger

indicates when the card has closed all the necessary switches for the next

scan and the switches have settled, or debounced. This trigger is typically

wired to a measurement device, such as a DMM, which is configured to

take a reading when it receives the trigger.

The External Trigger Input trigger is sourced by another instrument, such

as the DMM, and causes the NI2501/2503 to advance to the next entry

inthe scan list. The triggers can be routed to the front connector of the

NI2501/2503, to any of the PXI TTL triggers, or to the PXI star trigger. If

no external trigger input is available, you can have the software trigger the

NI2501/2503 to advance to the next entry in the scan list.

NI 2501/2503 User Manual 1-2

©

National Instruments Corporation

Page 10

Refer to Chapter 2, NI 2501/2503 Operation, for more inf o r mation on

triggers.

Cold-Junction Sensor Channel

For low-voltage measurements, such as those provided by thermocouples,

the NI 2503 has very low thermal offset—less than 2 µV—to ensure

accurate measurements. For cold-junction compensation when switching

thermocouples, the NI 2501/2503 has a dedicated channel for a

temperature sensor. The National Instruments TB-2605 and TBX-68S

terminal blocks both have onboard temperature sensors that connect to the

dedicated cold-junction sensor channel.

NI 2501 Amplifier

The NI 2501 has an amplifier with a gain of 1. This amplifier can be

switched in-line before the COM0 signal and the AB0 signal. The amplifier

helps to decrease the settling time of the FET switch. The amplifier’s

high impedance isolates the FET from the resistance, capacitance,

and inductance in the external wiring. This isolation decreases the

resistance/capacitance time constant seen by the FET, which improves

settling time.

Chapter 1 Routing Signals with Your NI 2501/2503

The amplifier has an offset that should be calibrated for more accurate

measurements. The calibration data can be stored into and retrieved from

the EEPROM on the board. The software you received with your switch

card includes API function calls to retrieve and store calibration data.

When the amplifier is used, the switch card becomes directional, where

CHx is for signal inputs and COM0 or AB0 are for signal outputs.

The NI 2501 also has an amplifier in the CJS0+ to COM0+ signal path.

This amplifier in the cold-junction sensor signal path is used to improve

settling time performance. It prevents the impedance of the cold-junction

sensor from increasing the settling time when switching the CJS channel.

As a result, when scanning thermocouples, the settling time for the

cold-junction sensor channel should be about the same as for the channels

with the thermocouples.

©

National Instruments Corporation 1-3 NI 2501/2503 User Manual

Page 11

Chapter 1 Routing Signals with Your NI 2501/2503

Connecting Signals

This section describes the signal connections to the NI 2501/2503 module

via the module front connector. This section also includes specifications

and connection instructions for the signals on the NI 2501/2503 module

connectors.

Caution

!

Static electricity is a major cause of component failure. To prevent damage to the

electrical components in the module, observe antistatic precautions whenever

removing a module from the chassis or whenever working on a module.

Front Connector

Warning

Any connections that exceed the maximum settings for the NI 2501/2503 can

result in an electrical shock hazard and damage to the NI 2501/2503 module and

any or all of the boards connected to the PXI backplane. National Instruments

is NOT liable for any damages or injuries resulting from exceeding maximum

voltage ratings. Refer to Appendix A, Specifications, for information.

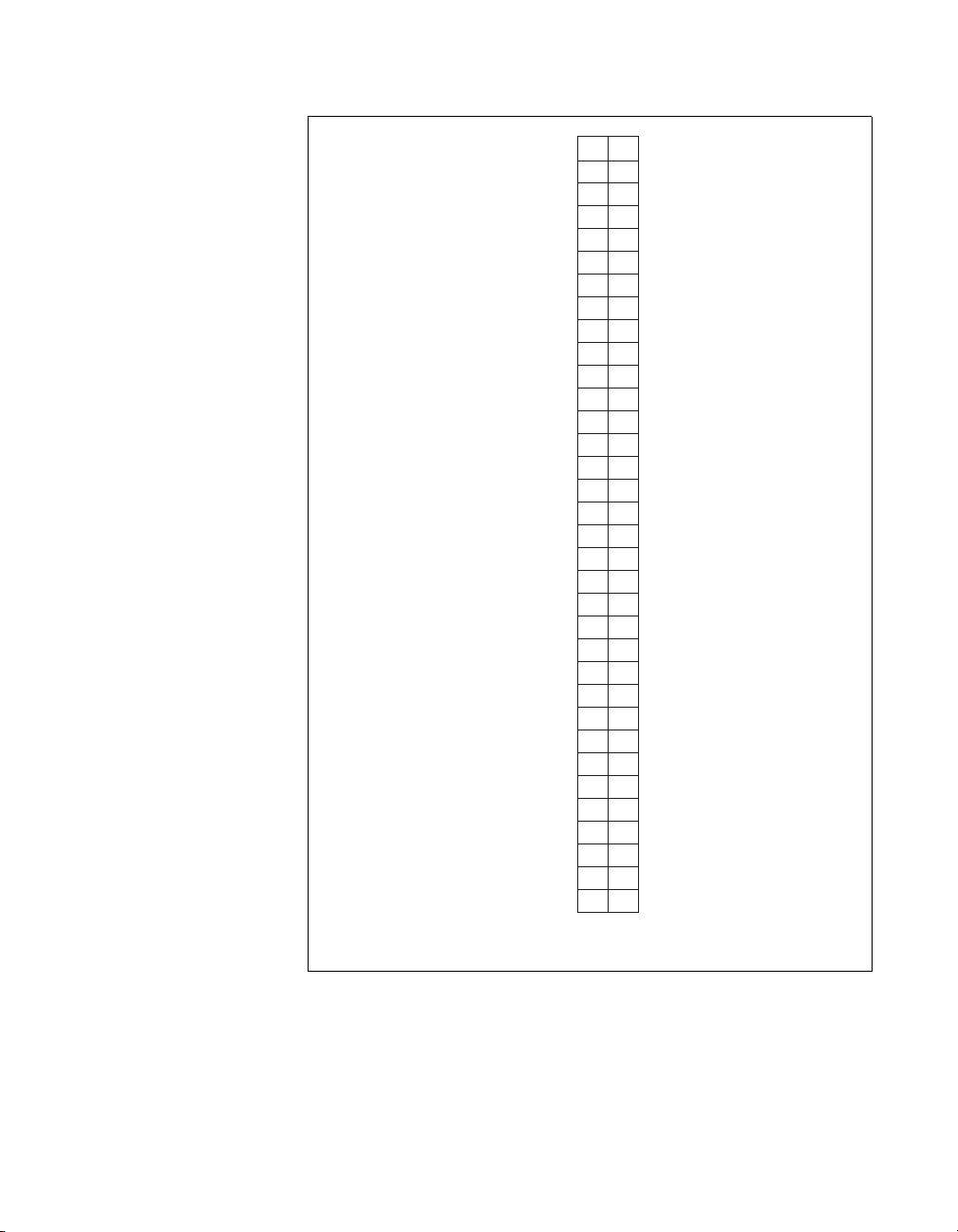

The pinout assignments for the NI 2501/2503 front connecto r vary

depending on the wiring mode you use. The following four diagrams show

the pin assignments for two-wire mode, one-wire mode, four-wire mode,

and matrix mode, respectively. Two-wire mode is shown first because it is

the most common configuration. Table 1-1, following the diagrams,

describes the connector signals. For more information on the wiring modes,

refer to the Multiplexer section in Chapter 2, NI 2501/2503 Operation.

NI 2501/2503 User Manual 1-4

©

National Instruments Corporation

Page 12

Chapter 1 Routing Signals with Your NI 2501/2503

CJS0–

CH0–

CH1–

CH2–

CH3–

CH4–

CH5–

COM0–

COM1–

CH6–

CH7–

CH8–

1_WIRE_LO_REF

CH9–

CH10–

CH11–

AB0–

AB1–

CH12–

CH13–

CH14–

CH15–

CH16–

CH17–

COM2–

COM3–

+5 V

GND

CH18–

CH19–

CH20–

CH21–

CH22–

CH23–

1

34 68

33 67

32 66

31 65

30 64

29 63

28 62

27 61

26 60

25 59

24 58

23 57

22 56

21 55

20 54

19 53

18 52

17 51

16 50

15 49

14 48

13 47

12 46

11 45

10 44

943

842

741

640

539

438

337

236

135

CJS0+

CH0+

CH1+

CH2+

CH3+

CH4+

CH5+

COM0+

COM1+

CH6+

CH7+

CH8+

GND

CH9+

CH10+

CH11+

AB0+

AB1+

CH12+

CH13+

CH14+

CH15+

CH16+

CH17+

COM2+

COM3+

SCAN_ADV

EXT_TRIG_IN

CH18+

CH19+

CH20+

CH21+

CH22+

CH23+

1

not used in two-wire mode

Figure 1-1. Front Connector Pinout Assignments for Two-Wire Mode

©

National Instruments Corporation 1-5 NI 2501/2503 User Manual

Page 13

Chapter 1 Routing Signals with Your NI 2501/2503

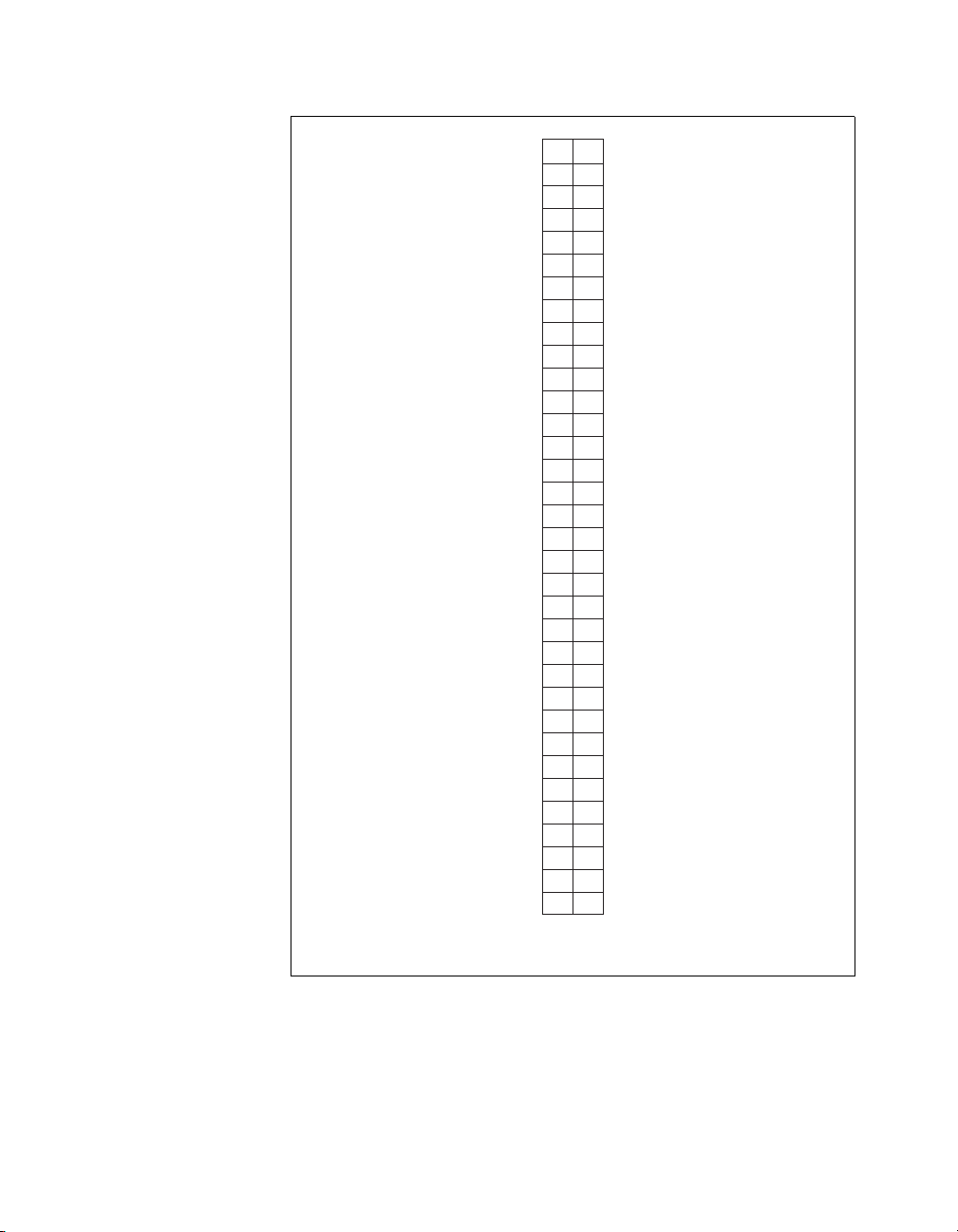

CJS–

CH24

CH25

CH26

CH27

CH28

CH29

COM0–

COM1– (CH30–CH35)

CH30

CH31

CH32

1_WIRE_LO_REF

CH33

CH34

CH35

AB0–

AB1–

CH36

CH37

CH38

CH39

CH40

CH41

COM2– (CH36–CH41)

COM3– (CH42–CH48)

+5 V

GND

CH42

CH43

CH44

CH45

CH46

CH47

1

1

1

1

1

34 68

33 67

32 66

31 65

30 64

29 63

28 62

27 61

26 60

25 59

24 58

23 57

22 56

21 55

20 54

19 53

18 52

17 51

16 50

15 49

14 48

13 47

12 46

11 45

10 44

943

842

741

640

539

438

337

236

135

1

CJS+

CH0

CH1

CH2

CH3

CH4

CH5

COM0+

COM1+ (CH6–CH11)

CH6

CH7

CH8

GND

CH9

CH10

CH11

AB0+

1

AB1+

CH12

CH13

CH14

CH15

CH16

CH17

COM2+ (CH12–CH17)

COM3+ (CH18–CH23)

SCAN_ADV

EXT_TRIG_IN

CH18

CH19

CH20

CH21

CH22

CH23

1

1

1

1

not used in one-wire mode

Figure 1-2. Front Connector Pinout Assignments for One-Wire Mode

NI 2501/2503 User Manual 1-6

©

National Instruments Corporation

Page 14

Chapter 1 Routing Signals with Your NI 2501/2503

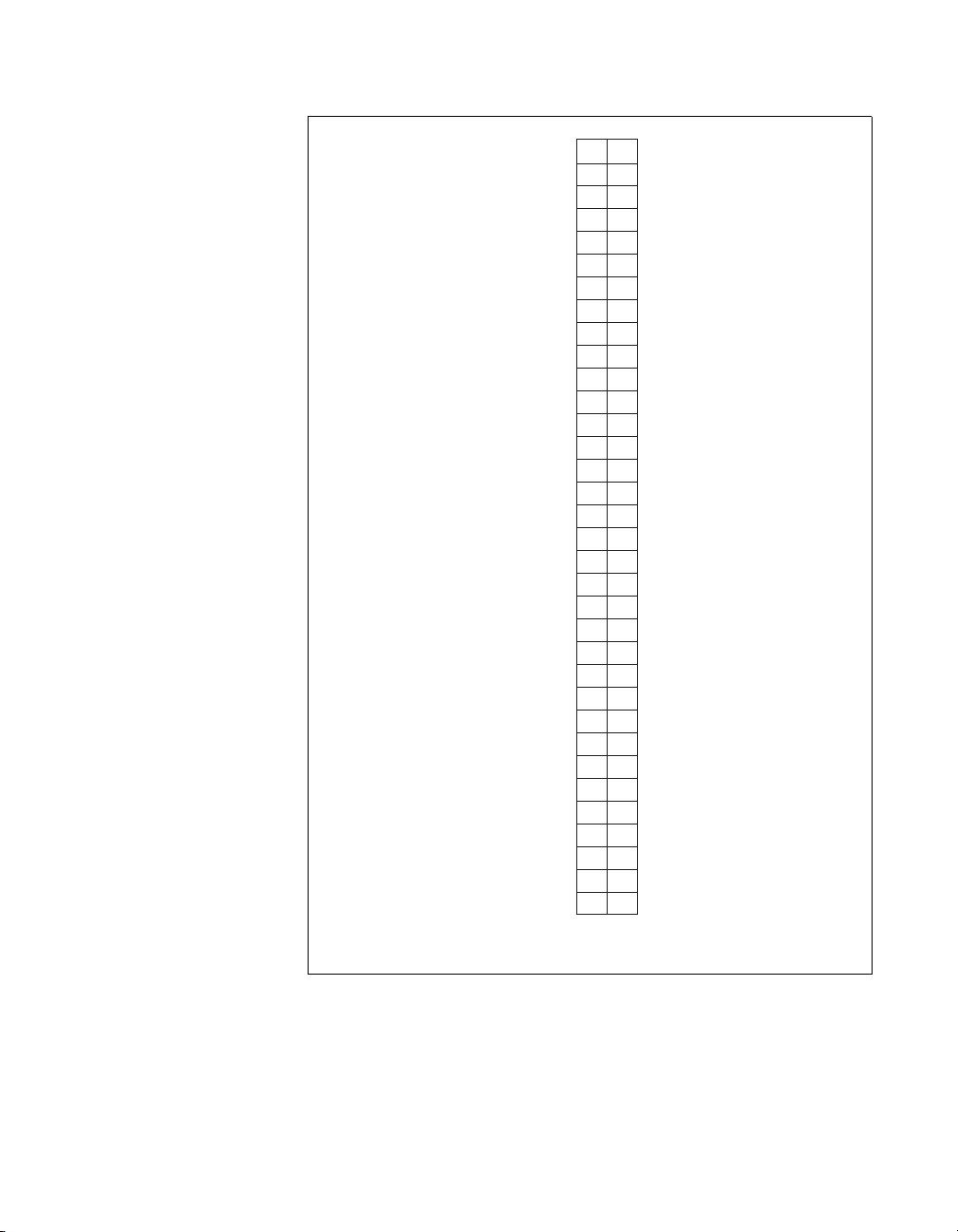

CJS–

CH0A–

CH1A–

CH2A–

CH3A–

CH4A–

CH5A–

COM0A–

COM1A–

CH6A–

CH7A–

CH8A–

1_WIRE_LO_REF

CH9A–

CH10A–

CH11A–

AB0A–

AB0B–

CH0B–

CH1B–

CH2B–

CH3B–

CH4B–

CH5B–

COM0B–

COM1B–

+5 V

GND

CH6B–

CH7B–

CH8B–

CH9B–

CH10B–

CH11B–

1

1

34 68

33 67

32 66

31 65

30 64

29 63

28 62

27 61

26 60

25 59

24 58

23 57

22 56

21 55

20 54

19 53

18 52

17 51

16 50

15 49

14 48

13 47

12 46

11 45

10 44

943

842

741

640

539

438

337

236

135

1

CJS+

CH0A+

CH1A+

CH2A+

CH3A+

CH4A+

CH5A+

COM0A+

COM1A+

CH6A+

CH7A+

CH8A+

GND

CH9A+

CH10A+

CH11A+

AB0A+

AB0B+

CH0B+

CH1B+

CH2B+

CH3B+

CH4B+

CH5B+

COM0B+

COM1B+

SCAN_ADV

EXT_TRIG_IN

CH6B+

CH7B+

CH8B+

CH9B+

CH10B+

CH11B+

1

not used in four-wire mode

Figure 1-3. Front Connector Pinout Assignments for Four-Wire Mode

©

National Instruments Corporation 1-7 NI 2501/2503 User Manual

Page 15

Chapter 1 Routing Signals with Your NI 2501/2503

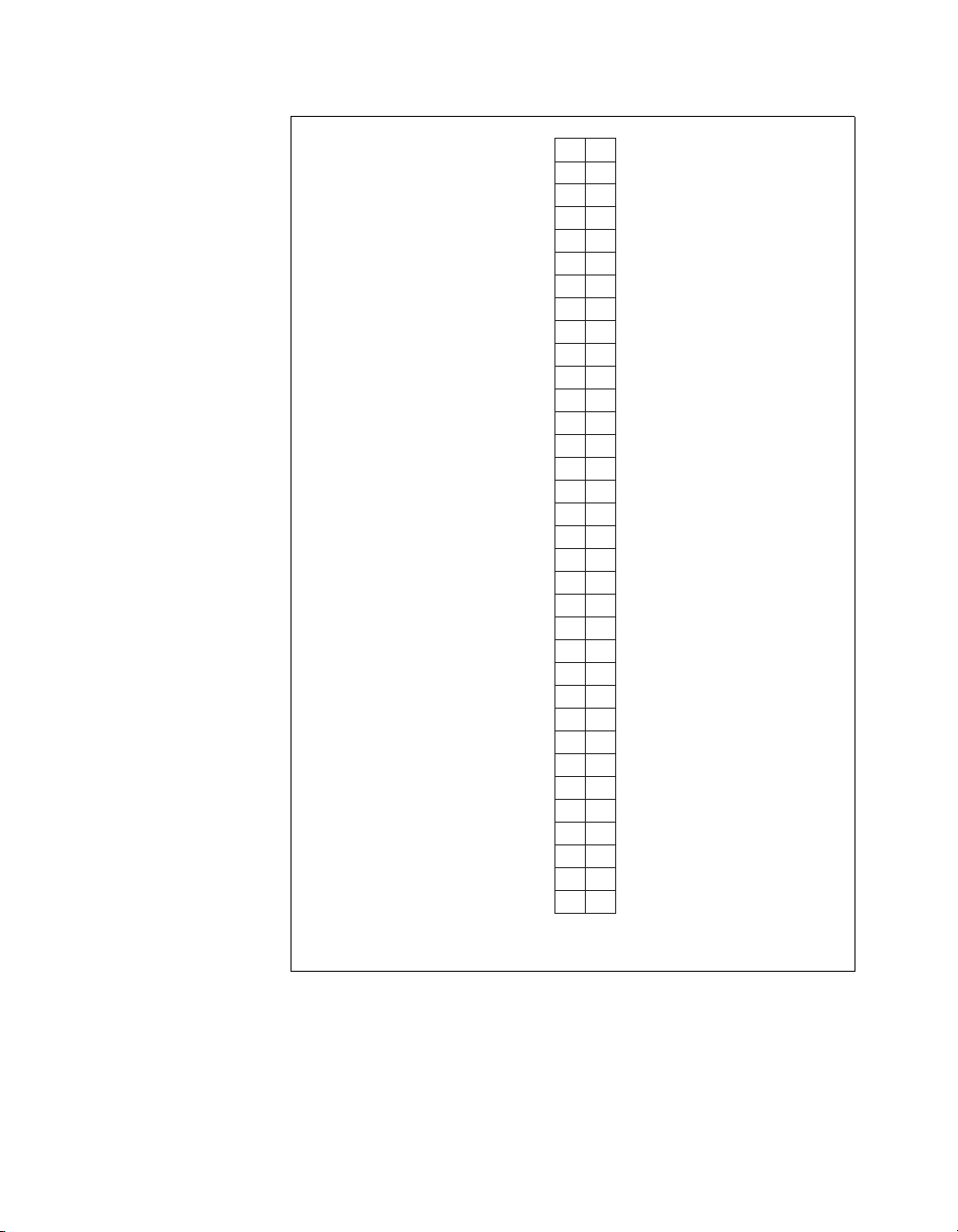

CJS–

COL0–

COL1–

COL2–

COL3–

COL4–

COL5–

ROW0–

ROW1–

COL0–

COL1–

COL2–

1_WIRE_LO_REF

COL3–

COL4–

COL5–

AB0– (ROW0–)

AB1– (ROW2–)

COL0–

COL1–

COL2–

COL3–

COL4–

COL5–

ROW2–

ROW3–

+5 V

GND

COL0–

COL1–

COL2–

COL3–

COL4–

COL5–

1

1

34 68

33 67

32 66

31 65

30 64

29 63

28 62

27 61

26 60

25 59

24 58

23 57

22 56

21 55

20 54

19 53

18 52

17 51

16 50

15 49

14 48

13 47

12 46

11 45

10 44

943

842

741

640

539

438

337

236

135

1

CJS+

COL0+

COL1+

COL2+

COL3+

COL4+

COL5+

ROW0+

ROW1+

COL0+

COL1+

COL2+

GND

COL3+

COL4+

COL5+

AB0+ (ROW0+)

AB1+ (ROW2+)

COL0+

COL1+

COL2+

COL3+

COL4+

COL5+

ROW2+

ROW3+

SCAN_ADV

EXT_TRIG_IN

COL0+

COL1+

COL2+

COL3+

COL4+

COL5+

1

not used in matrix mode

Figure 1-4. Front Connector Pinout Assignments to Create a 6 x 4 Matrix

For matrix mode, connect all pins with the same name together external to

the switch card. The National Instruments TB-2606 terminal block

connects the necessary pins to create the 6 x 4 matrix.

NI 2501/2503 User Manual 1-8

©

National Instruments Corporation

Page 16

Chapter 1 Routing Signals with Your NI 2501/2503

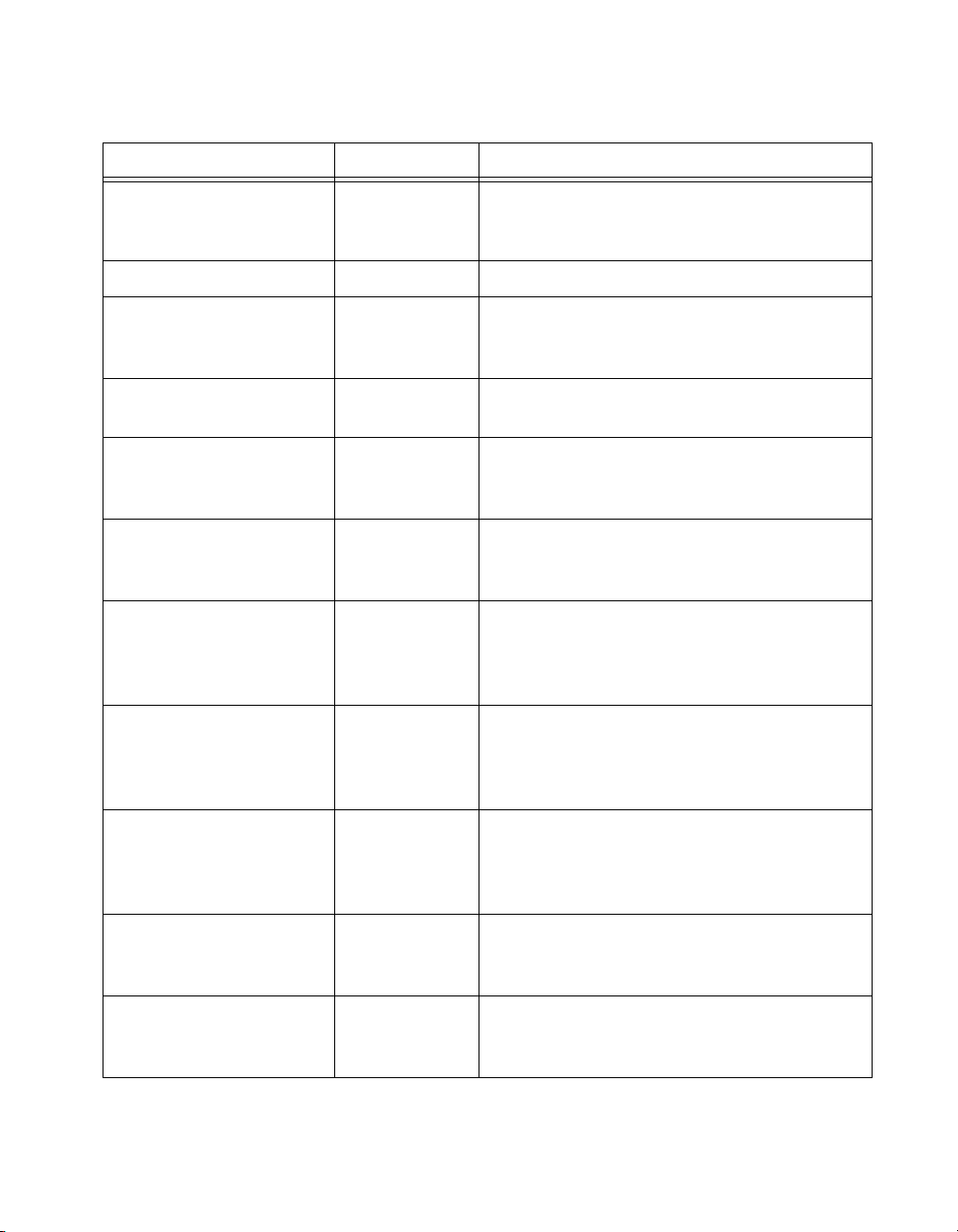

Table 1-1. Front Connector Signal Description

Signal Name Type Description

+5 V Output +5 VDC Source—Powers the temperature sensor

on the terminal block. 0.2 mA of source protected

by a resettable poly fuse.

GND Output Ground

CJS± Input Cold-junction Temperature Sensor Input—

Connects to the temperature sensor of the

terminal block.

1_WIRE_LO_REF Input The common reference signal used in one-wire

mode.

EXT_TRIG_IN Input External Trigger Input—Trigger from an

instrument to advance the switch card to the

next scan entry.

SCAN_ADV Output Scanner Advanced—Trigger to an instrument

that indicated the switch card has advanced to

the next scan and relays are debounced.

CH<0..47> (one wire)

CH<0..23>± (two wire)

CH<0..11>A± (four wire)

Input/Output Channels—Where signals are connected to the

switch card. CHx+ and CHx– are switched

together.

CH<0..11>B± (four wire)

COM0± (one wire)

Input/Output Common—The common for each bank.

COM<0..3>± (two wire)

COM<0..1>A± (four wire)

COM<0..1>B± (four wire)

AB0± (one wire)

AB<0..1>± (two wire)

Input/Output Analog Bus—Used to wire multiple switch cards

to an instrument such as a DMM.

AB0A± (four wire)

AB0B± (four wire)

COL<0..5>± Input/Output Columns—Where signals are connected to the

switch card. The card behaves as a matrix when

proper external wiring is added.

ROW<0..3>± Input/Output Rows—Where signals are connected to the

switch card. In matrix configuration any row

can be connected to any column.

©

National Instruments Corporation 1-9 NI 2501/2503 User Manual

Page 17

Chapter 1 Routing Signals with Your NI 2501/2503

Contact Protection

Caution

!

When inductive loads are connected to the relays, a large counter electromotive

force may occur at relay switching time due to the energy stored in the inductive

load. These flyback voltages can severely damage the relay contacts and greatly

shorten the life of the relay.

It is best to limit flyback voltages at your inductive load by installing a flyback

diode for DC loads or a movistor for AC loads.

Terminal Blocks

Several terminal blocks with screw terminals are available for easy signal

connection to the NI 2501/2503 inputs. Refer to Appendix B, Accessories.

Software Choices

You have several options to choose from when programming your National

Instruments switch card. You can use the NI-SWITCH driver software, or

National Instruments application software.

NI-SWITCH Driver Software

The NI-SWITCH instrument driver is an Intelligent Virtual Instrument

(IVI) compliant instrument driver that is bundled with NI-SWITCH cards

at no cost.

NI-SWITCH features a set of operations and attributes that exercise all

the functionality of the switching hardware, including configuration,

opening/closing, and scanning. In addition, NI-SWITCH comes with

an interactive soft front panel and online documentation.

NI-SWITCH eliminates the need to understand complex register

programming and interrupt handling in the Microsoft operating systems,

and frees you to focus on creating your test system.

NI 2501/2503 User Manual 1-10

©

National Instruments Corporation

Page 18

Chapter 1 Routing Signals with Your NI 2501/2503

National Instruments Application Software

LabVIEW and LabWindows/CVI are innovative program development

software packages for data acquisition and control applications. LabVIEW

uses graphical programming, whereas LabWindows/CVI enhances

traditional programming languages. Both packages include extensive

libraries for data acquisition, instrument control, data analysis, and

graphical data presentation. Using LabVIEW or LabWindows/CVI can

significantly reduce the development time for your data acquisition and

control application.

LabVIEW features interactive graphics, a state-of-the-art user interface,

and a powerful graphical programming language. The LabVIEW

NI-SWITCH VI Library, a series of virtual instruments (VIs) for using

LabVIEW with National Instruments switch hardware, is included with

the NI-SWITCH driver.

LabWindows/CVI features interactive graphics, a state-of-the-art user

interface, and uses the ANSI standard C programming language. The

LabWindows/CVI NI-SWITCH Library, a series of functions for using

LabWindows/CVI with National Instruments switch hardware, is included

with the NI-SWITCH driver.

Third Party Software

The NI-SWITCH instrument driver also includes support files for

Microsoft Visual C++ and Microsoft Visual Basic. Please see the

NI-SWITCH readme file for version support information.

©

National Instruments Corporation 1-11 NI 2501/2503 User Manual

Page 19

NI 2501/2503 Operation

This chapter contains a functional overview of the NI 2501/2503

module and explains the operation of each functional unit making up

the NI 2501/2503 module.

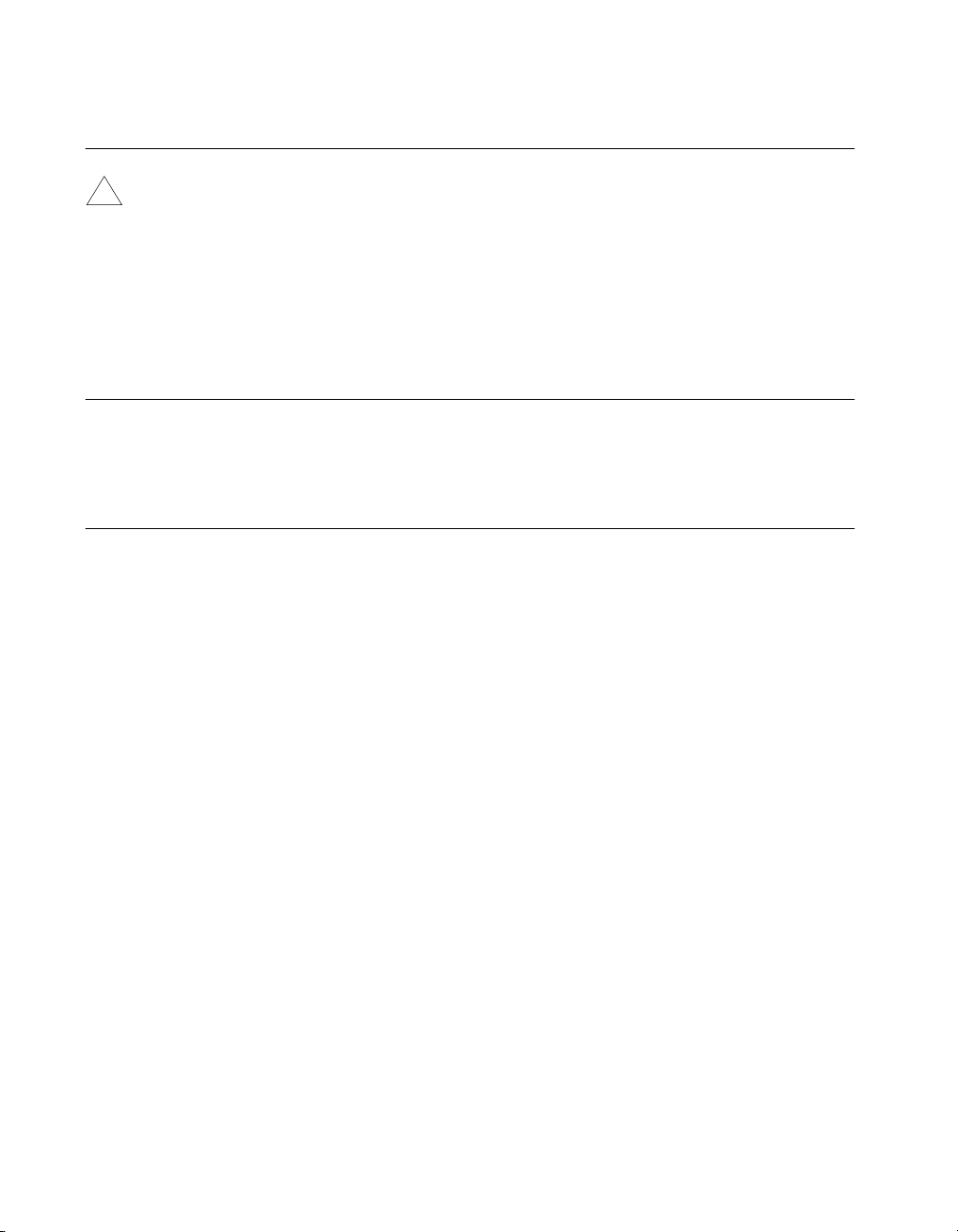

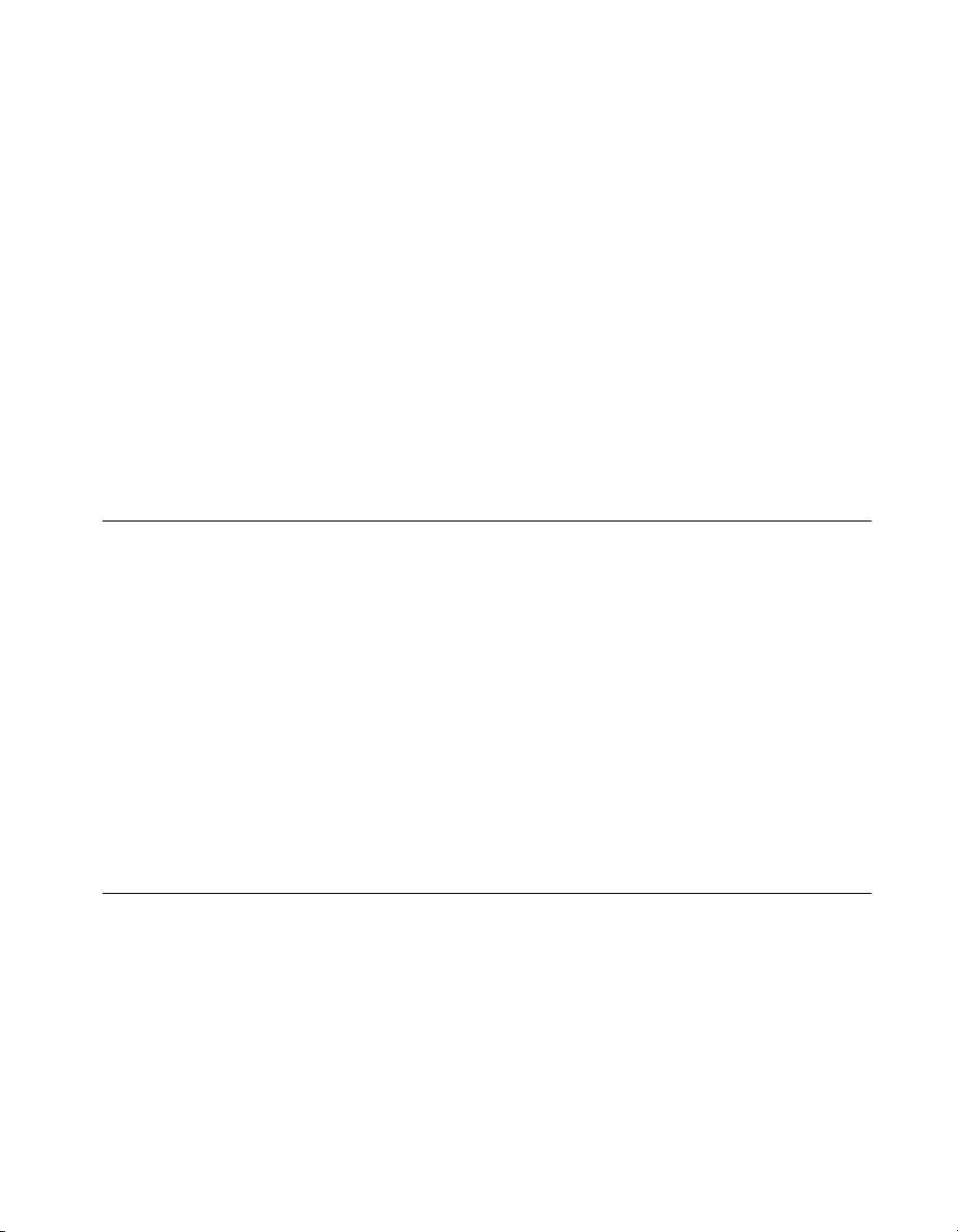

Functional Overview

The block diagrams on the following pages illustrate the key functional

components of the switch card modules. Figure 2-1 shows the NI 2501 and

Figure 2-2 shows the NI 2503.

The major components of the NI 2501/2503 modules are as follows:

• Multiplexer

• Relay/FET switch control circuitry

• Random scanning

• PXIbus interface

• Triggers

2

©

National Instruments Corporation 2-1 NI 2501/2503 User Manual

Page 20

Chapter 2 NI 2501/2503 Operation

Analog Bus0

Com0

CH0

CH5

AISENSE

Cold Junction Sensor

Com1

CH6

FET Mux

One Wire /

Two Wire

Select

FET Mux

Unity Gain

Amplifier

Select

CH11

Analog Bus1

Com2

CH12

Front Connector

CH17

Com3

CH18

CH23

FET Mux

FET Mux

FET Mux

Scan Memory

PXI Interface

PXIbus Connector

FET Switch Control

Triggers

Figure 2-1. NI 2501 Module Block Diagram

NI 2501/2503 User Manual 2-2

©

National Instruments Corporation

Page 21

Analog Bus0

Com0

CH0

CH5

AISENSE

Cold Junction Sensor

Com1

CH6

Relay Mux

Chapter 2 NI 2501/2503 Operation

One Wire /

Two Wire

Select

Relay Mux

CH11

Analog Bus1

Com2

CH12

Front Connector

CH17

Com3

CH18

CH23

Relay Mux

Relay Mux

Relay Mux

Scan Memory

PXI Interface

PXIbus Connector

Relay Control

Triggers

Figure 2-2. NI 2503 Module Block Diagram

©

National Instruments Corporation 2-3 NI 2501/2503 User Manual

Page 22

Chapter 2 NI 2501/2503 Operation

Multiplexer

The relay multiplexer consists of four banks of six channels. The switches

for the six channels in each bank connect the channels to a common output

for each bank.

• Bank 0 consists of Channels 0–5 and Common 0.

• Bank 1 consists of Channels 6–11 and Common 1.

• Bank 2 consists of Channels 12–17 and Common 2.

• Bank 3 consists of Channels 18–23 and Common 3.

Each channel connects to the corresponding bank common by closing its

relay/FET switch. You can have multiple channels connected to the bank

common at the same time. Bank connection relay/FET switches can

combine the commons of the four banks. See Appendix D, Architecture

Drawings, for illustrations of the NI 2501 and NI 2503 architecture.

The NI 2503 relays are single-side stable. When power is removed from the

relay coil, the relay returns to its de-energized state. The de-energized state

opens all the relays, disconnecting the device from external inputs and

outputs.

See Figures 1-1 through 1-4 in Chapter 1, Routing Signals with Your

NI 2501/2503, for the pin names used for the different modes of operation.

Different names are used for the pin assignments in the different modes to

better reflect the operation in the different modes and to simplify the task

of wiring.

Two-Wire Mode

Two-wire mode is the default and most common configuration for the

NI 2501/2503 switch cards. The CHx+ and CHx– channels are switched

together to the COMx+ and COMx– signals for the corresponding bank.

One-Wire Mode

One-wire mode doubles the channel count of what is available in two-wire

mode. However, the signals connected to the switch card need a common

reference. For one-wire measurements, Bank 0 includes extra relays

between the multiplexed channel relays and COM0. The 1WIRE relay

switch connects COM0– to the 1-Wire Lo Ref signal. The HLSELECT

relay connects COM0+ to either CHx+ or CHx–. The de-energized states

for these relays configure the device for two-wire measurements.

NI 2501/2503 User Manual 2-4

©

National Instruments Corporation

Page 23

Four-Wire Mode

Four-wire mode is typically used for resistance measurements. In this

mode, CHxA+, CHxA–, CHxB+, and CHxB–, are switched together to

COMxA+, COMxA–, COMxB+, and COMxB–.

Matrix Mode

By adding some external wiring, you can configure the switch card as

a two-wire 6 x 4 crosspoint matrix. (See Figure 1-4 in Chapter 1.) The

TB-2606 terminal block simplifies your wiring task by connecting the

necessary pins on the switch card’s front connector to create the 6 x 4

matrix.

In the matrix configuration, you can connect any R OWx signal to an y COLx

signal.

Switch Control Circuitry

The switch control circuitry (SCC) is responsible for opening and closing

FET switches on the NI 2501 or relays on the NI 2503. You can load

commands for the SCC into memory storage using the driver software

you received with your kit. Consult the online help or your software

documentation for specific information on the appropriate commands.

There are two reasons for storing the commands in memory before the

SCC can process them:

• The operate/release time for the NI 2503 is 3 to 5 ms. Using memory

storage, the software can send multiple commands to the SCC without

having to wait for a relay action to complete.

• The memory is used to store a scan list necessary for hardware random

scanning.

Chapter 2 NI 2501/2503 Operation

Random Scanning

The NI 2501/2503 can perform random scanning. In random scanning,

the switch card can scan the channels in any order.

The scan list is downloaded to onboard memory. Commands in the scan

list can:

• Open or close relays

• Wait for an external trigger

©

National Instruments Corporation 2-5 NI 2501/2503 User Manual

Page 24

Chapter 2 NI 2501/2503 Operation

• Generate a scanner advanced trigger

• Generate a breakpoint interrupt

Y ou can use the driv er software to configure the switch card for continuous

or one-time scanning. In continuous scanning, the switch card cycles

through the scan list until you disable scanning. For one-time scanning, the

switch card cycles through the scan list only once.

You can also use software commands to clear the scan list or reset it to the

beginning at any time.

The onboard control logic for the NI 2501/2503 switch card gives you

direct access to open and close the relays, and also the capability to

download up to 1024 random scanning instructions. The software included

with the card automatically configures the NI 2501/2503 and downloads

the scan list to hardware for you. The scan list itself downloads directly into

the memory of the card to deliver the fastest scan possible with no

controller intervention. You can configure the switch card to process the

scan list once or to continuously loop through the scan list.

When configured to operate as a single switch card with multiple

multiplexers—such as four 6 x 1 two-wire multiplexers—the scan

architecture makes it possible for each multiplexer to have its o wn parallel

scan list (which must be triggered together). Also, if the switch card is

configured as a matrix, the scanning architecture scans the matrix through

a series of user-definable states.

PXI Interface

The NI 2501/2503 switch card has a PXI interface through which you

can use your driver software to configure and control the card. The

NI 2501/2503 takes advantage of PXI features. It uses the PXI TTL triggers

to synchronize scanning with a measurement device such as a National

Instruments NI-4060 PXI digital multimeter (DMM).

Triggers

External Trigger Input

The NI 2501/2503 can use an external trigger input to advance between

scan setups in a scan list. Using the driver software, you can configure the

switch card to route the external trigger from any of the PXI TTL trigger

lines, the PXI star trigger, or the EXT TRIG IN pin on the front connector.

Alternatively, you can use a software command to trigger the switch card.

NI 2501/2503 User Manual 2-6

©

National Instruments Corporation

Page 25

Chapter 2 NI 2501/2503 Operation

Routing the external trigger from the front connector to the PXI trigger

lines gives you the capability to trigger multiple switch cards with only one

board connected to the external trigger from the measurement device.

All external trigger lines are compatible with TTL voltage levels and are

edge sensitive.

The external trigger from the front connector requires a minimum pulse

width of 500 ns. The line has a low pass filter to prevent false triggering.

The minimum pulse width from the PXI TTL triggers and PXI star trigger

is 70 ns.

Scanner Advanced

The NI 2501/2503 can generate a scanner advanced trigger to indicate

when the switch card is set up and ready to take measurements. Using the

driver software, you can configure the switch card to route the scanner

advanced (SCANADV) trigger to any PXI TTL trigger line, the PXI star

trigger, or the SCAN_ADV pin on the front connector. You can configure

the switch card to generate the SCANADV trigger when a relay has settled

(or debounced).

All SCANADV trigger lines are compatible with TTL voltage levels.

Because the NI 2501/2503 has open collector drives on the PXI TTL trigger

lines, you can have multiple switch cards using the same trigger line in the

multicard SCANADV mode.

Modes

SCANADV has two modes of operation. In its default mode, the

SCANADV trigger asserts for 1 µs after the relay has debounced. You

can also configure the switch card for handshaking mode, in which the

SCANADV trigger goes high after a relay settles, and the SCANADV

trigger goes low after the external trigger input asserts. Use this

handshaking mode for multicard scanning.

Note

©

National Instruments Corporation 2-7 NI 2501/2503 User Manual

The NI 2501/2503 ignores external triggers when it is not in a wait-for-trigger

state while scanning.

Page 26

Chapter 2 NI 2501/2503 Operation

Initiating Scanning

When you use the NI 2501/2503 to initiate a scan, make sure the

measurement device is armed (waiting for trigger) before enabling

scanning on the switch card. Enabling scanning causes the first switch(es)

in the scan list to close and generates a scanner advanced trigger after the

relay/FET switches have settled or debounced.

When you use the measurement device to initiate a scan, make sure

scanning is enabled on the NI 2501/2503 before the measurement device

starts to take measurements. This ensures that the switch card has the

correct signal routed and that the switch card is waiting for an external

trigger from the measurement device.

Always configure the triggers in a system before configuring the

measurement device or the NI 2501/2503 for scanning. When triggers are

configured, a state change or pulse could occur on the trigger line. This is

also possible when you reset the switch card.

Multicard Triggering

You can use multiple NI 2501/2503 switch cards together in conjunction

with an instrument such as a DMM. In multiple switch-card systems,

be sure to identify one switch card as the master switch card.

All other switch cards for the system are identified as slave switch cards.

The master switch card can route an external trigger from the front

connector to a PXI backplane trigger. In addition, the master switch card

can route the SCANADV trigger from the PXI backplane to the front

connector. This functionality makes it possible to wire external triggers

from/to only one switch card in the system, which simplifies the wiring

scheme.

For more information, refer to the NI-SWITCH Software User Manual.

NI 2501/2503 User Manual 2-8

©

National Instruments Corporation

Page 27

Specifications

This appendix lists the specifications for the NI 2501 and NI 2503

switch cards. These specifications are typical at 25° C unless otherwise

noted.

NI 2501

Input Characteristics

Number of Channels ..............................24

Maximum Working Voltage ..................± 10 VDC from chassis ground

Overvoltage Protection

Signals CH<0..23>, COM<0..3>

Signals AB<0..1>

A

Powered on or off ....................± 25 VDC

Powered on..............................± 25 V DC

Powered off..............................± 15 VDC

FET Switch On Resistance

Typical ............................................50 Ω

Max @ 25° C..................................85 Ω

Max @ 85° C..................................100 Ω

Total Signal Path Resistance (Channel x to Analog Bus x)

Typical ............................................1650 Ω

Maximum........................................1900 Ω

Total Signal Path Resistance (Channel x to Common x)

Typical ............................................1900 Ω

Maximum........................................2150 Ω

©

National Instruments Corporation A-1 NI 2501/2503 User Manual

Page 28

Appendix A Specifications for NI 2501

Transfer Characteristics

Channel Amplifier (Unity Gain)

Offset Voltage (Differential) ..................1.2 mV max

Cold-Junction Sensor Channel Amplifier (Unity Gain)

Offset Voltage

Maximum ........................................60 µV

Frequency Bandwidth (50 Ω source, 1 MΩ 25 pF load)

–3 dB ...............................................400 KHz

–10 dB .............................................1 MHz

Channel to Channel

Crosstalk/Isolation..................................50 dB

Dynamic Characteristics

Operating Speed

Typical.............................................25,000 cycles/s

Maximum ........................................250,000 cycles/s

Settling Time (+5 V to –5 V Step) 6 in. AB connector to PXI-MIO

0.012% Accuracy

With output buffer selected......8.5 µs

Without output buffer...............9.0 µs

0.006% Accuracy

With output buffer selected......10 µs

Without output buffer...............11.5 µs

0.0015% Accuracy

With output buffer selected......16 µs

Without output buffer...............18 µs

Settling Time (+5 V to –5 V Step) 3 m cable to PXI-MIO

0.012% Accuracy

With output buffer selected......21 µs

Without output buffer...............45 µs

NI 2501/2503 User Manual A-2

©

National Instruments Corporation

Page 29

Appendix A Specifications for NI 2501

0.006% Accuracy

With output buffer selected .....30 µs

Without output buffer..............60 µs

0.0015% Accuracy

With output buffer selected .....80 µs

Without output buffer..............160 µs

Note Settling time is greatly affected by the external wiring to the switch card. You can

improve the settling time by minimizing the wiring from the analog bus connection

to the measurement device.

PXI Bus Interface

Slave

PXI Trigger Bus

Trigger Lines..........................................8

Star Trigger............................................1

Power Requirement

+5 V

Typical............................................300 mA

+12 V

Typical............................................30 mA

–12 V

Typical............................................30 mA

Physical

Dimensions.............................................10 by 16 cm (3.9 by 6.3 in.)

Weight....................................................0.254 kg (0.56 lb.)

I/O Connector.........................................68-pin male SCSI

©

National Instruments Corporation A-3 NI 2501/2503 User Manual

Page 30

Appendix A Specifications for NI 2501

Environment

Operating Temperature........................ 0° to 50° C

Storage Temperature............................–55° to 150° C

Relative Humidity...................................5% to 90% non-condensing

Shock and Vibration

Functional Shock

MIL-T-28800E Class 3 (30 g half-sine shock pulse)

Also meets IEC 60068-2-27

Random Vibration

MIL-T-28800E, MIL-STD-810E Category 1

Operational...............................5 to 500 Hz, 0.3 g

Non-operational........................5 to 500 Hz, 2.4 g

Certifications and Compliances CE Mark Compliance

rms

rms

This product meets applicable EU directives as follows:

Safety Isolation................................low-voltage safety,

EMC Directive

Immunity..................................EN 50082-1:1992

Emissions .................................EN 55011:1991,

NI 2501/2503 User Manual A-4

EN 61010-1:1993

Group 1 Class A at 10 m

©

National Instruments Corporation

Page 31

NI 2503

Input Characteristics

Number of Relays Available

as Channels ..................................... ... ....24

Common Mode Voltage

Maximum Allowed Voltage—Differential Mode or Single ended

Maximum Switching Capacity—Differential Mode or Single ended

Maximum Switching Power per

Differential Channel or Single ended.....60 VA, 30 W

Appendix A Specifications for NI 2503

Channel to Channel.........................30 V

Channel to Earth .............................30 V

AC...................................................30 V

DC...................................................60 VDC

DC...................................................1 A @ 30 VDC

/60 VDC

rms

/60 VDC

rms

rms

Contact on Resistance (Initial)...............100 mΩ

Contact Material.....................................Gold-clad Silver Alloy

Transfer Characteristics

Thermal E.M.F. (Differential)................<2 µV

Maximum Frequency Bandwidth 50 Ω Termination

Worst case channel .........................35 MHz

©

National Instruments Corporation A-5 NI 2501/2503 User Manual

Page 32

Appendix A Specifications for NI 2503

Channel to Channel Crosstalk/Isolation

Differential........................................ .. ....50 Ω termination

Dynamic Characteristics

Maximum Operating Speed....................200 cycles/s

Relay Operate Time (@ 20° C)..............3 ms typical, 5 ms max

Relay Release Time (@ 20° C)..............1.5 ms typical, 5 ms max

Expected Life

Mechanical (@ 180 cpm)................5 × 10

Electrical at Maximum Load...........2 × 10

Frequency Crosstalk

10 KHz < –100 dB

100 KHz < –80 dB

1 MHz < –55 dB

10 MHz < –30 dB

35 MHz < –25 dB

7

operations

6

operations

PXI Bus Interface

Slave

PXI Trigger Bus

Trigger Lines ..........................................8

Star Trigger.............................................1

Power Requirement

+5 V

Typical.................................... .........370 mA

Maximum ........................................700 mA

NI 2501/2503 User Manual A-6

©

National Instruments Corporation

Page 33

Physical

Environment

Shock and Vibration

Appendix A Specifications for NI 2503

Dimensions.............................................10 by 16 cm (3.9 by 6.3 in.)

Weight....................................................0.118 kg (0.4 lb.)

I/O Connector.........................................68-pin male SCSI

Operating Temperature......................... 0° to 50° C

Storage Temperature............................–55° to 150° C

Relative Humidity..................................5% to 85% non-condensing

Functional Shock

MIL-T-28800E Class 3 (30 g half sine shock pulse)

Also meets IEC 60068-2-27

Random Vibration

MIL-T-28800E, MIL-STD-810E Category 1

Operational ..............................5 to 500 Hz, 0.3 grams

Non-operational....................... 5 to 500 Hz, 2.4 grams

Certifications and Compliances CE Mark Compliance

This product meets applicable EU directives as follows:

Safety Isolation...............................low-voltage safety,

EN 61010-1:1993

EMC Directive

Immunity .................................EN 50082-1:1992

Emissions.................................EN 55011:1991,

Group 1 Class A at 10 m

©

National Instruments Corporation A-7 NI 2501/2503 User Manual

Page 34

Accessories

This appendix lists various National Instruments products you can use with

your NI 2501/2503 module.

• The TB-2605 terminal block has screw terminal connections for all

• The TB-2606 terminal block converts the switch card to a 6 x 4

• Analog bus connectors plug into TB-2605 and TB-2606 terminal

• The TBX-68S I/O connector block is a DIN rail-mounted terminal

• SH68-68S shielded 68-conductor cable connects the NI 2501/2503 to

• The TBX-68LP and TBX-68LPR are lo w-cost termination accessories

• CA-1000 is a configurable signal conditioning enclosure. It uses the

B

channels, bank commons, analog bus, and trigger signals. Y ou can use

this card for multiplexer switching applications. The terminal block

has a temperature sensor that is used for thermocouple cold-junction

compensation.

two-wire matrix configuration. This terminal block creates the matrix

configuration by connecting channels (0, 6, 12, 18) (1, 7, 13, 19) …

(5, 11, 17, 23).

blocks. These analog bus plugs connect the analog bus of two cards

and terminate in banana plugs.

block with screw terminal connections you can use for all channels,

bank outputs, analog bus, and trigger signals. You can use this card

for multiplexer switching applications. The terminal block has a

temperature sensor that is used for thermocouple cold-junction

compensation. This is connected to the switch card through the

SH68-68S cable.

the TBX-68S, TBX-68LP, or TBX-68LPR.

with 68 screw terminals.

TBX-68LPR terminal block.

Contact National Instruments for more specific information about these

products.

©

National Instruments Corporation B-1 NI 2501/2503 User Manual

Page 35

Customizing Your Card

This appendix describes options for customizing your NI 2501/2503 card.

Current-Loop Receivers

The NI 2501/2503 modules have sockets for transforming individual

channels to current-to-voltage converters. National Instruments offers

a process-current pack of four 249 Ω, 0.1%, 5 ppm, 0.25 W resistors.

The reference designator format for the current-loop resistors is such that

for input channel x, the resistor is RCLx. For example, the resistor for

channel 14 is RCL14.

C

Caution

!

Before installing the resistors in your module, make sure that no signals are

connected to your module front connector.

Before installing your module in the PXI chassis, you must install the

resistors by performing the following steps:

1. Ground yourself via a grounding strap or a ground connected to

your PXI chassis. Properly grounding yourself prevents damage to

your PXI module from electrostatic discharge.

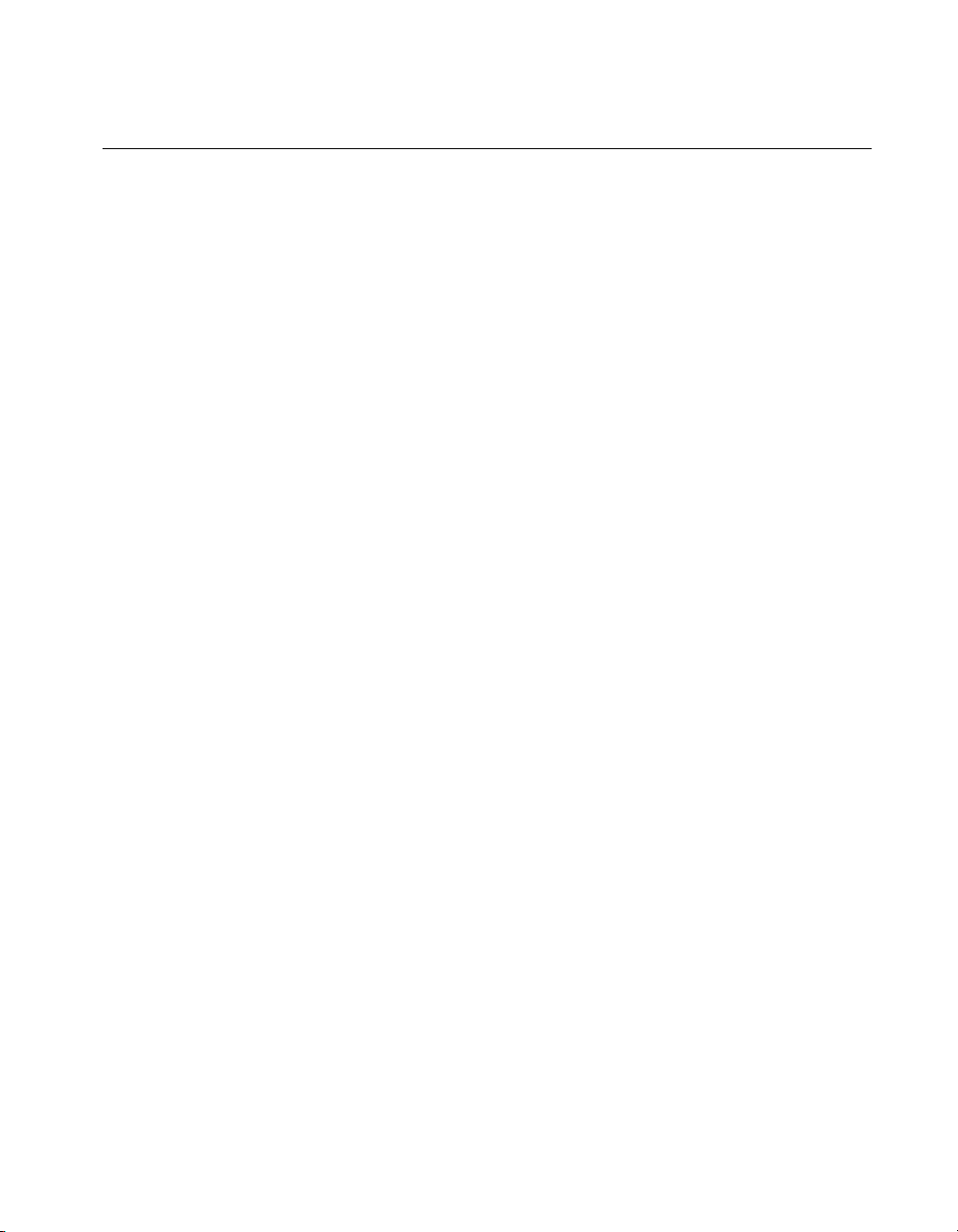

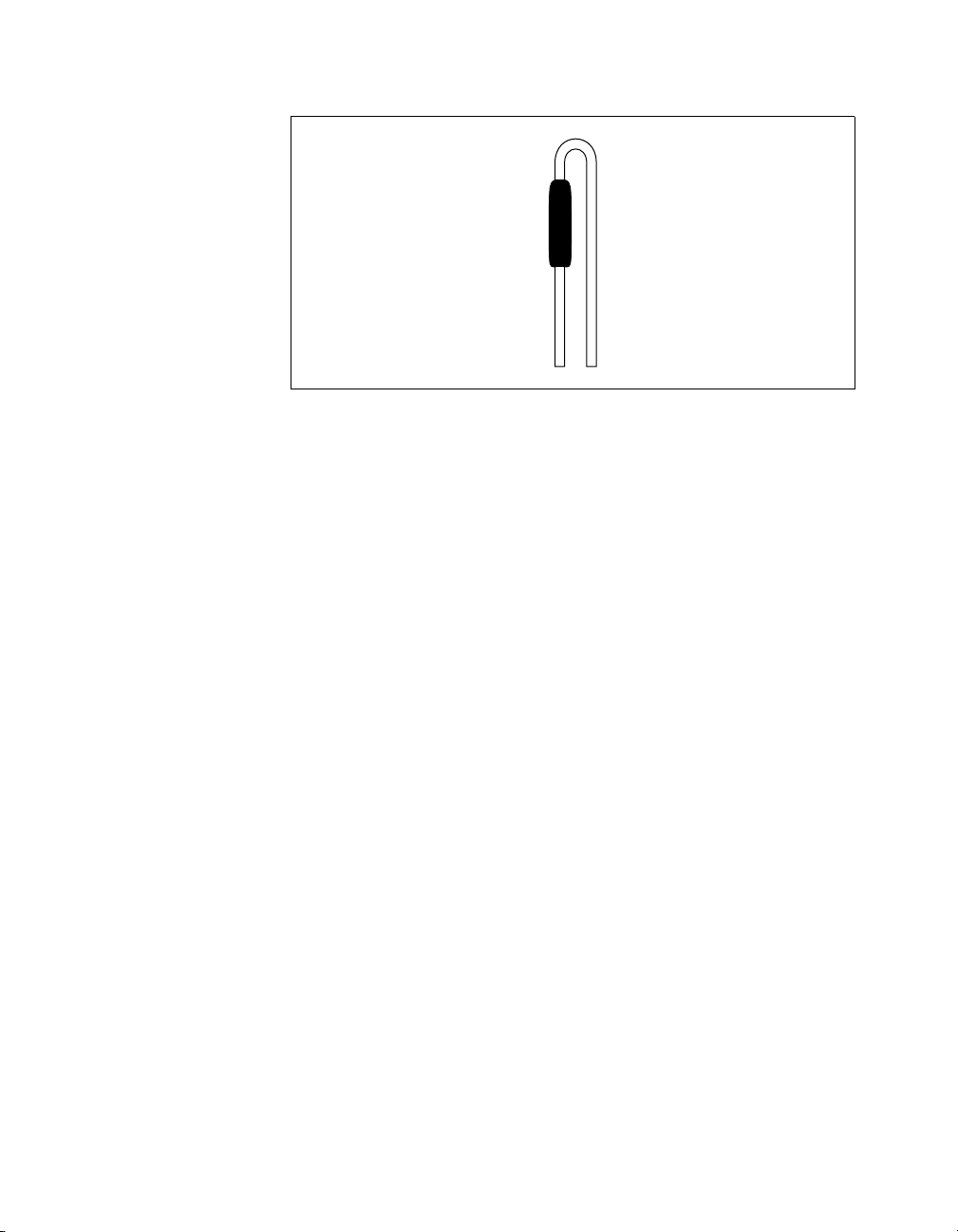

2. Bend and trim the resistor lead as shown in Figure C-1. Be sure that

the resistor does not extend more than 0.5 in. above the surface of the

circuit board.

3. Insert the resistor into the appropriate socket, labeled RCLx.

©

National Instruments Corporation C-1 NI 2501/2503 User Manual

Page 36

Appendix C Customizing Your Card

Figure C-1. Bent and Trimmed Resistor

NI 2501/2503 User Manual C-2

©

National Instruments Corporation

Page 37

Architecture Drawings

This appendix contains architecture drawings for the NI 2501 and NI 2503

switch cards. The drawings show the signal names that are used when the

boards are in two-wire mode. To make these drawings relevant for

one-wire mode, four-wire mode, or 6 x 4 matrix mode, use the signal names

shown in Figures 1-2 through 1-4, respectively, in Chapter 1, Routing

Signals with Your NI 2501/2503.

Relay or switch names are based on the signal names where applicable. For

example, the switch that connects CH9+ to COM1 and CH9– to COM1– is

named CH9.

For the other configuration relays, the names are as follows:

• For the relays that connect banks, the switch name is BCx-y, where

x and y are the bank numbers that are being connected.

• For the relay that switches 1-Wire Lo Ref to COM0–, the name is

1WIRE.

• For the relay that switches CHx+ or CHx– to COM0+, the name is

HLSELECT.

• F or the Amp Select switches (NI 2501 only), the names are AMP0 and

AMP1.

D

©

National Instruments Corporation D-1 NI 2501/2503 User Manual

Page 38

Appendix D Architecture Drawings

COM1+

COM1–

AB0

AB0+

AB0–

COM0+

COM0–

AB1+

AB1–

COM2+

COM2–

COM3+

COM3–

AMP1

AB1

AMP0

BC01

HLSELECT

1WIRE

BC02

BC23

CH11+

CH11–

CH10+

CH10–

CH9+

CH9–

CH8+

CH8–

CH7+

CH7–

CH6+

CH6–

CH5+

CH5–

CH4+

CH4–

CH3+

CH3–

CH2+

CH2–

CH1+

CH1–

CH0+

CH0–

1-Wire Lo Ref

CJS+

CJS–

CH12+

CH12–

CH13+

CH13–

CH14+

CH14–

CH15+

CH15–

CH16+

CH16–

CH17+

CH17–

CH18+

CH18–

CH19+

CH19–

CH20+

CH20–

CH21+

CH21–

CH22+

CH22–

CH23+

CH23–

Bank1

Bank0

Bank2

Bank3

Figure D-1. NI 2501 Switch Architecture

NI 2501/2503 User Manual D-2

©

National Instruments Corporation

Page 39

COM1+

COM1–

AB0+

AB0–

COM0+

COM0–

AB1+

AB1–

COM2+

COM2–

COM3+

COM3–

AB0

AB1

HLSELECT

1WIRE

BC01

BC02

BC23

Appendix D Architecture Drawings

CH11+

CH11–

CH10+

CH10–

CH9+

CH9–

CH8+

CH8–

CH7+

CH7–

CH6+

CH6–

CH5+

CH5–

CH4+

CH4–

CH3+

CH3–

CH2+

CH2–

CH1+

CH1–

CH0+

CH0–

1-Wire Lo Ref

CJS+

CJS–

CH12+

CH12–

CH13+

CH13–

CH14+

CH14–

CH15+

CH15–

CH16+

CH16–

CH17+

CH17–

CH18+

CH18–

CH19+

CH19–

CH20+

CH20–

CH21+

CH21–

CH22+

CH22–

CH23+

CH23–

Bank1

Bank0

Bank2

Bank3

Figure D-2. NI 2503 Switch Architecture

©

National Instruments Corporation D-3 NI 2501/2503 User Manual

Page 40

Common Questions

This appendix addresses common questions you may have while using

your NI 2501 or NI 2503 switch card.

How fast can I scan with the NI 2501 switch card?

The NI 2501 can be scanned as fast as 250 Kscans/s. However, at faster

scan rates, the accuracy of the card declines due to the settling time of the

card. National Instruments recommends you set the scan rate to allow for

enough settling time to ensure the desired accuracy.

How fast can I scan with the NI 2503 switch card?

The NI 2503 uses relays that have typical operate and release times of 3 ms.

In addition to the operate and release times, the NI 2503 also requires from

0.5 to 1.0 ms for the relay contacts to stop bouncing. The combination of

these two times are known as debounce time. The default debounce time for

the NI 2503 switch card is set to just under 5 ms. This set tin g allows the

card to be scanned at 200 scans/s. However, if the software implements

break-before-make, this would reduce the scan rate to 100 scans/s.

Typically , when using a DMM to make accurate measurements, the DMM

requires hundreds of ms. Consequently, the DMM becomes the limiting

factor in determining the scan rate.

E

What should I do if the software detects th e board b u t the swit ches do

not switch?

• Verify that the switches do not switch. Close your application program

and then launch the soft front panel as described in the Setup and Test

document you received with your kit. The soft front panel shows the

state of each relay or FET switch on the board. Try closing and opening

the switches.

• Also be sure to check the return codes of the NI-SWITCH operation to

ensure that there are no errors (negative value) or warnings (positive

value). You can also use the NI-Spy utility to check for error codes.

©

National Instruments Corporation E-1 NI 2501/2503 User Manual

Page 41

Appendix E Common Questions

• Finally, verify that your code is correct. For reference, see the

examples described in the NI-SWITCH Software User Manual. The

NI-SWITCH driver also ships with several examples in source code.

Compare your algorithm to the ones in the examples.

What should I do if scanning does not work?

• First, ensure that you have configured the switch card and the

instrument to match trigger lines. The output trigger of the instrument

should connect to the trigger input of the switch card. In addition, the

scanner advanced trigger of the switch card should be connected to the

input trigger of the instrument.

• If the switch card is used to initiate the scan, make sure the DMM is

waiting for a trigger before enabling scanning on the switch card. This

is the recommended method for hardware scanning.

• If the DMM is used to initiate the scan, enable scanning on the switch

card before configuring the DMM to start taking measurements.

• Also be sure to check the return codes of the NI-SWITCH operation to

ensure that there are no errors (negative value) or warnings (positive

value). You can also use the NI-Spy utility to check for error codes.

• Finally, verify that your code is correct. For reference, see the

examples described in the NI-SWITCH Software User Manual. The

NI-SWITCH driver also ships with several examples in source code.

Compare your algorithm to the ones in the examples.

Do I need to program the switch card myself?

The NI 2501/2503 comes with the NI-SWITCH driver software, which

exports the full functionality of the card. NI-SWITCH handles the complex

issues of direct memory access, interrupts, and operating system

interfacing.

NI 2501/2503 User Manual E-2

©

National Instruments Corporation

Page 42

F

Customer Communication

For your convenience, this appendix contains forms to help you gather the information necessary

to help us solve your technical problems and a form you can use to comment on the product

documentation. When you contact us, we need the information on the Technical Support Form and

the configuration form, if your manual contains one, about your system configuration to answer your

questions as quickly as possible.

National Instruments has technical assistance through electronic, fax, and telephone systems to quickly

provide the information you need. Our electronic services include a bulletin board service, an FTP site,

a fax-on-demand system, and e-mail support. If you have a hardware or software problem, first try

the electronic support systems. If the information available on these systems does not answer your

questions, we offer fax and telephone support through our technical support centers, which are staffed

by applications engineers.

Electronic Services

Bulletin Board Support

National Instruments has BBS and FTP sites dedicated for 24-hour support with a collection of files

and documents to answer most common customer questions. From these sites, you can also download

the latest instrument drivers, updates, and example programs. For recorded instructions on how to use

the bulletin board and FTP services and for BBS automated information, call 512 795 6990. You can

access these services at:

United States: 512 794 5422

Up to 14,400 baud, 8 data bits, 1 stop bit, no parity

United Kingdom: 01635 551422

Up to 9,600 baud, 8 data bits, 1 stop bit, no parity

France: 01 48 65 15 59

Up to 9,600 baud, 8 data bits, 1 stop bit, no parity

FTP Support

To access our FTP site, log on to our Internet host, ftp.natinst.com, as anonymous and use

your Internet address, such as

documents are located in the

©

National Instruments Corporation F-1 NI 2501/2503 User Manual

joesmith@anywhere.com, as your password. The support files and

/support directories.

Page 43

Fax-on-Demand Support

Fax-on-Demand is a 24-hour information retrieval system containing a library of documents on a wide

range of technical information. You can access Fax-on-Demand from a touch-tone telephone at

512 418 1111.

E-Mail Support (Currently USA Only)

You can submit technical support questions to the applications engineering team through e-mail at the

Internet address listed below . Remember to include your name, address, and phone number so we can

contact you with solutions and suggestions.

support@natinst.com

Telephone and Fax Support

National Instruments has branch offices all over the world. Use the list below to find the technical

support number for your country. If there is no National Instruments office in your country, contact

the source from which you purchased your software to obtain support.

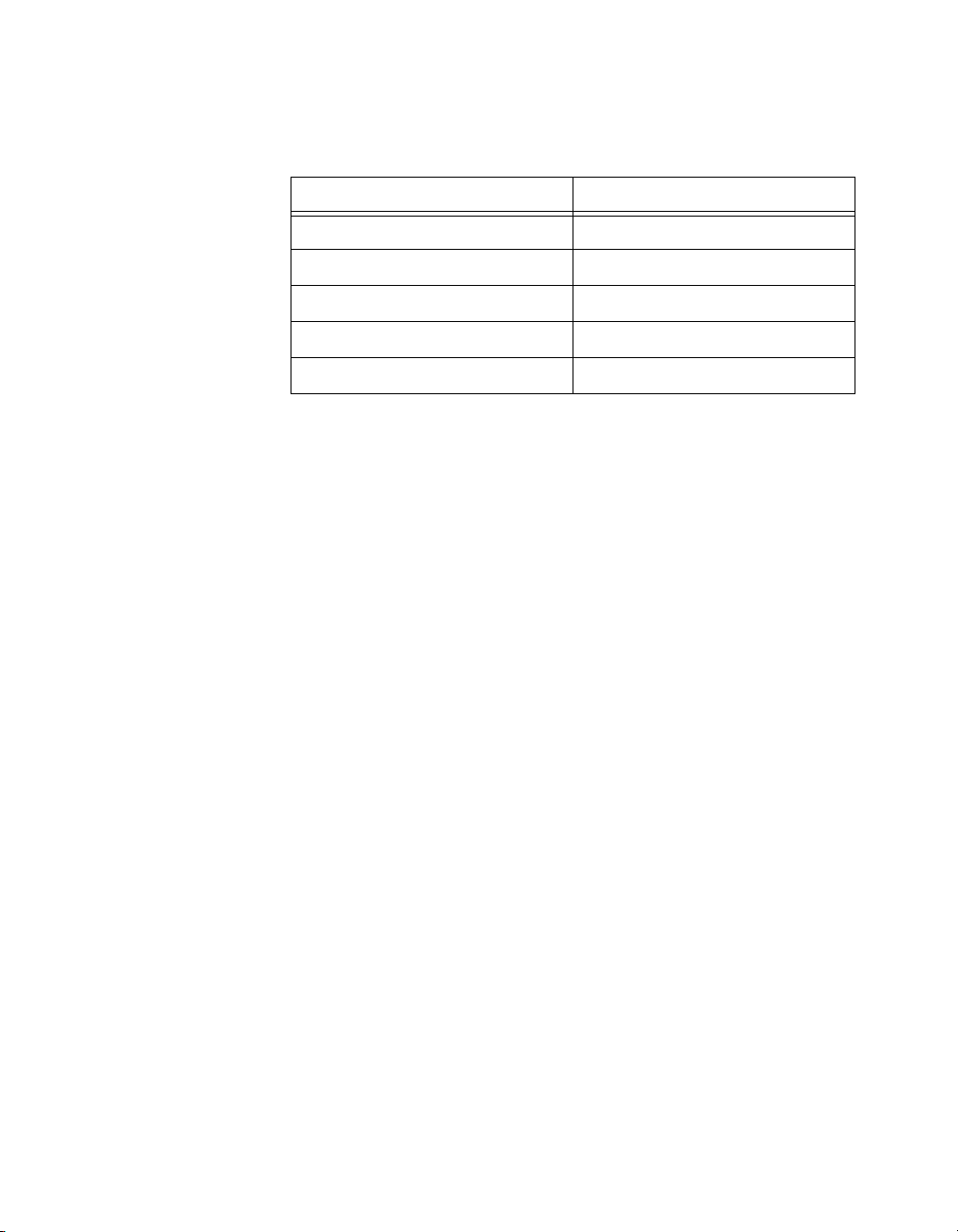

Country Telephone Fax

Australia 03 9879 5166 03 9879 6277

Austria 0662 45 79 90 0 0662 45 79 90 19

Belgium 02 757 00 20 02 757 03 11

Brazil 011 288 3336 011 288 8528

Canada (Ontario) 905 785 0085 905 785 0086

Québec

Canada (

Denmark 45 76 26 00 45 76 26 02

Finland 09 725 725 11 09 725 725 55

France 01 48 14 24 24 01 48 14 24 14

Germany 089 741 31 30 089 714 60 35

Hong Kong 2645 3186 2686 8505

Israel 03 6120092 03 612009 5

Italy 02 413091 02 41309215

Japan 03 5472 2970 03 5472 2977

Korea 02 596 7456 02 596 7455

Mexico 5 520 2635 5 520 3282

Netherlands 0348 433466 0348 430673

Norway 32 84 84 00 32 84 86 00

Singapore 2265886 2265887

Spain 91 640 0085 91 640 0533

Sweden 08 730 49 70 08 730 43 70

Switzerland 056 200 51 51 056 200 51 55

Taiwan 02 377 1200 02 737 4644

United Kingdom 01635 523545 01635 523154

United States 512 795 8248 512 794 5678

) 514 694 8521 514 694 4399

NI 2501/2503 User Manual F-2

©

National Instruments Corporation

Page 44

Technical Support Form

Photocopy this form and update it each time you make changes to your software or hardware, and use

the completed copy of this form as a reference for your current configuration. Completing this form

accurately before contacting National Instruments for technical support helps our applications

engineers answer your questions more efficiently.

If you are using any National Instruments hardware or software products related to this problem,

include the configuration forms from their user manuals. Include additional pages if necessary.

Name __________________________________________ ________________________________

Company _______________________________________________________________________

Address ________________________________________________________________________

______________________________________________________________________________ _

Fax ( ___ ) ________________Phone ( ___ ) __________________________________________

Computer brand____________ Mod e l ___________________Processor _____________________

Operating system (include version number) _________________________________ ___________

Clock speed ______MHz RAM _____MB Display adapter __________________________

Mouse ___yes ___no Other adapters installed_______________________________________

Hard disk capacity _____MB Brand_________________________________________________

Instruments used _____________________________________ ____________________________

______________________________________________________________________________ _

National Instruments hardware product model_____________ Revision ____________________

Configuration ______________ _____________________________________________________

National Instruments software product ________________ ___ Version _____________________

Configuration ______________ _____________________________________________________

The problem is: __________________________________________________________________

_______________________________________________________________________________

_______________________________________________________________________________

_______________________________________________________________________________

_______________________________________________________________________________

List any error messages: ___ _________________________________________ _______________

______________________________________________________________________________ _

______________________________________________________________________________ _

The following steps reproduce the problem: ___________________________________________

______________________________________________________________________________ _

______________________________________________________________________________ _

______________________________________________________________________________ _

______________________________________________________________________________ _

Page 45

NI 2501/2503 Hardware and Software

Configuration Form

Record the settings and revisions of your hardware and software on the line to the right of each item.

Complete a new copy of this form each time you re vise your softw are or hardw are configuration, and

use this form as a reference for your current configuration. Completing this form accurately before

contacting National Instruments for technical support helps our applications engineers answer your

questions more efficiently.

National Instruments Products

Using NI 2501 or NI 2503?___________________________________ ______________________

Hardware revision ___________ __________________________________________ ___________

Switching mode_______________________________ ___________________________________

List National Instruments Software Installed and Version

NI-SWITCH version ______________________________________________________________

LabVIEW version ________________________________________________________________

LabWindows/CVI version __________________________________________________________

Other National Instruments software version _______________ _____________________________

______________________________________________________________________________ __

Programming choice _______________________________________________________________

Other Products

PXI Chassis make and model ____________________ ___________________________________

Microprocessor ______________________________________ ____________________________

Clock frequency or speed __________________________________________________________

Type of video board installed ____________________ ___________________________________

Operating system version __________________________________________________________

Operating system mode___________ _________________________________________ ________

Programming language ___________________________________________________________ _

Programming language version___________________________________________ ___________

Switch accessories________________________________________________________________

_______________________________________________________________________________

Instruments connected to switch ___________ _________________________________________ _

______________________________________________________________________________ _

Page 46

List All Boards in PXI Mainframe

PXI Slot Manufacturer, Description, and Function

1

2

3

4

5

6

7

8

Page 47

Documentation Comment Form

National Instruments encourages you to comment on the documentation supplied with our products.

This information helps us provide quality products to meet your needs.

Title: NI 2501/2503 User Manual

Edition Date:July 1998

Part Number:

Please comment on the completeness, clarity, and organization of the manual.

______________________________________________________________________________ _

______________________________________________________________________________ _

______________________________________________________________________________ _

______________________________________________________________________________ _

______________________________________________________________________________ _

______________________________________________________________________________ _

______________________________________________________________________________ _

If you find errors in the manual, please record the page numbers and describe the errors.

______________________________________________________________________________ _

______________________________________________________________________________ _