Page 1

NI-DAQ™ Function

Reference Manual

for PC Compatibles

Version 6.1

Data Acquisition Software for the PC

NI-DAQ FRM for PC Compatibles

April 1998 Edition

Part Number 321645C-01

© Copyright 1991, 1998 National Instruments Corporation. All rights reserved.

Page 2

Internet Support

E-mail: support@natinst.com

FTP Site: ftp.natinst.com

Web Address: www.natinst.com

Bulletin Board Support

BBS United States: 512 794 5422

BBS United Kingdom : 01635 551422

BBS France: 01 48 65 15 59

Fax-on-Demand Support

512 418 1111

Telephone Support (USA)

Tel: 512 795 8248

Fax: 512 794 5678

International Offices

Australia 03 9879 5166, Austria 0662 45 79 90 0, Belgium 02 757 00 20, Brazi l 011 288 3336,

Canada (Ontario) 905 785 0085, Canada (Québec) 514 694 8521, Denmark45 76 26 00,

Finland 09 725 7 25 11, France 01 48 14 24 24, Germany 089 741 31 30, Hong Kong 2645 3186,

Israel 03 6120092, Italy 02 413091, Japan 03 5472 2970, Korea 02 596 7456, Mexico 5 520 2635,

Netherlands 0348 433466, Norway 32 84 84 00, Singapore 2265886, Spain 91 640 0085, Sweden 08 730 49 70,

Switzerland 056 200 51 51, Taiwan 02 377 1200, United Kingdom 01635 523545

National Instruments Corporate Headquarters

6504 Bridge Point Parkway Austin, Texas 78730-5039 USA Tel: 512 794 0100

Page 3

Important Information

Warranty

The media on which you receive National Instruments software are warranted not to fail to execute programming

instructions, due to defects in materials and workmanship, for a period of 90 days from date of shipment, as evidenced

by receipts or other documentation. National Instruments will, at its option, repair or replace software media that do not

execute programming instructions if National Instruments receives notice of such defects during the warranty period.

National Instruments does not warrant that the operation of the software shall be uninterrupted or error free.

A Return Material Autho rization (RMA) number must be obtained from the factory a nd clearly marked on the ou ts ide of

the package before any equipment will be accepted for warranty work. National Instruments will pay the shipping costs

of returning to the owner parts which are covered by warranty.

National Instruments believes that the informatio n in this manual is accurate. The docume nt has been ca refully review ed

for technical accurac y. In th e even t that te ch nical o r typograp hic al errors exis t, Nation al Inst ruments rese rves th e right to

make changes to subsequent editions of this document without prior notice to holders of this edition. The reader should

consult National Instruments if errors are suspected. In no event shall National Instruments be liable for any damages

arising out of or related to this document or the information contained in it.

E

XCEPT AS SPECIFIED HEREIN

SPECIFICALLY DISCLAIMS ANY WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE

RIGHT TO RECOVER DAMAGES CAUSED BY FAULT OR NEGLIGENCE ON THE PART OF NATIONAL INSTRUMENTS SHALL BE

LIMITED TO THE AMOUNT THERETOFORE PAID BY THE CUSTOMER

DAMAGES RESULTING FROM LOSS OF DATA, PROFITS, USE OF PRODUCTS, OR INCIDENTAL OR CONSEQUENTIAL DAMAGES

EVEN IF ADVISED OF THE POSSIBILITY THEREOF

regardless of the form of action, wheth er in contrac t or tort, inc luding neglig ence. Any ac tion against N ational Inst ruments

must be brought within one year after the cause of action accrues. National Instruments shall not be liable for any delay

in performance due to causes beyond its reasonable control. The warranty provided herein does not cover damages,

defects, malfunctions, or service failures caused by owner’s failure to follow the National Instruments installation,

operation, or maintenance instructions; owner’s modification of the product; owner’s abuse, misuse, or negligent acts;

and power failure or surges, fire, flood, accident, actions of third parties, or other events outside reasonable control.

, N

ATIONAL INSTRUMENTS MAKES NO WARRANTIES, EXPRESS OR IMPLIED, AND

. This limitation of the liability of National Instruments will apply

. C

USTOMER’S

. N

ATIONAL INSTRUMENTS WILL NOT BE LIABLE FOR

,

Copyright

Under the copyright laws, this publication may not be reproduced or transmitted in any form, electronic or mechanical,

including photocopyi ng, recordi ng, st oring in an info rmation ret riev al syste m, or translating , in whole or in part, wit hout

the prior written consent of National Instruments Corporation.

Trademarks

CVI™, DAQArb™, DAQCard™, DAQ Designer™, DAQPad™, DAQ-PnP™, DAQ-STC™, DAQWare™,

LabVIEW™, NI-DAQ™, NI-DSP™, NI-PGIA™, RTSI™, and SCXI™ are trademarks of National Instruments

Corporation.

Product and company names referenced in this document are trademarks or trade names of their respective companies.

WARNING REGARDING MEDICAL AND CLINICAL USE OF NATIONAL INSTRUMENTS PRODUCTS

National Instruments products are not designed with components and testing intended to ensure a level of reliability

suitable for use in treatment and diagnosis of humans. Applications of National Instruments products involving medical

or clinical treatment can create a potential for accidental injury caused by product failure, or by errors on the part of the

user or application des igner. Any us e or ap plica tion of Na tiona l Instrum ents pr oducts for or inv olving m edi cal or clin ica l

treatment must be performed by properly trai ned and qualifi ed medic al pe rsonne l, and al l tra ditiona l medic al safegu ards,

equipment, and procedu res that are appropriate in the particula r situation to prevent serious injury or dea th should al ways

continue to be used when Natio nal Instrume nts products are being use d. National In struments prod ucts are N OT intended

to be a substitute for any form of establis hed process, procedure, or e quipment us ed to monit or or safeguard human heal th

and safety in medical or clinical treatment.

Page 4

About This Manual

How to Use the NI-DAQ Manual Set..............................................................................xiii

Organization of This Manual................................................ ...... .....................................xiii

Conventions Used in This Manual...................................................................................xiv

MIO and AI Device Terminology.....................................................................xvii

About the National Instruments Documentation Set.......................................................xix

Related Documentation....................................................................................................xx

Customer Communication............................................................................................ ...xx

Chapter 1

Using the NI-DAQ Functions

Status Codes, Device Numbers, and SCXI Chassis IDs..................................................1-1

Variable Data Types ........................................................................................................1-2

Primary Types ...................................................................................................1-2

Arrays................................................................................................................1-3

Multiple Types............................ ...... ..... ............................................................1-3

Programming Language Considerations..........................................................................1-4

Borland Delphi..................................................................................................1-4

Visual Basic for Windows.................................................................................1-4

NI-DAQ Constants Include File .........................................................1-5

NI-DAQ for LabWindows/CVI.......................................................................................1-5

Contents

Chapter 2

Function Reference

AI_Change_Parameter..................................................................................................... 2-1

AI_Check.........................................................................................................................2-3

AI_Clear...........................................................................................................................2-5

AI_Configure...................................................................................................................2-6

AI_Mux_Config...............................................................................................................2-10

AI_Read...........................................................................................................................2-12

AI_Read_Scan ................................................................................................................. 2-14

AI_Setup..........................................................................................................................2-15

AI_VRead........................................................................................................................2-17

AI_VRead_Scan ..............................................................................................................2-19

©

National Instruments Corporation v NI-DAQ FRM for PC Compatibles

Page 5

Contents

AI_VScale .......................................................................................................................2-20

Align_DMA_Buffer........................................................................................................2-22

AO_Calibrate...................................................................................................................2-25

AO_Change_Parameter ...................................................................................................2-27

AO_Configure.................................................................................................................2-38

AO_Update......................................................................................................................2-42

AO_VScale......................................................................................................................2-43

AO_VWrite .....................................................................................................................2-45

AO_Write........................................................................................................................2-47

Calibrate_1200 ................................................................................................................2-49

Calibrate_DSA ................................................................................................................2-55

Calibrate_E_Series..........................................................................................................2-58

Config_Alarm_Deadband................................................................................................2-63

Config_ATrig_Event_Message.......................................................................................2-67

Config_DAQ_Event_Message........................................................................................2-71

Configure_HW_Analog_Trigger....................................................................................2-83

CTR_Config....................................................................................................................2-90

CTR_EvCount.................................................................................................................2-92

CTR_EvRead...................................................................................................................2-94

CTR_FOUT_Config........................................................................................................2-96

CTR_Period.....................................................................................................................2-98

CTR_Pulse.......................................................................................................................2-100

CTR_Rate........................................................................................................................2-104

CTR_Reset ...................................................................................................................... 2-106

CTR_Restart....................................................................................................................2-107

CTR_Simul_Op...............................................................................................................2-108

CTR_Square....................................................................................................................2-110

CTR_State .......................................................................................................................2-113

CTR_Stop........................................................................................................................2-114

DAQ_Check....................................................................................................................2-115

DAQ_Clear......................................................................................................................2-117

DAQ_Config ...................................................................................................................2-118

DAQ_DB_Config............................................................................................................2-121

DAQ_DB_HalfReady......................................................................................................2-122

DAQ_DB_Transfer .........................................................................................................2-124

DAQ_Monitor .................................................................................................................2-126

DAQ_Op..........................................................................................................................2-129

DAQ_Rate.......................................................................................................................2-132

DAQ_Set_Clock..............................................................................................................2-134

DAQ_Start.......................................................................................................................2-136

DAQ_StopTrigger_Config..............................................................................................2-140

DAQ_to_Disk..................................................................................................................2-142

DAQ_VScale...................................................................................................................2-145

NI-DAQ FRM for PC Compatibles vi

©

National Instruments Corporation

Page 6

Contents

DIG_Block_Check........................................................................................................... 2-147

DIG_Block_Clear............................................................................................................2-148

DIG_Block_In .................................................................................................................2-149

DIG_Block_Out...............................................................................................................2-152

DIG_Block_PG_Config...................................................................................................2-154

DIG_DB_Config..............................................................................................................2-158

DIG_DB_HalfReady ....................................................................................................... 2-160

DIG_DB_Transfer...........................................................................................................2-162

DIG_Grp_Config.............................................................................................................2-164

DIG_Grp_Mode...............................................................................................................2-166

DIG_Grp_Status ..............................................................................................................2-169

DIG_In_Grp .....................................................................................................................2-171

DIG_In_Line....................................................................................................................2-173

DIG_In_Port .................................................................................................................... 2-175

DIG_Line_Config............................................................................................................ 2-177

DIG_Out_Grp..................................................................................................................2-178

DIG_Out_Line.................................................................................................................2-179

DIG_Out_Port..................................................................................................................2-181

DIG_Prt_Config...............................................................................................................2-183

DIG_Prt_Status................................................................................................................ 2-186

DIG_SCAN_Setup...........................................................................................................2-188

DIG_Trigger_Config.......................................................................................................2-192

Get_DAQ_Device_Info...................................................................................................2-195

Get_NI_DAQ_Version....................................................................................................2-197

GPCTR_Change_Parameter............................................................................................ 2-198

GPCTR_Config_Buffer...................................................................................................2-209

GPCTR_Control ..............................................................................................................2-211

GPCTR_Read_Buffer......................................................................................................2-213

GPCTR_Set_Application.................................................................................................2-215

GPCTR_Watch................................................................................................................2-245

ICTR_Read......................................................................................................................2-248

ICTR_Reset .....................................................................................................................2-250

ICTR_Setup.....................................................................................................................2-251

Init_DA_Brds...................................................................................................................2-255

Lab_ISCAN_Check.........................................................................................................2-263

Lab_ISCAN_Op ..............................................................................................................2-266

Lab_ISCAN_Start............................................................................................................2-270

Lab_ISCAN_to_Disk.......................................................................................................2-274

Line_Change_Attribute ...................................................................................................2-277

LPM16_Calibrate............................................................................................................. 2-279

MIO_Calibrate.................................................................................................................2-280

MIO_Config.....................................................................................................................2-284

RTSI_Clear......................................................................................................................2-286

©

National Instruments Corporation vii NI-DAQ FRM for PC Compatibles

Page 7

Contents

RTSI_Clock .....................................................................................................................2-287

RTSI_Conn......................................................................................................................2-289

RTSI_DisConn................................................................................................................2-291

SC_2040_Config.............................................................................................................2-292

SCAN_Demux................................................................................................................. 2-294

SCAN_Op........................................................................................................................2-296

SCAN_Sequence_Demux...............................................................................................2-300

SCAN_Sequence_Retrieve.............................................................................................. 2-303

SCAN_Sequence_Setup..................................................................................................2-304

SCAN_Setup ...................................................................................................................2-307

SCAN_Start .....................................................................................................................2-309

SCAN_to_Disk................................................................................................................2-315

SCXI_AO_Write.............................................................................................................2-319

SCXI_Cal_Constants....................................................................................................... 2-322

SCXI_Calibrate_Setup....................................................................................................2-330

SCXI_Change_Chan.......................................................................................................2-332

SCXI_Configure_Filter...................................................................................................2-333

SCXI_Get_Chassis_Info.................................................................................................2-336

SCXI_Get_Module_Info.................................................................................................2-338

SCXI_Get_State..............................................................................................................2-340

SCXI_Get_Status ............................................................................................................2-342

SCXI_Load_Config.........................................................................................................2-344

SCXI_ModuleID_Read...................................................................................................2-345

SCXI_MuxCtr_Setup......................................................................................................2-347

SCXI_Reset.....................................................................................................................2-349

SCXI_Scale .....................................................................................................................2-352

SCXI_SCAN_Setup........................................................................................................2-355

SCXI_Set_Config............................................................................................................2-357

SCXI_Set_Gain...............................................................................................................2-360

SCXI_Set_Input_Mode...................................................................................................2-361

SCXI_Set_State ...............................................................................................................2-362

SCXI_Set_Threshold.......................................................................................................2-364

SCXI_Single_Chan_Setup..............................................................................................2-366

SCXI_Track_Hold_Control ............................................................................................2-367

SCXI_Track_Hold_Setup................................................................................................2-368

Select_Signal...................................................................................................................2-372

Set_DAQ_Device_Info ...................................................................................................2-389

Timeout_Config ..............................................................................................................2-400

WFM_Chan_Control.......................................................................................................2-402

WFM_Check ...................................................................................................................2-404

WFM_ClockRate.............................................................................................................2-406

WFM_DB_Config...........................................................................................................2-411

WFM_DB_HalfReady.....................................................................................................2-413

NI-DAQ FRM for PC Compatibles viii

©

National Instruments Corporation

Page 8

WFM_DB_Transfer.........................................................................................................2-415

WFM_from_Disk............................................................................................................. 2-417

WFM_Group_Control .....................................................................................................2-420

WFM_Group_Setup......................................................................................................... 2-423

WFM_Load......................................................................................................................2-425

WFM_Op.........................................................................................................................2-434

WFM_Rate.......................................................................................................................2-437

WFM_Scale .....................................................................................................................2-439

WFM_Set_Clock............................................................................................................. 2-441

Appendix A

Status Codes

Appendix B

Analog Input Channel, Gain Settings, and Voltage Calculation

DAQ Device Analog Input Channel Settings..................................................................B-1

Valid Internal Analog Input Channels......................................................... ..... ...... .........B-2

DAQ Device Gain Settings..............................................................................................B-5

Voltage Calculation .........................................................................................................B-5

Offset and Gain Adjustment............................................................................................B-7

Measurement of Offset......................................................................................B-7

Measurement of Gain Adjustment.....................................................................B-7

Contents

Appendix C

NI-DAQ Function Support

Appendix D

Customer Communication

Glossary

Index

Figures

Figure 2-1. High Alarm Deadband.............................................................................2-65

Figure 2-2. Low Alarm Deadband.............................................................................2-66

Figure 2-3. Analog Trigger Event..............................................................................2-70

Figure 2-4. ND_BELOW_LOW_LEVEL.................................................................2-85

Figure 2-5. ND_ABOVE_HIGH_LEVEL.................................................................2-85

©

National Instruments Corporation ix NI-DAQ FRM for PC Compatibles

Page 9

Contents

Figure 2-6. ND_INSIDE_REGION........................................................................... 2-85

Figure 2-7. ND_HIGH_HYSTERESIS.....................................................................2-86

Figure 2-8. ND_LOW_HYSTERESIS......................................................................2-86

Figure 2-9. Pulse Generation Timing ........................................................................2-102

Figure 2-10. Pulse Timing for pulseWidth = 0............................................................2-103

Figure 2-11. Square Wave Timing ..............................................................................2-112

Figure 2-12. Digital Scanning Input Group Handshaking Connections ...................... 2-190

Figure 2-13. Digital Scanning Output Group Handshaking Connections...................2-191

Figure 2-14. Simple Event Counting...........................................................................2-217

Figure 2-15. Single Period Measurement....................................................................2-219

Figure 2-16. Single Pulse Width Measurement...........................................................2-221

Figure 2-17. Single Triggered Pulse Width Generation Measurement ....................... 2-224

Figure 2-18. Start-Stop Measurement..........................................................................2-226

Figure 2-19. Single Pulse Generation..........................................................................2-228

Figure 2-20. Single Triggered Pulse Generation......................................................... 2-230

Figure 2-21. Retriggerable Pulse Generation ..............................................................2-232

Figure 2-22. Pulse Train Generation ...........................................................................2-233

Figure 2-23. Frequency Shift Keying..........................................................................2-235

Figure 2-24. Buffered Event Counting........................................................................2-236

Figure 2-25. Buffered Period Measurement................................................................2-238

Figure 2-26. Buffered Period Measurement when No Source Edges Are

Present between Gate Edges...................................................................2-239

Figure 2-27. Buffered Semi-Period Measurement when No Source Edges Are

Present between Gate Edges...................................................................2-239

Figure 2-28. Buffered Semi-Period Measurement when No Source Edges Are

Present between Gate Edges...................................................................2-240

Figure 2-29. Buffered Pulse Width Measurement.......................................................2-241

Figure 2-30. Buffered Pulse Width when Gate Is High during Arming...................... 2-241

Figure 2-31. Buffered Two-Signal Edge Separation Measurement............................2-243

Figure 2-32. Mode 0 Timing Diagram ........................................................................2-252

Figure 2-33. Mode 1 Timing Diagram ........................................................................2-252

Figure 2-34. Mode 2 Timing Diagram ........................................................................2-252

Figure 2-35. Mode 3 Timing Diagram ........................................................................2-253

Figure 2-36. Mode 4 Timing Diagram ........................................................................2-253

Figure 2-37. Mode 5 Timing Diagram ........................................................................2-253

Tables

Table 1. MIO and AI Devices...............................................................................xvii

Table 1-1. Status Values...........................................................................................1-1

Table 1-2. Primary Type Names ..............................................................................1-2

Table 1-3. The LabWindows/CVI Function Tree for Data Acquisition .................. 1-6

NI-DAQ FRM for PC Compatibles x

©

National Instruments Corporation

Page 10

Contents

Table 2-1. Parameter Settings for AI_Configure......................................................2-7

Table 2-2. Port 0 Digital I/O Lines Reserved...........................................................2-11

Table 2-3. Reglitching Parameters for Permissible Devices....................................2-28

Table 2-4. Voltage or Current Output Parameters....................................................2-29

Table 2-5. Parameter Values for FIFO Transfer Conditions....................................2-29

Table 2-6. Default Values for FIFO Transfer Condition..........................................2-30

Table 2-7. Parameter Setting Information for the Analog Filter .............................. 2-31

Table 2-8. Parameter Setting Information for the Digital Filter...............................2-31

Table 2-9. Parameter Setting Information for Output Enable..................................2-32

Table 2-10. Parameter Setting Information for Output Impedance............................2-32

Table 2-11. Parameter Setting Information for Output Attenuation...........................2-33

Table 2-12. Parameter Setting Information for Frequency Correction for

the Analog Filter......................................................................................2-34

Table 2-13. Parameter Setting Information for the Trigger Mode .............................2-35

Table 2-14. Parameter Setting Information for PLL Reference Frequency ...............2-35

Table 2-15. Parameter Setting Information for the SYNC Duty Cycle......................2-36

Table 2-16. Possible Calibrate_1200 Parameter Values.............................................2-51

Table 2-17. DAQEvent Messages ..............................................................................2-74

Table 2-18. Valid Counters and External Timing Signals for DAQEvent = 9...........2-78

Table 2-19. Usable Parameters for Different DAQ Events Codes............................. 2-79

Table 2-20. Legal Values for gpctrNum Parameter....................................................2-199

Table 2-21. Legal Values for paramValue when paramID = ND_SOURCE.............2-199

Table 2-22. Definition of Other Co unter for paramValue Set to

ND_OTHER_GPCTR_TC......................................................................2-200

Table 2-23. Default Source Selection for ND_SIMPLE_EVENT_CNT or

ND_BUFFERED_EVENT_CNT............................................................2-200

Table 2-24. Legal Values for paramValue when paramID = ND_GATE..................2-203

Table 2-25. Default Gate Selection............................................. ................................2-204

Table 2-26. Default Second Gate Selection...................................... ...... ....................2-205

Table 2-27. Legal Values for paramValue when

paramID = ND_INITIAL_COUNT........................................................2-206

Table 2-28. Legal Values for paramValue when paramID =

ND_COUNT_2, ND_COUNT_3, and ND_COUNT_4 .....................................2-206

ND_COUNT_1,

Table 2-29. Default Up/Down Selection ....................................................................2-207

Table 2-30. Legal Values for the action Parameter....................................................2-211

Table 2-31. Descriptions for application....................................................................2-216

Table 2-32. Terminal Count........................................................................................2-218

Table 2-33. SCXI Module Scan List ..........................................................................2-348

Table 2-34. MIO or AI Scan List................................................................................ 2-348

Table 2-35. Possible Values for signal....................................................................... 2-374

Table 2-36. Legal Parameters for the 6602 Devices...................................................2-385

Table 2-37. E Series Signal Name Equivalencies.......................................................2-387

Table 2-38. RTSI Bus Line and VXIbus Trigger Mapping........................................2-387

©

National Instruments Corporation xi NI-DAQ FRM for PC Compatibles

Page 11

Contents

Table 2-39. Data Ranges for the Buffer Parameter for DAQArb 5411 Devices........ 2-426

Table 2-40. Mode Values for the Count Parameter for DAQArb 5411 Devices.......2-427

Table 2-41. Mode Values for the Iterations Parameter for

DAQArb 5411 Devices.................................... .................................. .....2-428

Table 2-42. Array Structures for DDS Mode.............................................................2-430

Table 2-43. Array Structures for ARB Mode.............................................................2-431

Table A-1. Status Code Summary.............................................................................A-1

Table B-1. Valid Analog Input Channel Settings .....................................................B-1

Table B-2. Valid Internal Analog Input Channels....................................................B-2

Table B-3. Internal Channel Purposes for Analog Input Devices.............................B-4

Table B-4. Valid Gain Settings.................................................................................B-5

Table B-5. The Values of maxReading and maxVolt............................................... B-6

Table C-1. MIO and AI Device Functions................................................................C-1

Table C-2. Lab/516/DAQCard-500/700 Functions ..................................................C-6

Table C-3. DSA Device Functions ...........................................................................C-9

Table C-4. Analog Output Family Functions............................................................C-11

Table C-5. Digital I/O Family Functions..................................................................C-12

Table C-6. Timing Device Functions........................................................................C-14

Table C-7. SCXI Functions.......................................................................................C-16

NI-DAQ FRM for PC Compatibles xii

©

National Instruments Corporation

Page 12

The NI-DAQ Functi on Refe re nce M anu al f or PC Co mpat i ble s is f or users

of the NI-DA Q s oftware for PC com patibles version 6.1 . NI-D A Q software

is a powerful application programming interface (API) between your data

acquisition (DAQ) application and the National Instruments DAQ boards

for ISA, PCI, PXI, XT, PC Card (PCMCIA), VXIbus, EISA, and USB bu s

computers.

How to Use the NI-DAQ Manual Set

You should begin by reading the NI-DAQ User Manual for PC

Compatibles. Chapter 1, Introduction to NI-DAQ, contains a f low chart that

illustrates the sequence of steps you sh ould take to learn about and get

started with NI-DAQ software.

When you are familiar with the material in the NI-DAQ User Manual for

PC Compatibles, you can use the NI-DAQ Function Refer ence M anual for

PC Compatibles, which contains detailed descriptions of the NI-DAQ

functions. You also can use the Windows help file

contains all of the function reference material. Other documentation

includes the DAQ Hardware Overview Guide (

Configuration Utility help file (

Wizard help file (

CHANWIZ.HLP).

NIDAQCFG.HLP

About

This

Manual

NIDAQPC.HLP, which

HWOG.PDF), the NI-DAQ

and the DAQ Channel

,

)

Organization of This Manual

The NI-DAQ Function Reference Manual for PC Compatibles is organized

as follows:

• Chapter 1, Using the NI-DAQ Functions, contains important

information about how to apply the function descriptions in this

manual to your programming language and environment.

• Chapter2, Function Reference, contains a detailed explanation o f each

NI-DAQ function. The functions are arranged alphabetically.

•AppendixA, Status Codes, lists the status codes returned by NI-DA Q,

including the name and description.

©

National Instruments Corporation xiii NI-DAQ FRM for PC Compatibles

Page 13

About This Manual

•AppendixB, Analog Input Channel, Gain Settings, and

Voltage Calculation, lists the valid channel and gain settings for DA Q

boards, describes how NI-DAQ calculates voltage, and describes the

measurement of offset and gain adjustment.

•AppendixC, NI-DAQ Function Support, contains tables that show

which DAQ hardware each NI-DAQ function call supports.

•AppendixD, Customer Communication, contains forms you can use to

request help from Nati onal Instruments o r to comment on our products

and manuals.

•The Glossary contains an alphabetical list and description of terms

used in this manual, including abbreviations, acronyms, metric

prefixes, mnemonics, and symbols.

•The Index contains an alphabetical list of key terms and topics in this

manual, including the page where you can find each one.

Conventions Used in This Manual

The following conventions are used in this manual.

This icon to the left of bold italicized text denotes a note, which alerts you

to important information.

!

1102/B/C modules Refers to the SCXI-1102, SCXI-1102B, and SCXI-1102C modules and

12-bit device These MIO and AI d evice s are listed in T able 1.

16-bit device These MIO and AI d evice s are listed in T able 1.

445X device Refers to the PCI-4 451 a nd PCI-44 52.

455X device Refers to the PCI-4 551 a nd PCI-45 52.

516 device Refers to the DAQCard-516 and PC-516.

611X device Refers to the PCI-6110E and PCI-6111E.

6602 device Refers to the PCI-6 602 a nd PXI- 6602 .

AI device These analog input devices are listed in Table 1.

NI-DAQ FRM for PC Compatibles xiv

This icon to the left of bold italicized text denotes a caution, which advises

you of precautions to take to avoid injury, data loss, or a system crash.

the VXI-SC-1102, VX I-S C-1 102B, an d V XI- SC-1 102C su bm odules .

©

National Instruments Corporation

Page 14

About This Manual

Am9513-based de vice These dev ice s a re the A T-MI O-16 , AT -MIO - 16F-5, A T-MI O -16X,

AT-MIO-16D, and AT-MIO-64F-5.

bold Bold text denotes the names of menus, menu items, paramete rs, dialog

boxes, dialog box buttons or options, icons, windows, Windows 95 tabs

or pages, or LEDs.

bold italic Bold italic text denotes a note, caution, or warning.

DAQArb 5411 device Refers to the AT-5411 and PCI-5411.

DAQCard-500/700 Refers to the DAQCard-500 and DAQCard-700.

DAQMeter 4350 Refers to the PC-4350, DAQCard-4350, and DAQPad-4350.

DIO 6533 Refers to the AT-DIO- 32HS, PCI-D IO-3 2HS, D AQCa rd-6 533, a nd

PXI-6533.

DIO-24 Refers to the PC -D IO -24, P C- DIO -24 PnP, a nd DAQC ard -D IO- 24.

DIO-32F Refers to the AT-DIO-32F.

DIO-96 Refers to the PC -D IO-9 6, PC -DI O -96 PnP, P CI -DIO -9 6,

DAQPad-6507, DA QP ad-6 508 , an d PXI -65 08.

DIO device Refers to any DIO-24, DIO-32, DIO-6533, or DIO-96.

DSA device Refers to the PC I-4451 , PCI- 445 2, PCI -45 51, a nd PCI-45 52.

E Series device These are MIO and AI devices. Refer to Table 1 for a complete list of

these devices.

italic Italic text denotes emphasis, a cross reference, or an introduction to

a key concept. This font a lso denotes text fo r which you supply the

appropriate word or value, such as in NI-DAQ 5.x.

Lab and 1200 analog Refers to the DAQCard-1200, DAQPad-1 200, La b-PC+, Lab-PC-1200,

output device PCI-1200, and SCXI-1200.

Lab and 1200 device Refers to the DAQCard-1200, DAQPad-1200, Lab-PC+, Lab-PC-1200,

Lab-PC-1200AI, PCI-1200, a nd SCXI-1200 .

LPM device Refers to the PC-L P M-16 an d PC -LP M-16P n P.

MIO device Refe rs to multifunction I/O devices. See Table 1 for a list of these

devices.

©

National Instruments Corporation xv NI-DAQ FRM for PC Compatibles

Page 15

About This Manual

MIO-F-5/16X d ev ice Refers to the A T-M IO - 16F- 5, AT- MI O-16 X, a nd the AT -M IO -64F -5 .

MIO-16/16D d ev ice Refers to the A T -MIO - 16 an d AT -M IO- 16D .

MIO-16XE-50 d evi ce Refers to the A T-M IO -16X E -50, DA QP ad-M IO- 16X E-50 , an d

NEC-MIO-16XE-5 0, a nd PCI- MIO -16 XE-5 0.

MIO-64 Refers to the AT-MIO-64F-5, AT-MIO-64E-4, PCI-6031E, PCI-6033E,

PCI-6071E, VXI-MIO -64E-1, and VXI-M IO-64X E-10.

monospace Text in this font denotes text or characters that you should literally enter

from the keyboard, sections of co de, pro gramming ex ample s, and

syntax examples. This fo nt a lso is used for the pro per n am es of d isk

drives, paths, directories, programs, subprogram s, subroutines, device

names, functions, operations, variables, filenames, and extensions, and

for statements and c omm en ts take n from p rogra m code .

monospace italic

Italic text in this font denotes th at you mu st su pply the appr opriate

words or values in the place of these items.

NI-DAQ Refers to the NI-DA Q softwa re for PC co mpat ible s, unless other wi se

noted.

PC Refers to the IBM PC/XT, IBM PC AT, and compatible computers.

PCI Series Refers to the National Instrum ents p rod ucts that use the

high-performance expan sion bus architec ture origin ally develope d

by Intel to replace ISA and EISA.

Remote SCXI Refers to an SCXI configuration where either an SCXI-2000 chassis or

an SCXI-2400 remote commu nications module is connected to the PC

serial port.

SCXI-1102/B/C SCXI-1102/B/C refers to the SCX I-11 02, SCX I-11 02B , an d

SCXI-1102C devices.

SCXI-1120/D SCXI-1120/D refers to the SCXI-112 0 and SCXI-11 20D.

SCXI analog i np ut Refers to t he S C XI -1 100, SC X I-1102 , S CXI-1 120 , S CXI-1 120 D,

module SCXI-1121, SCXI-1122, SCXI- 1140, and SCX I-1141 .

SCXI chassis Refers to the SCXI-1000, SCXI-1000DC, SCXI-1001, and SCXI-2000.

SCXI digital modul e Refers to the SCXI -1160 , SCXI-1 161, S CXI-1 162, SCX I-1162 HV,

SCXI-1163, and SCXI-1163 R.

NI-DAQ FRM for PC Compatibles xvi

©

National Instruments Corporation

Page 16

About This Manual

Simultaneous sampling Refers to the PCI-6110E, PCI-6111E, PCI-4451, PCI-4452, PCI-4551,

device and PCI-4552.

VXI-MIO device Refers to the VXI-MIO-64E-1 and VXI-MIO-64XE-10.

VXI-SC-1102/B/C Refers to the VXI-SC-1102 , VXI-SC- 110 2B, a nd V XI-SC -11 02C.

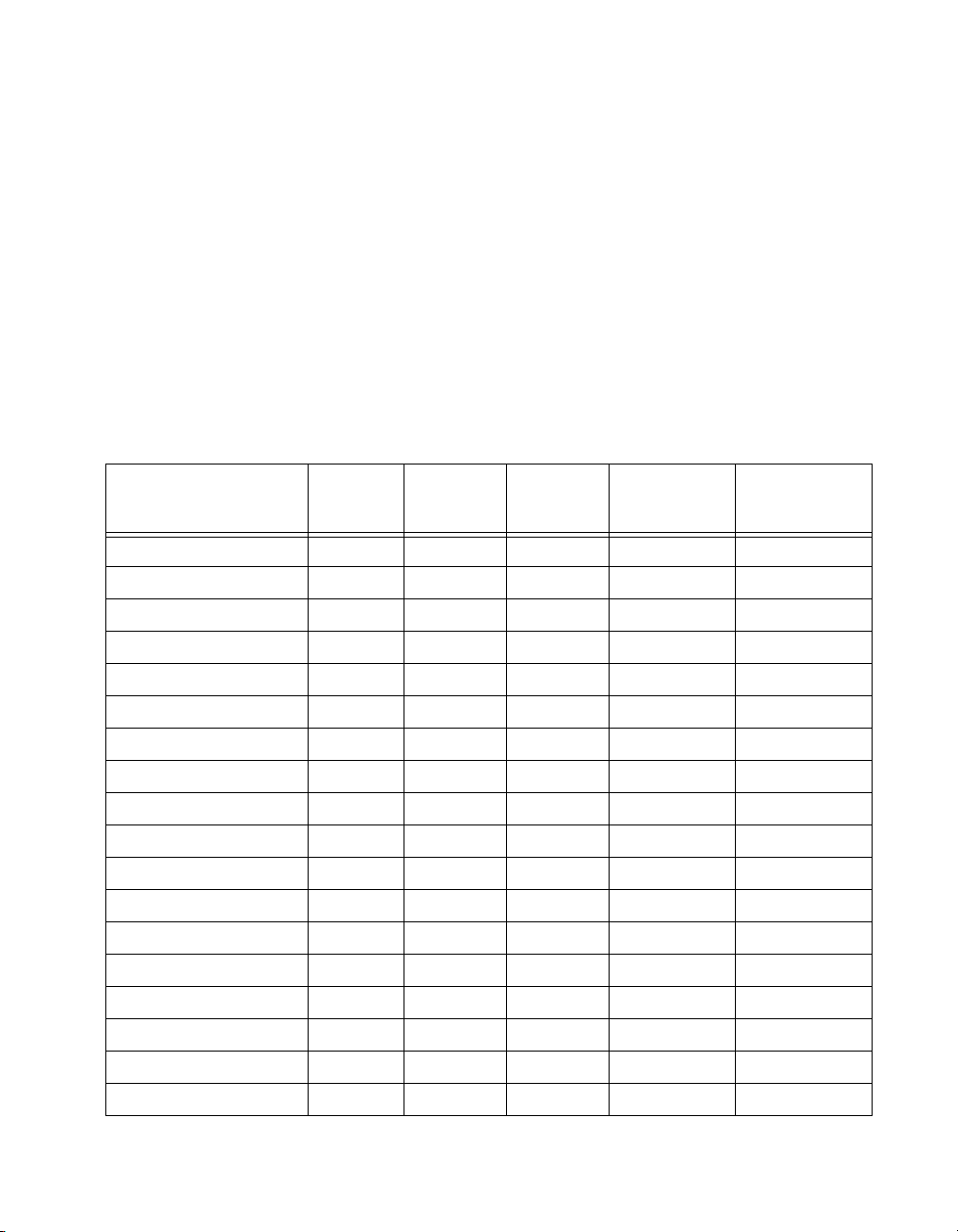

MIO and AI Device Terminology

This manual uses generic terms to describe groups of devices whenever

possible. The generic terms for the MIO and AI devices are based on

the number of bits, the platform, the functionality, and the series name

of the devices. Table 1 lists each MIO and AI device and the possible

classifications for each.

Table 1.

Number

of SE

Device

AT-AI-16XE-10 16 16-bit AT AI E Series

AT-MIO-16 16 12-bit AT MIO Am9513-based

AT-MIO-16D 16 12-bit AT MIO Am9513-based

AT-MIO-16DE-10 16 12-bit AT MIO E Series

AT-MIO-16E-1 16 12-bit AT MIO E Series

AT-MIO-16E-2 16 12-bit AT MIO E Series

AT-MIO-16E-10 16 12-bit AT MIO E Series

AT-MIO-16F-5 16 12-bit AT MIO Am9513-based

AT-MIO-16X 16 16-bit AT MIO Am9513-based

AT-MIO-16XE-10 16 16-bit AT MIO E Series

AT-MIO-16XE-50 16 16-bit AT MIO E Series

AT-MIO-64E-3 64 12-bit AT MIO E Series

AT-MIO-64F-5 64 12-bit AT MIO Am9513-based

DAQCard-AI-16E-4 16 12-bit PCMCIA AI E Series

Channels

MIO and AI Devices

Bit Type Functionality Series

DAQCard-AI-16XE-50 16 16-bit PCMCIA AI E Series

DAQPad-MIO-16XE-50 16 16-bit Parallel Port MIO E Series

DAQPad-6020E 16 12-bit USB MIO E Series

NEC-AI-16E-4 16 12-bit NEC AI E Series

©

National Instruments Corporation xvii NI-DAQ FRM for PC Compatibles

Page 17

About This Manual

Table 1. MIO and AI Devices (Continued)

Number

Device

NEC-AI-16XE-50 16 16-bit NEC AI E Series

NEC-MIO-16E-4 16 12-bit NEC MIO E Series

NEC-MIO-16XE-50 16 16-bit NEC MIO E Series

PCI-6031E (MIO-64XE-1 0) 64 16-bit PCI MIO E Series

PCI-6032E (AI-16XE-10) 16 16-bit PCI AI E Series

PCI-6033E (AI-64XE-10) 64 16-bit PCI AI E Series

PCI-6071E (MIO-64E-1) 64 12-bit PCI MIO E Series

of SE

Channels

Bit Type Functionality Series

PCI-6110E 4 diff.

only

PCI-6111E 2 diff.

only

PCI-MIO-16E-1 16 12-bit PCI MIO E Series

PCI-MIO-16E-4 16 12-bit PCI MIO E Series

PCI-MIO-16XE-10 16 16-bit PCI MIO E Series

PCI-MIO-16XE-50 16 16-bit PCI MIO E Series

PXI-6011E 16 16-bit PXI MIO E Series

PXI-6030E 16 16-bit PXI MIO E Series

PXI-6040E 16 12-bit PXI MIO E Series

PXI-6070E 16 12-bit PXI MIO E Series

VXI-MIO-64E-1 64 12-bit VXI MIO E Series

VXI-MIO-64XE-10 64 16-bit VXI MIO E Series

12-bit AI

16-bit AO

12-bit AI

16-bit AO

PCI MIO E Series

PCI MIO E Series

NI-DAQ FRM for PC Compatibles xviii

©

National Instruments Corporation

Page 18

About This Manual

About the National Instruments Documentation Set

The NI-DAQ Function Reference Manual for PC Compatibles is one piece

of the documentation set for your DAQ system. You might have any of

several types of manuals, depending on the hardware and software in your

system. Use these manuals as follows:

• Your SCXI hardware user manuals—If y ou are using SCXI, read these

manuals next for detailed information about signal connections and

module configuration. They also explain in greater detail how the

module works and contain application hints.

• Your DAQ hardware user manuals—These manuals have detailed

information about the DAQ hardware that plugs into or is connected

to your computer. Use these manuals for hardware installation and

configuratio n i ns truct i on s, speci fication informati o n abo ut you r DAQ

hardware, and application hint s .

• Software documentation—Examples of software documentation you

might have are the ComponentWorks, LabVIEW and

LabWindows/CVI, VirtualBench, and NI-DAQ documentation. After

you have set up your hardware system, use either the application

software or the NI-D AQ do cuments to help you write your application.

If you have a large and complicated system, it is worthwhile to look

through the software manuals before you configure your hardware.

• Accessory installation guides or manuals—If you are using accessory

products, read the terminal block and cable assembly installation

guides or accessory board user manuals. They explain how to

physically connect the relevant pieces of the system. Consult these

guides when you are making your connections.

• SCXI Ch assis User Ma nual—If you are us ing SCXI, read this manual

for maintenance information on the chassis an d installation

instructions.

©

National Instruments Corporation xix NI-DAQ FRM for PC Compatibles

Page 19

About This Manual

Related Documentation

The following documen ts contai n i nfo rmati on yo u may find useful as you

read this manual:

For detailed hardware information, refer to the user manual included with

each board. The following manuals are available from National

Instruments:

• Microsoft Visual C++ User Guide to Programming

• Ome ga Temperature Handbook

• NIST Monograph 125, Thermocouple Reference Tables

Customer Communication

National Instruments wants to receive your comments on our products

and manuals. We are interested in the applications you develop with

our products, and we want to help if you have problems with them.

To make it easy for you to contact us, this manual contains comment

and configuration forms for you to complete. These forms are in

Appendix D, Custome r Communication, at the end of this manual.

NI-DAQ FRM for PC Compatibles xx

©

National Instruments Corporation

Page 20

Chapter

Using the NI-DAQ Functions

This chapter contains important information about how to apply the

function descriptions in this manual to your programming language and

environment.

When you are familiar with the material in the NI-DAQ User Manual for

PC Compatibles, you can use this manual for detailed information about

each NI-DAQ function.

1

Status Codes, Device Numbers, and SCXI Chassis IDs

Every NI-DAQ function is of the following form:

status

=

Function_Name (parameter 1, parameter 2, … parameter n)

where n ≥ 0. Each function returns a value in the

indicates the success or failure of the function, as shown in Table 1-1.

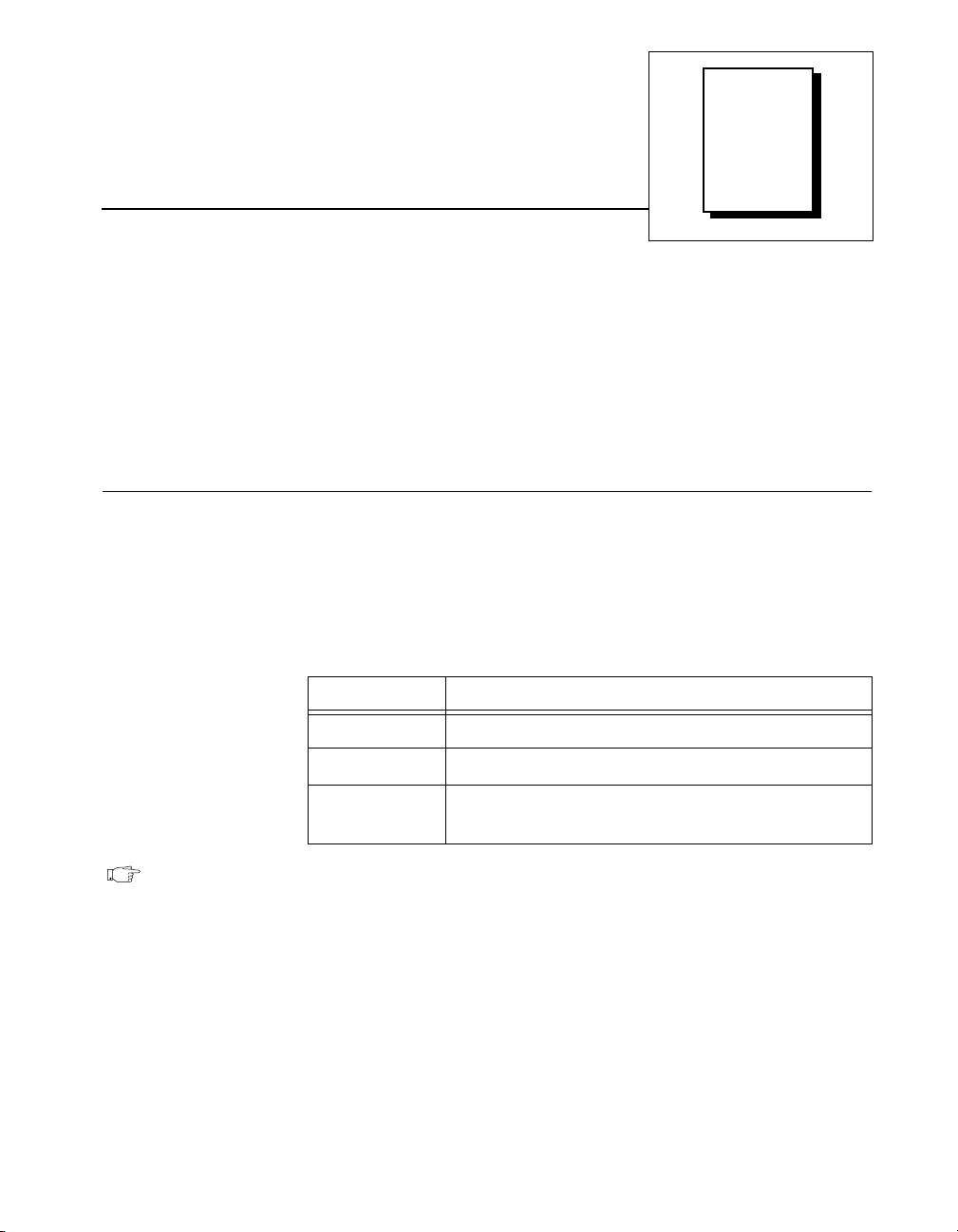

Table 1-1.

Status Result

Status Values

status

variable that

Negative Function did not execute because of an error

Zero Function completed successfully

Positive Fu nction executed but with a potentially serious

side effect

Note

©

National Instruments Corporation 1-1 NI-DAQ FRM for PC Compatibles

In all applications,

contains a list of

In the parameter tables that follow the status codes, the first parameter to

almost ev ery NI-DA Q functi on is the device n umber of the D AQ d evice you

want NI-DAQ to use for the given operation. After you have followed the

installation and configuration instructions in the NI-D A Q release notes and

Chapter 1, Introduction to NI-DAQ, of the NI-DAQ User Manual for PC

Compatibles, you can use the NI-DAQ Configuration Utility to determine

the device number for each de vice you ha ve installed in the system.You can

status

status

is always a 16-bit integer. Appendix A,

codes.

Status Codes

,

Page 21

Chapter 1 Using the NI-DAQ Functions

use the configuration utility to verify your device numbers. You can use

multiple DAQ devices in one application; to do so, simply pass the

appropriate device number to each function.

If you are using SCXI, you must pass the chassis ID that you assigned to

your SCXI chassis in the configuration utility to the SCXI functions that

you use. For many of the SCXI functions, you must also pass the module

slot number of the module you want to use. The slots in the SCXI chassis

are numbered from left to rig ht, beginning wi th slot 1. The controlle r on the

left side of the chassis is referred to as Slot 0. Y ou can use the configuration

utility to verify your chassis IDs and your module slot numbers.

Variable Data Types

The NI-DAQ API is identical in Windows 95 and Windows NT. Every

function description has a parameter table that lists the data types in each

of the environments. LabWindows/CVI uses the same types as Windows.

The following sections describe the notation used in those parameter tables

and throughout the manual for variable data types.

Primary Types

Table 1 -2 shows the primary type names and their ranges.

Type

Name

u8 8-bit ASCII

i16 16-bit signed

Description Range

0 to 255

character

–32,768 to 32,767

integer

Table 1-2.

Primary Type Names

C/C++ Visual BA SIC

char

short Integer

Not supported by

BASIC. For functions

that require ch arac ter

arrays, use string

types instead. See the

STR description.

(for example:

deviceNum%

Type

Pascal (Borland

Delphi)

Byte

SmallInt

)

NI-DAQ FRM for PC Compatibles 1-2

©

National Instruments Corporation

Page 22

Chapter 1 Using the NI-DAQ Functions

Type

Name

u16 16-bit uns igned

i32 32-bit signed

u32 32-bit uns igned

f32 32-bit

f64 64-bit

STR BASIC or

Description Range

integer

integer

integer

single-precision

floating point

double-precisio

n floating point

Pascal characte r

string

Table 1-2.

0 to 65,535

–2,147,483,648 to

2,147,483,647

0 to 4,294,967,295

–3.402823 x 1038 to

3.402823 x 10

–1.797683134 862 31 5

30

8

×

10

to

1.797683134862315

308

×

10

Primary Type Names (Continued)

38

—

C/C++ Visual BASIC

unsigned

short for

32-bit

compilers

long Long

unsigned

long

float Single

double Double

Use character

array terminat ed

by the null

character

\0

Not supported by

BASIC. For functions

that require unsigned

integers, use the

signed integer type

instead. See the i16

description.

(for example:

count&

Not supported by

BASIC. For functions

that require unsigned

long integers, us e the

signed long integer

type instead. See th e

i32 description.

example:

example:

voltage#

String

example:

filename$

Type

)

(for

num!

(for

(for

Pascal (Borland

Delphi)

Word

LongInt

Cardinal

32-bit operating

systems). Refer to

the i32

description.

Single

)

Double

)

String

)

(in

Arrays

When a primary type is inside square brackets (for example, [i16]) an array

of the type named is required for that parameter.

Multiple Types

Some parameters can be in multiple types. Combinations of the primary

types separated by commas denote parameters with th is ability, as in the

following example:

[i16], [f32]

©

National Instruments Corporation 1-3 NI-DAQ FRM for PC Compatibles

Page 23

Chapter 1 Using the NI-DAQ Functions

The previous example describes a parameter that can accept an array of

signed integers or an array of floating-point numbers.

Programming Language Considerations

Apart from the data type differences, there are a few language-dependent

considerations you need to be aware of when you use the NI-DAQ API.

Read the following sections that apply to your programming language.

Note

Be sure to include the NI-DAQ function prototype files by including the

appropriate NI-DAQ header file in your source code.

Borland Delphi

When you pass arrays to NI-DAQ functions using Borland Delphi in

Windows, you need to pass a pointer to the array. You can either declare an

array and pass the array address to the NI-DAQ function, or you can

declare a pointer, dynamically allocate memory for the pointer, and pass

the pointer directly to the NI-DAQ function. For example,

var

buffer : array [1..1000] of Integer;

bufPtr : ^Integer;

status := DAQ_Start (device, chan, gain, @buffer, count,

timebase, sampInterval);

or

(* allocate memory for bufPtr first using AllocMem or

New *)

status := DAQ_Start (device, chan, gain, bufPtr, count,

timebase, sampInterval);

Visual Basic for Windows

When you pass arrays to NI-DAQ functions using Visual Basic for

Windows, you need to pass the first element of the array by referen ce. For

example, you would call the

syntax:

status% = DAQ_Start (device%, chan%, gain%, buffer%(0),

count&, timebase%, sampInterval%)

DAQ_Start

function using the following

NI-DAQ FRM for PC Compatibles 1-4

©

National Instruments Corporation

Page 24

Chapter 1 Using the NI-DAQ Functions

NI-DAQ Constants Include File

The file NIDAQCNS.INC contains definitions for constants required for

some of the NI-DAQ functions. You should use the constants symbols in

your programs; do not use the numerical values.

In Visual Basic for Windows, you can add the entire

NIDAQCNS.INC file

into your project. You then will be able to use any of the constan ts def i ned

in this file in any module in your program.

T o add the

NIDAQCNS.INC file for your pr oject in V isual Ba sic 3.0 and 4.0,

go to the File menu and select the Add File... option. Select

NIDAQCNS.INC, which is the Include subdirectory of NI-DAQ

subdirectory. Then, select Open to add the file to the project.

To add the

NIDAQCNS.INC file to your project in Visual Basic 5.0, go to

the Project menu and select Add Module. Click on the Existing tab page.

NIDAQCNS.INC, which is the Include subdirectory of your

Select

NI-DAQ directory. Then, select Open to add the file to the project.

This procedure is identical to the procedure you would follow wh en loading

the Visual Basic f ile

CONSTANT.TXT. Search on the word CONSTANT for

more information from the V isual Basic on-line help. Alternatively , you can

cut and paste individual lines from this file and place them in the module

where you need them. Ho wever , if you do so, yo u shoul d remo v e the w or d

Global from the CONSTANTS definition.

For example,

GLOBAL CONST ND_DATA_XFER_MODE_AI& = 14000

would become:

CONST ND_DATA_XFER_MODE_AI& = 14000

NI-DAQ for LabWindows/CVI

Inside the LabWindows/CVI environment, the NI-DAQ functions appear

in the Data Acquisition function panels under the Libraries menu. Each

function panel represents an NI-DAQ function, which is displayed at the

bottom of the panel. The function panels have help text for each function

and each parameter; however, if you n eed ad ditional inf ormatio n, y ou can

look up the appropriate NI-DAQ function alphabetically in Chapter 2,

Function Reference of this manual.

©

National Instruments Corporation 1-5 NI-DAQ FRM for PC Compatibles

Page 25

Chapter 1 Using the NI-DAQ Functions

Table 1-3 shows how the LabWindows/CVI function panel tree is

organized, and the NI-DAQ function name that corresponds to each

function panel.

Table 1-3.

LabWindows/CVI Function Panel NI-DAQ Function

Data Acquisition

Initialization/Utilities

Initialize Board

Configure Timeout

Get Device Information

Set Device Information

Align DMA Buffer

Get DAQ Library Version

Select E-Series Signals

Config Analog Trigger

Change Line Attribute

Board Config & Calibrate

Configure MIO Boards

Configure AMUX Boards

The LabWindows/CVI Function Tree for Data Acquisition

Init_DA_Brds

Timeout_Config

Get_DAQ_Device_Info

Set_DAQ_Device_Info

Align_DMA_Buffer

Get_NI_DAQ_Version

Select_Signal

Configure_HW_Analog_Trigger

Line_Change_Attribute

MIO_Config

AI_Mux_Config

Configure SC-2040

Calibrate MIO Boards

Calibrate E Series

Calibrate LPM-16

Calibrate Analog Output

Calibrate 1200 Devices

Calibrate DSA Devices

NI-DAQ FRM for PC Compatibles 1-6

SC_2040_Config

MIO_Calibrate

Calibrate_E_Series

LPM16_Calibrate

AO_Calibrate

Calibrate_1200

Calibrate_DSA

©

National Instruments Corporation

Page 26

Chapter 1 Using the NI-DAQ Functions

LabWindows/CVI Function Panel NI-DAQ Function

Analog Input

Single Point

Change Analog Input Parameter

Measure Voltage

Clear Analog Input

Read Analog Binary

Scale Binary to Voltage

Setup Analog Input

Check Analog Input

Configure Analog Input

Multiple Point

Acquire Single Channel

Scan Multiple Channels

Scan Lab Channels

Table 1-3.

The LabWindows/CVI Function Tree for Data Acquisition (Continued)

AI_Change_Parameter

AI_VRead

AI_Clear

AI_Read

AI_VScale

AI_Setup

AI_Check

AI_Configure

DAQ_Op

SCAN_Op

Lab_ISCAN_Op

Single Scan Binary

Single Scan Voltage

Single Channel to Disk

Multiple Chan to Disk

Scan Lab Chan to Disk

AI_Read_Scan

AI_VRead_Scan

DAQ_to_Disk

SCAN_to_Disk

Lab_ISCAN_to_Disk

Low-Level Functions

Convert DAQ Rate

Start DAQ

Setup Scan

Setup Sequence of Scans

Retrieve Scan Sequence

©

National Instruments Corporation 1-7 NI-DAQ FRM for PC Compatibles

DAQ_Rate

DAQ_Start

SCAN_Setup

SCAN_Sequence_Setup

SCAN_Sequence_Retrieve

Page 27

Chapter 1 Using the NI-DAQ Functions

Table 1-3.

The LabWindows/CVI Function Tree for Data Acquisition (Continued)

LabWindows/CVI Function Panel NI-DAQ Function

Start Scan

Check DAQ or Scan

Assign Rate to DAQ Group

Monitor DAQ or Scan

Start Lab Scan

Check Lab Scan

Clear DAQ or Scan

Scale DAQ or Scan

Reorder Scan Data

Reorder Scan Seq Data

Configure DAQ

Config DAQ Pretrigger

Config Double Buffering

Is Half Buffer Read y?

SCAN_Start

DAQ_Check

DAQ_Set_Clock

DAQ_Monitor

Lab_ISCAN_Start

Lab_ISCAN_Check

DAQ_Clear

DAQ_VScale

SCAN_Demux

SCAN_Sequence_Demux

DAQ_Config

DAQ_StopTrigger_Config

DAQ_DB_Config

DAQ_DB_HalfReady

Half Buffer to Array

Analog Output

Single Point

Generate Voltage

Scale Voltage to Binary

Write Analog Binary

Update Analog DACs

Configure Analog Output

Change Analog Output Parameter

NI-DAQ FRM for PC Compatibles 1-8

DAQ_DB_Transfer

AO_VWrite

AO_VScale

AO_Write

AO_Update

AO_Configure

AO_Change_Parameter

©

National Instruments Corporation

Page 28

Chapter 1 Using the NI-DAQ Functions

Table 1-3.

The LabWindows/CVI Function Tree for Data Acquisition (Continued)

LabWindows/CVI Function Panel NI-DAQ Function

Waveform Generation

Generate WFM from Array

Generate WFM from Disk

WFM_Op

WFM_from_Disk

Low-Level Functions

Scale Waveform Buffer

Convert Waveform Rate

Assign Waveform Group

Load Waveform Buffer

Assign Rate to WFM Group

Control Waveform Group

Pause/Resume WF M Cha nnel

Check Waveform Channel

Enable Double Buffering

Is Half Buffer Read y?

WFM_Scale

WFM_Rate

WFM_Group_Setup

WFM_Load

WFM_ClockRate, WFM_Set_Clock

WFM_Group_Control

WFM_Chan_Control

WFM_Check

WFM_DB_Config

WFM_DB_HalfReady

Copy Array to WFM Buffer

WFM_DB_Transfer

Digital Input/Output

Configure Port

Configure Line

Read Port

Read Line

Write Port

Write Line

Get Port Status

Configure Trigger

©

National Instruments Corporation 1-9 NI-DAQ FRM for PC Compatibles

DIG_Prt_Config

DIG_Line_Config

DIG_In_Port

DIG_In_Line

DIG_Out_Port

DIG_Out_Line

DIG_Prt_Status

DIG_Trigger_Config

Page 29

Chapter 1 Using the NI-DAQ Functions

Table 1-3.

The LabWindows/CVI Function Tree for Data Acquisition (Continued)

LabWindows/CVI Function Panel NI-DAQ Function

Group Mode

Configure Group

Read Group

Write Group

Get Group Status

Set Group Mode

DIG_Grp_Config

DIG_In_Grp

DIG_Out_Grp

DIG_Grp_Status

DIG_Grp_Mode

Block Transfer

Read Block

Write Block

Check Block

Clear Block

Set Up Pattern Generation

Set Up Digital Scanning

Enable Double Buffering

DIG_Block_In

DIG_Block_Out

DIG_Block_Check

DIG_Block_Clear

DIG_Block_PG_Config

DIG_SCAN_Setup

DIG_DB_Config

Is Half Buffer Read y?

Transfer To/From Array

SCXI

Load SCXI Configuration

Change Configuration

Get Chassis Config Info

Get Module Config Info

Read Module ID Register

Reset SCXI

Set Up Single AI Channel

Set Up Muxed Scanning

NI-DAQ FRM for PC Compatibles 1-10

DIG_DB_HalfReady

DIG_DB_Transfer

SCXI_Load_Config

SCXI_Set_Config

SCXI_Get_Chassis_Info

SCXI_Get_Module_Info

SCXI_ModuleID_Read

SCXI_Reset

SCXI_Single_Chan_Setup

SCXI_SCAN_Setup

©

National Instruments Corporation

Page 30

Chapter 1 Using the NI-DAQ Functions

Table 1-3.

The LabWindows/CVI Function Tree for Data Acquisition (Continued)

LabWindows/CVI Function Panel NI-DAQ Function

Set Up Mux Counter

Set Up Track/Hold

Control Track/Hold State

Select Gain

Configure Filter

Select Scanning Mode

Change AI Channel

Scale SCXI Data

Write to AO Channel

Set Digital or Relay State

Get Digital or Relay State

Get Status Register

Set Up Calibration Mode

Change Cal Constants

SCXI_MuxCtr_Setup

SCXI_Track_Hold_Setup

SCXI_Track_Hold_Control

SCXI_Set_Gain

SCXI_Configure_Filter

SCXI_Set_Input_Mode

SCXI_Change_Chan

SCXI_Scale

SCXI_AO_Write

SCXI_Set_State

SCXI_Get_State

SCXI_Get_Status

SCXI_Calibrate_Setup

SCXI_Cal_Constants

Set Threshold Values

SCXI_Set_Threshold

Counter/Timer

DAQ-STC Counters (GPCTR)

Select Ctr Application

Change Ctr Parameter

Configure Ctr Buffer

Control Ctr Operation

Monitor Ctr Properties

GPCTR_Set_Application

GPCTR_Change_Parameter

GPCTR_Config_Buffer

GPCTR_Control

GPCTR_Watch

Am9513 Counters (CTR)

Configure Counter

Count Events

©

National Instruments Corporation 1-11 NI-DAQ FRM for PC Compatibles

CTR_Config

CTR_EvCount

Page 31

Chapter 1 Using the NI-DAQ Functions

Table 1-3.

The LabWindows/CVI Function Tree for Data Acquisition (Continued)

LabWindows/CVI Function Panel NI-DAQ Function

Count Periods

Read Counter

Stop Counter

Restart Counter

Reset Counter

Get Counter Output State

Convert CTR Rate

Generate Pulse

Generate Square Wave

Generate Freq OUT Signal

Operate Multi Counters

CTR_Period

CTR_EvRead

CTR_Stop

CTR_Restart

CTR_Reset

CTR_State

CTR_Rate

CTR_Pulse

CTR_Square

CTR_FOUT_Config

CTR_Simul_Op

8253 Counters (ICTR)

Setup Interval Counter

Read Interval Counter

ICTR_Setup

ICTR_Read

Reset Interval Counter

RTSI Bus

Connect RTSI

Disconnect RTSI

Clear RTSI

Clock RTSI

Event Messagi n g

Config Alarm Deadband

Config Analog Trigger Event

Config Event Message

NI-DAQ FRM for PC Compatibles 1-12

ICTR_Reset

RTSI_Conn

RTSI_DisConn

RTSI_Clear

RTSI_Clock

Config_Alarm_Deadband

Config_ATrig_Event_Message

Config_DAQ_Event_Message

©

National Instruments Corporation

Page 32

Chapter 1 Using the NI-DAQ Functions

Initialization/Utilities is a class of functions used for general board

initialization and configuration, for configuration retrieval, and for setting

NI-DA Q properties. This class also contains several useful utility functions.

Board Config & Calibrate is a class of functions that perform calibration

and configuration that is specific to a single type of board.

The Analog Input class contains all of the classes of functions that perform

A/D conversions.

Single Point is a class of Analog Input functions that perform A/D

conversions of a single sample.

Multiple Point is a class of functions that perform clocked, buffered

multiple A/D conversions typically used to capture waveforms. This class

includes high-level functions and a Low-Level Functions subclass. The

high-level functions are synchronous; that is, your application is blocked

while these functions are performing the requested number of A/D

conversions. The low-level functions are asynchronous; that is, your

application continues to run while the board performs A/D conversions in

the background. The low-level functions al so in cl ude th e doubl e- buffered

functions.

The Analog Output class contains all the classes of functions that perform

D/A conversions.

Single Point is a class of Analog Output functions that perfo rm single D/A

conversions.

Waveform Generation is a class of functions that perform buffered analog

output. The W avefo rm Generation functions generate wav eforms from data

contained in an array or a disk file. The Low-Level Functions subclass

provides a finer level of control in generating multiple D/A conversions.

Digital Input/Output is a class of functions that perform digital input and

output operations. It also contains two subclasses. Group Mode is a

subclass of the Digital Input/Output class that contains functions for

handshaked digital input and output operations. Block Transfer is a

subclass of the Group Mode class that contains functions for handshaked or

clocked, buffered or double-buffered digital input and output operations.

SCXI is a class of functions used to configure the SCXI line of signal

conditioning products.

©

National Instruments Corporation 1-13 NI-DAQ FRM for PC Compatibles

Page 33

Chapter 1 Using the NI-DAQ Functions

Counter/Timer is a class of function panels that perform counting and

timing operations. DAQ-STC Counters (GPCTR) is a subclass of

Counter/Timer that contains functions that perform operations on the

DAQ-STC counters on the E Series devices. Am9513 Counters (CTR) is

another subclass of Counter/Timer that contains functions that perform

operations on the Am9513 counters on t he Am9513-bas ed devi ces, and the

PC-TIO-10. 8253 Counters (ICTR) is a subclass of Counter/Timer that

contains functions that perform counting and timing operations for the

DAQCard-500/700 and 516, Lab and 1200 series, and LPM devices.

RTSI Bus is a class of function panels that connect control signals to the

RTSI bus and to other boards.

The DAQ Event Messages class contains functions that set up conditions

for sending messages to your application when certain events occur.

NI-DAQ FRM for PC Compatibles 1-14

©

National Instruments Corporation

Page 34

Chapter

Function Reference

This chapter contains a detailed explanation of each NI-DAQ function. The functions are

arranged alphabetically.

AI_Change_Parameter